1. Introduction

Post-harvest handling and ripening techniques have a considerable impact on the quality and shelf life of peaches, as well as consumer satisfaction and market competitiveness. This review study focuses on the most current advancements in ripening techniques and post-harvest technologies with the goal of enhancing peach fruit quality and sustainability. The paper begins out by thoroughly describing the physiological changes that take place during peach ripening as well as the components that influence fruit quality after harvest. We look into new handling techniques including controlled atmosphere storage (CAS) and modified atmosphere packaging (MAP) that preserve peach freshness while minimizing losses.

Ethylene is produced and accumulated up during fruit ripening, which can affect fruit quality and hasten fruit senescence. Post-harvest peaches are at considerable danger from diseases and infections, which can lead to losses during shipping and storage. These issues need to be addressed with the use of innovative post-harvest technologies and ripening processes. Even though handling and ripening after harvest are essential maintaining fruit quality and extending its shelf life are challenging problems for the peach sector [

1,

2]. [

3] Stated one of the primary issues is that peaches are susceptible to damage during handling, which can lead to bruising and decay. Peaches should be stored in the proper circumstances to prevent rapid ripening and softening [

4,

5]. Post-harvest handling and ripening are key stages in the peach industry because they have a direct impact on the quality, shelf life, and market value of the fruit [

6]. Peaches are perishable fruits, and their quality degrades quickly after harvesting. Proper post-harvest handling techniques are critical for minimizing losses, maintaining fruit quality, and ensuring that peaches reach consumers in optimum shape [

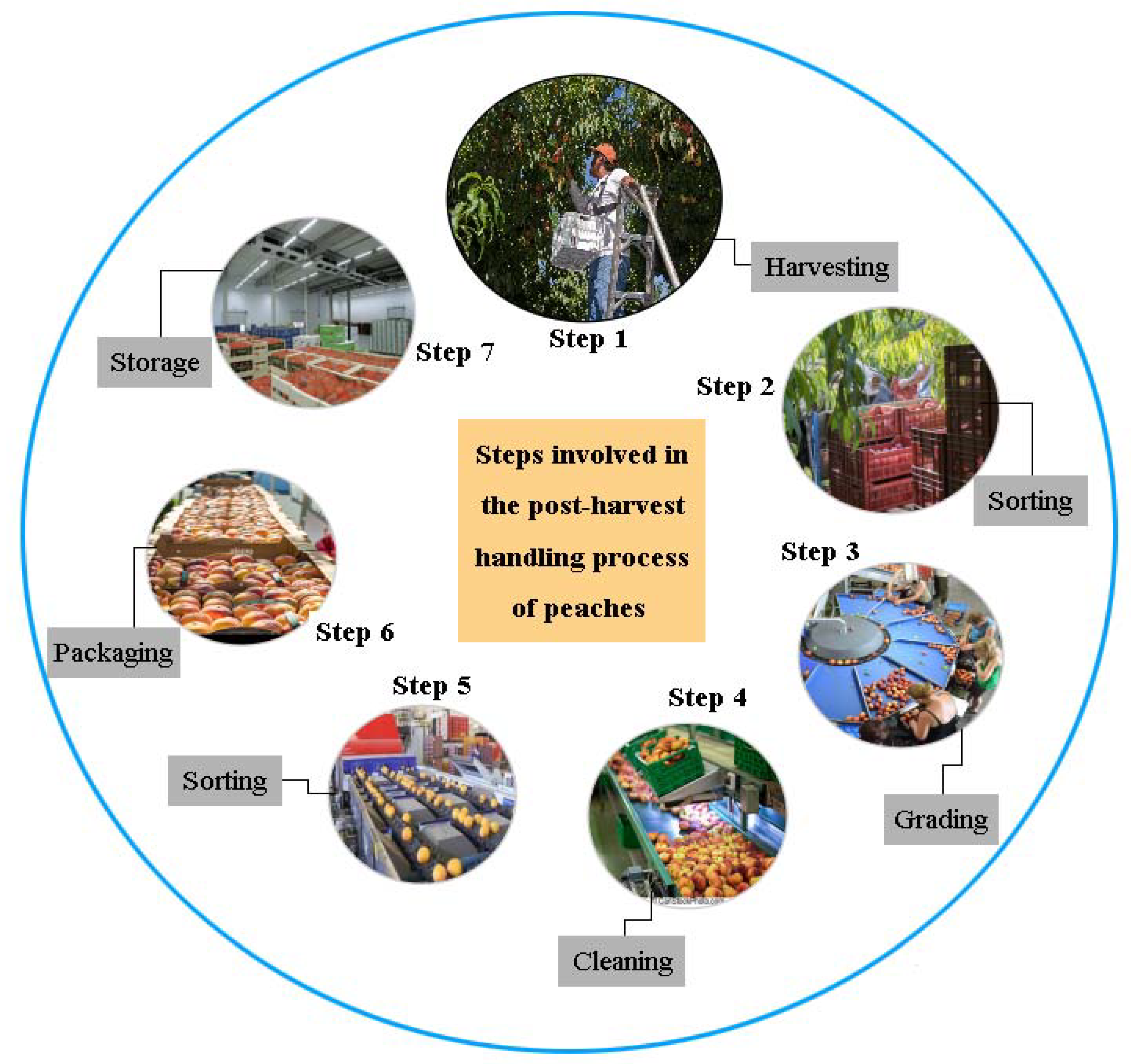

7]. Harvesting, sorting, grading, cleaning, and packaging are merely some of the procedures that make up post-harvest handling [

8], multiple factors including temperature, humidity, ethylene exposure, and mechanical damage, have an impact on the quality of peaches during this stage. To develop efficient handling and ripening processes for peaches, it is essential to comprehend their post-harvest physiology [

9].

