Submitted:

25 September 2023

Posted:

26 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

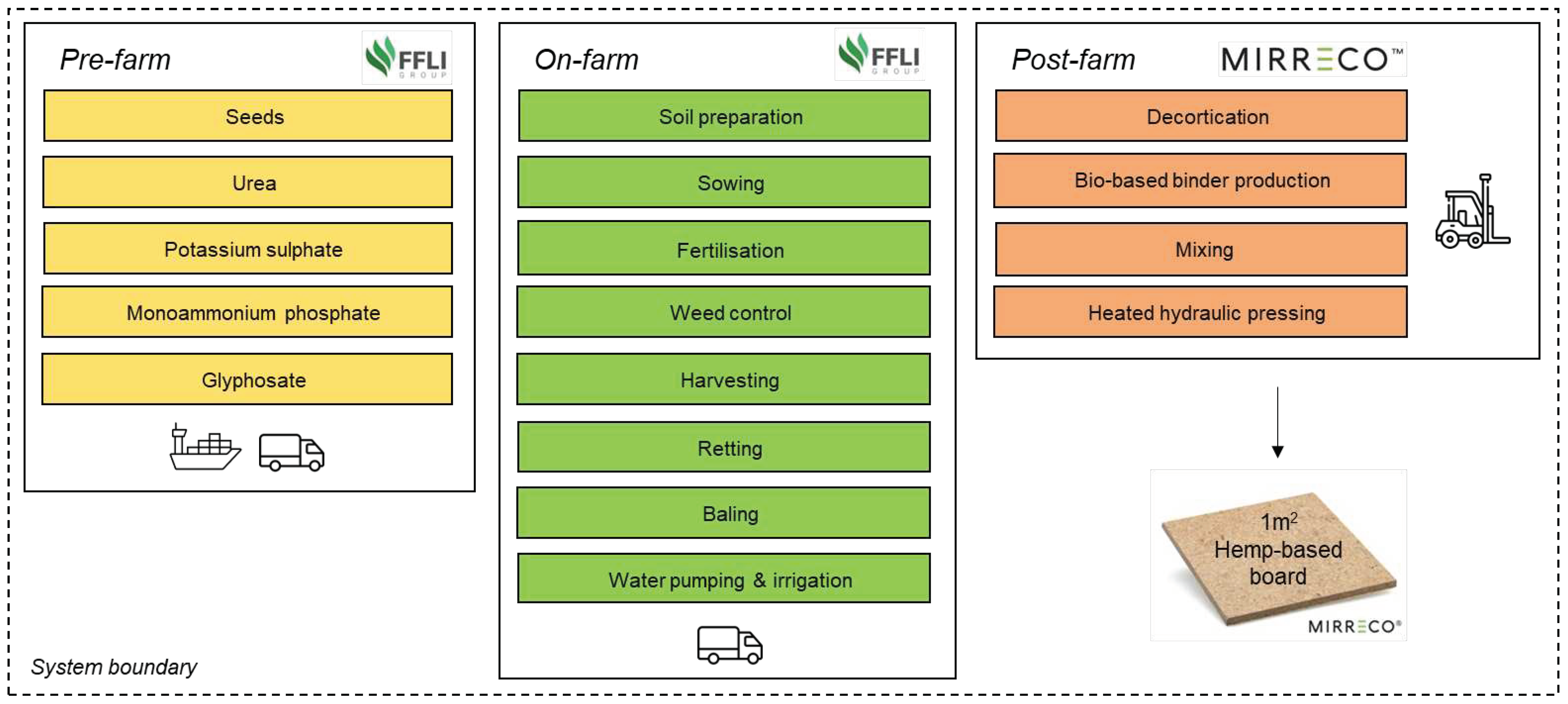

2.1. Goal and scope definition

- Pre-farm: production of agricultural inputs and its transport to paddock (plot of land on a farm).

- On-farm: operation of farming machinery, transportation of hemp bales from paddock to processing plant, soil emissions from N fertilisation, and biogenic sequestration.

- Post-farm: indoor transportation of raw materials, decortication, bio-based binder production, mixing of hurds and binder, and heated hydraulic pressing.

2.2. Life cycle inventory analysis (LCI)

2.2.1. Pre-farm stage

2.2.2. On-farm stage

2.2.3. Post-farm stage

2.3. Life cycle impact assessment (LCIA)

- Hemp seed production: Information collected during interviews with farmers was utilised to construct this process since inputs and machinery for hemp seed production align with those for hemp biomass production (Edkins, R., hemp grower, pers. comm., April 18, 2023).

- Direct CO2 emissions from urea application: These emissions due to urea hydrolysis were estimated using a CO2-C emission factor (EF, the percentage of urea that is lost as CO2-C) of 20%. This is a default value proposed by the Intergovernmental Panel on Climate Change (IPCC) [49]. This value was applied due to the absence of specific data for Kaloorup. CO2-C emissions were multiplied by 44/12 to determine CO2 emissions.

- Direct N2O emissions from N fertilisation: The estimations about the fraction of the N fertiliser that is transformed and emitted as N2O emissions have a significant effect on the CF of agricultural products grown in WA's South West, as evidenced in the literature [25,50,51]. Moreover, various regional studies have measured N2O emissions in situ instead of relying on default values to calculate them [24,51,52,53]. However, this study was limited to estimate direct N2O emissions using scholarly sources because specific data was not available for the study-site. Accordingly, the EF for direct N2O emissions was sourced from a meta-analysis conducted by Cayuela, Aguilera [23] which included prior regional studies [24,51,52,53]. The meta-analysis suggests that 0.63% of the N input is lost as N2O-N emissions in WA's South West soils under irrigation. N2O-N emissions were multiplied by 44/28 to determine NO2 emissions.

