1. Introduction

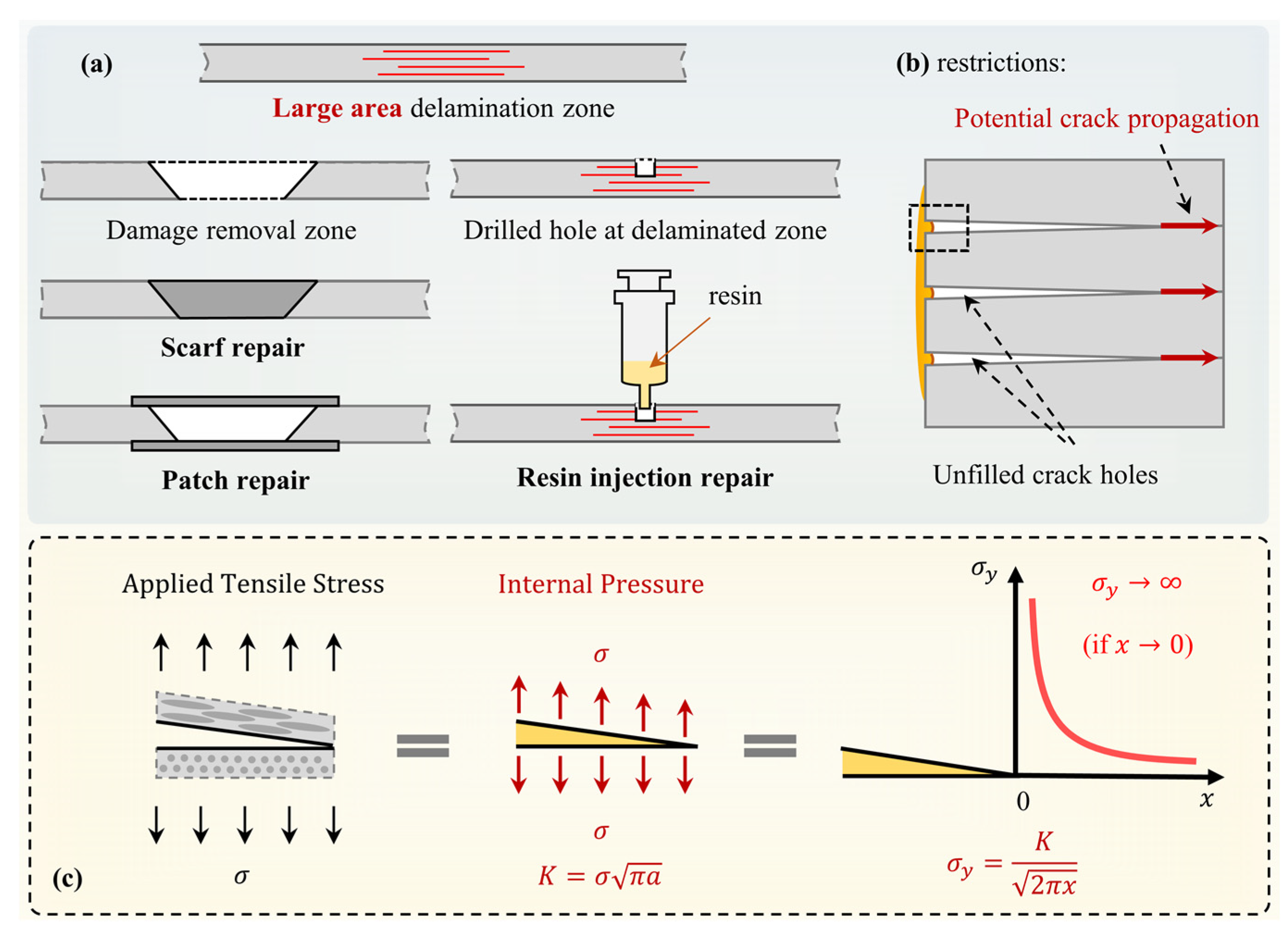

Standard methods are currently adopted in composite industries for repairing large-area delamination damage in laminar carbon-fibre-reinforced polymer (CFRP) composites. Typically, a large area of delamination damage in CFRP is machined and repaired with patches [

1,

2,

3] or scarfs [

4,

5,

6] with a similar configuration of adhesive-bonded CFRP patch, as illustrated in

Figure 1a. There are discussions in the literature on the effectiveness of scarf and patch-joint repairs [

7,

8,

9,

10,

11]. Both techniques (including extended applications such as single-sided strap, double-sided strap, stepped lap, and double scarf) have been adopted with excellent restoration results. A resin injection method was also developed, i.e., resin was injected into delamination cracks by external pressure and resin penetration was facilitated by drilled holes around the edge of the delamination area [

12,

13,

14]. The applied pressure is necessary because delamination cracks between carbon fibre plies are extremely narrow and sharp due to closely packed plies and the high stiffness of CFRP. The above repair methods including the pressurized repair are suitable for large delamination area that requires machining and drilling processes although this may create micro-delamination cracks due to the brittle nature of carbon fibres and epoxy matrix. If the viscous adhesive is not able to penetrate into sharp crack tips, there is a possibility that the infinite stress concentration may remain within the CFRP structure (

Figure 1).

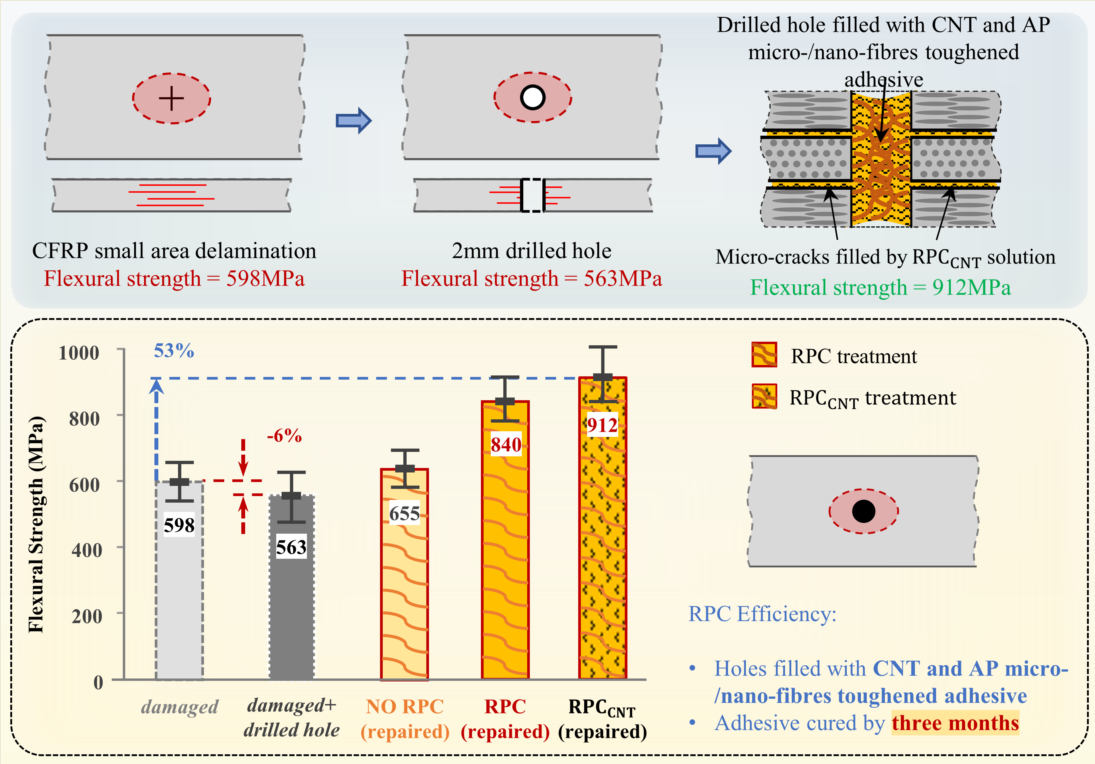

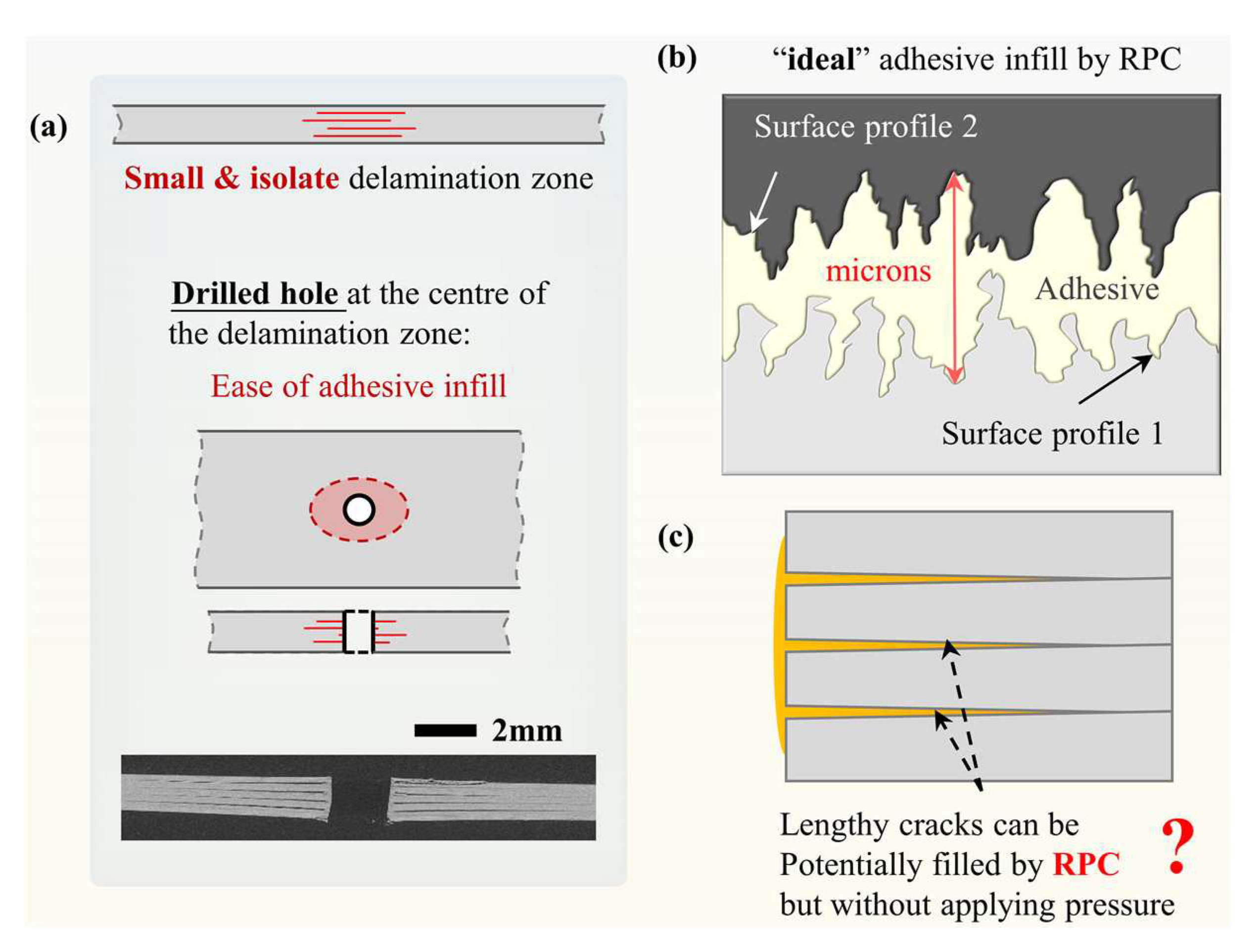

It is possible that sometimes only small area delamination only a few millimetres across is detected, as shown in

Figure 2a, which may be too small to use the standard scarf or patch-joint repair methods. However, this small area delamination may propagate in serve if left unrepaired due to the high-stress concentration at the crack tips. It seems the issue on how to repair small-area delamination has not been reported in the literature. It is also true that a regular safety inspection in conjunction with removing sharp crack tips in the small area delamination can significantly improve the reliability of the CFRP structure. But small area delamination needs to be repaired at some stage.

