1. Introduction

The assessment of a bridge deck's condition requires the use of multiple Non-Destructive Evaluation (NDE) technologies. Some of the commonly used techniques are Half-Cell Potential (HCP) and Electrical Resistivity (ER). HCP is used to determine the likelihood of active corrosion in reinforcing steel bars, while ER is employed to assess the corrosive environment. However, the NDE technologies have limitations in detecting certain types of defects and deterioration, as their detection and characterization are influenced by various factors. For instance and as discussed later, the accuracy of HCP measurements can be impacted by factors such as moisture content, concrete cover, and anode/cathode ratio. Similarly, ER measurements can be influenced by factors such as moisture content, carbonation, and temperature. Therefore, it is crucial to have a thorough understanding of the strengths and limitations of NDE technologies to make the best use of them in a complementary manner.

The primary goal of this research is to address the foregoing issue by enhancing the interpretation of the results of ER and HCP through the use of machine-learning algorithms to analyze the results of surveys by multiple NDE techniques. Additionally, the research aims to:

Integrate information from various NDE technologies to gain a better understanding of how different factors can impact their measurements and, consequently, the detection and characterization of defects or deterioration.

Establish connections between the results from different technologies and the various factors that can influence the measurements to further improve their interpretation.

In summary, this research seeks to overcome the limitations of NDE technologies by conducting a joint analysis of multiple techniques and considering the influence of various factors on their results.

2. Parameters Affecting HCP and ER Measurements

A comprehensive review of the relevant literature was conducted to identify the factors impacting the results of the HCP and ER measurements. The sections below provide a summarized description of the parameters that affect the responses of these technologies, providing an understanding of the underlying principles that govern their behavior. This information serves as the foundation for identifying the parameters that are of the highest interest for this research

2.1. Parameters affecting the HCP

The HCP measurements can be impacted by various parameters, which can result in incorrect interpretation of the data. One such factor is the moisture content, which was shown to reduce the electrical resistivity and lead to lower (more negative) HCP values (Keßler and Gehlen, 2016)(Hussain, 2011) (NEGRUTIU, 2011) (Chabi et al., 2013) (Yodsudjai and Pattarakittam, 2017) (Bourreau et al., 2019) (Rodrigues et al., 2021). Another crucial parameter is the concrete cover thickness, which affects the distribution of the potential that leads to the potential at the steel/concrete interface significantly different from the potential on the concrete surface as the concrete cover thickness increases (Pour-Ghaz et al., 2009). However, the effect of concrete cover is still not conclusive, with some studies suggesting it can impact the accuracy of HCP measurements (Yodsudjai and Pattarakittam, 2017) (Gucunski et al., 2010). The anode/cathode ratio also affects the potential distribution due to corrosion, with a smaller ratio potentially leading to difficulty in detecting localized corrosion (Pour-Ghaz et al, 2009). Furthermore, (Sassine et al., 2018) concluded that the relationship between HCP potential values and the size of the corroded area in the steel bar needs to be further investigated to improve HCP measurements.

2.2. Parameters affecting the ER

Many factors can influence ER measurements, and these factors can have a significant effect on the measured values. Specifically, parameters such as degree of saturation, rebar corrosion, and the depth and moisture condition of delamination (Khudhair and Gucunski, 2023). Also, (Hornbostel et al., 2013) found that the electrical resistivity of concrete is sensitive to moisture, with an increase in moisture content leading to a decrease in electrical resistivity. This conclusion is supported by the findings of (Weiss et al., 2013). However, they recommend further studies be done to better understand the response of partially saturated concrete. (Larsen et al., 2006), as cited in (Azarsa and Gupta, 2017), discovered an interesting behavior in concrete where a decrease in the degree of saturation from 88% to 77% led to an average two-fold increase in resistivity, and from 88% to 66%, a six-fold increase. The temperature also affects ER measurements, and according to (Elkey and Sellevold, 1995), cited in (Sanchez Marquez, 2015), an increase in temperature leads to a decrease in ER values. This study found that ER values changed by 5% for each 1 oC in concrete with a degree of saturation under 30%, and 3% for each 1 oC in concrete with a degree of saturation under 70%. Moreover, cracks and delaminations can also impact ER measurement values. (Khudhair and Gucunski, 2018) found that the effect of delaminations decreases as the delamination depth from the surface increases. The orientation angle of the delamination has a significant effect on ER measurements in the 45o to 90o range but only a minor impact in the 0o to 30o range. Finally, the concrete resistivity may be affected by carbonation (Gowers and Millard, 1999).

3. Finite Element Simulations

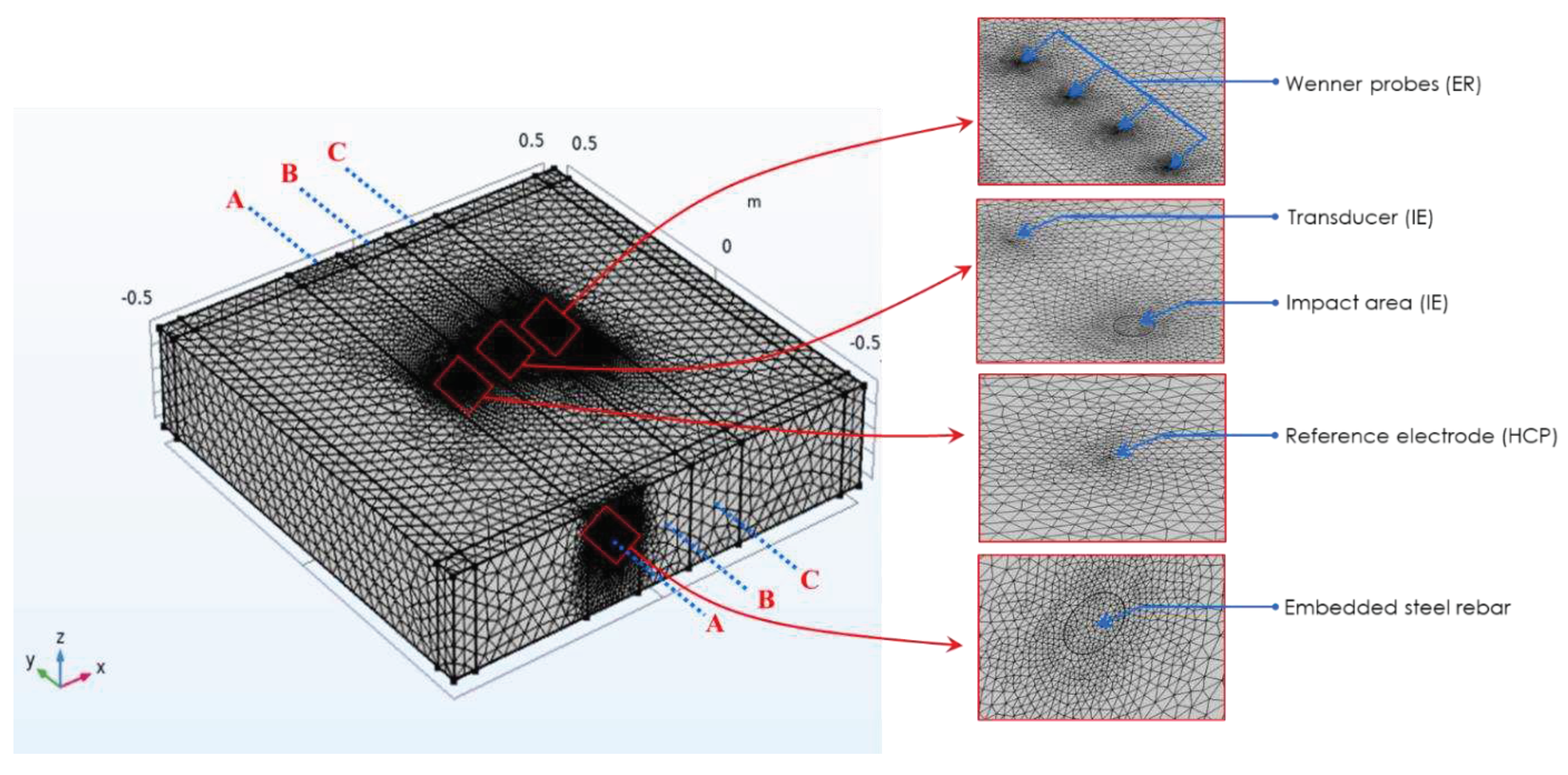

The present study utilized finite element models to examine all of the non-destructive evaluation (NDE) techniques included in the research. The models were created using the COMSOL Multiphysics® software and each NDE technique was given its own unique set of parameters and criteria to account for its distinct properties. The objective was to build a single model that could simulate three NDE technologies of interest in this study (half-cell potential, electrical resistivity, and impact echo (IE)) and to examine the effect of different parameters on their measurements. The software was used to integrate properties of interest for all three technologies into a single model, allowing for the simultaneous simulation of measurements by the three NDE technologies. The concrete slab was modeled as a block with dimensions of 1.0m×1.0m×0.2m, with Perfect Match Layers (PLM) that simulate the absorbing boundaries for the four sides to avoid reflection of elastic waves from the sides for the impact echo measurement. The model components, including various NDE probes, are illustrated in

Figure 1. The model was sliced for meshing purposes, allowing for finer discretization during the solution process. The extra-fine mesh was used around the contact points of the probes of the NDE technologies, such as around the electrodes of the Wenner probe for ER, around the HCP reference electrode, around the transducer and impact area for the impact echo, and the embedded steel bar. The reason for creating an extra-fine mesh is to get a precise simulation of the electrical field distribution for ER, wave propagation for IE, and the potential differences for HCP. The maximum element size for the free tetrahedral element is 0.001m, with a growth factor equal to 1.2. Additionally, the model components encompass the defects, such as corrosion of steel bars and delamination inside the concrete slab, which have been incorporated within the scope of this study.

Five parameters have been included to investigate their impact on the interpretation of NDE measurements. The five parameters chosen for the study include the degree of saturation (DoS), rebar corrosion length (CL), delamination depth (DL), concrete cover thickness (CC), and delamination moisture content whether it’s air-filled delamination (AFD) or water-filled delamination (WFD). This chapter focuses on the changes in the electrical field and resistivity of the concrete deck that occur as a result of these parameters and the corresponding HCP and ER measurements. The results from the simulation will be utilized for the development of machine learning algorithms. The impact of these parameters is determined by conducting several parametric studies. Below is a description of the variations of the five parameters in the study:

- 1.

Degree of saturation (DoS): A variety of saturation levels were selected to investigate the influence of pore saturation on the NDE measurements. These values span the different saturation conditions that the structure may encounter. Seven saturation levels were chosen, covering a range from 20% to 80% in increments of 10%.

- 2.

Corrosion length (CL): The term "corrosion length" refers to the length of the anode portion of the steel reinforcing bar. A set of eight values was selected to simulate the corrosion length, which ranges from 2.5 cm to 35 cm in increments of 5 cm.

- 3.

Delamination depth (DD): A set of six values was selected to reflect various depths of delamination. These values range from 40mm to 90mm below the surface of the concrete deck, with increments of 10mm.

- 4.

Concrete cover (CC): The concrete cover thickness has a substantial impact on the HCP measurement readings due to the presence of non-uniform corrosion on the steel bars. A set of four values have been selected to represent the concrete cover thickness, which are 38mm, 51mm, 63mm, and 76mm.

- 5.

Delamination moisture condition: Two values have been selected to simulate the moisture condition of the delamination within the concrete deck for this parameter. The first case represents air-filled delamination (AFD) which simulates completely dry conditions, while the second case represents water-filled delamination (WFD), which simulates fully saturated delamination.

3.1. Half-cell potential simulation result

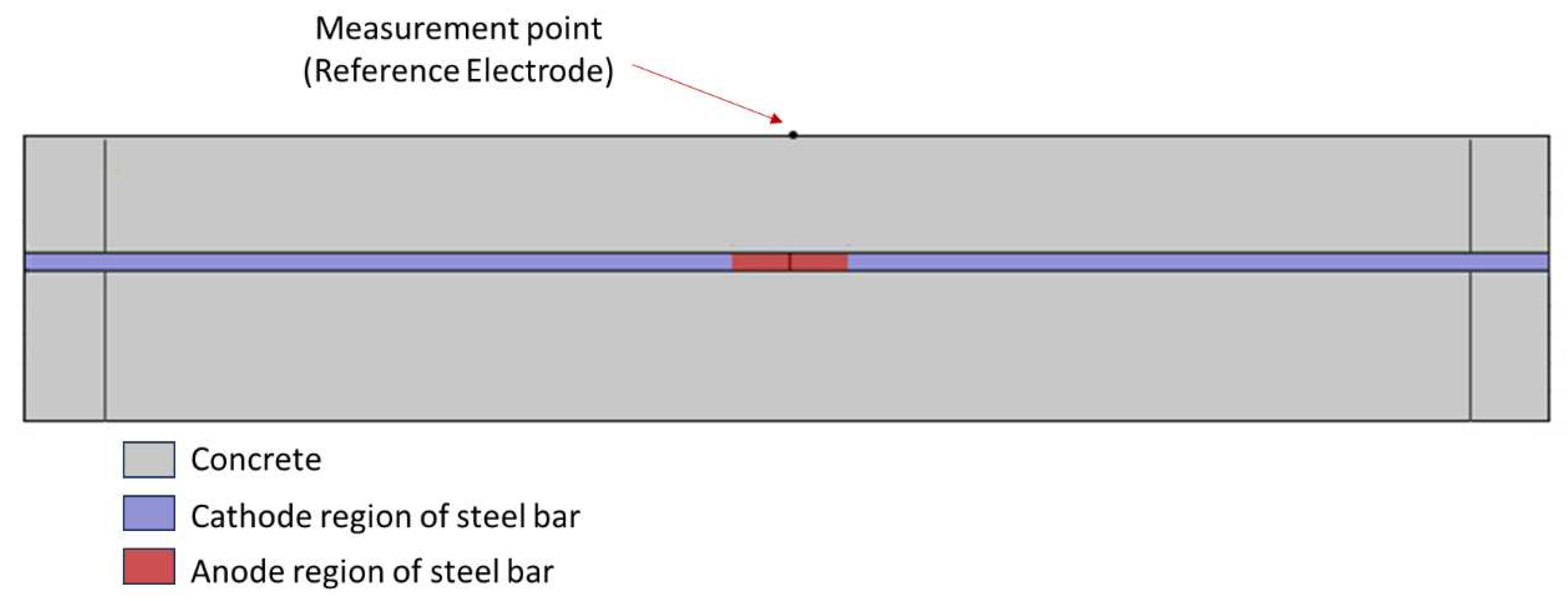

A half-cell can be simulated as an electrode placed within an electrolyte. To determine the potential difference, a reference electrode be used on the surface of the concrete. The FE (finite element) model for simulating HCP (

Figure 1) is the same concrete slab that has been utilized for IE and ER technologies and has a block size of 1.0m x 1.0m x 0.2m. Cross-section A-A, shown in

Figure 2, illustrates the internal steel bar, the cathodic region, and the anodic region (the active corrosion area) within the concrete.