- Indirect N2O emissions from N fertilisation: these emissions correspond to the portion of the N fertilliser that is lost through leaching and volatilisation. According to the IPCC, N leaching only occurs when the evapotranspiration to annual precipitation ratio is between 0.8 and 1.8 [49]. This ratio was 2.3 in 2022 for the study area, thus, emissions from leaching were considered to be zero. For N volatilisation, emissions were estimated according to the IPCC default EF, which assumes that 10% of N fertiliser is lost as NH3, with 1% of the NH3 then emitted as N2O-N following atmospheric deposition. IPCC default values were used since regional-specific data was not available.

- Biogenic carbon uptake: to the best of the authors’ knowledge there are no studies that have estimated the biogenic uptake of hemp production in Australia. Therefore, The study used a sequestration factor obtained from an Australian Parliament House report, which estimated 1.37 tonnes of CO2 absorbed per tonne of hemp stalks based on data from the United Kingdom (UK) [54].

2.3.1. Allocation method

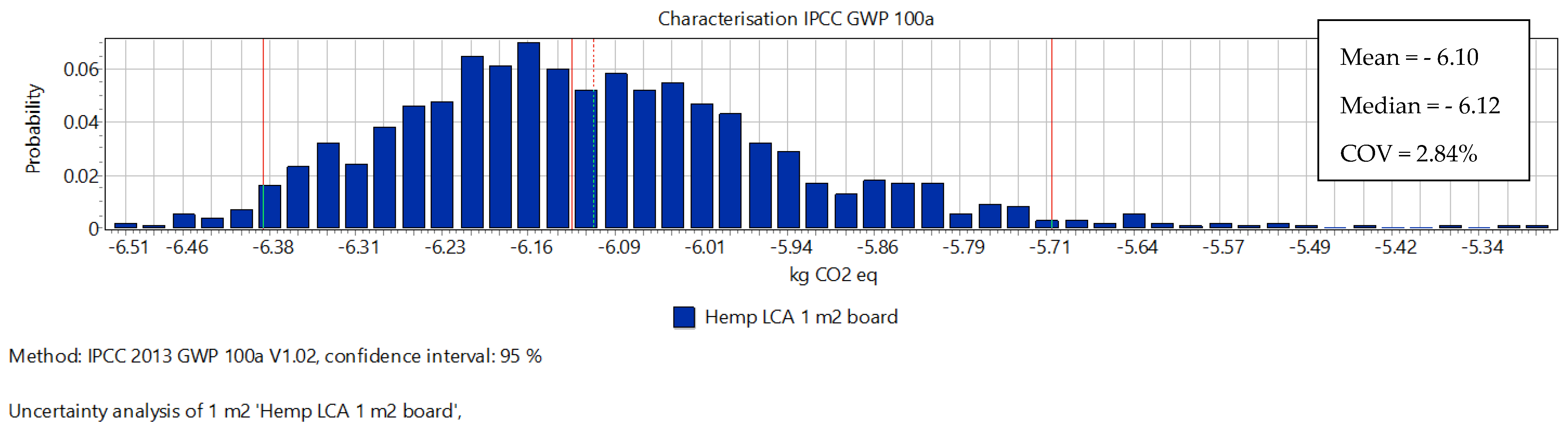

2.3.2. Monte Carlo simulations (Uncertainty analysis)

3. Results and discussion

3.1. Monte Carlo simulations results

3.2. Life cycle interpretation

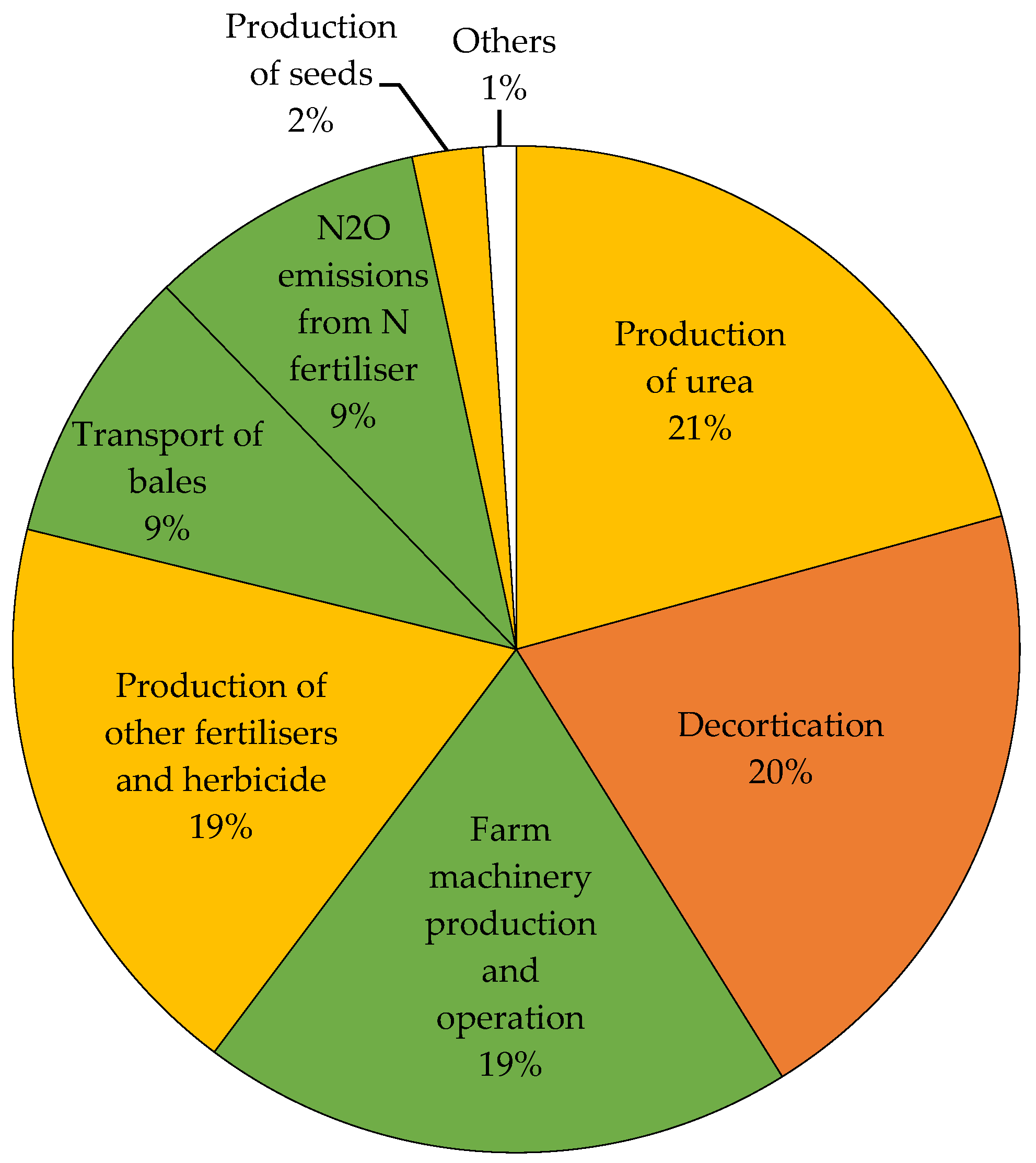

3.2.1. CF of hemp hurds

3.2.1.1. Sensitivity analyses

3.2.1.2. Mitigation strategy: reduction of synthetic N fertiliser

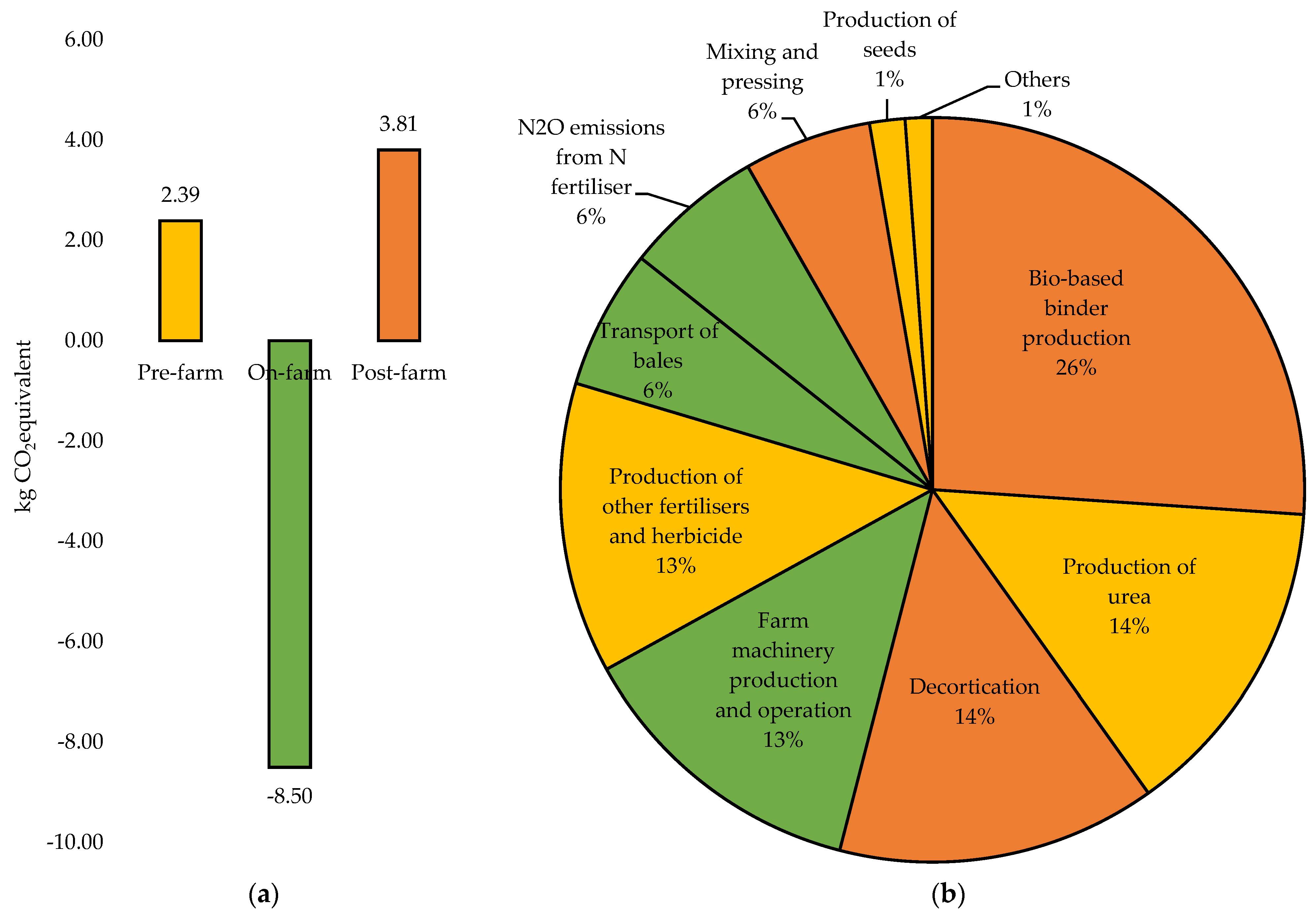

3.2.2. CF of hemp-based boards

3.2.3. Sensitivity analysis

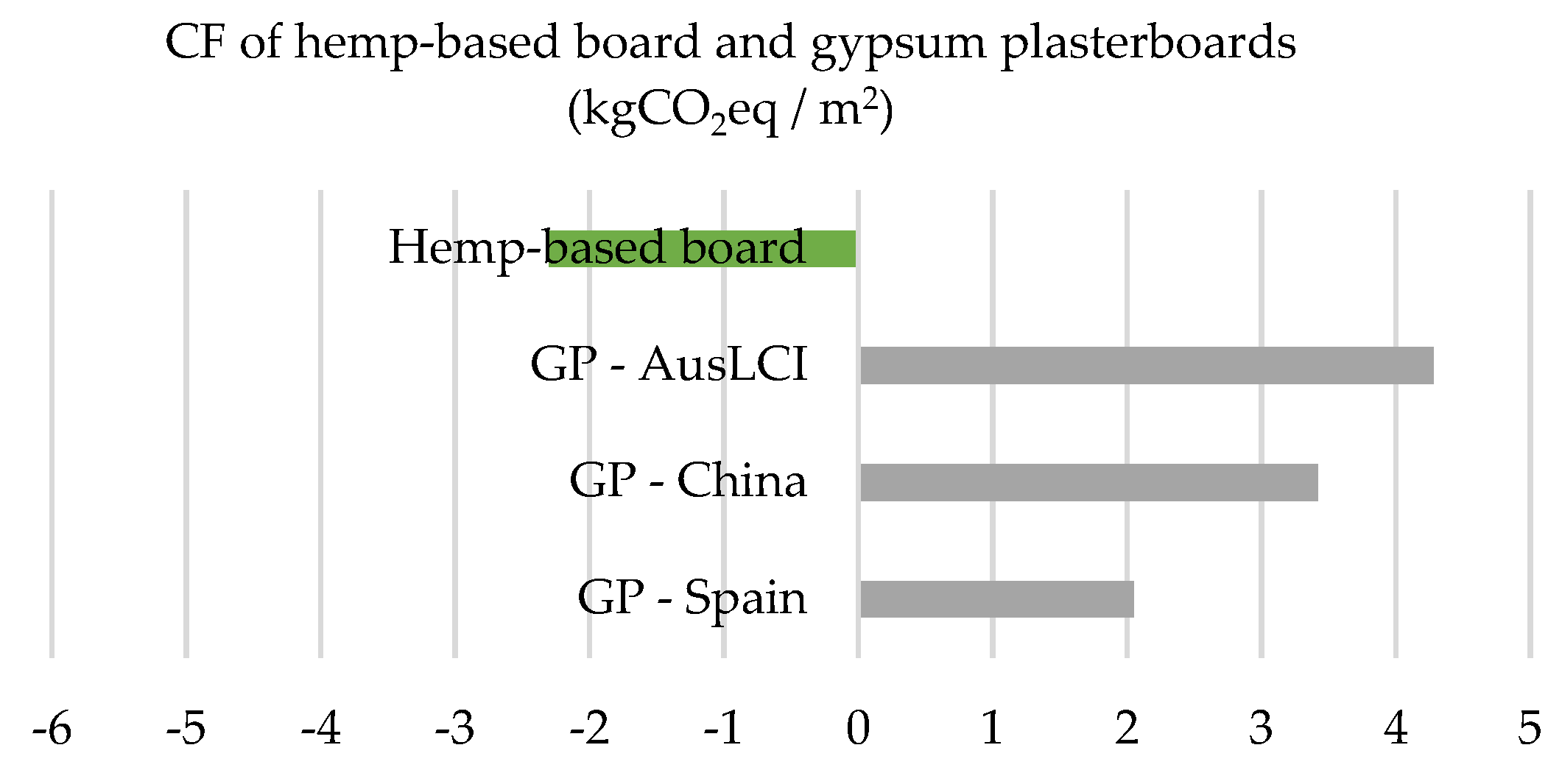

3.3. Comparison with traditional materials

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Acronyms

References

- Hoegh-Guldberg, O.; et al. The human imperative of stabilizing global climate change at 1. 5 C. Science 2019, 365, eaaw6974. [Google Scholar] [CrossRef] [PubMed]

- IPCC, Climate Change 2023: Synthesis Report, in Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change, H. Lee; et al., Editors. 2023, Intergovernmental Panel on Climate Change: Cambridge, UK and New York, NY, USA. p. 37-118.

- UNFCCC. The Paris Agreement. 2023 11/09/2023]. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement.

- UNEP, 2022 Global status report for buildings and construction: Towards a zero-emission efficient and resilient buildings and construction sector. 2022, United Nations Environment Programme: Nairobi.

- Yu, M.; et al. The carbon footprint of Australia's construction sector. Procedia engineering 2017, 180, 211–220. [Google Scholar] [CrossRef]

- DCCEEW, Australia’s emissions projections 2022. 2022.

