You are currently viewing a beta version of our website. If you spot anything unusual, kindly let us know.

Preprint

Article

Modeling Role of Sustainable Supply Management Practices on performance and sustainable development of South Africa’s listed companies.

Altmetrics

Downloads

111

Views

31

Comments

0

This version is not peer-reviewed

Abstract

The effective implementation of a sustainable supply chain leadership (SSCL) strategy at each organization’s level, positively impacts on corporation’s competitive advantage and sustainable development. While fears have been acknowledged in previous literature, the benefit of designing Sustainable supply chain models for operational excellence and sustainable development is a noteworthy exploration. The study collected statistical data using an online Survey- monkey questionnaire from 46 of the top 100 JSE-listed companies with the intention to elucidate the large firms’ transition from longstanding linear approaches to sustainable production and consumption to a more circular approach. A bivariate data analysis was used to generate the results in SPSS. The results indicate a positive contribution of SSCL strategy to operational excellence and sustainable development of large corporations if only the entire supply chain system is well-coordinated and implemented. This study makes a vital contribution by proposing a new SSCL model for fast-tracking corporate sustainability and enhancing corporate contributions to sustainable growth.

Keywords:

Subject: Business, Economics and Management - Business and Management

1. Introduction

In recent years, the concept of the supply chain has garnered a robust literature which has studied how supply chain management (SCM) practices and operational excellence can be integrated with sustainable development (Vermeulen & Metselaar, 2015; Silvestre, 2015), along with environmental sustainability to facilitate collaboration and organisational performance across nations (Suhong- Li et al., 2006; Svensson & Funck, 2019; Del Giudice et al., 2021; Marino, & Pariso, 2022). Research indicates that operational excellence driven by SCM practice can lead to improved competitive advantage and enhanced organisational performance (Luthra and Mangla, 2018). Accordingly, the demand for innovative corporate models that lead to higher performance in social-economic and nascent environmental standings is inevitable to appreciate the benefits of sustainable production and consumption. Although prior literature on SCM has made many valuable contributions, there is a dearth of empirical evidence and theoretical reflection on the characteristics of supply chains that operate mainly in emerging economies. Yet, transformation from the conventional SCM mechanisms to the ecologically sustainable supply chain management (SSCM) practices and firm performance permits resourceful usage of materials and reduction of waste production (Geissdoerfer et al., 2018; Sehnem et al., 2019).

The notion of SCM has received an analogous growing interest from researchers, experts and business managers (Suhong-Li et al., 2016). Several large firms have started to acknowledge the reputation of SCM strategic actions in fostering sustainable competitive edge for their goods services in a fragile fourth industrial revolution. However, the concept of SCM has been studied from different perspectives in the diverse bodies of literature. Scholars (Kayikci, 2021; Kuei et al., 2013) offer unrelated conclusions and insights on specific aspects or perspectives of SCM and posit that the need to observe the sustainability elements in a manufacturing globalization era has raised mounting pressure on the large companies across countries. In the same line, Walker and Jones (2012) added that the global transformation of manufacturing companies has created destructive effects on the ecosystem, such as carbon emissions, hazardous chemical leakages, and pollution.

Still from an academic standpoint, even though the literature on SCM leadership offers various conceptual insights focused on different research fields, that is, resourceful usage of supplies and their productivity (e.g. Goyal, Esposito & Kapoor, 2018), the evolution to CE approaches still is not well presented (e.g., Del Giudice, 2021; Marino, & Pariso, 2022). In contrast, Aboelmaged (2012; ) explored the operation of CE policies in diverse nations and sectors. However, the knowledge of such policies and its drivers remains questionable in the current literature. Besides, Da Silva, Jerónimo, and Vieira (2019) contend that additional studies are desirable to demonstrate the characteristic benefit of a leadership-driven environment. Although many challenges have been identified, Geissdoerfer et al. (2017) confirm that the rewards of implementing sustainable development in a circular economy (CE) are notable.

Notwithstanding the growing prominence of CE, the concept has garnered relatively little attention in the supply chain management (SCM) literature (Tjahjono and Ripanti, 2019). This absence of sustainable supply chain management (SSCM) -)-related research is outstanding, given that efficient management of global supply chains is critical to advancing CE. Therefore, there is a general consensus that whereas innovative SCM practices must inspire industrial profits and rapid growth, again, environmental damage that arises from the operations of these multinational companies has been ignored (Lai and Wong, 2012; Fernandez et al., 2021). In spite of the rich literature about SCM practices, it has been observed that empirical studies in this field do not effectively address the specific questions of SCM in a CE context, exclusively in emerging countries (Fahimnia et al., 2015; Khalid et al., 2015). As a result, manufacturers have started to realise the implication of adopting environmental responsive approaches, plus recycling arrangements, together with consumers and manufacturers as pathway to mitigating the negative ecological effects of their services and commodities (Lee et al., 2013; Goyal, Esposito & Kapoor, 2018). Progressively, the environmental-oriented supply chain cooperation (ESCC) with manufacturers and consumers accentuating ecological worries, is considered as a viable management approach for enterprises’ success to achieving environmental and productivity gains (Georgiadis and Besiou, 2008).

To this end, this article evaluates the role of supply chain leadership model in a CE with reference to operational excellence and innovation of the JSE-listed companies in South Africa. The study further tests JSE-listed companies’ capabilities to design and implement business models grounded on the reduction of waste and salvage of resources, including recycle standards. By doing so, the article fills the knowledge gap connected to the CE. Indeed, this study anticipates answering the ensuing primary research question:

RQ1: What is the role of sustainable supply chain leadership strategy on operational excellence and sustainable development of listed companies in South Africa?

SSCM is defined by Seuring and Müller (2008) as “the management of material, information and capital flows as well as cooperation among companies along the supply chain while considering goals from all three dimensions of sustainable development, i.e., economic, environmental and social. SCCM is a study area that has received growing attention in the last decade. Since SSCM is a topic of global interest, the lack of emerging economy’s originated research is perceived as a gap, as well as a source of discontent by suppliers from developing countries who feel underrepresented in business policies and strategies towards sustainability (Bartley, 2010; Ras et al., 2007).

Rapid urbanisation in developing countries and rising living standards bring associated dilemmas and threats to sustainability that may not be considered in global business scenarios (Abreu et al., 2012; Jayanti et al., 2014). However, the relationship between sustainable development and supply chain management does not only concern the development of local communities, it must also address a wide range of interconnected environmental issues that have global consequences (Bendul et al., 2016; Diniz and Fabbe-Costes, 2007; Tan, 2016). Since a large part of operations concerning extraction, production and manufacturing are based in developing countries, it is important to recognise those countries as key players in global supply chains and to analyse their initiatives towards sustainable development, as they have increasing global relevance (Abreu et al., 2012; Zhu and Sarkis, 2006). SSCM practices present opportunities for exporting enterprises in developing countries to improve their environmental and social performance (Luken and Stares, 2005; Park et al., 2010) while improving their competitiveness and achieving their business goals (McMurray et al., 2014; van Hoof and Thiell, 2015).

We also seek to fill the gap in the literature by analysing the significance of SCM leadership and innovation strategies in fostering sustainable growth in a CE. To achieve this objective, a SCCM model is developed to assist in operationalising and contributing to achieving the sustainable development goals as stipulated by N Sustainable Goals 2030 and 2050 respectively. In the next section 2 of this article, we debate the correlated empirical literature underpinning SCM best practices, trends, and dilemmas of sustainability approaches in a CE. Subsequently, in section 3 we explain the research methodology and data used in this article plus the definition of the independent and dependent variables. This section is followed by results and discussion (section 4). In section 5, we conclude this study with research implications highlighting key findings of the study, research limitations and future research directions to fill such gaps.

2. Empirical Literature and Hypothesis Development

2.1. SCM Practices and sustainability elements in emerging Economies

Many of the previous studies on supply chains have mainly been unconnected, wherein limited or no credit is dispensed to the interrelations among topics such as the environment sustainability elements as they are applied to SCM (Carter and Jennings, 2002). SCM is an important concept that brings efficiency and effectiveness to organisational activities, provided it is understood and practiced correctly. Notwithstanding the importance of SCM, it is a concept that is susceptible to misunderstandings. Hence, the opportunity prevails for continuous engagements and clarifications for the benefit of organisations in the quest for proper implementation. It is unlikely that organisations can function optimally without the proper implementation of SCM. Hence, it is regarded as one of the vital instruments to use for the success of companies and their envisaged sustainability.

Sustainable supply chain management has developed as a significant method for enterprises targeting to become environmentally sustainable. In a CE, the focus of the manufacturers and customers is entirely focused on effective design and managing economic activities towards the revival of resources by continuously keeping materials at their maximum usefulness and value. Unlike the traditional supply value chain strategies, the CE embodies a development strategy that empowers economic growth while targeting to optimise the value chain of consumption of materials (Svensson & Funck, 2019). For this to occur, there must be a profound transformation for firms and consumer from a linear production and consumption system to a new approach based on reduction, reuse, recycling and recovery (Hina, et al., 2022). Therefore, SSCM is now the new normal and a popular management approach to achieve cost effective products and competitive advantages (Lai and Cheng, 2009).

Increasingly, SSCM methods coupled with continuous cooperation with suppliers and customers with a special attention to sustainability concerns, is considered a practical management approach for enterprises towards achieving environmental and productivity gains (Georgiadis and Besiou, 2008). While several previous research articulates the strength of SCM practices on achieving the dual environmental and economic performance goals (Zhu, Geng & Lai, 2010), surveys exploring SCM leadership impact in a CE with orientation to innovation and operational excellence, is seriously missing. Like earlier mentioned in the preceding section, CE approach has significant strategic value in the emerging economies, where resource exhaustion and ecological crisis are critical obstacles impeding further regional development (Zhu, Geng & Lai, 2010). The Ecological Management Theory (EMT) postulates that ecological difficulties may be alleviated by eco-innovations in the form of technological, organisational and operational innovations (Janicke, 2008). It is also alleged by prior studies that EMT is identical with strategic and innovative environmental management for the distinct institutions at the micro level (Søndergård et al., 2004, Pataki, 2005, Revell, 2007). Previous studies have recognised the CE practices as one of the developed approaches trusted to promote economic development and sustainable performance (Singh Sanjay and Singh Ajai, 2019), as in CE the value of goods and resources is sustained, while waste and resource use are minimised, and resources are kept within the economy until product end life (Kristoffersen et al., 2021).

The driving forces for presenting and executing the SSCM concept into the company operations are several and encompass a range of “reactive regulatory reasons to proactive strategies and competitive advantage reasons (Ashby, Leat and Hudson-Smith., 2012) such as, cleaner production, environmental management systems and ecological efficiency have been implemented for green management practices. The factors driving the competitive advantage through environmental performance have been identified as market expectations, risk management, regulatory compliance and business efficiency [4]. SSCM has a key role in ensuring that all of these factors are addressed. Therefore, SSCM has emerged as an important new standard for enterprises to achieve profit and market share objective by lowering the environmental risks and impacts and while raising their ecological efficiency.

