Submitted:

02 October 2023

Posted:

03 October 2023

You are already at the latest version

Abstract

Keywords:

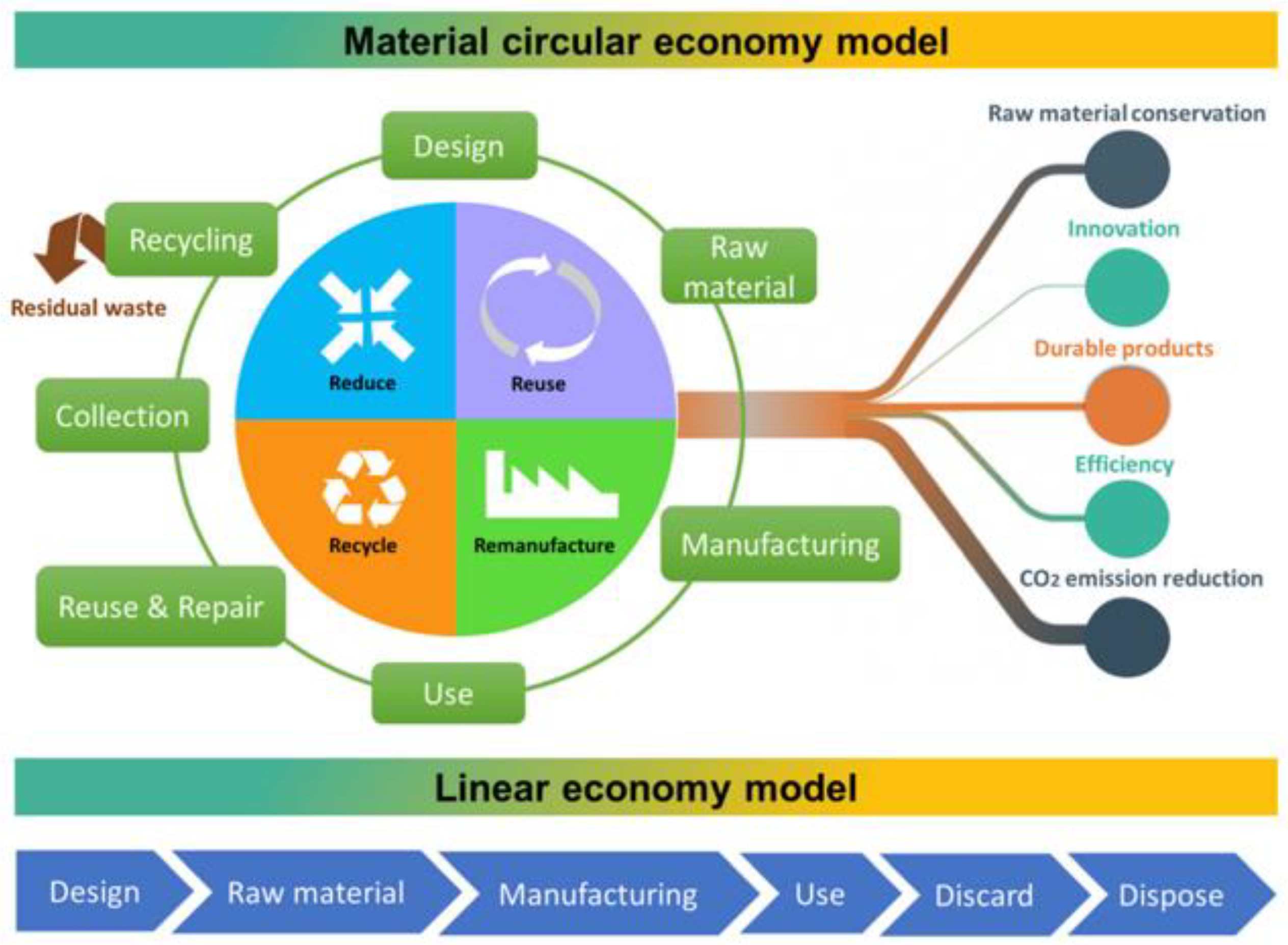

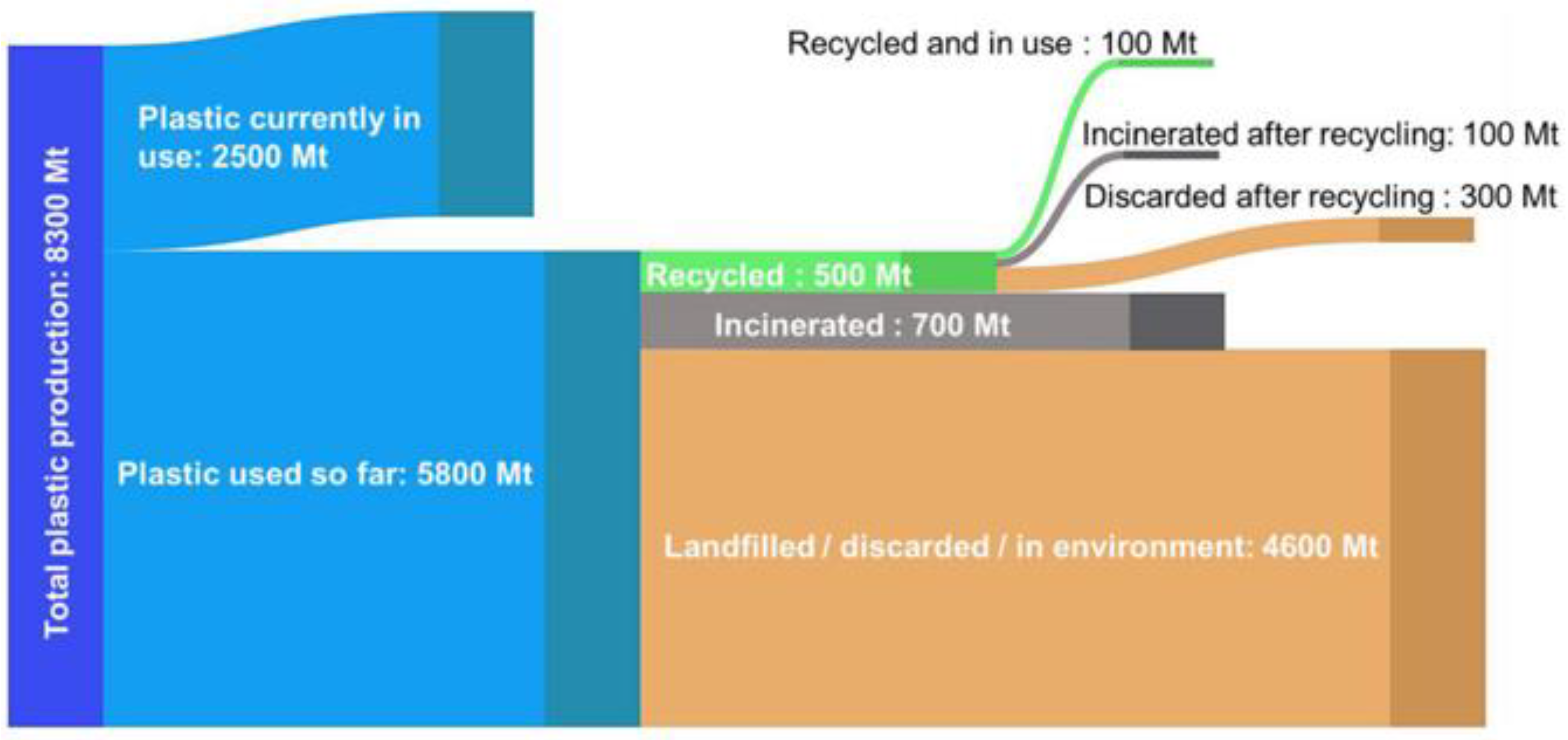

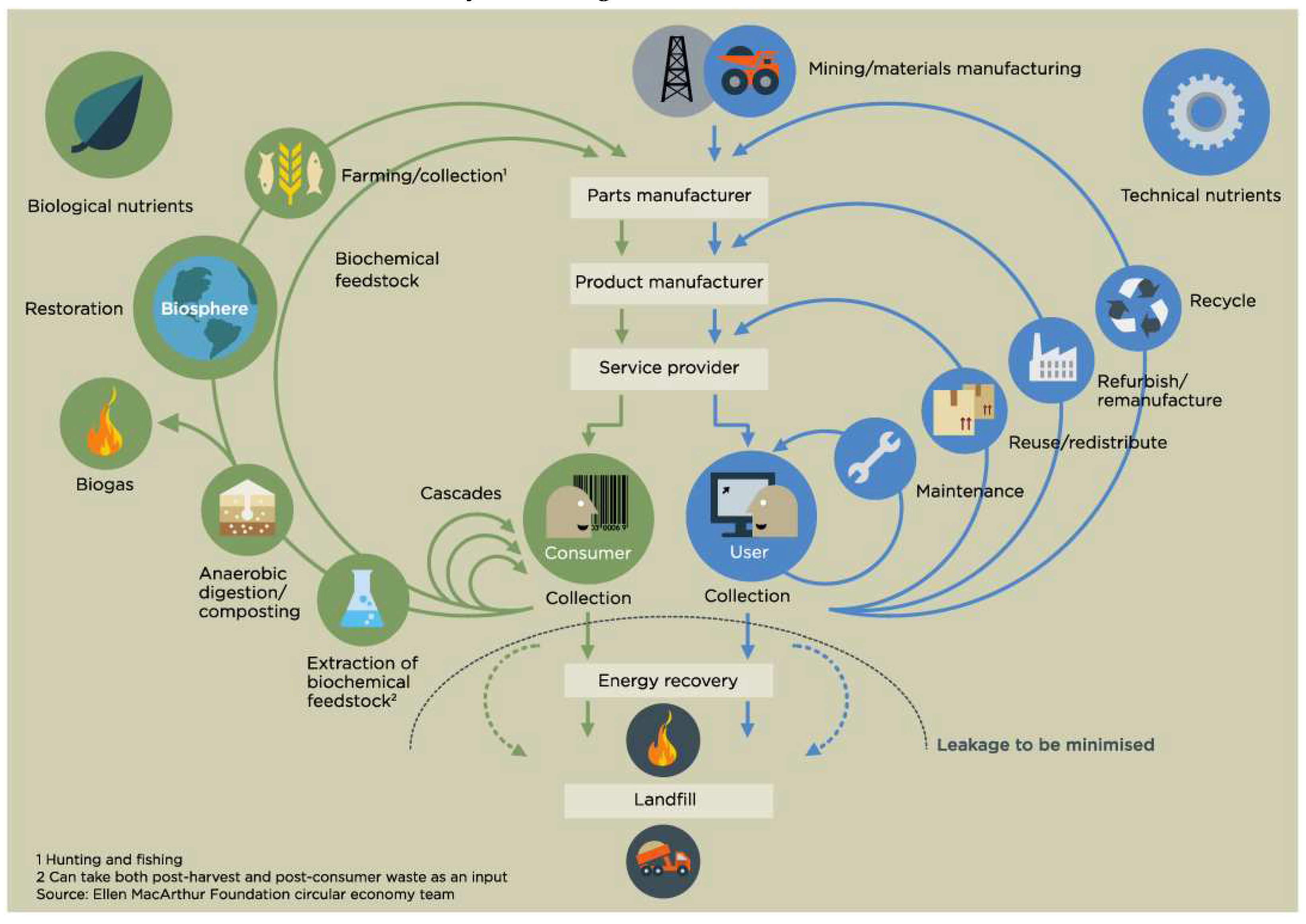