Figure 1.

Processing of peaches after harvest This diagram represents the several sequential steps that go into handling peaches once they are harvested, such as harvesting, sorting, grading, cleaning, packaging, and storage.

Figure 1.

Processing of peaches after harvest This diagram represents the several sequential steps that go into handling peaches once they are harvested, such as harvesting, sorting, grading, cleaning, packaging, and storage.

Despite the significance of handling and ripening after harvest, maintaining fruit quality and extending shelf life are difficult tasks for the peach industry. Peaches are also quite sensitive to variations in temperature and humidity, so it's important to store them in the right conditions to avoid quick ripening and softening. During fruit ripening, ethylene is produced and accumulates up, which can has an impact on fruit quality and speed up fruit senescence [

10]. Diseases and pathogens also serious risk to post-harvest peaches, resulting in losses during transportation and storage. Innovative post-harvest technologies and ripening techniques that can successfully improve peach fruit quality and extend shelf life are required to solve these difficulties [

11,

12].

The goal of this review is to thoroughly examine recent developments in ripening and post-harvest technology in order to address issues facing the peach industry. Improving peach fruit quality, decreasing losses, and extending shelf life are all objectives of our research. We explore new post-harvest handling strategies such as modified atmosphere packing (MAP), controlled atmosphere storage (CAS), smart sensors, and cold chain management through a detailed analysis of the body of existing research. Additionally, we investigate promising techniques for preserving peaches that keep both freshness and nutritional value, including bioactive coatings and nanotechnology [

13]. Additionally, we are looking into innovative ripening strategies, including ethylene-based and non-ethylene-based ones, as well as new techniques like gene editing and genetic modification. These methods could improve peach taste and texture, synchronise ripening, lessen the adverse impacts of ethylene, and improve the quality of the fruit [

14]. By shedding light on the most recent research and advancements, we aim to contribute to the body of knowledge aimed at enhancing peach fruit quality, post-harvest efficiency, and sustainability in the peach industry.

2. Peach Post-Harvest Physiology

2.1. Recognizing the Physiological Changes that Occur during Peach Ripening

The process of ripening peach is intricate and dynamic, involving a number of physiological changes such as softening, color development, and flavor accumulation. Numerous endogenous and external factors control the ripening process, which is accompanied by inner metabolic and enzymatic activity in the fruit.

Peach cell walls disintegrate when the fruit ripens, softening the fruit. Cell wall-modifying enzymes like polygalacturonase and cellulase are mostly responsible for this stage [

15]. The fruit becomes sweeter through the conversion of starch into sugars like sucrose and fructose. In addition, fruit acidity decreases due to the breakdown of organic acids like malic acid, which results in a less tart flavor character. Peaches undergo significant changes in colour as they ripen. As the chlorophyll pigments in green degrade, other pigments like carotenoids and anthocyanins can be seen more clearly. Ripe peaches have yellow, orange, and red coloring from carotenoids, while other peach cultivars have red or purple coloring from anthocyanins [

16,

17].

Figure 2.

Physiological changes that occur during peach ripening This diagram demonstrates the numerous physiological changes that take place during peach ripening, including softening, colour development, flavour accumulation, starch breakdown, and a decrease in fruit acidity.

Figure 2.

Physiological changes that occur during peach ripening This diagram demonstrates the numerous physiological changes that take place during peach ripening, including softening, colour development, flavour accumulation, starch breakdown, and a decrease in fruit acidity.

2.2. Factors Affecting the Post-Harvest Quality and Shelf Life of Peach Fruit

2.2.1. Humidity and Temperature

The handling and storage of peaches after harvest depends largely on temperature and humidity [

18]. Low temperatures have the ability to delay ripening and lessen microbial activity, extending shelf life. Extremely low temperatures, on the other hand, can result in chilling injury, which can damage tissue and produce off flavors. Maintaining peach quality and preventing excessive softening during transportation and storage requires proper temperature and humidity control [

19].

2.2.2. Ethylene, Along with Other Ripening Regulators:

Natural plant hormone ethylene is essential for the maturation of climacteric fruits like peaches. It causes a number of changes in metabolism and accelerates the ripening process [

20]. To prevent premature ripening and maintain fruit quality, post-harvest handling must be tightly controlled to reduce ethylene exposure. Auxins and gibberellins are additional ripening regulators that might affect peach ripening and should be taken into consideration during storage [

21].

2.2.3. Susceptibility to Disease and Mechanical Injury

When peaches are harvested, handled, and transported, they are susceptible to mechanical damage that can cause bruising and decay. To reduce mechanical damage, proper handling techniques are essential, such as gentle harvesting and careful packing. The shelf life of peaches can also be considerably affected by post-harvest diseases caused by pathogens like fungi and bacteria. Post-harvest diseases must be managed with the use of fungicides, temperature control, and proper sanitation [

22].

Table 1.

The effect of many conditions on the quality and shelf life of peaches fruit.

Table 1.

The effect of many conditions on the quality and shelf life of peaches fruit.

| Factor |

Effects on the quality and shelf life of peach fruit |

| Temperature |

(1) Accelerated ripening and softening may result from high temperatures.

(2) Chilling damage from low temperatures can have an impact on the texture and flavor of food.

(3) By slowing ripening processes, controlled temperatures can extend shelf life. |

| Humidity |

(1) High humidity can keep fruit from losing moisture and keep it turgid.

(2) High humidity can encourage the growth of mold and decay. |

| Exposure to Ethylene |

(1) Exposure to ethylene can cause ripening, which affects the development of firmness and flavor.