2.2. Influence of SCL strategic actions on firm performance and sustainable development

Existing literature documents a growing interest in SCM practices for sustainable development from academics, policymakers, and international development agencies (Bag et al., 2021; Chen et al., 2022). Yet, empirical studies on the effect of SCM practices on enterprise performance in a CE are questionable. To reinforce this claim, Lo (2013) found that the operation of the CE exercise has not led to financial growth for Chinese industrial enterprises. CE practice implementation was still in their infancy, implying heavy investment costs that may have increased firms’ operating costs and hence decreased commercial profits. However, the recent survey by Mitra and Datta (2014) found a positive correlation between CE practices and financial benefits. Inspired by the contradictions in earlier research, our study pursues to better appreciate the role of SCM leadership practices on the innovation and operational excellence of JSE-listed companies in South Africa in a CE context. This empirical overview is essential as the operation of CE practices is a multifaceted phenomenon. Furthermore, this subject has offered a firm foundation and a demand for future research direction to measure if adaptation to SCM practices can lead to favourite firm performance (Kuei et al., 2013; Bag et al., 2021). In other words, large firms must develop innovative capabilities for handling the supply chain based on general corporate abilities, and grounded on these high-level capabilities, a set of detailed operating competences can be developed for each process within the supply chain (Lummus et al. 1998). Hence, an improved understanding of the shape of the interactive association between corporate competitive capability and SC operational capability is desirable.

Research also shows that productivity and shareholder economic value added are goals of supply chain strategy. Evidence indicates that manufacturing transaction costs intensely continue to decrease as the price for moving material is little and supplies can be situated optimally in anyplace in the world through empowering technologies (Diabat, Kannan and Mathiyazhagan, 2014) Bendul., et al, 2016). However, fabulous innovations which bring supplies close to the customers’ doorstep certainly negatively impact on the environment and depletion of resources owing to increasing demand from the customers. This problem has been execrated because most a big number of large companies have typically paid less attention to CE phenomenon. Yet, it is an acceptable strategy trusted to render applied solutions to uphold the concept of sustainable development in emerging economies like South Africa.

Earlier studies have primary focused on SCM practices on firm level performance and development (Kao, Redekop and Mark-Herbert, 2012; Golicic & Smith, 2013) but have dedicated little consideration to the fundamental aspects of an ecological friendly environment value chain and sustainability components in a CE. Its relevance has also attracted the attention of academics, interested not only in the implementation methods of the CE, but also in the ways in which companies communicate information about them. However, although in recent years some scholars have begun to investigate the CE, research on this topic is still in an embryonic state (Turker and Altuntas, 2014; Vitolla, et al., 2023).

In this perspective, CE is strongly related to supply chain management practices, as both are based on effective business process management. Traditionally, to achieve sustainability, firms have focused on a vertical integrated system for their supply chain. In contrast, in a CE perspective, firms are building sustainable cross industry networks that allow the setting up of interconnected supply chains that use resources according to the 3Rs strategy: recycle, reduce and reuse (Tseng et al., 2018). Although previous studies have argued for the need to combine CE and supply chain management (De Angelis et al., 2018; Sauve et al., 2016; Schulte, 2013), empirical studies are still scarce. Limited attention has been given in the academic literature to the embodiment of CE principles within the supply chain (Aminoff and Kettunen, 2016; De Angelis et al., 2018; Lewandowski, 2016). Therefore, the circular supply chain remains an underexplored research area (Geissdoerfer et al., 2018).

From this standpoint, we can undertake the ensuing hypothesis:

H1: The SCL strategic actions positively influence large firms’ performance and sustainable development through the innovation capabilities and operational excellence.

2.3. Fostering SSCM practices through innovation capabilities and operational excellence

There is also a body of literature that submits a positive connection between environmental practices and firms’ performance. Recent studies have offered insight on the potential pattern of SCM practices for fostering environmental performance. The literature that underwrites this positive connection is comparatively robust. Earlier research assert that SCL management leadership positively impacts on sustainable growth of the listed companies. However, they did not clearly explain how this concept might impact environmental sustainability in a developing country. In contrast, Bowen et al. (2022) posit that the economic performance of large firms often is not achieved in immediate profitability or sales turnover.

Despite the potency of SCM leadership, especially for large companies, there is vast knowledge deficit about how this model works in many components of the value chain framework. This makes it a prerequisite to advance the knowledge base to support the transition to derive real benefits from it (Korhonen, et al., 2018). The role of digital technologies in this process is crucial to overcome barriers to the CE transition and support companies’ decision-making process, fostering the implementation of circular business models. Therefore, the CE involves, on the one hand, the correct management of the scarce resources available to a company for its production processes and, on the other hand, the creation of value from the waste produced. Nevertheless, there is a lack of consensus among researchers on the actual benefits of the CE, which appears to be far from being as promising as its supporters claim.

SCM is a wide-ranging subject and has been studied by scholars from diverse perspectives in the previous years. Both theoretical and empirical studies about SCM practices and SCL have been rising progressively in the last decade (Carter and Easton, 2011; Ahi and Searcy, 2013). Research shows that SSCM permits corporations to implement company responsibility policies and attain an advanced productivity and resource usage (e.g., Gold et al., 2010; Carter and Easton, 2011) while observing the sustainability elements, that is, economic, social and environment goals. Nonetheless, the constant changes of supply chain formations have raised up serious anxieties if this could underwrite sustainability (Halldorsson et al., 2009) and compelling strategic actions to be taken.

Even though SSCM considerably influences large corporation development, there is only a limited empirical and theoretical foundation to explain the entirety of the construct. The new concept of CE is always employed to describe the firms’ need to adopt sustainability aspects in all form of manufacturing. In a nutshell, the CE has established itself progressively as an answer to environmental difficulties, particularly in terms of recycling and resource salvage. Until now, in several nations globally, it embodies one of the supports of sustainable policies and one of the main drivers of the ecological transition towards global sustainability (García-Sánchez., et al., 2022).

Notwithstanding the prominence of the SCL strategic actions to foster the large firms’ resiliency performance and sustainable development, SCL has largely been studied as a standard alone without focus on sustainability elements in a CE. Previous literature on SCL and SCM practices mainly focused on how best large firms could raise-up more profits and market share and remain relevant, yet if large scale manufacturing of multinational corporations is not well managed, it negatively impacts environmental sustainability for which SCL strategic actions would be well placed to address. Such argument leads to the following Hypothesis H2: Implementing the SCL strategies positively impact on sustainable development of large firms with focus to innovation capabilities and operational excellence of corporate companies.

3. Research Methodological Approach

3.1. Research sample and data collection

The purpose of the study reported on this paper is to investigate the effect of CE practices on firm performance for circular supply chain and the moderating role of big-data-driven capability. The study, therefore, adopts a quantitative approach, using multiple regression analyses to test the hypotheses on data retrieved from a sample of Italian firms. Italy was chosen as a SCM in CE 343 suitable research setting, since in 2018 it registered a substantial improvement in CE practices by adopting innovative waste management practices and implementing new business and consumption models centred around the sharing economy, thereby reducing waste and use of secondary raw materials (The Circular Economy Network, 2019).

