1. Introduction

The reuse of wood elements in architectural projects has gained popularity in recent years due to potential benefits in terms of sustainability and cost-effectiveness. Architects who incorporate reused wood elements into their designs may experience a range of advantages and challenges. From an environmental perspective, reusing wood can reduce waste and carbon footprint, and help to conserve natural resources. Additionally, reuse can be more cost-effective than buying new wood and add value to a building by creating a rustic or vintage look that appeals to clients.

Circular construction is a design and construction approach that promotes sustainability and resource efficiency by using renewable resources and recycling materials, and reducing waste [

1]. It aligns with the principles of the circular economy and aims to create a closed-loop system where resources are used and reused in a sustainable manner [

2]. Key aspects of circular construction are sustainable material sourcing and use, reusing and repurposing materials, designing for longevity and adaptability, efficient deconstruction and recycling practices, minimizing waste and energy consumption, embracing renewable resources like wood, and promoting a circular economy for construction.

However, incorporating reused wood elements can also present structural challenges for architects. The structural integrity of the reused wood may be compromised, requiring careful evaluation and design adjustments. Despite several challenges (such as health concerns, or special care and maintenance demands), the aesthetic appeal and sustainability-related benefits make the reuse of wood elements a trend in architecture that is likely to continue in the years to come.

1.1. Background

Building sector is currently responsible for about 28% of global energy-related carbon dioxide (CO

2) emissions. The share rises to about 40% if CO

2 emissions from the production of building materials are included. Furthermore, construction products have a significant amount of embodied energy that is the energy used for their processing. Materials are, therefore, a key to mitigating the embodied emissions of buildings [

3,

4]. At the end of a building’s lifespan, materials with high embodied energy often end up in landfills. “Only in 2018, about 2.4 billion tons of waste was generated in the member countries of the European Union (EU), highlighting the magnitude of the problem [

5]. Construction and demolition waste (C&D waste) is one of the heaviest and the most voluminous waste streams generated in the EU; approximately a quarter of all waste generated consists of various materials that could be recycled [

6].

The circular economy (or circularity) transition of the built environment is seen as one of the ways forward to cope with the huge amount of construction and demolition waste generation [

7]. Buildings must be viewed as material repositories, and their disassembly must be considered already during the design stage of a project. In this way, waste will be avoided and materials returned to the cycle repeatedly. Deconstruction, therefore, has the potential to reduce greenhouse gas (GHG) emissions from the construction sector by making reusable construction materials available, and by reducing the demand for new materials in construction projects [

8]. Deconstruction can be more cost-effective than demolition when considering the reduction in landfill disposal costs and the revenue from salvage [

9]. Salvaged materials from deconstruction can be reused or recycled [

10].

Boyd et al. [

11] estimated that the reuse and recycling of salvaged materials could lower GHG emissions by more than 50% when compared to emissions from demolition activities, thus favourably contributing to global warming mitigation. The environmental benefits of deconstruction include cuts in the GHG emissions due to avoided landfill material disposal and energy conservation due to avoided transportation to terminal disposal. Moreover, salvaged materials can be reused in new construction, building rehabilitation or remodeling projects, thus avoiding energy consumption and GHG emissions attributed to all processes between raw material extraction and the final stage of product manufacturing [

12]. The European Directive on waste encourages the recovery of all waste for material purposes, i. e. reuse and recycling, as a key way of reducing the use of primary resources [

8].

The utilization of wood in construction offers numerous advantages, making it a promising material for environmentally conscious building practices. Arehart et al. [

13] have highlighted that increasing the amount of wood-based building materials is one of the most important and effective ways of storing carbon above ground. Wood stands out as the CO

2-neutral material as it absorbs throughout the growth period the same amount of CO

2 from the environment as it later releases during decomposition or when used for energy generation, regardless of whether it is chipped or utilized differently. On the contrary, other common building materials, such as concrete, metals, or plastics, contribute to CO

2 formation during various phases, including raw material extraction, production, and eventual decommissioning. The research of Gorgolewski [

14] on salvaged materials after building deconstruction showed that wood has greater potential for reuse than other common building materials, such as concrete, brick and glass. In the long term, the reuse or recycling of wood construction products increases carbon storage and potentially reduces CO

2 emissions when substituting non-wood materials [

15]. Furthermore, with reuse and recycling the materials can be utilized for a longer time, which reduces waste and the need for virgin raw materials as well as the energy associated with processing [

16].

The reuse of wood elements depends on the way buildings are demolished. In current demolition practices, buildings are crushed using heavy machinery. After demolition, waste materials are sorted into different containers based on their composition for recycling and proper disposal [

17,

18]. This means that the structural elements, including those made of wood, cannot be reused. Chipping wood for particleboard or fibreboard is possible but it means down-cycling the original high-value solid material [

19]. However, studies [

20] have demonstrated that intact wooden beams and columns with larger cross-sections hold significant potential for reuse when they have suitable fixings in place. Glued connections are not suitable because they cannot be separated without damaging the elements. Carpentry joints are sometimes suitable – notches can cause stress concentration if the elements are used in different configurations. Sometimes suitable are also nails and staples, however they fail in bending and therefore are difficult to remove without damaging the element. Screws are mostly suitable because the same connector is not so effective in the same hole. The most suitable are bolts and dowels – the holes and the cracks should be checked [

19]. Sakaguchi et al. [

17] discovered that the method of demolition and the building’s design influence the feasibility of reuse. In the transition towards a circular economy, material reuse in the building sector has attracted increasing attention [

21,

22,

23]. Material reuse has been promoted in the field of urban mining for many years [

24]. The urban mine, with its multitude of anthropogenic stocks, is viewed as a promising source of secondary material supply [

25,

26].

Wood’s importance in circular construction lies in its renewable nature, carbon sequestration capabilities, low embodied energy, circular supply chain potential, waste reduction, biophilic design advantages, thermal performance, and positive economic impact. Integrating wood into construction practices can contribute to a more sustainable and resilient built environment.

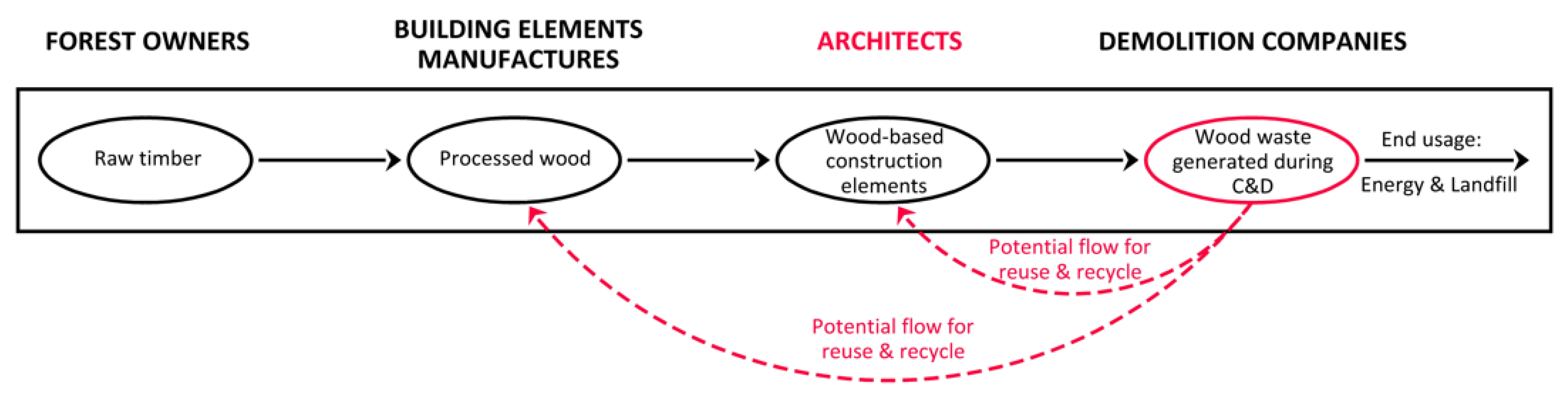

Figure 1 shows the material flow of wood, addressing the circular construction approach, which involves designing products and processes to minimize waste, maximize recycling and reuse, and preserve materials in use for as long as possible.

1.2. The building sector with emphasis on wood in Slovenia, Serbia, North Macedonia, Bosnia and Herzegovina and Montenegro

The building sector in Slovenia, Serbia, North Macedonia, Bosnia and Herzegovina (BiH), and Montenegro varies based on each country’s economic, social, and cultural context. Slovenia has a well-developed and sustainable building sector, while Serbia is only at the beginning of the path to introduce and implement more comprehensive sustainability and circularity-related principles, following the introduced set of laws and regulations to improve energy efficiency of buildings. North Macedonia is rebuilding its sector after political and economic instability, and BiH has a mix of traditional and modern practices focusing on sustainability. Montenegro’s sector has experienced significant growth driven by tourism and foreign investment, yet persistent challenges such as transparency issues persist. Some basic key figures for all four countries are shown in

Table 1.

