Submitted:

28 September 2023

Posted:

29 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Aerodynamic performance of wind turbines

3. Aerodynamic performance of wind turbines under hazard environmental conditions

3.1. Icing

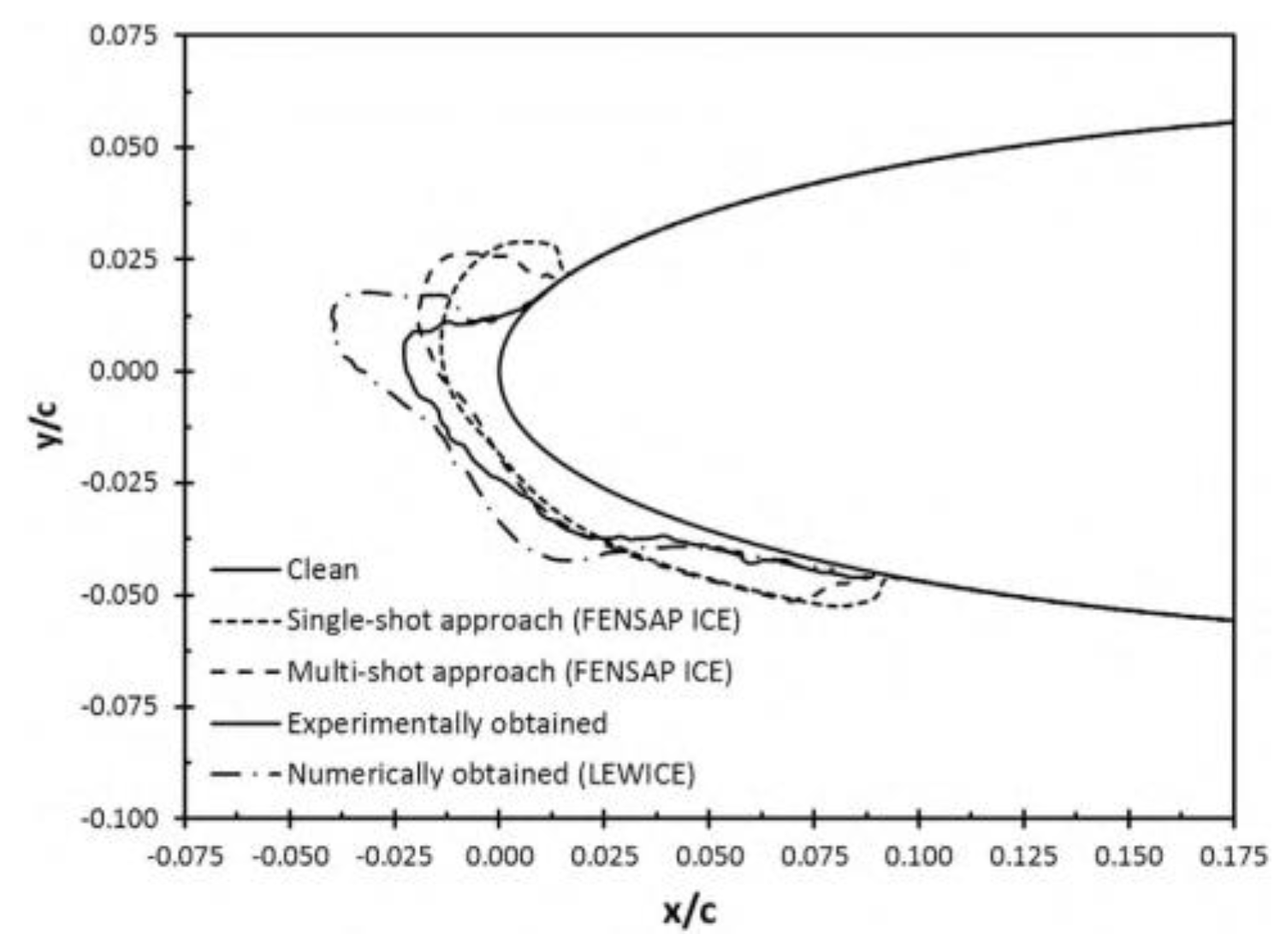

- LEWICE is a 2-D ice accretion code created by NASA Glenn Research Center [31]. It utilizes a time-stepping procedure to forecast the shape of ice accretion. The flow field calculations are performed using the Douglas Hess-Smith 2-D panel code. The obtained solution is then used to determine particle trajectories and the points at which they impinge on the object. Additionally, LEWICE incorporates an icing model to estimate the rate and shape of ice growth.

- Turbine Blade Icing Model (TURBICE) is a two-dimensional simulation program specifically designed to anticipate ice accretion on HAWT blades [32,33]. It employs panel methods to calculate the potential flow field around the blade and utilizes a Lagrangian technique for droplet trajectories and impingement calculations. TURBICE can also estimate the amount of energy required for heating to prevent ice accretion on the blade surface.

- FENSAP ICE represents a premier 3-D in-flight icing simulation solver [34,35]. It simulates the flow field, droplet impingements, ice shapes, and predicts anti/de-icing heat loads. FENSAP ICE incorporates built-in computational fluid dynamics (CFD) modules to perform these calculations. The software employs 3D Navier-Stokes and energy equations for flow field calculations, along with a 3-D Eulerian model for droplet calculations.

| Author | Investigation Method | Airfoil Type | Main Conclusions |

|---|---|---|---|

| Seifert and Richert [53] | experimental | NACA 4415 | More ice on the leading edge led to worse aerodynamic performance. |

| AEP dropped by 6% to 19% for a 300 kW turbine. | |||

| Jasinski et al. [54] | experimental | S809 | The rotor with variable speed and pitch had about a 20% decrease in performance. |

| numerical | The stall-regulated rotor experienced higher performance losses even with a small amount of ice. | ||

| Hochart et al. [55] | experimental | NACA 63-415 | Reduced lift by 40% in both icing events |

| Increased drag by 365% for glaze and 250% for rime ice. | |||

| Zhao et al. [56] | theoretical | S830 | Icing creates an unbalanced mass, causing vibrations at the power frequency of HAWT. |

| experimental | Decreased power output and power frequency vibrations are signs of icing. | ||

| Homola et al. [57] | numerical | NACA 64-618 | Horn-shaped glazed ice had a more significant reduction of lift than streamlined rime ice. |

| Accurate measurement of atmospheric conditions during icing events is crucial to estimate energy production losses, considering ice shape and type. | |||

| Villalpando et al. [58] | numerical | NACA 63-415 | The ice on the airfoil increases the minimum pressure coefficient value, reducing the suction effect on the airfoil. |

| Turkia et al. [30] | numerical | NACA 64-618 | In the early stages of ice formation, power production decreased by about 17% below rated wind speed. |

| As more ice accumulated, the reduction increased to 18% for a short icing event and 24% for a prolonged one. | |||

| Hudecz et al. [59] | experimental | NACA 64-618 | Mixed ice had the biggest impact on reducing lift, while rime ice had the smallest. |

| numerical | Within the first hour of ice formation, there was a noticeable decrease in lift and a loss in power production. | ||

| Hu et al. [60] | numerical | S809 | Ice mass and thickness increase linearly from the blade root to the blade tip. |

| Both asymmetric and symmetric icing reduce rotor thrust force and blade root moments. | |||

| Asymmetric icing on the low-speed shaft can cause an extra shear force imbalance. | |||

| This asymmetric load can increase blade fatigue damage by up to 97.6% and tower damage by up to 70.8%. | |||

| Virk et al. [61] | numerical | NACA 63-215 | The decrease in torque is more significant for smaller turbines, supporting the hypothesis that dry rime icing affects them more than larger turbines. |

| NACA 63-417 | |||

| NACA 63-416 | |||

| Han et al. [62] | numerical | NACA 64-618 | The airfoil’s shape changed due to ice, causing a 37% decrease in lift and a 550% increase in drag. |

| Ice on the blade tip’s leading edge reduced HAWT performance by about 8-29%. | |||

| Ibrahim et al. [43] | numerical | S809 | Ice accumulation reduces lift coefficient by 10%-65%, depending on the ice shape. |

| Jin and Virk [63] | numerical | NACA 0012 | The airfoil’s shape and dimensions affect ice formation. |

| NACA 23012 | For the symmetric airfoil, streamlined ice formations were seen, while the asymmetric one had different structures. | ||

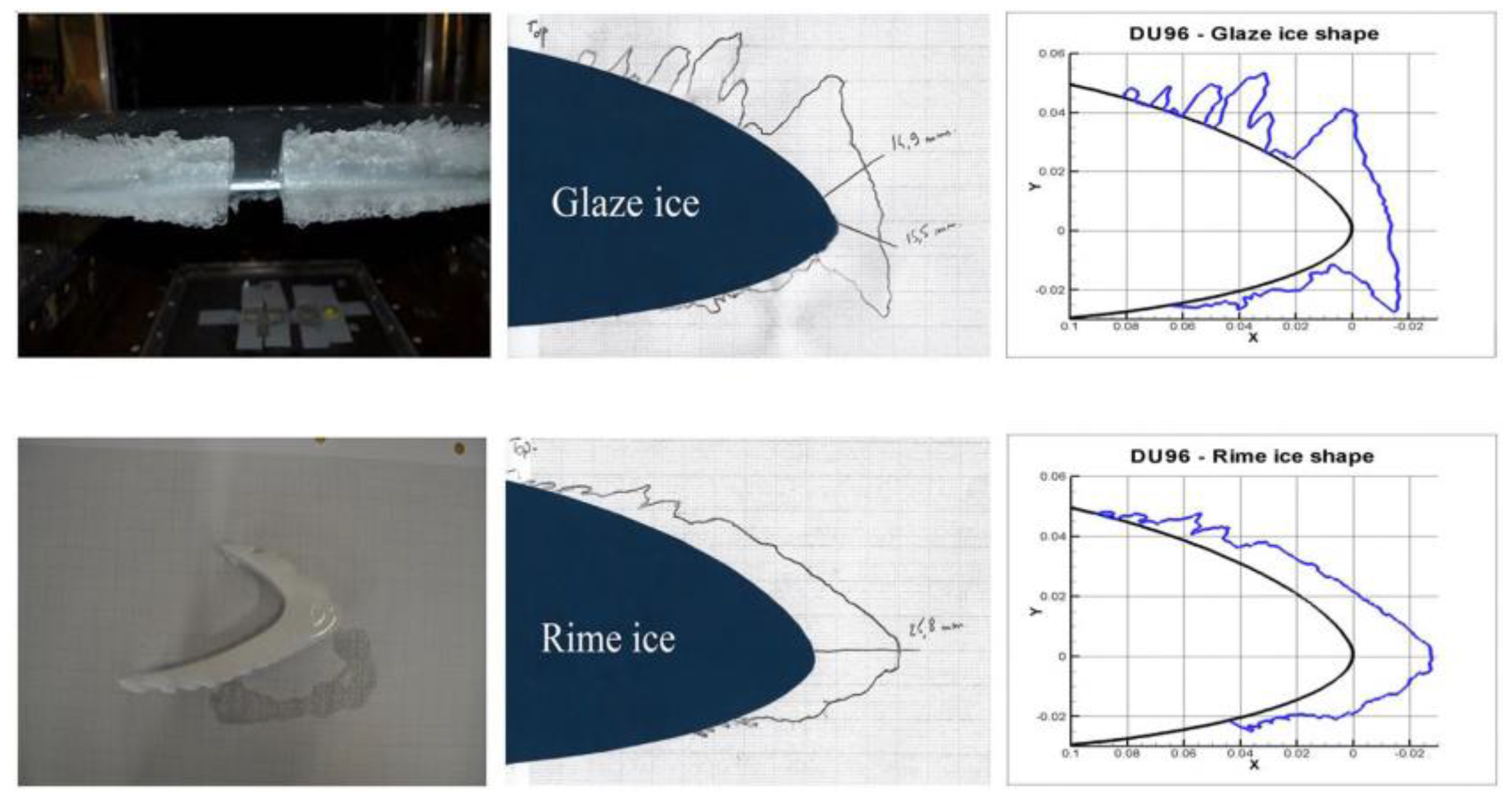

| Jin and Virk [64] | DU96-W-180 | Glaze ice led to more complex formations that affected aerodynamic performance more than rime ice. | |

| Jin and Virk [65] | S826 | Aerodynamic performance deteriorated more with glaze ice, especially at higher angles of attack. | |

| S832s | The S832 airfoil showed significant changes, especially with wet ice. | ||

| Yirtici et al. [66] | numerical | NACA 64-618 | Icing causes a power loss of 24%. |

| S809 | |||

| Yirtici et al. [67] | S809 | The estimated quantities of rime and glaze ice, and the maximum ice thickness, exhibit variances ranging from 3% to 25% when compared to experimental data. | |

| DU93-W210 | |||

| Yirtici et al. [68] | NACA 23012 | During exposure to icing conditions for an hour, there is a reduction in power of around 20%. | |

| NACA 0012 | |||

| DU93-W210 | |||

| Gao et al. [69] | experimental | DU91-W2-250 | Ice formed quickly on the blade, disrupting airflow and causing flow separations and vortex shedding., negatively affecting the blade’s aerodynamic performance. |

| The degree of degradation depended on the blade’s angle of attack, with greater deterioration at lower angles. | |||

| At a 5.0° angle of attack, lift force decreased to about 12% of the initial value after 10 minutes, while drag force increased by a factor of 4.5. | |||

| Jiang and Qiu [70] | numerical | NACA 0012 | Icing affects airflow around the airfoil, causing flow separation vortex. |

| Clear ice is more harmful than frost ice. | |||

| Icing can result in up to 4.8% power loss in HAWT. | |||

| Martini et al. [71] | numerical | NACA 64-618 | Iced airfoils experienced higher drag and lower lift. |

| The k- ω SST model was more effective for the iced airfoil, while the Spalart–Allmaras model had limitations at high angles of attack but worked well at low angles. | |||

| Surface roughness played a significant role in ice growth and should be considered when estimating the effects of icing on aerodynamic performance. | |||

