Submitted:

08 October 2023

Posted:

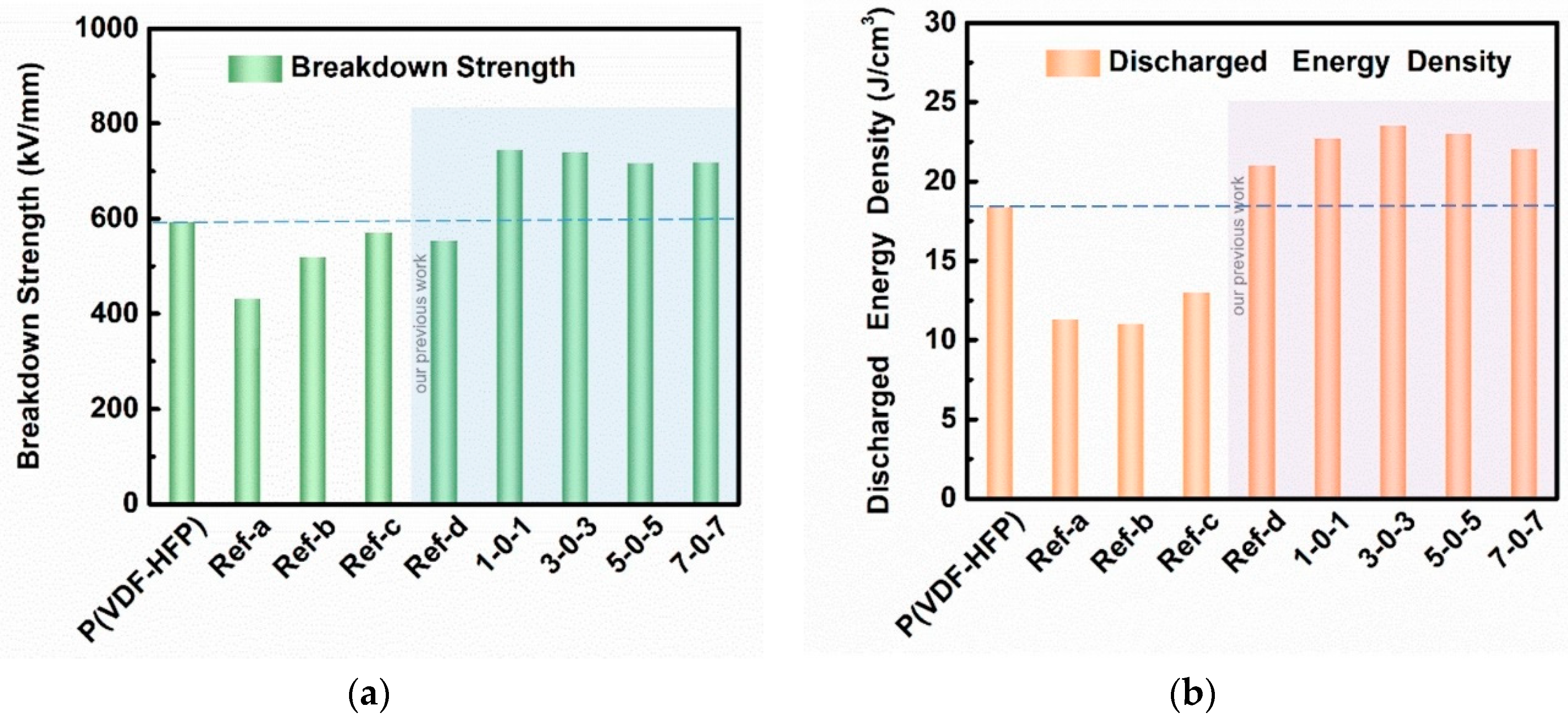

09 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experiment

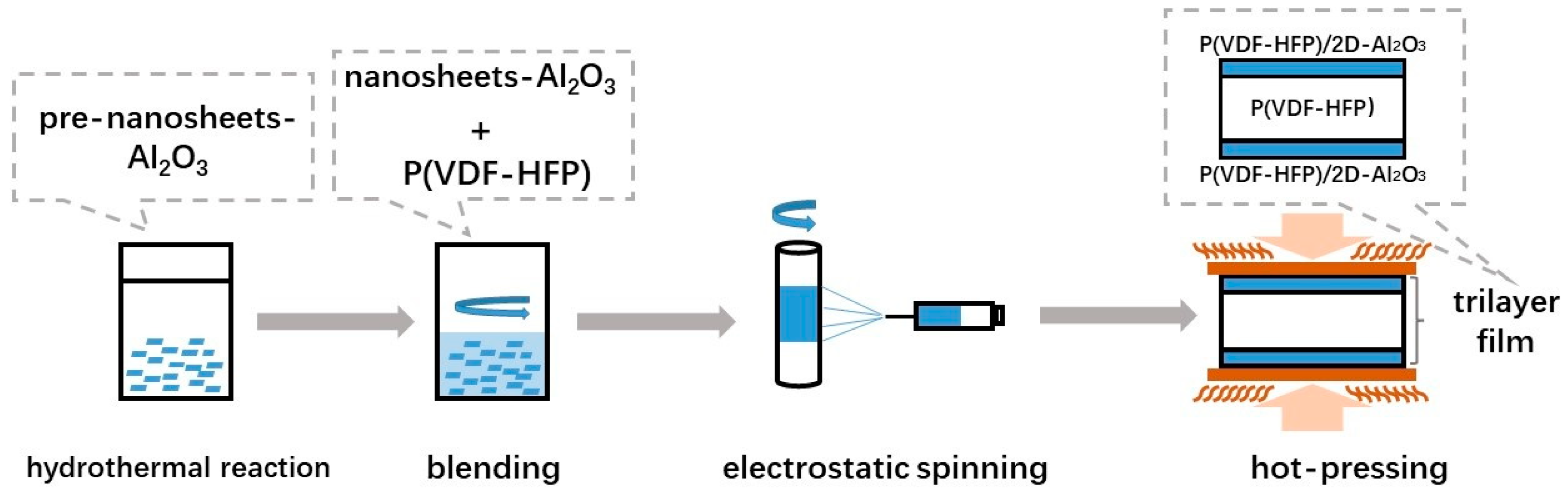

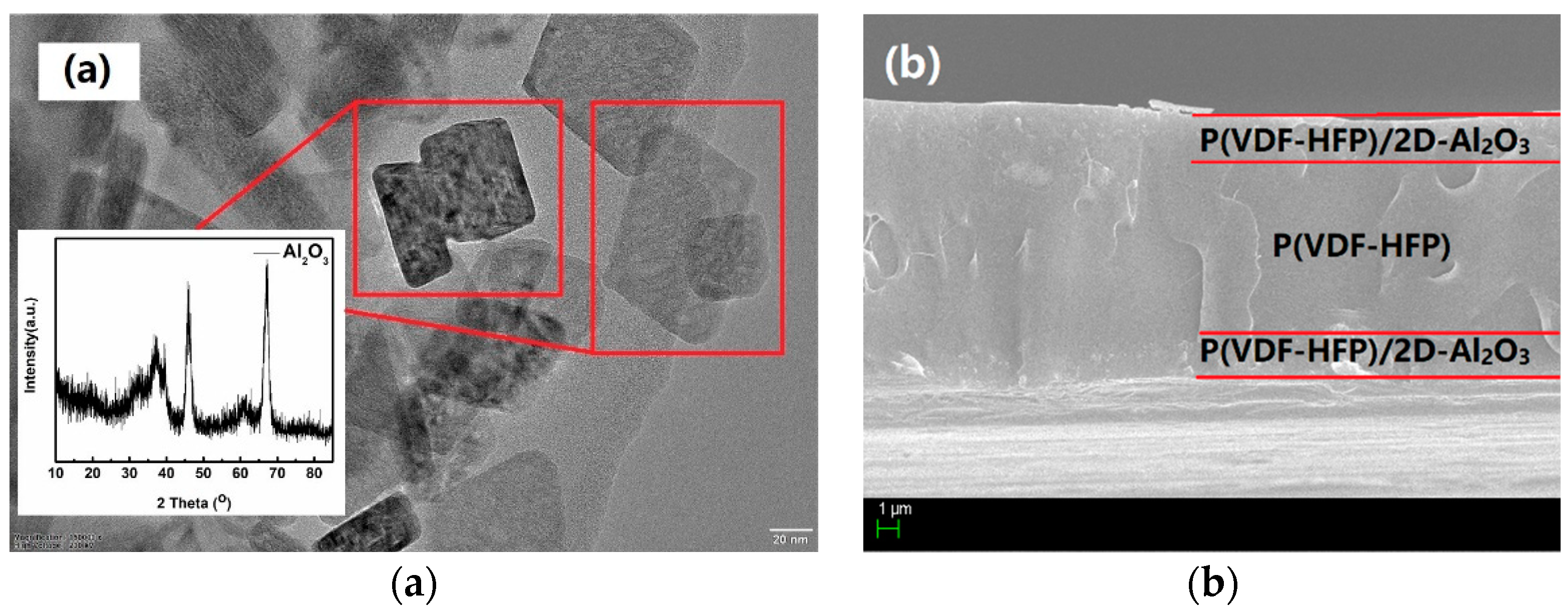

2.1. Preparation of Samples

2.2. Characterization

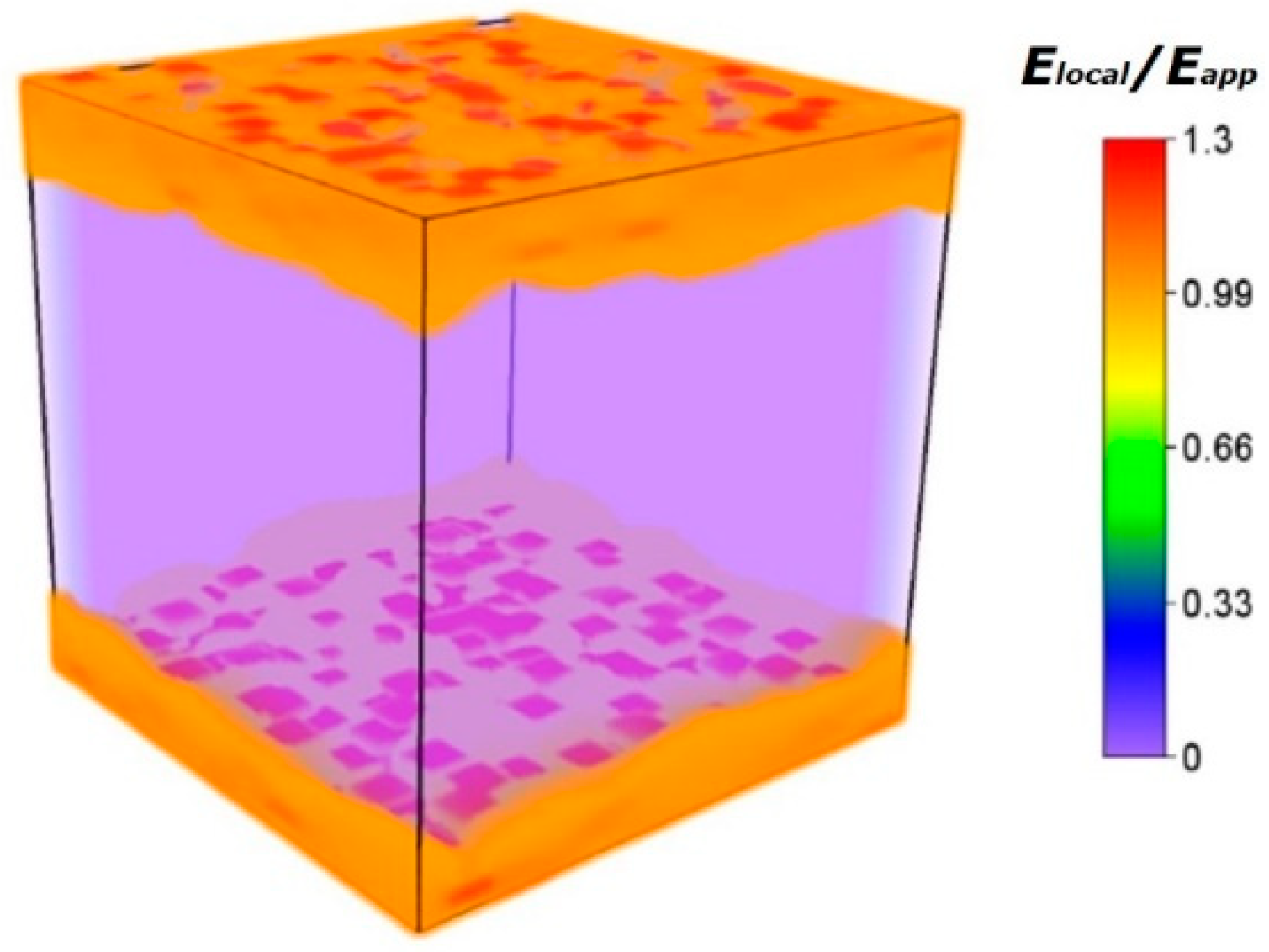

2.3. Model of Phase-Field [31]

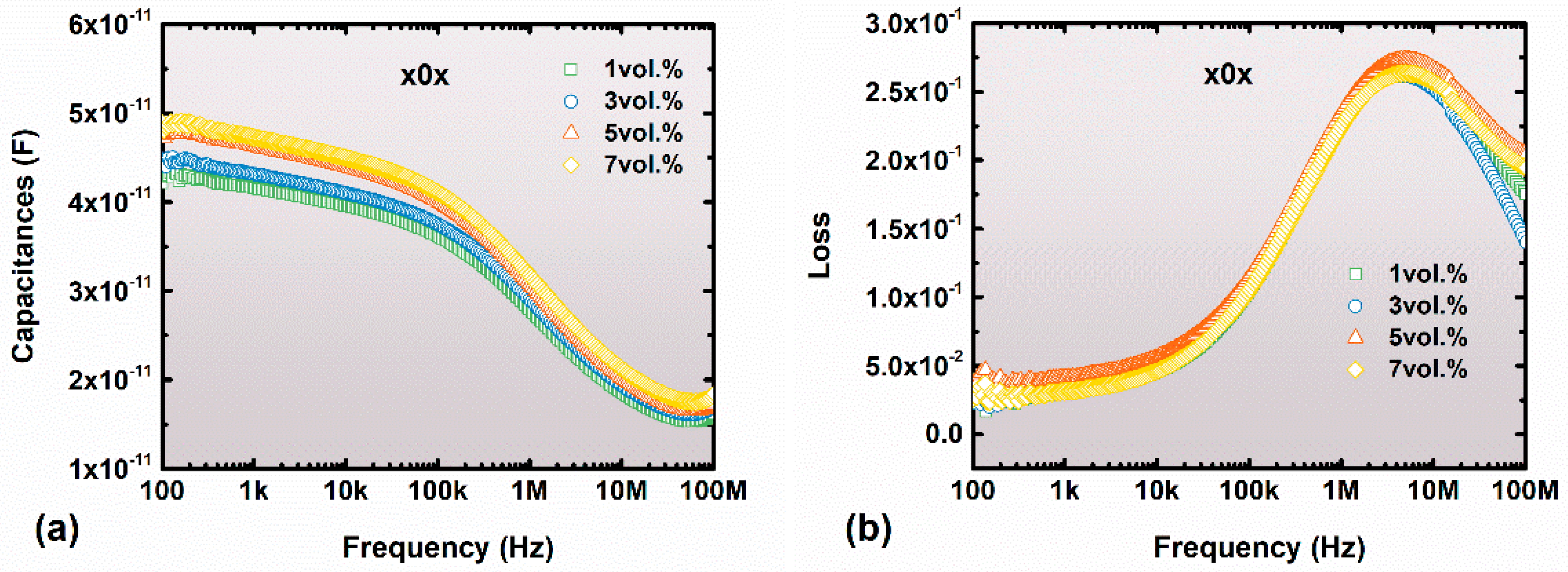

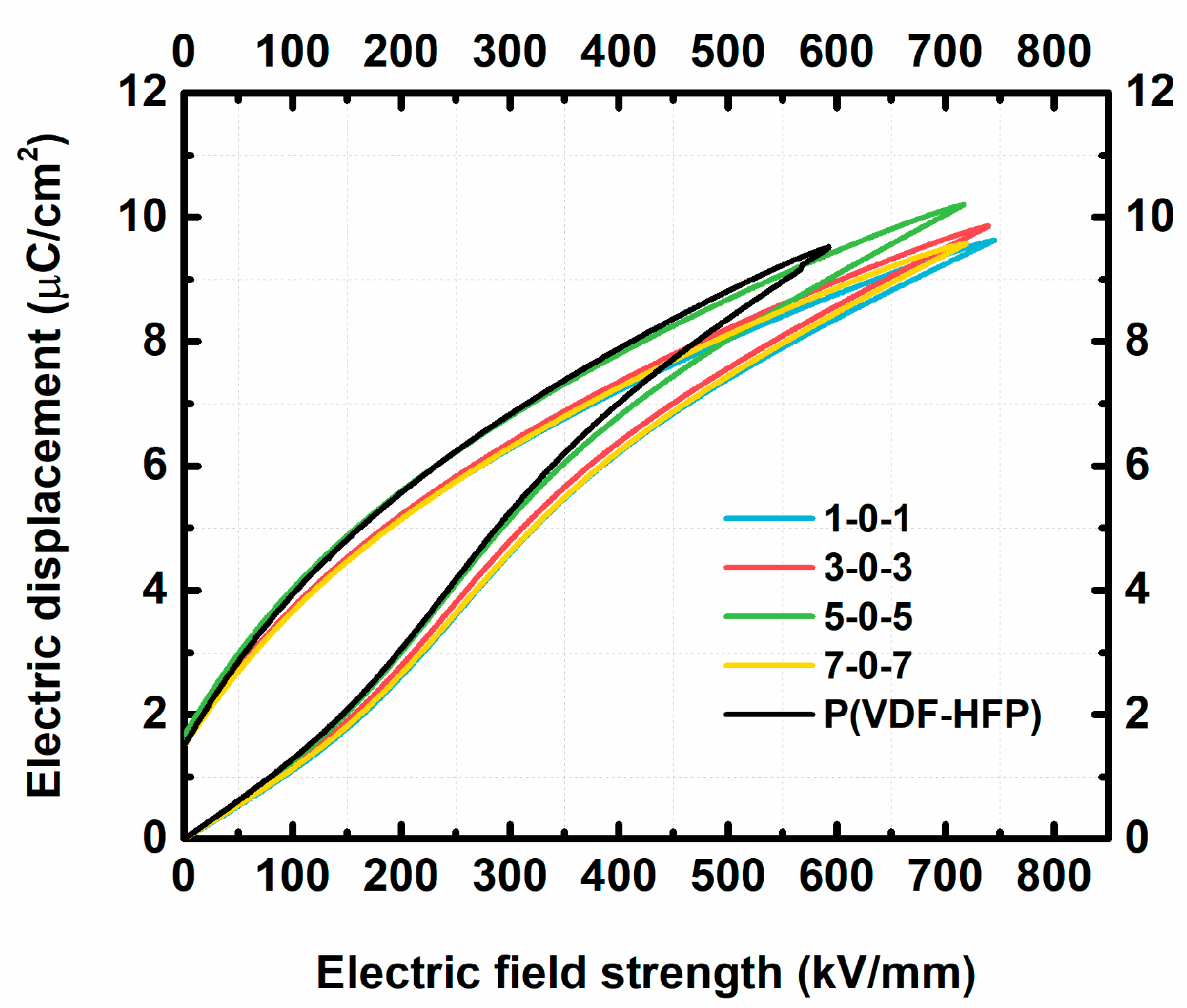

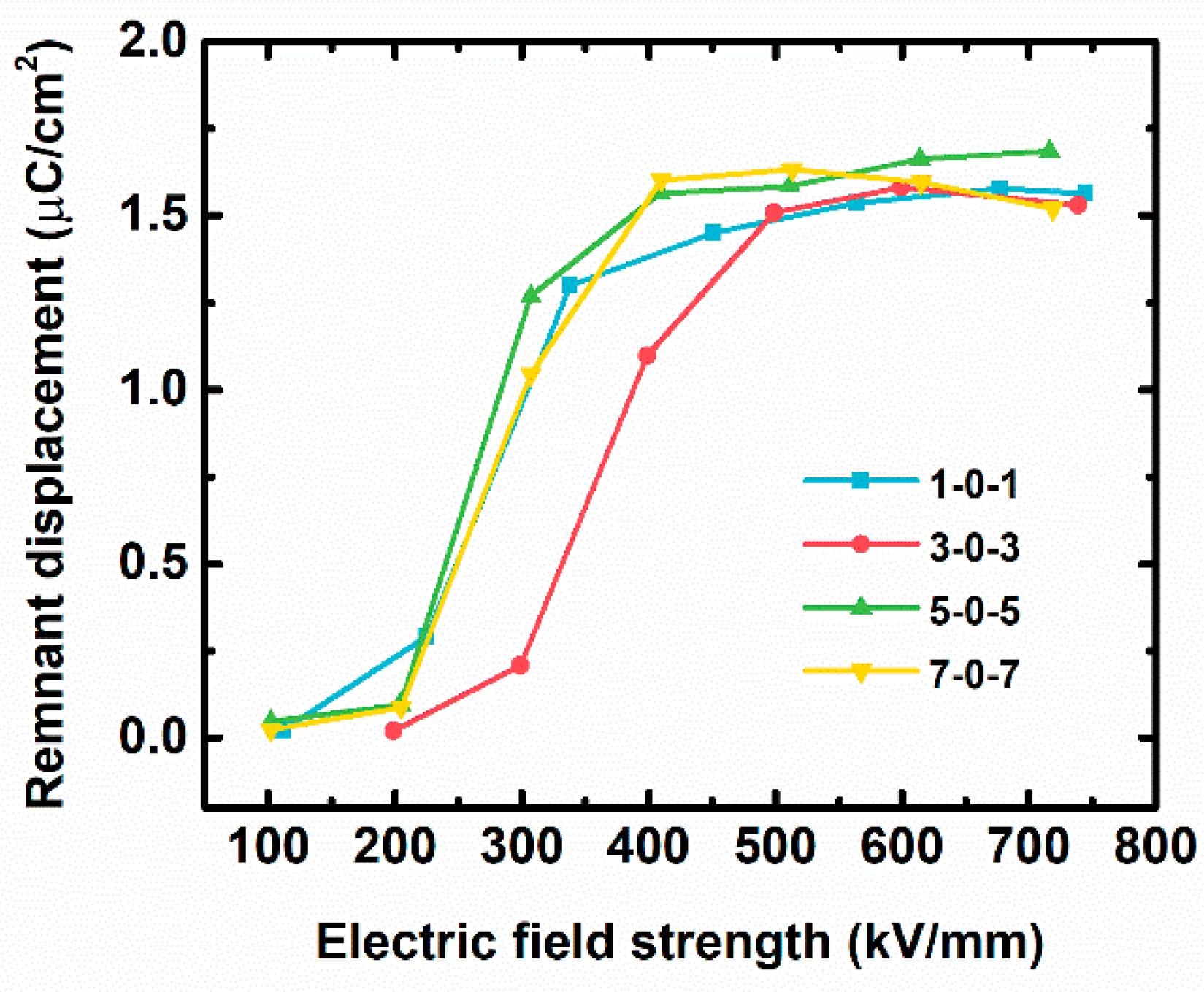

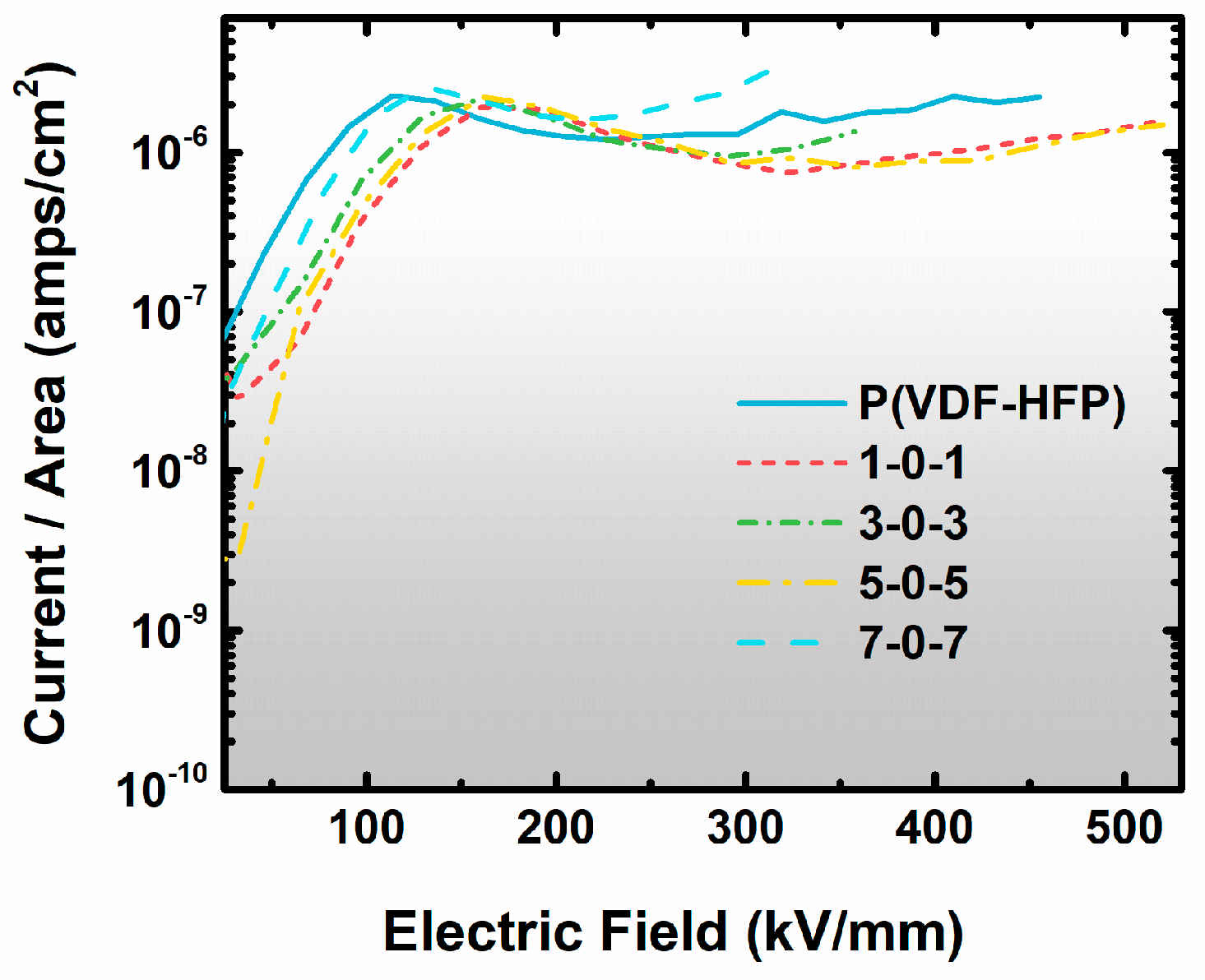