The primary objective of this study is to repair the small area delamination that cannot be easily handled by common existing repair methods for large delamination. In particular, we aim at filling sharp delamination crack tips without applying pressure. This is stimulated by research on maximizing adhesive bond strength.

Figure 2b illustrates an ideal adhesive bonding scenario that all substrate micro-cavities are entirely filled by adhesive [

16]. Clearly, this is the optimum bonding scenario as all micro-cavities are filled and the entire bonding area is fully utilized. The pressureless resin pre-coating (RPC) method has been used to achieve the ideal adhesive bonding conditions illustrated in

Figure 2b.

Figure 2c illustrates the possibility of extending the pressureless RPC technology for repair of sharp delamination cracks in CFRP.

This study verifies the above hypothesis illustrated in

Figure 2 that pressureless repair method can be adopted for the small area delamination in CFRP. A small drill hole around 2 mm in diameter was introduced at the center of the delamination area around a few millimetres across. The sharp delamination cracks were then filled through the capillary action of an acetone-rich resin solution (without hardener). Carbon nanotubes (CNT) could be pre-mixed with this resin pre-coating (RPC) solution and infiltrate into those sharp delamination crack tips. The pressureless RPC and RPC

CNT techniques have been successfully used for enhanced adhesive bonding between CFRP and various metal substrates [

16,

17,

18,

19,

20,

21,

22,

23,

24]. A recent preliminary study on the repair of edge delamination in CFRP also supported potential applications of the RPC method for composite repairs [

25], and the latest research has achieve 100% restoration on repairing of edge delamination [

26]. Therefore, relevant repair results of edge delamination using the same RPC

CNT method are compared with those of small area delamination with small drilled holes. This simple and effective technique can be conveniently applied in laboratory for small-sized CFRP tests and adopted on-site for large structures with small delamination zone.

2. Results and Discussion

2.1. Functional Theories Discussion

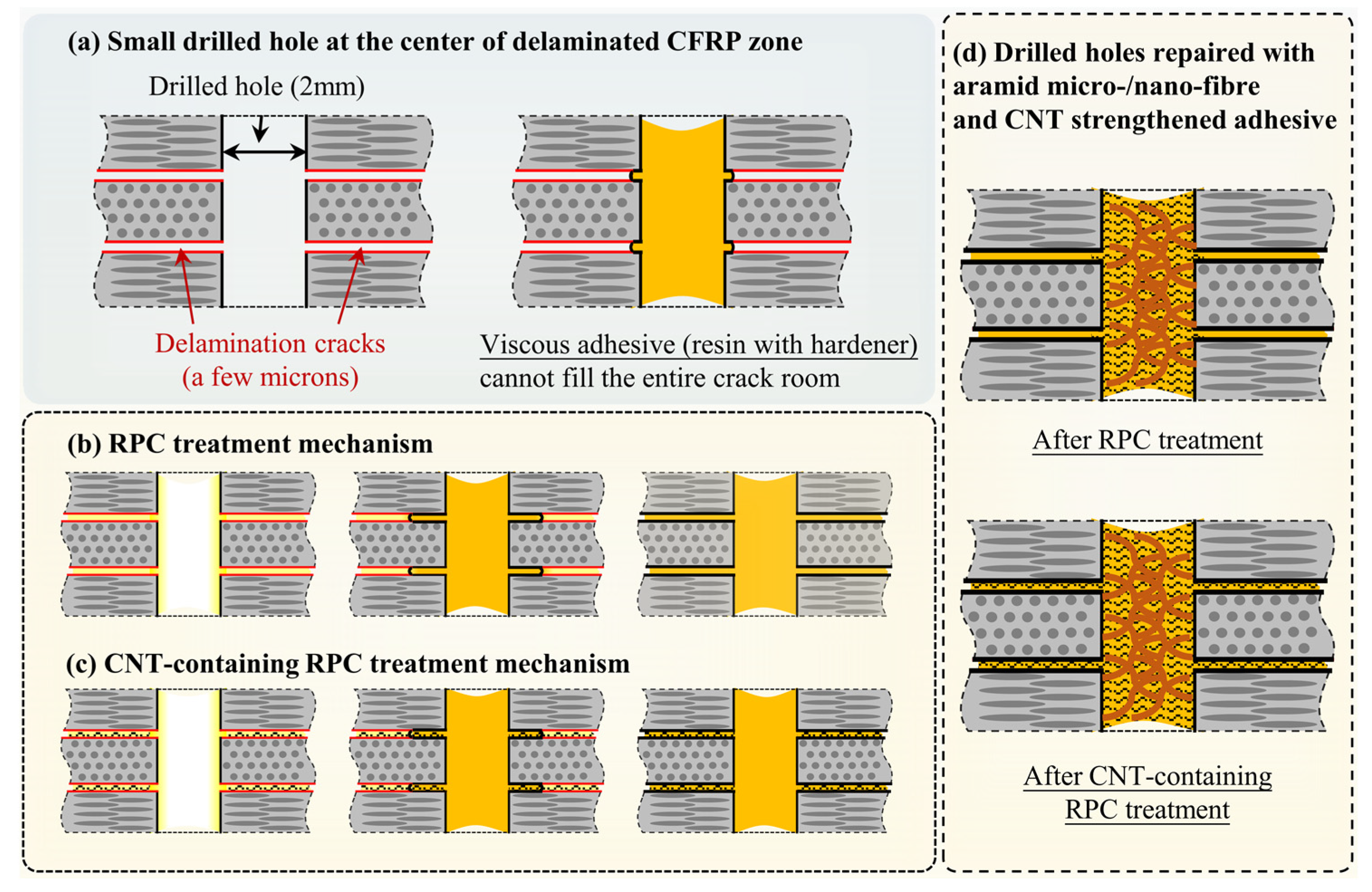

2.1.1. Pressureless repair of sharp delamination crack tips using RPCCNT solution

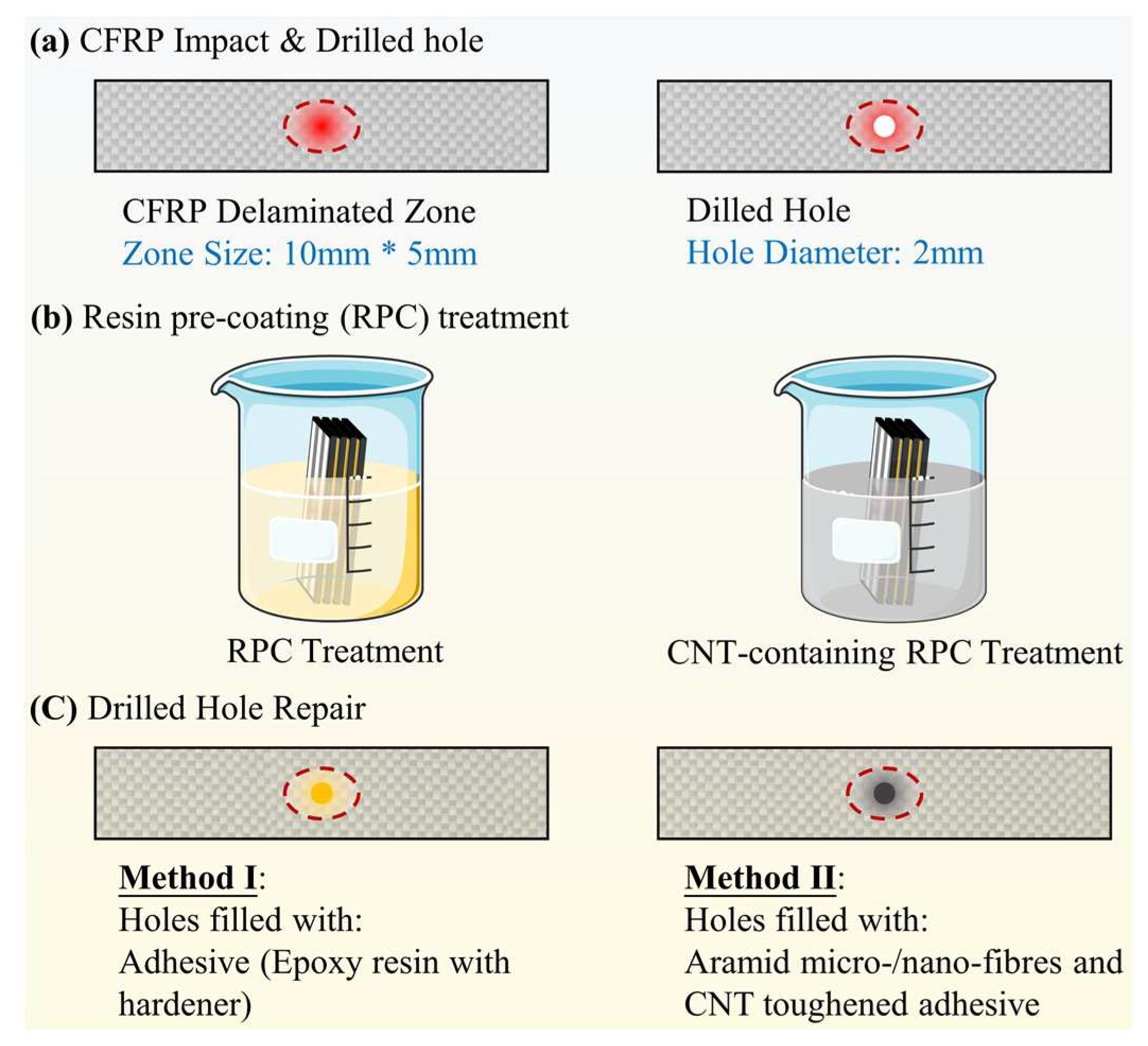

It can be envisaged that even with a drilled hole at the delamination site, complete adhesive filling of sharp delamination crack tips in CFRP is still challenging. The pressureless adhesive repair procedure adopted in the current study is illustrated in

Figure 3. The 1st step is to repair the delamination cracks using the acetone-rich resin pre-coating (RPC) solution with or without CNT. The 2nd step is to fill the drilled hole with epoxy adhesive with or without short or micro-fibre reinforcement. It should be mentioned that the RPC method was first used to penetrate micro-cavities on CFRP and metal substrates to be bonded by adhesives [

24].

Figure 3a illustrates possible adhesive infill if a normal viscous epoxy (with hardener) is used without applying any pressure. Sharp delamination crack tips cannot be filled with epoxy because, without the assistance of external force, normal epoxy adhesive with high viscosity can’t travel into limited crack openings.

Figure 3b,c show the possible repair results using the RPC and RPC

CNT solutions. The acetone-rich RPC and RPC

CNT solutions can easily penetrate deep into the delamination cracks through the capillary action. Only normal epoxy adhesive is used in the drilled holes in

Figure 3a–c. For an optimum repair result,

Figure 3d shows that the drilled hole is filled by the toughened epoxy adhesive reinforced by CNT and aramid pulp (AP) micro-/nano-fibers. Curing of the precoated thin resin layer (without hardener) can only happen gradually from the drilled hole edge from the contact with the normal epoxy (with hardener). Depending on the depth of delamination cracks, the curing time of resin (no hardener) within the delamination cracks may differ. So curing periods of two weeks and three months were tested in this study. It is worth mentioning that it may not actually take that long for the resin to fully cure. The three-month term was selected to prolong the curing time to ensure the adhesive absolutely healed; thus, the repairments can be ideally maximized.

