Submitted:

25 September 2023

Posted:

26 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

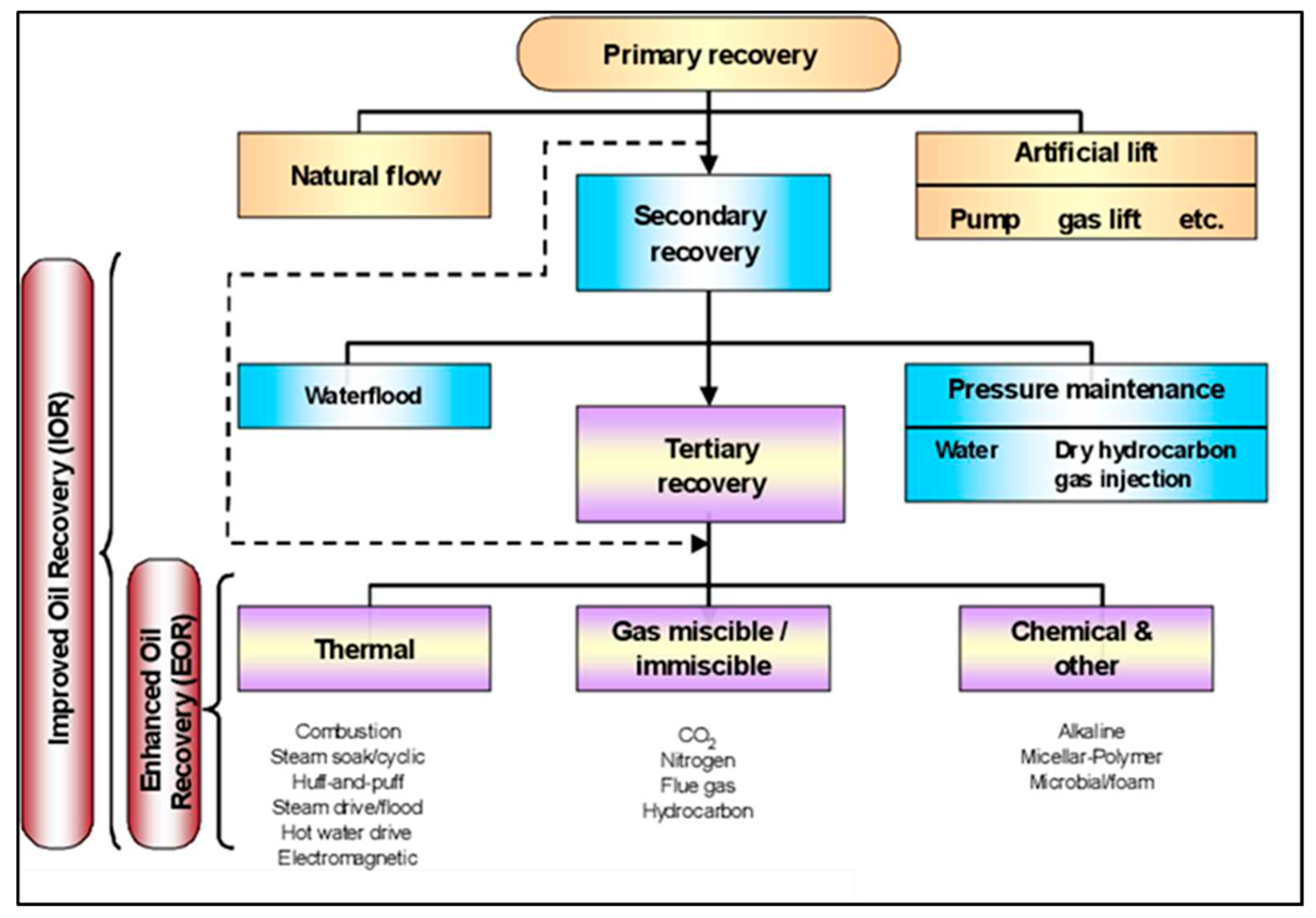

1.1. Enhanced Oil Recovery

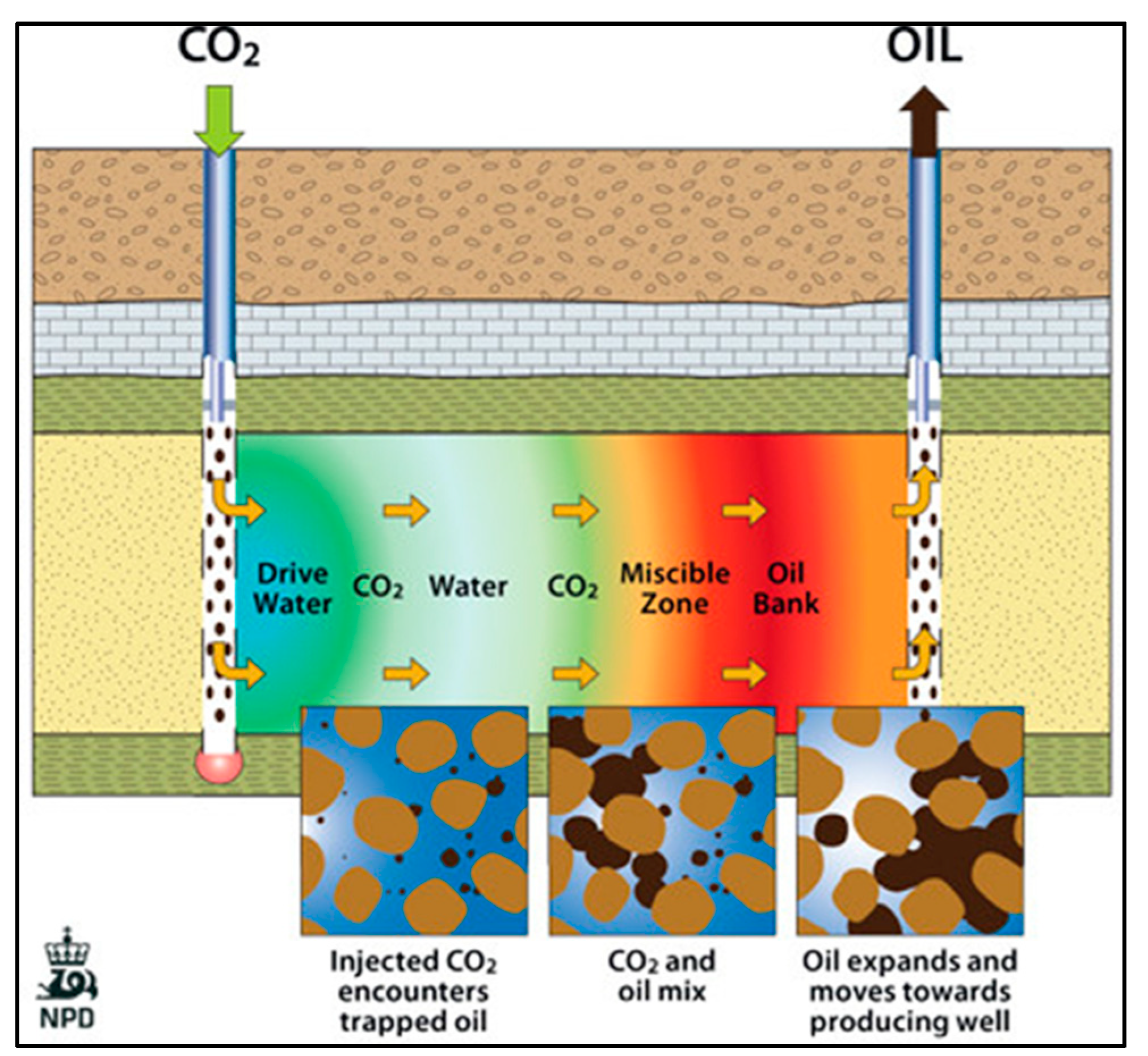

1.2. Miscible Gas Injection Method

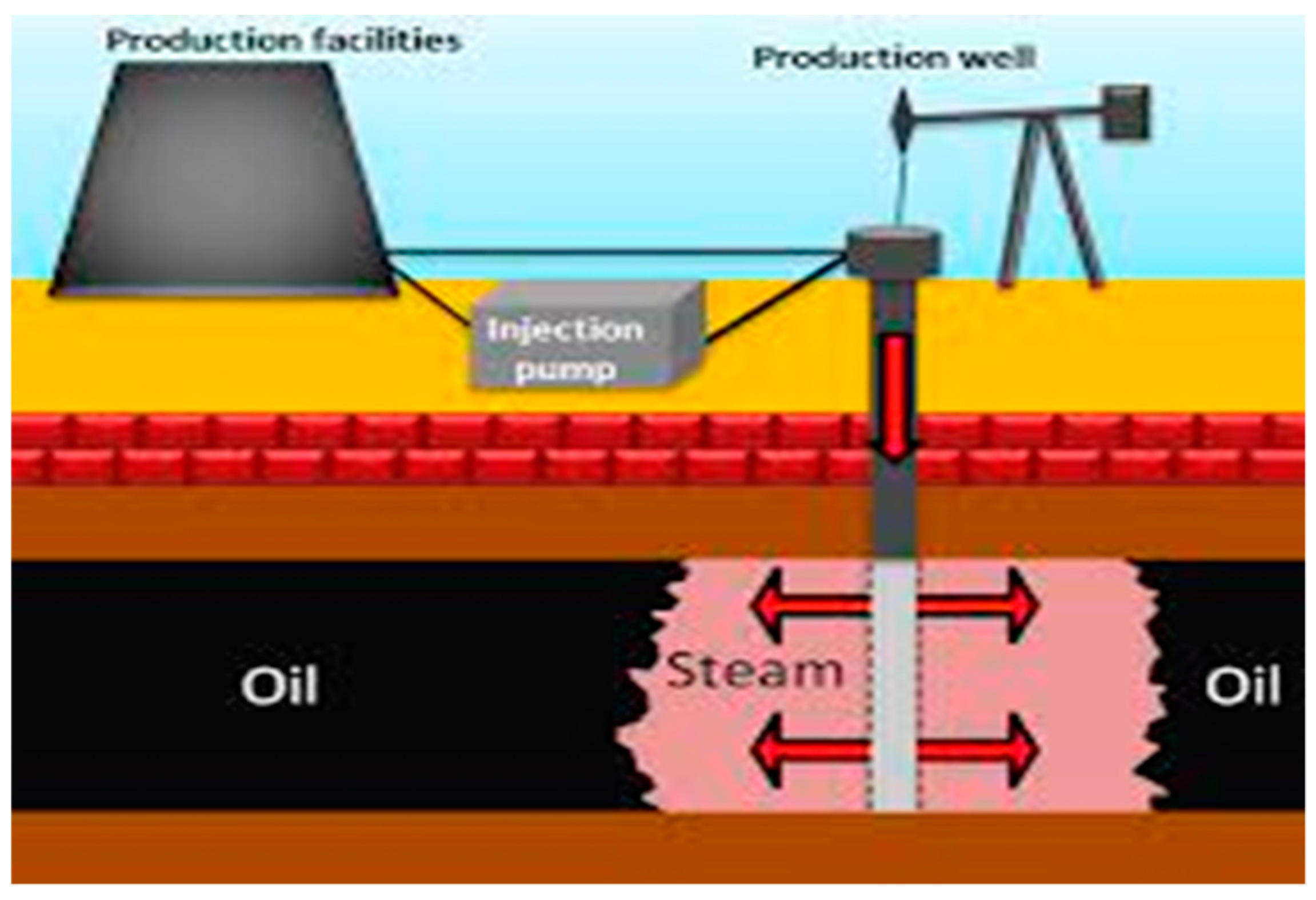

1.3. Thermal method

1.4. Chemical method

1.5. Polymeric Surfactants in EOR

1.6. Low-salinity water flooding (LS-WF)

1.7. Cellulose nanocrystal EOR agents

1.7.1. Structure-function relationships for EOR surfactants and EOR polymers

1.7.2. Carbonate reservoir overview

2. Parameters that affect EOR mechanisms

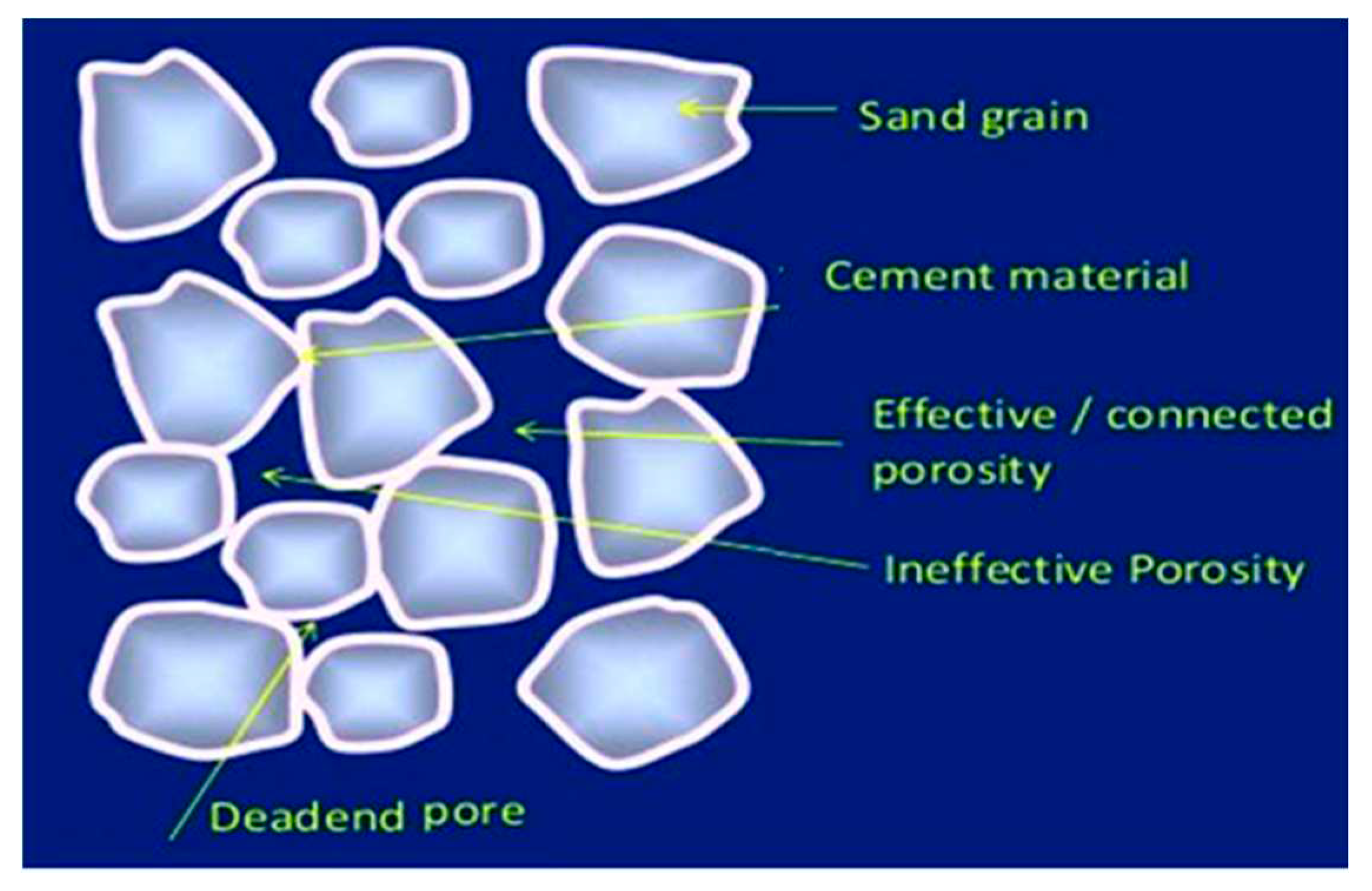

2.1. Porosity

2.2. Permeability

| EOR Method | Permeability, md |

|---|---|

| Steam | > 200 |

| In situ | > 200 |

| Alkaline | > 20 |

| Surfactant | > 20 |

| Polymer | > 20 |

| CO2 | Any range |

| HP gas | Not a critical factor |

2.3. Reservoir Pressure

2.4. Temperature

2.5. Viscosity

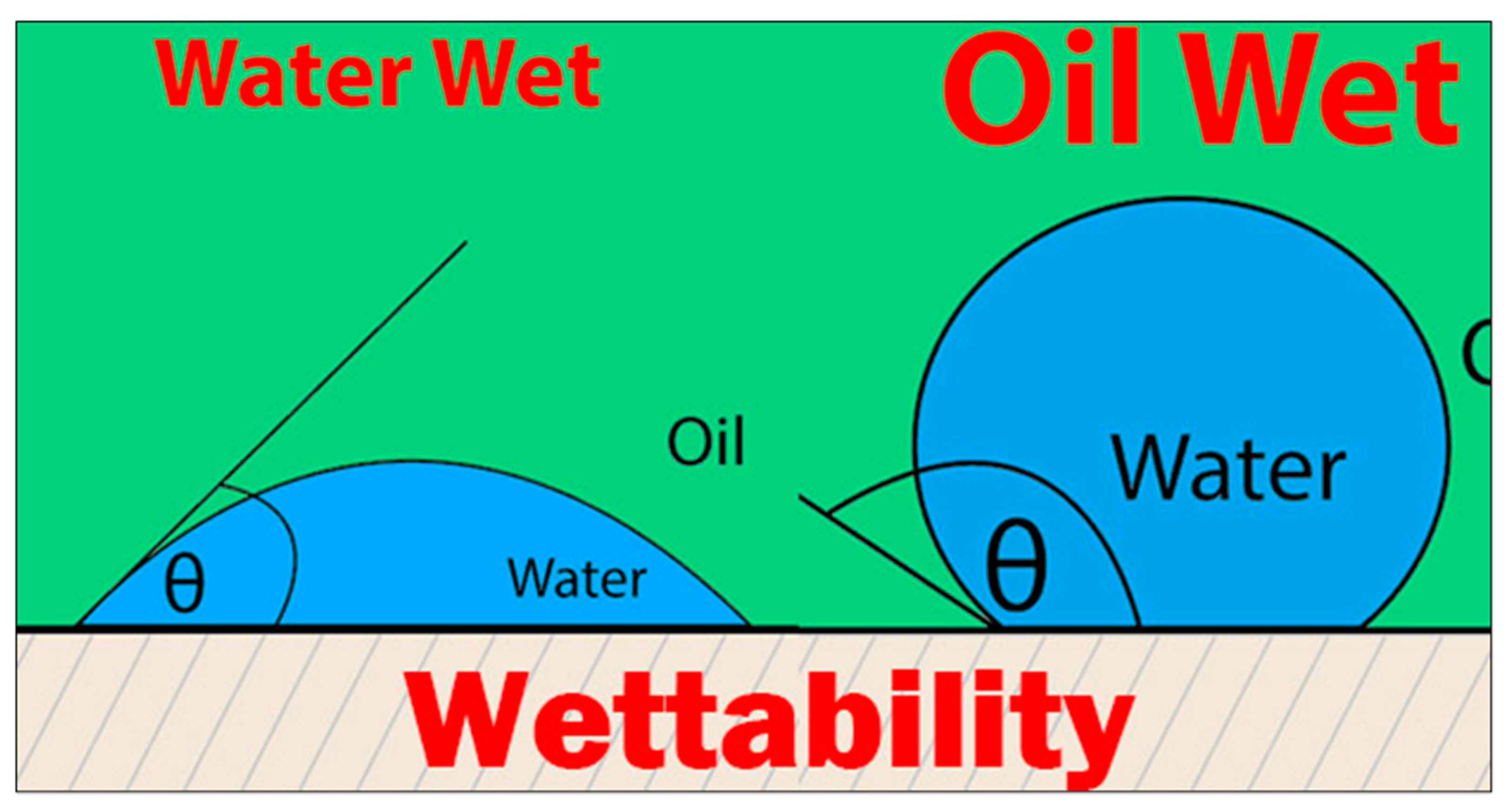

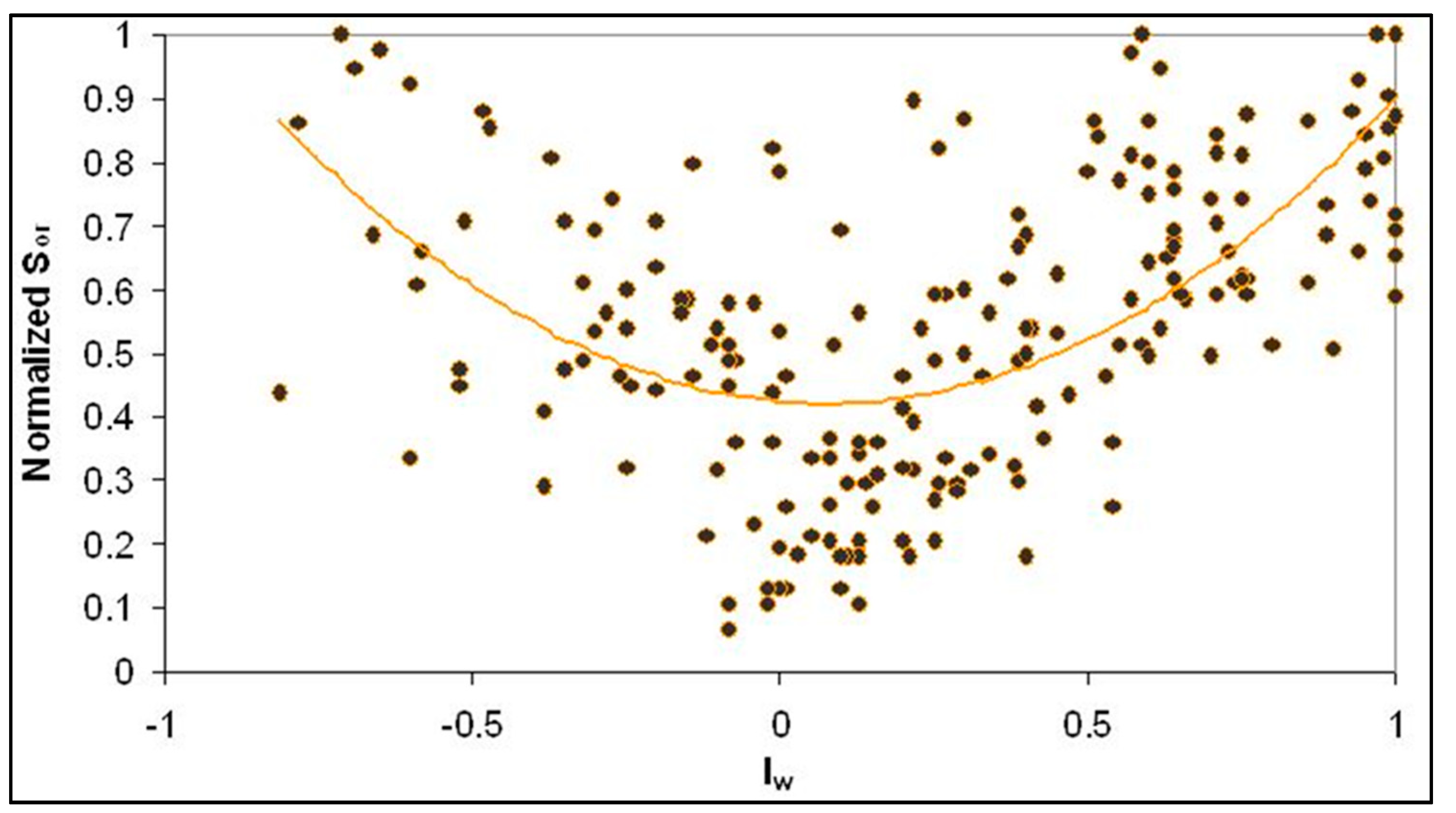

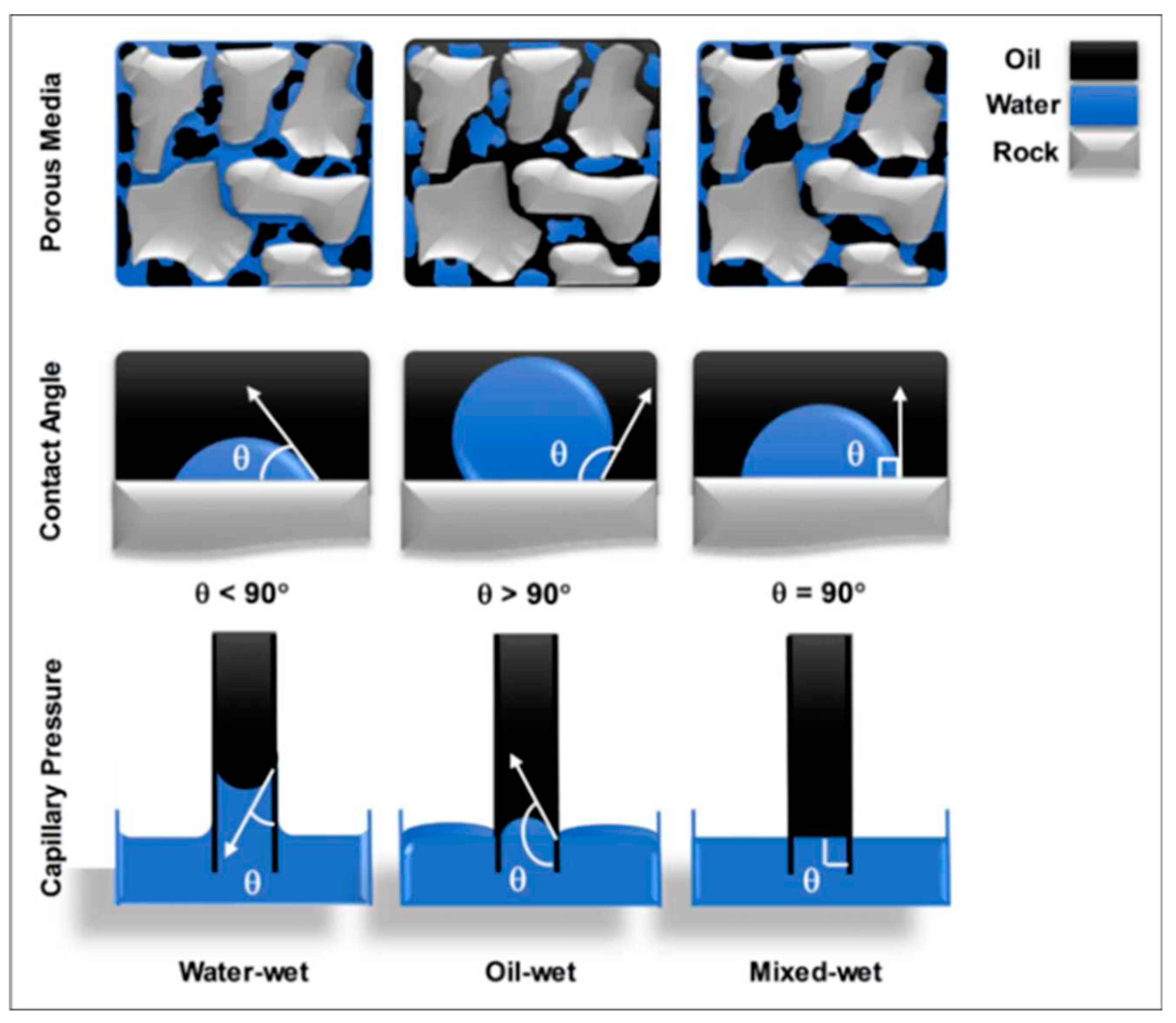

2.6. Wettability Alteration

2.7. Capillary pressure effect

2.8. The relative permeability effect.

2.9. Interfacial tension

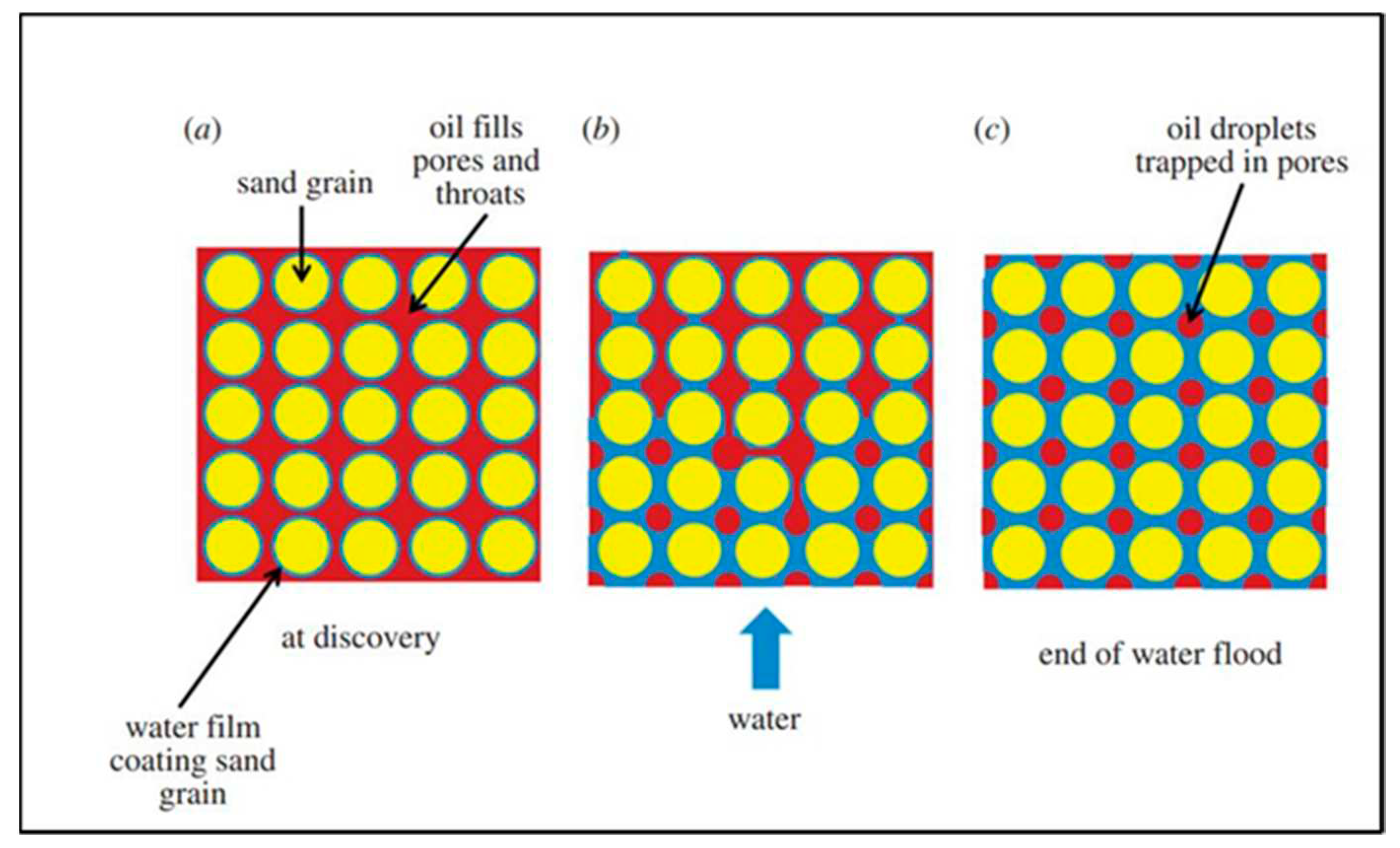

3. Fluid Displacement Efficiency

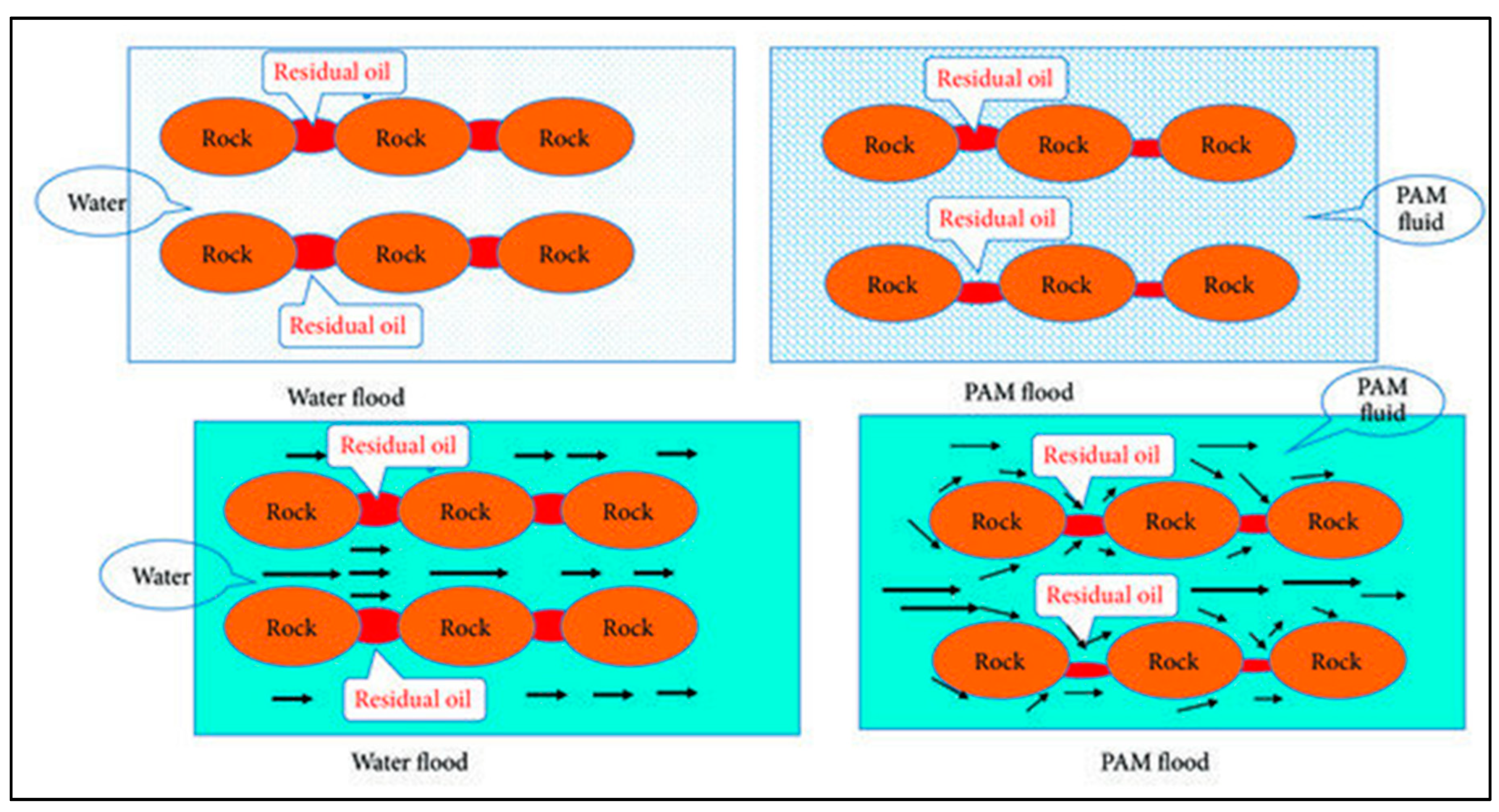

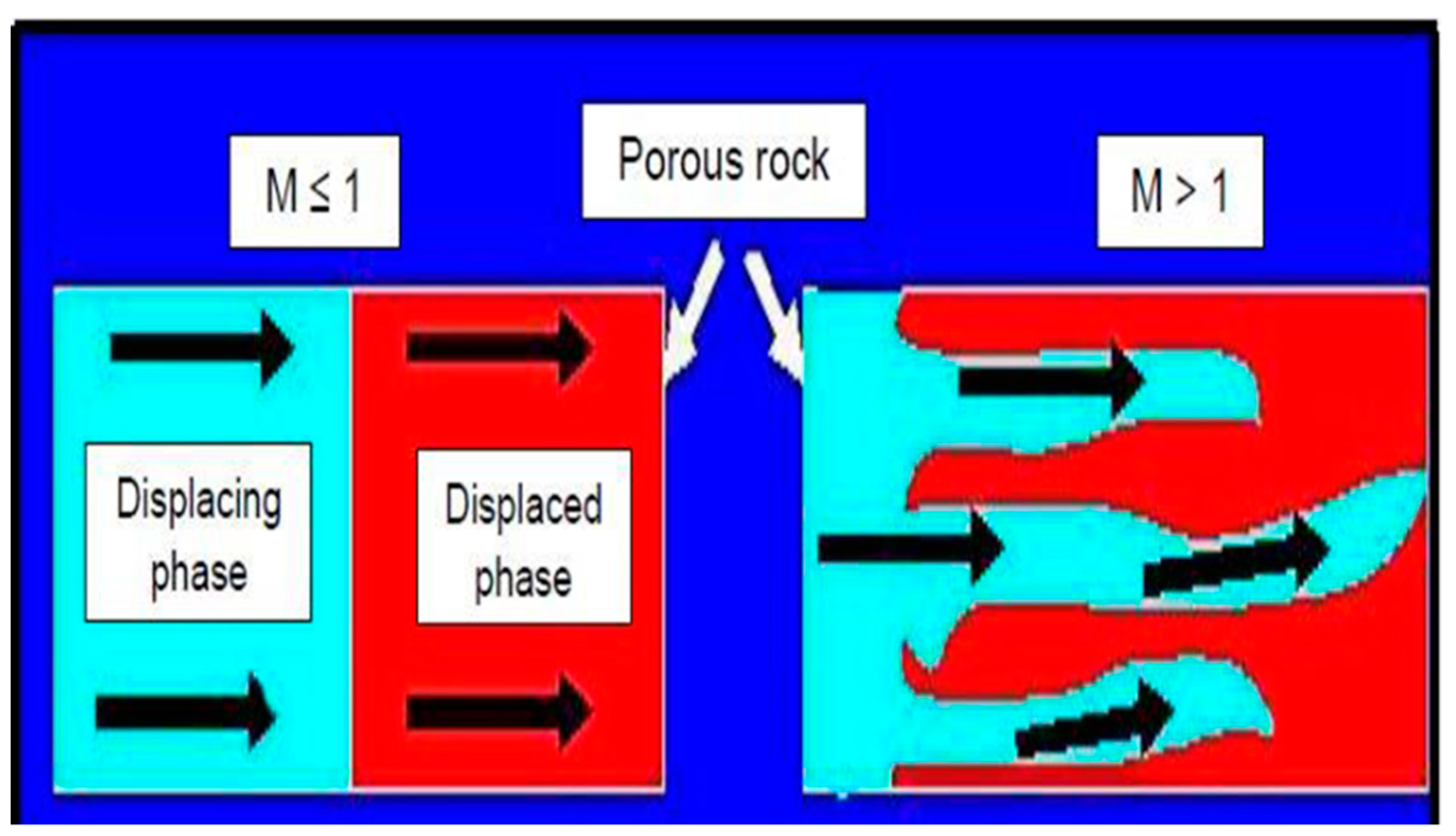

3.1. Mobility Ratio

3.2. Causative factors for poor mobility of oil to the production site

3.3. Assessment of EOR

4. Transport of nanoparticles through a reservoir

4.1. Discussion

5. Conclusion and Future Prospect

- ❖

- Surfactant structure, additives, and environmental conditions (salt, temperature, pH) all substantially influence microemulsion properties, which impacts its application on IOR.

- ❖

