1. Introduction

The state of Qatar is ranked as the world’s 5th (nominal, 2022) Gross Domestic Product (GDP) per capita with

$106,004 and with a GDP of PPP at

$316 billion (nominal, 2022), which makes it ranked as world 56th (nominal, 2022) GDP [

4]. The backbone of Qatar’s economy comprises oil and natural gas, contributing to over 70% of the government’s total revenue, representing over 60% of the GDP, and making up approximately 85% of export earnings. The State of Qatar is one of the major LNG producers in the world, with a total production capacity of more than 75 million tons/annum, and is expected to increase to 43%, reaching 110 million tons/annum by 202 [

5,

6]. As the oil and gas sector is the most important sector, it is vital to ensure its reliability and protect it from future crises by developing its resilience capacity. Qatar has gone through major challenges in recent years, such as the June 2017 blockade by some of the neighboring countries, mainly Saudi Arabia, United Arab Emirates, Bahrain, and Egypt, as well as the global pandemic of COVID-19. The blockade and global pandemic had significant economic consequences on the country. However, the country quickly implemented strategic measures to mitigate the blockade’s impact. The oil and gas sector has shown a remarkable resilience during these crises due to its well-preparedness and readiness to deal with such a disruptive event.

The term resilience has recently gained much attention globally, especially after the recent COVID-19 pandemic and other natural disasters. People have realized the importance of developing resilient systems and organizations capable of absorbing disruption and returning its a stable state [

7]. So, what does Resilience mean? Resilience originates from a Latin word that means “bouncing back” and has been used in modern business terms as the ability of an organization or a system to rebound to its steady state conditions after going through a disruptive event that disrupts its normal conditions [

8]. The American Society of Mechanical Engineers (2009) defines Resilience as “the ability of a system to control internal and external disruptions to continue its operation” [

9].

Similarly, the definition used by Wreathall [

2], defined Resilience as “the ability of an organization (system) to keep or recover quickly to a stable state, allowing it to continue operations during and after a major mishap or in the presence of continuous significant stresses”. Resilience Engineering concentrates on assessing an organization’s capacity to cope with disruptive occurrences. In this study, an attempt is made to use the expertise of oil & gas professionals to develop a set of 24 resilient indicators (REIs) and rank them in importance, which can then be applied to develop organizational Resilience. In other words, the study will provide the most important resilient indicators that made Qatar’s Oil and Gas sector resilient. Furthermore, it will answer the main question of how we can improve organizational Resilience by applying the learnings from Qatar’s Oil and Gas sector. The term Resilience Engineering (RE) is related to the safe approach [

10] for systems and organizations to adopt to allow them to deal with complicated and unpredictable working conditions. “RE acknowledges the inability to specify all possible threats and responses; instead, it provides methods and tools to manage safety and productivity” [

11]. Wreathall [

2] stated that “If resilience is to ensure the organization keeps (or recovers to) a safe, stable state, there are several processes that must go on to accomplish this goal”. Wreathall [