| Chitransh and Kaur [72] | numerical | NACA 4412 | The presence of ice on the airfoil significantly affects power generation by modifying the shape of the airfoil. |

| Significant reduction in the lift coefficient and an increase in the drag coefficient. | |||

| Rotich and Kollár [73] | numerical | NACA 2412 | The lift-to-drag ratio reaches its peak shortly after ice accumulation begins for angles of attack up to 10°. |

| The ratio decreases significantly as the accretion time becomes longer. | |||

| Yang et al. [74] | numerical | NACA64_A17 | Ice concentrated more on NACA64_A17 airfoil’s tip. |

| DU21_A17 | Icing reduced lift coefficient by 34% and increased drag coefficient up to 200%. | ||

| DU25_A17 | HAWT power production decreased by 17% with icing. |

| Author | Investigation Method | HAWT | Main Conclusions |

|---|---|---|---|

| Virk et al. [75] | numerical | NREL 5 MW | Ice formation exhibited lower severity in the proximity of the blade root. |

| The growth of ice varied along the blade, with a greater presence of ice observed towards the tip. | |||

| Barber et al. [76] | experimental | ETH Zurich subscale model | Ice reduces power coefficient by up to 22% and AEP by up to 17% for severe icing. |

| numerical | Blade tip icing has the greatest impact, while high-altitude icing has less impact than lower-altitude icing on AEP. | ||

| Homola et al. [77] | numerical | NREL 5 MW | 27% decrease in power production for wind speeds 7m/s-11m/s |

| Modeling can help estimate icing effects and find ways to reduce them. | |||

| Homola et al. [78] | numerical | NREL 5 MW | Adjusting the turbine controller can improve power production with iced blades. |

| Dimitrova et al. [79] | numerical | Vestas V80 1.8 MW | Aerodynamic performance declines with light icing, causing up to 30% loss in lift coefficient and a maximum increase of 140% in drag coefficient. |

| This leads to a 3.4% power loss and <1% decrease in AEP. | |||

| Lamraoui et al. [80] | numerical | Vestas V80 1.8 MW | Both glaze and rime ice on the blade affect power. |

| Outer section from r/R=0.8 significantly affects aerodynamics. | |||

| Freezing fraction is non-uniform, with rime ice near the root and glaze ice towards the tip. | |||

| Major power reduction occurs around r/R ~ [0.93 0.96] with a maximum reduction of 40%. | |||

| Ice shape has a bigger local impact than thickness, but blade-wide, thickness matters most for power loss, regardless of ice type. | |||

| Etemaddar et al. [81] | numerical | NREL 5 MW | In the linear region of the lift curve, ice-induced performance degradation mainly occurs due to higher drag coefficient. |

| At high angles of attack, the differences between the lift coefficients of iced and clean rotors become more pronounced, while the differences in drag coefficients decrease. | |||

| Myong [82] | numerical | NREL 5 MW | Many aircraft icing features can be applied to icing on HAWTs. |

| Ice thickness increases from the base to the tip of the blade. | |||

| Ice on the blade reduces power coefficients at all tip speeds. | |||

| Reid et al. [83] | numerical | NREL phase VI | Some icing conditions showed power losses over 60%. |

| Simulations with rime ice had less power losses than glaze ice. | |||

| Glaze ice at the largest droplet size caused the greatest performance decline due to thicker ice and a larger contaminated area. | |||

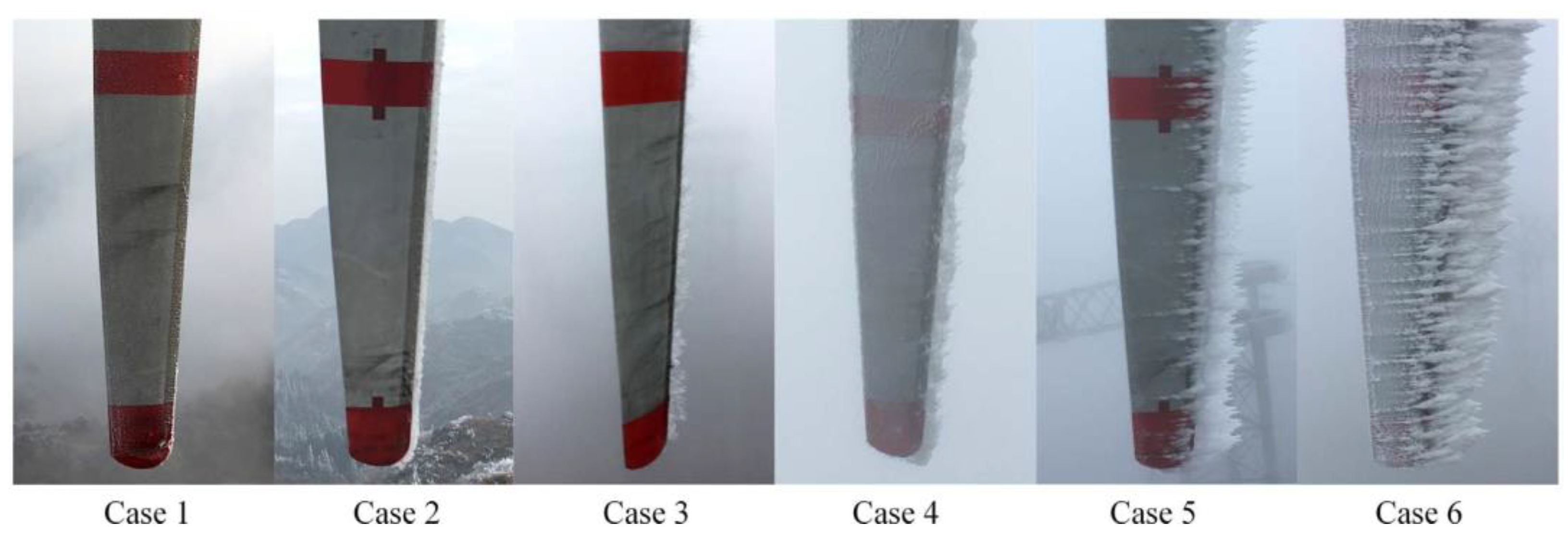

| Shu et al. [84] | experimental | Small HAWT (with blade radius 0.5m) | The presence of ice slows down the turbine and reduces its power. |

| Ice builds up more at the front edge and increases from the base to the tip of the turbine. | |||

| As the speed decreases, the ice shifts to the other side. | |||

| Higher wind and lower temperature make ice less effective but don’t change its shape. | |||

| Ice load affects small HAWTs more than changes in aerodynamics. | |||

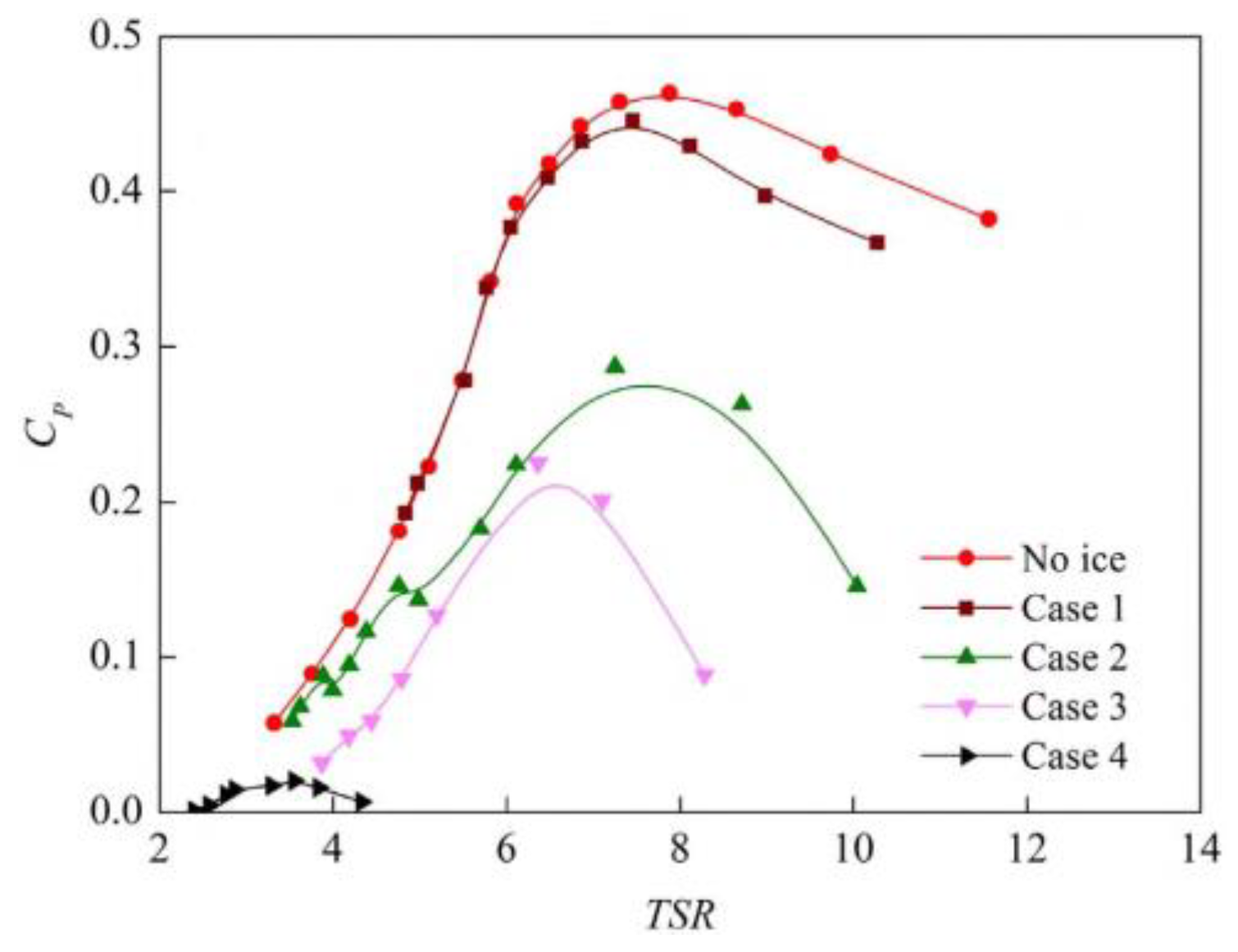

| Shu et al. [85] | experimental | 300 kW HAWT (with blade radius 14.6m) | Power output decreases as wind speed increases and ice thickness at the blade tip grows. |

| Irregular and coarse ice formations have a more negative impact on power performance. | |||

| Iced rotors experience a noticeable decrease in rotor speed as ice thickness increases. | |||

| In icing conditions, power and moment coefficients decline more as ice thickness increases, at the same tip speed ratio. | |||

| Maximum power and moment coefficients in icing conditions occur at lower tip speed ratios. | |||

| Shu et al. [86] | numerical | 300 kW HAWT (with blade radius 14.6m) | Computational and experimental results show agreement for clean and rime-iced rotors at rated wind speed, but overestimate for glaze-iced rotors at high wind speed. |

| Higher wind speed reduces rotor speed and power output when icing occurs. | |||

| Ice shapes mainly affect pressure distribution at the airfoil’s front edge, decreasing normal and tangential forces, causing more stalls at the same wind speed and increased flow separation, especially with glaze ice. | |||

| Zanon et al. [87] | numerical | NREL 5 MW | By lowering the turbine’s rotational speed during icing, the performance can increase by up to 6% once normal operation resumes. |

| Maintaining the speed during icing can lead to a 3% decrease in performance compared to the baseline. | |||

| Tabatabaei et al. [88] | numerical | NREL 5MW | The BEM method agrees closely with the 3D CFD results for the clean blade (4% deviation) but underestimates the total power for the iced blade by 28%. |

| The 3D CFD predicts a 32% loss in extracted power due to ice, mainly when the ice horn height is over 8% of the chord length. | |||

| Caccia and Guardone [89] | numerical | NREL 5 MW | When the ice shape is complex, roughness can greatly affect the aerodynamics of an iced area if the roughness is significant enough. |

| In the high-roughness case, there was a 50% higher power loss compared to the low-roughness case. | |||

| Yirtici and Tuncer [90] | numerical | Aeolos-H | The optimization of HAWT blades reduced losses by about 4% for Aeolos-H turbine and 1% for NREL 5 MW. |

