Submitted:

24 October 2023

Posted:

25 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

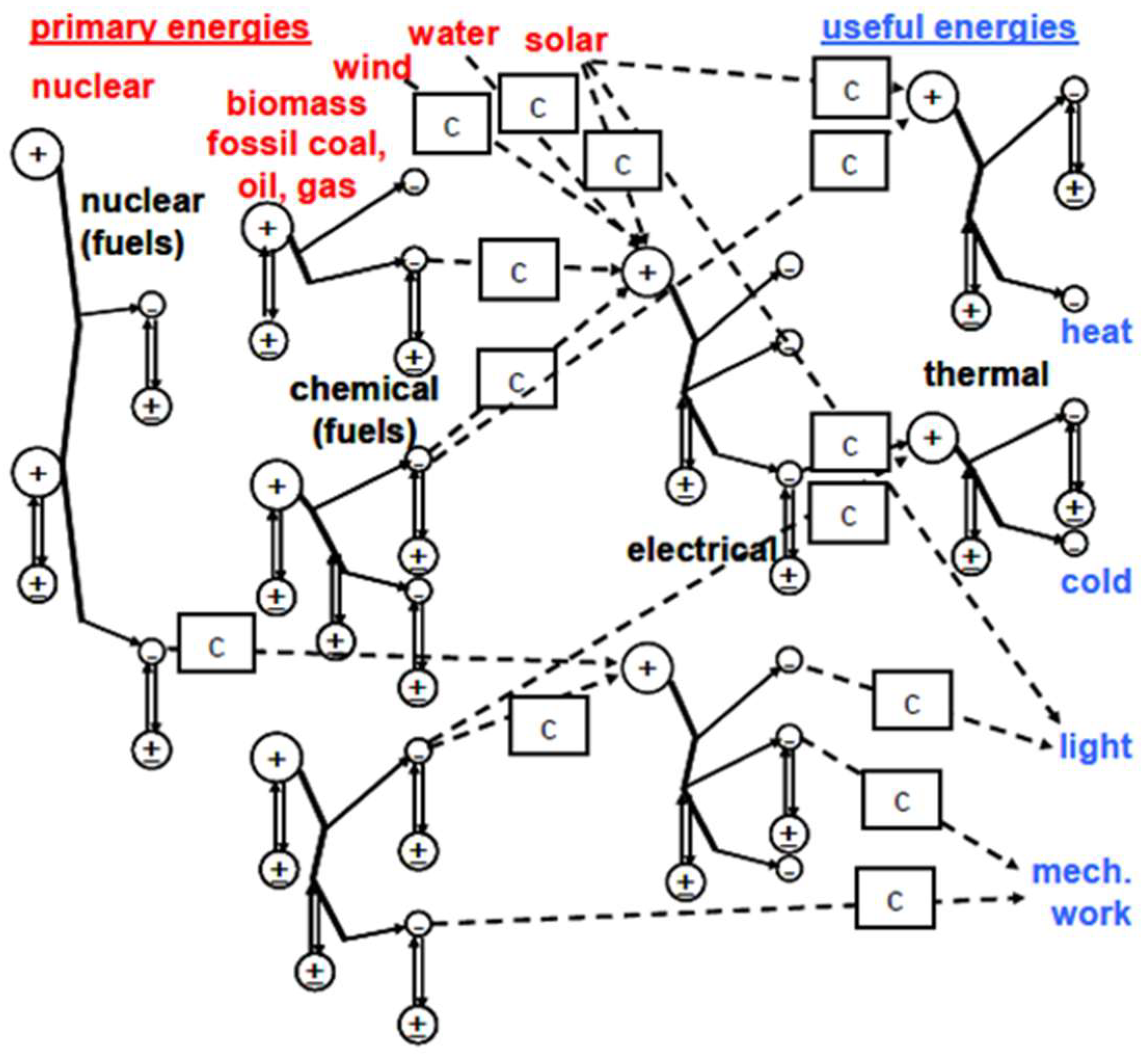

1.1. Background – The transition of the energy system, incl. challenges and options

1.2. Previous investigations of the potential of TES

1.3. Aims and purposes of the research

2. Materials and Methods

2.1. Methodology

- Analysis of existing application examples (general and individual)

- 2.