The five countries of Slovenia, Serbia, North Macedonia, Bosnia and Herzegovina, and Montenegro differ in their use of wood in the building sector. Slovenia prioritizes sustainable and energy-efficient construction as well as passive houses [

29] with significant use of wood [

30]. Serbia is increasing its use of wood due to government incentives for energy efficient buildings. North Macedonia is exploring the potential of using wood in sustainable building practices. Bosnia and Herzegovina traditionally used wood in construction and now incorporates it into modern sustainable building practices. In Montenegro, wood is used in construction, but stricter regulations are needed to ensure sustainability. Slovenia and Montenegro are among the most forested countries in South-Central Europe, and expectations are high yet depending on each country’s specific policies, priorities, and socio-economic conditions. The current situation in the field of wood reuse in the European area is different – they are more actively engaged in Finland, Sweden, Norway, and Denmark [

31], also in Germany, while in the southern part of Europe, this kind of practice has not yet been detected. The primary objective of this study was to solicit insights regarding the viability of recycling wood products, concerns regarding the durability of wood-based materials over time, the incentives for repurposing wood from existing structures, particularly for structural applications, and the significance of ecological, technical, and economic considerations.

Drawing from the collected data, the study delves into the prospects for cascading practices and examines potential avenues for future development. Furthermore, this research serves as an inaugural step toward conducting distinct case studies on various building construction and furniture scenarios, exploring cascading wood practices in diverse international contexts.

2. Methods

A survey questionnaire was designed and developed by an international group of certified architects. Based on the research objectives, a questionnaire was developed to address issues related to the reuse of wood in building construction. Research methods included an exploratory web-based survey in the English language. The target group of the survey included practising architects, with lists compiled from members of professional architectural societies and associations: in Slovenia, the Chamber of Architecture and Spatial Planning of Slovenia; in Serbia, the Alumni Association Database of the University of Priština in Kosovska Mitrovica; in North Macedonia, the Chamber of Certified Architects and Certified Engineers of the Republic of North Macedonia; in Bosnia and Herzegovina, the Association of Architects of Bosnia and Herzegovina, as well as the Alumni Association of the University of Banja Luka and the Faculty of Architecture, Civil Engineering and Geodesy, whose members are working as architects in various companies and studios in Bosnia; and in Montenegro, the Alumni Association of the University of Montenegro and the Association of Architects in Montenegro.

Respondent data were collected using an online survey, created with 1KA, a free web survey software developed by the Centre for Social Informatics at the Faculty of Social Sciences, University of Ljubljana. The questionnaire was implemented in five countries from Central and South-East Europe: Slovenia, Serbia, North Macedonia, Bosnia and Herzegovina, and Montenegro. 1093 questionnaires in total were sent out: 200 in Slovenia, 200 in Serbia, 200 in North Macedonia, 293 in BiH, and 200 in Montenegro. The survey took place from late November 2022 to mid-February 2023. We received 96 valid responses from Slovenia, 87 from Serbia, 101 from North Macedonia, 101 from Bosnia and Herzegovina, and 99 from Montenegro, for a total of 484 responses. Taking into account undeliverable emails due to invalid email addresses or companies that no longer exist, the response rate was 48.0% for Slovenia, 43.5% for Serbia, 50.5% for North Macedonia, 34.5% for Bosnia and Herzegovina, and 49.5% for Montenegro. Based on similar studies [

32,

33,

34,

35], a response rate of 15-35% is considered reasonable for analysis purposes in business surveys, with the main reasons for non-participation in surveys often being an unattractive survey topic or the length of the questionnaire [

36]. In our study, the overall response rate was 44.3% which is adequate.

The questionnaire (

Table 2) consisted of four parts:

A general questionnaire that reflected the profile of the respondents who participated in the survey: the industry sector, the company size, and the product type.

Questions about the potential of wood products reuse.

Questions related to doubts, motivation and potential to use and reuse wood products.

Material/construction choice by investors and architects in their practice

Statistical software JASP 0.16.4 was used for data analysis. The statistical significance level was set at p<0.05. Descriptive statistics such as frequency counts and percentages were obtained and presented in bar graphs. Pearson chi-square test for cross-tabulations was used to assess differences between countries and groups of respondents. Spearman rank correlation coefficient, a nonparametric measure of dependence, was used to measure the correlation between two ordinal variables.

3. Results and discussion

3.1. Respondents Profiles

Part of the questionnaire consisted of questions reflecting the profile of the architects participating in the survey. The results presented in

Table 3 show that slightly more than half of the respondents were female in all countries except Slovenia, with the highest proportion in BiH. The age of the respondents varied from country to country. In all countries except Slovenia, most respondents (63%-84%) were between 25 and 44 years old. In Slovenia, this percentage was only 29%, and 62% were between 45 and 64 years old. All respondents are certified architects who have completed a professional master’s degree or a university degree.

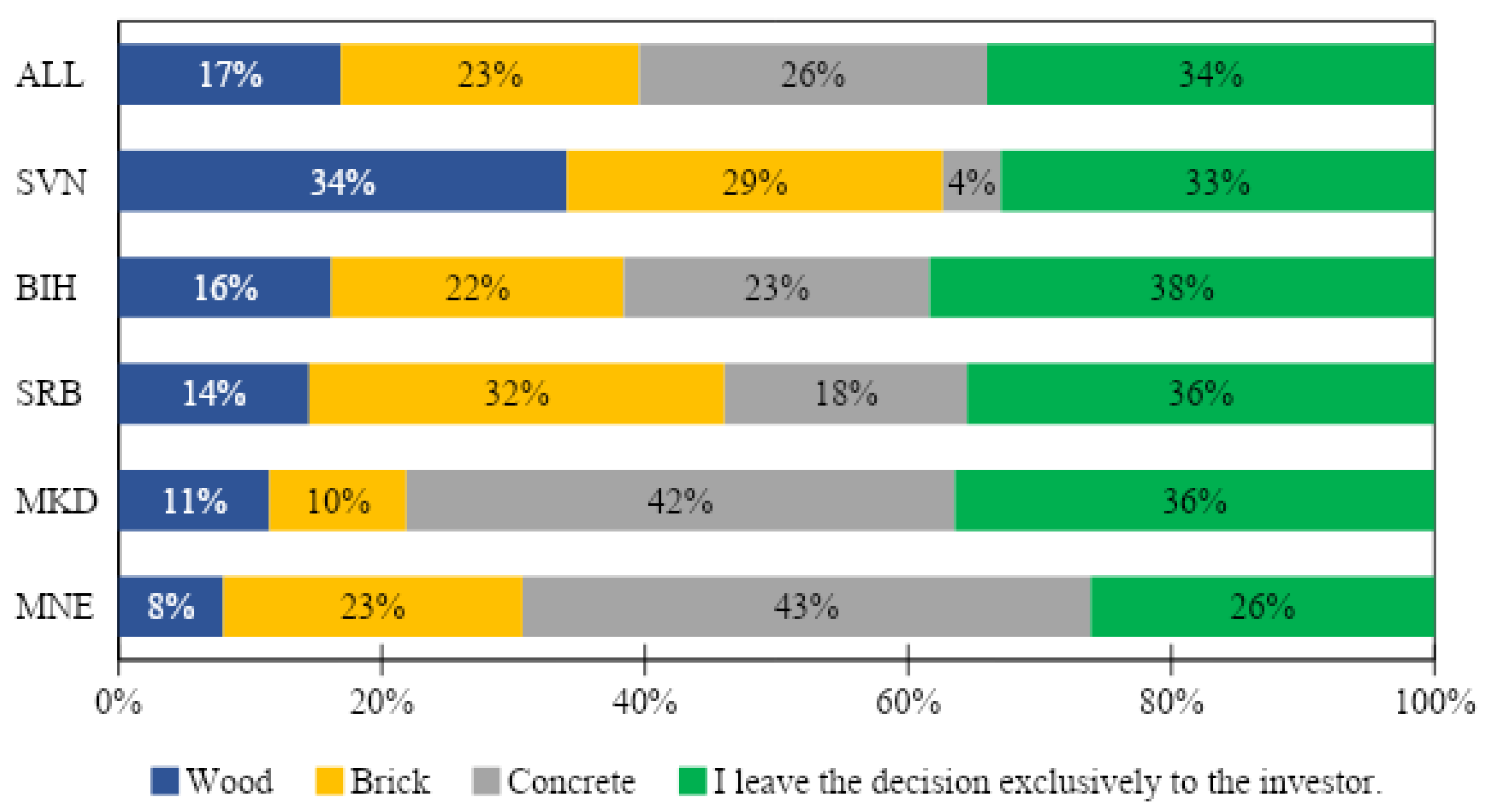

3.2. Material/construction choice by investors and architects

Architects believe that investors most often choose concrete as a building material. However, there are significant differences between countries (χ

2(12)=145.521, p<0.001) (

Figure 2). In more than 30% of cases, the architects leave the decision about the building material exclusively to the investors. Recommendations on building materials also differ significantly between countries (χ

2(12)=71.565, p<0.001) (

Figure 3). In North Macedonia (88%) and Montenegro (83%), architects most often recommend concrete to investors (42% and 43%, respectively), and investors use concrete 88% and 83% of the time. In Serbia, architects most often recommend brick (32%), followed by concrete and wood. In Bosnia and Herzegovina, architects recommend concrete (23%) or brick (22%) and, to a slightly lesser extent, wood (16%). In both countries, most investors use concrete (69% in Bosnia and Herzegovina and 67% in Serbia), followed by brick, while 5 % use other materials such as steel, glass, or stone. Slovenia stands out the most; it is the only country where architects mostly recommend wood as a building material (34%), followed by brick (29%) and very rarely concrete (4%) which is align with new Slovenian building regulation. Investors, on the other hand, most often chose brick (78%). The survey has shown that wood is very rarely chosen as a building material in all countries.

