1. Introduction

The demand for the electricity is growing day by day with the rapid growth in infrastructure in India. The thermal power plants are primarily fulfilling this demand but producing huge quantity of fly ash as by product during burning of coal. As per the Central Electricity Authority [

1] report published in August 2022, Indian thermal plants have generated 270.82 million tonnes of fly ash in the year 2021-22 and around 95.95% have been used [

1]. Still huge quantity of fly ash needs to utilized to reduce pollution. Road sectors is such an area where this could be used in bulk quantity. Road construction also need sustainable materials as good quality natural aggregate is depleting rapidly.

In essence, there are two primary categories of fly ash: Class C and Class F. In India, Class F fly ash is predominantly encountered. Class C fly ash, produced through the combustion of lignite coal, possesses inherent self-hardening properties due to its calcium oxide content exceeding 20%. On the other hand, Class F fly ash is derived from the incineration of anthracite coal, containing less than 10% calcium oxide, making it non-self-cementing. Therefore, it necessitates the addition of an activator such as cement, lime, gypsum, or other alkali activators (e.g., NaOH, KOH) to attain initial strength development.

The pozzolanic characteristic of fly ash renders it a superb substance for applications like filling and embankment, especially in areas where subsidence is a concern, as well as for soil stabilization [

2,

3,

4,

5,

6]. Due to the low strength and large concentration of fine particles, untreated fly ash is not suitable for use in subbase/base layer of pavements. Few studies also highlight the inadequacy of stabilized fly ash as subbase/base material due to its poor gradation and low strength [

7,

8]. This shortcoming can be eliminated by adding materials with coarser particle such as stone dust generated from stone quarry and stabilizing the mix with lime or cement [

9]. Addition of coarser particle would improve the gradation whereas stabilizer would improve the strength. Bakare et al. [

10] and Pai et al. [

11] have evaluated the performance of stabilized fly ash and slag mixture and found it to be suitable for subbase/base layer.

Usmen et al. [

12] assessed class C fly ash stabilized with lime and cement, observing that higher lime content increased Optimum Moisture Content (OMC) and decreased Maximum Dry Density (MDD) during compaction. Cement-stabilized samples did not exhibit significant OMC-MDD changes. In short curing periods, cement content notably boosted strength, while elevated lime content reduced strength due to slow pozzolanic reaction. Freeze-thaw cycles caused strength loss in both lime and cement-stabilized samples, with cement-stabilized samples showing increased residual strength due to C-S-H gel formation. Generally, cement-stabilized samples outperformed lime-stabilized ones in terms of strength and durability.

Ghosh and Subbarao [

13] investigated the shear strength properties of a low-lime Class F fly ash that had been modified with lime either on its own or in conjunction with gypsum. Unconfined compression tests were carried out on specimens that had not been soaked and on specimens that had been soaked, with curing periods extending up to 90 days. The introduction of a small quantity of gypsum, specifically 0.5% and 1.0%, in combination with lime ranging from 4% to 10%, resulted in a notable improvement in the shear strength of the modified fly ash over relatively short curing durations of 7 and 28 days.

Dimter et al. [

14] studied the elastic properties of fly ash-stabilized mixes using two nondestructive methods: resonant frequency and ultrasonic pulse velocity. Increasing fly ash content in the binder reduced elastic modulus values in both methods, with the highest observed in fly ash-free cement mixes. Elastic modulus increased with longer curing and higher temperatures. The ultrasound method yielded a lower average elasticity modulus than the resonant frequency method.

As stabilized fly ash behaves as a brittle material, research is being undertaken to include fibers to enhance the ductility of the mixture [

15]. In the experiments, two distinct sizes of polyester fibers (6 mm and 20 mm) were employed alongside a consistent fiber content of 1% (based on dry weight). The study included compaction tests, triaxial shear tests, and various geotechnical characterization examinations conducted on both the untreated and fiber-reinforced fly ashes. The findings revealed that the addition of fibers did not influence the Optimum Moisture Content (OMC) and Maximum Dry Density (MDD) of fly ash. Moreover, addition of fibers results in enhancement of the indirect tensile strength and flexural strength. Similar observation has also been reported by other researchers [

15,

16,

17,

18,

19]. However, Kumar and Singh [

16] reported that compressive strength increases up to certain dosage of fiber and any further addition of fiber results in decrease of compressive strength. The enhancement in unconfined compressive strength was attributed to the frictional interaction between the fibers and the fly ash. The relationship between unconfined compressive strength and fiber content exhibited a linear pattern, while the influence of aspect ratio followed a nonlinear trend, conforming to a second-degree polynomial curve.

Though compressive strength is considered as one of the vital mechanical parameters, study of indirect tensile strength and flexural strength of stabilized subbase and base is also of paramount importance, as the failure of a stabilized layer is largely governed by tensile stress i.e.; indirect tensile stress or flexural tensile stress [

20,

21,

22,

23,

24]. Static Indirect tensile stress and four-point flexural stress test are conducted to determine the indirect tensile strength and flexural tensile strength and cyclic load is applied which simulate the traffic load to determine the cyclic modulus, which is used as an elastic parameter for design of pavement. In this study, an extensive laboratory investigation has been done to evaluate strength and stiffness of the fiber reinforced cement stabilized fly ash-stone dust-aggregate mixture as a sustainable material for base layer application in flexible pavement.

2. Materials and Methods

2.1. Materials

2.1.1. Fly Ash

Fly Ash (See

Figure 1) used in the study was collected from Captive Thermal power Plant (CPP) of NALCO, located at Angul, Odisha, India. The chemical composition of the fly ash is presented in

Table 1. It can be classified as Class F as per ASTM C618 [

25].

2.1.2. Cement

The cement (see

Figure 1) used in the study was conforming to Ordinary Portland Cement (OPC) of grade 43 as per IS 8112 [

26].

2.1.3. Stone Dust and Crushed Stone Aggregates

Stone dust are fine dust particle generated during the crushing of aggregate in the crusher plant. Both the stone dust and crushed stone aggregate (

Figure 1) were collected from local stone crushing plant located at Bhubaneswar, India.

2.1.4. Polypropylene Fiber (randomly oriented)

The Poly Propylene Fiber (

Figure 1) was procured from XETEX Industries Pvt. Ltd, Mumbai of Cetex Brand. The detailed properties of the fiber are presented in

Table 2.

2.1.5. Mix Proportioning:

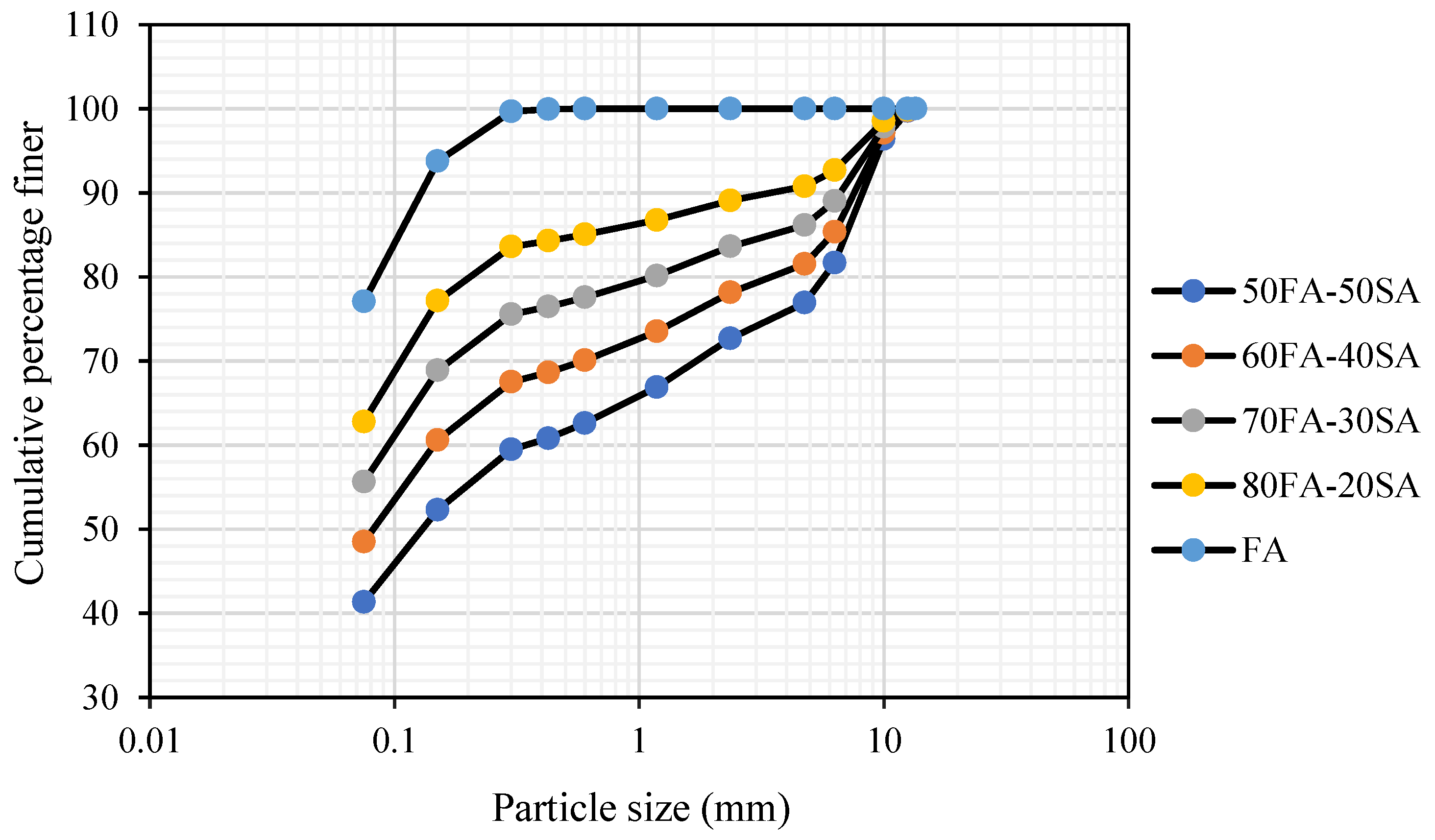

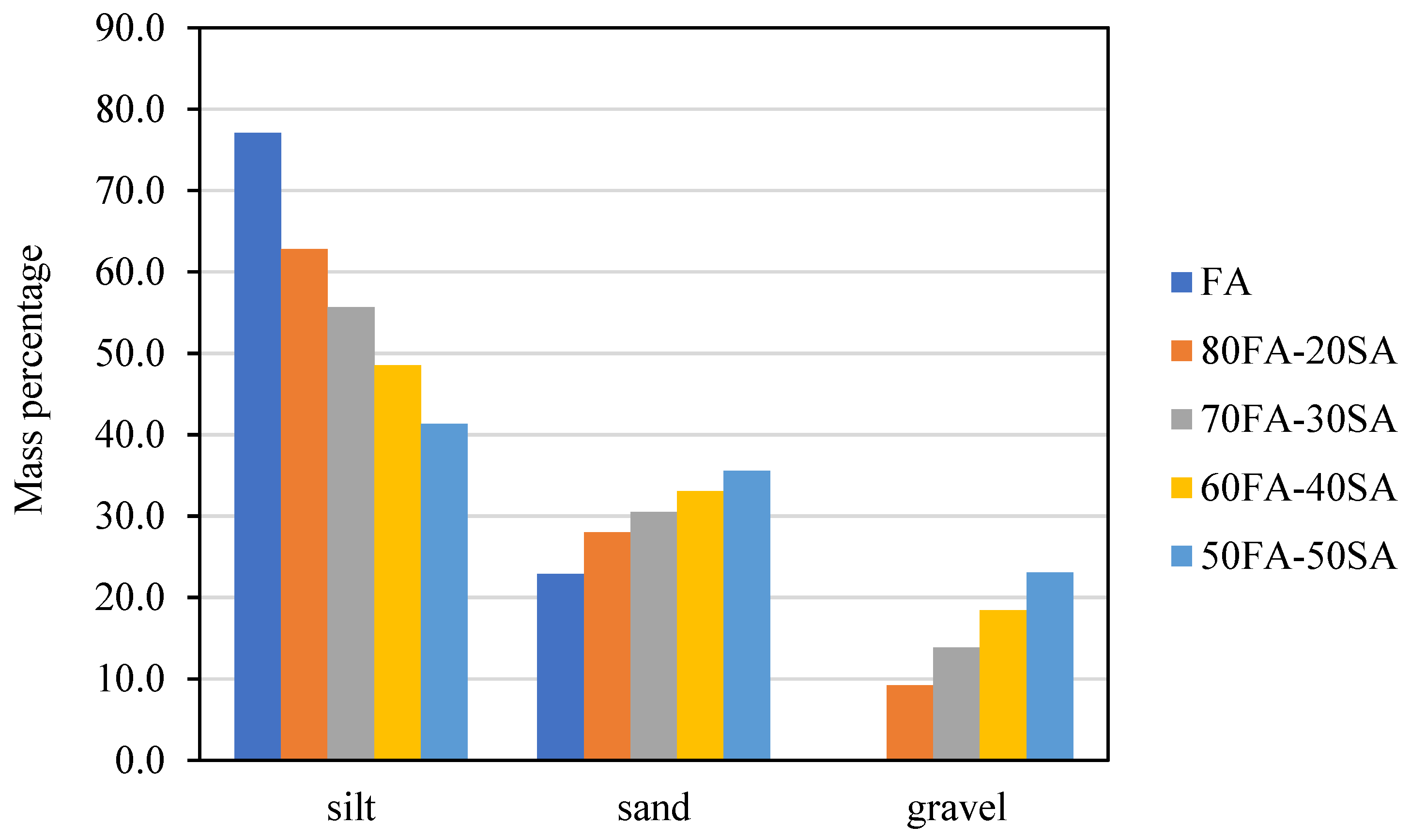

Fly ash was mixed with stone dust and aggregates to improve the gradation. The maximum particle size of fly ash, stone dust and aggregates used in these studies are 1.18mm, 4.75mm and 12.5mm respectively. Stone dust and aggregates are mixed in 50-50 ratio and this has been donated as SA. Various combinations of fly ash and SA i.e., 80FA-20SA, 70FA-30SA, 60FA-40SA and 50FA-50SA was tried to improve the gradation. The minimum percentage of fly ash used in the mixture to 80% in order to maximize the use of fly ash. The improvement of gradation can be observed in the particle size distribution curve of mixtures shown in

Figure 2. It can be seen from the

Figure 3 that the gravel and sand percentages increased with increase in SA percentages whereas the silt percentage decreased with increase in SA percentages.

