Submitted:

30 October 2023

Posted:

31 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

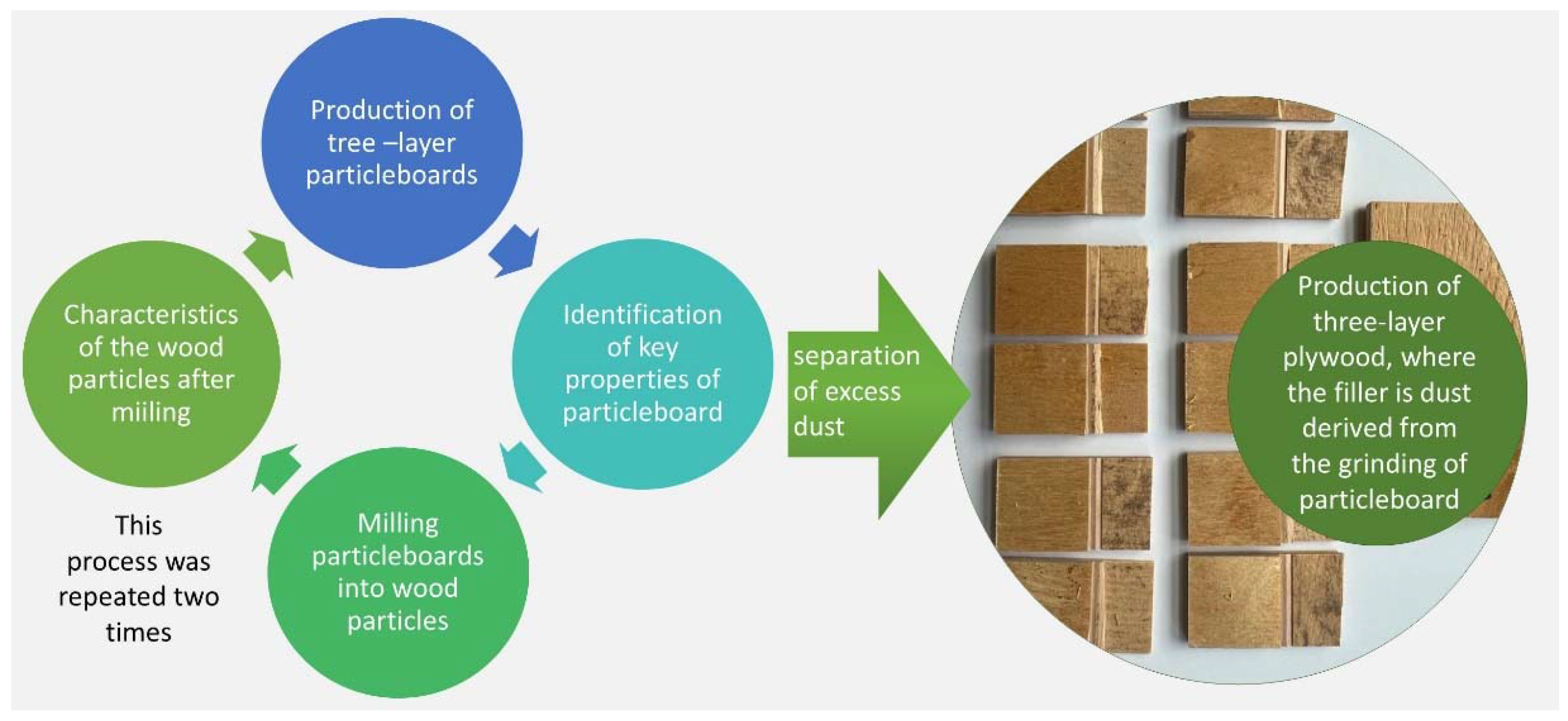

2. Materials and Methods

2.1. Materials

2.2. Preparations of panels

2.3. Characterization of panels

2.3. Statistical Analysis

3. Results and discussion

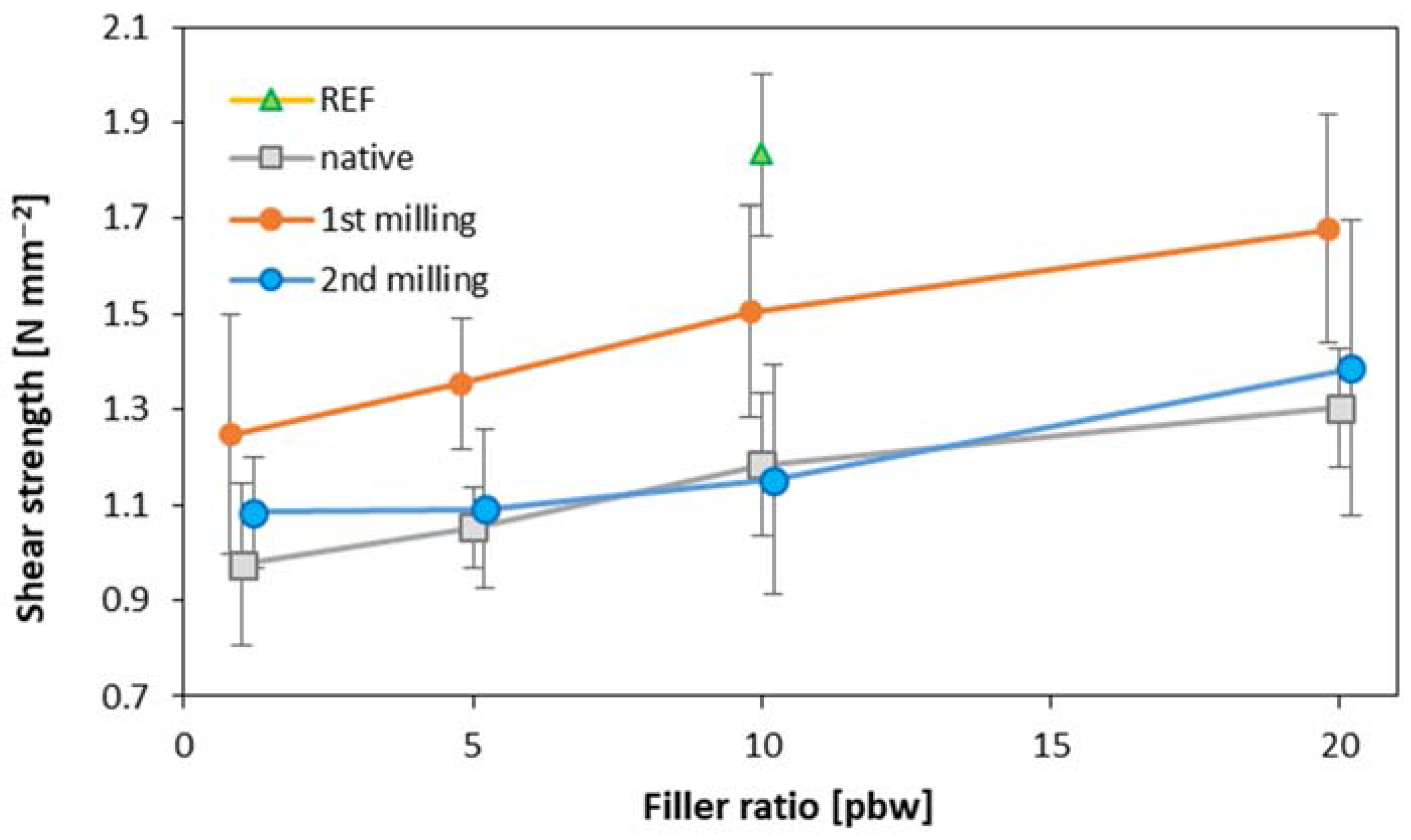

3.1. Bonding Quality