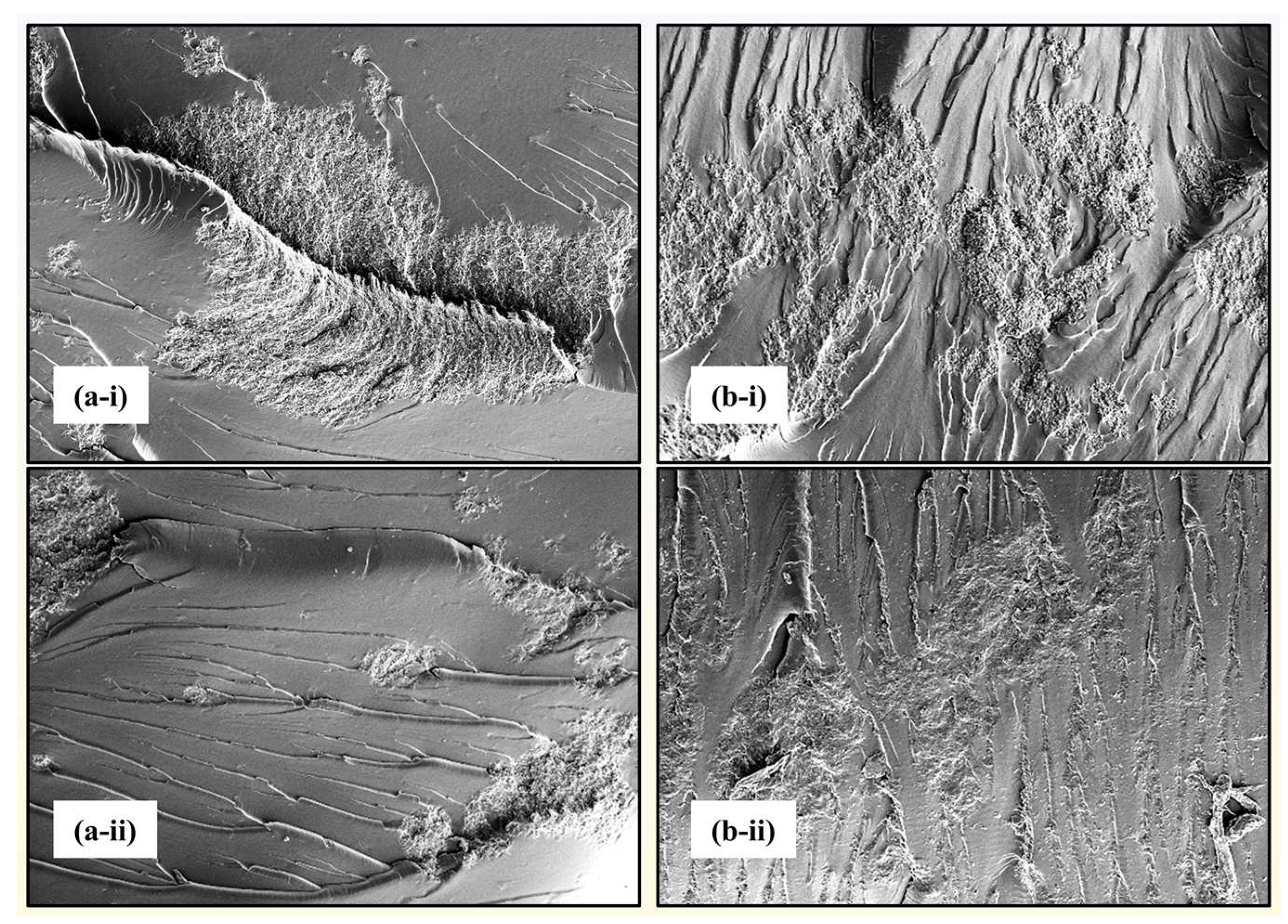

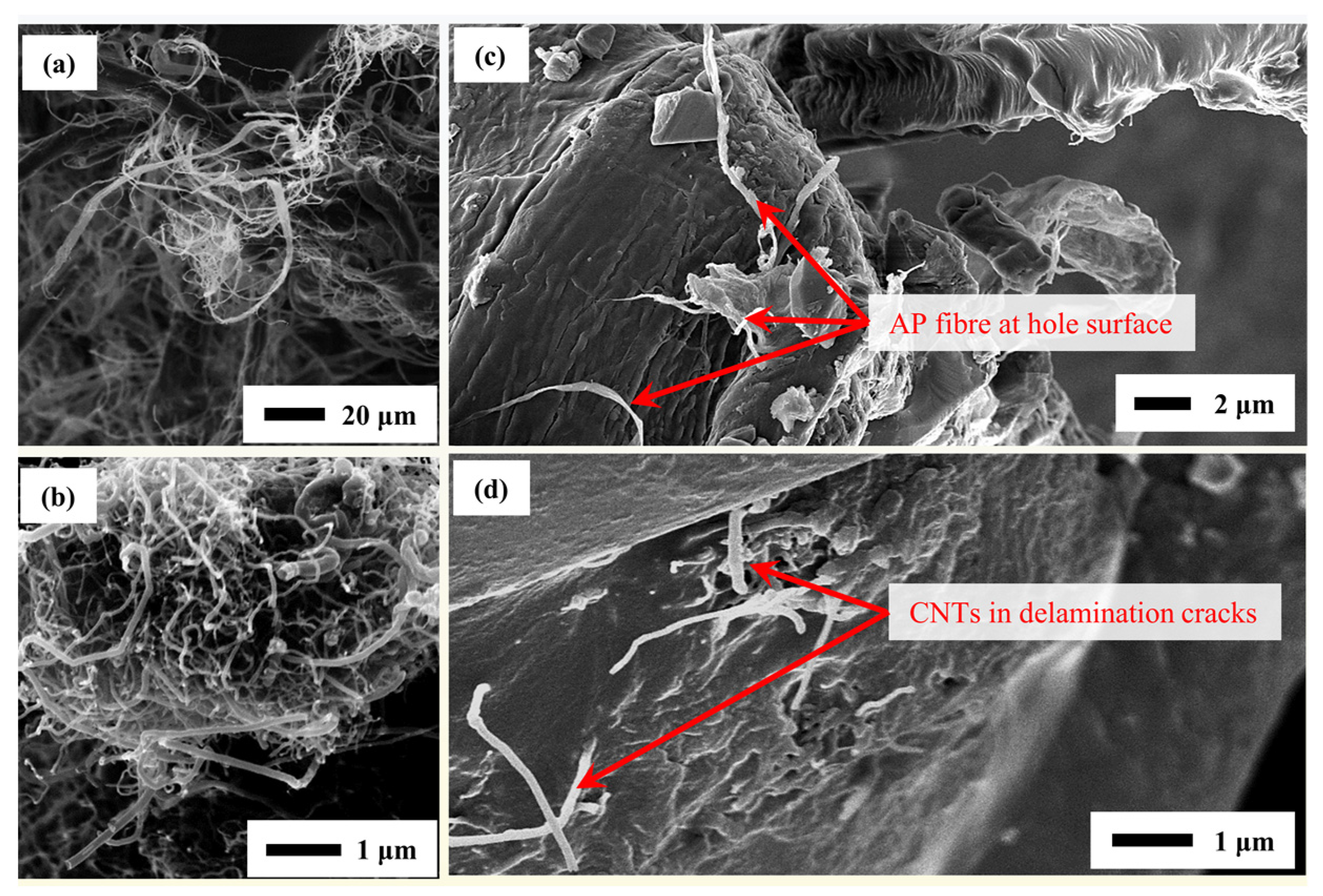

For better understanding how small fibers behaves by RPC treatment, two trails were examined: (1) 15 m/m% of CNT mixed with west system epoxy adhesive (resin to hardener: 5:1) directly by 1 minute mechanical stirring; (2) 15 m/m% of CNT mixed with RPC solution first by 1 minute mechanical stirring; the same portion of hardener was added to the RPC

CNT solution once acetone was completely evaporated. These two sets of mixes were pored into a Teflon mould with standard dumbbell shapes and left until cured. Specimens were failed by extension and the structural details of failed surfaces were detected by SEM. It is clearly demonstrated in

Figure 4 that CNT fibers in adhesive is tangled and distributed unevenly. Thus, relatively slippery fracture surfaces can be witnessed. Contrarily, CNT dispersed in RPC solution can distribute well; therefore, rough surfaces with disentangled fibers are presented. Consequently, this perfect dispersed RPC

CNT solution employed in CFRP delamination repair could receive better restoration outcomes.

RPC solution contains about 90 m/m% of acetone and 10 m/m% of resin (without hardener), and the RPC

CNT solution, consisting of 89 m/m% of acetone, 10 m/m% of resin and 1 m/m% of CNT, contains well-dispersed CNTs. The acetone-rich RPC and RPC

CNT solutions can penetrate deep into those sharp delamination cracks without applying any pressure. However, it should be emphasized that enough time (one hour in a fume hood) should be allocated to allow the evaporation of acetone from those narrow delamination cracks before filling the drilled hole with the normal epoxy (with hardener). After the complete evaporation of acetone, the final epoxy adhesive properties are not affected, as shown by a recent publication [

27].

The necessity of pressureless repair illustrated in

Figure 3 can be understood from the crack-tip stress concentrations illustrated in

Figure 1. Firstly, delamination cracks are very narrow due to the high stiffness of CFRP around 200 GPa. Secondly, without applying any pressure, the viscous epoxy adhesive cannot penetrate deep into those sharp delamination cracks. However, it should be mentioned that both the far-field tensile stress and internal pressure can generate the same positive stress intensity factor K [

15], which can potentially lead to further delamination growth. Therefore, instead of those common repair methods documented in the literature, we propose the pressureless RPC

CNT technique to repair the sharp delamination cracks through the capillary action of the RPC solution.

