1. Introduction

Terramechanics, the discipline focused on the dynamic interaction between vehicles and terrain, is instrumental in shaping the performance of off-road vehicles [

1]. This field is paramount in developing and accessing off-road machinery tailored for specific terrain types. Over the years, researchers have devised various methodologies to probe the mobility of these vehicles [

2,

3,

4,

5,

6], given their crucial role in navigating challenging terrains [

7,

8]. Distinct from their wheeled counterparts, tracked vehicles promise a multitude of advantages in off-road applications. Their design ensures a broader contact surface with the ground, leading to uniform weight distribution and a reduced risk of sinking. This design feature has garnered prominence across sectors such as the military, construction, agriculture, and mining. These vehicles, equipped with rubber tracks, promise enhanced grip, lower ground pressure, and elevated mobility. Understanding the behavior of these rigid-flexible tracked vehicles across different soil beds is paramount. Further, the vehicle facilitates accurate monitoring and analysis of different soils’ behavior under varying moisture conditions [

9,

10]. Their ability to traverse varying terrains stems from the complex interplay between the vehicle’s characteristics and the soil’s inherent properties, including its texture, moisture content, temperature, and structural stability.

Off-road operation of a tracked vehicle induces resistance to motion comprised of internal and external components. Internal resistance is widely acknowledged as the intrinsic force that opposes the motion of a vehicle. It is caused by friction, vibrations, and other factors that originate from within the vehicle. On the contrary, external resistance is caused by soil deformation, not soil thrust generation; instead, it is primarily ascribed to the formation of ruts and sinkage, specifically soil compaction beneath the tracks[

11]. Until now, it has been widely accepted that the external resistance resulting from the sinkage of a tracked vehicle consists of two main components: bulldozing resistance and compaction resistance [

1,

2]. Bulldozing resistance refers to the resistance encountered when soil is pushed forward by bulldozing at the front section of the tracks. Resistance might manifest itself when the degree of sinkage exceeds the vertical clearance of the vehicle. Nevertheless, there is a suspicion that this resistance does not manifest when the sinkage is below the clearing threshold [

12,

13,

14].

Understanding the relationship between soil compaction and vehicle encounters is crucial for off-road vehicle design and performance. A recent study [

3] has outlined various techniques for applying data from plate-loading experiments in civil engineering and off-road mobility. One notable contribution is an approximate pressure-sinkage model that considers plate size and two soil parameters. As vehicles apply force to the soil, it undergoes compression, leading to increased track sinkage, primarily due to soil compaction and particle transfer beneath the track. The dynamic interaction between soil and vehicle tracks involves tractive effort and motion resistance, influencing vehicle mobility. Researchers like Bekker (1969), Wong (2001), Harnisch and Lach (2002), and Wong (2010) have expanded the pressure-sinkage model, while Benoit and Gotteland (2005) introduced a model unaffected by pressure plate shape. Liu et al. (2010a, 2010b) examined soil and vehicle factors in rut formation, while Alaoui and Diserens (2011) studied soil structure’s impact on heavy vehicles. To address the dynamic nature of track-terrain interactions, Meirion-Griffith and Spenko (2011), Ding et al. (2011), Irani et al. (2011), and Meywerk et al. (2016) have developed enhanced models. Soil bins have been instrumental in this study, allowing controlled experiments to explore the intricate dynamics between machinery and soil [

7]. The previous studies collectively highlight the versatile applications of soil bins in investigating soil-vehicle pressure sinkage, soil-machine interactions, energy dissipation, and the performance attributes of agricultural machinery. This emphasizes the pivotal role of soil bins in advancing our understanding of pressure sinkage and bearing capacity within the realm of soil mechanics. To comprehensively hold the multitude of factors affecting the mobility of tracked vehicles across diverse terrains and conditions, extensive research is required. Tracked vehicles have proven to be superior performers in off-road environments, owing to their unique design advantages compared to conventional wheeled vehicles [

20]. With their substantial ground contact area, resulting in even weight distribution, they offer remarkable stability in challenging terrains. The introduction of rubber tracks has further augmented these vehicles, promising exceptional traction and optimized ground pressure. Nevertheless, despite these advancements, there remains a significant research challenge in achieving a comprehensive understanding of how tracked vehicles behave on various types of soil.

A critical aspect of this challenge involves the complex interplay of mechanical properties between the vehicle and the terrain. Soil, in all its diverse forms—whether it’s moisture-rich Bentonite or granular Diatom—presents distinct challenges to vehicle mobility. Questions arise, such as how a tracked vehicle’s weight interacts with the moisture content of the soil or how its mechanical treads engage with the granular structure of the soil. Researchers have tackled these questions using tools like soil bins for controlled experiments, delving into pressure sinkage and bearing capacity [

7,

15,

16,

17]. However, while these findings have been groundbreaking, they have often been limited by laboratory settings, highlighting the need for real-time validations.

The performance and mobility of vehicles greatly depend on their interaction with the terrain they traverse [

24]. Terrain mechanical characteristics can be broadly categorized into two key aspects: the expected pressure-sinkage relationship and the tangential shear load versus slippage dynamics. While classical models, such as those proposed by M.G. Bekker [

25] and Reece [

2], have aimed to capture these interactions, they often fall short in replicating real-world scenarios, especially when crucial factors like soil moisture content are overlooked. Traditional thermomechanical models, while pioneering, sometimes struggle to accurately simulate the intricate relationship between vehicle tracks and various soil types, particularly when variables like soil moisture and loading conditions come into play [

8,

24]. To bridge this gap, our study aims to navigate this complex terrain by presenting an improved model that combines the foundational principles of established models with insights from contemporary research. In this study, we analyze the connection between tracked vehicles and terrains. Through experiments conducted on custom test tracks and in-depth analysis, we aim to address existing gaps in Terramechanics research and provide valuable insights to inform future considerations, criteria for rubber-track vehicles, challenges encountered in their development, pressure sensor implementation, and studies on soil bed terrains. In addition, the study of soil behavior holds immense significance in various fields, including geotechnical engineering, agriculture, and environmental science. A comprehensive understanding of how soils interact with varying moisture levels is essential for predicting ground stability, assessing sinkage performance, and evaluating environmental impacts. This study introduces an innovative approach to conducting controlled tests on Bentonite and Diatom soil mixed with sand and gravel, with a primary focus on monitoring pressure sinkage using a specially designed rigid rubber-tracked vehicle.