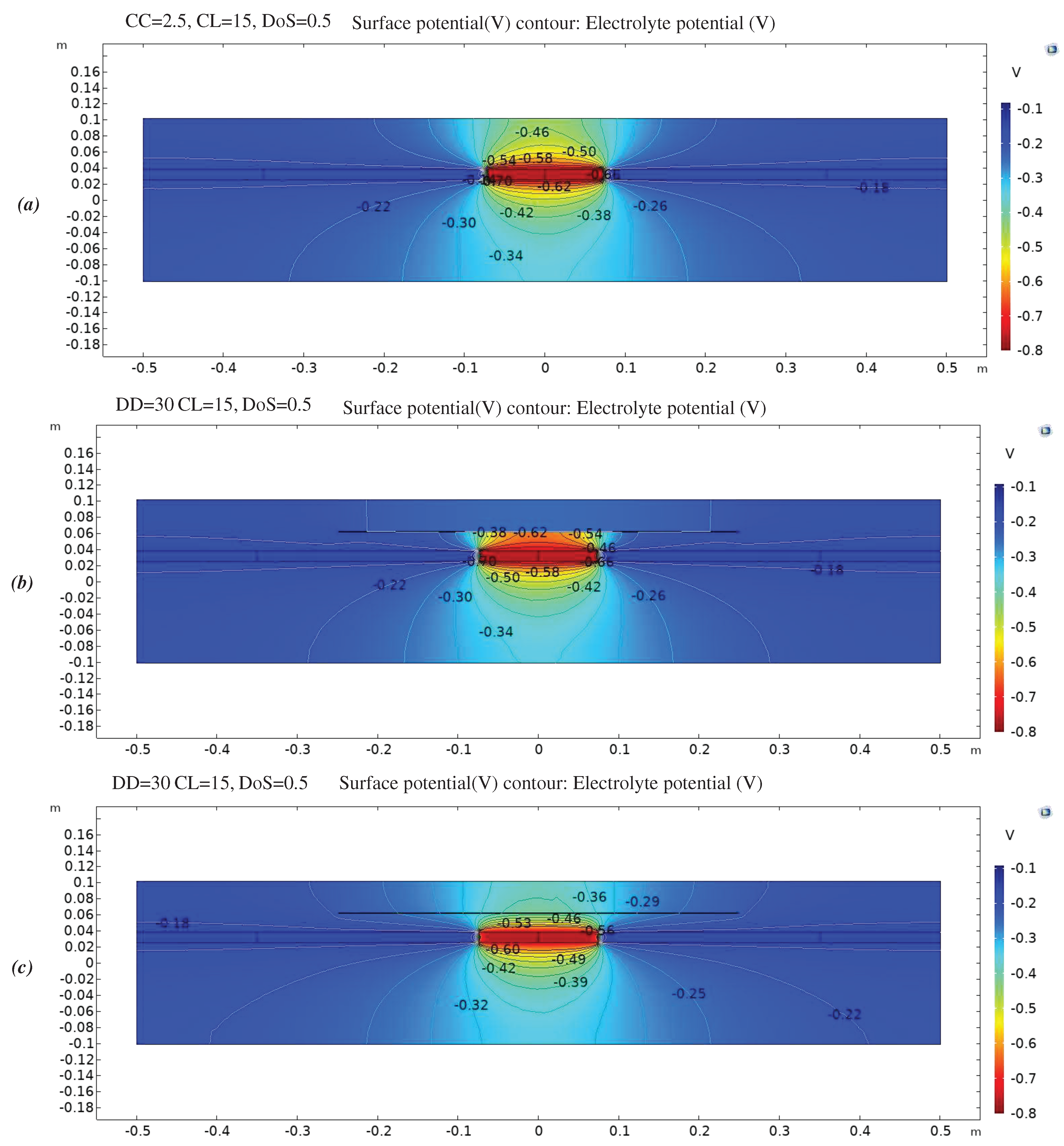

The simulation results indicate that the equipotential lines between the anode and cathode are highly sensitive to certain parameters such as shallow delamination and the saturation level of the delamination. To demonstrate the impact of these and other parameters on the electrochemical corrosion process inside concrete, different simulation scenarios have been presented.

Figure 3a displays the potential distribution within concrete caused by a 15 cm long steel rebar corrosion with 50% saturation and no delamination. On the other hand,

Figure 3b,c show the potential distribution inside concrete with the same parameters but the presence of 30mm deep delamination.

Figure 3b illustrates the scenario with air-filled delamination (AFD), while

Figure 3c illustrates the scenario with water-filled delamination (WFD).

The half-cell potential (HCP) results are influenced by the physical properties of two materials, the rebar steel where corrosion occurs and the surrounding concrete, as well as by the characteristics of the pores that regulate electrolyte flow. The results of HCP are impacted by all five parameters analyzed in this study. In general, the (HCP) results are positively correlated with both the corrosion length (CL) and the degree of saturation (DoS). As these two parameters increase, the measured potential becomes more negative. Conversely, HCP results are negatively correlated with the increase of concrete cover (CC) and delamination depth (DD).

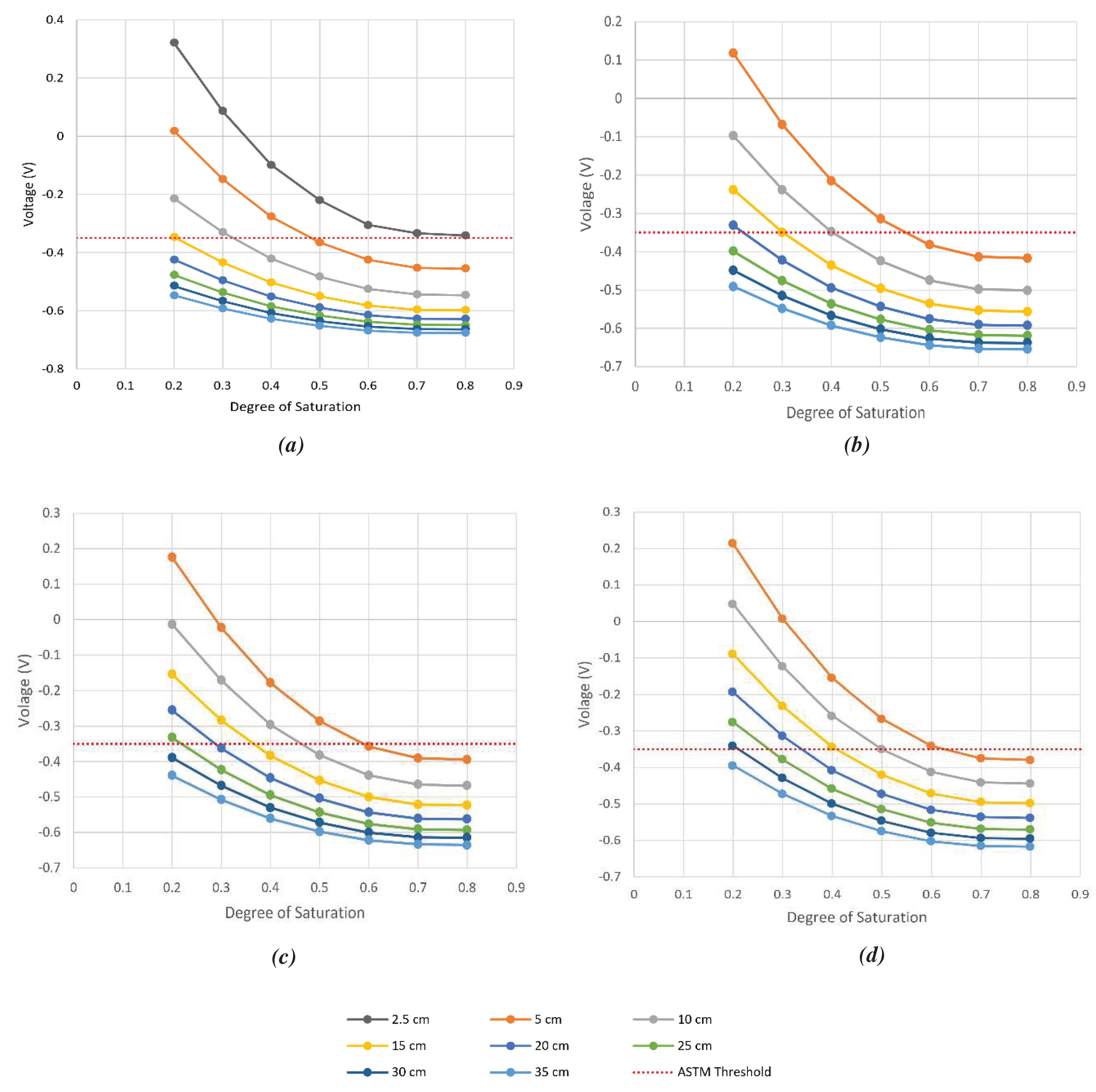

Figure 4 presents the HCP measurement values for sound concrete with varying corrosion lengths and degrees of saturation, at concrete cover thicknesses of 38mm, 51mm, 63mm, and 76mm. The dashed lines in the figures describe the boundary of the 90% probability of an active corrosion zone according to the standard specification ASTM C876-15.

In

Figure 4a, It can be seen clearly that the corrosion length of 2.5 cm cannot be detected by the HCP as the potential is larger than the threshold for all values of DoS. Also, the minimum detectable corrosion length is 5 cm with a DoS equal or greater to 0.5, 10 cm with a DoS equal or greater to 0.4, and 15 cm with a DoS equal or greater to 0.3. Furthermore, the corrosion length that is greater than 20 cm can be detected in all values of the DoS. These behaviors are changing with the change of the concrete cover as shown in

Figure 4b–d.

3.2. Electrical resistivity simulation results

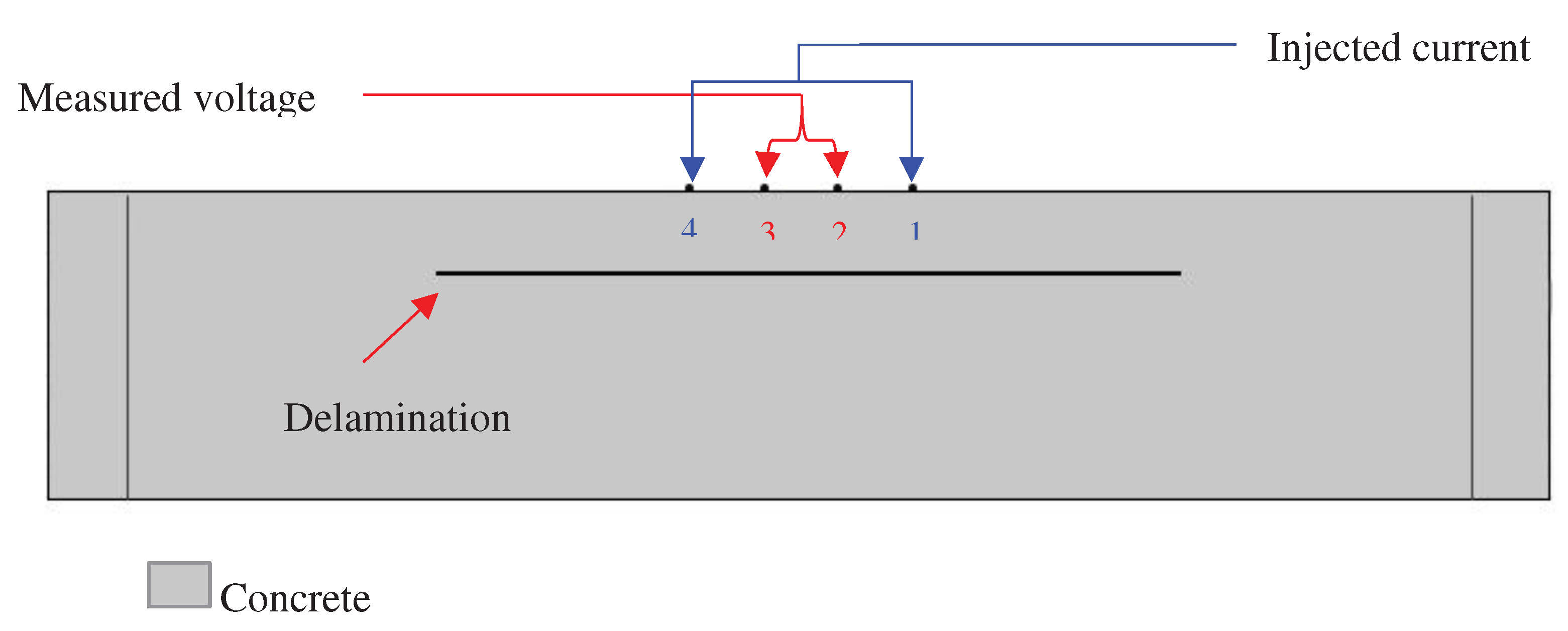

The concrete slab model used for ER simulation is the same one utilized for the HCP simulation and is represented as a block measuring 1m x 1m x 0.2m. The center of the ER model contains the probe contact area represented by four electrodes spaced 5 cm apart. ER technology simulation was carried out by mimicking the operation of the Resipod Proceq probe (according to the Resipod Proceq manual, 2017). This probe injects a current of 200 μA from the two outer electrodes, while the two inner electrodes measure the potential difference in the resulting electrical field, as illustrated in

Figure 5. Specifically, probe No. 1 has a current intensity of +200 μA, and probe No. 4 has a current intensity of -200 μA.