2.2. Experimental Programme

2.2.1. Sample Preparation

FA and SA were oven dried and mixed in above mentioned percentages to obtain the desired mix. To each mix, cement was added in three percentages by mass i.e., 4%, 6% and 8% and PP fiber was added in three percentages by mass i.e., 0.25%, 0.35% and 0.5%. The mixing was performed manually using a trowel, ensuring the production of a consistent mix. Particular attention was given to achieving uniform fiber distribution within the mix and preventing the formation of any lumps. Subsequently, the Modified Proctor test, as per ASTM D 1557 [

27], was conducted on each mix type to determine the maximum dry density (MDD) and optimum moisture content (OMC).

Three different types of test specimens were prepared for each mix i.e., cylindrical (100 mm in diameter and 115 mm height), cylindrical (100 mm in diameter and 63 mm height) and prismatic beam specimen (75 mm × 75 mm × 285 mm). The test specimens were kept inside the respective moulds for 2 hours before demoulding to avoid breaking. The specimens after demoulding were wrapped in polythene and cured for 7 days and 28 days.

2.2.2. Unconfined Compressive Strength Test (UCS)

The UCS test was conducted on cylindrical specimen of size of 100 mm in diameter and 115 mm in height as per ASTM D1633 [

28]. A minimum of three samples were tested for each mix type.

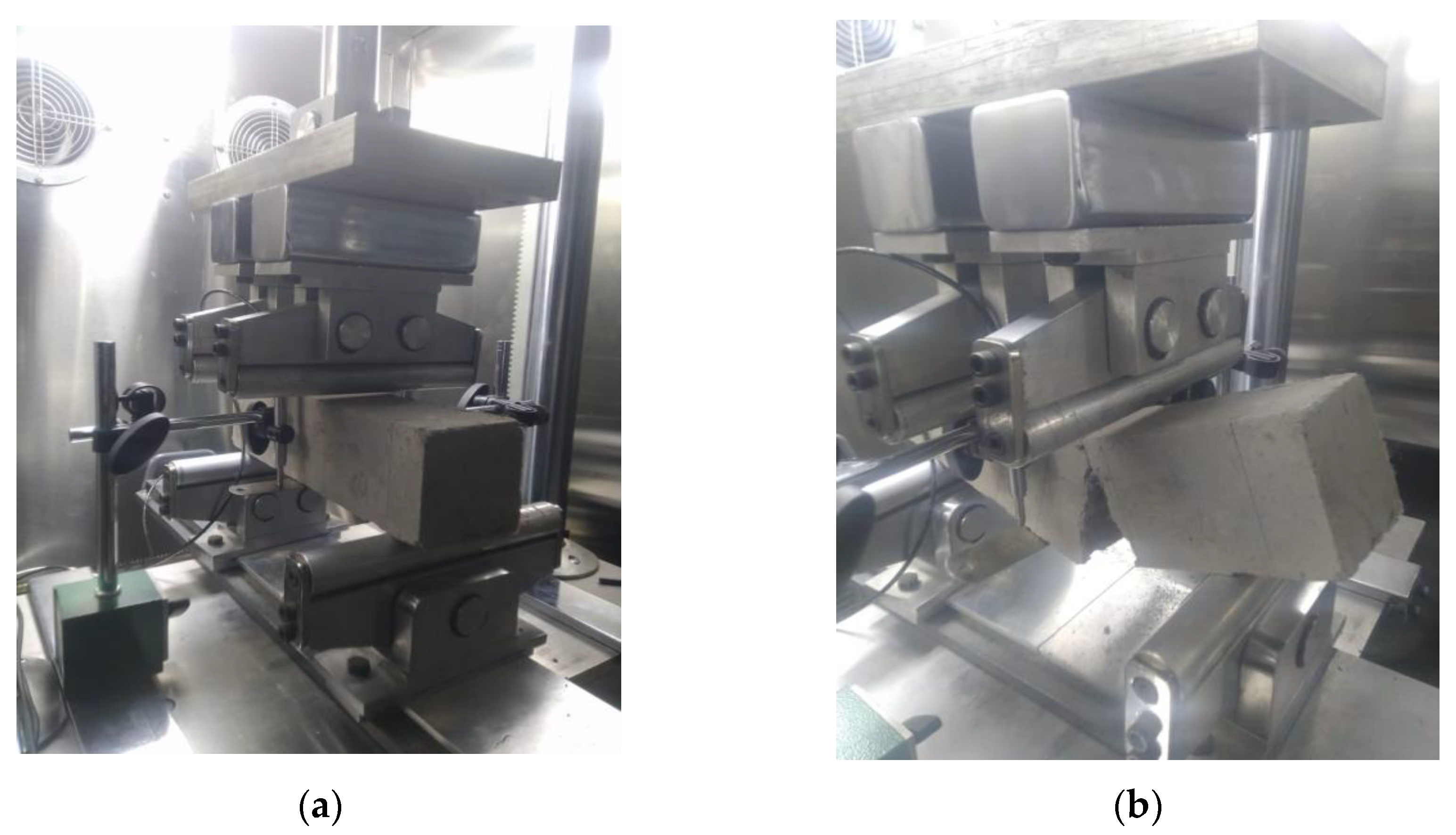

2.2.3. Indirect Tensile Test (IDT)

Monotonic IDT was conducted for determining Indirect Tensile Strength (ITS) and cyclic IDT for determining the cyclic IDT modulus/Resilient Modulus (IDTM). The test was conducted as per method suggested by Yeo [

29]. The ITS and IDTS values were determined using the Equation (1) and Equation (2) respectively.

Figure 4 shows the cyclic IDT test setup.

Where;

P = ultimate load applied to the specimen to cause failure in monotonic loading

D = diameter of specimen

t = thickness of the specimen

Where;

P = peak load during cyclic loading

ν = Poisson’s ratio (assumed to be 0.2),

H = horizontal displacement of the specimen after application of load

h = the height of specimen

2.2.4. Flexure Test

In this study, flexure tests were conducted at a constant stress of 690kPa/min following the procedure laid down in ASTM D1635 [

30]. Similar to IDT test, flexure test was conducted in two phases i.e., Phase 1: Monotonic flexure test for determining flexural strength (FS) or modulus of rupture (MOR); phase 2: cyclic flexure test for determining the flexural modulus (FM) at varying stress ratio of 0.3, 0.5, 0.7, 0.9. The FS and FM was calculated using Equation (3) and Equation (4) respectively.

Figure 5 shows the cyclic flexure test set up.

Where;

F = ultimate load applied to the specimen to cause failure in monotonic flexure loading

l = distance between two supports during flexure test

b = width of the beam specimen

d = depth of the beam specimen

Where;

F = peak load applied during cyclic flexure test

∆ = maximum mid span deflection during cyclic flexure test

3. Results

The strength and stiffness of fiber reinforced cement stabilized fly ash aggregate mixture have been presented in this section. The effect of fiber on various strength and stiffness properties have also been described in each subsection.