1. Introduction

2. Case Study

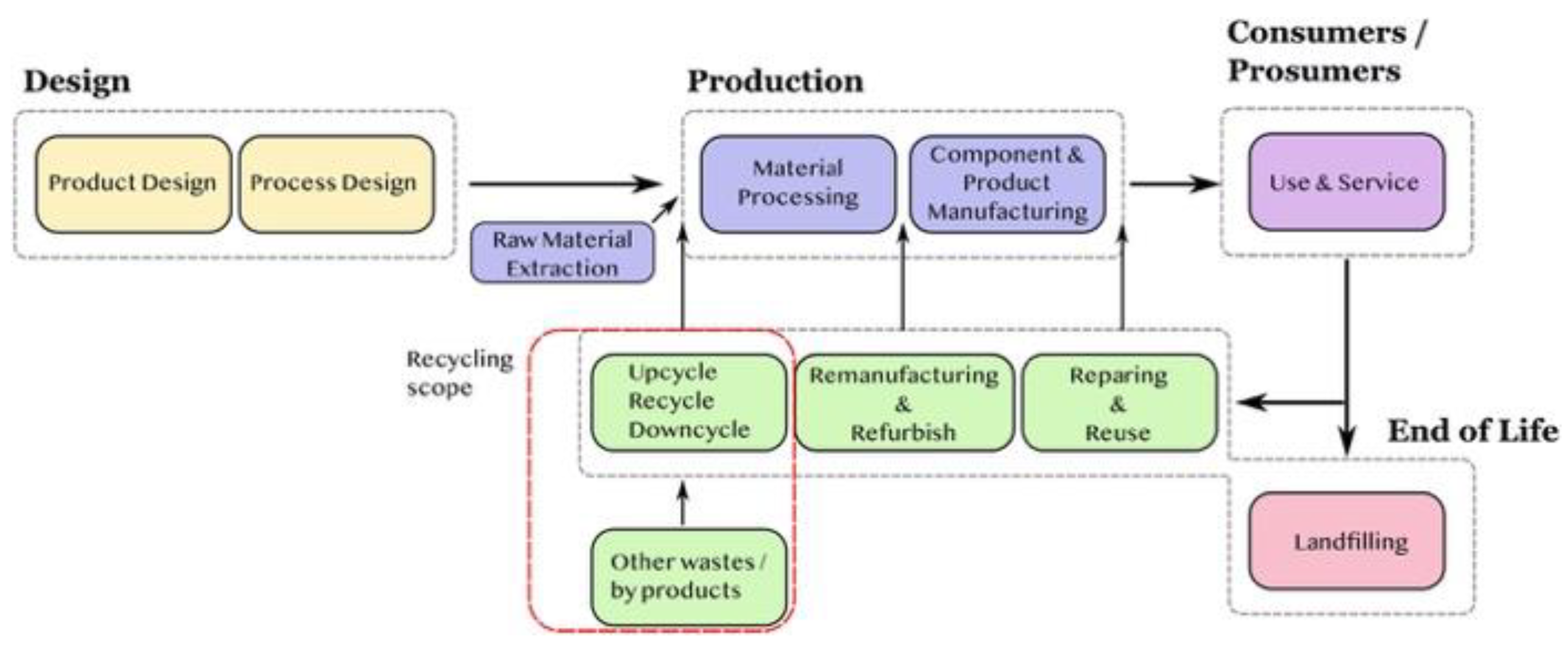

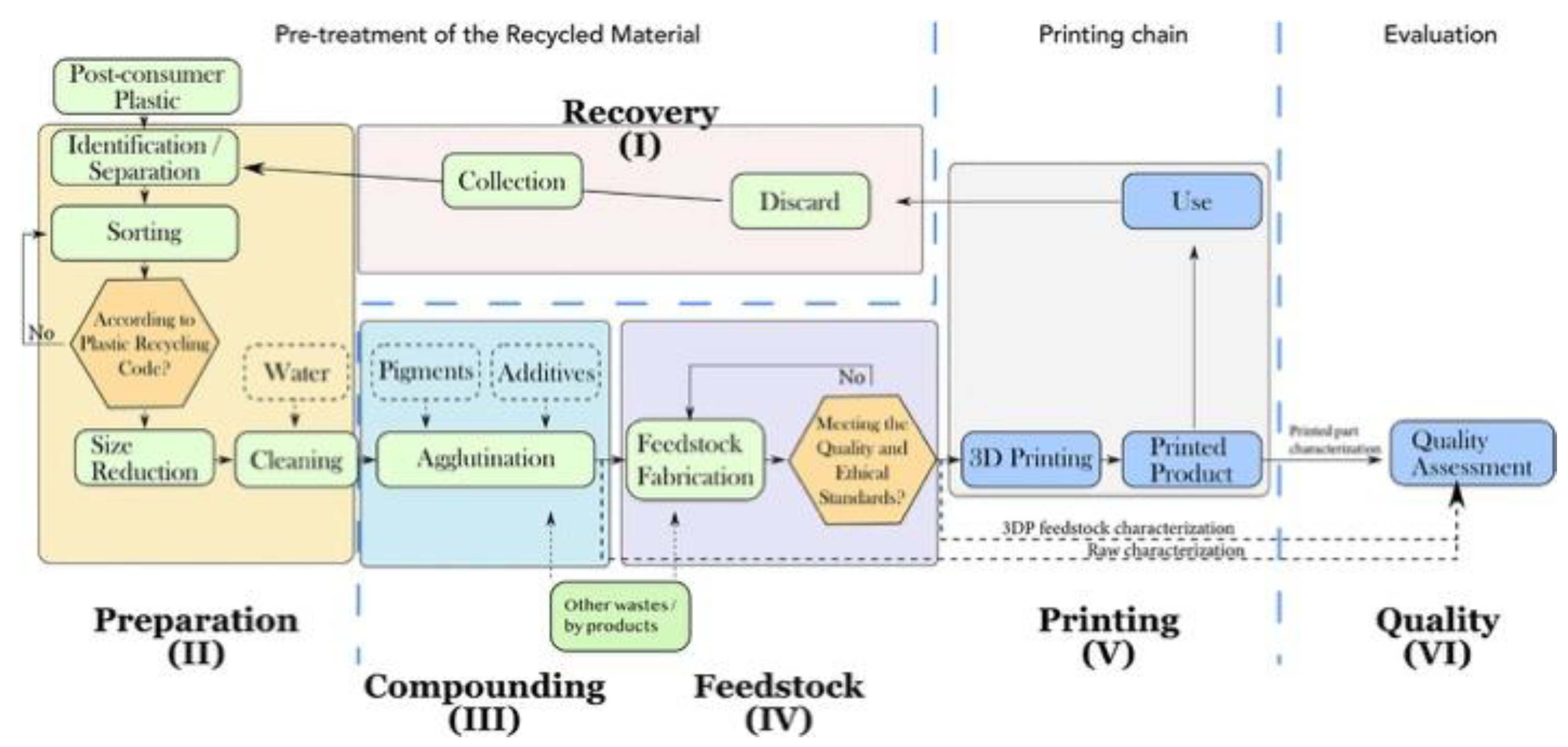

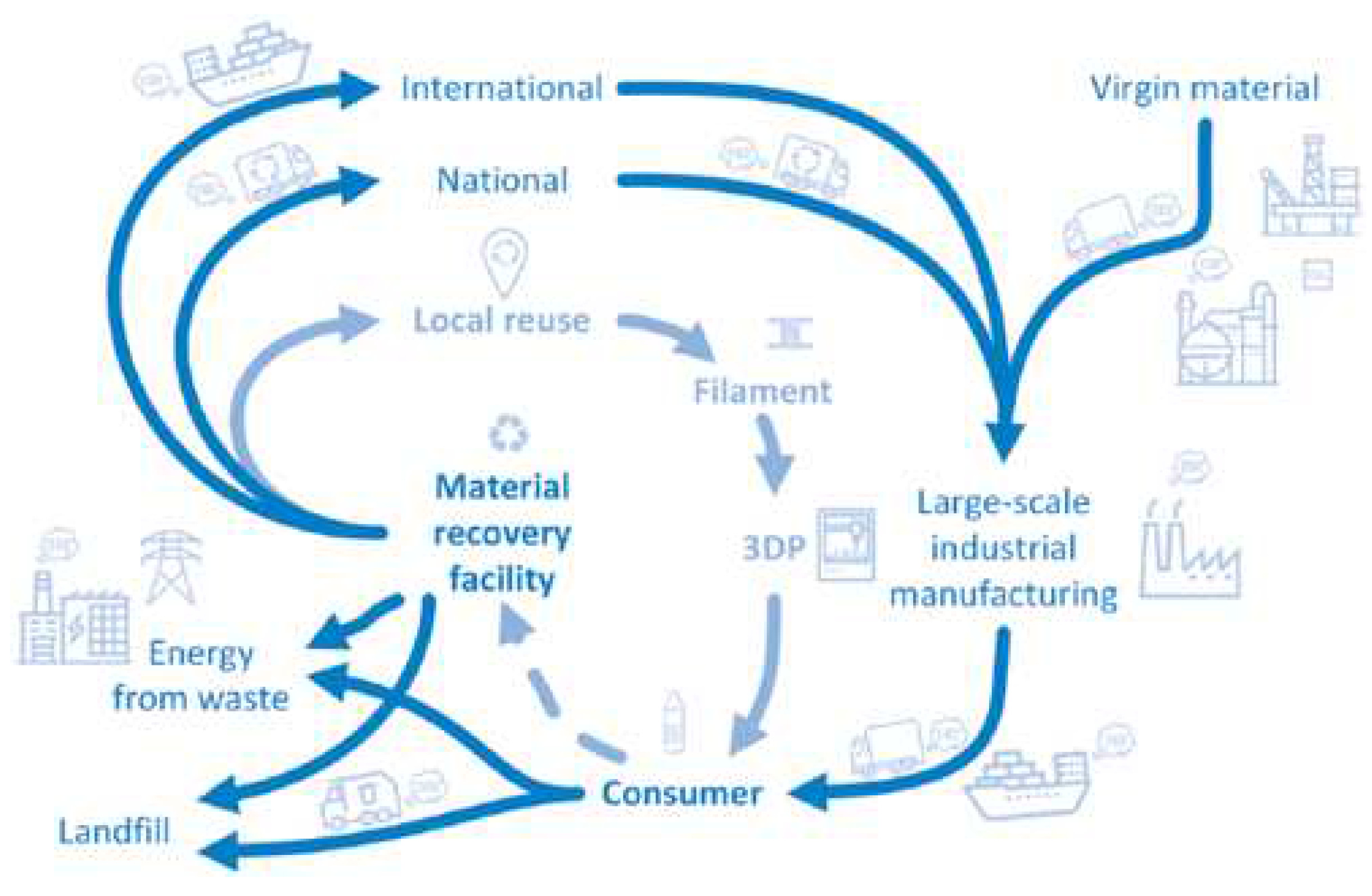

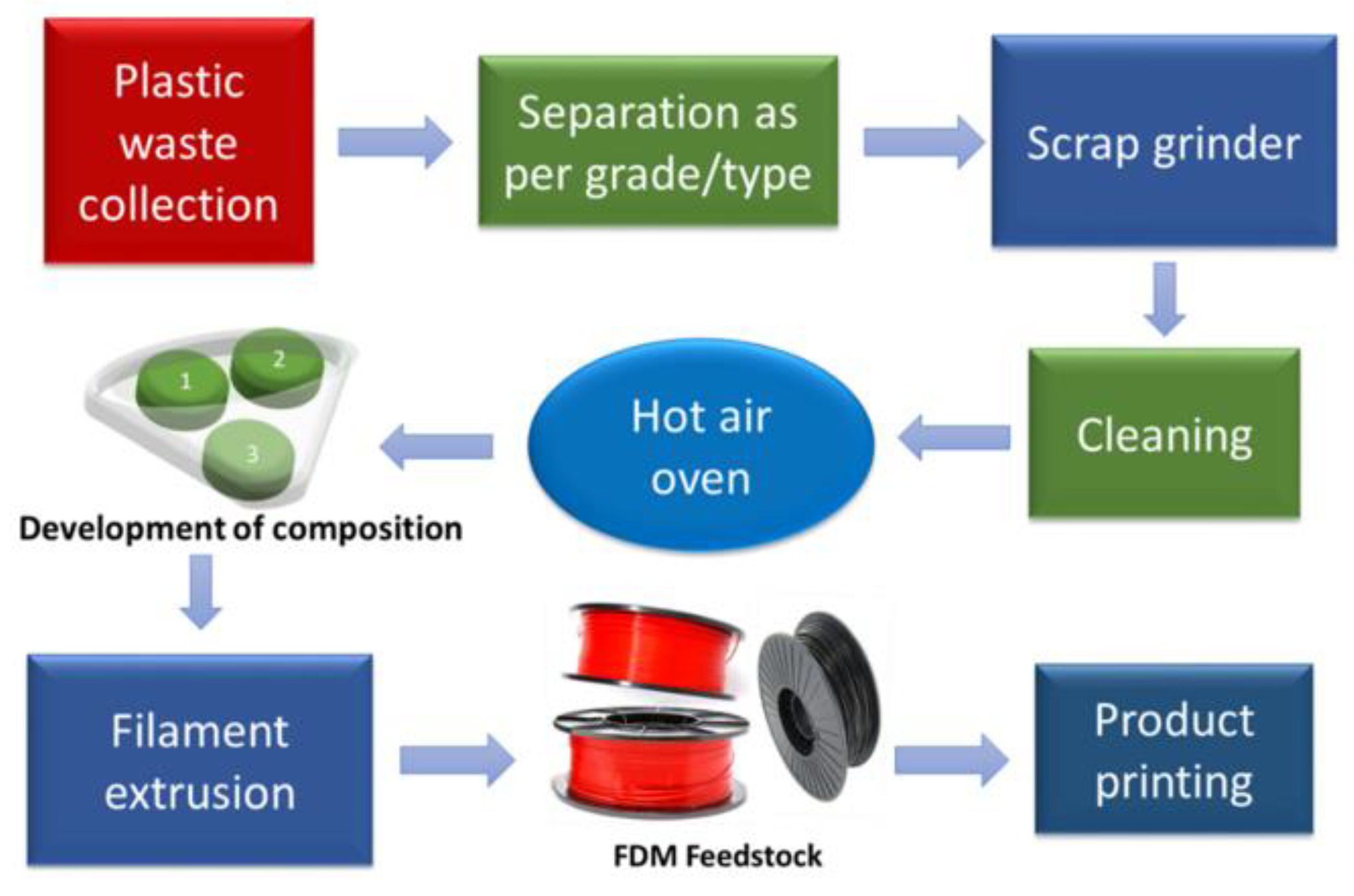

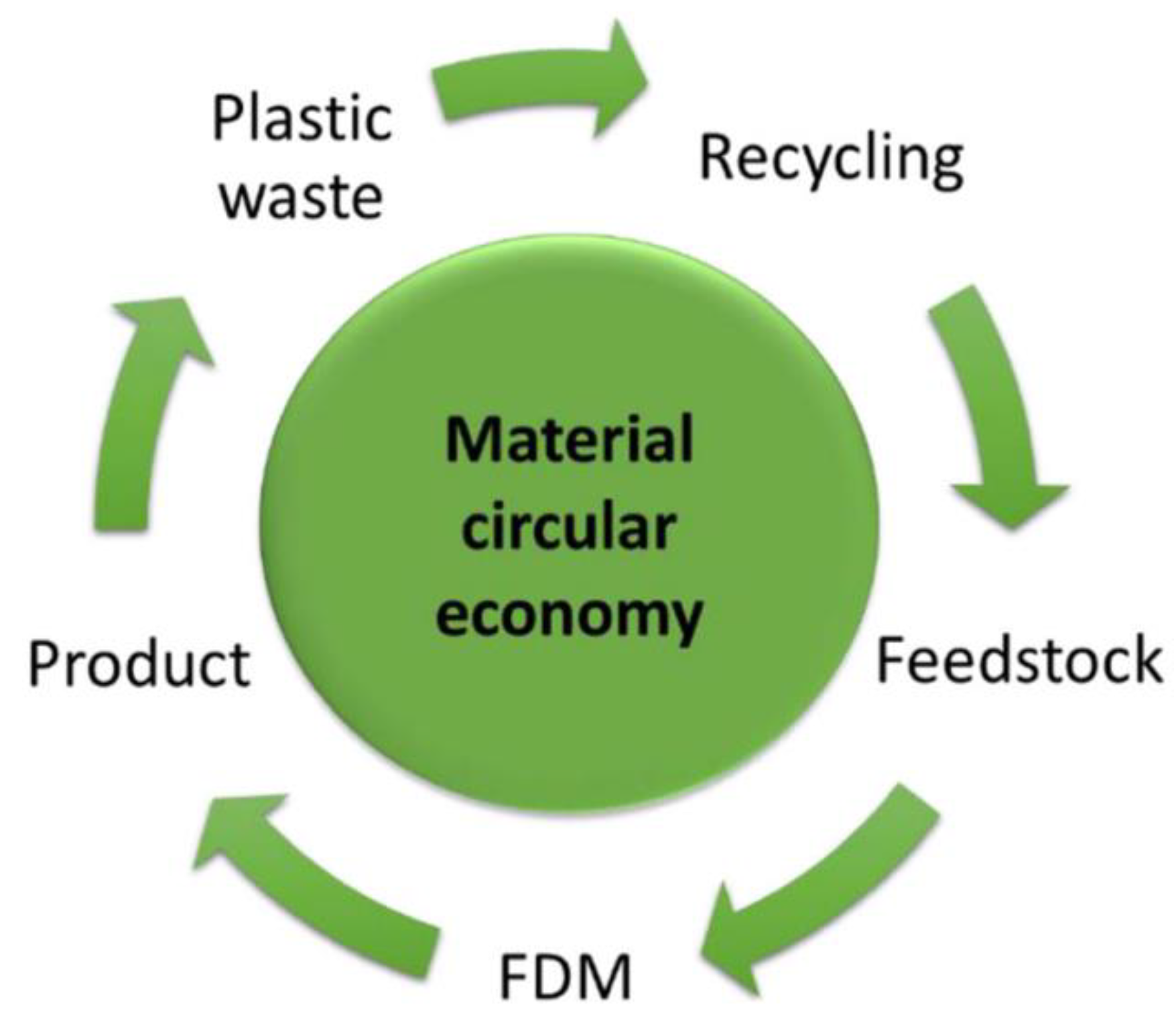

2.1. Case Study 1: Recycling Plastics in Additive Manufacturing

2.1.1. Option 1: Recycled PET as 3D Printing Feedstock

2.1.2. Option 2: Recycled HPDE as 3D Printing Feedstock

2.2. Case Study 2: Recycling Polymers in Additive Manufacturing

3. Discussion

References

- Rahimi, M.; Esfahanian, M.; Moradi, M. Effect of reprocessing on shrinkage and mechanical properties of ABS and investigating the proper blend of virgin and recycled ABS in injection molding. Journal of Materials Processing Technology 2014, 214, 2359–2365. [Google Scholar] [CrossRef]

- Gibson, I.; et al. Additive manufacturing technologies; Springer, 2021; Vol. 17. [Google Scholar]

- Baumers, M.; et al. Charting the environmental dimensions of additive manufacturing and 3D printing. Journal of Industrial Ecology 2017, 21. [Google Scholar] [CrossRef]

- Muthu, S.S.; Savalani, M.M. Handbook of sustainability in additive manufacturing. 2016.