- The adsorption of surfactants is a significant barrier to using microemulsions in forms. An anionic surfactant or its compound system is frequently utilized, and pre-fluid is usually injected to decrease adsorption.

- ❖

- Different chemical floodings agents such as nanoparticles, foam, polymer, and alkali affect the EOR mechanisms and their displacement efficacies.

- ❖

- Issues exacerbated by severe reservoir conditions typically complicate surfactant flooding. These issues mainly concern surfactant adsorption and instability at high (or standard) temperatures and salinities. Consequently, researchers established criteria for surfactant screening based on reservoir conditions and rock type. Based on this recommendation, surface adsorption should not exceed 1 mg/g rock. Furthermore, the surfactant under consideration should be capable of reducing the oil-water IFT to 0.01-0.001 dynes/cm. Moreover, the surfactant should be effective at low concentrations ranging from 0.1 to 0.3 percent. If the concentration limit is exceeded, the economic feasibility of surfactant flooding may be jeopardized.

- ❖

- In the form of nanofluids, nano-emulsions, and Nano-catalysts, NPs offer enormous promise for EOR. The application procedures determine their EOR techniques. Nanofluids can be utilized as a tertiary recovery technology to boost oil recovery from floods caused by water or gas. Nano catalysts are constantly employed with thermal EOR procedures to execute in-situ upgrading inside reservoirs via aqua thermolysis. Nano-emulsions offer a broader range of applications, including water, gas, and chemical flooding.

Acknowledgments

References

- N. Ogolo, O. Olafuyi, and M. Onyekonwu, "Enhanced oil recovery using nanoparticles," in SPE Saudi Arabia section technical symposium and exhibition, 2012: Society of Petroleum Engineers.

