1. Introduction

When it is talked about interventions on the Cultural Heritage or on the historical built heritage it is fundamental to investigate, in a transversal way, the themes inherent to traditional materials and techniques and their degradation as well as the innovative approach of modern techniques and materials that respond in a global way both to the compatibility problems and to the growing environmental emergencies that characterise today's daily life.

In fact, it is important to emphasise that in addition to the problems created by the huge quantities of waste material produced [

1], in Italy most of the building stock is not only extremely poorly maintained [

2], but is also characterised by a historical building that, although not subject to constraints, requires all those measures related to the compatibility of materials typical of the sensitivity adopted in the field of restoration.

The Cultural Heritage and Landscape Code defines restoration, in Art. 29, paragraph 4, as: "the direct intervention on the property through a complex of operations aimed at the material integrity and recovery of the property itself, at the protection and transmission of its cultural values."; interaction with the environment, in fact, entails over time an alteration of the original characteristics of the artefacts and the materials that compose them that undergo degradation phenomena due to physical agents such as humidity, water, thermal shock or even wind erosion or photo-oxidative phenomena caused by solar radiation, biological agents and chemical agents. The study of materials and techniques to be used for the recovery of this 'material integrity', which must also be guaranteed for that part of the unrestricted historical heritage that needs to be recovered. Moreover, reuse of materials as a recovery practice has its origins in a very ancient time where the practice of spoliation was very common and abandoned building heritage, both residential and monumental, was literally reused as a quarry of materials to be reused in the construction of new buildings [

3].

Actually, valorisation of construction and demolition waste (CDW) materials represents a kind of return to the origins, suitable to solve the disposal of huge quantities of waste and at the same time guarantee compatibility with the historical substrate using innovative mixtures that reproduce the same mineralogical and physical features [

4,

5,

6,

7]. Accordingly, geopolymers and alkali-activated materials represent the most promising and sustainable alternative to cement-based binders/concretes [

8,

9,

10,

11,

12] Geopolymers are obtained by chemically reacting a starting alumino-silicate powder with a strongly concentrated aqueous alkali hydroxide and/or silicate solution with the production of a synthetic amorphous-to-semicrystalline alkali alumino-silicate new phase [

13,

14]. In the last decade, the production of geopolymeric materials from industrial waste has been widely explored [

15,

16,

17,

18,

19,

20,

21]. In particular, considering the chemical nature of construction and demolition (C&D) wastes, geopolymerization technology started to be considered as an advantageous and smart reuse possibility for them instead of landfilling [

22,

23,

24,

25]. The use of alkali-activated material in building sector can provide a low environmental impact either in terms of energy consumption or natural resource saving, together with high mechanical and durability performances [

11]. Furthermore, as regards historical building restoration, chemical, physical and mechanical compatibility with the original material becomes mandatory, including showing similar aesthetic features [

26,

27,

28,

29,

30]. Starting from this consideration, this paper reports the progress of the research experience carried out on the production of sustainable construction materials, geocomposites, starting from waste produced by demolition and construction activities of historical heritage for possible future applications in restoration and conservation activities.

2. Experimental

Details of geopolymer precursors, additives and alkaline activator solution used for the production of geocomposites are provided.

