Submitted:

26 September 2023

Posted:

28 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

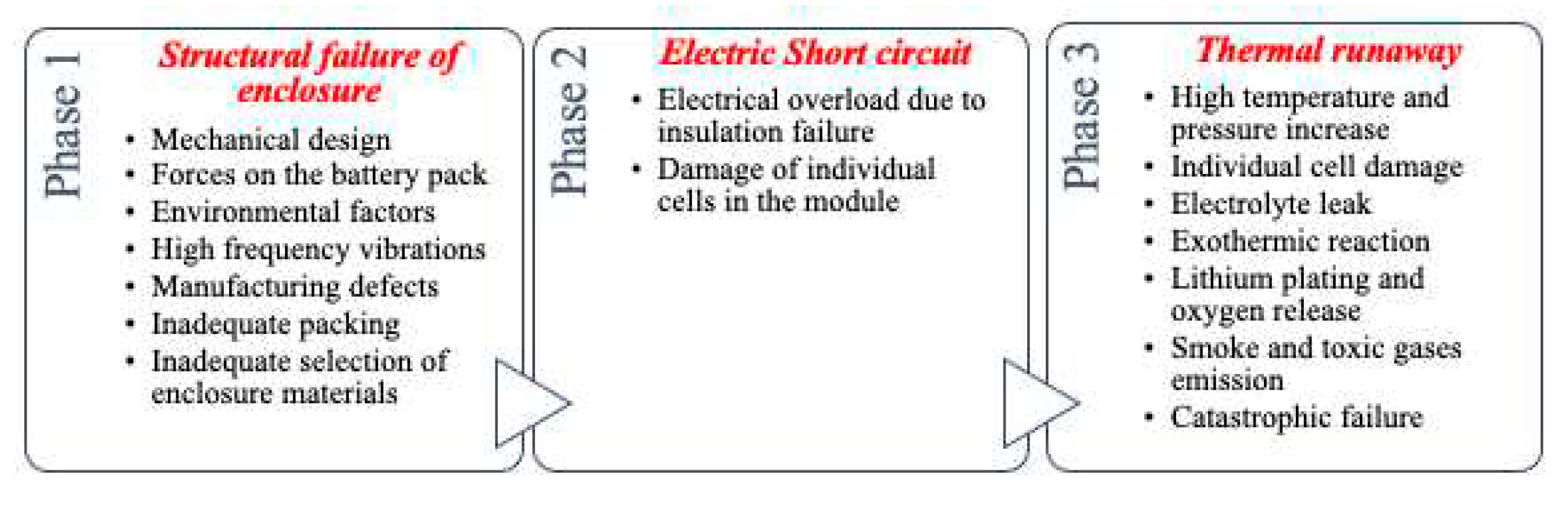

1.1. Failure, Modes, Mechanisms and Effects Analysis (FMMEA)

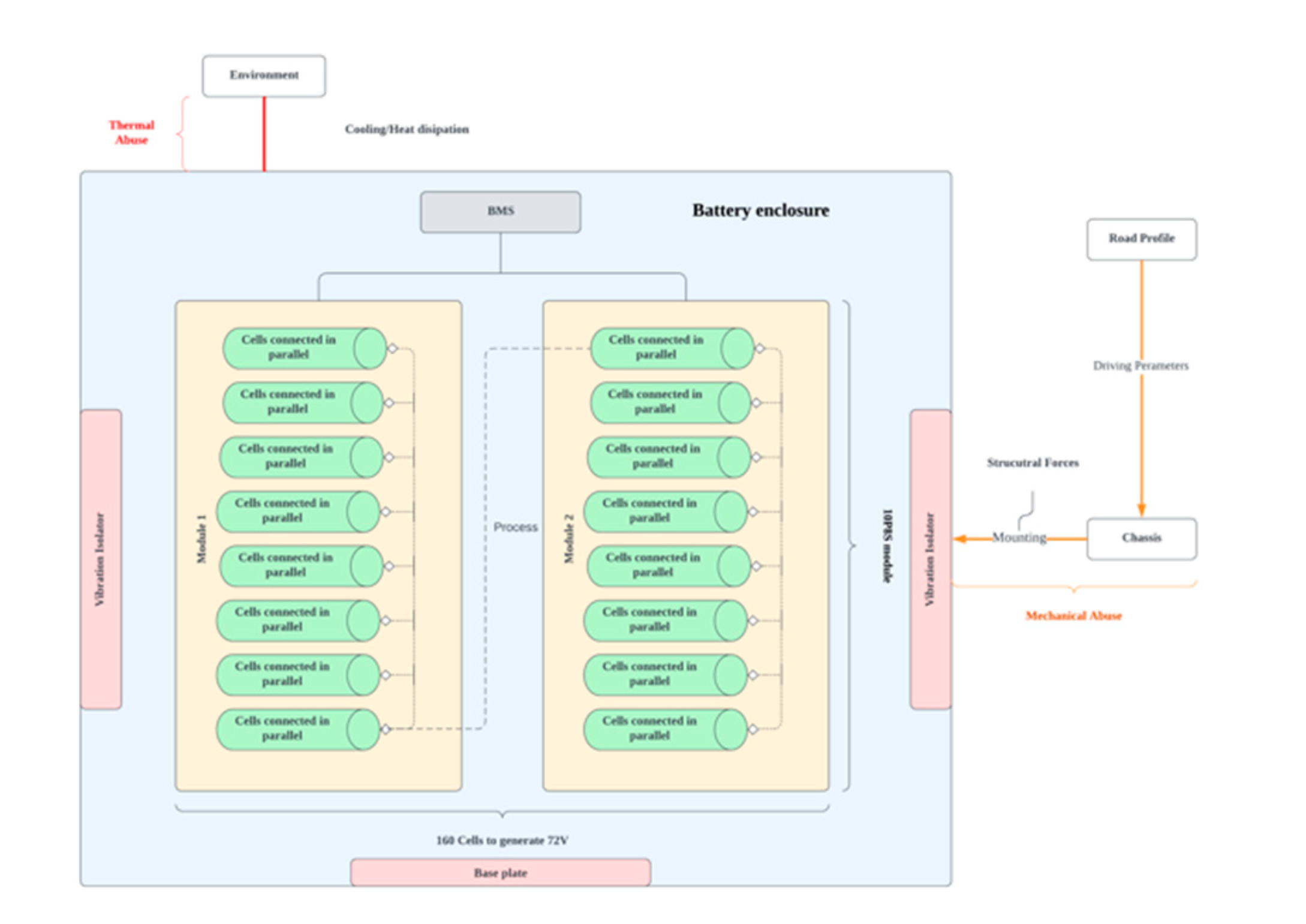

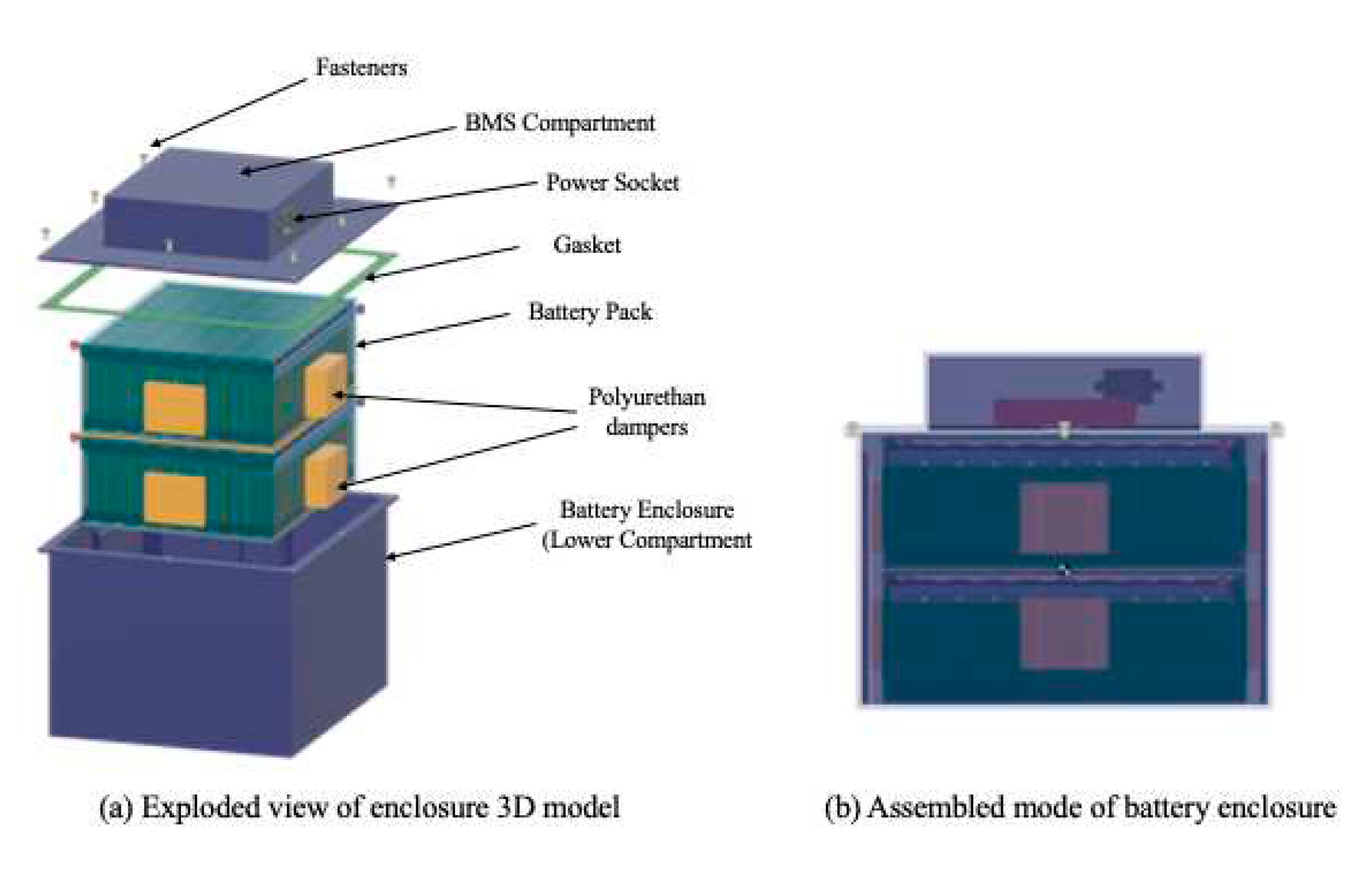

- Boundary diagram: It is a visual representation that defines the interface between different components within the battery enclosure. The interconnected elements are displayed in Figure 2. This boundary diagram helps to identify the inputs, outputs and interaction of the structural chassis and environment, ensuring the potential failure modes.

- Interface matrix: This is also known as the input-output matrix, providing clear highlights through the boundary diagram. It systematically maps the failure at their interfaces and evaluates to assess how failures in one part of the system propagate to another. Table 1 presents different interaction matrices of the battery pack concerning the battery enclosure.