| NREL 5 MW |

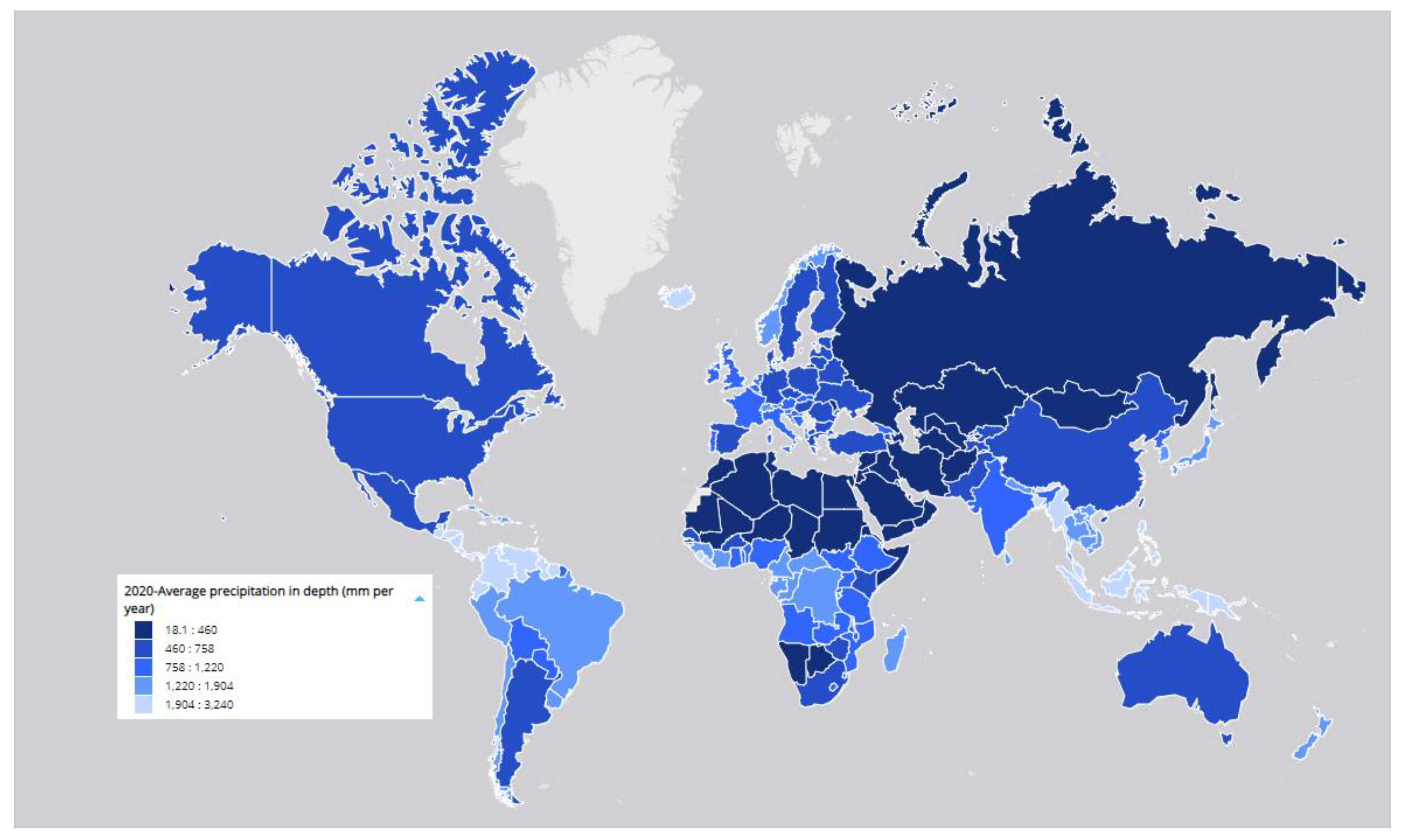

3.2. Rainfall

| Author | Investigation Method | HAWT or airfoil type | Main Conclusions |

|---|---|---|---|

| Corrigan and Demiglio [105] | experimental | two-bladed Mod-0 HAWT | Light rainfall caused up to a 20% decrease, while heavy rainfall caused up to a 30% decrease in aerodynamic performance. |

| When snow mixed with drizzle, performance dropped by as much as 36% in low winds. | |||

| 31% performance loss in high winds with moderate rainfall, which aligned with the experimental data. | |||

| Luers [108] | theoretical | two-bladed Mod-0 HAWT | A 25% power loss occurs at a wind speed of 10 m/s and a rain rate of 50 mm/hr. |

| Even under lighter rain and lower wind speeds, noticeable performance issues are seen. | |||

| The decrease in performance is due to the roughness caused by raindrops and the waviness of the water film on the HAWT’s blades. | |||

| Cai et al. [109] | numerical | S809 airfoil | They observed water forming on the airfoil and estimated how it affected performance. |

| Heavy rain can significantly degrade the airfoil’s performance. | |||

| Douvi and Margaris [110] | numerical | NACA 0012 airfoil | Heavy rain affects airfoil performance, reducing lift and increasing drag, due to water film formation on the airfoil’s surface and impact-induced cratering from raindrops. |

| The degradation is more significant at higher angles of attack. | |||

| Droplets breakup near areas with severe pressure gradients, creating an “ejecta fog” near the airfoil and causing water streams to flow from the trailing edge. | |||

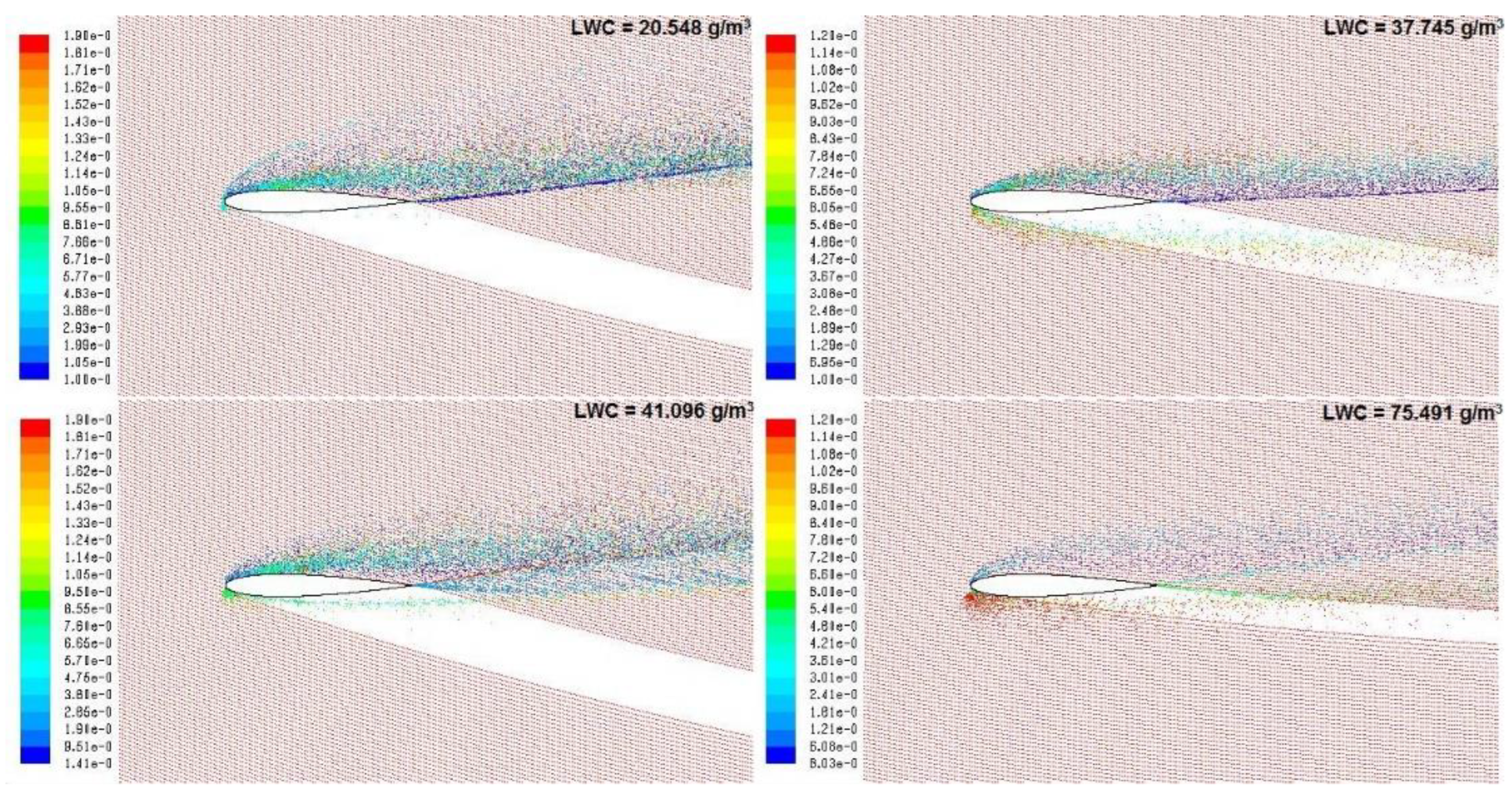

| Douvi et al. [92,94] | numerical | NACA 0012 airfoil | Increasing LWC degrades aerodynamic performance, especially up to stall angle. |

| Rainfall delays stall onset. Larger droplets break up more in areas with pressure gradients near the airfoil. | |||

| Higher LWC increases water film thickness on the upper airfoil surface. | |||

| The maximum water film height near trailing edge occurs at 0° angle, shifting towards leading edge at higher angles. | |||

| With higher angles of attack, less water accumulates on the upper surface. | |||

| Rivulet formation point on upper surface moves from trailing edge to leading edge with increasing angle of attack. | |||

| Cohan and Arastoopour [111] | numerical | S809 airfoil | At low rainfall rates, the airfoil’s performance is affected by rainfall. |

| When the rainfall rate is enough to form a water film on the airfoil surface, further increase in rainfall doesn’t significantly affect performance. | |||

| Higher rainfall rates increase the lift coefficient but also the drag coefficient detrimentally. | |||

| Arastoopour and Cohan [112] | numerical | S809 airfoil | Increasing the angle of attack in the airfoil simulation increased the lift coefficient but also resulted in a higher drag coefficient. |

| NREL Phase VI HAWT | Rain film accumulation and flow on the airfoil surface reduced power output by up to 25% at a wind speed of 7 m/s and a rainfall rate of 40 mm/h. | ||

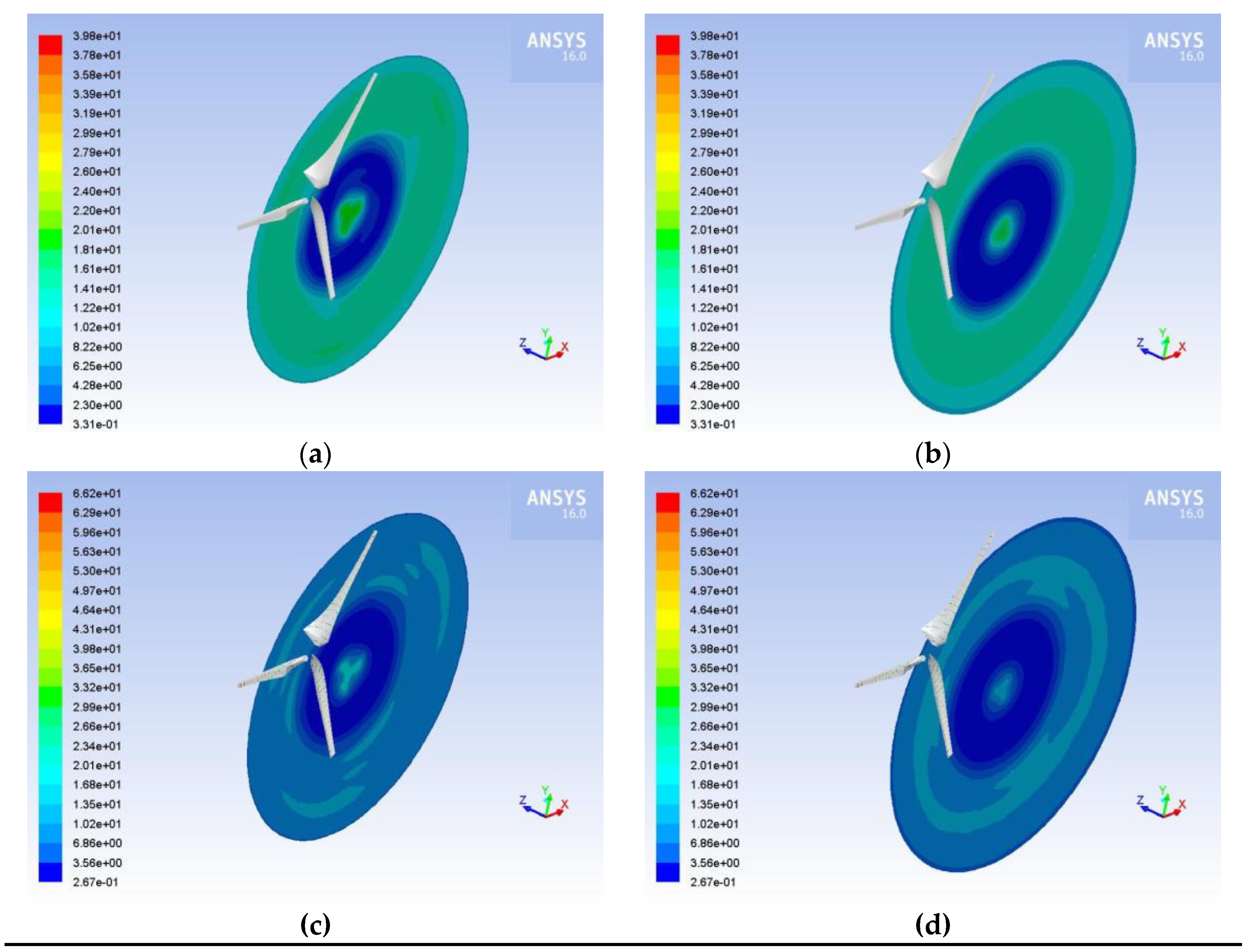

| Wu et al. [113,114] | numerical | NREL 5 MW | The results show that rain affects the HAWT differently at the blade tip and root. |

| Rain intensity increases the impact. | |||

| Empirical formulae describe the relationship between wind speed, rotation speed, rain intensity, and the load caused by rain. | |||

| Barfknecht et al. [115] | numerical | IEA 15 MW and NREL 5 MW offshore HAWTs | The IEA 15MW turbine had higher erosion-related performance loss at lower wind speeds compared to the NREL 5MW turbine. |

| Turbine design had little sensitivity to the Erosion-Safe Mode break-even point. | |||

| Anh and Duc [116] | numerical | --- | The wetness on turbine blades correlates with the impact force of rain. |

| The optimum wind speed reduces both the impact force and power loss. | |||

| Larger raindrops lower power output and affect blade rotation. | |||

| Anh and Duc [117] | numerical | --- | Optimal wetness levels based on the blade shape were determined. |

| Pitch angles should decrease when wind speed exceeds a set threshold during rain. | |||

| Douvi et al. [118] | numerical | Optimized three-bladed HAWT, with blades constructed by NACA 4418 airfoil | Rain has a detrimental impact on HAWT aerodynamics, causing a decrease in power coefficient as raindrop size and liquid water content (LWC) increase. |

| Significant reductions in aerodynamic efficiency were observed, with declines of 11.84%, 16.87%, and 23.9% for rain densities of 10g/m³, 30g/m³, and 60g/m³, respectively. | |||

| The thickest water film accumulated near the hub, where the blade chord is longest, while less water collected near the blade tip due to centrifugal force. | |||

| Under rainfall with an LWC of 30g/m³, power coefficient reductions of 15.33%, 16.87%, and 17.99% occurred for raindrop diameters of 0.5mm, 1mm, and 2mm, respectively. |