2.1. Raw materials and preparation of the geocomposites

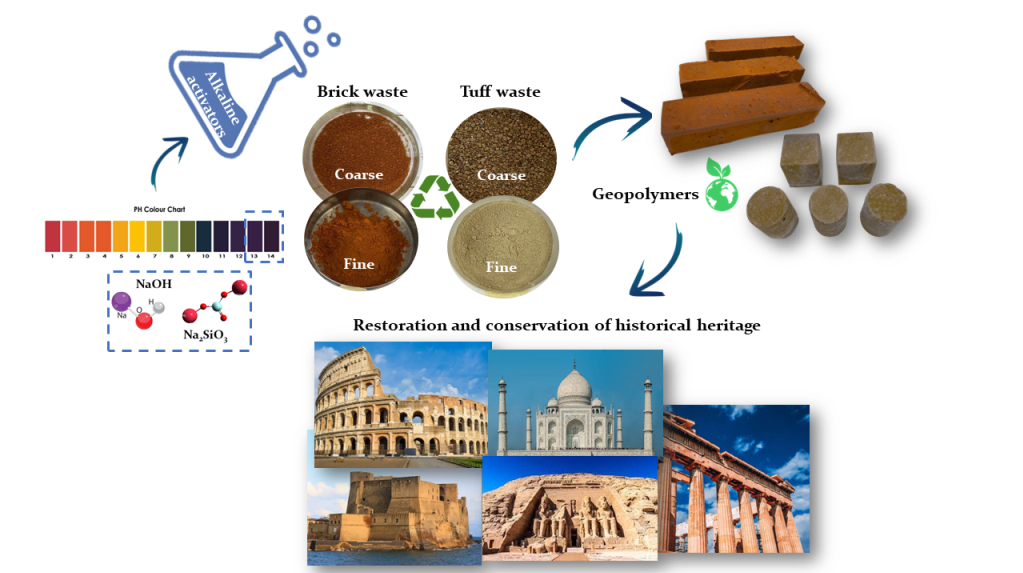

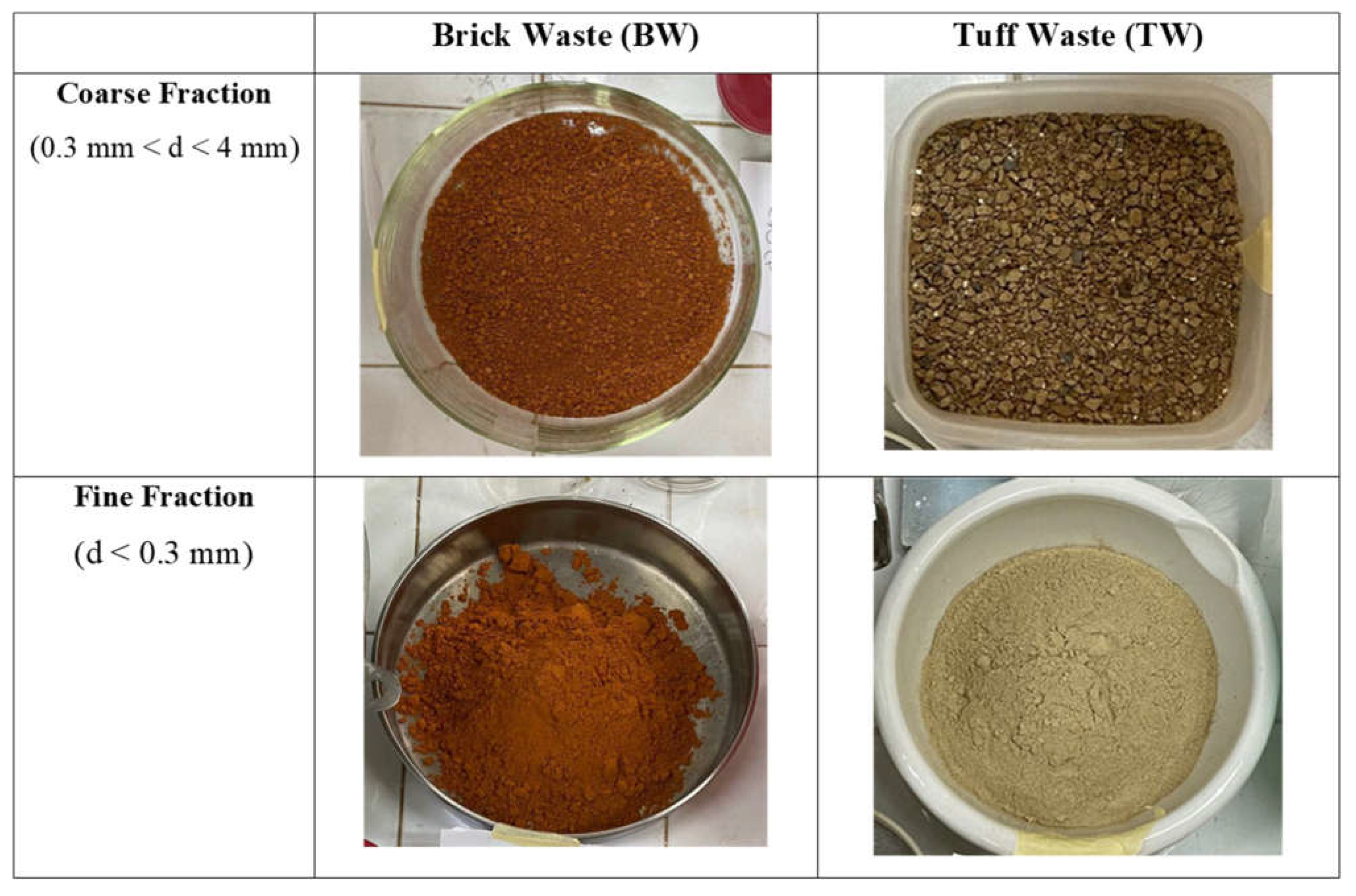

Starting with the identification of local resources, strongly integrated with the territory also from a historical point of view, different types of construction and demolition waste were used to produce geocomposites either as geopolymer precursors or as natural aggregates replacement: (

Figure 1):

- (1)

Waste of red clay bricks (BW): it is a commercial product supplied by CTS s.r.l. (Altavilla Vicentina, Italy) and recovered from construction and demolition activities, properly sieved and divided it into two particle size fractions: less than 0.3 mm and between 0.3 - 4 mm.

- (2)

Waste of tuff sawing (TW): two different tuffs were used, Neapolitan Yellow Tuff (NYT) and Viterbo red tuff (VT). Each tuff was crushed and sieved to select two particle size fractions: less than 0.3 mm and between 0.3 - 4 mm.

- (3)

Fly ashes (FA), deriving from combustion in coal-fired power plants for the production of electricity, were also added as partial replacement of the waste (10 or 20%).

A sodium silicate solution (SS) (Na2O 8.15%, SiO2 27.40%) provided by Prochin Italia S.r.L. (Caserta, Italy) and a 10 M sodium hydroxide solution (N) prepared dissolving NaOH in pellets (NaOH 98%, J.T. Baker) in bi-distilled water, were used as activators.

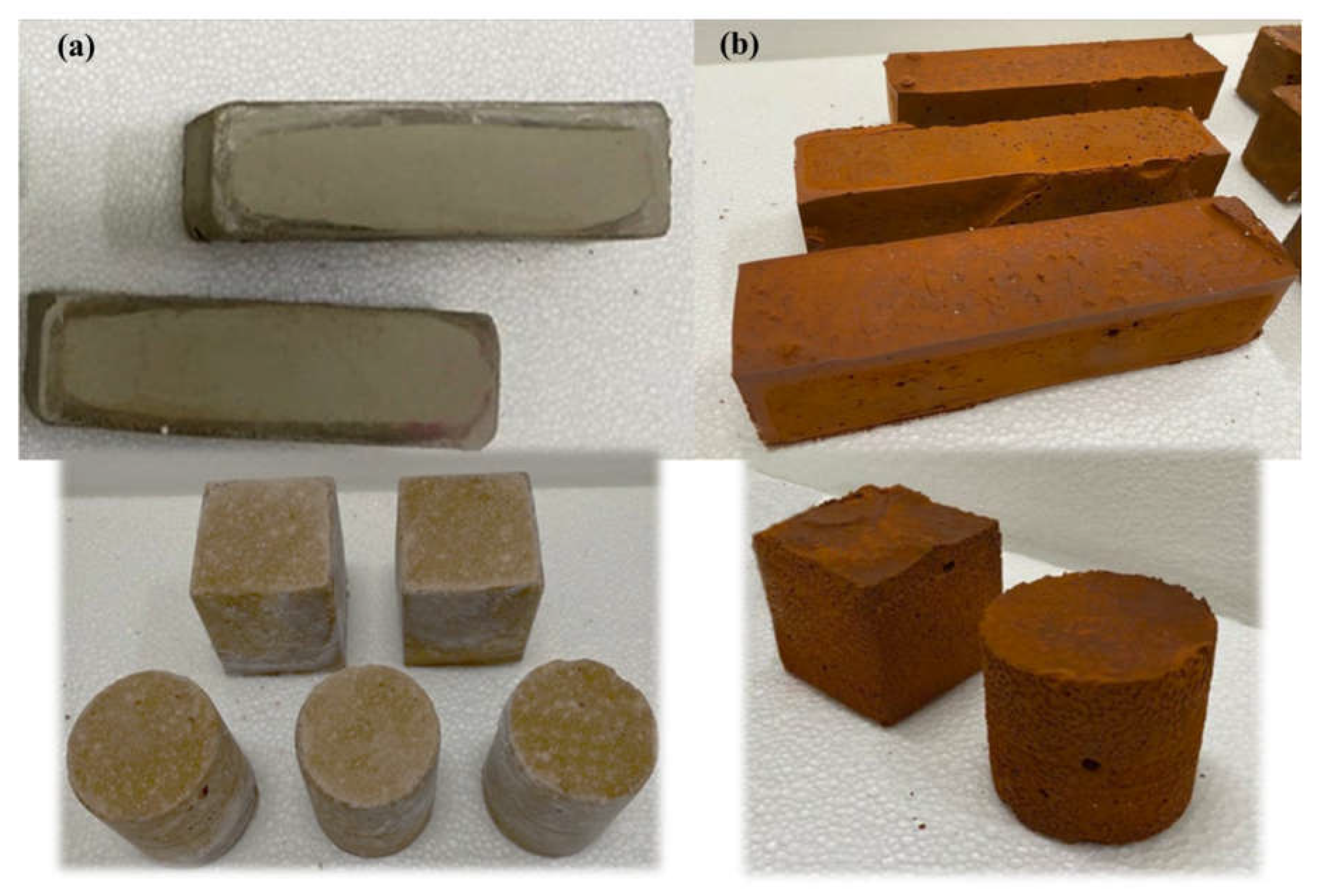

Geocomposites were produced as follows: powdered materials were previously dry mixed and homogenized, and then the activator solution was added to the dry mixture. An aggregate/binder ratio of 0.5 was selected.

The alkaline activator solution has been prepared mixing sodium silicate solution (SS) with 10M sodium hydroxide solution (N). The weight ratio SS/N/binder was 1: 1: 3. The activator/binder ratio was fixed at 0.66 for all the mixtures. For each waste three mixtures were prepared using 0, 10 or 20% of fly ashes as partial replacement. Specimens were prepared in three different geometries according to specific requirement of the European standards for physical and mechanical characterization (see

Figure 2):

- -

cylindrical (diameter 45 mm; height 50 mm),

- -

cubic (side 50 mm) and

- -

prismatic (40x40x160mm3).