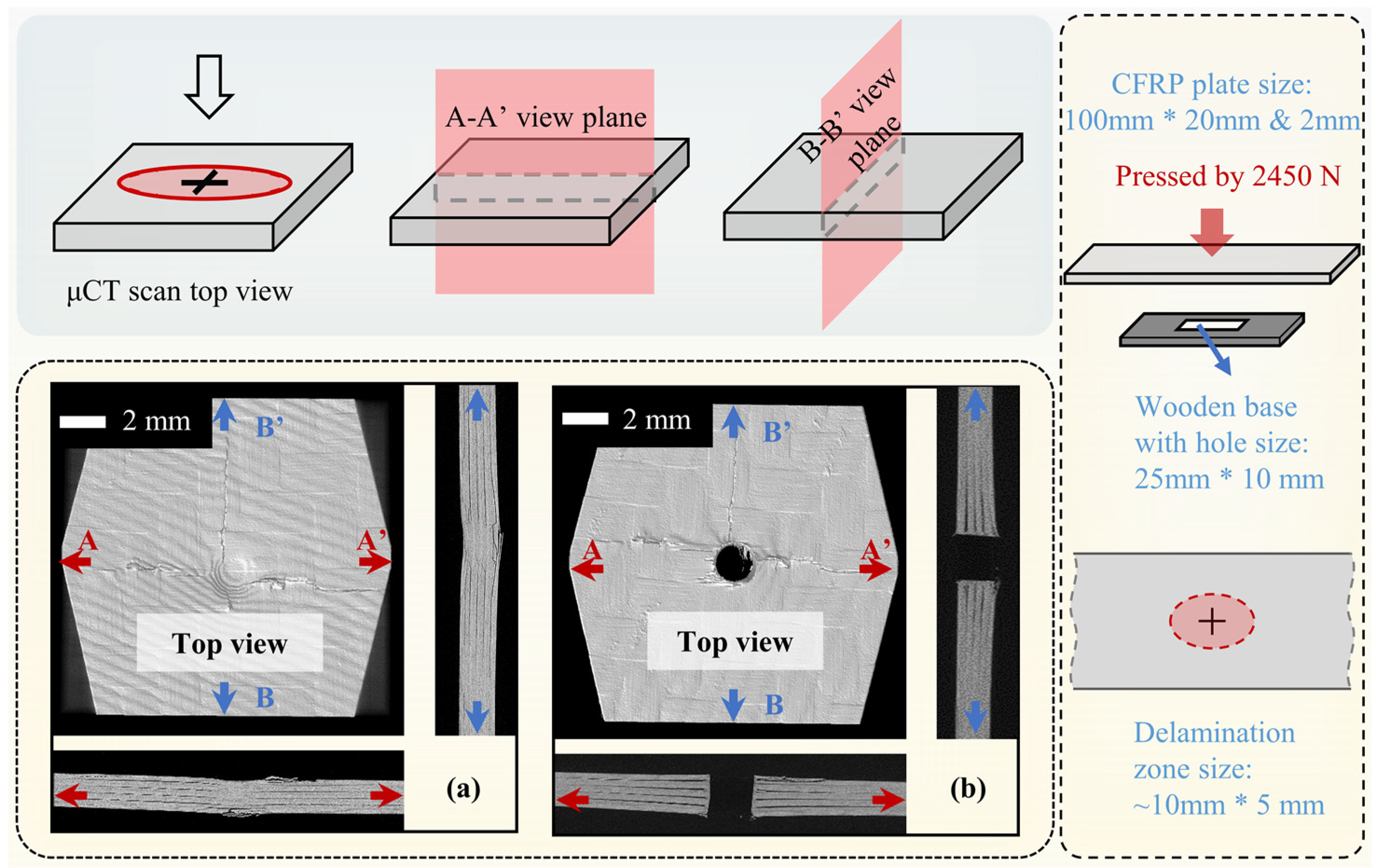

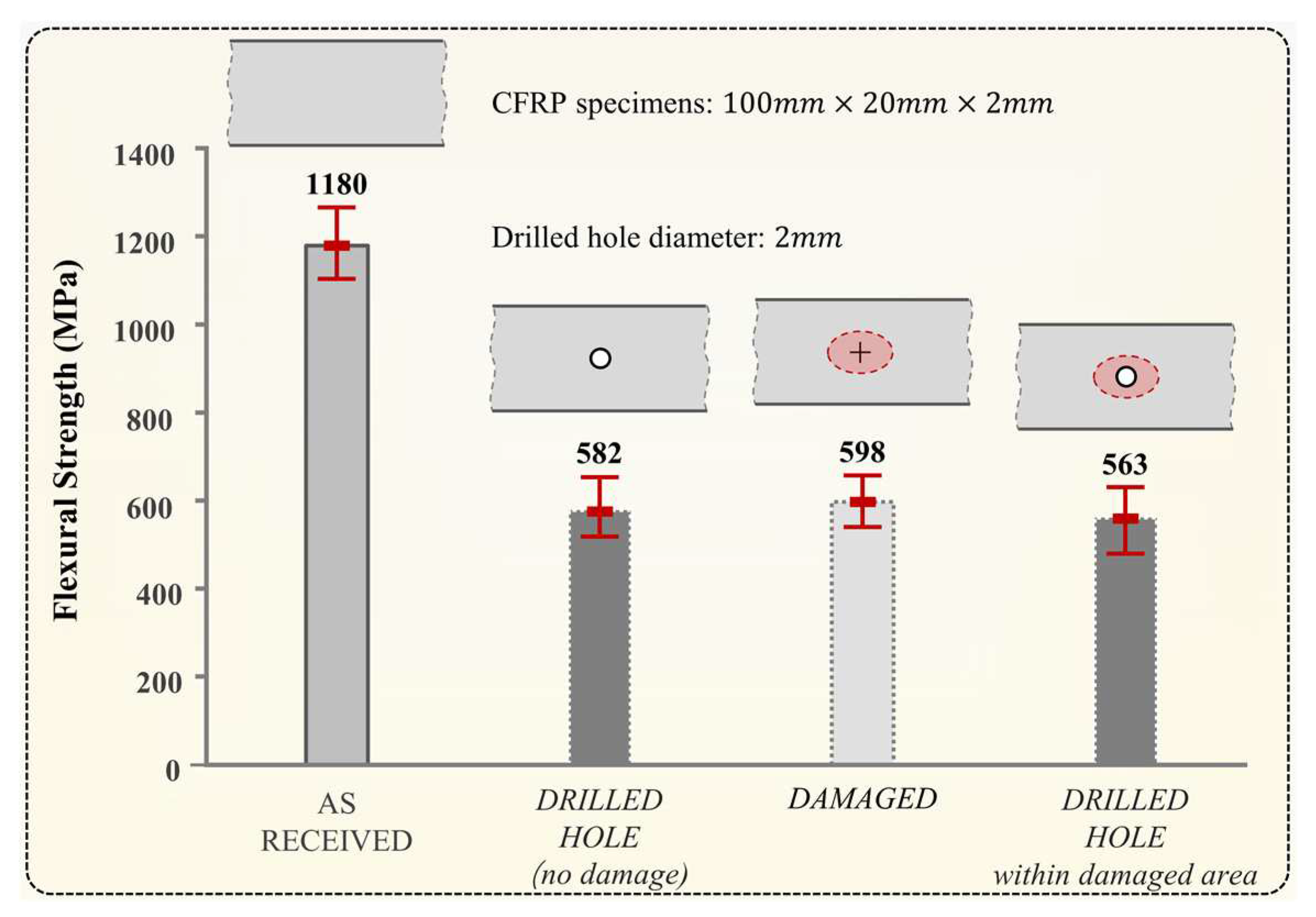

2.1.2. Effects of small drilling hole on flexural strengths of CFRP specimens

Designed 2 mm small hole in

Figure 5 was introduced by an Ozito 500W drill. The drill bit was a tungsten carbide twist drill having a point angle of 140° and a helix angle of 35° with a drill diameter of 2 mm. During the drilling tests, all CFRP specimens were firmly clamped on a wooden base. The drill speed was 1500 RPM with a 10 mm/min moving speed. Then all drilled specimens were ultrasonically cleaned in 97% alcohol base for 30 minutes to remove all CFRP debris.

Composite machining and drilling can introduce edge delamination as discussed in [

28,

29,

30,

31,

32], and the comparison of

Figure 5a,b indeed shows the drilled hole edge has been widened. The effects of drilled holes were measured before the composite repair and shown in

Figure 6. The average flexural strength of “as-received” specimens from three-point-bend (3-P-B) tests is around 1,180 MPa. The as-received specimens were prepared from the commercial CFRP (Carbonwiz Technology Limited, China, consisting of two plies of unidirectional prepreg for inner layers and nine plies of 3K plain-weaved prepreg for outer layers).

The effects of the small drilled hole (1,180 → 582 MPa) are obvious for the CFRP specimens without delamination damage, but are limited for the specimens with the delamination damage (598 → 563 MPa or < 6% reduction). The flexural strength measurements in

Figure 6 provide good references for the effectiveness of the RPC

CNT repair method.

