2. Literature Review

The works of Ferebee and Powers (1987) and Ferebee and Allen (1991) are probably the first use of numerical optimization methods for the layout of spacecraft equipment during the conceptual phase. Rocco et al. (2003) also presented a multi-objective optimization method for a set of satellites to minimize time-limited fuel consumption. A detailed study of approaches and solution algorithms for the arrangement of three-dimensional equipment was presented by Cagan et al. (2002). They showed that the use of CAD software for the arrangement of equipment, especially in the arrangement of electrical board parts, is very common, while the three-dimensional arrangement of this software is not very efficient and innovative and meta-innovative methods such as genetic algorithm and simulated annealing (SA) (Like the research of Jang (2008) who used the SA algorithm to investigate the location of three-dimensional equipment with unknown geometric shapes) have been used more in this field.

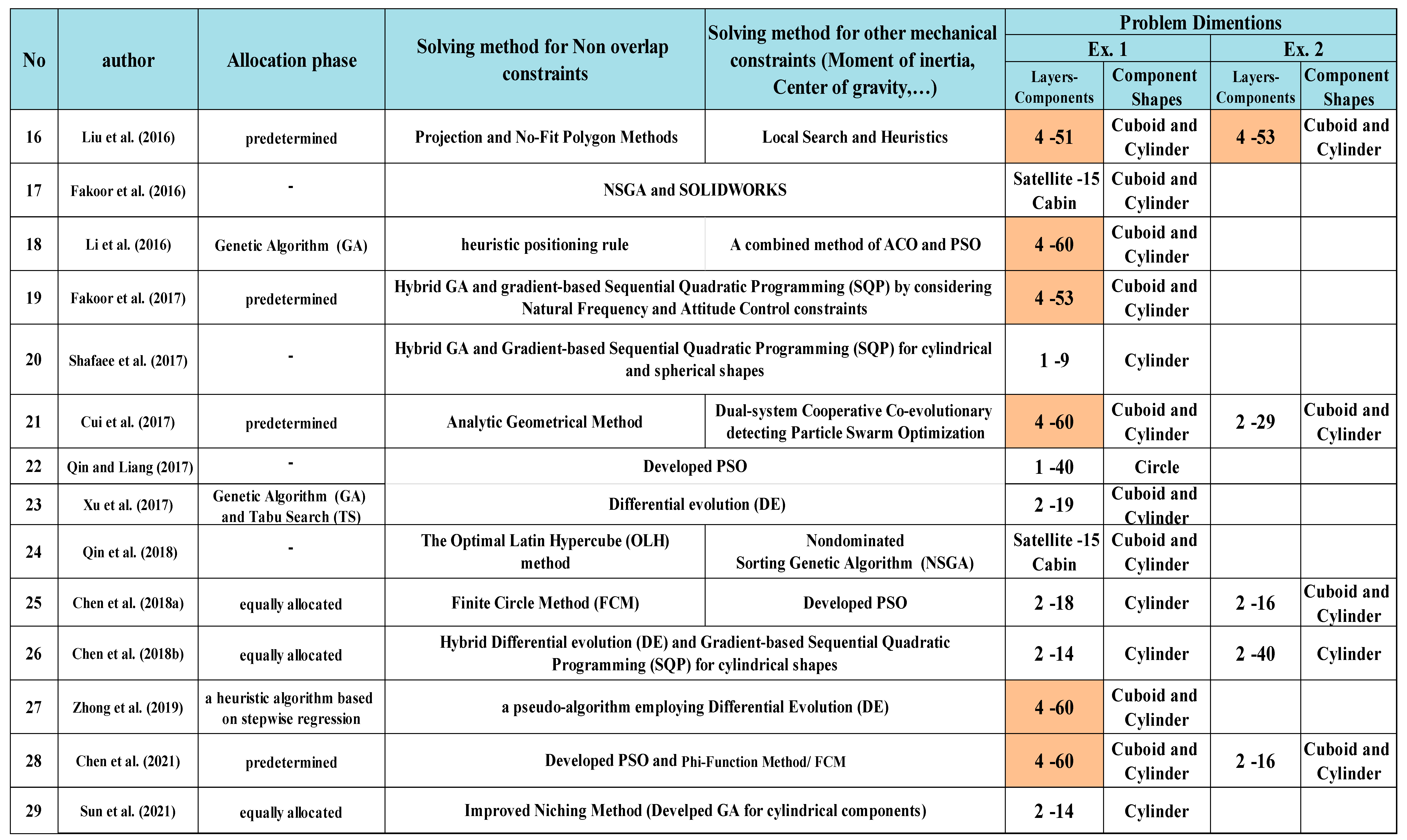

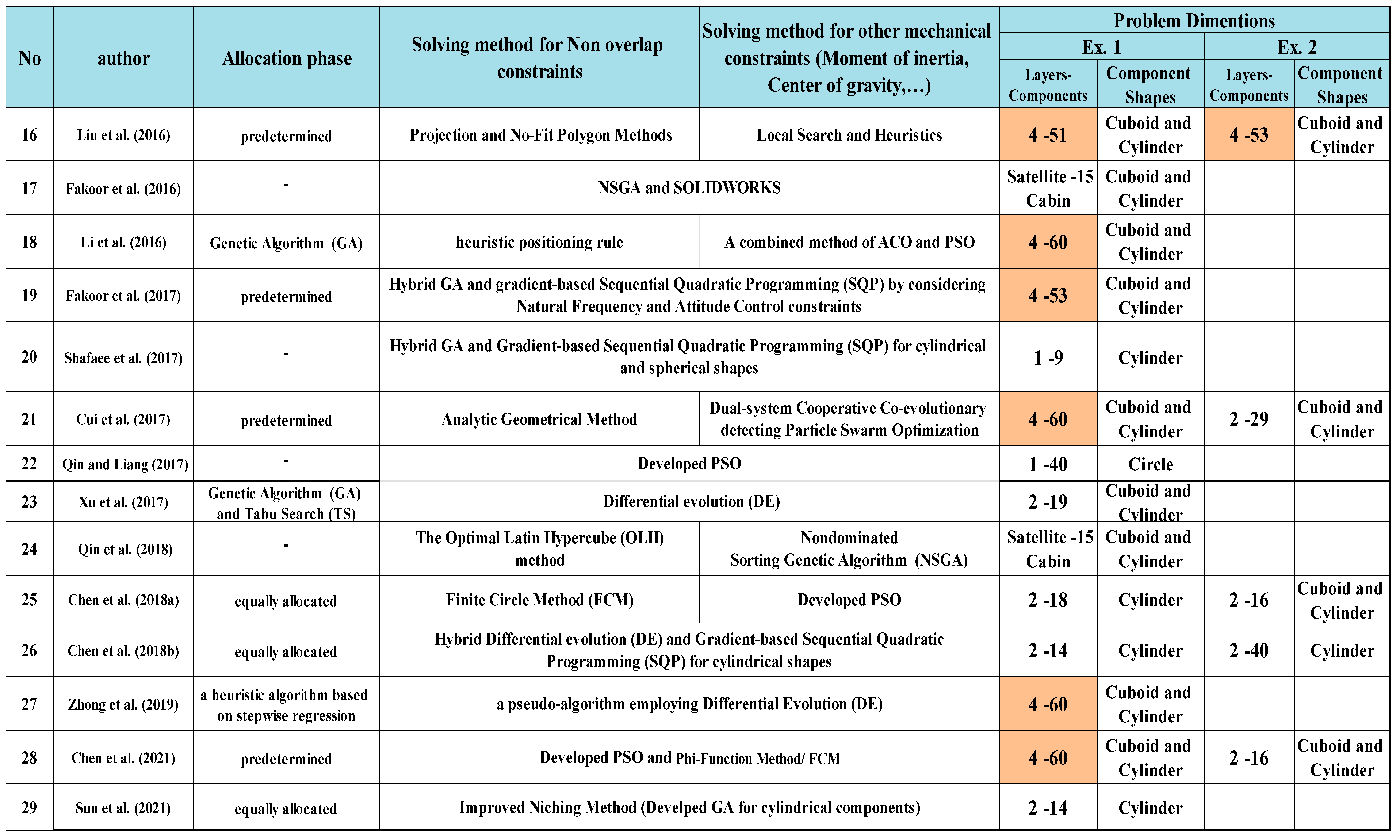

Published articles in the field of satellite layout are summarized in Table 1. In this table, the solution methods for allocating equipment to the carrier plates or locating the equipment on each plate are specified, and the dimensions of the problems mentioned by the articles as case studies or numerical examples can be observed in this table. As demonstrated in the table, there are only four articles discussing the allocation of equipment between carrier plates and the rest of the others have just considered the DM opinion or have used arrangement of previous articles.

In addition, regarding the dimensions of problem-solving, as illustrated in

Table 1, only 11 articles have examined issues with the design of 4 carrier plates. Three papers by Zhang et al. (2013), Zhang et al. (2017a) and Zhang et al. (2017b) adapted the data from Zhang et al. (2008) to a multi-cabin satellite with 120 components and 8 layers, as opposed to the single-cabin satellite of the original article. These three articles that established the concept of docking two satellites are excluded from

Table 1. In the remaining cases, the layout of the equipment is either described on a smaller number of plates or is located within the satellite’s cabin, with the latter being more suitable for cube-shaped satellites. In the subsequent, most of the research that has been published in the field of satellite equipment arrangement will be introduced.

One of the essential constraints in satellite layout is to consider all components not to be overlapped in all bearing plates named layers. One common method is based on integrating Computer-Aided Design (CAD) tools, engineering analysis packages and optimization algorithms. Coupling optimization algorithms with Computer Aided Design (CAD) and engineering analysis packages for finding the optimal layout of spacecraft equipment was proposed firstly by Pühlhofer and Baier (2003). After that this method has been applied in the study of Pühlhofer et al. (2004), Cuco (2011), Lau et al. (2014), Cuco et al. (2015), Fakoor et al. (2016), Qin et al. (2018).

The following are the most important articles in the field of satellite equipment arrangement that have presented various methods on the subject of non-overlapping.

For the first time, Teng et al. (2001) studied the arrangement of equipment on several satellite layers, and then they analyzed the 3-dimensional layout problem on a rotating vessel. Because of the spiral rotation movement of the vessel, they took into account dynamic equilibrium constraints and used heuristic algorithms represented by Albano and Sapuppo (1980) applied for non-convex polygons to determine the amount of overlap among objects.

Sun and Teng (2003) introduced a centripetal balancing heuristic algorithm to allocate objects between bearing plates. To distribute objects in a bearing plate, they applied a Genetic Algorithm (GA) to produce random populations and finally to reach a feasible (near-optimal) solution. Eventually, they developed an Ant Colony Optimization (ACO) method to tune the position of each object in detailed design within bearing surfaces.

Huo et al. (2007) developed a human-guided GA and compared the results with the GA library to demonstrate the priority of their algorithm for the 2-dimensional layout of objects in a satellite. They added artificial individuals to the population of GA to cope with overlapping volumes of components.

Liu and Teng (2008) presented a Human–Algorithm–Knowledge based on the support of GA to layout equipment in a satellite and applied CAD software for prior knowledge in their GA.

Zhang et al. (2008) developed a two-stage model for layout optimization of satellites. The first stage was about allocating objects to different bearing plates and the second one dealt with the detailed design of each bearing plate in which no overlapped was allowed. To reach an optimal layout in each bearing plate, they applied a combinatorial method including GA and Particle Swarm Optimization (PSO) metaheuristics. They explained that GA inherently is suitable for finding global convergence while PSO is a proper method for local convergence and the disadvantage of GA in local convergence was compensated by using PSO as a replacement of a random population in the initial phase of GA and the weakness of PSO in global converge was satisfied by using the best solution of GA as a replacement of the first population of PSO. To tackle the overlapping issue, they borrowed the concept of compaction and separation algorithm introduced by Li and Milenkovic (1995) who applied locality heuristics for star-shaped non-convex polygons.

Huo and Teng (2009) presented a co-evolutionary method in which a genetic algorithm (GA) was used to determine the rotation angle of the final layout scheme of equipment layout and a heuristic combination-rotation method was introduced to determine the entire layout scheme by reference to the rotation strategy of a heuristic constraint rubik cube method (CRCM).