Architects may have varying degrees of confidence in wood as a building material for several reasons. It is important to note that these perceptions can vary among professionals and are often influenced by a combination of factors: historical perception, lack of familiarity, misconceptions about wood’s structural capabilities or durability, regulatory constraints (building codes and regulations), aesthetic preferences, market dynamics (availability of material), and influence of an architect’s educational background.

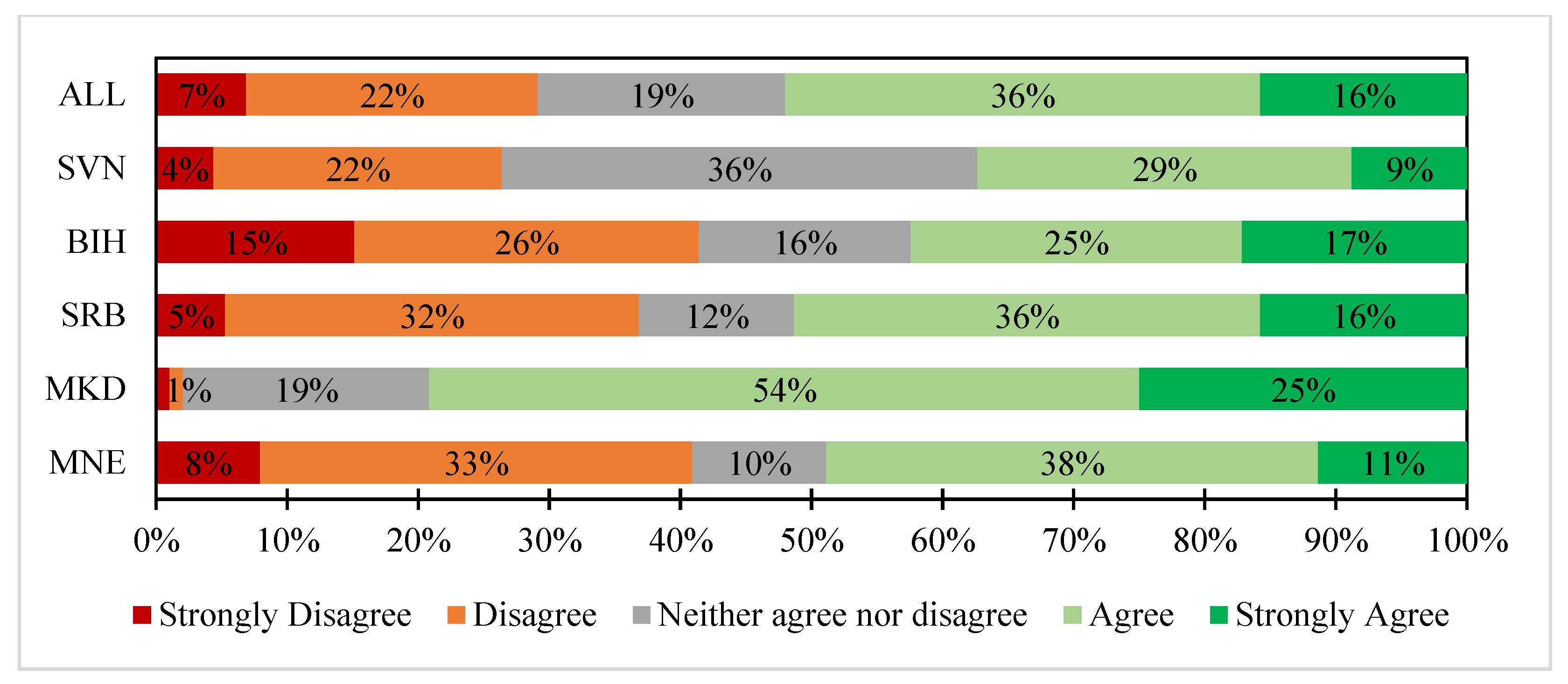

Furthermore, architects mostly agree or strongly agree with the statement that choosing ecologically friendly materials is an important criterion for investors. However, differences between the countries are significant (χ

2(16) =86.469, p<0.001); the percentage varies between 38% in Slovenia and 79% in North Macedonia (

Figure 4).

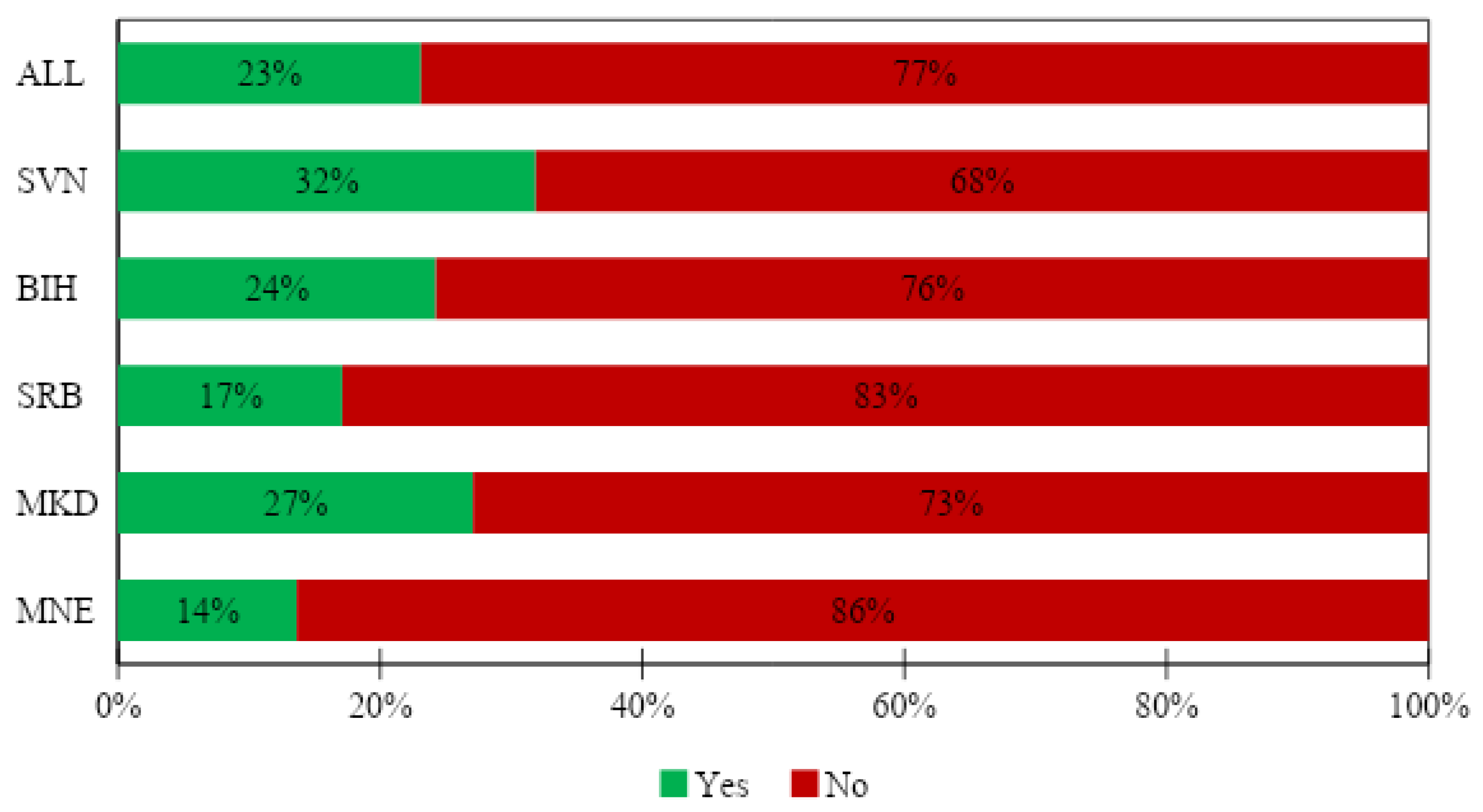

The relatively low percentage of architects have experience with investors who decided to reuse wood. The percentage differs between the countries (χ

2(4)=10.839, p=0.028); the lowest (14%) is in Montenegro, and the highest (32%) in Slovenia (

Figure 5).

Wooden elements (beams and columns) with larger cross-sections can be reused in the prefabricated timber roof trusses connected with metal connectors or some other type of mechanical connectors [

37], where the width of the cross-section of the chords and webs is in range from 24 to 60 mm. When the elements of existing timber trusses are reused, the damage at the end of the element caused by the nails [

38] can be removed by shortening that rod. Cross-laminated wood panels are formed with 20–40 mm thick lamellas. Such lamellas can be obtained after deconstructing wooden elements with larger cross-sections. Depending on their quality, these elements can be used in different panel section zones to accept both static and dynamic loads [

39].

