1. Introduction

Recent adaptations of smart systems for on-body wearable applications for human well-being, health monitoring, and observing human movements have grabbed attention [

1,

2]. Following recent developments, more flexible electronic components are becoming a part of wearable systems as they offer greater flexibility, comfort during wearability, and ease of handling [

3,

4]. Wearable sensors, energy harvesting devices, epidermal electronics, and a variety of electronic circuits have been developed and used in health monitoring [

3,

5,

6,

7]. To convey sensory information and access remote diagnosis through wearable wireless communication, an antenna is required. Real-time measurements related to physiological aspects such as heart rate, human body movements, intrinsic strain measurements, environmental humidity, and body temperature, through wireless sensor networks (WSNs) and body sensor networks (BSNs), require more flexible electronic components [

8,

9,

10,

11]. Applications such as humanoid robotics, human-machine interactions, and prosthetics also require flexible electronic components. WSNs and BSNs integrated with functional devices for such end-use applications demand flexibility, stretchability, and conformability from embedded devices in these networks. Materials that offer such a variety of properties create the possibility of making flexible electronic components [

12]. Additionally, such materials can also be used to produce multifunctional devices with added functions. Many flexible antennas have been fabricated and are effective for wearable applications, but they are limited to a single end-use application, namely the receiving or transmission of electromagnetic (EM) radiations [

13,

14]. In some other reported literature, an antenna and a strain sensor are typically treated as separate devices within a wearable system [

15,

16]. Application, such as strain-sensing parallel to communication, requires antennas to be made off stretchable materials with high modulus, that can attain high elongation before break. Antenna sensitivity toward stretching can be utilized as a strain-sensing factor [

17]. During the practical end-use application, when a stretchable antenna experiences uniaxial strain or deformation, its resonance frequency changes accordingly. This change in antenna resonance frequency can serve as a signature of deformation due to applied strain, indicating the potential use of a stretchable antenna as a strain sensor [

17,

18,

19,

20]. Using a multifunctional antenna in a wearable system can be beneficial in reducing the number of devices in the wearable system without compromising its functionality.

The use of multifunctional devices also minimizes the problem of complex wiring, which is prone to damage and is required to acquire sensory data in wearable smart systems. Similarly, a wearable system with multifunctional devices can solve integration challenges into any garment [

4,

21]. Considering these practical end-use challenges and limitations, a wearable system with multifunctional devices that offers equal functionalities, similar to a wearable system with more nodes and sensors required for separate functions to analyze but with less complexity, would be advantageous [

22].

Figure 1 illustrates the overview of the potential end-use applications of a strain sensor stretchable antenna, including the detection of Edema disease, monitoring joint angles in robotic hands to control movement, assessing inflated food packages due to spoilage, and various fields such as sports, healthcare, rehabilitation, structural health monitoring, and smart packaging. These are some of the possible applications where the proposed stretchable textile microstrip patch antenna can be used.

This manuscript presents a fully textile-based, flexible, and stretchable antenna. Our proposed work focuses on fabricating a stretchable textile patch antenna for strain sensing and communication, which can be used in wearable applications. Furthermore, we present a novel and simpler method to fabricate a stretchable antenna on a non-stretchable e-textile fabric. Our research follows an adapted and simplified antenna design, making it an interesting progression. The antenna is realized using a non-stretchable turned stretchable e-textile fabric, accompanied by a transparent, flexible, and stretchable non-conductive polydimethylsiloxane (PDMS) substrate.

This paper is organized as follows:

Section 2 presents the state-of-the-art stretchable antennas and the general strategy adopted in this research work to realize the stretchable textile microstrip patch antenna.

Section 3 includes the materials and methods used to develop the stretchable textile microstrip patch antenna. The antenna design, its fabrication method, modeling, and simulation are described in

Section 4. The methodology to characterize the EM performance of the stretchable antenna is discussed in

Section 5. The simulated and measured EM results of the developed antenna are discussed in detail in

Section 6, and last, the key conclusions are discussed in

Section 7.

2. State-of-the-art stretchable antennas

In recent years, several stretchable antennas have been developed [

13,

23,

24]. The choice to fabricate a stretchable antenna with the desired electromagnetic (EM) properties for a wearable system depends on various factors. These include the availability of stretchable materials, both conductive and non-conductive, the space available for antenna integration in the wearable system, and the required operating frequency range [

25,

26]. More importantly, the incompatibility of physical parameters among different materials used in fabricating a patch antenna makes the task of pasting multiple layers challenging, while still leaving their stretchability intact.

Various conductive materials have been employed to construct stretchable antennas, including Silver-Polydimethylsiloxane (Ag-PDMS) composite, metal nanowires, and liquid metal alloys. However, the poor conductivity of these materials remains a significant concern [

23,

27,

28]. While these materials offer improved stretchability, their electromagnetic (EM) performance in radio-frequency (RF) wireless technologies still requires enhancement. To address this issue, more recently [

17], conductive textile fabrics such as copper and silver-coated polymeric textile fabrics have been utilized and given a serpentine structure. Consequently, using a highly conductive textile fabric with a serpentine structure provides better stretchability and suitable EM performance.

To fabricate a stretchable patch antenna, one option is to use conductive and dielectric materials, that have a stretchable character. However, this way of constructing a stretchable patch antenna is difficult as both the conductive and dielectric materials will not be compatible in their stretchability. One will offer more stretchability than the other when sandwiched together in a patch antenna shape. Alternatively, the antenna design itself can be modified to allow for an extra amount of stretching, or a combination of both approaches can be employed. Each method of fabricating a stretchable antenna has its advantages and limitations. In recent developments, an example where antenna design is modified to get stretchability by a patch antenna, optimally patterned 3D structures such as serpentine and helical coils made from conventional non-stretchable materials like copper foil have been utilized for fabricating stretchable patch antennas [

12,

17]. These structures are then deposited onto stretchable dielectric materials such as Ecoflex, Solaris, and PDMS. This approach involves a complex process of designing the antenna with a 3D serpentine pattern, simulating it, using specialized software to design and cut the intricate pattern, and finally, employing a delicate fabrication process to deposit the 3D serpentine patterns onto the stretchable material. Various parameters, including the arc angle, need to be considered while simulating the serpentine structure-based antenna [

17,

29]. The resulting serpentine patch antennas exhibit improved stretchability, but they also result in a higher Surface Absorption Rate (SAR) due to the serpentine-structured ground plane. The limited surface area of conductive material in the serpentine ground plane compared to a solid layer in the traditional patch antenna topology contributes to this increase in SAR [

30,

31].

Other recent advancements in the field of stretchable antennas include the use of serpentine structures (stretchable 3-dimensional structures with repeated unit cells of the same shape), materials such as silver nanowires (AgNWs), and liquid metal alloys [

15,

26,

32,

33,

34]. In another notable development [

17] to fabricate a stretchable antenna, where the antenna is based on a serpentine structure. Here, a stretchable knitted silver-plated textile fabric (MedTex, UK) is converted into a serpentine structure first and then joined with the stretchable Ecoflex substrate to fabricate a stretchable patch antenna. Though the serpentine structure exhibits high sensitivity toward stretching due to the use of stretchable conductive fabric over a stretchable dielectric substrate, the fabrication process in shaping the serpentine structure involves a few steps followed by a delicate step of depositing the serpentine conductive layers over the stretchable Ecoflex layer to ensure their integrity and shape remain intact. There is always a trade-off between mechanical stretchability and the EM performance of the meshed/serpentine antenna. Another recently reported approach [

35] employs conventional non-stretchable electrodes or sheets (such as stiff metals like copper foil) patterned in a repeated unit cell to make them stretchable. These serpentine layers are combined with a PDMS substrate to fabricate a stretchable antenna. Other literature explores strategies such as Kirigami-like structures and twisted helical spring structures to enable stretchability in materials originally non-stretchable [

36]. Quantifying the stretchability, AgNWs achieve a minimum of 15% stretchability, while serpentine-based antennas can achieve a maximum stretchability of 100% [

17,

26].