- A. O. Gbadamosi, R. Junin, M. A. Manan, A. Agi, and A. S. Yusuff, "An overview of chemical enhanced oil recovery: recent advances and prospects," International Nano Letters, vol. 9, no. 3, pp. 171-202, 2019. [CrossRef]

- S. Sikiru et al., "Graphene: Outlook in the enhance oil recovery (EOR)," Journal of Molecular Liquids, vol. 321, p. 114519, 2021. [CrossRef]

- H. Soleimani, S. Sikiru, H. Soleimani, L. Khodapanah, and M. Sabet, "Impact of Graphene Nanofluid on Ionic Polarization in Reservoir Sandstone under Electric Double Layer," in Defect and Diffusion Forum, 2022, vol. 420, pp. 152-161: Trans Tech Publ. [CrossRef]

- A. H. Alagorni, Z. B. Yaacob, and A. H. Nour, "An overview of oil production stages: enhanced oil recovery techniques and nitrogen injection," International Journal of Environmental Science and Development, vol. 6, no. 9, p. 693, 2015. [CrossRef]

- A. Shafie, N. Yahya, M. Kashif, H. M. Zaid, H. Soleimani, and M. S. Alnarabiji, "The band structures of single-walled carbon nanotubes and ZnO nanoparticles used for oil recovery in water flooding system," in Journal of Nano Research, 2014, vol. 26, pp. 101-110: Trans Tech Publ. [CrossRef]

- S. Sikiru, H. Soleimani, A. Shafie, and G. Kozlowski, "Simulation and experimental investigation of dielectric and magnetic nanofluids in reduction of oil viscosity in reservoir sandstone," Journal of Petroleum Science and Engineering, p. 109828, 2021. [CrossRef]

- S. Sikiru, N. Yahya, H. Soleimani, A. M. Ali, and Y. Afeez, "Impact of ionic-electromagnetic field interaction on Maxwell-Wagner polarization in porous medium," Journal of Molecular Liquids, vol. 318, p. 114039, 2020. [CrossRef]

- S. Sikiru, N. Yahya, and H. Soleimani, "Photon–phonon interaction of surface ionic adsorption within electric double layer in reservoir sandstone," Journal of materials research and technology, vol. 9, no. 5, pp. 10957-10969, 2020. [CrossRef]

