Submitted:

28 October 2023

Posted:

31 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

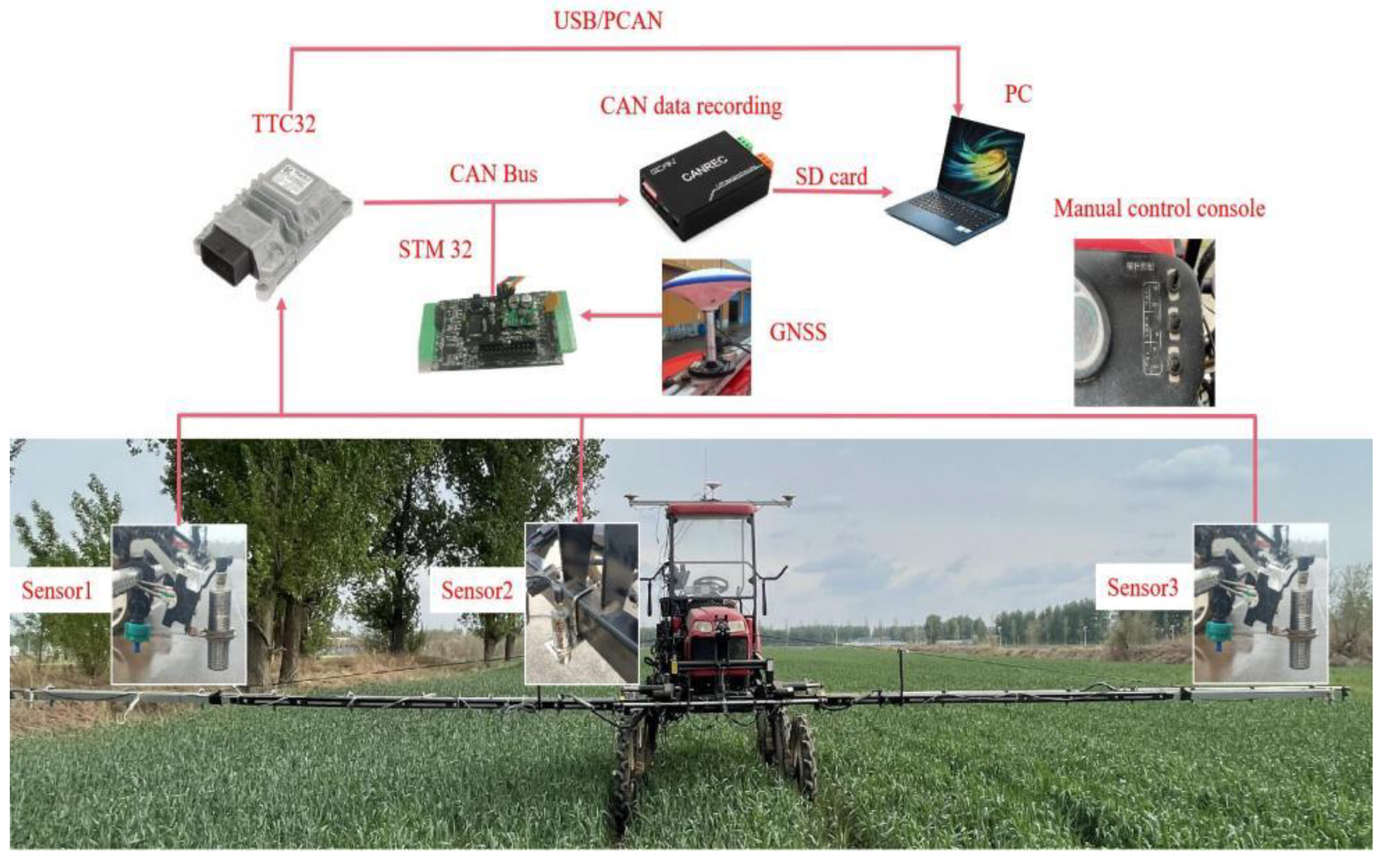

2.1. Boom Height Detection System

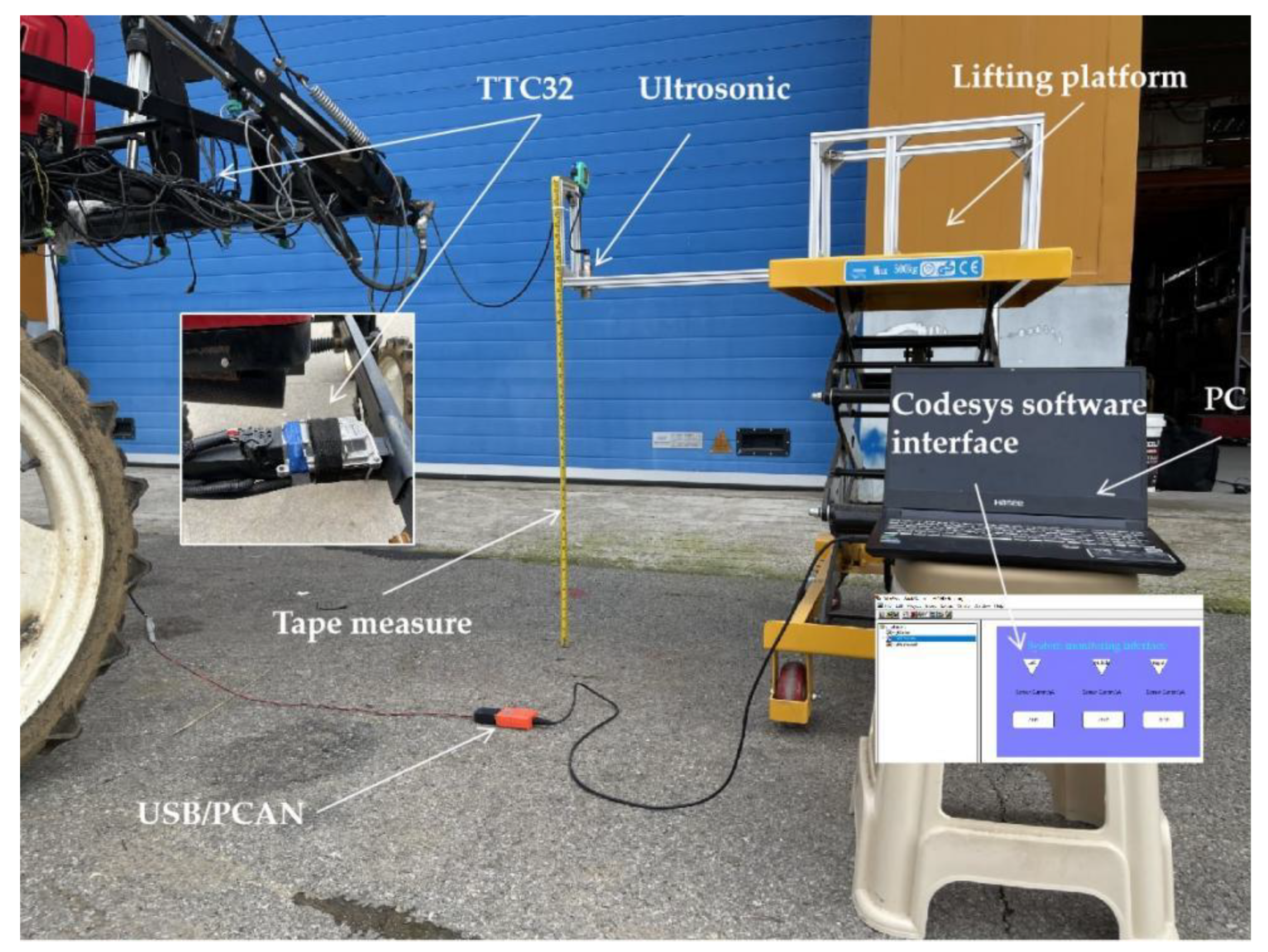

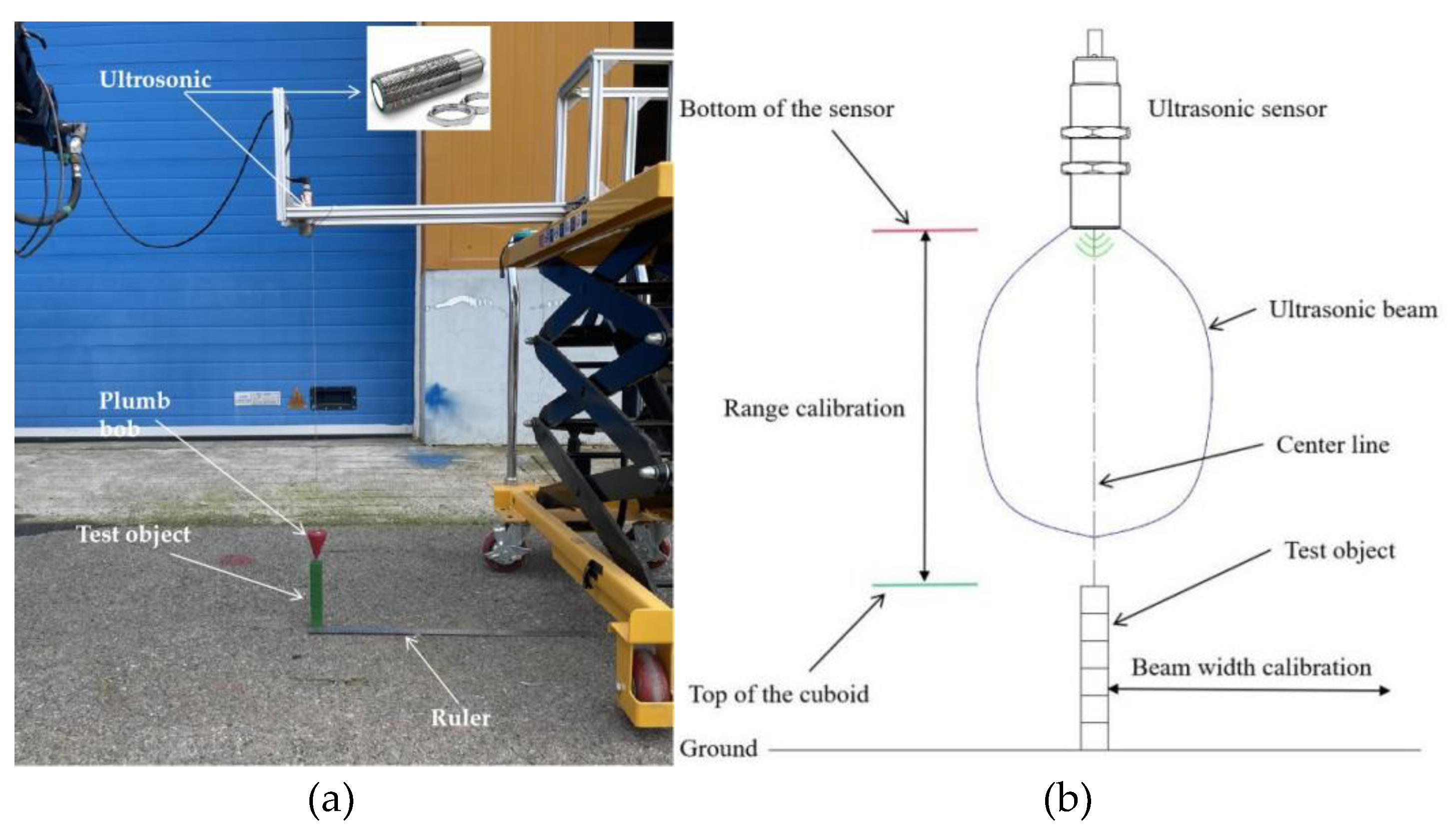

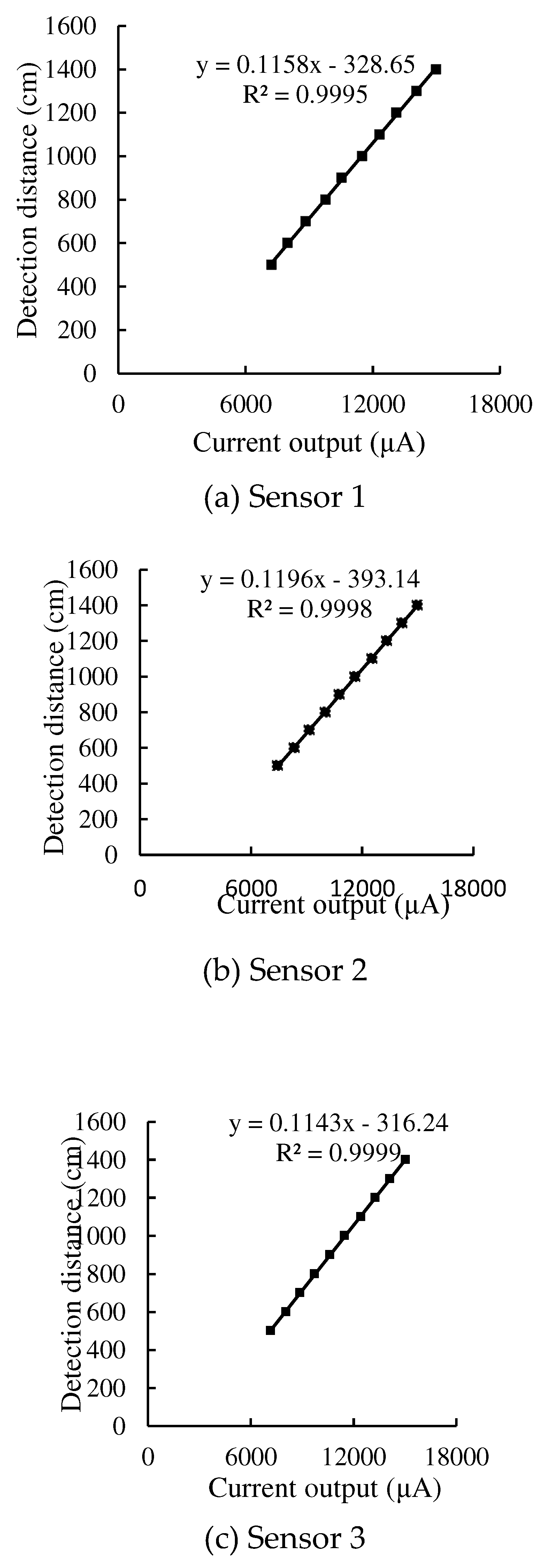

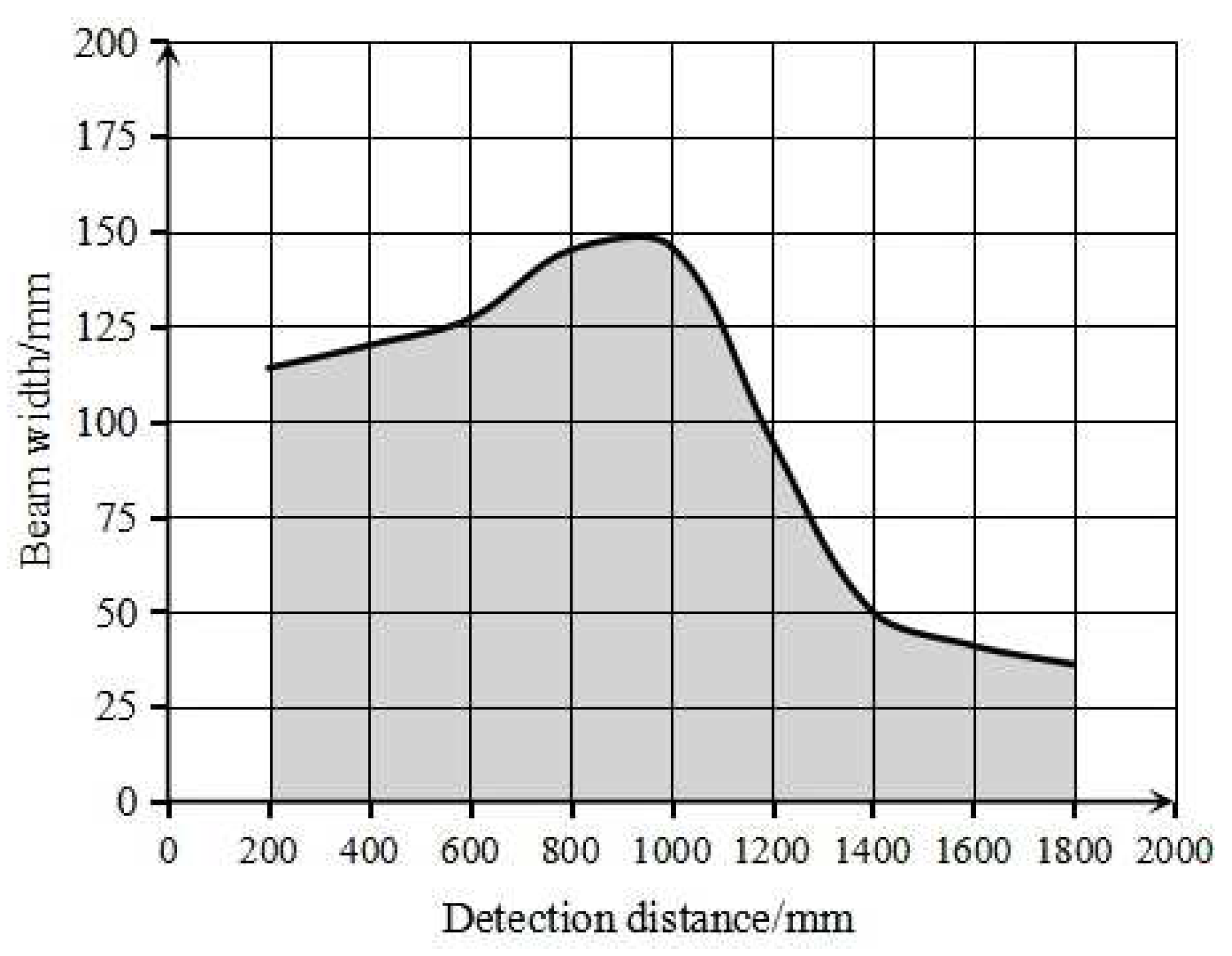

2.2 Calibration Test of the Initial Detection Curve and Detection Range of the Ultrasonic Sensor

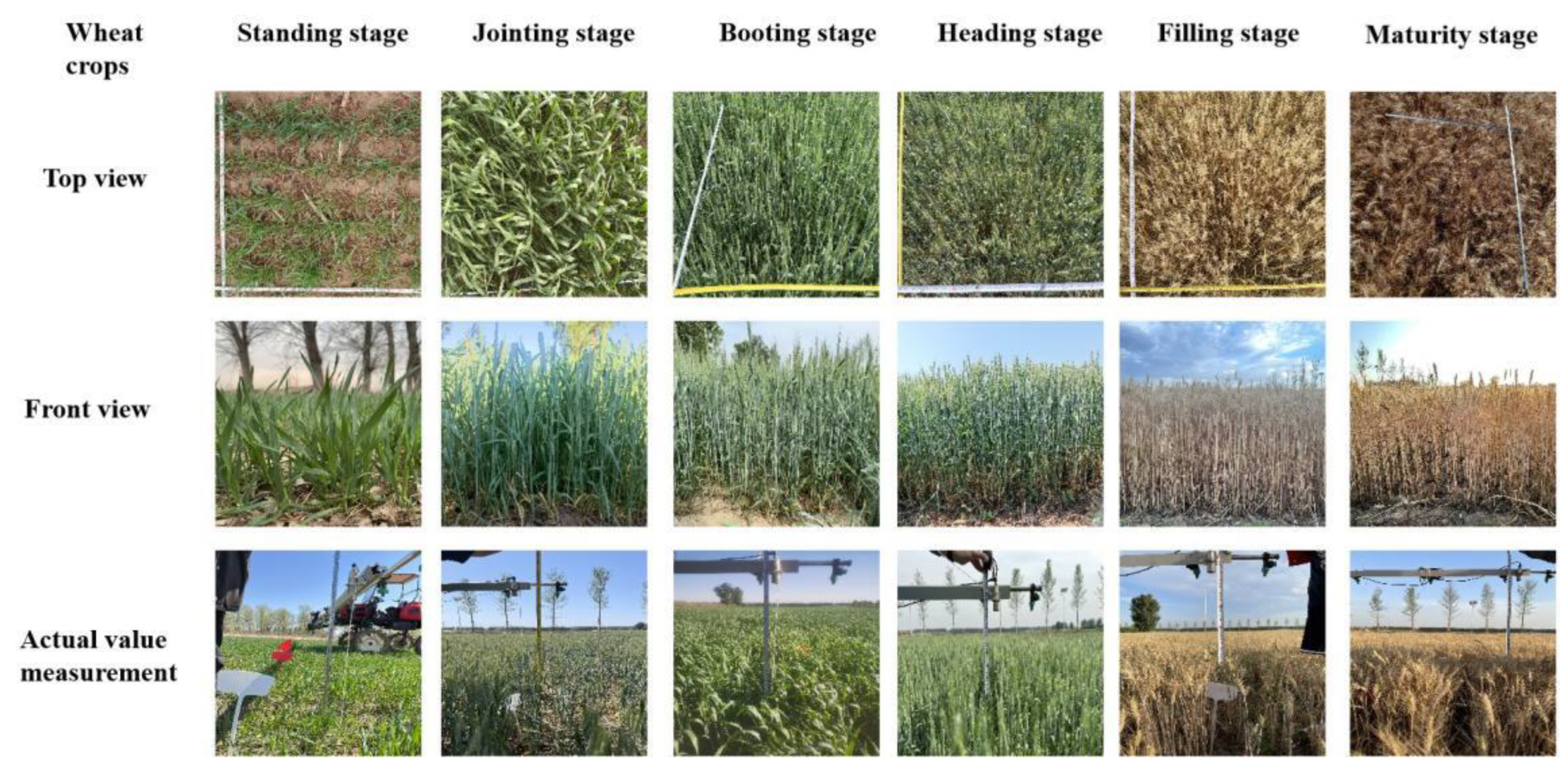

2.3. Construction of a Field Detection Model of Spray Boom Height during the Wheat Growth Cycle

3. Results