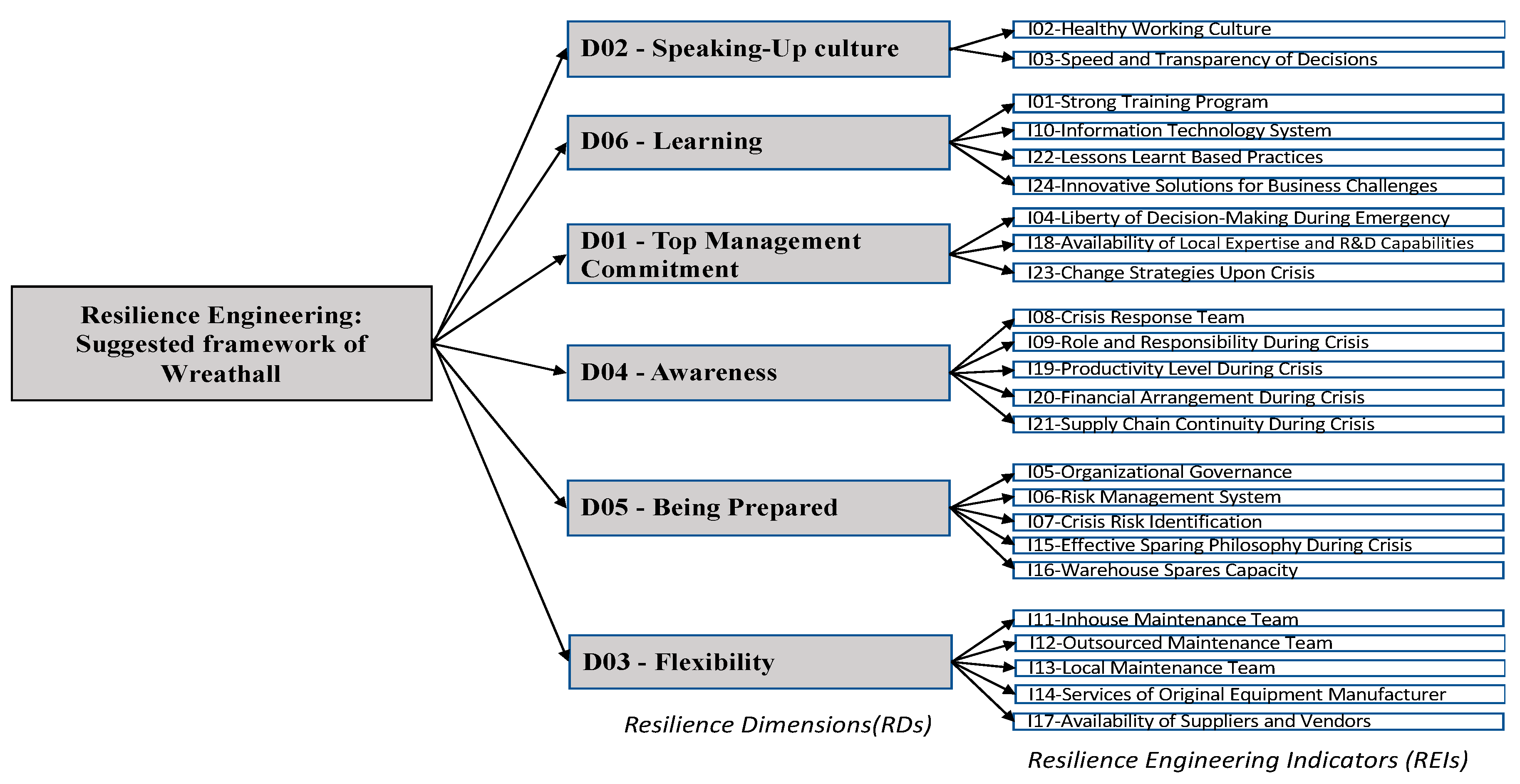

2] defined six themes or dimensions (RDs) which make organizations resilient. These resilience groups are Management Commitment, Learning Culture, Reporting Culture, Awareness, Preparedness, and Flexibility. This study uses 24 developed REIs derived from published literature and the experts’ opinions from the oil and gas industry to validate these indicators under the umbrella of six dimensions (RDs) by Wreathall for resilient systems [

2].

2. Research Significance and Contribution

The research question focuses on understanding what enabled Qatar’s oil and gas sector to absorb and recover from these events and how other sectors can increase their resilience by learning from the oil and gas experience. Because there is no scientifically accepted method for measuring organizational Resilience, it is interesting for this paper to focus on the main factors that describe organizational resilience characteristics, such as resources, strategy [

7], human capacity, organizational governance and culture, and processes and systems. Using the judgment of the oil & gas industry professionals, the study provides a ranking of the most important 10 REFs and their associated resilient themes or dimensions (RDs) developed by Wreathall [

2].

3. Research Methodology

This section presents the methodology used in this study.