- S. Surajudeen, N. Yahya, H. Soleimani, A. A. Musa, Y. Afeez, and A. Rostami, "EFFECT OF ADSORPTION ON SATURATED SANDSTONE WITHIN ELECTRIC DOUBLE LAYER ON SOLID/LIQUID INTER-PHASE," Petroleum & Coal, vol. 61, no. 6, 2019.

- A. O. Yusuff, N. Yahya, M. A. Zakariya, and S. Sikiru, "Investigations of graphene impact on oil mobility and physicochemical interaction with sandstone surface," Journal of Petroleum Science and Engineering, vol. 198, p. 108250, 2021. [CrossRef]

- N. R. A. Latiff, N. Yahya, H. M. Zaid, and B. Demiral, "Novel enhanced oil recovery method using dielectric zinc oxide nanoparticles activated by electromagnetic waves," in 2011 National Postgraduate Conference, 2011, pp. 1-7: IEEE.

- A. Muggeridge et al., "Recovery rates, enhanced oil recovery and technological limits," Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, vol. 372, no. 2006, p. 20120320, 2014.

- Y. Afeez et al., "Investigation On Nanoparticles’ Effect On Interfacial Forces For Enhanced Oil Recovery," 2019.

- S. K. Rai, A. Bera, and A. Mandal, "Modeling of surfactant and surfactant–polymer flooding for enhanced oil recovery using STARS (CMG) software," Journal of Petroleum Exploration and Production Technology, vol. 5, no. 1, pp. 1-11, 2015. [CrossRef]

- H. Soleimani et al., "Impact of carbon nanotubes based nanofluid on oil recovery efficiency using core flooding," Results in Physics, vol. 9, pp. 39-48, 2018. [CrossRef]

- N. Yahya, A. M. Ali, F. A. Wahaab, and S. Sikiru, "Spectroscopic analysis of the adsorption of carbon based nanoparticles on reservoir sandstones," Journal of Materials Research and Technology, vol. 9, no. 3, pp. 4326-4339, 2020. [CrossRef]

- P. Behnoudfar, A. Rostami, and A. Hemmati-Sarapardeh, "Chapter Four. Miscible Gas Injection Processes," Fundamentals of Enhanced Oil and Gas Recovery from Conventional and Unconventional Reservoirs, pp. 101-138, 2018.