3.1 Initial Detection Curve and Detection Range Calibration Test Results of the Ultrasonic Sensor

3.2 Results of the Field Spray Boom Height Detection Test

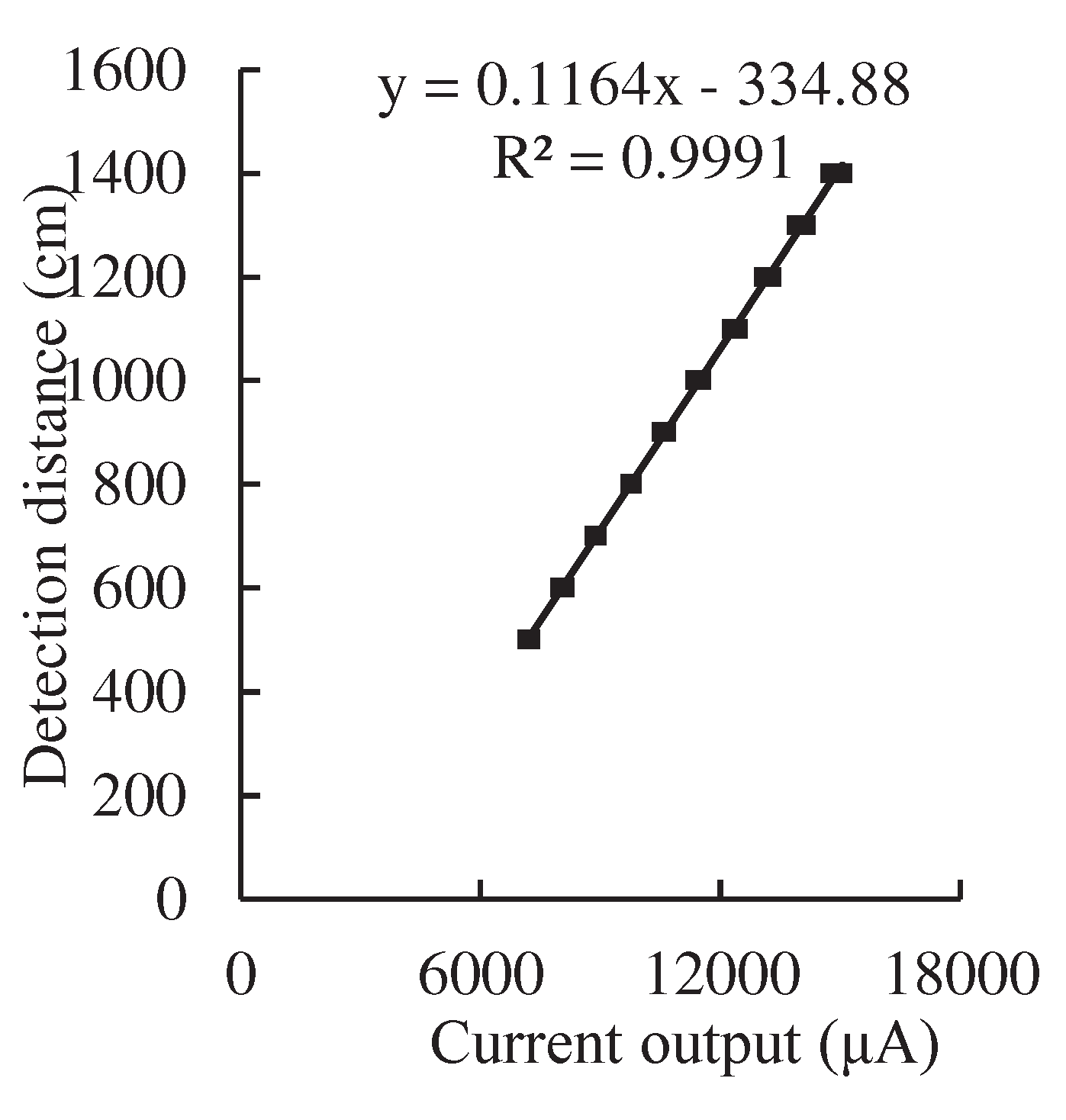

3.2.1. Construction of the Detection Model

| Model equation | Compensation value/mm | Applicable scope | |

|---|---|---|---|

| Dd/mm | Stage | ||

| y = 0.1164x - 334.88+A | 13.85 | 450~701 | Standing |

| 26 | 734~961 | ||

| 27.75 | 450~850 | Jointing | |

| 70 | 864~973 | ||

| 40.58 | 450~858 | Booting | |

| 89.86 | 869~991 | ||

| 46.44 | 450~850 | Heading | |

| 91.86 | 860~951 | ||

| 47.53 | 450~867 | Filling | |

| 109.5 | 880~1000 | ||

| 36.88 | 450~850 | Maturity | |

| 120.75 | 860~966 | ||

3.2.2. Validation and Optimization Results of the Spray Boom Height Detection Model

4 Discussion

4.1. The Distance between the Ultrasonic Sensor and the Wheat Canopy within a Certain Range Can Guarantee the Detection Accuracy

4.2 Effects of Different Wheat Growth Stages on the Detection of the Location of Wheat in the Field by the Ultrasonic Sensor

5. Conclusions

- (1)

- The ultrasonic sensor detects the wheat canopy, and its detection position is actually under the canopy. If Hdbw is directly used as the control input of the spraying operation, it will lead to a large detection position offset, and the offset of Hdbw can reach 191 mm when Dd is in the range of 450~1000 mm.

- (2)

- When the Dd of the ultrasonic sensor is within 450~1000 mm, the larger the Dd is, the closer the detection position is to the root of wheat, and vice versa, the closer to the top of wheat. When the detection distance was more than 1000 mm, the detection value fluctuated violently, the position offset reached a maximum of 511 mm, and the detection results were mostly concentrated near the wheat roots. Therefore, when the detection distance is greater than 1000 mm, it is not suitable for the height detection of wheat.