2. Literature Review

3. Methodology

3.1. Forces on the Enclosure

3.1.1. Isolation of Forces on the Enclosure

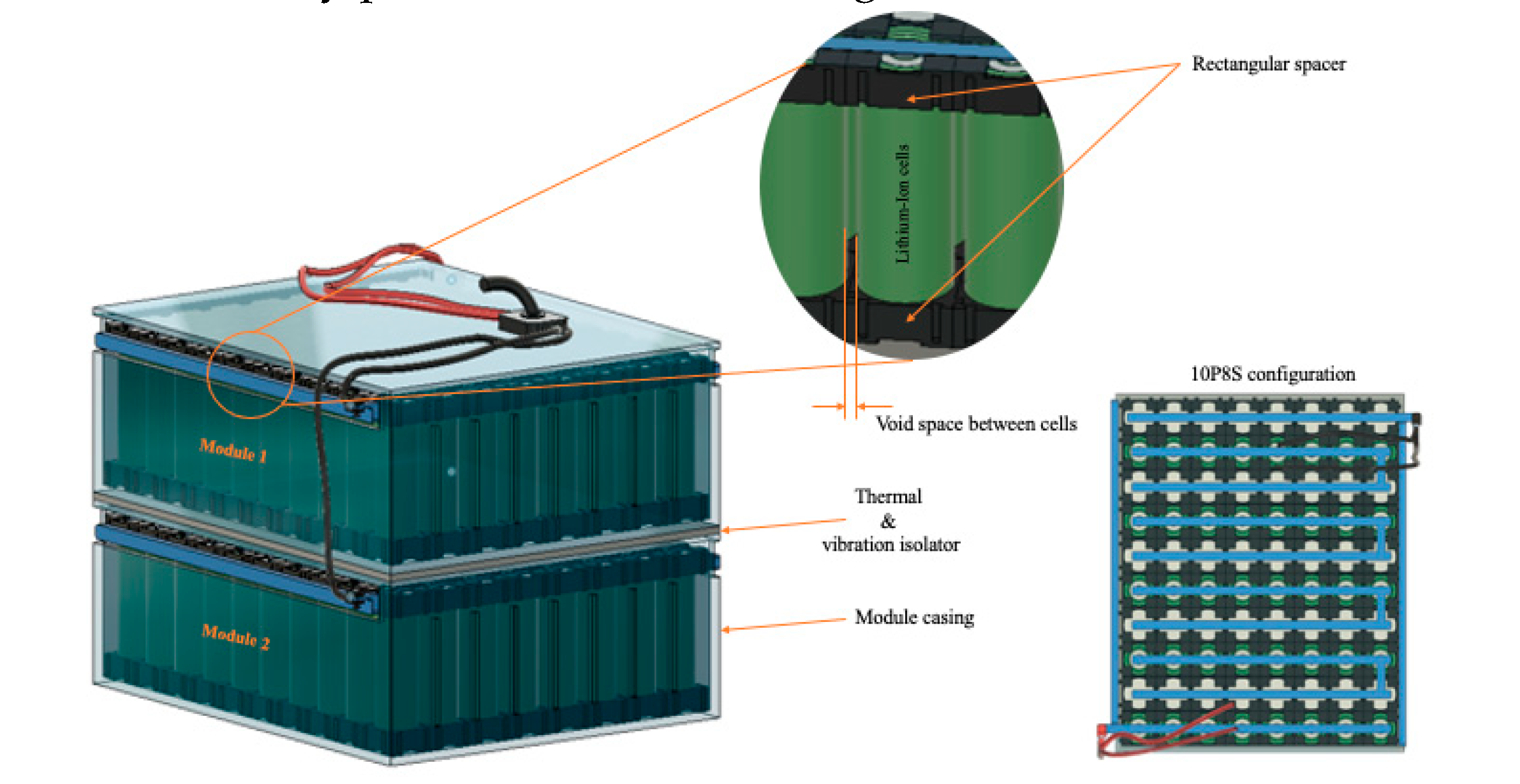

- Self-weight of the pack fixed within the vehicle frame, forming the rigid support. For example, in this work, we considered two 8P10S configurations having 160 cells based on the single cell configuration of 18650 each cell is 0.045kg, which comes to 7.2 Kg uniform weight acting on the base plate of the enclosure.

- Bump forces generated from the improper road profile to the contact point of the tire. The generated forces are damped by mono-shock suspension at the rear and a telescopic suspension system at the front. A partial number of vibrations are transferred from the suspension to the chassis in turn to the battery enclosure.