- 19. A. Bahadori, Fundamentals of enhanced oil and gas recovery from conventional and unconventional reservoirs. Gulf Professional Publishing, 2018.

- A. M. Ali, N. Yahya, A. Mijinyawa, M. Y. Kwaya, and S. Sikiru, "Molecular simulation and microtextural characterization of quartz dissolution in sodium hydroxide," Journal of Petroleum Exploration and Production Technology, vol. 10, no. 7, pp. 2669-2684, 2020. [CrossRef]

- B. Alqasem et al., "Effect of electromagnetic energy on net spin orientation of nanocatalyst for enhanced green urea synthesis," Journal of Materials Research and Technology, vol. 9, no. 6, pp. 16497-16512, 2020. [CrossRef]

- L. Hendraningrat, B. Engeset, S. Suwarno, and O. Torsæter, "Improved oil recovery by nanofluids flooding: an experimental study," in SPE Kuwait international petroleum conference and exhibition, 2012: OnePetro. [CrossRef]

- N. Yahya et al., "Percolation threshold of multiwall carbon nanotube-PVDF composite for electromagnetic wave propagation," Nano Express, vol. 1, no. 1, p. 010060, 2020. [CrossRef]

- A. A. Yousef, S. Al-Saleh, and M. Al-Jawfi, "New recovery method for carbonate reservoirs through tuning the injection water salinity: Smart waterflooding," in SPE EUROPEC/EAGE annual conference and exhibition, 2011: OnePetro.

- B. A. Suleimanov, F. Ismailov, and E. Veliyev, "Nanofluid for enhanced oil recovery," Journal of Petroleum science and Engineering, vol. 78, no. 2, pp. 431-437, 2011.

- M. F. Hamza, H. Soleimani, S. Ridha, A. A. Ahmed, and S. Sikiru, "Double layer chemical encapsulation of SiO2 nanoparticles for interfacial tension reduction under low salinity condition," Journal of Molecular Liquids, vol. 371, p. 121100, 2023. [CrossRef]

- T. Babadagli, "Dynamics of capillary imbibition when surfactant, polymer, and hot water are used as aqueous phase for oil recovery," Journal of colloid and interface science, vol. 246, no. 1, pp. 203-213, 2002. [CrossRef]

- A. Karimi et al., "Wettability alteration in carbonates using zirconium oxide nanofluids: EOR implications," Energy & Fuels, vol. 26, no. 2, pp. 1028-1036, 2012. [CrossRef]

- 29. L. Romero-Zerón, Introduction to enhanced oil recovery (EOR) processes and bioremediation of oil-contaminated sites. BoD–Books on Demand, 2012.

- V. Khosravi, "Developing surfactant to increase the production in heavy oil reservoirs," in Trinidad and Tobago Energy Resources Conference, 2010: OnePetro.

- Z. Liu, G. Zhao, M. Brewer, Q. Lv, and E. J. Sudhölter, "Comprehensive review on surfactant adsorption on mineral surfaces in chemical enhanced oil recovery," Advances in Colloid and Interface Science, vol. 294, p. 102467, 2021. [CrossRef]

- M. Mohammed and T. Babadagli, "Wettability alteration: A comprehensive review of materials/methods and testing the selected ones on heavy-oil containing oil-wet systems," Advances in colloid and interface science, vol. 220, pp. 54-77, 2015. [CrossRef]

- S. Sikiru, H. Soleimani, A. Shafie, R. I. Olayemi, and Y. M. Hassan, "Prediction of Electromagnetic Properties Using Artificial Neural Networks for Oil Recovery Factors," Colloid Journal, vol. 85, no. 1, pp. 151-165, 2023. [CrossRef]

- M. F. Hamza, H. Soleimani, S. Ridha, A. A. Ahmed, and S. Sikiru, "Double layer chemical encapsulation of SiO2 nanoparticles for interfacial tension reduction under low salinity condition," Journal of Molecular Liquids, p. 121100, 2022. [CrossRef]

- Y. M. Hassan, B. H. Guan, L. K. Chuan, S. Sikiru, A. A. Adam, and B. A. Abdulkadir, "Interfacial tension of brine-oil interface using Fe2O3, ZnO, and SiO2 nanoparticles endorsed by electromagnetic waves," Chemical Thermodynamics and Thermal Analysis, vol. 8, p. 100083, 2022. [CrossRef]

- V. Alvarado and E. J. E. Manrique, "Enhanced oil recovery: an update review," vol. 3, no. 9, pp. 1529-1575, 2010. [CrossRef]

- A. Ramírez-Estrada et al., "Development of a Zwitterionic compound derived from β-amino acid as a green inhibitor for CO2 corrosive environments," ACS Sustainable Chemistry & Engineering, vol. 5, no. 11, pp. 10396-10406, 2017. [CrossRef]

- V. A. Lifton, "Microfluidics: an enabling screening technology for enhanced oil recovery (EOR)," Lab on a Chip, vol. 16, no. 10, pp. 1777-1796, 2016. [CrossRef]

- E. Mokheimer, M. Hamdy, Z. Abubakar, M. R. Shakeel, M. A. Habib, and M. Mahmoud, "A comprehensive review of thermal enhanced oil recovery: Techniques evaluation," Journal of Energy Resources Technology, vol. 141, no. 3, 2019. [CrossRef]

- H. Mahani et al., "Analysis of field responses to low-salinity waterflooding in secondary and tertiary mode in Syria," in SPE Europec/EAGE Annual Conference and Exhibition, 2011: OnePetro.

- L. Hendraningrat, S. Li, and O. Torsaeter, "Enhancing oil recovery of low-permeability Berea sandstone through optimized nanofluids concentration," in SPE enhanced oil recovery conference, 2013: OnePetro.

- J. G. Maas, K. Wit, and N. R. Morrow, "Enhanced oil recovery by dilution of injection brine: Further interpretation of experimental results," SCA2001-13, 2001.

- K. Oglesby, "Improved Mobility Control for Carbon Dioxide (CO {sub 2}) Enhanced Oil Recovery Using Silica-Polymer-Initiator (SPI) Gels," Impact Technologies Llc2014.

- I. Khan, K. Saeed, and I. Khan, "Nanoparticles: Properties, applications and toxicities," Arabian journal of chemistry, vol. 12, no. 7, pp. 908-931, 2019.

- G. Cheraghian and L. Hendraningrat, "A review on applications of nanotechnology in the enhanced oil recovery part A: effects of nanoparticles on interfacial tension," International Nano Letters, vol. 6, pp. 129-138, 2016. [CrossRef]

- H. C. Lau, M. Yu, and Q. P. Nguyen, "Nanotechnology for oilfield applications: Challenges and impact," Journal of Petroleum Science and Engineering, vol. 157, pp. 1160-1169, 2017.

- K. Uleberg and L. Høier, "Miscible gas injection in fractured reservoirs," in SPE/DOE Improved Oil Recovery Symposium, 2002: Society of Petroleum Engineers.

- 48. F. I. Stalkup Jr, "Status of miscible displacement," Journal of Petroleum Technology, vol. 35, no. 04, pp. 815-826, 1983.

- A. Kamari, M. Arabloo, A. Shokrollahi, F. Gharagheizi, and A. H. Mohammadi, "Rapid method to estimate the minimum miscibility pressure (MMP) in live reservoir oil systems during CO2 flooding," Fuel, vol. 153, pp. 310-319, 2015. [CrossRef]

- A. Kamari, A. Hemmati-Sarapardeh, A. H. Mohammadi, H. Hashemi-Kiasari, and E. Mohagheghian, "On the evaluation of Fast-SAGD process in naturally fractured heavy oil reservoir," Fuel, vol. 143, pp. 155-164, 2015. [CrossRef]

- M. Vafaie-Sefti and S. Mousavi-Dehghani, "Application of association theory to the prediction of asphaltene deposition: Deposition due to natural depletion and miscible gas injection processes in petroleum reservoirs," Fluid phase equilibria, vol. 247, no. 1-2, pp. 182-189, 2006. [CrossRef]

- M. Masoud, "Comparing carbon dioxide injection in enhanced oil recovery with other methods," Austin Chemical Engineering, vol. 2, no. 2, p. 11, 2015.

- S. Guedes, "70% Recovery Factor: Petrobras Perspective," in Proceedings of Rio Oil & Gas Exposition and Conference, Rio de Janeiro, Brazil, 2008, pp. 15-18.

- A. Shokrollahi, M. Arabloo, F. Gharagheizi, and A. H. Mohammadi, "Intelligent model for prediction of CO2–reservoir oil minimum miscibility pressure," Fuel, vol. 112, pp. 375-384, 2013. [CrossRef]

- R. Moghadasi, A. Rostami, and A. Hemmati-Sarapardeh, "Enhanced oil recovery using CO2," Fundamentals of Enhanced Oil and Gas Recovery from Conventional and Unconventional Reservoirs. Elsevier Inc, pp. 61-99, 2018.

- O. A. Alomair, K. M. Matar, and Y. H. Alsaeed, "Nanofluids application for heavy oil recovery," in SPE Asia Pacific oil & gas conference and exhibition, 2014: Society of Petroleum Engineers.

- M. Sohrabi, A. Danesh, D. H. Tehrani, and M. Jamiolahmady, "Microscopic mechanisms of oil recovery by near-miscible gas injection," Transport in Porous Media, vol. 72, no. 3, pp. 351-367, 2008. [CrossRef]

- T. Xu and T. Hoffman, "Hydraulic fracture orientation for miscible gas injection EOR in unconventional oil reservoirs," in Unconventional Resources Technology Conference, 2013, pp. 1863-1873: Society of Exploration Geophysicists, American Association of Petroleum ….

- A. Ocampo et al., "successful foam EOR pilot in a mature volatile oil reservoir under miscible gas injection," in IPTC 2013: International Petroleum Technology Conference, 2013, pp. cp-350-00418: European Association of Geoscientists & Engineers.

- M. Kulkarni and D. Rao, "Experimental investigation of various methods of tertiary gas injection," in SPE annual technical conference and exhibition, 2004: Society of Petroleum Engineers.

- A. O. Gbadamosi, J. Kiwalabye, R. Junin, and A. Augustine, "A review of gas enhanced oil recovery schemes used in the North Sea," Journal of Petroleum Exploration and Production Technology, vol. 8, pp. 1373-1387, 2018. [CrossRef]

- A. O. Gbadamosi, J. Kiwalabye, R. Junin, and A. Augustine, "A review of gas enhanced oil recovery schemes used in the North Sea," Journal of Petroleum Exploration and Production Technology, vol. 8, no. 4, pp. 1373-1387, 2018. [CrossRef]

- N. Yekeen et al., "A comprehensive review of experimental studies of nanoparticles-stabilized foam for enhanced oil recovery," Journal of Petroleum Science and Engineering, vol. 164, pp. 43-74, 2018. [CrossRef]

- A. Agi, R. Junin, and A. Gbadamosi, "Mechanism governing nanoparticle flow behaviour in porous media: insight for enhanced oil recovery applications," International Nano Letters, vol. 8, no. 2, pp. 49-77, 2018. [CrossRef]

- A. Al Adasani and B. Bai, "Analysis of EOR projects and updated screening criteria," Journal of Petroleum Science and Engineering, vol. 79, no. 1-2, pp. 10-24, 2011. [CrossRef]

- S. Sikiru, N. Yahya, H. Soleimani, A. M. Ali, and Y. Afeez, "Impact of ionic-electromagnetic field interaction on Maxwell-Wagner polarization in porous medium," Journal of Molecular Liquids, p. 114039, 2020. [CrossRef]

- S. Thomas, "Enhanced oil recovery-an overview," Oil & Gas Science and Technology-Revue de l'IFP, vol. 63, no. 1, pp. 9-19, 2008.