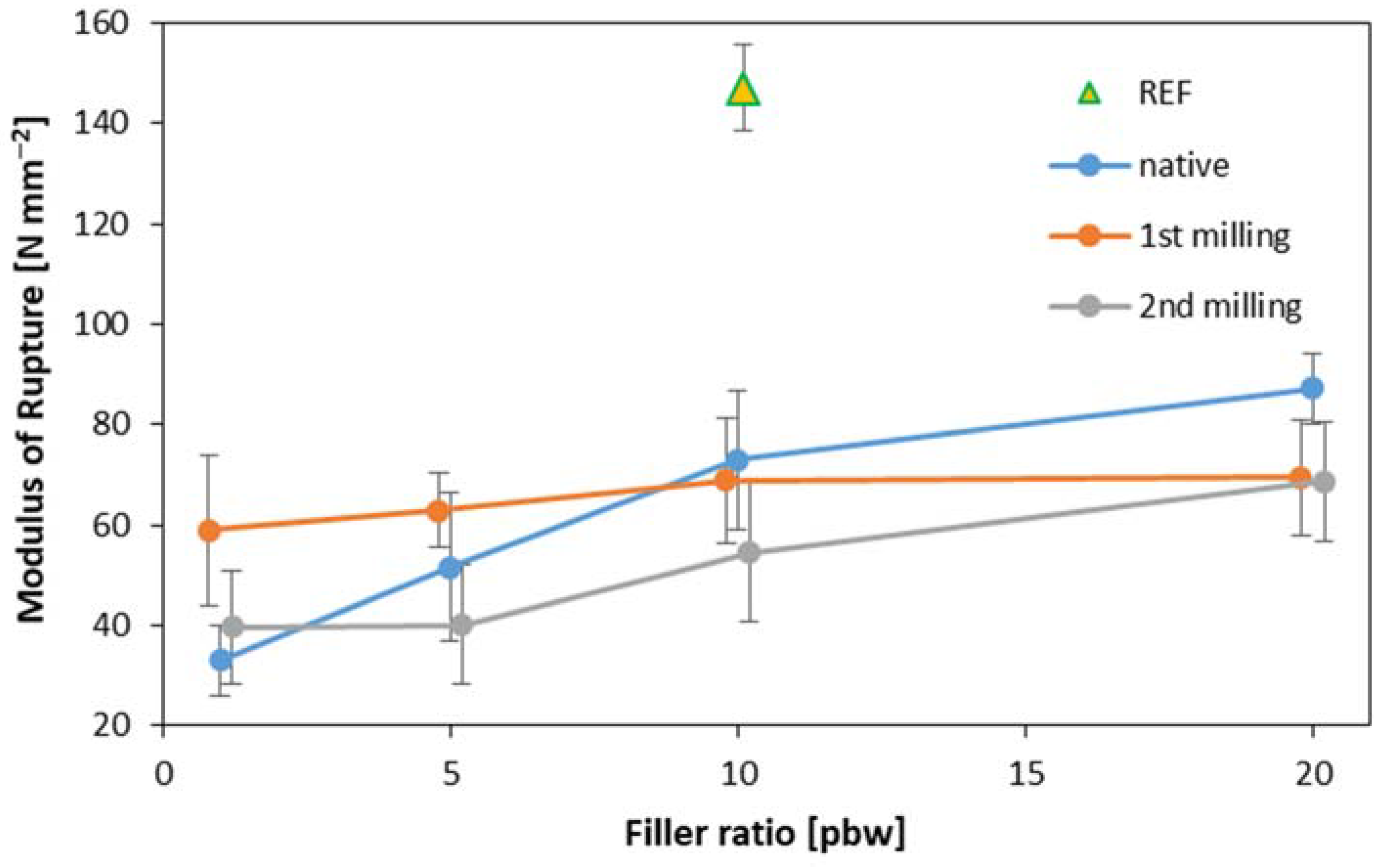

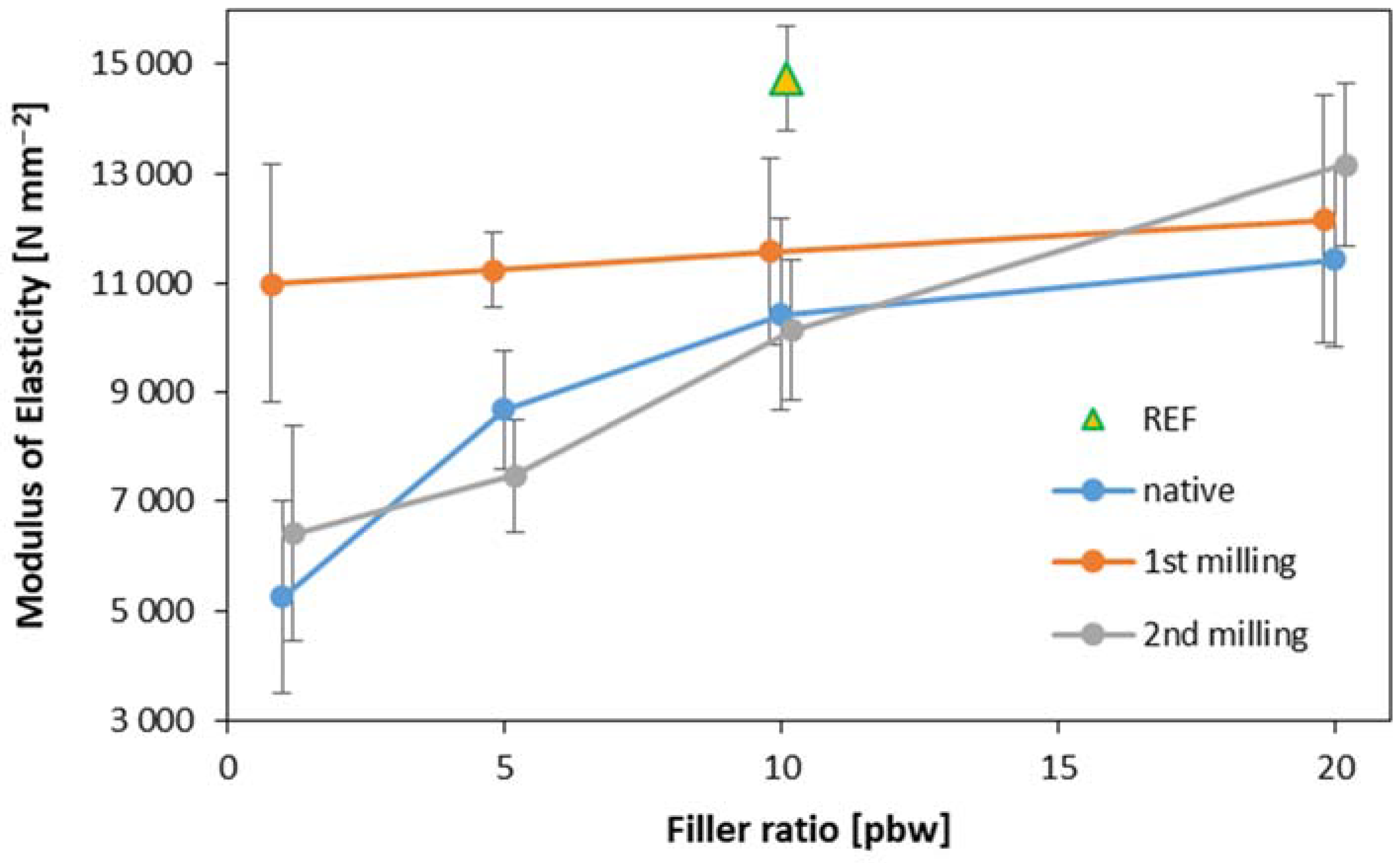

3.2. Modulus of Rupture and Modulus of Elasticity

3.3. The Thickness Swelling and Water Absorption tests

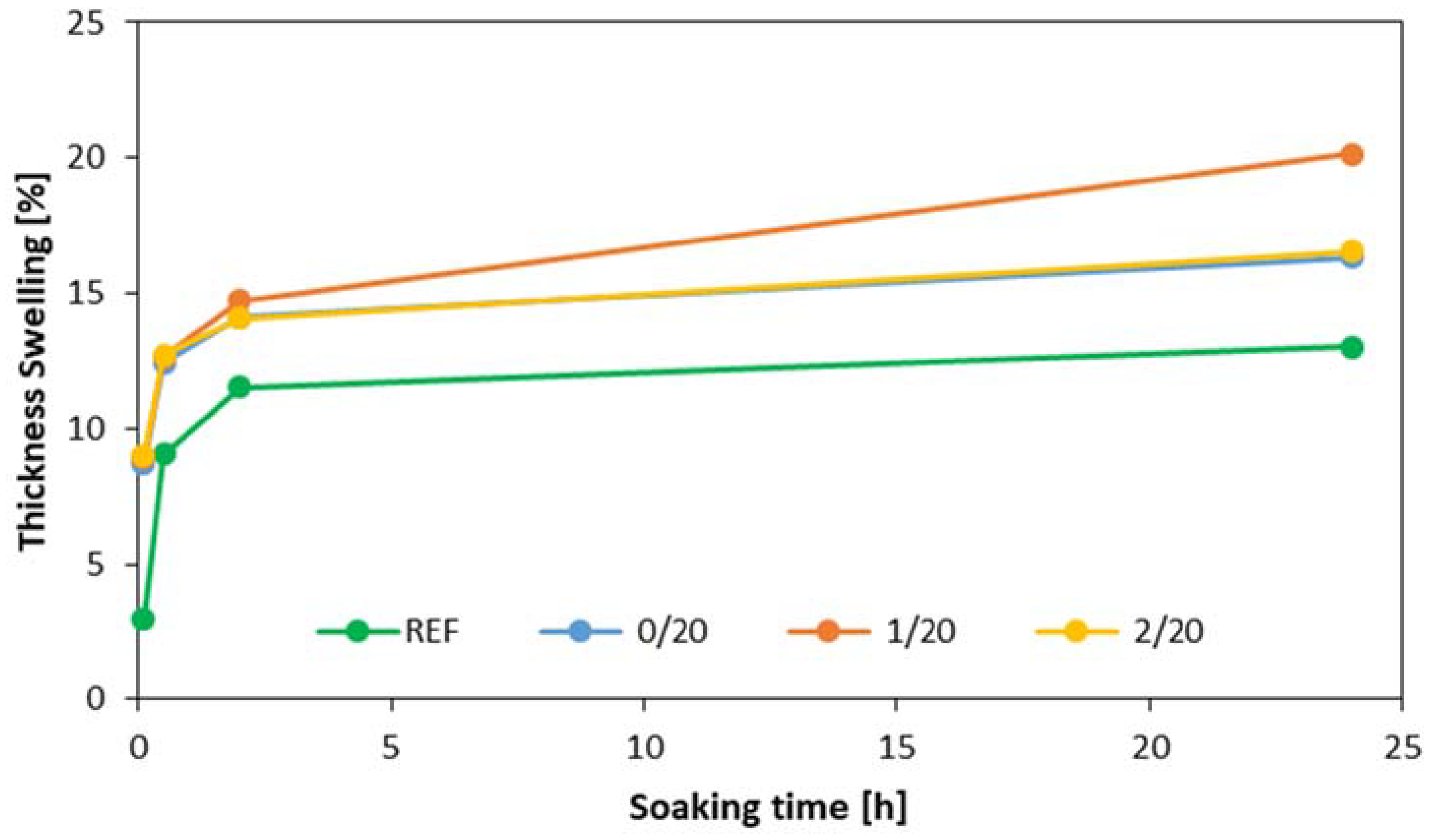

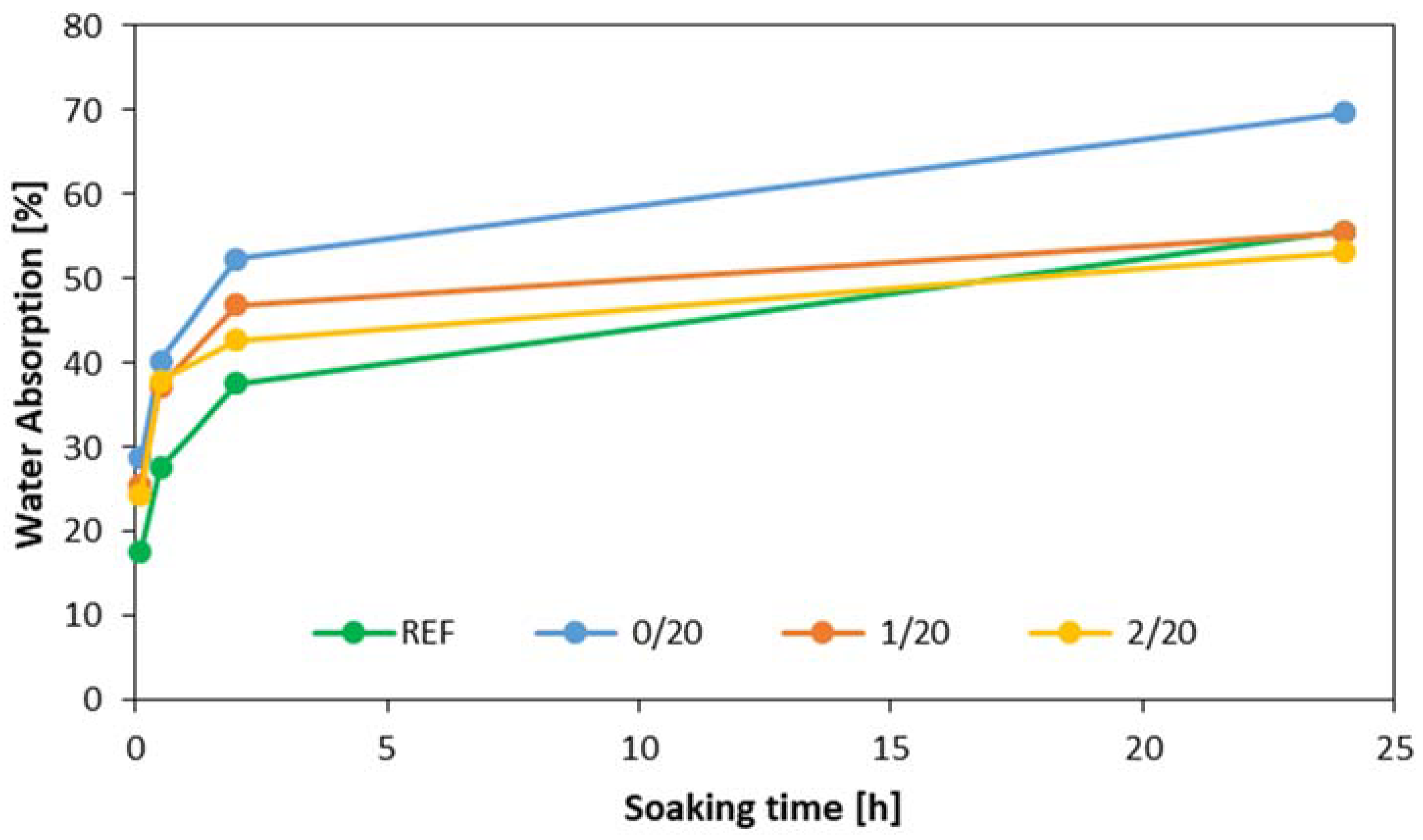

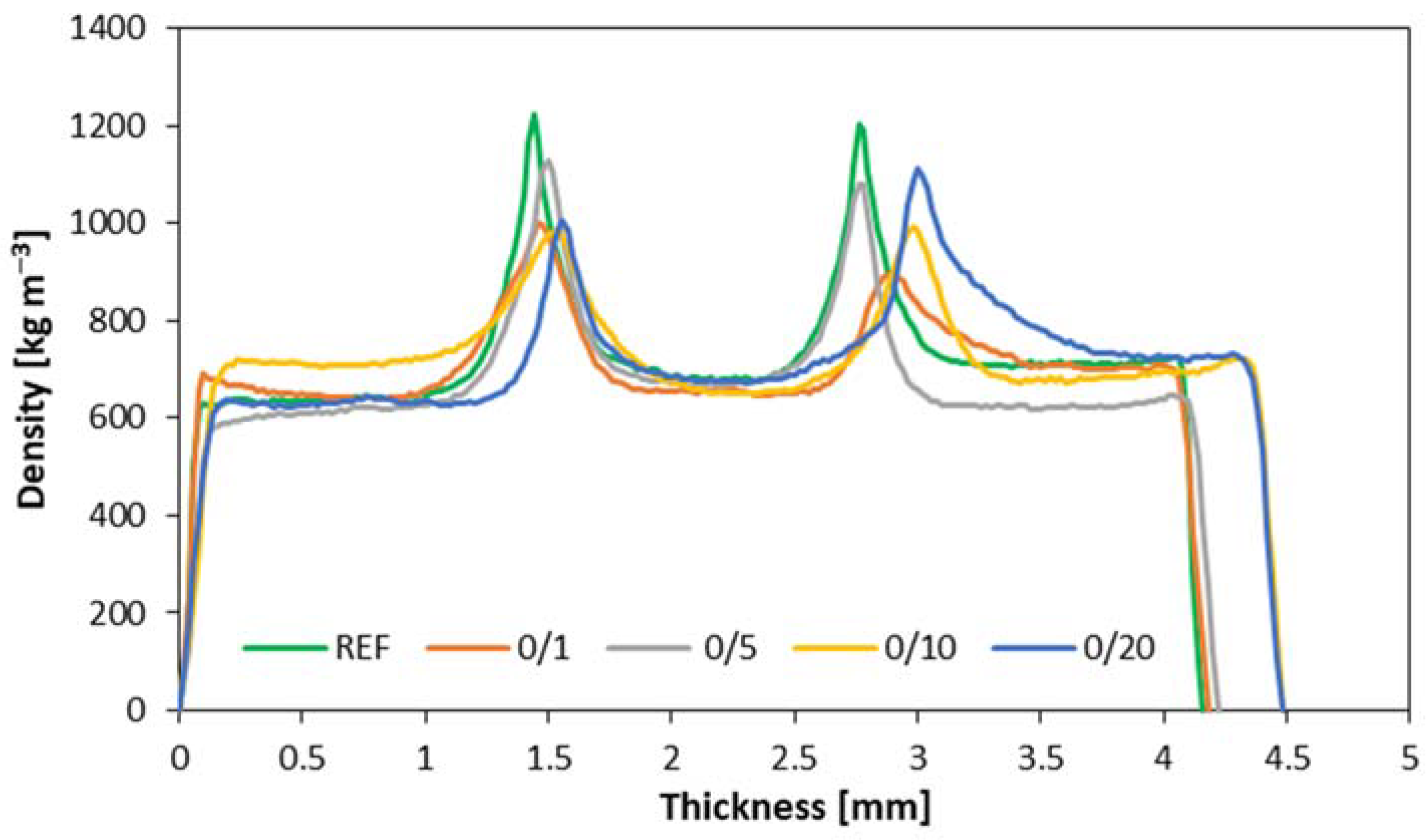

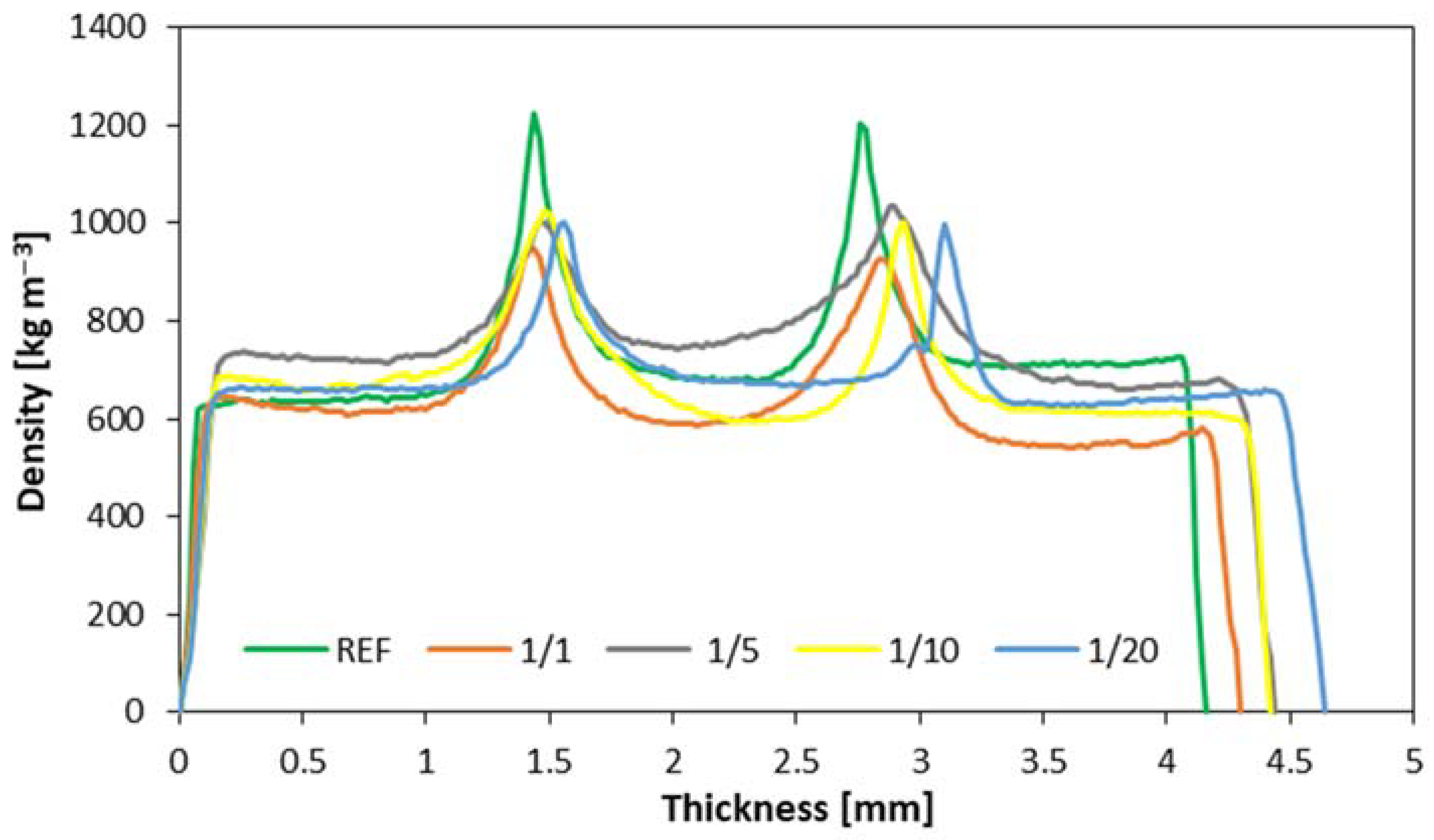