3.3. Hailstorm

| Author | Investigation Method | HAWT or airfoil type | Main Conclusions |

|---|---|---|---|

| Fiore et al. [123] | numerical | DU 97-W-300 airfoil DU 96-W-212 airfoil DU 96-W-180 airfoil |

Thinner airfoil sections captured more raindrops and hailstones. |

| Hailstones generated significant impact forces at the blade’s leading edge due to their trajectory angle. | |||

| Raindrops were more influenced by the blade’s flow field and angle of attack, affecting their impact force. | |||

| Raindrop erosion rate correlated with the cube of the blade’s relative wind velocity, while impact force followed a power-law relationship with wind velocity squared. | |||

| Douvi et al. [124] | numerical | S809 airfoil | Hailstorms significantly affect airfoil aerodynamics, leading to decreased lift coefficients and increased drag coefficients compared to normal airflow. |

| These effects were particularly notable at the airfoil’s trailing and leading edges. | |||

| Douvi et al. [125] | numerical | NACA 0012 airfoil | Hailstones and water droplets impacting the airfoils fragmented into smaller particles, and shadow zones were observed. |

| Increasing the angle of attack resulted in a wider distribution of smaller hailstones on the airfoil’s upper surface and a higher concentration below it. | |||

| The power coefficient prediction for a three-bladed HAWT indicated a decrease during hailstorm conditions. | |||

| Douvi and Douvi [126] | numerical | S809 airfoil | The airfoil’s upper surface near the leading edge consistently had the highest wall film height, suggesting that particle accumulation contributes to airfoil aerodynamic deterioration, especially at the leading edge. |

| The shape of wall film curves implies the water film’s wavy shape on the airfoils. | |||

| Increasing the angle of attack led to reduced water accumulation on the upper surface and more on the lower surface of the airfoil. | |||

| Decrease of power coefficient of a three-bladed HAWT using the S809 airfoil profile during hailstorm conditions across different tip speed ratios. | |||

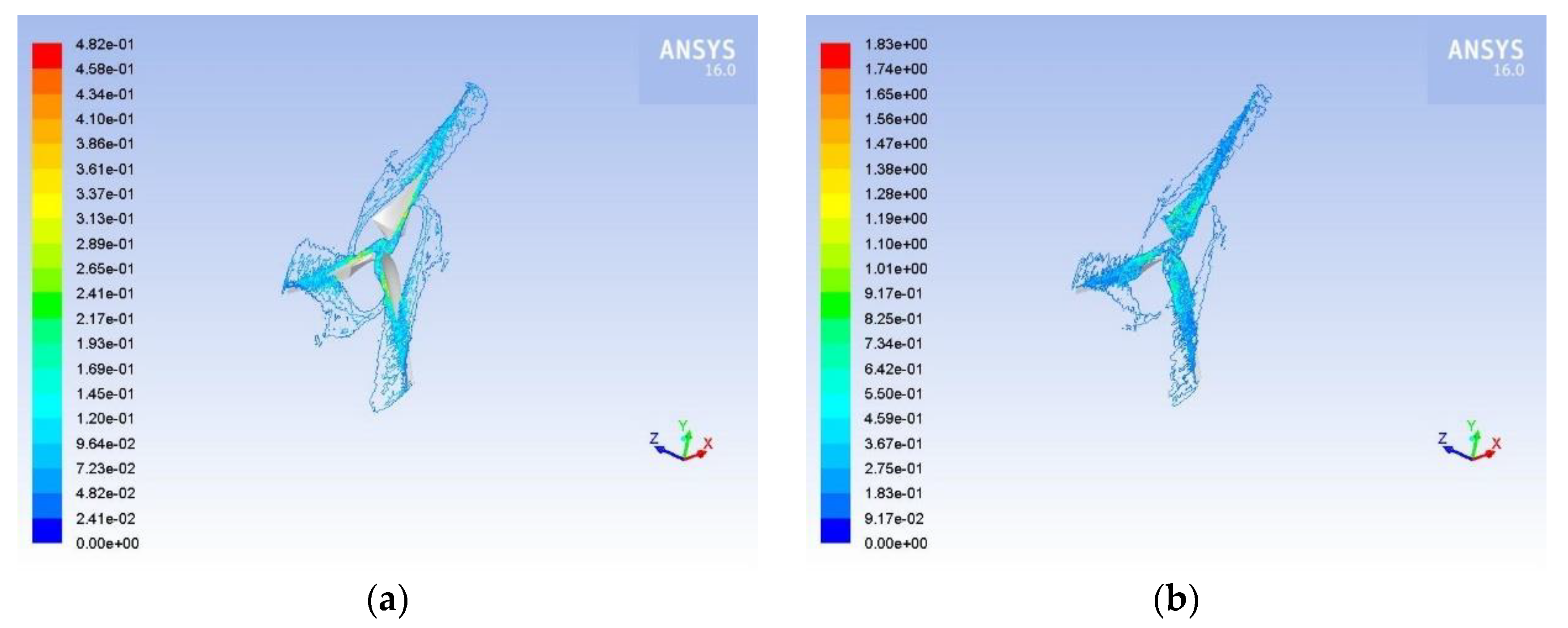

| Douvi et al. [127] | numerical | Optimized three-bladed HAWT with blades constructed by S809 airfoil | The turbine’s power decreases by 6.4% at an wind speed of 10 m/s and by 3.0% at 15 m/s under hailstorm conditions. |

| Hailstorms create rings of varying speeds and diameters in the wake, weakening the wake. | |||

| Particles are concentrated on the pressure side and mainly on 50% of the blade near the hub. | |||

| With increased air velocity, particles move closer to the hub and appear on the upper surface, causing erosion. |

3.4. Dust and sand

| Author | Investigation Method | HAWT or airfoil type | Main Conclusions |

|---|---|---|---|

| Khalfallah and Koliub [128] | experimental | Nordtank 300 kW HAWT | The impact of dust on HAWTs depends on rotor speed, specifications, nacelle height, power regulation, and wind farm site conditions. |

| Khakpour et al. [129] | numerical | S819 airfoil | Introducing sand reduces airfoil pressure, lowering drag. |

| Fine sand particles have a stronger effect than coarse particles. | |||

| Lift remains mostly unaffected by sand, except at high angles of attack. | |||

| Small particles erode the most at high angles, while coarse particles erode the most at 0°. | |||

| Increasing particle mass flow rate lowers pressure coefficient in the downstream region. | |||

| Ren and Ou [131] | numerical | NACA 63-430 airfoil | HAWT blade performance is greatly influenced by small roughness height. |

| Roughness located in the front 50% of the chord length significantly affects performance. | |||

| It is recommended to clean the blades every 3 months if there is no rain. | |||

| Li et al. [132] | numerical | DU 95-W-180 airfoil | For a smooth surface with roughness heights up to 0.5 mm, the lift coefficient increased while the drag coefficient decreased significantly. |

| For roughness heights greater than 0.7 mm, the changes in aerodynamic coefficients were more gradual. | |||

| Salem et al. [133] | numerical | NACA 63-215 airfoil | Their findings aligned with Ren and Ou [131] and Li et al. [132]. |

| Roughness leads to an early shift to turbulent boundary layer. | |||

| Wu et al. [134] | numerical | FFA-W3-211 airfoil | The rough areas on the airfoil surface were at the suction site (53% and 92% from the chord line towards the leading edge) and the pressure site (44% and 88% distances). |

| These rough areas caused a delay in the transition point. | |||

| Fiore and Selig [135,136] | numerical | 1.5 MW HAWT blade, constructed by DU 97-W-300, DU 96-W-212 and DU 96-W-180 airfoils along the blade | The blade sections where particles hit depend on the type of airfoil, angle of attack, freestream velocity, and particles themselves. |

| Sand particles mostly collide near the blade’s front edge, causing the highest erosion rate on the low-pressure side. | |||

| At a radial position of r/R = 0.75, the erosion rate increased tenfold compared to the inboard section at r/R = 0.35. | |||

| Steep impact angles were seen near the front edge, minimizing erosion. | |||

| Moving slightly downstream, the erosion rate reached its maximum. | |||

| Fiore and Selig [137] | numerical | DU 96-W-180, DU 96-W-212, and DU 96-W-250 airfoils | The erosion from sand impacts creates two peaks on the blade surface, which can shift due to angle of attack, particle size, and inlet velocity. |

| A rounded upper edge helps the erosion peak move downstream, while a flat inclined lower edge causes particles to slow down, resulting in impacts at nearly perpendicular angles. | |||

| Fiore and Selig [138] | numerical | DU 96-W-180, S804, S810, S813, S817, S820, S821, S828, and S832 airfoils | The sand particle diameter affects the blade’s lifespan. Larger diameters decrease lifespan. |

| Higher lift coefficients and turbine hub heights increase lifespan. | |||

| Airfoils with bulbous and rounded leading edges, as well as moderately aft-cambered airfoils, have the longest observed lifespans. | |||

| Diab et al. [139] | numerical | various types of airfoils | HAWT airfoils less affected by dust perform better. |

| Adding a leading-edge slat can reduce the negative impact of dust, avoiding frequent cleaning. | |||

| Srinivasan and Surasani [140] | numerical | S814 and S826 airfoils | The transition model accurately predicts flow over clean airfoils, while the fully turbulent model represents surface fouled conditions better. |

| The Reynold’s number doesn’t significantly affect aerodynamic performance for both airfoils, when comparing normal and fouled conditions. | |||

| S826 airfoil shows better resistance to performance degradation due to surface fouling than S814 airfoil. | |||

| Jafari et al. [141] | numerical | E387 airfoil and a turbine blade | Applying roughness only on the pressure side of the airfoil improves the lift coefficient by 8.62% compared to a rough surface and by 1.2% compared to a smooth surface. |

| Roughness on the pressure side has a smaller negative impact on the lift coefficient compared to roughness on the suction side or both sides. | |||

| Zidane et al. [142] | numerical | NACA 63-415 airfoil | Lift coefficient can decrease by 28% during hailstorm conditions. |

| Han et al. [143] | numerical | NACA 64-618 airfoil | Blades with sand on their leading edge had 27% less lift and 159% more drag. |

| Eroded blades at the leading edge had 53% less lift and 314% more drag. | |||

| The impact was worse at high angles (10° and above) and the damaged area was wider at the leading edge. | |||

| Energy production dropped by 2% to 3.7%, depending on the level of damage at the leading edge. | |||

| Chen and Agarwal [144] | numerical | S809 and S814 airfoils | 10% dust concentration caused more severe power degradation for HAWTs. |

| Guo et al. [145] | numerical | S809, NH6MW25 and NACA 0012 airfoils | When flow separation happens, the performance degradation worsens due to more extensive separation caused by particles. |

| Unlike the NACA 0012 airfoil, the other two airfoils have a specific angle of attack in the light stall region that is highly influenced by particles. | |||

| For the S809 airfoil, the most sensitive angle of attack is about 3° higher than the angle for maximum lift-to-drag ratio. | |||

| ElMessiry et al. [146] | numerical | same airfoils with Diab et al. [139] | Most airfoils experienced a significant 40% decrease in lift. |

| The DU 84-132V3 airfoil performed well under clean conditions, but its performance was uncertain in dusty environments due to changes in the airfoil’s geometry. | |||

| The NACA 63-215 airfoil was the least affected by dust accumulation and maintained good performance at different angles of attack with only a minor decrease. | |||

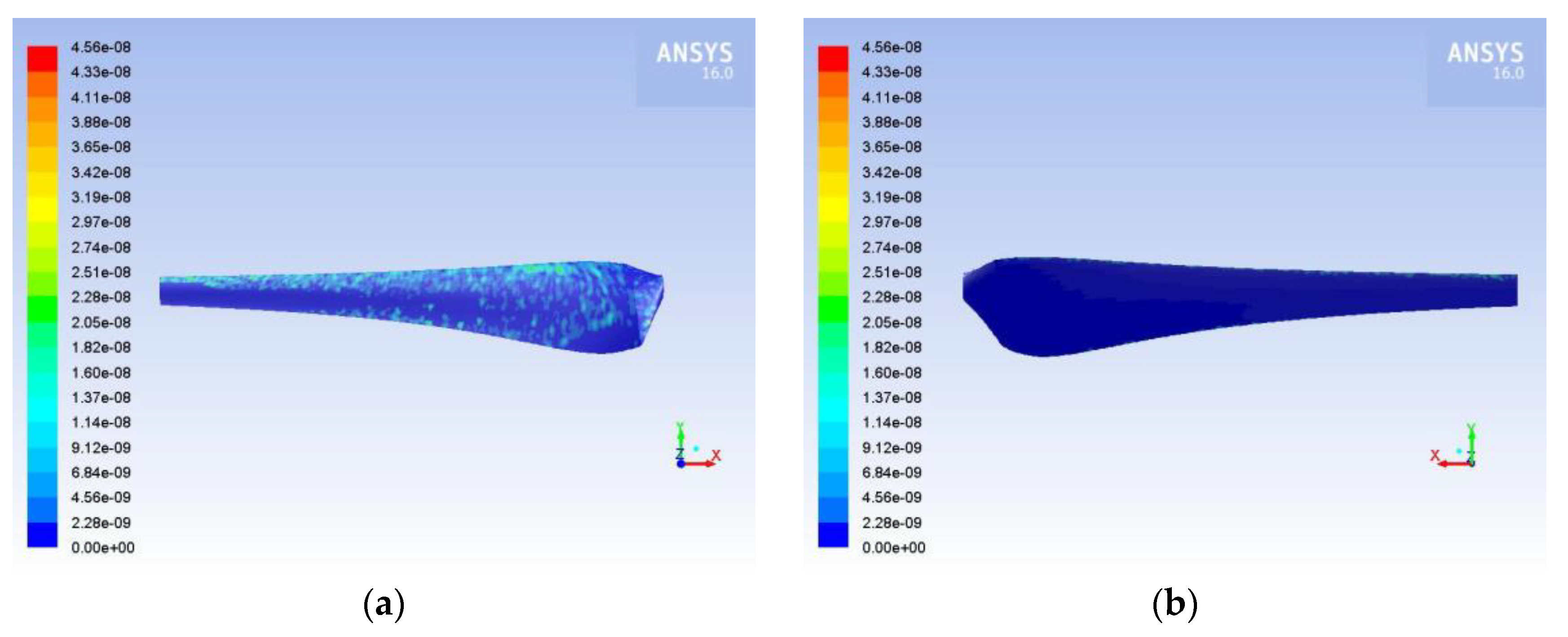

| Douvi et al. [147,148] | numerical | S809 airfoil | Increasing the angle of attack and sand particle concentration degrades the performance of a three-bladed HAWT, regardless of Re. |

| The power coefficient decreases due to sand particles, influenced by blade twist angle and particle concentration in the airflow. | |||

| Douvi et al. [149,150] | numerical | NACA 0012 airfoil | Sand particles tend to accumulate on the upper surface and from the leading edge to the central area of the lower surface, especially at small angles of attack. |

| With higher angles of attack, particle concentration narrows to a smaller section of the airfoil. | |||

| Douvi et al. [151] | numerical | Optimized three-bladed HAWT, constructed by S809 airfoil blades | The power output of the HAWT decreases by 1.24% to 9.04% depending on conditions. |

| As sand particle concentration in the air increases, the wake becomes weaker and minimum velocity decreases. | |||

| Sand particles tend to gather more at the hub, and as concentration and wind speed rise, the particles on the rotor become more abundant. | |||

| Approaching the hub, particles gather over a larger area on the pressure surface, negatively impacting power production. | |||

| The areas with the highest sand dissipation rate correlate with the highest erosion rate. | |||

| Zare et al. [153] | numerical | NREL Phase VI HAWT | The HAWT’s performance decreases in dusty conditions, especially when it’s in a post-stall state and for particle diameters > 0.1 mm. |

| The average power generated decreases by 4.3% and 13.3% for particles with diameters of 0.05 mm and 0.9 mm, respectively. | |||

| Particles significantly change the flow, reducing the pressure difference between the blade’s suction and pressure sides, increasing the separation of the boundary layer, and strengthening recirculation zones. |