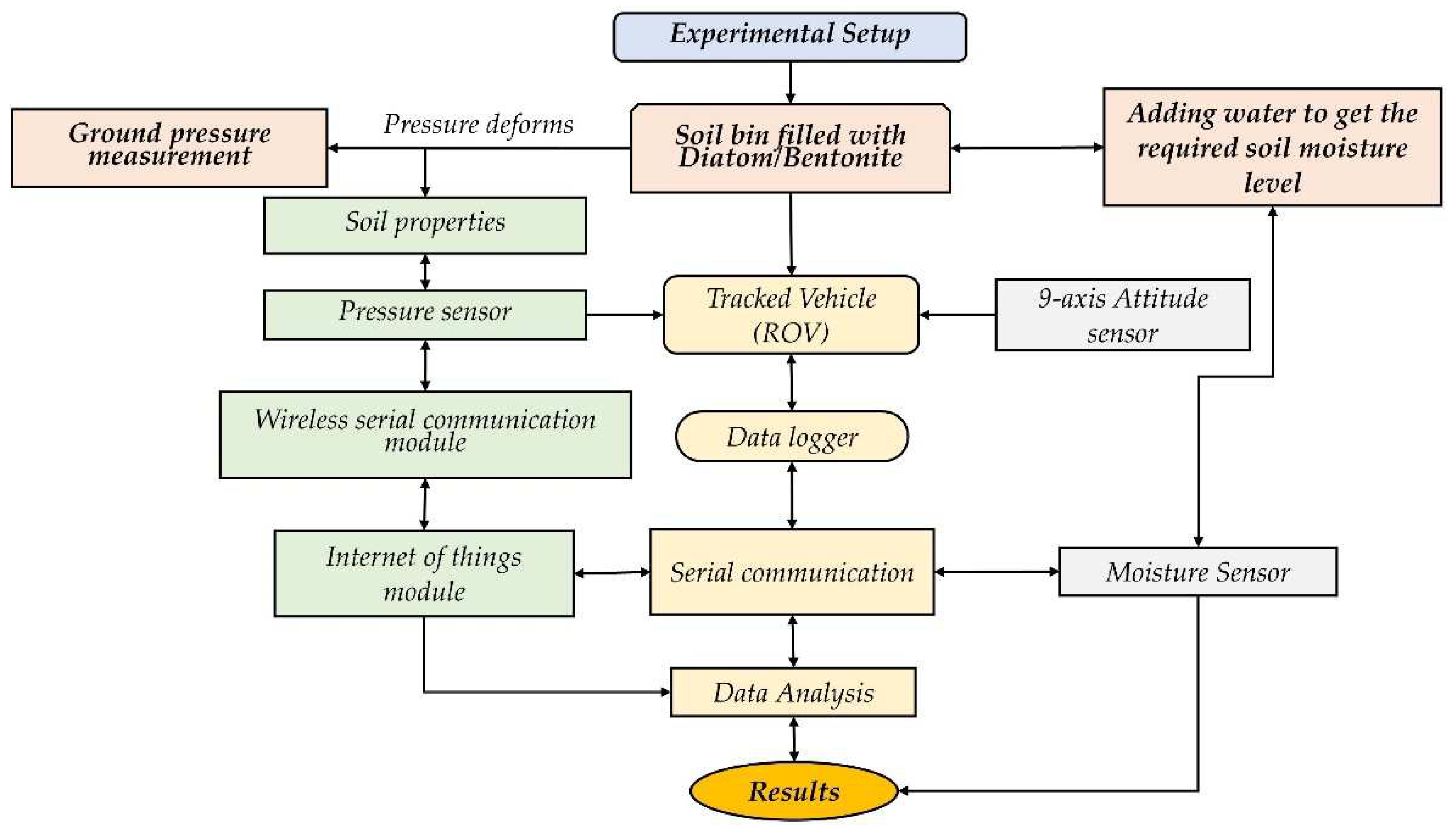

2. Materials and Methods

2.1. Tools and Sensors

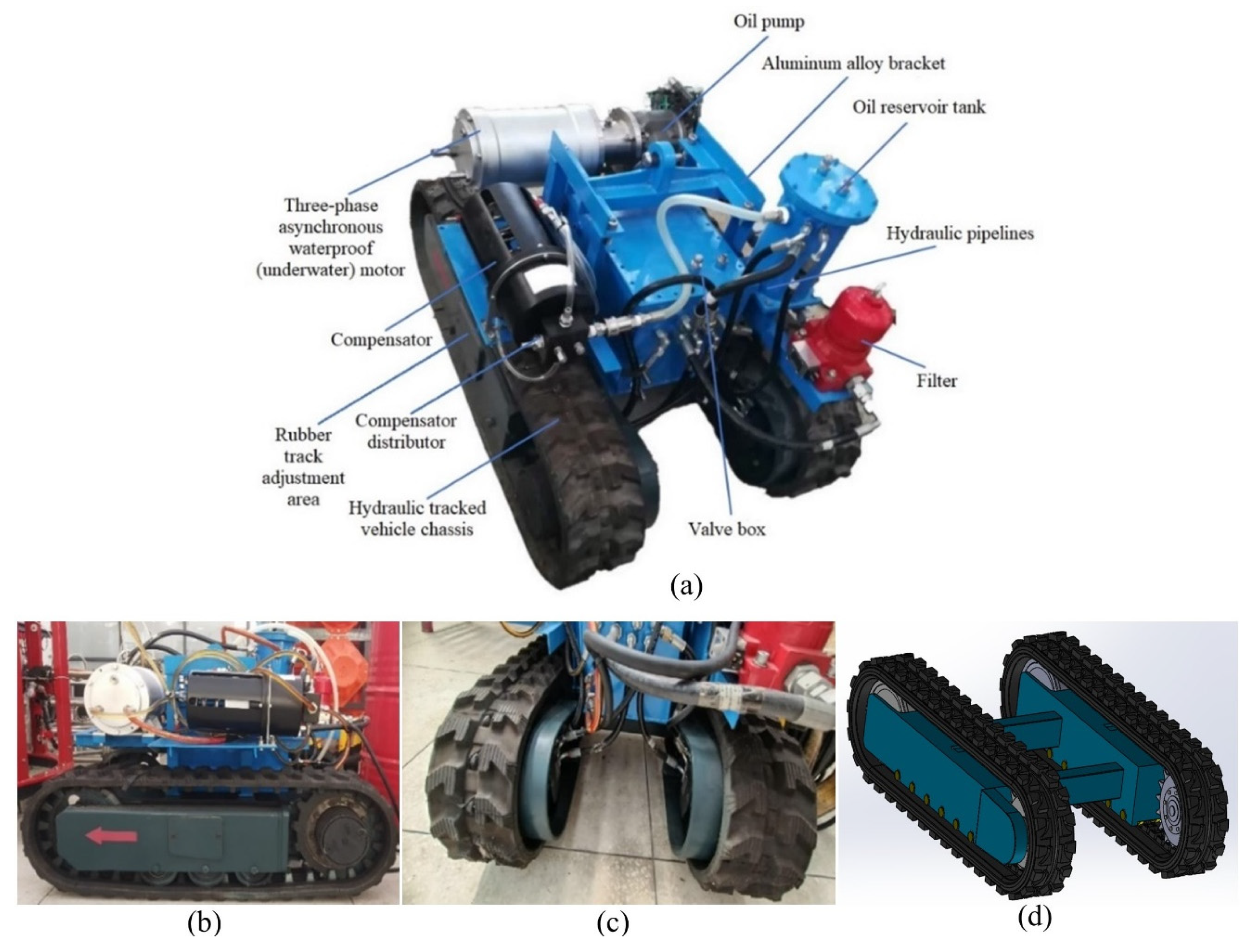

In this study, we utilized various tools and sensors illustrated in

Table 1, and in

Figure 1, the whole apparatus setup for the experiment is presented. To gather accurate and detailed information about the vehicle’s interaction with different types of terrain, including a pressure sensor known as the ZNHM-D1-2T-22121401 model. This sensor works with a voltage range of 5-15V DC and can measure pressures of up to 214.5 kPa/214500 N/m2. It’s incredibly accurate, with a precision of 99.9%. To monitor soil moisture levels, the JXBS-3001-TR_4G moisture and temperature sensor was used (illustrated in

Supplementary Figure S5. Soil moisture sensors’ real-time data monitoring web-based interface tool shows temperature, humidity, and signal strength.

Supplementary Figure S6. (a) 4G wireless soil temperature and moisture sensor, and

Supplementary Figure S6. (b) shows Wireless communication module.). This sensor operates with 12-24V DC and can measure moisture levels from 0-100% over a temperature range of -40 ℃ to 80 ℃ and provides accurate readings, with a 3% margin of error for moisture levels between 0-53% and a 5% margin of error for moisture levels between 53-100%. For assessing soil compaction, the SC-900 Cone Penetrometer was used, which is powered by four AAA alkaline batteries and can measure depths from 0-18” (0-45 cm) and pressures from 0-1000 PSI (0-7000 kPa). It has a depth accuracy of ±0.5” (±1.25 cm) and a pressure accuracy of ±15 PSI (±103 kPa).

Data collection was managed using the FD0843 data logger, which features a wireless serial communication module that operates on 9~24V DC power and consumes less than 10W. This device can handle various A/D update rates, with the capability to go up to 1600 Hz. In addition, it was designed to operate in high temperatures ranging from -30° to 65 ℃ and relative humidity levels of 10% to 95%, with the data transfer rate for this logger being 100 Mb/s. The WT901BLECL5.0 sensor model was utilized to capture vehicle orientation data. This sensor operates on 3.7V with a 260 mAh battery and can transmit data at different rates, with an angular accuracy of 0.20 for the X and Y axes and 10 for the Z axis. More details about the sensor and data logger are given in supplementary (

Supplementary Figure S7) sections, and the data logger’s detailed specifications are illustrated in

Supplementary Table S1.

2.2. Experimental Procedure

This study focuses on monitoring pressure sinkage in cohesion soils such as Bentonite and Diatom soil, especially when they are mixed with sand and gravel, using a specially designed small rigid rubber-tracked vehicle. Creating a prototype vehicle for conducting pressure sinkage experiments in a soil bin involves careful consideration of various critical factors. This vehicle utilizes rubber tracks to minimize surface disturbance and ensure adequate traction on the soil. The choice of narrower track dimensions is based on the unique characteristics of the soil types involved. These narrower rubber tracks are particularly effective for enhancing penetration in cohesive soils like Bentonite and Diatom soil mixed with sand and gravel, improving the monitoring process. We selected a rubber-based flexible tracked vehicle for our experiments, suitable for various applications—the vehicle measured 120 cm in length, 90 cm in width, and 80 cm in height, has 90 cm contact length of rubber track, 20 cm width of single rubber track, illustrated in

Figure 2, and detailed parameters are illustrated in Table 2.

Figure 2.

(a) Image of bodies of a mini rigid tracked vehicle; (b) Proposed tracked vehicle’s side view; (c) Proposed tracked vehicle’s front view; (d) Solidworks schematic track diagram.

Figure 2.

(a) Image of bodies of a mini rigid tracked vehicle; (b) Proposed tracked vehicle’s side view; (c) Proposed tracked vehicle’s front view; (d) Solidworks schematic track diagram.