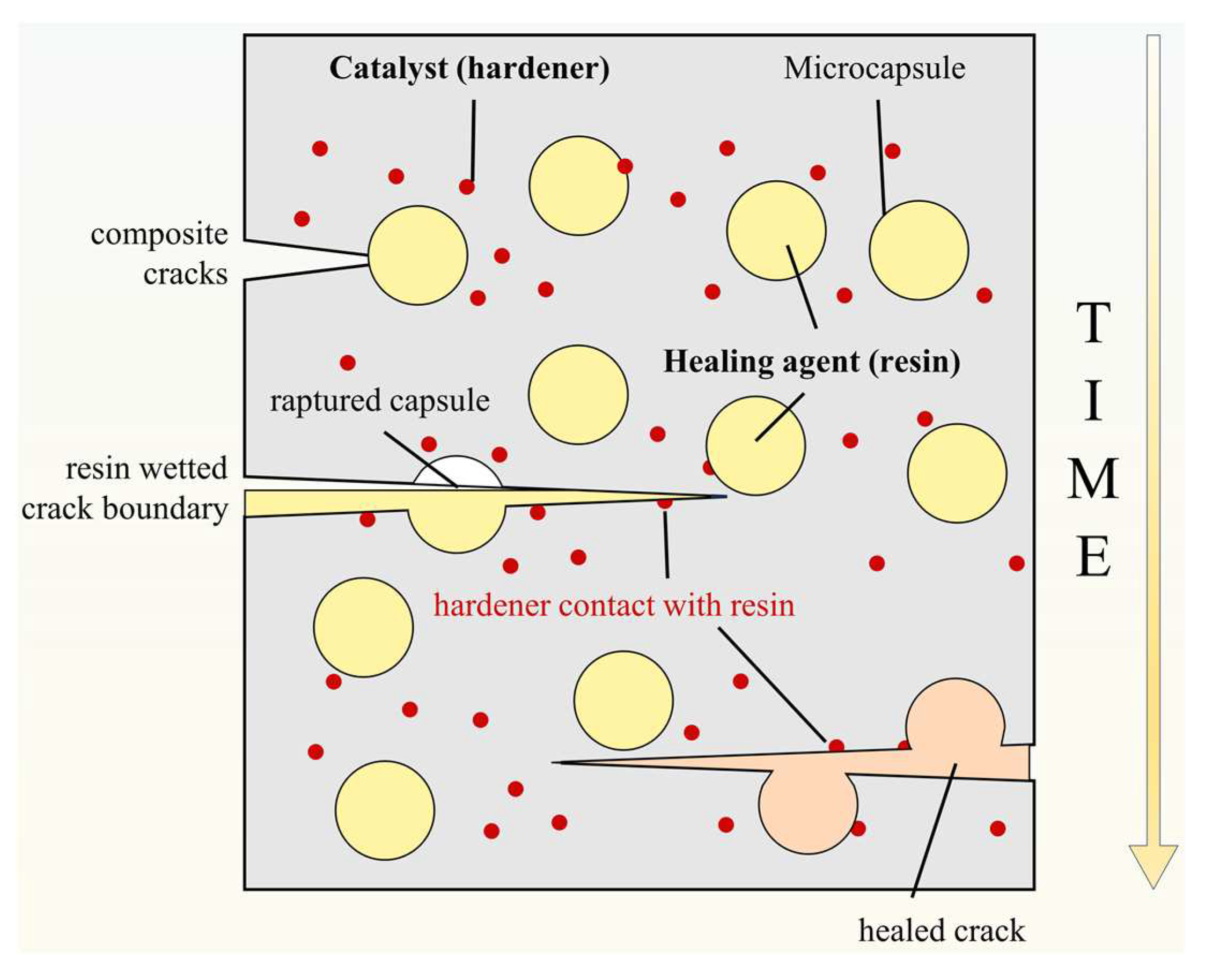

2.1.3. Surface contact curing of resin filled by RPC

Well-studied composite self-healing mechanisms illustrated in

Figure 7 [

33,

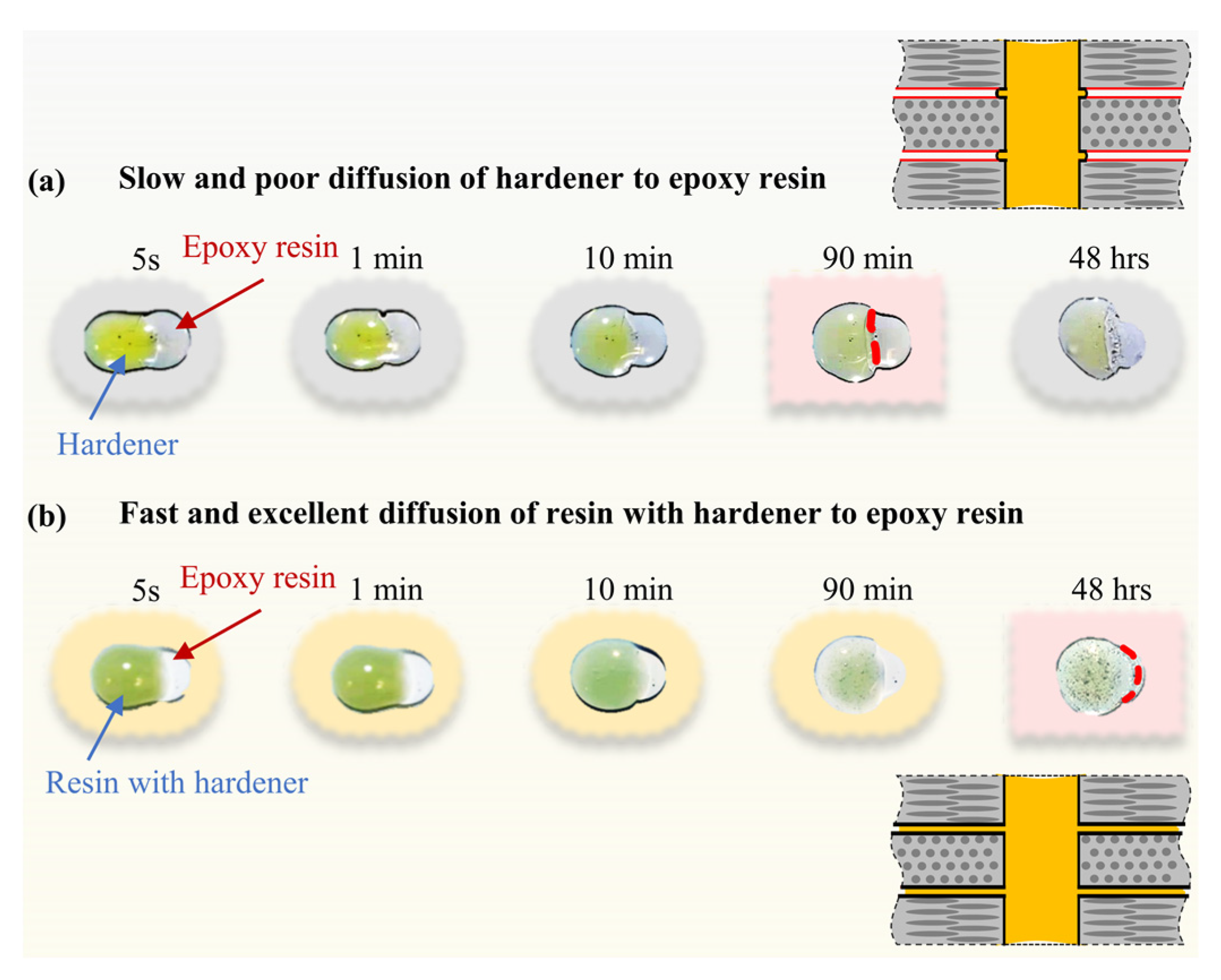

34] can explain how the resin in those delamination cracks filled by RPC is cured after repair. There is no mixing of resin and hardener, and the composite self-repair was completed through diffusion-like contact curing of resin and hardener. The delamination repair in this study follows the same principle. However, the curing time period, e.g., weeks, may vary depending on the lengths or depths of delamination cracks. Two different surface contact curing processes, (1) hardener → resin and (2) resin/hardener mix → resin, have been tested and shown in

Figure 8. For convenience and illustrative purposes, a commercially available Selleys Aradite Super Strength Two-part Epoxy Glue (similar epoxy resin but different type of hardener compared with Western System adhesive) was used for the experiments.

The two experiments in

Figure 8 show the epoxy and hardener mixture is more favorable for the contact curing required by the composite repair since the curing process is faster and more complete by the testing time of 48 hours. The simple experiments in

Figure 8 prove that the composite self-repair mechanisms illustrated in

Figure 7 are feasible. Also, the design of adhesive mix repair after RPC treatment is verified to be more favorable for hardener diffusion.

2.2. Results

2.2.1. Delamination repairs using resin pre-coating (RPC) and RPCCNT solutions

Because of the small drilled hole at the center of a delamination area, it will be interesting to check whether normal epoxy adhesive (resin + hardener) can repair sharp delamination cracks without applying any pressure and whether the micro-/nano-fiber toughened epoxy (used to fill the drilled hole) can have any effect on the flexural strength of CFRP plates.

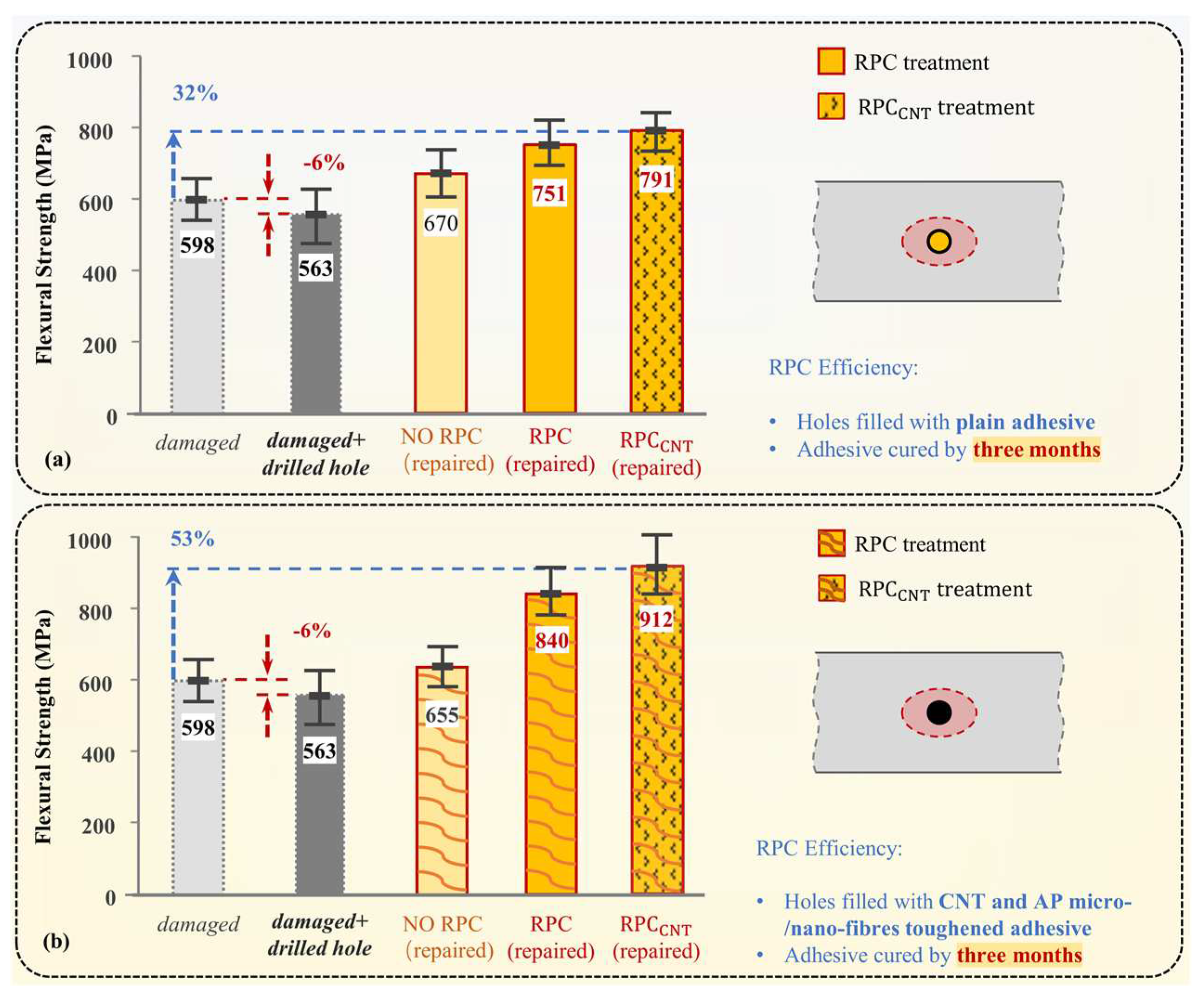

Five specimen groups with different conditions are shown in

Figure 9. The 1st group is for specimens with indentation-induced delamination damage (no repair), and the 2nd group is for specimens with open drilled holes (no repair). Open drilled holes in the remaining three groups in

Figure 9a were filled by normal epoxy adhesive (resin + hardener). In

Figure 9b, the last three groups were filled with CNT&AP micro-/nano-fiber toughened adhesive.

Firstly, the drilled hole at the delamination center only reduced the flexural strength by around 6%. Delamination repair using normal epoxy or CNT and AP toughened epoxy did not make any difference as the flexural strength increase is only around 10%. The resin pre-coating (RPC) method is promising as the strength has been improved by up to 40% (840 MPa). The best result of 912 MPa was obtained by the RPCCNT with the drill hole filled by CNT and AP micro-/nano-fiber toughened epoxy, which shows 53% increase in the flexural strength (from 598 MPa).

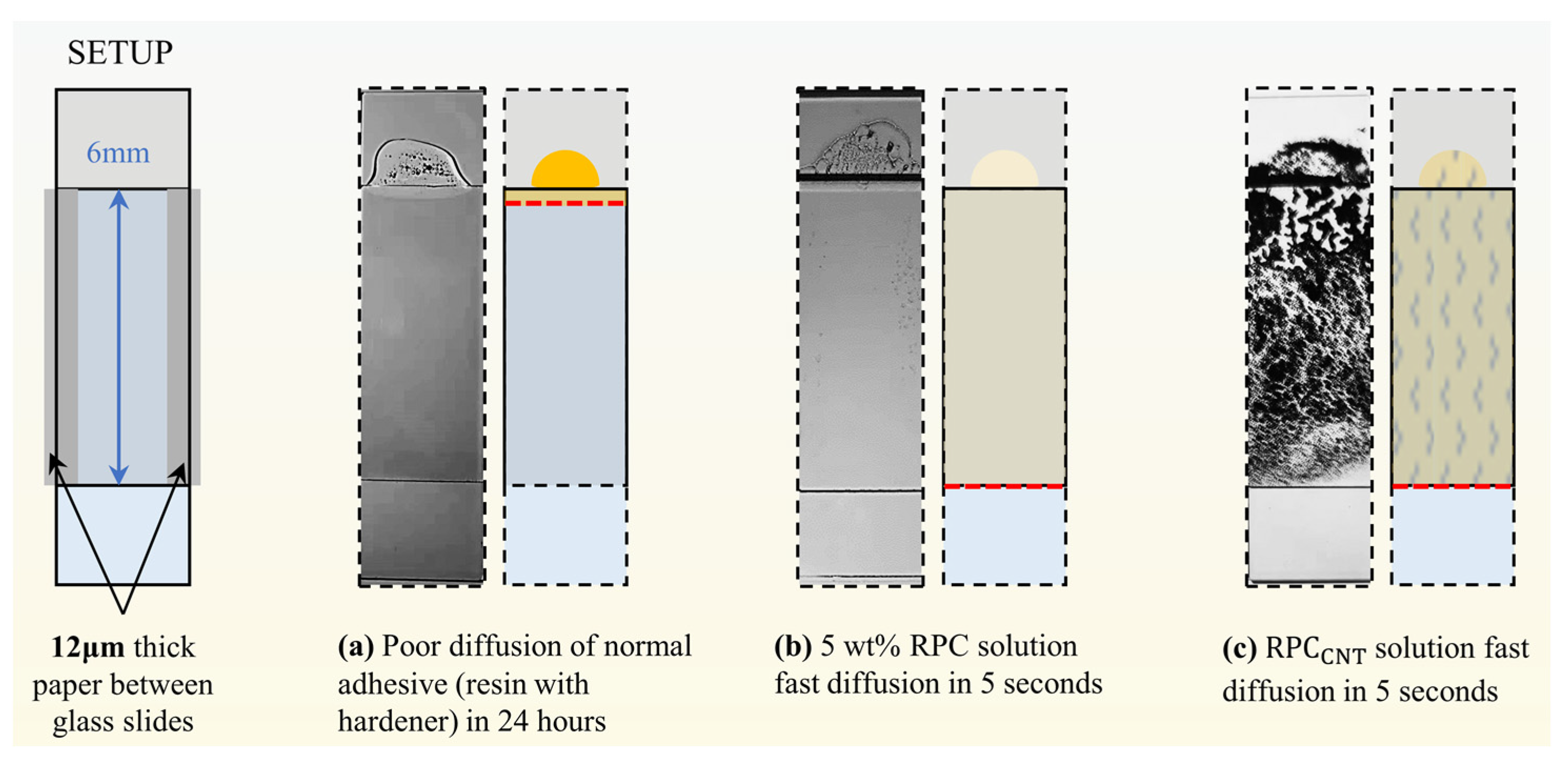

The last group in

Figure 9 with CNT cannot be observed directly in CFRP specimens. So separate experiments were conducted and shown in

Figure 10. Two glass slides were stacked together with a 12μm separation and a 6mm cross-section to simulate similar delamination crack dimensions. Acetone has ultralow viscosity that is feasibly for RPC solution penetrate any crack-like structure easily. So glass slides simulation could tell similar story as in CFRP delamination cracks. Of course, it could be more difficult for viscous epoxy to penetrate into microscopically rough delamination surfaces. As shown in

Figure 10a, the viscous epoxy adhesive (resin + hardener) penetration into the micro-gap between two glass slides was very limited even after 24 hours. In contrast, the RPC solution could penetrate the entire micro-gap in 5 seconds as low viscus RPC solution can diffuse easier and faster by capillary action, as in

Figure 10b. The RPC

CNT solution could do the same in 5 seconds, as shown by the distributed black CNT in

Figure 10c. The CNT inside delamination cracks could provide a useful fiber bridging mechanism, making the pressure repair from the PRC method more effective.