3.1. Compressive Strength

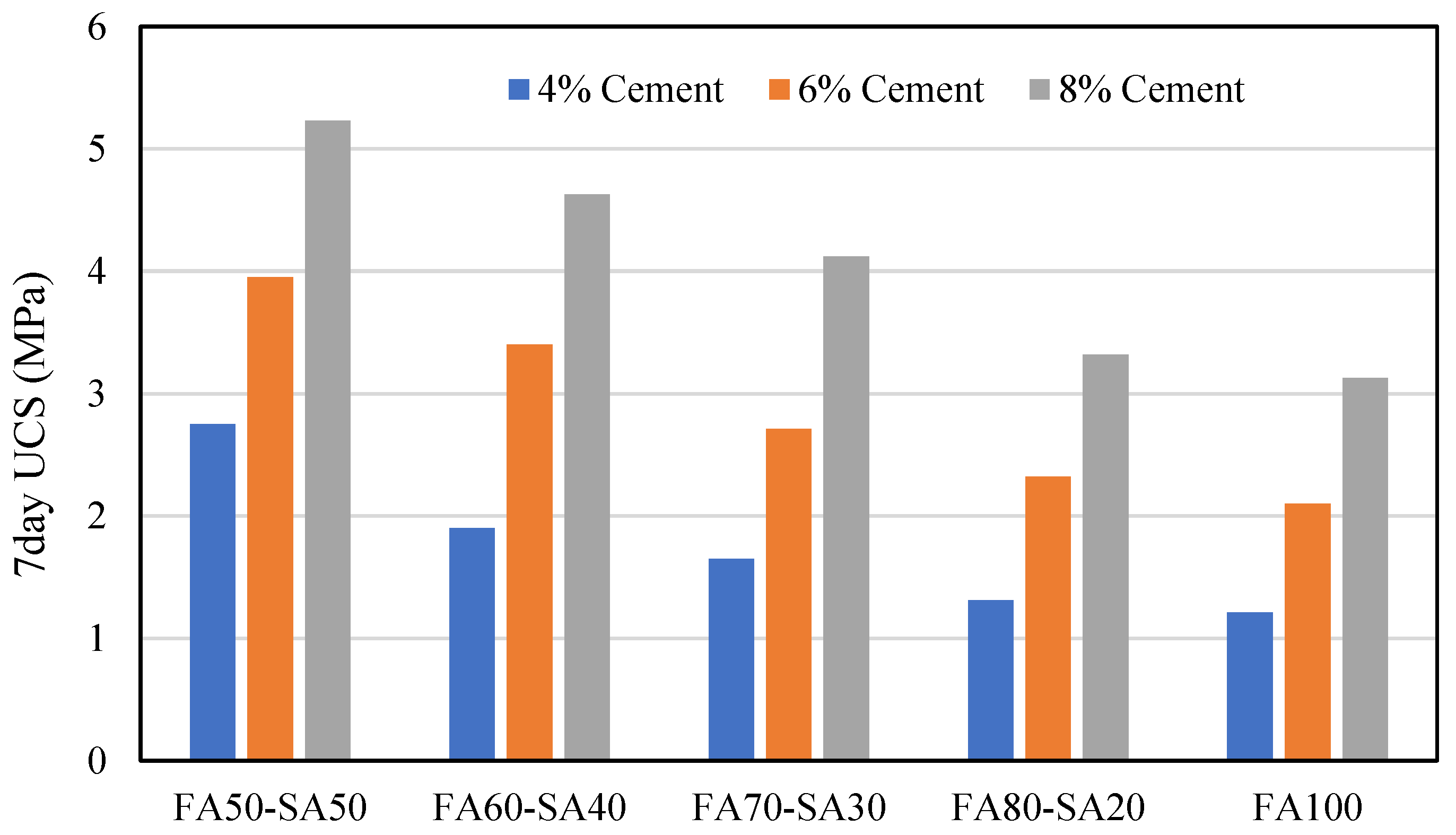

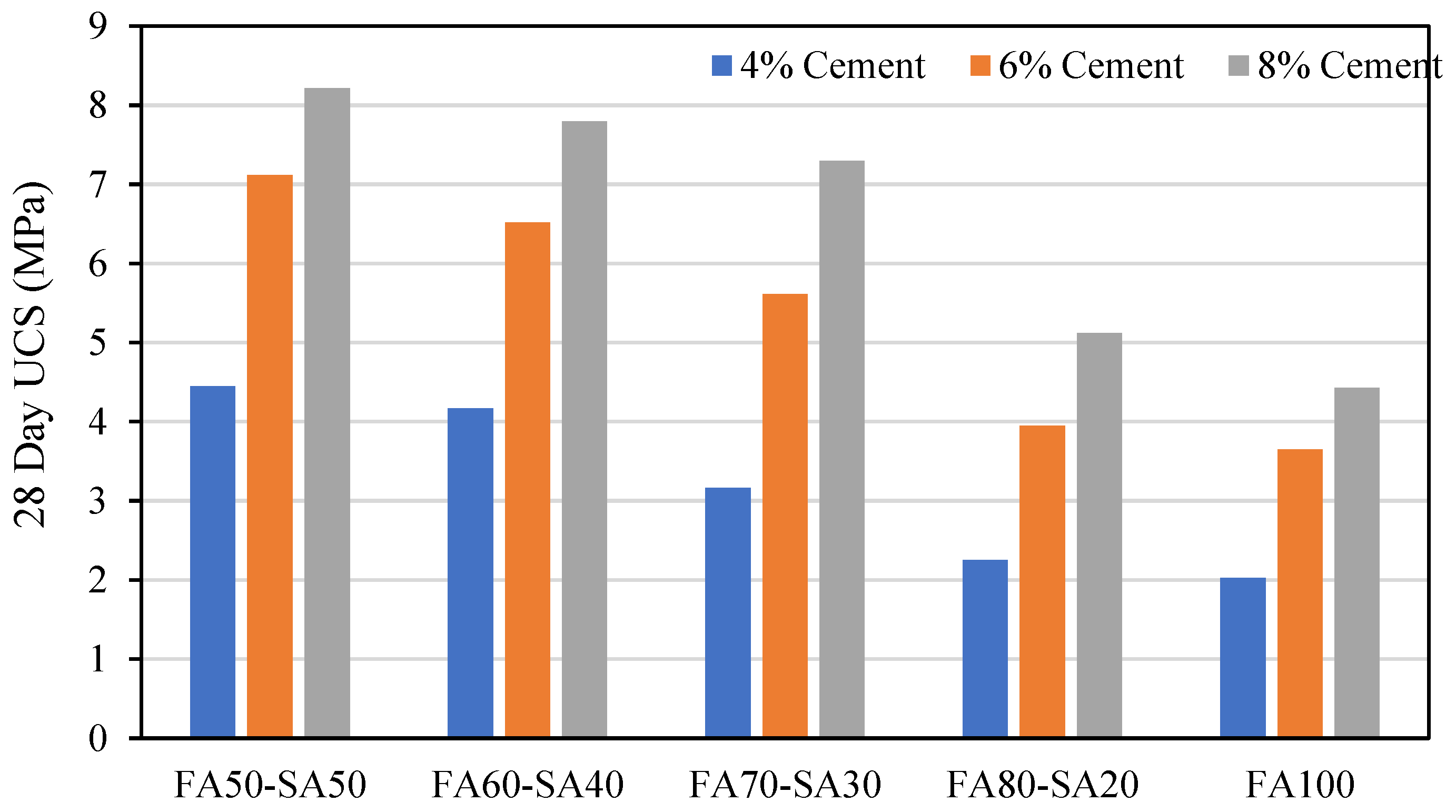

It can be observed from

Figure 6 and

Figure 7 that both 7-day and 28-day UCS values increased with increase in SA percentage which may attributed to the improvement in gradation due to addition of SA to FA. It can also be seen from

Figure 6 that the UCS values increased with increase in cement percentages and curing days for all mixture types. As per IRC SP 89 [

31], cement stabilized material having minimum 7-day UCS value of 4.5MPa are suitable for base layer application. Hence 50FA-50SA and 60FA-40SA mixture with 8% cement stabilization are full filling the criteria. Whereas IRC SP 89 (2010) also suggest that for lime-fly ash or lime-cement-fly ash bound materials if the minimum UCS of 4.5 MPa is achieved in 28 days, it can be considered suitable for base later application. In that context the mixtures such as 50FA-50SA, 60FA-40SA and 70FA-30SA with 6% cement can also be used in base layer.

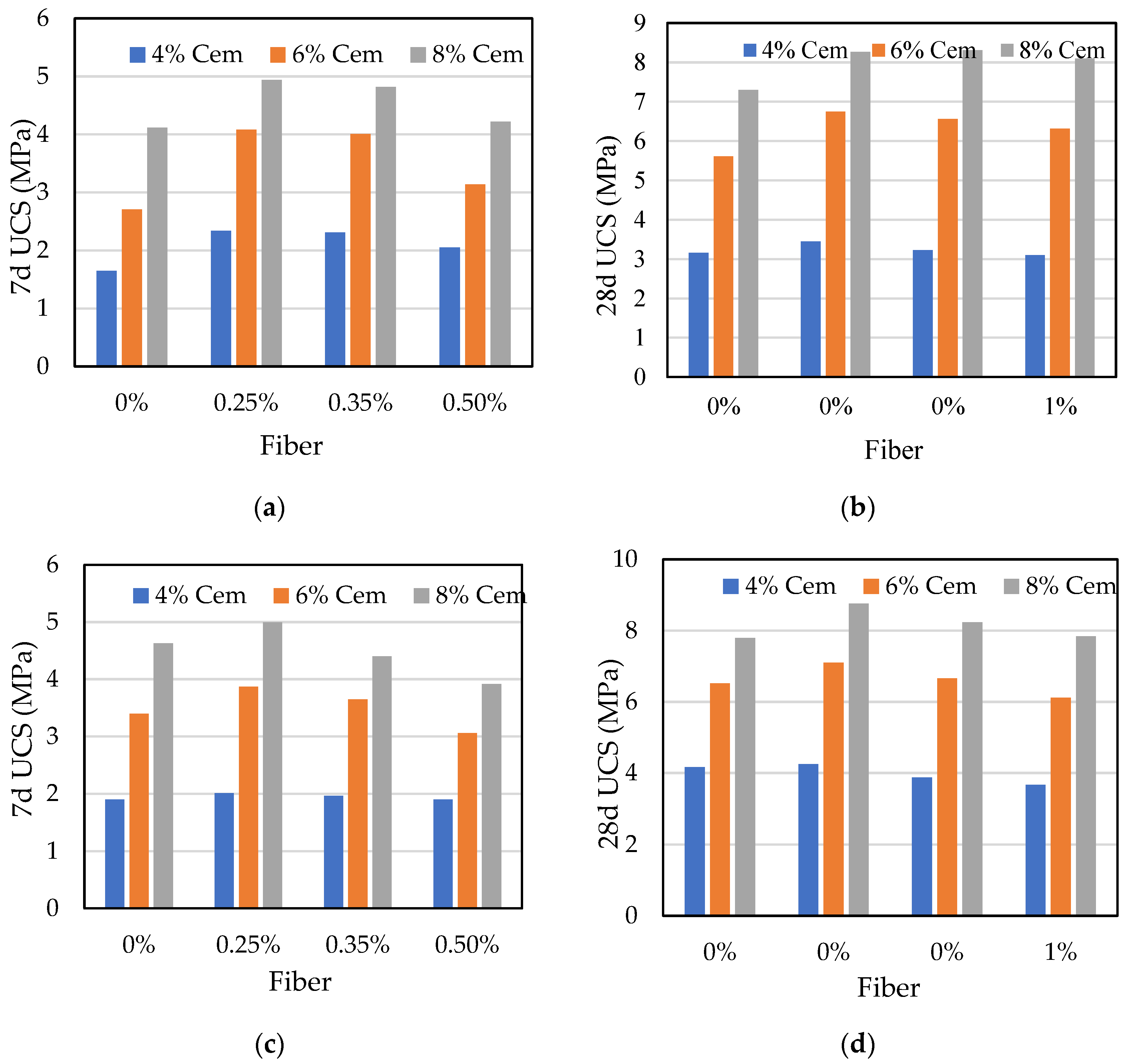

3.1.1. Effect of Fiber on UCS value

To study the effect of fiber, two mixtures i.e., 60FA-40SA and 70FA-30SA was chosen and mixed with three dosages of fiber (0.25 %, 0.35% and 0.5% by mass of mixture). The UCS values of fiber reinforced 70FA-30SA and 60FA-40SA mixture are presented in

Figure 8. The UCS data form these figures shows that the inclusion of fiber increases the UCS up to 0.25% of fiber and beyond that it decreases. With this optimum fiber content (i.e., 0.25%), fiber-reinforced fly ash attained a UCS of 4.25 MPa, 7.1MPa, and 8.76MPa for 4,6 and 8% cement which is 1.01,1.08 and 1.13-fold higher than the stabilized fly Ash with 4% cement without fiber. The enhancement of strength of FA-SA mixtures may be attributed to the mobilization of tensile strength of randomly distributed fibers due to interparticle friction between fibers and surrounding FA-SA mixtures. The decrease in UCS value beyond 0.25% fiber dosage may be attributed to the development of numerous slip surface in the mixture matrix.

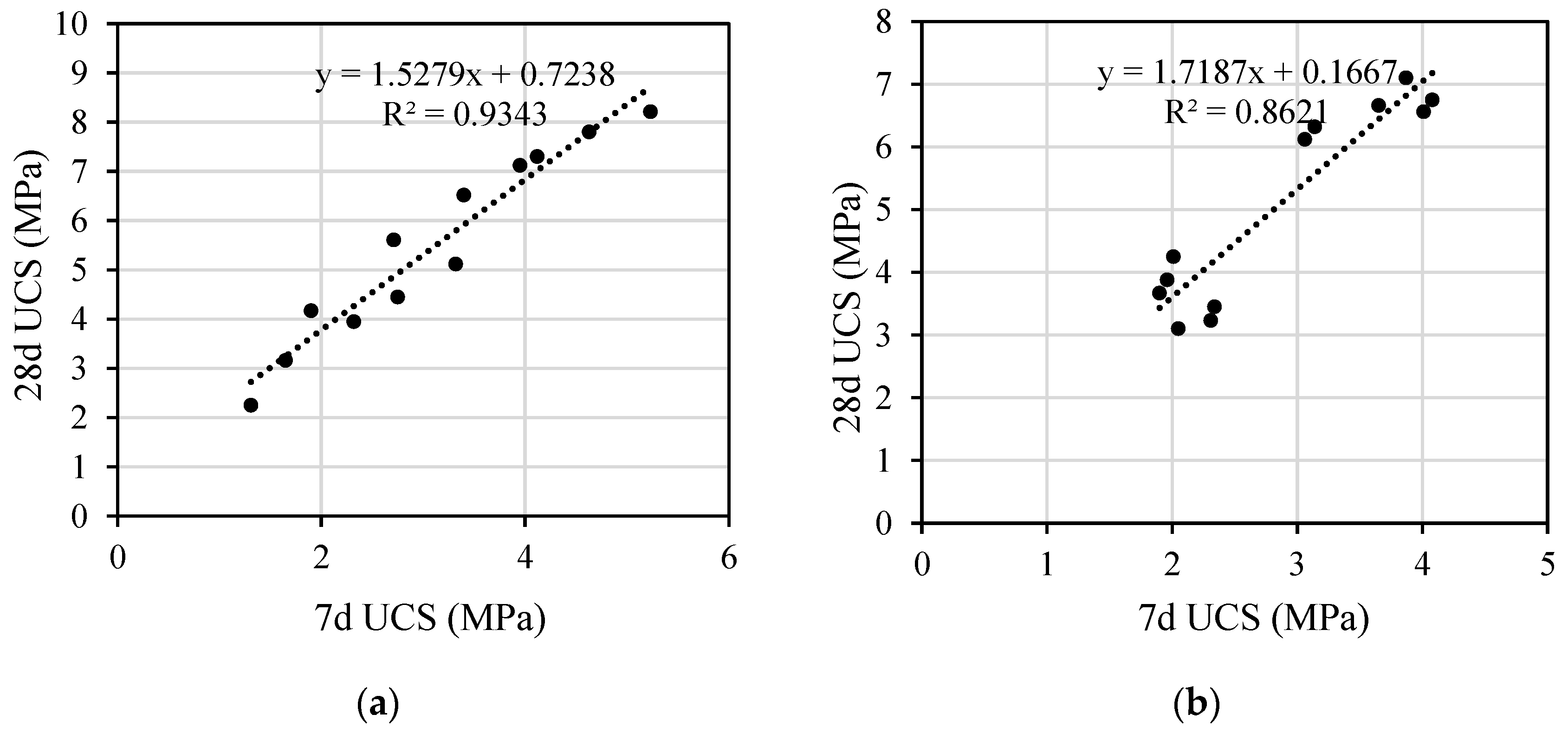

A linear correlation is established between 7 days and 28 days UCS of FA-SA mixture with or without fiber and presented in

Figure 9. The coefficient of linear relation (R

2) of samples without fiber is 0.96, whereas the R

2 is 0.86 in the case of fiber addition. The scattered data in case of UCS plot with fiber is due to the alteration of strength behavior with addition of fiber.