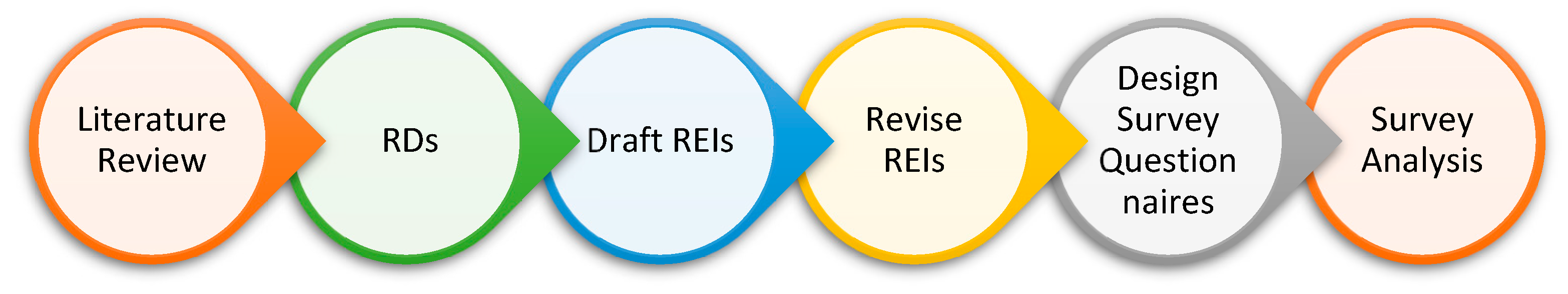

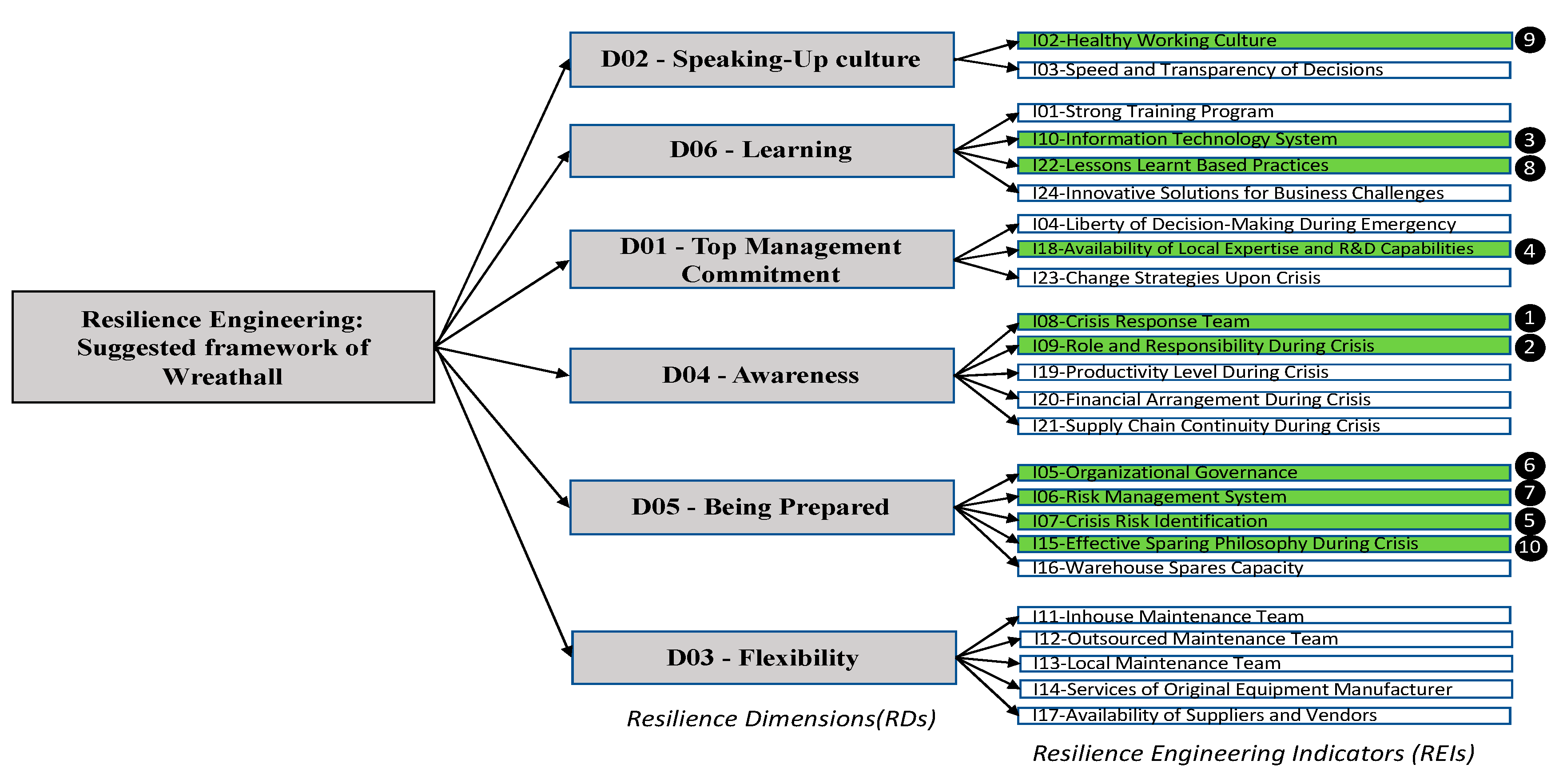

Figure 1 below depicts and explains the steps involved in the methodology applied in this study. This study has employed a qualitative research approach by first developing a draft list of resilient engineering indicators (REIs) gathered from literature relevant to resilience and complying with the resilient dimensions (RDs) developed by Wreathall [

2]. Then, a survey questionnaire assesses these indicators’ importance and relevance in building organizational resilience capacity.