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chu, B. J.; Zhou, X.; Ren, K. L.; Neese, B.; Lin, M. R.; Wang, Q.; Bauer, F.; Zhang, Q. M. , A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313(5785), 334–336. [Google Scholar] [CrossRef] [PubMed]

- Dang, Z. M.; Yuan, J. K.; Yao, S. H.; Liao, R. J. , Flexible Nanodielectric Materials with High Permittivity for Power Energy Storage. Adv. Mater. 2013, 25(44), 6334–6365. [Google Scholar] [CrossRef] [PubMed]

- Yang, B. B.; Zhang, Q. H.; Huang, H. B.; Pan, H.; Zhu, W. X.; Meng, F. Q.; Lan, S.; Liu, Y. Q.; Wei, B.; Liu, Y. Q.; Yang, L. T.; Gu, L.; Chen, L. Q.; Nan, C. W.; Lin, Y. H. , Engineering relaxors by entropy for high energy storage performance. Nature Energy 2023, 13. [Google Scholar] [CrossRef]

- Li, D.; Zhou, D.; Wang, D.; Zhao, W.; Guo, Y.; Shi, Z.; Zhou, T.; Sun, S.-K.; Singh, C.; Trukhanov, S.; Sombra, A. S. B., Lead-Free Relaxor Ferroelectric Ceramics with Ultrahigh Energy Storage Densities via Polymorphic Polar Nanoregions Design. Small 2023, 19 (8). [CrossRef]