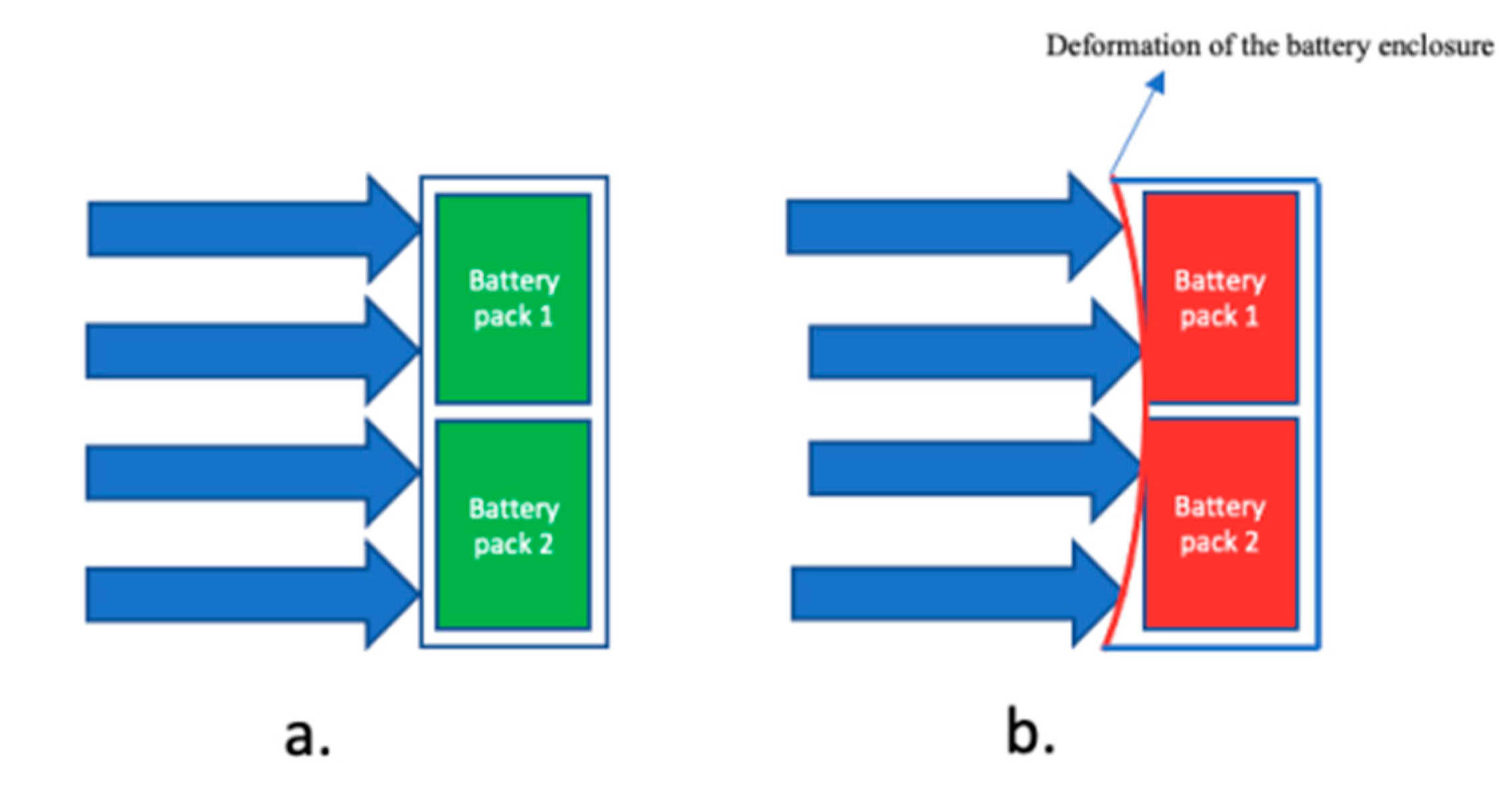

- Forces while taking turns exert centrifugal lateral forces on the side walls of the pack which is due to the centrifugal movement of the ETW. This inertial load pushes the right portion of the pack to the left and vice versa.

- Deceleration and acceleration force due to sudden braking or acceleration generates longitudinal weight transfer, pushing the components in the battery in the forward or backwards direction, forcing the battery pack towards the restraining bars. Ploy carbon materials (HL6157) [35] sheets for restraining bars in this work have good fracture toughness and can absorb deformation load. These restraining bars hold the modules secure during downward forces.

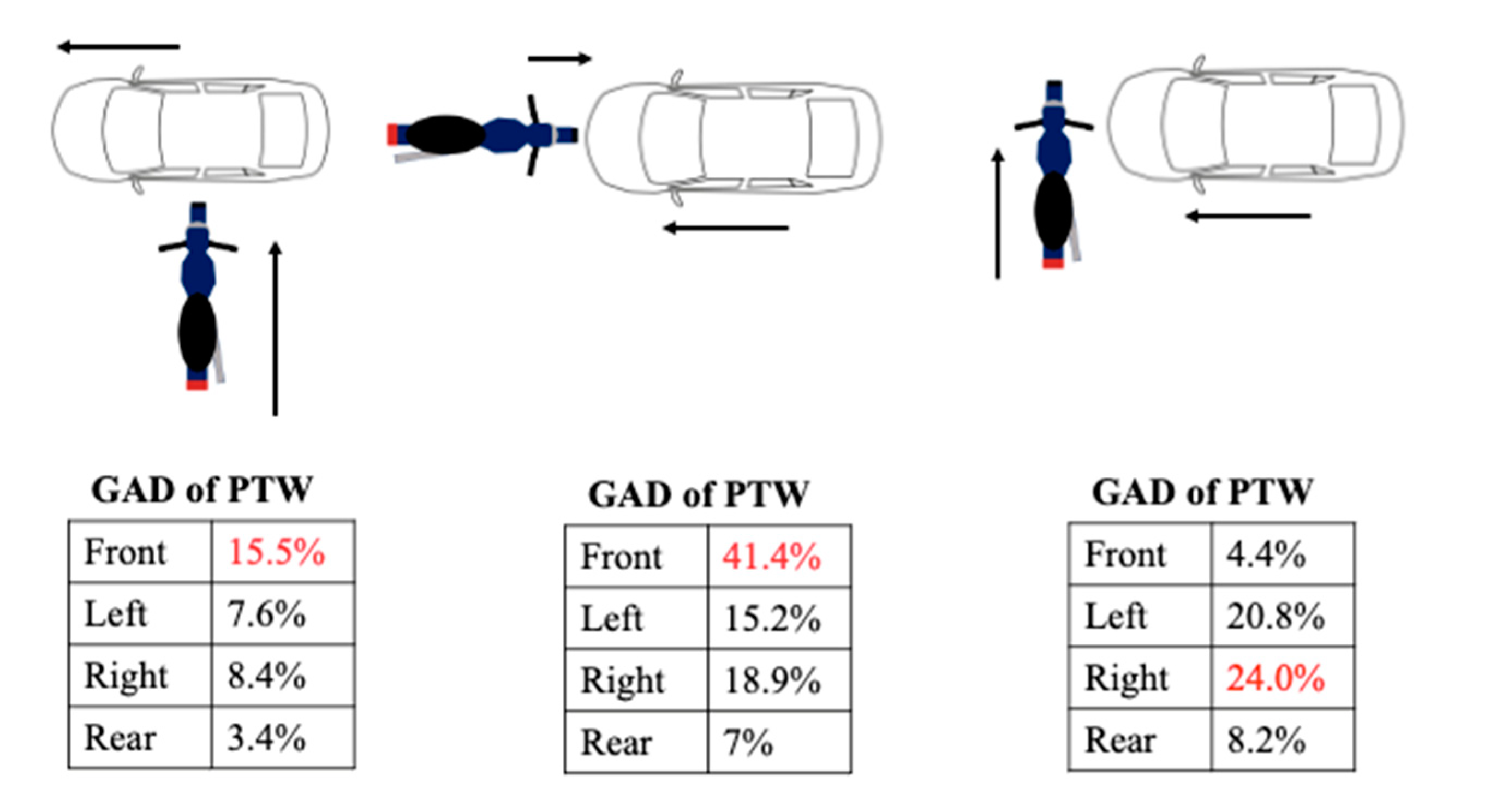

- Impulse force or crushing force developed due to a sudden crash exerts an enormous number of forces transferring to the module of the pack and to the individual cells which can result in premature failure. The exerted load on the pack is unpredictable and can lose mechanical stability, resulting in thermal runaway [36,37].