Teng et al. (2010) proposed an evolutionary method called dual system variable grain algorithm to decompose the satellite layout system into several tractable and also to avoid premature convergence problems. In their model, they took into account the constraints of interference between objects, the centroid offset of the satellite system and constraints of inertia angles. They applied analytic geometry to handle discontinuous constraints related to overlapping volumes. Li et al. (2016) presented a three-step strategy for first distributing equipment throughout the layers of a satellite and then determining the location of each component inside its assigned layer. In the initial phase, each piece of equipment was assigned to one of the four bearing layers using a genetic algorithm (GA). In the second step, they suggested a heuristic positioning rule to address the challenge of satisfying overlapping constraints between circles and rectangles in the 2D scale precise design of equipment for each layer. In this step, an ACO algorithm and a heuristic adjustment approach are used to manage the detailed design of each layer’s equipment. Lastly, they presented a PSO algorithm to combine subproblems and attempt to minimize errors in the mass centre and moment of inertia while preserving the other components of the objective function. Liu et al. (2016) proposed a hybrid method based on local and heuristic search algorithms to find the optimal arrangement of satellite equipment. They calculated the amount of equipment overlap based on their geometric shape; In this way, if two devices were rectangular or one was rectangular and the other was circular, projection and no-fit polygon methods were used respectively. The second method is utilized for the non-overlapping of polyhedra, in which all possible placements of a polyhedron concerning others are illustrated, and the topic of overlapping between two polyhedra is relegated to overlapping between a polyhedron and a vector which is more computationally efficient. Cui et al. (2017) represented a new dual algorithm in which the combination of detecting PSO and a cooperative co-evolution method was applied in a multi-layer satellite. Similar to Teng et al. (2010), analytic geometry was the method they proposed to deal with the overlapping problem among components. Xu et al. (2017) presented an integrated method for satellite equipment assignment and layout. They used GA and Tabu Search (TS) to reassign equipment before attempting to lay out 19 components and 2 layers using the Differential Evolution (DE) method. Zhong et al. (2019) stated that the assignment of satellite equipment can be achieved based on Multiple Bin Packing Problem research (MBPP). They offered a method based on stepwise regression to assign equipment, and after comparing assignment schemes, the optimal one was chosen as the beginning input for the layout phase, which was solved by a pseudo-algorithm employing DE and random mutation operation. Chen et al. (2021) evaluated the overlap between equipment in the satellite’s centre planes utilizing the method given in the paper by Chernov et al. (2012) and the phi-function method. For two components, if the value of the Phi-Function is positive, the two components will not overlap, if the value of the function is zero, they are tangent to each other, and if it is negative, they intersect. They showed that unlike most of the research done in this field, they also considered the interaction between the equipment. They researched 5 numerical examples of different satellites; The first example involved six equilateral triangles in a circular enclosure, the second example involved resolving the overlapping problem between two diagonally placed rectangles, the third example was for cylindrical satellites, the fourth example was for nano satellites, and the final example was also investigated to fix the overlap of parts in cube-shaped satellites. They solved the third and fifth instances using an adaptive PSO approach and the fourth example using the Finite Circle Method (FCM), all of which were developed by Chen et al (2018a). Finally, the existing limitations in the use of this method were also addressed and it was shown that due to the use of geometric non-linear and non-convex restrictions, the proposed model does not provide a correct answer for some conditions and it is necessary that in the future Efficient and effective algorithms should be produced to solve this problem.

In the field of uncertainty, Galbraith J.R. (1973) defined uncertainty as the difference between the amount of information needed and the amount of available information to perform a task. The uncertainty related to decision-making occurs in the conditions of incomplete information. Mula et al. (2007) divided the discussion of uncertainty as flexibility in limitations and different levels of acceptability of goals and uncertainty in input data; In this way, the flexibility in the constraints includes the decision maker’s preferences. Klibi et al. (2010) divided decision-making conditions into two groups according to the quality of available information: decision-making under conditions of certainty (when information is fully available) and decision-making under conditions of uncertainty (when information is incomplete). Pishvaee and Fazli (2016) indicated that developments in robust optimization occurred in three historical waves. The first wave begun by Mulvey et al. (1995) was about robust optimization related to a scenario-based stochastic planning approach. After that, Yu and Li (2000) and Leung et al. (2007) developed this approach. The second wave, known as robust convex programming, was first introduced by Ben-Tal and Nemirovski (1998, 2000) and El-Ghaoui et al. (1998). The cone programming method is used to solve convex problems due to existing complexities, which is done according to duality theorems and optimality conditions for solving convex problems. The third wave by Pishvaee et al. (2012) presented different approaches to robust planning. They demonstrated that robust fuzzy mathematical programming (RFMP) is divided into two parts: possibilistic programming and flexible programming.

As the literature analysis demonstrates, there are two fundamental aspects to the satellite layout issue. First, there is the issue of component distribution across different bearing layers, and second, there is the problem of cuboid component overlapping. As a result, this paper addresses both problems: we offer a heuristic solution for the assignment problem and then the RFMP to evolve the distance between cuboid components. In conclusion, the main issue to be investigated in this study is how to deal with the component assignment problem along with the growing number of bearing layers and components and the complexity of technical requirements of the satellite layout problem.

In the next Section, the mathematical modelling of a satellite component layout is described completely.

3. Problem Statement

Conceptual design, preliminary design, and detailed design are the three basic stages of satellite design. One of the fundamental subjects in the detailed design phase is layout design which raises the issue of whether the integration of operational components from various subsystems can function properly and effectively in a unique environment, such as a space that is constantly exposed to cosmic rays.

The major goal of designing satellite equipment is to optimize a satellite’s stability, control, and dimensions which results in a reduction in the size and weight of the satellite, so this optimization can have a direct impact on the satellite’s successful launch as well as its continuity and durability in space.

Numerous factors, such as size, stability, and optimum system performance, contribute to the best satellite layout and result in more variables and limitations. This intricacy emphasizes the need for industrial engineering optimization solution approaches rather than the typical try-and-error methods used in mechanical engineering in this subject.

The challenge of placing many pieces of equipment in a cylinder, cube, or polygonal volume on different floors to deploy multiple distinct plates within the satellite is known as the problem of optimizing telecommunication and measurement satellite equipment.

The layout optimization problem of a communication satellite module can be described as follows.

A total number of n components will be located in a cylindrical satellite module with two floors. Four plates including the upper and lower and two middle plates of the inner space of the satellite attached to a standing column in the module are used to hold all the components, and in this proposed methodology, all the components are simplified as cylindrical and cubic shapes and regarded as rigid bodies with uniform mass allocation.

There is an even distribution of mass across every piece of equipment, which is in the shape of a cube or cylinder.

An extensive analysis of the influencing factors, such as distance constraints, heat constraints, radiation constraints, functional constraints, and stability, is crucial because the goal of this paper is to optimize the interior space of the satellite and ultimately reduce its dimensions and weight. The problem becomes more complex after a full analysis of these constraints, necessitating the employment of specialized optimization software. Therefore, the ultimate objective is to provide an optimization model and its output with the aid of software so that manufacturing units can optimally use the placement of equipment to build satellites with smaller dimensions and weights.

The objective is to reduce the satellite’s size and weight while still maintaining stability, taking into account the major inertia moments, cross-inertia moments, and centre of gravity, as well as distance, heat, and radiation limits.

The problem of equipment placement is NP-hard because of the engineering and mechanical complexity of satellites. This calls for the combination of numerous intricate and specialized limitations in addition to the design of a sophisticated system.

The objective function in this problem is multi-objective and in addition to taking into account the non-overlap between the equipment, it must also include all functional and equilibrium constraints. This is because to solve the model, the constraints of the weight coefficient problem are taken and added to the objective function.

An example of a satellite with two centre plcentrend 4 layers on which the equipment is located is shown in

Figure 1.

The assumptions of the model are as follows:

Three-dimensional layout: The difficulty of placing satellite equipment occurs in three dimensions so the Z axis is considered as a main part.

Multi-layer layout: The idea of multi-layer by the various layers of satellite space is another crucial consideration in the installation of satellite equipment. Because of this, the model must allocate equipment to plates or layers.

Non-interference and overlap constraints: No interference occurs between any pieces of components.

Equilibrium constraint: Namely equilibrium error of the system should be as small as possible.

Thermal constraints: The performance of electronic components may be directly impacted by the thermal environment. As a result, system equipment is generally more efficient and reliable when heat flow is distributed uniformly.

From a thermal point of view, each equipment has an effective area which can affect the performance of other equipment; Therefore, reducing the interaction space is equal to improving the uniform state of the thermal field in the satellite. To calculate the thermal effects of equipment, it is assumed that some components produce a thermal radius that uniformly forms a circle around the equipment. For this reason, no intersection between virtual thermal radii between equipment is allowed.

Obnoxious equipment limitations: Another constraint must be taken into account for some equipment with a high amount of heat radiation, or “hot parts,” such as batteries, radio transmitters, and photo transmitters that must be positioned as distant from one another as possible in the satellite space. In other words, there needs to be a modest bit of this hot equipment on each floor of the satellite.

Static stability constraint: Namely centre of gravity offset of the system should be as small as possible.

The stability limit of the satellite should be such that the device can move and rotate easily in space; Therefore, the sum of the inertia moments of the system should be at its minimum. Minimizing the sum of moments of inertia physically means that the satellite inherently tends to be stable, and this minimization can reduce the effort to stabilize the satellite by subsystems, resulting in moments of inertia including the axes of the main axis and impact or cross moments must be at a minimum.

System uncertainty: There is no fixed value for equipment that should be spaced apart, so it is important to use uncertainty to determine this distance. As mentioned in the previous section, uncertainties are included in the model for a variety of reasons one of them is uncertainty in the view of the decision maker (DM). In the design of satellite equipment layout, it is not easy to apply non-overlap constraints for cube-shaped equipment having a rectangular cross-section in the way that it has been used for cylindrical equipment having a circular cross-section; Because for two circular equipment, the overlap of the them can be easily prevented by calculating the radius and entering the distance between the two radii. On the other hand, for two pieces of equipment with a rectangular cross-section or two pieces of equipment, one circular and the other rectangular, the non-overlap restriction will not be observed easily. For this reason, the uncertainty argument is easily applicable and is very effective in solving the model.

Due to the nature of the problem, the concept of fuzzy is also used here, so that the constraints related to equipment distances are written in fuzzy form. By adding fuzzy constraints, a decision variable (α) is defined in the model and added to the objective function with a penalty coefficient (γ).

3.1. Model Development

3.1.1. Model Parameters

The model parameters are introduced as follows:

i: Indicator of the number of equipment

j: Index of the number of layers (j = 1,2,3,4)

: layer j of the satellite

: The cross-sectional length of the cuboid equipment i

: The cross-sectional width of the cuboid equipment i

: radius of the cross-sectional area of the cylindrical equipment i

: The height of the equipment i

: The mass of equipment i

: The angle between the positive direction of the x-axis and the horizontal edge of the cuboid equipment i

c: Number of cuboid equipment

n: total number of equipment

: The number of equipment located at layer j

: A segment of the radius of the hypothetical circumferential circle of a cross-section of cuboid equipment i

: Optimistic value of a triangular fuzzy number for

: Pessimistic value of a triangular fuzzy number for

: A triangular fuzzy number for

: The cost of the fine for each unit of violation of the soft limit

: Expected coordinates in the direction of the x-axis of the satellite’s centre of gravity

: Expected coordinates in the y-axis direction of the satellite’s centre of gravity

: Expected coordinates in the direction of the z-axis of the satellite’s centre of gravity

Jxi: Moment of inertia of equipment in the direction of the x-axis

Jyi: Moment of inertia of equipment in the direction of the y-axis

Jzi: Moment of inertia of equipment in the direction of the z-axis

: Permissible error for deviating the coordinates of the real centre of gravity of the satellite from the expected value in the direction of the x-axis

: Permissible error for deviating the coordinates of the real centre of gravity of the satellite from the expected value in the direction of the y-axis

: Permissible error for deviating the coordinates of the real centre of gravity of the satellite from the expected value in the direction of the z-axis

: Permissible error for deviating the angle between the mass moment of inertia of the satellite in the direction of the x-axis with the axis of the coordinate of the satellite in the direction of the ox axis

: Permissible error for deviating the angle between the mass moment of inertia of the satellite in the direction of the y-axis and the axis of the satellite coordinates in the direction of the oy axis

: Permissible error for deviating the angle between the mass moment of inertia of the satellite in the direction of the z-axis with the coordinate axis of the satellite in the direction of the z-axis

3.1.2. Decision Variables of the Model

The model decision variables are as follows:

: The coordinates of the i equipment in the direction of the x-axis

: The coordinates of the i equipment in the direction of the y-axis

: The coordinates of the i equipment in the direction of the z-axis

: coordinates of the centre of gravity of the satellite in the direction of the x-axis

: The coordinates of the centre of gravity of the satellite in the direction of the y-axis

: coordinates of the centre of gravity of the satellite in the direction of the z-axis

: The angle between the mass moment of inertia of the satellite in the direction of the x-axis and the axis of the satellite coordinates in the direction of the x-axis

: The angle between the mass moment of inertia of the satellite in the direction of the y-axis and the coordinate axis of the satellite in the direction of the y-axis

: Angle between the mass moment of inertia of the satellite in the direction of the z-axis with the axis of coordinates of the satellite in the direction of the axis oz

: The mass moment of inertia of the satellite in the direction of the x-axis

: The mass moment of inertia of the satellite in the direction of the y-axis

: The mass moment of inertia of the satellite in the direction of the z-axis

: Product moment of inertia to calculate satellite imbalance in the direction of the x and y plane

: Product moment of inertia to calculate satellite imbalance in the x and z plane directions

: Product moment of inertia to calculate satellite imbalance in the y and z plane directions

: The final radius of the i equipment after performing the uncertainty calculations

: The minimum level of satisfaction in flexible constraints

There are three types of coordinate systems:

1. Oxyz reference coordinate system

O: The centre of this coordinate system is located on the geometric centre of the lower crust of the satellite.

z: The longitudinal symmetric axis of the satellite which is positive in the upward direction.

x: The axis perpendicular to the z-axis on the lower crust of the satellite

y: The axis perpendicular to the z-axis on the lower crust of the satellite and at a 90-degree angle to the x-axis

This coordinate system is used to find the centre of the satellite and determine the layout of the equipment.