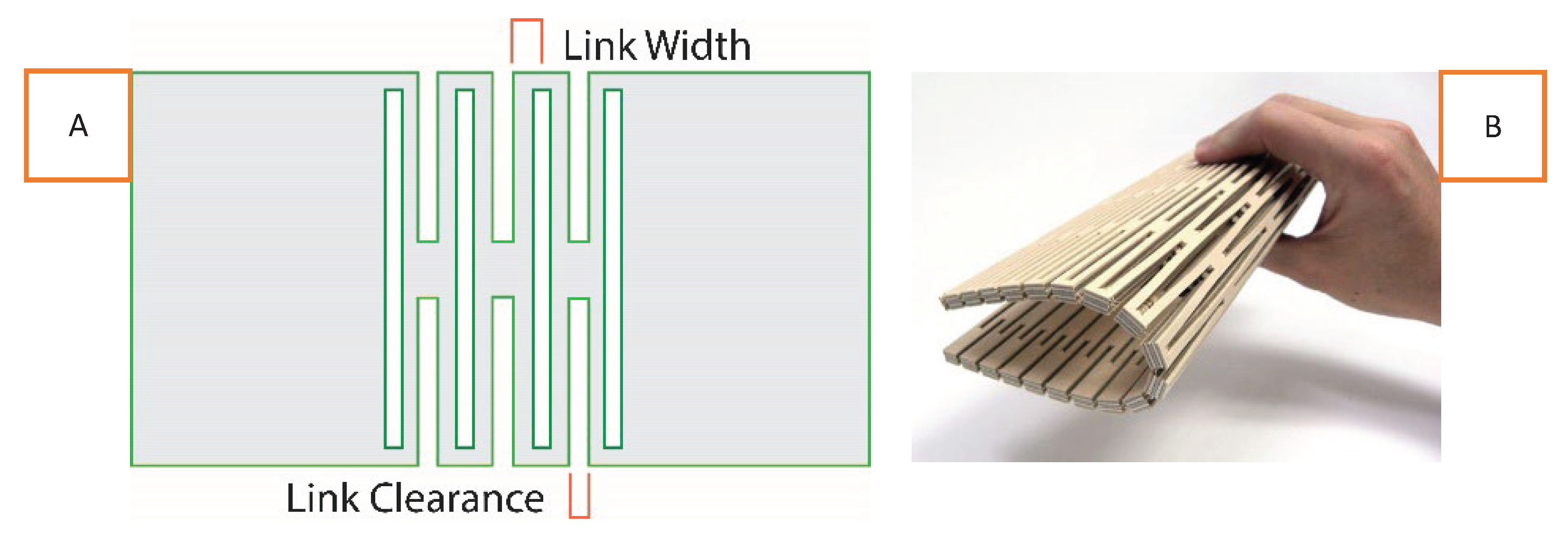

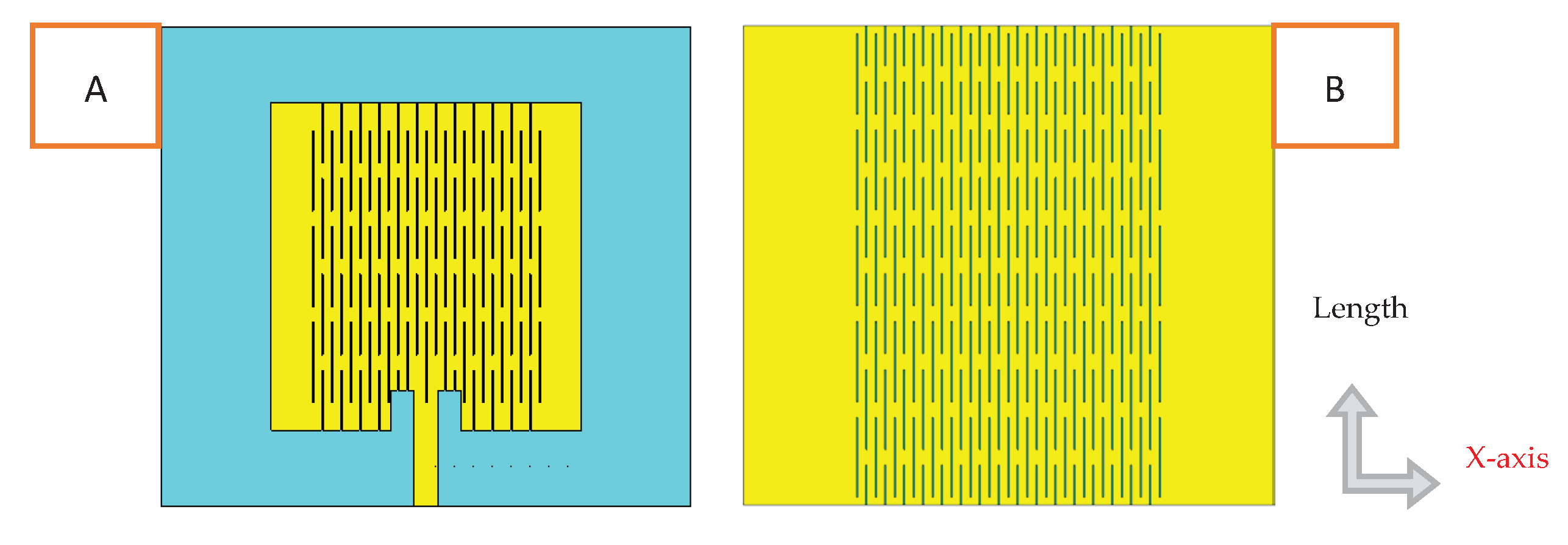

Our research proposes a simpler, easy, and novel method for fabricating stretchable textile-based antennas, based on transforming plain conductive layers of a patch antenna into the lattice hinge design (LHD) conductive layers. The structure of an LHD and its design parameters are shown in

Figure 2 (a) and (b), respectively. This design enables the transformation of a non-stretchable sheet (such as a wood sheet) into a stretchable and bendable one by patterning the sheet in a way that allows for deformation when stretched or subjected to uniaxial strain. Unlike the serpentine structure, this simple antenna design facilitates the transformation of a non-stretchable conductive electrotextile into a stretchable layer with minimal impact on its electrical performance. The LHD is formed by creating parallel, overlapping longitudinal slots of specific length and width, which divide the sheet into repeated linked sections capable of stretching compared to a plain sheet without such longitudinal slots. This way, an array of parallel columns of longitudinal slots is formed; this array helps sustain deformation in a uniaxial direction, while also enhancing the sheet's flexibility when handled. These design principles are followed in our research to convert a non-stretchable conductive textile fabric into a stretchable structure by incorporating the LHD. This innovative approach opens possibilities for diverse implementations and a variety of antenna designs to get enhanced antenna stretchability.

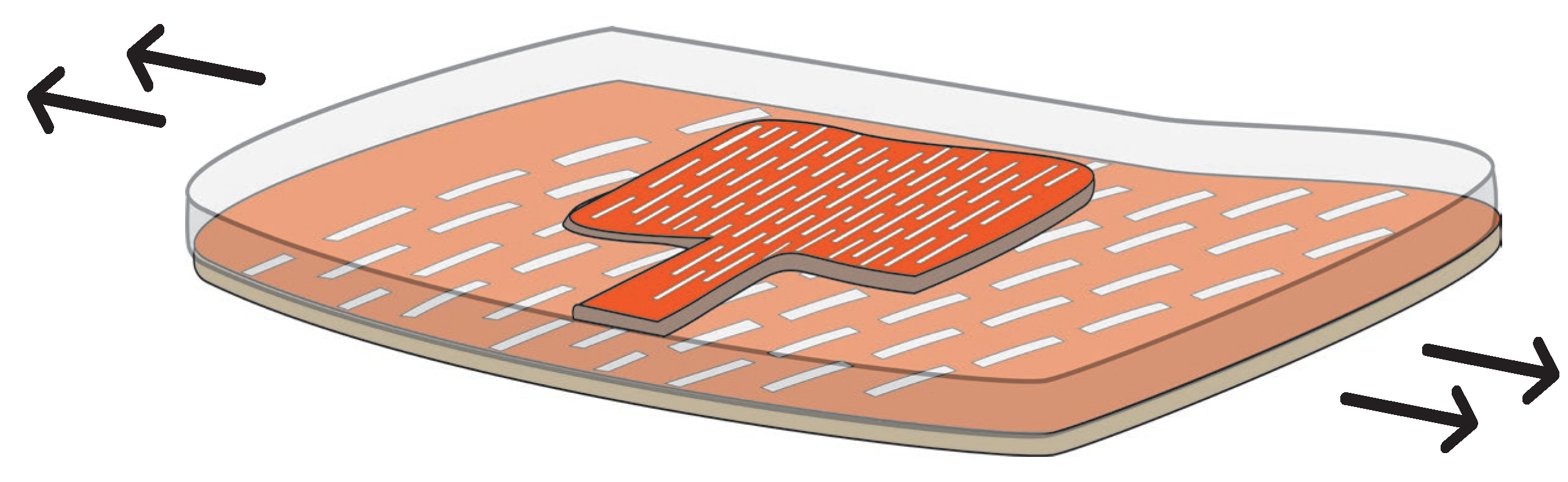

Figure 3 provides a conceptual overview of the developed conformable, flexible, and stretchable microstrip patch antenna through an LHD.

One significant advantage of using e-textiles with lower surface resistivity is the reduced cost of integrating antennas into garments. Additionally, our proposed LHD-based stretchable antenna fabrication method offers minimal change in its electrical performance while providing stretchable characteristics. The distinguishing feature of our research from existing stretchable antenna literature lies in a simpler and novel technique employed to create a fully textile stretchable antenna. This work can be further extended by exploring different design patterns to convert non-stretchable materials into stretchable ones.

3. Materials and Methods

The selection of both conductive and non-conductive/dielectric materials to fabricate a stretchable antenna was primarily based on the factor of stretchability. In recent literature, a variety of dielectric materials commercially available, such as Ecoflex, Solaris, and PDMS, have been utilized to fabricate stretchable antennas [

3,

37,

38,

39,

40]. These soft, transparent, flexible, and stretchable polymers offer improved wearability for wearable applications compared to conventional rigid dielectric materials like FR4, which are traditionally used in antenna fabrication.

3.1. Conductive Textile Materials

Among the various fabric geometries, knitted structures are the most suitable for fabricating stretchable textile antennas due to their superior stretchability compared to woven and non-woven structures. This research begins with the selection of knitted conductive materials to be used in stretchable antenna fabrication. Initially, a commercially available two-way stretchable conductive silver-coated knitted electrotextile (Shieldex® Technik-tex P130+B by Statex Produktions, Germany) was chosen because of its highly stretchable nature and lowest possible surface resistivity among other commercially available knitted structures. This silver-plated knitted fabric is composed of 78% polyamide and 22% elastomer, with a coating of 99% pure silver. However, this fabric has a surface resistivity of 2 Ohm/square (Ω/sq) and a conductivity of 909 S/m, significantly lower than that of a standard copper metal sheet with a conductivity of 5.96×10