The two different granulometry fractions were used as follows: fine fraction, less than 0.3 mm, as binder precursor and coarse fraction, with particle size between 0.3 and 4 mm, as aggregate.

The curing conditions selected for all the specimens are: 3 days, 60 °C in an oven, 100% relative humidity (sealed vessels). At the end of the curing, all the specimens were removed from the molds and stored at room temperature. All the tests were performed in triplicate.

2.2. Mineralogical and chemical characterization of raw materials

The mineralogical composition was evaluated by XRD analysis on a powder sample using a Panalytical X'Pert Pro diffractometer equipped with PixCel 1D detector (operative conditions: CuKa1/Ka2 radiation, 40 kV, 40 mA, 2θ range from 5 to 80, step size 0.0131 2θ, counting time 40s per step). X-ray fluorescence spectroscopy (XRF; AXIOS Panalytical Instrument; Malvern PANalytical, Almelo, Netherlands) have been performed to determine the chemical composition of samples in the form of pressed pellets.

2.3. Physical and chemical characterization of the geopolymeric mortars

The water absorption under vacuum and the open porosity of the geocomposites were measured according to the Italian Standard UNI 11060 [

31]. Firstly, the specimens were dried at 60±5°C until constant mass (M

1, g) was reached. Then they were immersed in water at room temperature in an evacuation vessel and the pressure was lowered to about 20mmHg and kept constant for 2 h. After that, pressure was returned to atmospheric value and the samples were first weighed immersed in water (hydrostatic weighing, M

2, g) and finally, after being gently wiped with a damp cloth, they were weighed again, determining their water-saturated mass (M

3, g). Each test was performed in triplicate and the results are the average values.

The water absorption (WA%) and the open porosity (OP%) were expressed as follows:

The values of apparent and real density (δ

A and δ

R respectively) of the geopolymeric samples can be also deduced from the measurements performed according to Italian Standard [

31]. Moreover, capillarity tests were carried out in accordance with European Standard UNI EN 15801 [

32] in order to assess the amount of water absorbed (Q) per surface unit as a function of time. Tests were performed in triplicate and then the mean value of capillary absorption coefficient (CA, g⋅cm

-2⋅s

-1/2) was determined. Considering that, for short times, the relation between the water adsorbed (Q) and the square root of time is quite linear, CA value may be evaluated as the slope of the straight line in the first 30 minutes of the capillarity test [

32]. Finally, the degree of geopolymerization and the influence of the waste addition on the chemical features of the produced samples were deduced by means of FTIR spectroscopy, performed at room temperature by using a Spectra 3000 (Perkin Helmer) in ATR mode and selecting a wavenumber resolution of 4 cm

-1 for 32 scans from 4000 to 600 cm

-1.

2.4. Mechanical characterization of the geopolymeric mortars

The flexural strength tests were performed according to UNI EN 196-1:2016 [

33] on prismatic specimens with dimensions 40x40x160mm

3, using the Ibertest as testing machine. For the compressive strength tests, the load is applied to the two broken portions of the specimens from the previous flexural strength tests. All the tests were carried out after a curing time of 28 days. Further information about the mechanical properties have been obtained by surface hardness test [

34] considering the hole that is produced on the sample under test, following the application of a fixed force on each sample, measured in Shore D units varying in a range from 0 (softest) to 100 (hardest).

3. Results and discussion

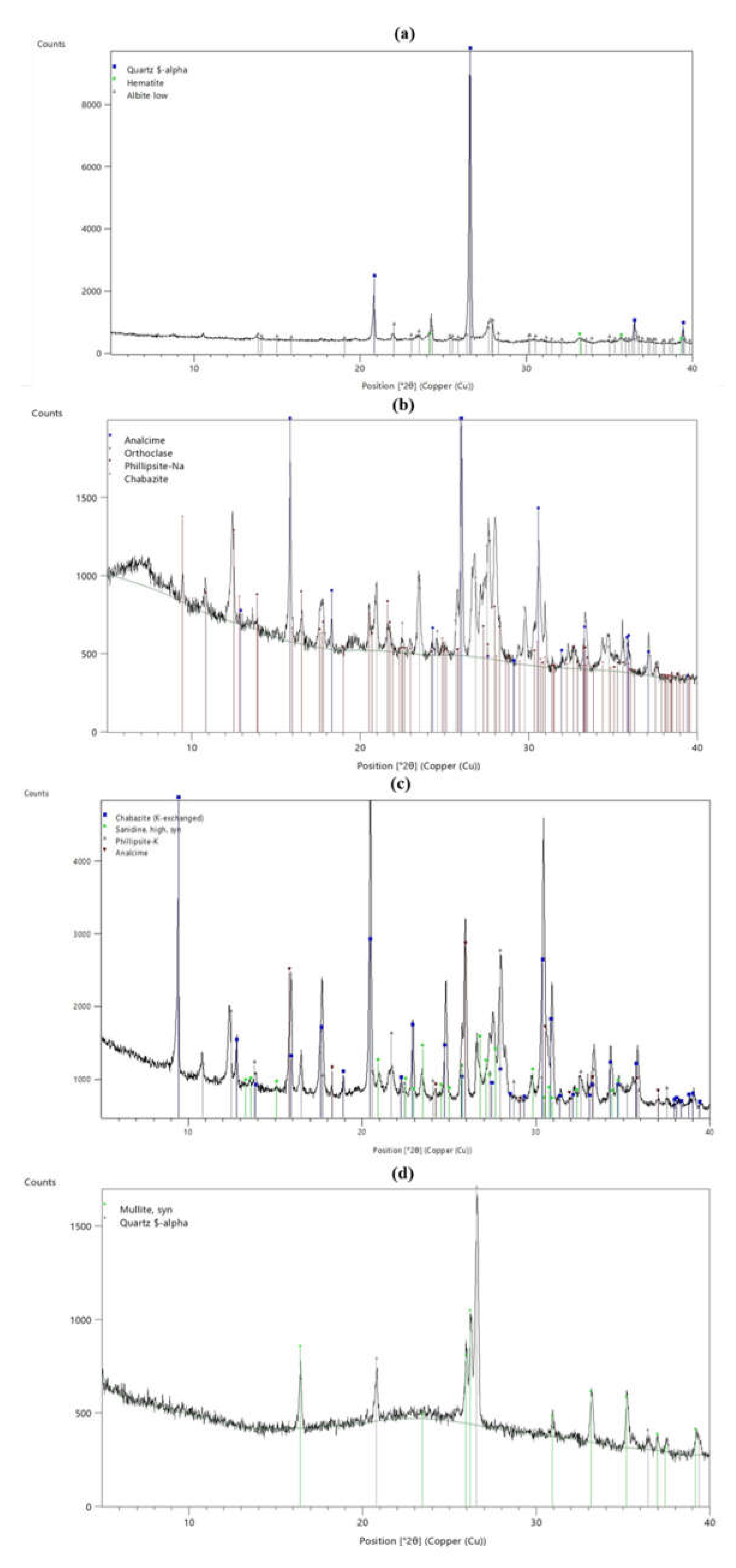

3.1. Characterization of the raw materials

Crystalline structures of the geopolymer precursors, which were analysed with X-ray diffraction (XRD) technique are shown in

Figure 3.