Table 1 displays the electrical conductivity values for concrete, water, and air used in the model. Concrete’s conductivity of 0.002 S/m corresponds to a resistivity of 500 Ω.m.

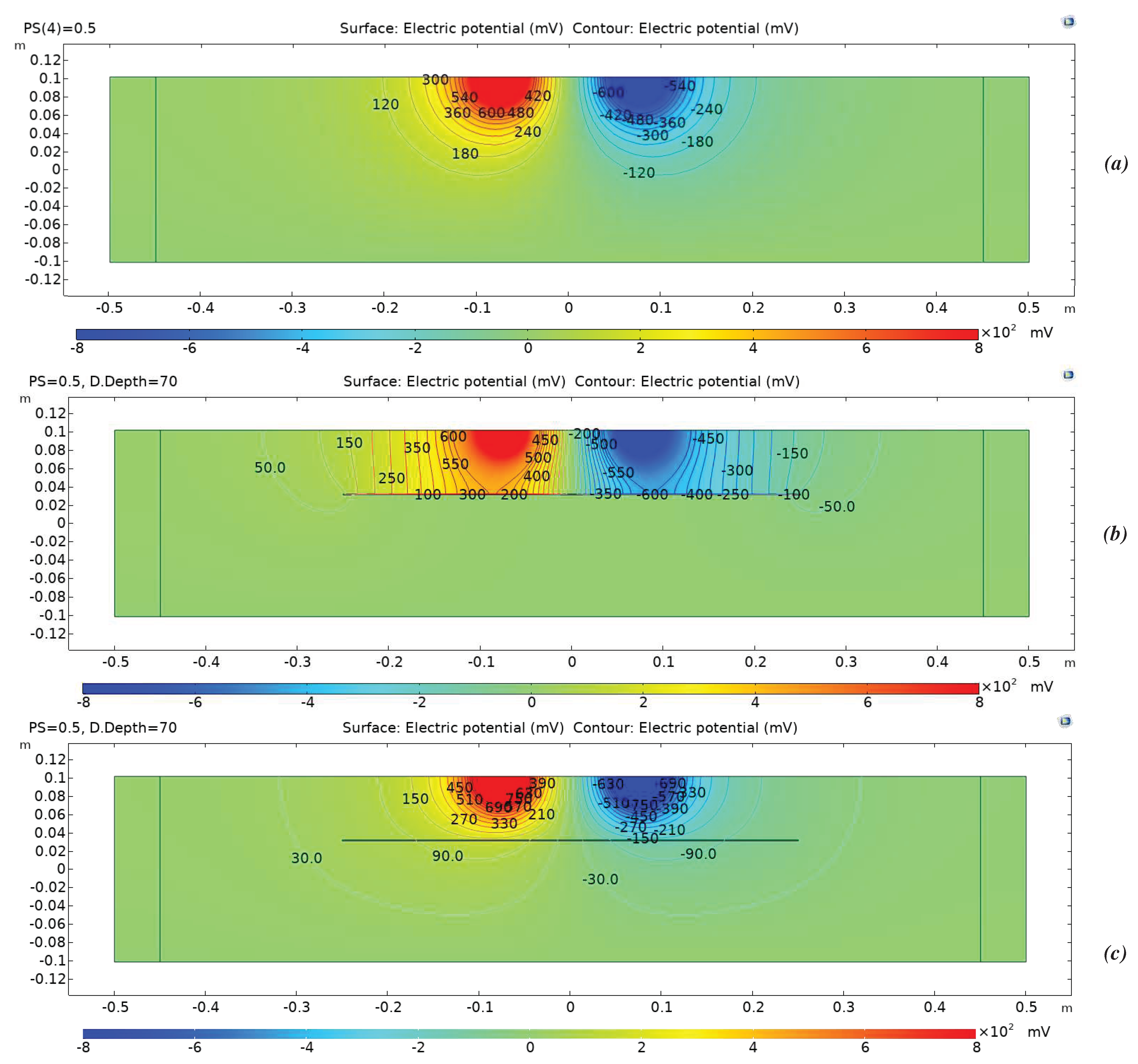

The electrical potential distribution measured in (mV) at the C-C cross-section (

Figure 1) for the sound concrete is shown in

Figure 6a. The model containing air-filled delamination (AFD) and water-filled delamination (WFD) is shown in

Figure 6b,c, respectively. The simulation results indicate that the measurement of ER technology is highly affected by the level of saturation, the presence and depth of delamination, and the moisture condition of the delamination. As a result, several models have been developed to assess the effect of these factors. The ER modeling results highlight a significant impact of these parameters. Generally, the ER values are inversely proportional to the degree of saturation. However, the ER measurements are directly proportional to the depth of delamination for the WFD case and inversely proportional to the AFD case.

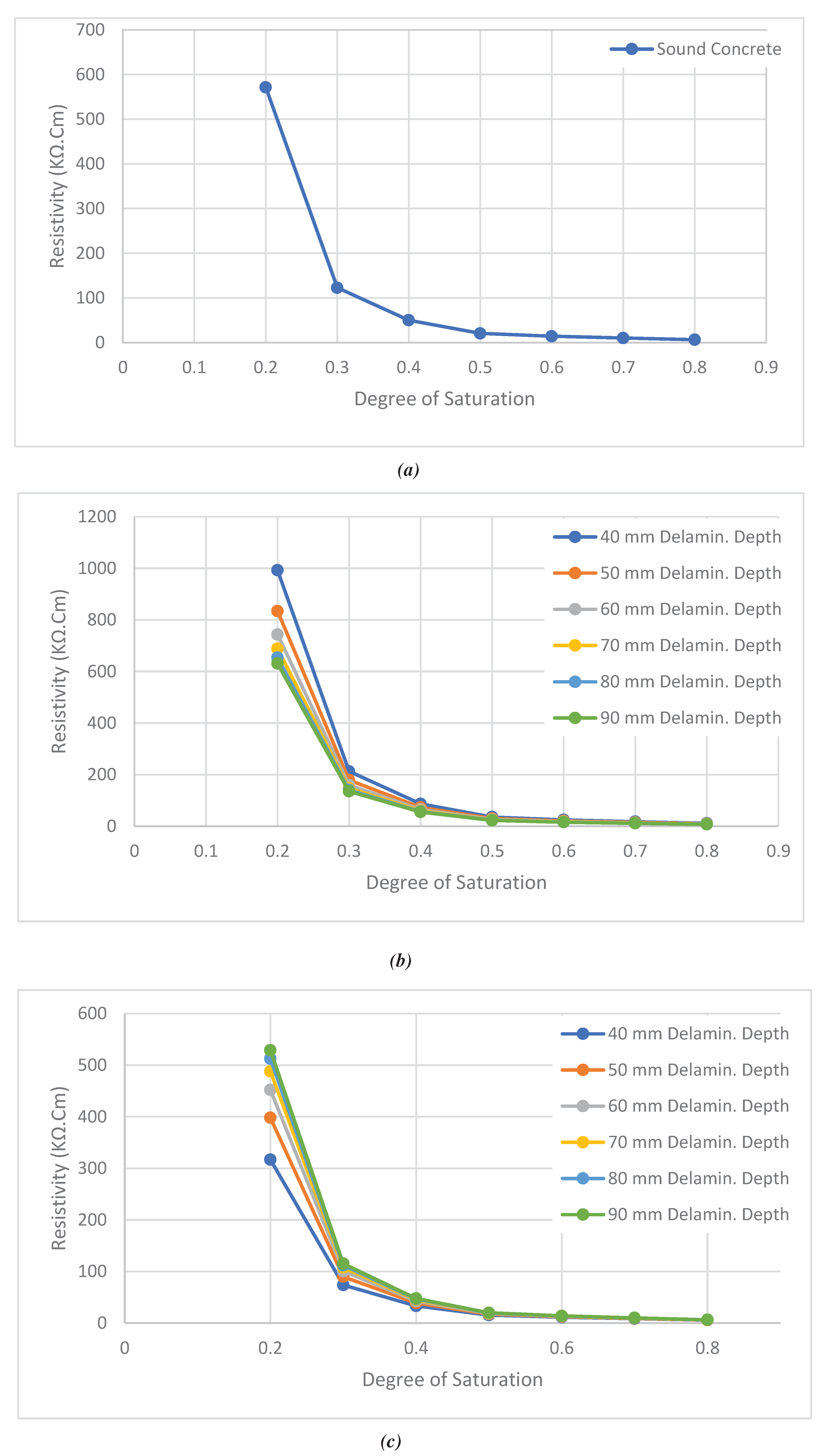

The change in electrical resistivity with the change in degree of saturation is illustrated in

Figure 7a for the sound concrete model, where the electrical resistivity decreases as the degree of saturation increases. The impact of air-filled delamination (AFD) on electrical resistivity (ER) measurements is demonstrated in

Figure 7b by presenting the ER values for different delamination depths and degrees of saturation. The trend in electrical resistivity lines is similar to those in

Figure 7a, with a drastic decrease in resistivity in the low degree of saturation range from 0.2 to 0.3. Furthermore, the resistivity decreases as the depth of the delamination increases. This can be explained by the fact that AFD serves as an insulator as the electrical conductivity of air is close to zero. In contrast, the electrical resistivity (ER) measurements for water-filled delamination (WFD) are directly proportional to the delamination depth, as demonstrated in

Figure 7c. This can be attributed to the higher electrical conductivity of water compared to concrete. Again,

Figure 7c shows a sharp decrease in ER values for all delamination depths in the low degree of saturation range from 0.2 to 0.3.

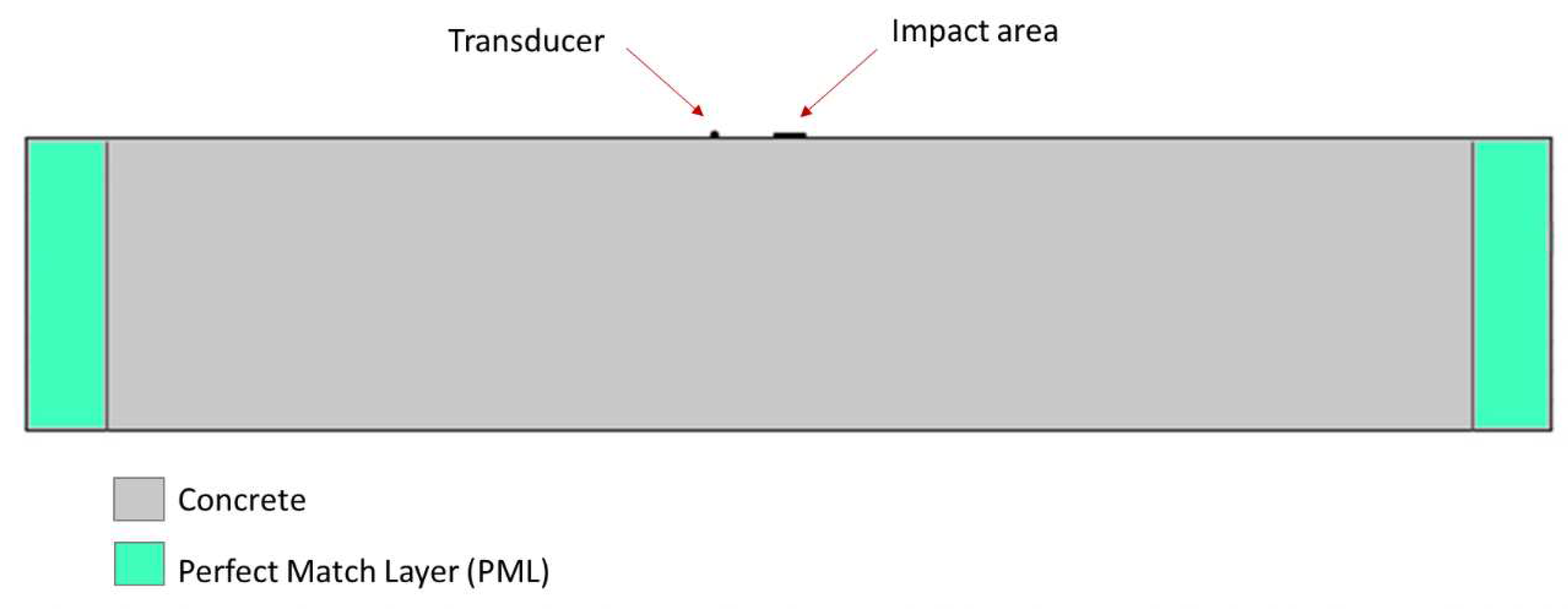

3.3. Impact echo simulation results

The model for the impact echo (IE) was based on the same model of a 1.0m x 1.0m x 0.2m concrete slab (

Figure 1) with Perfect Match Layers (PML) on all four sides to prevent reflection of elastic waves. The model includes a loading plate and measurement points to represent the impact area and transducer location, respectively. The transducer was positioned 5 cm from the impact point, as shown in

Figure 8. The IE test was simulated using a half-sine wave pulse with a maximum force of 1 N and a duration of 50 microseconds. The Poisson's ratio of concrete is 0.2, the speed of the compression wave (P-wave) is 4000 m/s, and the speed of the shear wave (S-wave) is 2312 m/s.