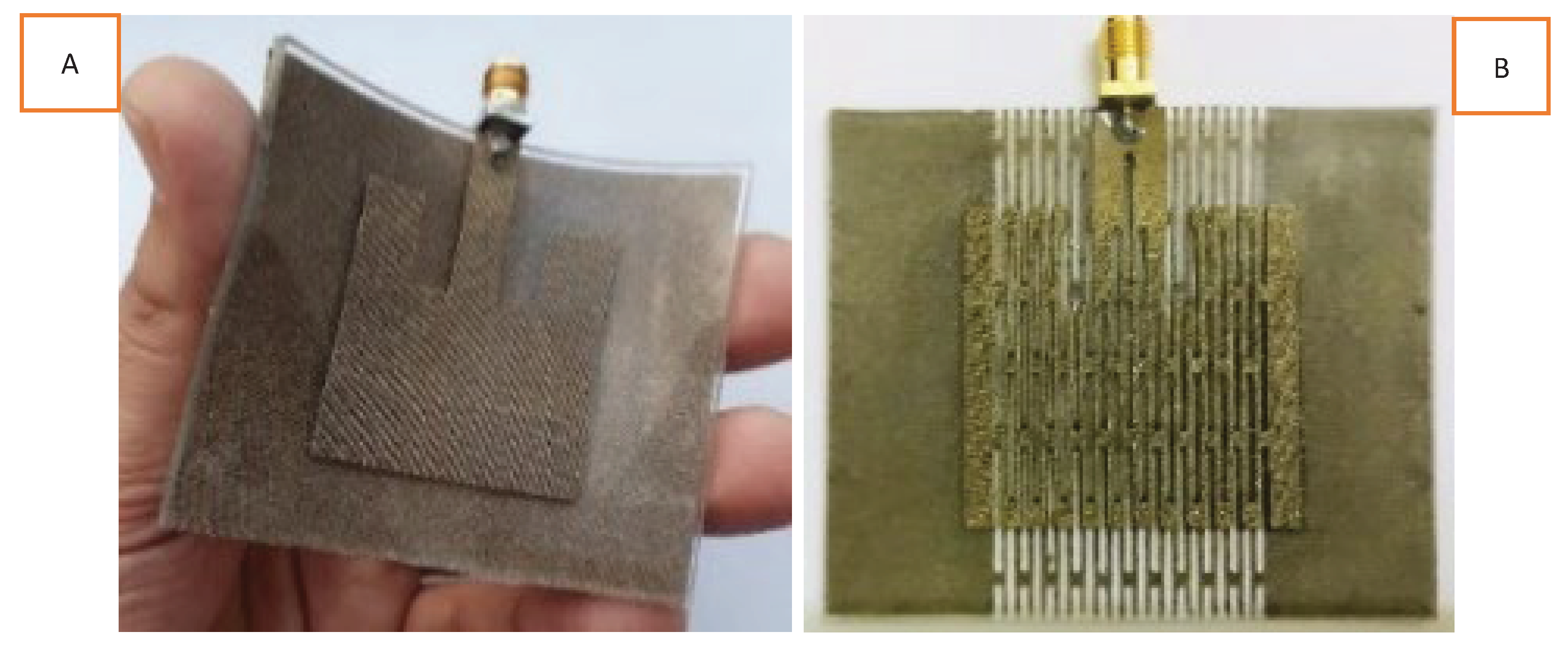

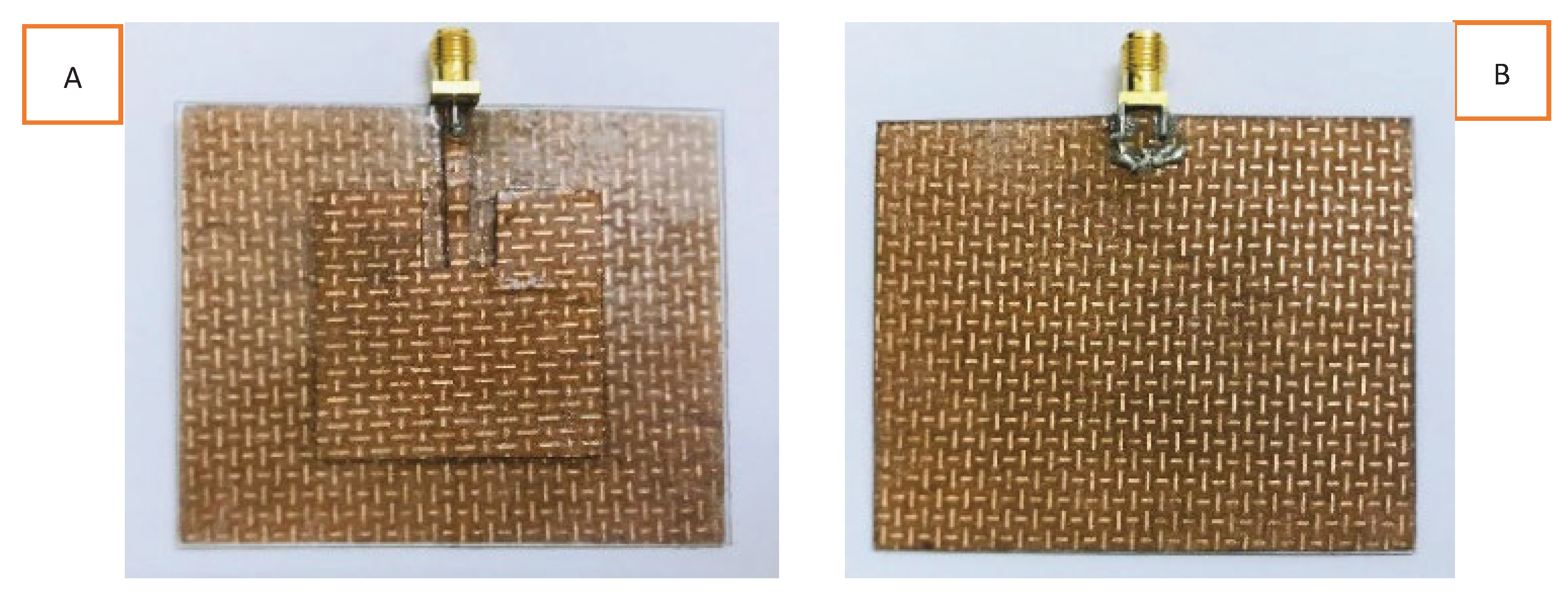

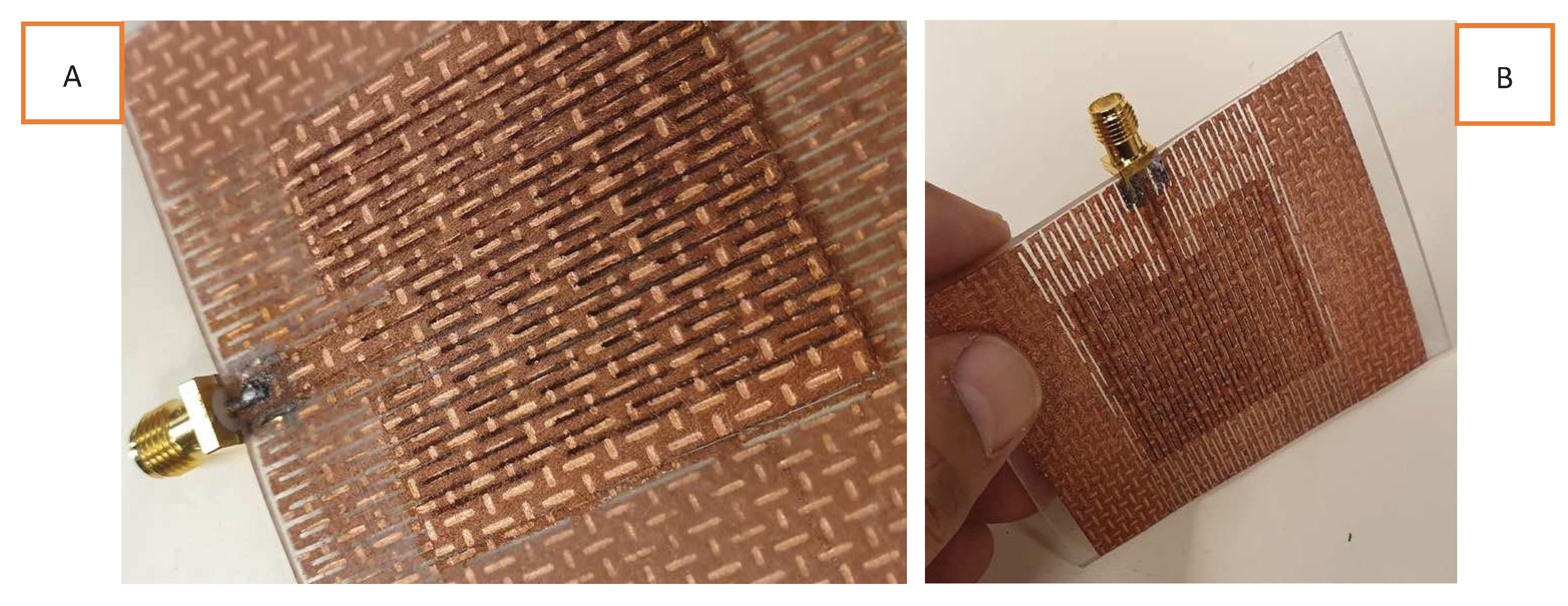

7 S/m. Both a basic patch antenna prototype (without the LHD) and an LHD patch antenna prototype were simulated and fabricated to observe their behavior upon stretching. While both antenna prototypes exhibited stretchability, the stretchability of the LHD antenna prototype was particularly better when experienced by hand. The fabricated antenna prototypes are depicted in

Figure 4. However, when the electric performance of these fabricated antenna prototypes was measured, as indicated by the S11 parameter, was unsatisfactory as the antenna did not achieve the -10 dB mark during resonance.

To fabricate a stretchable antenna with improved electrical performance, another conductive textile fabric, Shieldex® Kiel +30 from Statex Produktions, Germany, was utilized. This fabric is copper-plated, non-woven in structure, but non-stretchable. However, the selection of Shieldex® Kiel +30 only supports this research by offering a significantly lower surface resistivity of 0.02 Ω/sq and high conductivity of 108.895×10³ S/m compared to the stretchable Shieldex® Technik-tex P130+B e-textile. Its surface resistivity is approximately 100 times lower compared to the Shieldex® Technik-tex P130+B fabric.

As the selected Shieldex® Kiel +30 conductive fabric is non-stretchable, the possibilities to convert it into a stretchable material were examined. Here, the technique of converting a non-stretchable fabric into stretchable by implementing the lattice hinge design becomes relevant and adapted. Due to this innovative design approach in stretchable antenna fabrication, we finally settled with a non-stretchable copper-coated polyamide e-textile (Shieldex® Kiel +30) with better electrical conductivity and transformed it into an LHD for use in the stretchable antenna. Higher electrical conductivity is essential for any conductive material used in antenna fabrication as it minimizes electrical losses and contributes to improved electromagnetic (EM) characteristics of the antenna.

Table 1 tabulates all the related properties of both the Shieldex® Technik-tex P130+B and Shieldex® Kiel +30 conductive fabrics.

3.2. Dielectric Substrate and its Characterization

Among a variety of dielectric materials commercially available as mentioned above, the PDMS was selected. The choice of PDMS as the dielectric antenna substrate was made as it is a transparent, stretchable, and hyperplastic polymer. It offers a higher viscosity of 3500 centipoise, which strengthens the interfacial bonding between the dielectric substrate and the e-textiles. A 2 mm thick layer of PDMS substrate (SYLGARD™ 184 Silicone Elastomer, Dow®) is prepared in a custom-made mold for fabricating the stretchable textile antenna. PDMS is composed of two liquid components: the base and the curing agent, which are mixed in specific proportions (10:1). When the two components are thoroughly mixed, the mixture cures into a flexible and stretchable elastomer. The 10:1 mix ratio allows for better control over hardness and modulus, enabling improved stretchability and flexibility. With a higher Young's modulus of 1.5 MPa, PDMS demonstrates better conformation with human skin for on-body applications and can withstand high deformations.

The resonance frequency method was adopted to characterize the dielectric PDMS substrate [

4,

41]. The dielectric constant (E

r) and loss tangent (tan δ) values needed to be known for simulating the final antenna prototype. To do so; an iterative process was employed, which involved changing the E

r value and observing the corresponding change in the resonance frequency of the antenna at the 2.45 GHz operating frequency using CST Studio Suite, an Electromagnetic and Multiphysics simulation software. During antenna simulation, both the properties of the selected conductive and dielectric PDMS materials were defined in the CST simulator to characterize the dielectric PDMS substrate. A simple rectangular microstrip patch antenna was simulated using specific dimensions (length and width) of the 2 mm thick PDMS dielectric substrate, with arbitrary values of E

r and tan δ at the 2.45 GHz operating frequency. Subsequently, the antenna was physically fabricated. To compare the simulated results with the experimental results, the resonance frequency was measured using a Vector Network Analyzer (VNA). The difference between the resonance frequencies of the simulated and experimental antennas was initially observed. The E

r value in the CST simulator was then adjusted accordingly to match the simulated and experimental resonance frequencies. Once the resonance frequencies coincided with the new E

r value, it was considered the actual value for the PDMS substrate. The presence of substrate losses is reflected in a broader and less pronounced resonance peak in the return loss graph, with the depth of the peak indicating the level of substrate losses. Similarly, the value of tan δ was manipulated to match the depth of both the simulated and experimental resonance frequency peaks. In this way, the dielectric PDMS substrate was characterized. The measured characteristics of the stretchable PDMS dielectric substrate at a frequency of 2.45 GHz are listed in

Table 2.

4. Materials and Methods

4.1. Antenna Design and Simulation

The microstrip patch antenna topology was chosen for its numerous advantages in wearable radio frequency applications. Planar patch antennas offer simplicity in design, lightweight construction, and easy integration into garments [

42,

43]. When fabricated using soft, flexible, and stretchable materials, such antennas become highly suitable for ergonomic use in wearable applications. Additionally, the planar patch antenna design minimizes the dissipation of electromagnetic (EM) radiation in human body tissues during wearable usage, thanks to the presence of the conductive ground plane. The microstrip patch antenna topology, depicted in

Figure 3, consists of a dielectric substrate sandwiched between a radiating conductive patch and a conductive ground plane. This antenna topology is well-suited for intrinsic strain sensing applications, where uniaxial strain can be easily applied to the antenna during wearability, as reported previously. The strain sensing factor is detected by monitoring the shift in resonance frequency caused by external strain. The magnitude of the frequency shift can be used to quantify the deformation.

Figure 5(a) provides a schematic view of a simulated microstrip patch antenna design transformed into a stretchable antenna through the patterning of the conductive patch and ground plane in a lattice hinge design, as depicted from the front view, while

Figure 5(b) shows the back view.

In wearable applications, the dimensions of the antenna play a crucial role in determining its operating resonance frequency. For the design of the LHP patch antenna, the length and width of the patch were calculated using the transmission line model. The physical dimensions of the antenna, particularly the patch length, were adjusted to achieve resonance at the desired frequency of 2.45 GHz during simulation.

The antenna design and simulation were conducted at an operating frequency of 2.45 GHz using the CST Studio Suite. The overall dimensions of the proposed LHP stretchable antenna in this research work are listed in

Table 3. These dimensions were precisely cut using an automatic laser cutter, ensuring accurate fabrication.

