1. Introduction

Fused Filament Fabrication (FFF) is grouped inside the Additive Manufacturing (AM) Solid-State processes [

1]. These processes, commonly referred to as 3D Printing, allow layer-by-layer construction of complex and customized shaped parts from engineering materials directly from design, without using expensive tooling [

1,

2]. FFF uses a continuous feed of material or mixing of materials, typically in the form of a filament, but can assume other forms, like pellets. Metallic AM through FFF uses a mixture of metal powders with polymeric binder systems [

3], which are melted and deposited layer by layer to build an object [

4,

5,

6,

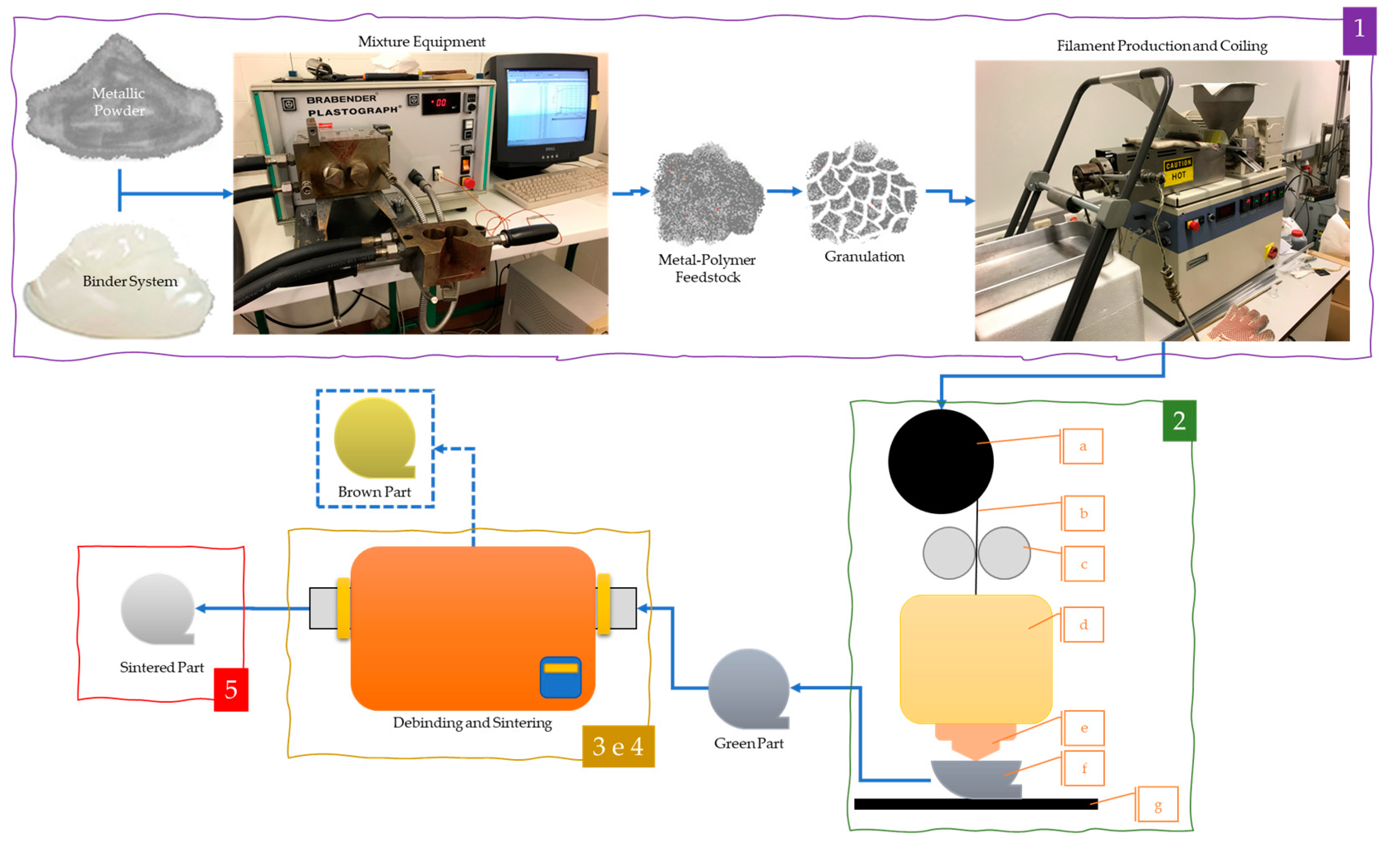

7]. FFF for metallic parts can be divided into five steps: (1) raw materials selection and feedstock mixture (including palletizing), (2) filament production (extrusion), (3) production of AM components using the filament extrusion process, (4) debinding, and (5) sintering. The pellets and inkjet processes use similar steps.

AM processes are getting the attention of several industries, like automotive, aero-space, healthcare, as well as consumer and markets in general, since they allow to design, create, develop, and produce almost any product with design freedom, flexibility, and versatility when compared to traditional manufacturing [

2,

8,

9,

10]. To accomplish the AM potential, continued research and development on processes and equipment are essential to enable full manufacturing readiness and understanding of the materials [

8,

10]. AM processes in general, and metal AM processes, from laser to solid-state processes, can create complex shapes and components from various materials, including plastics, metals, ceramics, and composites, like Metal Matrix Composites (MMC), Functionally Graded Materials (FGM), High Entropy Alloys (HEA), and others [

11,

12,

13,

14,

15]. The beam (laser or electron powder processes are the most used technologies in Metal AM. The pertinence and capabilities of this type of process are widely demonstrated and recognized. Thus, this technology has emerged as challenging since layer-by-layer manufacturing with a heat source leads to l columnar grain formation, mainly due to the directionality of heat extraction. This microstructure has characteristics dissimilar from those of traditional processes; it usually reveals an anisotropy that degrades mechanical strength in Z-axis directions (or with enhanced strength in the XY-axis), resulting in components that can have unpredictable mechanical behavior, incompatible with parts that requires stringent properties [

3,

16,

17,

18]. The metal AM processes require high-end and digital technology, like hardware, software, and procedures. They are an intrinsic part of a new industrial paradigm to increase efficiency and productivity by ensuring sustainability and the improvement of the circular economy [

8,

19,

20,

21,

22].

One of the mandatory requirements to achieve an effective layer joining in AM, independently of the selected technology, is to have an effective combination of the feedstock (or raw) material and good energy delivery [

23]. As mentioned before, in the FFF process, the most common way is to use a filament composed of binder systems mixed with metal powder particles, which is fed through a nozzle, produced according to the 3D model, and layered according to it; in the end, a green part is achieved [

24,

25,

26] Afterward, the steps of debinding and sintering treatments are required to create fully metallic parts. The debinding is performed to remove most of the polymeric binder systems, obtaining the densified brown parts and getting full metallic parts with the desired composition after sintering [

27,

28,

29]. Known for its cost-effectiveness and versatility, FFF is a popular choice for many applications [

24,

26,

28,

30,

31]. Additionally, it is possible to use pellets as feedstocks (also a mixture of binders and powder metals) [

4,

5,

32,

33,

34], which avoids filament production using almost directly the materials from the mixture process [

4,

5,

6] and Direct Ink Writing Processes where an ink with nanometric metal powder is used as feedstock [

35,

36,

37,

38]. This paper aims to provide a comprehensive overview of metallic materials FFF, including its principles, advantages, limitations, design considerations, advanced materials utilization, potential applications and prospects, and directions for research and development of metal FFF.

2. The FFF process for metallic materials

The FFF Process, referred to as Fused Deposition Modeling (FDM), is widely acknowledged as a prominent AM technique. It involves the systematic layer-by-layer deposition of thermoplastic materials to construct objects [

8,

10,

39]. Due to its unique characteristics, FFF occupies a significant position in polymer-based AM processes. Notably, it has gained recognition as a potential substitute for laser or electron beam processes, creating new opportunities for advancing metal AM technology [

2,

11,

39,

40]. The ability to produce such diverse objects highlights the flexibility and utility of the FFF process in various domains, including engineering, design, research, and art. The versatility and widespread accessibility of FFF make it a practical AM solution. It facilitates the production of a wide range of objects, catering to diverse requirements. These objects can encompass prototypes, models, functional components, and even intricate artistic sculptures [

24,

39,

41].