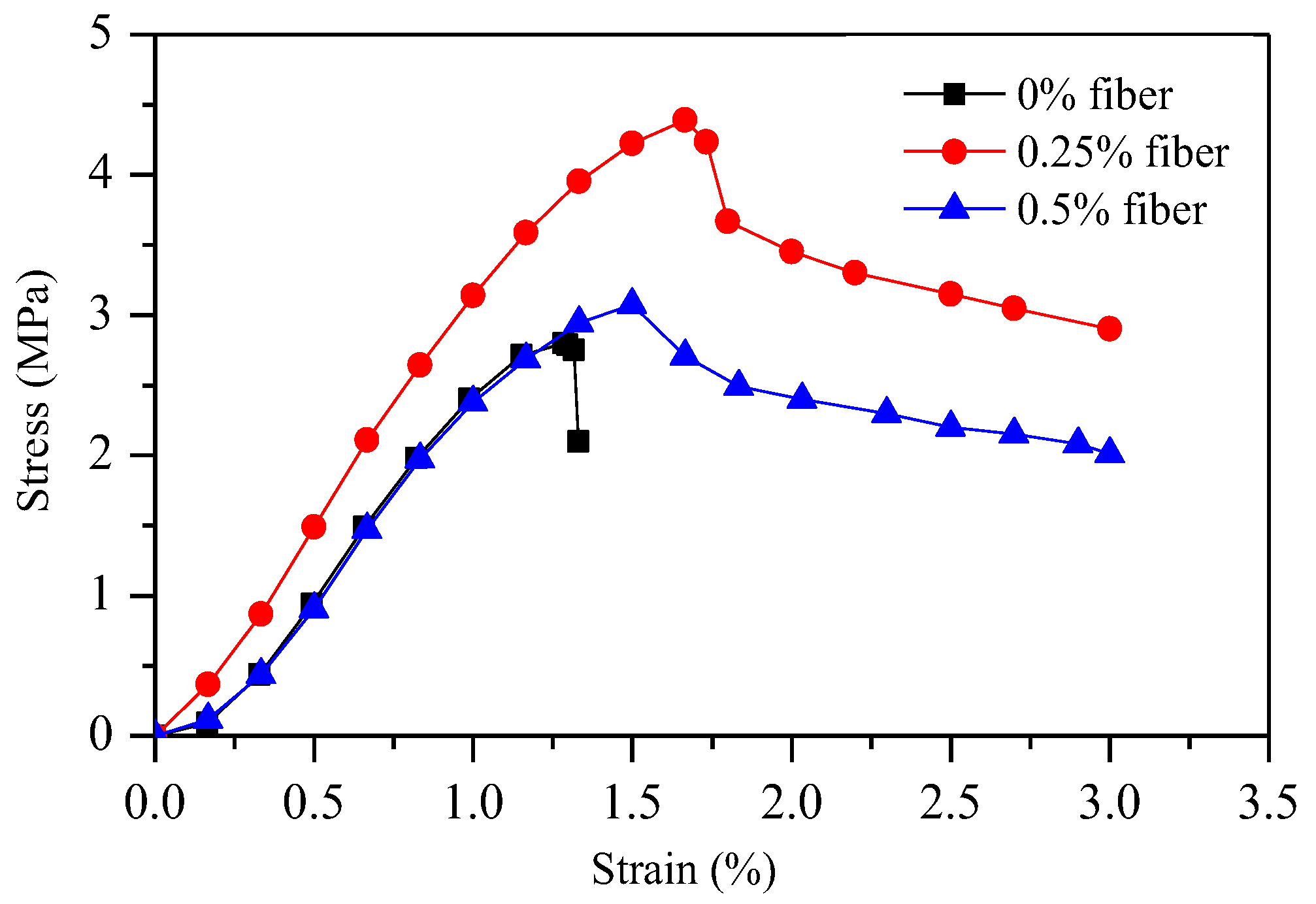

3.1.2. Effect of fiber on Stress-strain relationship

Stress-strain curve of the cement (6%) stabilized 70FA-30SA mixture with and without fiber is presented in

Figure 10 which shows that in absence of fiber (0%), the mixtures failed suddenly demonstrating brittle behavior. However, inclusion of fiber imparted ductility to the samples and it did not fail suddenly. But inclusion of fiber may increase or decrease the failure stress. Brittle failure of stabilized samples without fiber was due to development of a shear surface. Whereas fiber-reinforced samples failed due to a combination of shear and bulging which is due to the internal confinement of mixture materials caused by randomly oriented fibers.

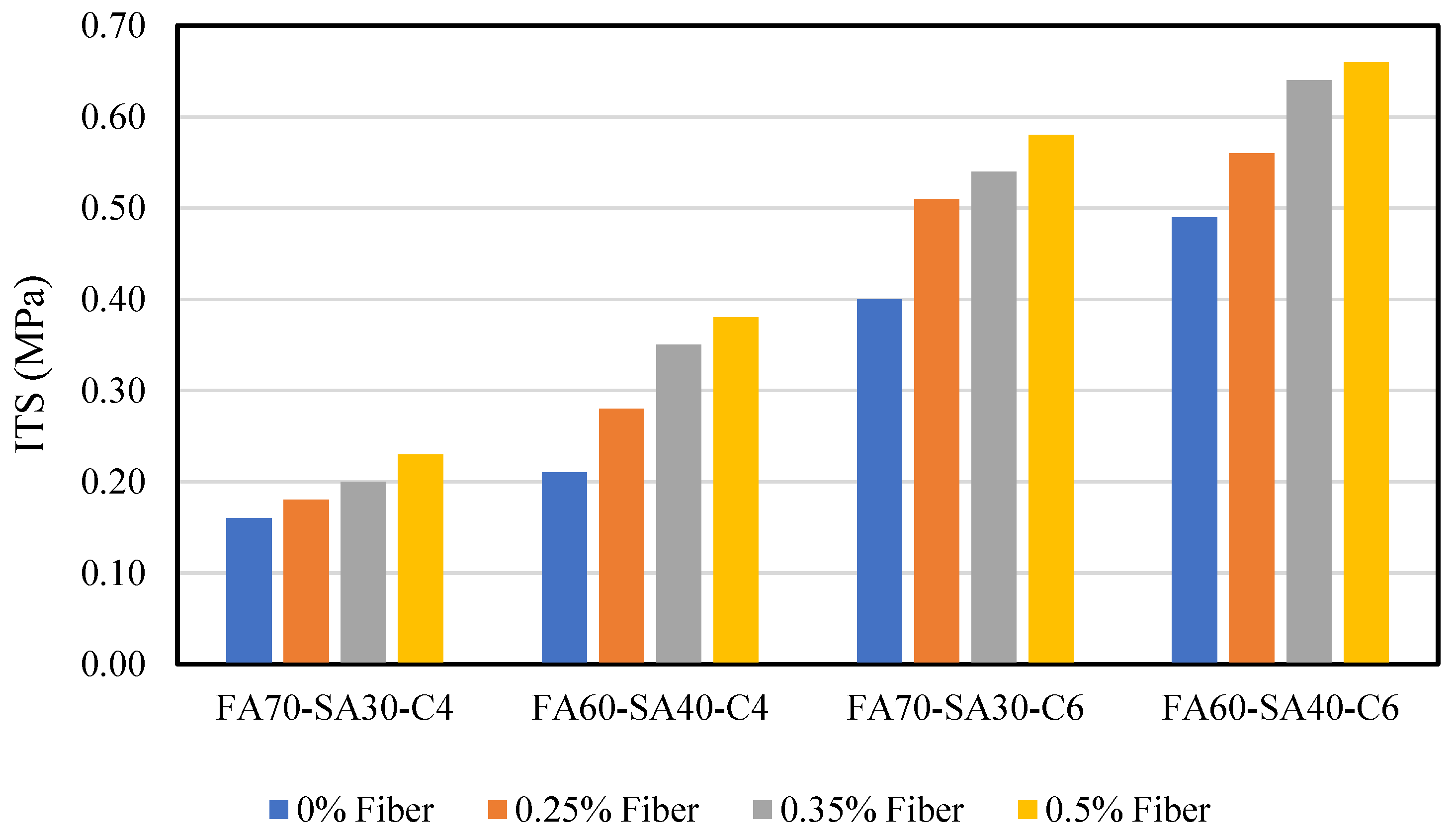

3.1.3. Indirect Tensile Strength (ITS)

The ITS values two mixtures i.e., 60FA-40SA and 70FA-30SA at various cement and fiber percentages are presented in

Figure 11. It can be observed from

Figure 11 that the addition of fiber has a notable effect on the tensile strength of blended fly ash at different cement content. The ITS increases with an increase in fiber content. The increase in ITS is about 65%when the percentage of stone aggregate increases from 30 to 40 at 4% cement. However, the increase is only 14% for 6% cement. The beneficial effect of fiber reinforcement on tensile strength can be attributed to the interfacial mechanical interactions between fibers and fly ash matrix. The increase in tensile strength with increases in fiber content can therefore be explained by the increased number of fibers per unit volume and the corresponding total contact area between the fibers and the fly ash matrix.

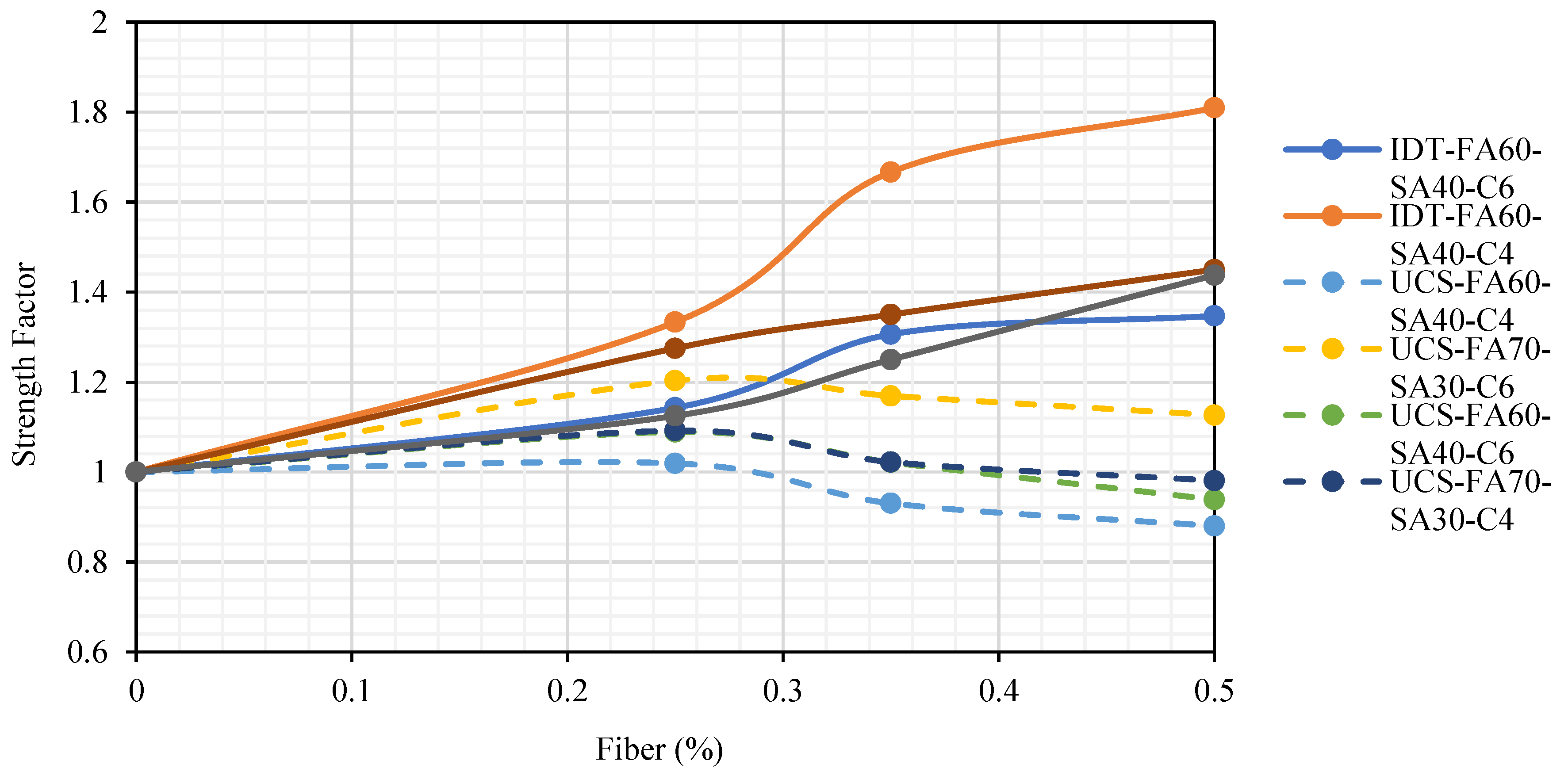

The bonding strength and friction between fibers and fly ash particles were the dominant factors controlling the reinforcement benefit. The strength factor which is expressed as the ratio between strength at x % fiber and strength of at 0% fiber increases with increase in fiber content for ITS. The strength factor for both the mixtures i.e., 60FA-40SA and 70FA-30SA mixture for UCS and ITS are presented in

Figure 12 which shows that the strength factor increases up to 0.25% fiber content and then decreases with further addition in the case of UCS. This indicates that, addition of fiber increases the tensile strength of stabilized fly ash blended with stone aggregates. When the particles are subjected to tensile strain, tensile stress is mobilized in the fiber due to the bonding and inter particle friction between the cemented matrix and the fibers. As fiber has a remarkable tensile strength, it results in a positive effect on the ITS due to addition of fiber.