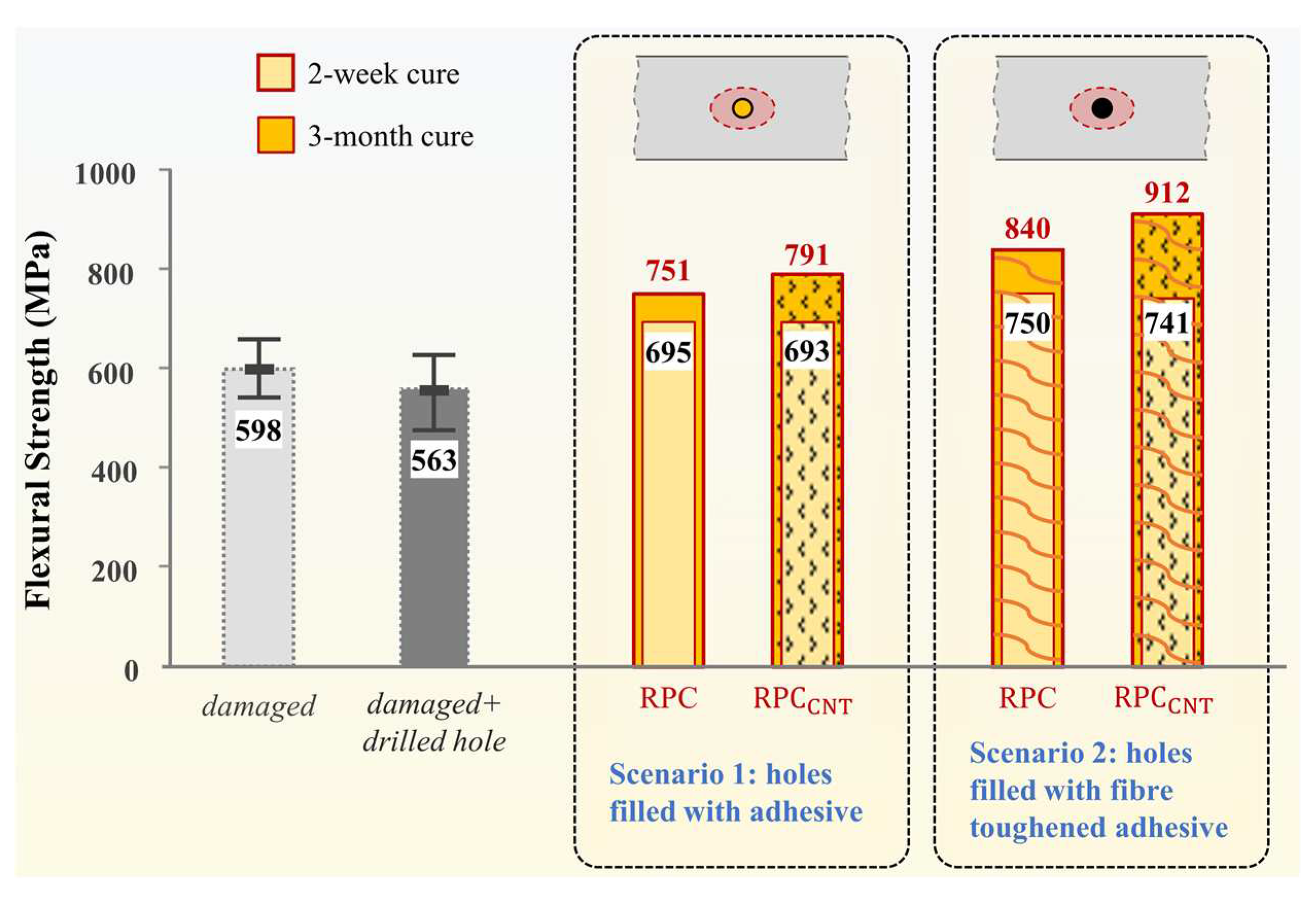

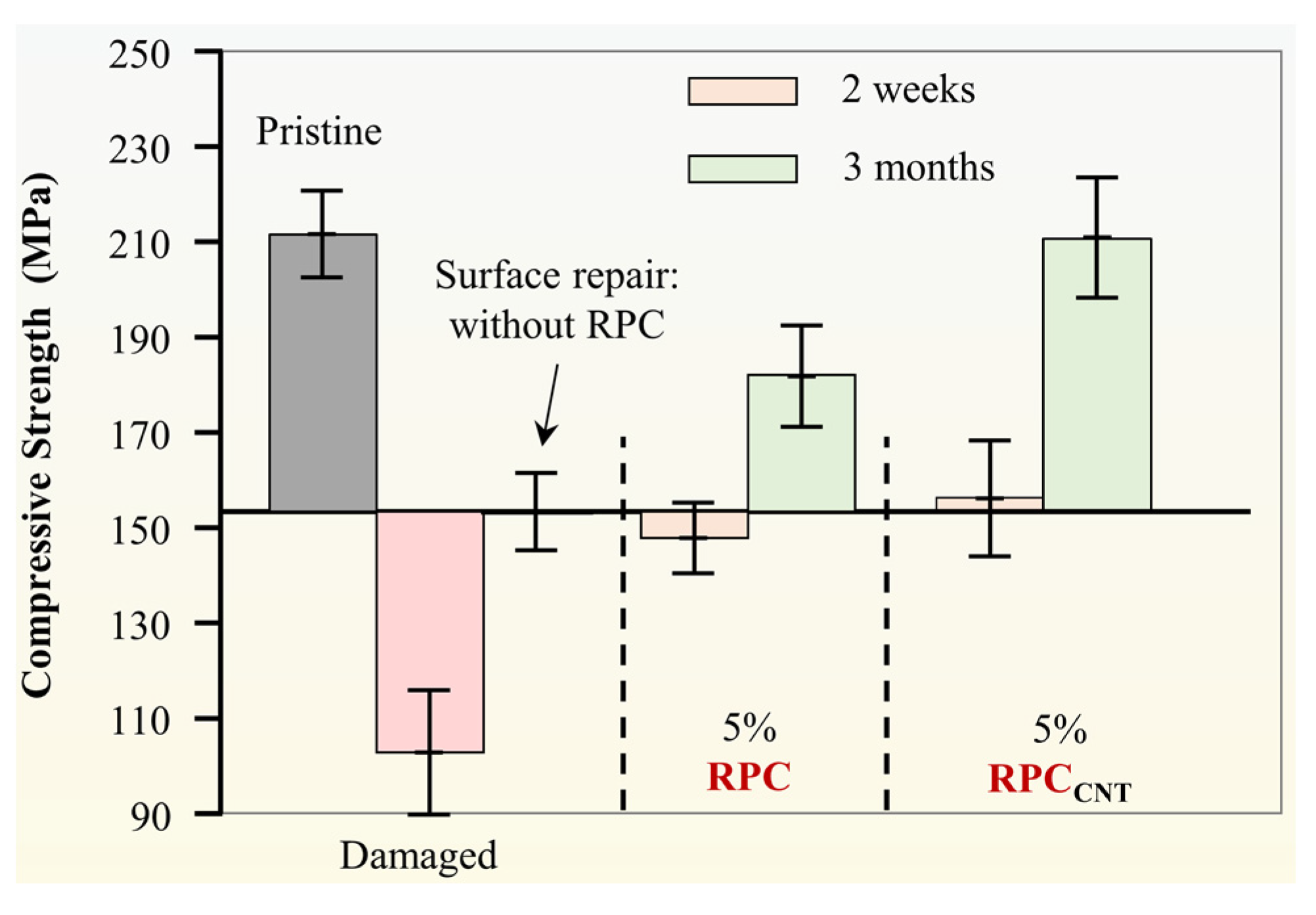

2.2.2. Curing time periods required by RPC and PRCCNT repair methods

The contact curing process for the RPC repair method can be lengthy because the narrow delamination cracks are a few mm deep. So, two curing time periods were tested in this study: 2 weeks and 3 months after the delamination repair. But again, actual complete curing time may not 3-month long.

Figure 11 summarise the flexural strengths with various repair conditions. Interestingly, there was no difference between RPC and RPC

CNT repair methods within the first two weeks, but the advantage of RPC

CNT was evident after three months of curing. The results in

Figure 11 show the curing time indeed should be longer than 2 weeks. This long-term result also confirms the assumption in the literature [

25] that a longer cure is expected to receive a better improvement, which has been approved in the latest research [

26].

2.2.3. CNT and micro-/nano-fibre toughened epoxy for drilled hole

The microstructure features of AP micro-/nano-fibres and CNT are shown in

Figure 12a,b. They were used to reinforce the epoxy adhesive used to fill the drill hole (as illustrated in (c) where AP fibres are presented at drilled hole surface and (d) where CNTs are dispersed into delamination cracks for structural enhancements). The acetone-rich RPC solution again played an important role, which was used to wet CNT and AP to have an even dispersion and removal of any air pockets within the clusters of micro-/nano-fibers. The hardener was added after the evaporation of acetone. The composite adhesive design is as follows: 1 m/m% of AP, 0.5 m/m% of CNT and 98.5 m/m% of adhesive (resin with hardener).

Figure 13 emphasizes the effects of drill hole epoxy filling with and without CNT and AP. All results have the 3 months curing period. The best repair result was achieved by the RPC

CNT and CNT-AP toughened epoxy filling. It should be mentioned the “as-received” specimens in

Figure 13 do not contain drilled holes and delamination damage, so a “77% restoration” (912/1180 MPa) from the RPC

CNT specimens with drilled holes and previous delamination damage was a good outcome.

Since the specimen width is only 20 mm wide, the 2 mm drill hole may have a significant effect on the flexural strength of the narrow specimen or structure. So the same RPC

CNT was tested on specimens with edge delamination (i.e., no drilling is required for delamination repair). Also, Instron 5982 universal testing machine, Instron Corp., USA, was applied to test compressive strengths according to ASTM d 3410/D 3410M - 03. The testing rate was set to 1mm/min and automatically recorded every 0.1s for load and crosshead displacement. The corresponding repair results for 2 weeks and 3 months are shown in

Figure 14. In the case of edge delamination, 100% restoration in the compressive strength is achieved, showing that the RPC

CNT technique is effective in delamination repair. Potentially, the repair results in

Figure 13 can be further improved to close to 100% recovery based on the results in

Figure 14.

3. Materials and Methods

The commercially fabricated CFRP panels (Carbonwiz Technology Limited, China) consisting of two plies of unidirectional prepreg for inner layers and nine plies of 3K plain-weaved prepreg for outer layers were utilized in this research. All specimens were trimmed to sizes of 100 mm

20 mm

2 mm for the repair study, as shown in

Figure 15.

The West System adhesives containing 2,2-bis[p-(2,3-epoxypropoxy)phenyl]-, polymers in the epoxy resin and reaction products of triethylenetetramine with phenol and formaldehyde in the hardener (standard resin to hardener ratio is 5:1) were selected in this study to repair the sharp delamination cracks in CFRP using the RPC technique described in

Section 2. The damaged areas of CFRP introduced by static load are consistent and reproducible compared with impact load [

35]. Thus, the small area delamination in the CFRP plate specimen was introduced by the compressive load up to 2450 N through a spherical indenter with a diameter of around 2 mm. The damaged area at the specimen centre was about 10 by 5 mm, as shown in

Figure 15a. Then the same 2 mm open hole was created at the centre of the delaminated area by a 2 mm drill.