To validate these REIs and its relevancy to the RDs along with the rating questions, a smaller focus group of senior management from the oil and gas sector was selected for its validation. The survey questionnaire was first sent in May 2022 to this focus group of 13 participants, mostly from the oil and gas and academic sectors. This validation process aimed to ensure that these questions are clearly understood, and it assesses the REIs and their impact on organization resilience. The respondents were instructed to assess the influence of these REIs on their organization based on a 5-point Likert Scale. The number of REIs and their relevance to these RFs were changed based on interviews with industry experts, and the survey questionnaire was modified and updated. As a result, a recommendation of 24 REIs was considered for this study.

The final survey questionnaire was designed with 34 questions, with six general questions about participants and their organization’s demographic information. It was followed by 24 ranking-based questions for the REIs, including general questions related to resilience management. Developing the questionnaire was through an online website tool called Survey Monkey website. The survey questionnaire was distributed to participants via the Survey Monkey website link. The survey questionnaire was sent in January 2023 to a larger sample, and 113 responses were collected. The survey result was then analyzed using statistical methods, which will be discussed in the subsequent sections.

4. Case Study: Organization Resilience: Lessons Learned from the Oil and Gas Sector in Qatar

4.1. Survey Structure

This study uses 24 developed REIs derived from the six resilience principles or dimensions to assess the main drivers for organizational Resilience in Qatar’s Oil and Gas sector, as listed in

Table 1. The six resilience dimensions (RDs) and some indicators are referred to in research made by [

1,

2,

10,

12] and as listed below:

Top Management Commitment: This dimension covers top management commitment-related indicators, as shown in

Table 1. Providing continuous monitoring for all human performance-related issues demonstrates the importance of human performance to the organization [

1,

2,

10,

12].

Speaking-Up culture: It covers speaking-up culture-related Indicators, as shown in

Table 1. for creating a culture that allows reporting issues and concerns throughout the organization without fearing punishment. Such a culture allows the organization to recognize and learn from its weaknesses [

1,

2,

10,

12].

Learning: It covers learning-related Indicators as shown in

Table 1 and indicates how much the organization learns from disruptive accidents and its own mistakes [

1,

2,

10,

12].

Awareness: This part covers awareness-related Indicators, as shown in

Table 1. Collecting data that provides management with insights into what is going on with a plant by analyzing the quality of human performance, the extent to which it is a problem, and the actions taken to defeat the problems [

1,

2,

10,

12].

Being Prepared: It covers being prepared related Indicators as shown in

Table 1. Being on top of issues concerning human performance and making sure that the organization is alerted and actively engaged in resolving these issues [

1,

2,

10,

12].

Flexibility: This dimension covers flexibility-related Indicators, as shown in

Table 1. This deals with the capability of an organization to cope with disruptive problems and to be able to resolve problems without impacting its functionality. Front-line supervisors must be given the authority to make necessary decisions to deal with situations during disruptive events without having to wait for approval from top management [

1,

2,

10,

12].

The survey participants were asked to assess the importance of the 24 REIs affecting organizational Resilience within the oil and gas sector as identified from the literature review. The 24 quantitative questions and its related resilience dimensions (RDs) are listed in

Table 1, namely (D01-Top Management Commitment, D02-Speaking-up Culture, D06-Learning, D04-Awareness, D05- Being Prepared, and D03-Flexibility). For the 24 REIs, the participants were requested to evaluate the attributes based on a 5-point Likert Scale (1= Strongly agree, 2= Agree, 3= Neither agree nor disagree, 4= Disagree, 5= Strongly disagree). For example, Q08. Does your organization have a strong training program for professional development? The participant was asked to choose the 5-point Likert Scale to answer this question.