Architects mentioned many possible ways to reuse wood elements in their design. More often, the following were reported: flooring - reclaimed wood can be salvaged from old buildings or other structures, and can be refinished to create a unique and rustic look; wall paneling to create a feature wall or to add texture and warmth to a space; building facades, furniture to create one-of-a-kind pieces that add warmth and character to a space; doors and windows, staircases – can add a unique and rustic charm to building project while also promoting sustainability by reusing old materials. By following these good practices, architects can benefit from using reclaimed wood in their designs by promoting sustainability, creating unique aesthetics, saving costs, and adding historical context to their projects. Architects should possess comprehensive knowledge of materials, including wood, and be prepared to provide investors with informed recommendations, highlighting the advantages of using wood as a construction material.”

3.3. The potential of wood products reuse

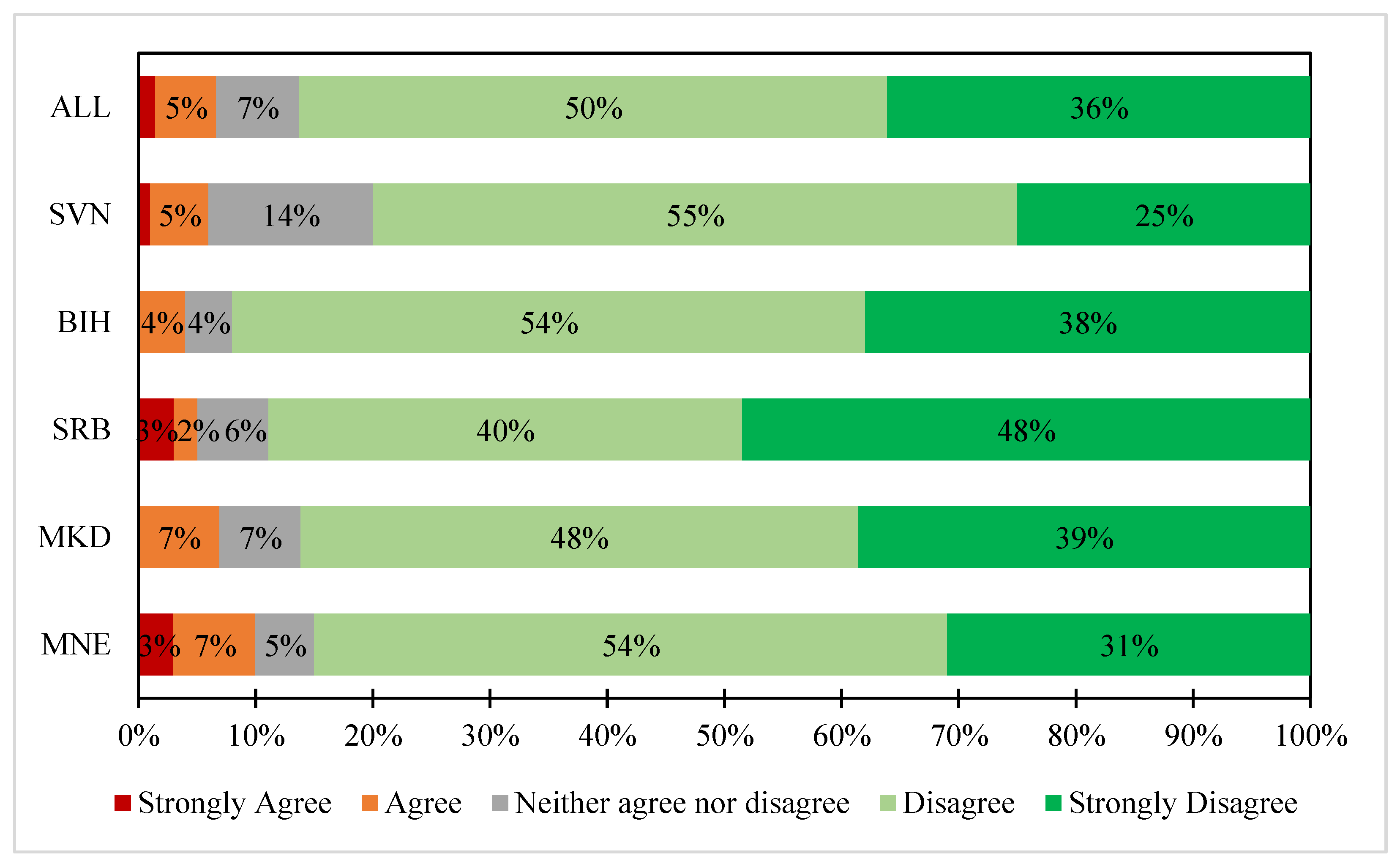

Only 4% to 10% of respondents agree or strongly agree with the statement that wood elements used in construction are made for single use and cannot be recycled, while 80% to 92% of respondents disagree or strongly disagree with this statement (

Figure 6). There are statistically significant differences between countries (χ

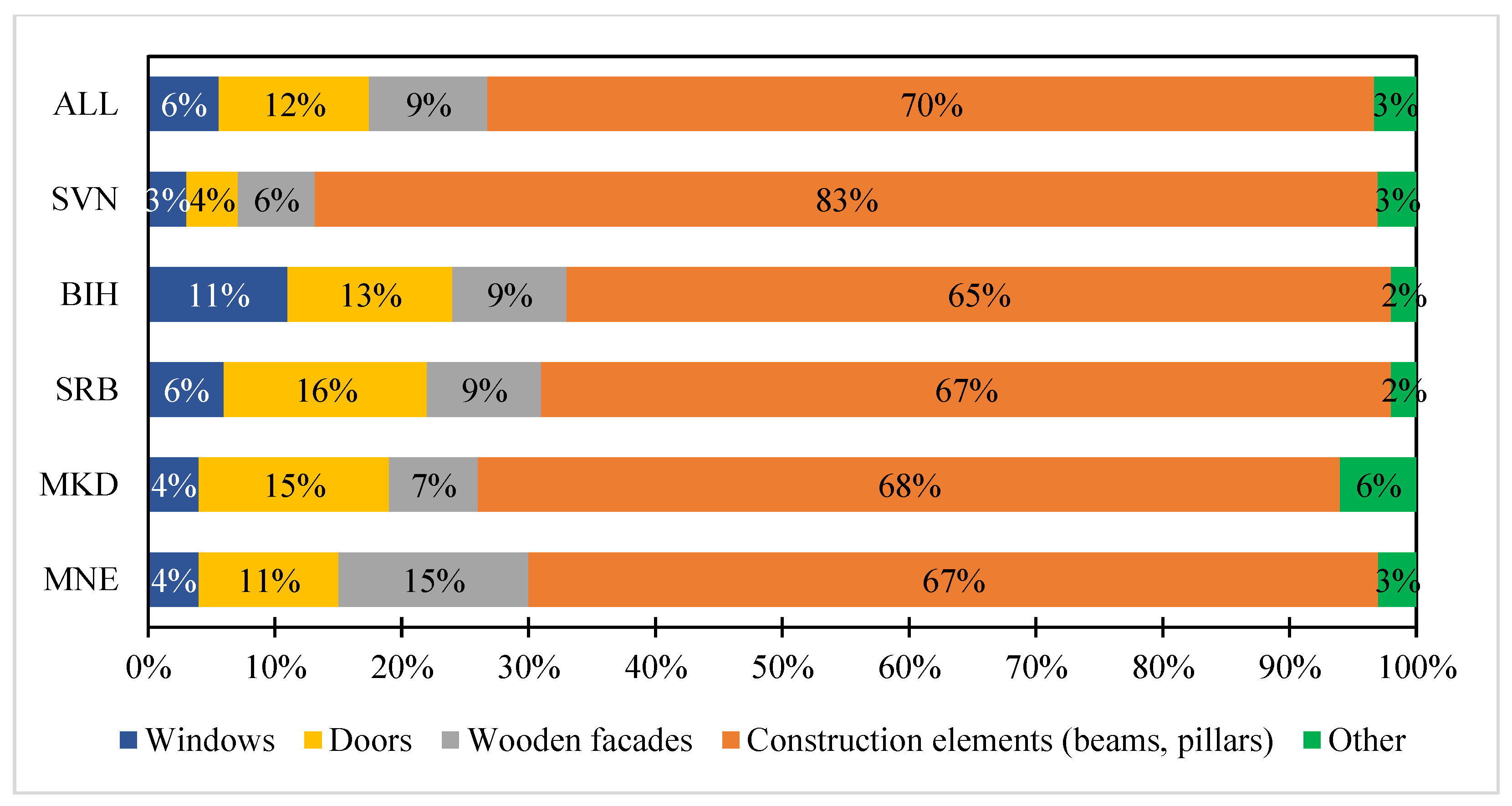

2(16)=28.381, p=0.028). The highest percentage of undecided is found in Slovenia (14%). Most respondents consider construction elements like beams and pillars wood products with the highest reuse potential (

Figure 7). The percentage varies from 65% in Bosnia and Herzegovina to 83% in Slovenia, but the differences are not significant.