- V. Alvarado and E. Manrique, "Enhanced oil recovery: an update review," Energies, vol. 3, no. 9, pp. 1529-1575, 2010. [CrossRef]

- A. Abubakar, T. Al-Wahaibi, A. Al-Hashmi, Y. Al-Wahaibi, A. Al-Ajmi, and M. Eshrati, "Influence of drag-reducing polymer on flow patterns, drag reduction and slip velocity ratio of oil–water flow in horizontal pipe," International Journal of Multiphase Flow, vol. 73, pp. 1-10, 2015.

- T. S. Urbissinova and E. Kuru, "Effect of elasticity during viscoelastic polymer flooding: a possible mechanism of increasing the sweep efficiency," Journal of Canadian Petroleum Technology, vol. 49, no. 12, pp. 49-56, 2010.

- S. K. Veerabhadrappa, A. Doda, J. J. Trivedi, and E. Kuru, "On the effect of polymer elasticity on secondary and tertiary oil recovery," Industrial & Engineering Chemistry Research, vol. 52, no. 51, pp. 18421-18428, 2013. [CrossRef]

- D. T. Wasan and A. D. Nikolov, "Spreading of nanofluids on solids," Nature, vol. 423, no. 6936, pp. 156-159, 2003. [CrossRef]

- A. Roustaei, J. Moghadasi, A. Iran, H. Bagherzadeh, and A. Shahrabadi, "An experimental investigation of polysilicon nanoparticles’ recovery efficiencies through changes in interfacial tension and wettability alteration," in SPE international oilfield nanotechnology conference and exhibition, 2012: OnePetro.

- M. M. Rehman and M. Meribout, "Conventional versus electrical enhanced oil recovery: a review," Journal of Petroleum Exploration and Production Technology, vol. 2, no. 4, pp. 157-167, 2012.

- A. Peng et al., "A review of nanomaterials for nanofluid enhanced oil recovery," RSC advances, vol. 7, no. 51, pp. 32246-32254, 2017. [CrossRef]

- F. Afolabi, S. M. Mahmood, N. Yekeen, S. Akbari, and H. Sharifigaliuk, "Polymeric surfactants for enhanced oil recovery: A review of recent progress," Journal of Petroleum Science and Engineering, vol. 208, p. 109358, 2022. [CrossRef]

- A. A. Olajire, "Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: Prospects and challenges," Energy, vol. 77, pp. 963-982, 2014. [CrossRef]

- L. Guo, M. Han, A. Fuseni, and A. AlSofi, "Laboratory investigation of polymeric surfactants for EOR in high salinity and high temperature reservoir," in SPE EOR Conference at Oil and Gas West Asia, 2016: OnePetro.

- X. Chen, Y. Li, W. Gao, and C. Chen, "Experimental investigation on transport property and emulsification mechanism of polymeric surfactants in porous media," Journal of Petroleum Science and Engineering, vol. 186, p. 106687, 2020. [CrossRef]

- T. G. Sorop et al., "Integrated approach in deploying low salinity waterflooding," in SPE Enhanced Oil Recovery Conference, 2013: OnePetro.

- N. Morrow and J. Buckley, "Improved oil recovery by low-salinity waterflooding," Journal of petroleum Technology, vol. 63, no. 05, pp. 106-112, 2011. [CrossRef]

- R. A. Nasralla et al., "Low salinity waterflooding for a carbonate reservoir: Experimental evaluation and numerical interpretation," Journal of Petroleum Science and Engineering, vol. 164, pp. 640-654, 2018.

- B. Yuan and R. G. Moghanloo, "Nanofluid pre-treatment, an effective strategy to improve the performance of low-salinity waterflooding," Journal of Petroleum Science and Engineering, vol. 165, pp. 978-991, 2018. [CrossRef]

- J. Wang, H. Song, and Y. Wang, "Investigation on the micro-flow mechanism of enhanced oil recovery by low-salinity water flooding in carbonate reservoir," Fuel, vol. 266, p. 117156, 2020. [CrossRef]

- K. Webb, C. a. Black, and H. Al-Ajeel, "Low salinity oil recovery-log-inject-log," in SPE/DOE Symposium on Improved Oil Recovery, 2004: OnePetro.

- P. McGuire, J. Chatham, F. Paskvan, D. Sommer, and F. Carini, "Low salinity oil recovery: An exciting new EOR opportunity for Alaska's North Slope," in SPE western regional meeting, 2005: OnePetro.

- P. Vledder, J. C. Fonseca, T. Wells, I. Gonzalez, and D. Ligthelm, "Low salinity water flooding: proof of wettability alteration on a field wide scale," in SPE Improved Oil Recovery Symposium, 2010: OnePetro.

- S. N. Molnes, A. Mamonov, K. G. Paso, S. Strand, and K. Syverud, "Investigation of a new application for cellulose nanocrystals: a study of the enhanced oil recovery potential by use of a green additive," Cellulose, vol. 25, no. 4, pp. 2289-2301, 2018. [CrossRef]

- J. F. Snyder, J. Steele, H. Dong, J. A. Orlicki, R. S. Reiner, and A. W. Rudie, "Optical properties of nanocellulose dispersions in water, dimethylformamide and poly (methyl methacrylate)," ARMY RESEARCH LAB ABERDEEN PROVING GROUND MD WEAPONS AND MATERIALS RESEARCH …2013.

- Y. Si, Y. Zhu, T. Liu, X. Xu, and J. Yang, "Synthesis of a novel borate ester Anion-Nonionic surfactant and its application in viscosity reduction and emulsification of heavy crude oil," Fuel, vol. 333, p. 126453, 2023. [CrossRef]

- L. Zhou et al., "Efficient inhibition of montmorillonite swelling through controlling flexibly structure of piperazine-based polyether Gemini quaternary ammonium salts," Chemical Engineering Journal, vol. 383, p. 123190, 2020. [CrossRef]

- A. S. Abd and A. S. Abushaikha, "On the performance of the node control volume finite element method for modeling multi-phase fluid flow in heterogeneous porous media," Transport in Porous Media, vol. 135, no. 2, pp. 409-429, 2020. [CrossRef]

- B. Berkowitz, "Characterizing flow and transport in fractured geological media: A review," Advances in water resources, vol. 25, no. 8-12, pp. 861-884, 2002. [CrossRef]

- M. A. Kargarpour, "Carbonate reservoir characterization: an integrated approach," Journal of Petroleum Exploration and Production Technology, vol. 10, no. 7, pp. 2655-2667, 2020. [CrossRef]

- 95. J. Lage, "The fundamental theory of flow through permeable niedia from darcy to turbulence," Transport phenomena in porous media, vol. 1, 1998.

- J. L. Miskimins, H. D. J. Lopez, and R. D. Barree, "Non-Darcy flow in hydraulic fractures: does it really matter?," in SPE Annual Technical Conference and Exhibition, 2005: Society of Petroleum Engineers.

- C. T. Simmons, "Henry Darcy (1803–1858): Immortalised by his scientific legacy," Hydrogeology Journal, vol. 16, no. 6, p. 1023, 2008.

- G. Brown, "Henry Darcy and the making of a law," Water Resources Research, vol. 38, no. 7, pp. 11-1-11-12, 2002. [CrossRef]

- H. A. Ohen and D. G. Kersey, "Permeability: Part 5. Laboratory Methods," 1992.

- V. Khosravi and S. Ketabi, "Well test analysis of gas condensate reservoirs from pressure build up and draw down tests," in Offshore Technology Conference-Asia, 2014: Offshore Technology Conference.

- 101. Y. M. Hassan et al., "The Influence of ZnO/SiO2 nanocomposite concentration on rheology, interfacial tension, and wettability for enhanced oil recovery," Chemical Engineering Research and Design, 2022.

- S. Sikiru, H. Soleimani, A. Shafie, and G. Kozlowski, "Simulation and experimental investigation of dielectric and magnetic nanofluids in reduction of oil viscosity in reservoir sandstone," Journal of Petroleum Science and Engineering, vol. 209, p. 109828, 2022. [CrossRef]

- A. Zeberg-Mikkelsen, "Viscosity study of hydrocarbon fluids at reservoir conditions," Thesis/dissertation, Technical University of Denmark, 2001.

- E. M. majeed and T. M. Naife, "Viscosity reduction of Iraqi crude oil by different additives," in AIP Conference Proceedings, 2020, vol. 2213, no. 1, p. 020142: AIP Publishing LLC.

- S. Fakher, A. Imqam, and E. Wanas, "Investigating the viscosity reduction of ultra-heavy crude oil using hydrocarbon soluble low molecular weight compounds to improve oil production and transportation," in SPE International Heavy Oil Conference and Exhibition, 2018: Society of Petroleum Engineers.

- G. Cheraghian, "Effects of nanoparticles on wettability: A review on applications of nanotechnology in the enhanced Oil recovery," 2015.

- A. M. Alhammadi, A. AlRatrout, K. Singh, B. Bijeljic, and M. J. Blunt, "In situ characterization of mixed-wettability in a reservoir rock at subsurface conditions," Scientific Reports, vol. 7, no. 1, pp. 1-9, 2017. [CrossRef]

- H. Sharifigaliuk, S. M. Mahmood, W. Al-Bazzaz, and V. Khosravi, "Complexities Driving Wettability Evaluation of Shales toward Unconventional Approaches: A Comprehensive Review," Energy & Fuels, vol. 35, no. 2, pp. 1011-1023, 2021. [CrossRef]

- V. Khosravi, S. M. Mahmood, and D. Zivar, "Application of Molecular Dynamics Simulation: A Case Study to Estimate Wettability," in Advances in Manufacturing Engineering: Springer, 2020, pp. 445-455.

- M. Christensen and Y. Tanino, "Waterflood oil recovery from mixed-wet limestone: dependence upon the contact angle," Energy & Fuels, vol. 31, no. 2, pp. 1529-1535, 2017. [CrossRef]

- Y. M. Hassan et al., "Electromagnetically Modified Wettability and Interfacial Tension of Hybrid ZnO/SiO2 Nanofluids," Crystals, vol. 12, no. 2, p. 169, 2022. [CrossRef]

- H. ShamsiJazeyi, C. A. Miller, M. S. Wong, J. M. Tour, and R. Verduzco, "Polymer-coated nanoparticles for enhanced oil recovery," Journal of applied polymer science, vol. 131, no. 15, 2014. [CrossRef]

- Y. Wang, H. Xu, W. Yu, B. Bai, X. Song, and J. J. P. S. Zhang, "Surfactant induced reservoir wettability alteration: Recent theoretical and experimental advances in enhanced oil recovery," vol. 8, no. 4, pp. 463-476, 2011. [CrossRef]

- M. Mohammed, T. J. A. i. c. Babadagli, and i. science, "Wettability alteration: A comprehensive review of materials/methods and testing the selected ones on heavy-oil containing oil-wet systems," vol. 220, pp. 54-77, 2015. [CrossRef]

- A. Cense and S. Berg, "The viscous-capillary paradox in 2-phase flow in porous media," in International Symposium of the Society of Core Analysts held in Noordwijk, The Netherlands, 2009, pp. 27-30: Citeseer.