(2) Scavengers for ethylene or storage in a controlled environment can lessen these effects. |

| Mechanical Damage |

(1) Physical damage and bruises can hasten deterioration and quality loss.

(2) Mechanical damage can be reduced by careful handling and packaging. |

| Pathogens |

(1) Pathogens such as fungi and bacteria can cause decay, reducing shelf life.

(2) Post-harvest treatments and sanitary practices may minimize pathogen growth. |

2.3. Important Biochemical Procedures in Peach Ripening

The biochemical process of peach ripening is intricate and regulated by several enzymes and metabolic pathways. According to [

23], the fruit is made softer by cell wall-degrading enzymes such polygalacturonase and cellulase breaking down pectin and cellulose. These enzymes' activity is regulated by other chemicals, like ethylene, which encourages the production of them during fruit ripening. In terms of sugar metabolism, starch is converted into sugars such as sucrose and fructose through the action of amylase enzymes. The decrease in fruit acidity during ripening is assumed to be caused by the enzymatic degradation of malic acid into simpler molecules. The reduction in acidity leads to the sweet flavour associated with ripe peaches [

24].

3. Developments in Post-Harvest Technologies

3.1. Novel Approaches to Manage Peaches after Harvest

Controlled Atmosphere Storage (CAS) and Modified Atmosphere Packaging (MAP)

Advanced procedures like Modified Atmosphere Packaging (MAP) and Controlled Atmosphere Storage (CAS) modify the atmospheric composition around the peaches to increase their shelf life. In order to inhibit respiration and minimize spoilage, MAP involves placing peaches in packaging with changed gas compositions, often low oxygen and elevated carbon dioxide levels. This idea is refined further by CAS, which maintains ideal conditions for fruit preservation by carefully regulating the gas composition within storage facilities. According to studies [

25], these strategies have been demonstrated to considerably lower respiration rates and microbiological activity, maintaining peach quality and extending shelf life.

Post-harvest management has been transformed by the Internet of Things (IoT) and the incorporation of smart sensors. Real-time data on important factors including temperature, humidity, ethylene levels, and fruit quality can be provided via smart sensors. Remote access and control of storage facilities are made possible by IoT applications, allowing for fast corrections and interventions based on sensor data. The efficiency of post-harvest handling improves, losses are reduced, and peaches are stored in the best possible circumstances thanks to this real-time monitoring [

26].

3.1.1. Innovative Storage Methods to Increase Shelf Life

A common method to slow down fruit ripening and increase peach shelf life is low-temperature storage. However, extended exposure to cold temperatures can cause chilling injury, which can cause interior collapse, surface pitting, and off flavors. Researchers have investigated a number of techniques to reduce chilling damage, such as intermittent warming, the use of plant growth regulators, and the use of fruit covers or edible films [

27].

3.2. Utilizing Nanotechnology in Food Preservation

A possible strategy for enhancing post-harvest storage and prolonging the shelf life of fruits, especially peaches, is nanotechnology. Advanced coatings with antibacterial and gas-barrier characteristics can be developed via nanostructures like nanoparticles and nanocomposites. These coatings protect peaches against microbial deterioration and delay the beginning of ripening, maintaining fruit quality [

28].

Natural substances with antibacterial and antioxidant capabilities, such as plant extracts, essential oils, and bioactive compounds, have the potential to increase the shelf life of peaches. These compounds can be included in bioactive coatings, offering a natural and sustainable approach to fruit quality maintenance [

26,

29]. In accordance with , bioactive coatings reduce deterioration and retain peach freshness by forming a barrier of defense against outside influences.

3.3. Post-Harvest Processes Mechanization and Automation

Post-harvest procedures have seen a substantial transformation due to mechanization and automation, which has improved productivity and reduced labor costs. Modern innovations in peach handling include robotic harvesting, industrial packing, and automated sorting and grading systems. These developments reduce damage to the skin while also increasing productivity.

4. Peach Ripening Techniques to Improve Quality

4.1. Ripening Techniques Based on Ethylene

4.1.1. Application Techniques and Dosages of Ethylene

Natural plant hormone ethylene is essential for the ripening of climacteric fruits like peaches. Application of ethylene can be used to accelerate and coordinate the ripening of peaches, resulting in a consistent and predictable ripening process. Commercial operations have used a variety of ethylene application techniques, including gaseous ethylene exposure and ethylene-releasing sachets. In order to achieve optimal fruit ripening and maintain fruit quality, the dosage and timing of ethylene treatment must be key considerations [

30].

4.1.2. Controlled Ripening with Ethylene Inhibitors

Ethylene inhibitors are used to prevent ethylene action or production in order to control and slow down the ripening process. Ethylene receptors are bound by ethylene inhibitors like 1-MCP (1-methylcyclopropene), which prevent ethylene signaling and delay fruit ripening. Post-harvest managers may prolong the shelf life of peaches, minimize softening, and retain firmer fruit texture for an extended period of time through the use of ethylene inhibitors [

28,

31].

4.2. Ripening Agents that are not Ethylene-based

4.2.1. Acetylene- and Calcium-Carbide-based Ripening

In the past, calcium carbide was used to initiate the process of ripening in some fruits, like peaches. Calcium carbide generates acetylene when it comes into contact with moisture, which has comparable effects to ethylene in promoting fruit ripening. However, since calcium carbide may leave behind toxic residues, there are now safety and health concerns about its use. As a result, safer substitutes are being used in place of it [

32].

4.2.2. Ethephon and Other Compounds that Release Ethylene

Ethephon is a compound that releases ethylene and has been used to enhance fruit ripening in a variety of fruits, including peaches. Ethephon is transformed into ethylene upon application, beginning the ripening process.Prior to marketing, ethephon treatment can be used to promote even ripening; meanwhile, during storage, it can improve colour development and soften peaches. Its use must be handled cautiously, exactly like with calcium carbide, to prevent excessive softening and decay [

33,

34].