3.2. Mechanical Failure Mitigation

4. Design Overview

4.1. Packing and Volumetirc Efficiency

5. Material Selection

6. Static Analysis

7. Dynamic, Thermal and Modal analysis

7.1. Dynamic boundary conditions

7.2. Thermal boundary conditions

8. Results and Discussions

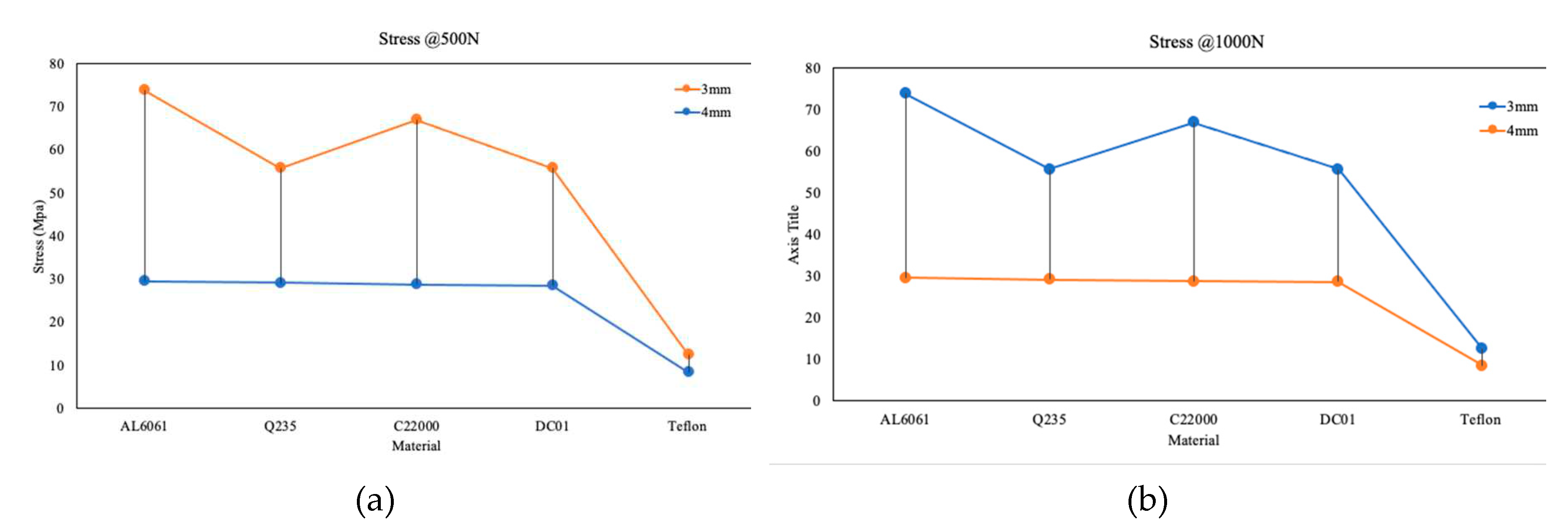

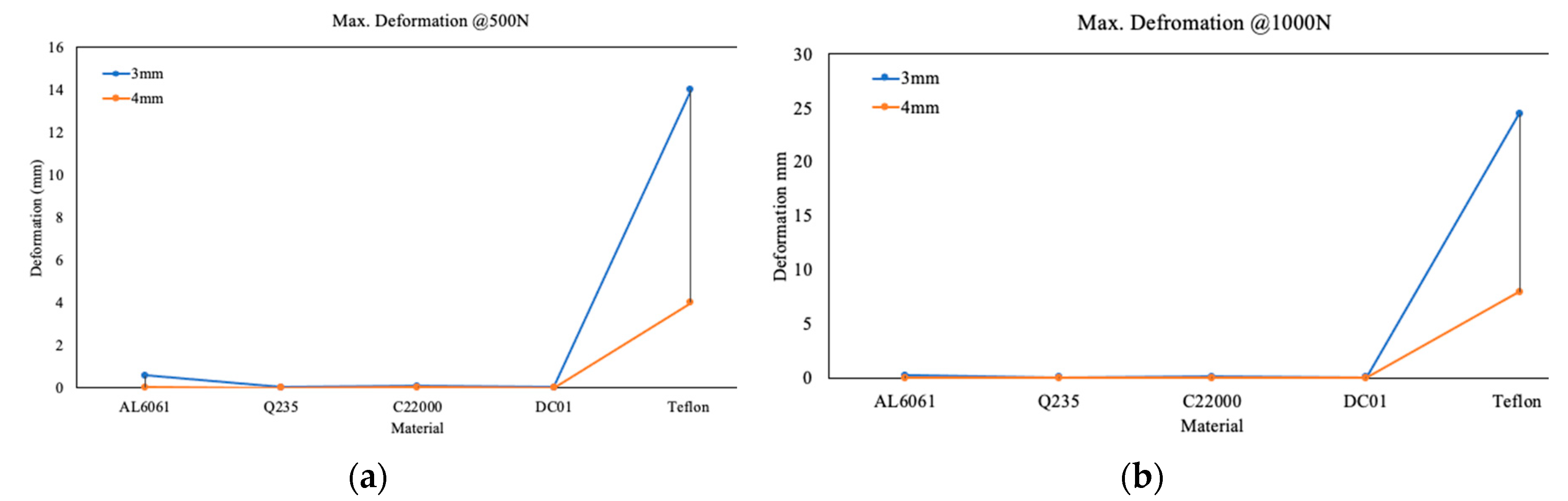

8.1. Structural analysis

8.2. Modal Analysis

8.3. Thermal Analysis

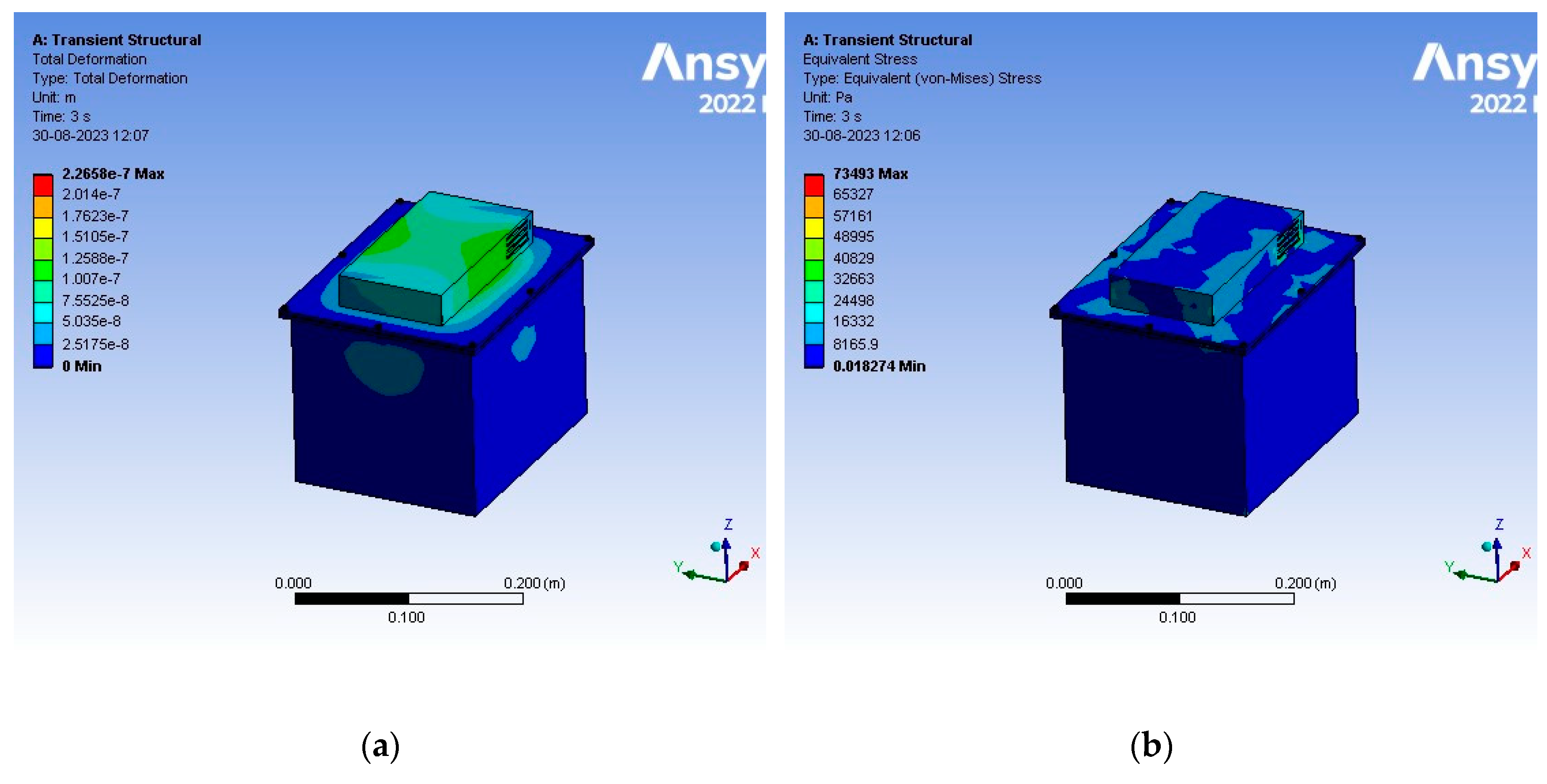

8.4. Transient Analysis

9. Conclusion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Q. Dai, J. C. Kelly, L. Gaines, and M. Wang, “Life cycle analysis of lithium-ion batteries for automotive applications,” Batteries, vol. 5, no. 2, 2019. [CrossRef]

- V. Ruiz, A. Pfrang, A. Kriston, N. Omar, P. Van den Bossche, and L. Boon-Brett, “A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles,” Renewable and Sustainable Energy Reviews, vol. 81. 2018. [CrossRef]