4.2. Antenna Fabrication

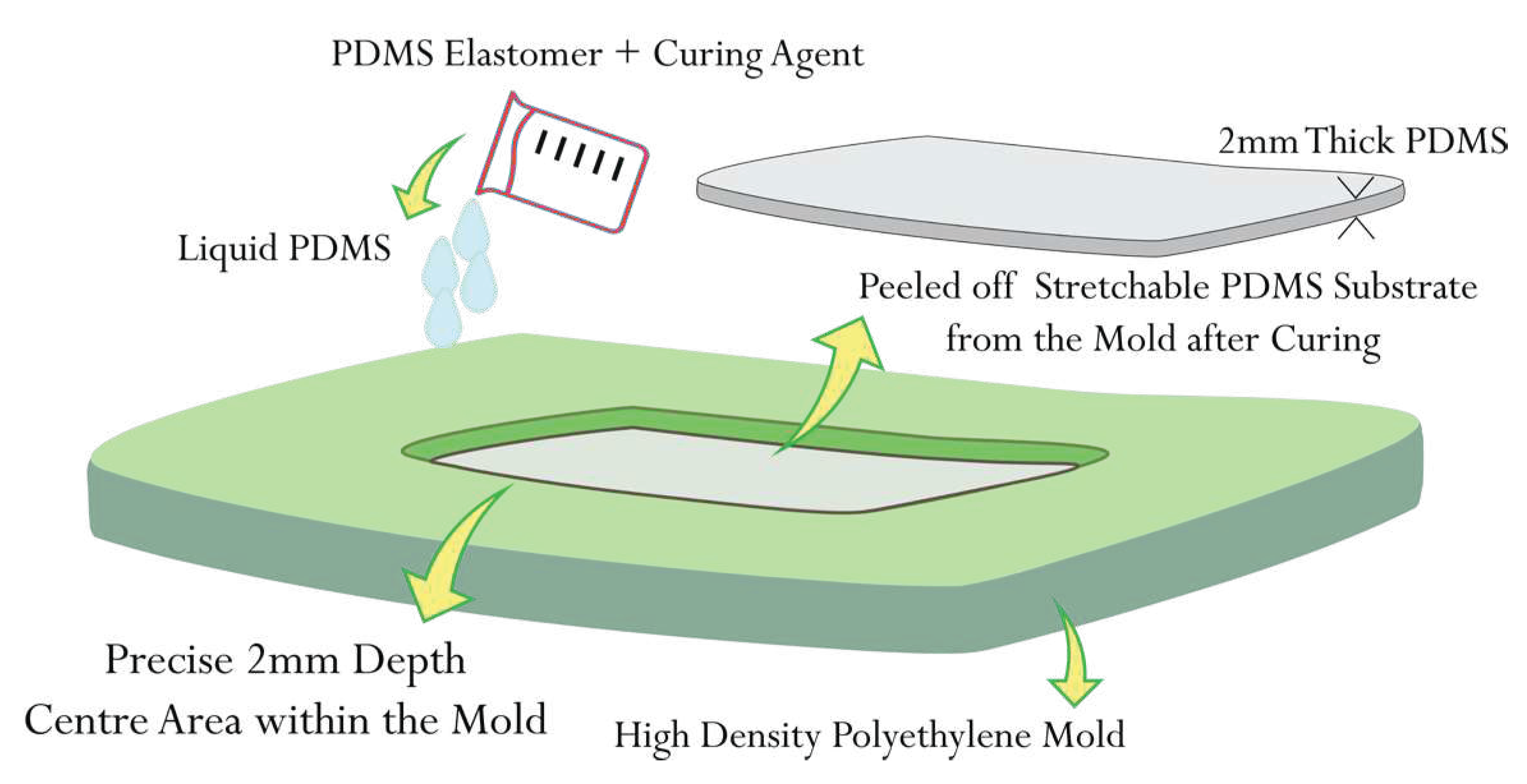

A mold was designed using AutoDesk Fusion, a modeling software, to shape the liquid PDMS polymer. The mold was created from high-density polyethylene with precise dimensions of 80×70×2 mm³ (width×length×depth) using a Computer Numeric Control (CNC) machine. This mold was utilized to pour the liquid PDMS polymer, allowing it to take on the accurate shape specified above, as depicted in

Figure 6. PDMS is a flowable liquid with excellent dielectric properties. It can be cured at various temperature ranges, from room temperature to 150°C, and the curing time can range from 48 hours to 35 minutes.

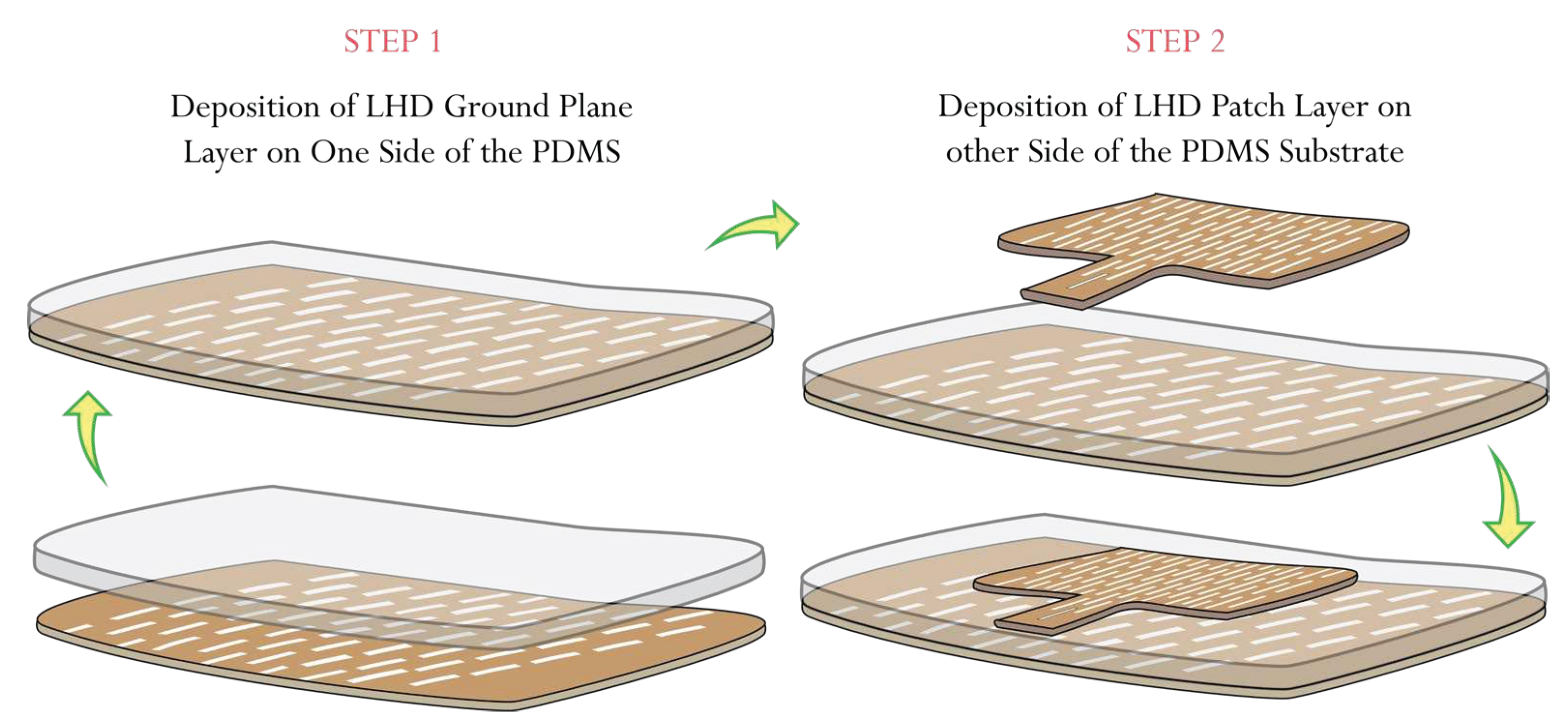

The antenna fabrication process involved several steps. Initially, samples of the LHD for both the patch and the ground plane were cut from the Shieldex® Kiel +30 e-textile fabric using a laser cutter. Next, the liquid PDMS polymer was prepared and placed in a desiccator to remove any air bubbles. Once prepared, the PDMS was poured into a pre-prepared mold with specific dimensions and placed in a curing chamber set at a temperature of 60°C. A few minutes into the curing process, the surface of the liquid PDMS polymer started to solidify, becoming sticky. At this stage, the pre-cut sample of the conductive ground plane was carefully placed onto the partially cured sticky surface of the PDMS polymer and left to continue curing. The PDMS polymer typically takes around 50 minutes to fully cure at 60°C. Once fully cured, the PDMS polymer sample, with the conductive ground plane layer adhered on one side, was peeled off from the mold. Finally, a thin layer of fresh liquid PDMS polymer was applied to the other side of the fully cured PDMS polymer, and the patch layer was deposited, leveled, and left to cure once again at 60°C. Through these process steps, the fabrication of both the solid patch antenna samples and the LHP patch antenna samples was carried out.

Figure 7 provides a schematic view of the fabrication process for the LHP stretchable antenna samples, respectively. The porous nature of Shieldex® Kiel +30 e-textile fabric facilitated better bonding with the PDMS polymer.

During the fabrication process, special attention was given to aligning the LHD links in the patch with the links in the ground plane. This alignment ensures that uniform stretchability is achieved throughout the fabricated antenna.

Considering the limitations of the chosen conductive e-textiles and the fabrication method involving laser cutting, it was determined that the clearance between adjacent links in the lattice hinge design should not be less than 2.5 mm on materials chosen for our research work. Laser cutting of the selected e-textile fabric in an LHD provides flexibility but reduces its strength when the clearance is decreased below 2.5 mm. On the other hand, reducing the clearance between adjacent links significantly increases the flexibility and stretchability of the e-textile, albeit at the expense of its strength. The length of the lattice hinge link plays a critical role in the stretchability of the antenna, with a longer link length resulting in better stretchability. During the simulation, a trade-off was observed between the length of the link and the electrical performance of the antenna at the chosen resonance frequency. The width of the link should be minimized to maximize the available area for inserting more links in the patch and ground plane. Increasing the number of links in the conductive layers of the antenna enhances its stretchability.

Furthermore, rough antenna samples were fabricated with varying thicknesses of the PDMS substrate, ranging from 1.5 mm to 3 mm. It was found that thinner substrates provided better overall stretchability but reduced the strength of the antenna when stretched, and vice versa. Therefore, a 2 mm thick PDMS substrate was finally chosen as it sustained reasonably good deformation during stretching. The front and back views of the fabricated solid patch antenna using Shieldex® Kiel +30 e-textile are depicted in

Figure 8(a) and (b), respectively. Similarly, the front and back views of the fabricated LHP stretchable patch antenna using Shieldex® Kiel +30 e-textile fabric are shown in

Figure 9(a) and (b), respectively. Previous studies have also highlighted the trade-off between mechanical stretchability and EM performance in stretchable and flexible antennas, which aligns with our research. In summary, the overall mechanical stretchability of the antenna depends on the morphological parameters of the lattice hinge design, including link width, link length, and clearance between adjacent links.