3.5. Humidity

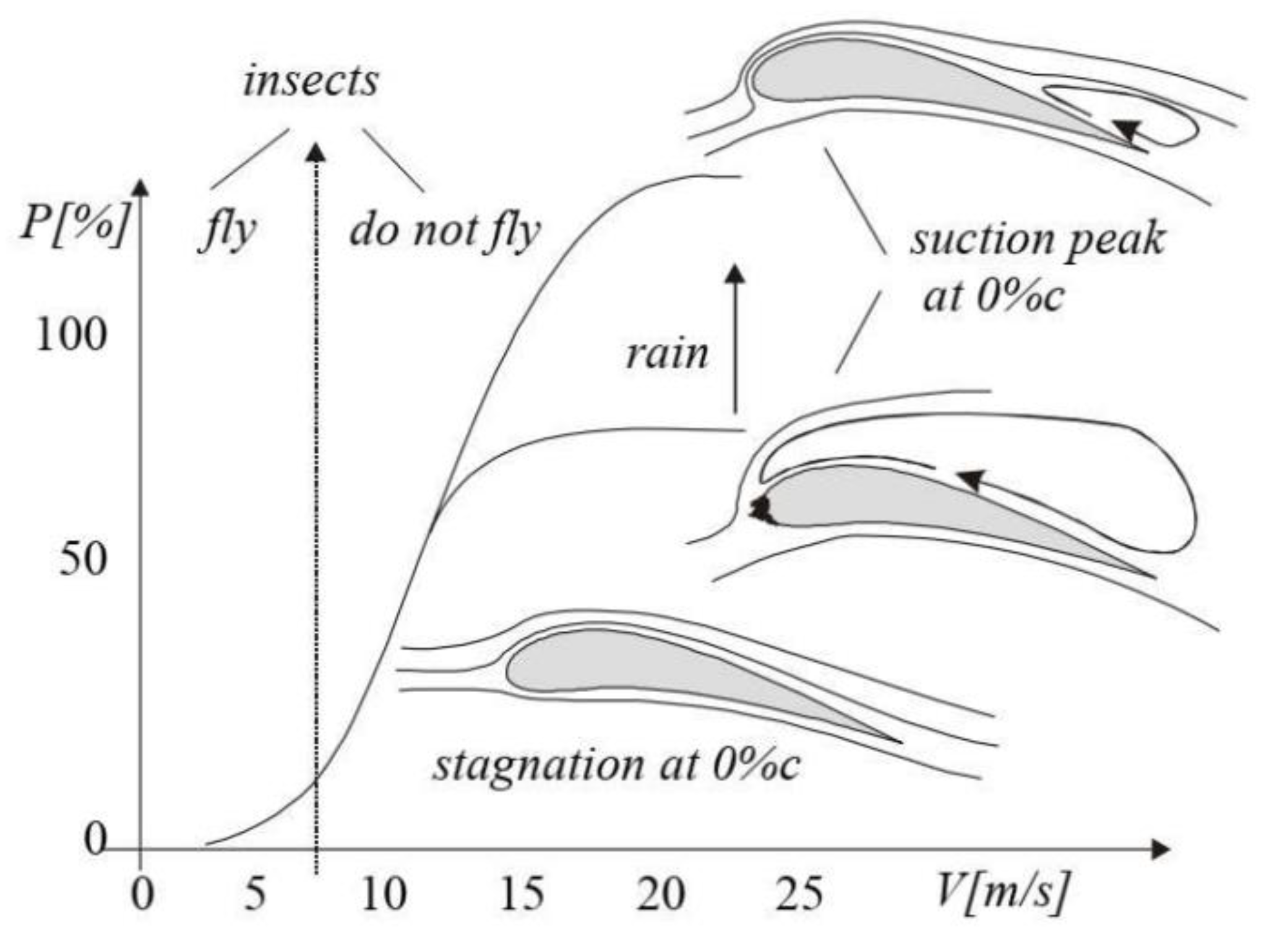

3.6. Insects

3.7. Sea spray

4. Conclusions

- Operation of HAWTs in various hailstorm conditions and in environments with sea spray;

- Design and analysis of additional airfoils and HAWT blades, aiming to optimize their performance across hazard environmental conditions;

- Employing user-defined functions (UDFs), to introduce particles of varying shape and size, facilitating the study of multiphase flows;

- Investigate the impact of these multiphase flows in wind farms, specifically in conjunction with terrain; this case would necessitate significant computational power.

Conflicts of Interest

References

- Intergovernmental Panel on Climate Change (IPCC); Renewable Energy Sources and Climate Change Mitigation; Cambridge University Press, Cambridge, United Kingdom, 2011.

- IRENA; Renewable Capacity Statistics 2023; International Renewable Energy Agency, Abu Dhabi, 2023.

- IEA; Renewable Energy Market Update - June 2023; IEA, Paris, 2023.

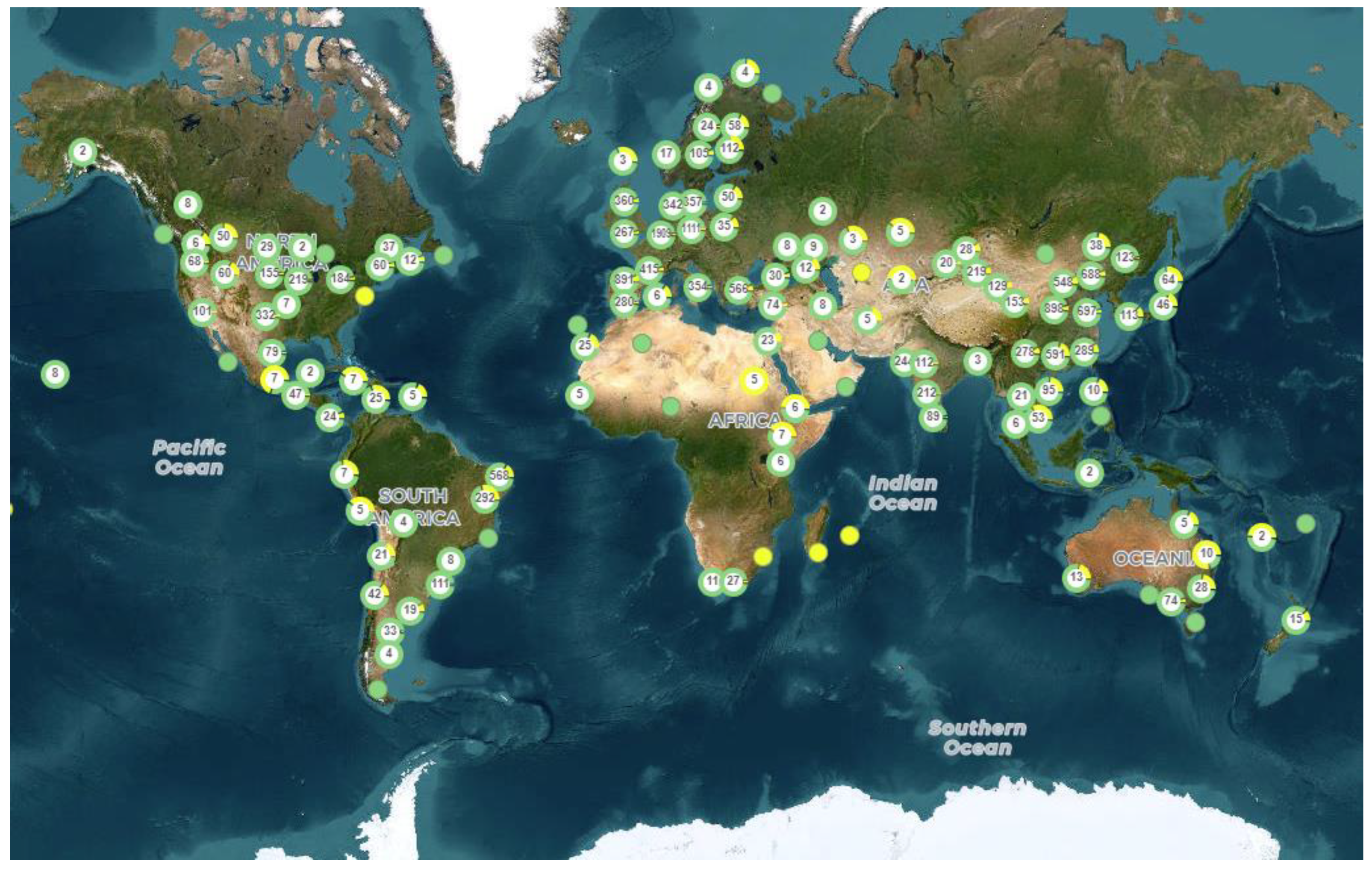

- Global Energy Monitor; Global Wind Power Tracker; Global Energy Monitor, Covina, CA 91723, May 2023 release.

- Papiez, M.; Smiech, S.; Frodyma, K. Factors affecting the efficiency of wind power in the European Union countries. Energy Policy 2019, 132, 965–977. [Google Scholar] [CrossRef]

- Dalili, N.; Edrisy, A.; Carriveau, R. A review of surface engineering issues critical to wind turbine performance. Renew. Sust. Energ. Rev. 2007, 13(2), 428–438. [Google Scholar] [CrossRef]

- Corten, G. V. H. Insects can halve wind-turbine power. Nature 2001, 412, 41–42. [Google Scholar] [CrossRef]

- Moroz, E.; Eggleston, D. A comparison between actual insect contamination and its simulation. Wind Power 1992, 7, 418–425. [Google Scholar]

- Kumar, K.; Safiulla, M.; Ahmed, A. An experimental evaluation of fiber-reinforced polypropylene thermoplastics for aerospace applications. J. Mech. Eng. 2014, 43, 92–97. [Google Scholar] [CrossRef]

- Amirzadeh, B.; Louhghalam, A.; Raessi, M.; Tootkaboni, M. A computational framework for the analysis of rain-induced erosion in wind turbine blades, part I: Stochastic rain texture model and drop impact simulations. J. Wind. Eng. Ind. Aerodyn. 2017, 163, 33–43. [Google Scholar] [CrossRef]

- Wu, Z.; Cao, Y.; Nie, S.; Yang, Y. Effects of rain on vertical axis wind turbine performance. J. Wind. Eng. Ind. Aerodyn. 2017, 170, 128–140. [Google Scholar] [CrossRef]

- Castorrini, A.; Corsini, A.; Rispoli, F.; Venturini, P.; Takizawa, K.; Tezduyar, T.E. Computational analysis of wind-turbine blade rain erosion. Comput. fluids 2016, 141, 175–183. [Google Scholar] [CrossRef]

- Verma, A.S.; Castro, S.G.; Jiang, Z.; Teuwen, J.J. Numerical investigation of rain droplet impact on offshore wind turbine blades under different rainfall conditions: A parametric study. Compos. Struct. 2020, 241. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Hasager, C.B.; Bak, C.; Tilg, A.-M.; Bech, J.I.; Rad, S.D.; Fæster, S. Leading edge erosion of wind turbine blades: Understanding, prevention, and protection. Renew. Energy 2021, 169, 953–969. [Google Scholar] [CrossRef]

- Pryor, S.; Barthelmie, R.; Cadence, J.; Dellwik, E.; Hasager, C.; Kral, S.; Reuder, J.; Rodgers, M.; Veraart, M. Atmospheric Drivers of Wind Turbine Blade Leading Edge Erosion: Review and Recommendations for Future Research. Energies 2022, 15(8553), 1–41. [Google Scholar] [CrossRef]

- Pugh, K.; Nash, J.; Reaburn, G.; Stack, M. On analytical tools for assessing the raindrop erosion of wind turbine blades. Renew. sustain. energy rev. 2021, 137. [Google Scholar] [CrossRef]

- Sareen, A.; Sapre, C.; Selig, M. Effects of leading edge erosion on wind turbine blade performance. Wind Energy 2014, 17, 1531–1542. [Google Scholar] [CrossRef]