4.2. Target Sample & Sample Size

The research questionnaire targets professionals and leaders of the oil and gas sector in the State of Qatar and other organizations (i.e., government employees of Qatar Ministry of Entergy and Qatar Energy, private sector, and academic institutions). The survey was circulated to around 200 practitioners and experts in the oil & gas industry. A total of 113 responses were received, which is an acceptable sample size, according to Azadeh et al. [

10], wherein the sample size was 99 participants.

4.3. Data Analysis

Data cleaning and preparation is a very important step to ensure that the results are not biased, and we don’t compromise the data quality. Before the analysis, the data were reviewed for unengaged responses, outliers, and data normality. The design of the questionnaire nonetheless permits certain values to be missing.

4.3.1. Data Screening for Careless Responses and Outliers

All the inputs by respondents were checked against outliers and careless responses. We examined participants’ responses to assess their level of attentiveness. The participants’ response patterns were analyzed to identify careless responses, where a respondent might repeatedly select the same response option for consecutive items, and outliers, which may indicate observations that significantly differ from the normal [

13]. Within the scope of this study, we measured careless responses by considering both the standard deviation and dimension ratings compared to the average factor ratings. Specifically, we found that two participants consistently provided identical answers, resulting in a standard deviation of zero.

Additionally, the two participants’ group ratings deviated significantly from the average factor ratings within their respective factors. We employed the Mahalanobis distance metric to identify potential multivariate outliers using multiple regression analysis within the SPSS software. In standard units, the Mahalanobis distance measures the squared distance between an observation’s vector and the vector of sample means for all variables [

13]. Notably, the probability associated with the Mahalanobis distance fell below 0.001 for four responses. Consequently, these four responses were removed from the dataset [

14], leaving us 109 out of the original 113 responses for further analysis.

4.3.2. Normality Test

The normality of the data can be assessed through two main approaches: visual methods (utilizing data histograms, box plots, and Q-Q plots) or numerical techniques (employing measures such as skewness, kurtosis, the Kolmogorov-Smirnov test, or the Shapiro-Wilk normality test). Therefore, the data collected underwent scrutiny for normality distribution using SPSS V26 software. We specifically examined skewness and kurtosis to evaluate the univariate normality of the data for each indicator. As per Pallant [

15], skewness reflects the symmetry of the distribution, while kurtosis describes the distribution’s peaks (distribution picks). A skewness and kurtosis value of zero signifies that the data is perfectly normal. However, it’s worth noting that different authors have differing criteria for acceptable skewness and kurtosis values to ensure adherence to normality assumptions, as observed by Byrne [

16]. As Kline [

17] suggests, absolute values exceeding 3 for skewness and 8 for kurtosis indices indicate severe deviations from normality. Additionally, as per the findings of Xiong et al. [

18], skewness and kurtosis values exceeding extreme thresholds serve as clear indications of non-normality. The normality tests for this study show that the absolute skewness values ranged from 0.009 to 2.468 for Indicators Q24 and Q18, respectively. The absolute kurtosis values ranged from 0.057 to 8.915 for factors Q36 to Q18. Both results are not within [

18] criteria. Moderate to severe skewness were observed for 6 Indicators (i.e., Q8, Q15, Q17, Q18, Q19 and Q21). Moderate to severe kurtosis were observed for 10 Indicators (i.e., Q8, Q9, Q14, Q15, Q17, Q18, Q19, Q21, Q27 and Q34).

In a Likert-scaled questionnaire, it is common that most respondents select the same scale point, leading to an extremely peaked distribution, resulting in a multivariate positive kurtotic distribution [

16]. We employ Maria’s coefficient along with its critical ratio to assess the multivariate kurtosis of the dataset. We employ Maria’s coefficient along with its critical ratio to assess the multivariate kurtosis of the dataset. The dataset is considered to meet the assumption of multivariate normality when the critical ratio (c.r.) falls below 1.96 at a significance level of 0.05. Consequently, the coefficient of multivariate kurtosis approaches nearly zero. A high-value demonstration in Maria’s coefficient suggests of significant positive kurtosis [

16]. However, in the present dataset, the z-statistic (c.r.) of 9.85, as depicted in Table 3.2, strongly suggests non-normality within the dataset.