Based on the observation, the experimentally fabricated solid patch antenna using Shieldex® Kiel +30 e-textile fabric did not exhibit any stretchability, despite the stretchable nature of the PDMS substrate. However, in contrast, the experimentally fabricated LHP patch antenna using Shieldex® Kiel +30 e-textile offered some stretchability. Additionally, the antenna showed improved flexibility when manually handled. Each antenna prototype was soldered with an SMA connector of 50 Ω characteristic impedance to provide power to the antenna through the microstrip feed line. It should be noted that the microstrip feed line in the LHP antenna was kept solid, without lattice hinge links, to ensure a robust connection to the SMA connector and enable a uniform flow of input power.

5. Experimental Electromagnetic Characterization

The experimental characterization of the fabricated antenna prototype involved the use of a custom-made setup to evaluate its electromagnetic (EM) performance under uniaxial stretching. The EM performance of the antenna was assessed by measuring its S11 parameter at varying strain ranges. The S11 parameter represents the reflection coefficient of the antenna, indicating how well it can radiate power at a specific operating frequency. Power that is not reflected at the antenna’s interface to the transmission line is either radiated or resistively dissipated. However, due to the good conductivity of the materials used, dissipation is assumed to be very low, which will be confirmed by the radiation pattern measurements further in this paper. By measuring S11 during the stretching process, the antenna's performance under different strain conditions could be analyzed and evaluated.

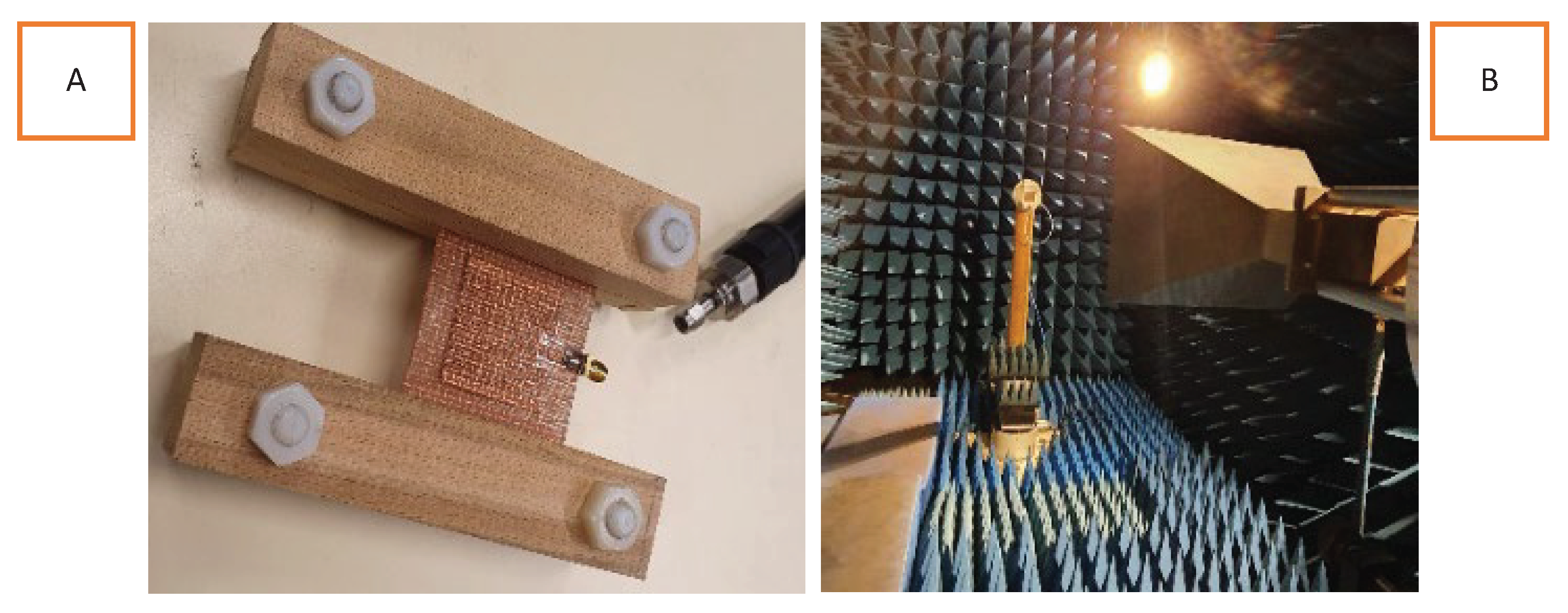

Figure 10(a) illustrates the custom-made setup used for the experimental characterization of the fabricated antenna prototype to measure its reflection coefficient. The setup involved the use of rectangular wooden blocks to clamp the antenna, with two blocks placed on each side of the antenna in the widthwise direction. The blocks were bolted together using bolts made of high-density polyethylene material. Since the wooden blocks only touch the antenna’s ground plane and not its radiating patch, the influence of the wooden parts is very limited. The RF characterization of the antenna was performed using an Agilent E5071C Vector Network Analyzer (VNA) to measure the scattering parameters and observe the effect of applied strain on the resonance frequency.

The radiation patterns of the fabricated antenna prototype were measured in an anechoic chamber, as depicted in

Figure 10(b). The anechoic chamber provides a controlled environment free from reflections and external interference, allowing accurate measurements of the antenna's radiation pattern.

To measure the S11 of the antenna at different strain ranges, uniform uniaxial tension was applied using laser-cut wooden block spacings. These block spacings represented the amount of applied strain and were placed between the main wooden clamps of the custom-made setup. By adjusting the spacing, different elongation ranges were achieved, allowing the measurement of S11 at varying strain levels. To validate the experimental results, the antenna prototype was also simulated at varying strain levels using the CST studio suite. The simulation results were compared with the experimental measurements to assess the correlation between both the simulated and experimental results. This comprehensive characterization process helps to understand the antenna's behavior under strain and validate the effectiveness of the proposed design and fabrication methods.

6. Results and Discussions

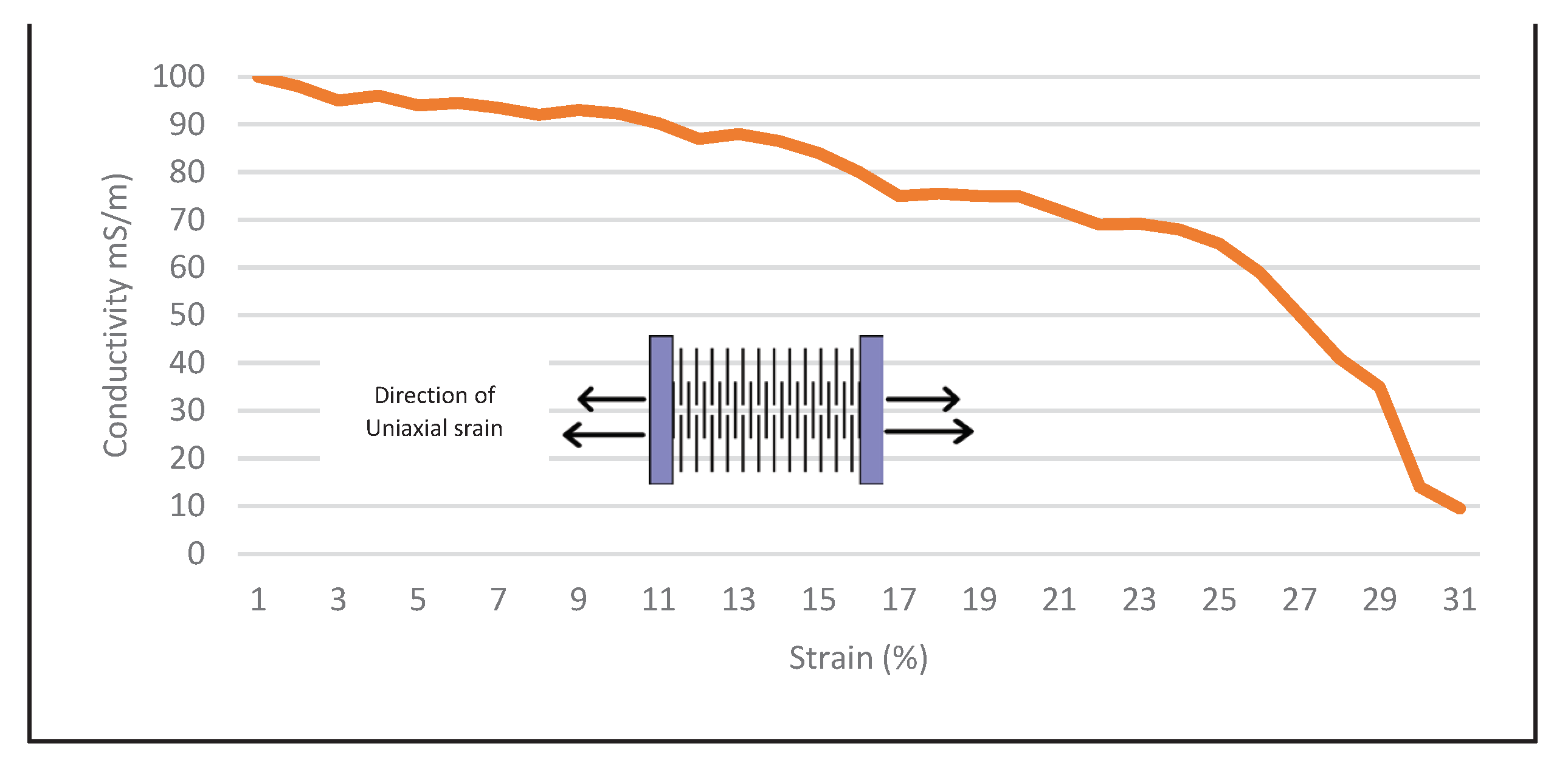

To see the effect of change in the electrical properties (i.e., conductivity) of LHP stretchable patch antenna upon uniaxial stretching, the same custom-made tensile setup as mentioned in

Figure 11 (a) was used involving a digital multimeter.

Figure 11 indicates that as the strain gradually and uniformly increases up to 25%, the end-to-end conductance of the patch decreases. At around 30% strain, the conductivity reaches approximately one-fifth of its starting value at 0% strain. At strain levels beyond 30%, the antenna experiences failure observed as a decrease in conductance at multiple lattice hinge links in both the patch and the ground plane. Note that the DC values measured with the multimeter only provide a rough indication, as resistivity at higher frequencies is seriously influenced by skin and proximity effects.