The resin pre-coating (RPC) solution consists of 90 m/m% of acetone and 10 m/m% of resin (without hardener) and the CNT-containing RPC solution (RPC

CNT) consists of 89 m/m% of acetone, 10 m/m% of resin and 1 m/m% of CNT. Simple mechanical stirring with a glass rod is sufficient for the acetone-rich solutions. As shown in

Figure 15b, two different pre-coating methods were utilized (RPC and RPC

CNT treatments) to fill micro-crack tips. For both methods, specimens were soaked into these solutions for 1 minute, then taken out and placed in a fume hood for one hour to ensure complete acetone evaporation. The RPC and RPC

CNT processes were repeated five times.

Finally, the drilled hole was filled with the epoxy adhesive (resin with hardener, 4.5:1) for Method I, and CNT and micro-/nano-fiber toughened epoxy adhesive (resin with hardener, 4.5:1) for Method II, as shown in

Figure 15c. The mixture for Method II consisted of 1 m/m% of Aramid pulp (AP) micro-/nano-fibers, 0.5 m/m% of CNT and 98.5 m/m% of epoxy. Then all repaired specimens were placed in the fume hood for two different curing periods: two weeks and three months. Before flexural testing, all specimens were placed in a dry oven at 80 °C for 24 hours to guarantee the epoxy adhesives were completely cured.

To compare the effectiveness of the repair techniques adopted in this article, simple three-point bend tests (3-P-B) of CFRP plates with different repair conditions were performed using an Instron 5982 testing machine with a 100 KN load cell and at a displacement rate of 1mm/min. Every specimen condition/group had 10 specimens and the average flexural strength and scatters (maximum and minimum) were calculated and recorded.

Specimens with the delamination damage and drilled hole were scanned at 80 KV and 74 μA using an X-ray micro-computed tomography (X-ray μCT) system (Versa 520, Zeiss, Pleasanton, CA, USA) running Scot and Scan software (v12.0.8164.19636 Zeiss). The CT images of overall views and cross-section views (A-A and B-B directions) are shown in

Figure 4, where the drilling process seems to have widened delamination crack openings at the drilled hole edge. Suitable X-ray transmission was achieved using an Air beam filter (no filter). A total of 1602 projections were collected over 360°, each with a 5s exposure. Raw projection data were reconstructed automatically using XMReconstructor softer (v12.0.8164.19636, Zeiss) using the standard 0.7 kernel size recon filter setting. The visualization and analysis of data generated from X-ray μCT scans were performed using Avizo (v.8.1.1, ThermoFisher) software using a customized workflow. The presence of CNT and AP and their distribution inside the delamination cracks were examined by Verios SEM at 5 kV and 100 pA using a TLD detector. All specimens were coated with Pt for SEM observations.

4. Conclusions

The pressureless resin pre-coating (RPC) technique, initially developed for stronger adhesive bonding [

24], was adopted successfully to repair sharp delamination cracks in CFRP in this study. With CNT reinforcement, the RPC

CNT was able to take CNT deep into the narrow delamination cracks because of the excellent penetrating behavior of acetone and the capillary action generated by acetone evaporation, as shown in

Figure 13, 77% restoration of flexural strength had been achieved by the RPC

CNT method for the small area internal delamination and 100% restoration of compressive strength was achieved for edge delamination. Specific findings are summarized as follows.

- (1)

A small drilled hole of 2 mm in diameter introduced at the center of delamination zone did not significantly weaken the CFRP specimens of 20 mm in width, but created access to the internal delamination cracks required by the RPC method.

- (2)

The RPC solution consisting of 90 m/m% of acetone and 10 m/m% of resin has excellent penetrating properties and no pressure is required. The repair results with and without RPC in

Figure 9 and

Figure 14 show that the acetone-rich RPC solution plays a significant role in successful delamination repairs.

- (3)

The CNT-containing RPC solution or RPCCNT is more effective due to CNT-toughening and strengthening of the filled adhesive. The RPC solution can transport CNT deep into narrow cracks, as shown by the tests in

Figure 10 and

Figure 12.

- (4)

The contact curing experiments in

Figure 8 show that a resin and hardener mixture contact with resin (without hardener) is more favorable for “diffusion of polymerization” than the simple hardener and resin contact. A long curing period (> 2 weeks), e.g., 3 months, is required for complete contact curing, depending on the depth of delamination cracks.

- (5)

Finally, the CNT and AP micro-/nano-fibers toughened epoxy for the drilled hole provides extra benefits because of fiber strengthening

Author Contributions

Gang Han: Conceptualization, Methodology, Formal analysis, Investigation, Writing—Original Draft. Xiaozhi Hu: Project administration, Supervision, Writing—review & editing.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Shiekh, P.A., Mohammed, S.A., Gupta, S., Das, A., Meghwani, H., Maulik, S.K., Banerjee, S.K. and Kumar, A., 2022. Oxygen releasing and antioxidant breathing cardiac patch delivering exosomes promotes heart repair after myocardial infarction. Chemical Engineering Journal, 428, p.132490. [CrossRef]

- Aabid, A., Hrairi, M. and Ali, J.S.M., 2020. Optimization of composite patch repair for center-cracked rectangular plate using design of experiments method. Materials Today: Proceedings, 27, pp.1713-1719. [CrossRef]

- Fong, L.S., Winlaw, D.S. and Orr, Y., 2019. Is the modified single-patch repair superior to the double-patch repair of complete atrioventricular septal defects?. Interactive CardioVascular and Thoracic Surgery, 28(3), pp.427-431. [CrossRef]

- Srinivasan, D.V., Padma, S.R. and Idapalapati, S., 2022. Comparative study of composite scarf and strap joints for equivalent repair signature under uniaxial tension. Composites Part A: Applied Science and Manufacturing, 158, p.106950. [CrossRef]

- Campilho, R.D.S.G., De Moura, M.F.S.F., Pinto, A.M.G., Morais, J.J.L. and Domingues, J.J.M.S., 2009. Modelling the tensile fracture behaviour of CFRP scarf repairs. Composites Part B: Engineering, 40(2), pp.149-157. [CrossRef]

- Gunnion, A.J. and Herszberg, I., 2006. Parametric study of scarf joints in composite structures. Composite structures, 75(1-4), pp.364-376. [CrossRef]

- Yang, L., Yang, Y., He, S., Chen, G., Ao, C. and Zhang, W., 2021. Scarf patch repair of honeycomb sandwich composites and its simulation optimisation. Plastics, Rubber and Composites, 50(6), pp.307-314. [CrossRef]

- Sun, C., Zhao, W., Zhou, J., Altenaiji, M., Cantwell, W.J., Wang, Q.Y. and Guan, Z.W., 2021. Mechanical behaviour of composite laminates repaired with a stitched scarf patch. Composite Structures, 255, p.112928. [CrossRef]

- Jiang, H., Ren, Y., Zhang, S., Liu, Z., Yu, G. and Xiang, J., 2019. Damage and perforation resistance behaviors induced by projectile impact load on bonding-patch repaired and scarf-patch repaired composite laminates. International Journal of Damage Mechanics, 28(4), pp.502-537. [CrossRef]

- Guan, W., Su, Y. and Tong, G., 2019, December. Static and Fatigue Properties of Scarf Patch Repaired Composite Laminates: An Experimental Study. In IOP Conference Series: Materials Science and Engineering (Vol. 677, No. 2, p. 022010). IOP Publishing. [CrossRef]

- Feng, W., Xu, F., Yuan, J., Zang, Y. and Zhang, X., 2019. Focusing on in-service repair to composite laminates of different thicknesses via scarf-repaired method. Composite Structures, 207, pp.826-835. [CrossRef]

- Lai, W.L., Saeedipour, H. and Goh, K.L., 2021. Experimental assessment of drilling-induced damage in impacted composite laminates for resin-injection repair: Influence of open/blind hole-hole interaction and orientation. Composite Structures, 271, p.114153. [CrossRef]

- Lai, W.L., Saeedipour, H. and Goh, K.L., 2020. Mechanical properties of low-velocity impact damaged carbon fibre reinforced polymer laminates: effects of drilling holes for resin-injection repair. Composite Structures, 235, p.111806. [CrossRef]

- Thunga, M., Bauer, A., Obusek, K., Meilunas, R., Akinc, M. and Kessler, M.R., 2014. Injection repair of carbon fiber/bismaleimide composite panels with bisphenol E cyanate ester resin. Composites science and technology, 100, pp.174-181. [CrossRef]

- Irwin, G.R., 1968. Linear fracture mechanics, fracture transition, and fracture control. Engineering fracture mechanics, 1(2), pp.241-257.

- Han, G., Tan, B., Cheng, F., Wang, B., Leong, Y.K. and Hu, X., 2022. CNT toughened aluminium and CFRP interface for strong adhesive bonding. Nano Materials Science, 4(3), pp.266-275. [CrossRef]

- Jiang, H., Ji, Y., Hu, Y., Hu, X. and Ren, Y., 2022. Interfacial design and flexural property of CFRP/aluminum-honeycomb sandwich with Aramid-pulp micro/nano-fiber interlays. Composite Structures, 289, p.115486. [CrossRef]

- Hu, Y., Zhang, J., Wang, L., Jiang, H., Cheng, F. and Hu, X., 2022. A simple and effective resin pre-coating treatment on grinded, acid pickled and anodised substrates for stronger adhesive bonding between Ti-6Al-4V titanium alloy and CFRP. Surface and Coatings Technology, 432, p.128072. [CrossRef]

- Tan, B., Hu, Y., Yuan, B., Hu, X. and Huang, Z., 2021. Optimizing adhesive bonding between CFRP and Al alloy substrate through resin pre-coating by filling micro-cavities from sandblasting. International Journal of Adhesion and Adhesives, 110, p.102952. [CrossRef]

- Cheng, F., Hu, Y., Zhang, X., Hu, X. and Huang, Z., 2021. Adhesive bond strength enhancing between carbon fiber reinforced polymer and aluminum substrates with different surface morphologies created by three sulfuric acid solutions. Composites Part A: Applied Science and Manufacturing, 146, p.106427. [CrossRef]

- Tan, B., Ji, Y., Hu, Y., Yuan, B., Hu, X. and Huang, Z., 2020. Pretreatment using diluted epoxy adhesive resin solution for improving bond strength between steel and wood surfaces. International Journal of Adhesion and Adhesives, 98, p.102502. [CrossRef]

- Cheng, F., Hu, Y., Lv, Z., Chen, G., Yuan, B., Hu, X. and Huang, Z., 2020. Directing helical CNT into chemically-etched micro-channels on aluminum substrate for strong adhesive bonding with carbon fiber composites. Composites Part A: Applied Science and Manufacturing, 135, p.105952. [CrossRef]

- Liu, W., Zheng, Y., Hu, X., Han, X. and Chen, Y., 2019. Interfacial bonding enhancement on the epoxy adhesive joint between engineered bamboo and steel substrates with resin pre-coating surface treatment. Wood Science and Technology, 53, pp.785-799. [CrossRef]

- Wang, B., Bai, Y., Hu, X. and Lu, P., 2016. Enhanced epoxy adhesion between steel plates by surface treatment and CNT/short-fibre reinforcement. Composites Science and Technology, 127, pp.149-157. [CrossRef]

- Ji, Y., Yuan, B., Hu, X., Jiang, H. and Qiao, Y., 2022. Repairing sharp delamination cracks in CFRP through capillary action of acetone-diluted resin solution. Composites Science and Technology, 219, p.109249. [CrossRef]

- Han, G., Yuan, B. and Hu, X., 2023. Restoration of Compressive Strength of CFRP Plates with Edge Delamination through CNT Crack-Bridging Deposited by Resin Pre-Coating Solution. Composites Part A: Applied Science and Manufacturing, p.107798. [CrossRef]

- Ji, Y., Chen, Y., Han, X., Hu, X., Yuan, B. and Qiao, Y., 2020. Effect of acetone on mechanical properties of epoxy used for surface treatment before adhesive bonding. Polymer Testing, 86, p.106492. [CrossRef]

- Xu, J., Lin, T., Davim, J.P., Chen, M. and El Mansori, M., 2021. Wear behavior of special tools in the drilling of CFRP composite laminates. Wear, 476, p.203738. [CrossRef]

- Xu, C., Wang, Y., Xu, J. and Liu, X., 2020. Design of internal-chip-removal drill for CFRP drilling and study of influencing factors of drilling quality. The International Journal of Advanced Manufacturing Technology, 106, pp.1657-1669. [CrossRef]

- Kwon, B.C., Mai, N.D.D., Cheon, E.S. and Ko, S.L., 2020. Development of a step drill for minimization of delamination and uncut in drilling carbon fiber reinforced plastics (CFRP). The International Journal of Advanced Manufacturing Technology, 106, pp.1291-1301. [CrossRef]

- Qiu, X., Li, P., Li, C., Niu, Q., Chen, A., Ouyang, P. and Ko, T.J., 2019. New compound drill bit for damage reduction in drilling CFRP. International Journal of Precision Engineering and Manufacturing-Green Technology, 6, pp.75-87.