- Matsumoto, M.; et al. Trends and research challenges in remanufacturing. International journal of precision engineering and manufacturing-green technology 2016, 3, 129–142. [Google Scholar] [CrossRef]

- Mani, M.; Lyons, K.W.; Gupta, S. Sustainability characterization for additive manufacturing. Journal of research of the National Institute of Standards and Technology 2014, 119, 419. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, H.; Asiabanpour, B. A Smart Circular Economy for Integrated Organic Hydroponic-Aquaponic Farming. 2023, Texas State University.

- Commission, E., D.-G.f. Research, and Innovation. Accelerating the transition to the circular economy : improving access to finance for circular economy projects. 2019: Publications Office.

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product design in a circular economy: Development of a typology of key concepts and terms. Journal of Industrial Ecology 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: the concept and its limitations. Ecological economics 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Giurco, D.; et al. Circular economy: questions for responsible minerals, additive manufacturing and recycling of metals. 2014, 3, 432–453. [Google Scholar] [CrossRef]

- Santander, P.; et al. Closed loop supply chain network for local and distributed plastic recycling for 3D printing: a MILP-based optimization approach. 2020, 154, 104531. [Google Scholar] [CrossRef]

- Ponis, S.; et al. A systematic literature review on additive manufacturing in the context of circular economy. 2021, 13, 6007. [Google Scholar] [CrossRef]

- Dertinger, S.C.; et al. Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades. 2020, 157, 104810. [Google Scholar] [CrossRef]

- Sanchez, F.A.C.; et al. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Chowdhury, H.; Islam, M.T. Multiple Charger with Adjustable Voltage Using Solar Panel. in International Conference on Mechanical Engineering and Renewable Energy 2015 (ICMERE2015). 2015. Chittagong University of Engineering and Technology.

- Hart, K.R.; Frketic, J.B.; Brown, J.R.J.A.M. Recycling meal-ready-to-eat (MRE) pouches into polymer filament for material extrusion additive manufacturing. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Sauerwein, M.; Doubrovski, E.L.J.M.T.C. Local and recyclable materials for additive manufacturing: 3D printing with mussel shells. 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Juraschek, M.; et al. Experiencing closed loop manufacturing in a learning environment. 2017, 9, 57–64. [Google Scholar] [CrossRef]

- Despeisse, M.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technological Forecasting and Social Change 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of additive manufacturing: the circular economy of materials and environmental perspectives. Journal of Materials Research and Technology 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Byard, D.J.; et al. Green fab lab applications of large-area waste polymer-based additive manufacturing. Additive Manufacturing 2019, 27, 515–525. [Google Scholar] [CrossRef]

- Woern, A.L.; Pearce, J.M. 3-D printable polymer pelletizer chopper for fused granular fabrication-based additive manufacturing. Inventions 2018, 3, 78. [Google Scholar] [CrossRef]

- Reich, M.J.; et al. Mechanical properties and applications of recycled polycarbonate particle material extrusion-based additive manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef]

- Woern, A.L.; et al. Fused particle fabrication 3-D printing: Recycled materials’ optimization and mechanical properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef]

- Giurco, D.; et al. Circular economy: questions for responsible minerals, additive manufacturing and recycling of metals. Resources 2014, 3, 432–453. [Google Scholar] [CrossRef]

- Angioletti, C.M.; et al. , et al. Additive Manufacturing as an opportunity for supporting sustainability through the implementation of circular economies. in 21st Summer School Francesco Turco 2016. 2016. AIDI-Italian Association of Industrial Operations Professors.

- Leino, M.; Pekkarinen, J.; Soukka, R. The role of laser additive manufacturing methods of metals in repair, refurbishment and remanufacturing–enabling circular economy. Physics Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Angioletti, C.M.; Despeisse, M.; Rocca, R. Product circularity assessment methodology. in IFIP International Conference on Advances in Production Management Systems. 2017. Springer.

- Reijonen, J.; et al. Circular Economy Concept in Additive Manufacturing. in Euro PM2017 Congress & Exhibition. 2017. European Powder Metallurgy Association (EPMA).

- Alghamdi, A.; Prickett, P.; Setchi, R. A conceptual framework to support decision-making in remanufacturing engineering processes. in International Conference on Sustainable Design and Manufacturing. 2017. Springer.

- Voet, V.S.; et al. Biobased acrylate photocurable resin formulation for stereolithography 3D printing. ACS omega 2018, 3, 1403–1408. [Google Scholar] [CrossRef]

- Unruh, G. Circular economy, 3D printing, and the biosphere rules. California Management Review 2018, 60, 95–111. [Google Scholar] [CrossRef]

- Garmulewicz, A.; et al. Disruptive technology as an enabler of the circular economy: what potential does 3D printing hold? California Management Review 2018, 60, 112–132. [Google Scholar] [CrossRef]

- Navarro, J.C.; et al. Policies and motivations for the CO2 valorization through the Sabatier reaction using structured catalysts. A review of the most recent advances. Catalysts 2018, 8, 578. [Google Scholar]

- Clemon, L.; Zohdi, T. On the tolerable limits of granulated recycled material additives to maintain structural integrity. Construction and Building Materials 2018, 167, 846–852. [Google Scholar] [CrossRef]

- Pavlo, S.; et al. 3D-printing based distributed plastic recycling: a conceptual model for closed-loop supply chain design. in 2018 ieee international conference on engineering, technology and innovation (ice/itmc). 2018. IEEE.