2- Satellite coordinate system

: The centre of this coordinate system is located on the real centre of gravity of the satellite.

: is the longitudinal symmetric axis of the satellite that coincides with or parallel to the z-axis.

: These two axes are parallel to the x and y axes, respectively.

This coordinate system is used to calculate the mass and product moment of inertia of the satellite.

3- The local coordinate system of the equipment

: The centre of this coordinate system is located on the centre of gravity of the equipment.

: is the longitudinal symmetric axis of the equipment which is parallel to the z-axis.

: These two axes form an angle αi parallel to the x and y-axes, respectively.

This coordinate system is used to calculate the moment of inertia of the equipment according to its axis.

3.1.3. Optimization Model

Minimizing the sum of the moments of inertia physically suggests that the satellite is inherently stable. This means that minimizing the sum of the moments of inertia can reduce the efforts of the attitude control subsystem in the stabilization of the satellite.

The moments of inertia of both cubic and cylindrical components are calculated in the

xyz direction. The total moments of inertia of all the components which need to be minimized can be expressed as follows:

The constraints are as below:

Non-overlap constraint:

Static stability constraint:

where x

e, y

e, z

e are the expected centroid position of the satellite and

,

,

are the allowance errors of x

m, y

m, z

m (real centroid position of the satellite) respectively.

Equilibrium constraints:

where

,

,

are angles between the principal axes of inertia of the satellite with the principle axes oz, oy and oz and

,

,

are their allowance errors.

The objective function (1) shows the minimization of mass moments of inertia in the main directions of the coordinate axis. Constraint (2) represents the constraint of non-overlapping between equipment by requiring that the distance between the centres of two pieces of equipment be equal to or larger than the sum of their two radii. For cuboid equipment, the radius of the circumferential circle of the rectangular cross-section is considered as the radius.

Constraints (3) to (5) show static stability where xe, ye, ze coordinates of the expected centre of gravity of the satellite and , ,

are permissible error for the coordinates of the actual centre of gravity of the satellite (xm, ym, zm). The deviation of the centre of gravity of the satellite after the placement of all equipment should not be greater than the expected centre of gravity of the satellite in the middle of it. Constraints (6) to (8) are equilibrium constraints in which , are the angles between the directions of the mass moments of inertial of the satellite with the major axes and , are their allowable errors. The following shows how to calculate , .

The centre of mass of the i

th component in the local xyz coordinate system can be stated as shown below:

where (

and

are the coordinates of the centre and the mass of the equipment i, respectively. The reason that in the denominator of these equations, the sum starts from zero is that in addition to the number of equipment (n) the mass of the shell, the middle cylinder and the floors must also be taken into account in calculating the true centre of gravity of the satellite.

The computational formulas of moments of inertia in the main directions of the satellite coordinate axis are as follows:

where

Jxi and

Jyi are moments of inertia of the i

th component concerning the local coordinate system (to the

x and

y axis respectively).

ai and

bi are the length and width of a cubic component respectively and

hi and

ri are the height and radius of the i

th component (for both cubic and cylindrical shape components). Similarly, the derivations of moments of inertia in the y direction of both cylindrical and cubic components are shown below:

Similarly, the derivations of moments of inertia in the

z direction of both cylindrical and cubic components are illustrated below:

: this parameter is the placement angle of the cubic object, it equals the included angle between the positive direction axis x and the long edge of the cubic component. Here, it is assumed that the cubic equipment only rotates 90 degrees, so the only possible values for this parameter are zero or 90.

The formula of

, , are as below:

Where

Ixy, Ixz and

Iyz are the products of moments of inertia in the x–y, x-z and y-z planes respectively for both cylindrical and cubic components and are calculated as below:

Moments of inertia for the i

th cylindrical component are defined by

Jxi, Jyi and

Jzi concerning the local coordinate system as follows:

Also, moments of inertia for the i

th cubic component indicated by

Jxi, Jyi and

Jzi are shown below:

5. Implication and Sensitivity Analysis

In this section, the efficiency of the proposed model is investigated by comparing its performance with previous models in the literature review.

Since some of the constraints of the model are flexible, new parameters are introduced that are valued for the possibility of exceeding the aforementioned constraints. For this purpose, the maximum permissible flexibility for soft constraints (sT) is considered.

To analyze the performance sensitivity of a model based on flexible robust planning, we first compare it with a simple flexible model with certain levels of satisfaction (for example ). The numerical examples from Sun and Teng (2003), Zhang et al. (2008), and Liu and Teng (2008) were used for this purpose. These three numerical examples served as the foundation for numerous papers; therefore, the eleven articles that used these numerical examples are compared to the suggested model.

Case Study 1: investigating the work of Sun and Teng (2003)

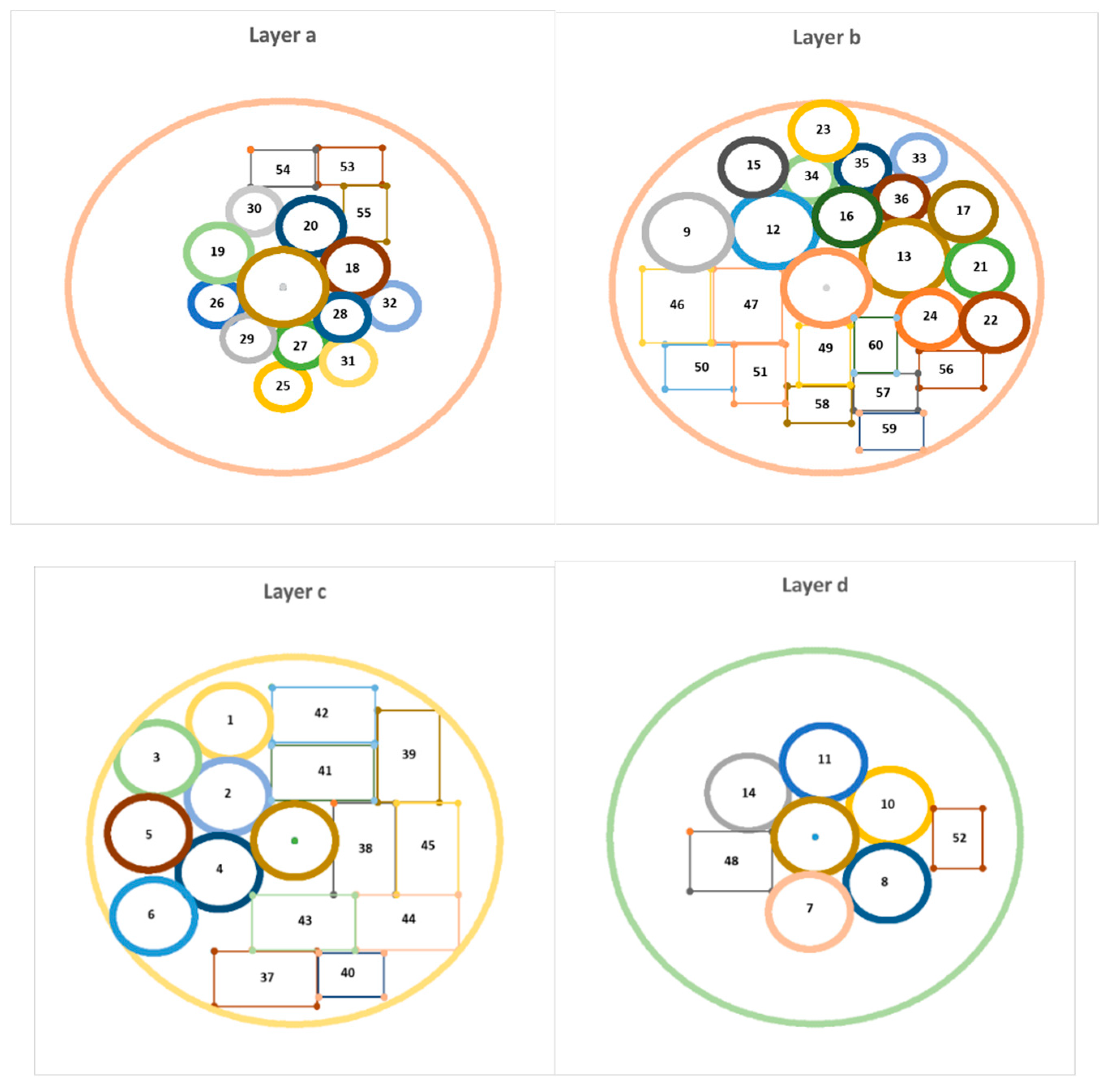

In this example, there are 53 pieces of equipment, of which 24 pieces of pieces of equipment are cuboids and 29 pieces of equipment are cylindrical. In this example, the satellite equipment is arranged in two levels and 4 layers. By considering

Figure 8, the parameters of the satellite body are as follows: the radius of the circular cross-section of the satellite surfaces is 500 mm, the radius of the middle cylinder of the satellite connecting the surfaces is 100 mm, the H

1, H

2 and H

t parameters are 300 mm, 830 mm and 1150 mm respectively and the diameter of the first and second levels is 20 mm each. The mass of the empty satellite consists of 4 plates (two middle levels and two floor and top levels of the satellite), the satellite shell and its middle cylinder are equal to 776.53 kg. To perform more accurate calculations, it was assumed that the density of materials used in the body of this satellite was 3.006 g/cm

3 (a combination of aluminum and titanium alloys) and the thickness of the satellite’s shell was 41.25 mm. Also, the two middle plates on which the components are placed were considered hollow cylinders with inner and outer diameters of 100 and 500 mm, respectively, and the upper and lower plates were considered as complete cylinders with 100 mm diameter. With these hypotheses, it was simple to calculate the weight of each component in the satellite’s empty container and to determine the satellite’s moment of inertia as

and

kg.m

2. Since the moment of inertia is higher than the empty state of the satellite when the components are added to the empty container of the satellite, it is expected that the values obtained from the moment of inertia in each of the principal directions of the coordinate axes are greater than the values calculated for Empty satellite compartment. Also, the coordinates of the centre of gravity of the empty satellite were calculated as C

0 = (0,0,595).