- M. V. Faria, P. C. Baptista, and T. L. Farias, “Electric vehicle parking in European and American context: Economic, energy and environmental analysis,” Transp Res Part A Policy Pract, vol. 64, 2014. [CrossRef]

- S. Z. Rajper and J. Albrecht, “Prospects of electric vehicles in the developing countries: A literature review,” Sustainability (Switzerland), vol. 12, no. 5, 2020. [CrossRef]

- R. T. Doucette and M. D. McCulloch, “Modeling the CO2 emissions from battery electric vehicles given the power generation mixes of different countries,” Energy Policy, vol. 39, no. 2, 2011. [CrossRef]

- M. Weiss, P. Dekker, A. Moro, H. Scholz, and M. K. Patel, “On the electrification of road transportation - A review of the environmental, economic, and social performance of electric two-wheelers,” Transp Res D Transp Environ, vol. 41, 2015. [CrossRef]

- Velázquez-Martínez, J. Valio, A. Santasalo-Aarnio, M. Reuter, and R. Serna-Guerrero, “A critical review of lithium-ion battery recycling processes from a circular economy perspective,” Batteries, vol. 5, no. 4. 2019. [CrossRef]

- J. P. Aditya and M. Ferdowsi, “Comparison of NiMH and Li-ion batteries in automotive applications,” in 2008 IEEE Vehicle Power and Propulsion Conference, VPPC 2008, 2008. [CrossRef]

- A. Brogi et al., “Survey High-Performance Modelling and Simulation for Selected Results of the COST Action IC1406 cHiPSet,” Future Generation Computer Systems, vol. 29, no. 1, 2018.

- H. Löbberding et al., “From cell to battery system in BEVs: Analysis of system packing efficiency and cell types,” World Electric Vehicle Journal, vol. 11, no. 4, 2020. [CrossRef]

- Kaliaperumal, M., Dharanendrakumar, M. S., Prasanna, S., Abhishek, K. V., Chidambaram, R. K., Adams, S.,... & Reddy, M. V. (2021). Cause and mitigation of lithium-ion battery failure—A review. Materials, 14(19), 5676.C. Carlson, G. Sarakakis, D. J. Groebel, and A. Mettas, “Best practices for effective reliability program plans,” in Proceedings - Annual Reliability and Maintainability Symposium, 2010. [CrossRef]

- S. Ganesan, V. Eveloy, D. Das, and M. Pecht, “Identification and utilization of failure mechanisms to enhance FMEA and FMECA,” in Proceedings of the IEEE workshop on accelerated stress testing & reliability (ASTR), Austin, Texas, 2005.

- M. Held and R. Brönnimann, “Safe cell, safe battery? Battery fire investigation using FMEA, FTA and practical experiments,” Microelectronics Reliability, vol. 64, 2016. [CrossRef]

- L. Wang, X. K. Chen, and Q. H. Zhao, “Muti-objective topology optimization of an electric vehicle’s traction battery enclosure,” in Energy Procedia, 2016. [CrossRef]

- N. Yang, R. Fang, H. Li, and H. Xie, “Dynamic and static analysis of the battery box structure of an electric vehicle,” in IOP Conference Series: Materials Science and Engineering, 2019. [CrossRef]

- G. Wang, S. Zhang, M. Li, J. Wu, B. Wang, and H. Song, “Deformation and failure properties of high-ni lithium-ion battery under axial loads,” Materials, vol. 14, no. 24, 2021. [CrossRef]

- S. Arora, W. Shen, and A. Kapoor, “Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles,” Renewable and Sustainable Energy Reviews, vol. 60. 2016. [CrossRef]

- S. Arora, A. Kapoor, and W. Shen, “Application of robust design methodology to battery packs for electric vehicles: Identification of critical technical requirements for modular architecture,” Batteries, vol. 4, no. 3, 2018. [CrossRef]

- P. Maguire, H. Baek, S. Liptak, O. Lomax, R. Palma, and Y. Zhang, “Thermoplastic Enclosure for a High Voltage Battery System,” in SAE Technical Papers, 2017. [CrossRef]

- S. K. Pal, S. Singh, H. Singh, M. L. Le Phung, S. Yooyen, and S. Sleesongsom, “Intelligent design optimization of battery pack enclosure for electric vehicle by considering cold-spraying as an additive manufacturing technology,” Energy Storage, vol. 2, no. 3, 2020. [CrossRef]

- C. H. Choi, J. M. Cho, Y. Kil, and Y. Yoon, “Development of polymer composite battery pack case for an electric vehicle,” in SAE Technical Papers, 2013. [CrossRef]

- N. Bao and R. Zhao, “Design optimization of battery holder for electric vehicle,” in 2018 6th International Conference on Mechanical, Automotive and Materials Engineering, CMAME 2018, 2018. [CrossRef]

- Q.-S. Chen, H. Zhao, L.-X. Kong, and K.-W. Chen, “Research on Battery Box Lightweight Based on Material Replacement,” 2017. [CrossRef]

- H. Merrow, “Design and analysis of a battery pack enclosure for Formula SAE,” Massachusetts institute of Technology, Massachusetts, 2017.

- Y. Zhang et al., “Multi-objective optimization of lithium-ion battery pack casing for electric vehicles: Key role of materials design and their influence,” Int J Energy Res, vol. 44, no. 12, 2020. [CrossRef]

- G. Naresh, T. Praveen Kumar, B. Aadhithyan, S. Utkarsh, and J. V. Nithin, “Transient thermal analysis of passive air-cooled battery-pack for various casing material,” in IOP Conference Series: Materials Science and Engineering, 2020. [CrossRef]

- L. Shui, F. Chen, A. Garg, X. Peng, N. Bao, and J. Zhang, “Design optimization of battery pack enclosure for electric vehicle,” Structural and Multidisciplinary Optimization, vol. 58, no. 1, 2018. [CrossRef]

- M. Hartmann, M. Roschitz, and Z. Khalil, “Enhanced battery pack for electric vehicle: Noise reduction and increased stiffness,” in Materials Science Forum, 2013. [CrossRef]

- F. Zhu, X. Du, J. Lei, L. Audisio, and D. Sypeck, “Experimental study on the crushing behaviour of lithium-ion battery modules,” International Journal of Crashworthiness, vol. 26, no. 6, 2021. [CrossRef]

- R. Shankavaram, J. R. Neelam, P. Schiffbaenker, G. Rekhi, N. Flagmeier, and K. Siyal, “Modular and Swappable 48V Battery Systems for Emerging Markets,” in SAE Technical Papers, 2019. [CrossRef]

- Kulkarni, A. Kapoor, and S. Arora, “Battery Packaging and System Design for an Electric Vehicle,” in SAE Technical Papers, 2015. [CrossRef]

- T. Kondaiah and D.Pavan Kumar, “Shape And Material Optimization Of A Two Wheeler Front Suspension Frame For Pipe Type And Rectangular Cross Sections,” International Journal of Emerging Trends in Engineering Research, vol. 4, no. 6, 2016.

- S. Rege, C. Khatri, M. Nandedkar, and N. Wagh, “Design and analysis of frame for electric motorcycle,” Int J Innov Res Sci Eng Technol, vol. 6, no. 10, 2017.

- S. Zhang, B. Wang, X. Meng, and Y. Chen, “Mechanical Properties and Fracture Microstructure of Polycarbonate under High Strain Rate Tension,” Materials, vol. 16, no. 9, 2023. [CrossRef]

- R. Uerlich, K. Ambikakumari Sanalkumar, T. Bokelmann, and T. Vietor, “Finite element analysis considering packaging efficiency of innovative battery pack designs,” International Journal of Crashworthiness, vol. 25, no. 6, 2020. [CrossRef]

- S. Arora and A. Kapoor, “Mechanical Design and Packaging of Battery Packs for Electric Vehicles,” in Green Energy and Technology, 2018. [CrossRef]

- J. M. Hu, D. Barker, A. Dasgupta, and A. Arora, “Role of failure-mechanism identification in accelerated testing,” Journal of the IES, vol. 36, no. 4, 1993. [CrossRef]

- P. Puthan, N. Lubbe, J. Shaikh, B. Sui, and J. Davidsson, “Defining crash configurations for Powered Two-Wheelers: Comparing ISO 13232 to recent in-depth crash data from Germany, India and China,” Accid Anal Prev, vol. 151, 2021. [CrossRef]

- H. A. Gabbar, A. M. Othman, and M. R. Abdussami, “Review of Battery Management Systems (BMS) Development and Industrial Standards,” Technologies, vol. 9, no. 2. 2021. [CrossRef]