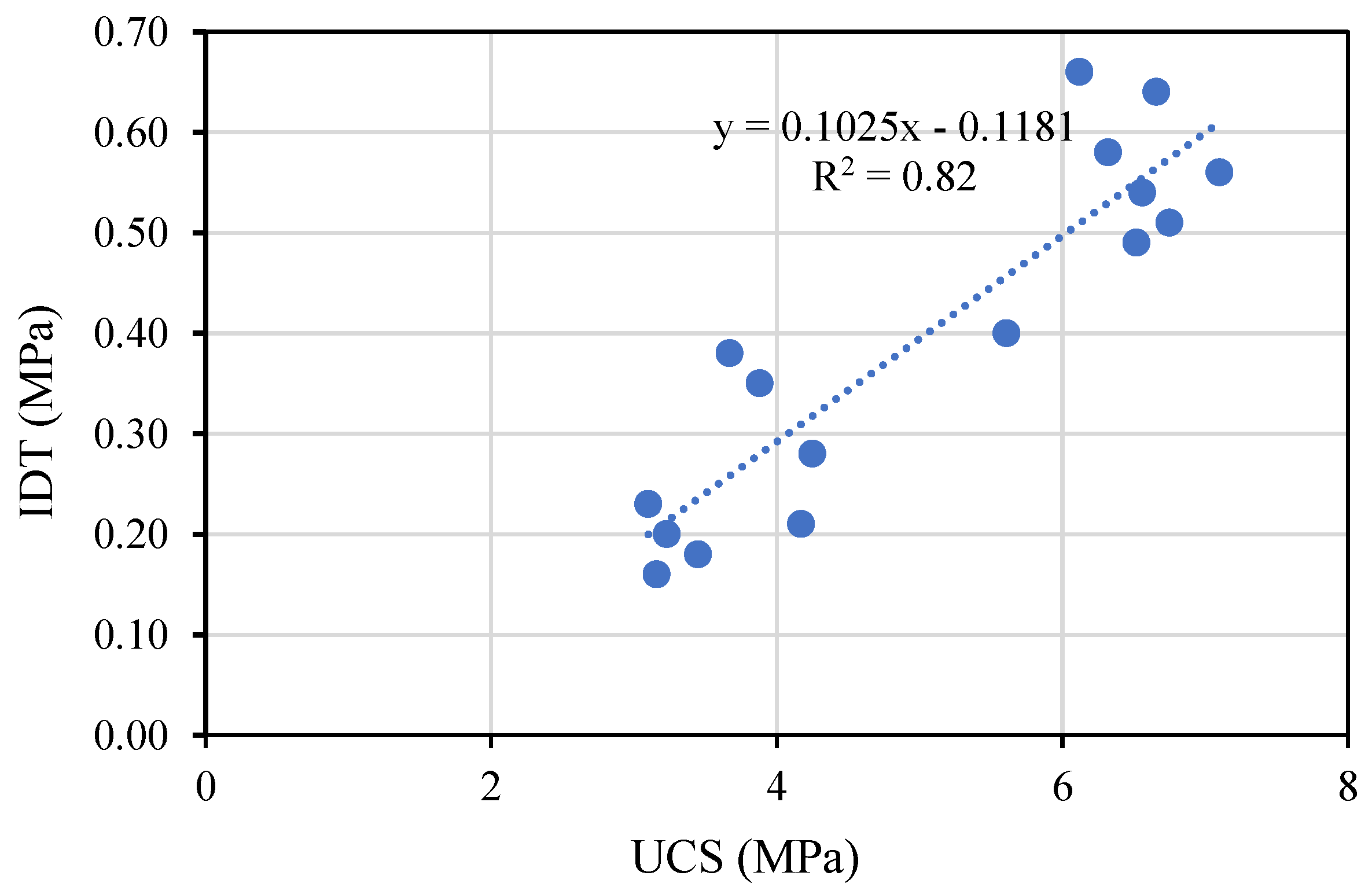

3.1.4. Correlation between ITS and UCS

A linear relationship is observed between the ITS and UCS of stabilized fly Ash mixtures (60FA-40SA and 70FA-30SA) and presented in

Figure 13. The R

2 value of the correlation was found to be 0.81. The correlation indicates that the ITS increases with increasing the UCS in the treated fly ash stone dust mixture.

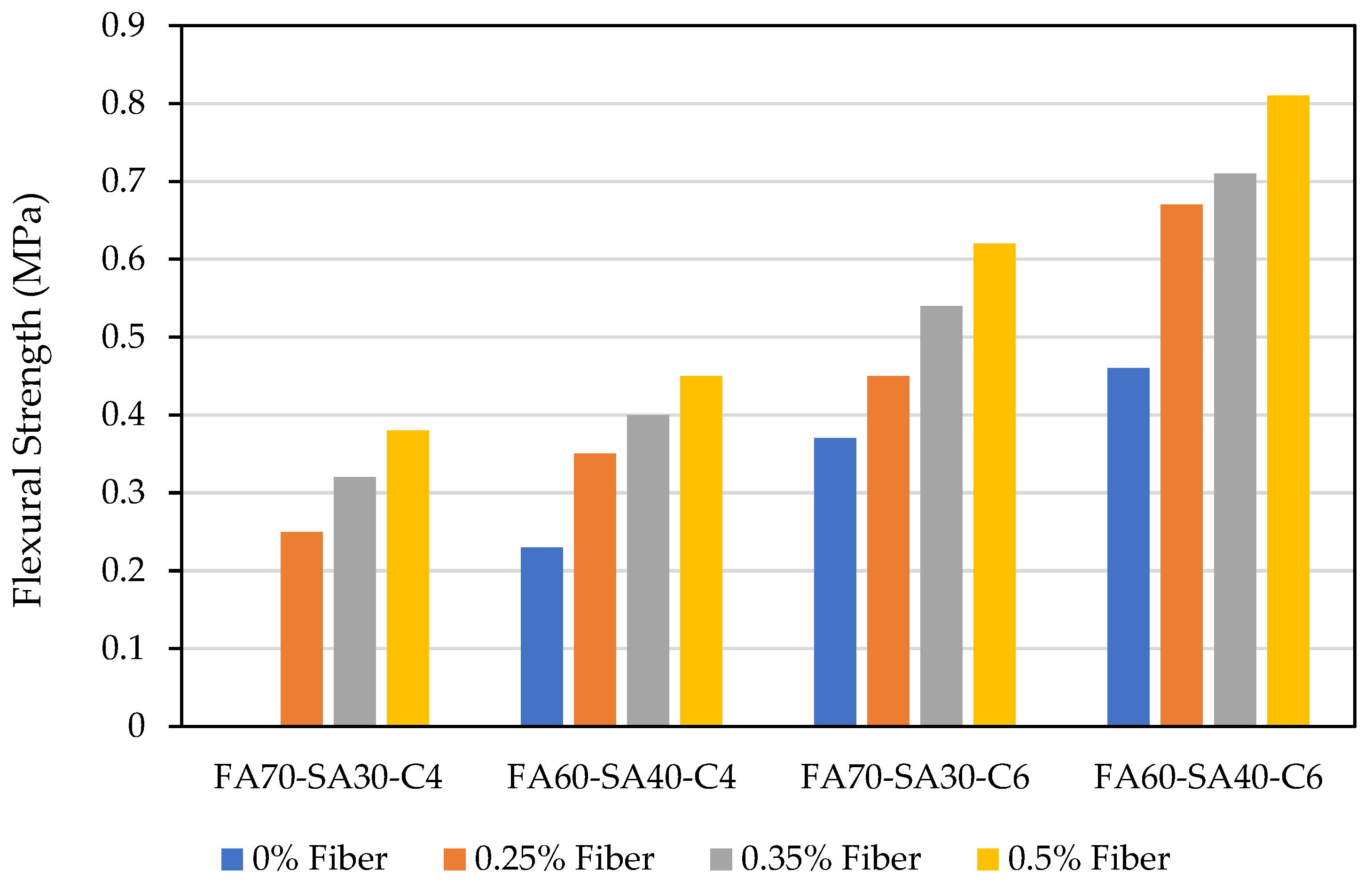

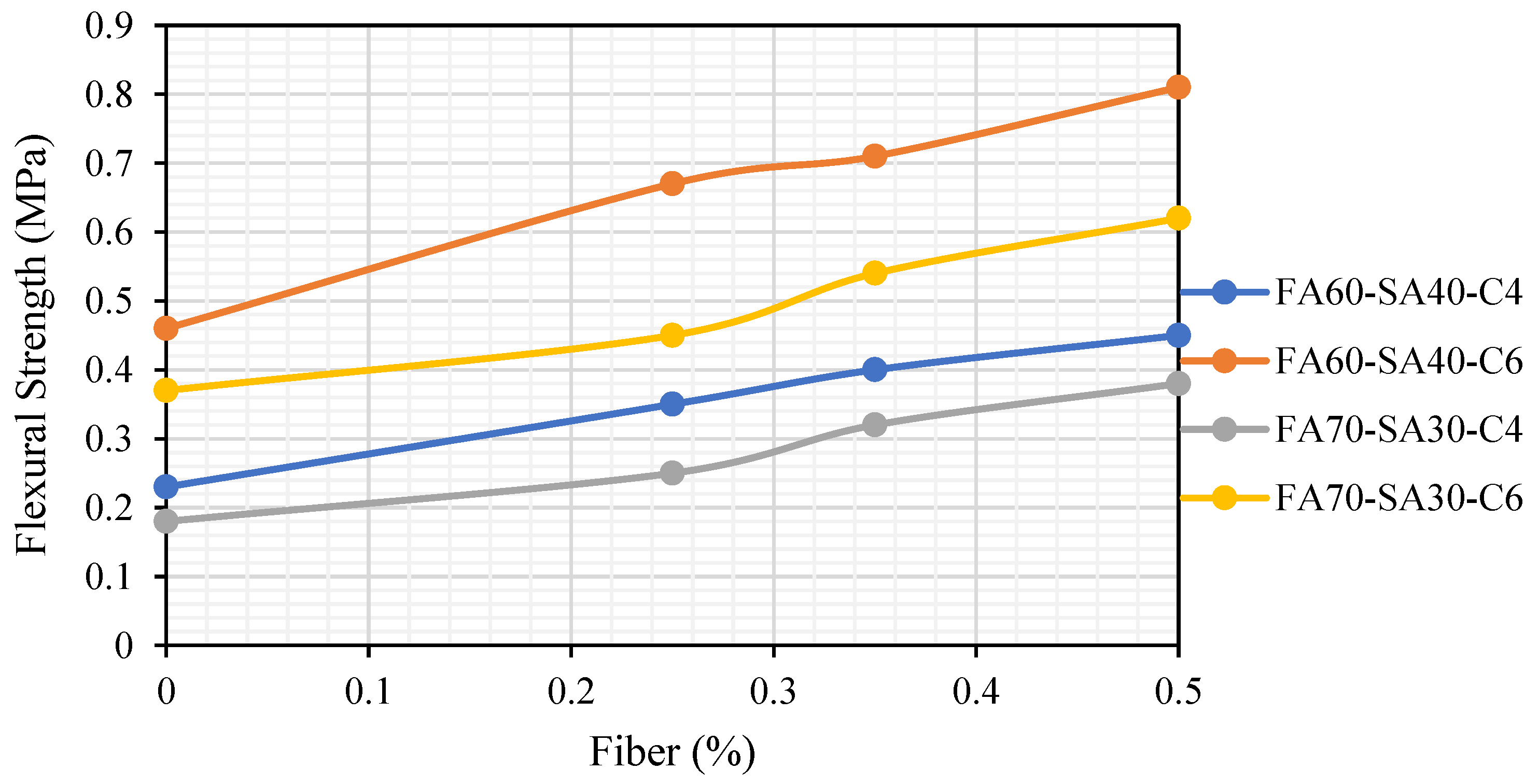

3.2. Flexural Strength (FS)

The FS values two mixtures i.e., 60FA-40SA and 70FA-30SA at various cement and fiber percentages are presented in

Figure 14. It can be observed from

Figure 14 that the flexural strength increases with increase in cement content for 0% to 0.5% fiber content. The flexural strength increased by 78%-100% by increasing cement content 4% to 6% with or without fibers.

3.2.1. Effect of fiber on flexural strength

Unlike the behavior of the mixture under compression, the flexural strength of mixtures i.e., FA60-SA40 and 70FA-30SA increased with increase in fiber quantity (see

Figure 15). The flexural strength of FA60-SA40-C4 increases by 50% when the fiber content is raised from 0% to 0.25%. The increase in FS may be due to development of a friction mechanism between the fly ash and the fibers, depending on the cement content, preventing microcracking. When the particles experience tensile strain during flexure, tensile stress is generated in the fibers due to the bonding and interparticle friction between the cemented matrix and the fibers. Since the fibers possess notable tensile strength, their inclusion yields a positive impact on the flexural strength.