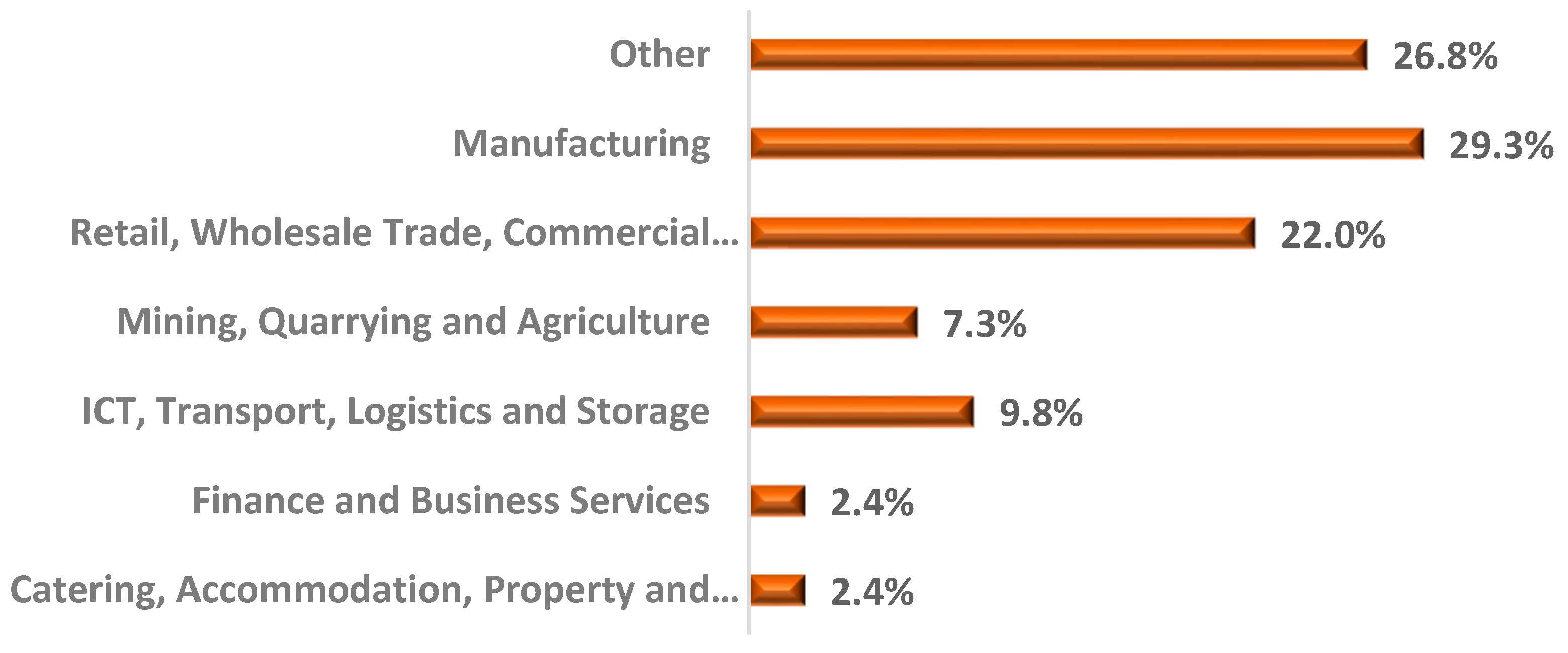

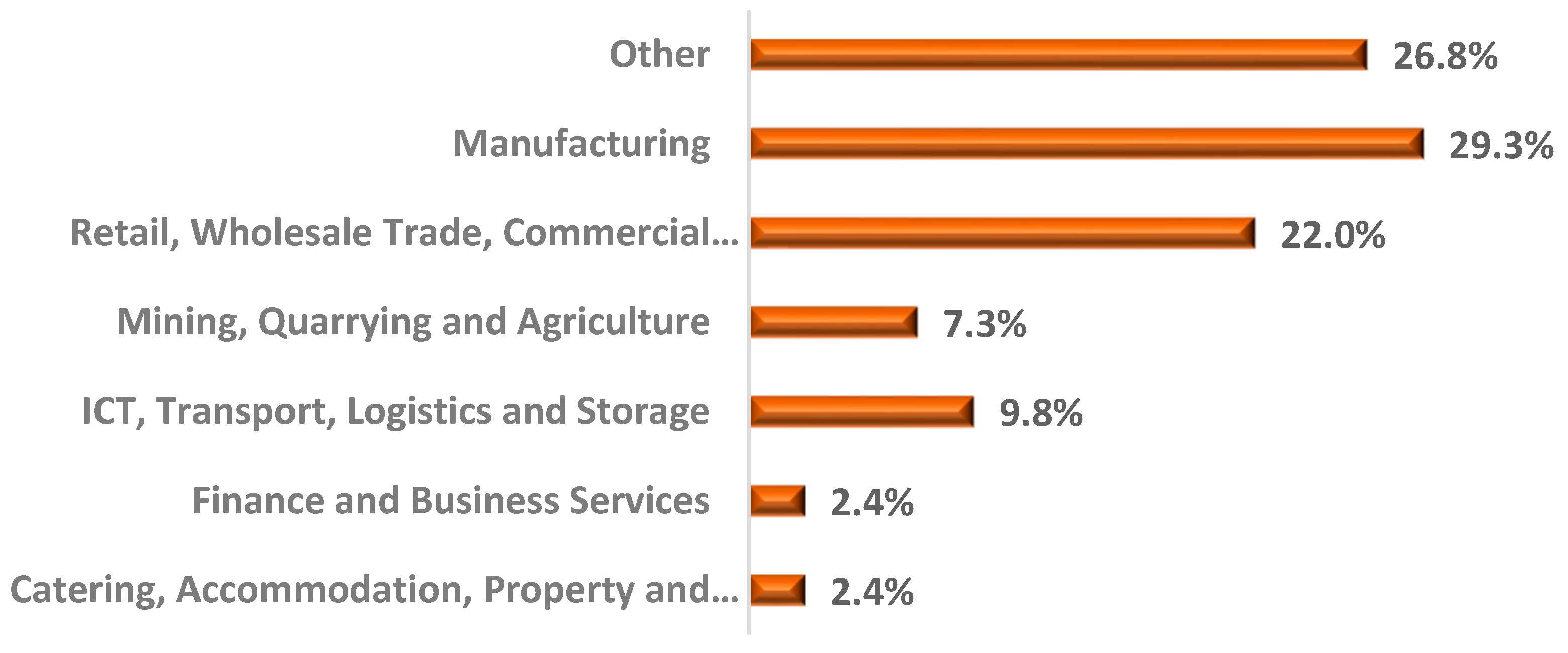

To empirically examine the distinct research hypothesis, cross-sectional data about Johannesburg Stock Exchange (JSE) listed companies was collected from the database made accessible, that consisted of 400 listed companies (N=400) as of 31 December 2015. This total quantity of JSE-listed companies was offered on both the board for well-established companies seeking to attain the next level in growth (Main Board) and the board for companies promising good quality and SMEs. A purposive sample of the top 100 JSE-listed companies was considered for this study (n = 100). The choice of the best 100 JSE listed companies in this study was influenced by their highest shareholder returns over the past five years, when they were acknowledged by the Sunday Times in 2015 as the best-performing businesses on the JSE owing to their highest shareholder returns over the past five years. Furthermore, the annual reports of the companies in the top 100 JSE-listed companies were reviewed for more information gathering using a content analysis approach. The top 100 JSE-listed companies are stratified into the following industries, as depicted in Table 1.

The use of stratified sampling was aimed at categorising the companies into relatively homogeneous sub-groups in accordance with the standard industrial classification relevant to the research. The method (stratified sampling method) was also applied to attain greater precision as well as representativeness of the sample. The standard industrial classification was used to classify the JSE top 100 companies into six industries: manufacturing; retail, wholesale trade, commercial agents, and allied services; mining, quarrying and agriculture; information and communications technology (ICT), transport, logistics and storage; finance and business services; and catering, accommodation, property, and hospitality.

3.2. Data collection

The collection of primary data in this study was executed through an online survey monkey questionnaire. Considering the difficulties of using of online questionnaires connected with non-response bias, we applied control measures to mitigate this problem. For instance, first, the questionnaire subjected to a pre-test of 10 selected experts in the field of supply chain management. This activity was intended to ensure that the questionnaire clear and free from ambiguity. To create a free environment of anonymity of the respondents, any data that could recognise the respondents was detached. Finally, Alpha Cronbach formular was used to compute the confidence interval of the questionnaire with a margin of error of 5% and standard deviation of 0.5, with the results revealing a confidence level of 97%, therefore, implying that our data collection instrument was reliable.

According to Page (2014), the advantage of survey research is its efficiency because many variables can be measured with less time and costs. Questionnaires and interview schedules were the two survey instruments applicable to this study for both the quantitative approach, with closed-ended questions, and the qualitative approach, with open-ended questions. The view held was that the questions were designed and defined with or without explicit response choices. By means of an online Survey Monkey questionnaire, a series of questions were posed to participants using a five-point Likert scale to indicate the extent to which they agreed or disagreed with statements. In total, 46 out of 100 top JSE-listed companies completed the online questionnaire. This constitutes a 46% response rate of the target population of top 100 JSE-listed companies in South Africa.

Since this study adopted a mixed-method approach, semi-structured interviews were used for the qualitative data in which the same questions were asked in each interview, while simultaneously allowing flexibility for other important information to arise. The statistical data were complemented by open-ended semi-questionnaires to generate qualitative data from eight industry experts and specialists in the field of SCM, logistics chemical and industrial engineering as well as production and manufacturing engineering (Table 1). Of the eight participants, six were selected locally from South Africa and two from abroad to have opinions from both local and international perspectives. Earlier studies (Dworkin, 2012; Mason, 2010) support the use of a smaller interview sample because it assists to gather data that is beneficial to understand the complexity, depth, variation along with the context that surrounds a phenomenon. Specifically, any interview selection sample amidst five and 50 participants is acceptable. On this backdrop, eight industry specialists were selected in this study (n = 8). These were experts specialised in implementation of SCM practices in the different industrial categories, such as, logistics, chemical and industrial engineering on top of production and manufacturing engineering. Six of these specialists were intentionally selected locally from South Africa and two from abroad to have opinions from both local and international perspectives.

3.3. Measuring of Variables

The dependent variable applied in this study, the innovation and operational excellence of listed companies towards a CE were proxied by the indicator that measures the overall performance in terms of sustainability and CE as the output. To estimate the model, the bivariate analysis was used estimate the results. Regressing innovation and operational excellence enhanced the performance related to sustainability and CE by using the output of listed companies.

It is against this backdrop that for the quantitative data analysis in this study, preference was given to the use of descriptive statistical analysis and inferential statistical methods of testing for relationships among variables, such as t-tests, analysis of variance (ANOVA) and tests for normality and homogeneity of variance.

Entirely, all the study variables were estimated on a 5-point Likert scale, ranging from 1 (strongly disagree) to 5 (strongly agree). The proposed model includes five exogenous variables adapted from the literature to suit the research context: In particular, the dependent variable (firm performance for CE supply chain) was evaluated using a three-item scale taken from Zeng et al. (2017). Respondents had to evaluate their firm’s overall CE performance in terms of improvement of the production–consumption–recycling/reuse model within their supply chain process. On the one hand, SCM practices toward a CE at the national level is measured by using SDGs set out by UN. Precisely, this study estimates entrepreneurial SCM practices toward innovation and operational excellence to the CE in South Africa context. In order to proxy innovation within the entrepreneurial context, the study utilised the patents related to recycling and secondary raw materials per million inhabitants. The adoption of this set of indicators is consistent with the purpose of the study because competitiveness and innovation are considered drivers of industrial growth (Chabani, 2021), and specifically in this case, embracing outcome indicators related to CE can be considered a proxy to determine the orientation of entrepreneurial competitiveness.

3.4. Control Variables

Observing our cardinal goal to estimate the impact of SCM practices on innovation capabilities and operational excellence of the large companies on JSE within our empirical model, we developed a set of control variables as illustrated in the SCM model. Firstly, firm size could affect sustainability performance toward the CE of the firm (Vijayvargy et al., 2017; Zhu et al., 2008) in that larger firms are more able to implement sustainable environmental practices than smaller ones (Balasubramanian et al., 2021). Hence, a categorical control variable for firm size (Firm size), by number of employees was included in the model. Furthermore, firms’ greater experience in monitoring and reporting sustainability performance may affect the hypothesised relationship. The relationship between effective monitoring and reporting processes and sustainability performance has not been clearly identified within the existing literature, even though there is a consistent stream that strictly connects high environmental concern and performance with a high level of disclosure and consequently with monitoring and reporting processes (e.g., Aboagye-Otchere et al., 2020; Clarkson et al., 2011).

Finally, to avoid bias and in line with the review of the literature, several control variables were included. This study also takes industry as a control variable, since field of activity seems to shape the adoption of SCL business models and the availability of big data (Urbinati et al., 2017).

4. Results and Discussion

4.1. Descriptive statistics

A descriptive statistics technique was used to analyse the raw data in a beneficial and easy way to recognise some of the emerging trends in the data. This method allowed the researcher to create tables and figures that facilitated statistical debate of the results. The study variables (dependent and independent) facilitated the use of t-tests for non-parametric analyses in the form of Mann-Whitney and Kruskal Wallis tests. As previously mentioned in the research methodology section, a total of 46 out of 100 top JSE-listed companies completed and returned the survey monkey online questionnaire. This constituted 46% response rate in connection to the target population.

Almost 30% (29.3%, n=12) of the respondents operate in the manufacturing industry. Quite a large number of respondents (26.8%, n=11) indicated industries other than what was listed. Manufacturing and retail, wholesale trade, commercial agents and allied services seemed to be the preferred industries. Therefore, the results suggest a correlation between manufacturers and retailers, wholesalers, commercial agents, and other allied service providers in the sense that once goods are manufactured, they reach consumers via retailers, wholesalers, commercial agents, and other allied service providers. For this nature of business relationship to thrive, an effective SCM framework is essential to influence firms’ performance and sustainable development of the large firms.

4.2. Influence of SCL strategic actions on firm performance and sustainable development

In this favour, if the large corporations have to remain germane in a dynamic global environment manifested with mounting pressure to adhere to the UN sustainable development goals, obviously SCM practices which uphold the notion of sustainability are unavoidable. Therefore, sustainability of social, economic and environmental systems must continue to grow throughout the development phase. Notably, SCM practices must not only encompass the economic and environmental scopes, but similarly the social influence of supply chain processes, for instance the “triple bottom line” (social, environmental, and economic) that have been recognised as critical performance drivers for SSCM (Seuring and Muller, 2008; Zailani et al., 2012).