Table 2.

A tracked vehicle was used for the experiment’s basic parameters.

Table 2.

A tracked vehicle was used for the experiment’s basic parameters.

| Parameter name |

Symbol |

Parameter content |

| Track length × width × Height (cm) |

Lx×Ly×Lz |

120 × 90 × 80 |

| Contact length of rubber track |

cm |

90 |

| Width of single rubber track |

cm |

20 |

| Drive wheel diameter |

cm |

26 |

| Front idler diameter |

cm |

32 |

| Lugs |

cm |

19 |

| Weight of the tracked vehicle |

W (kg) |

530 |

| Weight of the vehicle in the water |

Ww (kg) |

10.3 |

| Contact Pressure |

P (kPa) |

13.889 |

| Contact Pressure in the water |

Pw (kPa) |

12.5 |

The compact size of the vehicle allows it to navigate within the limited space of the soil bin while minimizing soil disturbance, ensuring stable and even weight distribution to avoid affecting pressure sinkage measurements. The rubber-tracked vehicle is designed to distribute its load evenly across the tracks, preventing localized pressure points and ensuring sufficient traction for effective movement on the soil surface. The track system is optimized with durable and wear-resistant materials suitable for the specific soil conditions, including Bentonite and Diatom soil mixed with sand and gravel. The study involved a comprehensive examination of soil sampling techniques, which encompassed the selection of soil combinations such as Bentonite, Diatom, sand, and gravel. Precise gravimetric methods were employed to maintain consistent moisture levels within predetermined ranges, ensuring the reproducibility of experiments. These experiments took place within an indoor soil bin located at the Institute of Deep-Sea Science and Engineering (IDSSE) of the Chinese Academy of Sciences. Measuring ground pressure within the confines of the 610 cm x 245 cm x 180 cm soil bin while the unmanned tracked vehicle was in motion posed distinctive challenges. The soil bin was filled with a mixture comprising 17% sand, 13% gravel (2-5 mm), and 70% Diatom/Bentonite soil. After each trial, the soil was meticulously prepared by tilling, leveling, and compacting. Cone penetration tests (CPT) were utilized to evaluate soil resistance and compaction at different depths and on different moisture levels, as illustrated in

Supplementary Table S9. The paper also delves into the setup and instrumentation configuration of the test stand, including the strategic placement of sensors for pressure measurements. A sophisticated data logger was utilized to record ground sinkage pressure data, enhancing the study’s capacity for replication and practical application.

Figure 3.

Experimental setup for Soil Bin and pressure sensor installation location(a) Soil Bin used for the experiment, (b) Diatom soil in soil bin, (c) Bentonite soil in soil bin, (d) Sand gravel mixture mixed with bentonite soil, (e) Tracked vehicle and pressure sensor installation location, (f) front, mid, and Rear pressure sensor location in soil bin.

Figure 3.

Experimental setup for Soil Bin and pressure sensor installation location(a) Soil Bin used for the experiment, (b) Diatom soil in soil bin, (c) Bentonite soil in soil bin, (d) Sand gravel mixture mixed with bentonite soil, (e) Tracked vehicle and pressure sensor installation location, (f) front, mid, and Rear pressure sensor location in soil bin.

Figure 4.

Cone penetrometer and sampling by cone penetrometer.

Figure 4.

Cone penetrometer and sampling by cone penetrometer.

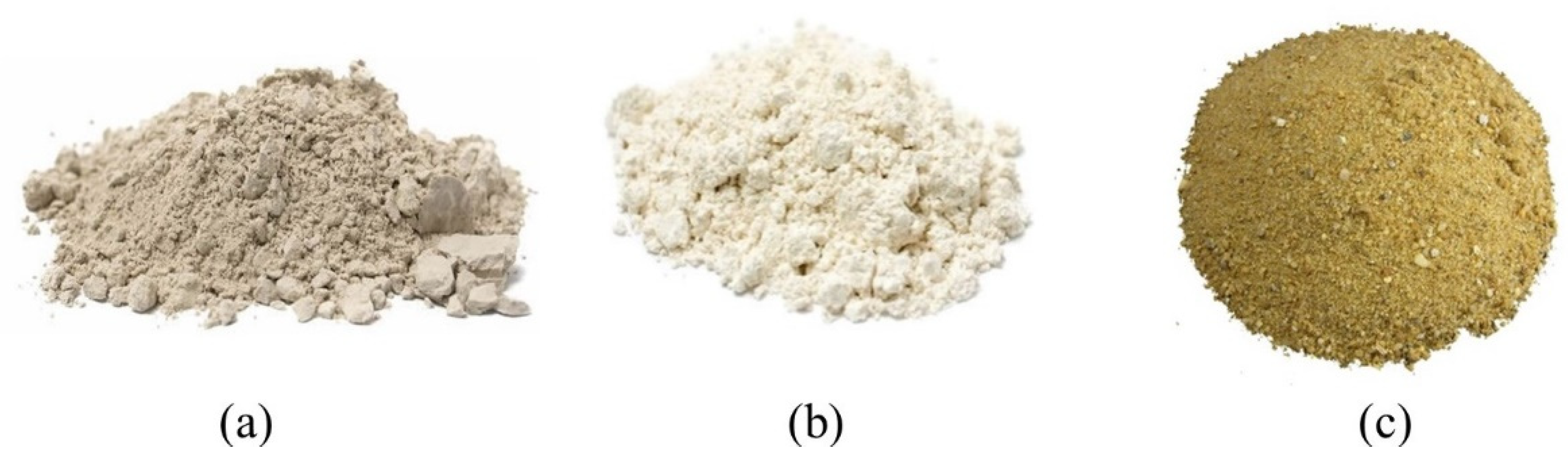

A significant quantity of Bentonite, Diatom, sand, and gravel (ranging from 2mm to 5mm) was initially obtained. The mixture consisted of approximately 16 to 19% sand, 11 to 16% gravel, and 70% Diatom/Bentonite soil. Both Bentonite and Diatom were dried in the sunlight until they became loose powder, making it possible to adjust their moisture content later. This dried soil was then transported to the soil bin and added layer by layer in 5 cm increments, evenly distributed using a small wooden roller and hand shovel. The parameters for the soil bin used in the pressure sinkage and bearing capacity experiments are, and the detailed parameters for the soil bin used in the pressure sinkage experiment are shown in

Supplementary Table S6. Soil deposition continued until the depth reached 40 cm in the bin. A calculated amount of water was added, and the standard gravimetric method was used to determine moisture content by comparing wet and dry weights. This process ensured uniformity and brought moisture levels within specified ranges (approximately 9 to 13%, 18 to 23%, and 29 to 33%) for both Bentonite and Diatom soil. The exact amount of water needed for each moisture level was determined using real-time data from a wireless moisture sensor (shown in

Supplementary Figure S4). To maintain desired moisture levels, a wireless moisture sensor continuously monitored soil moisture in real-time, allowing for precise adjustments in water content. This careful monitoring and adjustment ensured that the soil samples remained within the specified moisture content ranges throughout the experiment. After mixing with water, the soil was left in the bin to settle for 24 hours. Separate containers were used for each moisture level within each soil type to control moisture content accurately. The soil bin was assigned distinct moisture ranges for targeted analysis and regulation of soil behavior under varying moisture levels for both Bentonite and Diatom soil samples.

Supplementary Figure S5 illustrates an online moisture sensor that monitors real-time temperature, soil moisture, and signal intensity.

The testing bin, measuring 610 cm x 245 cm x 180 cm and reinforced with steel sheets and bars, was constructed to withstand the applied loads and prevent soil leakage, as illustrated in

Supplementary Figure S2. Before initiating the experiments, a geomembrane liner was used to prevent moisture evaporation, and a layer of drainage gravel was added for proper drainage. The sand-gravel mixture was carefully added to the bin in layers approximately 30 cm thick. To ensure uniform compaction, the surface was prepared by removing debris, large stones, and potential obstructions that could hinder the process. The bin underwent thorough inspection and cleaning before the placement and compaction of soils, creating a well-defined workspace conducive to achieving uniform soil compaction. After confirming even distribution and slight dampness of the soil, the surface was allowed to settle for an additional 24 hours before the experiments began. Following each trial, the soil was manually loosened using a hand shovel. A moisture sensor was embedded horizontally within the compacted Bentonite/Diatom soil layer to monitor any fluctuations during the experiments. These sensors were wirelessly connected to a data logger for real-time monitoring. Each test was repeated three times to account for any inconsistencies arising from the random non-uniformity of the soil samples.