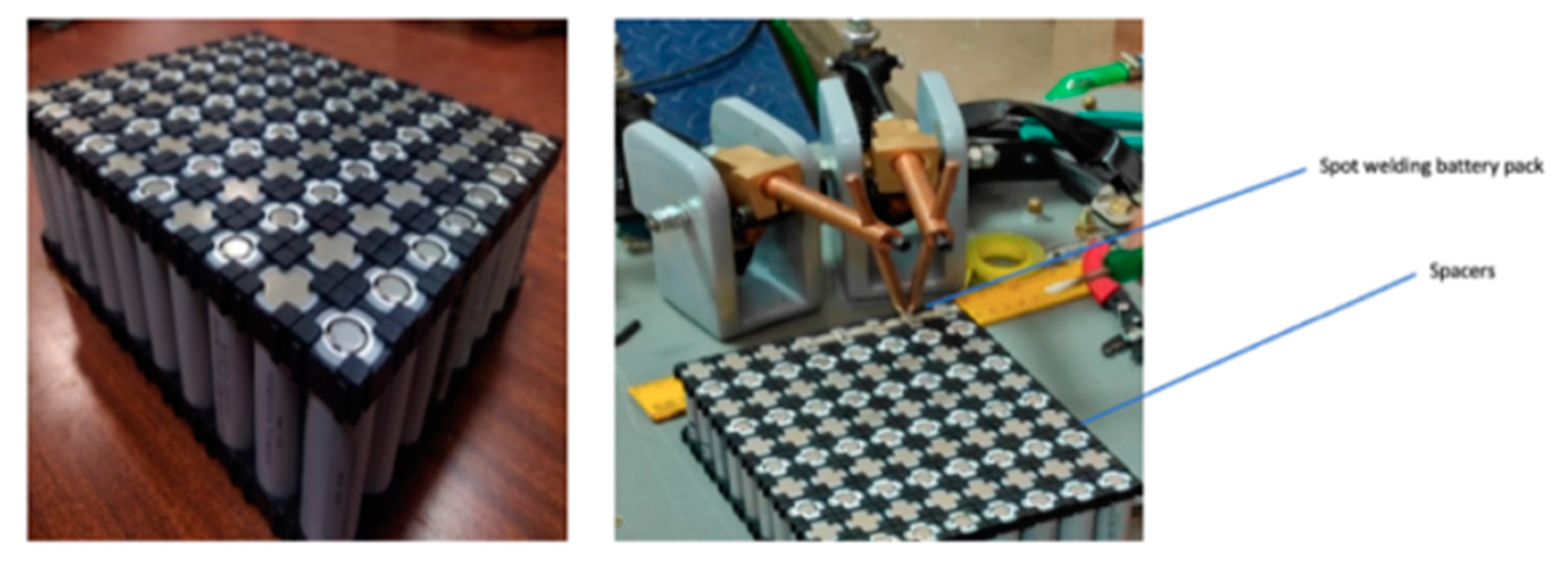

- S. Liu, X. Liu, R. Dou, W. Zhou, Z. Wen, and L. Liu, “Experimental and simulation study on thermal characteristics of 18,650 lithium–iron–phosphate battery with and without spot–welding tabs,” Appl Therm Eng, vol. 166, 2020. [CrossRef]

- X. Wu, “Crashworthiness analysis and optimization of fourier varying section tubes,” Int J Non Linear Mech, vol. 92, 2017. [CrossRef]

- E. Maiser, “Battery packaging - Technology review,” in AIP Conference Proceedings, 2014. [CrossRef]

- T. M. Bandhauer, S. Garimella, and T. F. Fuller, “A Critical Review of Thermal Issues in Lithium-Ion Batteries,” J Electrochem Soc, vol. 158, no. 3, 2011. [CrossRef]

| Description | Interface Type |

Function | Measure | Failure type | Severity index |

|---|---|---|---|---|---|

| UC-Gasket | Touch | Seal to prevent moisture | Crush | Ingress of moisture or contaminants | M |

| UC-LC | Touch | Allow the assembly to lock with 6mm bolts and prevent loss of contact | Holding tight | Mechanical instability and separation of casing | H |

| LC-Vibration Isolators | Touch | Isolates the stress and deformation from the external force | Crush | Degradation of Isolators over time | L |

| Module-Thermal Isolators | Touch | Isolates the thermal and electrical conductivity | Crush | Uneven thermal dissipation from one module to another | H |

| Chassis-Battery casing | Touch | Distribution of mechanical loads and forces while vehicle operation | Structural integrity | Potential damage to the battery due vibrations and forces | H |

| Battery Casing-Environment | Heat convection | Transfer of ambient temperature to the battery module | Heat energy | Corrosion, Heat dissipation failure | H |

| Standard | Description |

|---|---|

| SAEJ240 | Life test for automotive storage batteries |

| SAEJ1766 | Practice for EV hybrid vehicle battery systems crash integrity testing |

| SAEJ1797 | Packaging of Electric Vehicle Battery Modules |

| SAEJ1798 | Recommended Practice for Performance Rating of Electric Vehicle Battery Modules |

| SAEJ2185 | Life test for heavy-duty Storage batteries |

| SAEJ2289 | Electric-Drive Battery Pack System: Functional Guidelines |

| SAEJ2344 | Technical Guidelines for Electric Vehicle Safety |

| SAEJ2380 | Vibration Testing of Electric Vehicle Batteries |

| SAEJ2464 | Electric Vehicle Battery Abuse Testing |

| SAE2929 | Electric and Hybrid Vehicle Propulsion Battery System Safety Standard |