Chemical compositions of the raw materials, used for the production of geopolymeric samples and reported in

Table 1, confirmed the main silico-aluminate nature of all of them. The oxides of the major elements determined were SiO

2, TiO

2, Al

2O

3, Fe

2O

3, MgO, CaO, Na

2O and K

2O whose concentrations are expressed in weight percentages (wt.%).

3.2. Physical and chemical characterization of the geopolymeric mortars

The effects of waste addition on some relevant physical characteristics of the geopolymeric composites (i.e., density, open porosity and water absorption) were evaluated and the experimental results, as average values of triplicate tests, are reported in

Table 2. The apparent density values of both TW-based and BW-based geopolymeric mortars remain basically unchanged regardless of the waste content. It is worth noting that the BW-based geocomposites showed higher density values compared to the TW-based ones revealing a higher compactness, further confirmed also by the lower values of open porosity and water absorption, as well as the experimental results presented in the following sections. Moreover, considering the effects of waste addition on the open porosity of all the geopolymeric samples, it is possible to deduce that samples produced without FA as partial replacement resulted to be the most porous ones. This can be explained considering that FA, even in low percentages, promoted the formation of more compact geopolymeric matrices [

15,

37], as confirmed also by the lower values of water absorption of all the samples containing FA. In particular, this effect is more evident for the BW-based samples, which showed very similar values of open porosity and water absorption regardless of the specific amount (10 or 20%) of FA added and lower if compared to BW100 sample. On the contrary, the open porosity and water absorption of TW-based geocomposites resulted to be affected by the percentages of FA added exhibiting increasing values with decreasing FA amount. This could be explained taking into account the lower reactivity of tuff waste powders, due to the higher crystallinity of their silico-aluminate species, which caused that TW-based samples were more affected by the presence of FA.

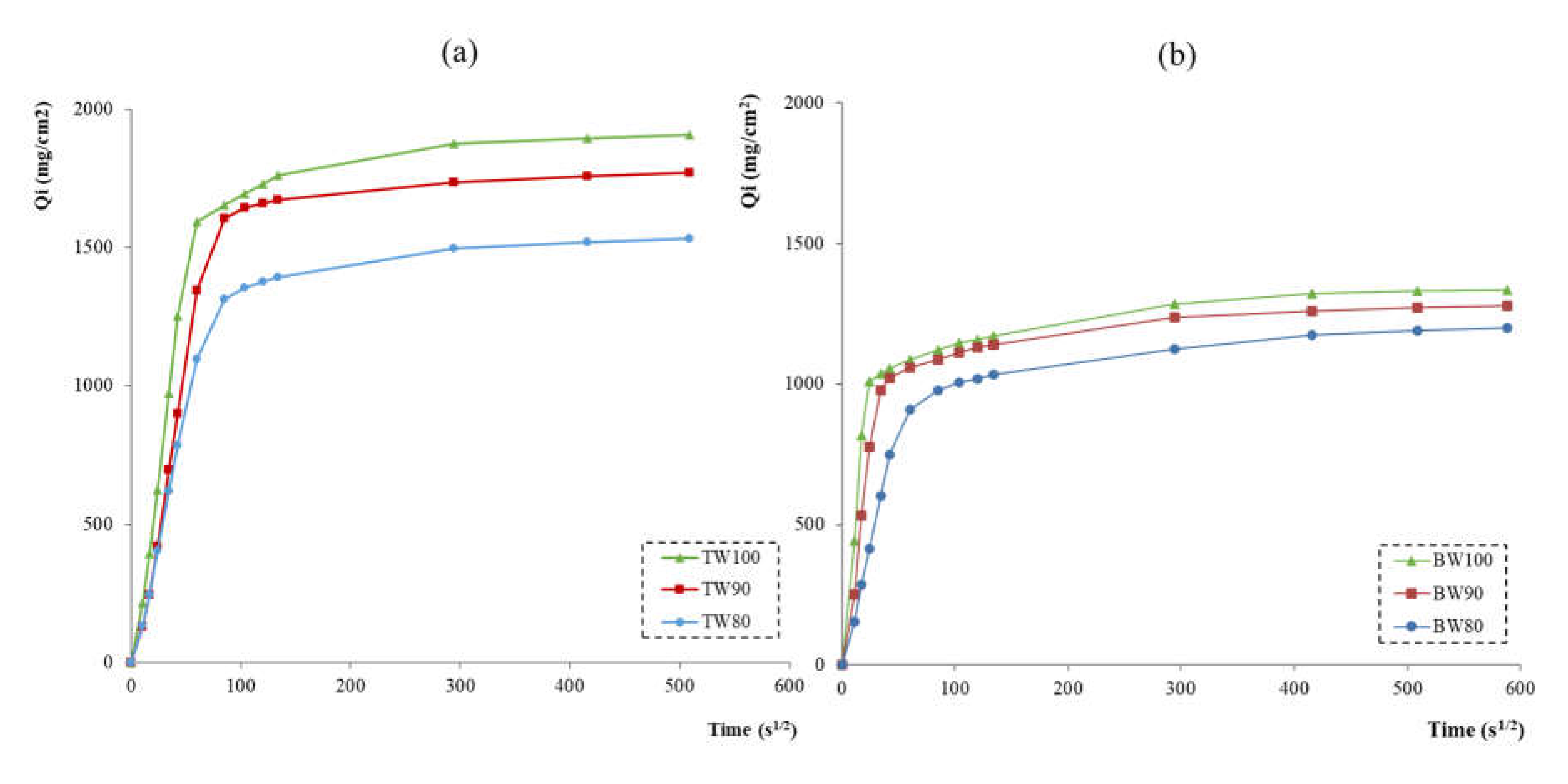

The capillary absorption curves and the relative values of capillary absorption coefficients for all geocomposites are reported respectively in

Figure 4 and in

Table 2. The data indicated that all the samples reached water saturation after 48h. Moreover, the water absorption rate decreased with time, probably as consequence of the increased water content inside the specimen and of the always more reduced participation of the less-accessible pores [

38]. At the same time, it is possible to note that the absorption rate, especially in the first minutes of the test, increased with increasing of waste amount added, following the same trend of the porosity values (

Table 2). Capillary absorption coefficients showed higher values for the geopolymeric samples produced without FA addition, as expected from the porosity results (see

Table 2). Finally, considering the values of Q

max reported in

Table 2, it is worth noting that, in accordance with previous results, BW-based geopolymers showed lower amounts of absorbed water by capillarity, further confirming their higher compactness.