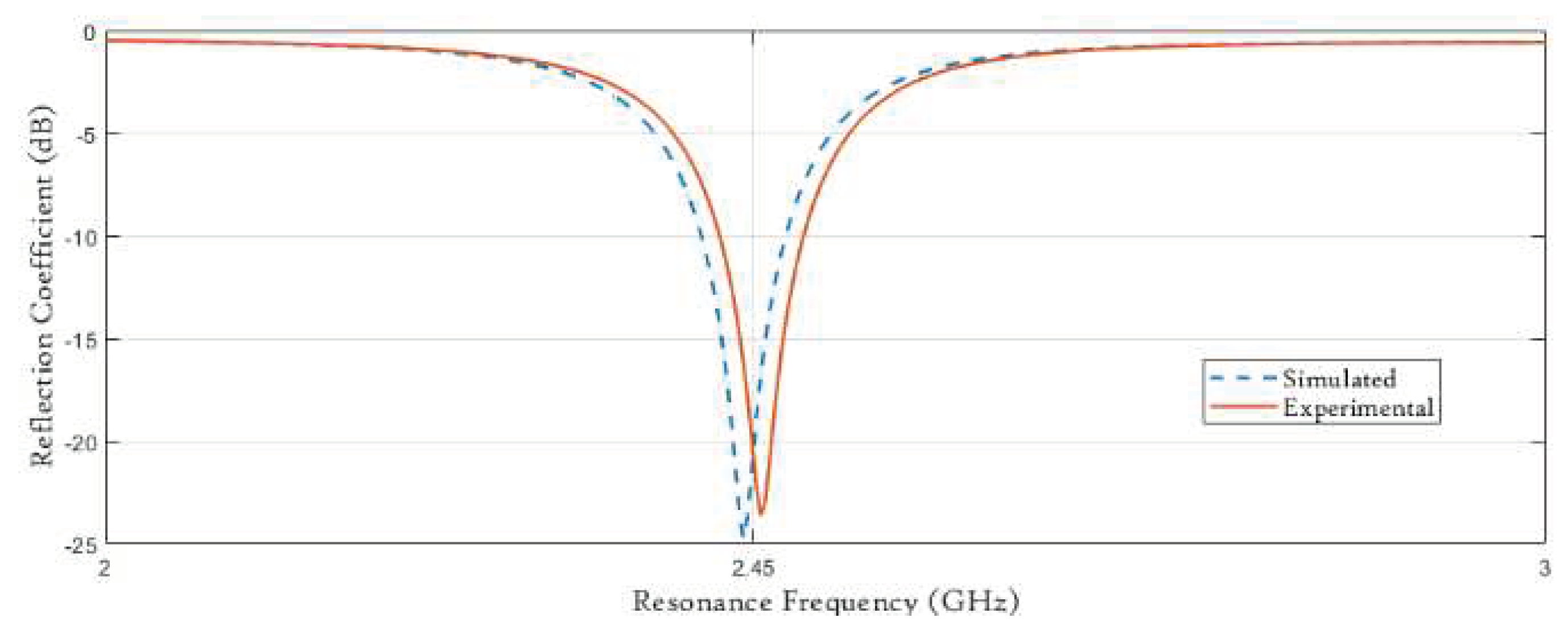

To measure the S11 of the fabricated antenna prototypes, a Vector Network Analyzer (VNA) was used. Before conducting the S11 measurements, a calibration process known as the short-open-load-through (SOLT) calibration was performed using a Keysight 85052D calibration kit. The SOLT calibration helps establish a reference for accurate measurements by compensating for the inherent reflections and losses in the measurement setup.

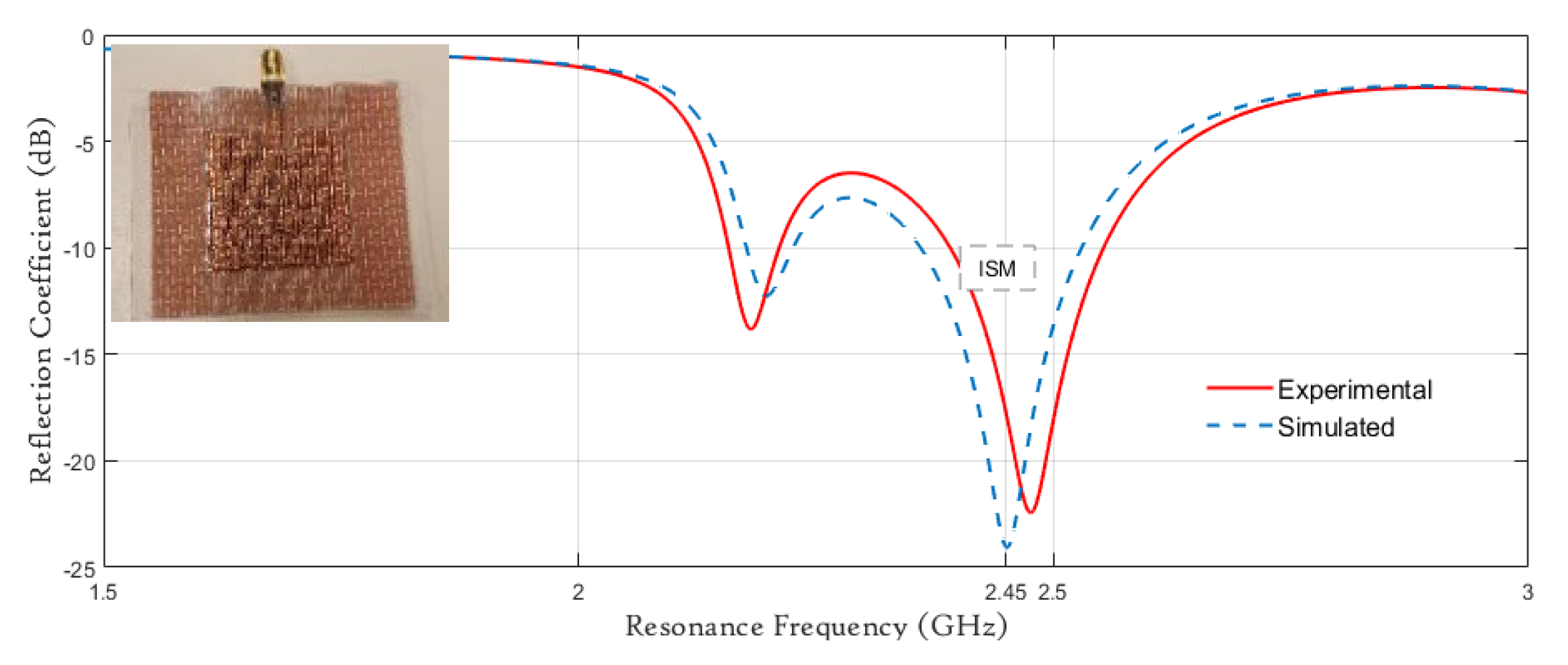

Figure 12 illustrates the resonance frequencies of the simulated and experimental results of the Shieldex® Kiel +30-based solid patch antenna. Both the simulated and experimental results, in terms of S11, show resonance at the 2.45 GHz operating frequency. This indicates a good agreement between the simulated and measured data. On the other hand,

Figure 13 depicts the correlation between the simulated and experimental reflection characteristics of the LHP Shieldex® Kiel +30-based stretchable patch antenna. The reflection coefficient measurements show dual frequency peaks, both in the simulated and experimental data when the lattice hinge design is implemented. The curves in the figure match the 2.45 GHz resonance frequency in the unstretched position. Additionally, another resonance peak at a lower frequency can also be observed.

These results demonstrate the similarity between the simulated and experimental data, validating the accuracy of the simulation model and the successful fabrication of the stretchable patch antenna.

During the design and simulation of the LHP stretchable patch antenna, it was observed that the resonance frequency shifted towards the lower end when the lattice hinge design was incorporated into the patch and ground plane of the solid antenna. This shift in resonance frequency indicates the possibility of tuning the antenna to the desired operating frequency of 2.45 GHz by changing the solid antenna into the LHD antenna. To achieve the same frequency tuning in conventional antennas, the resonance frequency can be adjusted by changing the length of the patch or the thickness of the substrate. In our research, the focus was to design and simulate the LHP stretchable patch antenna at an operating frequency of 2.45 GHz. To achieve the desired resonance frequency, the length of the newly formed LHP stretchable patch antenna was adjusted compared to the patch length of the solid antenna. The incorporation of the LHD allows for the transformation of a solid patch antenna into a stretchable and tunable LHP antenna suitable for wearable applications.

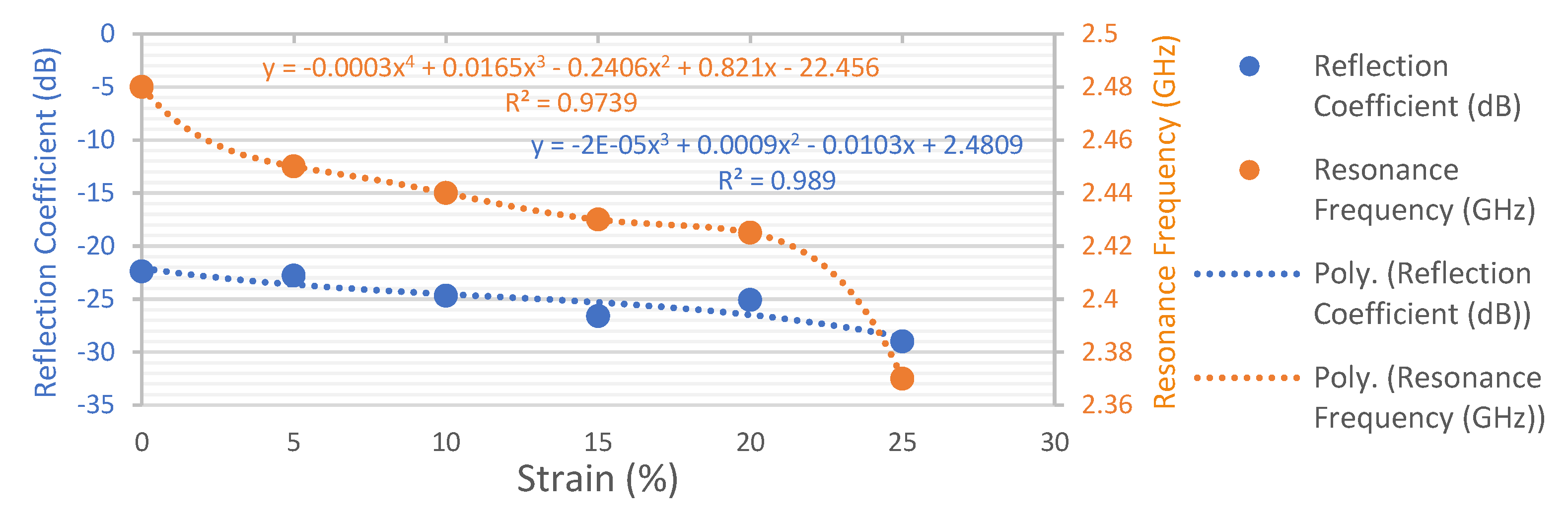

The effect of applied strain on the change in the resonance frequency and reflection coefficient values for the fabricated LHP stretchable patch antenna at the different levels of elongation is illustrated in

Figure 14. The antenna exhibits a maximum elongation of up to 25% before experiencing failure. It was observed upon a gradual increase in applied strain, the resonance frequency of the LHD stretchable antenna slightly shifts towards lower frequencies while experiencing minor deviation in its reflection coefficient values at the same time. While discussing both the reflection coefficient and resonance frequency trends from the data mentioned in the graph, a linear trend is observed in the change of resonance frequency from 2.48 to 2.41 GHz as the strain increased up to 20%. As the strain was further increased up to 25%, the resonance frequency trend of the LHD stretchable antenna observed a rapid change and started to show a non-linear trend and at last, the antenna experienced a failure when strain was applied beyond 25%. On the other side, a linear trend in the change in the reflection coefficient values was observed upon a gradual increase in the applied strain up to 25%. Throughout the 25% elongation range, the reflection coefficient remains below -10 dB, indicating good antenna performance. The change in resonance frequency before antenna failure at break suggests that the fabricated LHP stretchable patch antenna has the potential to function as a strain sensor with up to 25% elongation. This additional functionality enhances the versatility of the LHP stretchable antenna.