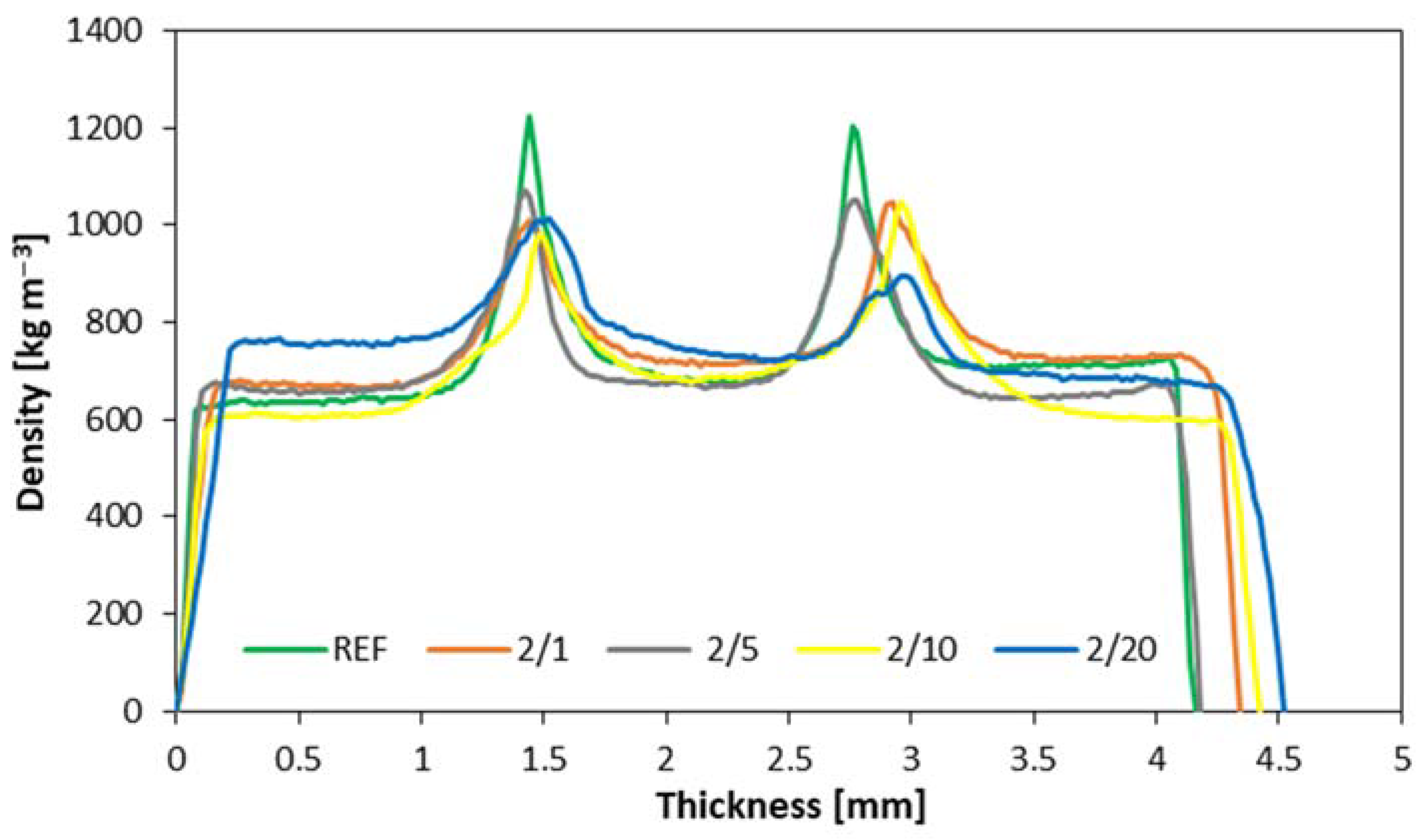

3.4. The Density Profile

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zuo, S.; Liang, Y.; Wu, Y.; Ge, S.; Shi, J.; Ma, X.; Cai, L.; Li, J.; Lam, S.S.; Xia, C. Using Environmentally Friendly Technology for Fabricating Special Plywood with Ultra-High Strength. J. Clean. Prod. 2023, 396, 136462. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, J.; Shen, Z.; Bi, H.; Shentu, B. Flame Resistance and Bonding Performance of Plywood Fabricated by Guanidine Phosphate-Impregnated Veneers. Forests 2023, 14. [Google Scholar] [CrossRef]

- Amini, M.H.M.; Hermawan, A.; Sulaiman, N.S.; Sobri, S.A.; Demirel, G.K. Evaluation of Environmentally Friendly Plywood Made Using Glutaraldehydemodified Starch As the Binder. Bull. Transilv. Univ. Brasov, Ser. II For. Wood Ind. Agric. Food Eng. 2022, 15–64, 65–76. [Google Scholar] [CrossRef]

- Salunke, A. Bio-Degradable Plastic From Corn Starch & Cassava Starch. 2022, 959–964.

- Sari, R.A.L.; Lubis, M.A.R.; Sari, R.K.; Kristak, L.; Iswanto, A.H.; Mardawati, E.; Fatriasari, W.; Lee, S.H.; Reh, R.; Sedliacik, J.; et al. Properties of Plywood Bonded with Formaldehyde-Free Adhesive Based on Poly(Vinyl Alcohol)–Tannin–Hexamine at Different Formulations and Cold-Pressing Times. J. Compos. Sci. 2023, 7, 113. [Google Scholar] [CrossRef]

- Richards, A.P.; Clapp, W.F. Control of Marine Borers in Plywood. Trans. Am. Soc. Mech. Eng. 2022, 69, 519–524. [Google Scholar] [CrossRef]