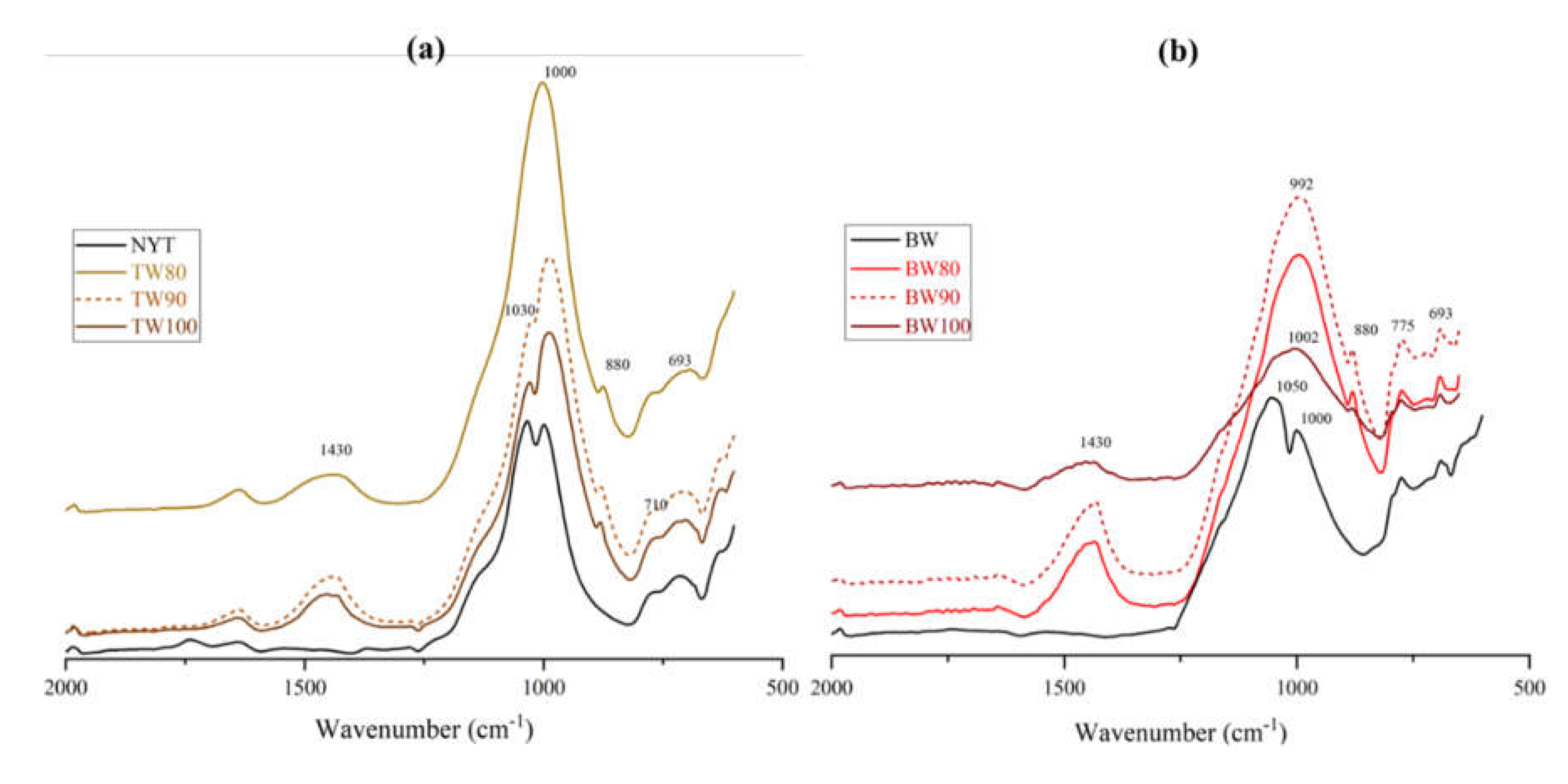

The analysis of FTIR spectra is a valid method to investigate and monitor the chemical modification of the silico–aluminate phases involved during the geopolymerization process [

39]. FTIR spectra of waste-based geopolymers (Figures 5a and 5b) resulted to be characterized by a broad absorbance band, ranging between around 700 and 1200 cm

−1, typical of the overlapping of single peaks related to the asymmetric stretching of T–O–Si (T = Si and Al) bonds present in the amorphous structure of aluminosilicate [

40]. Moreover, all the geopolymeric systems showed absorbance at around 1430 cm

−1 and at 880 cm

-1 attributed to the stretching of carbonate ions in sodium carbonate [

41]. In the FTIR spectra of NYT and TW-based samples (

Figure 5a) the symmetric stretching vibration of Si–O and Al–O was noticed in the range of 750–690 cm

−1 and attributed to the presence of phillipsite [

42]. The peaks appearing at about 780 cm

−1 and at 693 cm

−1 in

Figure 5b are assigned to quartz as the crystalline phase in the starting brick waste powder. The comparison between the spectra of raw materials (black lines in Figures 5a and 5b) and geocomposites, evidenced a slight shift of the T–O–Si asymmetric stretching band towards lower wavenumbers, in particular from region about 1030-1000 cm

-1, typical of zeolites, for NYT [

42] and from around 1050 cm

-1 for BW. This spectral change can be related to chemical modifications of the aluminosilicate structure of the raw materials induced by the alkaline activation [

43].

3.3. Mechanical characterization of the geopolymeric mortars

The average values of flexural and compressive strength for each geopolymeric mixtures are reported in

Table 3.

Mechanical properties followed the same trend already evident for the physical properties. In fact, the addition of FA, regardless of the 10 or 20%, led to more resistant geopolymeric matrices, in terms of both flexural and compressive behavior, for both TW-based and BW-based specimens, as expected also from porosity values (

Table 2). Moreover, it is worth noting that BW-based geocomposites showed definitely better mechanical performance with a compressive strength equal to ≈13 MPa for BW80 and BW90 samples which is much higher if compared to that equal to ≈1.5 MPa of the corresponding TW-based geopolymeric samples. Probably, the improvement of compressive strength for BW-based samples can be related to a more effective leaching of silica and alumina from the brick waste powder at high alkalinity, which promoted the geopolymerization process [

44]. Furthermore, mechanical properties of geocomposites depend not only on the strength of the geopolymeric binder, but also on the mechanical response of aggregates and on the interface between binder and aggregate produced during the consolidation process [

15]; so in this case, the adherence at interface developed by tuff powder, used as aggregate, resulted to be worse than brick waste.