4.3. New Methods for Coordinating and Managing Ripening

4.3.1. Genetic Modification and Gene Editing for Delayed Ripening

Improvements in genome editing techniques such as CRISPR-Cas9 can be used to modify genes involved in the ripening process. By focusing on the genes involved in ripening, researchers may be able to generate peach cultivars with delayed ripening traits. Consider a genetic performance in which researchers meticulously compose a symphony of ripening-related genes. This entails working in harmony with nature rather than simply manipulating it. By focusing on these genetic subtleties, scientists look for to create peach cultivars with a distinct trademark delayed ripening, an arrangement that reverberates across time. Let us now turn our attention to gene editing, the story's unsung hero. Each change to the genetic code is a stroke that influences how a peach ripens. It is an art form that ensures each peach is at its peak of freshness; it is more than just modifying the DNA[

35]. The story, however, does not end there; it continues through markets and orchards. Consider a world in which delayed ripening is not merely a scientific advance but also a useful invention. Consumers may enjoy peaches at their peak thanks to improved transportation decisions and a longer shelf life. Farmers observe a paradigm shift that improves the economic viability of their harvests by reducing post-harvest losses [

36].

The focus of this genetic saga is on gene editing, which is what makes peaches stay fresher. Let us be amazed not only by the fruit, but also by the intricate gene dance that creates a symphony of flavours, which is elegantly enhanced by the talent of CRISPR-Cas9.

5. Effect on Peach Fruit Quality and Shelf Life

5.1. Nutritional Composition Changes during Post-Harvest Handling and Ripening

The nutritional composition of peaches can be greatly influenced by post-harvest management and ripening. Peaches' carbohydrate, organic acid, and levels of antioxidants all change when they ripen. The conversion of starch into sugars like sucrose and fructose increases total soluble sugars, which contributes to the sweetness of ripe peaches. At the same time, fruit acidity decreases due to the degradation of organic acids such as malic acid. These variations in sugar and acid content change the fruit's flavor profile, making it more pleasant.

Besides, the ripening process affects the quantities of bioactive compounds like carotenoids, phenolics, and flavonoids, all of which are essential antioxidants. These compounds serve a crucial purpose in reducing oxidative damage to peaches and improving human health. Certain post-harvest actions, such as as controlled environment storage and cold chain management, have been proven in studies to help retain the nutritional content of peaches by limiting important nutrient losses during storage and transit [

37].

Figure 3.

Levels of Nutrients at Various Peach Ripening Stages The line graph shows how the nutritional components dynamically fluctuate throughout the different stages of peach ripening. Each stage of ripening is represented by the x-axis, and the height of the bars shows how much of the essential nutrients (sugars, organic acids, antioxidants, and bioactive compounds) are present at each step. The (blue line) represents sugars, the (silver line) antioxidants, the (orange line) organic acid, and the (yellow line) bioactive compounds. A considerable increase in sugars, such as sucrose and fructose, which contribute to increased taste, can be seen as peaches grow from Stage 1 to Stage 4. Malic acid, the main organic acid that decreases concurrently, lowers the acidity of fruit and gives it a more pleasing taste character. The figure additionally demonstrates the changes in essential antioxidants and bioactive substances over the course of ripening. A comprehensive understand of the changing nutritional composition of peaches is made possible by this visual representation, which also makes it easier to understand how handling and ripening during the post-harvest process affect fruit quality.

Figure 3.

Levels of Nutrients at Various Peach Ripening Stages The line graph shows how the nutritional components dynamically fluctuate throughout the different stages of peach ripening. Each stage of ripening is represented by the x-axis, and the height of the bars shows how much of the essential nutrients (sugars, organic acids, antioxidants, and bioactive compounds) are present at each step. The (blue line) represents sugars, the (silver line) antioxidants, the (orange line) organic acid, and the (yellow line) bioactive compounds. A considerable increase in sugars, such as sucrose and fructose, which contribute to increased taste, can be seen as peaches grow from Stage 1 to Stage 4. Malic acid, the main organic acid that decreases concurrently, lowers the acidity of fruit and gives it a more pleasing taste character. The figure additionally demonstrates the changes in essential antioxidants and bioactive substances over the course of ripening. A comprehensive understand of the changing nutritional composition of peaches is made possible by this visual representation, which also makes it easier to understand how handling and ripening during the post-harvest process affect fruit quality.

5.2. The Impact of Advanced Technologies on the Texture, Flavor, and Aroma of Peaches

Advanced post-harvest technology can have a significant impact on peach texture, flavor, and aroma. Modified atmosphere packing (MAP) and controlled atmosphere storage (CAS) assist in maintaining of peach firmness and texture, minimizing the incidence of fruit softening and preserving an excellent mouthfeel. These procedures also help to reduce the deterioration of flavor components, which enhances the overall taste quality of the fruit.

Also, controlled ethylene release or the use of ethylene inhibitors can modulate the rate of ripening, allowing for better flavor development control [

38]. Ripening methods based on ethylene can increase the production of volatile chemicals responsible for peach aroma, resulting in a more powerful and pleasant aroma [

39]. The use of nanotechnology for food preservation and bioactive coatings can protect peaches from microbial decomposition while retaining their natural flavor and aroma throughout storage [

40]. These technologies reduce the loss of volatile molecules responsible for peach scent.