- Robati, M.; Daly, D.; Kokogiannakis, G. A method of uncertainty analysis for whole-life embodied carbon emissions (CO2-e) of building materials of a net-zero energy building in Australia. Journal of Cleaner Production 2019, 225, 541–553. [Google Scholar] [CrossRef]

- GBCA and thinkstep-anz, Embodied Carbon & Embodied Energy in Australia’s Buildings. 2021, Green Building Council of Australia (GBCA) & Thinkstep-anz: Sydney. p. 75.

- Mouton, L.; Allacker, K.; Röck, M. Bio-based building material solutions for environmental benefits over conventional construction products–Life cycle assessment of regenerative design strategies (1/2). Energy and Buildings 2023, 282, 112767. [Google Scholar] [CrossRef]

- Röck, M.; et al. Embodied GHG emissions of buildings – The hidden challenge for effective climate change mitigation. Applied Energy 2020, 258. [Google Scholar] [CrossRef]

- Essaghouri, L.; Mao, R.; Li, X. Environmental benefits of using hempcrete walls in residential construction: An LCA-based comparative case study in Morocco. Environmental Impact Assessment Review 2023, 100, 107085. [Google Scholar] [CrossRef]

- Rivas-Aybar, D.; John, M.; Biswas, W. Can the Hemp Industry Improve the Sustainability Performance of the Australian Construction Sector? Buildings 2023, 13, 1504. [Google Scholar] [CrossRef]

- Bumanis, G.; Korjakins, A.; Bajare, D. Environmental Benefit of Alternative Binders in Construction Industry: Life Cycle Assessment. Environments (Basel, Switzerland) 2022, 9, 6. [Google Scholar] [CrossRef]

- Cappucci, G.M.; et al. Life cycle assessment of wheat husk based agro-concrete block. Journal of Cleaner Production 2022, 349, 131437. [Google Scholar] [CrossRef]

- Arehart, J.H.; Nelson, W.S.; Srubar, W.V., III. On the theoretical carbon storage and carbon sequestration potential of hempcrete. Journal of Cleaner Production 2020, 266, 121846. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. A comprehensive review on the use of hemp in concrete. Construction and Building Materials 2022, 341, 127857. [Google Scholar] [CrossRef]

- Scrucca, F.; et al. Energy and carbon footprint assessment of production of hemp hurds for application in buildings. Environmental Impact Assessment Review 2020, 84. [Google Scholar] [CrossRef]

- Bošković, I.; Radivojević, A. Life cycle greenhouse gas emissions of hemp-lime concrete wall constructions in Serbia: The impact of carbon sequestration, transport, waste production and end of life biogenic carbon emission. Journal of Building Engineering 2023, 66, 105908. [Google Scholar] [CrossRef]

- Zampori, L.; Dotelli, G.; Vernelli, V. Life cycle assessment of hemp cultivation and use of hemp-based thermal insulator materials in buildings. Environmental Science and Technology 2013, 47, 7413–7420. [Google Scholar] [CrossRef]

- Heidari, M.D.; et al. Regionalised life cycle assessment of bio-based materials in construction; the case of hemp shiv treated with sol-gel coatings. Materials 2019, 12, 2987. [Google Scholar] [CrossRef] [PubMed]

- Ip, K.; Miller, A. Life cycle greenhouse gas emissions of hemp-lime wall constructions in the UK. Resources. Conservation and Recycling 2012, 69, 1–9. [Google Scholar] [CrossRef]

- Cleverly, J.; et al. Carbon, water and energy fluxes in agricultural systems of Australia and New Zealand. Agricultural and Forest Meteorology 2020, 287, 107934. [Google Scholar] [CrossRef]

- Cayuela, M.L.; et al. Direct nitrous oxide emissions in Mediterranean climate cropping systems: Emission factors based on a meta-analysis of available measurement data. Agriculture, Ecosystems & Environment 2017, 238, 25–35. [Google Scholar]

- Barton, L.; et al. Nitrous oxide emissions from a cropped soil in a semi-arid climate. Global Change Biology 2008, 14, 177–192. [Google Scholar] [CrossRef]

- Biswas, W.K.; Barton, L.; Carter, D. Global warming potential of wheat production in Western Australia: A life cycle assessment. Water and environment journal : WEJ 2008, 22, 206–216. [Google Scholar] [CrossRef]

- Bouwman, A.; Boumans, L.; Batjes, N. Emissions of N2O and NO from fertilized fields: Summary of available measurement data. Global biogeochemical cycles 2002, 16, 6-1–6-13. [Google Scholar] [CrossRef]

- Jefferies, S. Australian Industrial Hemp Strategic RD&E Plan (2022-2027). 2022, AgriFutures Australia: Wagga Wagga, NSW. p. 25.