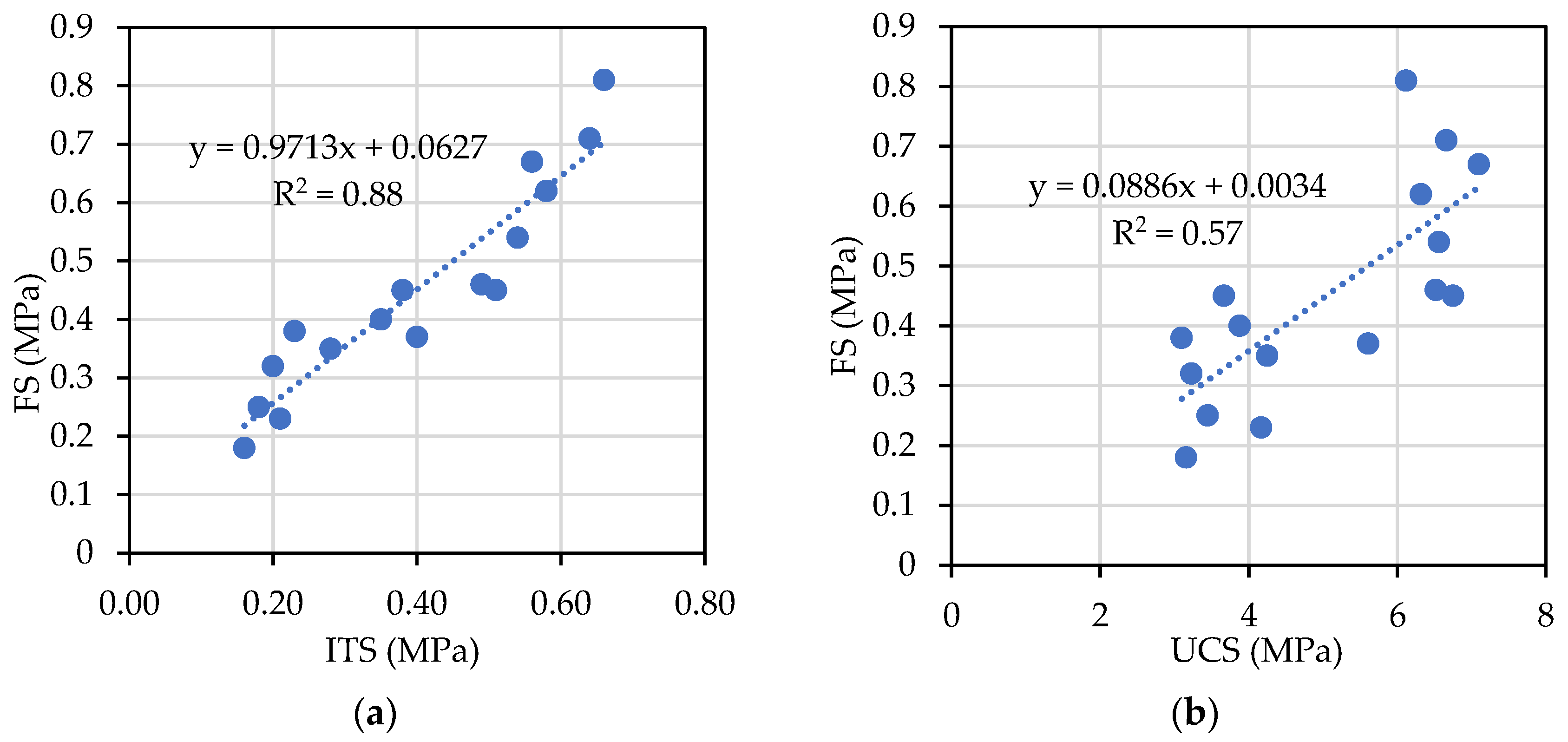

3.2.2. Relationship between FS, UCS and ITS (7day or 28 day)

In an attempt, FS was correlated with ITS (28days) and UCS (28 days) value for 60FA-40SA and 70FA-30SA together and presented in

Figure 16. A linear correlation was found with R

2 0.88 between FS and ITS. Similarly, a linear correlation with R

2=0.57 was established between FS and UCS.

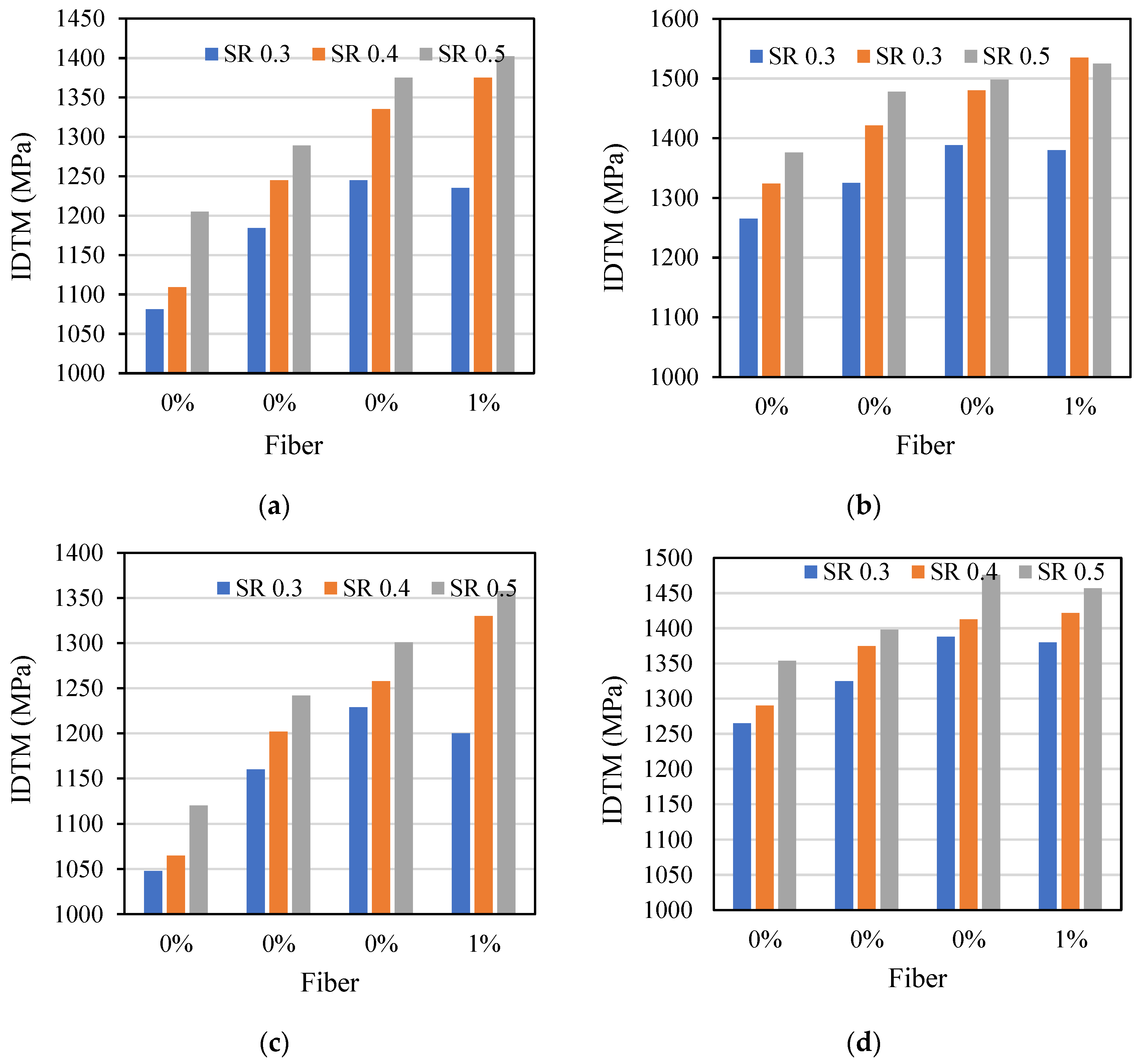

3.3. Cyclic Indirect Tensile Modulus/Resilient Modulus (IDTM)

Figure 17 presents the Indirect tensile modulus (IDTM) FA-SA mixture at various cement, fiber and stress ratio. The Cyclic IDT Modulus increases with the stress ratio. This is in consistent with Wen et al. 2014 [

24] and Biswal et al. 2020 [

23]. The Modulus increases with an increase in cement content. The presence of stone aggregate also has an effect in increasing the IDT Modulus. IDT modulus value is found to be higher than the beam modulus which is in consistent with Yeo 2008 [

29].

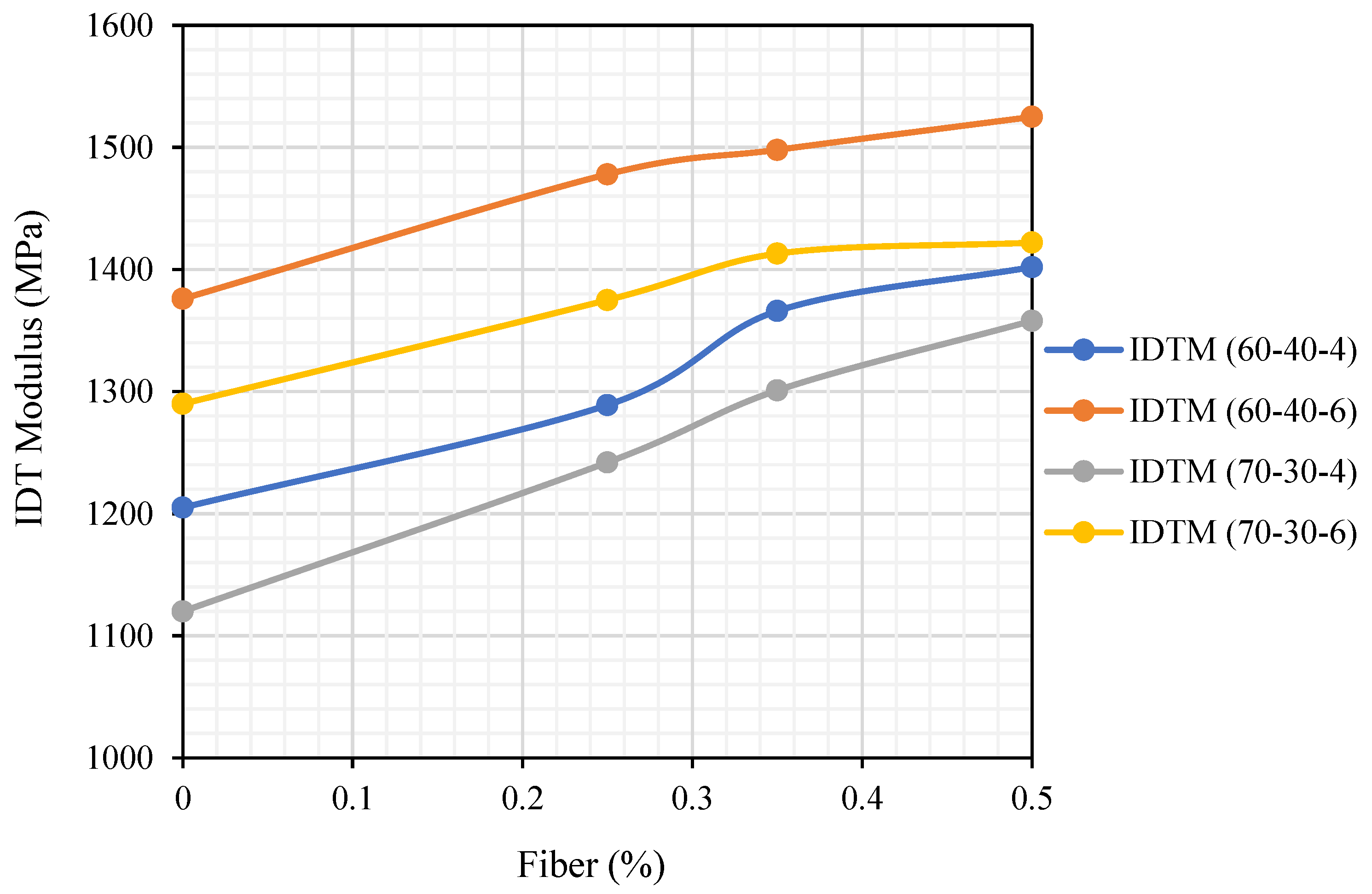

3.3.1. Effect of Fiber on IDTM

To the study the effect of fiber on IDTM value, a graph was plotted between IDTM modulus and fiber dosage in percentages as shown in

Figure 18. The IDTM value used in the graph was obtained at SR value of 0.3 and based on the study [

29]. In

Figure 18, a remarkable enhancement of modulus can be observed up to 0.35% fiber content and any further addition of fibers has less effect on modulus. This may be attributed to the development a greater number of slip surface in the mixture matrix. Considering 0.35% as the optimum dosage, a cyclic IDT modulus of 1300 MPa can be used for the mechanistic design of pavement.