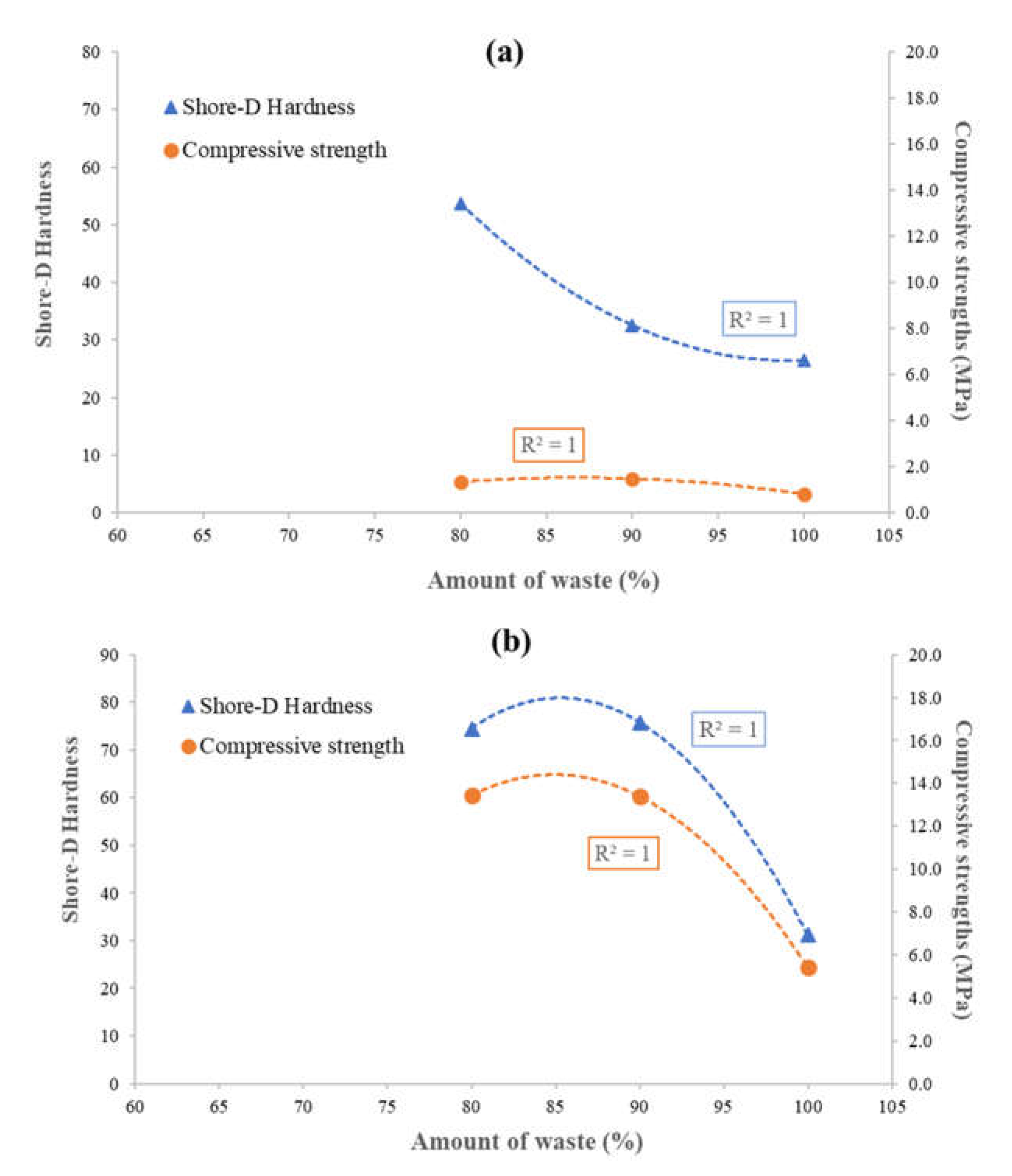

The results obtained from the Shore-D surface hardness tests are shown in

Table 4 and further confirmed the tendency of the mechanical properties previously discussed. In fact, as expected, all the BW-based geocomposites exhibited higher hardness values, in particular, BW80 and BW90 samples which showed very similar hardness in accordance with density values (see

Table 2).

The correlations of the waste amount with shore-D hardness and compressive strength values for TW-based and BW-based geocomposites are reported in

Figure 6. For all the typologies of waste-based geopolymers, correlation resulted to be well described by second-degree polynomial function with a correlation coefficient equal to R

2 =1 for both shore-D hardness and compressive strength. This means that the increase of waste amount causes a decrease of mechanical properties, following a fluctuating trend.

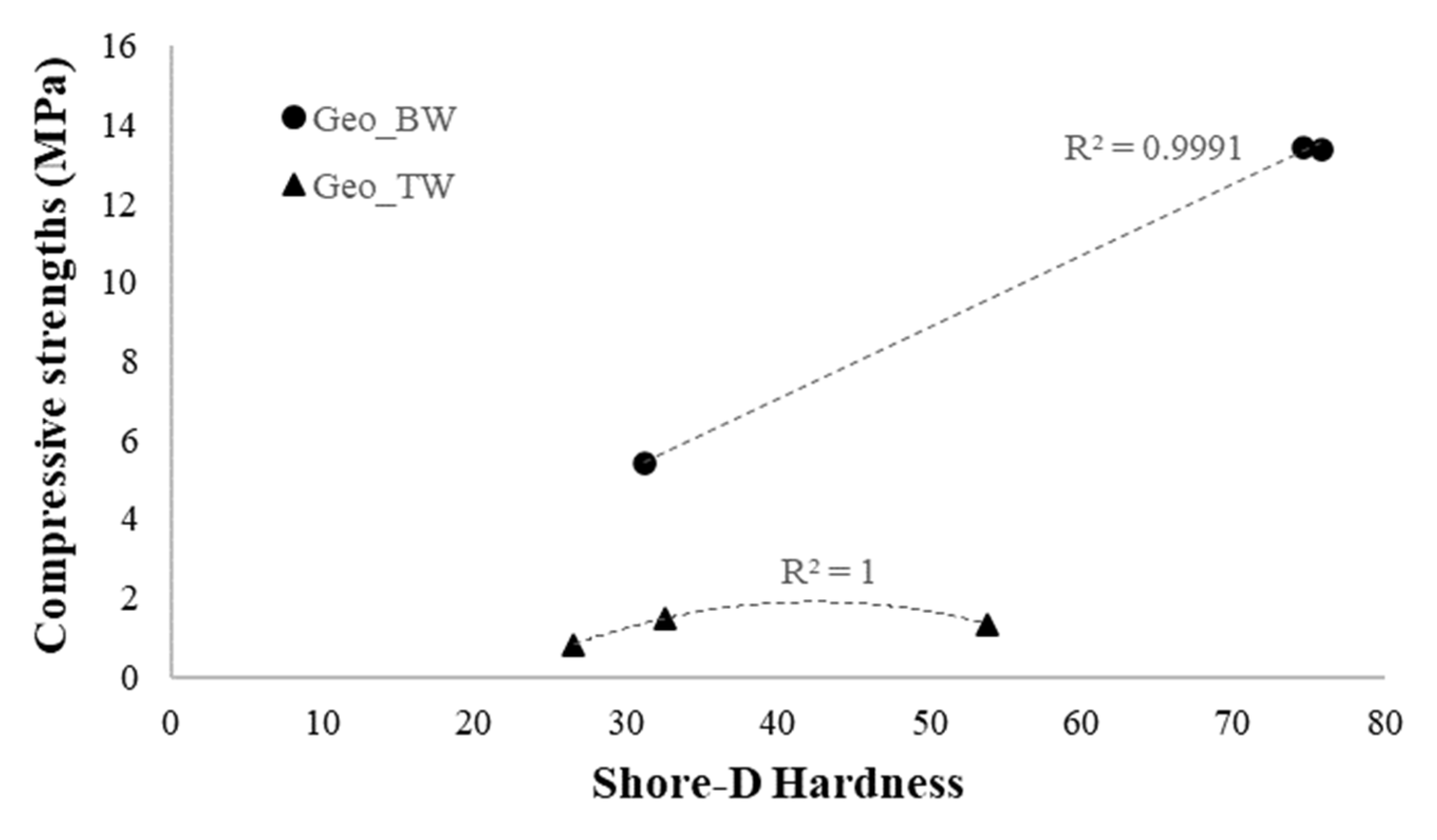

Figure 7 shows the relationship between compressive strength and Shore-D hardness of all the geocomposites. For the BW-based geopolymers, compressive strengths are linearly correlated to the hardness value, with a correlation coefficient R

2 ≈1, while the data of the TW-based samples do not follow a linear relationship, but a second-degree polynomial function (R

2 =1). This suggests that the typical methods of using hardness testing to estimate the strength may not be applicable to TW-based geocomposites.