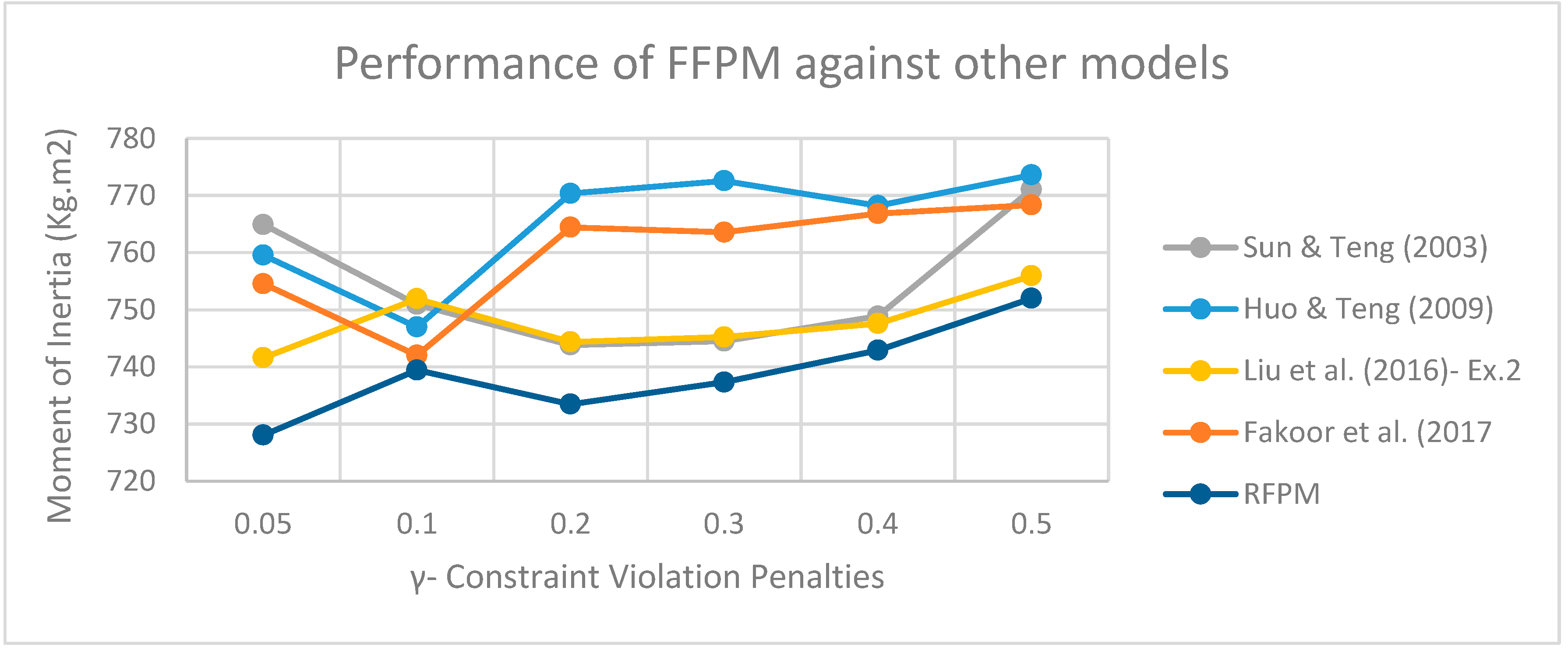

After that the case was introduced by Sun and Teng (2003), Huo and Teng (2009), the second example by Liu et al. (2016) and the article by Fakoor et al. (2017) also used the data of this numerical example and compared their results with each other. Huo and Teng (2009) similarly utilized comparable data, but the coordinates of their layout result were not given for comparison with other studies. With the assumptions mentioned above and according to the coordinates of the equipment after placement that is available in the mentioned articles, the moments of inertia were recalculated and the results were compared, which can be seen in

Table 2.

As illustrated in

Table 2, the best answer in these articles is related to Liu et al. (2016) in which the objective function is less than the others. Therefore, in this paper, we use the output in this paper to determine

in cuboid equipment.

Then, using the heuristic method provided in

Section 4.1.1.1, all conceivable modes of equipment allocation to different layers for these data were investigated, and 25 viable forms of equipment allocation were determined. Here, each of these feasible modes was implemented using the RFPM provided in

Section 4.1.2.1 and GAMS software, and the results were compared to those of previous works that utilized this numerical example. (

Table 3).

As can be seen from the table, the minimum moment of inertia is related to the possible state number 9, in which the total moment of inertia in the main directions of the coordinate axes is equal to 728.07 kg.m

2, and on the other hand in 24 of the 25 possible states of total moments of Inertia are slightly better than Liu et al. (2016).

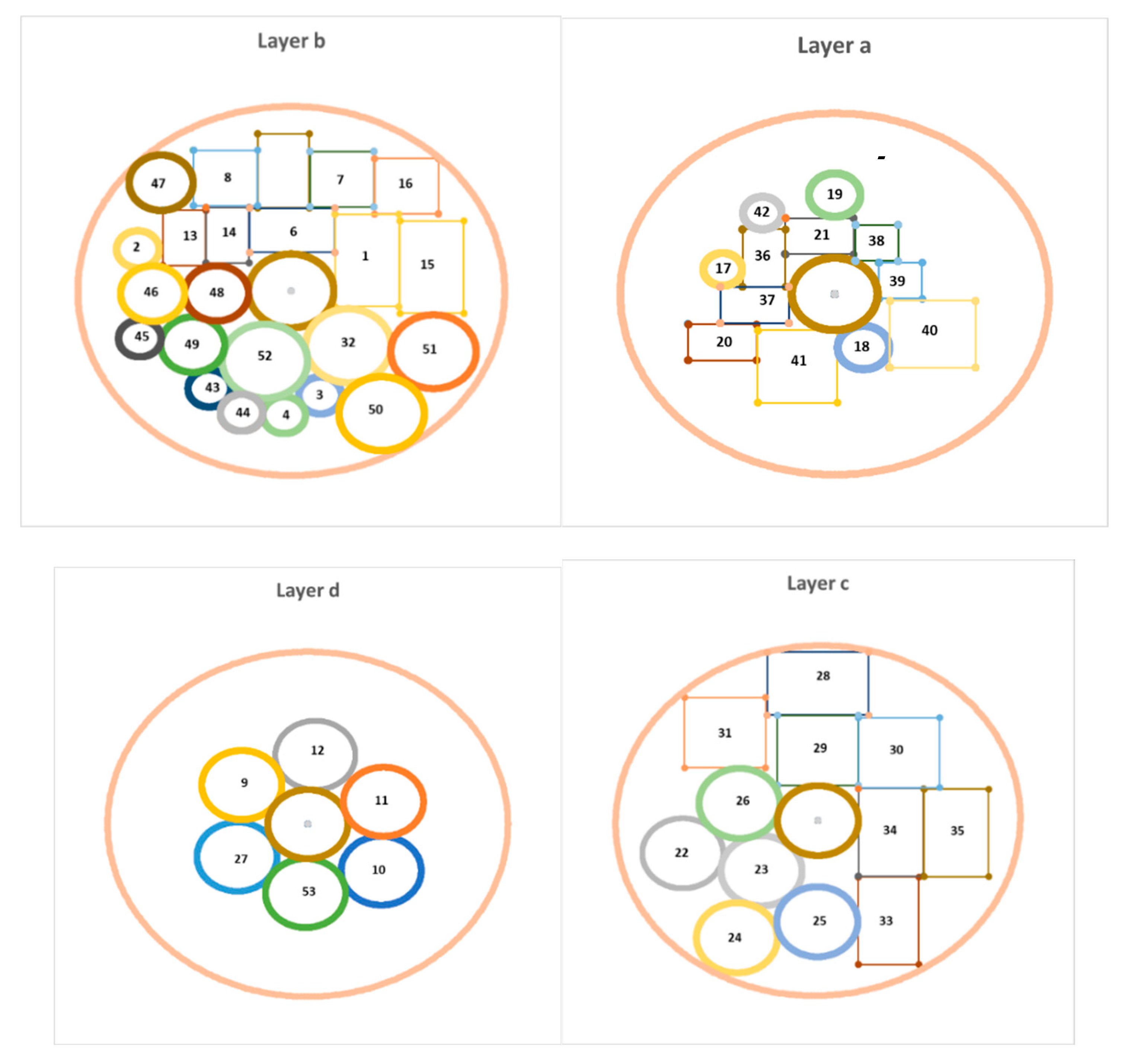

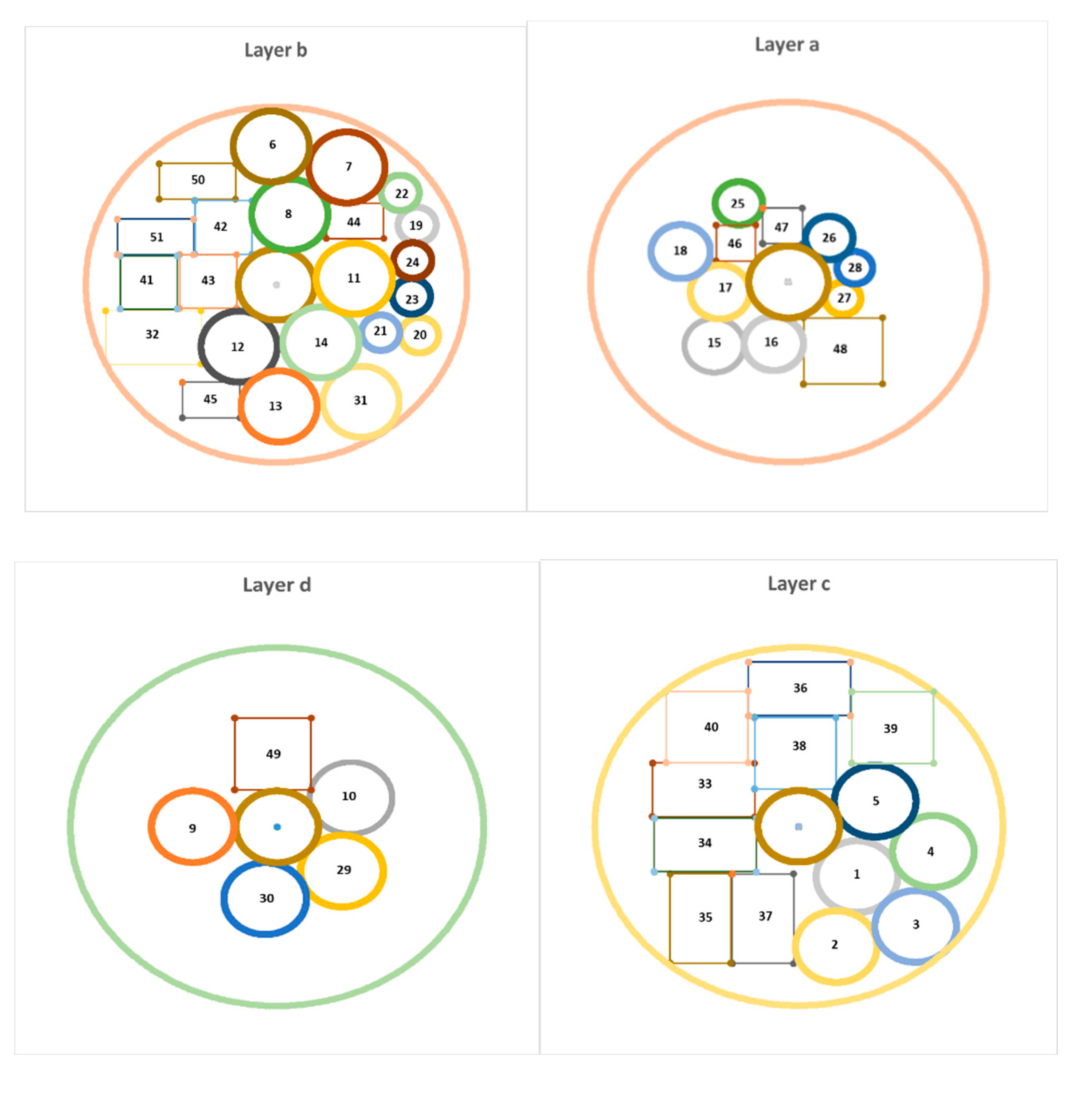

Figure 3,

Figure 4 and

Table 4 depict the output of the model in the case where the sum of the moment of inertia is at its lowest possible value (layout of equipment on different layers of the satellite) and the coordinates of the equipment in this optimal state respectively.