As shown in

Figure 1b, an ultra-fine mesh was utilized in the vicinity of the transducer and impact point. The purpose of this mesh was to achieve a highly accurate simulation of wave propagation for the IE technology. The maximum size of the free tetrahedral element was set to 0.001 meters, with a growth factor of 1.2.

The effect of the impact echo can precisely determine the plate-like structure's thickness. The thickness is calculated based on the dominant frequency and the velocity of the P-wave in the material, as illustrated in the work of

(Sansalone and Streett, 1997):

where:

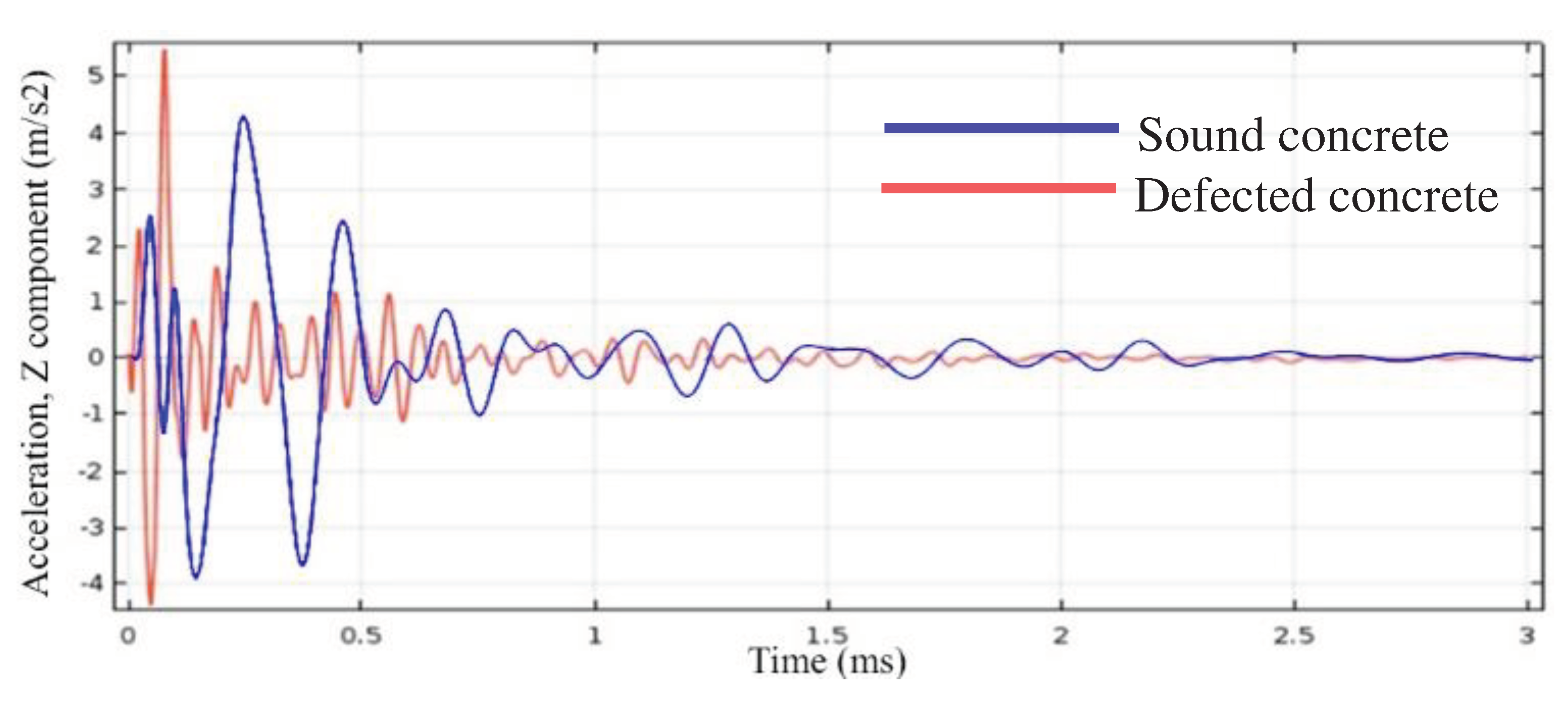

The acceleration time history of the sound and the defected concrete models are displayed in

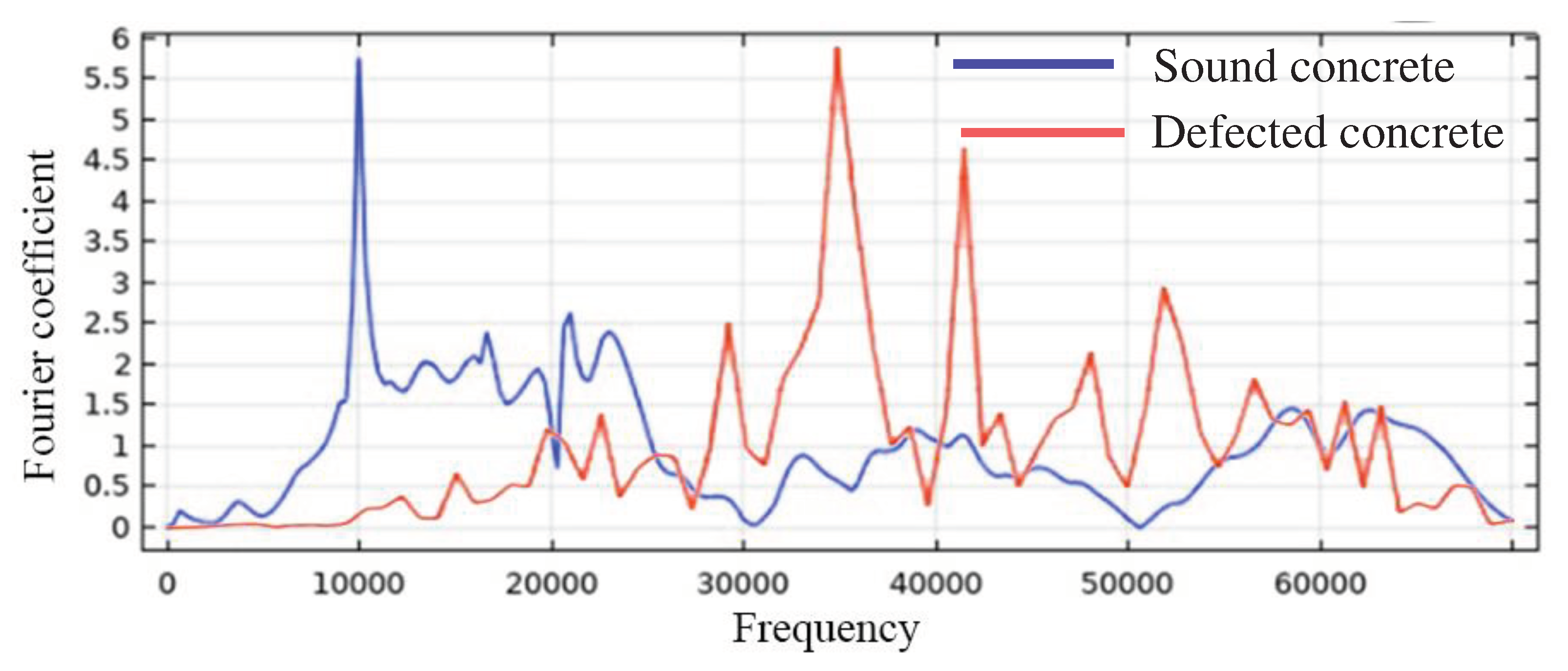

Figure 9, while the corresponding frequency spectrum for both models are shown in

Figure 10. The frequency spectrum of the impact-echo tests on the sound concrete, as seen in a blue line in

Figure 10, reveals that the main frequency is 10,000 Hz. This leads to a calculation of the concrete slab's thickness of 0.192 m using Equation (1), which is nearly the same as the actual thickness of 0.200 m. On the other hand, the dominant frequency caused by the flaw (5 cm deep crack), as seen in red line in

Figure 10, is 34,900 Hz. The calculated depth of the crack in the concrete slab using Equation (1) is [0.96 × 4000/(2 × 34900)] = 0.055 m, which is very close to the known crack depth of 0.050 m.

4. Machine Learning Algorithms

Machine learning is a method of using computer algorithms to predict a target output using multiple input features. The accuracy of the prediction improves over time through the use of a high-quality data set. Different algorithms can be employed, depending on the type of study, data set, and desired output. Machine learning can be divided into two main categories: supervised and unsupervised learning algorithms. A supervised learning algorithm is used when there is a known relationship between the input features and the target output, whereas an unsupervised learning algorithm is used when it is difficult to determine clear relationships between the input features and the desired output. Machine learning was utilized to enhance the interpretation of ER and HCP results by using data from the three NDE methods. Machine learning has been extensively utilized in various applications of structural assessment by NDE, as reported by several researchers, such as (Sengupta et al., 2021)(Mohamadi et al., 2020)(Harley and Sparkman, 2019)(Zhang et al., 2016). Artificial intelligence (AI) has also been employed for concrete evaluation in NDE for various technologies, including impact echo (Sengupta et al., 2021) and (Zhang et al., 2016), half-cell potential (Kruschwitz et al., 2018), and electrical resistivity (Chun et al., 2020).

A supervised learning algorithm was utilized in this study. The supervised learning algorithm is commonly used when there are well-defined attributes that can be linked to the target. Some of the algorithms that can be used for supervised learning include Neural Network, Naive Bayes, K Nearest Neighbors, and Random Forest, among others. The supervised learning algorithms can be further divided into two categories: regression for continuous target values, and classification for discrete target values. For this research, the Random Forest algorithm has been employed since it is known for its high accuracy as it generates a multitude of decision trees using the training data set. The algorithm then returns the prediction as either the average of the individual tree predictions in the case of regression or the class chosen by most of the trees in the case of classification.

4.1. Random Forest algorithms development

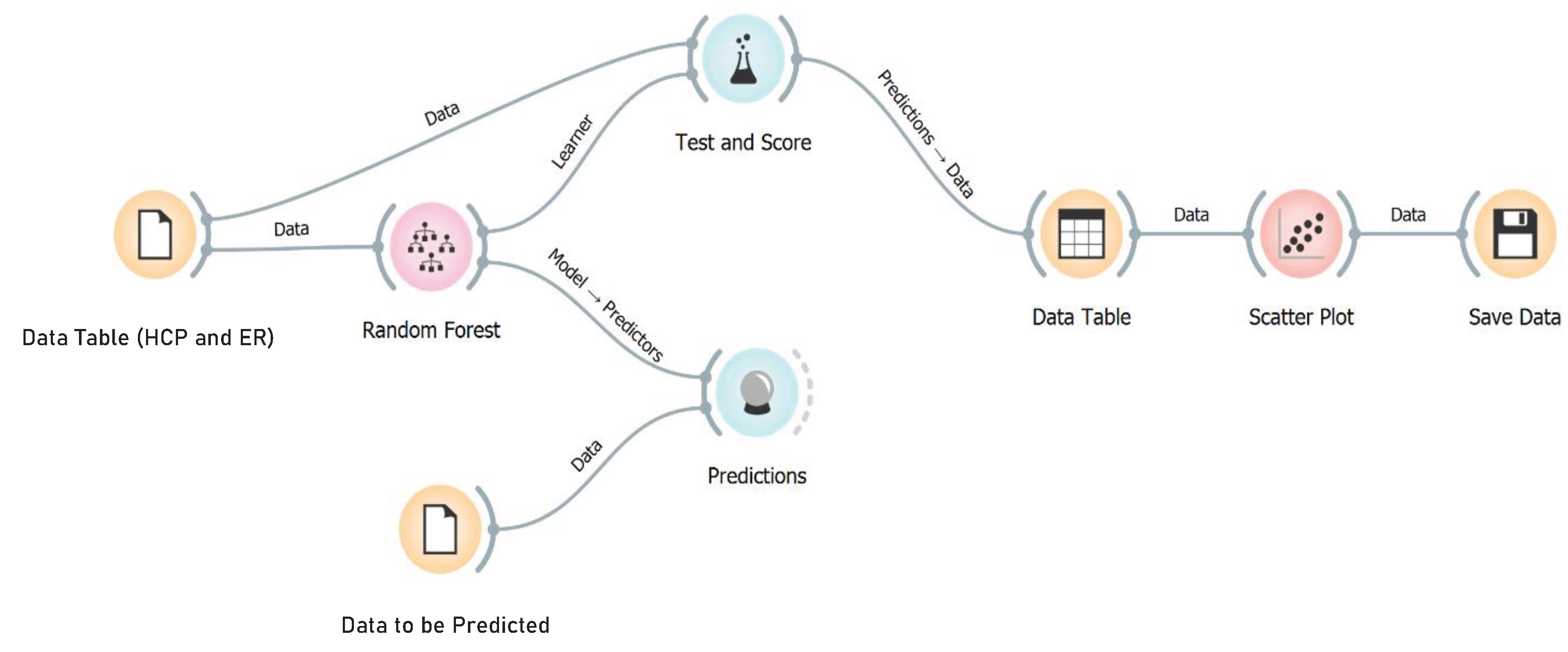

The algorithms were designed to provide corrected measurements of both half-cell potential and electrical resistivity technologies, which are impacted by the presence of five parameters discussed earlier. The correction of the measurements is based on a reference model with DoS=40%, DD=0, CC=63mm, and CL=0. The Orange® open-source software was used to build the algorithm. Orange® is a visual programming tool for machine learning, data mining, and data visualization and is written in Python, Cython, C++, and C. It can be used without any programming experience and all procedures can be performed through a graphical user interface (GUI).