- P. Jadhunandan and N. R. Morrow, "Effect of wettability on waterflood recovery for crude-oil/brine/rock systems," SPE reservoir engineering, vol. 10, no. 01, pp. 40-46, 1995. [CrossRef]

- O. Owolabi and R. Watson, "Effects of rock-pore characteristics on oil recovery at breakthrough and ultimate oil recovery in water-wet sandstones," in SPE Eastern Regional Meeting, 1993: Society of Petroleum Engineers.

- S. Ayatollahi and M. M. Zerafat, "Nanotechnology-assisted EOR techniques: New solutions to old challenges," in SPE international oilfield nanotechnology conference and exhibition, 2012: Society of Petroleum Engineers. [CrossRef]

- J. Yan, "Effect of rock wettability on oil recovery by waterflooding," JOURNAL-UNIVERSITY OF PETROLEUM CHINA NATURAL SCIENCE EDITION, vol. 22, pp. 43-46, 1998.

- H. Chun, T. Zhiqiang, and J. Guancheng, "Effect of wettability on water injection recovery factor of heavy oil reservoir of Kendong Block 29," Oil Drilling & Production Technology, vol. 21, no. 3, pp. 92-94, 1999.

- K. Li and A. Firoozabadi, "Phenomenological modeling of critical condensate saturation and relative permeabilities in gas/condensate systems," Spe Journal, vol. 5, no. 02, pp. 138-147, 2000. [CrossRef]

- R. Barnum, F. Brinkman, T. Richardson, and A. Spillette, "Gas condensate reservoir behaviour: productivity and recovery reduction due to condensation," in SPE annual technical conference and exhibition, 1995: Society of Petroleum Engineers.

- S. Surajudeen et al., "Graphene: Outlook in the enhance oil recovery (EOR)," Journal of Molecular Liquids, p. 114519, 2020.

- A. Maghzi, S. Mohammadi, M. H. Ghazanfari, R. Kharrat, M. J. E. T. Masihi, and F. Science, "Monitoring wettability alteration by silica nanoparticles during water flooding to heavy oils in five-spot systems: A pore-level investigation," vol. 40, pp. 168-176, 2012.

- S. Al-Anssari, A. Barifcani, S. Wang, L. Maxim, S. J. J. o. c. Iglauer, and i. science, "Wettability alteration of oil-wet carbonate by silica nanofluid," vol. 461, pp. 435-442, 2016.

- S. Al-Anssari, S. Wang, A. Barifcani, M. Lebedev, and S. J. F. Iglauer, "Effect of temperature and SiO2 nanoparticle size on wettability alteration of oil-wet calcite," vol. 206, pp. 34-42, 2017.

- R. Nazari Moghaddam, A. Bahramian, Z. Fakhroueian, A. Karimi, S. J. E. Arya, and Fuels, "Comparative study of using nanoparticles for enhanced oil recovery: wettability alteration of carbonate rocks," vol. 29, no. 4, pp. 2111-2119, 2015.

- T. Sharma, S. Iglauer, J. S. J. I. Sangwai, and E. C. Research, "Silica nanofluids in an oilfield polymer polyacrylamide: interfacial properties, wettability alteration, and applications for chemical enhanced oil recovery," vol. 55, no. 48, pp. 12387-12397, 2016.

- N. K. Jha, S. Iglauer, A. Barifcani, M. Sarmadivaleh, J. S. J. E. Sangwai, and fuels, "Low-salinity surfactant nanofluid formulations for wettability alteration of sandstone: role of the SiO2 nanoparticle concentration and divalent cation/SO42–ratio," vol. 33, no. 2, pp. 739-746, 2019. [CrossRef]

- A. Dehghan Monfared, M. H. Ghazanfari, M. Jamialahmadi, A. J. E. Helalizadeh, and Fuels, "Potential application of silica nanoparticles for wettability alteration of oil–wet calcite: A mechanistic study," vol. 30, no. 5, pp. 3947-3961, 2016. [CrossRef]

- D. Afekare, I. Gupta, D. J. J. o. P. S. Rao, and Engineering, "Nanoscale investigation of silicon dioxide nanofluids and implications for enhanced oil recovery–An atomic force microscope study," vol. 191, p. 107165, 2020. [CrossRef]

- E. Joonaki, S. J. P. S. Ghanaatian, and Technology, "The application of nanofluids for enhanced oil recovery: effects on interfacial tension and coreflooding process," vol. 32, no. 21, pp. 2599-2607, 2014. [CrossRef]

- J. L. Iovenitti, T. Rynne, and J. Spencer Jr, "Acoustically enhanced remediation of contaminated soil and ground water," 1994.

- Q. Sun, A. Retnanto, and M. Amani, "Seismic vibration for improved oil recovery: A comprehensive review of literature," International Journal of Hydrogen Energy, vol. 45, no. 29, pp. 14756-14778, 2020. [CrossRef]

- O. Kuznetsov, E. Simkin, G. Chilingar, M. Gorfunkel, and J. R. Jr, "Seismic techniques of enhanced oil recovery: experimental and field results," Energy Sources, vol. 24, no. 9, pp. 877-889, 2002. [CrossRef]

- V. N. Nikolaevskiy, "Non-linear evolution of P-waves in viscous–elastic granular saturated media," Transport in porous media, vol. 73, no. 2, pp. 125-140, 2008. [CrossRef]

- M. Amani, A. Retnanto, S. AlJuhani, M. Al-Jubouri, S. Shehada, and R. Yrac, "Investigating the role of ultrasonic wave technology as an asphaltene flocculation inhibitor, an experimental study," in International petroleum technology conference, 2015: OnePetro.

- S. Gadiev, "Use of vibrations in oil production (Ispol’zovaniye vibratsii v dobyche nefti)," ed: Nedra Press, 1977.

- 139. Y. M. Hassan et al., "The Influence of ZnO/SiO2 nanocomposite concentration on rheology, interfacial tension, and wettability for enhanced oil recovery," Chemical Engineering Research and Design, vol. 179, pp. 452-461, 2022.

- Q. Sun, Z. Li, S. Li, L. Jiang, J. Wang, and P. Wang, "Utilization of surfactant-stabilized foam for enhanced oil recovery by adding nanoparticles," Energy & Fuels, vol. 28, no. 4, pp. 2384-2394, 2014. [CrossRef]

- S. C. Ayirala, D. N. J. C. Rao, S. A. Physicochemical, and E. Aspects, "Multiphase flow and wettability effects of surfactants in porous media," vol. 241, no. 1-3, pp. 313-322, 2004.

- R. Cao, H. Yang, W. Sun, Y. Z. J. J. o. P. S. Ma, and Engineering, "A new laboratory study on alternate injection of high strength foam and ultra-low interfacial tension foam to enhance oil recovery," vol. 125, pp. 75-89, 2015. [CrossRef]

- X. Wu, M. Han, B. H. Zahrani, and L. Guo, "Effect of surfactant-polymer interaction on the interfacial properties for chemical EOR," in SPE Middle East Oil & Gas Show and Conference, 2015: Society of Petroleum Engineers.

- G. Zhang, J. Yu, C. Du, and R. Lee, "Formulation of surfactants for very low/high salinity surfactant flooding without alkali," in SPE international symposium on oilfield chemistry, 2015: Society of Petroleum Engineers.

- F.-Q. Yuan et al., "Effect of organic alkali on interfacial tensions of surfactant solutions against crude oils," vol. 470, pp. 171-178, 2015. [CrossRef]

- M. Sharma, D. Shah, and W. Brigham, "The influence of temperature on surface and microscopic properties of surfactant solutions in relation to fluid displacement efficiency in porous media," AIChE journal, vol. 31, no. 2, pp. 222-228, 1985. [CrossRef]

- T. Smith and K. Ravi, "Investigation of drilling fluid properties to maximize cement displacement efficiency," in SPE Annual Technical Conference and Exhibition, 1991: Society of Petroleum Engineers.

- Z. Wang, K. Chauhan, J.-M. Pereira, and Y. Gan, "Disorder characterization of porous media and its effect on fluid displacement," Physical Review Fluids, vol. 4, no. 3, p. 034305, 2019. [CrossRef]

- D. Wang, G. Wang, W. Wu, H. Xia, and H. Yin, "The influence of viscoelasticity on displacement efficiency--from micro to macro scale," in SPE Annual Technical Conference and Exhibition, 2007: Society of Petroleum Engineers.

- D.-m. Wang, G. Wang, W.-x. WU, H.-f. XIA, and H.-j. YIN, "Influence of the micro-force produced by viscoelastic displacement liquid on displacement efficiency," Journal of Xi’an Shiyou University (Natural Science Edition), vol. 23, no. 1, pp. 43-55, 2008.

- E. Barsotti, S. P. Tan, S. Saraji, M. Piri, and J.-H. Chen, "A review on capillary condensation in nanoporous media: Implications for hydrocarbon recovery from tight reservoirs," Fuel, vol. 184, pp. 344-361, 2016. [CrossRef]

- M. Josh, L. Esteban, C. Delle Piane, J. Sarout, D. Dewhurst, and M. Clennell, "Laboratory characterisation of shale properties," Journal of Petroleum Science and Engineering, vol. 88, pp. 107-124, 2012. [CrossRef]

- H. Gao and H. A. Li, "Pore structure characterization, permeability evaluation and enhanced gas recovery techniques of tight gas sandstones," Journal of Natural Gas Science and Engineering, vol. 28, pp. 536-547, 2016. [CrossRef]

- L. Xiao, C.-c. Zou, Z.-q. Mao, Y. Jin, and J.-c. Zhu, "A new technique for synthetizing capillary pressure (Pc) curves using NMR logs in tight gas sandstone reservoirs," Journal of Petroleum Science and Engineering, vol. 145, pp. 493-501, 2016. [CrossRef]

- Z. Hua, M. Li, X. Ni, H. Wang, Z. Yang, and M. Lin, "Effect of injection brine composition on wettability and oil recovery in sandstone reservoirs," Fuel, vol. 182, pp. 687-695, 2016. [CrossRef]

- Y. Zhang, Z. Bao, F. Yang, S. Mao, J. Song, and L. Jiang, "The controls of pore-throat structure on fluid performance in tight clastic rock reservoir: a case from the upper Triassic of Chang 7 Member, Ordos Basin, China," Geofluids, vol. 2018, 2018. [CrossRef]

- J. Gardner, F. Orr, and P. Patel, "The effect of phase behavior on CO2-flood displacement efficiency," Journal of Petroleum Technology, vol. 33, no. 11, pp. 2,067-2,081, 1981. [CrossRef]

- R. Wright and R. Dawe, "Fluid Displacement Efficiency in Layered Porous Media. Mobility Ratio Influence," Revue de l'Institut Français du Pétrole, vol. 38, no. 4, pp. 455-474, 1983.

- X. Tian et al., "A new approach to calculate permeability stress sensitivity in tight sandstone oil reservoirs considering micro-pore-throat structure," Journal of Petroleum Science and Engineering, vol. 133, pp. 576-588, 2015. [CrossRef]

- H. Zhao et al., "Petrophysical characterization of tight oil reservoirs using pressure-controlled porosimetry combined with rate-controlled porosimetry," Fuel, vol. 154, pp. 233-242, 2015. [CrossRef]

- K. Xi et al., "How does the pore-throat size control the reservoir quality and oiliness of tight sandstones? The case of the Lower Cretaceous Quantou Formation in the southern Songliao Basin, China," Marine and Petroleum Geology, vol. 76, pp. 1-15, 2016. [CrossRef]

- L. Xiao et al., "An empirical approach of evaluating tight sandstone reservoir pore structure in the absence of NMR logs," Journal of Petroleum Science and Engineering, vol. 137, pp. 227-239, 2016. [CrossRef]

- K.-x. Li, X.-q. Jing, S. He, H. Ren, and B. Wei, "Laboratory study displacement efficiency of viscoelastic surfactant solution in enhanced oil recovery," Energy & fuels, vol. 30, no. 6, pp. 4467-4474, 2016. [CrossRef]

- N. C. Wardlaw, "Factors affecting oil recovery from carbonate reservoirs and prediction of recovery," Developments in Petroleum Science, vol. 44, pp. 867-903, 1996.