- Analysis of applications by current technology data and comparison

2.2. Scope

2.2.1. Applications considered

2.2.2. Energy storage technologies considered

3. Results

3.1. Analysis of existing application examples (general and individual)

3.2. Analysis of current technology data and comparison

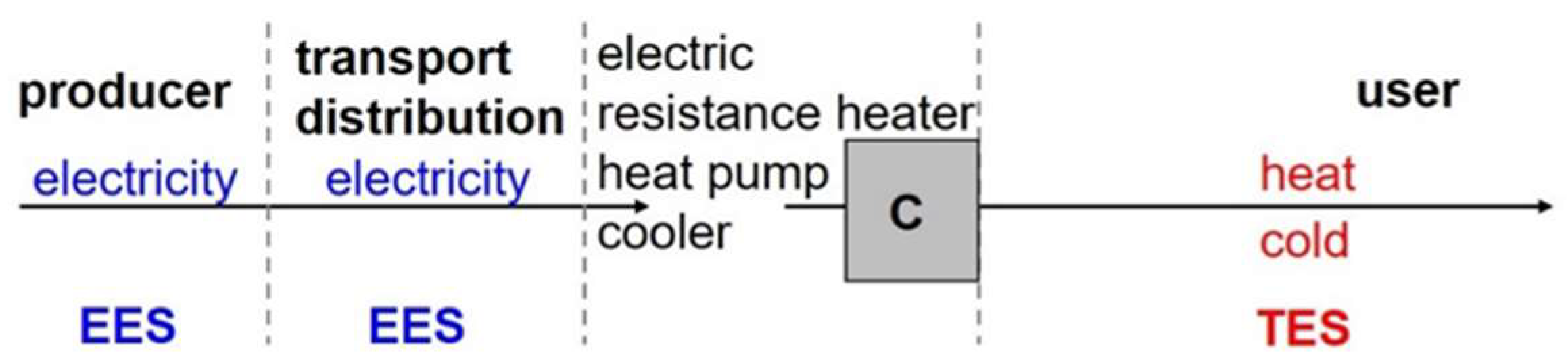

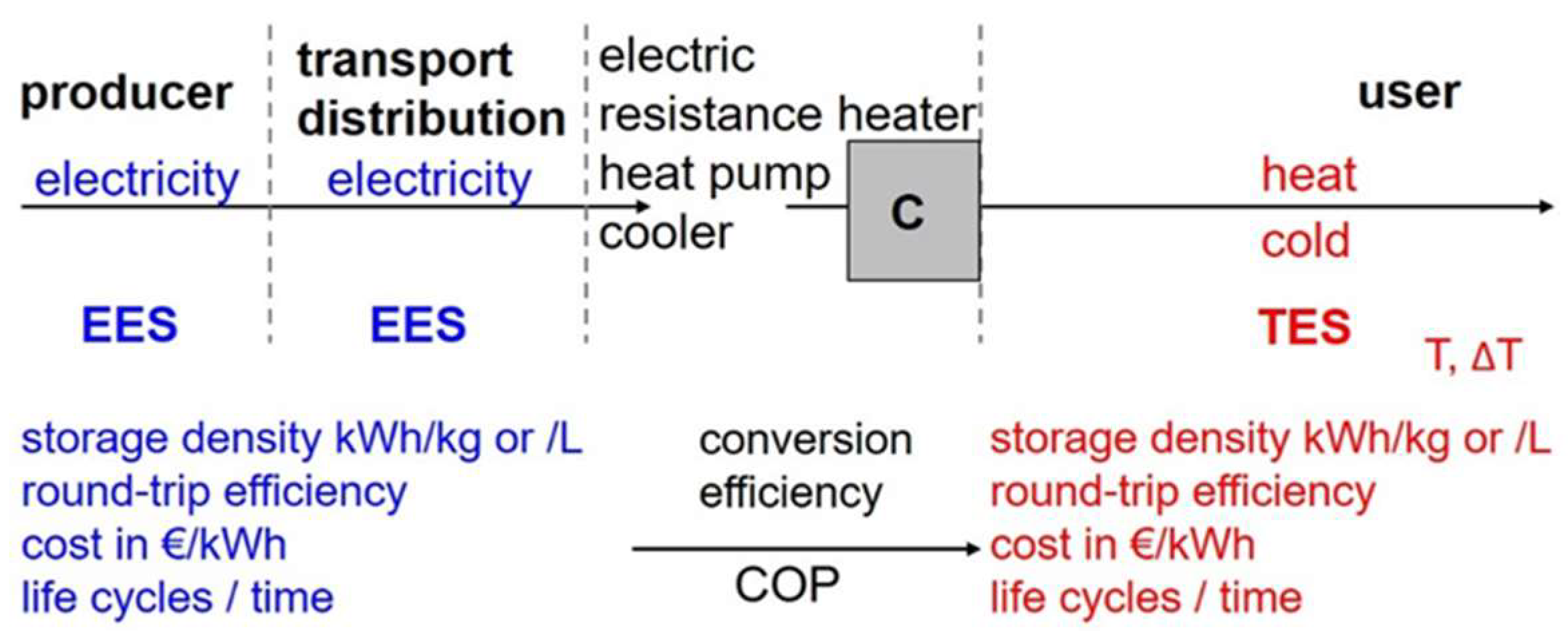

3.2.1. Background

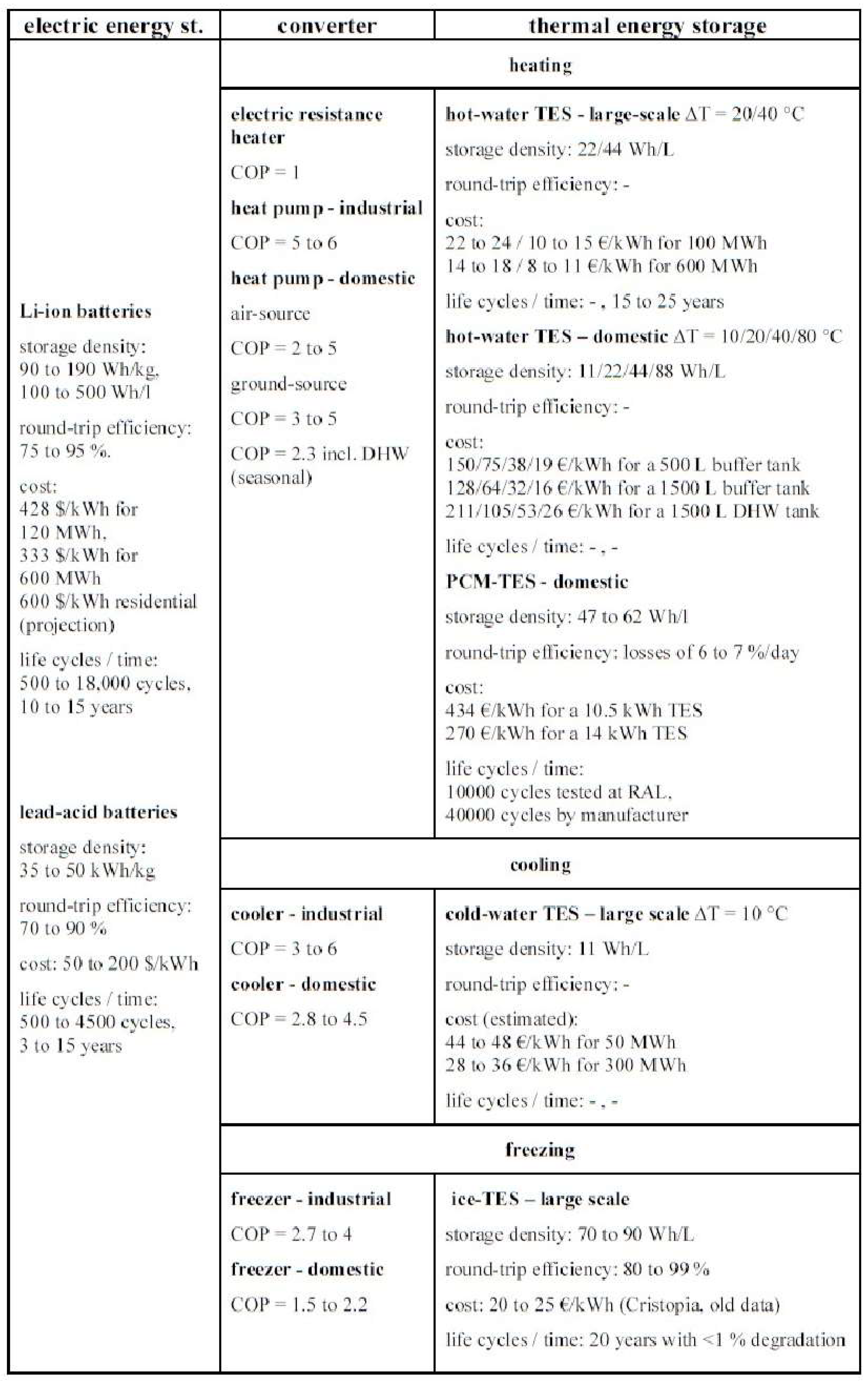

3.2.2. EES data

3.2.3. TES data

3.2.4. Converter data

4. Discussion

4.1. Discussion of existing application examples (general and individual)

4.1.1. General features from basic principles

4.1.2. Perspective of the user side only

4.1.3. Perspective of the energy system as a whole

4.2. Discussion of applications by current technology data

4.2.1. Perspective of the energy system as a whole

4.2.2. Sensitivity analysis