Adjacent to the FFF process, it is required to design the components using computer-aided design (CAD) software, enabling the CAD 3D model. Once it is complete, and to proceed with the AM process, the CAD 3D model must be sliced using specific software. This software will be used to define the manufacturing strategy; it can specify the path for the deposition of material layer-by-layer (slicing) and define the production parameters such as layer thickness, the number of shells, pattern, raster gap, and speed [

5,

8,

42,

43]. The slicer software will convert the CAD 3D in a set of paths (coordinates defined by X, Y, and Z) and layer upon layer; it creates the tracing, which the nozzle will run in manufacturing to the production of the designed component. Each slice is no more than a 2D and is the path that will have to be travelled to build each slice, and the set will originate the 3D object. Slicers enable the optimization and parametrization of several properties, impacting the final component’s overall quality and surface finish [

8,

44,

45]. The deposition strategies (material quantities, density, and rastering), the support struc-tures, the scaffold architectures, and others, likewise in other metal AM processes, are de-fined by specific software, using the component CAD 3D file as a base to develop/design it [

5,

46,

47,

48].

The FFF process can use one of the three types of feedstocks: filament, – the most common, pellets and inkjet. The core features for the FFF process in metallic materials for filaments are the correct powder load and melt of the filament, adequate pressure to push the molten material through the nozzle to enable a controlled extrusion in the correct coordinate (defined in slicing), and proper bonding of the material extruded which will create a solid structure [

26,

39,

40,

48].

Figure 1 represents the schematics for the 5 steps of the FFF process, as described before.

The production of filaments for metal-based AM is a critical step in the process. It includes materials selection and mixture and the extrusion process into the form of the filament. The selection of appropriate materials, including metallic powders, binders, and additives, is essential to producing successful parts. The filaments utilized in metal-based AM result from the extrusion of feedstock, a combination of metallic powders and a polymer binder system in specific proportions, typically with 60% metallic powders and 40% polymeric materials. The objective of this mixture, similar to metal hot embossing and metal injection molding, is to distribute the metal powder evenly throughout the binder, preventing internal porosity and agglomeration and resulting in a homogeneous biphasic mixture [

8,

11,

26,

49,

50,

51]. The powder characteristics and properties have a significant impact on the rheological behavior of the filaments during their manufacture and the FFF process. Ideally, filament characterization should include results such as particle size distribution of the powder, powders morphology, density, specific surface area, inter-particle interaction, thermo-gravimetric analysis, and differential scanning calorimetry [

8,

51,

52,

53,

54]. Filament production is a complex operation, where the selected process parameters must suit the specific compound and extrusion system used, and preliminary optimized for each filament. The filament is usually extruded into a spool and must be preoptimized to ensure that the blend is homogeneous and has a consistent shape and diameter (usually 1.75 mm or 2.85 mm diameter). A suitable and practical FFF process requires the combi-nation of an appropriate feedstock and extrusion, which will enable a stable and effective (and profitable) process [

8,

24]. Alternatively, can be used pellets, skipping the extrusion into filament; using pellets instead of filament in FFF offers several benefits, including a broader range of material options, lower costs, and reduced waste production. However, using pellets also presents challenges, such as higher temperatures required to melt the pellets, more force needed to push them through the nozzle, and limited availability of specific materials [

5,

32]. Both ways are firstly required to produce a suitable feedstock.

The production process for polymer or metal-based components is similar from an equipment perspective. The feeding mechanism is positioned differently depending on whether the filament is metal, or polymer based. In the case of filaments constituted by binder systems and metal powder, which are fragile and prone to breakage, the filament spool is usually located at the top of the machine and directly connected to the feed mechanism. To avoid breakage, metallic filaments are fed vertically to the direct extrusion head and are typically used in a temperature-controlled chamber during AM processes. When heated to a temperature range of 150 °C to 200 °C, the filaments acquire a pseudo-plastic state enabling fed into a hot nozzle in the nozzle and head. The material is then extruded through an orifice diameter ranging from 0.25 mm to 1 mm [

1,

2,

55,

56,

57]. The material is deposited along the rastering paths created in the slicing software. The software determines the deposition of successive layers to create the desired geometry. FFF equipment may feature various heated die nozzle that enables the extrusion of different materials, such as component material, a release layer, or soluble support material, along a predefined path based on the sliced layers of the CAD 3D model [

9,

12,

44,

57]. The layer thickness and infill pattern can also be modified to control object strength and weight. The resulting part from this process is called the green part [

30,

58,

59].

Debinding optimization is contingent upon the attributes of the binder system and constituents. Multiple debinding methods are available, such as solvent debinding, cata-lytic debinding, thermal treatment, or combining two or more techniques [

49]. The debinding aims to eliminate the binder systems progressively, keeping the produced components' shape [

8,

50]. Obtaining proper components after debinding (brown parts) requires a gradual and stable binder removal to avoid defects and shape loss [

11,

49]. Poor debinding conditions can influence the components' porosity since carbon residues (prevenient from polymer/binder residues) influence the sintering process, promoting bloating, blistering, surface cracking, and large internal voids, which will increase the difficulty of achieving a highly dense component [

8,

24]. The process of transforming the brown part into a fully dense metal component is sintering, where a heat treatment is applied to transform the loosely bound metal powder particles into a bulk material. The initial temperature used in sintering is below the melting point (between 70 and 90%) of the metal powder, or the major metallic component, to get solid components, with all geometries created in the FFF process [

11,

24]. In sintering, the combination of high temperature and high porosity of the components, created by removing binders during debinding, promotes intense mass transport. As the sintering temperature increase, the system progressively reduces surface energy forming solid bonds (or necks) between the metal powder particles; these bonds continue to grow by diffusion, thus decreasing the porosity, and densifying the components, resulting in a shrinkage of components, usually around 20% of the initial volume [

26,

60,

61]. To optimize the sintering parameters and enhance component consolidation, it is required to monitor the process thru microstructural evaluation and mechanical characterization [

8,

24].

3. Design considerations for FFF with metallic materials

When compared to the FFF of polymeric materials, the application of the process to metallic materials requires specific concerns due to the differences in material properties, equipment capabilities, bed adhesion, layer height, cooling, and post-processing. Optimizing these factors makes it possible to produce high-quality metallic parts using FFF technology. To produce high-quality metallic parts using FFF technology, some specific design considerations must be taken. Metallic materials have different properties than polymers, such as higher melting points, higher thermal conductivity, and higher mechanical strength [

62]. These properties can affect the part's production process and final quality. Therefore, selecting a metallic material suitable for FFF and understanding its properties is essential to optimize the manufacturing process [

7,

10,

60]. Another consideration is the capabilities of the FFF equipment. They were designed to produce polymeric materials and may not be suitable for metallic materials [

6,

40]. It is essential to use equipment specifically designed for producing metallic materials or one that can be modified to produce them [

30]. The adhesion to the build plate is also crucial when using metallic materials since they tend to warp more than polymers due to their higher thermal conductivity. Therefore, it is necessary to use a production plate surface that provides good adhesion and prevents warping. The build plates for metallic materials include paper, glass, polyetherimide, and others. The layer height in FFF affects the surface finish and the strength of the finished part. For metallic materials, it is recommended to use a layer height of less than 50% of the nozzle diameter to ensure good adhesion between the layers and avoid delamination [

6]. Cooling is also essential since metallic materials require adequate cooling during production to prevent overheating and warping. It is recommended to use equipment with a cooling fan. Finally, after component production, likewise in other AM processes, like Powder Bed Fusion (PBF), metallic parts produced with FFF may require post-processing to remove support structures, smooth the surface, and improve the part's mechanical properties. Standard post-processing techniques for metallic parts include sandblasting, polishing, and heat treatment. Regarding supports, some equipment suppliers currently use a ceramic filament to enable an easier separation from parts; the ceramic particles do not sinter, due to higher temperatures required to solid-state diffusion when compared with metallic powders [

7,

10,

39].