- J. Melrose, "Role of capillary forces in detennining microscopic displacement efficiency for oil recovery by waterflooding," Journal of Canadian Petroleum Technology, vol. 13, no. 04, 1974. [CrossRef]

- B. Lund, J. D. Ytrehus, A. Taghipour, and A. Saasen, "Displacement Efficiency In Eccentric Annuli," in ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering, 2020: American Society of Mechanical Engineers Digital Collection.

- D. Wang, H. Xia, Z. Liu, and Q. Yang, "Study of the mechanism of polymer solution with visco-elastic behavior increasing microscopic oil displacement efficiency and the forming of steady" Oil thread" flow channels," in SPE Asia Pacific oil and gas conference and exhibition, 2001: Society of Petroleum Engineers.

- A. M. Moghadam and M. B. Salehi, "Enhancing hydrocarbon productivity via wettability alteration: a review on the application of nanoparticles," Reviews in Chemical Engineering, vol. 35, no. 4, pp. 531-563, 2019. [CrossRef]

- J. Hagoort, "Displacement stability of water drives in water-wet connate-water-bearing reservoirs," Society of Petroleum Engineers Journal, vol. 14, no. 01, pp. 63-74, 1974. [CrossRef]

- C. Erle, "Donaldson, Waqi Alam. Wettability," 2008.

- M. Kumar, V. T. Hoang, C. Satik, and D. H. Rojas, "High-mobility-ratio waterflood performance prediction: challenges and new insights," SPE Reservoir Evaluation & Engineering, vol. 11, no. 01, pp. 186-196, 2008. [CrossRef]

- 172. F. F. Craig, The reservoir engineering aspects of waterflooding. HL Doherty Memorial Fund of AIME New York, 1971.

- L. P. Dake, Fundamentals of reservoir engineering. Elsevier, 1983.

- Y.-S. Wu and K. Pruess, "Flow of non-Newtonian fluids in porous media," in Advances in porous media, vol. 3: Elsevier, 1996, pp. 87-184.

- A. Fletcher and J. Davis, "How EOR can be transformed by nanotechnology," in SPE improved oil recovery symposium, 2010: Society of Petroleum Engineers.

- A. Sorbie and A. Skauge, "Mobilization of By-Passed Oil by Viscous Crossflow in EOR Processes," in IOR 2019–20th European Symposium on Improved Oil Recovery, 2019, vol. 2019, no. 1, pp. 1-16: European Association of Geoscientists & Engineers.

- A. Meiqin, H. Zhao, L. J. P. E. Mingyuan, and Development, "Surface wettability control of reservoir rocks by brine," vol. 45, no. 1, pp. 145-153, 2018.

- 178. R. J. J. J. o. a. s. Good and technology, "Contact angle, wetting, and adhesion: a critical review," vol. 6, no. 12, pp. 1269-1302, 1992.

- V. Bergeron, J. E. Hanssen, F. J. C. Shoghl, S. A. Physicochemical, and E. Aspects, "Thin-film forces in hydrocarbon foam films and their application to gas-blocking foams in enhanced oil recovery," vol. 123, pp. 609-622, 1997. [CrossRef]

- A. Kamari, M. Nikookar, A. Hemmati-Sarapardeh, L. Sahranavard, and A. H. Mohammadi, "SCREENING OF POTENTIAL APPLICATION OF EOR PROCESSES IN A NATURALLY FRACTURED OIL RESERVOIR.".

- P.-S. Kang, J.-S. Lim, and C. Huh, "Screening criteria and considerations of offshore enhanced oil recovery," Energies, vol. 9, no. 1, p. 44, 2016.

- A. Kamari and A. H. Mohammadi, "Screening of enhanced oil recovery methods," Handbook on Oil Production Research, Nova Science Publishers, Inc: USA, 2014.

- P. Zhang et al., "Silica-templated synthesis of novel Zinc-DTPMP nanoparticles, their transport in carbonate and sandstone porous media and scale inhibition," in SPE International Conference on Oilfield Scale, 2010: Society of Petroleum Engineers.

- H. Yu et al., "Transport and retention of aqueous dispersions of paramagnetic nanoparticles in reservoir rocks," in SPE improved oil recovery symposium, 2010: Society of Petroleum Engineers.

- T. Zhang, D. Davidson, S. L. Bryant, and C. Huh, "Nanoparticle-stabilized emulsions for applications in enhanced oil recovery," in SPE improved oil recovery symposium, 2010: Society of Petroleum Engineers.

- B. Ju and T. J. P. T. Fan, "Experimental study and mathematical model of nanoparticle transport in porous media," vol. 192, no. 2, pp. 195-202, 2009. [CrossRef]

- B. Ju, T. Fan, and M. J. C. P. Ma, "Enhanced oil recovery by flooding with hydrophilic nanoparticles," vol. 4, no. 1, pp. 41-46, 2006. [CrossRef]

- L. Hendraningrat, S. Li, and O. Torsater, "A coreflood investigation of nanofluid enhanced oil recovery in low-medium permeability Berea sandstone," in SPE International Symposium on Oilfield Chemistry, 2013: Society of Petroleum Engineers.

- K. C. Lee et al., "Effect of zinc oxide nanoparticle sizes on viscosity of nanofluid for application in enhanced oil recovery," in Journal of Nano Research, 2016, vol. 38, pp. 36-39: Trans Tech Publ. [CrossRef]

- H. Soleimani et al., "Synthesis of ZnO nanoparticles for oil–water interfacial tension reduction in enhanced oil recovery," vol. 124, no. 2, p. 128, 2018. [CrossRef]

- L. J. Giraldo, J. Gallego, J. P. Villegas, C. A. Franco, F. B. J. J. o. P. S. Cortés, and Engineering, "Enhanced waterflooding with NiO/SiO2 0-D Janus nanoparticles at low concentration," vol. 174, pp. 40-48, 2019. [CrossRef]

- M. R. Haroun et al., "Smart nano-EOR process for Abu Dhabi carbonate reservoirs," in Abu Dhabi international petroleum conference and exhibition, 2012: Society of Petroleum Engineers.

| Authors | Method | EOR Factor influenced | Result/finding | Parameters Value |

|---|---|---|---|---|

| Ibrahim Khan et al. (2017) [44] | Nano flooding | Physiochemical properties. | Temperature, pressure, time, and pH value can play important role in controlling the shape and morphology of nanoparticles materials | 10−4 to 10−2 mN/m |

| Baoliang Peng et al.,2017 [75] | Nano flooding | Wettability alteration, Reduction of interfacial tension, Controllable viscosity, and Disjoint pressure for oil displacement. | Salinity, temperature, and pH value, Surface modification of nanomaterial, intrinsic properties; electrical, magnetic, rheological, and thermal Potential mechanism of nanofluid flooding are explained. | 10−3 to 10−2 mN/m |

| Goshtasp Cheraghian et al., 2016 [45] | Nano Chemical flooding | Reduction IFT, emulsion formation, wettability alteration, Capillary forces | Nanotechnology has the potential to have a positive effect on the chemical EOR process. | 10−3 to 10−2 mN/m |

| Hon Chung Lau et al,2017 [46] | Chemical EOR | Rock wettability alteration, oil-water IFT reduction, Oil viscosity, and injection fluid viscosity | Six applications of nanoparticles are considered, and it is discovered that reservoir imaging,Drilling, tight reservoir applications and EOR ranked higher and have the highest potential impact. | 10−5 to 10−3 mN/m |

| Properties | Condition | Nanofluid & Variables | Substrate | Result | Ref. |

|---|---|---|---|---|---|

| Hydrophilic, 14 nm, Spherical | Based Fluid: DW. NPs conc. (0.1-5 wt.%) |

Glass | The surface was completely altered to water wet (0o) at 5wt% NF conc. | [124] | |

| Hydrophobic, 10nm, Spherical | NPs conc. = 0.5-4wt%, NaCl = 0-20 wt%, | Calcite | SiO2 altered θ from 120o to 45o at 2wt% optimum conc. This was altered further to 40o at 30000 ppm salinity. | [125] | |

| Hydrophobic, 5nm, Spherical | Based Fluid = DW, Size = 5 & 25nm, Temp. = 23&50oC |

Calcite | Size has no effect. θ decreased with higher temp. |

[126] | |

| Spherical, 35nm | T= 70oC, P = 600psi | Based Fluid = DW, NPs conc. = 5wt% Salinity = 3-12wt% |

Calcite | SiO2 NPs reduced the θ below 90o up until 8wt% salinity. | [127] |

| Hydrophilic, 15nm | T<30oC | Based Fluid = DI NPs conc= 0.1wt% Surfactant conc. = 0.14wt%. |

Sandstone | SiO2 NPs with and without surfactant altered wettability to strong water wet by 9.87% and 6.15% respectively. | [128] |

| 15nm | N.A | NF=H2O+NPs+ SF(AOT, 11.25mM)+SA(NaCl+Na2SO4+CaCl2+ MgSO4·7H2O). | Berea Sandstone | Increase in NPs conc. does not magnify W.A. Highest W.A. was achieved with 0.1wt% conc. of NPs at 0.3wt% salinity. | [129] |

| Spherical,15nm | Room | NF = H2O+NPs+SA(NaCl) |

Calcite | W.A. reduces with an increase in NP conc. (73.72% changes). The reduction was further enhanced in the presence of NaCl |

[130] |

| Hydrophilic (40nm) and surface modified (6nm) SiO2, Spherical. | Room | NF= H2O +NPs+ SA (NaCl+CaCl2+KCL+MgSO4+MgCl2, 73050 ppm). | Sandstone | Adhesion forces reduce up until 0.5wt% NPs conc. Treated NPs outperformed unmodified ones due to increased interfacial activity, | [131] |

| Silane treated SiO2 (15nm) | Room | NF = Propanol+NPs. | θ reduces with increase in conc. | [132] |

| Force | Indication | Ref |

|---|---|---|

| Viscous force | This is the force occurring as a result of the difference in the viscosity of two fluids, leading to the displacement of one by another | [176] |

| Gravitational/ buoyancy force | This is the force accounting for the separation of less dense fluid (e.g., oil) from the dense fluid (e.g., water) at the microscale | [176] |

| Capillary force | This is the force responsible for the difference in pressure between two fluid phases when the interfaces of a fluid are curve | [176] |

| Coulombic force | These are intermolecular forces and include van der Waal forces such as induced dipole (London), hydrogen bond, and dipole. In the case ions and polar molecules are present, forces such as ionic bonding and ion-dipole bond occur | [177] |

| Mahogany force | This force arises as a result of variation or gradient of properties such as interfacial tension or concentration | [178] |

| Disjoining force | These are surface forces such as an electric double layer, steric force, and van der Waal forces. They are associated with the thin film due to their separation from bulk properties. | [179] |

| Parameters | Outcomes | Ref |

|---|---|---|

|

|

[183] |

|

|

|

|

|

[187] |

|

|

[188] |

|

|

[189] |

|

|

[190] |

|

|

[191] |

|

|

[192] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).