- Barfknecht, N.; Kreuseler, M.; de Tavernier, D.; von Terzi, D. Performance analysis of wind turbines with leading-edge erosion and erosion-safe mode operation. J. Phys. Conf. Ser. 2022, 2265(3), 032009. [Google Scholar] [CrossRef]

- Papi, F.; Cappugi, L.; Salvadori, S.; Carnevale, M.; Bianchini, A. Uncertainty Quantification of the Effects of Blade Damage on the Actual Energy Production of Modern Wind Turbines. Energies 2020, 13(3785), 1–17. [Google Scholar] [CrossRef]

- Schramm, M.; Rahimi, H.; Stoevesandt, B.; Tangager, K. The Influence of Eroded Blades on Wind Turbine Performance Using Numerical Simulations. Energies 2017, 10(9), 1–15. [Google Scholar] [CrossRef]

- Manwell, J.; McGowan, J.; Rogers, A. Wind Energy Explained: Theory, Design and Application; John Wiley & Sons: Chichester, West Sussex, United Kingdom, 2009. [Google Scholar] [CrossRef]

- Sagol, E.; Reggio, M.; Ilinca, A. Issues concerning roughness on wind turbine blades. Renew. Sust. Energ. Rev. 2013, 23, 514–525. [Google Scholar] [CrossRef]

- Zidane, I.; Saqr, K.; Swadener, G.; Ma, X.; Shehadeh, M. On the role of surface roughness in the aerodynamic performance and energy conversion of horizontal wind turbine blades: A review. Int. J. Energy Res. 2016, 40(15), 2054–2077. [Google Scholar] [CrossRef]

- Betz, A. Introduction to the Theory of Flow Machines; Pergamon Press: Oxford, 1966. [Google Scholar]

- Burton, T.; Sharpe, D.; Jenkins, N.; Bossanyi, E. Wind Energy Handbook, 2nd edition ed.; John Wiley & Sons: West Sussex, 2011. [Google Scholar] [CrossRef]

- Wilson, R.; Lissaman, P.; Walker, S. Aerodynamic performance of wind turbines. Oregon State University, Corvallis, USA, 1976. [CrossRef]

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg Sci Technol 2011, 65(1), 88–96. [Google Scholar] [CrossRef]

- Fortin, G.; Perron, J.; Ilinca, A. A study of icing events at Murdochville: Conclusions for the wind power industry. in International Symposium “Wind Energy in Remote Regions”, Magdalen’s Island, 2005, October.

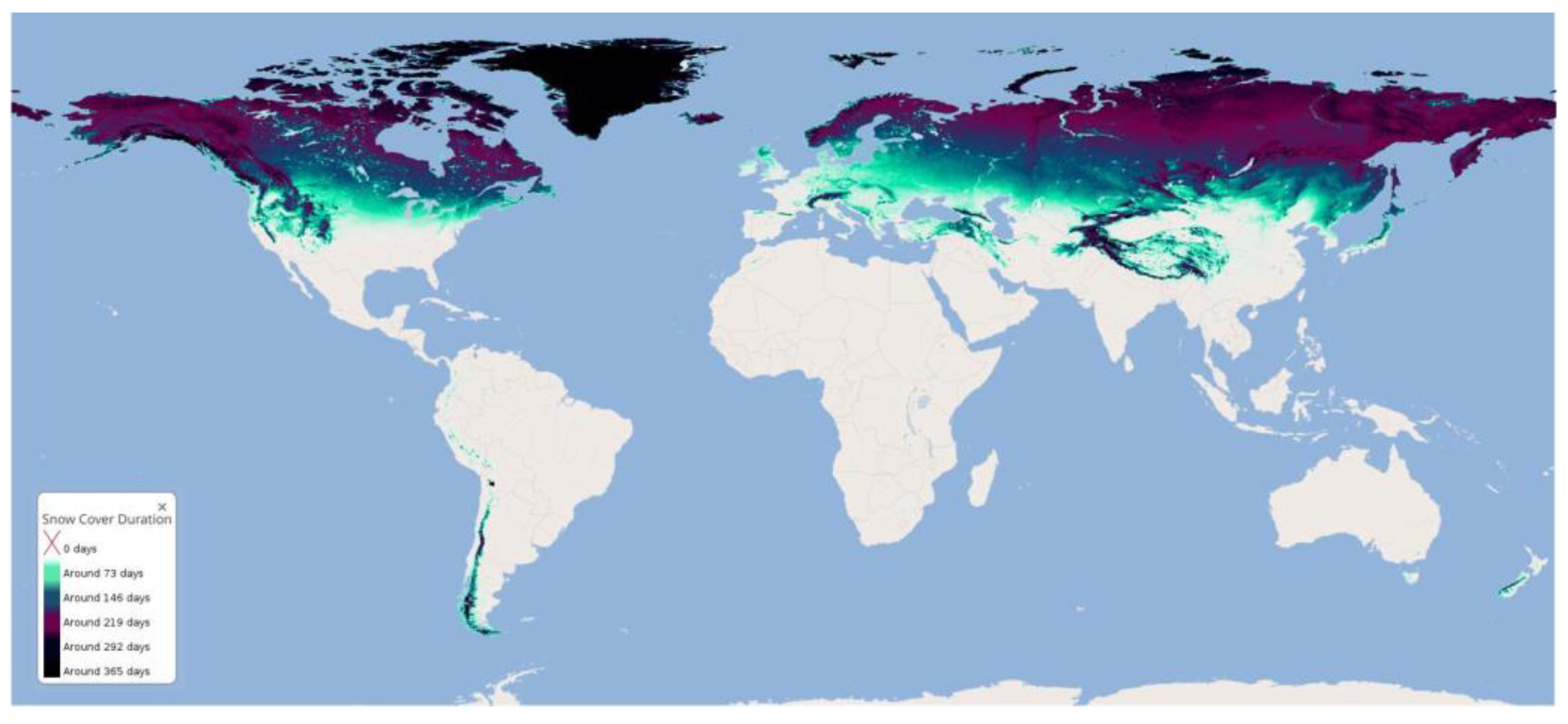

- EOC Geoservice. GSP - Global SnowPack Mean. Earth Observation Center, Available online:. Available online: https://geoservice.dlr.de/web/maps/eoc:gsp:mean (accessed on 25 May 2023).

- Turkia, V.; Huttunen, S.; Wallenius, T. Method for Estimating Wind Turbine Production Losses Due to Icing, VTT Technology No. 114. VTT Technical Research Centre of Finland, Espoo, Finland, 2013.

- Ruff, G.; Berkowitz, B. Users manual for the NASA Lewis ice accretion prediction code (LEWICE) (No. NAS 1.26: 185129). Lewis Research Center Group, Brook Park, Ohio, 1990.

- Marjaniemi, M.; Makkonen, L.; Laakso, T. Turbice-the wind turbine blade icing model. In Proceedings of the International Conference BOREAS V: Wind power production in cold climates, Finnish Meteorological Institute, Levi, Finland, (29 November – 1 December 2000). [Google Scholar]

- Makkonen, L.; Laakso, T.; Marjaniemi, M.; Finstad, K. Modelling and Prevention of Ice Accretion on Wind Turbines. Wind. Eng. 2001, 25(1), 3–21. [Google Scholar] [CrossRef]

- Habashi, W.; Morency, F.; Beaugendre, H. FENSAP-ICE: A comprehensive 3D Simulation Tool for In-flight Icing. In Proceedings of the 7th International Congress of Fluid Dynamics and Propulsion, Sharm-El-Sheikh, Egypt, (19–21 December 2001). [Google Scholar] [CrossRef]

- Beaugendre, H.; Morency, F.; Habashi, W. FENSAP-ICE’s three-dimensional in-flight ice accretion module: ICE3D. J. Aircr. 2003, 40(2), 239–247. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, C. Numerical simulation for in-cloud icing of three-dimensional wind turbine blades. Simulation 2017, 94(1), 31–41. [Google Scholar] [CrossRef]

- Jin, J.; Virk, M.; Hu, Q.; Jiang, X. Study of Ice Accretion on Horizontal Axis Wind Turbine Blade Using 2D and 3D Numerical Approach. IEEE Access 2020, 8, 166236–166245. [Google Scholar] [CrossRef]

- Son, C.; Kim, T. Development of an icing simulation code for rotating wind turbines. J. Wind. Eng. Ind. Aerodyn. 2020, 203, 104239. [Google Scholar] [CrossRef]

- Li, Y.; Tagawa, K.; Feng, F.; Li, Q.; He, Q. A wind tunnel experimental study of icing on wind turbine blade airfoil. Energy Convers. Manag. 2014, 85, 591–595. [Google Scholar] [CrossRef]

- Jolin, N.; Bolduc, D.; Swytink-Binnema, N.; Rosso, G.; Godreau, C. Wind turbine blade ice accretion: A correlation with nacelle ice accretion. Cold Reg. Sci. Technol. 2019, 157, 235–241. [Google Scholar] [CrossRef]

- Madi, E.; Pope, K.; Huang, W.; Iqbal, T. A review of integrating ice detection and mitigation for wind turbine blades. Renew. Sust. Energ. Rev. 2019, 103, 269–281. [Google Scholar] [CrossRef]

- Pinar Pérez, J.; García Márquez, F.; Ruiz, H. Economic viability analysis for icing blades detection in wind turbines. J. Clean. Prod. 2016, 135, 1150–1160. [Google Scholar] [CrossRef]

- Ibrahim, G.; Pope, K.; Muzychka, Y. Effects of blade design on ice accretion for horizontal axis wind turbines. J. Wind. Eng. Ind. Aerodyn. 2018, 173, 39–52. [Google Scholar] [CrossRef]

- Martini, F.; Contreras Montoya, L.; Ilinca, A. Review of Wind Turbine Icing Modelling Approaches. Energies 2021, 14(16), 1–26. [Google Scholar] [CrossRef]

- Bose, N. Icing on a small horizontal-axis wind turbine — Part 1: Glaze ice profiles. J. Wind. Eng. Ind. Aerodyn. 1992, 45(1), 75–85. [Google Scholar] [CrossRef]

- Rong, J.; Bose, N.; Brothers, C.; Lodge, M. Icing Test on a Horizontal Axis Wind Turbine. Wind. Eng. 1991, 15(2), 109–113. [Google Scholar]

- Han, Y.; Palacios, J.; Schmitz, S. Scaled ice accretion experiments on a rotating wind turbine blade. Journal of J. Wind. Eng. Ind. Aerodyn. 2012, 109, 55–67. [Google Scholar] [CrossRef]

- Hu, L.; Zhu, X.; Chen, J.; Shen, X.; Du, Z. Numerical simulation of rime ice on NREL Phase VI blade. J. Wind. Eng. Ind. Aerodyn. 2018, 178, 57–68. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Hu, H. An experimental investigation of dynamic ice accretion process on a wind turbine airfoil model considering various icing conditions. Int. J. Heat Mass Transf. 2019, 133, 930–939. [Google Scholar] [CrossRef]

- Gao, L.; Tao, T.; Liu, Y.; Hu, H. A field study of ice accretion and its effects on the power production of utility-scale wind turbines. Renew. Energy 2021, 167, 917–928. [Google Scholar] [CrossRef]

- Gao, L.; Hu, H. Wind turbine icing characteristics and icing-induced power losses to utility-scale wind turbines. Proc. Natl. Acad. Sci. 2021, 118. [Google Scholar] [CrossRef]

- Li, X.; Jia, Y.; Zhang, H.; Cheng, B. Research on the Change of Airfoil Geometric Parameters of Horizontal Axis Wind Turbine Blades Caused by Atmospheric Icing. Energy Eng. 2022, 119(6), 2549–2567. [Google Scholar] [CrossRef]

- Seifert, H.; Richert, F. Aerodynamics of iced airfoils and their influence on loads and power production. In Proceedings of the EWEC ‘97, European Wind Energy Conference, Dublin Castle, Ireland, (6 October 1997). [Google Scholar]

- Jasinski, W.; Noe, S.; Selig, M.; Bragg, M. Wind Turbine Performance Under Icing Conditions. J. Sol. Energy Eng. 1998, 120(1), 60–65. [Google Scholar] [CrossRef]

- Hochart, C.; Fortin, G.; Perron, J.; Ilinca, A. Wind turbine performance under icing conditions. Wind Energy 2008, 11, 319–333. [Google Scholar] [CrossRef]

- Zhao, M.; Jiang, D.; Li, S. Research on fault mechanism of icing of wind turbine blades. In Proceedings of the 2009 World Non-Grid-Connected Wind Power and Energy Conference, Nanjing, China, (24–26 September 2009). [Google Scholar] [CrossRef]

- Homola, M. C.; Virk, M. S.; Wallenius, T.; Nicklasson, P. J.; Sundsbø, P. A. Effect of atmospheric temperature and droplet size variation on ice accretion of wind turbine blades. J. Wind Eng. Ind. Aerodyn. 2010, 98(12), 724–729. [Google Scholar] [CrossRef]

- Villalpando, F.; Reggio, M.; Ilinca, A. Numerical Study of Flow Around Iced Wind Turbine Airfoil. Eng. Appl. Comput. Fluid Mech. 2012, 6(1), 39–45. [Google Scholar] [CrossRef]

- Hudecz, A.; Koss, H.; Hansen, M. Ice Accretion on Wind Turbine Blades. In Proceedings of the 15th International Workshop on Atmospheric Icing of Structures (IWAIS XV), St. John’s, Newfoundland & Labrador, Canada, (8–13 September 2013). [Google Scholar]

- Hu, L.; Zhu, X.; Hu, C.; Chen, J.; Du, Z. Wind turbines ice distribution and load response under icing conditions, Renew. Energy 2017, 113, 608–619. [Google Scholar] [CrossRef]

- Virk, M.; Homola, M.; Nicklasson, P. Effect of Rime Ice Accretion on Aerodynamic Characteristics of Wind Turbine Blade Profiles. Wind Eng. 2010, 34(2), 207–218. [Google Scholar] [CrossRef]

- Han, W.; Kim, J.; Kim, B. Study on correlation between wind turbine performance and ice accretion along a blade tip airfoil using CFD. J. Renew. Sustain. Energy 2018, 10(2). [Google Scholar] [CrossRef]