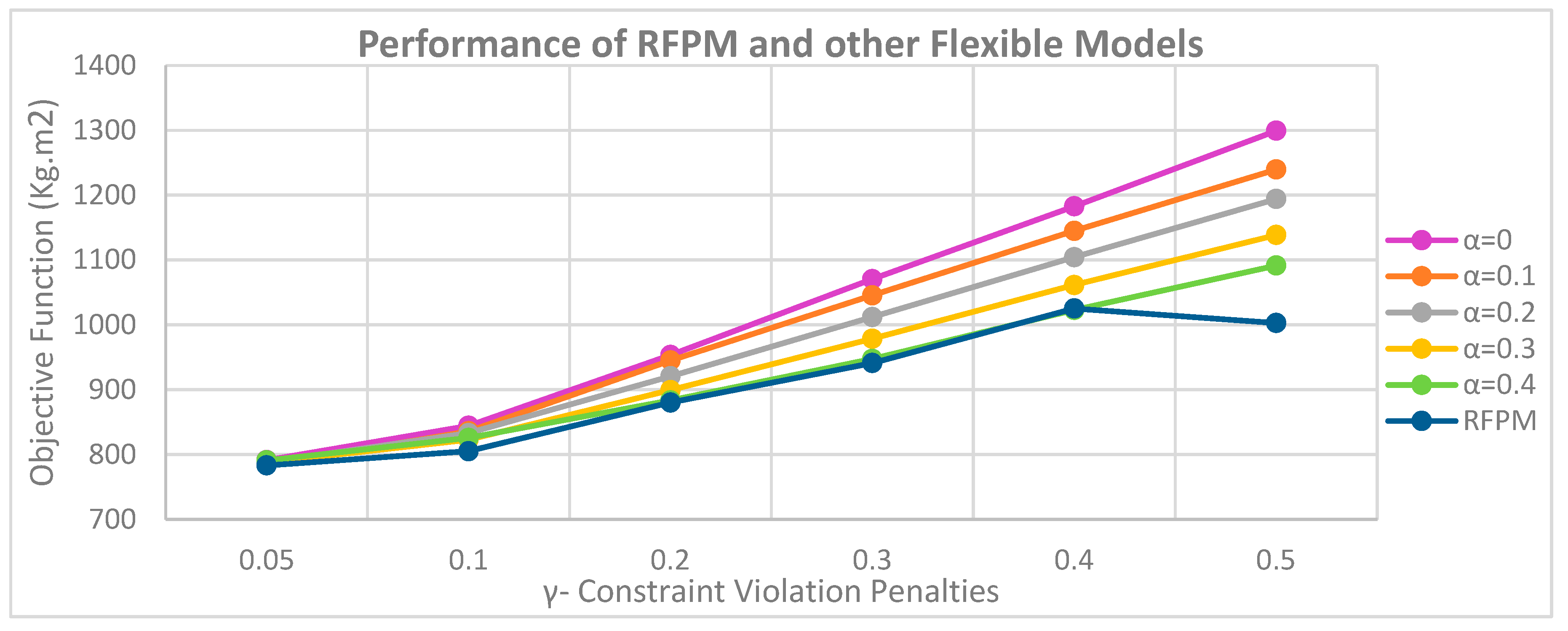

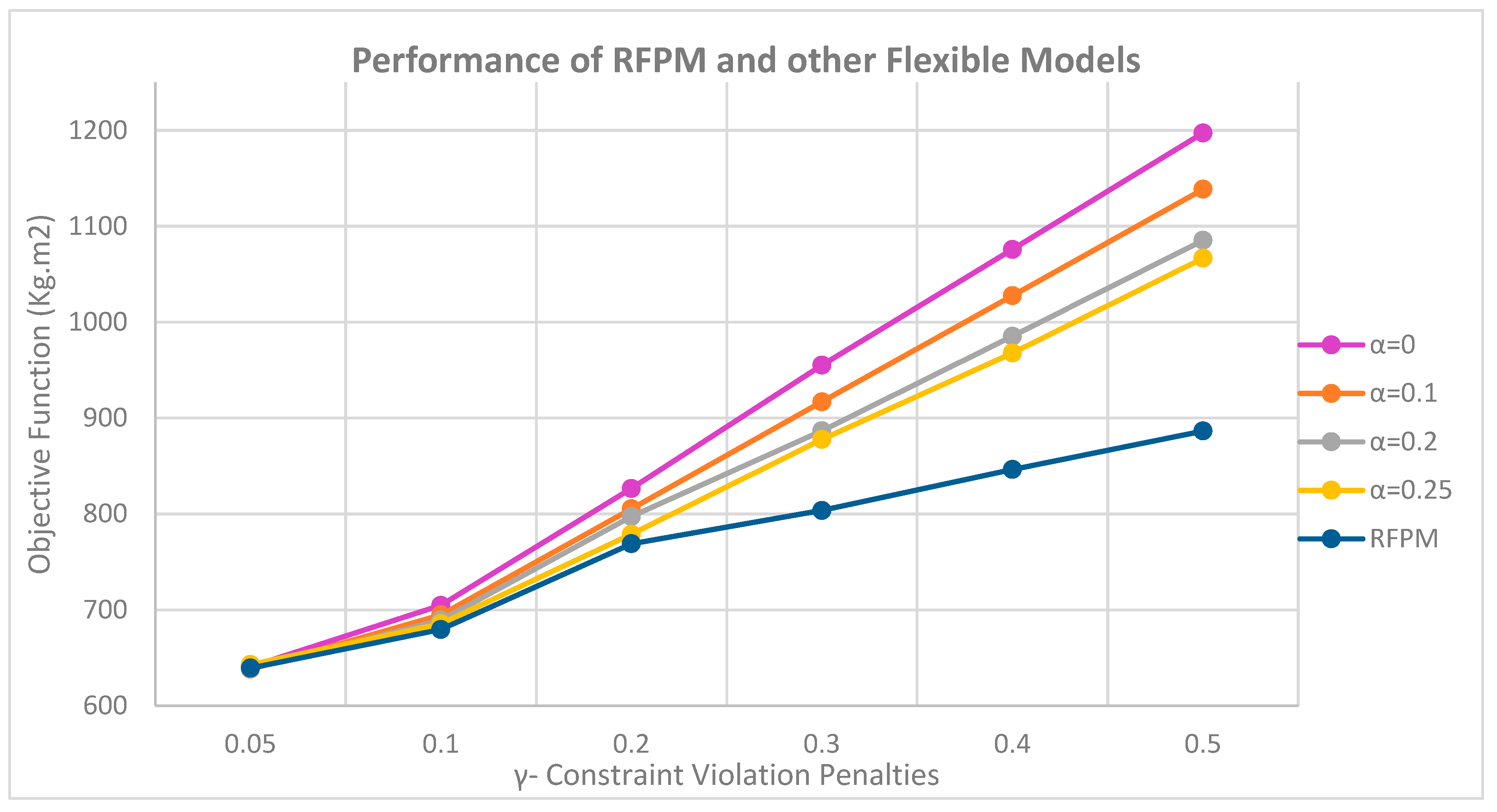

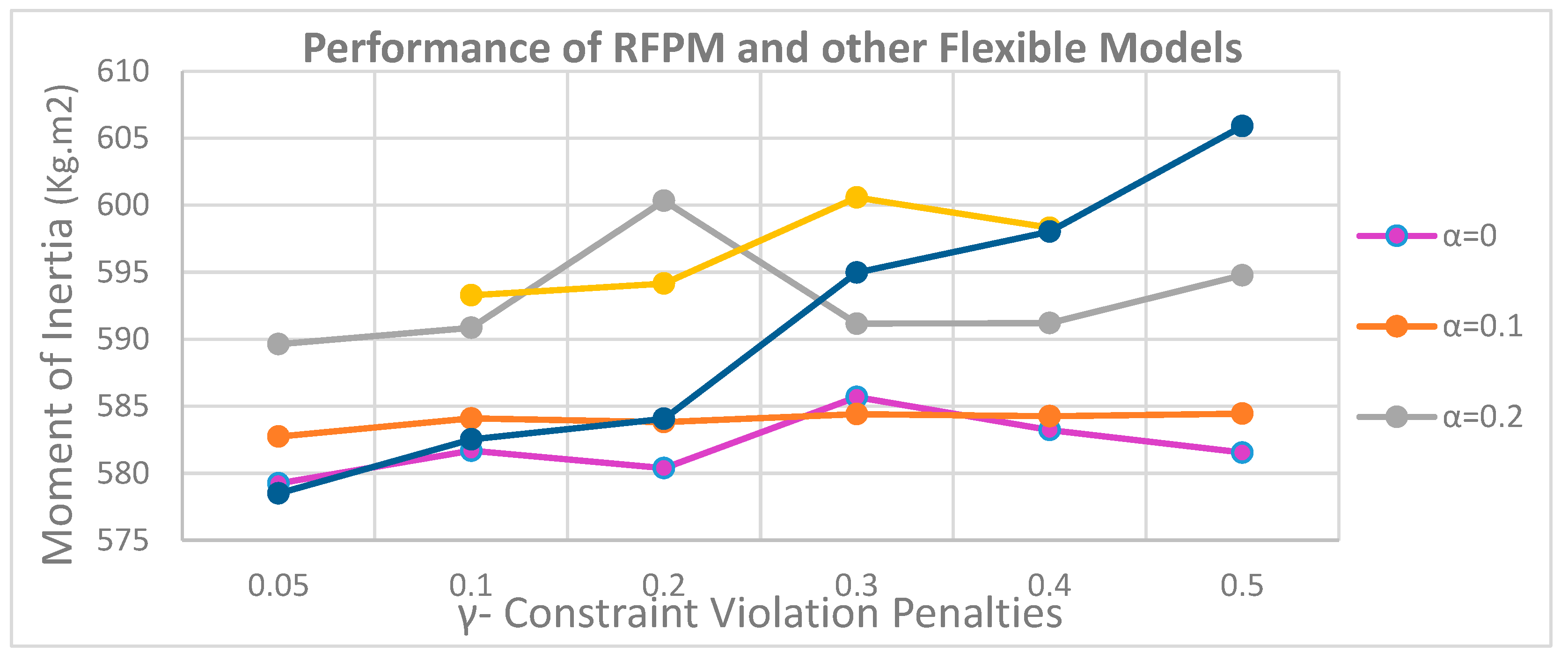

To compare the best answer obtained from the possible answers (

Table 3) with the flexible model in the flexible state, we run the model in all possible modes and compare the objective functions with each other. The results can be seen in

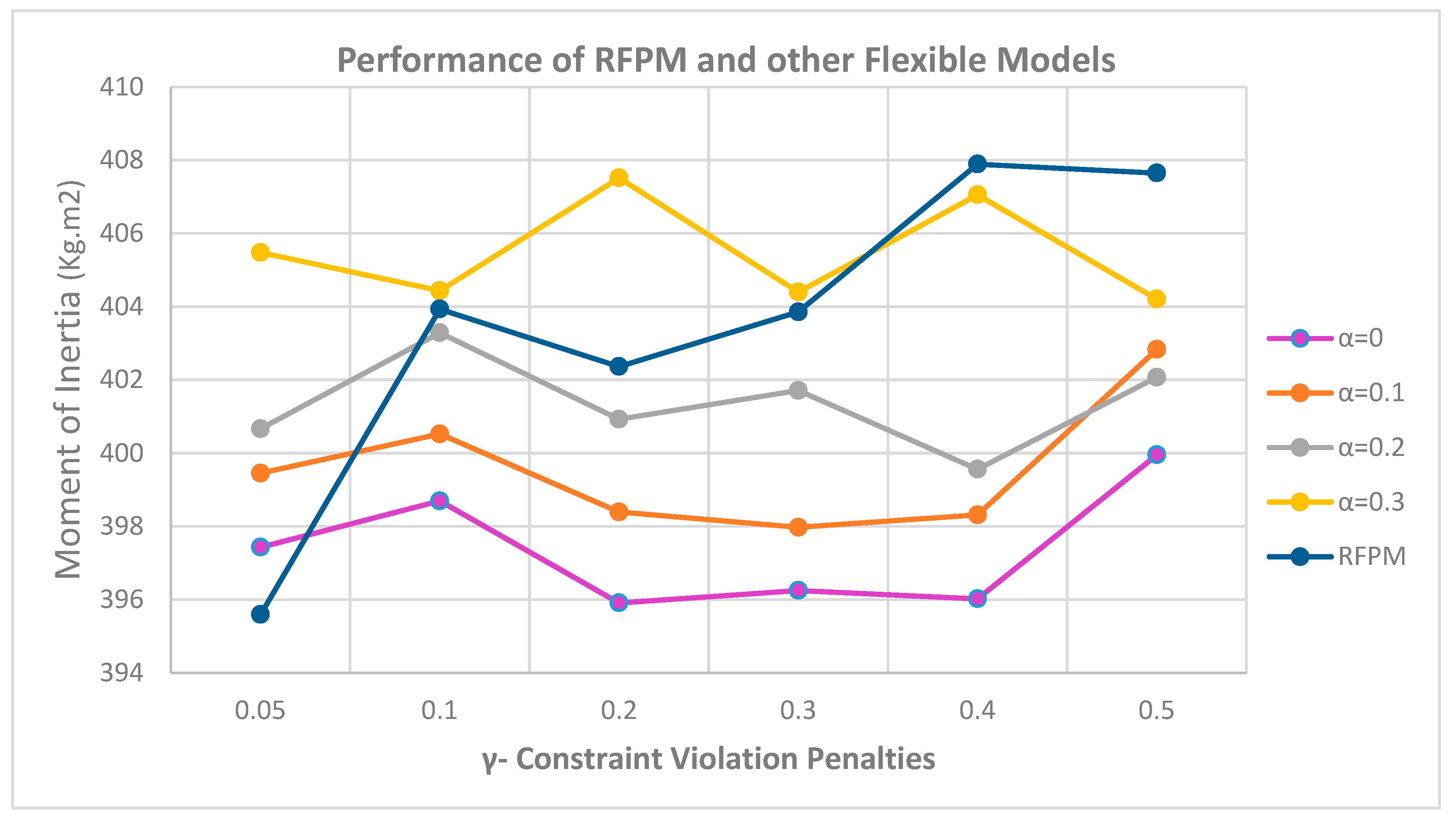

Figure 5.

As demonstrated in

Figure 5, in cases where the minimum level of satisfaction for exceeding the flexible constraints (

) is greater than 0.4, the models will not be responsive in the flexible state because if this parameter tends to 1 the constraint loses its flexibility and the radius of the rectangular of cuboid equipment becomes the radius of their circumference and the limit of non-overlap between the equipment will not be practically met.