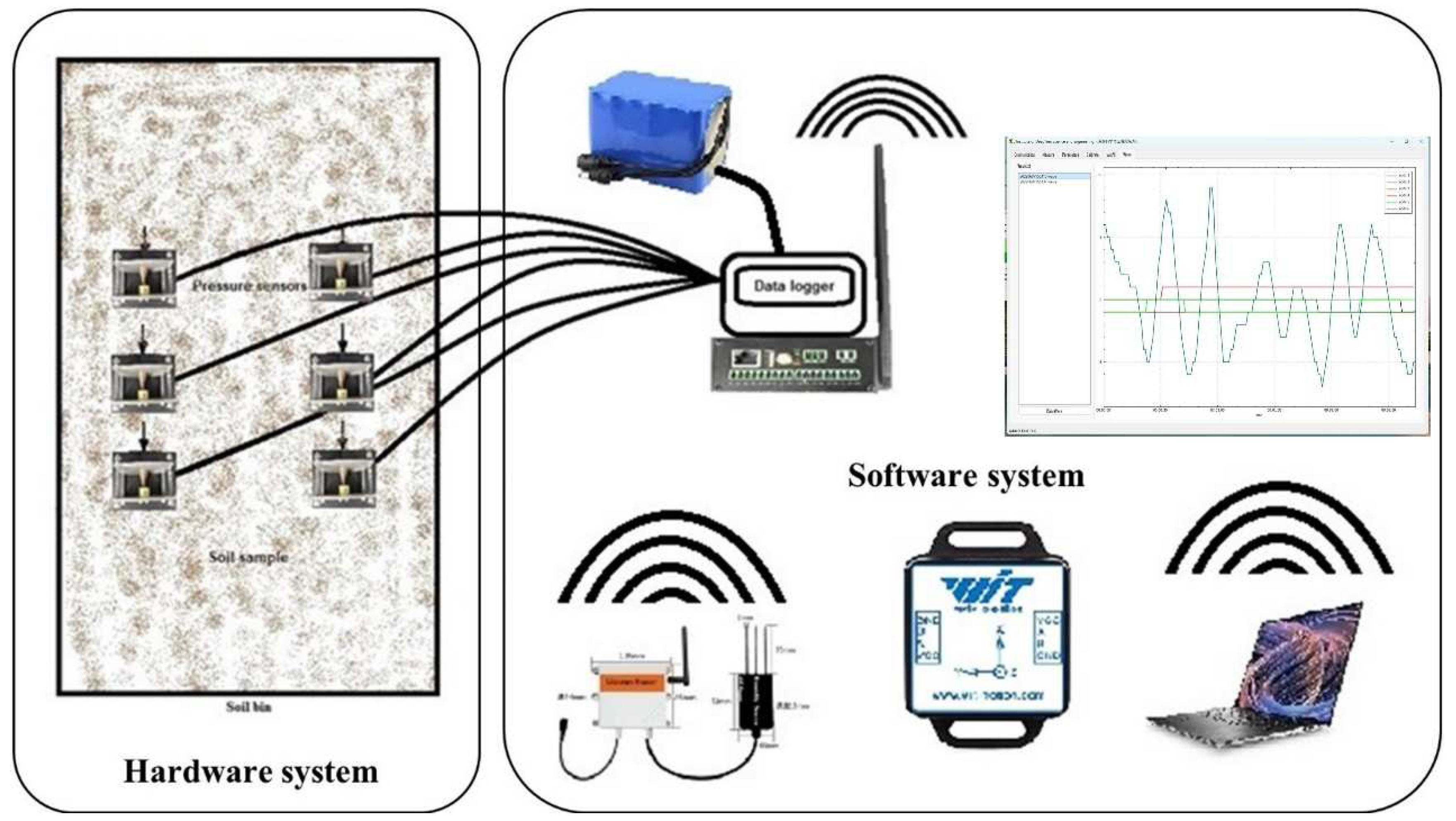

2.3. Soil Path Setup and Experimentation

A specific path within the soil bin was designated for soil compaction and testing. Before adding soil to the bin, the base was carefully leveled using a mixture of sand and gravel to ensure a consistent and sturdy foundation. This step aimed to remove potential obstacles and establish a uniform surface for compaction and testing. The mechanical properties of Bentonite and Diatom soils used in the experiment are outlined in

Supplementary Table S2. In contrast, loose and compact soil properties for the tracked vehicle soil bin experiment are detailed in

Supplementary Table S3 and in

Supplementary Table S4. Detailed soil properties, including soil particle density, natural moisture content, grain size distribution, maximum dry density and the optimum moisture content for the Bentonite, Diatom and sand gravel mixture, are illustrated in

Supplementary Table S7. To collect essential data during the testing process, pressure sensors enclosed in brackets containing moisture sensors were strategically placed within the bin and connected to a wireless data-collection system. This setup allowed continuous monitoring of pressure distribution and moisture fluctuations in the soil, providing valuable insights into the soil’s behavior under external forces. The careful arrangement and equipment used in the soil bin ensured accurate and thorough experimentation, generating valuable data for analysis and interpretation. This methodology has significantly improved our understanding of how soil behaves under various load conditions, contributing to the field of soil mechanics and geotechnical engineering. A calibration procedure was conducted to ensure the accuracy of pressure measurements and validate the vehicle’s response to varying moisture levels. The design of the setup allowed easy access to the soil bin for experimental setup, equipment maintenance, and data collection. Safety features such as guards, emergency stop buttons, and operational protections were included in both the soil bin experiment and vehicle design. The collected pressure sinkage data from the vehicle’s sensors were analyzed to assess the behavior of Bentonite and Diatom soil mixed with sand and gravel under different moisture conditions.

The rubber-tracked vehicle was positioned at one end of the soil bin and driven at speeds ranging from 0.1 to 0.3 m/sec motion test on Diatom and Bentonite Soil at loose and compacted soil density along a predetermined path as outlined in

Supplementary Table S8. During these tests, parameters like sinkage, vehicle speed, and pass count were carefully recorded. This testing process was repeated at various speeds to gain a better understanding of soil behavior, including the physical properties of the Bentonite, Diatom, and Sand-Gravel mixture under different loading conditions, as shown in

Supplementary Table S5. Upon completing the tests, data was analyzed to comprehend pressure distribution and its relationship with factors such as sinkage, soil-bearing capacity, vehicle speed, and moisture content. It’s worth noting that test procedures may vary depending on the specific goals of the pressure sinkage test, the type of soil, and the specific tracked vehicle used. Multiple parameters were recorded during the pressure sinkage test on the Bentonite/Diatom terrain using the rubber-tracked vehicle. These parameters included contact pressure, sinkage, soil moisture content, and vehicle speed. Pressure sensors strategically placed within the bin were calibrated and synchronized with a data logger to capture real-time data. Prior to the main tests, a dry run was conducted to ensure sensor functionality and to habituate the operator with the terrain and path. Soil moisture levels were regularly checked using a moisture meter, given its significant impact on sinkage and pressure distribution. As the vehicle traversed the terrain, sensors recorded data on the pressure exerted by the tracks, and sinkage was measured either using displacement sensors or visually observed based on side bin markings. Additional parameters such as load, inclination, and vehicle speed were assessed. An attitude sensor with 9-axis monitoring capability was used to track the vehicle’s speed and trajectory within the bin, as shown in

Supplementary Figure S3. Following the experiments, the collected data was applied for external validation to establish pressure-sinkage relationships. Graphs showing the sinkage versus pressure for both Bentonite and Diatom soil were generated using Python. A comprehensive overview of the experimental setup, including the soil bin, track vehicle, pressure sensors, data acquisition system, and data analysis methods, is provided in

Figure 5, which illustrates the key components of the experimental configuration, outlining the process for collecting data and analyzing it to gain meaningful insights into ground pressure, bearing capacity, and sinkage in rigid-flexible tracked vehicles.

2.4. Pressure Sensors and Brackets

Pressure sensors are commonly used in various applications, including in underwater environments, and play a fundamental role in track-soil interaction studies by providing essential data to measure the distribution and magnitude of pressure exerted by tracked vehicles on the soil surface. These sensors are instrumental in understanding the mechanical behavior of the soil when subjected to the weight and movement of the vehicle. The data gathered from pressure sensors enables researchers to analyze how the ground pressure is distributed and how it varies over time. In underwater vehicles, such as Remotely Operated Vehicles (ROVs), pressure sensors are utilized in track soil interaction studies to measure the distribution and magnitude of pressure the tracked vehicle exerts on the soil surface. These sensors provide crucial data to understand the mechanical behavior of the soil under the influence of the vehicle’s weight and movement.

Table 1 illustrates the ZNHM-D1-2T-22121401 pressure sensor’s detailed parameters used in the experiment.

The importance of pressure sensors in rubber-track soil interaction studies lies in their ability to capture real-time pressure variations. This real-time data collection is crucial as it enables researchers to observe how the vehicle’s weight is distributed across the soil surface and how this distribution changes as the vehicle moves. By capturing static and dynamic pressure changes, pressure sensors provide insights into the localized stresses applied to the soil, allowing for a detailed analysis of the interaction between the vehicle and the soil. Moreover, pressure sensors contribute to establishing a comprehensive understanding of the ground pressure distribution beneath the tracked vehicle. This information is valuable for evaluating how different types of soil and varying moisture levels may impact the pressure exerted by the vehicle. By studying the ground pressure distribution, researchers can gain insights into the soil’s load-bearing capacity and its deformation characteristics under the influence of the vehicle.