3.4. Comparison with typical materials used in Cultural Heritage

To validate and verify the suitability of TW-based and BW-based geocomposites in restoration and conservation of Cultural Heritage, some of the experimental results obtained in this paper were compared with the scientific literature for several typologies of traditional and widely used products. Historical mortars, in fact, are very complex systems, containing aerial or hydraulic binders or blend of them, aggregates and eventually additions. For this reason, different traditional mortars made with aerial lime and natural hydraulic lime (NHL) were selected as basis for comparison (see

Table 5). Moreover, considering that, in order to design compatible restoration mortars, it is fundamental to investigate the physical and mechanical properties of both the original and repair mortars, also an experimental repair mortar, a natural limestone and a cement-based mortar were considered as reference materials for the comparison with geopolymeric samples.

Porosity, capillary absorption as well as mechanical properties have been selected as the main factors to verify the compatibility between ancient and restored structures [

45]. As regards physical properties, it is possible to assess that BW-based samples showed similar values of open porosity and capillary absorption coefficient, especially BW80 and BW90 samples (see

Table 2), and even lower amounts of water absorbed by capillarity, if compared to all the reference mortars (

Table 5). TW-based geocomposites exhibited higher open porosity and capillary absorption coefficients (

Table 2) but always comparable to existing building materials [

46].

Taking into account that repair mortars should have similar behaviour in presence of water, especially for permeability to water and to water vapour, than the existing masonry materials, the geocomposites performance can be considered more than adequate in terms of compatibility, because their physical features should allow a quick water evaporation through the mortar pores, which is also a key factor in salt induced decay. Moreover, a repair mortar should not be stronger than the existing one and at the same time quite weaker than the masonry units [

47]. Accordingly, TW-based samples showed compressive strengths very similar to the reference mortars. BW-based geopolymers were characterized by higher values of flexural and compressive strength (

Table 2 and

Table 5), in accordance with the requirements for historical mortars.

Table 5.

Physical and mechanical properties of some mortars widely used for restoration purpose.

Table 5.

Physical and mechanical properties of some mortars widely used for restoration purpose.

| Sample |

Open Porosity (%) |

CA (mg/cm2 s−1/2) |

Qmax (mg/cm2) |

Compressive strength (MPa) |

Flexural strength (MPa) |

| Aerial lime mortar CL-90 [48,49] |

25.90 |

13.90 |

2870 |

0.48 |

0.24 |

| Hydraulic lime mortar NHL 5 [48,49] |

23.50 |

9.40 |

3970 |

3.70 |

1.00 |

| OPC mortar (CEM II B/L 32.5) [49] |

18.80 |

3.40 |

2030 |

24.80 |

4.70 |

| Repair mortar NHL-Z 3.5 with crushed bricks and silica sand [45] |

26.23*

|

24.16* |

n. d. |

3.48 |

n. d |

| Historical magnesian mortar [45] |

30-40 |

28.51 |

n. d. |

n. d |

n. d |

| Natural Bioclastic Limestone [45] |

24-30 |

31.32 |

n. d. |

10.09 |

n. d |

4. Conclusions

Working on the heritage means not only preserving its historical, cultural and landscape value, but also promoting a unique economic resource, promoting social development and environmental protection. The direction to follow must therefore aim at the approach of circular economies, considering conservation not only as a limitation, but re-functionalizing and redeveloping spaces in an innovative way without forgetting or erasing the intrinsic value of the territory.

Bricks and tuff wastes coming from construction and demolition activities have been successfully used to produce geocomposites suitable to restoration practice. A deepened physical-chemical and mechanical characterization of the geopolymeric samples was carried out order to investigate their performance. In particular, brick waste-based samples showed higher density and lower values of open porosity and water absorption, than the tuff-based ones. The higher compactness of the brick waste-based geocomposites was further confirmed by their mechanical performance. Finally, experimental results showed that the physical and mechanical properties of both brick and tuff waste – based geocomposites, also with different waste content, are compatible with existing building materials and with all the traditional repairing products.

Accordingly, alkali-activation of construction waste can represent a novel and sustainable approach promoting performance and compatibility achievement in building heritage protection and restoration.

References

- Istituto Superiore per la Protezione e la Ricerca Ambientale (ISPRA), Rapporto Rifiuti Speciali, 2020.

- Agostini, I. La cultura della città storica in Italia. Sci. Del Territ. 2015, 3, 97–103. Available online: https://www.torrossa.com/gs/resourceProxy?an=3132843&publisher=FF3888#page=97 (accessed on 8 May 2023).

- Mancini, R. Il recupero dei materiali nella costruzione e nella riparazione delle mura aureliane di Roma. Recuper. Dei Mater. Nella Costr. e Nella Riparazione Delle Mura Aureliane Di Roma. 2008, 1000–1011. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Valencia-Saavedra, W.; de Gutiérrez, R.M. Construction and demolition waste (Cdw) recycling—as both binder and aggregates—in alkali-activated materials: A novel re-use concept. Sustain. 2020, 12, 1–18. [Google Scholar] [CrossRef]

- Koda, E.; Podlasek, A. Sustainable use of construction and demolition wastes in a circular economy perspective. In Sustain. Circ. Manag. Resour. Waste Towar. a Green Deal; 2023; pp. 137–147. [Google Scholar] [CrossRef]

- Adams, M.; Burrows, V.; Richardson, S. Bringing embodied carbon upfront; World Green Building Council: London, 2019. [Google Scholar]

- Sánchez-Garrido, A.J.; Navarro, I.J.; Yepes, V. Multi-criteria decision-making applied to the sustainability of building structures based on Modern Methods of Construction. J. Clean. Prod. 2022, 330. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer cement to minimize carbon-dioxde greenhouse-warming. 1993. Available online: https://www.researchgate.net/publication/284682578_Geopolymer_cement_to_minimize_carbondioxde_ greenhouse-warming.

- Davidovits, J. Global Warming Impact on the Cement and Aggregates Industries. 1994, 6, 263–278. [Google Scholar]

- Palomo, A.; Maltseva, O.; Garcia-Lodeiro, I.; Fernández-Jiménez, A.; Cement, P.V.A. Portland Versus Alkaline Cement: Continuity or Clean Break: A Key Decision for Global Sustainability. Front. Chem. 2021, 9, 705475. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. Geopolymerisation of multiple minerals. Miner. Eng. 2002, 15, 1131–1139. [Google Scholar] [CrossRef]

- Capasso, I.; Lirer, S.; Flora, A.; Ferone, C.; Cioffi, R.; Caputo, D.; Liguori, B. Reuse of mining waste as aggregates in fly ash-based geopolymers. J. Clean. Prod. 2019, 220, 65–73. [Google Scholar] [CrossRef]

- Ferone, C.; Capasso, I.; Bonati, A.; Roviello, G.; Montagnaro, F.; Santoro, L.; Turco, R.; Cioffi, R. Sustainable management of water potabilization sludge by means of geopolymers production. J. Clean. Prod. 2019, 229, 1–9. [Google Scholar] [CrossRef]

- Lirer, S.; Liguori, B.; Capasso, I.; Flora, A.; Caputo, D. Mechanical and chemical properties of composite materials made of dredged sediments in a fly-ash based geopolymer. J. Environ. Manage. 2017, 191, 1–7. [Google Scholar] [CrossRef]

- Capasso, I.; Liguori, B.; Ferone, C.; Caputo, D.; Cioffi, R. Strategies for the valorization of soil waste by geopolymer production: An overview. J. Clean. Prod. 2021, 288. [Google Scholar] [CrossRef]

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Ling, Y.; Wang, K.; Li, W.; Shi, G.; Lu, P. Effect of slag on the mechanical properties and bond strength of fly ash-based engineered geopolymer composites. Compos. Part B Eng. 2019, 164, 747–757. [Google Scholar] [CrossRef]