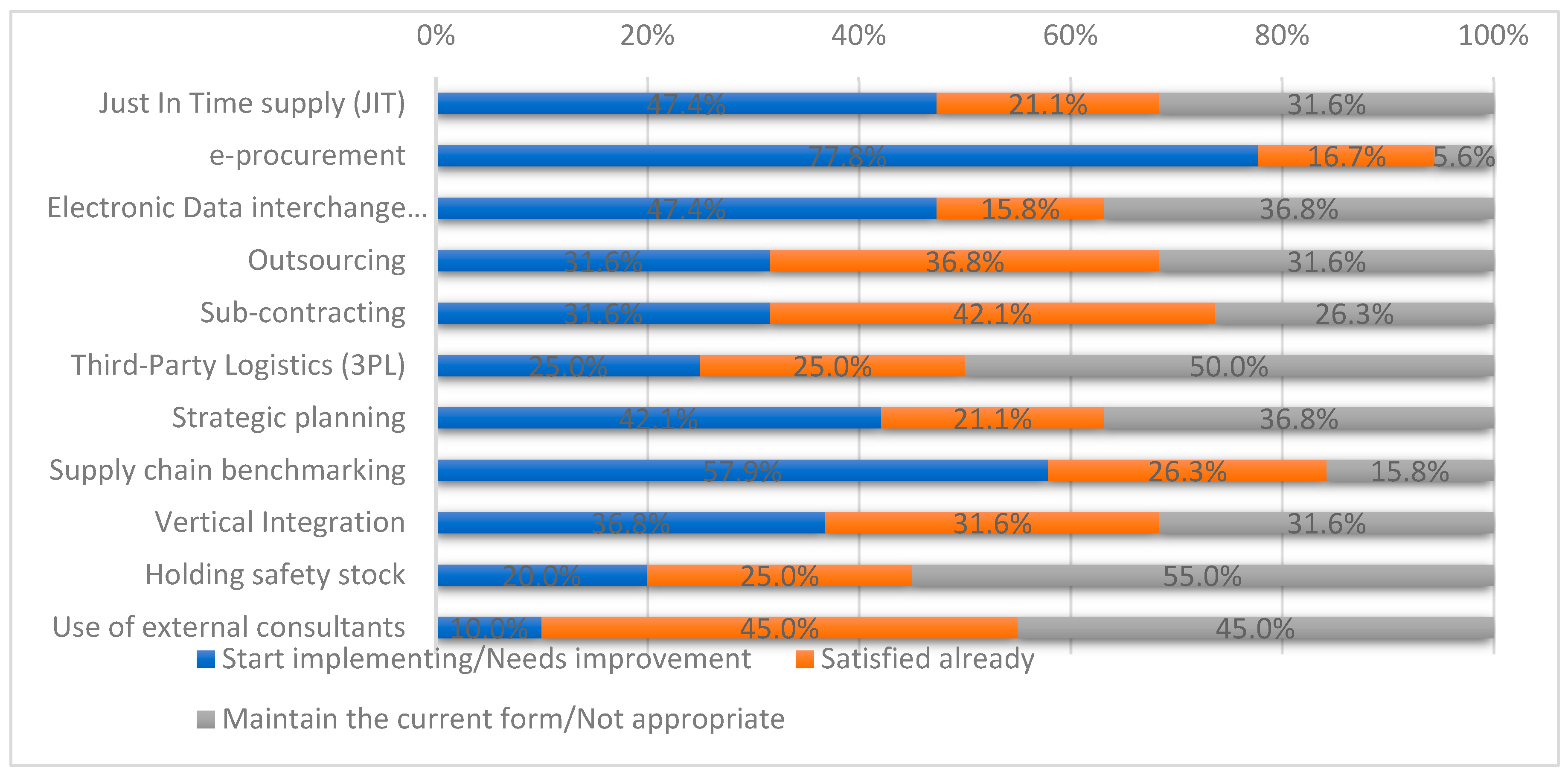

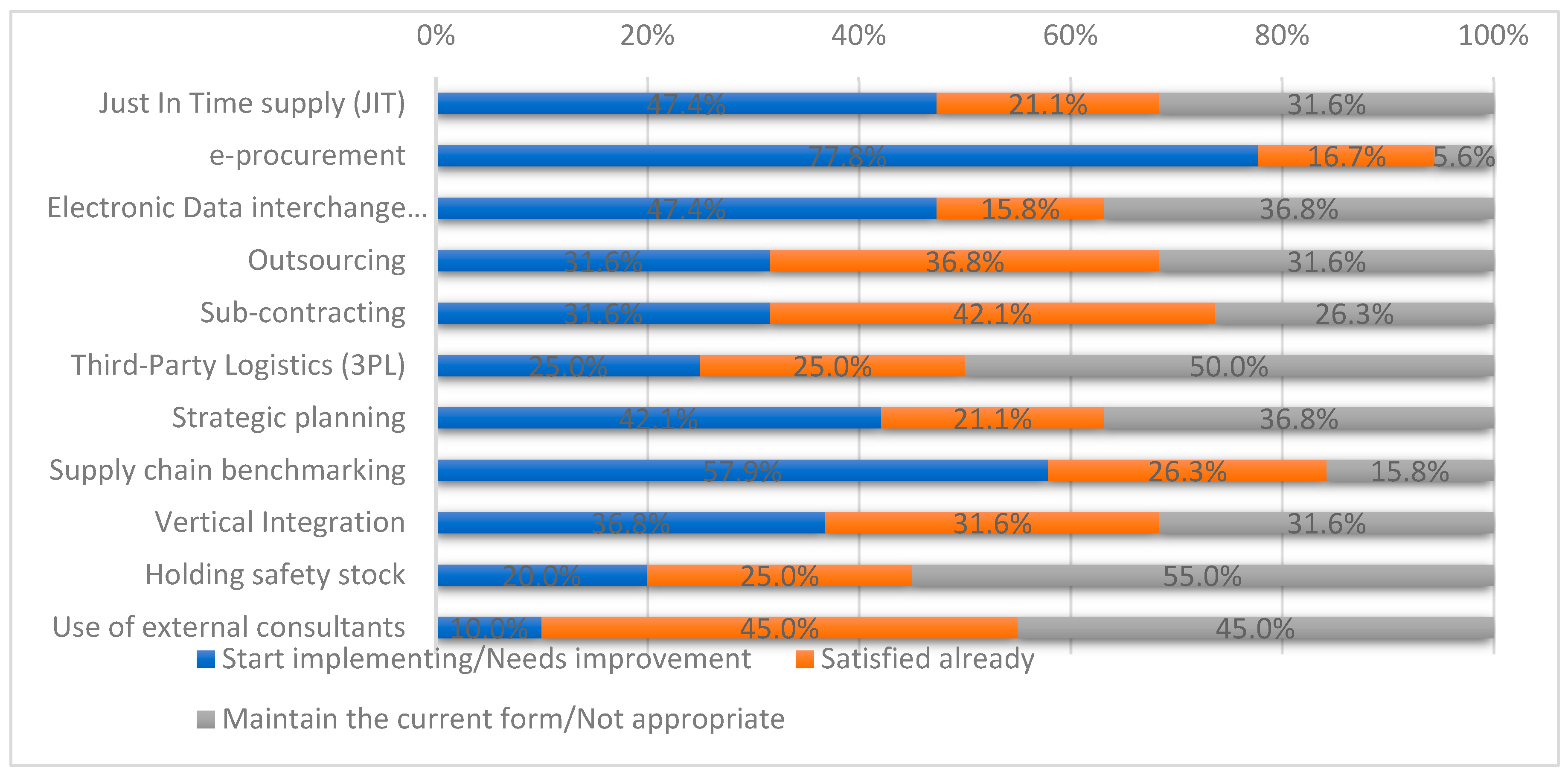

In Figure 2, we discuss how the listed companies are increasingly stable and well positioned to implement the different SCM practices in a bid to enhance firms’ performance in a developing economy.

As can be seen from Figure 1, there is a pressing demand to improve on e-procurement (77.8%), benchmarking (57.9%), just in time supply (47.4%) and electronic data interchange (47.4%). The listed results show that listed companies have not yet implemented or taken the initiatives to improve on these SCM practices to enhance organisational sustainable operational excellence. The results suggest that for SCM practices to thrive in the multinational companies, ineffective practices are expected to be improved to the satisfaction of SCL potentials. This suggests that the performance of each supply chain practice must be assessed contingent on how the practice has an important outcome on the resourceful integration of entire supply chain ecosystem. Our results are supported by the previous work of Dawe (2004) who exposed that for effective SCM, there must be an all-inclusive struggle to enhancement all of supply chain functions within a firm. Earlier works estimate that 76% of world-wide populace currently have access to the internet with 50% of them vigorously using social media (Facebook, LinkedIn, Instagram, twitter). More notably, nine out of ten internet users order conduct e-procurement, while 43% of corporations make usage of sophisticated big data analytics. On a light note, if digital SCM strategies are adopted in many of the business activities that take account of the social and environmental aspects, then matching of these issues may lead to the growth of manufacturing enterprises connected with the CE.

Furthermore, (e.g. Zhu et al., 2008; Silvestre, 2015) argue that management decision processes should consider the impact of SCM practices on the natural environment. Sehnmen et al, (2019) posit that corporations that are more proactive towards the CE exhibit improved management of critical success factors. But since the SCM practices compete against each other, it is imperative that the entire system of the supply chain function operates proficiently and hastily. Because, if management is ineffective to match economic development with the environmental sustainability aspects , such oversight may negatively impact on the society’s wellbeing and usage of natural resources.

While the sustainability concept has received great attention as a novel business technique to achieving sustainable operational excellence and improved firms’ performance in a CE, evidence in the emerging literature has still not been well documented in the developing nations (Craig and Carter, 2011; Del Giudice et al., 2021; Hina et al., 2022). This is attributable to a lack of resilience for the large enterprises to adapt the environmental sustainability strategies, which has left behind huge damage on sustainable development and economic development (Vermeulen and Metselaar, 2015; Hina et al., 2022; Beske, 2012). Succinctly, attention on supply chain practices must be focused on changing from functional and independent system to general and integrative system to attain firm’s sustainable operational excellence. Therefore, the positive accomplishment of SCL integration can be conceivable by the systematic application of several supply chain practice and central organisational structure (e.g. Figure 2).