| Description | Specifications |

|---|---|

| Motor | BLDC, 3 kW, 27 Nm |

| Estimated Range | 120-140 km |

| Cell configuration | 8P10S |

| Maximum Speed | 100 kmph |

| Battery type | Lithium-ion cylindrical cell (18650), 3.7 V |

| Pack power, capacity | 72 V, 1.4 kWh, 19.2 Ah |

| Description | Value |

|---|---|

| Number of cells per module (18650) | 80 |

| The volume of single battery cell | 16 cm3 |

| Weight of the battery pack (2 modules) | 7.2 kg |

| The volume of 80 cells in the pack | 1280 cm3 |

| The measured volume of a single module | 2240 cm3 |

| Volumetric Efficiency (For single module) |

63% |

| Volumetric Efficiency of the battery pack (Two modules) |

66% |

| Space Occupancy rate | 34% |

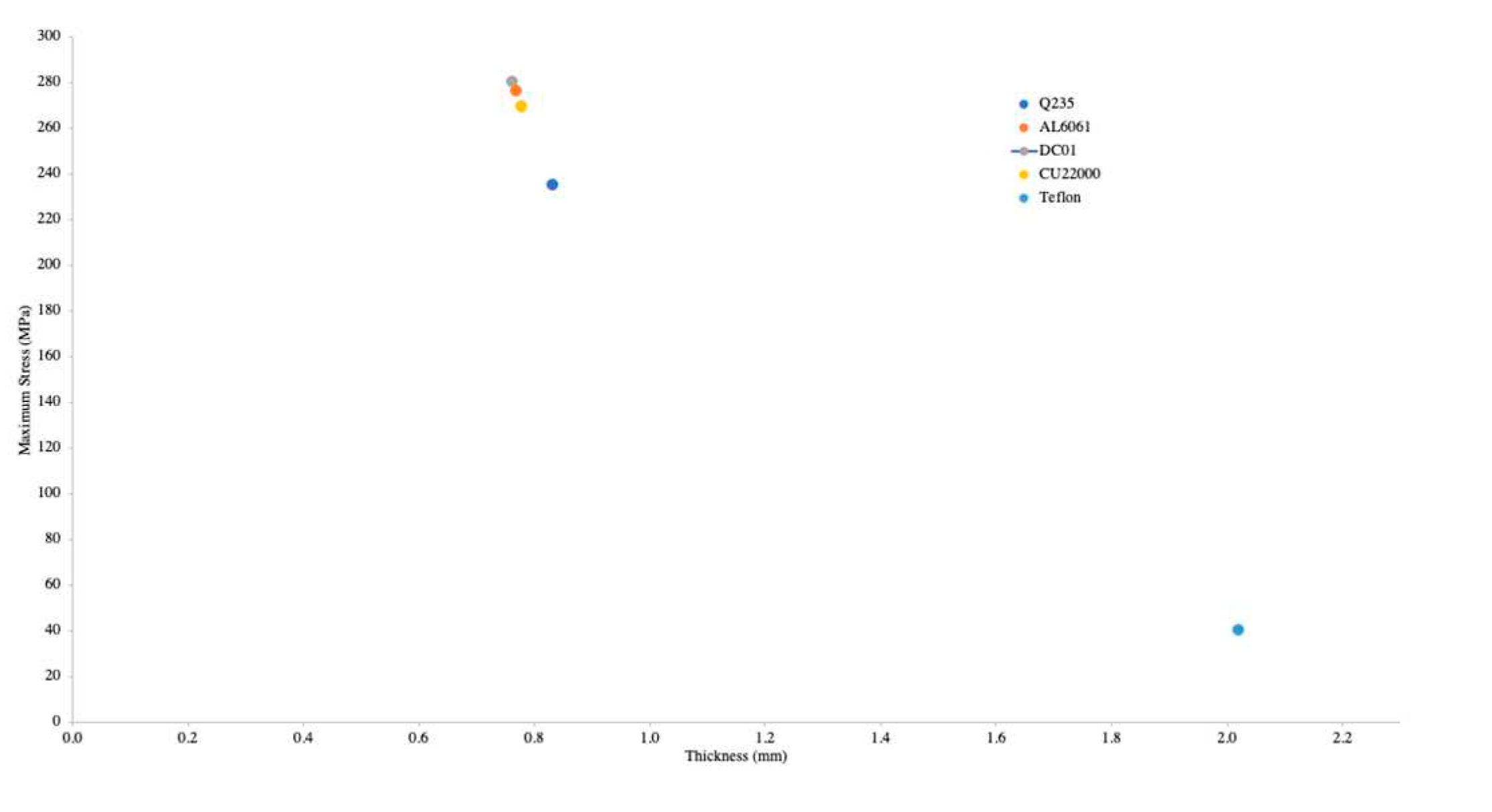

| Component | Material | δ |

ρ kg/m3 |

MPa |

MPa |

|---|---|---|---|---|---|

| Enclosure | Q235 | 7850 | 0.28 | 326.3 | 422 |

| Al 6061 | 2713 | 0.33 | 126.3 | 222.4 | |

| DC 01 | 7850 | 0.3 | 171.5 | 307.4 | |

| C22000 | 8800 | 0.31 | 76.49 | 275.5 | |

| Teflon | 2170 | 0.35 | 20.68 | 26.72 | |

| Mechanical or Thermal Isolators |

Polyurethane |

31.94 | 0.39 | 0.0041 | 0.144 |

| |

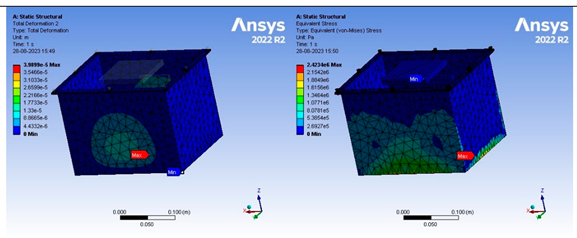

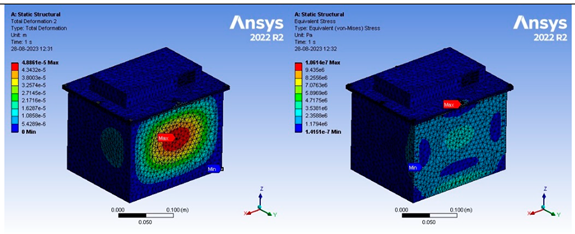

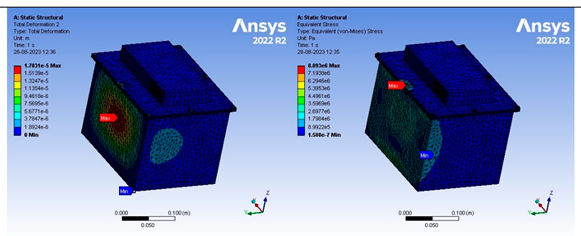

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3 mm thickness using AL6061 | |

| Maximum equivalent stress | 2.423 MPa |

| Maximum deformation | 0.0398 mm |

| |

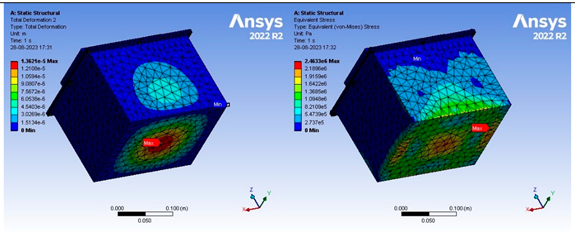

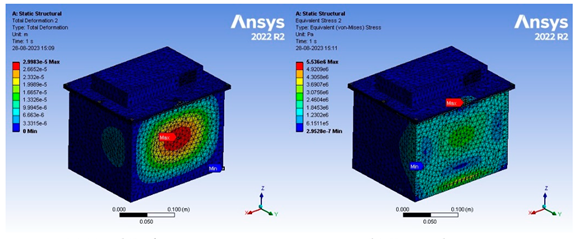

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3 mm thickness using Q235 | |

| Maximum equivalent stress | 2.46 Mpa |

| Maximum deformation | 0.0136 mm |

| |

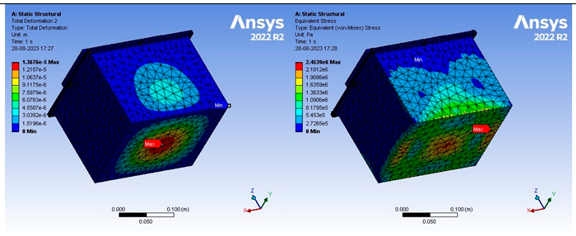

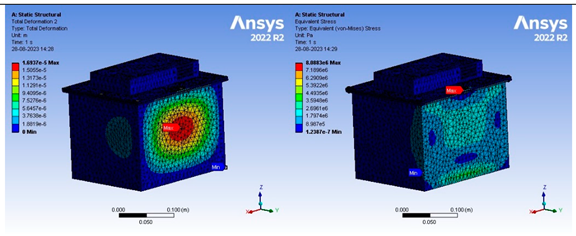

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3 mm thickness using DC01 | |

| Maximum equivalent stress | 2.46 Mpa |

| Maximum deformation | 0.0136 mm |

| |

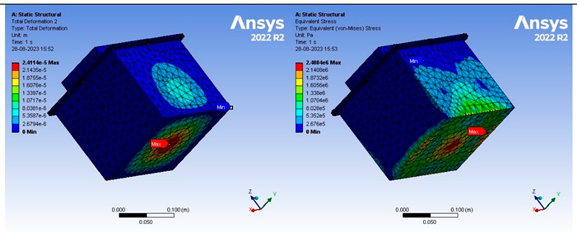

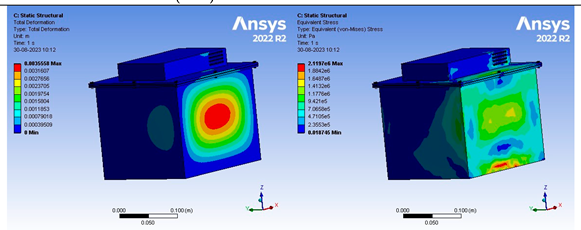

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3 mm thickness using C22000 | |

| Maximum equivalent stress | 2.408 Mpa |

| Maximum deformation | 0.02411 mm |

| |

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3 mm thickness using AL6061 | |