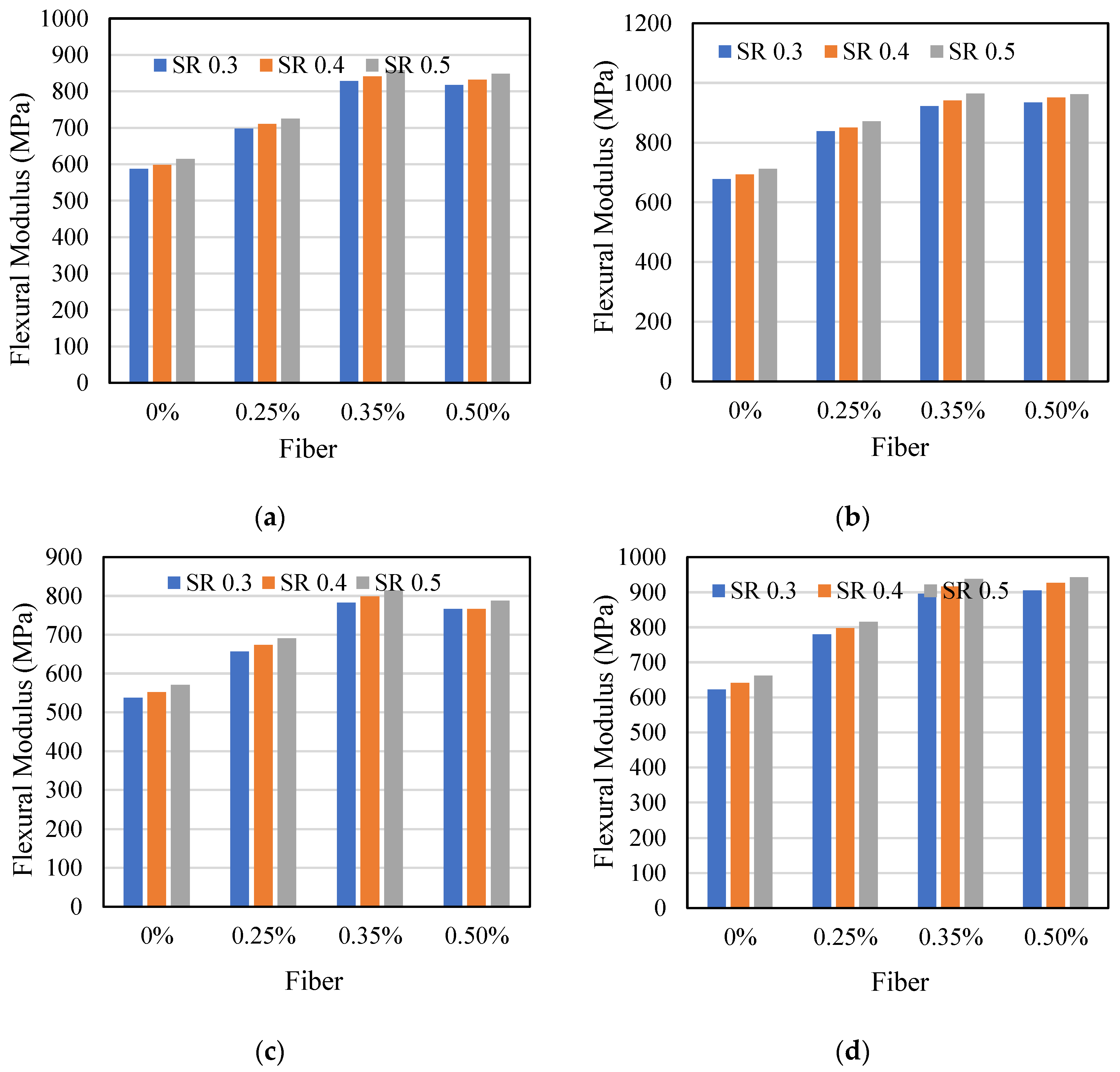

3.4. Flexural Modulus

Figure 19 present the flexural modulus of 60FA-40SA and 70FA-30SA mixtures at 4% and 6% cement dosage. The flexural modulus of mixtures varies between 538MPa and 965MPa. The flexural modulus of 60FA-40SA mixtures is found to be more than 70FA-30SA at a particular cement dosage.

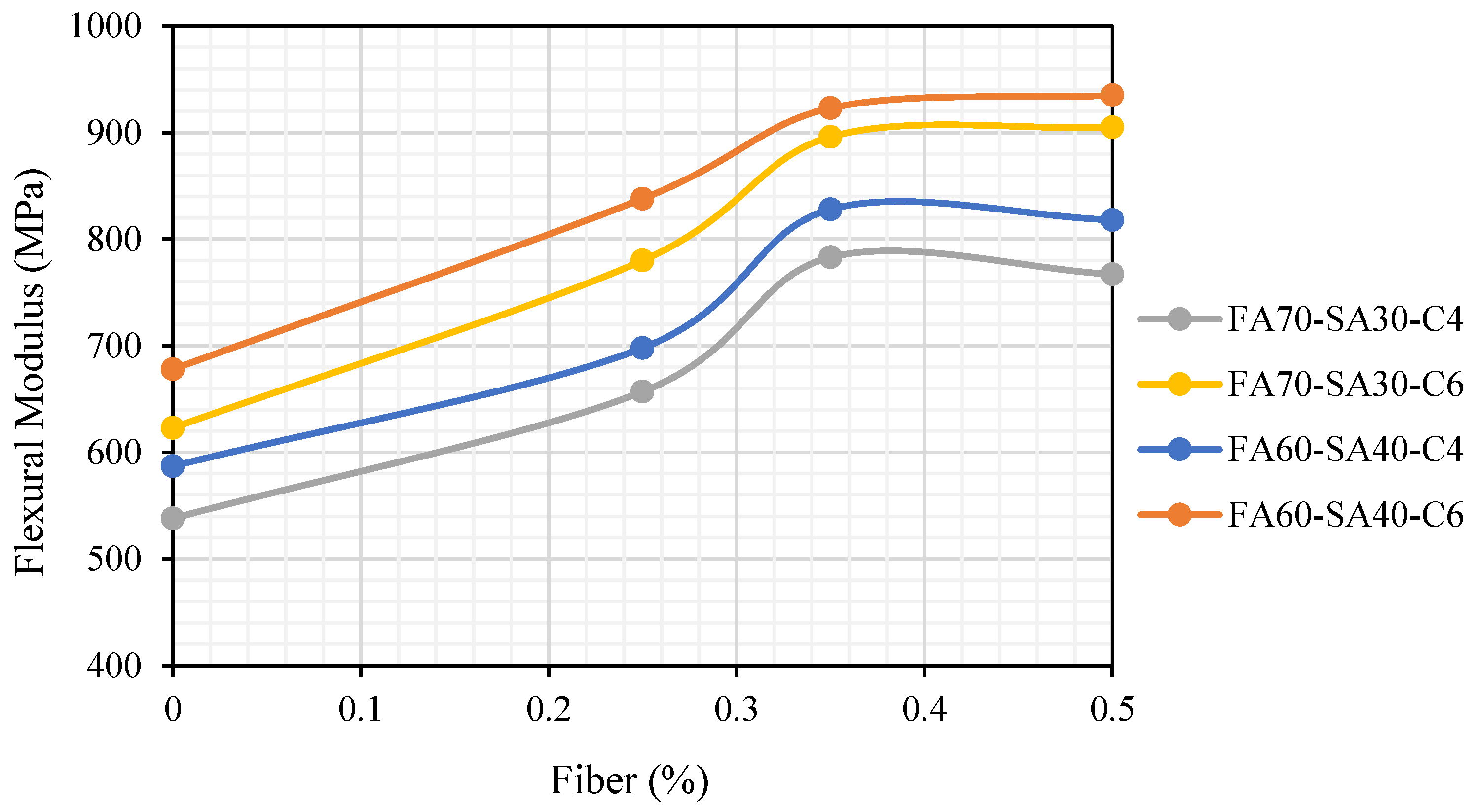

3.4.1. Effect of fiber on Flexural Modulus

To the study the effect of fiber on FM value, a graph was plotted between FM modulus and fiber dosage in percentages as shown in

Figure 20. It was observed that FM increased with the addition of fiber up to 0.35% and further addition of fiber has minimal effect on FM. However, FM value increased with increase in cement content and FM value of FA60-SA40 was found to be more than FA70-SA30 for same cement dosage.

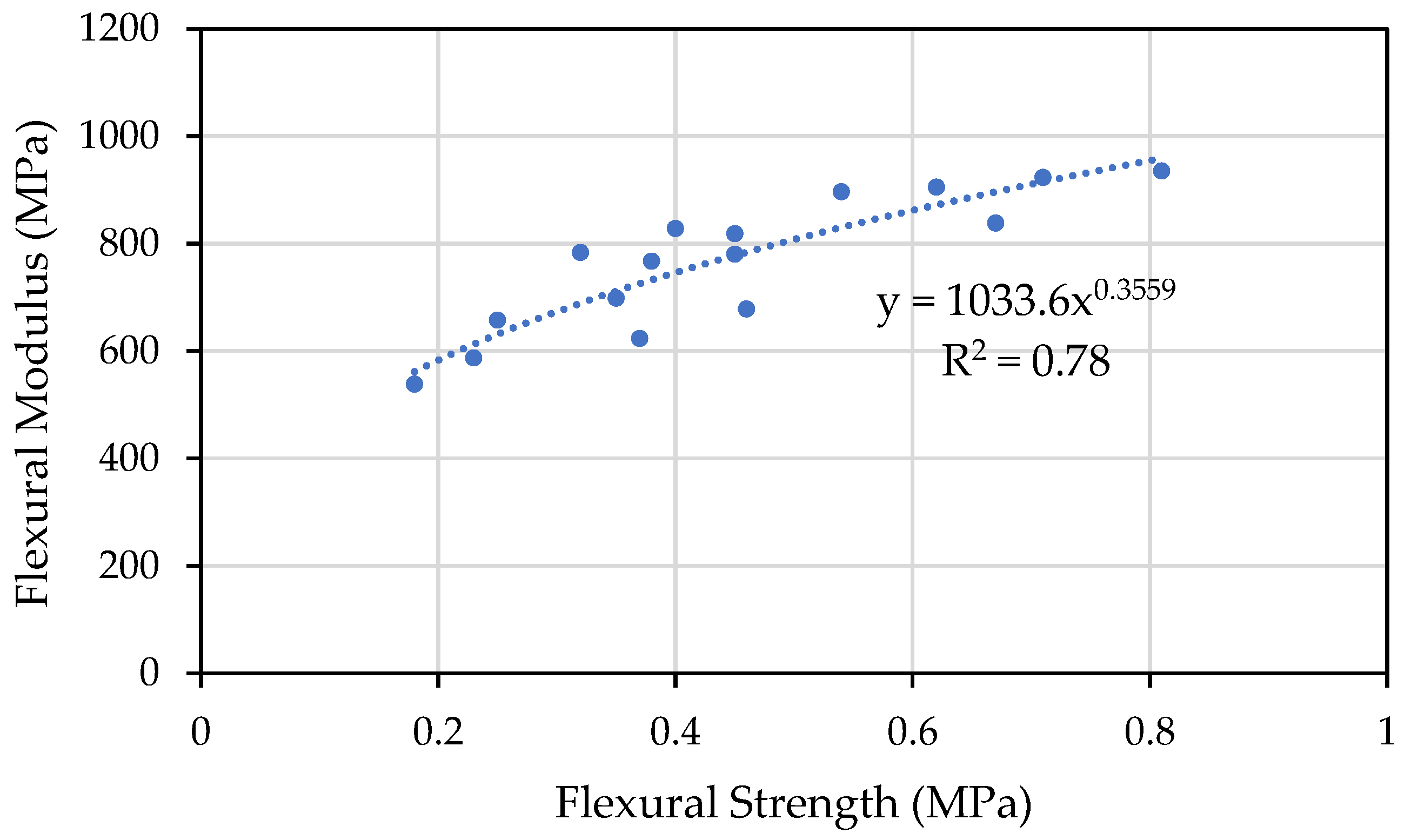

3.4.2. Relationship between flexural modulus and flexural strength

A power relationship with R

2 = 0.78 has been established (shown in

Figure 21) between FM and FS of 60FA-40SA and 70FA-30SA mix together. The data used where the correlation includes all fiber dosages and cement content.

4. Summary and Conclusion

In this current study, a task was undertaken to check the feasibility of cement stabilized fly ash for base layer application. The FA was mixed with SA for improving its gradation and strength. The FA-SA was stabilized with various dosage of cement and fiber was added to the mixtures in different quantities to reduce the brittleness of the mixtures. The strength and stiffness values of the fiber reinforced cement stabilized FA-SA mixtures were studied.

The major findings of the current study are as follows:

The addition of SD and aggregate not only enhanced the gradation of FA-SA mixture but also increased the UCS value of the mix.

The UCS value increases with cement content with linear trend.

The UCS increases from 0% fibers to 0.25% fibers and there after decreases with the addition of more fibers.

Inclusion of fiber in the FA-SA mixture imparted ductility to the mixture and prevented brittle failure.

An optimum fiber dosage of 0.25% can be considered for FA-SA mixture.

28-day UCS is found to be 52%-75% more than 7-day UCS which shows slow strength gain nature of the mixtures; hence, it is proposed to consider 28-day UCS for assessing the suitability of stabilized base or subbase.

UCS of 70FA-30SA and 60FA-40SA with 6% cement at 28 days was more than 4.50 MPa and hence can be used in base layer based upon 28 days compressive strength criteria laid down by IRC SP :89 (2010).

Unlike the compressive strength the indirect tensile strength increases with increase in fiber content of the cement stabilized mixtures in the entire range (0-0.5%). The beneficial effect of fiber reinforcement on tensile strength can be attributed to the interfacial mechanical interactions between fibers and fly ash matrix.

A strong linear relationship has been developed between the indirect tensile strength and the unconfined compressive strength of stabilized fly ash.

The Cyclic IDT Modulus increases with the stress ratio. IDT modulus value is found to be higher than the beam modulus which is in consistent with Yeo. R (2008).

A remarkable enhancement of modulus is observed up to 0.35% fiber content and any further addition of fibers has less effect on modulus.

Considering 0.35% as the optimum dosage, a Cyclic IDT modulus of 1300 MPa can be used for the mechanistic design of pavement.

A strong linear relationship has been developed between the indirect tensile strength and the cyclic indirect tensile modulus of stabilized fly Ash stone aggregate mixtures.

Similar to the indirect tensile strength, the flexural strength increases with increase in cement content for 0% to 0.5% fiber content.