- Jin, J. Y.; Virk, M. S. Study of ice accretion along symmetric and asymmetric airfoils. J. Wind Eng. Ind. Aerodyn. 2018, 179, 240–249. [Google Scholar] [CrossRef]

- Jin, J. Y.; Virk, M. S. Study of ice accretion and icing effects on aerodynamic characteristics of DU96 wind turbine blade profile. Cold Reg. Sci. Technol. 2019, 160, 119–127. [Google Scholar] [CrossRef]

- Jin, J. Y.; Virk, M. S. Experimental study of ice accretion on S826 & S832 wind turbine blade profiles. Cold Reg. Sci. Technol. 2020, 169, 102913. [Google Scholar] [CrossRef]

- Yirtici, O.; Tuncer, I. H.; Ozgen, S. Ice Accretion Prediction on Wind Turbines and Consequent Power Losses. J. Phys. Conf. Ser. 2016, 753(2). [Google Scholar] [CrossRef]

- Yirtici, O.; Ozgen, S.; Tuncer, I. Predictions of ice formations on wind turbine blades and power production losses due to icing. Wind Energy 2019, 22(7), 945–958. [Google Scholar] [CrossRef]

- Yirtici, O.; Cengiz, K.; Ozgen, S.; Tuncer, I. H. Aerodynamic validation studies on the performance analysis of iced wind turbine blades. Comput. Fluids 2019, 192, 104271. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Zhou, W.; Hu, H. An experimental study on the aerodynamic performance degradation of a wind turbine blade model induced by ice accretion process. Renew. Energy 2019, 133, 663–675. [Google Scholar] [CrossRef]

- Jiang, F.; Qiu, T. Research on the effect of icing on aerodynamic performance of airfoil and power generation performance of wind turbine. J. Phys. Conf. Ser. 2020, 1684(1), 012141. [Google Scholar] [CrossRef]

- Martini, F.; Ibrahim, H.; Contreras Montoya, L.; Rizk, P.; Ilinca, A. Turbulence Modeling of Iced Wind Turbine Airfoils. Energies 2022, 15(22), 1–20. [Google Scholar] [CrossRef]

- Chitransh, A.; Kaur, S. Investigation of Single Shot Ice Accretion on Aerofoil of Wind Turbine Blade using ANSYS. In Proceedings of the 2022 International Conference on Smart Generation Computing, Communication and Networking (SMART GENCON), Bangalore, India, (23–25 December 2022). [Google Scholar] [CrossRef]

- Rotich, I.; Kollár, L. Numerical simulation of the performance of an asymmetrical airfoil under extreme weather conditions. Mérn. inform. megold. 2022, 3(2), 19–29. [Google Scholar] [CrossRef]

- Yang, X.; Bai, X.; Cao, H. Influence analysis of rime icing on aerodynamic performance and output power of offshore floating wind turbine. Ocean Eng. 2022, 258, 111725. [Google Scholar] [CrossRef]

- Virk, M.S.; Nicklasson, P.J.; Homola, M.C. Atmospheric icing on large wind turbine blades. Int. J. Energy Environ. Eng. 2012, 3(1), 1–8. [Google Scholar]

- Barber, S.; Wang, Y.; Jafari, S.; Chokani, N.; Abhari, R. The Impact of Ice Formation on Wind Turbine Performance and Aerodynamics. ASME. J. Sol. Energy Eng. 2011, 133(1), 011007. [Google Scholar] [CrossRef]

- Homola, M.C.; Virk, M.S.; Nicklasson, P.J.; Sundsbø, P.A. Modelling of ice induced power losses and comparison with observations. Proceedings of Winterwind 2011, Umea, Sweden, (8–10 February 2011). [Google Scholar]

- Homola, M.; Virk, M.; Nicklasson, P.; Sundsbø, P. Performance losses due to ice accretion for a 5 MW wind turbine. Wind Energy 2012, 15, 379–389. [Google Scholar] [CrossRef]

- Dimitrova, M.; Ibrahim, H.; Fortin, G.; Ilinca, A.; Perron, J. Software tool to predict the Wind Energy production losses due to icing. In Proceedings of the 2011 IEEE Electrical Power and Energy Conference, Winnipeg, MB, Canada, (3–5 October 2011). [Google Scholar] [CrossRef]

- Lamraoui, F.; Fortin, G.; Benoit, R.; Perron, J.; Masson, C. Atmospheric icing impact on wind turbine production. Cold Reg. Sci. Technol. 2014, 100, 36–49. [Google Scholar] [CrossRef]

- Etemaddar, M.; Hansen, M.; Moan, T. Wind turbine aerodynamic response under atmospheric icing conditions. Wind Energy 2014, 17, 241–265. [Google Scholar] [CrossRef]

- Myong, R. Atmospheric Icing Effects on Aerodynamics of Wind Turbine Blade. In Proceedings of the IMECE2013 ASME International Mechanical Engineering Congress and Exposition, 10.1115/IMECE2013-64085, San Diego, California, USA, (15-21November 2013). [Google Scholar] [CrossRef]

- Reid, T.; Baruzzi, G.; Ozcer, I.; Switchenko, D.; Habashi, W. FENSAP-ICE Simulation of Icing on Wind Turbine Blades, Part 1: Performance Degradation. In Proceedings of the 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Grapevine (Dallas/Ft. Worth Region), Texas, (07 - 10 January 2013). [Google Scholar] [CrossRef]

- Shu, L.; Liang, J.; Hu, Q.; Jiang, X.; Ren, X.; Qiu, G. Study on small wind turbine icing and its performance. Cold Reg. Sci. Technol. 2017, 134, 11–19. [Google Scholar] [CrossRef]

- Shu, L.; Li, H.; Hu, Q.; Jiang, X.; Qiu, G.; McClure, G.; Yang, H. Study of ice accretion feature and power characteristics of wind turbines at natural icing environment. Cold Reg. Sci. Technol. 2018, 147, 45–54. [Google Scholar] [CrossRef]

- Shu, L.; Li, H.; Hu, Q.; Jiang, X.; Qiu, G.; He, G.; Liu, Y. 3D numerical simulation of aerodynamic performance of iced contaminated wind turbine rotors. Cold Reg. Sci. Technol. 2018, 148, 50–62. [Google Scholar] [CrossRef]

- Zanon, A.; De Gennaro, M.; Kühnelt, H. Wind energy harnessing of the NREL 5 MW reference wind turbine in icing conditions under different operational strategies. Renew. Energ. 2018, 115, 760–772. [Google Scholar] [CrossRef]

- Tabatabaei, N.; Gantasala, S.; Cervantes, M. Wind Turbine Aerodynamic Modeling in Icing Condition: Three-Dimensional RANS-CFD Versus Blade Element Momentum Method. J. Energy Resour. Technol. 2019, 141(7). [Google Scholar] [CrossRef]

- Caccia, F.; Guardone, A. Numerical simulations of ice accretion on wind turbine blades: Are performance losses due to ice shape or surface roughness? Wind Energy Sci. 2023, 8(3), 341–362. [Google Scholar] [CrossRef]

- Yirtici, O.; Tuncer, I. H. Aerodynamic shape optimization of wind turbine blades for minimizing power production losses due to icing. Cold Reg. Sci. Technol. 2021, 185, 103250. [Google Scholar] [CrossRef]

- Douvi, E.; Margaris, D. Aerodynamic Performance Investigation under the Influence of Heavy Rain of a NACA 0012 Airfoil for Wind Turbine Applications. Int. Rev. Mech. Eng. (I.RE.M.E.) 2012, 6(6), 1228–1235. [Google Scholar] [CrossRef]

- Douvi, E.; Margaris, D.; Lazaropoulos, S.; Svanas, S. Experimental and Computational Study of the Effects of Different Liquid Water Content on the Aerodynamic Performance of a NACA 0012 Airfoil at Low Reynolds Number. In Proceedings of the 5th International Conference on Experiments/Process/System Modeling/Simulation/ Optimization (5th IC-EpsMsO), Athens, Greece, (3–6 July 2013). [Google Scholar]

- Cao, Y.; Wu, Z.; Xu, Z. Effects of rainfall on aircraft aerodynamics. Prog. Aerosp. Sci. 2014, 71, 85–127. [Google Scholar] [CrossRef]

- Douvi, E.; Margaris, D.; Lazaropoulos, S.; Svanas, S. Low Reynolds Number Investigation of the Flow over a NACA 0012 airfoil at Different Rainfall Rates. Int. Rev. Mech. Eng. (I.RE.M.E.) 2013, 7(4), 625–632. [Google Scholar] [CrossRef]

- Rhode, R. Some Effects on Rainfall on Flight of Airplanes and on Instrument Indications. NACA TN 803 1941.

- Dunham, R.; Bezos, G.; Gentry, G.; E.M., M. E. Two-dimensional wind tunnel tests of a transport-type airfoil in a water spray. In Proceedings of the AIAA 23rd Aerospace Sciences Meeting, Reno, NV, U.S.A., (14–17 January 1985). [Google Scholar] [CrossRef]

- Hastings, E.; Manuel, G. Scale–Model Tests of Airfoils in Simulated Heavy Rain. J. Aircraft 1985, 22(6), 536–540. [Google Scholar] [CrossRef]

- Haines, P.; Luers, J. Aerodynamic Penalties of Heavy Rain on Landing Airplanes. J. Aircraft 1983, 20, 111–119. [Google Scholar] [CrossRef]

- Bilanin, A. Scaling Laws for Testing of High Lift Airfoils Under Heavy Rainfall. In Proceedings of the AIAA 23rd Aerospace Science Meeting, Reno, NV, U.S.A. (14–17 January 1985). [Google Scholar] [CrossRef]

- Thompson, B. E.; Jang, J. Aerodynamic Efficiency of Wings in Rain. J. Aircraft 1996, 33(6). [Google Scholar] [CrossRef]

- Wan, T.; Wu, S.W. Aerodynamic Analysis Under the Influence of Heavy Rain. J. Aeronaut. Astronaut. Aviat. 2009, 41(3), 173–180. [Google Scholar]

- Zhang, R.M.; Cao, Y.H. Study of Aerodynamics Characteristics of an Airfoil in Rain. J. Aerosp. Power 2010, 25(9), 2064–2069. [Google Scholar]

- Hansman, J.; Craig, A. Low Reynolds Number Tests of NACA 64-210, NACA 0012, and Wortman FX67-K170 Airfoils in Rain. J. Aircraft 1987, 24(8). [Google Scholar] [CrossRef]

- World Development Indicators (WDI). Average precipitation in depth (mm per year). Food and Agriculture Organization, 2020. Available online: https://databank.worldbank.org/reports.aspx?source=2&type=metadata&series=AG.LND.PRCP.MM (accessed on 23 March 2023).

- Corrigan, R.; DeMiglio, R. Effect of Precipitation on Wind Turbine Performance. NASA Lewis Research Center, Cleveland, OH, May 1985. [CrossRef]

- Valentine, J.R.; Decker, R.A. A Langrangian-Eulerian Scheme for Flow around an Airfoil in Rain. Int. J. Multiphase Flow 1995, 21(4), 639–648. [Google Scholar] [CrossRef]

- Durst, F. Durst, F.; Milojevic, D.; Schonung, B. Eulerian and Lagrangian predictions of particulate two-phase flows: A numerical study. Appl. Math. Modelling 1984, 8, 101–115. [Google Scholar] [CrossRef]

- Luers, J. Rain influences on a wind turbine theoretical development and applications. In Proceedings of the AIAA 23rd Aerospace Sciences Meeting, Reno, Nevada, (14–17 January 1985). [Google Scholar] [CrossRef]

- Cai, M.; Abbasi, E.; Arastoopour, H. Analysis of the Performance of a Wind-Turbine Airfoil under Heavy-Rain Conditions Using a Multiphase Computational Fluid Dynamics Approach. Ind. Eng. Chem. Res. 2013, 52(9), 3266–3275. [Google Scholar] [CrossRef]

- Douvi, E.; Margaris, D. Simulation of heavy rain flow over a NACA 0012 airfoil. In Proceedings of the 4th International Conference on Experiments/Process/System Modeling/Simulation/ Optimization (4th IC-EpsMsO), Athens, Greece, (6–9 July 2011). [Google Scholar]

- Cohan, A. C.; Arastoopour, H. Numerical simulation and analysis of the effect of rain and surface property on wind-turbine airfoil performance. Int. J. Multiphase Flow 2016, 81, 46–53. [Google Scholar] [CrossRef]

- Arastoopour, H.; Cohan, A. C. CFD simulation of the effect of rain on the performance of horizontal wind turbines. AIChE J. 2017, 63, 5375–5383. [Google Scholar] [CrossRef]

- Wu, S.; Sun, H.; Zheng, X. A numerical study on dynamic characteristics of 5 MW floating wind turbine under wind-rain conditions. Ocean Eng. 2022, 262, 112095. [Google Scholar] [CrossRef]

- Wu, S.; Sun, H.; Li, X. Response of 5 MW Floating Wind Turbines to Combined Action of Wind and Rain. J. Mar. Sci. Eng. 2022, 10, 1–16. [Google Scholar] [CrossRef]

- Barfknecht, N.; Kreuseler, M.; de Tavernier, D.; von Terzi, D. Performance analysis of wind turbines with leading-edge erosion and erosion-safe mode operation. J. Phys. Conf. Ser. 2022, 2265, 032009. [Google Scholar] [CrossRef]

- Anh, N. T.; Duc, N. H. A study on power output of horizontal-axis wind turbines under rain. Vietnam J. Sci. Technol. 2019, 57(3), 356–365. [Google Scholar] [CrossRef]

- Anh, N. T.; Duc, N. H. Effect Analysis of Performance and Pitch Controller Operation for Wind Turbine under Rain. GMSARN Int. J. 2022, 16, 339–347. [Google Scholar]

- Douvi, E.; Douvi, D.; Pylarinos, D.; Margaris, D. Effect of Rain on the Aerodynamic Performance of a Horizontal Axis Wind Turbine – A Computational Study. Int. J. Energetica (IJECA) 2021, 6(1), 35–43. [Google Scholar] [CrossRef]