Unlike traditional manufacturing methods, AM technologies build parts layer by layer, using CAD data to create complex geometries and intricate internal structures that would be impossible or difficult to produce with conventional manufacturing methods. Regarding design, it does not make sense to design components as if they were produced with the same principles as for traditional manufacturing processes structures. The De-sign for AM (DfAM) framework trusts sophisticated design methods, such as Topology Optimization (TO) and lattice structures, to design and optimize parts for AM processes [

63,

64,

65,

66]. It is a worthy process, as it enables the creation and simulation of thousands of designs promptly and the production of highly customized components with complex shapes [

67]. DfAM enables the optimization of AM by leveraging its unique capabilities to create printable designs that enhance performance, functionality, and efficiency, enabling de-signers to create parts optimized explicitly for AM processes. It differs from other design processes because it starts with an arbitrary formulation of an initial design concept and combines the algorithms' critical structures and variables transformed by the algorithms [

68,

69]. It unlocks innovative design possibilities and overcomes traditional manufacturing limitations.

When designing for AM processes, designers must contemplate crucial factors like material properties, layer thickness, speed, and support structures. DfAM processes entail unique considerations, depending on the process to be used. In direct energy deposition (DED), a process which also uses laser or electron beam as energy source, designers must ensure proper cooling of the metal parts during the build process to prevent distortion and minimize the use of support structures; in PBF, thorough selection of powder material and consideration of layer thickness and build orientation is required [

8,

70]. DfAM to the FFF process is peculiar, takes in the limitations of the process, and considers these constraints like part of the design process, orientation and overhangs, support structures for steep overhangs, wall thickness, part consolidation, and geometric complexity [

71,

72,

73]. These limitations are common on AM processes, and even more evident in FFF. DfAM practices are commonly implemented through specialized software that facilitates optimization, which provides insights into printability, structural integrity, and potential manufacturing issues, allowing designers to iterate and refine their models for optimal results in FFF [

2,

36,

74]. DfAM incorporate applicable requirements address and solves the typical conflicts between design and engineering allowing the creation of parts with well-defined functional requirements to obtain lightweight components and optimized parts, by the combination of design and simulation tools [

64,

69,

73]. DfAM guidelines and best practices consider the unique characteristics and limitations of AM processes, including the need for support structures, layer-by-layer build-up, and the choice of materials. Lattice structures are topologically ordered, 3D open structures with one or more repeating unit cells. AM lattice structures have outperformed cellular structures produced by other manufacturing methods with equivalent porosity due to the AM process's greater geometric control and predictability [

75,

76]. By optimizing parts for AM, companies can lower production costs and turnaround times, resulting in faster product development cycles and increased competitiveness in the market.

By adhering to DfAM guidelines, designers can create parts that perform better, cost less, and can be produced more quickly than traditional manufacturing methods [

73,

77]. With the continuous advancement of AM technology, the importance of DfAM is set to increase even further. DfAM is a crucial aspect of modern manufacturing, enabling the production of parts optimized for AM processes. Understanding this is overwhelmingly important, as choosing the most suitable process for an intended component application is crucial in AM. By considering factors such as material properties, production volume, lead time, cost, manufacturers, and the constraints from the component requirements (like tolerances, dimensions, wall thickness, and relative density, among others) can make informed decisions and optimize their AM for the specific needs. Stating this, understanding the strengths and limitations of each AM technology is essential in selecting the most suitable one for the intended application of the component to produce.

4. Challenges to overcome from using FFF with metallic materials

FFF has been used with various materials, and its application to certain materials presents unique challenges. Thus, other technologies are available for AM with metals, like PBF, DED and binder jetting (BJT), that have been developed specifically for AM for metals and offer advantages such as higher speeds and better control over material properties. However, these technologies also have limitations and challenges to overcome [

9,

39,

78,

79,

80].

There are several challenges to overcome regarding FFF for metallic materials. Finding the correct combination between metal powders and polymer/binder systems can be challenging since it will change the properties of materials, and – when compared with feedstocks – will need higher melting temperatures, higher extrusion pressures, and slower cooling rates to achieve a good production. The quality of the metallic filament used in FFF can also considerably affect the final component since the distribution of the metal particles within the filament can vary, affecting the final product's quality and mechanical properties [

1,

81,

82]. It can be challenging to ensure that the metal particles are evenly dispersed, avoiding the particles clumping together or settling in specific areas; it can result in inconsistent production and reduced mechanical properties of the final product. FFF is susceptible to various production quality issues, including an anisotropic feature that reduces the mechanical strength of the part in specific directions (mainly in the Z-axis), warping, delamination, and poor surface finish [

1,

8,

16,

19,

60,

82,

83]. Metal parts produced using FFF may have rough or uneven surfaces, affecting their functionality or aesthetics. It is common to find defects like pores, even between the rastering, and the presence of inclusions, which are common on the surface too [

26,

84].

The post-processing is also an issue and transversal to all Metal AM since it often require post-processing to achieve the desired mechanical and aesthetic properties, including heat treatments, polishing, electroplating, hot isostatic pressure, among others, which will add additional time and cost to the process [

19,

81,

82]. FFF must be better suited for producing parts with complex geometry or internal structures. The layer-by-layer process can result in the formation of voids or gaps in the produced component, which can compromise its strength and integrity [

1,

19,

60].

Not all processes are suitable for producing all components. It is crucial to consider several aspects, like the component geometry, material properties, production volume, and other factors affecting the final product's quality and suitability. Choosing the most viable and suitable technology can help achieve better results and reduce production costs. Therefore, it is pertinent to carefully evaluate the various AM processes available and determine the most appropriate one for the intended use.

5. Metallic materials for FFF and new/advanced materials utilization

FFF with metallic materials is becoming increasingly popular due to user-friendliness and cost-effective manufacturing technique. It enables producing parts with excellent mechanical properties comparable to conventionally manufactured parts. As already mentioned, AM – in general – enables design freedom, creating intricate shapes and complex geometries with improved mechanical properties, which would be difficult or impossible to produce using traditional manufacturing methods [

2,

8,

9,

10,

25,

26,

40,

85].

FFF with metallic materials research has demonstrated that FFF-produced parts can have similar tensile strength, ductility, and fatigue resistance as parts made by traditional methods, such as machining, casting, and forging [

2,

7,

8,

19]. The ability to produce hollow parts with reduced weight and cost is a significant advantage of metal-based FFF, which is particularly beneficial in industries like aerospace that require lightweight and durable components. FFF with metallic materials also offers enhanced mechanical properties, making it an ideal method for manufacturing high-strength and durable parts comparable to those produced using traditional manufacturing techniques [

2,

11,

16,

26].

The layer-by-layer deposition of material during the FFF process creates a characteristic microstructure that differs from conventionally manufactured parts. Adjusting sintering temperature, FFF-produced parts can have microstructure characterized by small grains, a fine distribution of strengthening phases, and the presence of defects such as voids, cracks, porosity, and inclusions [

60,

84,

86]. Another advantage of FFF with metallic materials is its ability to produce graded materials, which vary in composition or properties over their volume, resulting in a smooth transition from one material or property to another. FFF with metallic materials can create graded materials by changing the composition of the feedstock or adjusting the process parameters [

15,

87,

88]. Graded materials can be used to tailor the properties of parts to specific requirements, such as reducing weight while maintaining strength or improving wear resistance at a critical surface [

87,

89,

90]. Ongoing research is exploring the potential of FFF with metallic materials for additional applications, such as in the aerospace and biomedical industries [

91,

92,

93].