5.3. Post-Harvest Treatment Microbiological and Sensory Aspects

Post-harvest treatments may have significant effects on the microbiological and sensory aspects of peaches. Microbial development must be controlled during post-harvest handling and storage to prevent rot and ensure fruit safety [

14]. Advanced post-harvest technologies such as MAP and CAS can provide an environment that restricts the growth of spoiling bacteria, hence improving peach shelf life [

41]. Furthermore, peach sensory qualities such as color, scent, and taste are highly related to their quality and consumer approval. Post-harvest procedures that assist peaches retain their original color and flavor and taste contribute to a favorable sensory experience. Sensory evaluation by trained panels and consumer surveys are critical for assessing the impact of post-harvest interventions on peach quality and sensory attributes [

42].

5.4. Consumer Preferences and Market Response to Improved Peach Quality

Consumer preferences and market demand for high-quality fruit often drive the introduction of innovative post-harvest technologies and ripening processes in the peach industry. Aspects such as appearance, flavor, aroma, and shelf life influence consumer opinion of peach quality. Consumers are expected to respond positively to technologies that maintain fruit appearance and flavor while prolonging shelf life.

More importantly, factors like as pricing, availability, and customer knowledge influence market response to enhanced peach quality. Consumers are willing to pay a premium for peaches with a longer shelf life, improved flavor, and lower post-harvest losses. As a result, producers and retailers who implement innovative post-harvest technology and ripening procedures may enjoy a competitive advantage[

43,

44].

6. Future Prospects and Sustainability

6.1. Advanced Post-Harvest Technologies' Effects on the Environment

The peach industry's embrace of innovative post-harvest technologies may have both beneficial and detrimental effects on the environment. On the other hand, innovations like controlled atmosphere storage (CAS) and modified atmosphere packing (MAP) can lessen food waste, minimize post-harvest losses, and increase the shelf life of peaches. As a result, fresh produce production and transportation use resources more effectively and emit fewer greenhouse gases [

41,

45]. However, some post-harvest technologies could need energy-consuming procedures, including refrigeration for cold storage. If not handled properly, the increased energy usage could result in bigger carbon footprints. Concerns regarding chemical residues and potential environmental effects may also arise from the use of specific synthetic substances for fruit ripening, such as ethylene inhibitors. To ensure their sustainability and reduce their environmental impact, post-harvest technologies must take into account the full life cycle evaluation [

46].

6.2. Optimizing Resources and Reducing Waste

Modern post-harvest technologies can help the peach sector reduce waste and maximize resources [

47]. To reduce fruit losses from mechanical damage, decay, or overripens, implement precision handling and storage procedures such rigorous sorting, grading, and controlled environment storage. As a result, there are more peaches that are marketable and less waste is produced across the supply chain [

48] . Additionally, resource optimization as a whole is aided by sustainable post-harvest methods that put an emphasis on resource efficiency, such as water recycling in processing facilities and energy-efficient cooling systems. The peach industry could decrease costs, increase competitiveness, and reduce its environmental effect by optimizing resource utilization [

49].

6.3. Possibilities for Including Sustainable Practices in the Peach Sector

In order to improve environmental and social responsibility, the peach the industry has the ability to include sustainable practices throughout the supply chain. Promising approaches include:

6.3.1. Packaging:

Packaging that is environmentally friendly, biodegradable, or compostable can lessen plastic waste production and its negative effects on the environment [

50]. Utilizing the concepts of the circular economy, post-harvest trash and byproducts can be reused, recycled, and put to new uses to maximize resource usage [

51].

6.3.2. Energy-Efficient Technologies:

By using energy-efficient cooling and storage systems, post-harvest operations can leave a less carbon footprint [

51].

6.3.3. Social Accountability:

Fair labor practices and community support can help the peach sector achieve social sustainability [

52].

6.4. Recent Developments and Future Directions of Peach Post-Harvest Research

Peach post-harvest research is projected to concentrate on numerous new trends and future directions as demand for sustainable and high-quality produce increases:

6.4.1. Applications of Nanotechnology:

includes the use of bioactive coatings and the controlled release of ripening chemicals as viable post-harvest treatments.

6.4.2. Gene Editing and Biotechnology:

Improved peach varieties with longer shelf lives may result from further study of gene editing and biotechnological methods to control ripening-related genes.

6.4.3. IoT and Smart Sensors:

New developments in Internet of Things (IoT) and smart sensor technologies may make it possible to monitor and improve post-harvest procedures in real time for resource efficiency.

6.4.4. Waste Optimization:

Research into the possible use of peach byproducts for value-added goods like bioactive substances or nutraceuticals can help reduce waste and make better use of available resources.

Table 2.

Comparing the effects of several post-harvest technologies on peach quality, shelf life extension, and the environment

Table 2.

Comparing the effects of several post-harvest technologies on peach quality, shelf life extension, and the environment

| Post-Harvest Technology |

Peach Quality Effect |

Extension of Shelf Life |

Impact of the environment |

| Packaging for Modified Atmospheres (MAP) |

(1) Reduces decay and preserves firmness.

(2) Maintains flavor and aroma.

(3) Decreases microbial growth. |

(1) Decreases oxygen levels to prolong shelf life.

(2) Inhibits the ripening processes.

(3) Reduces moisture loss. |

(1) When compared to traditional packaging, it reduces packaging waste.

(2) Controlled atmospheric conditions are required. |

| Controlled Atmosphere Storage (CAS ) |

(1) Preserves fruit texture and firmness.

(2) Postpones ripening and senescence.

(3) Maintains nutrient content. |

(1) Significantly increases shelf life by changing the composition of the gas.

(2) Reduces losses after harvest.

(3) Prevents chilling damage. |

(1) Need specific monitoring tools and storage facilities.