- Pan, H.; Feng, N.; Xu, X.; Li, W. W.; Zhang, Q. H.; Lan, S.; Liu, Y. Q.; Sha, H. Z.; Bi, K.; Xu, B.; Ma, J.; Gu, L.; Yu, R.; Shen, Y.; Wang, X. R.; MacManus-Driscoll, J. L.; Chen, C. L.; Nan, C. W.; Lin, Y. H. , Enhanced electric resistivity and dielectric energy storage by vacancy defect complex. Energy Storage Materials 2021, 42, 836–844. [Google Scholar] [CrossRef]

- Pan, H.; Zeng, Y.; Shen, Y.; Lin, Y.-H.; Ma, J.; Li, L.; Nan, C.-W. , BiFeO3-SrTiO3 thin film as a new lead-free relaxor-ferroelectric capacitor with ultrahigh energy storage performance. Journal of Materials Chemistry A 2017, 5(12), 5920–5926. [Google Scholar] [CrossRef]

- Pan, H.; Zeng, Y.; Shen, Y.; Lin, Y. H.; Nan, C. W., Thickness-dependent dielectric and energy storage properties of (Pb0.96La0.04)(Zr0.98Ti0.02)O3 antiferroelectric thin films. J. Appl. Phys. 2016, 119 (12). [CrossRef]

- Rabuffi, M.; Picci, G. , Status quo and future prospects for metallized polypropylene energy storage capacitors. IEEE Trans. Plasma Sci. 2002, 30(5), 1939–1942. [Google Scholar] [CrossRef]

- Laihonen, S. J.; Gafvert, U.; Schutte, T.; Gedde, U. W. , DC breakdown strength of polypropylene films: Area dependence and statistical behavior. IEEE Trans. Dielectr. Electr. Insul. 2007, 14(2), 275–286. [Google Scholar] [CrossRef]

- Li, W. J.; Meng, Q. J.; Zheng, Y. S.; Zhang, Z. C.; Xia, W. M.; Xu, Z., Electric energy storage properties of poly(vinylidene fluoride). Appl. Phys. Lett. 2010, 96 (19). [CrossRef]