6. Metallic materials for FFF and new/advanced materials utilization

Materials perform a crucial role, and FFF brings flexibility compared to beam-based and jetting processes. FFF involves melting filaments of various materials, such as polymers and metals, and then cooling them to form the desired shape. FFF equipment typically uses a spool of thermoplastic filament, which is heated and extruded through a nozzle onto a build platform to create the object. Advancements in materials science have led to the development of metallic materials that can be used in FFF. These metallic filaments are typically made by combining metal powders with a binder material, which allows the filament to be extruded through the nozzle. Different metallic filaments can be used with FFF equipment, including bronze, copper, stainless steel, aluminum, and titanium, known from AM processes. By using the unique properties of MMCs, HEAs, and FGMs, and taking advantage of AM, it is possible to develop high-performance components with enhanced properties that can be tailored to specific applications. As research into these materials continues, it is expected that they will be widely adopted and used in a variety of industries around the world [

13,

14,

94].

MMCs are composite materials that combine a metal or alloy matrix with a reinforcement material such as ceramic, metal, or fiber. They are known for their high strength, durability, lightweight, good thermal and electrical conductivity, and excellent wear resistance, making it suitable for various industries such as aerospace, automotive, and medical. FFF is a promising AM technique for producing MMCs. However, several challenges must be addressed to achieve optimal results. One of the most important factors is ensuring sufficient adhesion between material layers during production to maintain bonding after cooling. Other essential factors include selecting the appropriate feedstock material, controlling the temperature, and optimizing slicing parameters such as layer height and infill pattern. By considering these factors and making the appropriate adjustments, optimized FFF processes can be achieved for creating high-performing metallic components using composite materials. However, additional research is needed before the widespread adoption of MMCs using FFF can occur. Developing improved processing techniques and an increased understanding of how different parameters affect material performance will facilitate increased adoption rates and result in better products at lower costs for various markets worldwide [

13,

94,

95,

96,

97,

98,

99].

HEAs, unlike conventional alloys, consist of multiple principal elements, offering a wide range of compositions. HEAs are promising multi-component alloys with unique combination of novel microstructures and excellent properties, and using FFF in AM will bring a new paradigm, by offering unique properties and enabling new applications. HEAs possess high strength, good ductility, improved fracture toughness, high-temperature stability, and superior corrosion resistance. The ongoing research focuses on alloy design, process optimization, feedstock development, and comprehensive characterization. HEAs provide a broad range of compositions, enabling tailored alloys for specific FFF applications. This versatility balances printability, mechanical strength, and corrosion resistance. HEAs exhibit exceptional stability at elevated temperatures, making them ideal for thermal cycling applications or high operating temperatures. Furthermore, certain HEAs outperform traditional alloys in corrosive environments, ensuring durability and longevity in challenging conditions [

15,

100,

101,

102].

FGMs are materials with a graded composition, microstructure, and properties, enabling them to smooth the transition between different material phases. Due to their unique properties, FGMs are widely used in aerospace, automotive, and biomedical industries. The production of FGMs using FFF involves modifying the composition of the filaments fed into the equipment, allowing the creation of custom-designed parts with varying mechanical, thermal, and electrical properties. Furthermore, FGMs can be designed with specific characteristics, such as thermal conductivity and electrical resistivity, to address needs in different industries. For example, in the aerospace industry, FGMs can be utilized to improve the performance of jet engine components. In the biomedical sector, FGMs can be used to develop customized implants that mimic the mechanical properties of human bones. Moreover, FGMs can be used in energy harvesting devices, such as thermoelectric generators, to enhance energy conversion efficiency. The production of FGMs using FFF presents several challenges, including the need for a well-controlled extrusion system to maintain a constant and precise flow of composite materials. Additionally, FFF for FGMs requires a thorough understanding of the mechanical properties and behavior of the materials involved to achieve optimal results. Nevertheless, the potential benefits of FGMs make them a promising field of research for future materials development [

15,

103,

104,

105].

7. Applications

As discussed above, FFF technology is rapidly growing in popularity and is widely adopted in various industries – like aeronautical, aerospace, automotive, and medical industries, among others – and is widely used with metallic materials to create complex and lightweight components [

7,

21,

39,

106,

107,

108,

109]. The versatility and cost-effectiveness of FFF technology make it an attractive option for a wide range of applications [

7,

59].

In recent years, advancements in FFF technology have made it possible to produce a range of metallic materials. FFF technology is getting much attention from the aeronautical and aerospace industry due to creating complex, lightweight components for their vehicles [

71,

110]. This technology can produce lightweight, high-strength components, improving fuel efficiency and reducing emissions. There are several components, such as structural components, frames, supports, sensors, and actuators for aircraft and spacecraft. FFF with metallic materials is an efficient and cost-effective way to create aircraft and spacecraft components prototypes [

71]. It allows engineers to quickly design, evaluate, and modify different parts, reducing development time and costs [

111,

112,

113]. It can also be used to create customized components that meet the specific needs of aircraft and spacecraft manufacturers. It is beneficial for small-scale production runs or retrofitting existing aircraft or spacecraft with new components. Tooling made using FFF can be produced quickly, and using metallic materials ensures that the tools are durable and can withstand the harsh environments of the aerospace industry. Furthermore, metallic materials used in FFF can withstand high temperatures, making them suitable for creating heat-resistant components for aircraft and spacecraft [

7,

114]. It includes engine components, exhaust systems, and other parts exposed to high temperatures during flight. Additionally, FFF with metallic materials can be used to repair and maintain aircraft and spacecraft components, extend the life of existing components, and reduce the need for costly replacements [

7,

39].

FFF gained attention in the automotive industry due to its various applications. One of the most significant applications is the ability to create prototypes of new parts or components quickly. This technology enables automotive manufacturers to reduce the time and cost associated with traditional prototyping methods, making the design process more efficient. Furthermore, FFF with metallic materials can produce custom tooling for automotive manufacturing processes, which can help reduce the time and cost associated with traditional tooling methods. It can also improve fuel efficiency and performance and lower manufacturing costs [

6,

111,

113,

115]. In addition, the technology enables manufacturers to create replacement parts for older vehicles that are no longer in production, extending the life of these vehicles and reducing the need for costly repairs or replacements. Another significant benefit of FFF with metallic materials is its ability to help manufacturers reduce the weight of their vehicles while maintaining strength and durability. This can result in improved fuel efficiency, performance, and safety [116-118].

FFF technology has emerged as a promising manufacturing process for the medical industry, particularly for prosthetics and medical devices. Using it has opened new possibilities for creating more precise and biocompatible parts and components [

103,

113,

119]. The process enables the production of intricate parts and geometry. FFF with metallic materials offers significant advantages over conventional manufacturing methods for medical devices, such as computerized numerical control machining and casting. The technology is more cost-effective, has shorter lead times, and offers greater design flexibility. It is significant to produce custom implants, which must be tailored to the patient's anatomy [

103,

113,

119]. One of the most important applications of FFF with metallic materials in the medical industry is the production of implantable medical devices, such as dental, cranial, and spinal implants. These implants must be biocompatible, durable, and have precise geometries that match the patient's anatomy. FFF technology is an effective method for producing such implants with high precision and biocompatibility. The use of metallic materials in FFF also enables the production of implants with high strength and corrosion resistance, which are crucial for long-term implant stability [

48,

120,

121,

122]. FFF with metallic materials has also been used to create surgical instruments, such as scalpels, forceps, and tweezers. The technology enables the production of surgical instruments with complex geometries and customized designs. The devices produced using FFF with metallic materials have also been found to have good mechanical properties, such as high strength and wear resistance, similar with conventional materials. FFF with metallic materials has immense potential in the medical industry, particularly for producing prosthetics and medical devices. The technology offers several advantages over conventional manufacturing methods, including cost-effectiveness, faster turnaround times, and greater design flexibility [

103,

113,

123]. FFF with metallic materials can help improve patient care quality and advance medical innovation by enabling the production of precise and biocompatible parts and components.