Considering the uncertainty arising from the skewness and kurtosis tests, we further investigated the univariate normality of the data using the Shapiro-Wilk normality test (Ws) within SPSS. As recommended by [

19], nonparametric statistical methods are advisable when dealing with fewer than 30 experts or when responses exhibit non-normal distribution, as indicated by skewness. The Shapiro-Wilk Test is particularly well-suited for assessing normality in small sample sizes. A data distribution significantly deviates from normality if the p-value is less than 0.05 [

20,

21]. The Shapiro-Wilk test (Ws) evaluates the correlation between the provided data and the ideal normal scores. A test value closer to one signifies that the data approximates a normal distribution and supports accepting the null hypothesis, indicating that the data is normally distributed. The formula for the W value is:

Where:

|

constants generated from the covariances, variances, and means of the sample from a normally distributed sample |

|

order statistic of a statistical sample |

|

sample values |

|

sample size |

|

sample mean |

As shown in Table 3, The outcome of the Ws test showed that for all indicators, i.e., 24 out of 24 indicators, p-values were consistently below 0.05 and thus is evidence of data non-normality [

21,

22]. Based on the preceding information, nonparametric estimates are employed in the subsequent sections.

Table 2.

Examination of normality of Indicators by the Skewness, Kurtosis values, and Shapiro-Wilk.

Table 2.

Examination of normality of Indicators by the Skewness, Kurtosis values, and Shapiro-Wilk.

| Code |

skew and kurtosis |

Shapiro-Wilk |

| skew |

c.r. |

kurtosis |

c.r. |

Statistic |

p-value |

| I01 |

-0.808 |

-3.444 |

0.131 |

0.279 |

0.857 |

0.000 |

| I02 |

-0.963 |

-4.106 |

1.041 |

2.218 |

0.814 |

0.000 |

| I03 |

-0.776 |

-3.308 |

0.107 |

0.227 |

0.836 |

0.000 |

| I04 |

-0.471 |

-2.007 |

-0.357 |

-0.761 |

0.885 |

0.000 |

| I05 |

-0.984 |

-4.196 |

1.05 |

2.238 |

0.771 |

0.000 |

| I06 |

-1.234 |

-5.261 |

2.252 |

4.799 |

0.771 |

0.000 |

| I07 |

-1.392 |

-5.933 |

2.052 |

4.372 |

0.760 |

0.000 |

| I08 |

-2.434 |

-10.375 |

8.457 |

18.023 |

0.609 |

0.000 |

| I09 |

-1.144 |

-4.875 |

1.185 |

2.525 |

0.733 |

0.000 |

| I10 |

-1.16 |

-4.942 |

1.128 |

2.404 |

0.744 |

0.000 |

| I11 |

-0.542 |

-2.31 |

-0.461 |

-0.981 |

0.868 |

0.000 |

| I12 |

-0.192 |

-0.817 |

-0.443 |

-0.944 |

0.855 |

0.000 |

| I13 |

-0.009 |

-0.04 |

-0.459 |

-0.979 |

0.863 |

0.000 |

| I14 |

-0.396 |

-1.689 |

-0.346 |

-0.737 |

0.856 |

0.000 |

| I15 |

-0.97 |

-4.132 |

1.159 |

2.47 |

0.807 |

0.000 |

| I16 |

-0.504 |

-2.15 |

-0.275 |

-0.586 |

0.848 |

0.000 |

| I17 |

-0.021 |

-0.091 |

-0.382 |

-0.815 |

0.879 |

0.000 |

| I18 |

-0.624 |

-2.66 |

-0.477 |

-1.017 |

0.792 |

0.000 |

| I19 |

-0.186 |

-0.795 |

-1.045 |

-2.227 |

0.890 |

0.000 |

| I20 |

-0.544 |

-2.318 |

-0.255 |

-0.544 |

0.877 |

0.000 |

| I21 |

-0.471 |

-2.007 |

-0.109 |

-0.232 |

0.868 |

0.000 |

| I22 |

-0.81 |

-3.453 |

0.383 |

0.816 |

0.794 |

0.000 |

| I23 |

-0.261 |

-1.113 |

-0.202 |

-0.431 |

0.880 |

0.000 |

| I24 |

-0.651 |

-2.776 |

0.353 |

0.752 |

0.853 |

0.000 |

4.3.3. Cronbach Alpha

When developing research using Likert Scale data, an important consideration is the questionnaire’s internal consistency. To assess this internal consistency, researchers commonly rely on a widely recommended method, the application of Cronbach’s Alpha coefficient of reliability [