Additionally, pressure sensors enable the measurement of pressure sinkage, which refers to the depth to which an object, in this case, the track of the vehicle, penetrates the soil under the applied pressure. This data is crucial for assessing the soil’s resistance to penetration and the vehicle’s ability to traverse different soil types and conditions.

Supplementary Figure S1 shows that the purpose of the sensor bracket is to hold the pressure sensors in place securely and keep them aligned and safe from haphazard, ensuring accurate and consistent measurements during the interaction between the tracked vehicle and the soil. These brackets are typically made of aluminum or stainless steel, which are corrosion-resistant and can help absorb impacts from debris and protect the pressure sensor from damage. The frames can be attached to the soil bin or vehicle using bolts, clamps, or other fastening methods. The sensor bracket can enclose the pressure sensor, creating a protective barrier around the sensor that can help prevent debris from contacting the sensor, potentially damaging it, and serves to maintain the alignment and positioning of the pressure sensors, preventing displacement or disturbances that could compromise the reliability of the collected data. This allows for precise monitoring of pressure variations at specific locations, contributing to a comprehensive understanding of the impact of the tracked vehicle on the soil surface.

2.5. Safety Protocols

Stringent safety protocols were consistently followed during the experiments to ensure the safety of participants and minimize potential hazards. These safety measures included the use of personal protective equipment (PPE), hazard identification, emergency response planning, and compliance with established safety guidelines and regulations. These measures played a crucial role in creating a safe and controlled environment for the experiments, reducing the risk of accidents or unexpected incidents. In addition to prioritizing safety, the experimental data collected was subjected to careful analysis, interpretation, and review using a rigorous and systematic methodology. This comprehensive analysis considered various parameters, including soil-bearing capacity, compaction behavior, shear strength, and deformation characteristics. The results provided a deep understanding of how the soil responds under different experimental conditions, offering valuable insights applicable to various engineering applications, such as predicting vehicle mobility, foundation design, and construction procedures. By constantly adhering to safety protocols and conducting thorough analyses of experimental data, a comprehensive understanding of soil behavior under varying conditions was achieved.

3. Results and discussion

3.1. Track Vehicle and Sinkage Observations

This study analyzed the effects of varying soil moisture levels on the sinkage of a tracked vehicle moving at a constant speed of 0.1 m/s across two soil types, Bentonite and Diatom (Table 2). As the moisture content increased from 5% to 30% for bentonite, there was a notable progression in sinkage, from 1.10 cm with normal track wear at 5% to a significant 3.80 cm with increased track slippage at 30%. This progression in Bentonite sinkage, especially at increased moisture levels, resonates with prior findings that heightened water content tends to soften soil aggregates and the bond between them, leading to increased compressibility, particularly at lower vertical stresses [

18,

19]. The consequence of this is evident in the severe rutting and track deformation observed starting at 20% moisture content in our study.

Table 2.

Vehicle Pressure Sinkage Test Observations @ 0.1m/sec velocity.

Table 2.

Vehicle Pressure Sinkage Test Observations @ 0.1m/sec velocity.

| Soil |

Moisture (%) |

Speed (m/s) |

Sinkage (cm) |

Track-Soil Observations |

| Bentonite |

5 |

0.1 |

1.10 |

Normal wear and tear on tracks |

| Bentonite |

10 |

0.1 |

1.50 |

Rutting beginning tracks deforming |

| Bentonite |

15 |

0.1 |

2.40 |

Deep rutting, tracks digging in |

| Bentonite |

20 |

0.1 |

2.70 |

Severe rutting, tracks stuck |

| Bentonite |

25 |

0.1 |

3.20 |

Severe track deformation and sinking |

| Bentonite |

30 |

0.1 |

3.80 |

Increased track slippage |

| Diatom |

5 |

0.1 |

0.55 |

Normal wear and tear on tracks |

| Diatom |

10 |

0.1 |

0.80 |

Minor rutting |

| Diatom |

15 |

0.1 |

0.83 |

Rutting |

| Diatom |

20 |

0.1 |

0.90 |

Deep Rutting |

| Diatom |

25 |

0.1 |

1.21 |

very soft soil, tracks dug in |

| Diatom |

30 |

0.1 |

1.30 |

Severe track deformation and sinking |

On the other hand, the Diatom soil exhibited a different trend. At 5% moisture, sinkage was a modest 0.55 cm with regular wear on the tracks. As the moisture content ramped to 30%, the peak sinkage noted was 1.30 cm, marked by profound track deformation and sinking. This disparity in the response of the two soils indicates that the tracked vehicle confronted more formidable challenges on bentonite, especially at elevated moisture levels, than on the Diatom soil under analogous conditions. The shift in hydraulic conductivity with moisture, which affects soil permeability, might provide an added layer of explanation for the marked sinkage and deformation at high moisture levels, drawing parallels with observations from Cuisinier et al. [

20] and Wang et al. [

21], making navigation more taxing for the vehicle. The presented track-soil data holds significance as it facilitates a comprehensive understanding of the interplay between vehicle tracks and soil under varying moisture conditions. By examining the behavior of vehicle tracks on the soil surface, researchers and engineers can acquire valuable knowledge regarding the soil’s reaction to different wetness levels. The data mentioned above offers promising potential for applications in diverse sectors such as mining, agriculture, construction, and geotechnical engineering.

3.2. Soil behavior

The experiment placed significant emphasis on examining the behavior of soil, particularly Bentonite and Diatom soil, when subjected to a load of a tracked vehicle illustrated in

Figure 7., focusing on several metrics, including loose density, compacted density, compaction percentage, depth, and cone index measurement for Bentonite and Diatom illustrated in

Figure 7., and in

Supplementary Table S10. It is imperative to comprehend the reaction of these soils to the weight and motion of the vehicle to evaluate their compaction, load-bearing capability, and deformation properties. The term “sinkage behavior” pertains to the extent of soil penetration by vehicle tracks during their terrain traversal. The objective of this study was to monitor and analyze the sinkage behavior of Bentonite and Diatom soil under varying situations. The information provides valuable insights into the soil’s capacity to withstand external loads and compaction properties.

When a tracked vehicle exerts pressure on the soil surface, it initiates a process where the soil particles undergo rearrangement and compaction. This compaction behavior of the soil is subject to various influencing factors, including the soil type, moisture content, and the magnitude of the applied load. By closely observing the sinkage behavior, we gain valuable insights into the compaction characteristics of both Bentonite and Diatom soil when subjected to the weight of the tracked vehicle.

In the case of Bentonite soil with a moisture content of 10%, we observed two distinct density values: a loose density of 1.3 g/cm³ and a compacted density of 1.5 g/cm³. This resulted in a compaction percentage of 15.38%. This level of compaction can be attributed to the inherent response of the soil to stress, a phenomenon that has been highlighted by Alaoui and Helbling [30]. Their research also emphasized the structural collapse of soil due to compaction at similar depths. Specifically, the cone index values presented noticeable variability at this moisture level: 94.12 kPa at 10 cm, soaring to 215.25 kPa at 20 cm, then decreasing to 127.36 kPa at 30 cm, and again increasing to 179.48 kPa at 40 cm. As the moisture content for bentonite increased to 20%, the loose density reduced slightly to 1.2 g/cm³ and the compacted density to 1.4 g/cm³. Yet, intriguingly, the compaction percentage rose to 17.67%. Zhang et al. [

22], in their observations on the impact of tractor movement on soil compaction, might shed some light on this. They found increased soil bulk density with enhanced tractor movement, hinting at the likelihood of a similar relationship between moisture content and compaction in bentonite. In this moisture setting, the cone index exhibited a pattern, starting with an initial spike to 184.16 kPa at 10 cm depth, then a reduction to 94.28 kPa at 20 cm, before alternating between 179.4 kPa at 30 cm and 127.52 kPa at 40 cm. At the apex moisture content of 30% for bentonite, the loose and compacted densities further declined to 1.1 g/cm³ and 1.3 g/cm³, respectively. This was coupled with a compaction percentage of 18.18%, suggesting even more pronounced effects of moisture on soil’s structural integrity. The cone index at this moisture level shows a diverse landscape, displaying values of 94.44 kPa, 162.36 kPa, 127.6 kPa, and 215.72 kPa for depths of 10 cm, 20 cm, 30 cm, and 40 cm, respectively. The study assessed load-bearing capacity and deformation characteristics of Bentonite and Diatom soil under a rubber-tracked vehicle, offering insights for engineering applications. The soil exhibited increased sinkage and compaction with higher moisture content, impacting its load-bearing capacity.