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- IEA. Net Zero by 2050 - A Roadmap for the Global EnergySector. IEA Report. IEA 2021. Available online: https://iea.blob.core.windows.net/assets/0716bb9a-6138-4918-8023-cb24caa47794/NetZeroby2050-ARoadmapfortheGlobalEnergySector.pdf (downloaded 2.6.2021).

- Mehling, H.; Technologies of energy conversion, storage, and transport in the energy system - A brief introduction. Tredition, 2016, ISBN: 978-3-7345-4049-3.

- Rathgeber, C.; Lävemann, E.; Hauer, A.; Economic top–down evaluation of the costs of energy storages — A simple economic truth in two equations. Journal of Energy Storage, 2015, volume 2, pages 43-46. [CrossRef]

- Rathgeber, C.; Hiebler, S.; Lävemann, E.; Dolado, P.; Lazaro, A.; Gasia, J.; de Gracia, A.; Miró, L.; Cabeza, L. F.; König-Haagen, A.; Brüggemann, D.; Campos-Celador, Á.; Franquet, E.; Fumey, B.; Dannemand, M.; Badenhop, T.; Diriken, J.; Nielsen, J. E.; Hauer, A.; IEA SHC Task 42 / ECES Annex 29 – A simple tool for the economic evaluation of thermal energy storages. SHC 2015, International Conference on Solar Heating and Cooling for Buildings and Industry, Energy Procedia 2016, 91, 197 – 206. [CrossRef]

- Flammini, A.; Bracco, S.; Sims, R.; Cooke, J.; Elia, A.; Costs and Benefits of Clean Energy Technologies in the Milk, Vegetable and Rice Value Chains. Published by the Food and Agriculture Organization of the United Nations (FAO) and the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH. 2018. Available online: https://www.fao.org/documents/card/en/c/I8017EN (accessed on 29 June 2022).

- Khelifa, N.; Krämer, W.; Standklimatisierung von Nutzfahrzeugkabinen über Kältespeicherung. 6. Karlsruher Fahrzeugklima-Symposium, 17. Sept. 2004. Available online: http://www.twk-karlsruhe.de/download/symposium_06/manwebasto.pdf (downloaded 14th May 2020).