It is also clear that by increasing the penalty coefficient for violating the flexible constraints () in the objective function, the values of the objective function increase. As a result, the higher the coefficient, the faster the minimum level of satisfaction () rises in flexible models with lower . The reason for this is that with decreasing the level of satisfaction, the value of (1-) increases and the product of the penalty for violating the soft limits in the amount of (1-) in the objective function increases more sharply.

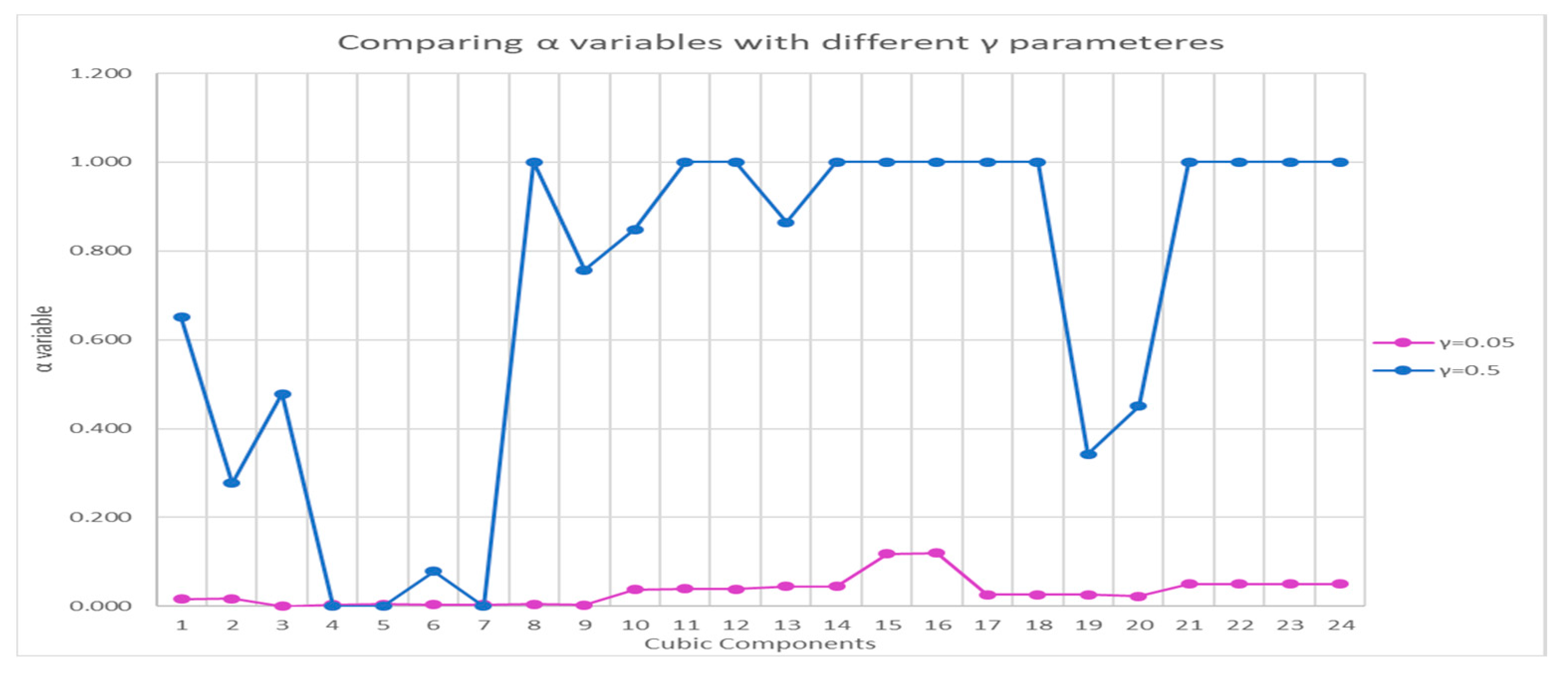

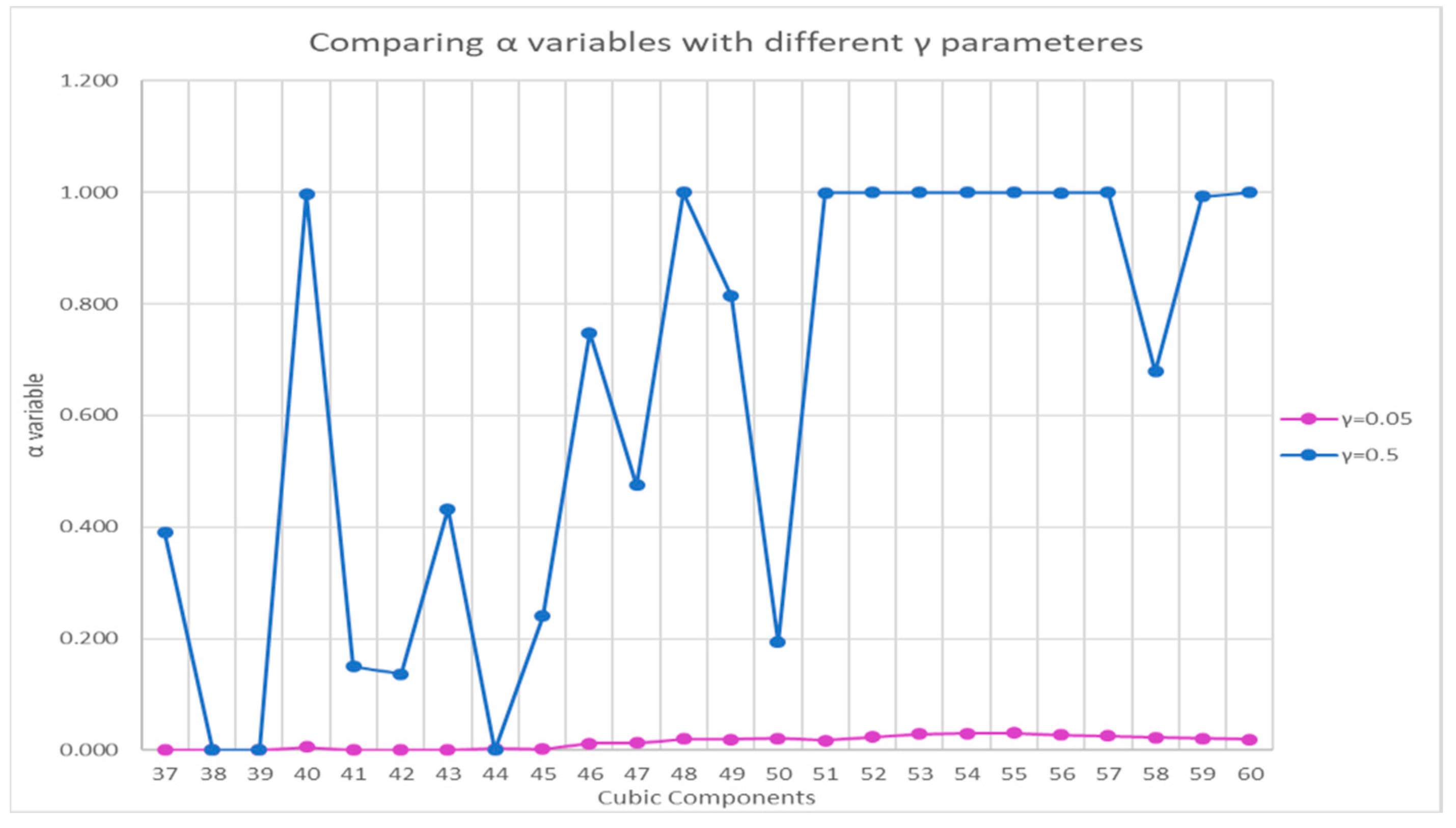

In the RFPM, the model provides a better answer in all cases; however, in case

, this difference is more pronounced than in other flexible cases, as the penalty coefficients are increased and the model attempts to reduce the value of the objective function, causing the minimum variables Satisfaction levels (

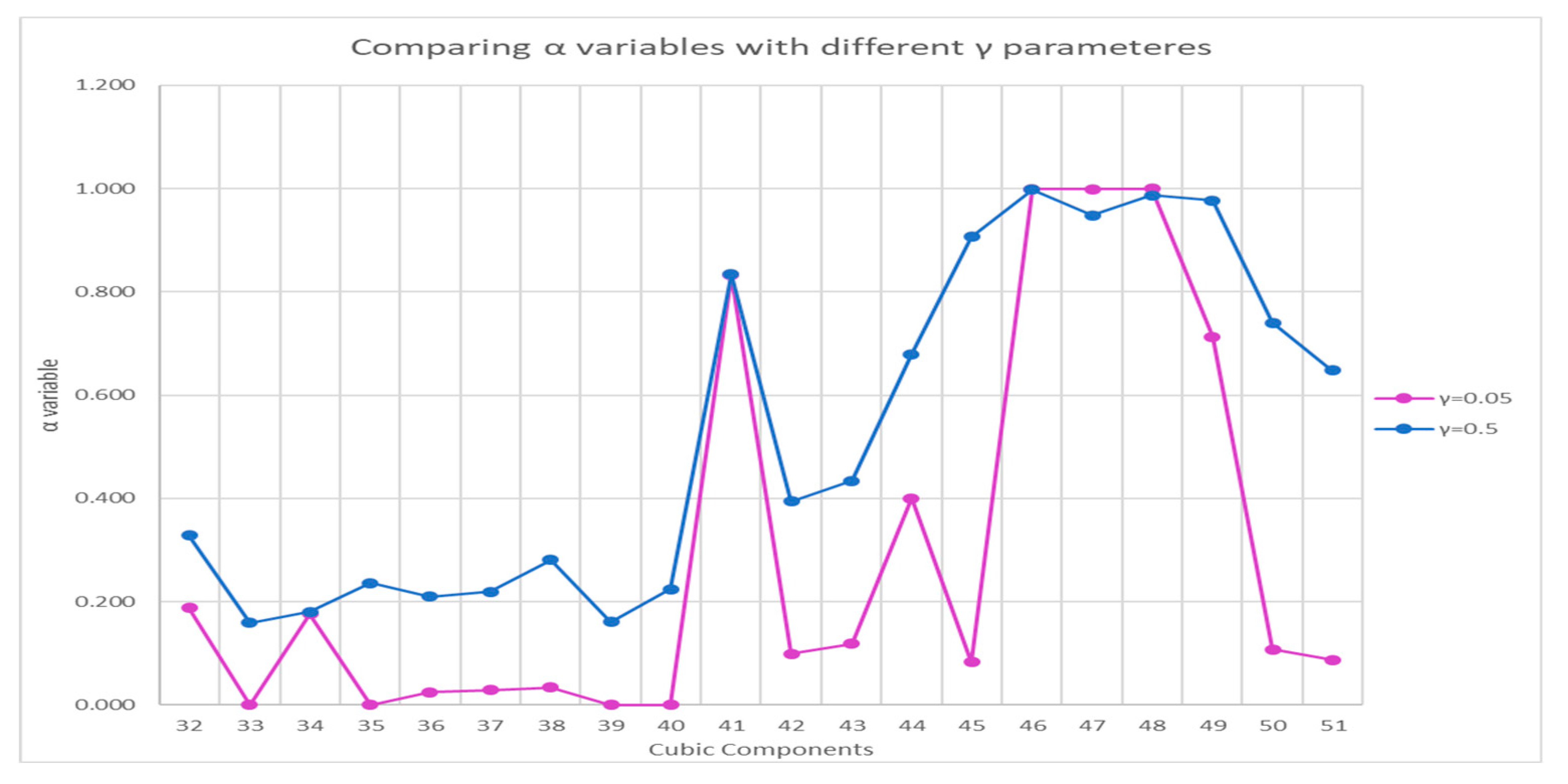

) to take on greater values. The values of the minimum satisfaction level variables (α) for γ = 0.05 and γ = 0.5 were compared. As shown in

Figure 6, the satisfaction level at γ = 0.5 has higher values, which, as previously stated, is due to the model’s desire to reduce the objective function, but can prevent greater flexibility of soft constraints and increase the values of moment of inertia by increasing the distances between equipment.

Therefore, moments of inertia must also be compared to conclude the best case of the penalty coefficient.

The total of moments of inertia in the principal directions of the coordinate axes was also examined for the aforementioned models to determine with which coefficient the model yields the most accurate response. The outcomes are depicted in

Figure 7.