Figure 6.

(a) Bentonite clay (-0.063mm), (b) Diatom soils (>20μm), and (c) Sand (2mm~5mm) were used in the experiment.

Figure 6.

(a) Bentonite clay (-0.063mm), (b) Diatom soils (>20μm), and (c) Sand (2mm~5mm) were used in the experiment.

Figure 7.

Measurement of Bentonite and ‘Diatom’s Cone Index, Moist Level, and Penetration Depth.

Figure 7.

Measurement of Bentonite and ‘Diatom’s Cone Index, Moist Level, and Penetration Depth.

Diatom soil, unlike bentonite, shows distinct reactions to moisture variations. At 10% moisture, the densities suggest a 22.29% compaction, potentially influenced by Diatom’s unique properties. The consistent cone index progression from 269.14 kPa at 10 cm to 342.59 kPa at 40 cm signifies a growing resistance with depth, possibly due to overlying soil pressures. As moisture rises to 20%, densities drop, but compaction grows to 25.4%. This could be attributed to water-soil particle dynamics affecting particle arrangement, a phenomenon aligning with Alaoui and Helbling [

23], were compaction restricted water movement. The increasing cone index from 219.38 kPa to 278.59 kPa can be related to increased resistance from soil layer pressures or decreased porosity, as Samuel and Ajav [

24] observed. At 30% moisture, despite lower densities, there’s a peak compaction of 28.57%. This tighter packing, coupled with the rise of the cone index, resonates with findings from Zhang et al. [

22] and Botta et al. [

25], indicating similarities between mechanical impact and moisture’s effect on soil.

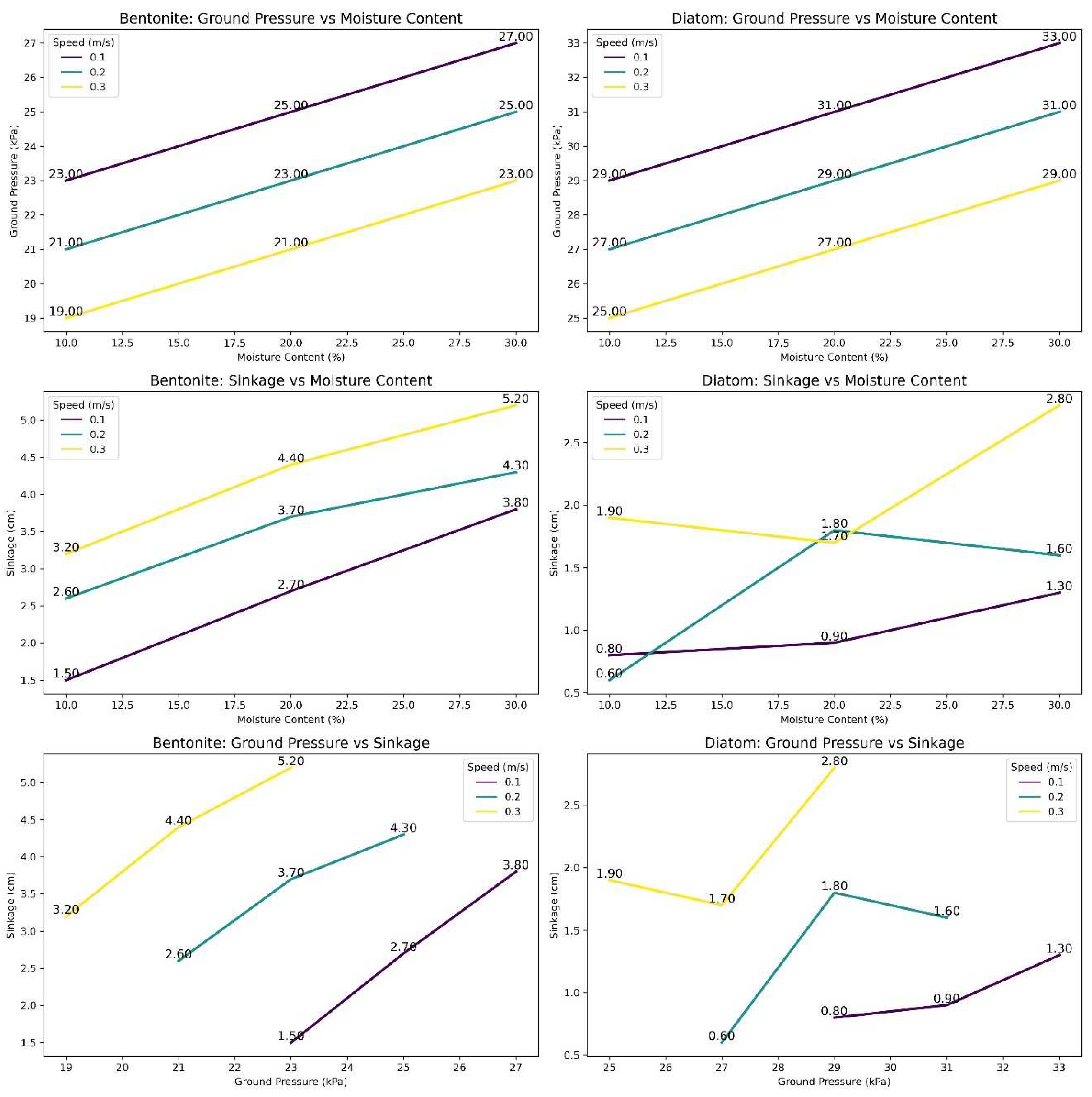

3.3. Ground Pressure and Sinkage Test Results

Ground pressure, quantifying the force exerted by the track car on the ground, was measured using high-precision sensors. Sinkage data provided insights into soil load-bearing capacity and compaction behavior across varying moisture and soil conditions. In dense Diatom soil, higher ground pressure led to increased sinkage, indicating limited load-bearing capacity, while loose Diatom soil exhibited lower ground pressure and reduced sinkage. As vehicle weight increased, both ground pressure and sinkage rose, but the even weight distribution of rubber tracks mitigated excessive sinkage. The behavior of bentonite, as observed in

Figure 8 (rubber-tracked vehicle’s pressure sinkage, ground pressure, and speed test results in detailed data is given in the

Supplementary Table S11.), offers valuable insights into its response to different speed and moisture conditions. At a relatively lower speed of 0.1 m/s, as moisture content increases, there’s an apparent linear increase in ground pressure from 23 kPa to 27 kPa. The linearity suggests that moisture content directly influences the mechanical properties of bentonite, potentially affecting its cohesive and adhesive characteristics. Comparatively, a past study by Mishra et al. [

26] observed a slightly lower range, suggesting a different mechanical response to moisture. This progression in pressure is mirrored in the sinkage values, which grow from 1.5 cm to 3.8 cm. One could posit that at this speed, the moisture aids in binding the Bentonite soil particles, thereby increasing the resistance to external pressures, a phenomenon also supported by the rise in sinkage values.

Interestingly, when the speed is increased to 0.2 m/s, the ground pressure inversely correlates with moisture content, decreasing from 21 kPa to 25 kPa. This inverse correlation can possibly signify a mechanical threshold for bentonite, where increased kinetic energy (speed) may mitigate moisture’s binding effect. Yet, the sinkage consistently rises, possibly indicating that while the ground may resist pressure effectively, it may not be as adept at supporting weight or volume at this speed. The trend is further accentuated at 0.3 m/s, where even lower ground pressures of 19 kPa to 23 kPa are contrasted with the highest sinkage values, suggesting diminished structural integrity of bentonite at higher speeds and moisture levels, as shown in

Table 3.

In contrast, the behavior of diatom soil shows a different picture. At the base speed of 0.1 m/s, even as ground pressures are notably higher than bentonite (29 kPa to 33 kPa), sinkage values are comparatively subdued, ranging between 0.8 cm and 1.3 cm. Despite higher ground pressures, the relative stability in Diatom’s sinkage alludes to its potentially higher shear strength or internal friction, possibly attributed to its structural composition. This hints at Diatom soil’s inherent higher compaction or density, potentially due to its unique mineralogical composition [

27]. As speeds increase to 0.2 m/s and 0.3 m/s, the ground pressures reduce across the moisture gradient, but there’s a more erratic behavior in sinkage values. This erraticism could potentially underscore a complexity in ‘Diatom’s response to mechanical stress, revealing an intricate interplay between its physical structure and moisture content. This could indicate the intricate interplay between soil particle arrangement, moisture, and external pressure in Diatom soil, making it react differently than bentonite.