- (3)

- Different growth stages of wheat also affect detection by the ultrasonic sensor. During the standing stage, the Dd range had a higher Upp only in the range of 450~701 mm (Upp ≥85%), which means that only when Dd is in this range can the detection position corresponding to Hdbw be close to the top of the wheat. However, as the wheat growth cycle extends, Hdbw can also have a higher Upp in the larger Dd range of 450~850 mm. Even at the maturity stages, Upp corresponding to Dd in the range of 450~850 mm were both ≥90%.

- (4)

- This study obtained detection compensation values considering different wheat growth stages and different detection heights. Based on the compensation values, a wheat full-range detection model was established, the model was validated and optimized, and the applicable range Dd of the model was determined to be 450~950 mm, and the error of the optimized model was <5 cm.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Luo,X.W., Liao,J., Hu,L., Zhou, Z.Y., Zhang, Z.G., Zang, Y., et al.(2021).Research Progress of Intelligent Agricultural Machinery in China and Practice of Unmanned Farming Fields. South China Agricultural University Journal.42(06):8-17+5. [CrossRef]

- Li,D.L.,and Li,Z.(2020).Analysis and Development Prospects of Unmanned Farming Systems.Journalof Agricultural Machinery.51(07):1-12. [CrossRef]

- Zhao,C.J.(2021).Current Development and Future Prospects of Smart Agriculture.South China Agricultural University Journal.42(06):1-7. [CrossRef]

- Speelman, L.,and Jansen, J. W. (1974). The effect of spray-boom movement on the liquid distribution of field crop sprayers. J. Agric. Eng.Res.19(2), 117-129. [CrossRef]

- Ramon, H., De Baerdemaeker, J. (1997). Spray boom motions and spray distribution: Part 1, derivation of a mathematical relation. J. Agric. Eng. Res. 66(1), 23-29. [CrossRef]

- Griffith, J., Strelioff, B., and Schnaider, J. (2012). The Hockley Index. ASABE Annual International Meeting . 2012(2),1325-1332. [CrossRef]

- Holterman, H. J., van de Zande, J. C., Porskamp, H. A., and Huijsmans, J. F. (1997). Modelling spray drift from boom sprayers. Comput. Electron. Agric. 19(1), 1-22. [CrossRef]

- Nuyttens, D., De Schampheleire, M., Baetens, K., and Sonck, B. (2007). The influence of operator-controlled variables on spray drift from field crop sprayers. Trans. ASABE, 50(4), 1129-1140. [CrossRef]

- Baetens, K., Ho, Q. T., Nuyttens, D., De Schampheleire, M., Endalew, A. M., Hertog, M. L.,et al.(2009). A validated 2-D diffusion-advection model for prediction of drift from ground boom sprayers. Atmos. Environ., 43(9), 1674-1682. [CrossRef]

- Tumbo, S.D., Salyani, M., Whitney, J.D., Wheaton, T.A.,and Miller, W.M.(2002). Investigation of laser and ultrasonic ranging sensors for measurements of citrus canopy volume. Appl. Eng. Agric 18, 367–372. [CrossRef]

- Ehlert, D., Adamek, R.,and Horn, H. J. (2009) .Laser rangefinder-based measuring of crop biomass under field conditions. Precision Agriculture.10(5), 395–408. [CrossRef]

- Dou, H.J., Wang, S.L., Zhai, C.Y., Chen, L.P., Wang, X., and Zhao, X.G.(2021). A 1idar sensor based spray boom height detection method and the corresponding experimenta1 va1idation. Sensors 21 (6), 2107. [CrossRef]

- Jimenez-Berni, J. A., Deery, D. M., Rozas-Larraondo, P., Condon, A. G., Rebetzke, G. J., James, R. A., et al. (2018). High throughput determination of plant height, ground cover, and above-ground biomass in wheat with LiDAR. Front. Plant Sci. 9. [CrossRef]

- Llorens, J.,Gil, E.,Llop, J., and Escolà, A.(2011).Ultrasonic and LIDAR Sensors for Electronic Canopy Characterization in Vineyards: Advances to Improve Pesticide Application Methods. Sensors .11(2), 2177-2194. [CrossRef]

- Cui, L.F., Xue, X.Y., Ding, S.M., and Le, F.X.(2019b). Development of a DSP-based electronic control system for the active spray boom suspension. Comput. Electron. Agric 166, 1–9. [CrossRef]

- Sinfort, c., A.Miralles, F.Sevila and G.M.Maniere .(1994). Study and development of a test method for spray boom suspensions. J.Agr. Eng Res.59(4), 245-252. [CrossRef]

- Wang,S.L.,Zhao,C.J.,and Wang,X.(2014).Design and test of boom height adjustment system.J. Agric Mechanization Res.36(08),161-164+173. [CrossRef]

- Pittman, J.J., Arnall, D.B., Interrante, S.M., Moffet, C.A.,and Butler, T.J.(2015). Estimation of biomass and canopy height in bermudagrass, alfalfa, and wheat using ultrasonic, laser, and spectral sensors. Sensors . 15(2), 2920–2943. [CrossRef]

- Barmeier, G., Mistele, B.,and Schmidhalter, U.(2016). Referencing laser and ultrasonic height measurements of barleycultivars by using a herbometre as standard. Crop. Pasture Sci. 67(12), 1215–1222. [CrossRef]

- Chang, Y.K., Zaman, Q.U., Rehman, T.U., Farooque, A.A., Esau, T., and Jameel, M.W.(2017) .A real-time ultrasonic system to measure wild blueberry plant height during harvesting. Biosyst. Eng. 157, 35–44. [CrossRef]

- Bronson, K.F., French, A.N., Conley, M.M., and Barnes, E.M.(2021). Use of an ultrasonic sensor for plant height estimation in irrigated cotton. Agron. J. 113 (2), 2175–2183. [CrossRef]

- Farooque, A.A.,Chang, Y.K.,Zaman, Q.U.,Groulx, D.,Schumann, A.W.,Esau, T.J.,et al.(2013).Performance evaluation of multiple ground based sensors mounted on a commercial wild blueberry harvester to sense plant height, fruit yield and topographic features in real-time. Comput. Electron. Agric. 91(2), 135–144 . [CrossRef]

- Schumann, A.W.,and Zaman, Q.U. (2005).Software Development for Real-Time Ultrasonic Mapping of Tree Canopy Size. Comput. Electron. Agr. 47(1), 25-40. [CrossRef]

- Planas, S., Rosell, J.R., Pomar, J., Camp, F., Solanelles, F., Gràcia, F., et al. (2011). Performance of an ultrasonic ranging sensor in apple tree canopies. Sensors.11(3), 2459–2477. [CrossRef]

- Zaman, Q.U., Salyani, M., Zaman, Q.U., and Salyani, M.( 2004). Effects of foliage density and ground speed on ultrasonic measurement of citrus tree volume. Appl. Eng. Agric. 20(2), 173–17. [CrossRef]