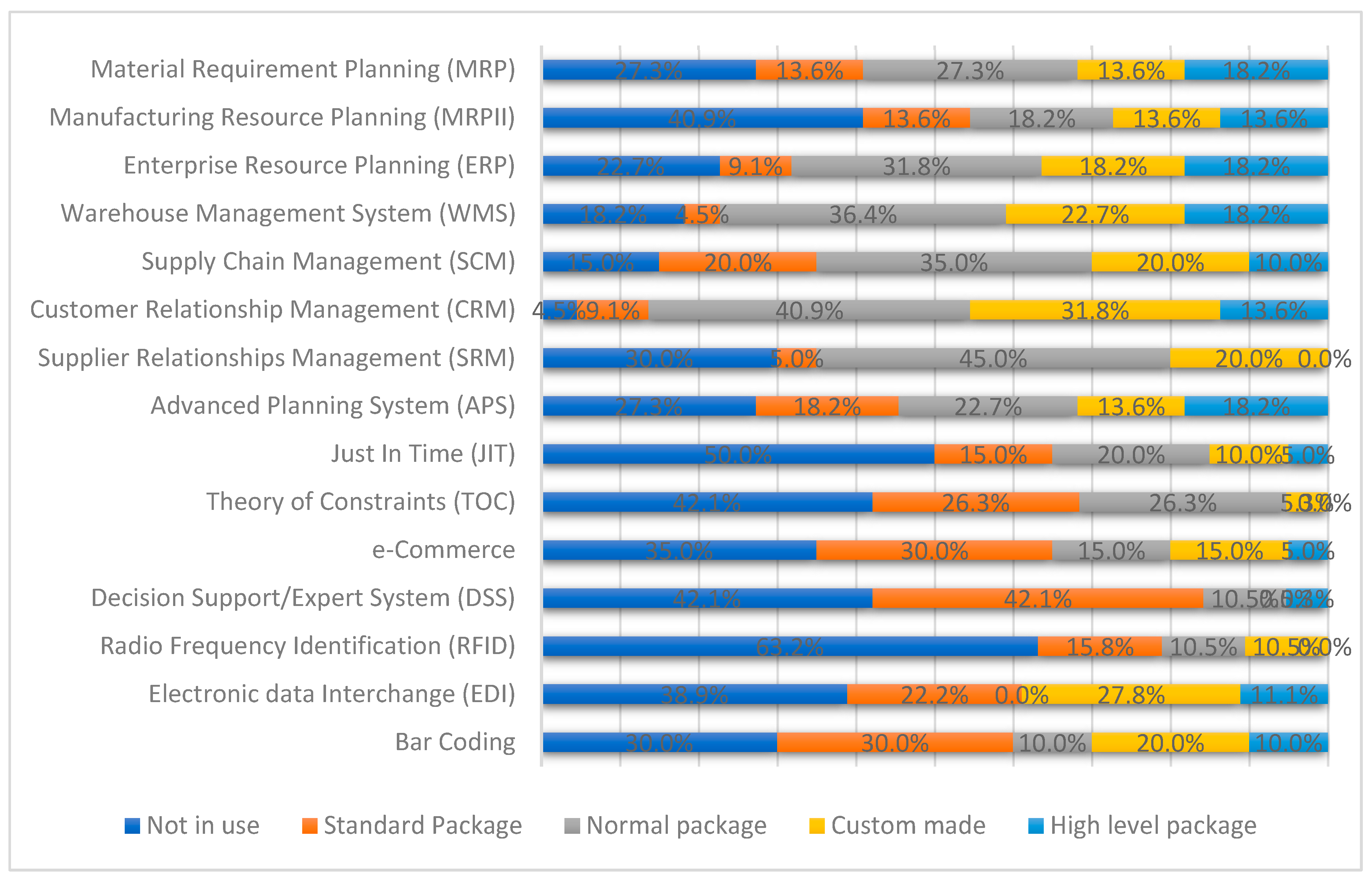

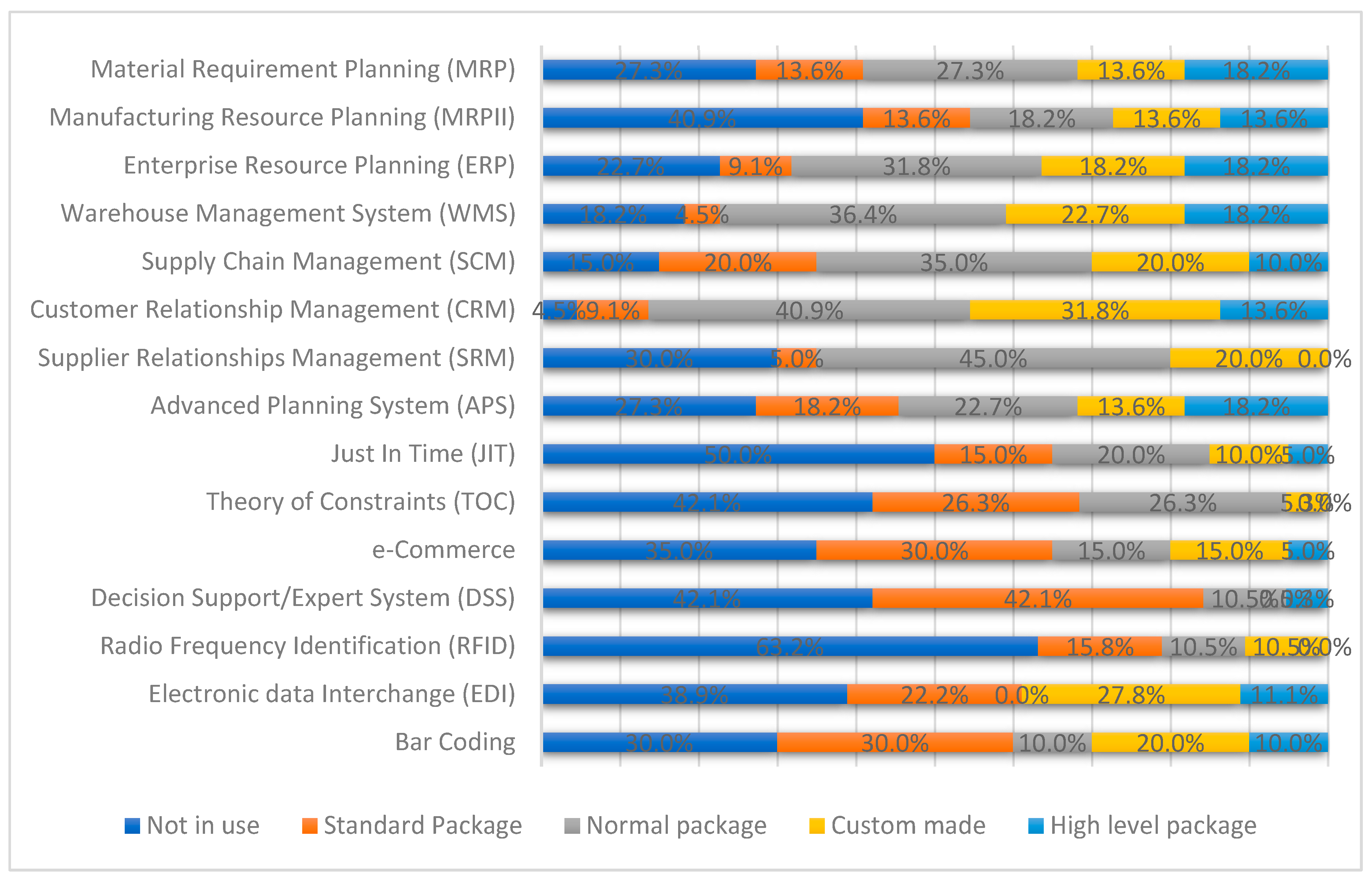

In the ensuing section, we evaluated the current approaches that the listed companies have implemented to support and adopt to SCL in a CE. In our analysis, a range of SCM strategies in reference to digitalisation of SCM systems in large companies were studied as illustrated in Figure 3. As demonstrated in Figure 2, although many of the SCM strategies indicated positive performance, we observe that RFID (63.2%), TOC (41.1%), JIT (50%), EDI (38.9%), DSS (42.1%) and e-commerce (35%) were found to be in not in use. The point to make is that given the evolutionary scene of supply chain sustainability trajectories, we highlight that natural resource-based supply chains are often more geographically restricted and disposed to local social demands than other supply chains. In other words, where a company is reluctant to quickly shift to the dynamics of the fourth industrial revolution and CE demands, this may influence the company’s returns and customer satisfaction and relationships.

Precisely, the results demonstrate a lack of corporate integration of some digitalised supply chain systems in a bid to achieve a sustainable business environment, such as, radio frequency identification (63.2%), just in time supply deliveries (50%), theory of constraints (42.06%), manufacturing resource planning (40.09%), and e-commerce (30%). These are essential digital supply chain management systems which can influence the company’s sustainable operational excellence and innovation capabilities, hence influencing the company’s returns, market share including sustenance of customer satisfaction. A quick comparison of our findings reveals comparable results with the work of Buyukozkan and Goçer (2017). They equally stated that emerging new technologies influence the growth and performance of every industry, and the supply chains and logistics services are no exception. Furthermore, previous work of Forbes Insights (2018) expose those disruptive technologies, such as big data analytics and artificial intelligence, impact how supply chain managers make strategic and operational decisions. Precisely, existing big data distributed on commercial digital mobile platforms, business analytics and social networks have not only provocatively transformed the modus operandi of numerous companies but then have also been utilised to attain enhanced performance by improving SSCM solutions (Muller et al., 2018; Tseng et al., 2018)

In light of foregoing, even if the listed companies in South Africa have made strides to realising digitalised SCM systems, there is room for improvement in the current approaches to support SCM in large companies. Particularly, numerous corporate processes for manufacturing and transporting goods and services to customers are still performed using the conventional supply chains, which involves geographically physical service centres dispersed in different provinces and countries, to assist in upholding effective SCM systems among them. In contrast, Buyukozkan and Goçer (2017) confirms this nature of structures demise the corporation’s economic independence owing to technological developments. It has been mentioned in previous literature that the recent industrial revolution has nearly influenced every aspect of society wellbeing across countries, and South Africa is not an exception. This revolution has not left the JSE listed-companies’ supply chain processes the same either.

First, digitalisation of the supply chain is seen as a shrewd, value-driven, efficient process to engender the company’s revenue and business value, plus a leverage with novel innovative technological and analytical methods as exhibited above (Figure 3). Silvestre (2015) asserts that SCL often face extra hurdles to execute sustainability strategies in developing economies. Such hurdles lead to more difficulties and fears on account of survival in an extremely turbulent business environments and institutional voids. Undeniably, the technological barriers sooner or later hamper the innovative capabilities and operational excellence of corporate, hence, reducing the slope of supply chains sustainability trajectories. In this regard, there is apparent need for multinational companies to adapt the technological changes, in a way to survive in the fourth industrial revolution while observing the environment turbulences triggered by the manufacturing activities. Our declaration for the large corporations to observe sustainability elements within the SCM processes is similar to the findings of Theeraworawit , Suriyankietkaew and Hallinger (2022). They contend that companies need to create sustainability business models considering a CE perspective, to allow SCM systems boost company contributions to sustainable production and consumption. Unfortunately, this concept continues to be misunderstood by corporate SCL of large manufacturing companies.

Hypothesis H2: Fostering SCM practices through innovation capabilities and operational excellence will make a positive contribution to sustainable development in the large firms.

4.3. Bivariate analysis

In this section, the quantitative analysis focuses on the research hypotheses and statistical hypotheses of the study. Both dependent and independent variables in this study informed the use of t-tests as well as ANOVAs for nonparametric analyses in the form of Mann-Whitney and Kruskal Wallis tests as ANOVA tests. Therefore, with regard to inferential statistical analysis, the inferences about the JSE-listed companies were made by estimating the parameters as well as testing the hypotheses. To see whether the two groups differed regarding how successful they thought their companies in general are in managing their supply chain operations, the non-parametric Mann-Whitney U test was used (Table 2).

Table 1 and Table 2 illustrate the operation of companies under any SCM public policy. There is a significant difference between the groups at a 1% level of significance (U = 15.00, p < 0.01). Specifically, those participants with lower values on the three indices (MR = 13.25) were significantly more satisfied with the current public policy regarding SCM than those with higher values on the three indices (MR = 6.38). The results provide insight to arrive at a conclusion that how well the company is positioned for effective SCM is not an indicator of annual sales/turnover and also not for total assets. The discussion under this hypothesis is centred on operations under any public policy in SCM that accelerate smooth operations for the attainment of a competitive advantage. Therefore, two major activities of operational excellence and innovation are necessary to achieve competitive advantage.