(2) Process that uses a lot of energy since the temperature and gas are controlled. |

| Applications of Nanotechnology |

(1) Increases the delivery of bioactive compounds and nutritional absorption.

(2) Maintains the appearance and texture.

(3) Lessens post-harvest damage. |

(1) Slows down enzymatic activity to prolong shelf life.

(2) Decreases microbial growth and decay.

(3) Increases the pathogen resistance of fruit. |

(1) Potential environmental risks associated to nanoparticles release.

(2) To completely comprehend the effects of nanomaterials, research is required. |

| Gene Editing |

(1) Gives fine control over the traits and processes of ripening.

(2) Can improve nutritional value

(3) May lessen vulnerability to diseases and pests. |

(1) Prolongs the shelf life through delaying off ripening.

(2) Keeps fruit quality intact.

(3) Prevents overripening, thus decreasing waste. |

(1) Impact on the environment relies on particular changes and legal procedures.

(2) Social and moral problems concerning genetic modifications.

|

5. Conclusions

The post-harvest and ripening technologies covered in this review have the potential to completely reshape the peach market, improving peach fruit quality, shelf life, and customer satisfaction. Exploring the challenges of maintaining fruit quality and prolonging shelf life necessitated the development of novel methods. Innovations like modified atmosphere packing (MAP) and controlled atmosphere storage (CAS) have the potential to maintain freshness and minimise decay. Post-harvest management has changed as a result of real-time monitoring made possible by smart sensors and IoT apps, which has increased production and reduced losses. With technologies like CAS and MAP potentially requiring energy-intensive procedures, sustainability considerations are important. Through resource optimisation strategies, the peach industry can further minimise its ecological impact. Incorporating modern ripening techniques and post-harvest technologies, then, provides revolutionary advantages to both growers and consumers. Implementation can improve fruit quality, lengthen shelf life, and reduce post-harvest losses, increasing market competitiveness. Collaboration between researchers, business stakeholders, and policymakers is necessary for successful, sustainable adoption. The industry will continue to develop as a result of future advancements in nanotechnology, gene editing, and IoT-based monitoring. The peach sector is well-positioned for ongoing success in a changing world by embracing ecologically responsible practises and satisfying customer expectations.

References

- Ansari, M.; W, N.J.P.č; Tuteja. Post-harvest quality risks by stress/ethylene: management to mitigate. Protoplasma 2015, 252, 21–32. [Google Scholar] [CrossRef] [PubMed]

- Thompson, A.K.; Prange, R.K.; Bancroft, Roger, P.; Tongchai, Controlled atmosphere storage of fruit and vegetables. CABI, 2018: p. 1-48.

- Usall, J.; Casals, C.; Sisquella, M.; Palou, L. ; De Cal, Alternative technologies to control postharvest diseases of stone fruits. Stewart Postharvest Review. 2015, 11, 1–6. [Google Scholar]

- Florkowski, W.J.; Banks, Nigel. H.; Shewfeltet, Robert.L.; Prussia, E.; Stanley, Postharvest handling: a systems approach. 2021: Academic press.

- Salyari, R.; Seifi, E.; Varasteh, F. ; Alizadeh, Mahdi, Effects of pre-harvest salicylic acid treatment on the post-harvest quality of peach cultivar Robin. Journal of Chemical Health Risks 2022, 12, 355–362. [Google Scholar]

- Cao, Z.; Zhou, D.; Ge, X.; Luo, Y. ; Su, Jingyi, The role of essential oils in maintaining the postharvest quality and preservation of peach and other fruits. Journal of Food Biochemistry 2022, 46, e14513. [Google Scholar] [CrossRef] [PubMed]

- Benichou, M.; Ayour, J.; Sagar, M.; Alahyane, A. ; Elateri, I.; Aitoubahou, Ahmed, Postharvest technologies for shelf life enhancement of temperate fruits. Postharvest biology technology of temperate fruits 2018, 77–100. [Google Scholar]

- Pokhrel, H.J.I.J.O. ;Binod, Review on post-harvest handling to reduce loss of fruits and vegetables. International Journal of Horticulture Food Science 2021, 2, 48–52. [Google Scholar] [CrossRef]

- Mahajan, P. V.; Caleb, O. J.; Gil, Maria. I.; Izumi, H.; Colelli, G.; Watkins, C. B.; Zude, Manuela, Quality and safety of fresh horticultural commodities: Recent advances and future perspectives. Food Packaging Shelf Life 2017, 14, 2–11. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, L.; Fan, C.; Wang, P.; Cui, M.; Liu, L.; Yang, H.; W. ; Junjie, Impact of methyl salicylate on storage quality, ethylene action, and protein profiling of ‘Zaosu’pear (Pyrus bretschneideri). Scientia Horticulturae. 2020, 264, 109196. [Google Scholar] [CrossRef]

- Ramaswamy, Hosahalli.; S, Post-harvest technologies of fruits & vegetables. DEStech Publications, Inc. 2014, .

- Alegbeleye, O.; Odeyemi, O.A.; Strateva, M. ; Stratev, Deyan, Microbial spoilage of vegetables, fruits and cereals. Applied Food Research 2022, 2, 100122. [Google Scholar] [CrossRef]

- de Oliveira, K.R.; Fernandes, K.D.d.S.; Guedes, J.P.d.; Souza, E.L.; Magnani, Marciane, Chitosan-based coatings and plant extracts, in Chitosan: Novel Applications in Food Systems. Elsevier. 2023, p. 31-68. 31.

- Sudheer, K.; Indira, V.; Indira, Post harvest technology of horticultural crops. New India Publishing. 2007: Vol. 7.