Three-dimensional simulation results of NDE technologies, explained in the foregoing sections, were utilized to develop the Random Forest algorithms. The simulation generated 2548 models with specific values for the NDE technologies, forming a data set of 2548 instances for building two machine learning algorithms. The first is the Classification Algorithm, and the second the Regression Algorithm.

4.1.1. Classification Algorithm

The data set includes 9 attribute types involved in the process. These attributes serve various functions in the algorithm, some of which are Features - data that can be input as real numbers from NDE technology measurements on-site, some are Meta - data that cannot be measured as real numbers by NDE technologies, and the rest are referred to as Targets, as described below:

Degree of Saturation: the attribute is Numerical variable that has a Feature role.

Length of Corrosion: the attribute is Numerical variable that has a Meta role.

Delamination Depth: the attribute is Numerical variable that has a Feature role

Concrete Cover: the attribute is Numerical data variable that has a Feature role

Delamination M.C: the attribute is Categorical variable that has a Meta role

Measured Resistivity: the attribute is Numerical variable that has a Feature role

Measured HCP: the attribute is Numerical variable that has a Feature role

Actual Resistivity: the attribute is Categorical variable that has a Target role

Actual HCP: the attribute is Categorical variable that has a Target role

The targets considered are both Actual Resistivity and Actual HCP, which will be predicted by the classification algorithm as discrete classification values rather than continuous values. The choice of discrete classification values for the ER method is based on the correlation between resistivity and corrosion risk (Polder, 2001) while for the HCP method, the choice is based on the link between potential measurements and active corrosion probability (ASTM C876). The classification values for HCP and ER are:

Predicted values (Target) for HCP = {No Corrosion, Transition, Corrosion}.

Predicted values (Target) for ER = {Negligible, Weak, Moderate, High}.

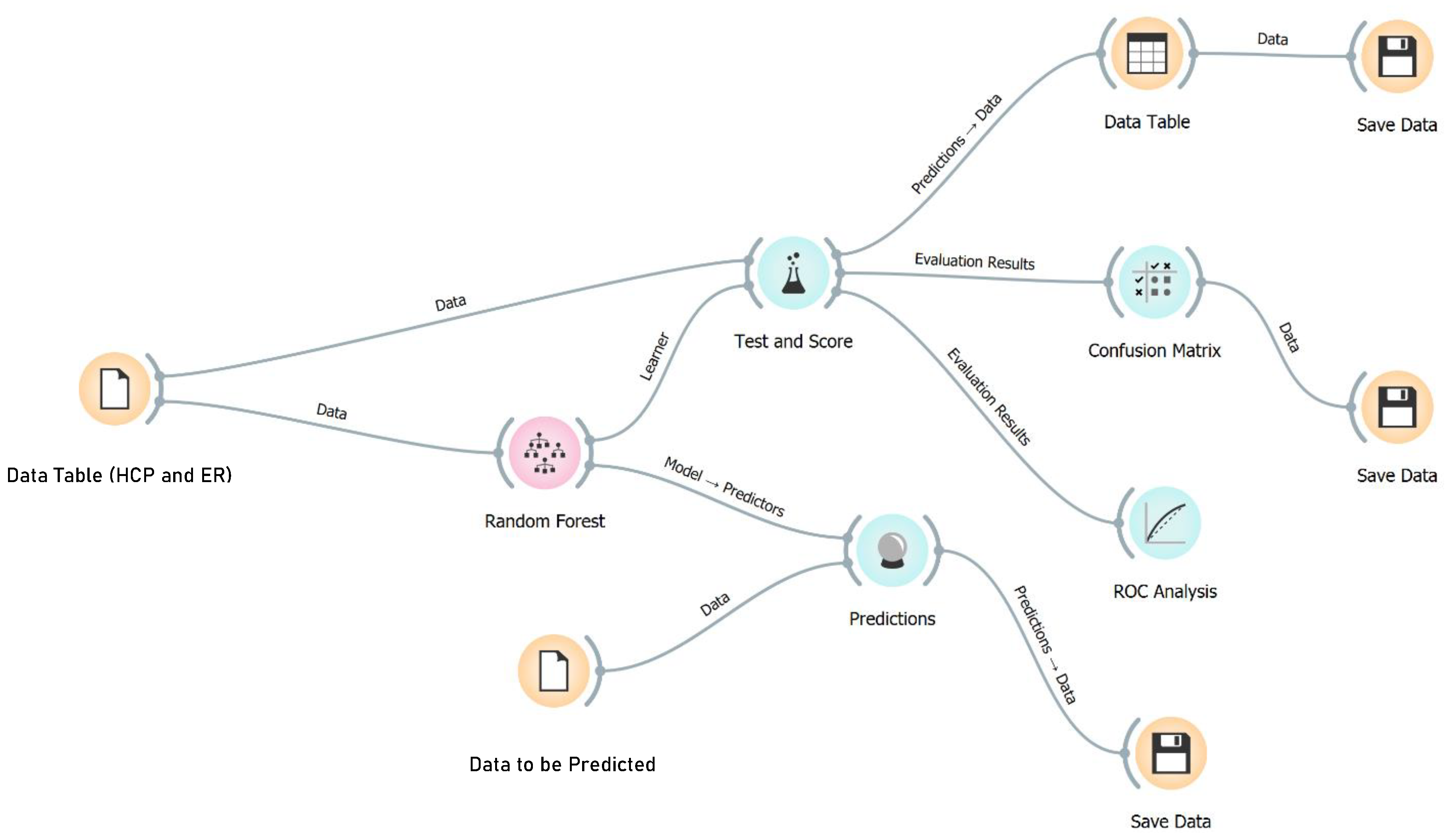

The algorithm workflow for the HCP and ER technologies is shown in

Figure 11

The algorithm demonstrates exceptional precision in predicting both Actual ER classification and Actual HCP classification. On average across classes, the algorithm's accuracy was 92.6% for ER and 85.9% for HCP. However, the accuracy varies when the target class is altered, as illustrated in

Table 2.

Additionally, the algorithm's efficiency is tied to other evaluation results that provide a numerical evaluation of its quality, known as a classifier performance measure, including Area under ROC curve (AUC), F1, Precision, and Recall. The evaluation results for this algorithm based on the classifier performance measures indicate that the AUC, CA, F1, precision, and recall for the average across classes are 0.989, 0.926, 0.926, 0.927, and 0.926, respectively.

Table 3 below displays the evaluation results for the other classes.

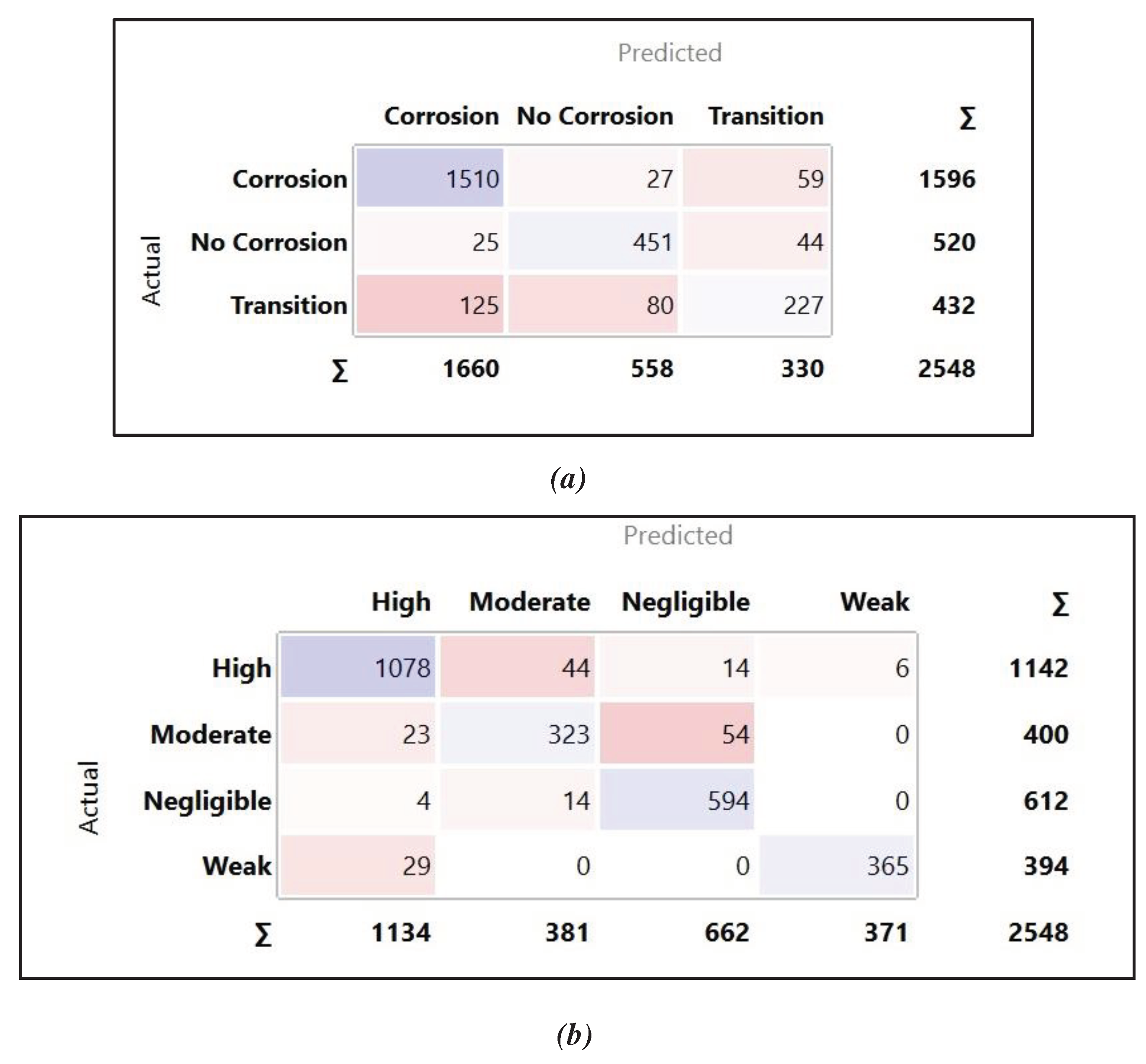

Moreover, the performance of the algorithm can be determined by creating a confusion matrix. This matrix displays the relationship between the predicted and actual classes and is used to evaluate the classification algorithm's results.

Figure 12a,b display the confusion matrix in terms of the number of instances for HCP and ER, respectively.

4.1.2. Regression Algorithm

Another way to utilize the machine learning algorithm in NDE is by developing a regression algorithm. Unlike the classification algorithm described earlier, which predicts discrete targets, the regression algorithm predicts continuous target values. Additionally, the regression algorithm can be more precise by forecasting the exact values of targets that fall within the boundaries of two distinct classes. This makes the predicted targets more concrete in numerical terms. The regression algorithm incorporates 9 types of attributes based on the data set. These attributes have varying functions in the process and can be classified as Features, Meta, or Target, as explained below:

Degree of Saturation: the attribute is Numerical variable that has a Feature role.

Length of Corrosion: the attribute is Numerical variable that has a Meta role.

Delamination Depth: the attribute is Numerical variable that has a Feature role.

Concrete Cover: the attribute is Numerical data variable that has a Feature role.

Delamination M.C: the attribute is Categorical variable that has a Meta role.

Measured Resistivity: the attribute is Numerical variable that has a Feature role.

Measured HCP: the attribute is Numerical variable that has a Feature role.

Actual Resistivity: the attribute is Numerical variable that has a Target role.

Actual HCP: the attribute is Numerical variable that has a Target role.