- Mehling, H.; Brütting, M.; Haussmann, T.; PCM products and their fields of application - An overview of the state in 2020/2021. Journal of Energy Storage, 2022, 51. [CrossRef]

- HPTCJ. About Thermal Storage Air Conditioning. published 2104, updated later Available online: https://www.hptcj.or.jp/e/learning/tabid/367/Default.aspx (accessed 25 Feb. 2023).

- BAC. Ice Thermal Storage. Brochure. Available online: https://baltimoreaircoil.com/download_api_endpoint/1088/g1_ice_20150914.pdf (downloaded 15 Nov. 2022).

- Roselund, C.; Ice Energy brings the deep freeze to U.S. energy storage. pv magazine USA, 2019, available at https://pv-magazine-usa.com/2019/02/13/ice-energy-brings-the-deep-freeze-to-u-s-energy-storage/, accessed 24 Feb. 2023.

- Cameron Murray. Edison validates Viking Cold Solution’s cooling thermal energy storage tech. March 25, 2022, Available online: https://www.energy-storage.news/thermal-energy-storage-comes-of-age-with-edison-validation-100-round-trip-efficiency-pilot-and-ip-acquisition/ (accessed 18th Oct. 2022).

- Lipp. Tanks and system solutions. Available online: https://www.lipp-system.de/tanks/thermal-storage-tanks/?lang=en, (accessed 8th Nov. 2022).

- N-ERGIE Aktiengesellschaft. Wahrzeichen der Energiewende - Der Wärmespeicher der N-ERGIE. Stand: Juni 2015; Available online: https://www.n-ergie.de/n-ergie/unternehmen/unsere-energie/kraftwerksstandort (downloaded 6 Dec. 2022).

- IRENA. INNOVATION OUTLOOK THERMAL ENERGY STORAGE. 2020, Available online: https://www.irena.org/publications/2020/Nov/Innovation-outlook-Thermal-energy-storage (downloaded 17 Feb. 2023).

- Baltimore Aircoil Company. Ice Thermal Storage. Brochure, 2012. Available online: https://baltimoreaircoil.com/products/ice-thermal-storage (downloaded 15th Nov. 2022).

- Mehling, H.; Use of Phase Change Materials for Food Applications - State of the Art in 2022. Appl. Sci., 2023, 13. [CrossRef]

- May, G. J.; Davidson, A.; Monahov, B.; Lead batteries for utility energy storage: A review. Journal of Energy Storage, 2018, 15, 145–157. [CrossRef]

- Kebede, A. A.; Coosemans, T.; Messagie, M.; Jemal, T.; Behabtu, H. A.; Van Mierlo, J.; Berecibar, M.; Techno-economic analysis of lithium-ion and lead-acid batteries in stationary energy storage application. Journal of Energy Storage, 2021, 40. [CrossRef]

- He, W.; King, M.; Luo, X.; Dooner, M.; Li, D.; Wang, J.; Technologies and economics of electric energy storages in power systems: Review and perspective. Advances in Applied Energy, 2021, 4. [CrossRef]

- Lemian D.; Bode, F.; Battery-Supercapacitor Energy Storage Systems for Electrical Vehicles: A Review. Energies, 2022, 15. [CrossRef]

- NREL. 2022 Annual technology baseline: Utilityscale battery storage. Available online: https://atb.nrel.gov/electricity/2022/utility-scale_battery_storage, data updated 07/21/2022 (accessed 17 Feb. 2023).

- Figgener, J.; Stenzel, P.; Kairies, K.-P.; Linßen, J.; Haberschusz, D.; Wessels, O.; Angenendt, G.; Robinius, M.; Stolten, D.; Sauer, D. U.; The development of stationary battery storage systems in Germany – A market review. Journal of Energy Storage, 2020, 29. [CrossRef]

- Martin Placek. Electric vehicles - global lithium-ion battery pack costs 2011-2030. Published by Martin Placek, Feb 15, 2021. Available online: https://www.statista.com/statistics/883118/global-lithium-ion-battery-pack-costs/ (accessed 15.12.2021).