- Pretot, S.; Collet, F.; Garnier, C. Life cycle assessment of a hemp concrete wall: Impact of thickness and coating. Building and Environment 2014, 72, 223–231. [Google Scholar] [CrossRef]

- Arrigoni, A.; et al. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. Journal of Cleaner Production 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Sinka, M.; et al. Comparative life cycle assessment of magnesium binders as an alternative for hemp concrete. Resources, conservation and recycling 2018, 133, 288–299. [Google Scholar] [CrossRef]

- Di Capua, S.E.; et al. Evaluation of the Environmental Sustainability of Hemp as a Building Material, through Life Cycle Assessment. Environmental and Climate Technologies 2021, 25, 1215–1228. [Google Scholar] [CrossRef]

- Lecompte, T.; Levasseur, A.; Maxime, D. Lime and hemp concrete LCA: A dynamic approach of GHG emissions and capture. Academic Journal of Civil Engineering 2017, 35, 513–521. [Google Scholar]

- Haik, R.; Meir, I.A.; Peled, A. Lime Hemp Concrete with Unfired Binders vs. Conventional Building Materials: A Comparative Assessment of Energy Requirements and CO2 Emissions. Energies 2023, 16, 708. [Google Scholar] [CrossRef]

- Jitsanigam, P.; Biswas, W.K.; Compton, M. Sustainable utilization of lime kiln dust as active filler in hot mix asphalt with moisture damage resistance. Sustainable Materials and Technologies 2018, 17, e00071. [Google Scholar] [CrossRef]

- Collet, F.; Pretot, S. Experimental highlight of hygrothermal phenomena in hemp concrete wall. Building and Environment 2014, 82, 459–466. [Google Scholar] [CrossRef]

- Kinnane, O.; et al. Acoustic absorption of hemp-lime construction. Construction & building materials 2016, 122, 674–682. [Google Scholar]

- Shen, Z.; Tiruta-Barna, L.; Hamelin, L. From hemp grown on carbon-vulnerable lands to long-lasting bio-based products: Uncovering trade-offs between overall environmental impacts, sequestration in soil, and dynamic influences on global temperature. The Science of the total environment 2022, 846, 157331. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; et al. Life-cycle assessment and acoustic simulation of drywall building partitions with bio-based materials. Polymers 2020, 12, 1965. [Google Scholar] [CrossRef] [PubMed]

- Rivero, A.J.; Sathre, R.; Navarro, J.G. Life cycle energy and material flow implications of gypsum plasterboard recycling in the European Union. Resources, Conservation and Recycling 2016, 108, 171–181. [Google Scholar] [CrossRef]

- Stephan, A.; Athanassiadis, A. Towards a more circular construction sector: Estimating and spatialising current and future non-structural material replacement flows to maintain urban building stocks. Resources, Conservation and Recycling 2018, 129, 248–262. [Google Scholar] [CrossRef]

- ISO, ISO 14040:2006 Environmental management - Life cycle assessment - Principles and framework. 2006, International Organization for Standardization: Geneva, Switzerland.

- ISO, ISO 14044:2006 Environmental management — Life cycle assessment — Requirements and guidelines. 2006, International Organization for Standardization: Geneva, Switzerland.

- Finkbeiner, M.; Tan, R.; Reginald, M. Life cycle assessment (ISO 14040/44) as basis for environmental declarations and carbon footprint of products. in ISO Technical Committee 207 Workshop, Norway. 2011.

- Biswas, W.K. Carbon footprint and embodied energy consumption assessment of building construction works in Western Australia. International Journal of Sustainable Built Environment 2014, 3, 179–186. [Google Scholar] [CrossRef]

- IPCC, Climate Change 2013: The Physical Science Basis. 2013, Intergovernmental Panel on Climate Change: Cambridge University Press.

- Smith, P. Is your diesel pump costing you money? 2015, Department of Primary Industries.

- Kim, T.H.; et al. Extraction behaviors of lignin and hemicellulose-derived sugars during organosolv fractionation of agricultural residues using a bench-scale ball milling reactor. Energies 2020, 13, 352. [Google Scholar] [CrossRef]

- Society, A.L.C.A. The Australian Life Cycle Inventory Database Initiative. 2011 24/08/2023]. Available online: https://www.auslci.com.au/.

- Hergoualc'h, K.; et al. N2O emissions from managed soils, and CO2 emissions from lime and urea application. 2019, IPCC.

- Biswas, W.K.; Barton, L.; Carter, D. Biodiesel production in a semiarid environment: A life cycle assessment approach. Environmental science & technology 2011, 45, 3069–3074. [Google Scholar]

- Barton, L.; et al. Soil nitrous oxide and methane fluxes are low from a bioenergy crop (canola) grown in a semi-arid climate. GCB Bioenergy 2010, 2, 1–15. [Google Scholar] [CrossRef]

- Barton, L.; Murphy, D.V.; Butterbach-Bahl, K. Influence of crop rotation and liming on greenhouse gas emissions from a semi-arid soil. Agriculture, Ecosystems & Environment 2013, 167, 23–32. [Google Scholar]

- Li, Y.; Barton, L.; Chen, D. Simulating response of N2O emissions to fertiliser N application and climatic variability from a rain-fed and wheat-cropped soil in Western Australia. Journal of the Science of Food and Agriculture 2012, 92, 1130–1143. [Google Scholar] [CrossRef]

- Vosper, J. The Role of Industrial Hemp in Carbon Farming. N.D., GoodEarth Resources.

- Senga Kiessé, T.; et al. Introducing economic actors and their possibilities for action in LCA using sensitivity analysis: Application to hemp-based insulation products for building applications. Journal of Cleaner Production 2017, 142, 3905–3916. [Google Scholar] [CrossRef]

- Ardente, F.; Cellura, M. Economic allocation in life cycle assessment: The state of the art and discussion of examples. Journal of Industrial Ecology 2012, 16, 387–398. [Google Scholar] [CrossRef]

- Andrianandraina, H.; et al. Sensitivity Analysis of Environmental Process Modeling in a Life Cycle Context: A Case Study of Hemp Crop Production. Journal of Industrial Ecology 2015, 19, 978–993. [Google Scholar] [CrossRef]

- Barton, L.; et al. Does growing grain legumes or applying lime cost effectively lower greenhouse gas emissions from wheat production in a semi-arid climate? Journal of Cleaner Production 2014, 83, 194–203. [Google Scholar] [CrossRef]

- Sinergy. What makes up the electricity generation mix in Western Australia? 2023 [cited 2023 17th of June]. Available online: https://www.synergy.net.au/Blog/2022/06/What-makes-up-the-electricity-generation-mix-in-Western-Australia.