- Aziz, S. A., Steward, B. L., Birrell, S. J., Kaspar, T. C., and Shrestha, D. S. (2004). Ultrasonic sensing for corn plant canopy characterization. American Soc. Agri. Biol. Eng., 041120. [CrossRef]

- Li, H.Z., Zhai, C.Y., Weckler, P., Wang, N., Yang, S.,and Zhang, B. (2017).A Canopy Density Model for Planar Orchard Target Detection Based on Ultrasonic Sensors. Sensors . 17(1), 31. [CrossRef]

- Nan, Y.L., Zhang, H.C., Zheng, J.Q., Bian, L.M., Li, Y.X., Yang, Y., et al. (2019). Estimating leaf area density of Osmanthus trees using ultrasonic sensing. Biosystems Engineering, 186, 60-70. [CrossRef]

- Gil, E., Escolà, A., Rosell, J. R., Planas, S., and Val, L. (2007). Variable rate application of plant protection products in vineyard using ultrasonic sensors. Crop Protection.26(8), 1287–1297. [CrossRef]

- Maghsoudi, H., Minaei, S., Ghobadian, B., and Masoudi, H. (2015). Ultrasonic sensing of pistachio canopy for low-volume precision spraying. Comput. Electron. Agric. 112 (Sp. Iss. SI), 149–160. [CrossRef]

- Zhou, H.T., Jia, W.D., Li.,Y., and Ou, M.X. (2021). Method for estimating canopy thickness using ultrasonic sensor technology. Agriculture .11(10),1011. [CrossRef]

- Andújar, D., Weis, M.,and Gerhards, R.(2012). An Ultrasonic System for Weed Detection in Cereal Crops. Sensors.12, 17343-17357. [CrossRef]

- Li, B.,Bai X.H.,and Li, Y.K.(2020). A crop canopy localization method based on ultrasonic ranging and iterative self-organizing data analysis technique algorithm. Sensors .20 (3), 818. [CrossRef]

- Dou,H.J.,Zhai,C.Y.,Chen, L.P.,Wang,S.L.,and Wang, X. (2021b). Field variation characteristics of sprayer boom height using a newly designed boom height detection system. IEEE Access .9, 17148–17160. [CrossRef]

- Zhao, X.G., Zhai, C.Y., Wang, S.L., Dou, H.J.,Yang, S.,Wang, X.et al.(2022). Sprayer boom height measurement in wheat field using ultrasonic sensor: An exploratory study. Front Plant Sci. 13,1008122. Published 2022 Nov 22. [CrossRef]

- Scotford, I.M., and Miller, P.C.H. (2004). Combination of Spectral Reflectance and Ultrasonic Sensing to monitor the Growth of Winter Wheat. Biosystems Engineering. 87(1), 27–38. [CrossRef]

- Wei, J.,and Salyani, M.(2004) .Development of a Laser Scanner for Measuring Tree Canopy Characteristics: Phase 1. Prototype Development. Trans. ASAE , 47(6), 2101-2107. [CrossRef]

| Current values/µA | Detection values/mm | Difference/mm | |||

| Sensor | Sensor 2 | Sensor 3 | max | min | |

| 4000 | 135 | 115 | 141 | 26 | 20 |

| 6000 | 366 | 354 | 370 | 16 | 12 |

| 8000 | 598 | 594 | 598 | 4 | 0 |

| 10000 | 829 | 833 | 827 | 6 | 2 |

| 12000 | 1061 | 1042 | 1055 | 19 | 6 |

| 14000 | 1293 | 1311 | 1284 | 27 | 9 |

| 16000 | 1524 | 1550 | 1513 | 37 | 11 |

| 18000 | 1756 | 1790 | 1741 | 49 | 15 |

| 20000 | 1987 | 2029 | 1970 | 59 | 17 |

| Current values/μA | Detection values/mm | Difference/mm | ||||

|---|---|---|---|---|---|---|

| Sensor 1 | Sensor 2 | Sensor 3 | Fusion | Max | Min | |

| 4000 | 135 | 115 | 141 | 131 | 16 | 4 |

| 6000 | 366 | 354 | 370 | 364 | 10 | 2 |

| 8000 | 598 | 594 | 598 | 596 | 2 | 2 |

| 10000 | 829 | 833 | 827 | 829 | 4 | 0 |

| 12000 | 1061 | 1042 | 1055 | 1062 | 20 | 1 |

| 14000 | 1293 | 1311 | 1284 | 1295 | 16 | 2 |

| 16000 | 1524 | 1550 | 1513 | 1528 | 22 | 4 |

| 18000 | 1756 | 1790 | 1741 | 1760 | 30 | 4 |

| 20000 | 1987 | 2029 | 1970 | 1993 | 36 | 6 |

| Stage | Hdbw/mm | Habw/mm | Offset/mm | Hapw/mm | Upp/% | ||||||||||

| S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | |

| P1 | 468 | 471 | 460 | 450 | 460 | 450 | 18 | 11 | 10 | 139 | 120 | 113 | 87.05 | 90.83 | 91.15 |

| 542 | 514 | 530 | 532 | 500 | 523 | 10 | 14 | 7 | 139 | 120 | 113 | 92.81 | 88.33 | 93.81 | |

| 640 | 613 | 595 | 625 | 598 | 580 | 15 | 15 | 17 | 139 | 120 | 113 | 89.21 | 87.5 | 86.73 | |

| 699 | 694 | 631 | 680 | 680 | 615 | 19 | 14 | 16 | 139 | 120 | 113 | 86.33 | 88.33 | 85.84 | |

| 758 | 819 | 715 | 734 | 799 | 701 | 24 | 20 | 14 | 139 | 120 | 113 | 82.73 | 83.33 | 87.61 | |

| 815 | 887 | 818 | 784 | 865 | 796 | 31 | 22 | 22 | 139 | 120 | 113 | 77.7 | 81.67 | 80.53 | |

| 865 | 989 | 980 | 840 | 961 | 947 | 25 | 28 | 33 | 139 | 120 | 113 | 82.01 | 76.67 | 70.8 | |

| 920 | 1110 | 1120 | 891 | 1058 | 1075 | 29 | 52 | 45 | 139 | 120 | 113 | 79.14 | 56.67 | 60.18 | |

| 1121 | 1200 | 1214 | 1008 | 1160 | 1138 | 113 | 40 | 76 | 139 | 120 | 113 | 18.71 | 66.67 | 32.74 | |

| 1231 | 1374 | 1300 | 1135 | 1274 | 1231 | 96 | 100 | 69 | 139 | 120 | 113 | 30.94 | 16.67 | 38.94 | |

| 1331 | 1487 | 1450 | 1220 | 1397 | 1357 | 111 | 90 | 93 | 139 | 120 | 113 | 20.14 | 25 | 17.7 | |

| P2 | 535 | 578 | 450 | 510 | 552 | 445 | 25 | 26 | 5 | 447 | 393 | 442 | 94.41 | 93.38 | 98.87 |

| 567 | 626 | 548 | 540 | 610 | 520 | 27 | 16 | 28 | 447 | 393 | 442 | 93.96 | 95.93 | 93.67 | |