- Goulao, L.; F, C.M.J.T.i.f.s. ; Oliveira, Cristina, Cell wall modifications during fruit ripening: when a fruit is not the fruit. Trends in food science technology. 2008, 19, 4–25. [Google Scholar] [CrossRef]

- Zhu, N.; Huang, W.; Wu, D.; Chen, K. ; He, Yong, Quantitative visualization of pectin distribution maps of peach fruits. Scientific Reports. 2017, 7, 9275. [Google Scholar] [CrossRef] [PubMed]

- Li, B.J.; Lecourt, G.J.P. ; Bishop, Advances in non-destructive early assessment of fruit ripeness towards defining optimal time of harvest and yield prediction—A review. Plants. 2018, 7, 3. [Google Scholar] [CrossRef] [PubMed]

- Hussein, Z.O.A.; Fawole, U.L.J.H.P.; J. Opara, Harvest and postharvest factors affecting bruise damage of fresh fruits. Horticultural Plant Journal. 2020, 6, 1–13. [Google Scholar] [CrossRef]

- Wang, X.; Matetić, M.; Zhou, H.; Zhang, X. ; Jemrić, Tomislav, Postharvest quality monitoring and variance analysis of peach and nectarine cold chain with multi-sensors technology. Applied Sciences. 2017, 7, 133. [Google Scholar] [CrossRef]

- Kou, X.; Feng, Y.; Yuan, S.; Zhao, X.; Wu, C.; Wang, C. ; Xue, Zhaohui, Different regulatory mechanisms of plant hormones in the ripening of climacteric and non-climacteric fruits: a review. Plant Molecular Biology. 2021, 1–21. [Google Scholar]

- Wang, X.; Pan, L.; Wang, Y.; Meng, J.; Deng, L.; Niu, Liang. ; Liu, H.; Ding, Y.; Yao, J.L.; Nieuwenhuizen, Nicolaas Jacobus, PpIAA1 and PpERF4 form a positive feedback loop to regulate peach fruit ripening by integrating auxin and ethylene signals. Plant Science. 2021, 313, 111084. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.S.; Siddiqui, M.Wasim.; Ahmad, M.S.; Siddiqui, M.; Wasim, Factors affecting postharvest quality of fresh fruits. Postharvest quality assurance of fruits: practical approaches for developing countries. 2015: p. 7-32.

- Chen, H.; Cao, S.; Fang, X.; Mu, H.; Yang, H.; Wang, X.; Xu, Q. ; Gao, Haiyan, Changes in fruit firmness, cell wall composition and cell wall degrading enzymes in postharvest blueberries during storage. Scientia Horticulturae. 2015, 188, 44–48. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, L.; Yu, M.; An, X.; Ma, R. ; Yu, Zhifang, Proteomic analysis of changes in mitochondrial protein expression during peach fruit ripening and senescence. Journal of Proteomics. 2016, 147, 197–211. [Google Scholar] [CrossRef]

- Toivonen, P.; MA, New approaches to production and quality assessment of fruits. XXX International Horticultural Congress IHC2018: International Symposium on Fruit and Vegetables for Processing, International 1292, 2018.

- Lutz, É.; Coradi, P. ; Carteri, Applications of new technologies for monitoring and predicting grains quality stored: Sensors, internet of things, and artificial intelligence. Measurement. 2022, 188, 110609. [Google Scholar] [CrossRef]

- Rodrigues, C.; Gaspar, P.D.; Simões, M.P.; Silva, P.D. ; Andrade, Luís, Review on techniques and treatments toward the mitigation of the chilling injury of peaches. Journal of Food Processing Preservation. 2022, 46, e14358. [Google Scholar] [CrossRef]

- Kondle, R.; Sharma, K.; Singh, G. ; Kotiyal, A Using Nanotechnology for Enhancing the Shelf Life of Fruits. Food Processing and Packaging Technologies. 2022. [CrossRef]

- El Khetabi, A.; Lahlali, R.; Ezrari, S.; Radouane, N.; Lyousfi, N.; Banani, H.; Askarne, L.; Tahiri, A.E.; Ghadraoui, L. ; Belmalha, Saadia, Role of plant extracts and essential oils in fighting against postharvest fruit pathogens and extending fruit shelf life: A review. Trends in Food Science Technology. 2022, 120, 402–417. [Google Scholar] [CrossRef]

- Gong, D.; Cao, S.; Sheng, T.; Shao, J.; Song, C.; Wo, F.; Chen, W. ; Yang, Zhenfeng, Effect of blue light on ethylene biosynthesis, signalling and fruit ripening in postharvest peaches. Scientia Horticulturae. 2015, 197, 657–664. [Google Scholar] [CrossRef]

- Li, L.; Lichter, A.; Chalupowicz, D.; Gamrasni, D.; Goldberg, T.; Nerya, O.; Ben-Arie, R. ; Porat, Ron, Effects of the ethylene-action inhibitor 1-methylcyclopropene on postharvest quality of non-climacteric fruit crops. Postharvest Biology Technology. 2016, 111, 322–329. [Google Scholar] [CrossRef]

- Mahmood, T.; Saeed, I.; Anwer, H.; Mahmood, I. ; Zubair, Arif, Comparative study to evaluate the effect of calcium carbide (cac 2) as an artificial ripening agent on shelf life, physio-chemical properties, iron containment and quality of prunus persica l. Batsch Eur J Res. 2013, 1, 685–700. [Google Scholar]

- Ali,T.J.; A, C.; Subramanian, J.; Peter K, Pauls, Ethephon-induced abscission of “Redhaven” peach. American Journal of Plant Sciences. 2012, 7 pages. [CrossRef]

- Maduwanthi, S.D.T. Maduwanthi, S.D.T.; Marapana, Rauj, Induced ripening agents and their effect on fruit quality of banana. International journal of food science. 2019, 8 pages. [CrossRef]