As depicted in

Figure 7, the greater the minimal satisfaction level (

) in flexible models, the greater the radius estimated in the cuboid equipment to become a circumscribed circle. It tends to place equipment further apart from one another, hence increasing the total moments of inertia. The intriguing phenomenon is the distinction between modifying the model’s trend in RFPM and flexible models in return for increasing the penalty coefficient for violating soft constraints. This indicates that by increasing the penalty coefficient, the RFPM produces a superior sum of moments of inertia output. Consequently, the optimal instance for this model occurs when

;

Because as this coefficient increases, to avoid increasing the objective function of the model, it tries to increase the value of the minimum satisfaction level (), but the RFPM prevents this from occurring so that the soft constraints are met and the value of is not excessively high, causing the objective function to be greater than the flexible states; As a result, the best case of a RFPM is when the value of the penalty coefficient is . In cases where the cost factor is less than this value, the model loses efficiency because the penalty for violating the soft constraints on the objective function is drastically reduced, the model tends to zero the minimum satisfaction level (), and flexible constraints are at their softest state, which increases the probability of equipment overlapping.

Now that it has been determined that the RFPM is more capable than the other flexible models, we will compare this model to the models proposed in prior articles. Here, four articles that used this example in their case studies were analyzed, and the data from each article were used as input for the suggested robust model based on the existing equipment positions on different satellite layers. In addition, the model was applied to these data. The outcomes are depicted in

Figure 8.

As shown in

Figure 8, the suggested RFPM has a lower total number of moments of inertia than previous articles in all scenarios of penalty coefficients for violation of soft constraints. Also, the proposed RFPM has the lowest values for the sum of moments of inertia at

.

There has been a 1.75 percent improvement when comparing the moments of inertia from Liu et al. (2016) (741.6 kg.m2) and the suggested RFPM (728 kg.m2). It implies that if an identical force is required to spin these two satellites, at least 13 kilograms of mass could be conserved. This quantity of improvement will be vital for satellite design specialists to increase the functionality of their products in the field of satellite launching where the reduction of every single kilogram would be essential to have a more successful mission.

As can be seen, as the penalty coefficient increases, the values of moments of inertia tend to increase due to the objective function attempting to reduce the penalty values, resulting in less flexibility of soft constraints, which causes equipment to be placed far apart from one another, thereby increasing the total moments of inertia.

Case Study 2: investigating the work of Zhang et al. (2008)

In this example, there are 60 pieces of equipment, of which 24 pieces of equipment are cuboids and 36 pieces of equipment are cylindrical. In this example, the satellite equipment is arranged in two levels and 4 layers. The parameters of the satellite body are as follows: the radius of the circular cross-section of the satellite surfaces is 500 mm, the radius of the middle cylinder of the satellite connecting the surfaces is 100 mm, the H1, H2 and Ht parameters are 300 mm, 830 mm and 1150 mm respectively and the diameter of the first and second levels is 20 mm each.

The mass of the empty satellite consists of 4 plates (two middle levels and two floor and top levels of the satellite), the satellite shell and its middle cylinder are equal to 576.53 kg. To perform more accurate calculations, it was assumed that the density of materials used in the body of this satellite was 3.006 g/cm3 (a combination of aluminum and titanium alloys) and the thickness of the satellite’s shell was 24.5 mm.

Also, the two middle plates on which the components are placed were considered as hollow cylinders with inner and outer diameters of 100 and 500 mm, respectively, and the upper and lower plates were considered as complete cylinders with 100 mm diameter. With these hypotheses, the weight of each part in the empty chamber of the satellite was calculated and the moment of inertia of the empty satellite was calculated as and kg.m2.

Since the moment of inertia is higher than the empty state of the satellite when the components are added to the empty container of the satellite, it is expected that the values obtained from the moment of inertia in each of the principal directions of the coordinate axes are greater than the values calculated for Empty satellite compartment. Also, the coordinates of the centre of gravity of the empty satellite were calculated as C0 = (0,0,595).

After that the case was introduced by Zhang et al. (2008), Five articles including Wang et al. (2009), the second example by Teng et al. (2010), Cui et al. (2017), Zhong et al. (2019) and the third example in the article Chen et al. (2021) also used the data of this numerical example and compared their results with each other. Li et al. (2016) also utilized this numerical data but the output places of equipment were not organized diagonally therefore the findings were not comparable here. With the assumptions mentioned above and according to the coordinates of the equipment after placement that are available in the mentioned articles, the moments of inertia were recalculated and the results were compared, which can be seen in

Table 5.

As depicted in

Table 5, the best answer in these articles is related to the article by Zhong et al. (2019) in which the objective function is less than other articles. Therefore, in this paper, we use the output to determine

in cuboid equipment. As explained in Case Study No. 1, here, according to the heuristic method presented in

Section 4.1.1.1, all possible modes of equipment allocation to different layers for this data were examined and 25 feasible modes of equipment allocation were obtained.

Here, each of these feasible modes was implemented using the RFPM presented in

Section 4.1.2.1 and by GAMS software, and the results were compared with other papers that used this numerical example (

Table 6).

As can be seen from the table, the minimum sum of moments of inertia in the main directions of the coordinate axes is equal to 578.49 kg / m

2, and also in 24 feasible states, the sum of moments of inertia is slightly better than Zhong et al. (2019).

Figure 9 and

Table 7 show the output of the model in the case where the sum of the moment of inertia is at its minimum possible (layout of equipment on different layers of the satellite) and the coordinates of the equipment in this optimal state respectively.

To compare the best answer obtained from the possible answers (

Table 6) with the flexible model in the flexible state, we run the model in all possible modes and compare the objective functions with each other. The results can be seen in

Figure 10.

As illustrated in

Figure 10, in cases where the minimum level of satisfaction for exceeding the flexible constraints (

) is greater than 0.25, the models will not be responsive in the flexible state because, as in Case No. 1, if this parameter tends to 1, the constraint loses its flexibility and the radius of the rectangular of cuboid equipment becomes the radius of their circumference and the constraint of non-overlapping between the equipment will not be practically met. The only difference with Case Study No. 1 is that in flexible states, the minimum level of satisfaction becomes infeasible if it is greater than 0.25.

This is due to the increased quantity of positioning equipment, which reduces the flexibility of the non-overlap constraints by increasing the (

) variable and making the model infeasible. As previously, the objective function values increase as the penalty coefficient for violating the flexible constraints (

) in the objective function increases. In reality, in flexible models with a smaller (

) variable, increasing (

) will increase the objective function more. In the RFPM, the model behaves similarly to the first case study, and at

=0.5, the difference in the output of the objective function between the robust and flexible models becomes more obvious. As before,

Figure 11 presents, for greater clarity, the minimal satisfaction level variables obtained for these two modalities.

Observing

Figure 11 and similar to Case Study No. 1, it is evident that at

, greater values are obtained for the variable, but this leads to an increase in moments of inertia. This case demonstrates substantially lesser values for (

) variables than Case Study No. 1 due to the bigger quantity of equipment. It indicates that soft constraints must be set to their softest mode to prevent components from overlapping.

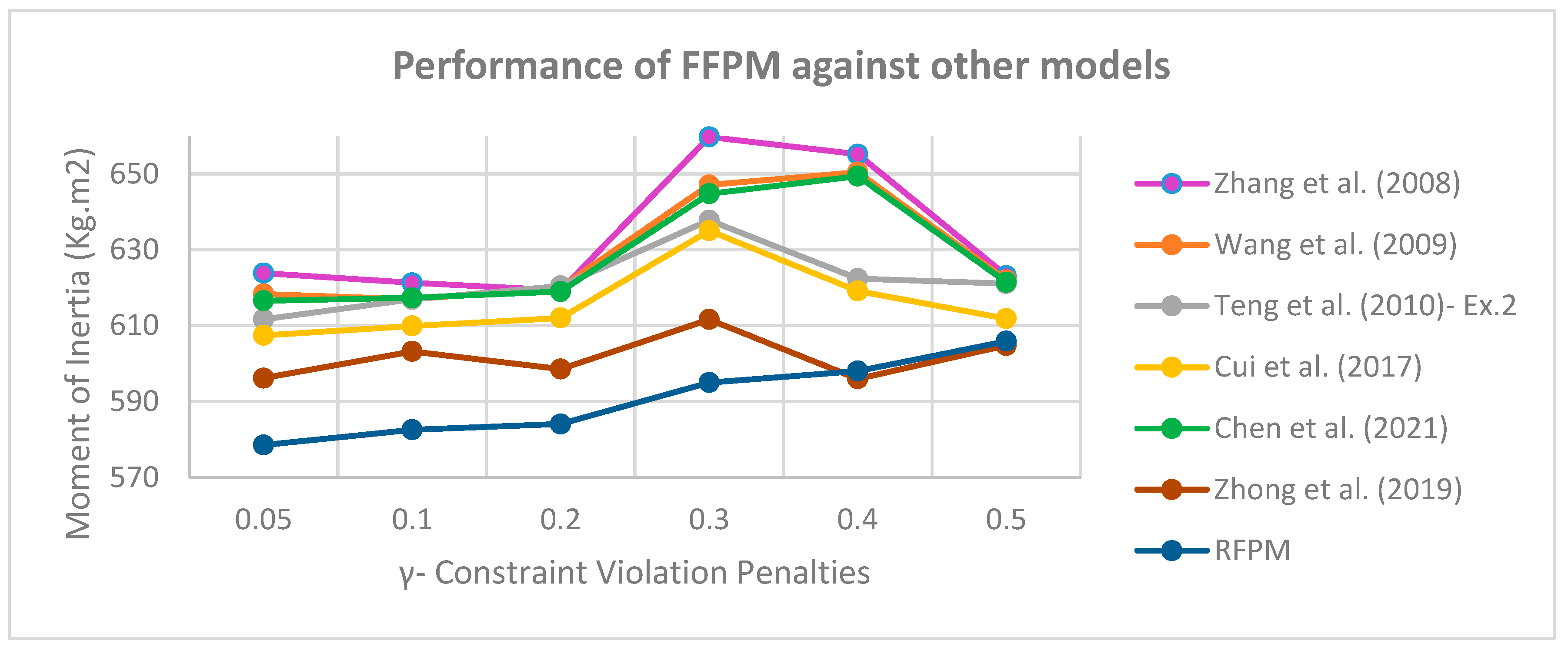

Therefore, the sum of moments of inertia in the main directions of the coordinate axes was also compared for the mentioned models, and the results can be seen in

Figure 12.

As depicted in

Figure 12, the behavior of the models has not changed significantly since Case Study No. 1, and it is only due to the increase in the number of equipment that the flexibility of soft constraints becomes more important; even in the flexible Models where the minimum satisfaction level (

) exceeds 0.25, the model is infeasible. Similarly, by increasing the penalty factor (

), the model in its robust form will gain more moments of inertia, due to the tendency of the model to shrink the objective function and increase the

variables, as well as the tendency of the equipment to move away from one another and raise the moments of inertia.

As a result, the best case of a RFPM is when . As said before, in cases of less than this value for the cost factor, the model loses its efficiency because the penalty for violating the soft constraints in the objective function is sharply reduced and the model tends to zero the minimum level of satisfaction (α) and Makes flexible constraints at their softest mode, increasing the likelihood of equipment overlapping.

Now that it has been found that the RFPM has a higher capability compared to the other flexible models, we now compare this model with the proposed models in similar articles. Here, five articles that used this example in their case studies were reviewed and according to the existing equipment layout on different satellite layers that were available in the articles, the data of each article were used as an input for the proposed RFPM and the model was implemented for these data. The results are shown in

Figure 13.

As depicted in

Figure 13, the sum of moments of inertia in the suggested RFPM in circumstances when the penalty coefficients for violation of soft constraints are less than 0.3 provides a significantly superior solution than other articles. Compared to Zhong et al. (2019), the sum of moments of inertia has increased marginally only in cases

and

. This is to confirm that the best choice for the value of the penalty coefficient occurs in the case

and that increasing this coefficient reduces the model’s efficiency. Therefore, similar to case study No. 1, an improvement of 2.95 percent has been made when comparing the moments of inertia in Zhong et al. (2019) (596.1 kg.m2) and the suggested RFPM (578.5 kg.m2). It means that if an identical force is required to spin these two satellites, at least 17.6 kilograms of mass could be preserved.

Case Study 3: investigating the work of Liu and Teng (2008)

Liu and Teng (2008) utilized the data from Li (2003). In this example, there are 51 pieces of equipment, of which 20 pieces of equipment are cuboid and 31 pieces of equipment are cylindrical. In this example, the satellite equipment is arranged in two levels and 4 layers. The parameters of the satellite body are as follows: the radius of the circular cross-section of the satellite surfaces is 500 mm, the radius of the middle cylinder of the satellite connecting the surfaces is 100 mm, the H1, H2 and Ht parameters are 500 mm, 1050 mm and 1400 mm respectively and the diameter of the first and second levels is 20 mm each.

The mass of the empty satellite consists of 4 plates (two middle levels and two floor and top levels of the satellite), the satellite shell and its middle cylinder are equal to 349.557 kg.