The tool and mold-making industry has found numerous applications for FFF technology, including prototyping, creating jigs and fixtures, low-volume production, and custom tooling [

124,

125]. FFF technology enables designers and manufacturers to make quick and inexpensive prototypes of tools and molds before investing in expensive tooling. It can also be used to create custom jigs and fixtures that hold workpieces in place during manufacturing processes. These jigs and fixtures can be designed and quickly produced, which reduces lead time and costs [

44,

82,

113,

126]. FFF technology is helpful for low-volume production of tooling components, such as inserts, cores, and cavities, particularly for small businesses that cannot afford expensive tooling or require frequent design changes. Custom tooling is another application of FFF technology, where the molds can be designed to create unique shapes or textures that are difficult to achieve with traditional molding techniques. FFF technology has revolutionized the tool and mold-making industry by enabling faster, cheaper, and more flexible manufacturing processes. With the ability to easily create customized and complex designs, FFF technology has become an increasingly popular option for manufacturers looking to improve their productivity and reduce costs [

5,

48,

60,

124,

127].

Additionally, several other industries employ FFF with metallic materials as a successful AM technique, including marine engineering, architecture and construction, jewelry and watchmaking, art and sculpture, electronics manufacturing, and sports equipment manufacturing. As stated before, the versatility and cost-effectiveness allowed by the FFF technology make it an appealing alternative for various applications [

24,

127,

128].

8. Conclusions

FFF of metallic materials has shown enormous potential to revolutionize the way metallic parts are produced. Its versatility and cost-effectiveness offer promising technology for various industries and applications. Metal-based AM can help create more efficient, cost-effective, and sustainable products, enabling greater customization, faster prototyping, and lighter-weight components. AM technology can transform industries from aeronautical to aerospace, automotive, medical, and others. Ongoing research and development are expected to lead to further improvements in the technology and expand its range of applications. FFF of metallic materials is an exciting area of research with the potential to transform industries by enabling the production of complex, custom parts with reduced lead times and costs. Even though its advantages, several challenges still need to be addressed. One of the most significant challenges is the limited range of metallic materials available as filaments. The materials available for FFF of metallic materials are limited compared to other metal-based AM processes. This limits the application of FFF of metallic materials to specific parts and industries. Furthermore, the size of the produced parts is limited, and the post-processing requirements can be significant. Additionally, the manufacturing orientation and support structures can affect the properties of the printed metallic parts, requiring careful consideration.

Researchers are exploring new techniques and materials, including hybrid systems that combine FFF with other AM technologies, to address the challenges of limited material range, size limitations, and post-processing requirements. MMCs and FGMs offer a promising area of research that can enable the creation of custom parts with varying mechanical properties. FFF of metallic materials is a technology to watch in the coming years with the potential to create more efficient, cost-effective, and sustainable products. The continued research and development of FFF of metallic materials will enable the creation of more complex and custom parts, further revolutionizing manufacturing across various industries. With MMCs and FGMs, this technology can be used to create custom parts with varying mechanical properties, such as stiffness, strength, and thermal conductivity, which can benefit various applications.

The widespread adoption of metal-based FFF could significantly impact the manufacturing industry. Metal-based FFF has the potential to democratize manufacturing by enabling small businesses and individuals to produce custom parts on-demand. This could significantly impact the supply chain, reducing the need for large-scale manufacturing facilities and enabling greater customization of products. Additionally, metal-based FFF can potentially reduce the carbon footprint of the manufacturing industry by reducing waste and enabling the creation of lighter-weight products.

Summarizing, the FFF of metallic materials is a promising technology with several advantages, including its ease of use, affordability, and versatility. This technology has the potential to revolutionize manufacturing across a range of industries. However, several challenges still need to be addressed, including the limited range of metallic materials available as filaments, the limited size of the printed parts, and the post-processing requirements. Continued research and development are needed to overcome the remaining challenges and enable the widespread use of FFF to produce metallic parts.

9. Prospects for the Metal FFF Future

One of the most significant prospects for metal-based FFF is developing new materials. Currently, the range of commercial metallic materials available as filaments for FFF is limited, which restricts the range of applications that can be achieved. However, ongoing research and development are expected to lead to the development of new materials suitable for FFF, expanding the range of applications that can be achieved. In the materials, it is also critical to investigate and find new binders, more adapted to FFF and to the processes of removal of binder and sintering to enable better final components. To achieve the desired properties, the parts must also be subjected to post-processing, such as heat treatment or machining. This can be time-consuming and expensive, reducing the cost-effectiveness of the technology. Continued research and development are needed to develop new post-processing techniques that are more cost-effective and time efficient. Another significant challenge is the manufacturing orientation and support structures required for metal-based FFF. The orientation of the part and the support structures used can affect the properties of the printed part, requiring careful consideration during the design process. Continued research and development are needed to develop new software and hardware to optimize the printing process and reduce the need for support structures.

The improvement of the manufacturing process itself is required. One of the most significant challenges is the limited size of the produced parts. Continued research and development are expected to lead to the development of larger printers capable of printing larger parts. Additionally, improvements in the development of new software and hardware are expected to improve the precision and accuracy of the printing process, enabling the creation of more complex parts with greater accuracy. Also, improving the debinding and sintering process is necessary to enable better components in a quicker and more feasible way. Additionally, research is being conducted on hybrid systems that combine FFF with other AM technologies, such as PBF or DED processes, to create new materials with enhanced properties.

Author Contributions

Conceptualization, J.M.C., E.W.S. and M.F.V.; writing—original draft preparation, J.M.C.; writing—review and editing, J.M.C., E.W.S. and M.F.V. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| AM |

Additive Manufacturing |

| BJT |

Binder Jetting |

| CAD |

Computer-Aided Design |

| DED |

Direct Energy Deposition |

| DfAM |

Design for Additive Manufacturing |

| FFF |

Fused Filament Fabrication |

| FDM |

Fused Deposition Modeling |

| FGM |

Functionally Graded Materials |

| HEA |

High Entropy Alloys |

| MMC |

Metal Matrix Composites |

| PBF |

Powder Bed Fusion |

| TO |

Topology Optimization |

References

- Tuncer, N.; Bose, A. Solid-State Metal Additive Manufacturing: A Review. JOM 2020, 72, 3090–3111. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components - Process, structure and properties. Progress in Materials Science 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Bai, S.Y.; Riede, M.; Garratt, E.; Roch, A. A comprehensive study on fused filament fabrication of Ti-6Al-4V structures. Additive Manufacturing 2020, 34. [Google Scholar] [CrossRef]

- Shaik, Y.P.; Schuster, J.; Shaik, A. A Scientific Review on Various Pellet Extruders Used In 3D Printing FDM Processes. OALib 2021, 08, 1–19. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Extrusion-based additive manufacturing process for producing flexible parts. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2018, 40. [Google Scholar] [CrossRef]

- Boyle, B.M.; Xiong, P.T.; Mensch, T.E.; Werder, T.J.; Miyake, G.M. 3D printing using powder melt extrusion. Additive Manufacturing 2019, 29, 100811. [Google Scholar] [CrossRef] [PubMed]

- Gibson, M.A.; Mykulowycz, N.M.; Shim, J.; Fontana, R.; Schmitt, P.; Roberts, A.; Ketkaew, J.; Shao, L.; Chen, W.; Bordeenithikasem, P.; et al. 3D printing metals like thermoplastics: Fused filament fabrication of metallic glasses. Mater Today 2018, 21, 697–702. [Google Scholar] [CrossRef]

- Costa, J.; Sequeiros, E.; Vieira, M.T.; Vieira, M. Additive Manufacturing: Material Extrusion of Metallic Parts. U.Porto Journal of Engineering 2021, 7, 53–69. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J Mater Eng Perform 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Herderick, E. Additive Manufacturing of Metals: A Review In Proceedings of the MS&T 2011: Proceedings from the Materials Science & Technology Conference, Columbus, Ohio, 2011; pp. 1413 - 1425. [Google Scholar]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials (Basel) 2018, 11, 840. [Google Scholar] [CrossRef]