- Australia, G.o.W. SWIS Demand Assessment 2023 to 2042. 2023.

- Zhang, Y.J.; et al. Comparative life cycle assessment between ordinary gypsum plasterboard and functional phase-change gypsum plasterboard. in Materials Science Forum. 2020. Trans Tech Publ.

- Soonsawad, N.; Martinez, R.M.; Schandl, H. Material demand, and environmental and climate implications of Australia's building stock: Current status and outlook to 2060. Resources, Conservation and Recycling 2022, 180, 106143. [Google Scholar] [CrossRef]

- Steau, E.; Mahendran, M. Elevated temperature thermal properties of fire protective boards and insulation materials for light steel frame systems. Journal of Building Engineering 2021, 43, 102571. [Google Scholar] [CrossRef]

- Keerthan, P.; Mahendran, M. Numerical studies of gypsum plasterboard panels under standard fire conditions. Fire Safety Journal 2012, 53, 105–119. [Google Scholar] [CrossRef]

| Location of the Study | CF kgCO2eq /kg Hurds |

Reference |

|---|---|---|

| United Kingdom | - 1.335 | [21] |

| Italy | - 1.730 to - 1.750 | [19] |

| France | - 1.550 to - 1.630 | [20] |

| France | - 0.315 to - 0.558 | [17] |

| Serbia | - 1.182 to - 1.380 | [18] |

| Location of the Study | U-Value W/m2K |

Thermal Conductivity W/mK |

Hotspot | CF kgCO2eq / m2 LHC |

Reference |

|---|---|---|---|---|---|

| United Kingdom | 0.19 | 0.057 | Lime production | - 36.08 | [21] |

| France | 0.36 | 0.086 | Lime production | - 0.016 | [28] |

| Italy | 0.27 | N.D. | Lime production | - 12.09 | [29] |

| Serbia | 0.30 | 0.0894 | Lime production | - 9.69 to - 14.89 | [18] |

| Inputs | Quantity | Unit | Source and Collecting Method |

|---|---|---|---|

| Pre-farm | |||

| Materials | |||

| Seeds | 1.55E-02 | kg/FU | FFLI and DPIRD, interviews and questionnaires |

| Urea | 1.03E-01 | kg/FU | |

| Potassium sulphate | 6.18E-02 | kg/FU | |

| Monoammonium phosphate (MAP) | 1.03E-01 | kg/FU | |

| Glyphosate | 8.76E-04 | L/FU | |

| Transport from manufacturer to paddock | |||

| Small truck | 1.10E-02 | tkm/FU | FFLI and DPIRD, interviews and questionnaires / Assumptions (see Table 4) |

| Freight ship | 4.88E-01 | tkm/FU | |

| Articulated truck | 2.34E-01 | tkm/FU | |

| On-farm | |||

| Ripper | 3.09E-03 | ha/FU | FFLI, interviews and questionnaires / Technical specifications (Tractor John Deere 9R 390 and associated attachments) |

| Seeder | 3.87E-03 | ha/FU | |

| Sprayer (weed control) | 6.87E-04 | ha/FU | |

| Sprayer (fertilisation) | 9.16E-04 | ha/FU | |

| Harvester | 2.21E-03 | ha/FU | Technical specifications (Hemp cutter Laumetris KP - 4) |

| Harrowing | 3.63E-04 | ha/FU | FFLI, interviews and questionnaires / Technical specifications (Tractor John Deere 9R 390 and associated implements) |

| Baler | 3.09E-03 | ha/FU | |

| Irrigation | 4.85E-03 | ha/FU | DPIRD Report [46] |

| Transport from paddock to board manufacturer | |||

| Articulated truck | 1.25E+00 | tkm/FU | FFLI & MIRRECO®, interviews and questionnaires |

| Post-farm | |||

| Indoor transportation (diesel use) | |||

| Forklift | 1.04E-03 | L/FU | Technical specifications (Hyster H2.0XT) |

| Electricity use | |||

| Decorticator | 4.68E-01 | kw/FU | Technical specifications (HempTrain™) |

| Mixer | 3.54E-03 | kw/FU | Technical specifications (Nasser Machinery) |

| Bio-based binder | 3.30E+00 | kw/FU | MIRRECO®, interviews and questionnaires / Literature review [47] |

| Presser (boiler) | 1.17E-01 | kw/FU | MIRRECO® and technical specifications (Italpresse Model XL/10 38-16 PMBO Hydraulic Hot Press) |