- Su, F., Zheng, L., Sun, F., Wang, Z., Deng, Z. and Qiu, X., 2018. Novel drill bit based on the step-control scheme for reducing the CFRP delamination. Journal of Materials Processing Technology, 262, pp.157-167. [CrossRef]

- Kanu, N.J., Gupta, E., Vates, U.K. and Singh, G.K., 2019. Self-healing composites: A state-of-the-art review. Composites Part A: Applied Science and Manufacturing, 121, pp.474-486.

- Patrick, J.F., Robb, M.J., Sottos, N.R., Moore, J.S. and White, S.R., 2016. Polymers with autonomous life-cycle control. Nature, 540(7633), pp.363-370. [CrossRef]

- Thunga, M., Larson, K., Lio, W., Weerasekera, T., Akinc, M. and Kessler, M.R., 2013. Low viscosity cyanate ester resin for the injection repair of hole-edge delaminations in bismaleimide/carbon fiber composites. Composites Part A: Applied Science and Manufacturing, 52, pp.31-37. [CrossRef]

Figure 1.

(

a) Large area delamination in CFRP repaired with scarf, patch, and resin injection method. (

b) Those CFRP repair methods can potentially trigger further crack propagation or leave unfilled crack tips in CFRP. (

c) Applying either external tensile stress or internal pressure will create the same infinite stress concentration at the delamination crack tip [

15], i.e., further delamination may be induced by the internal pressure applied during the g repair.

Figure 1.

(

a) Large area delamination in CFRP repaired with scarf, patch, and resin injection method. (

b) Those CFRP repair methods can potentially trigger further crack propagation or leave unfilled crack tips in CFRP. (

c) Applying either external tensile stress or internal pressure will create the same infinite stress concentration at the delamination crack tip [

15], i.e., further delamination may be induced by the internal pressure applied during the g repair.

Figure 2.

Small area delamination around a few millimeters may be too small for scarf and patch repair. A small drilled hole at the delamination site with pressureless resin pre-coating (RPC) can “ideally” repair small area delamination cracks to prevent further delamination propagation.

Figure 2.

Small area delamination around a few millimeters may be too small for scarf and patch repair. A small drilled hole at the delamination site with pressureless resin pre-coating (RPC) can “ideally” repair small area delamination cracks to prevent further delamination propagation.

Figure 3.

(a) Cross-section of a small drilled hole at the delamination site, and the infill of epoxy (resin with hardener) is hindered by limited delamination crack opening and high epoxy viscosity. (b) Through capillary action, the RPC solution can fill the entire delamination crack (left), then normal adhesive (resin and hardener) is used to fill the drilled hole. Partial curing within the delamination cracks in two weeks (middle) and completely cured in three months (right). (c) The RPCCNT solution is used for optimum repair result (left), followed normal epoxy adhesive with the two-week curing period (middle), and complete curing after three months (right). (d) The drilled hole can also be reinforced by epoxy with aramid pulp micro-/nano-fibers and CNT.

Figure 3.

(a) Cross-section of a small drilled hole at the delamination site, and the infill of epoxy (resin with hardener) is hindered by limited delamination crack opening and high epoxy viscosity. (b) Through capillary action, the RPC solution can fill the entire delamination crack (left), then normal adhesive (resin and hardener) is used to fill the drilled hole. Partial curing within the delamination cracks in two weeks (middle) and completely cured in three months (right). (c) The RPCCNT solution is used for optimum repair result (left), followed normal epoxy adhesive with the two-week curing period (middle), and complete curing after three months (right). (d) The drilled hole can also be reinforced by epoxy with aramid pulp micro-/nano-fibers and CNT.

Figure 4.

(a) CNT mixed with adhesive directly witnesses an uneven distribution in the cured adhesive block and trunky fibers can only accumulate at separate spots; (b) CNT dispersed into RPC solution can distribute more evenly and disentangled fibers tend to increase the roughness of the entire surface.

Figure 4.

(a) CNT mixed with adhesive directly witnesses an uneven distribution in the cured adhesive block and trunky fibers can only accumulate at separate spots; (b) CNT dispersed into RPC solution can distribute more evenly and disentangled fibers tend to increase the roughness of the entire surface.

Figure 5.

CFRP specimens of dimensions of 100mm 20mm 2mm were compressed by 2450 N. The supporting base has a 25mm 10mm hole in the middle. A small delamination zone (around 10mm 5mm) was generated. Micro-CT scan of CFRP before and after drilling the small hole (2mm in diameter) on the damaged CFRP strip.

Figure 5.

CFRP specimens of dimensions of 100mm 20mm 2mm were compressed by 2450 N. The supporting base has a 25mm 10mm hole in the middle. A small delamination zone (around 10mm 5mm) was generated. Micro-CT scan of CFRP before and after drilling the small hole (2mm in diameter) on the damaged CFRP strip.

Figure 6.

The specimens with the drilled hole and delamination damage (10 per group) have similar flexural strengths (582–598 MPa). The drilled hope through the delamination area has limited influence on the flexural strength (598 → 563 MPa).

Figure 6.

The specimens with the drilled hole and delamination damage (10 per group) have similar flexural strengths (582–598 MPa). The drilled hope through the delamination area has limited influence on the flexural strength (598 → 563 MPa).

Figure 7.

Contact curing in self-repaired composites [

33,

34], i.e., no resin and hardener mixing, and the polymerization (or curing) occurred through surface contact and “diffusion”.

Figure 7.

Contact curing in self-repaired composites [

33,

34], i.e., no resin and hardener mixing, and the polymerization (or curing) occurred through surface contact and “diffusion”.

Figure 8.

Epoxy contact curing on clean glass slide. (a) Slow contact “diffusion” of hardener → resin (without hardener). Curing of the contacting interface started at 90 minutes. There was little change around the original contact region even after 48 hours. (b) Fast contact “diffusion” of the resin/hardener mixture → resin (without hardener). After 90 min, self-mixing and curing had occurred. The curing process was continued to 48 hours.

Figure 8.

Epoxy contact curing on clean glass slide. (a) Slow contact “diffusion” of hardener → resin (without hardener). Curing of the contacting interface started at 90 minutes. There was little change around the original contact region even after 48 hours. (b) Fast contact “diffusion” of the resin/hardener mixture → resin (without hardener). After 90 min, self-mixing and curing had occurred. The curing process was continued to 48 hours.

Figure 9.

Flexural strengths (3-P-B) with drilled hole effects and reinforcements and with a 3-month curing period. (a) Drilled hole filled by plain epoxy (except 2nd condition), (b) drilled hole filled by CNT and AP micro-/nano-fiber toughened epoxy (except 2nd condition). Each group contains 10 specimens. Without RPC, the drill hole reinforcements have no effect. RPCCNT together with drill hole reinforcements produced the best repair result.

Figure 9.

Flexural strengths (3-P-B) with drilled hole effects and reinforcements and with a 3-month curing period. (a) Drilled hole filled by plain epoxy (except 2nd condition), (b) drilled hole filled by CNT and AP micro-/nano-fiber toughened epoxy (except 2nd condition). Each group contains 10 specimens. Without RPC, the drill hole reinforcements have no effect. RPCCNT together with drill hole reinforcements produced the best repair result.

Figure 10.

Infiltration experiments between two glass slides. (a) Very limited infiltration from normal epoxy adhesive (resin + hardener) even after 24 hours due to its high viscosity. (b) The acetone-rich RPC solution filled the micro-opening between two glass slides in 5 seconds. (c) The RPCCNT solution also filled in the micro-opening in 5 seconds, as shown by the distributed black CNT.

Figure 10.

Infiltration experiments between two glass slides. (a) Very limited infiltration from normal epoxy adhesive (resin + hardener) even after 24 hours due to its high viscosity. (b) The acetone-rich RPC solution filled the micro-opening between two glass slides in 5 seconds. (c) The RPCCNT solution also filled in the micro-opening in 5 seconds, as shown by the distributed black CNT.

Figure 11.

Effect of curing time periods (2-week & 3-month) on RPC and RPCCNT repairs. By 2 weeks, RPC and RPCCNT produced similar results. By 3 months, RPCCNT produced noticeably higher strengths.

Figure 11.

Effect of curing time periods (2-week & 3-month) on RPC and RPCCNT repairs. By 2 weeks, RPC and RPCCNT produced similar results. By 3 months, RPCCNT produced noticeably higher strengths.

Figure 12.

(a) Aramid pulp (AP) micro-/nano-fibres with diameters from around 200 nm up to around 8 μm and lengths less than around 500 μm. (b) CNT with the diameter from around 5 nm to 100 nm and length up to 10 μm. The RPC solution was used to wet CNT and AP first for easy mixing and removal of air pockets. (c) AP fibres are witnessed at drilled hole surface and (d) CNTs are well engineered into delamination cracks by RPC solution.

Figure 12.

(a) Aramid pulp (AP) micro-/nano-fibres with diameters from around 200 nm up to around 8 μm and lengths less than around 500 μm. (b) CNT with the diameter from around 5 nm to 100 nm and length up to 10 μm. The RPC solution was used to wet CNT and AP first for easy mixing and removal of air pockets. (c) AP fibres are witnessed at drilled hole surface and (d) CNTs are well engineered into delamination cracks by RPC solution.

Figure 13.

Dilled hole epoxy filling with and without CNT-AP toughening, based on the three-month curing period. The best result is from RPCCNT with the CNT-AP toughened epoxy for the drilled hole.

Figure 13.

Dilled hole epoxy filling with and without CNT-AP toughening, based on the three-month curing period. The best result is from RPCCNT with the CNT-AP toughened epoxy for the drilled hole.

Figure 14.

Edge delamination repair using the same RPC

CNT method (used for repair of the small area delamination with drilled hole), which produced 100% of restoration of the compressive strength [

26].

Figure 14.

Edge delamination repair using the same RPC

CNT method (used for repair of the small area delamination with drilled hole), which produced 100% of restoration of the compressive strength [

26].

Figure 15.

(a) Small delamination area (around 10 5 mm) was generated in CFRP specimen of 20 mm wide (left) and 2mm drilled hole was introduced at the centre. (b) All CFRP specimens were put into the RPC or RPCCNT solution and then taken out for acetone evaporation. The RPC process was repeated several times to ensure delamination cracks were filled. (c) Final filling with epoxy (resin and hardener mixture) or with CNT and micro-fiber toughened epoxy (with hardener) for the long process of curing or polymerization within the thin resin fillings (no hardener) in delamination cracks deposited by RPC.

Figure 15.

(a) Small delamination area (around 10 5 mm) was generated in CFRP specimen of 20 mm wide (left) and 2mm drilled hole was introduced at the centre. (b) All CFRP specimens were put into the RPC or RPCCNT solution and then taken out for acetone evaporation. The RPC process was repeated several times to ensure delamination cracks were filled. (c) Final filling with epoxy (resin and hardener mixture) or with CNT and micro-fiber toughened epoxy (with hardener) for the long process of curing or polymerization within the thin resin fillings (no hardener) in delamination cracks deposited by RPC.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).