15]. In this research, we employ Cronbach’s Alpha coefficient to validate that the Likert Scale measures align with the hypothesis, in line with the Resilience Engineering Indicators (REIs) within the oil and gas sector we intend to assess. Cronbach’s Alpha values range from 0 to 1, “A value of 0.7 is considered acceptable, and 0.8 or higher indicates good internal consistency” [

15]. The Cronbach’s Alpha coefficient formula is:

Where:

|

= |

the number of items (factors) |

|

= |

correlation between the items |

The alpha value (∝) increases as the value of k rises. Additionally, a higher Alpha is observed when the items have substantial inter-correlation. The general guideline for Alpha values that typically applies in most situations is as follows:

| - The reliability can be considered as excellent when, |

0.9 ≤ ∝ ≤ 1.0 |

| - The reliability can be considered as good when, |

0.8 ≤ ∝ < 0.9 |

| - The reliability can be considered as acceptable when, |

0.7 ≤ ∝ < 0.8 |

| - The reliability can be considered as questionable when, |

0.6 ≤ ∝ < 0.7 |

| - The reliability can be considered as poor when, |

0.5 ≤ ∝ < 0.6 |

| - The reliability can be considered as unacceptable when, |

0.0 ≤ ∝ < 0.5. |

We calculated the Cronbach Alpha value for the survey data using the Statistical Package for the Social Sciences (SPSS v.26). The obtained coefficient value, which is 0.869, demonstrates a high level of consistency, as indicated in

Table 3.

We employed the reliability coefficient, Cronbach’s alpha (α), from the SPSS package to evaluate the overall scale’s consistency, with a predefined threshold of 0.7 [

13]. The reliability analysis results for all variables in this study are presented in

Table 3, where all values exceed 0.857. Therefore, the data provided by the respondents exhibit both consistency and reliability, making them suitable for further analysis [

21]. Additionally, the alpha value for the entire dataset, measuring 0.869, indicates that the questionnaire scale has achieved acceptable internal consistency and reliability.

5. Results & Discussion

The data was collected from the Survey Monkey website, which was reviewed and analyzed. The incomplete responses were discarded, and only the complete responses were selected for the analysis, leading to 113 completed questionnaires. IBM SPSS software version 26 was used for statistical and data analysis.

5.1. Respondents Profile

Respondents’ profiles are provided based on numerous classification factors such as sector, job family, experience, and level of Resilience. A breakdown of the respondents’ profiles is presented in

Table 4, and their details are covered in the following sections.

5.2. Ranking Approach

5.2.1. Relative Importance Index (RII)

One of the aims of this study is to gather insights from professionals in the oil and gas industry regarding the most notable REIs. Participants in the survey assessed each REF using a 5-point Likert Scale. The collected data was then analyzed to compute the RII values for each factor. These REIs were subsequently organized in ascending order based on their RII values. To illustrate, a REF with a ranking of 1 signifies the highest level of agreement regarding its impact on organizational Resilience. At the same time, the REF ranked 24th is perceived as the least significant by the participants.

The Relative Importance Index (RII) is employed to establish rankings based on the degree of agreement for each REF. To assess the importance of these resilient indicators and Dimensions, a 5-point Likert Scale was utilized. The RII value falls from 0 to 1, with a higher value signifying greater agreement. The Relative Importance Index has been widely adopted in various studies to rank Dimensions, including several studies in Engineering Management. This method is commonly used to investigate and establish rankings for Indicators based on their relative significance [

22,

23,

24,

25]. The authors employed the Relative Importance Index (RII) to assess and arrange the data gathered from the questionnaires. Thus, the calculation of RII can be performed according to the formula presented in Equation 3 below:

Where:

|

= |

The weight given to each factor by the respondents (1 to 5) |

|

= |

The highest weight (in this case, the highest weight is 5) |

|

= |

The total number of responses |

RII value ranges from 0 to 1, with a value approaching 1 given more importance than the others lesser than that. According to [

26], the RII ranking is as follows:

| - The RII can be considered as high when, |

0.8 ≤ RII ≤ 1.0 |

| - The RII can be considered as High-Medium when, |

0.6 ≤ RII < 0.8 |

| - The RII can be considered as Medium when, |

0.4 ≤ RII < 0.6 |

| - The RII can be considered as Medium-Low when, |

0.2 ≤ RII < 0.4 |

| - The RII can be considered as Low when, |

0.0 ≤ RII < 0.2 |

Table 5 below displays the RII values and the rankings of the proposed REIs, determined through the agreement scale values provided by all the survey respondents.