- Martín-Pizarro, C. ; Posé, David, Genome editing as a tool for fruit ripening manipulation. Frontiers in Plant Science. 2018, 9, 1415. [Google Scholar] [CrossRef] [PubMed]

- García-Gómez, B.E.; Salazar, J.A.; Nicolás-Almansa, M.; Razi, M.; Rubio, M.; Ruiz, D. ; Martínez-Gómez, Pedro, Molecular bases of fruit quality in Prunus species: An integrated genomic, transcriptomic, and metabolic review with a breeding perspective. International journal of molecular sciences. 2020, 22, 333. [Google Scholar] [CrossRef]

- Brandi, F.; Bar, E.; Mourgues, F.; Horváth, G.; Turcsi, E.; Giuliano, G.; Liverani, A.; Tartarini, S.; Lewinsohn, E. ; Rosati, Carlo, Study of'Redhaven'peach and its white-fleshed mutant suggests a key role of CCD4 carotenoid dioxygenase in carotenoid and norisoprenoid volatile metabolism. BMC plant biology. 2011, 11, 1–14. [Google Scholar] [CrossRef]

- Fenn, M.A. ; Giovannoni, James, Phytohormones in fruit development and maturation. The Plant Journal. 2021, 105, 446–458. [Google Scholar] [CrossRef]

- Minas, I.S.; Tanou, G. ; Molassiotis, Athanassios, Environmental and orchard bases of peach fruit quality. Scientia Horticulturae. 2018, 235, 307–322. [Google Scholar] [CrossRef]

- Belisle, C.; Adhikari, K.; Chavez, D.; Phan, U. T. ; Xuan, Development of a lexicon for flavor and texture of fresh peach cultivars. Journal of Sensory Studies. 2017, 32, e12276. [Google Scholar] [CrossRef]

- Shin, J.S.; Park, H.S.; Lee, K.W.; Song, J.S.; Han, H.Y.; Kim, H.W.; Cho, T. ; Jin, Advances in the Strategic Approaches of Pre-and Post-Harvest Treatment Technologies for Peach Fruits (Prunus persica). Horticulturae. 2023, 9, 315. [Google Scholar] [CrossRef]

- Serra, S.; Anthony, B.; Masia, A.; Giovannini, D. Musacchi, Stefano, Determination of biochemical composition in peach (Prunus persica L. Batsch) accessions characterized by different flesh color and textural typologies. Foods. 2020, 9, 1452. [Google Scholar] [CrossRef] [PubMed]

- Taiti, C.; Costa, C.; Petrucci, W.A.; Luzzietti, L.; Giordani, E.; Mancuso, S. ; Nencetti, Valter, Are peach cultivars used in conventional long food supply chains suitable for the high-quality short markets? Foods 2021, 10, 1253. [Google Scholar] [CrossRef] [PubMed]

- Moreno, S.R.; Curtis, S.J.; Sarkhosh, A.; Sarnoski, P.J.; Sims, C.A.; Dreyer, E.; Rudolph, A.B.; Thompson-Witrick, K.A. ; MacIntosh, Andrew, Considerations when brewing with fruit juices: A review and Case study using peaches. Fermentation. 2022, 8, 567. [Google Scholar] [CrossRef]

- Alonso-Salinas, R.; Acosta-Motos, J.R.; Núñez-Delicado, E.; Gabaldón, J.A. ; López-Miranda, Santiago, Combined effect of potassium permanganate and ultraviolet light as ethylene scavengers on post-harvest quality of peach at optimal and stressful temperatures. Agronomy. 2022, 12, 616. [Google Scholar] [CrossRef]

- Liu,F.; Wen, Development and application of citrus storage technologies with concurrent consideration of fruit quality preservation, energy use, and costs. in Technology on Reducing Post-harvest Losses and Maintaining Quality of Fruits and Vegetables Proceedings of 2010 AARDO Workshop. 農業試驗所. 2010.

- Fernandez, C.M.; Alves, J.; Gaspar, P.D.; Lima, M. ; Tânia, Fostering awareness on environmentally sustainable technological solutions for the post-harvest food supply chain. Processes. 2021, 9, 1611. [Google Scholar] [CrossRef]

- Gradziel, T.; McCaa, J. Gradziel, T.; McCaa, J.; P, Processing peach cultivar development, in The peach: botany, production and uses. 2008, CABI Wallingford UK. p. 175-192.

- Lamidi, R.O.; Jiang, L.; Pathare, P.B.; Wang, Y.D. ; Roskilly, AP, Recent advances in sustainable drying of agricultural produce: A review. Applied energy. 2019, 233, 367–385. [Google Scholar] [CrossRef]

- Allison, A.L.; Lorencatto, F.; Michie, S. ; Miodownik, Mark, Barriers and enablers to buying biodegradable and compostable plastic packaging. Sustainability. 2021, 13, 1463. [Google Scholar] [CrossRef]

- Tu Nguyen, M.B.; Nguyen, T.K.; Dang, K.; Luu, T.H.; Thach, P.L.; Phuong Nguyen, K.Q.; Nguyen, Hong, Current and potential uses of agricultural by-products and waste in main food sectors in Vietnam—A circular economy perspective, in Circular Economy and Waste Valorisation: Theory and Practice from an International Perspective. Springer. 2022, p. 131-151.

- Pohlmann, C.; Rosa, Scavarda, A. J.; Alves, M.B.; Korzenowski, A.; Luis, The role of the focal company in sustainable development goals: A Brazilian food poultry supply chain case study. Journal of Cleaner Production. 2020, 245, 118798. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).