Question 17 sought to get an indication of how satisfied the participants are regarding their current policy on SCM. The results provide a reflection that operational excellence and innovation are necessary for the company and contribute towards a competitive advantage. However, it is unclear as to whether public policies on SCM in developing economies are needed, especially about JSE-listed companies. Given that JSE-listed companies are multinational, it is difficult to assess the efficacy of public policies on SMC, for instance, from which country should the multinational companies comply with these public policies. Aware that more than 85% of companies reported that they were not operating under any public policy on SCM, this is a clear confirmation for noncompliance to government SCM policies in the developing economies. While the answer is not definite, perhaps the point of departure should be whether the policies are needed for multinational companies and from which country they are applicable to multinational companies. Interestingly, we discovered that compliance to public policies had minimal impact on the actual functions that are perceived to affect the efficiency of SCM in the company. Therefore, the functions of inventory, transportation, lead time, purchasing and production planning are independent functions that are not dictated by how well the company is positioned for effective SCM.

In the next step, using the nonparametric Mann-Whitney U test, we compared the participants who were well positioned to those who still need to get there in terms of assessing their SCL standing in of driving sustainable operational excellence. Table 3 illustrates that nine of the most important supply chain strategies available to companies for SCL position are improved customer satisfaction, increased profitability, reduction of bureaucracy/paperwork, increased market competitiveness, cost reduction, improved quality assurance, increased revenue growth, increased capacity for decision making and improved product management. On each strategy, the determination is made on how well the company is positioned for effective SCM to ultimately culminate in SCL for the company.

Table 3.

Major supply chain management strategies for sustainable development of large firms.

| Research questions | How well the company is positioned for effective SCM | N | Mean Rank | Sum of Ranks |

| Q26_1 Improved customer satisfaction | Well, positioned | 6 | 10.00 | 60.00 |

| Still to get there | 12 | 9.25 | 111.00 | |

| Total | 18 | |||

| Q26_2 Increased profitability | Well, positioned | 6 | 11.00 | 66.00 |

| Still to get there | 12 | 8.75 | 105.00 | |

| Total | 18 | |||

| Q26_3 Reducing bureaucracy/paperwork | Well positioned | 6 | 12.00 | 72.00 |

| Still to get there | 11 | 7.36 | 81.00 | |

| Total | 17 | |||

| Q26_4 Increased market competitiveness | Well positioned | 6 | 8.92 | 53.50 |

| Still to get there | 11 | 9.05 | 99.50 | |

| Total | 17 | |||

| Q26_5 Cost reduction within organisation | Well positioned | 6 | 12.50 | 75.00 |

| Still to get there | 12 | 8.00 | 96.00 | |

| Total | 18 | |||

| Q26_6 Improved quality assurance | Well positioned | 6 | 8.67 | 52.00 |

| Still to get there | 11 | 9.18 | 101.00 | |

| Total | 17 | |||

| Q26_7 Increased revenue growth | Well positioned | 6 | 9.17 | 55.00 |

| Still to get there | 12 | 9.67 | 116.00 | |

| Total | 18 | |||

| Q26_8 Increased capacity for decision making | Well positioned | 6 | 11.17 | 67.00 |

| Still to get there | 11 | 7.82 | 86.00 | |

| Total | 17 | |||

| Q26_9 Improved product management | Well positioned | 6 | 11.67 | 70.00 |

| Still to get there | 11 | 7.55 | 83.00 | |

| Total | 17 |

Table 3.

The non-parametric Mann-Whitney U Test Statisticsa.

| Mann-Whitney U | Wilcoxon W | Z | Asymp. Sig. (2-tailed) | Exact Sig. [2*(1-tailed Sig.)] | |

| Q26_1 Improved customer satisfaction | 33.000 | 111.000 | -.390 | .697 | .820b |

| Q26_2 Increased profitability | 27.000 | 105.000 | -1.304 | .192 | .437b |

| Q26_3 Reducing bureaucracy/paperwork | 15.000 | 81.000 | -2.153 | .031 | .078b |

| Q26_4 Increased market competitiveness | 32.500 | 53.500 | -.057 | .955 | .961b |

| Q26_5 Cost reduction within organization | 18.000 | 96.000 | -2.038 | .042 | .102b |

| Q26_6 Improved quality assurance | 31.000 | 52.000 | -.254 | .799 | .884b |

| Q26_7 Increased revenue growth | 34.000 | 55.000 | -.216 | .829 | .892b |

| Q26_8 Increased capacity for decision making | 20.000 | 86.000 | -1.452 | .147 | .216b |

| Q26_9 Improved product management | 17.000 | 83.000 | -1.816 | .069 | .122b |

| a. Grouping Variable: How well the company is positioned for effective SCM | |||||

| b. Not corrected for ties. | |||||

Source; Primary data, (2019).

As can be seen in Table 3, the results confirm a significant difference between the groups at the 5% level of significance regarding how important they considered cost reduction to be within the organisation for its SCL position (U = 15.00, p < 0.05). Specifically, those participants with lower values on the three SCM readiness indices (MR = 7.36) considered the cost reduction as significantly less important for its SCL position than those with higher values on the three indices (MR = 12.00). Furthermore, there is a significant difference between the groups at the 5% level of significance regarding how important they considered the reduction of bureaucracy/paperwork for its SCL position (U = 18.00, p < 0.05). Specifically, those participants with lower values on the three SCM readiness indices (MR = 8.00) considered the reduction of bureaucracy/paperwork as significantly less important for its SCL position than those with higher values on the three indices (MR = 12.50).

These results answer our research Hypothesis (H2): Fostering SCM practices through innovation capabilities and operational excellence will make a positive contribution to sustainable development in the large firms.

In an ideal situation, this often does not go unopposed as multinational corporations have a duty to observe environmental sustainability in a CE. Our findings reveal that subject of integrating SSCM strategies into these companies to promote their innovation capabilities and operational excellence is still lacking. Several companies looked at sustainability concept in the lens of a going concern, that is to adequately make good profits and expand their market shares to meet their customer demands. Besides, adopting CE philosophy along the supply chain needs the success, explanation and use of satisfactory data and familiarity to effectively execute the desired fluctuations in business operations are still wanting (Gupta et al., 2019; Sumbal et al., 2019). Earlier report of dti, 2019 revealed that the manufacturing sector accounts for about 11% of the total South African workforce, down from 14% in 2008. The rise of digital and changes in manufacturing technologies, specifically SSCM approached might have led to the decline of employment in the sector. Therefore, it necessarily follows that large manufacturing corporations in South Africa have to quickly shift to the new approaches of SCM which consider the digital aspects and sustainability protectionism.