- Liguori, B.; Capasso, I.; De Pertis, M.; Ferone, C.; Cioffi, R. Geopolymerization Ability of Natural and Secondary Raw Materials by Solubility Test in Alkaline Media. Environments. 2017, 4, 56. [Google Scholar] [CrossRef]

- D’Angelo, G.; Fumo, M.; Del Rio Merino, M.; Capasso, I.; Campanile, A.; Iucolano, F.; Caputo, D.; Liguori, B. Crushed Bricks: Demolition Waste as a Sustainable Raw Material for Geopolymers. Sustain. 2021, 13, 7572. [Google Scholar] [CrossRef]

- Panizza, M.; Natali, M.; Garbin, E.; Tamburini, S.; Secco, M. Assessment of geopolymers with Construction and Demolition Waste ( CDW ) aggregates as a building material. Constr. Build. Mater. 2018, 181, 119–133. [Google Scholar] [CrossRef]

- Dadsetan, S.; Siad, H.; Lachemi, M.; Sahmaran, M. Construction and demolition waste in geopolymer concrete technology: A review. Mag. Concr. Res. 2019, 71, 1232–1252. [Google Scholar] [CrossRef]

- Allahverdi, A.; Kani, E.N. Construction wastes as raw materials for geopolymer binders. Int. J. Civ. Eng. 2009, 7, 154–160. [Google Scholar]

- Clausi, M.; Tarantino, S.C.; Magnani, L.L.; Riccardi, M.P.; Tedeschi, C.; Zema, M. Metakaolin as a precursor of materials for applications in Cultural Heritage: Geopolymer-based mortars with ornamental stone aggregates. Appl. Clay Sci. 2016, 132–133, 589–599. [Google Scholar] [CrossRef]

- Giacobello, F.; Ielo, I.; Belhamdi, H.; Plutino, M.R. Geopolymers and Functionalization Strategies for the Development of Sustainable Materials in Construction Industry and Cultural Heritage Applications: A Review. Mater. 2022, 15, 1725. [Google Scholar] [CrossRef]

- Kutlusoy, E.; Maras, M.M.; Ekinci, E.; Rihawi, B. Production parameters of novel geopolymer masonry mortar in heritage buildings: Application in masonry building elements. J. Build. Eng. 2023, 76, 107038. [Google Scholar] [CrossRef]

- Occhipinti, R.; Stroscio, A.; Finocchiaro, C.; Fugazzotto, M.; Leonelli, C.; Faro, M.J.L.; Megna, B.; Barone, G.; Mazzoleni, P. Alkali activated materials using pumice from the Aeolian Islands (Sicily, Italy) and their potentiality for cultural heritage applications: Preliminary study. Constr. Build. Mater. 2020, 259, 120391. [Google Scholar] [CrossRef]

- Moutinho, S.; Costa, C.; Andrejkovičová, S.; Mariz, L.; Sequeira, C.; Terroso, D.; Rocha, F.; Velosa, A. Assessment of properties of metakaolin-based geopolymers applied in the conservation of tile facades. Constr. Build. Mater. 2020, 259, 119759. [Google Scholar] [CrossRef]

- UNI 11060:2003 - Beni culturali - Materiali lapidei naturali ed artificiali - Determinazione della massa volumica e della percentuale di vuoti, (2003). http://store.uni.com/catalogo/uni-11060- 2003?josso_back_to=http://store.uni.com/josso-securitycheck. php&josso_cmd=login_optional&josso_partnerapp_host=store.uni.com.

- UNI EN 15801:2010 - Conservation of cultural property - Test methods - Determination of water absorption by capillarity. 2010.

- UNI EN 196-1:2016 - Methods of testing cement - Part 1: Determination of strength. 2016.

- UNI EN 13279-2: 2014 Gypsum binders and gypsum plasters - Part 2: Test methods. 2014.

- Liguori, B.; Iucolano, F.; De Gennaro, B.; Marroccoli, M.; Caputo, D. Zeolitized tuff in environmental friendly production of cementitious material: Chemical and mechanical characterization. Constr. Build. Mater. 2015, 99, 272–278. [Google Scholar] [CrossRef]

- Novembre, D.; Gimeno, D.; Cappelletti, P.; Graziano, S.F. A case study of zeolitization process: "Tufo Rosso a Scorie Nere" (Vico volcano, Italy): Inferences for a general model. Eur. J. Mineral. 2021, 33, 315–328. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Dick, W.A. Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Compos. 2010, 32, 142–147. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, M.G.; Real, S. Capillary absorption of structural lightweight aggregate concrete. Mater. Struct. Constr. 2015, 48, 2869–2883. [Google Scholar] [CrossRef]

- Verdolotti, L.; Iannace, S.; Lavorgna, M.; Lamanna, R. Geopolymerization reaction to consolidate incoherent pozzolanic soil. J. Mater. Sci. 2008, 43, 865–873. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.G.S.; Van Deventer, J.S.J.; Lukey, G.C. The characterisation of source materials in fly ash-based geopolymers. Mater. Lett. 2003, 57, 1272–1280. [Google Scholar] [CrossRef]

- Shahraki, B.K.; Mehrabi, B.; Gholizadeh, K.; Mohammadinasab, M. Thermal behavior of calcite as an expansive agent. J. Min. Metall. Sect. B Metall. 2011, 47, 89–97. [Google Scholar] [CrossRef]

- Osacký, M.; Pálková, H.; Hudec, P.; Czímerová, A.; Galusková, D.; Vítková, M. Effect of alkaline synthesis conditions on mineralogy, chemistry and surface properties of phillipsite, P and X zeolitic materials prepared from fine powdered perlite by-product. Microporous Mesoporous Mater. 2020, 294, 109852. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer chemistry and applications, 3rd ed.; 2011. [Google Scholar]

- Wong, C.L.; Mo, K.H.; Alengaram, U.J.; Yap, S.P. Mechanical strength and permeation properties of high calcium fly ash-based geopolymer containing recycled brick powder. J. Build. Eng. 2020, 32. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Karatasios, I.; Kilikoglou, V. Hydraulic lime mortars for the restoration of historic masonry in Crete. Cem. Concr. Res. 2005, 35, 1577–1586. [Google Scholar] [CrossRef]

- Kramar, S.; Zalar, V.; Urosevic, M.; Körner, W.; Mauko, A.; Mirtič, B.; Lux, J.; Mladenović, A. Mineralogical and microstructural studies of mortars from the bath complex of the Roman villa rustica near Mošnje (Slovenia). Mater. Charact. 2011, 62, 1042–1057. [Google Scholar] [CrossRef]

- Silva, B.A.; Pinto, A.P.F.; Gomes, A. Influence of natural hydraulic lime content on the properties of aerial lime-based mortars. Constr. Build. Mater. 2014, 72, 208–218. [Google Scholar] [CrossRef]

- Garijo, L.; Zhang, X.; Ruiz, G.; Ortega, J.J. Age effect on the mechanical properties of natural hydraulic and aerial lime mortars. Constr. Build. Mater. 2020, 236. [Google Scholar] [CrossRef]

- Silva, B.A.; Pinto, A.P.F.; Gomes, A. Natural hydraulic lime versus cement for blended lime mortars for restoration works. Constr. Build. Mater. 2015, 94, 346–360. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).