- Dey, A.; Roan Eagle, I.N.; Yodo, N. A Review on Filament Materials for Fused Filament Fabrication. J Manuf Mater Proc 2021, 5, 69. [Google Scholar] [CrossRef]

- Behera, M.P.; Dougherty, T.; Singamneni, S. Conventional and Additive Manufacturing with Metal Matrix Composites: A Perspective. Digital Manufacturing Transforming Industry Towards Sustainable Growth 2019, 30, 159–166. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Mater Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Materials Science and Engineering: A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater Design 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Chern, A.H.; Nandwana, P.; McDaniels, R.; Dehoff, R.R.; Liaw, P.K.; Tryon, R.; Duty, C.E. Build orientation, surface roughness, and scan path influence on the microstructure, mechanical properties, and flexural fatigue behavior of Ti–6Al–4V fabricated by electron beam melting. Materials Science and Engineering: A 2020, 772, 138740. [Google Scholar] [CrossRef]

- Chen, L.Y.; Huang, J.C.; Lin, C.H.; Pan, C.T.; Chen, S.Y.; Yang, T.L.; Lin, D.Y.; Lin, H.K.; Jang, J.S.C. Anisotropic response of Ti-6Al-4V alloy fabricated by 3D printing selective laser melting. Materials Science and Engineering: A 2017, 682, 389–395. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O'Donoghue, L.; Charitidis, C. Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Mater Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Leach, R.K.; Bourell, D.; Carmignato, S.; Donmez, A.; Senin, N.; Dewulf, W. Geometrical metrology for metal additive manufacturing. Cirp Ann-Manuf Techn 2019, 68, 677–700. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int J Adv Manuf Tech 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Study on unsupported overhangs of AlSi10Mg parts processed by Direct Metal Laser Sintering (DMLS). J Manuf Process 2015, 20, 500–506. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Additive Manufacturing 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Gonzalez-Gutierez, J.; Godec, D.; Guran, R.; Spoerk, M.; Kukla, C.; Holzer, C. 3d Printing Conditions Determination for Feedstock Used in Fused Filament Fabrication (Fff) of 17-4ph Stainless Steel Parts. Metalurgija 2018, 57, 117–120. [Google Scholar]

- Angelopoulos, P.M.; Samouhos, M.; Taxiarchou, M. Functional fillers in composite filaments for fused filament fabrication; a review. Materials Today: Proceedings 2021, 37, 4031–4043. [Google Scholar] [CrossRef]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Additive Manufacturing 2019, 30. [Google Scholar] [CrossRef]

- Singh, P.; Balla, V.K.; Tofangchi, A.; Atre, S.V.; Kate, K.H. Printability studies of Ti-6Al-4V by metal fused filament fabrication (MF3). Int J Refract Met H 2020, 91. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, S.; Riede, M.; Garratt, E.; Roch, A. A comprehensive study on fused filament fabrication of Ti-6Al-4V structures. Additive Manufacturing 2020, 34, 101256. [Google Scholar] [CrossRef]

- Schatt, W.W., K-P. Powder Metallurgy - Processing and Materials; EPMA: 1997.

- Matsuzaki, R.; Kanatani, T.; Todoroki, A. Multi-material additive manufacturing of polymers and metals using fused filament fabrication and electroforming. Additive Manufacturing 2019, 29. [Google Scholar] [CrossRef]

- Annoni, M.; Giberti, H.; Strano, M. Feasibility Study of an Extrusion-based Direct Metal Additive Manufacturing Technique. 44th North American Manufacturing Research Conference, Namrc 44 2016, 5, 916–927. [Google Scholar] [CrossRef]

- Volpato, N.; Kretschek, D.; Foggiatto, J.A.; Cruz, C.M.G.D. Experimental analysis of an extrusion system for additive manufacturing based on polymer pellets. Int J Adv Manuf Tech 2015, 81, 1519–1531. [Google Scholar] [CrossRef]

- Zhou, Z.; Salaoru, I.; Morris, P.; Gibbons, G.J. Additive manufacturing of heat-sensitive polymer melt using a pellet-fed material extrusion. Additive Manufacturing 2018, 24, 552–559. [Google Scholar] [CrossRef]

- Whyman, S.; Arif, K.M.; Potgieter, J. Design and development of an extrusion system for 3D printing biopolymer pellets. The International Journal of Advanced Manufacturing Technology 2018, 96, 3417–3428. [Google Scholar] [CrossRef]

- Xu, C.; Quinn, B.; Lebel, L.L.; Therriault, D.; L’Espérance, G. Multi-Material Direct Ink Writing (DIW) for Complex 3D Metallic Structures with Removable Supports. ACS Applied Materials & Interfaces 2019, 11, 8499–8506. [Google Scholar] [CrossRef]

- Ang, X.; Tey, J.Y.; Yeo, W.H.; Shak, K.P.Y. A review on metallic and ceramic material extrusion method: Materials, rheology, and printing parameters. J Manuf Process 2023, 90, 28–42. [Google Scholar] [CrossRef]

- Pandya, K.S.; Shindalkar, S.S.; Kandasubramanian, B. Breakthrough to the pragmatic evolution of direct ink writing: progression, challenges, and future. Progress in Additive Manufacturing 2023. [Google Scholar] [CrossRef]

- Bonada, J.; Xuriguera, E.; Calvo, L.; Poudelet, L.; Cardona, R.; Padilla, J.A.; Niubó, M.; Fenollosa, F. Analysis of printing parameters for metal additive manufactured parts through Direct Ink Writing process. Procedia Manufacturing 2019, 41, 666–673. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies : Rapid Prototyping to Direct Digital Manufacturing; Springer US: New York, 2010. [Google Scholar]

- Wagner, M.A.; Hadian, A.; Sebastian, T.; Clemens, F.; Schweizer, T.; Rodriguez-Arbaizar, M.; Carreño-Morelli, E.; Spolenak, R. Fused filament fabrication of stainless steel structures - from binder development to sintered properties. Additive Manufacturing 2022, 49, 102472. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Introduction and Basic Principles. In Additive Manufacturing Technologies; Springer International Publishing: Cham, 2021; pp. 1–21. [Google Scholar]

- Al, C.M.; Yaman, U. Improving the strength of additively manufactured objects via modified interior structure. 2017.

- Gao, W.; Zhang, Y.B.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput Aided Design 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyping J 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Greeff, G.P.; Schilling, M. Single print optimisation of fused filament fabrication parameters. Int J Adv Manuf Tech 2018, 99, 845–858. [Google Scholar] [CrossRef]

- Rane, K.; Strano, M. A comprehensive review of extrusion-based additive manufacturing processes for rapid production of metallic and ceramic parts. Adv Manuf 2019, 7, 155–173. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. Cirp Ann-Manuf Techn 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J Manuf Process 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Sequeiros, E.W.; Emadinia, O.; Vieira, M.T.; Vieira, M.F. Development of Metal Powder Hot Embossing: A New Method for Micromanufacturing. Metals-Basel 2020, 10, 388. [Google Scholar] [CrossRef]

- Singh, P.; Shaikh, Q.; Balla, V.K.; Atre, S.V.; Kate, K.H. Estimating Powder-Polymer Material Properties Used in Design for Metal Fused Filament Fabrication (DfMF3). Jom 2019, 72, 485–495. [Google Scholar] [CrossRef]

- Emadinia, O.; Vieira, M.T.; Vieira, M.F. Development and characterization of AISI 316L micro parts produced by metal powder hot embossing. The International Journal of Advanced Manufacturing Technology 2021, 113, 407–417. [Google Scholar] [CrossRef]

- Sequeiros, E.W.; Ferreira, T.J.; Neto, V.C.; Vieira, M.T.; Vieira, M.F. Microstructural Characterization of Metallic Parts Produced by Hot Embossing. Microsc Microanal 2015, 21 Suppl 5, 49–50. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C.; Antil, P.; Singh, R.; Krolczyk, G.; Pruncu, C.I. Dimensionless Analysis for Investigating the Quality Characteristics of Aluminium Matrix Composites Prepared through Fused Deposition Modelling Assisted Investment Casting. Materials (Basel) 2019, 12, 1907. [Google Scholar] [CrossRef]