- Sun, Q.; Shi, B.; Zhang, T.; Yang, W.; Wang, J.; Zhang, L.; Xue, D.; Wang, Z.; Kang, F.; Zhang, X. , Dielectric Properties’ Synergy of Stretched P(VDF-HFP) and P(VDF-HFP)/PMMA Blends Creates Ultrahigh Capacitive Energy Density in All-Organic Dielectric Films. ACS Applied Energy Materials 2022, 5(7), 8211–8221. [Google Scholar] [CrossRef]

- Liu, X.; Luo, H.; Yan, C.; Liu, Y.; Luo, H.; Zhang, D.; Chen, S. , Achieving synergistic improvement in dielectric constant and energy storage properties of all-organic liquid crystal molecule/PVDF composites. Journal of Materials Chemistry C 2022, 10(46), 17757–17767. [Google Scholar] [CrossRef]

- Behera, R.; K, E. , A review on polyvinylidene fluoride polymer based nanocomposites for energy storage applications. Journal of Energy Storage 2022, 48, 103788. [Google Scholar] [CrossRef]

- Jiang, Y. D.; Zhou, M. J.; Shen, Z. H.; Zhang, X.; Pan, H.; Lin, Y. H. , Ferroelectric polymers and their nanocomposites for dielectric energy storage applications. Apl Materials 2021, 9(2), 11. [Google Scholar] [CrossRef]

- Zhang, X.; Li, B. W.; Dong, L. J.; Liu, H. X.; Chen, W.; Shen, Y.; Nan, C. W. , Superior Energy Storage Performances of Polymer Nanocomposites via Modification of Filler/Polymer Interfaces. Advanced Materials Interfaces 2018, 5(11), 28. [Google Scholar] [CrossRef]

- Zhou, W. Y.; Cao, G. Z.; Yuan, M. X.; Zhong, S. L.; Wang, Y. D.; Liu, X. R.; Cao, D.; Peng, W. W.; Liu, J.; Wang, G. H.; Dang, Z. M.; Li, B. , Core-Shell Engineering of Conductive Fillers toward Enhanced Dielectric Properties: A Universal Polarization Mechanism in Polymer Conductor Composites. Adv. Mater. 2023, 35(2), 10. [Google Scholar] [CrossRef]

- Bi, K.; Bi, M.; Hao, Y.; Luo, W.; Cai, Z.; Wang, X.; Huang, Y. , Ultrafine core-shell BaTiO3@SiO2 structures for nanocomposite capacitors with high energy density. Nano Energy 2018, 51, 513–523. [Google Scholar] [CrossRef]

- Hu, P. H.; Jia, Z. Y.; Shen, Z. H.; Wang, P.; Liu, X. R. , High dielectric constant and energy density induced by the tunable TiO2 interfacial buffer layer in PVDF nanocomposite contained with core-shell structured TiO2@BaTiO3 nanoparticles. Appl. Surf. Sci. 2018, 441, 824–831. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, X.; Bi, K.; Zhang, J.; Huang, Y.; Wu, L.; Zhao, P.; Xu, K.; Lei, M.; Li, L. , Significantly enhanced energy storage performance promoted by ultimate sized ferroelectric BaTiO3 fillers in nanocomposite films. Nano Energy 2017, 31, 49–56. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, X.; Dan, Z.; Ma, J.; Lin, Y.; Li, M.; Nan, C.-W.; Shen, Y. , Tuning Phase Composition of Polymer Nanocomposites toward High Energy Density and High Discharge Efficiency by Nonequilibrium Processing. ACS Appl. Mat. Interfaces 2017, 9(35), 29717–29731. [Google Scholar] [CrossRef] [PubMed]

- Chen, G. R.; Wang, X.; Lin, J. Q.; Yang, W. L.; Li, H. D.; Wen, Y. N., Interfacial Polarity Modulation of KTa0.5Nb0.5O3 Nanoparticles and Its Effect on Dielectric Loss and Breakdown Strength of Poly(vinylidene fluoride) Nanocomposites with High Permittivity. J. Phys. Chem. C 2016, 120 (50), 28423-28431.

- Huang, X. Y.; Xie, L. Y.; Yang, K.; Wu, C.; Jiang, P. K.; Li, S. T.; Wu, S.; Tatsumi, K.; Tanaka, T., Role of Interface in Highly Filled Epoxy/BaTiO3 Nanocomposites. Part II-Effect of Nanoparticle Surface Chemistry on Processing, Thermal Expansion, Energy Storage and Breakdown Strength of the Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21 (2), 480-487.

- Liu, Y.; Luo, H.; Zhai, D.; Zeng, L.; Xiao, Z.; Hu, Z.; Wang, X.; Zhang, D., Improved Energy Density and Energy Efficiency of Poly(vinylidene difluoride) Nanocomposite Dielectrics Using 0.93Na0.5Bi0.5TiO3-0.07BaTiO3 Nanofibers. ACS Appl. Mat. Interfaces 2022, 14 (17), 19376-19387. [CrossRef]

- Zhang, H.; Marwat, M. A.; Xie, B.; Ashtar, M.; Liu, K.; Zhu, Y.; Zhang, L.; Fan, P.; Samart, C.; Ye, Z.-g. , Polymer Matrix Nanocomposites with 1D Ceramic Nanofillers for Energy Storage Capacitor Applications. ACS Appl. Mat. Interfaces 2020, 12(1), 1–37. [Google Scholar] [CrossRef]