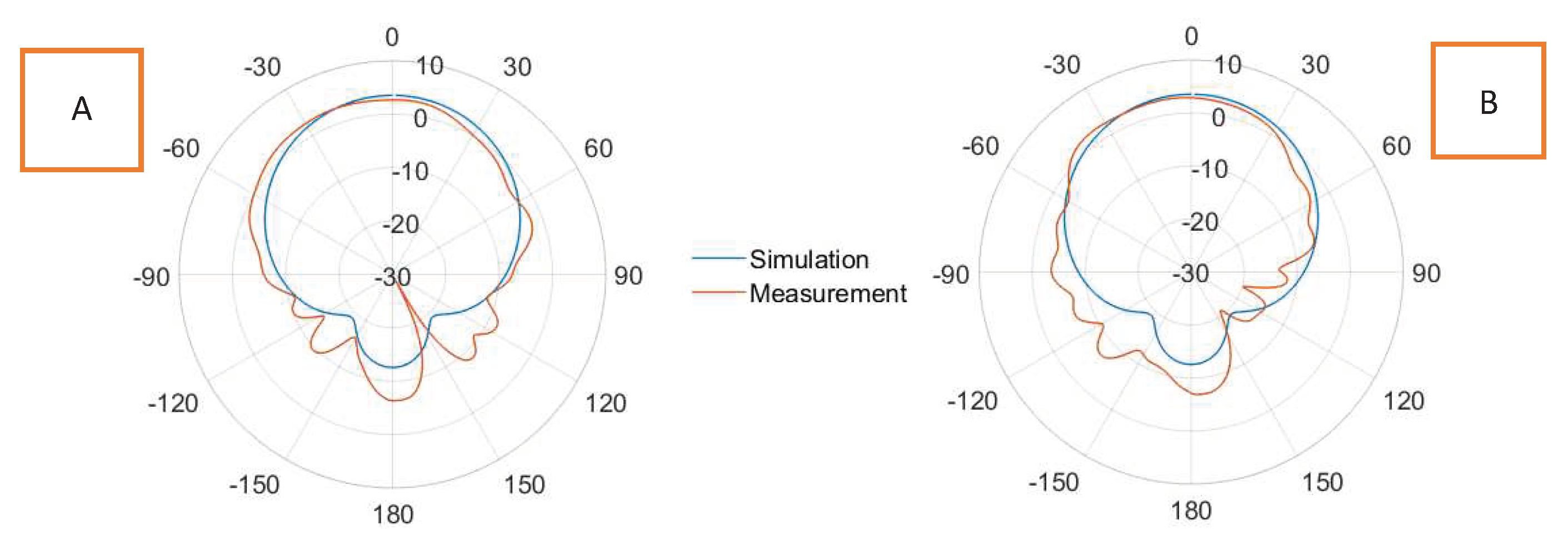

Figure 15 displays the radiation patterns of the Shieldex® Kiel +30-based solid patch antenna at 2.45 GHz resonance frequency in the (a) E-plane and (b) H-plane. The experimentally measured realized gains are 2.95 dBi and 2.98 dBi in the E-plane and H-plane, respectively. Illustrations shown in

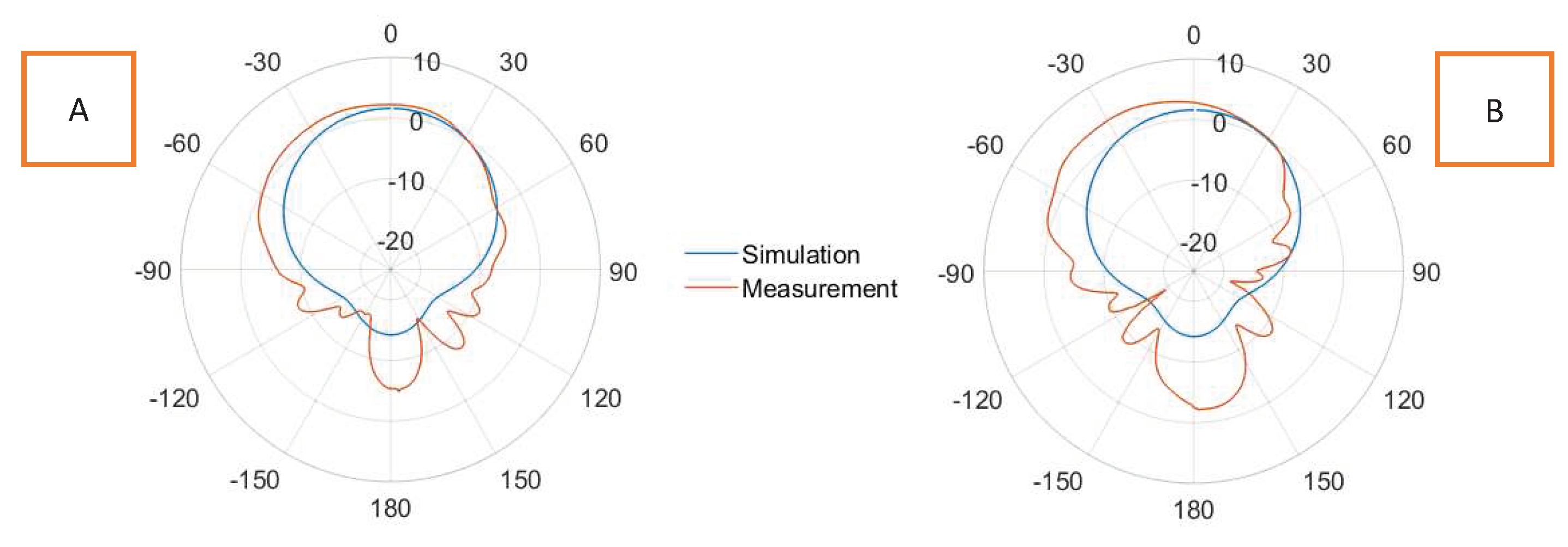

Figure 16 are the radiation patterns of the Shieldex® Kiel +30-based LHP stretchable antenna at 2.45 GHz resonance frequency in the (a) E-plane and (b) H-plane. The experimentally measured gains are 2.21 dBi and 2.34 dBi in the E-plane and H-plane, respectively.

In the radiation patterns of the Shieldex® Kiel +30-based LHP stretchable antenna, a slightly higher level of back radiation can be observed in both the E-plane and H-plane compared to the Shieldex® Kiel +30-based solid antenna. This is attributed to the presence of lattice hinge links in the ground plane, which reduces its overall conductive area and leads to increased back radiation. However, the differences in gains between the solid and LHP antennas are minimal, indicating that the stretchable nature of the LHP antenna does not significantly affect its radiation performance.

The Shieldex® Kiel +30-based solid patch antenna does not exhibit stretchability despite the stretchy nature of the PDMS substrate. However, it does provide a slightly higher realized gain compared to the LHP stretchable antenna. The solid antenna remains flexible and can still be used effectively in wearable applications. On the other hand, the Shieldex® Kiel +30-based LHP stretchable patch antenna compensates for this with enhanced flexibility and can stretch up to 25% in addition. The lattice hinge design significantly improves the overall flexibility and stretchability of the fabricated antenna, making it suitable for wearable applications where conformability and stretchability are desired.

7. Outcomes

In summary, our research aimed to design, fabricate, and characterize a multifunctional stretchable patch antenna operating at a resonance frequency of 2.45 GHz. The antenna was intended to serve as both a communication device and a strain sensor. Two antenna prototypes were fabricated using different conductive materials: Shieldex® Technik-tex P130+B (a stretchable knitted material) and Shieldex® Kiel +30 (a nonwoven non-stretchable material) in search for better stretchability and electrical performance. The former antenna exhibited enhanced stretchability but had lower electrical performance. On the other hand, the latter antenna had better electrical performance but limited stretchability. To address this trade-off, the lattice hinge design was incorporated into the non-stretchable antenna, improving its overall stretchability without significantly compromising its electrical performance.

The fabricated LHD stretchable patch antenna made from Shieldex® Kiel +30 demonstrated stretchability of up to 25% under uniaxial tensile strain before it went to rupture. The antenna showed a linear trend in its resonance frequency shift as the applied strain increased up to 20% but continued to resonate without reaching a point of rupture. This characteristic makes it suitable for use as a strain sensor in addition to its communication capabilities. The realized antenna gains at the E-plane and H-plane were measured as 2.21 dBi and 2.34 dBi, respectively.

Overall, our research successfully developed a multifunctional stretchable patch antenna at 2.45 GHz resonance frequency with strain sensing capabilities, providing conformability, flexibility, and stretchability for wearable applications while maintaining satisfactory electrical performance.

Author Contributions

A.W.M. conceived the research idea, study, methodology, testing, and drafting of the manuscript; A.W.M. and P.V.T. validated the results; B.M. and P.V.T. supervised, critically reviewed, and edited the manuscript; L.V.L. supervised and administered the research. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Higher Education Commission-HEC of Pakistan, under the scholarship scheme ‘HRDI-UESTPs/UETs Phase-I Batch-V’ under the reference number Ref-2003/HEC/HRD/PM-UESTP/Phae-I/Batch-V/2016/1879.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the relevant data presented in this study is contained within this article.

Acknowledgments

The authors acknowledge the financial support provided by the Higher Education Commission (HEC), Pakistan, for the PhD research funding. They also express their gratitude to the Department of Textiles and the Department of Information Technology at Ghent University, Belgium, for their support and provision of research facilities, and the Ingegno Maker Space for the use of their laser cutter and CNC for the creation of the mold to fabricate antenna prototypes. The authors appreciate the assistance and collaboration received from these institutions, which contributed to the successful completion of the research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Salvado, R.; et al. Textile materials for the design of wearable antennas: A survey. Sensors 2012, 12, 15841–15857. [Google Scholar] [CrossRef] [PubMed]

- Lai, X.; et al. A survey of body sensor networks. Sensors (Basel) 2013, 13, 5406–47. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; et al. Flexible and stretchable antennas for biointegrated electronics. Advanced Materials 2020, 32, 1902767. [Google Scholar] [CrossRef] [PubMed]

- Memon, A.W.; et al. Breathable Textile Rectangular Ring Microstrip Patch Antenna at 2.45 GHz for Wearable Applications. Sensors (Basel) 2021, 21. [Google Scholar] [CrossRef]

- Zhang, Z.; et al. Tunable stretchable strain sensors enabled by patterned Ecoflex-vertical aligned carbon nanotube arrays and pre-stretching transfer. Carbon 2022, 197, 218–225. [Google Scholar] [CrossRef]

- Dahiya, R.; Akinwande, D.; Chang, J.S. Flexible Electronic Skin: From Humanoids to Humans [Scanning the Issue]. Proceedings of the IEEE 2019, 107, 2011–2015. [Google Scholar] [CrossRef]

- Dahiya, R.; et al. Large-Area Soft e-Skin: The Challenges Beyond Sensor Designs. Proceedings of the IEEE 2019, 107, 2016–2033. [Google Scholar] [CrossRef]

- Daliri, A.; et al. Wireless strain measurement using circular microstrip patch antennas. Sensors and Actuators A: Physical 2012, 184, 86–92. [Google Scholar] [CrossRef]

- Daliri, A.; et al. Quality factor effect on the wireless range of microstrip patch antenna strain sensors. Sensors (Basel) 2014, 14, 595–605. [Google Scholar] [CrossRef]

- Li, M.; Kim, Y.T. Development of patch-type sensor module for wireless monitoring of heart rate and movement index. Sensors and Actuators A: Physical 2012, 173, 277–283. [Google Scholar] [CrossRef]

- Priya, A.; Kumar, A.; Chauhan, B. A review of textile and cloth fabric wearable antennas. International Journal of Computer Applications 2015, 116. [Google Scholar] [CrossRef]

- Kim, Y.S.; et al. Soft Materials, Stretchable Mechanics, and Optimized Designs for Body-Wearable Compliant Antennas. ACS Appl Mater Interfaces 2020, 12, 3059–3067. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Cheng, H. Recent development of flexible and stretchable antennas for bio-integrated electronics. Sensors 2018, 18, 4364. [Google Scholar] [CrossRef] [PubMed]