- Sauerwein, M.; Doubrovski, E.L. Local and recyclable materials for additive manufacturing: 3D printing with mussel shells. Materials Today Communications 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Minetola, P.; Eyers, D. Energy and cost assessment of 3D printed mobile case covers. Procedia CIRP 2018, 69, 130–135. [Google Scholar] [CrossRef]

- Lahrour, Y. ; Brissaud, D A technical assessment of product/component re-manufacturability for additive remanufacturing. Procedia Cirp 2018, 69, 142–147. [Google Scholar] [CrossRef]

- Baiani, S.; Altamura, P. Waste materials superuse and upcycling in architecture: design and experimentation. TECHNE-Journal of Technology for Architecture and Environment 2018, 142–151. [Google Scholar]

- Saboori, A.; et al. Application of directed energy deposition-based additive manufacturing in repair. Applied Sciences 2019, 9, 3316. [Google Scholar] [CrossRef]

- Wu, H.; Wu, R. The role of educational action research of recycling process to the green technologies, environment engineering, and circular economies. International Journal of Recent Technology and Engineering (IJRTE) 2019, 8, 1639–1645. [Google Scholar] [CrossRef]

- Sauerwein, M.; et al. Exploring the potential of additive manufacturing for product design in a circular economy. Journal of Cleaner Production 2019, 226, 1138–1149. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; et al. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. Journal of Manufacturing Technology Management 2019. [Google Scholar] [CrossRef]

- Turner, C.; et al. Sustainable production in a circular economy: A business model for re-distributed manufacturing. Sustainability 2019, 11, 4291. [Google Scholar] [CrossRef]

- Shanmugam, V.; et al. Polymer recycling in additive manufacturing: An opportunity for the circular economy. Materials Circular Economy 2020, 2, 1–11. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: an exploratory study of the advantages and challenges. Journal of cleaner Production 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Niaki, M.K.; et al. Economic sustainability of additive manufacturing: Contextual factors driving its performance in rapid prototyping. Journal of Manufacturing Technology Management 2019. [Google Scholar]

- Omer, L.; et al. Induction Initiated Curing of Additively Manufactured Thermoset Composites. in Solid Freeform Fabrication 2022: Proceedings of the 33rd Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference. 2022.

- Chen, D.; et al. Direct digital manufacturing: definition, evolution, and sustainability implications. Journal of Cleaner Production 2015, 107, 615–625. [Google Scholar] [CrossRef]

- Drizo, A.; Pegna, J. Environmental impacts of rapid prototyping: an overview of research to date. Rapid prototyping journal 2006. [Google Scholar] [CrossRef]

- Freitas, D.; et al. Sustainability in extrusion-based additive manufacturing technologies. Progress in Additive Manufacturing 2016, 1, 65–78. [Google Scholar] [CrossRef]

- Morrow, W.; et al. Environmental aspects of laser-based and conventional tool and die manufacturing. Journal of Cleaner Production 2007, 15, 932–943. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: technology, applications and research needs. Frontiers of mechanical engineering 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Vaezi, M.; et al. Multiple material additive manufacturing–Part 1: a review: this review paper covers a decade of research on multiple material additive manufacturing technologies which can produce complex geometry parts with different materials. Virtual and Physical Prototyping 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. International scholarly research notices, 2012. 2012. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Science advances 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Chonga, S.; et al. Cradle to Cradle® design for 3D printing. Chemical Engineering 2015, 45. [Google Scholar]

- Sanchez, F.A.C.; et al. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. Journal of Cleaner Production 2020, 264, 121602. [Google Scholar] [CrossRef]

- Foundation, E.M. Towards the circular economy. 2012: Ellen MacArthur Foundation.

- Pearce, J.; et al. 3-D printing of open source appropriate technologies for self-directed sustainable development. European Journal of Sustainable Development 2010, 3. [Google Scholar] [CrossRef]

- Kreiger, M.; et al. Distributed recycling of post-consumer plastic waste in rural areas. MRS Online Proceedings Library (OPL) 2013, 1492, 91–96. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of PET. European polymer journal 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Garside, M. Global plastic production 1950-2018. Statista. 2019. Available online: https://www. statista. com/statistics/282732/global-production-ofplastics-since-1950.

- Chen, S.; et al. Carbonization: a feasible route for reutilization of plastic wastes. Science of the Total Environment 2020, 710, 136250. [Google Scholar] [CrossRef] [PubMed]

- Atsani, S.; Mastrisiswadi, H. Recycled polypropylene filament for 3D printer: extrusion process parameter optimization. in IOP Conference Series: Materials Science and Engineering. 2020. IOP Publishing.

- Rahimizadeh, A.; et al. Recycling of fiberglass wind turbine blades into reinforced filaments for use in Additive Manufacturing. Composites Part B: Engineering 2019, 175, 107101. [Google Scholar] [CrossRef]

- Zhao, P.; et al. Close-looped recycling of polylactic acid used in 3D printing: An experimental investigation and life cycle assessment. Journal of Cleaner Production 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).