- Royer, A.; Barriere, T.; Gelin, J.C. Development and Characterization of a Metal Injection Molding Bio Sourced Inconel 718 Feedstock Based on Polyhydroxyalkanoates. Metals-Basel 2016, 6, 89. [Google Scholar] [CrossRef]

- Hertle, S.; Kleffel, T.; Worz, A.; Drummer, D. Production of polymer-metal hybrids using extrusion-based additive manufacturing and electrochemically treated aluminum. Additive Manufacturing 2020, 33, 101135. [Google Scholar] [CrossRef]

- Kumar, L.J.; Pandey, P.M.; Wimpenny, D.I. 3D printing and additive manufacturing technologies; Springer, 2019; Volume 311. [Google Scholar]

- Patel, A.; Taufik, M. Extrusion-Based Technology in Additive Manufacturing: A Comprehensive Review. Arabian Journal for Science and Engineering 2022. [Google Scholar] [CrossRef]

- Hui, W.; Shao, C.; Zhang, Y.; Zhao, X.; Weng, Y. Microstructure and mechanical properties of medium Mn steel containing 3%Al processed by warm rolling. Materials Science and Engineering: A 2017, 707, 501–510. [Google Scholar] [CrossRef]

- Nath, P.; Olson, J.D.; Mahadevan, S.; Lee, Y.-T.T. Optimization of fused filament fabrication process parameters under uncertainty to maximize part geometry accuracy. Additive Manufacturing 2020, 35, 101331. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.; Rohru, P.; Babbar, A.; Kumar, R.; Ranjan, N.; Chohan, J.S.; Kumar, R.; Gupta, M. Fused filament fabrication: A state-of-the-art review of the technology, materials, properties and defects. International Journal on Interactive Design and Manufacturing (IJIDeM) 2022. [Google Scholar] [CrossRef]

- Notzel, D.; Hanemann, T. New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts. Materials (Basel) 2020, 13, 4461. [Google Scholar] [CrossRef] [PubMed]

- Mulholland, T.; Goris, S.; Boxleitner, J.; Osswald, T.A.; Rudolph, N. Fiber Orientation Effects in Fused Filament Fabrication of Air-Cooled Heat Exchangers. JOM: The Journal of The Minerals, Metals & Materials Society (TMS) 2018, 70, 298. [Google Scholar]

- Li, S.; Wei, H.; Yuan, S.; Zhu, J.; Li, J.; Zhang, W. Collaborative optimization design of process parameter and structural topology for laser additive manufacturing. Chinese Journal of Aeronautics 2023, 36, 456–467. [Google Scholar] [CrossRef]

- Gebisa, A.W.; Lemu, H.G. Design for manufacturing to design for Additive Manufacturing: Analysis of implications for design optimality and product sustainability. Procedia Manufacturing 2017, 13, 724–731. [Google Scholar] [CrossRef]

- Sossou, G.; Demoly, F.; Montavon, G.; Gomes, S. An additive manufacturing oriented design approach to mechanical assemblies. Journal of Computational Design and Engineering 2017, 5, 3–18. [Google Scholar] [CrossRef]

- Mata, M.; Pinto, M.; Costa, J. Topological Optimization of a Metal Extruded Doorhandle using nTopology. U.Porto Journal of Engineering 2023, 9, 42–54. [Google Scholar] [CrossRef]

- Vuillemot, R.; Huron, S. Glitches as a generative design process. 2017.

- Cui, J.; Tang, M.X. Towards generative systems for supporting product design. International Journal of Design Engineering 2017, 7, 1–16. [Google Scholar] [CrossRef]

- Oliveira, C.; Maia, M.; Costa, J. Production of an Office Stapler by Material Extrusion Process, using DfAM as Optimization Strategy. U.Porto Journal of Engineering 2023, 9, 28–41. [Google Scholar] [CrossRef]

- Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Schmelzle, J.; Kline, E.V.; Dickman, C.J.; Reutzel, E.W.; Jones, G.; Simpson, T.W. (Re)Designing for Part Consolidation: Understanding the Challenges of Metal Additive Manufacturing. J Mech Design 2015, 137, 111404–111404. [Google Scholar] [CrossRef]

- Mass, Y.; Amir, O. Topology optimization for additive manufacturing: Accounting for overhang limitations using a virtual skeleton. Additive Manufacturing 2017, 18, 58–73. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, Y.F. Additive manufacturing-enabled design theory and methodology: a critical review. Int J Adv Manuf Tech 2015, 80, 327–342. [Google Scholar] [CrossRef]

- Langelaar, M. An additive manufacturing filter for topology optimization of print-ready designs. Struct Multidiscip O 2017, 55, 871–883. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater Design 2019, 183, 108137. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, P.; Biyikli, E.; Bai, J.; Pilz, S.; To, A.C. Integration of topology optimization with efficient design of additive manufactured cellular structures. In Proceedings of the Proceedings of the Solid Freeform Fabrication (SFF) Conference, Austin, TX; 2015. [Google Scholar]

- Yang, L.; Hsu, K.; Baughman, B.; Godfrey, D.; Medina, F.; Menon, M.; Wiener, S. Additive manufacturing of metals: the technology, materials, design and production; Springer, 2017. [Google Scholar]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J Manuf Sci E-T Asme 2015, 137, 014001. [Google Scholar] [CrossRef]

- Cooke, S.; Ahmadi, K.; Willerth, S.; Herring, R. Metal additive manufacturing: Technology, metallurgy and modelling. J Manuf Process 2020, 57, 978–1003. [Google Scholar] [CrossRef]

- Ciurana, J. New Opportunities and Challenges for Additive Manufacturing to Produce Biomedical Devices. IFAC Proceedings Volumes 2013, 46, 283–288. [Google Scholar] [CrossRef]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: a review of achievements and challenges. J Mater Sci 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyping J 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Wang, D.; Han, H.; Sa, B.; Li, K.; Yan, J.; Zhang, J.; Liu, J.; He, Z.; Wang, N.; Yan, M. A review and a statistical analysis of porosity in metals additively manufactured by laser powder bed fusion. Opto-Electronic Advances 2022, 5, 210058–210051. [Google Scholar] [CrossRef]

- Tosto, C.; Tirillò, J.; Sarasini, F.; Cicala, G. Hybrid Metal/Polymer Filaments for Fused Filament Fabrication (FFF) to Print Metal Parts. Applied Sciences 2021, 11, 1444. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.; Rodriguez, C.; Roman-Flores, A. Characterization of the Mechanical Properties of FFF Structures and Materials: A Review on the Experimental, Computational and Theoretical Approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Prediction of interlayer strength in material extrusion additive manufacturing. Additive Manufacturing 2020, 35, 101368. [Google Scholar] [CrossRef]

- Sam, M.; Jojith, R.; Radhika, N. Progression in manufacturing of functionally graded materials and impact of thermal treatment—A critical review. J Manuf Process 2021, 68, 1339–1377. [Google Scholar] [CrossRef]

- Reichardt, A.; Shapiro, A.A.; Otis, R.; Dillon, R.P.; Borgonia, J.P.; McEnerney, B.W.; Hosemann, P.; Beese, A.M. Advances in additive manufacturing of metal-based functionally graded materials. Int Mater Rev 2021, 66, 1–29. [Google Scholar] [CrossRef]

- Ostolaza, M.; Arrizubieta, J.I.; Lamikiz, A.; Plaza, S.; Ortega, N. Latest Developments to Manufacture Metal Matrix Composites and Functionally Graded Materials through AM: A State-of-the-Art Review. Materials 2023, 16, 1746. [Google Scholar] [CrossRef]

- Loh, G.H.; Pei, E.J.; Harrison, D.; Monzon, M.D. An overview of functionally graded additive manufacturing. Additive Manufacturing 2018, 23, 34–44. [Google Scholar] [CrossRef]