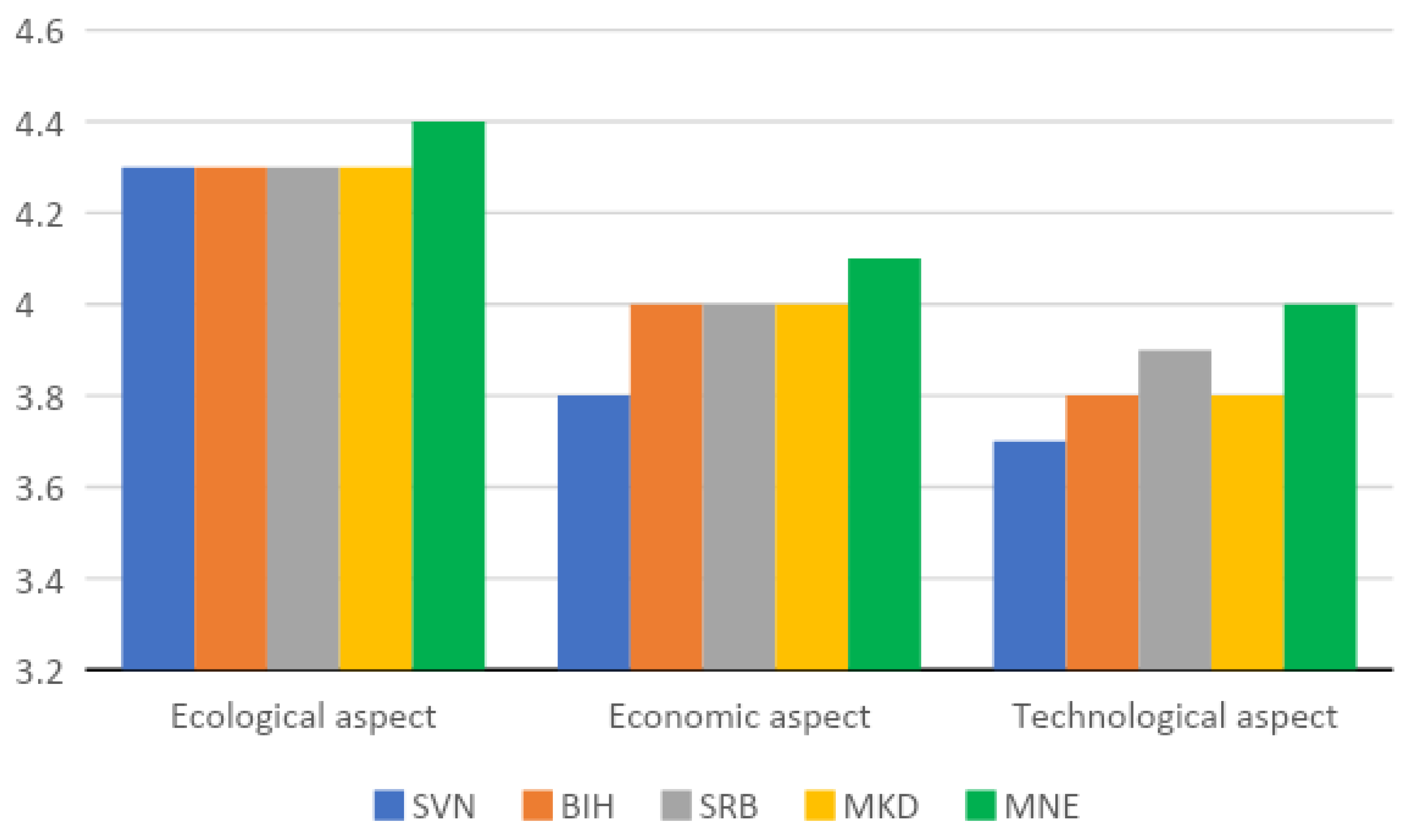

To enrich this study, architects were asked to rate the importance of ecological, economic, and technological aspects in the reuse of wood products on a scale from not at all important (1) to very important (5).

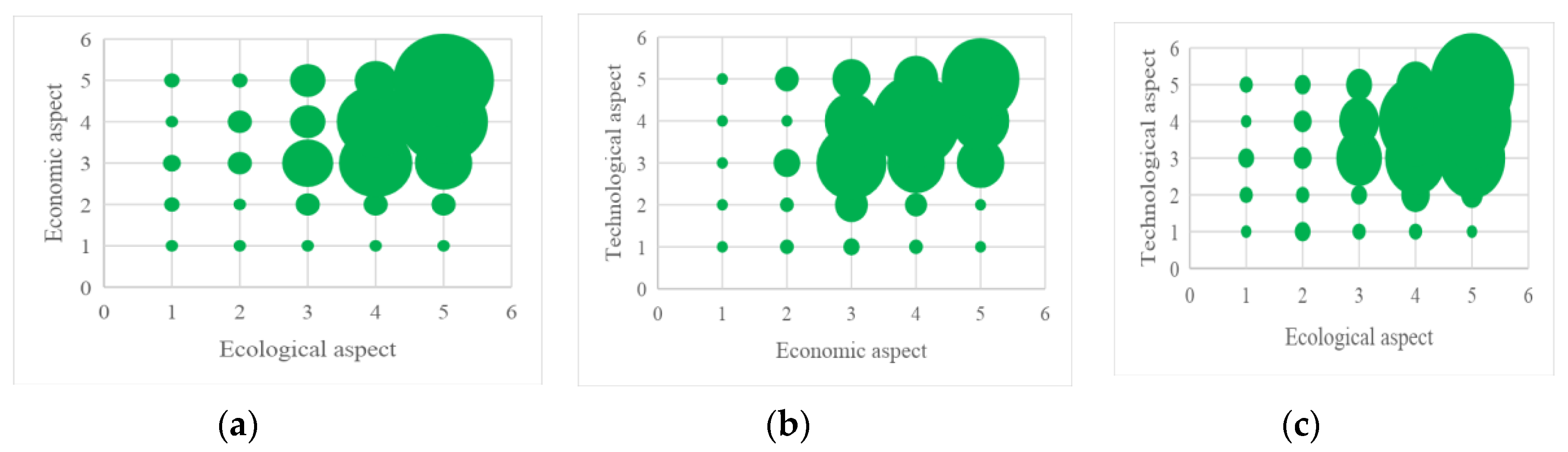

Figure 8 shows that the average scores were similar for all countries. Respondents rated the ecological aspect as the most important, followed by economic and technological aspects. The differences between the importance of the aspects are significant (χ

2(8)=90.344, p<0.001). The ecological aspect was rated as fairly or very important by 84 % of respondents, the economic aspect by 69 %, and the technological aspect by 65 % of respondents. Spearman’s rank-order coefficient confirms a significant low positive correlation between the importance of the ecological and the economic aspect (r

S(482) = 0.383, p<0.001) (

Figure 9), between the importance of the ecological and the technological aspect (r

S(482)=0.291, p<0.001) and between the importance of the economic and the technological aspect (r

S(482)=0.397, p<0.001).

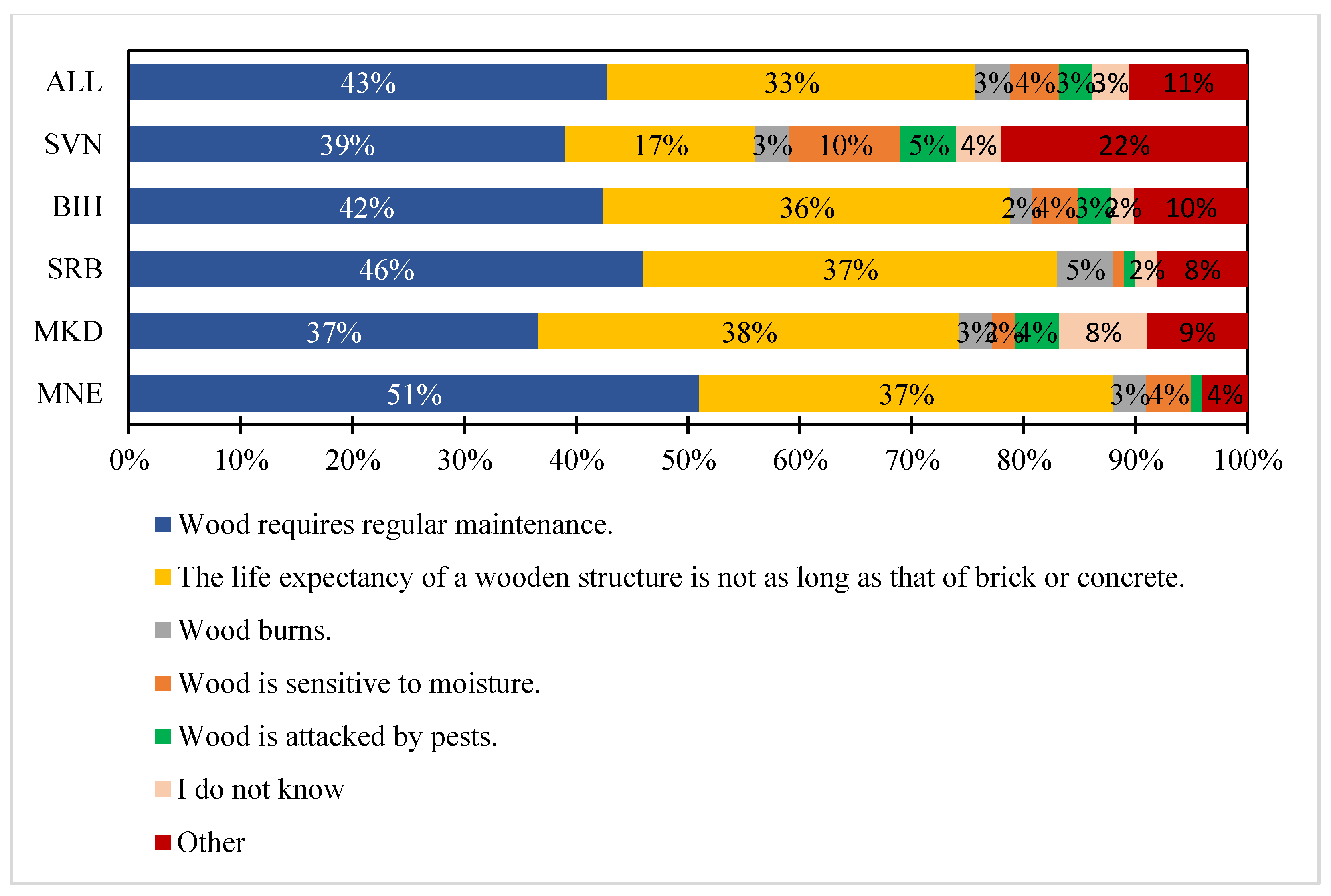

3.4. Doubts, motivation and potential to use and reuse wood products

Doubts about the long-term quality of wood products can arise due to several factors. While wood is a popular and versatile material, it is not immune to potential issues that can impact its long-term performance. There are several reasons that discourage investors from choosing a wooden house. The most important for the respondents was the need for regular maintenance of wood and the shorter life expectancy of a wooden structure than that of brick or concrete (