A power relationship with R

2 = 0.78 has been established (shown in

Figure 21) between FM and FS

Based on a comprehensive experimental programme conducted for characterization of fiber reinforced cement stabilized FA-SA mixture, it can be concluded that the material can be used in the base/sub-base layer of the pavement. The usage of this material will not only promote sustainable construction practice but also reduce the cost of the project as it uses fly ash in large quantity which is chiefly available.

Limitation

As per IRC SP: 89 (2010), stabilized material needs to satisfy both the minimum UCS strength criteria and wet-dry durability criteria. In this paper, the data related to the durability study of the mixture were not presented as it is out of the scope. All the durability related finding will be published in another paper.

References

- CEA. Report On Fly Ash Generation At Coal / Lignite Based Thermal Power Stations And Its Utilization In The Country For The Year 2021 – 22. Available online: http://www.cea.nic.in (accessed on 24 April 2023).

- Zabielska-Adamska, K. Laboratory Compaction of Fly Ash and Fly Ash with Cement Additions. J. Hazard. Mater. 2008, 151 (2–3), 481–489. [CrossRef]

- Šešlija, M.; Rosić, A.; Radović, N.; Vasić, M. , Đogo, M.; Jotić, M. Laboratory testing of fly ash. Tech. Gaz. 2016, 23(6), 1839–1848. [Google Scholar] [CrossRef]

- Lav, A. H.; Lav, M. A.; Göktepe, A. B. Analysis and Design of a Stabilized Fly Ash as Pavement Base Material. Fuel 2006, 85(16), 2359–2370. [Google Scholar] [CrossRef]

- Kumar, M.A.; Prasad, D.S.V.; Raju, G.P. Performance Evaluation of stabilized fly ash subbases. J. Eng. App. Sci. 2010, 5(8), 50–57. [Google Scholar]

- Patil, N. R.; Kulkarni, D.; Talegaonkar, S. D. Economical Pavement Design by Stabilizing Effect of Fly Ash and Lime. Indian. J. Res. 2012, 2(3), 121–124. [Google Scholar] [CrossRef]

- Amhadi, T.; Assaf, G. J. Improvement of Pavement Subgrade by Adding Cement and Fly Ash to Natural Desert Sand. Infrastruct. 2021, 6(11), 151. [Google Scholar] [CrossRef]

- Kelechi, S. E.; Adamu, M.; Uche, O. a. U.; Okokpujie, I. P.; Ibrahim, Y. E.; Obianyo, I. I. A Comprehensive Review on Coal Fly Ash and Its Application in the Construction Industry. Cogent Eng. 2022, 9(1). [Google Scholar] [CrossRef]

- Shahu, J. T.; Patel, S. J.; Senapati, A. K. Engineering Properties of Copper Slag–Fly Ash–Dolime Mix and Its Utilization in the Base Course of Flexible Pavements. J. Mater. Civ.Eng. 2013, 25(12), 1871–1879. [Google Scholar] [CrossRef]

- Bakare, M. D.; Pai, R. R.; Patel, S.; Shahu, J. T. Environmental Sustainability by Bulk Utilization of Fly Ash and GBFS as Road Subbase Materials. J. Hazard. Toxic. Radioact. Waste 2019, 23(4), 04019011. [Google Scholar] [CrossRef]

- Pai, R. R.; Bakare, M. D.; Patel, S. J.; Shahu, J. T. Structural Evaluation of Flexible Pavement Constructed with Steel Slag–Fly Ash–Lime Mix in the Base Layer. J. Mater. Civ. Eng. 2021, 33(6). [Google Scholar] [CrossRef]

- Usmen, M.; Bowders, J. J. Stabilization Characteristics of Class F Fly Ash, Transp. Res. Rec. 1990, 1288, 59–69. [Google Scholar]

- Ghosh, A.; Subbarao, C. Strength Characteristics of Class F Fly Ash Modified with Lime and Gypsum. J. Geotech. Geoenviron. Eng. 2007, 133(7), 757–766. [Google Scholar] [CrossRef]

- Dimter, S.; Rukavina, T.; Barišić, I. Application of the Ultrasonic Method in Evaluation of Properties of Stabilized Mixes. Baltic J. Road Bridge Eng. 2011, 6(3), 177–184. [Google Scholar] [CrossRef]

- Kaniraj, S. R.; Havanagi, V. G. Behavior of Cement-Stabilized Fiber-Reinforced Fly Ash-Soil Mixtures. J. Geotech. Geoenviron. Eng. 2001, 127(7), 574–584. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, S. P. Fiber-Reinforced Fly ash Subbases in rural Roads, J. Transp. Eng. 2008, 134(4), 171–180. [Google Scholar] [CrossRef]

- Vaidya, M. K.; Chore H., S.; Kousitha, P.; Ukrande, S. K. Geotechnical characterization cement - fly ash - fiber mix. J. Mech. Civ. Eng. 2015, 1(30), 60–66. [Google Scholar]

- Li, L.; Zhang, J.; Xiao, H.; Zhi, H.; Wang, Z. Experimental Investigation of Mechanical Behaviors of Fiber-Reinforced Fly Ash-Soil Mixture. Adv. Mater. Sci. Eng. 2019, 1–10. [Google Scholar] [CrossRef]

- Pasupuleti, V. K. R.; Kolluru, S. K.; Blessingstone, T. Effect of Fiber on Fly-Ash Stabilized Sub Grade Layer Thickness. Int. J. Eng. Technol. 2012, 4(3), 140–147. [Google Scholar]

- Chakrabarti, S., & Kodikara, J. Basaltic crushed rock stabilized with cementitious additives: Compressive strength and stiffness, drying shrinkage, and capillary flow characteristics. Transportation Research Record: Journal of the Transportation Research Board 2003, 1819, 18–26. [CrossRef]

- Paige-Green, P. (1998). Recent developments in soil stabilization. 19thARRB Transport Research Ltd Conference Sydney, New South Wales Australia.

- Yeo, R. , Jitsangiam, P., & Nikraz, H. (2011). Mix Design of Cementitious Basecourse. In M. Shahin &.

- Biswal DR, Sahoo UC, Dash SR. Mechanical characteristics of cement stabilised granular lateritic soils for use as structural layer of pavement. Road Materials and Pavement Design. 2020 Jul 3;21(5):1201-23. [CrossRef]

- Wen, H. , Muhunthan, B., Wang, J., Li, X., Edil, T., & Tinjum, J. M. (2014). Characterization of Cementitiously Stabilized Layers for Use in Pavement Design and Analysis. NCHRP Report No. 789, Transportation Research Board, Washington, D.C.

- ASTM. ASTM C618- Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete; ASTM International: West Conshohocken, PA, USA, 2022. [Google Scholar]

- Indian Standards. IS 8112- Ordinary Portland Cement, 43 Grade — Specification (Second Revision), BIS: New Delhi, India, 2003.

- ASTM. ASTM D1557-12- Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)); ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- ASTM. ASTM D1633- Standard Test Methods for Compressive Strength of Molded Soil-Cement Cylinders; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Yeo, R. The Development and Evaluation of Protocols for the Laboratory characterisation of Cemented Materials. Austroads Publication No. AP– T101/08. ARRB-Australia, 2008.

- ASTM. ASTM D1635-Standard Test Method for Flexural Strength of Soil-Cement Using Simple Beam with Third-Point Loading; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- IRC. IRC SP:89-Guidelines for the design of stabilized pavement (Part I), IRC- New Delhi, India, 2010.

Figure 1.

Materials used in present study.

Figure 1.

Materials used in present study.

Figure 2.

Particle size distribution of fly ash and SA mixture in different proportion.

Figure 2.

Particle size distribution of fly ash and SA mixture in different proportion.

Figure 3.

Percentages of silt, sand and gravel in fly ash and SA mixture in different proportion.

Figure 3.

Percentages of silt, sand and gravel in fly ash and SA mixture in different proportion.

Figure 4.

(a) Servo hydraulic cyclic test equipment: (b) Cyclic Indirect Tensile Test Arrangement.

Figure 4.

(a) Servo hydraulic cyclic test equipment: (b) Cyclic Indirect Tensile Test Arrangement.

Figure 5.

Cyclic Flexure test (a) test arrangement; (b) Failure of the beam sample.

Figure 5.

Cyclic Flexure test (a) test arrangement; (b) Failure of the beam sample.

Figure 6.

7-day UCS values of various mixtures without fiber

Figure 6.

7-day UCS values of various mixtures without fiber

Figure 7.

28-day UCS values of various mixtures without fiber.

Figure 7.

28-day UCS values of various mixtures without fiber.

Figure 8.

UCS of 60FA-40SA mixtures at different fiber % (a) 70FA-30SA-7 days; (b) 70FA-30SA-28 days; (c) 60FA-40SA-7 days; (b) 60FA-40SA-28 days.

Figure 8.

UCS of 60FA-40SA mixtures at different fiber % (a) 70FA-30SA-7 days; (b) 70FA-30SA-28 days; (c) 60FA-40SA-7 days; (b) 60FA-40SA-28 days.

Figure 9.

Correlation between 7-days and 28-days UCS of mixtures; (a) without fiber; (b) with fiber.

Figure 9.

Correlation between 7-days and 28-days UCS of mixtures; (a) without fiber; (b) with fiber.

Figure 10.

Stress-strain behavior 7-day cured unreinforced and fiber reinforced 70FA-30SA mixture stabilized with 6% cement.

Figure 10.

Stress-strain behavior 7-day cured unreinforced and fiber reinforced 70FA-30SA mixture stabilized with 6% cement.

Figure 11.

ITS of 60FA-40SA and 70FA-30SA at various cement and fiber percentages.

Figure 11.

ITS of 60FA-40SA and 70FA-30SA at various cement and fiber percentages.

Figure 12.

Strength Factor of 60FA-40SA and 70FA-30SA mixtures.

Figure 12.

Strength Factor of 60FA-40SA and 70FA-30SA mixtures.

Figure 13.

Correlation between UCS and ITS of 60FA-40SA and 70FA-30SA mixtures.

Figure 13.

Correlation between UCS and ITS of 60FA-40SA and 70FA-30SA mixtures.

Figure 14.

FS value of 60FA-40SA and 70FA-30SA at various cement and fiber percentages.

Figure 14.

FS value of 60FA-40SA and 70FA-30SA at various cement and fiber percentages.

Figure 15.

Effect of fiber content on FS of 60FA-40SA and 70FA-30SA at different dosage cement percentages

Figure 15.

Effect of fiber content on FS of 60FA-40SA and 70FA-30SA at different dosage cement percentages

Figure 16.

Relationship between strength parameters (A) FS vs. ITS (B) FS vs. UCS.

Figure 16.

Relationship between strength parameters (A) FS vs. ITS (B) FS vs. UCS.

Figure 17.

IDTM value of 70FA-30SA (a) 60FA-40SA with 4% cement (b) 60FA-40SA with 6% cement (c) 70FA-30SA with 4% cement (d) 70FA-30SA with 6% cement.

Figure 17.

IDTM value of 70FA-30SA (a) 60FA-40SA with 4% cement (b) 60FA-40SA with 6% cement (c) 70FA-30SA with 4% cement (d) 70FA-30SA with 6% cement.

Figure 18.

Effect of fiber on IDTM of 60FA-40SA and 70FA-30SA mix at different dosage cement percentages.

Figure 18.

Effect of fiber on IDTM of 60FA-40SA and 70FA-30SA mix at different dosage cement percentages.

Figure 19.

FM value of 70FA-30SA (a) 60FA-40SA with 4% cement, (b) 60FA-40SA with 6% cement, (c) 70FA-30SA with 4% cement, (d) 70FA-30SA with 6% cement.

Figure 19.

FM value of 70FA-30SA (a) 60FA-40SA with 4% cement, (b) 60FA-40SA with 6% cement, (c) 70FA-30SA with 4% cement, (d) 70FA-30SA with 6% cement.

Figure 20.

Effect of fiber on FM of 60FA-40SA and 70FA-30SA mix at different dosage cement percentages.

Figure 20.

Effect of fiber on FM of 60FA-40SA and 70FA-30SA mix at different dosage cement percentages.

Figure 21.

FM vs. FS for 60FA-40SA and 70FA-30SA mix together.

Figure 21.

FM vs. FS for 60FA-40SA and 70FA-30SA mix together.

Table 1.

The chemical composition of fly ash used in this study.

Table 1.

The chemical composition of fly ash used in this study.

| Sl No. |

Chemical Components |

percentage by weight (%) |

| 1 |

SiO2 |

61.34 |

| 2 |

Al2O3 |

29.54 |

| 3 |

Fe2O3 |

4.89 |

| 4 |

CaO |

1.05 |

| 5 |

MgO |

0.56 |

| 6 |

Na2O |

0.1 |

| 7 |

K2O |

0.25 |

| 8 |

TiO2 |

0.67 |

| 9 |

P2O5 |

0.1 |

| 10 |

LOI (Loss on Ignition) |

1.1 |

Table 2.

Properties of Poly Propylene Fiber (randomly oriented).

Table 2.

Properties of Poly Propylene Fiber (randomly oriented).

| Properties |

Value |

| Material |

100% Virgin Polypropylene (PP) |

| Length |

12.0 +/- 0.25 Mm |

| Diameter |

24 Micron (Approx.) |

| Aspect Ratio |

500 (Approx.) |

| Melt Point |

162°C |

| Specific Gravity |

0.91 |

| Thermal/Electrical Conductivity |

Low |

| Alkali Resistance |

100% Alkali Proof |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).