| Presser (hydraulic pump) | 9.77E-03 | kw/FU |

| Inputs | Transportation Mode | Average Distance (km) | ||

|---|---|---|---|---|

| Sea | Land | Sea | Land | |

| Seeds | - | 3.5- to 16-tonne truck | - | 716 |

| Urea | - | 20-tonne articulated truck | - | 1778 |

| Potassium sulphate | Freight ship | 20-tonne articulated truck | 7477 | 363 |

| Monoammonium phosphate (MAP) | - | 20-tonne articulated truck | - | 218 |

| Glyphosate | Freight ship | 20-tonne articulated truck | 17314 | 3720 |

| Location of the Study | EF for Direct N2O-N Emissions from N Fertilisers |

Hotspot | Co- Products |

Allocation Method & Percentage Allocated for Hurds |

Hemp Hurds (kgCO2eq/ kg of Hurds) |

CF (kgCO2eq /kg of hurds) |

Sensitivity Analysis |

Ref. | |

|---|---|---|---|---|---|---|---|---|---|

| Emissions | Uptake | ||||||||

| Existing literature | |||||||||

| UK | Not specified |

Fertiliser | f, d | Not specified |

≈ 0.192 | 1.527 | ≈ - 1.335 | - | [21] |

| Italy | 1.70% | Fertiliser | f, d | Mass 75% | ≈ 0.100 | -1.830 | 1.730 | - | [19] |

| Economic 61% | ≈ 0.080 | -1.830 | 1.750 | ||||||

| West France |

1.25%* | N fertiliser |

f, d, s | Mass 47% | ≈ 0.290 | -1.840 | 1.550 | - | [20] |

| Economic 32% | ≈ 0.210 | -1.840 | 1.630 | ||||||

| Vendée (France) | 1.25%* | N fertiliser |

f, s | Mass 56% | 0.975 | 1.290 | ≈ - 0.315 | Baseline | [17] |

| 0.853 | 1.290 | ≈ - 0.437 | Use of compost, 50% | ||||||

| 0.886 | 1.290 | ≈ - 0.404 | Use of compost, 75% | ||||||

| 0.732 | 1.290 | ≈ - 0.558 | Use of compost, 100% | ||||||

| Serbia | 1.25%* | Not specified |

f, d | Mass 60% | 0.167 | 1.448 | ≈ - 1.281 | Baseline | [18] |

| 0.167 | 1.349 | ≈ - 1.182 | Pessimistic | ||||||

| 0.167 | 1.547 | ≈ - 1.380 | Optimistic | ||||||

| Current study | |||||||||

| Kaloorup (Australia) | 0.63% | N fertiliser |

f, d | Mass 70% | 0.339 | 1.37 | -1.031 | Baseline | |

| 0.06% | 0.312 | 1.37 | -1.058 | EF, local literature [51] | |||||

| 1.00%* | 0.357 | 1.37 | -1.013 | EF, IPCC default value | |||||

| 0.63% | Economic 49% | 0.237 | 1.37 | -1.133 | Economic allocation | ||||

| Location of the Study | Hemp-Based Construction Material |

System boundary |

Binder | Hotspot | CF kgCO2eq / m2 |

Ref. |

|---|---|---|---|---|---|---|

| Existing literature | ||||||

| UK | Lime-hemp concrete | Cradle to gate | Lime | Binder production | - 36.08 | [21] |

| France | Lime-hemp concrete | Cradle to grave | Lime | Binder production | - 0.016 | [28] |

| Italy | Lime-hemp concrete blocks | Cradle to use | Lime | Binder production | - 12.09 | [29] |

| Latvia | Lime-hemp concrete | Cradle to gate | Lime | Fertiliser and leaching | - 19.28 to 4.88 | [30] |

| Magnesium-hemp concrete | Magnesium oxychloride | Fertiliser and leaching | - 12.68 to 54.29 | |||

| Serbia | Lime-hemp concrete | Cradle to grave | Lime | Binder production | - 9.696 to 14.899 | [18] |

| Current study | ||||||

| Australia | Hemp board | Cradle to gate | Bio-based binder | Binder production | - 2.302 | |

| Sensitivity Analysis | Emissions (kgCO2eq /m2) |

Uptake (kgCO2 /m2) |

CF (kgCO2eq /m2) |

Percentage of Reduction |

|---|---|---|---|---|

| Baseline - SWIS | 8.29 | -10.59 | - 2.30 | Baseline |

| Solar energy, 25% | 7.34 | -10.59 | -3.25 | 41% |

| Solar energy, 50% | 6.40 | -10.59 | -4.19 | 82% |

| Solar energy, 100% | 4.52 | -10.59 | -6.07 | 164% |

| Building Archetypes | Material Intensity* (kg/ m2 of UFA) |

Material Use** (m2/ m2 of UFA) |

GWP*** (kgCO2eq/ m2 of UFA) |

Carbon Reduction Potential**** (kgCO2eq/ m2 of UFA) |

|

|---|---|---|---|---|---|

| Plasterboard | Plasterboard | Plasterboard | Hemp-based board | ||

| Residential | |||||

| Single house | 28.8 | 2.90 | 10.43 | -6.67 | 17.10 |

| Semi-detached house | 28.3 | 2.85 | 10.25 | -6.55 | 16.80 |

| 1 and 2-storey apartment | 19.8 | 1.99 | 7.17 | -4.58 | 11.75 |

| 3-storey apartment | 14.5 | 1.46 | 5.25 | -3.36 | 8.61 |

| 4 and above storeys apartment | 7.1 | 0.71 | 2.57 | -1.64 | 4.21 |

| Commercial | |||||

| 1-3-storey commercial | 13.2 | 1.33 | 4.78 | -3.06 | 7.84 |

| 4–7-storey commercial | 5.7 | 0.57 | 2.06 | -1.32 | 3.38 |

| 8–35 storey commercial | 4.4 | 0.44 | 1.59 | -1.02 | 2.61 |

| Industrial | |||||

| 1-storey industrial | 22.6 | 2.27 | 8.18 | -5.23 | 13.42 |

| 2-storey industrial | 11.3 | 1.14 | 4.09 | -2.62 | 6.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).