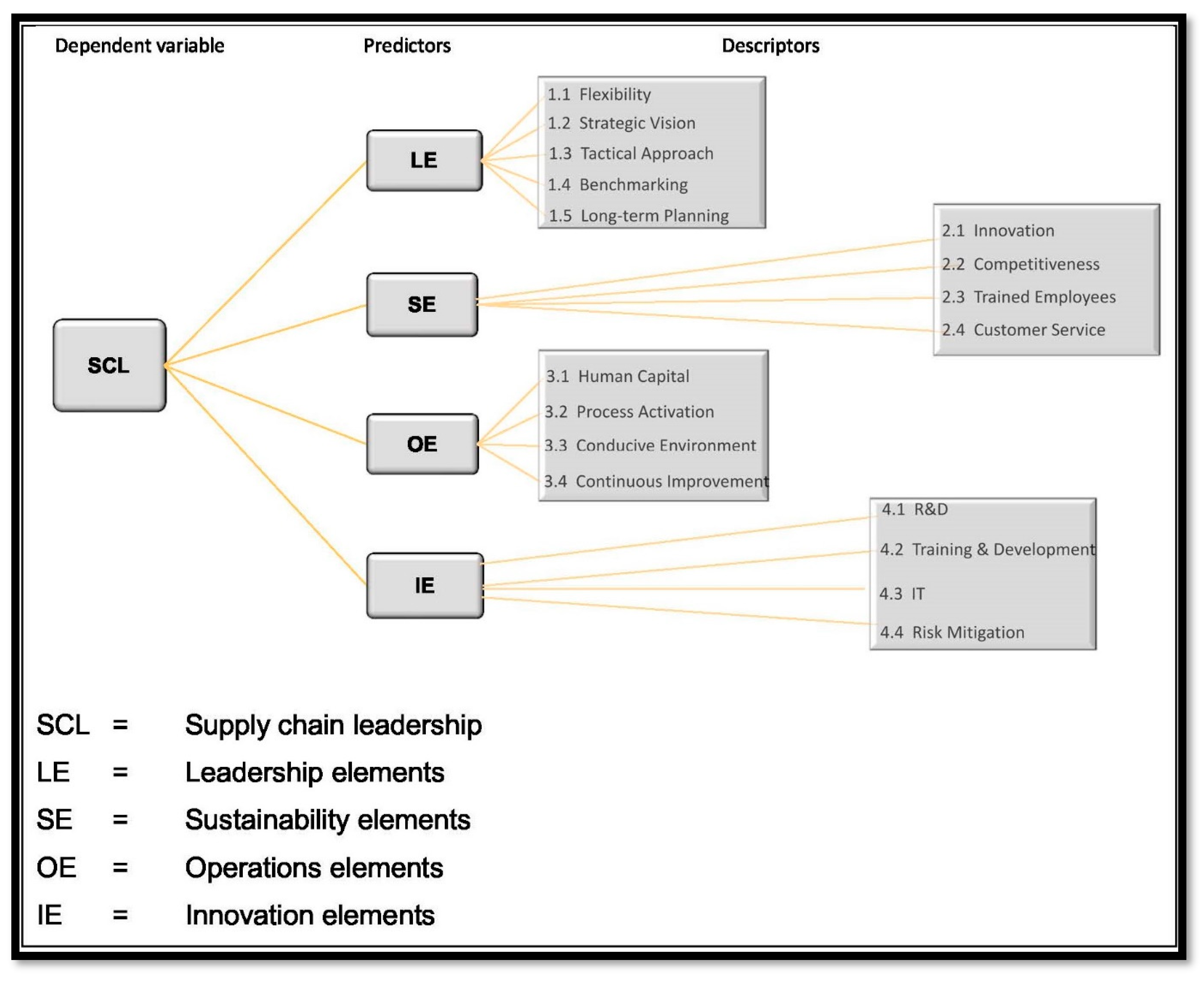

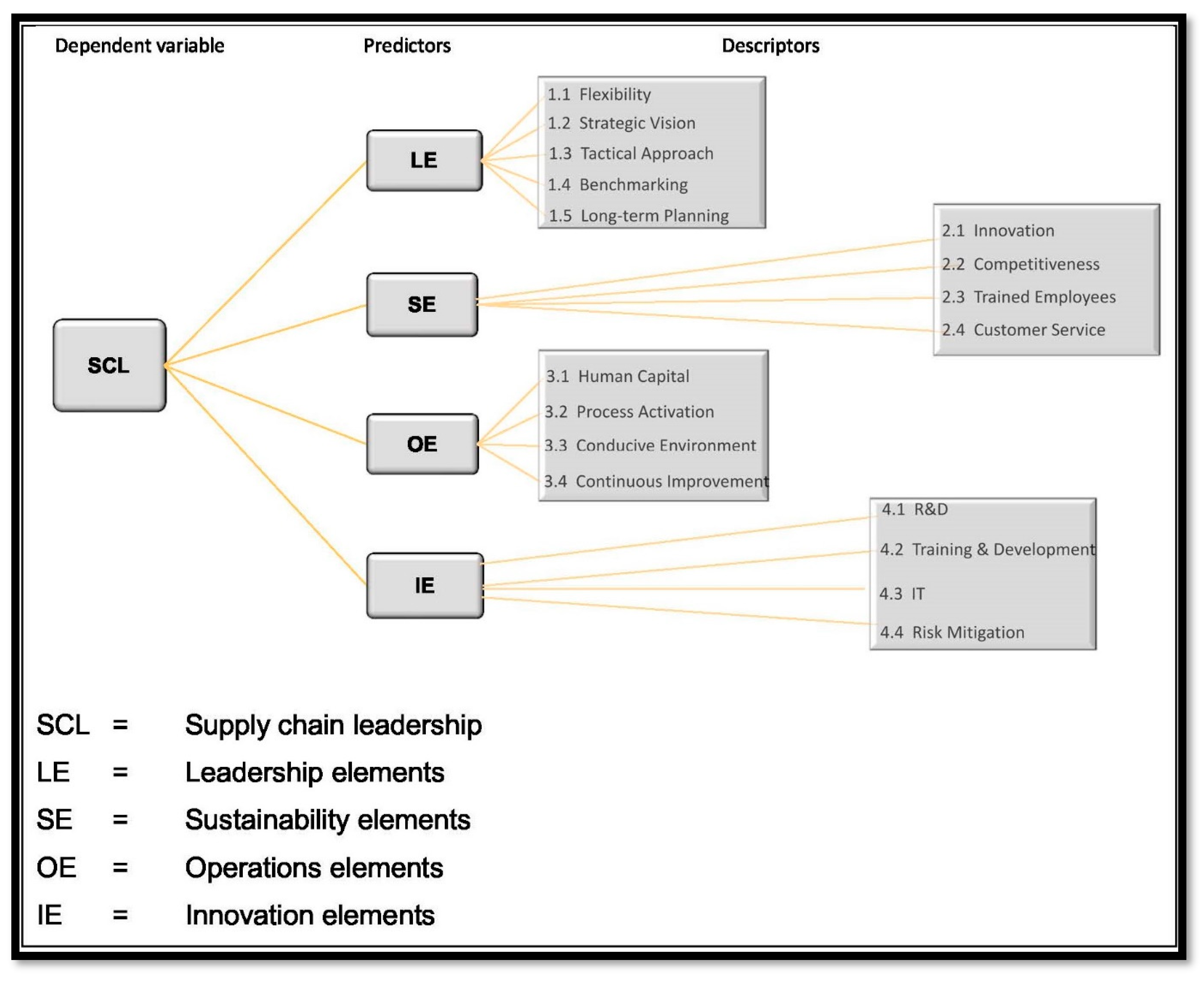

5. SCL Proposed Research Model

To achieve the primary objective of this study, the model for SCL with regard to operational excellence and innovation in a developing economy is presented in Figure 4. The model consists of a dependent variable (SCL) and four independent variables, also termed the predictors, namely, LE, SE, OE, and IE. As indicated in Figure 4, drawing on the proposed SCL model, each of the predictors in the model comprises various key variables (descriptors), which are explained are illustrated in Figure 5. The descriptors associated with the LE predictor are flexibility, strategic vision, tactical approach, benchmarking, and strategic planning; SE descriptors are innovation, competitiveness, trained employees, and customer service; OE descriptors are human capital, process activation, conducive environment, and continuous improvement; and IE predictors are R&D, training, and development, IT and risk mitigation. These are the descriptors of the predictors for building a SCL model. In general, the model is more significant, and all the predictors were found to contribute significantly.

Recently, many business leaderships of multinational companies have received mounting pressure from policymakers, experts, and environmental activists to tolerate the fundamental notion of a CE (Marino, & Pariso, 2022). The concept of innovative SCL in this context embodies a substantial transformation from the conventional supply chain management practices to the integration of economic activities and sustainable development (Jabbour et al., 2019). The novel approach to business operations demands for explanation of new corporate models that lead to higher performance in socio-economic and nascent environmental standings (Stahel, 2016; Teixeira et al., 2016). In order to appreciate the benefits of sustainable development, prodigious devotion is desirable to shift to a CE era that permits resourceful usage of materials and reduction of waste production (Gupta et al., 2019).

As can be seen in Figure 4, it can be concluded that SCL= f (LE, SE, OE, IE). This model was performed and applicable in South Africa as one of the developing economies. The JSE-listed companies were selected to ensure global relevance because a significant percentage of the top 100 JSE-listed companies are multinationals. As a result, to achieve SSCM with reference to operational excellence and innovation, companies ought to focus on the four predictors in the model, being LE, SE, OE, and IE that positively impact on SCL from a developing economy perspective. Among the four predictors, LE was unsurprisingly found to be at the highest level of the SCL model, while IE represented the lowest level of the model. In other words, when the model is implemented, the LE should represent the foundation on which the other three predictors are built.

Taking into consideration that SCM systems typically complement each other, it is inevitable to ensure that phases of SCM mechanism function resourcefully and rapidly so that the entire system can perform sustainably. This SCM model is consistent with the existing literature as discussed in section 2. Because previous scholars have exposed that if one stage of SCM system is defective or displays little degree of sensitivity to developing sustainability and social issues, then whole SCM system will suffer and ultimately be unsuccessful (Hall et al., 2011). We find three interconnected fundamentals needed for an operative and sustainable supply chain, that is integration, collaboration, and innovation which earlier studies ignored. In contrast, SCL model expounds clearly on innovation elements, the collaboration and integration aspect are missing. Yet, these are fundamental ingredients to realising a sustainable growth and development in a CE perspective. Consistent improvement in green manufacturing capacity and operational excellence, demand a “constant watch” of supply side issues such as labour, skills, and material costs (Dylan Slater, March 2018). To this end, innovation and technology, which is continually cultivating job creation and economic motivation, which remains government’s first priority in motivating domestic and foreign investment to the economy. Therefore, future studies can attempt to improve this model by considering how collaboration and integration elements might influence the supply chain governance system in the developing countries.

In addition, the study reveals that the issue of sustainability as a key aspect towards companies still remains a topic for future research. Sustainability involves the activities that companies tend to do to remain relevant in business for a long period while providing desired goods and services to their customers and entails all those supply chain activities that companies sought to implement from the beginning to the end in the quest of the provision of goods and services for customer satisfaction. Therefore, the company needs operational excellence, procurement excellence and logistics excellence plus innovation to survive. However, innovation should not only be applied in terms of the product, but also the processes of the company. To achieve SCL in a developing economy, a conducive environment should be created which allows sharing of information and trust among all the stakeholders within the organisation and proper coordination of SCM strategic activities within the organisation. Moreover, the management and leadership of the company should be exposed to global standards or international companies. Sustainability and the concept of CE demand the corporate companies to commit on all aspects of management of environmental issues as laid down in the UN development 17 SDGS.

6. Contribution to Knowledge and Implications

The study makes significant contribution to the body of knowledge because it provides SCL model for developing economies. The model should serve as a frame of reference for supply chain managers, practitioners and scholars in the field of SCM. For the first time in a developing economy, the SCM strategic actions were used to generate a SCL model that profiles supply chain leaders from a list of JSE-listed companies. The profiling sought to fill a significant gap in the body of knowledge by clarifying the important strategic actions and aspects that are critical for consideration to SCL in a developing economy to achieve operational excellence and innovation. Currently, there is no model in existence for SCL from a developing economy perspective. In this study, the model for SCL was developed in the context of a developing economy from JSE-listed companies in South Africa. More importantly, it is presumed that with this model, managers will be informed appropriately with the necessary information to make decisions to either maintain or forego their supply chain practices.

The SCL model is expected to assist in fostering the sharing of best practices as well as raising the bar of performance for South African companies and for the broader supply chain community from the South African perspective. This is an issue of great significance to the discipline of SCM because it is deemed necessary for firms that strive to create a competitive advantage to enhance their activities in terms of operational excellence and innovation. Besides, the study contributes to existing literature on SCL by partly closing the gap of the lack of understanding and inadequate knowledge about the vital strategic activities in the supply chains to realise operational excellence and innovation in a developing economy perspective.

7. Conclusion

The primary objective of this research was to develop a model that allows companies to identify strategic actions in SCM to be taken to attain SSCM in a developing economy. Therefore, it was critical to generate empirical evidence to ascertain the common characteristics of SCM in the context of developing economies for SCL to thrive. Undeniably, there is a renewed energy in the field of SCM in relation to sustainable development given the industrial revolution that focuses on operational excellence and innovation. Aware of international high-tech fluctuations, regulations and politics, developing economies need to be better equipped to handle social-economic and environmental sustainability challenges. In this context, the fundamentals of innovation, operational excellence, sustainability, and leadership are all called for to develop seamless supply chains individually and jointly for competitiveness.

In pursuit of operational excellence and innovation, SCM was considered as a viable alternative in a developing economy to improve on business activities for the satisfaction of customer needs. This is because the practice of SCM provides a positive contribution to the performance of a company, thereby creating a competitive advantage. Seemingly, the transformation in SCM activities has prompted companies to review their set goals and objectives together with those in the global competitive landscape of contemporary SCM for the achievement of SCL in a developing economy. On a different standpoint, several companies are only in the early stages of the circular economy agenda, demanding momentous material support in terms of technical and educational experiences to facilitate a sustainable transformation to a circular economy (Marino, & Pariso, 2022) Notwithstanding these obstacles, it is crucial for companies to identify strategic actions in SCM processes for operational excellence and innovation that lead to SCL.

8. Limitations and Directions for Future Research

Albeit the study makes vital contribution to the SCM domain in line of sustainable development in a CE, it was exposed to some limitations too, which offers openings for future research in this field. First, the survey was confined to 46 JSE listed companies, yet currently there are 349 companies listed on the JSE. Besides, it was observed that eight of the top ten companies listed on the JSE in 2017 were cross listed on other stock exchanges. These corporations combined accounted for 54% of the total JSE market capitalisation. Nonetheless, these limitations do not in any undermine the overall excellence of the study but rather offer greats insights for future research direction. Accordingly, aware of the global nature of the listed companies, it is important that future empirical studies involving large samples beyond JSE listed-companies, for instance, extending the sample to listed firms on Nairobi Stock Exchange, Lagos Stock Exchange and Cairo Stock Exchange and then again compare results with listed companies in the develop economies, would offer in-depth understanding about the subject, and interesting to establish the similarities as well as the contrasting outcomes from the two perspectives of the different economies.

Moreover, given the role SCL can play in enforcing sustainable development in a CE, such as, growing innovation capabilities and operations excellence to realise sustainability performance toward the CE, the study did not devolve much attention to interrelations with formal institutional antecedents, such as laws and regulations linked to a CE at the national level. Therefore, additional research in this field should try to examine the multi-layered interaction between SCM practices in a CE with reflection on sustainability aspects.

Furthermore, owing to the paucity of data regarding SCM practices in the lens of sustainable development and transition to CE, a future study that investigates the role of SSCM practices on the sustainable growth and development of large firms beyond the listed companies would be desirable. This is because it seems that an extensive participation of large firms in the struggle to promote green manufacturing and sustainability in a CE is the new normal if these firms are to remain competitive in a global dynamic economy. Therefore, there is an outward demand to use different sample criteria in future explorations to choose the companies and, increasing the time limit of the statistical data analysis with proficiency to examine the progress of sustainable development in CE over the years.