- Al-Haddad, M.; Jamel, N.; Nordin, A.N. Flexible antenna: a review of design, materials, fabrication, and applications. In Journal of Physics: Conference Series; IOP Publishing, 2021. [Google Scholar]

- Cheng, S.; et al. Liquid metal stretchable unbalanced loop antenna. Applied Physics Letters 2009, 94. [Google Scholar] [CrossRef]

- Escobedo, P.; et al. Smart bandage with wireless strain and temperature sensors and batteryless NFC tag. IEEE Internet of Things Journal 2020, 8, 5093–5100. [Google Scholar] [CrossRef]

- Nikbakhtnasrabadi, F.; et al. Textile-based stretchable microstrip antenna with intrinsic strain sensing. ACS Applied Electronic Materials 2021, 3, 2233–2246. [Google Scholar] [CrossRef]

- Xu, X.; Huang, H. Battery-less wireless interrogation of microstrip patch antenna for strain sensing. Smart Materials and Structures 2012, 21, 125007. [Google Scholar] [CrossRef]

- Cho, C.; et al. Passive Wireless Frequency Doubling Antenna Sensor for Strain and Crack Sensing. IEEE Sensors Journal 2016, 16, 5725–5733. [Google Scholar] [CrossRef]

- Yi, X.; et al. A Slotted Patch Antenna for Wireless Strain Sensing. 2014, 2734–2743. [Google Scholar] [CrossRef]

- Tata, U.; et al. Exploiting a patch antenna for strain measurements. Measurement Science and Technology 2009, 20, 015201. [Google Scholar] [CrossRef]

- Wan, C.; et al. Transverse deformation effect on sensitivity of strain-sensing patch antenna. International Journal of Distributed Sensor Networks 2020, 16, 155014772090819. [Google Scholar] [CrossRef]

- Zhu, J.; et al. Structural design for stretchable microstrip antennas. ACS applied materials & interfaces 2019, 11, 8867–8877. [Google Scholar] [CrossRef]

- Zhu, J.; et al. Stretchable wideband dipole antennas and rectennas for RF energy harvesting. Materials Today Physics 2021, 18, 100377. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; et al. Foldable and stretchable liquid metal planar inverted cone antenna. IEEE Transactions on antennas and propagation 2009, 57, 3765–3771. [Google Scholar] [CrossRef]

- Rai, T.; et al. A stretchable RF antenna with silver nanowires. IEEE Electron Device Letters 2013, 34, 544–546. [Google Scholar] [CrossRef]

- Atanasova, G.; Atanasov, N. Small Antennas for Wearable Sensor Networks: Impact of the Electromagnetic Properties of the Textiles on Antenna Performance. Sensors (Basel) 2020, 20. [Google Scholar] [CrossRef]

- Haji Omer, H.A.; et al. Structural Health Monitoring Sensor based on A Flexible Microstrip Patch Antenna. Indonesian Journal of Electrical Engineering and Computer Science 2018, 10, 917. [Google Scholar] [CrossRef]

- Abed, A.T. Highly compact size serpentine-shaped multiple-input–multiple-output fractal antenna with CP diversity. IET Microwaves, Antennas & Propagation 2018, 12, 636–640. [Google Scholar] [CrossRef]

- Vaudon, P.; et al. Influence of the ground plane structure on the radiation pattern of microstrip antennas. in Annales des télécommunications. 1993. [Google Scholar]

- Namiki, T.; Murayama, Y.; Ito, K. Improving radiation-pattern distortion of a patch antenna having a finite ground plane. IEEE Transactions on Antennas and Propagation 2003, 51, 478–482. [Google Scholar] [CrossRef]

- Huang, Y.; et al. Microfluidic serpentine antennas with designed mechanical tunability. Lab on a Chip 2014, 14, 4205–4212. [Google Scholar] [CrossRef]

- Song, L.; et al. Stretchable and reversibly deformable radio frequency antennas based on silver nanowires. ACS applied materials & interfaces 2014, 6, 4248–4253. [Google Scholar] [CrossRef]

- Won, Y.; et al. A highly stretchable, helical copper nanowire conductor exhibiting a stretchability of 700%. NPG Asia Materials 2014, 6, e132–e132. [Google Scholar] [CrossRef]

- Zhang, X.-R.; et al. Recent progress of patterned electrodes in wearable electronics: fabrication and application. Journal of Physics D: Applied Physics 2023. [Google Scholar] [CrossRef]

- Chen, S.; et al. Electromechanically reconfigurable optical nano-kirigami. Nature communications 2021, 12, 1299. [Google Scholar] [CrossRef]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. science 2010, 327, 1603–1607. [Google Scholar] [CrossRef]

- Kim, D.-H.; et al. Epidermal electronics. science 2011, 333, 838–843. [Google Scholar] [CrossRef]

- Rogers, J.A.; Ghaffari, R.; Kim, D.-H. Stretchable bioelectronics for medical devices and systems; Springer, 2016. [Google Scholar]

- Hussain, A.M.; et al. Metal/polymer based stretchable antenna for constant frequency far-field communication in wearable electronics. Advanced Functional Materials 2015, 25, 6565–6575. [Google Scholar] [CrossRef]

- Hertleer, C.; et al. The use of textile materials to design wearable microstrip patch antennas. Textile Research Journal 2008, 78, 651–658. [Google Scholar] [CrossRef]

- Sanders, J.W.; Yao, J.; Huang, H. Microstrip patch antenna temperature sensor. IEEE sensors journal 2015, 15, 5312–5319. [Google Scholar] [CrossRef]

- Wang, W.; et al. Study of patch antennas for strain measurement. Electromagn. Nondestruct. Eval.(XVIII) 2015, 40, 313–321. [Google Scholar]

Figure 1.

Overview of the potential strain-sensing end-use applications for a multifunctional stretchable textile antenna.

Figure 1.

Overview of the potential strain-sensing end-use applications for a multifunctional stretchable textile antenna.

Figure 2.

(a) The lattice hinge with parameters (b) the lattice hinge pattern on a wooden sheet.

Figure 2.

(a) The lattice hinge with parameters (b) the lattice hinge pattern on a wooden sheet.

Figure 3.

A schematic view of the lattice hinge design-based stretchable microstrip patch antenna.

Figure 3.

A schematic view of the lattice hinge design-based stretchable microstrip patch antenna.

Figure 4.

Shieldex® Technik-tex P130+B e-textile based solid (a) and Lattice hinge (b) stretchable patch antenna prototypes.

Figure 4.

Shieldex® Technik-tex P130+B e-textile based solid (a) and Lattice hinge (b) stretchable patch antenna prototypes.

Figure 5.

The front view (a) and the back view (b) of a simulated LHP stretchable antenna.

Figure 5.

The front view (a) and the back view (b) of a simulated LHP stretchable antenna.

Figure 6.

Schematic view of the PDMS substrate preparation process using a mold of high-density polyethylene.

Figure 6.

Schematic view of the PDMS substrate preparation process using a mold of high-density polyethylene.

Figure 7.

Shieldex® Kiel +30-based LHP stretchable patch antenna.

Figure 7.

Shieldex® Kiel +30-based LHP stretchable patch antenna.

Figure 8.

(a) Front view and (b) back view of Shieldex® Kiel +30 e-textile fabric-based solid antenna.

Figure 8.

(a) Front view and (b) back view of Shieldex® Kiel +30 e-textile fabric-based solid antenna.

Figure 9.

(a) Front view and (b) back view of Shieldex® Kiel +30 e-textile fabric-based LHP antenna.

Figure 9.

(a) Front view and (b) back view of Shieldex® Kiel +30 e-textile fabric-based LHP antenna.

Figure 10.

(a) shows a custom-made setup to measure the reflection coefficient of the fabricated antenna and (b) depicts the measurement setup for radiation pattern measurements in an anechoic chamber.

Figure 10.

(a) shows a custom-made setup to measure the reflection coefficient of the fabricated antenna and (b) depicts the measurement setup for radiation pattern measurements in an anechoic chamber.

Figure 11.

Illustration of the change in the conductivity of an LHP Shieldex® Kiel +30-based stretchable patch antenna at different values of uniaxial tensile strain. The inset image shows the schematic view of the electromechanical test setup of the lattice hinge design with wooden clamps from both sides.

Figure 11.

Illustration of the change in the conductivity of an LHP Shieldex® Kiel +30-based stretchable patch antenna at different values of uniaxial tensile strain. The inset image shows the schematic view of the electromechanical test setup of the lattice hinge design with wooden clamps from both sides.

Figure 12.

The simulated and experimental resonance frequency of Shieldex® Kiel +30-based solid patch antenna at 2.45 GHz.

Figure 12.

The simulated and experimental resonance frequency of Shieldex® Kiel +30-based solid patch antenna at 2.45 GHz.

Figure 13.

The simulated and experimental resonance frequency curves of LHP Shieldex® Kiel +30-based stretchable textile patch antenna (inset image) at 2.45 GHz.

Figure 13.

The simulated and experimental resonance frequency curves of LHP Shieldex® Kiel +30-based stretchable textile patch antenna (inset image) at 2.45 GHz.

Figure 14.

Change in the resonance frequency as a function of tensile strain up to 25% of fabricated LHP Shieldex® Kiel +30-based stretchable textile patch antenna (inset image).

Figure 14.

Change in the resonance frequency as a function of tensile strain up to 25% of fabricated LHP Shieldex® Kiel +30-based stretchable textile patch antenna (inset image).

Figure 15.

Radiation patterns at E-plane (a) and H-plane (b) of Shieldex® Kiel +30-based solid patch antenna at 2.45 GHz.

Figure 15.

Radiation patterns at E-plane (a) and H-plane (b) of Shieldex® Kiel +30-based solid patch antenna at 2.45 GHz.

Figure 16.

Radiation patterns at E-plane (a) and H-plane (b) of Shieldex® Kiel +30-based LHP stretchable patch antenna at 2.45 GHz.

Figure 16.

Radiation patterns at E-plane (a) and H-plane (b) of Shieldex® Kiel +30-based LHP stretchable patch antenna at 2.45 GHz.

Table 1.

The EM characteristics of conductive textiles.

Table 1.

The EM characteristics of conductive textiles.

| * Data Given by the Manufacturer |

Shieldex® Technik-tex P130+B |

Shieldex® Kiel +30 |

| Fabric Type* |

Knitted (stretchable) |

Non-woven (non-stretchable) |

| Surface Resistivity* (Ω/ sq) |

2 |

0.02 |

| Thickness* (mm) |

0.55 mm ± 15 % |

0.250 mm ± 0.12 mm |

| Weight* (g/m²) |

132 ± 18 % |

100 ± 15 % |

Table 2.

Characteristics of the PDMS dielectric substrate.

Table 2.

Characteristics of the PDMS dielectric substrate.

| |

Thickness (mm) |

Dielectric Constant (Er) |

Loss Tangent (tan δ) |

| PDMS Substrate |

2 |

2.7 |

0.01 |

Table 3.

Dimensions of the simulated LHP stretchable antenna.

Table 3.

Dimensions of the simulated LHP stretchable antenna.

| Parameters |

Dimensions (mm) |

| Patch width (x-axis) |

41 |

| Patch length (y-axis) |

40.5 |

| Substrate/ground plane width |

70 |

| Substrate/ground plane length |

60 |

| PDMS Substrate thickness |

2 |

| Lattice hinge link clearance/width |

0.2 |

| Lattice hinge link length |

10 |

| Clearance between adjacent links |

3 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).