Figure 10). The differences between countries are significant (χ

2(24)=56.501, p<0.001). In Slovenia, 39% of respondents cited regular maintenance as the most important reason, followed by other reasons (22%): fire risk – wood is considered a combustible material; certain pests, insects, and fungi have the ability to digest wood; wood rot; building code limitations; or other, less significant reasons. In Bosnia and Herzegovina, Serbia, and North Macedonia, the most important reason was regular maintenance (42 % - 51 %), followed by shorter life expectancy (36% – 37%). Respondents from Montenegro cited shorter life expectancy as the most important reason (38%), followed by regular maintenance (37%).

Respondents in all countries agreed (98%) that the profession and government do not adequately support or promote the reuse of wood in the spirit of circular construction.

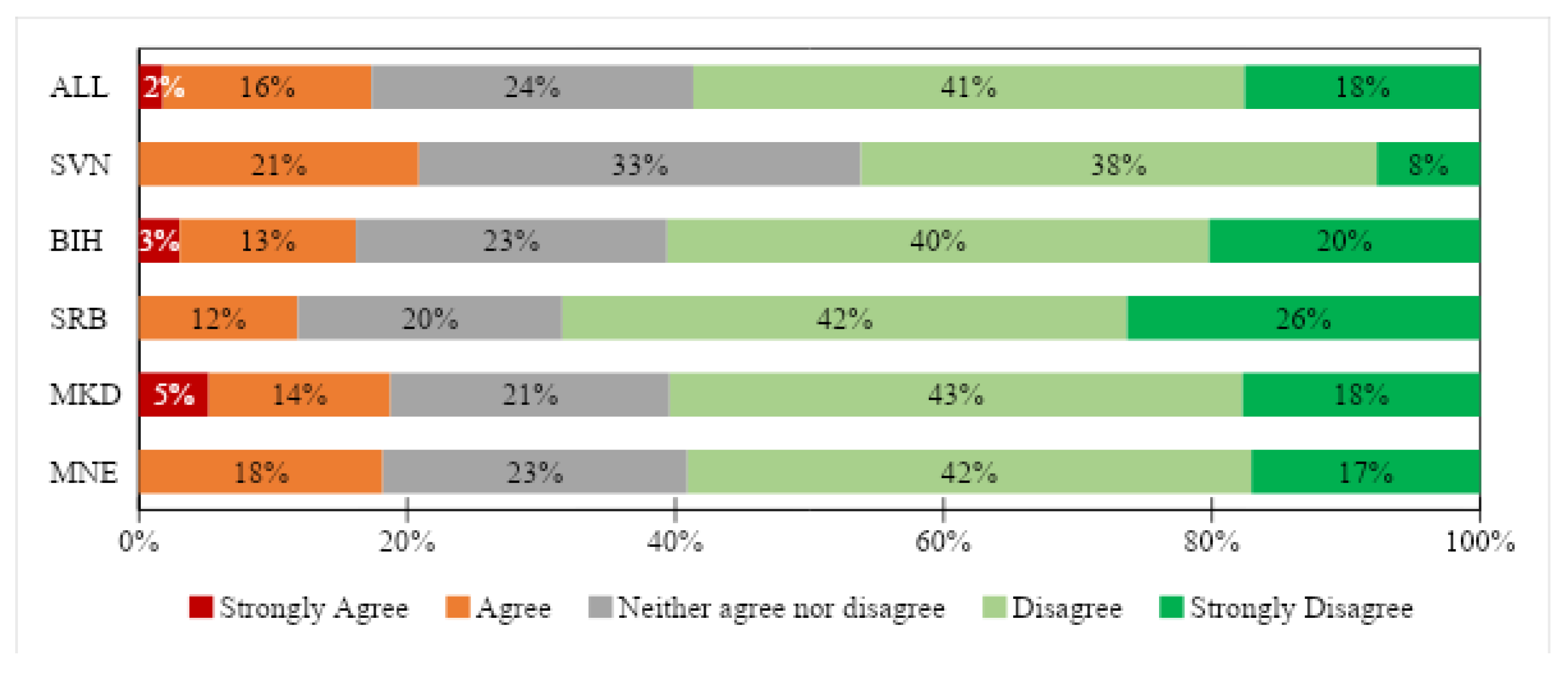

Most respondents disagree or strongly disagree that reclaimed wood has a lower value than other construction and demolition wastes, such as metals and plastics (

Figure 11). The percentage varies and may be influenced by cultural, regional, or personal preferences, from 46% in Slovenia to 68% in Serbia. The differences between countries are significant (χ

2(16)=28.256, p=0.029). In Slovenia, 21% agree with this statement, while another 33% neither agree nor disagree. In Serbia, however, only 12% agree and 20% neither agree nor disagree. The majority of architects tend to view used wood positively, attributing higher rather than lower value compared to other construction and demolition wastes like metals and plastics.

Respondents indicated that previously used wood is reused less than metals or plastics due to a variety of reasons: environmental benefits, unique aesthetics, history and storytelling, quality and durability, sustainability and recycling, artisanal and craftsmanship appeal, value appreciation, and other. Availability is a major factor as it is not always readily available, and salvaging it can be difficult and expensive. Cost is another consideration as salvaging and processing reclaimed wood can be more expensive than new wood or other materials. Difficulty in processing due to the components’ size, shape, and presence of hardware is also a concern. Additionally, the durability of reclaimed wood depends on its type and condition, and it may require inspection and testing before use. Regulations and building codes may also limit the use. Finally, location, industry, and cultural factors could also impact reclaimed wood reuse.

5. Conclusions

This study offers valuable insights into architects’ perspectives on wood reuse in construction across multiple countries. Primarily, this study provided state-of-the-art and information about the potential of the reuse of wood in the light of circular building construction. The construction sector has great potential for implementing CE strategies and generating both environmental and economic gains [

21,

40]. Key findings from this study demonstrate:

Common consent among architects in Slovenia, Serbia, Montenegro, Bosnia and Herzegovina, and North Macedonia as regards insufficient relevant actors’ support and the challenges in reclaimed wood reuse;

Variations among countries in terms of type of recommended construction materials;

General consent among respondents as regards recognized value of recycled wood;

Common expression of motivators for reclaimed wood reuse;

Recognition of significance of economy, ecology and technology related aspects of wood reuse;

Common recognition of limitations and expression of common doubts and concerns about wood reuse in construction;

Variable stand on timber buildings’ construction prioritization.

Architects from the surveyed nations commonly agree that their profession and government bodies do not adequately endorse or promote wood reuse in circular construction practices. They face shared challenges, including the availability of reclaimed wood, associated costs, complexities in processing, durability assessments, regulatory restrictions, and location-specific factors. Architects’ recommendations for building materials differ among countries, with Slovenia notably standing out as the only nation where architects predominantly recommend wood as a building material. The study also reveals a consensus among architects that selecting environmentally friendly materials is an essential criterion for investors, yet there are statistically significant variations among countries regarding respondents’ agreement with the statement that wood products used in construction are designed for single use and cannot be recycled.

A significant majority of respondents reject the idea that reclaimed wood has a lower value compared to other construction and demolition materials. However, some variations exist among countries.

Architects are motivated to incorporate reclaimed wood into their projects due to factors such as environmental benefits, unique aesthetics, historical significance, quality, sustainability, artisanal appeal, and value appreciation.

Architects were surveyed to assess the importance of ecological, economic, and technological aspects in reusing wood products. The results demonstrate a clear pattern of significance, with the ecological aspect rated highest by respondents, followed by the economic and technological aspects. Statistically significant differences exist in the ratings of these aspects. Furthermore, doubts about the use of reused wood products are prevalent in all countries, with respondents in agreement that the architectural profession and government insufficiently support or promote wood reuse within the context of circular construction. Concerns about the long-term quality of wood products often revolve around maintenance requirements and perceived shorter life expectancies compared to alternative building materials.