References

- Aboelmaged, M.G. Sustainable Supply Chain Management in a Developing Context: An Empirical Examination of Antecedents and Consequences. International Journal of Social Ecology and Sustainable Development (IJSESD) 2012, 3, 22–41. [Google Scholar] [CrossRef]

- Ashby, A.; Leat, M.; Hudson-Smith, M. Making connections: A review of supply chain management and sustainability literature. Supply Chain Management: An International Journal 2012, 17, 497–516. [Google Scholar] [CrossRef]

- Bendul, J.C.; Rosca, E.; Pivovarova, D. Sustainable supply chain models for base of the pyramid. Journal of Cleaner Production 2016, 162, S107–S120. [Google Scholar] [CrossRef]

- Craig, R. Carter. Sustainable supply chain management: Evolution and future directions’ International Journal of Physical Distribution & Logistics Management 2011, 41, 46–62. [CrossRef]

- Del Giudice, M.; Chierici, R.; Mazzucchelli, A.; Fiano, F. Supply chain management in the era of CE: the moderating effect of big data. The International Journal of Logistics Management 2021, 32, 337–356. [Google Scholar] [CrossRef]

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Diniz JD, A.S.; Fabbe-Costes, N. Supply Chain Management and Supply Chain Orientation: Key factors for sustainable development projects in developing countries? International Journal of Logistics: Research and Applications 2007, 10, 235–250. [Google Scholar] [CrossRef]

- García-Sánchez, I.M.; Somohano-Rodríguez, F.M.; Amor-Esteban, V.; Gonzalez-Valdueza, B. Circular Economy Projects and Firm Disclosures in an Encouraging Institutional Environment. Sustainability 2022, 14, 1149. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. Journal of Cleaner Production 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Golicic, S.L.; Smith, C.D. A meta-analysis of environmentally sustainable supply chain management practices and firm performance. Journal of Supply Chain Management 2013, 49, 78–95. [Google Scholar] [CrossRef]

- Goyal, S.; Esposito, M.; Kapoor, A. Circular economy business models in developing economies: Lessons from India on reduce, recycle, and reuse paradigms. Thunderbird International Business Review 2018, 60, 729–740. [Google Scholar] [CrossRef]

- Hina, M.; Chauhan, C.; Kaur, P.; Kraus, S.; Dhir, A. Drivers and barriers of circular economy business models: Where we are now, and where we are heading. J. Clean. Prod. 2022, 333, 130049. [Google Scholar] [CrossRef]

- Hoof, V.B.; Thiell, M. Anchor company contribution to cleaner production dissemination: experience from a Mexican sustainable supply programme. Journal of Cleaner Production 2015, 86, 245–255. [Google Scholar] [CrossRef]

- Jayanti, R.K.; Rajeev Gowda, M.V. Sustainability dilemmas in emerging economies. IIMB Management Review 2014, 26, 130–142. [Google Scholar] [CrossRef]

- Kao, P.; Redekop, W.; Mark-Herbert, C. Sustainable supply chain management-the influence of local stakeholder expectations in China's agri-food industry. Journal on Chain and Network Science 2012, 12, 273–289. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Marino, A.; Pariso, P. Africa’s View of the Circular Economy: Bottlenecks and Opportunities. The International Journal of Environmental Sustainability 2022, 19, 1. [Google Scholar] [CrossRef]

- Sehnem, S.; Jabbour, C.J.C.; Pereira, S.C.F.; de Sousa Jabbour, A.B.L. Improving sustainable supply chains performance through operational excellence: Circular economy approach. Resources, Conservation and Recycling 2019, 149, 236–248. [Google Scholar] [CrossRef]

- Silvestre, B.S. Sustainable supply chain management in emerging economies: Environmental turbulence, institutional voids and sustainability trajectories. International Journal of Production Economics 2015, 167, 156–169. [Google Scholar] [CrossRef]

- Svensson, N.; Funck, E.K. Management control in circular economy. Exploring and theorizing the adaptation of management control to circular business models. J. Clean. Prod. 2019, 233, 390–398. [Google Scholar] [CrossRef]

- Tan, C.L.; Zailani SH, M.; Tan, S.C.; Shaharudin, M.R. The impact of green supply chain management practices on firm competitiveness. International Journal of Business Innovation and Research 2016, 11, 539–558. [Google Scholar] [CrossRef]

- Tencati, A.; Russo, A.; Quaglia, V. Unintended consequences of CSR: protectionism and collateral damage in global supply chains: the case of Vietnam. Corporate Governance: The International Journal of Business in Society 2008, 8, 518–531. [Google Scholar] [CrossRef]

- Turker, D.; Altuntas, C. Sustainable supply chain management in the fast fashion industry: An analysis of corporate reports. European Management Journal 2014, 32, 837–849. [Google Scholar] [CrossRef]

- Vermeulen WJ, V. Sustainable supply chain governance systems: Conditions for effective market based governance in global trade. Progress in Industrial Ecology - An International Journal 2010, 7, 138–162. [Google Scholar] [CrossRef]

- Vermeulen WJ, V.; Metselaar, J.A. Improving sustainability in global supply chains with private certification standards: testing an approach for assessing their performance and impact potential. International Journal of Business and Globalisation 2015, 14, 226–250. [Google Scholar] [CrossRef]

- Vitolla, F.; L’Abate, V.; Petruzzella, F.; Raimo, N.; Salvi, A. Circular Economy Disclosure in Sustainability Reporting: The Effect of Firm Characteristics. Sustainability 2023, 15, 2200. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K.-h. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. Journal of Environmental Management 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K.H. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. Journal of Environmental Management 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

Figure 1.

Composition of the JSE listed companies. Source: Primary data, (2019).

Figure 2.

Status of implementation of SCM practices in the listed companies. Source: Primary data, (2019).

Figure 2.

Status of implementation of SCM practices in the listed companies. Source: Primary data, (2019).

Figure 3.

Assessment of current approaches to support SCM in large companies. Source; Primary data, (2019).

Figure 3.

Assessment of current approaches to support SCM in large companies. Source; Primary data, (2019).

Figure 5.

Corporate companies SCM Model.

Table 1.

Sample composition of JSE Listed companies.

| Category of Industries | Percentage (%) |

| Manufacturing | 9% |

| Retail, wholesale trade, commercial agents, and allied services | 18% |

| Mining, quarrying and agriculture | 8% |

| ICT, transport, logistics and storage | 18% |

| Finance and business services | 25% |

| Catering, accommodation, property, and hospitality | 22% |

| Total | 100% |

Source: Primary data, (2019).

Table 2.

Using non-parametric Mann-Whitney U to test level of integration of public policy and SCM strategies.

Table 2.

Using non-parametric Mann-Whitney U to test level of integration of public policy and SCM strategies.

| How well the company is positioned for effective SCM | N | Mean Rank | Sum of Ranks | |

| Q17_1 Operation under any SCM public policy | Well, positioned | 8 | 6.38 | 51.00 |

| Still to get there | 12 | 13.25 | 159.00 | |

| Total | 20 |

Source: primary data, (2019).

Table 3.

Mann-Whitney and Kruskal Wallis Test Statistics a.

| Q17_1 Operation under any SCM public policy | |

| Mann-Whitney U | 15.000 |

| Wilcoxon W | 51.000 |

| Z | -2.684 |

| Asymp. Sig. (2-tailed) | .007 |

| Exact Sig. [2*(1-tailed Sig.)] | .010b |

| a. Grouping Variable: How well the company is positioned for effective SCM | |

| b. Not corrected for ties. | |

Source: Primary data, (2019).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

Submitted:

26 October 2023

Posted:

27 October 2023

You are already at the latest version

Alerts

This version is not peer-reviewed

Submitted:

26 October 2023

Posted:

27 October 2023

You are already at the latest version

Alerts

Abstract

The effective implementation of a sustainable supply chain leadership (SSCL) strategy at each organization’s level, positively impacts on corporation’s competitive advantage and sustainable development. While fears have been acknowledged in previous literature, the benefit of designing Sustainable supply chain models for operational excellence and sustainable development is a noteworthy exploration. The study collected statistical data using an online Survey- monkey questionnaire from 46 of the top 100 JSE-listed companies with the intention to elucidate the large firms’ transition from longstanding linear approaches to sustainable production and consumption to a more circular approach. A bivariate data analysis was used to generate the results in SPSS. The results indicate a positive contribution of SSCL strategy to operational excellence and sustainable development of large corporations if only the entire supply chain system is well-coordinated and implemented. This study makes a vital contribution by proposing a new SSCL model for fast-tracking corporate sustainability and enhancing corporate contributions to sustainable growth.

Keywords:

Subject: Business, Economics and Management - Business and Management

1. Introduction

In recent years, the concept of the supply chain has garnered a robust literature which has studied how supply chain management (SCM) practices and operational excellence can be integrated with sustainable development (Vermeulen & Metselaar, 2015; Silvestre, 2015), along with environmental sustainability to facilitate collaboration and organisational performance across nations (Suhong- Li et al., 2006; Svensson & Funck, 2019; Del Giudice et al., 2021; Marino, & Pariso, 2022). Research indicates that operational excellence driven by SCM practice can lead to improved competitive advantage and enhanced organisational performance (Luthra and Mangla, 2018). Accordingly, the demand for innovative corporate models that lead to higher performance in social-economic and nascent environmental standings is inevitable to appreciate the benefits of sustainable production and consumption. Although prior literature on SCM has made many valuable contributions, there is a dearth of empirical evidence and theoretical reflection on the characteristics of supply chains that operate mainly in emerging economies. Yet, transformation from the conventional SCM mechanisms to the ecologically sustainable supply chain management (SSCM) practices and firm performance permits resourceful usage of materials and reduction of waste production (Geissdoerfer et al., 2018; Sehnem et al., 2019).

The notion of SCM has received an analogous growing interest from researchers, experts and business managers (Suhong-Li et al., 2016). Several large firms have started to acknowledge the reputation of SCM strategic actions in fostering sustainable competitive edge for their goods services in a fragile fourth industrial revolution. However, the concept of SCM has been studied from different perspectives in the diverse bodies of literature. Scholars (Kayikci, 2021; Kuei et al., 2013) offer unrelated conclusions and insights on specific aspects or perspectives of SCM and posit that the need to observe the sustainability elements in a manufacturing globalization era has raised mounting pressure on the large companies across countries. In the same line, Walker and Jones (2012) added that the global transformation of manufacturing companies has created destructive effects on the ecosystem, such as carbon emissions, hazardous chemical leakages, and pollution.

Still from an academic standpoint, even though the literature on SCM leadership offers various conceptual insights focused on different research fields, that is, resourceful usage of supplies and their productivity (e.g. Goyal, Esposito & Kapoor, 2018), the evolution to CE approaches still is not well presented (e.g., Del Giudice, 2021; Marino, & Pariso, 2022). In contrast, Aboelmaged (2012; ) explored the operation of CE policies in diverse nations and sectors. However, the knowledge of such policies and its drivers remains questionable in the current literature. Besides, Da Silva, Jerónimo, and Vieira (2019) contend that additional studies are desirable to demonstrate the characteristic benefit of a leadership-driven environment. Although many challenges have been identified, Geissdoerfer et al. (2017) confirm that the rewards of implementing sustainable development in a circular economy (CE) are notable.