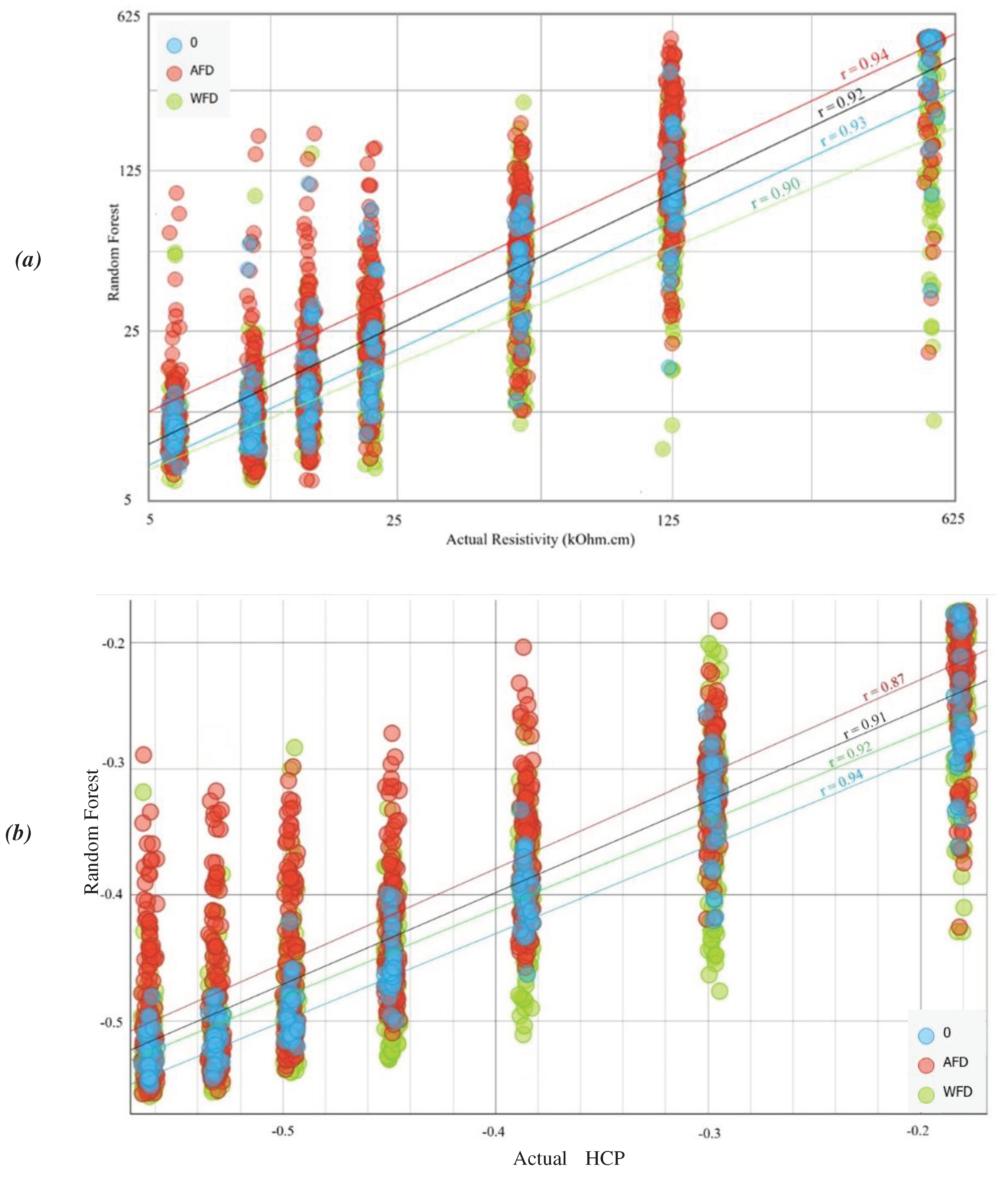

Figure 13 shows the workflow diagram of the algorithm for both HCP and ER technologies.

The regression algorithm was evaluated for both ER and HCP, and the results show that the coefficient of determination (R2) for ER was 0.861, indicating a strong positive relationship between the predicted and actual results with a CVRSM of 69.388. The R2 for HCP was 0.841, also indicating a strong positive correlation with a CVRSM of 16.267.

Figure 14a,b display the correlation between actual instances (on the x-axis) and random forest predictions (on the y-axis) for ER and HCP, respectively. The correlation is shown in three different colors, blue for no delamination, red for AFD, and green for WFD. In the case of ER, red instances have the highest correlation r value of 0.94, with 0.93, 0.90, and 0.92 for blue instances, green instances, and overall instances, respectively. This indicates that the regression algorithm is most accurate when ER technology is applied on concrete slabs with AFD and least accurate on those with WFD. On the contrary, HCP technology has a higher correlation value of r equal to 0.94 for blue instances. Conversely, the other correlation values are 0.87, 0.92, and 0.91 for red, green, and overall instances, respectively. Thus, the regression algorithm's prediction is most accurate when HCP technology is applied to sound concrete, but its accuracy decreases in the presence of WFD. The lowest accuracy occurs when AFD is present.

5. Implementation of the Algorithms

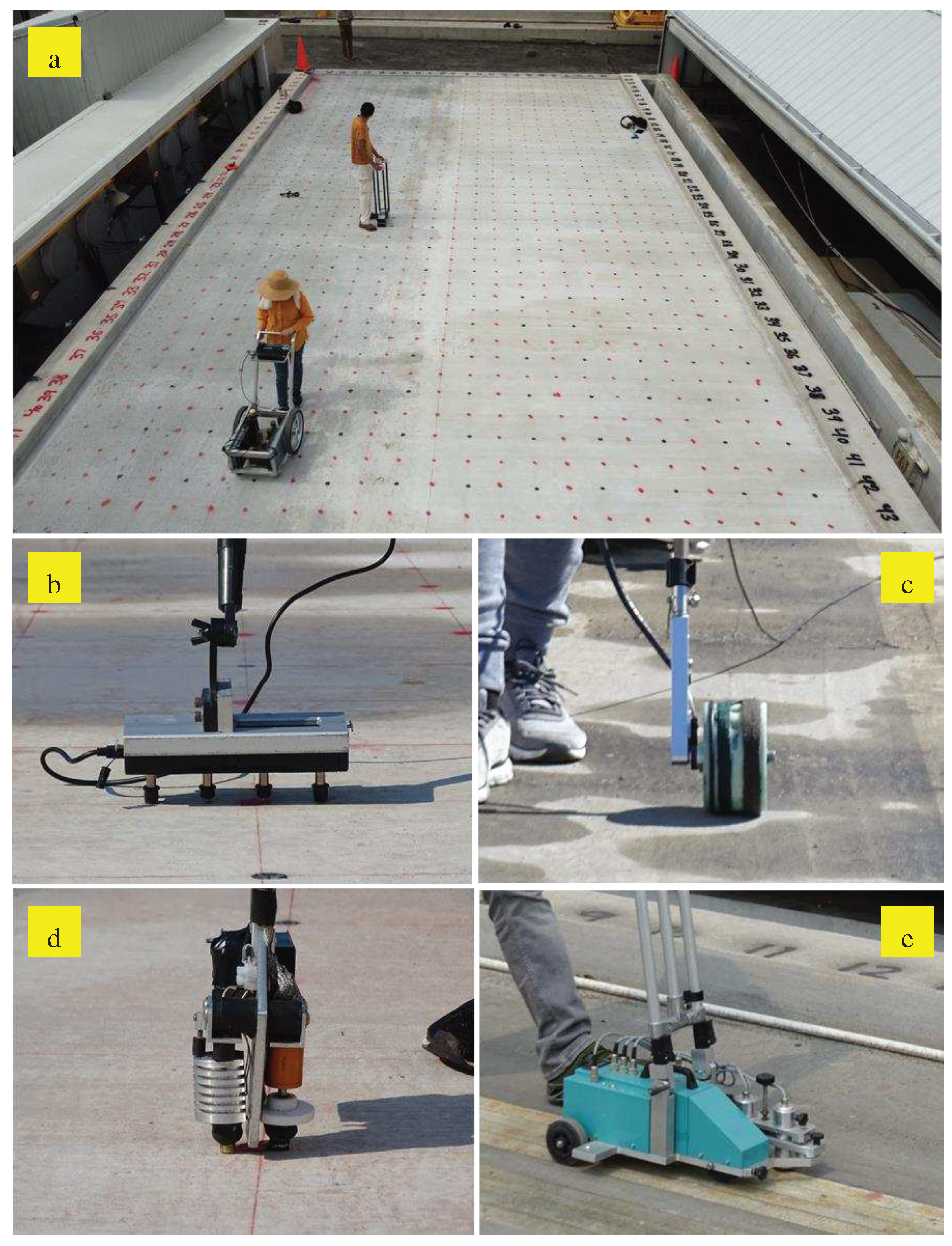

The data has been gathered on the concrete deck of the bridge specimen in the BEAST® (Bridge Evaluation and Accelerated Structural Testing) facility. The dual-axle truck carriage, with a weight equivalent to 50,000 pounds, runs continuously to simulate a truck crossing the deck more than 13,000 times a day. The facility allows the bridge deck to be exposed to various environmental conditions, such as freezing, thawing, salt exposure, and continuous truck traffic, to rapidly simulate its deterioration.

Figure 15 shows the loading device.

The BEAST facility allows for the assessment of actual bridge decks in regards to their dimensions, construction, exposure to environmental factors, and the loads put on them by truck axels. It functions as a full-scale prototype that mimics the conditions a real bridge deck experiences. The bridge deck structure is 15 meters long and 8.4 meters wide, with a 1ft by 1ft (0.3m by 0.3m) grid marked on it, as illustrated in

Figure 16a. Data is collected using three main NDE technologies: impact echo, electrical resistivity, and half-cell potential. The MOIST-Scan device, shown in

Figure 16e, is also utilized to gather information on the concrete's degree of saturation, it uses microwave technology to provide immediate, non-destructive analysis of residual moisture. The collected data on the moisture content was distributed in a range between 0% to 100%.

Figure 16 shows the data gathering by four NDE techniques. The data was usually gathered monthly to track the progression of deterioration.