To perform more accurate calculations, it was assumed that the density of materials used in the body of this satellite was 1.766 g/cm3 (a combination of fiberglass, Kevlar and carbon fiber and aluminum and titanium alloys) and the thickness of the satellite shell was 20 mm. is. Also, the two middle plates on which the equipment is placed were considered as hollow cylinders with inner and outer diameters of 100 and 500 mm, respectively, and the upper and lower plates were considered as complete cylinders with 100 mm diameter. With these hypotheses, the weight of each part in the empty chamber of the satellite was calculated and the moment of inertia of the empty satellite was calculated as and kg.m2.

Since the moment of inertia is higher than the empty state of the satellite when the equipment is added to the empty container of the satellite, it is expected that the values obtained from the moments of inertia in each of the principal directions of the coordinate axes are greater than the values calculated for Empty satellite compartment. The coordinates of the centre of gravity of the empty satellite were calculated as C0 = (0,0,732.96).

Except for Liu and Teng (2008), the first example Liu et al. (2016) utilized these numerical example’s data and compared their results. Huo et al. (2007) also employed similar data but the coordinates of their layout output were not disclosed in that article to be compared with other researches. With the assumptions mentioned above and according to the coordinates of the equipment after placement that are available in the mentioned articles, the moments of inertia were recalculated and the results were compared, which can be seen in

Table 8.

As can be seen in

Table 8, the best answer in these two articles is related to Liu et al. (2016) in which the objective function has a lower value compared to another article. Therefore, in this paper, we use the output to determine

in cuboid equipment. Then, according to the heuristic method presented in

Section 4.1.1.1, all possible modes of equipment allocation to different layers for this data were examined and 11 feasible modes of equipment allocation were obtained. Here, each of these feasible modes was implemented using the RFPM presented in

Section 4.1.2.1 and by GAMS software, and the results were compared with the outcome of other papers that used this numerical example (

Table 9).

As can be seen from the table, the minimum moment of inertia is related to the second possible state in which the total moment of inertia in the main directions of the coordinate axes is equal to 397.92 kg.m

2, and on the other hand in all possible states the total moment of inertia is better than the article of Liu et al. (2016).

Figure 14 and

Table 10 show the output of the model in the case where the sum of the moment of inertia is at its minimum possible (layout of equipment on different layers of the satellite) and the coordinates of the equipment in this optimal state respectively.

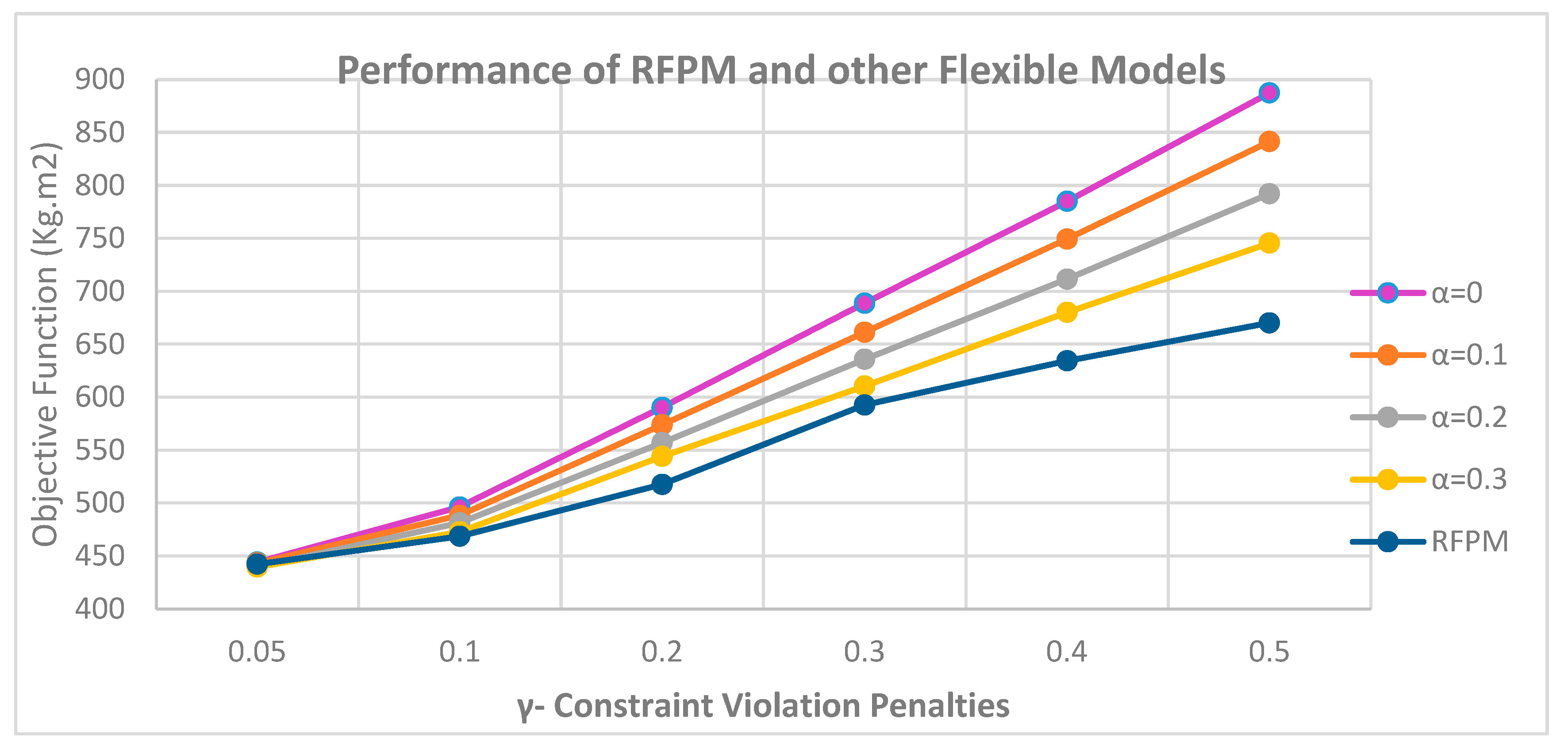

To compare the best answer obtained from the possible answers (

Table 9) with the flexible model in the flexible state, we run the model in all possible modes and compare the objective functions with each other. The results can be seen in

Figure 15.

As shown in

Figure 15, in cases where the minimum level of satisfaction for exceeding the flexible constraints (

) is greater than 0.3, the models will not be responsive in the flexible state because, as in case studies 1 and 2 It was stated that by increasing the value of (

), it loses its flexibility and the radius of the rectangular of cuboid equipment becomes their radius of circumference and as a result, the constant of non-overlap between the equipment will not be met.

The only difference with previous case studies is that in flexible states the minimum level of satisfaction becomes infeasible if it increases from 0.3. The reason is that the equipment occupies more space than case study No. 1, but this space is less compared to case study No. 2, and therefore in the case of also offers a feasible model. As said before, by increasing the penalty coefficient for violation of the flexible constraints () in the objective function, the objective will rise as flexible models with a lower minimum degree of satisfaction () increase dramatically as this coefficient increases.

In the robust state, the model acts like the previous case studies, and at

, the difference in the answer of the objective function with the flexible models is more obvious. As again,

Figure 16 provides, for more clarity, the minimal satisfaction level variables obtained for the two modes

and

.

According to

Figure 16, although the values obtained for the

variable at

are higher than previous case studies, it is only due to the location of the equipment that allows the robust model to prevent more flexibility of soft constraints by increasing the values of minimum satisfaction level (

) variables and therefore these non-overlap constraints are met more easily (less penalty in the objective function).

For a more detailed study, the sum of moments of inertia in the main directions of the coordinate axes was also compared for the mentioned models, and the results can be seen in

Figure 17.

As can be seen in

Figure 17, in general, the behavior of the models has not changed much compared to previous case studies, and by increasing the penalty coefficient

, the model will gain more moments of inertia in the robust state, due to the same tendency of the model to reduce the objective function by increasing the α variables which cause equipment to be placed far apart from one another, thereby increasing the total moments of inertia.

Therefore, as in case studies 1 and 2, the best case of a RFPM is when . As before, in cases of less than this value for the cost factor, the model loses its efficiency because the penalty for violating the soft constraints in the objective function is sharply reduced and the model tends to zero the minimum level of satisfaction () and forces flexible constraints to be at their softest state, increasing the probability of equipment overlapping. As before, we now compare the robust model presented with the proposed models in similar articles.

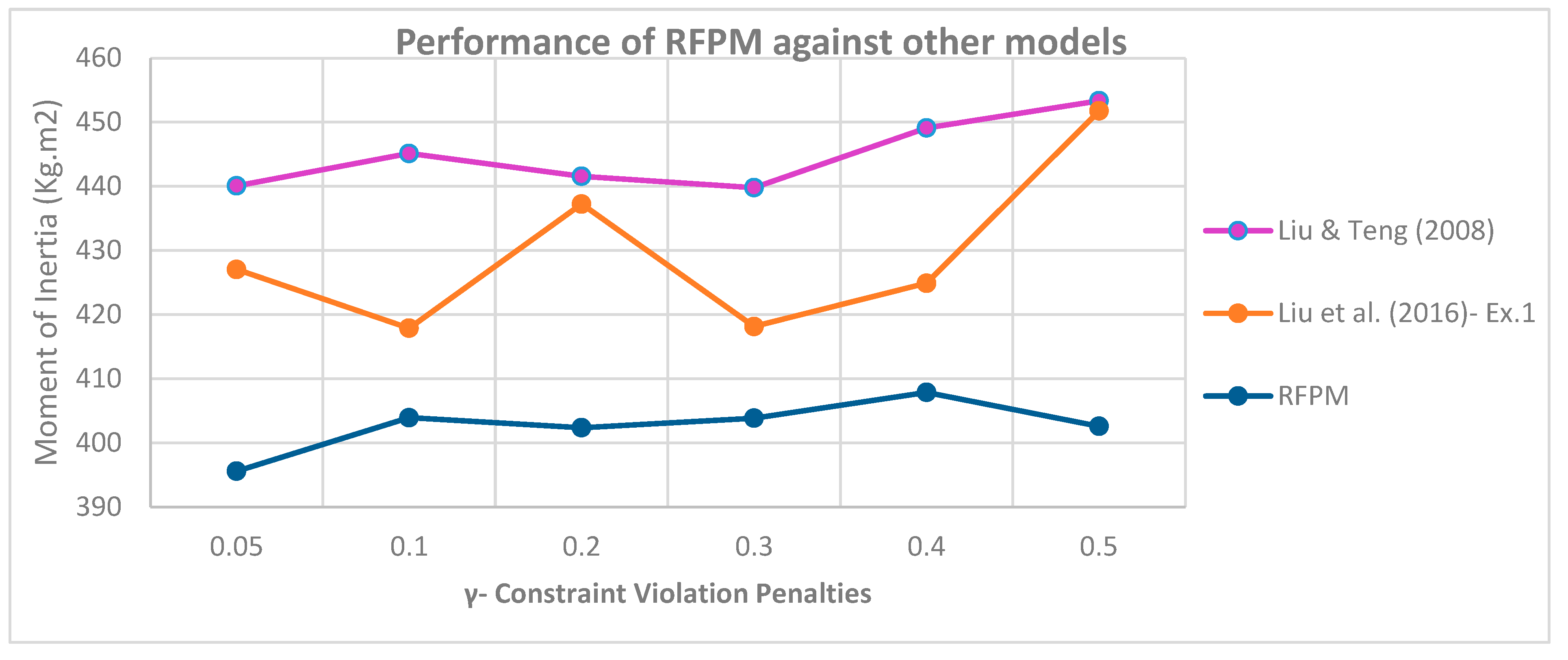

Here, 2 articles that used this example in their case studies were examined and according to the existing equipment layout on different satellite layers that were available in the articles, the data of each article were used as the input for the proposed robust model. The model was implemented for this data and the results are illustrated in

Figure 18.

As can be seen in

Figure 18, the sum of moments of inertia in the proposed RFPM in all cases of penalty coefficients for violation of soft constraints is much lower than in other articles. Also, as in previous case studies, the best and lowest values for the sum of moments of inertia occur in the proposed RFPM at

.

Similar to other case studies, an improvement of 7.35 percent may be seen by comparing the moments of inertia in Liu et al. (2016) (427 kg.m2) and the suggested RFPM (395.6 kg.m2). It suggests that if an identical force is required to spin these two satellites, at least 31.4 kilograms of mass could be preserved.

Finally, as can be seen, by increasing the penalty coefficient, the values of moments of inertia tend to increase due to the objective function trying to reduce the penalty values. As a result, less flexibility of soft constraints is obtained, which causes equipment to be placed at great distances apart, thereby increasing the total moments of inertia.