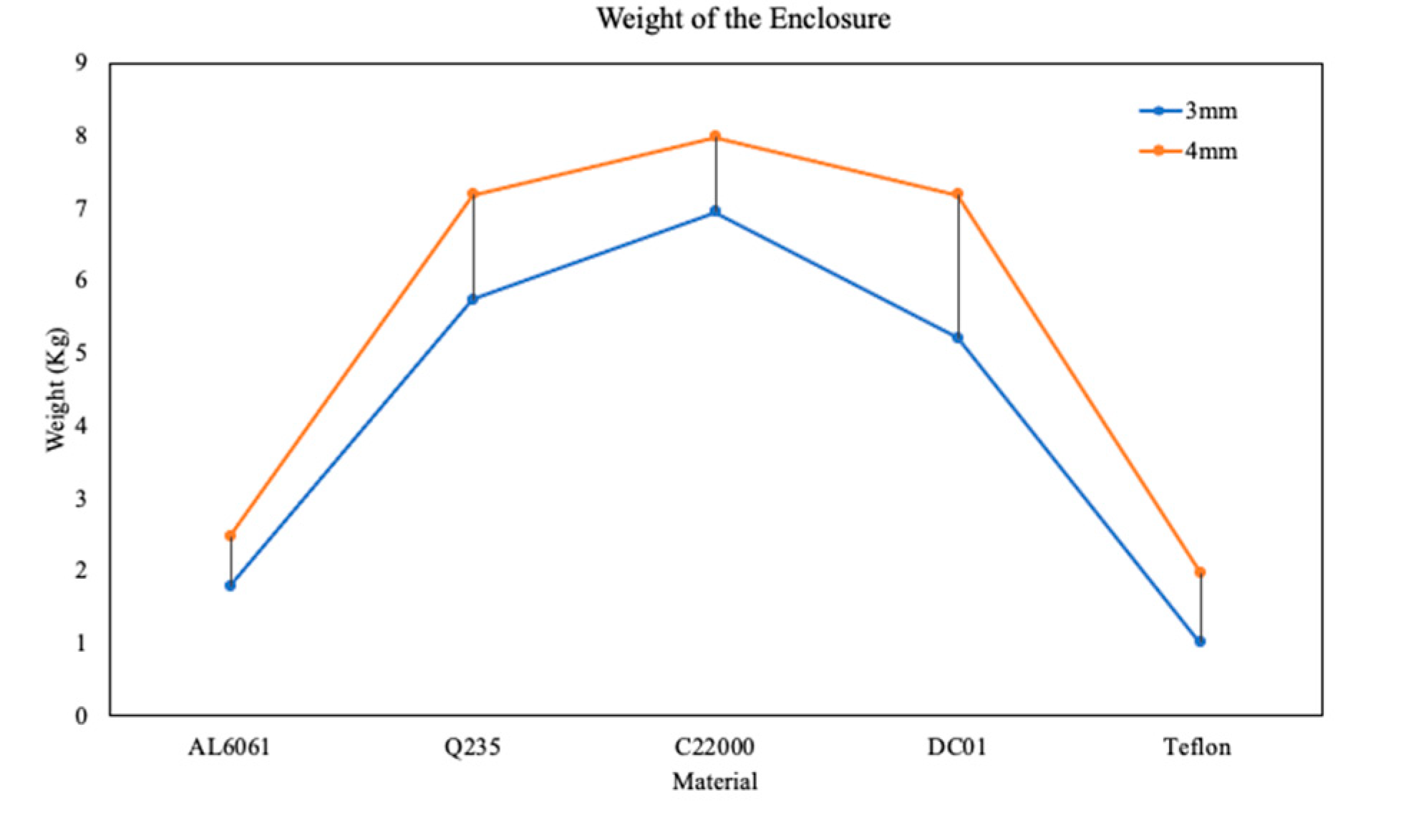

| Weight of the battery enclosure | 1.79 kg |

| Maximum equivalent strain (m/m) | 8.389⋅10-5 |

| Maximum equivalent stress | 10.61 Mpa |

| Maximum deformation | 0.048 mm |

| |

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3 mm thickness using C22000 | |

| Weight of the battery pack | 6.45 kg |

| Maximum equivalent strain | 5.0517⋅10-5 |

| Maximum equivalent stress | 5.53 Mpa |

| Maximum deformation | 0.029 mm |

| |

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3mm thickness using Q235 | |

| Weight of the battery pack (kg) | 4.027(L)+1.715(U) |

| Maximum equivalent strain | 2.6621⋅10-5 m/m |

| Maximum equivalent stress (Mpa) | 8.088 |

| Maximum deformation (mm) | 0.23 |

| |

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3 mm thickness using Teflon | |

| Weight of the battery pack (kg) | 0.685 L+0.325 U |

| Maximum equivalent strain | 0.0051 |

| Maximum equivalent stress (Mpa) | 2.11 |

| Maximum deformation (mm) | 3.5 |

| |

| (a) Total Deformation (b) Equivalent stress Static analysis of enclosure with 3mm thickness using DC01 | |

| Weight of the battery pack (kg) | 3.84L+1.37U |

| Maximum equivalent strain | 2.68e-5 |

| Maximum equivalent stress (Mpa) | 8.093 |

| Maximum deformation (mm) | 0.017 |

| Material | Description | Details |

|---|---|---|

| AL6061 | Mode 1 | 589.25 Hz |

| Mode 2 | 598.25 Hz | |

| Mode 3 | 591.34 Hz | |

| Ratio of Effective to Total mass | 0.234 x-direction |

|

| Q235 | Mode 1 | 829.38 Hz |

| Mode 2 | 837.97 Hz | |

| Mode 3 | 942.8 Hz | |

| Ratio of Effective to Total mass | 0.2331 x-direction |

|

| C22000 | Mode 1 | 589.66 Hz |

| Mode 2 | 596.28 Hz | |

| Mode 3 | 670.57 Hz | |

| Ratio of Effective to Total mass | 0.2382 x-direction |

|

| DC01 | Mode 1 | 829.01 Hz |

| Mode 2 | 837.63 Hz | |

| Mode 3 | 942.47 Hz | |

| Ratio of Effective to Total mass | 0.2332 x-direction |

| |

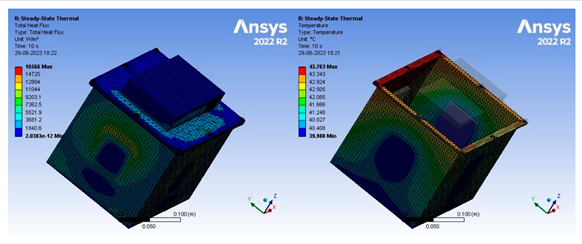

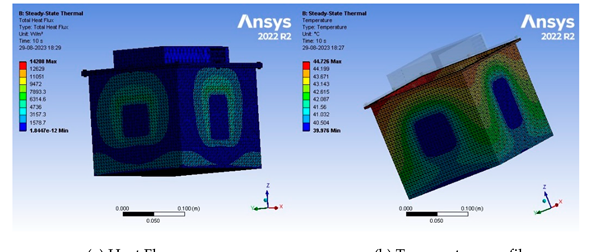

| (a) Heat Flux (b) Temperature profile Steady state thermal analysis of AL6061 material casing | |

| Heat Flux | 16566 W/m2 |

| Maximum Temperature | 43.763°C |

| |

| (a) Heat Flux (b) Temperature profile Steady state thermal analysis of Q235 material casing | |

| Heat Flux (W/m2) | 11324 W/m2 |

| Maximum Temperature | 44.78°C |

| |

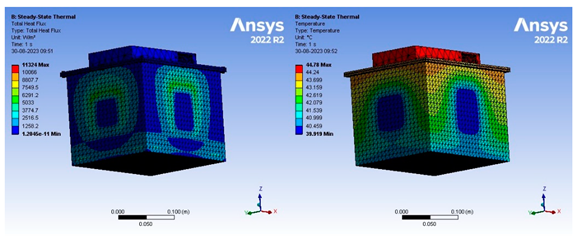

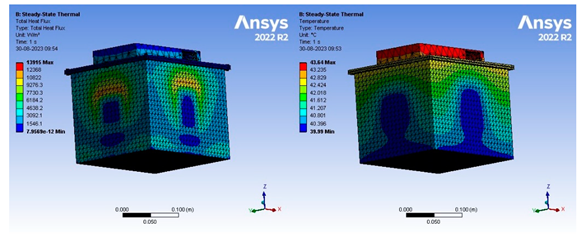

| (a) Heat Flux (b) Temperature profile Steady state thermal analysis of C22000 material casing | |

| Heat Flux | 13915 W/m2 |

| Maximum Temperature | 43.64°C |

| |

| (a) Heat Flux (b) Temperature profile Steady state thermal analysis of DC01 material casing | |

| Heat Flux | 14208 W/m2 |

| Maximum Temperature | 44.726°C |

| |

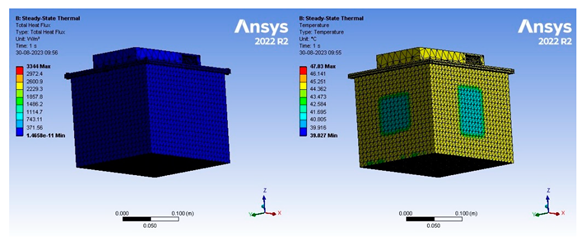

| (a) Heat Flux (b) Temperature profile Steady state thermal analysis of Teflon material casing | |

| Heat Flux | 3344 W/m2 |

| Maximum Temperature | 47.03°C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).