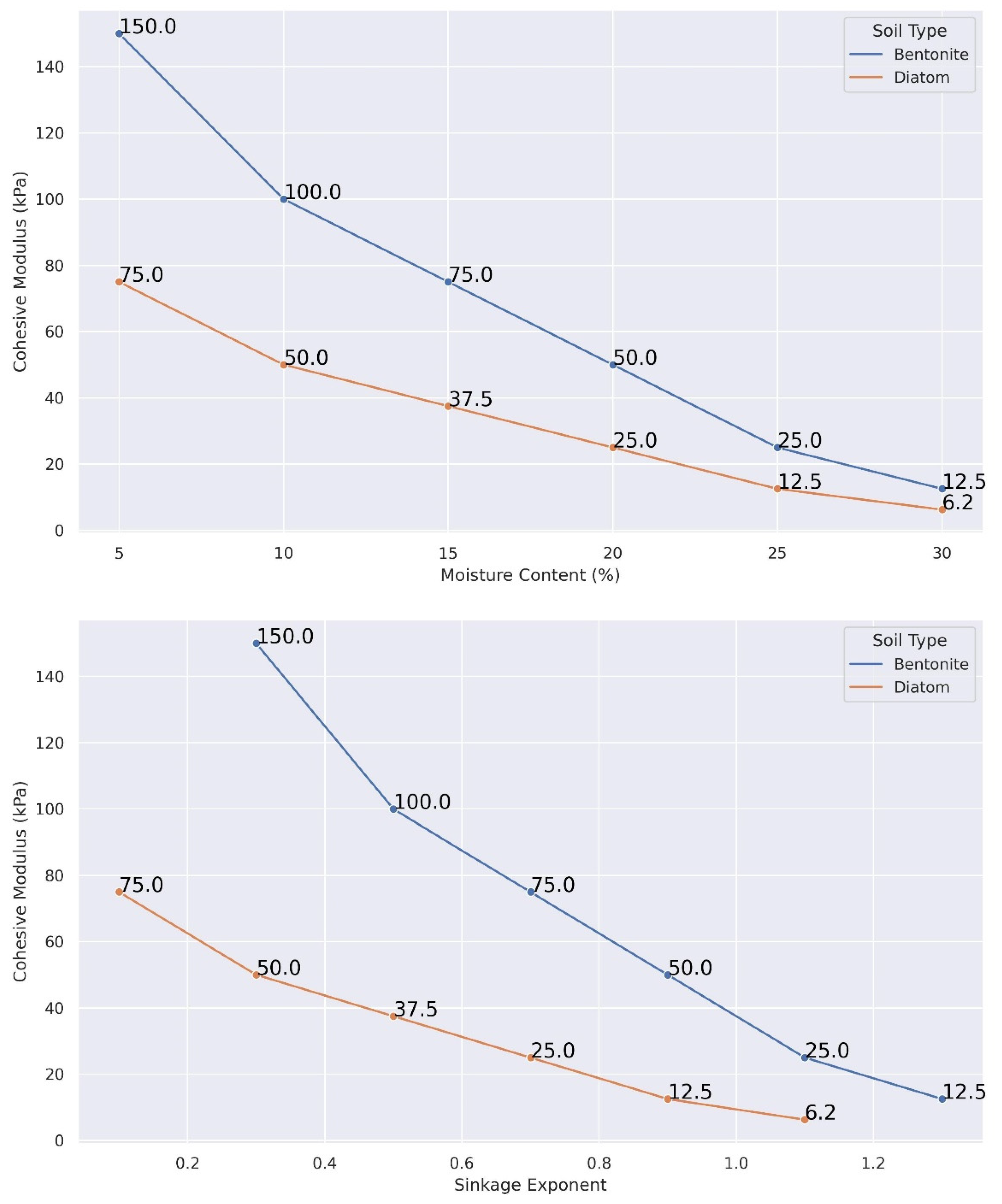

3.4. Impact of moist soil content on sinkage exponent

Moisture content significantly affects soil mechanical properties, especially sinkage. Higher moisture content correlates with an increased sinkage exponent, indicating reduced load-bearing capacity as saturation levels rise. Elevated moisture content reduces effective stress, diminishing shear strength, and increasing deformation. Assessing load-bearing capacity and sinkage propensity must account for soil moisture content. The moisture content, cohesive modulus, and sinkage exponent for Bentonite and Diatom soil types are displayed in

Figure 9., and comprehensive data is shown in the

Table 3. For bentonite, there is an evident progressive increase in the sinkage exponent with increasing moisture content. Starting at 5% moisture, the sinkage exponent is recorded at 0.3 and ascends steadily, reaching 1.3 at a moisture content of 30%. This indicates a direct relationship between moisture levels and the sinkage behavior of bentonite, suggesting that as the soil becomes wetter, its propensity to sink under pressure magnifies. Given these observations, it can be inferred that the complex interplay between water molecules and Bentonite soil particles may result in increased flexibility, thereby facilitating more significant sinkage under applied loads. Such behavior can have important implications, especially in construction or agricultural settings where precise knowledge of soil’s response to moisture is paramount [

28]. Contrarily, the cohesive modulus for bentonite depicts an inverse relationship with moisture. Commencing at a robust 150 kPa at 5% moisture, this value dwindles consistently to 12.5 kPa at 30% moisture. This sharp decline underscores that as bentonite becomes more saturated, its cohesive strength—or its ability to stick together—diminishes considerably. This weakening of cohesion with increased moisture content aligns with prior observations made in the field, emphasizing water’s critical role in altering soil’s mechanical properties. It’s interesting to note that even a slight increase in moisture can lead to significant changes in the cohesive modulus, potentially highlighting the sensitivity of bentonite to water content.

On the other hand, Diatom soil demonstrates a pattern somewhat parallel to bentonite but with certain distinct variations. The sinkage exponent for Diatom begins at a lower value of 0.1 for 5% moisture but experiences a consistent surge, reaching 1.1 at 30% moisture. This mirrors the trend observed in bentonite, pointing to an increased sinkage susceptibility with moisture saturation. The cohesive modulus of diatom, starting from 75 kPa at 5% moisture, follows a decreasing trajectory similar to that of bentonite. However, by the time we reach a moisture content of 30%, the cohesive modulus descends to a mere 6.25 kPa, suggesting that Diatom, at higher moisture levels, may possess even lesser cohesive strength compared to bentonite. The observed behavior in Diatom soil further establishes the pivotal role of moisture in dictating the structural characteristics of different soil types. Compared to bentonite, the steeper decline in the cohesive modulus of Diatom might indicate the inherent differences in their compositions and how they interact with water.

The vehicle is equipped with high-precision pressure sensors strategically placed at contact points between the tracks and soil. A 6-channel FD0843 data acquisition system (demonstrated in

Supplementary Figure S7.), along with Computer-Enabled Ground Pressure Measurement Software (elucidated in

Supplementary Figure S8.), records real-time pressure sinkage data at different moisture levels and different sinkage in cm elucidated in

Table 3 for detailed analysis and interpretation. The results of the rubber-tracked vehicle testing revealed that the pressure sensor readings increased as soil moisture content and vehicle speed increased, as illustrated in

Table 4. When compared to diatom soil, the results from the pressure sensor demonstrated that bentonite soil had consistently higher values. This is the explanation for the fact that bentonite soil contains a greater quantity of clay in comparison to diatom soil. When compared to sand particles, clay particles have a higher porosity and smaller diameters than sand particles. This would imply that they can retain a greater quantity of water and produce a more closely linked soil than other soils. Because of the higher clay concentration in bentonite soil, vehicles have a bigger hurdle to penetrate, resulting in increased pressure sensor readings.

Table 5 displays the recorded pressure sensor readings from the data logger during vehicle track testing. The testing was conducted on a soil bin consisting of bentonite and diatom soil mixed with sand and gravel particles ranging in size from 2-5 mm. The moisture levels of the soil bed were set at 10%, 20%, and 30%, while the speed of the vehicle was set at 0.1, 0.2, and 0.3 m/sec.

The vehicle’s pace also substantially impacted the pressure sensor readings. The pressure sensor readings increased as the vehicle’s speed increased. The vehicle imparts more force to the soil at higher velocities. The greater force compacts the soil more, resulting in higher pressure sensor readings.

This study has implications for the development of off-road vehicles. The results indicate that the soil type and moisture content can significantly impact the readings from the pressure sensor. This data can be used to design vehicles better adapted for various terrain types. The results also indicate that the vehicle’s speed can substantially influence the pressure sensor readings. This data can be used to design vehicles that are optimally adapted for various operating velocities. Overall, the study encompassing track vehicle analysis, sinkage observations, soil behavior, ground pressure, and sinkage tests, enhanced our understanding of track vehicles’ interaction with soil. These insights have practical applications in off-road vehicle design, soil compaction assessment, and predicting soil behavior under varying loads.