| 648 | 701 | 651 | 620 | 670 | 630 | 28 | 31 | 21 | 447 | 393 | 442 | 93.74 | 92.11 | 95.25 | |

| 686 | 780 | 703 | 664 | 750 | 678 | 22 | 30 | 25 | 447 | 393 | 442 | 95.08 | 92.37 | 94.34 | |

| 837 | 842 | 843 | 798 | 800 | 805 | 39 | 42 | 38 | 447 | 393 | 442 | 91.28 | 89.31 | 91.4 | |

| 944 | 926 | 891 | 871 | 864 | 850 | 73 | 62 | 41 | 447 | 393 | 442 | 83.67 | 84.22 | 90.72 | |

| 967 | 952 | 933 | 895 | 890 | 865 | 72 | 62 | 68 | 447 | 393 | 442 | 83.89 | 84.22 | 84.62 | |

| 995 | 1045 | 1052 | 964 | 971 | 973 | 31 | 74 | 79 | 447 | 393 | 442 | 93.06 | 81.17 | 82.13 | |

| 1142 | 1218 | 1283 | 1007 | 1096 | 1065 | 135 | 122 | 218 | 447 | 393 | 442 | 69.8 | 68.96 | 50.68 | |

| 1265 | 1317 | 1329 | 1089 | 1136 | 1143 | 176 | 181 | 186 | 447 | 393 | 442 | 60.63 | 53.94 | 57.92 | |

| 1376 | 1450 | 1468 | 1179 | 1248 | 1173 | 197 | 202 | 295 | 447 | 393 | 442 | 55.93 | 48.6 | 33.26 | |

| Stage | Hdbw/mm | Habw/mm | Offset/mm | Hapw/mm | Upp/% | ||||||||||

| S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | |

| P3 | 540 | 534 | 471 | 515 | 500 | 450 | 25 | 34 | 21 | 515 | 528 | 521 | 95.15 | 93.56 | 95.97 |

| 618 | 594 | 518 | 571 | 545 | 485 | 47 | 49 | 33 | 515 | 528 | 521 | 90.87 | 90.72 | 93.67 | |

| 680 | 638 | 535 | 643 | 600 | 508 | 37 | 38 | 27 | 515 | 528 | 521 | 92.82 | 92.8 | 94.82 | |

| 750 | 750 | 587 | 716 | 700 | 550 | 34 | 50 | 37 | 515 | 528 | 521 | 93.4 | 90.53 | 92.9 | |

| 955 | 788 | 741 | 869 | 764 | 620 | 86 | 24 | 121 | 515 | 528 | 521 | 83.3 | 95.45 | 76.78 | |

| 1011 | 864 | 664 | 927 | 812 | 637 | 84 | 52 | 27 | 515 | 528 | 521 | 83.69 | 90.15 | 94.82 | |

| 1034 | 914 | 762 | 951 | 858 | 715 | 83 | 56 | 47 | 515 | 528 | 521 | 83.88 | 89.39 | 90.98 | |

| 1087 | 1031 | 791 | 991 | 930 | 729 | 96 | 101 | 62 | 515 | 528 | 521 | 81.36 | 80.87 | 88.1 | |

| 1500 | 1081 | 901 | 1100 | 989 | 830 | 400 | 92 | 71 | 515 | 528 | 521 | 22.33 | 82.58 | 86.37 | |

| 1389 | 1320 | 1030 | 1217 | 1158 | 943 | 172 | 162 | 87 | 515 | 528 | 521 | 66.6 | 70.08 | 83.3 | |

| P4 | 480 | 511 | 487 | 450 | 495 | 470 | 30 | 16 | 17 | 526 | 552 | 603 | 94.3 | 97.1 | 97.18 |

| 595 | 543 | 540 | 570 | 520 | 520 | 25 | 23 | 20 | 526 | 552 | 603 | 95.25 | 95.83 | 96.68 | |

| 739 | 680 | 701 | 690 | 630 | 650 | 49 | 50 | 51 | 526 | 552 | 603 | 90.68 | 90.94 | 91.54 | |

| 829 | 781 | 700 | 760 | 710 | 657 | 69 | 71 | 43 | 526 | 552 | 603 | 86.88 | 87.14 | 92.87 | |

| 846 | 800 | 769 | 780 | 760 | 730 | 66 | 40 | 39 | 526 | 552 | 603 | 87.45 | 92.75 | 93.53 | |

| 894 | 897 | 941 | 835 | 820 | 850 | 59 | 77 | 91 | 526 | 552 | 603 | 88.78 | 86.05 | 84.91 | |

| 959 | 948 | 1025 | 870 | 860 | 932 | 89 | 88 | 93 | 526 | 552 | 603 | 83.08 | 84.06 | 84.58 | |

| 973 | 1035 | 1050 | 893 | 934 | 948 | 80 | 101 | 102 | 526 | 552 | 603 | 84.79 | 81.7 | 83.08 | |

| 1041 | 1238 | 1047 | 951 | 1030 | 970 | 90 | 208 | 77 | 526 | 552 | 603 | 82.89 | 62.32 | 87.23 | |

| 1241 | 1358 | 1321 | 1024 | 1062 | 1076 | 217 | 296 | 245 | 526 | 552 | 603 | 58.75 | 46.38 | 59.37 | |

| Stage | Hdbw/mm | Habw/mm | Offset/mm | Hapw/mm | Upp/% | ||||||||||

| S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | S1 | S2 | S 3 | |

| P5 | 560 | 483 | 486 | 533 | 455 | 450 | 27 | 28 | 36 | 542 | 568 | 622 | 95.02 | 95.07 | 94.21 |

| 608 | 539 | 563 | 560 | 510 | 530 | 48 | 29 | 33 | 542 | 568 | 622 | 91.14 | 94.89 | 94.69 | |

| 780 | 634 | 654 | 720 | 580 | 590 | 60 | 54 | 64 | 542 | 568 | 622 | 88.93 | 90.49 | 89.71 | |

| 894 | 727 | 720 | 818 | 690 | 670 | 76 | 37 | 50 | 542 | 568 | 622 | 85.98 | 93.49 | 91.96 | |

| 899 | 835 | 844 | 846 | 784 | 790 | 53 | 51 | 54 | 542 | 568 | 622 | 90.22 | 91.02 | 91.32 | |

| 1035 | 950 | 865 | 930 | 867 | 840 | 105 | 83 | 25 | 542 | 568 | 622 | 80.63 | 85.39 | 95.98 | |

| 1079 | 991 | 974 | 968 | 895 | 880 | 111 | 96 | 94 | 542 | 568 | 622 | 79.52 | 83.10 | 84.89 | |

| 1472 | 1041 | 1000 | 1025 | 940 | 899 | 447 | 101 | 101 | 542 | 568 | 622 | 17.53 | 82.22 | 83.76 | |

| 1625 | 1143 | 1100 | 1160 | 1000 | 975 | 465 | 143 | 125 | 542 | 568 | 622 | 14.21 | 74.82 | 79.90 | |

| 1700 | 1502 | 1354 | 1189 | 1040 | 1000 | 511 | 462 | 354 | 542 | 568 | 622 | 5.72 | 18.66 | 43.09 | |