- Traxel, K.D.; Bandyopadhyay, A. Reactive-deposition-based additive manufacturing of Ti-Zr-BN composites. Additive Manufacturing 2018, 24, 353–363. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Li, Z.; et al. A Review on Functionally Graded Materials and Structures via Additive Manufacturing: From Multi-Scale Design to Versatile Functional Properties. Advanced Materials Technologies 2020, 5, 1900981. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Bocklund, B.; Otis, R.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; McEnerney, B.; Liu, Z.-K.; Beese, A.M. Characterization of a functionally graded material of Ti-6Al-4V to 304L stainless steel with an intermediate V section. Journal of Alloys and Compounds 2018, 742, 1031–1036. [Google Scholar] [CrossRef]

- Togwe, T.; Gokce, A.; Chen, Y.Y.; German, R.M.; Atre, S. Metal matrix composites for fabricating tooling. Int J Refract Met H 2020, 87, 105169. [Google Scholar] [CrossRef]

- Sheydaeian, E.; Toyserkani, E. A new approach for fabrication of titanium-titanium boride periodic composite via additive manufacturing and pressure-less sintering. Compos Part B-Eng 2018, 138, 140–148. [Google Scholar] [CrossRef]

- Mostafaei, A.; Heidarzadeh, A.; Brabazon, D. Additive Manufacturing of Metal Matrix Composites. 2020.

- Mostafaei, A.; Heidarzadeh, A.; Brabazon, D. Production of Metal Matrix Composites Via Additive Manufacturing. In Reference Module in Materials Science and Materials Engineering; Elsevier, 2021. [Google Scholar]

- Sharma, D.K.; Mahant, D.; Upadhyay, G. Manufacturing of metal matrix composites: A state of review. Materials Today: Proceedings 2020, 26, 506–519. [Google Scholar] [CrossRef]

- Sharma, A.K.; Bhandari, R.; Aherwar, A.; Rimašauskienė, R. Matrix materials used in composites: A comprehensive study. Materials Today: Proceedings 2020, 21, 1559–1562. [Google Scholar] [CrossRef]

- Ron, T.; Shirizly, A.; Aghion, E. Additive Manufacturing Technologies of High Entropy Alloys (HEA): Review and Prospects. Materials 2023, 16, 2454. [Google Scholar] [CrossRef]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: challenges and prospects. Mater Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Sheikh, S.; Gan, L.; Tsao, T.-K.; Murakami, H.; Shafeie, S.; Guo, S. Aluminizing for enhanced oxidation resistance of ductile refractory high-entropy alloys. Intermetallics 2018, 103, 40–51. [Google Scholar] [CrossRef]

- Hasanov, S.; Gupta, A.; Nasirov, A.; Fidan, I. Mechanical characterization of functionally graded materials produced by the fused filament fabrication process. J Manuf Process 2020, 58, 923–935. [Google Scholar] [CrossRef]

- Hasanov, S.; Gupta, A.; Alifui-Segbaya, F.; Fidan, I. Hierarchical homogenization and experimental evaluation of functionally graded materials manufactured by the fused filament fabrication process. Compos Struct 2021, 275, 114488. [Google Scholar] [CrossRef]

- Chueh, Y.H.; Wei, C.; Zhang, X.J.; Li, L. Integrated laser-based powder bed fusion and fused filament fabrication for three-dimensional printing of hybrid metal/polymer objects. Additive Manufacturing 2020, 31. [Google Scholar] [CrossRef]

- Careri, F.; Khan, R.H.U.; Todd, C.; Attallah, M.M. Additive manufacturing of heat exchangers in aerospace applications: a review. Appl Therm Eng 2023, 235, 121387. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Materials Science and Engineering: R: Reports 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Rauer, M.; Kaloudis, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Computed tomography for characterization of fatigue performance of selective laser melted parts. Mater Design 2015, 83, 661–669. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int Mater Rev 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Petrovic, V.; Ninerola, R. Powder recyclability in electron beam melting for aeronautical use. Aircr Eng Aerosp Tec 2015, 87, 147–155. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. Effect of Material and Process Specific Factors on the Strength of Printed Parts in Fused Filament Fabrication: A Review of Recent Developments. Materials (Basel) 2019, 12, 1664. [Google Scholar] [CrossRef]

- Waalkes, L.; Langerich, J.; Holbe, F.; Emmelmann, C. Feasibility study on piston-based feedstock fabrication with Ti-6Al-4V metal injection molding feedstock. Additive Manufacturing 2020, 35. [Google Scholar] [CrossRef]

- . [CrossRef]

- Warrier, N.; Kate, K.H. Fused filament fabrication 3D printing with low-melt alloys. Progress in Additive Manufacturing 2018, 3, 51–63. [Google Scholar] [CrossRef]

- Gorelik, M. Additive manufacturing in the context of structural integrity. International Journal of Fatigue 2017, 94, 168–177. [Google Scholar] [CrossRef]

- Hinduja, S.; Fan, K.-C.; Hon, K.K.B. Digital Additive Manufacturing: From Rapid Prototyping to Rapid Manufacturing. 2007; p. 337.

- Yang, G.Q.; Mo, J.K.; Kang, Z.Y.; Dohrmann, Y.; List, F.A.; Green, J.B.; Babu, S.S.; Zhang, F.Y. Fully printed and integrated electrolyzer cells with additive manufacturing for high-efficiency water splitting. Appl Energ 2018, 215, 202–210. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers (Basel) 2020, 12, 1665. [Google Scholar] [CrossRef]

- Yang, G.Q.; Yu, S.L.; Mo, J.K.; Kang, Z.Y.; Dohrmann, Y.; List, F.A.; Green, J.B.; Babu, S.S.; Zhang, F.Y. Bipolar plate development with additive manufacturing and protective coating for durable and high-efficiency hydrogen production. J Power Sources 2018, 396, 590–598. [Google Scholar] [CrossRef]

- Munsch, M. Laser additive manufacturing of customized prosthetics and implants for biomedical applications. In Laser Additive Manufacturing; 2017; pp. 399–420. [Google Scholar]

- Sun, Y.X.; Tian, W.; Zhang, T.; Chen, P.; Li, M.J. Strength and toughness enhancement in 3d printing via bioinspired tool path. Mater Design 2020, 185, ARTN 108239. [Google Scholar] [CrossRef]

- . [CrossRef]

- Soundararajan, R.; Jayasuriya, N.; Vishnu, R.G.G.; Prassad, B.G.; Pradeep, C. Appraisal of Mechanical and Tribological Properties on PA6-TiO2 Composites through Fused Deposition Modelling. Mater Today-Proc 2019, 18, 2394–2402. [Google Scholar] [CrossRef]

- Jonnala, U.K.; sankineni, R.; Ravi Kumar, Y. Design and development of fused deposition modeling (FDM) 3D-Printed Orthotic Insole by using gyroid structure. Journal of the Mechanical Behavior of Biomedical Materials 2023, 145, 106005. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Kumar, M.; Chohan, J.S. The role of additive manufacturing for biomedical applications: A critical review. J Manuf Process 2021, 64, 828–850. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R.; Singh, H. Development of rapid tooling using fused deposition modeling: a review. Rapid Prototyping J 2016, 22, 281–299. [Google Scholar] [CrossRef]

- Masood, S.H.; Song, W.Q. Development of new metal/polymer materials for rapid tooling using Fused deposition modelling. Mater Design 2004, 25, 587–594. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R. Pre and post processing techniques to improve surface characteristics of FDM parts: a state of art review and future applications. Rapid Prototyping J 2017, 23, 495–513. [Google Scholar] [CrossRef]

- Singh, S.; Singh, G.; Prakash, C.; Ramakrishna, S. Current status and future directions of fused filament fabrication. J Manuf Process 2020, 55, 288–306. [Google Scholar] [CrossRef]

- Singh, R.; Davim, J.P. Additive Manufacturing: Applications and Innovations; CRC Press, 2018. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).