5.1. Applying the regression algorithm

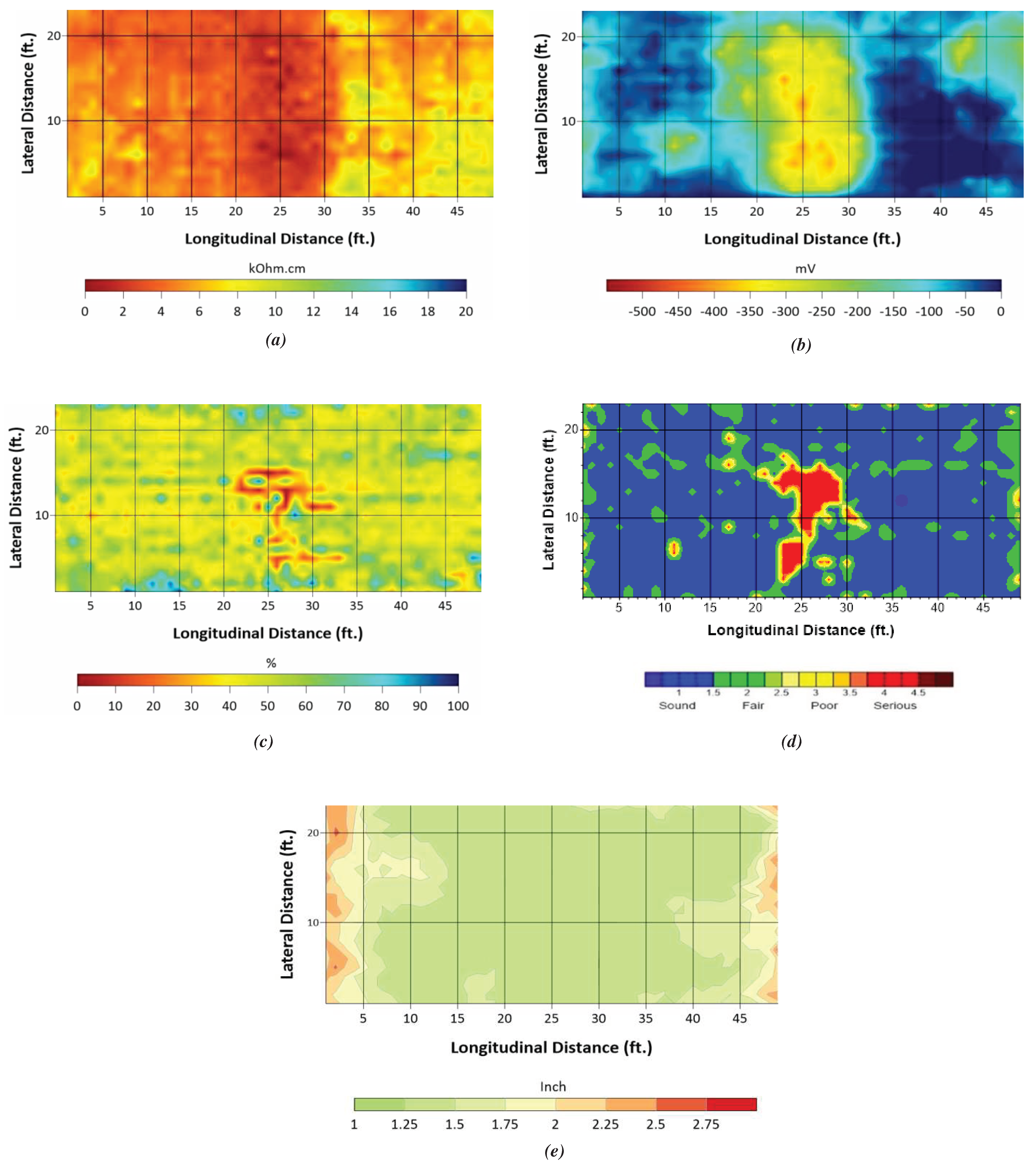

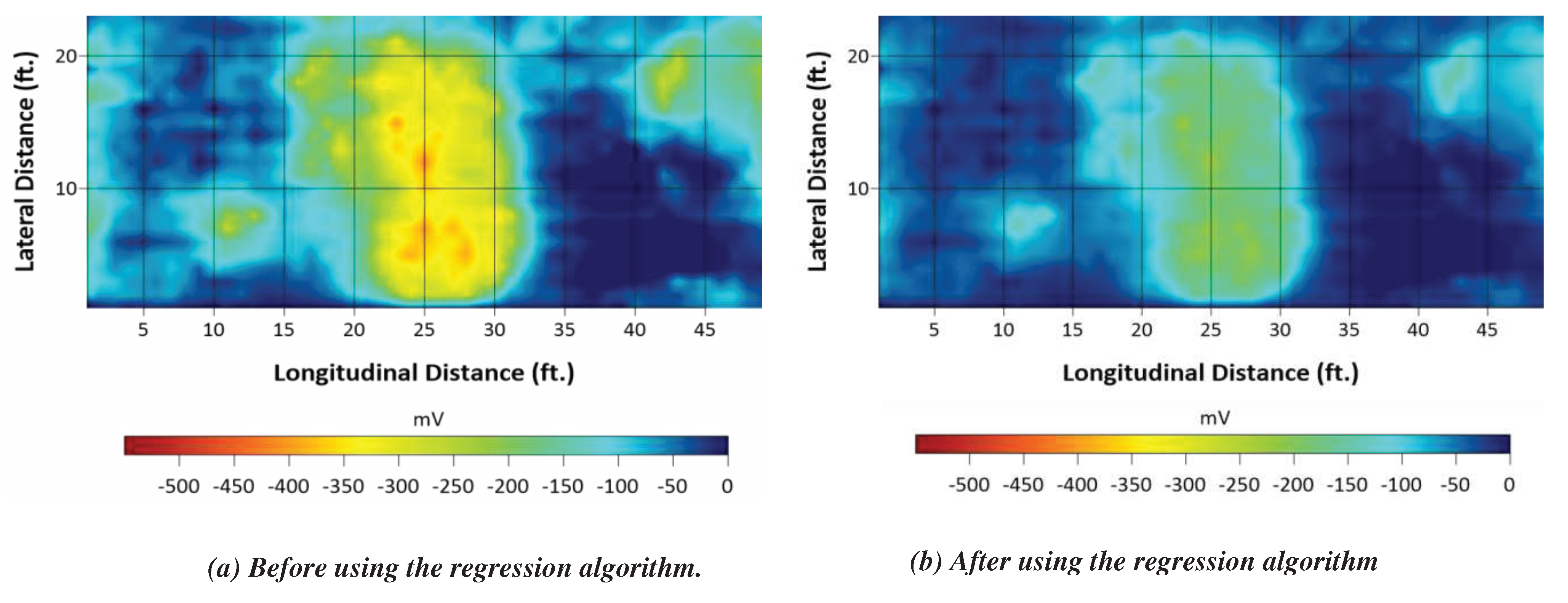

The presented data was obtained from the BEAST slab evaluation on July 21, 2021. By this time, the BEAST concrete slab had undergone 85 freeze-thaw cycles, 1,866,006 live load cycles, and had been sprayed with 3,478 gallons of salt brine. Before utilizing the regression algorithm, the data from each technology was analyzed and visualized to compare the differences in data interpretation with and without the ML algorithm.

Figure 17a–e present the surface map of the BEAST slab for the electrical resistivity, half-cell potential, degree of saturation, impact echo condition assessment, and concrete cover, respectively.

The results from the impact echo test were unable to determine the depth of delamination as it was shallow, with a maximum depth of about 3 cm (1.25 in). The delamination was found to be located within the concrete cover located at the boundary between the top reinforcement mesh and the concrete. As per the visible spalling, the shallow delamination corresponded with the top reinforcement layer as shown in

Figure 17d. Furthermore, the concrete cover measurements were obtained from the GPR survey, as illustrated in

Figure 17e. The comparison of results from before and after implementing the algorithm is displayed in

Figure 18 and

Figure 19 for ER and HCP, respectively. Significant modifications in the ER measurement values can be observed by comparing

Figure 18a (without the algorithm) to

Figure 18b (with the algorithm). The measurements increased from approximately 12 kOhm.cm to roughly 25 kOhm.cm, with the minimum resistivity after using the algorithm appearing in the center of the slab. These changes are due to the impact of the DoS and delamination, which have a considerable influence on the measurement values as discussed earlier in

Section 3. The algorithm improves the interpretation by correcting for the differences with reference values. The algorithm attempts to counteract the effect of DoS by reducing resistivity in areas with low DoS and increasing resistivity in areas with high DoS. Furthermore, the IE delamination map in

Figure 17d highlights the location of shallow delamination, which is reflected in the corrected ER values in

Figure 18b. The algorithm tries to mitigate the impact of delamination on the ER measurement values by decreasing resistivity in the delaminated area, primarily in the center of the deck as shown in

Figure 17d.

Similarly, the algorithm has produced significant changes in the HCP values. The corrected HCP values in

Figure 19b are a result of the impact of the DoS, delamination, and CC parameters. The algorithm corrects the impact of these parameters by moving the HCP values towards the right side of the scale (less negative values) for areas with high DoS. Likewise, the HCP values are shifted towards less negative values for areas with low CC values. However, the HCP values are shifted towards the left side (more negative values) for areas with low DoS values.

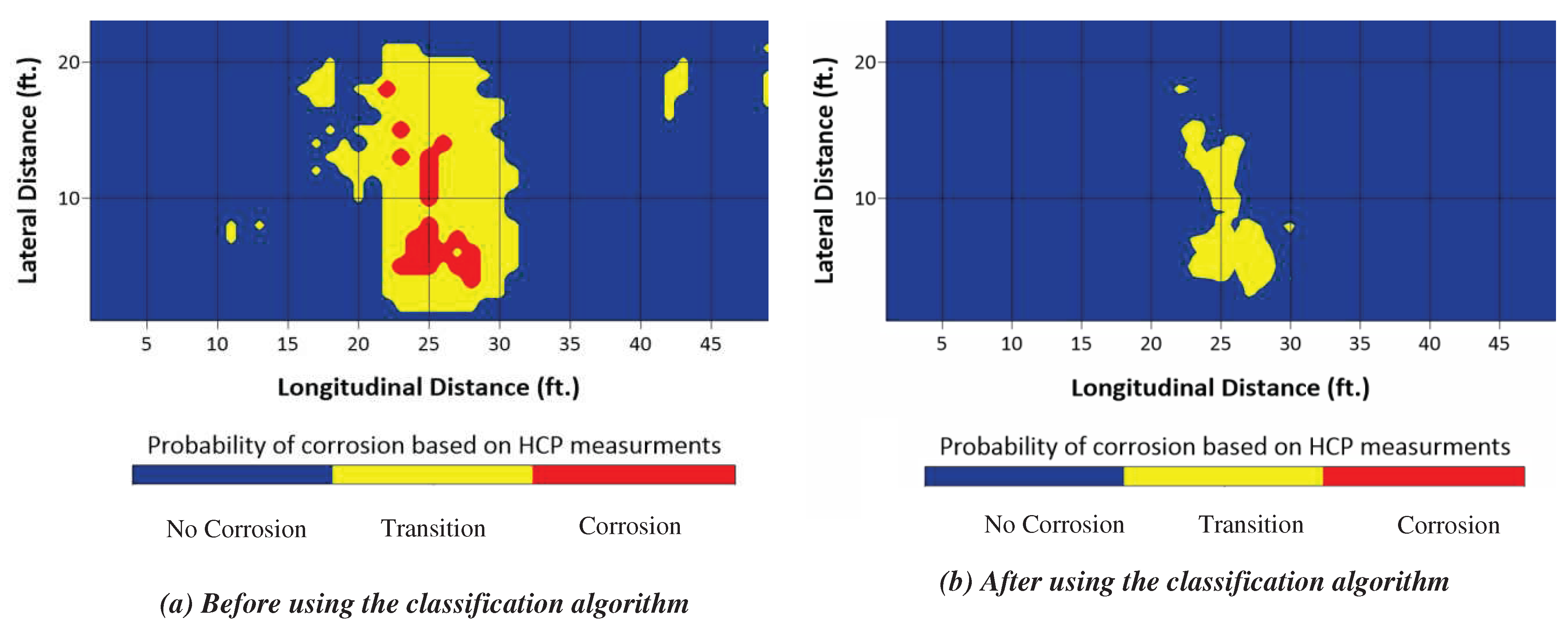

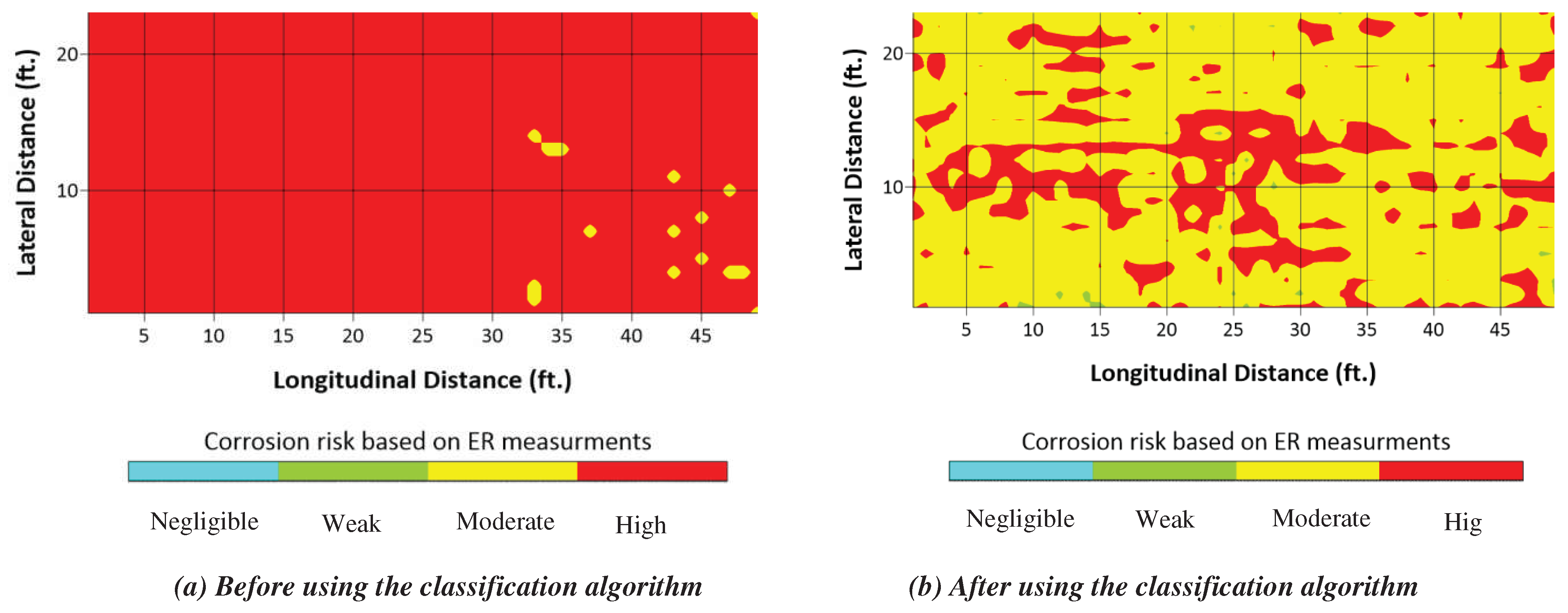

5.2. Applying the classification algorithm

The results produced by this algorithm are classifications, as opposed to the numerical outputs produced by the regression algorithm. Both algorithms were applied to the same BEAST data set. This algorithm makes predictions based on seven categories: four categories for ER (Negligible, Weak, Moderate, and High), and three categories for HCP (No Corrosion, Transition, and Corrosion).

Figure 20 and

Figure 21 illustrate the surface maps, before and after applying the classification algorithm, for the half-cell potential and electrical resistivity, respectively, based on the seven categories previously mentioned.

In

Figure 20b, the classification algorithm primarily corrects the HCP values located in the central area of the slab. These corrected values are a result of the influence of parameters such as DoS, delamination, and CC. The algorithm determines the impact of these factors by categorizing the corrosion area as a transition zone according to the ASTM standard. The high DoS and low CC levels cause the algorithm to interpret the increase in HCP potential as a result of improved conductivity. Meanwhile,

Figure 21b shows that the classification algorithm has reclassified most areas with low resistivity (high corrosion risk) as areas with higher resistivity (moderate corrosion risk). This is again due to the effect of high DoS and the slight impact of delamination, which is represented by a small red dot in the center, indicating a low resistivity value (high corrosion risk).

6. Summary and Conclusions

The research analyzed the impact of various parameters on the (NDE) measurement results of electrical resistivity (ER) and half-cell potential (HCP) measurements. The findings demonstrate that merging data from multiple technologies can enhance the interpretation of NDE results. The classification and regression algorithms used showed high accuracy in predicting the ER and HCP measurement classifications and values, respectively. The correlation between the predicted and actual values for ER was 0.92 and for HCP was 0.91, which suggests a strong positive correlation.

The results of numerical simulations and machine learning algorithms applied to an improved interpretation of NDE measurements led to several conclusions:

The ER measurements are significantly impacted by the degree of saturation, delamination depth, and moisture condition of the delamination, while HCP measurements are greatly affected by the degree of saturation, corrosion length, delamination depth, concrete cover, and moisture condition of the delamination.