4. Conclusions

In conclusion, this study provides valuable insights into the intricate interaction between tracked vehicles and diverse terrains, with a particular focus on the significant influence of soil moisture levels on vehicle sinkage. While traditional terramechanical models, exemplified by Bekker and Reece, have laid essential groundwork, our research highlights the pressing need for advanced models that can better capture the nuanced dynamics of real-world soil-vehicle interactions. The significant variations in sinkage behavior observed between Bentonite and Diatom soils, especially when subjected to varying moisture conditions, highlight the multifaceted nature of this phenomenon. These findings emphasize the importance of considering soil type, moisture content, and their inherent physical properties in the development of more accurate terramechanical models. By incorporating these understandings, future research can advance the design of off-road vehicles and deepen our understanding of terrain mechanics. This knowledge is crucial for optimizing vehicle performance and ensuring safe and efficient operation across diverse and challenging terrains. Ultimately, our study underlines the significance of a scientific approach in advancing our comprehension of rubber-tracked vehicle behavior in specific terrains, ultimately contributing to advancements in soil mechanics and off-road vehicle engineering.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on Preprints.org. Attached is all the technical information about the sensor, detailed experimental setup, and data acquisition.

Author Contributions

Conceptualization, OR and YN; methodology, OR and YN; software, OR; validation, OR and MHX; formal analysis, OR and YN; investigation, OR and YN; resources, OR; data curation, OR; writing—original draft preparation, OR; writing—review and editing, OR and YN; visualization, YN; supervision, YN; project administration, YN, MHX; funding acquisition, YN. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Special Fund from China Merchant Industry (CMI) and the Institute of Deep-sea Science and Engineering (IDSSE), Chinese Academy of Sciences (Grant no. 2019000075).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

New data was investigated in this study. Data sharing does not apply to this article.

Acknowledgments

I want to thank Dr. Ma Haoxiang and Dr. Ramganesh Selvarajan for supporting me during the experimentation and draft writing. I want to thank my spouse and kids for their consideration and encouragement throughout my research journey.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wong, J.Y. Terramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, off-road vehicle performance and design; 2010; pp. 129–149. [Google Scholar]

- Wong, J.-Y.; Reece, A.R. Prediction of Rigid Wheel Performance Based on the Analysis of Soil-Wheel Stresses: Part II. Performance of Towed Rigid Wheels. J Terramech 1967, 4, 7–25. [Google Scholar] [CrossRef]

- Beketov, S.A. The Concept of the Controlled Movement of the Tracked Vehicle. Izvestiya MGTU MAMI 2018, 12, 16–20. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiu, M.; Liu, X.; Li, J.; Song, H.; Zhai, Y.; Hu, H. Research on Characteristics of Tracked Vehicle Steering on Slope. Math Probl Eng 2021, 2021, 1–18. [Google Scholar] [CrossRef]

- Li, J.; Khajepour, A.; Huang, Y.; Wang, H.; Tang, C.; Qin, Y. A New Coordinated Control Strategy for Tracked Vehicle Ride Comfort. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-body Dynamics 2018, 232, 330–341. [Google Scholar] [CrossRef]

- Wong, J.Y. Optimization of the Tractive Performance of Articulated Tracked Vehicles Using an Advanced Computer Simulation Model. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering 1992, 206, 29–45. [Google Scholar] [CrossRef]

- Shibly, H.; Iagnemma, K.; Dubowsky, S. An Equivalent Soil Mechanics Formulation for Rigid Wheels in Deformable Terrain, with Application to Planetary Exploration Rovers. J Terramech 2005, 42, 1–13. [Google Scholar] [CrossRef]

- Bekker, M.G. Introduction to Terrain-Vehicle Systems. Part i: The Terrain. Part Ii: The Vehicle; University of Michigan Press, 1969. [Google Scholar]

- Dallas, J.; Jain, K.; Dong, Z.; Sapronov, L.; Cole, M.P.; Jayakumar, P.; Ersal, T. Online Terrain Estimation for Autonomous Vehicles on Deformable Terrains. J Terramech 2020, 91, 11–22. [Google Scholar] [CrossRef]

- Nampoothiri, M.G.H.; Vinayakumar, B.; Sunny, Y.; Antony, R. Recent Developments in Terrain Identification, Classification, Parameter Estimation for the Navigation of Autonomous Robots. SN Appl Sci 2021, 3, 1–14. [Google Scholar] [CrossRef]

- Vantsevich, V. V; Gorsich, D.J.; Paldan, J.R.; Ghasemi, M.; Moradi, L. Terrain Mobility Performance Optimization: Fundamentals for Autonomous Vehicle Applications. Part I. New Mobility Indices: Optimization and Analysis. J Terramech 2022, 104, 31–47. [Google Scholar] [CrossRef]

- Tsitouridis, G. Terramechanics and Soil-Wheel Interactions for Road Vehicle Applications, 2019.

- Thoesen, A.; Marvi, H. Planetary Surface Mobility and Exploration: A Review. Current Robotics Reports 2021, 2, 239–249. [Google Scholar] [CrossRef]

- Mohieddinne, H.; Brasseur, B.; Spicher, F.; Gallet-Moron, E.; Buridant, J.; Kobaissi, A.; Horen, H. Physical Recovery of Forest Soil after Compaction by Heavy Machines, Revealed by Penetration Resistance over Multiple Decades. For Ecol Manage 2019, 449. [Google Scholar] [CrossRef]

- Ani, O.A.; Uzoejinwa, B.B.; Ezeama, A.O.; Onwualu, A.P.; Ugwu, S.N.; Ohagwu, C.J. Overview of Soil-Machine Interaction Studies in Soil Bins. Soil Tillage Res 2018, 175, 13–27. [Google Scholar] [CrossRef]

- Badgujar, C.; Flippo, D.; Welch, S. Artificial Neural Network to Predict Traction Performance of Autonomous Ground Vehicle on a Sloped Soil Bin and Uncertainty Analysis. Comput Electron Agric 2022, 196, 106867. [Google Scholar] [CrossRef]

- Badgujar, C.M.; Flippo, D.; Brokesh, E.; Welch, S. Experimental Investigation on Traction, Mobility, and Energy Usage of a Tracked Autonomous Ground Vehicle on a Sloped Soil Bin. Journal of the ASABE 2022, 65, 835–847. [Google Scholar] [CrossRef]

- Tang, A.-M.; Cui, Y.-J.; Eslami, J.; Défossez, P. Analysing the Form of the Confined Uniaxial Compression Curve of Various Soils. Geoderma 2009, 148, 282–290. [Google Scholar] [CrossRef]

- Kochmanov, N.; Tanakai, H. Influence of the Soil Fabric on the Mechanical Properties of Unsaturated Clays. Soils and Foundations 2011, 51, 275–286. [Google Scholar] [CrossRef]

- Cuisinier, O.; Auriol, J.-C.; Le Borgne, T.; Deneele, D. Microstructure and Hydraulic Conductivity of a Compacted Lime-Treated Soil. Eng Geol 2011, 123, 187–193. [Google Scholar] [CrossRef]

- Wang, Q.; Cui, Y.-J.; Tang, A.M.; Barnichon, J.-D.; Saba, S.; Ye, W.-M. Hydraulic Conductivity and Microstructure Changes of Compacted Bentonite/Sand Mixture during Hydration. Eng Geol 2013, 164, 67–76. [Google Scholar] [CrossRef]

- Zhang, S.; Grip, H.; Lövdahl, L. Effect of Soil Compaction on Hydraulic Properties of Two Loess Soils in China. Soil Tillage Res 2006, 90, 117–125. [Google Scholar] [CrossRef]

- Alaoui, A.; Helbling, A. Evaluation of Soil Compaction Using Hydrodynamic Water Content Variation: Comparison between Compacted and Non-Compacted Soil. Geoderma 2006, 134, 97–108. [Google Scholar] [CrossRef]

- Samuel, T.M.; Ajav, E.A. Optimum Tillage System for Pepper Production in an Alfisol of South-Western Nigeria. Afr J Agric Res 2010, 5, 2647–2652. [Google Scholar]

- Botta, G.F.; Becerra, A.T.; Tourn, F.B. Effect of the Number of Tractor Passes on Soil Rut Depth and Compaction in Two Tillage Regimes. Soil Tillage Res 2009, 103, 381–386. [Google Scholar] [CrossRef]

- Mishra, A.K.; Ohtsubo, M.; Li, L.Y.; Higashi, T. Influence of the Bentonite on the Consolidation Behaviour of Soil–Bentonite Mixtures. Carbonates Evaporites 2010, 25, 43–49. [Google Scholar] [CrossRef]

- Sha, F.; Xi, M.; Chen, X.; Liu, X.; Niu, H.; Zuo, Y. A Recent Review on Multi-Physics Coupling between Deep-Sea Mining Equipment and Marine Sediment. Ocean Engineering 2023, 276, 114229. [Google Scholar] [CrossRef]

- Yang, C.; Yang, G.; Liu, Z.; Chen, H.; Zhao, Y. A Method for Deducing Pressure–Sinkage of Tracked Vehicle in Rough Terrain Considering Moisture and Sinkage Speed. J Terramech 2018, 79, 99–113. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).