| P6 | 612 | 541 | 460 | 580 | 510 | 450 | 32 | 31 | 10 | 638 | 654 | 688 | 94.98 | 95.26 | 98.55 |

| 720 | 637 | 560 | 670 | 600 | 523 | 50 | 37 | 37 | 638 | 654 | 688 | 92.16 | 94.34 | 94.62 | |

| 794 | 730 | 630 | 740 | 723 | 617 | 54 | 7 | 13 | 638 | 654 | 688 | 91.54 | 98.93 | 98.11 | |

| 859 | 804 | 752 | 810 | 760 | 700 | 49 | 44 | 52 | 638 | 654 | 688 | 92.32 | 93.27 | 92.44 | |

| 962 | 823 | 780 | 865 | 790 | 765 | 97 | 33 | 15 | 638 | 654 | 688 | 84.80 | 94.95 | 97.82 | |

| 1000 | 915 | 871 | 890 | 850 | 810 | 110 | 65 | 61 | 638 | 654 | 688 | 82.76 | 90.06 | 91.13 | |

| 1063 | 1030 | 964 | 950 | 930 | 860 | 113 | 100 | 104 | 638 | 654 | 688 | 82.29 | 84.71 | 84.88 | |

| 1304 | 1095 | 1050 | 1001 | 964 | 930 | 303 | 131 | 120 | 638 | 654 | 688 | 52.51 | 79.97 | 82.56 | |

| 1465 | 1322 | 1157 | 1013 | 1049 | 966 | 452 | 273 | 191 | 638 | 654 | 688 | 29.15 | 58.26 | 72.24 | |

| Stages | Upp/% | Dd/mm | Average offset /mm |

Standard deviation /mm |

|---|---|---|---|---|

| Standing stage | 85~98 | 450~701 | 13.85 | 3.48 |

| 70~84 | 734~961 | 26 | 4.47 | |

| Jointing stage | 85~98 | 450~850 | 27.75 | 9.59 |

| 70~84 | 864~973 | 70.00 | 6.35 | |

| Booting stage | 85~98 | 450~858 | 40.58 | 13.83 |

| 70~84 | 869~991 | 89.86 | 6.72 | |

| Heading stage | 85~98 | 450~850 | 46.44 | 22.35 |

| 70~84 | 860~951 | 91.86 | 7.69 | |

| Filling stage | 85~98 | 450~867 | 47.53 | 17.21 |

| 70~84 | 880~1000 | 109.5 | 16.7 | |

| Maturity stage | 85~98 | 450~850 | 36.88 | 18.26 |

| 70~84 | 860~966 | 120.75 | 30.45 |

| Model equation | Compensation value/mm | Application scope | |

|---|---|---|---|

| Dd/mm | Stage | ||

| y = 0.1164x - 334.88+A | 19.93 | 450~1000 | Standing stage |

| 39.84 | 450~850 | Jointing stage to maturity stage | |

| 96.39 | 851~1000 | ||

| Stage | Habw/mm | Hdbw1/mm | Hdbw2/mm | Ev1/mm | Ev2/mm | Aev1/mm | Aev2/mm |

|---|---|---|---|---|---|---|---|

| Standing | 460 | 463 | 457 | 3 | 3 | 9.50 | 9.10 |

| 518 | 507 | 501 | 11 | 17 | |||

| 552 | 545 | 539 | 7 | 13 | |||

| 645 | 650 | 644 | 5 | 1 | |||

| 717 | 733 | 727 | 16 | 10 | |||

| 764 | 773 | 779 | 9 | 15 | |||

| 799 | 791 | 797 | 8 | 2 | |||

| 895 | 889 | 895 | 6 | 0 | |||

| 961 | 961 | 967 | 0 | 6 | |||

| 998 | 968 | 974 | 30 | 24 | |||

| Jointing | 513 | 508 | 496 | 5 | 17 | 19.89 | 19.67 |

| 540 | 563 | 551 | 23 | 11 | |||

| 598 | 601 | 589 | 3 | 9 | |||

| 620 | 604 | 592 | 16 | 28 | |||

| 653 | 697 | 685 | 44 | 32 | |||

| 800 | 793 | 781 | 7 | 19 | |||

| 805 | 800 | 788 | 5 | 17 | |||

| 964 | 1024 | 998 | 60 | 34 | |||

| 996 | 1012 | 986 | 16 | 10 | |||

| Booting | 454 | 490 | 491 | 36 | 37 | 27.70 | 26.30 |

| 520 | 509 | 510 | 11 | 10 | |||

| 600 | 562 | 563 | 38 | 37 | |||

| 500 | 490 | 491 | 10 | 9 | |||

| 670 | 632 | 633 | 38 | 37 | |||

| 700 | 720 | 721 | 20 | 21 | |||

| 774 | 760 | 761 | 14 | 13 | |||

| 840 | 872 | 873 | 32 | 33 | |||

| 899 | 920 | 914 | 21 | 15 | |||

| 953 | 1010 | 1004 | 57 | 51 | |||

| Heading | 448 | 427 | 434 | 21 | 14 | 23.44 | 24.33 |

| 550 | 548 | 555 | 2 | 5 | |||

| 590 | 572 | 579 | 18 | 11 | |||

| 620 | 582 | 589 | 38 | 31 | |||

| 670 | 667 | 674 | 3 | 4 | |||

| 746 | 781 | 788 | 35 | 42 | |||

| 775 | 805 | 812 | 30 | 37 | |||

| 842 | 857 | 864 | 15 | 22 | |||

| 964 | 915 | 911 | 49 | 53 | |||

| Filling | 470 | 479 | 485 | 9 | 15 | 24.67 | 18.44 |

| 550 | 542 | 548 | 8 | 2 | |||

| 630 | 624 | 630 | 6 | 0 | |||

| 680 | 671 | 677 | 9 | 3 | |||

| 710 | 728 | 734 | 18 | 24 | |||

| 800 | 769 | 775 | 31 | 25 | |||

| 845 | 848 | 854 | 3 | 9 | |||

| 900 | 847 | 916 | 53 | 16 | |||

| 970 | 885 | 898 | 85 | 72 | |||

| Maturity | 430 | 424 | 421 | 6 | 9 | 19.30 | 18.90 |

| 500 | 472 | 469 | 28 | 31 | |||

| 550 | 538 | 535 | 12 | 15 | |||

| 730 | 715 | 712 | 15 | 18 | |||

| 750 | 740 | 737 | 10 | 13 | |||

| 790 | 800 | 797 | 10 | 7 | |||

| 850 | 878 | 875 | 28 | 25 | |||

| 930 | 911 | 936 | 19 | 6 | |||

| 940 | 943 | 968 | 3 | 28 | |||

| 980 | 918 | 943 | 62 | 37 |

| Model equation | Compensation value/mm | Applicable scope | |

|---|---|---|---|

| Dd/mm | Stage | ||

| y = 0.1164x - 334.88+A | 19.93 | 450~950 | Standing stage |

| 39.84 | 450~850 | Jointing stage to maturity stage | |

| 96.39 | 851~950 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).