- pv Europe. Average cost of lithium-ion battery cell below $100 kWh in 2023. published 09/24/2020, Available online: https://www.pveurope.eu/solar-storage/average-cost-lithium-ion-battery-cell-below-100-kwh-2023 (accessed 15.12.2021).

- Urbaneck, T.; Oppelt, T.; Sehwöster, I.; Banck, E. F.; Große Druckbehälter als thermische Energiespeicher - Teil 1: Vor- und Nachteile sowie Einsatzgrenzen. EuroHeat&Power, 2018, 47. Jg, Heft 11-12.

- GSC Tanks. An introduction to industrial hot water storage tanks. Available online: https://www.gsctanks.com/industrial-hot-water-storage-tanks/ (accessed 8th Nov. 2022).

- ofen.de. Pufferspeicher. Available online: https://www.ofen.de/pufferspeicher?p=1&o=2&n=16&f=326 (accessed 16 Dec. 2022).

- Sunamp, website. Available online: https://www.thermalearth.co.uk/sunamp-heat-batteries-and-thermal-en (accessed 10th Dec. 2021).

- Sunamp: Thermino. Product brochure, September 2022 - Version 2.3. Available online: https://sunamp.com/en-gb/wp-content/uploads/sites/2/2022/10/Sunamp-Thermino-Brochure-September-2022-English-V2.3.pdf (downloaded 7 Nov. 2022).

- Midsummer Wholesale. Sunamp heat batteries. Available online: https://midsummerwholesale.co.uk/buy/sunamp-heat-batteries (accessed 7th Nov. 2022).

- NOSTROMO. Technology. Available online: https://www.nostromo.energy/technology/ (accessed 17 Feb. 2023).

- UTILITY DIVE. Ice, ice energy: The hot market for cooled liquid energy storage. Contributing editor: Herman K. Trabish; available online: https://www.utilitydive.com/news/ice-ice-energy-the-hot-market-for-cooled-liquid-energy-storage/408356/ (accessed 17 Feb. 2023).

- BAC. District cooling with ice thermal storage. Movie. Available online: https://baltimoreaircoil.com/products/ice-thermal-storage/tsu-m-ice-chiller-thermal-storage-unit (accessed 11 March 2023).

- airconditionerlab. Coefficient of Performance Explained. Available online: https://airconditionerlab.com/coefficient-of-performance, published 2021 (accessed 15 Nov. 2022).

- Yu Chang Zhen. What is the COP of Heat Pumps? Available online: https://aircondlounge.com/what-is-the-cop-of-heat-pumps/ (accessed 15 Nov 2022).

- Montero, O.; Brischoux, P.; Callegari, S.; Fraga, C.; Rüetschi, M.; Vionnet, E.; Calame, N.; Rognon, F.; Patel, M.; Hollmuller, P.; Large Air-to-Water Heat Pumps for Fuel-Boiler Substitution in Non-Retrofitted Multi-Family Buildings—Energy Performance, CO2 Savings, and Lessons Learned in Actual Conditions of Use. Energies, 2022, 15. [CrossRef]

- Ahrens, M. U.; Braekken, A.; Foslie, S. S.; Moen, O. M.; Lovas, K. A.; Bantle, M.; Hafner, A.; Eikevik, T. M.; Performance analysis of high temperature heat pumps and thermal energy storages for a dairy. Proceedings of 15th IIR-Gustav Lorentzen Conference on Natural Refrigerants (GL2022), Trondheim, Norway, June 13-15th 2022. [CrossRef]

- ENERGY STAR. Most Efficient 2022 — Central Air Conditioners and Air Source Heat Pumps. Available online: https://www.energystar.gov/products/most_efficient (accessed 15 Nov. 2022).

- Ure, Z.; Thermal Energy Storage for Cold Chain Applications. 7th IIR conference on Sustainability and the Cold Chain, April 11-13 2022. [CrossRef]

- BAC. TSU Thermal Storage Products. Available online: https://www.baltimoreaircoil.eu/system/files/TSU.pdf (downloaded 15 March 2021).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).