- Douvi, E.; Margaris, D. Hydrodynamic Analysis of a Horizontal Axis Tidal Turbine, Based on the Blade Element Momentum Theory. In Proceedings of the 7th International Conference on “Experiments/ Process/ System Modeling/ Simulation/ Optimization” (7th IC-EPSMSO), Athens, Greece, (5–8 July 2017). [Google Scholar]

- Punge, H.; Kunz, M. Hail observations and hailstorm characteristics in Europe: A review. Atmos. Res. 2016, 176–177, 159–184. [Google Scholar] [CrossRef]

- Wang, P.K. Motions of Ice Hydrometeors in the Atmosphere: Numerical Studies and Implications; Springer Nature Singapore, 2020. [CrossRef]

- Letson, F.; Barthelmie, R.; Pryor, S. Radar-derived precipitation climatology for wind turbine blade leading edge erosion. Wind Energy Sci. 2020, 5(1), 331–347. [Google Scholar] [CrossRef]

- Fiore, G.; Fujiwara, G.; Selig, M. A damage assessment for wind turbine blades from heavy atmospheric particles. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, Florida, USA, (5–9 January 2015). [Google Scholar] [CrossRef]

- Douvi, D.; Georgakopoulos, A.-G.; Lekkas, D.; Douvi, E.; Margaris, D. Aerodynamic degradation of a three-bladed horizontal axis wind turbine operating during a hailstorm. In Proceedings of the 8th International Conference on “Experiments/Process/System Modeling/Simulation/Optimization” (8th IC-EPSMSO), Athens, Greece, 3–6 July 2019. [Google Scholar]

- Douvi, D.; Douvi, E.; Plessas, D.K.; Margaris, D.P. Numerical Simulation of NACA 0012 Airfoil Operating under Hailstorm Conditions. Int. j. new technol. res (IJNTR) 2021, 7(2), 73–80. [Google Scholar] [CrossRef]

- Douvi, D.; Douvi, E. Investigation into the impact of hailstorm on the aerodynamic characteristics of S809 airfoil: A comprehensive computational analysis. In Proceedings of the 10th International Conference on “Experiments/Process/System Modeling/Simulation/Optimization” (10th IC-EPSMSO), Loutraki, Greece, 5–8 July 2023. [Google Scholar]

- Douvi, D.; Douvi, E.; Margaris, D. The Operation of a Three-Bladed Horizontal Axis Wind Turbine under Hailstorm Conditions—A Computational Study Focused on Aerodynamic Performance. Inventions 2022, 7(2), 1–14. [Google Scholar] [CrossRef]

- Khalfallah, M.G.; Koliub, A.M. Effect of dust on the performance of wind turbines. Desalination 2007, 209(1–3), 209–220. [Google Scholar] [CrossRef]

- Khakpour, Y.; Bardakji, S.; Nair, S. Aerodynamic performance of wind turbine blades in dusty environments. In Proceedings of the ASME 2007 International Mechanical Engineering Congress and Exposition, IMECE2007, Seattle, Washington, USA, (11–15 November 2007). [Google Scholar] [CrossRef]

- Al-Khayat, M.; Al-Rasheedi, M.; Gueymard, C.A.; Haupt, S.E.; Kosović, B.; Al-Qattan, A.; Lee, J.A. Performance analysis of a 10-MW wind farm in a hot and dusty desert environment. Part 2: Combined dust and high-temperature effects on the operation of wind turbines. Sustain. Energy Technol. Assess. 2021, 47, 101461. [Google Scholar] [CrossRef]

- Ren, N.-x.; Ou, J.-p. Dust Effect on the Performance of Wind Turbine Airfoils. J. Electromagn. Waves Appl. 2009, 1, 102–107. [Google Scholar] [CrossRef]

- Li, D.; Li, R.; Yang, C.; Wang, X. Effects of Surface Roughness on Aerodynamic Performance of a Wind Turbine Airfoil. In Proceedings of the 2010 Asia-Pacific Power and Energy Engineering Conference (APPEEC 2010), Chengdu, China, 28–31 March 2010. [Google Scholar]

- Salem, H.; Diab, A.; Ghoneim, Z. CFD Simulation and Analysis of Performance Degradation of Wind Turbine Blades in Dusty Environments. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications (ICRERA 2013), Madrid, Spain, 20–23 October 2013. [Google Scholar] [CrossRef]

- Wu, P.; Li, C.; Li, Z. Numerical Simulation of Influence with Surface Contamination on Aerodynamic Performance of Dedicated Wind Turbine Airfoil. Adv. Mater. Res. 2013, 724–725, 572–575. [Google Scholar] [CrossRef]

- Fiore, G.; Selig, M. A Simulation of Operational Damage for Wind Turbine Blades. In Proceedings of the 32nd AIAA Applied Aerodynamics Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar] [CrossRef]

- Fiore, G.; Selig, M. Simulation of Damage for Wind Turbine Blades Due to Airborne Particles. Wind Eng. 2015, 39(4), 399–418. [Google Scholar] [CrossRef]

- Fiore, G.; Selig, M. Optimization of Wind Turbine Airfoils Subject to Particle Erosion. In Proceedings of the 33rd AIAA Applied Aerodynamics Conference, Dallas, TX, USA, 22–26 June 2015. [Google Scholar] [CrossRef]

- Fiore, G.; Selig, M. Time marching simulations of wind turbine blades subject to particle erosion. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, California, USA, 4–8 January 2016. [Google Scholar] [CrossRef]

- Diab, A.; Alaa, M.; Hossam El-Din, A.; Salem, H.; Ghoneim, Z. Performance Degradation of Wind Turbine Airfoils due to Dust Contamination: A Comparative Numerical Study. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition. Volume 9: Oil and Gas Applications; Supercritical CO2 Power Cycles; Wind Energy, Montreal, Quebec, Canada, 15–19 June 2015. [Google Scholar] [CrossRef]

- Srinivasan, S.; Surasani, V.K. CFD Analysis of Effects of Surface Fouling on Wind Turbine Airfoil Profiles. Int. j. power energy eng. Special Issue: Energy Systems and Developments 2015, 4(5-1), 1–11. [Google Scholar]

- Jafari, K.; Djavareshkian, M.; Feshalami, B. The Effects of Different Roughness Configurations on Aerodynamic Performance of Wind Turbine Airfoil and Blade. Int. J. Renew. Energy Dev. 2017, 6(3), 273–281. [Google Scholar] [CrossRef]

- Zidane, I.; Saqr, K.; Swadener, G.; Ma, X.; Shehadeh, M. Computational Fluid Dynamics Study of Dusty Air Flow Over NACA 63415 Airfoil for Wind Turbine Applications. J. Teknol. 2017, 79(7-3), 1–6. [Google Scholar] [CrossRef]

- Han, W.; Kim, J.; Kim, B. Effects of contamination and erosion at the leading edge of blade tip airfoils on the annual energy production of wind turbines. Renew. energy 2018, 115, 817–823. [Google Scholar] [CrossRef]

- Chen, S.; Agarwal, R.K. Numerical Investigation of Wind Turbine Airfoils under Clean and Dusty Air Conditions. Washington University Open Scholarship, St. Louis, 2019. [CrossRef]

- Guo, T.; Jin, J.; Lu, Z.; Zhou, D.; Wang, T. Aerodynamic Sensitivity Analysis for a Wind Turbine Airfoil in an Air-Particle Two-Phase Flow. Appl. Sci. 2019, 9(18). [Google Scholar] [CrossRef]

- ElMessiry, Y.; Kandil, H.; M.S., A.-E. Effect of surface contamination on the wind turbine performance. Wind. Eng. 2021, 45(3), 505–517. [Google Scholar] [CrossRef]

- Douvi, D.; Μargaris, D.; Davaris, A. Aerodynamic Performance of a NREL S809 Airfoil in an Air–Sand Particles Two Phase Flow. In Proceedings of the 7th International Conference “Scientific Computing to Computational Engineering” (7th IC-SCCE), Athens, Greece, 6–9 July 2016. [Google Scholar]

- Douvi, D.; Margaris, D.; Davaris, A.E. Aerodynamic Performance of a NREL S809 Airfoil in an Air–Sand Particle Two-Phase Flow. Computation 2017, 5(13), 1–17. [Google Scholar] [CrossRef]

- Douvi, D.; Douvi, E.; Margaris, D. Computational Study of NACA 0012 Airfoil in Air-Sand Particle Two-Phase Flow at Reynolds Number of Re=1.76×106. Int. j. new technol. res. (IJNTR) 2019, 5(4), 101–108. [Google Scholar] [CrossRef]

- Douvi, D.; Margaris, D. Numerical simulation of NACA 0012 airfoil in air phase flow and in high concentration air–sand particles two-phase flow. In Proceedings of the 8th International Conference from “Scientific Computing to Computational Engineering” (8th IC-SCCE), Athens, Greece, 4–7 July 2018. [Google Scholar]

- Douvi, D.; Douvi, E.; Margaris, D. Aerodynamic Performance of a Horizontal Axis Wind Turbine Operating with Dust—A Computational Study. Inventions 2023, 8(3), 1–21. [Google Scholar] [CrossRef]

- Marten, D.; Wendler, J.; Pechlivanoglou, G.; Nayeri, C.; Paschereit, C. QBlade: An Open Source Tool for Design and Simulation of Horizontal and Vertical Axis Wind Turbines. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 264–269. [Google Scholar]

- Zare, J.; Hosseini, S.; Rastan, M. NREL Phase VI wind turbine in the dusty environment. arXiv preprint arXiv:2304.06285 2023.

- Yu, X.; Yan, L. High Humidity Aerodynamic Effects Study on Offshore Wind Turbine Airfoil/Blade Performance Through CFD Analysis. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition Volume 9: Oil and Gas Applications; Supercritical CO2 Power Cycles; Wind Energy, Charlotte, North Carolina, USA, 26–30 June 2017. [Google Scholar]

- Yue, W.; Xue, Y.; Liu, Y. High Humidity Aerodynamic Effects Study on Offshore Wind Turbine Airfoil/Blade Performance through CFD Analysis. Int. J. Rotating Mach. 2017, 1–15. [Google Scholar] [CrossRef]

- Corten, G.; Veldkamp, H. Insects cause double stall. EWEC, Copenhagen, 2001.

- BladeCleaning. BladeCleaning. 2017. Available online: http://www.bladecleaning.com/ (accessed on August 4, 2023).

- Petrone, G.; de Nicola, C.; Quagliarella, D.; Witteveen, J.; Iaccarino, G. Wind Turbine Performance Analysis Under Uncertainty. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, Florida, U.S.A., 4–7 January 2011. [Google Scholar] [CrossRef]

- Lachmann, G. Aspects of insect contamination in relation to laminar flow aircraft. Aeronautical Research Center, London, 1960.

- Janiszewska, J.; Rastan, R. R.; Hoffmann, M.; Gregorek, G. Effects of grit roughness and pitch oscillations on the LS(1)-0417MOD airfoil. National Renewable Energy Laboratory, Golden, CO, USA, 1996. [CrossRef]

- Janiszewska, J.; Reuss Ramsay, R. R.; Hoffmann, M.; Gregorek, G. Effects of Grit Roughness and Pitch Oscillations on the S814 Airfoil. National Renewable Energy Laboratory, Golden, CO, USA, 1996. [CrossRef]

- Hoffman, M.; Reuss, R.; Gregorek, G. Effects of surface roughness and vortex generators on the NACA 4415 airfoil, NREL/TP-442-7815. National Renewable Energy Laboratory, Golden, CO, USA, 1996. [CrossRef]

- Ramsay, R.; Hoffman, M.; Gregorek, G. Effects of grit roughness and pitch oscillations on the S801 airfoil, NREL/TP-442-7818. National Renewable Energy Laboratory, Golden, CO, USA, 1996. [CrossRef]

- Reuss, R.; Hoffman, M.; Gregorek, G. Effects of surface roughness and vortex generators on the S809 airfoil, NREL/TP-442-7817. National Renewable Energy Laboratory, Golden, CO, USA, 1995. [CrossRef]

- Hoffmann, M.; Reuss Ramsay, R.; Gregorek, G. Effects of Surface Roughness and Vortex Generators on the S813 Airfoil, NREL/TP-442-7815. National Renewable Energy Laboratory, Golden, CO, USA, 1996.

- Ferrer, E.; Munduate, X. CFD Predictions of Transition and Distributed Roughness Over a Wind Turbine Airfoil. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including The New Horizons Forum and Aerospace Exposition, Orlando, Florida, U.S.A., 5–8 January 2009. [Google Scholar] [CrossRef]

- Wilcox, B.; White, E.; Maniaci, D. Roughness Sensitivity Comparisons of Wind Turbine Blade Sections. Sandia National Laboratories, Albuquerque, New Mexico, 2017. [CrossRef]

- Ehrmann, R.; Wilcox, B.; White, E.; Maniaci, D. Effect of Surface Roughness on Wind Turbine Performance. Sandia National Laboratories, Albuquerque, New Mexico, 2017. [CrossRef]

- Sathiesh Kumar, V.; Vasa, N.; Sarathi, R. Detecting salt deposition on a wind turbine blade using laser-induced breakdown spectroscopy technique. Appl. Phys. A 2013, 112, 149–153. [Google Scholar] [CrossRef]

- Yokoyama, S. Lightning protection of wind turbine blades. Electr. Power Syst. Res. 2013, 94, 3–9. [Google Scholar] [CrossRef]

- Huang, S.-L.; Chen, J.-F.; Liang, T.-J.; Su, M.-S.; Chen, C.-Y. Prediction of salt contamination in the rotating blade of wind turbine under lightning strike occurrence using fuzzy c-means and k-means clustering approaches. IET Sci. Meas. Technol. 2020, 14(1), 91–97. [Google Scholar] [CrossRef]

- Wright, J. M.; Colling, A. Seawater: Its Composition, Properties and Behaviour, 2nd ed.; Bearman, G., Ed.; Butterworth-Heinemann: Oxford, United Kingdom, 15 January 1995. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).