Attitudes towards timber construction vary between Slovenia, Serbia, North Macedonia, Bosnia and Herzegovina, and Montenegro, even though timber construction offers competitive solutions for more sustainable construction. Increasing the use of renewable materials, mainly wood, in buildings could make construction more sustainable and a part of the bioeconomy [

41]. There are in all country’s considerable activities, initiatives and legalization supporting timber constructions in relation to current European regulations with an emphasis on using wood as a sustainable architectural construction material for the future.

This study underscores the need for enhanced support mechanisms, addressing shared challenges, and raising awareness regarding ecological and economic advantages of reclaimed wood. These efforts could facilitate greater adoption of reclaimed wood in circular construction practices across the surveyed regions. Furthermore, this research contributes to a deeper understanding of circular construction practices within the broader context of the circular economy, offering insights into potential future developments in Slovenia, Serbia, North Macedonia, Bosnia and Herzegovina, and Montenegro.

Author Contributions

Conceptualization, M.K.K., M.Z.-S. and P.G.; Methodology, M.K.K and P.G.; Software, P.G.; Validation, M.Z.-S., P.G., M.M.J. and M.K.K.; Formal Analysis, P.G.; Investigation, M.K.K., M.Z.-S., S.K., M.M.J., N.N., I.R., P.G.; Resources, M.K.K., M.Z.-S, S.K., M.M.J., N.N., I.R.; Writing – Original Draft Preparation, M.K.K., P.G., M.Z.-S.; Writing – Review & Editing, M.M.J., N.N., I.R., S.K.; Visualization, M.M.J.; Supervision, M.K.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this article are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Acknowledgments

Funding

This study was supported by the Slovenian Research Agency, Research Programs P4-0015, P4-0059, P5-0068 and bilateral project BI-US/22-24-043. Technical support and specific data provision: The Authors would like to acknowledge the Erasmus+ project of the European Union entitled “Western Balkan Entrepreneurial University Alliances – Keeping in Touch for Lifelong Relations” (AL4LIFE) for technical support and specific data provision.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript; or in the decision to publish the results.

References

- Nußholz, J.L.K.; Nygaard Rasmussen, F.; Whalen, K.; Plepys, A. Material reuse in buildings: Implications of a circular business model for sustainable value creation. J. Clean. Prod. 2020, 245, 118546. [Google Scholar] [CrossRef]

- Circular concepts in wood construction. Food and Agriculture Organization of the United Nations (UNECE FAO). Available online: https://unece.org/sites/default/files/2023-05/ECE_TIM_DP95E_web.pdf (accessed on 2 May 2023).

- Pomponi, F.; Moncaster, A. Embodied carbon mitigation and reduction in the built environment –What does the evidence say? J. Environ. Manage. 2016, 181, 687–700. [Google Scholar] [CrossRef] [PubMed]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: a review. Renew. Sust. Energ. Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Eurostat. Generation of waste by waste category. 2018. Available online: https://ec.europa.eu/eurostat/databrowser/view/ENV_WASTRT/default/bar?lang=en (accessed on 26 July 2023).

- European Commission. Cascades. Study on the Optimised Cascading Use of Wood, Brussels. 2016. Available online: https://ec.europa.eu/newsroom/growth/items/48906/ (accessed on 26 July 2023).

- Litleskare, S.; Wuyts, W. Planning Reclamation, Diagnosis and Reuse in Norwegian Timber Construction with Circular Economy Investment and Operating Costs for Information. Sustainability 2023, 15, 10225. [Google Scholar] [CrossRef]

- Diyamandoglu, V.; Fortuna, L.M. Deconstruction of wood-framed houses: Material recovery and environmental impact. Resour. Conserv. Recycl. 2015, 100, 21–30. [Google Scholar] [CrossRef]

- Guy, B.; McLendon, S. Building deconstruction: reuse and recycling of building materials. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=10b3ae8cc4b95ac02831d680bc9865e187ecbdb4 (accessed on 26 September 2023).

- Białko, M.; Hoła, B. Identification of Methods of Reducing Construction Waste in Construction Enterprises Based on Surveys. Sustainability 2021, 13, 9888. [Google Scholar] [CrossRef]

- Boyd, S.A.; Stevenson, C.; Augenbraun, J.J. Deconstructing deconstruction: Is a Ton of Material Worth a Ton of Work? Sustainability 2012, 5, 391–400. [Google Scholar] [CrossRef]

- Bergman, R.D.; Gu, H.; Napier, T.; Salazar, J.; Falk, R. Life cycle primary energy and carbon analysis of recovering softwood framing lumber and hardwood flooring for reuse. In Instruments for Green Futures Markets, Proceedings of American Center for Life Cycle Assessment XI Conference, Chicago, IL, USA, 4-6 October 2011; American Center for Life Cycle Assessment, 2012; pp. 44–52. [Google Scholar]

- Arehart, J.H.; Hart, J.; Pomponi, F.; D’Amico, B. Carbon sequestration and storage in the built environment. Sustain. Prod. Consum. 2021, 27, 1047–1063. [Google Scholar] [CrossRef]

- Gorgolewski, M. Designing with reused building components: some challenges. Build. Res. Inf. 2008, 36, 175–188. [Google Scholar] [CrossRef]

- Brunet-Navarro, P.; Jochheim, H.; Cardellini, G.; Richter, K.; Muys, B. Climate mitigation by energy and material substitution of wood products has an expiry date. J. Clean. Prod. 2021, 303, 127026. [Google Scholar] [CrossRef]

- Niu, Y.; Rasi, K.; Hughes, M.; Halme, M.; Fink, G. Prolonging life cycles of construction materials and combating climate change by cascading: The case of reusing timber in Finland. Resour. Conserv. Recycl. 2021, 170, 105555. [Google Scholar] [CrossRef]

- Sakaguchi, D. Potential for cascading wood from building. Master’s thesis, Aalto University, School of Chemical Technology: Aalto, Finland, 2014.

- Akinade, O.O.; Oyedele, L.O.; Ajayi, S.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A.; Bello, S.A.; Jaiyeoba, B.E.; Kadiri, K.O. Design for Deconstruction (DfD): Critical success factors for diverting end-of-life waste from landfills. Waste Manage. 2017, 60, 3–13. [Google Scholar] [CrossRef] [PubMed]

- Hradil, P.; Talja, A.; Wahlström, M.; Huuhka, S.; Lahdensivu, J.; Pikkuvirta, J. Re-use of structural elements: Environmentally efficient recovery of building components. VTT Technical Research Centre of Finland, Espoo, 2014.

- Nakajima, S.; Futaki, M. National R&D project to promote recycle and reuse of timber construction in Japan. Available online: http://www.irbnet.de/daten/iconda/CIB753.pdf (accessed on 25 July 2023).

- Ellen MacArthur Foundation. Achieving ‘Growth within’. 2017. Available online: https://ellenmacarthurfoundation.org/achieving-growth-within (accessed on 25 July 2023).

- van Sante, M. Circular construction: Most opportunities for demolishers and wholesalers. ING. Available online: https://think.ing.com/uploads/reports/ING_EBZ_Circular-construction_Opportunities-for-demolishers-and-wholesalers_juni-2017_tcm162-127568.pdf (accessed on 29 July 2023).

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: current awareness, challenges and enablers. Waste and Resource Management 2017, 170, 1–11. [Google Scholar] [CrossRef]

- BAMB, Buildings as Material Banks: D1_ Synthesis of the State-Of-The-Art. VITO, Brussels. 2016. Available online: https://www.bamb2020.eu/wp-content/uploads/2016/03/D1_Synthesis-report-on-State-of-the-art_20161129_FINAL.pdf (accessed on 25 July 2023).

- Baccini, P.; Brunner, P.H. Metabolism of the Anthroposphere: Analysis, Evaluation, Design; The MIT Press, 2012. Available online: http://www.jstor.org/stable/j.ctt5vjrm9. (accessed on 25 July 2023).

- Cossu, R.; Williams, I. Urban mining: concepts, terminology, challenges. Waste Manage. 2015, 45, 1–3. [Google Scholar] [CrossRef] [PubMed]

- Worldometers. Available online: https://www.worldometers.info/world-population (accessed on 25 July 2023).

- Worldbank.org. 2020. Available online: https://www.worldbank.org/en/home (accessed on 25 July 2023).