- Mirski, R.; Kawalerczyk, J.; Dziurka, D.; Siuda, J.; Wieruszewski, M. The Application of Oak Bark Powder as a Filler for Melamine-Urea-Formaldehyde Adhesive in Plywood Manufacturing. Forests 2020, 11, 1–12. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliačik, J.; Noshchenko, G.; Kačík, F.; Bekhta, N. Characteristics of Beech Bark and Its Effect on Properties of UF Adhesive and on Bonding Strength and Formaldehyde Emission of Plywood Panels. Eur. J. Wood Wood Prod. 2021, 79, 423–433. [Google Scholar] [CrossRef]

- Walkiewicz, J.; Kawalerczyk, J.; Mirski, R.; Dziurka, D.; Wieruszewski, M. The Application of Various Bark Species as a Fillers for UF Resin in Plywood Manufacturing. Materials (Basel). 2022, 15. [Google Scholar] [CrossRef] [PubMed]

- Walkiewicz, J.; Kawalerczyk, J.; Mirski, R.; Szubert, Z. The Tea Leaves As a Filler for Uf Resin Plywood Production. Wood Res. 2023, 68, 200–207. [Google Scholar] [CrossRef]

- Dukarska, D.; Kawalerczyk, J.; Kmieciak, J. Modified Pine Needles as a Formaldehyde Scavenger for Urea-Formaldehyde Resin in Plywood Production. Eur. J. Wood Wood Prod. 2023, Preprint. [Google Scholar] [CrossRef]

- Marsal, A.; Cuadros, S.; Manich, A.M.; Izquierdo, F.; Font, J. Reduction of the Formaldehyde Content in Leathers Treated with Formaldehyde Resins by Means of Plant Polyphenols. J. Clean. Prod. 2017, 148, 518–526. [Google Scholar] [CrossRef]

- Mohamed Abdoul-Latif, F.; El Montassir, Z.; Ainane, A.; Gharby, S.; Sakar, E.H.; Merito, A.; Mohamed, J.; Ainane, T. Use of Thymus Plants as an Ecological Filler in Urea-Formaldehyde Adhesives Intended for Bonding Plywood. Processes 2022, 10. [Google Scholar] [CrossRef]

- Fitzpatrick, J.R. Plywood in the Aircraft Industry. Trans. Am. Soc. Mech. Eng. 2023, 53, 69–75. [Google Scholar] [CrossRef]

- Negro, F.; Cremonini, C.; Zanuttini, R.; Properzi, M.; Pichelin, F. A New Wood-Based Lightweight Composite for Boatbuilding. Wood Res. 2011, 56, 257–266. [Google Scholar]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Trociński, A. Flour Fillers with Urea-Formaldehyde Resin in Plywood. BioResources 2019, 14, 6727–6735. [Google Scholar] [CrossRef]

- Dasiewicz, J.; Wronka, A. Influence of the Use of Chestnut Starch as a Binder Filler in Plywood Technology. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 148, 137–148. [Google Scholar] [CrossRef]

- Dasiewicz, J.; Kowaluk, G. Characteristics of High-Density Fibreboard Produced with the Use of Rice Starch as a Binder. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 181, 169–181. [Google Scholar] [CrossRef]

- Fukui, K.; Momen, K.; Ichiba, G.; Fukasawa, T.; Ishigami, T. Utilization of Woody Biomass Combustion Fly Ash as a Filler in the Glue Used for Plywood Production. Adv. Powder Technol. 2020, 31, 4482–4490. [Google Scholar] [CrossRef]

- Hand, W.G.; Robert Ashurst, W.; Via, B.; Banerjee, S. Curing Behavior of Soy Flour with Phenol-Formaldehyde and Isocyanate Resins. Int. J. Adhes. Adhes. 2018. [Google Scholar] [CrossRef]

- Kang, H.; Wang, Z.; Wang, Y.; Zhao, S.; Zhang, S.; Li, J. Development of Mainly Plant Protein-Derived Plywood Bioadhesives via Soy Protein Isolate Fiber Self-Reinforced Soybean Meal Composites. Ind. Crops Prod. 2019, 133, 10–17. [Google Scholar] [CrossRef]

- Yan, Q.; Ma, C.; Liang, Z.; Zhang, S. High-Temperature Soybean Meal Adhesive Based on Disulfide Bond Rearrangement and Multiple Crosslinking: Water Resistance and Prepressing Adhesion. J. Clean. Prod. 2022, 373, 133709. [Google Scholar] [CrossRef]

- Sanghvi, M.R.; Tambare, O.H.; More, A.P. Performance of Various Fillers in Adhesives Applications: A Review; Springer Berlin Heidelberg, 2022; Vol. 79; ISBN 0028902104022.

- Oh, Y.-S. Evaluation of Chestnut Shell and Coffee Waste with Phenol-Formaldehyde Resin for Plywood Filler. Ciência Florest. 2021, 31, 1991–2001. [Google Scholar] [CrossRef]

- Yew, M.C.; Ramli Sulong, N.H.; Yew, M.K.; Amalina, M.A.; Johan, M.R. Eggshells: A Novel Bio-Filler for Intumescent Flame-Retardant Coatings. Prog. Org. Coatings 2015, 81, 116–124. [Google Scholar] [CrossRef]

- Daniłowska, A.; Kowaluk, G. The Use of Coffee Bean Post-Extraction Residues as a Filler in Plywood Technology. Ann. WULS, For. Wood Technol. 2020, 109, 24–31. [Google Scholar] [CrossRef]

- Ait Benhamou, A.; Boussetta, A.; Kassab, Z.; Nadifiyine, M.; Hamid Salim, M.; Grimi, N.; EL Achaby, M.; Moubarik, A. Investigating the Characteristics of Cactus Seeds By-Product and Their Use as a New Filler in Phenol Formaldehyde Wood Adhesive. Int. J. Adhes. Adhes. 2021, 110, 102940. [Google Scholar] [CrossRef]

- Hýsek, Š.; Šedivka, P.; Böhm, M.; Schönfelder, O.; Beran, R. Influence of Using Recycled Polyurethane Particles as a Filler on Properties of Polyurethane Adhesives for Gluing of Wood. BioResources 2018, 13, 2592–2601. [Google Scholar] [CrossRef]