The results indicate that HCP has limitations in detecting localized active corrosion, less than or equal to 2.5 cm because the potential distribution due to active corrosion can not exceed the ASTM threshold (-350 mV). Detection of larger localized corrosion depends on the degree of saturation.

The concrete cover thickness affects HCP measurements and proper correction must be made to describe it for the reference concrete cover thickness. As the thickness increases, the measured potential decreases, and vice versa.

The degree of saturation has a significant impact on both ER and HCP measurements. The HCP values decrease (become more negative) as saturation increases due to increased conductivity changing the potential distribution between the anode and cathode.

Strong correlations were established from numerical simulations between the selected parameters and NDE technology measurement values, enabling their improved interpretation.

Machine learning algorithms are effective correction tools that take into account the effects of all explored parameters.

Both regression and classification algorithms can be used as correction tools, but regression provides higher-resolution corrected values.

All five examined parameters have a significant impact on the measurements and should be considered in the interpretation process.

References

- ASTM, C. G. (2003) ‘Standard test method for corrosion potentials of uncoated reinforcing steel in concrete’, ASTM International: West Conshohocken, PA, USA.

- Awad, M. and Khanna, R. (2015) Efficient learning machines: theories, concepts, and applications for engineers and system designers. Springer nature.

- Azarsa, P. and Gupta, R. (2017) ‘Electrical Resistivity of Concrete for Durability Evaluation: A Review’, Advances in Materials Science and Engineering, 2017. https://doi.org/10.1155/2017/8453095. [CrossRef]

- Bourreau, L. et al. (2019) ‘Better understanding of tide ’ s influence on half-cell potential and electrical resistivity measurements for reinforced concrete in marine environment To cite this version : HAL Id : hal-02065141 environment’.

- Chabi, P. et al. (2013) ‘Effectiveness of half-cell potential mapping in corrosion assessment of reinforcement in loaded concrete bridge decks’, Proceedings, Annual Conference - Canadian Society for Civil Engineering, 5(January), pp. 4073–4081.

- Chun, P. et al. (2020) ‘Random Forest-based evaluation technique for internal damage in reinforced concrete featuring multiple nondestructive testing results’, Construction and Building Materials. Elsevier, 253, p. 119238.

- Elkey, W. and Sellevold, E. J. (1995) ‘Electrical resistivity of concrete’. Statens vegvesen. Vegdirektoratet.

- Gowers, K. and Millard, S. (1999) ‘Measurement of concrete resistivity for assessment of corrosion’, ACI Materials Journal, 96(5).

- Gucunski, N. et al. (2010) ‘Multiple complementary nondestructive evaluation technologies for condition assessment of concrete bridge decks’, Transportation Research Record, (2201), pp. 34–44. https://doi.org/10.3141/2201-05. [CrossRef]

- Harley, J. B. and Sparkman, D. (2019) ‘Machine learning and NDE: Past, present, and future’, in AIP Conference Proceedings. AIP Publishing LLC, p. 90001.

- Hornbostel, K., Larsen, C. K. and Geiker, M. R. (2013) ‘Relationship between concrete resistivity and corrosion rate - A literature review’, Cement and Concrete Composites. Elsevier Ltd, 39, pp. 60–72. https://doi.org/10.1016/j.cemconcomp.2013.03.019. [CrossRef]

- Hussain, R. R. (2011) ‘Underwater half-cell corrosion potential benchmark measurements of corroding steel in concrete influenced by a variety of material science and environmental engineering variables’, Measurement: Journal of the International Measurement Confederation. Elsevier Ltd, 44(1), pp. 274–280. https://doi.org/10.1016/j.measurement.2010.10.002. [CrossRef]

- Keßler, S. and Gehlen, C. (2016) ‘Influence of Concrete Moisture Condition on Half-Cell Potential Measurement’, International Conference on Durability of Concrete Structures, ICDCS 2016, (1140), pp. 257–264. https://doi.org/10.5703/1288284316142. [CrossRef]

- Khudhair, M. and Gucunski, N. (2023) ‘Multi-NDE Technology Approach to Improve Interpretation of Corrosion in Concrete Bridge Decks Based on Electrical Resistivity Measurements’, Sensors. MDPI, 23(19), p. 8052.

- Khudhair, M. J. and Gucunski, N. (2018) ‘Effects of Concrete Delamination and Cracking on Electrical Resistivity Measurement Results’, in NDE/NDT for Highways & Bridges: SMT 2018.

- Kruschwitz, S., Ebell, G. and Shen, J. (2018) ‘Towards Data Based Corrosion Analysis of Concrete with Supervised Machine Learning’.

- Larsen, C. K. et al. (2006) ‘Electrical resistivity of concrete part II: Influence of moisture content and temperature’, in Proceedings of the 2nd International RILEM Symposium on Advances in Concrete through Science and Engineering.

- Mohamadi, S., Lattanzi, D. and Azari, H. (2020) ‘Fusion and Visualization of Bridge Deck Nondestructive Evaluation Data via Machine Learning’, Frontiers in Materials. Frontiers, 7, p. 392.

- NEGRUTIU, C. M. (2011) ‘Aspects Regarding Half – Cell Potential Mapping for Reinforced High Strength Concrete’, 1(14), pp. 103–110.

- Polder, R. B. (2001) ‘Test methods for on site measurement of resistivity of concrete—a RILEM TC-154 technical recommendation’, Construction and building materials. Elsevier, 15(2–3), pp. 125–131.

- Pour-Ghaz, M., Isgor, O. B. and Ghods, P. (2009) ‘Quantitative interpretation of half-cell potential measurements in concrete structures’, Journal of materials in civil engineering. American Society of Civil Engineers, 21(9), pp. 467–475.

- Rodrigues, R. et al. (2021) ‘Reinforced concrete structures: A review of corrosion mechanisms and advances in electrical methods for corrosion monitoring’, Construction and Building Materials. Elsevier Ltd, 269, p. 121240. https://doi.org/10.1016/j.conbuildmat.2020.121240. [CrossRef]

- Sanchez Marquez, J. M. (2015) ‘Influence of Saturation and Geometry on Surface Electrical Resistivity Measurements’. Concordia University.

- Sansalone, M. J. and Streett, W. B. (1997) ‘Impact-echo. Nondestructive evaluation of concrete and masonry’.

- Sassine, E. et al. (2018) ‘A critical discussion on rebar electrical continuity and usual interpretation thresholds in the field of half-cell potential measurements in steel reinforced concrete’, Materials and Structures/Materiaux et Constructions, 51(4). https://doi.org/10.1617/s11527-018-1221-0. [CrossRef]

- Sengupta, A., Ilgin Guler, S. and Shokouhi, P. (2021) ‘Interpreting Impact Echo Data to Predict Condition Rating of Concrete Bridge Decks: A Machine-Learning Approach’, Journal of Bridge Engineering, 26(8), p. 04021044. https://doi.org/10.1061/(asce)be.1943-5592.0001744. [CrossRef]

- Weiss, J. et al. (2013) ‘Using a saturation function to interpret the electrical properties of partially saturated concrete’, Journal of Materials in Civil Engineering, 25(8), pp. 1097–1106. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000549. [CrossRef]

- Yodsudjai, W. and Pattarakittam, T. (2017) ‘Factors influencing half-cell potential measurement and its relationship with corrosion level’, Measurement: Journal of the International Measurement Confederation. Elsevier Ltd, 104, pp. 159–168. https://doi.org/10.1016/j.measurement.2017.03.027. [CrossRef]

- Zhang, J.-K., Yan, W. and Cui, D.-M. (2016) ‘Concrete condition assessment using impact-echo method and extreme learning machines’, Sensors. Multidisciplinary Digital Publishing Institute, 16(4), p. 447.

Figure 1.

Finite element 3-D model components.

Figure 1.

Finite element 3-D model components.

Figure 2.

A-A cross section.

Figure 2.

A-A cross section.

Figure 3.

Potential distribution for 15 cm corrosion length and 0.5 DoS: (a) No delamination (b) AFD at 30 mm (c) WFD at 30 mm.

Figure 3.

Potential distribution for 15 cm corrosion length and 0.5 DoS: (a) No delamination (b) AFD at 30 mm (c) WFD at 30 mm.

Figure 4.

HCP measurements for the sound concrete: (a) 38mm CC (b) 51mm CC (c) 63mm CC (d) 76mm CC.

Figure 4.

HCP measurements for the sound concrete: (a) 38mm CC (b) 51mm CC (c) 63mm CC (d) 76mm CC.

Figure 5.

C-C cross section.

Figure 5.

C-C cross section.

Figure 6.

Concrete potential distribution from ER simulation: (a) Sound concrete (b) AFD at 70 mm (c) WFD at 70 mm.

Figure 6.

Concrete potential distribution from ER simulation: (a) Sound concrete (b) AFD at 70 mm (c) WFD at 70 mm.

Figure 7.

ER for the models: (a) For sound concrete. (b) With AFD in different depths. (c) With WFD with different depth.

Figure 7.

ER for the models: (a) For sound concrete. (b) With AFD in different depths. (c) With WFD with different depth.

Figure 8.

B-B cross section for sound concrete.

Figure 8.

B-B cross section for sound concrete.

Figure 9.

Acceleration time history.

Figure 9.

Acceleration time history.

Figure 10.

Frequency spectrum.

Figure 10.

Frequency spectrum.

Figure 11.

Workflow diagram for the HCP and ER classification algorithm.

Figure 11.

Workflow diagram for the HCP and ER classification algorithm.

Figure 12.

Confusion matrix for the number of instances : (a) For the HCP. (b) For the ER.

Figure 12.

Confusion matrix for the number of instances : (a) For the HCP. (b) For the ER.

Figure 13.

Workflow diagram for the HCP and ER regression algorithm.

Figure 13.

Workflow diagram for the HCP and ER regression algorithm.

Figure 14.

Scatter plot for the Random Forest predictions against the Actual Values : (a) For the ER (b) For the HCP.

Figure 14.

Scatter plot for the Random Forest predictions against the Actual Values : (a) For the ER (b) For the HCP.

Figure 15.

The loading device that represents the trucks axel loads at BEAST® facility.

Figure 15.

The loading device that represents the trucks axel loads at BEAST® facility.

Figure 16.

Data collection of the NDE technologies on BEAST slab. (a) Grid mark on the concrete deck (b) Electrical resistivity (c) Half-cell potential (d) Impact echo (e) MOIST-Scan.

Figure 16.

Data collection of the NDE technologies on BEAST slab. (a) Grid mark on the concrete deck (b) Electrical resistivity (c) Half-cell potential (d) Impact echo (e) MOIST-Scan.

Figure 17.

NDE surface map from the collected data on the BEAST slab for : (a) Electrical resistivity (b) Half-cell potential (c) Degree of saturation (d) Impact echo condition assessment (e) Concrete cover abtained by GPR survey.

Figure 17.

NDE surface map from the collected data on the BEAST slab for : (a) Electrical resistivity (b) Half-cell potential (c) Degree of saturation (d) Impact echo condition assessment (e) Concrete cover abtained by GPR survey.

Figure 18.

Electrical resistivity results comparison.

Figure 18.

Electrical resistivity results comparison.

Figure 19.

Half-cell potential results comparison.

Figure 19.

Half-cell potential results comparison.

Figure 20.

Half-cell potential results comparision.

Figure 20.

Half-cell potential results comparision.

Figure 21.

Electrical resistivity results comparision.

Figure 21.

Electrical resistivity results comparision.

Table 1.

Material properties.

Table 1.

Material properties.

| Materials |

Properties |

| Electrical conductivity(S/m) |

Relative permittivity |

| Concrete |

0.002 |

4.5 |

| Water*

|

0.5 |

88.1 |

| Air*

|

3×10−15

|

1 |

| *used to fill the delamination. |

Table 2.

Classification Accuracy of the algorithm for different classes.

Table 2.

Classification Accuracy of the algorithm for different classes.

| |

The Target Class |

Classification Accuracy |

| ER |

Negligible |

96.6% |

| Weak |

98.6% |

| Moderate |

94.7% |

| High |

95.3% |

| Average over classes |

92.6% |

| HCP |

No Corrosion |

93.1% |

| Transition |

87.9% |

| Corrosion |

90.7% |

| Average over classes |

85.9% |

Table 3.

Evaluation results.

Table 3.

Evaluation results.

| |

Target Class |

Model |

AUC |

CA |

F1 |

Precision |

Recall |

| ER |

Negligible |

Random Forest |

0.991 |

0.966 |

0.932 |

0.897 |

0.971 |

| Weak |

Random Forest |

0.993 |

0.986 |

0.954 |

0.984 |

0.926 |

| Moderate |

Random Forest |

0.978 |

0.947 |

0.827 |

0.848 |

0.807 |

| High |

Random Forest |

0.990 |

0.953 |

0.947 |

0.951 |

0.944 |

| Average over classes |

Random Forest |

0.989 |

0.926 |

0.926 |

0.927 |

0.926 |

| HCP |

No Corrosion |

Random Forest |

0.979 |

0.931 |

0.837 |

0.808 |

0.867 |

| Transition |

Random Forest |

0.894 |

0.879 |

0.596 |

0.688 |

0.525 |

| Corrosion |

Random Forest |

0.971 |

0.907 |

0.928 |

0.910 |

0.946 |

| Average over classes |

Random Forest |

0.953 |

0.859 |

0.853 |

0.851 |

0.859 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).