- Pan, Z. B.; Zhai, J. W.; Shen, B. , Multilayer hierarchical interfaces with high energy density in polymer nanocomposites composed of BaTiO3@TiO2@Al2O3 nanofibers. Journal of Materials Chemistry A 2017, 5(29), 15217–15226. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, Y.; Zhang, Q.; Gu, L.; Hu, Y.; Du, J.; Lin, Y.; Nan, C.-W. , Ultrahigh Energy Density of Polymer Nanocomposites Containing BaTiO3 @TiO2 Nanofibers by Atomic-Scale Interface Engineering. Adv. Mater. 2015, 27(5), 819–24. [Google Scholar] [CrossRef]

- Cao, Q.; Zhu, W.; Chen, W.; Chen, X.; Yang, R.; Yang, S.; Zhang, H.; Gui, X.; Chen, J. , Nonsolid TiOx Nanoparticles/PVDF Nanocomposite for Improved Energy Storage Performance. ACS Appl. Mat. Interfaces 2022, 14(6), 8226–8234. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Shen, Z. H.; Shen, Y.; Lin, Y. H.; Nan, C. W. , High energy density and efficiency achieved in nanocomposite film capacitors via structure modulation Appl. Phys. Lett. 2018, 112(10), 103902. [Google Scholar]

- Zhu, Y. K.; Yao, H.; Jiang, P. K.; Wu, J. D.; Zhu, X.; Huang, X. Y. , Two-Dimensional High-k Nanosheets for Dielectric Polymer Nanocomposites with Ultrahigh Discharged Energy Density. J. Phys. Chem. C 2018, 122(32), 18282–18293. [Google Scholar] [CrossRef]

- Pan, Z.; Liu, B.; Zhai, J.; Yao, L.; Yang, K.; Shen, B. , NaNbO3 Two-Dimensional Platelets Induced Highly Energy Storage Density in Trilayered Architecture Composites. Nano Energy 2017. [CrossRef]

- Shen, Z. H.; Wang, J. J.; Lin, Y. H.; Nan, C. W.; Chen, L. Q.; Shen, Y. , High-Throughput Phase-Field Design of High-Energy-Density Polymer Nanocomposites. Adv. Mater. 2018, 30(2), 6. [Google Scholar] [CrossRef]

- Shen, Y.; Du, J.; Zhang, X.; Huang, X.; Song, Y.; Wu, H.; Lin, Y.; Li, M.; Nan, C.-W. , Enhanced breakdown strength and suppressed leakage current of polyvinylidene fluoride nanocomposites by two-dimensional ZrO2 nanosheets. Materials Express 2016, 6(3), 277–282. [Google Scholar] [CrossRef]

- Ghosh, S. K.; Rahman, W.; Middya, T. R.; Sen, S.; Mandal, D., Improved breakdown strength and electrical energy storage performance of gamma-poly (vinylidene fluoride)/unmodified montmorillonite clay nano-dielectrics. Nanotechnology 2016, 27 (21).

- He, J.; Yin, Y.; Xu, M.; Wang, P.; Yang, Z.; Yang, Q.; Shi, Z.; Xiong, C. , Regenerated Cellulose/NaNbO3 Nanowire Dielectric Composite Films with Superior Discharge Energy Density and Efficiency. ACS Applied Energy Materials 2021, 4(8), 8150–8157. [Google Scholar] [CrossRef]

- Budenstein, P. P. , On the mechanism of dielectric breakdown of solids. Ieee Transactions on Electrical Insulation 1980, 15(3), 225–240. [Google Scholar] [CrossRef]

- Danikas, M. G.; Tanaka, T. , Nanocomposites-A Review of Electrical Treeing and Breakdown. IEEE Electr. Insul. Mag. 2009, 25(4), 19–25. [Google Scholar] [CrossRef]

- Dissado, L. A.; Fothergill, J. C., Electrical degradation and breakdown in polymers. Peter Peregrinus: 1992; p xix+601. [CrossRef]

- Yu, K.; Niu, Y. J.; Xiang, F.; Zhou, Y. C.; Bai, Y. Y.; Wang, H., Enhanced electric breakdown strength and high energy density of barium titanate filled polymer nanocomposites. J. Appl. Phys. 2013, 114 (17). [CrossRef]

- Li, J. J.; Seok, S. I.; Chu, B. J.; Dogan, F.; Zhang, Q. M.; Wang, Q. , Nanocomposites of Ferroelectric Polymers with TiO2 Nanoparticles Exhibiting Significantly Enhanced Electrical Energy Density. Adv. Mater. 2009, 21(2), 217. [Google Scholar] [CrossRef]

- McQueen, D. H.; Jager, K. M.; Peliskova, M., Multiple threshold percolation in polymer/filler composites. Journal of Physics D-Applied Physics 2004, 37 (15), 2160-2169. [CrossRef]

- Nelson, J. K. In Overview of nanodielectrics: Insulating materials of the future, 2007 Electrical Insulation Conference and Electrical Manufacturing Expo, 22-24 Oct. 2007; 2007; pp 229-235.

- Smith, R. C.; Liang, C.; Landry, M.; Nelson, J. K.; Schadler, L. S. , The mechanisms leading to the useful electrical properties of polymer nanodielectrics. IEEE Trans. Dielectr. Electr. Insul. 2008, 15(1), 187–196. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).