- Ong, H.R.; Khan, M.R.; Yousuf, A.; Jeyaratnam, N.; Prasad, D.M.R. Effect of Waste Rubber Powder as Filler for Plywood Application. Polish J. Chem. Technol. 2015, 17, 41–47. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, A.; Sharma, K. V; Nasir, M.; Khan, T.A. Influence of Activated Charcoal as Filler on the Properties of Wood Composites. Int. J. Adhes. Adhes. 2013. [Google Scholar] [CrossRef]

- Ivanov, D. V.; Baka, K.E.; Konareikina, D.A. Powdered Paper-Resin Films as Reactive Fillers for Urea-Formaldehyde Resins. Lesn. Zhurnal (Forestry Journal). [CrossRef]

- Zhan, T.; Chen, W.; Zhu, J.Y.; Peng, H.; Lu, J. Strong, Durable and Eco-Friendly Plywood Bonded with Chemically-Upcycled Wasted Disposable Masks. Ind. Crops Prod. 2023, 204, 117283. [Google Scholar] [CrossRef]

- Arya, S.; Chauhan, S.; Kumar, R. Plastic Bonded Plywood Using Waste Polypropylene Container. Mater. Today Proc. 2022, 67, 471–477. [Google Scholar] [CrossRef]

- Janceva, S.; Andersone, A.; Spulle, U.; Tupciauskas, R.; Papadopoulou, E.; Bikovens, O.; Andzs, M.; Zaharova, N.; Rieksts, G.; Telysheva, G. Eco-Friendly Adhesives Based on the Oligomeric Condensed Tannins-Rich Extract from Alder Bark for Particleboard and Plywood Production. Materials (Basel). 2022, 15, 1–19. [Google Scholar] [CrossRef]

- Newton Balakrishnan, M.E.; Muralkar, P.; Ranjana Ponraj, M.; Nadiger, S.; Dhandayutham, S.; Justus, S.; Bhagavathsingh, J. Recycling of Saw Dust as a Filler Reinforced Cotton Seed Oil Resin Amalgamated Polystyrene Composite Material for Sustainable Waste Management Applications. Mater. Today Proc. 2022, 58, 783–788. [Google Scholar] [CrossRef]

- Yao, J.; Chen, Z.; Xu, C.; Chen, Y.; Guo, J.; Yue, H. Cottonseed Protein Bioadhesive with High Adhesion Performance Achieved by a Synergistic Dual-Crosslinking Strategy. Int. J. Adhes. Adhes. 2023, 127, 103514. [Google Scholar] [CrossRef]

- EN 827 Adhesives - Determination of Conventional Solids Content and Constant Mass Solids Content; European Committee for Standardization, Brussels, Belgium, 2005.

- Wronka, A.; Kowaluk, G. The Influence of Multiple Mechanical Recycling of Particleboards on Their Selected Mechanical and Physical Properties. Materials (Basel). 2022, 15. [Google Scholar] [CrossRef] [PubMed]

- Kminiak, R.; Kučerka, M.; Kristak, L.; Reh, R.; Antov, P.; Očkajová, A.; Rogoziński, T.; Pędzik, M. Granulometric Characterization of Wood Dust Emission from Cnc Machining of Natural Wood and Medium Density Fiberboard. Forests 2021, 12. [Google Scholar] [CrossRef]

- EN 310 Wood-Based Panels — Determination of Modulus of Elasticity in Bending and of Bending Strength; Brussels, Belgium, 1993.

- EN 314-1 Plywood—Bonding Quality—Part 1: Test Methods. European Committee for Standardization; Brussels, Belgium, 2004.

- EN 317 Particleboards and Fiberboards – Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization, Brussels, Belgium, 1993.

- Yang, X.; Frazier, C.E. Influence of Organic Fillers on Rheological Behavior in Phenol-Formaldehyde Adhesives. Int. J. Adhes. Adhes. 2016, 66, 93–98. [Google Scholar] [CrossRef]

- Ponomarenko, L.; Kantieva, E. Influence of Grinded Dust as a Filler of Carbamideoformaldehyde Adhesives on Their Technological Properties. For. Eng. J. Vol. 8 № 1, 2018. [CrossRef]

- Bekhta, P.; Sedliačik, J.; Kačík, F.; Noshchenko, G.; Kleinová, A. Lignocellulosic Waste Fibers and Their Application as a Component of Urea-Formaldehyde Adhesive Composition in the Manufacture of Plywood. Eur. J. Wood Wood Prod. 2019, 77, 495–508. [Google Scholar] [CrossRef]

- Ong, H.R.; Khan, M.M.R.; Prasad, D.M.R.; Yousuf, A.; Chowdhury, M.N.K. Palm Kernel Meal as a Melamine Urea Formaldehyde Adhesive Filler for Plywood Applications. Int. J. Adhes. Adhes. 2018. [Google Scholar] [CrossRef]

- Réh, R.; Igaz, R.; Krišt’ák, L.; Ružiak, I.; Gajtanska, M.; Božíková, M.; Kučerka, M. Functionality of Beech Bark in Adhesive Mixtures Used in Plywood and Its Effect on the Stability Associated with Material Systems. Materials (Basel). 2019, 12. [Google Scholar] [CrossRef] [PubMed]

- Réh, R.; Krišťák, Ľ.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Vozárová, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of Birch Bark as an Eco-Friendly Filler in Urea-Formaldehyde Adhesives for Plywood Manufacturing. Polymers (Basel). 2021, 13, 1–21. [Google Scholar] [CrossRef]

- Sala, C.M.; Robles, E.; Gumowska, A.; Wronka, A.; Kowaluk, G. Influence of Moisture Content on the Mechanical Properties of Selected Wood-Based Composites. BioResources 2020, 15, 5503–5513. [Google Scholar] [CrossRef]

- Ashori, A.; Ayrilmis, N.; Heydari, V. Enhancing Interfacial Adhesion through Coupling Agent Incorporation in Plywood/ Plastic Waste Composite Materials. Int. J. Adhes. Adhes. 2023, 127, 103513. [Google Scholar] [CrossRef]

- Wronka, A.; Robles, E.; Kowaluk, G. Upcycling and Recycling Potential of Selected Lignocellulosic Waste Biomass. Materials (Basel). 2021, 1–14. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).