- Zbašnik-Senegačnik, M.; Koprivec, L. Timber Passive House in the Light of New European Bauhaus – an Answer to Crisis Management and Safety Foresight in Forest-based Sector. In Crisis management and safety foresight in forest-based sector and smes operating in the global environment, Proceedings of the WoodEMA 2022, Trnava, Slovakia; Jun 8th – 10th 2022; Nováková, R, (Ed.); International Association for Economics, Management, Marketing, Quality and Huma Resources in Forestry and Forest Based Industry – WoodEMA, i.a.; Slovak Association for Quality, n.o.: Trnava, Slovakia, 2022; pp. 8–10. [Google Scholar]

- Kitek Kuzman, M.; Sandberg, D.; Moutou Pitti, R. Produits d’Ingénierie en Bois pour l’Architecture Contemporaine – Cas d’étude; Engineered Wood Products in Contemporary Architectural use: Case Studies, University of Ljubljana, Biotechnical Faculty: Slovenia, 2018; pp. 15–113. [Google Scholar]

- Plavina, A.; Gruner, M. Selbukassa – A Case Study for Aiming at Low Emission Buildings through Extensive Reuse of Materials. IOP Conference Series: Earth and Environmental Science, 1st Nordic conference on Zero Emission and Plus Energy Buildings, Trondheim, Norway, 6–7 November 2019; 352, p. 012067. [Google Scholar]

- Kozak, R.A.; Cohen, D.H. Architects, and structural engineers:An examination of wood design and use in nonresidential construction. For. Prod. J. 1999, 49, 37–46. [Google Scholar]

- O’Connor, J.; Kozak, R.; Gaston, C.; Fell, D. Wood use in nonresidential buildings: opportunities and barriers. For. Prod. J. 2004, 54, 19–28. [Google Scholar]

- Wagner, E.; Hansen, E. The dynamic impacts of the COVID-19 pandemic on Log prices in China: An analysis based on the TVP-VAR model. Forests 2021, 12, 449–425. [Google Scholar] [CrossRef]

- Damery, D.T.; Fisette, P. Decision making in the purchase of siding: a survey of architects, contractors, and homeowners in the US northeast. For. Prod. J. 2001, 51, 29–36. [Google Scholar]

- Fan, W.; Yan, Z. Factors affecting response rates of the web survey: a systematic review. Comput. Hum. Behav. 2010, 26(2), 132–139. [Google Scholar] [CrossRef]

- Tekić, Ž.; Đorđević, S.; Tomić, D. Nail metal connector plate – experimental determination of load-bearing capacity of timber member connections. Tehnički vjesnik - Technical Gazette 2017, 24, 35–42. [Google Scholar] [CrossRef]

- Tekić, Ž.; Kozarić, L.; Vojnić Purčar, M.; Lukić, S. Load-bearing capacity of metal connector plates depending on location and geometry of the nail. Wood Res. 2019, 64, 677–690. [Google Scholar]

- Kozarić, L.; Bursać, S.; Vojnić, M.P.; Bešević, M.; Tekić, Ž. Finite Element Analysis of Dynamic Characteristics and Bending Stiffness for Cross Laminated Timber Floor Panels with and without Openings. Drv. Ind. 2021, 72, 373–379. [Google Scholar] [CrossRef]

- Koutamanis, A.; van Reijn, B.; van Bueren, E. Urban mining and buildings: a review of possibilities and limitations. Resour. Conserv.Recycl. 2018, 138, 32–39. [Google Scholar] [CrossRef]

- Riala, M.; Ilola, L. Multi-storey timber construction and bioeconomy – barriers and opportunities. Scand. J. For. Res. 2014, 29, 267–377. [Google Scholar] [CrossRef]

Figure 1.

In circular construction, wood and wood-based materials are reincorporated into the construction process of other buildings after the end of their life cycle. This closed-loop system ensures that only a small portion of materials end up in landfills, while the rest may be used as firewood for energy production.

Figure 1.

In circular construction, wood and wood-based materials are reincorporated into the construction process of other buildings after the end of their life cycle. This closed-loop system ensures that only a small portion of materials end up in landfills, while the rest may be used as firewood for energy production.

Figure 2.

Material/construction choice by investors (Q: According to your experience, which construction material/method of construction/do investors most often choose? Wood/Brick/Concrete/Other).

Figure 2.

Material/construction choice by investors (Q: According to your experience, which construction material/method of construction/do investors most often choose? Wood/Brick/Concrete/Other).

Figure 3.

Architects recommendations as regards material/construction choice (Q: As an architect, which construction material do you most often recommend to investors? Wood/Brick/Concrete/Other).

Figure 3.

Architects recommendations as regards material/construction choice (Q: As an architect, which construction material do you most often recommend to investors? Wood/Brick/Concrete/Other).

Figure 4.

Importance of choice of ecological material/construction method for investors (Q: The choice of ecological material/construction method is an important criterion for investors?).

Figure 4.

Importance of choice of ecological material/construction method for investors (Q: The choice of ecological material/construction method is an important criterion for investors?).

Figure 5.

Architects’ experience about reusing wood elements (Q: In your practice as an architect, has the investor ever decided to use wooden elements that were previously installed in the building (reclaimed wood)?).

Figure 5.

Architects’ experience about reusing wood elements (Q: In your practice as an architect, has the investor ever decided to use wooden elements that were previously installed in the building (reclaimed wood)?).

Figure 6.

Circularity potential of wood products used in building construction (Q: Wood products used in building construction are made for one use only and cannot be recycled.).

Figure 6.

Circularity potential of wood products used in building construction (Q: Wood products used in building construction are made for one use only and cannot be recycled.).

Figure 7.

Reuse potential of specific wood products (Q: Which wood products have the highest reuse potential?).

Figure 7.

Reuse potential of specific wood products (Q: Which wood products have the highest reuse potential?).

Figure 8.

The average scores of the importance of ecological, economic, and technological aspects (Q: How important are the following aspects when reusing wood products?).

Figure 8.

The average scores of the importance of ecological, economic, and technological aspects (Q: How important are the following aspects when reusing wood products?).

Figure 9.

Spearman’s rank-order coefficient confirms a significantly low positive correlation between the importance of the Ecological and the Economic aspect (a), Economic and Technological aspect (b), and Ecological and Technological aspect (c).

Figure 9.

Spearman’s rank-order coefficient confirms a significantly low positive correlation between the importance of the Ecological and the Economic aspect (a), Economic and Technological aspect (b), and Ecological and Technological aspect (c).

Figure 10.

Doubts about the long-term quality of wood products (Q: What, in your opinion, discourages investors from choosing a wooden house?).

Figure 10.

Doubts about the long-term quality of wood products (Q: What, in your opinion, discourages investors from choosing a wooden house?).

Figure 11.

Reclaimed wood has a lower value compared to other construction and demolition waste such as metals, plastics, …? (Q: Do you agree that reclaimed wood has a lower value compared to other construction and demolition waste such as metals, plastics, …?).

Figure 11.

Reclaimed wood has a lower value compared to other construction and demolition waste such as metals, plastics, …? (Q: Do you agree that reclaimed wood has a lower value compared to other construction and demolition waste such as metals, plastics, …?).

Table 1.

Key figures for Slovenia, Serbia, North Macedonia, BiH, Montenegro.

Table 1.

Key figures for Slovenia, Serbia, North Macedonia, BiH, Montenegro.

| |

Slovenia |

Serbia |

North

Macedonia |

BiH |

Montenegro |

| Population (2022) [27] |

2,119,844 |

7,221,365 |

2,093,599 |

3,233,526 |

627,082 |

| Tot. Area (km2) [28] |

20.273 |

88.499 |

25.713 |

51.209 |

13.812 |

| Forest area (% of land area) [28] |

61.47 |

31.13 |

39.71 |

42.73 |

61.49 |

Table 2.

The questionnaire.

Table 2.

The questionnaire.

| 1 |

General questions:

Please indicate your gender. M/F

What age group do you belong to?

What is your highest completed education? |

| 2 |

According to your experience, which construction material/method of construction/do investors most often choose?

Wood/Brick/Concrete/Other |

| 3 |

As an architect, which construction material do you most often recommend to investors? Wood/Brick/Concrete/Other |

| 4 |

The choice of ecological material/construction method is an important criterion for investor? |

| 5 |

In your practice as an architect, has the investor ever decided to use wooden elements that were previously installed in the building (reclaimed wood)? |

| 6 |

In what cases, in what way? |

| 7 |

Wood products used in building construction are made for one use only and cannot be recycled. |

| 8 |

Which wood products have the highest reuse potential?

Windows/Doors/Wood facades/Construction elements: beams, pillars/Other: |

| 9 |

How important are ecological, economic, technological aspects when reuse wood products? |

| 10 |

What, in your opinion, discourages investors from choosing a wooden house?

Wood requires regular maintenance./The life expectancy of a wooden structure is not as long as that of brick or concrete./Wood burns./Wood is sensitive to moisture./Wood is attacked by pests.

I don’t know./Other: |

| 11 |

Do the profession and the state sufficiently support or promote the reuse of wood in the sense of circular construction? |

| 12 |

If yes then how? |

| 13 |

Do you agree that reclaimed wood has a lower value compared to other construction and demolition waste such as metals, plastics, …?

If agree, then (open question) |

| 14 |

What do you think is the reason that reclaimed wood is reused less than metals or plastics? (Open question) |

| 15 |

What do you suggest to reuse the reclaimed wood more often? (open question) |

Table 3.

Demographic characteristics of the architects surveyed.

Table 3.

Demographic characteristics of the architects surveyed.

| |

|

Slovenia |

Serbia |

North Macedonia |

BiH |

Montenegro |

| Gender |

Female |

42% |

54% |

55% |

68% |

52% |

| Male |

58% |

46% |

45% |

32% |

48% |

| Age |

18-24 years |

2% |

7% |

5% |

2% |

10% |

| 25-34 years |

7% |

33% |

10% |

55% |

48% |

| 35-44 years |

22% |

30% |

71% |

31% |

36% |

| 45-54 years |

29% |

22% |

12% |

9% |

3% |

| 55-64 years |

33% |

4% |

2% |

2% |

0% |

| 65-74 years |

4% |

4% |

0% |

1% |

2% |

| more than 75 years |

3% |

0% |

0% |

0% |

0% |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).