The results indicate that the REIs affecting resilience performance have different significance levels, as listed in

Table 5. The list of REIs is associated with building organizational capacity (human and systems) and developing the right culture to deal with crises. It is important to note that organizational resilience can be built by effectively implementing these REIs through a competent team working towards achieving the organization’s objectives.

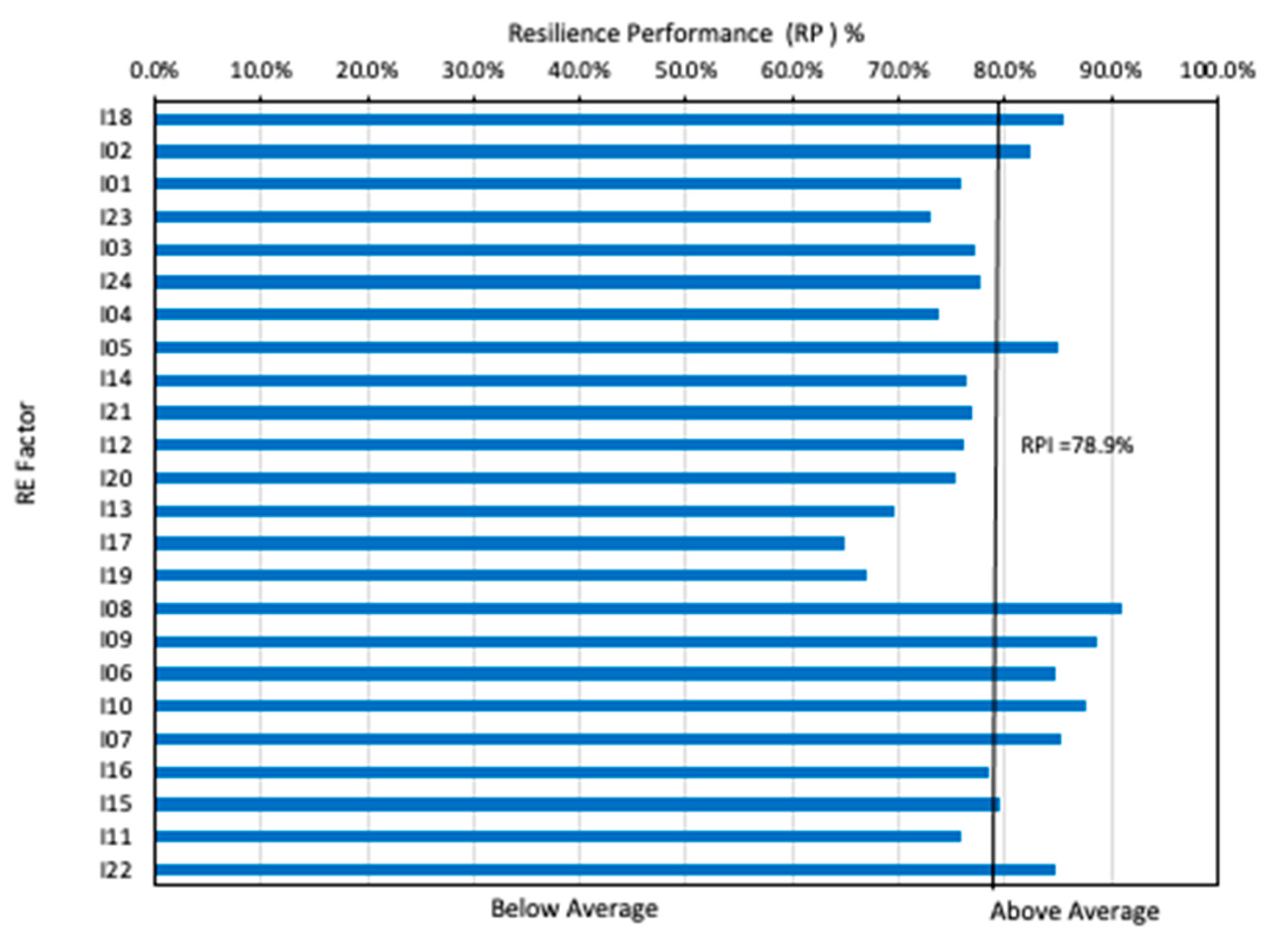

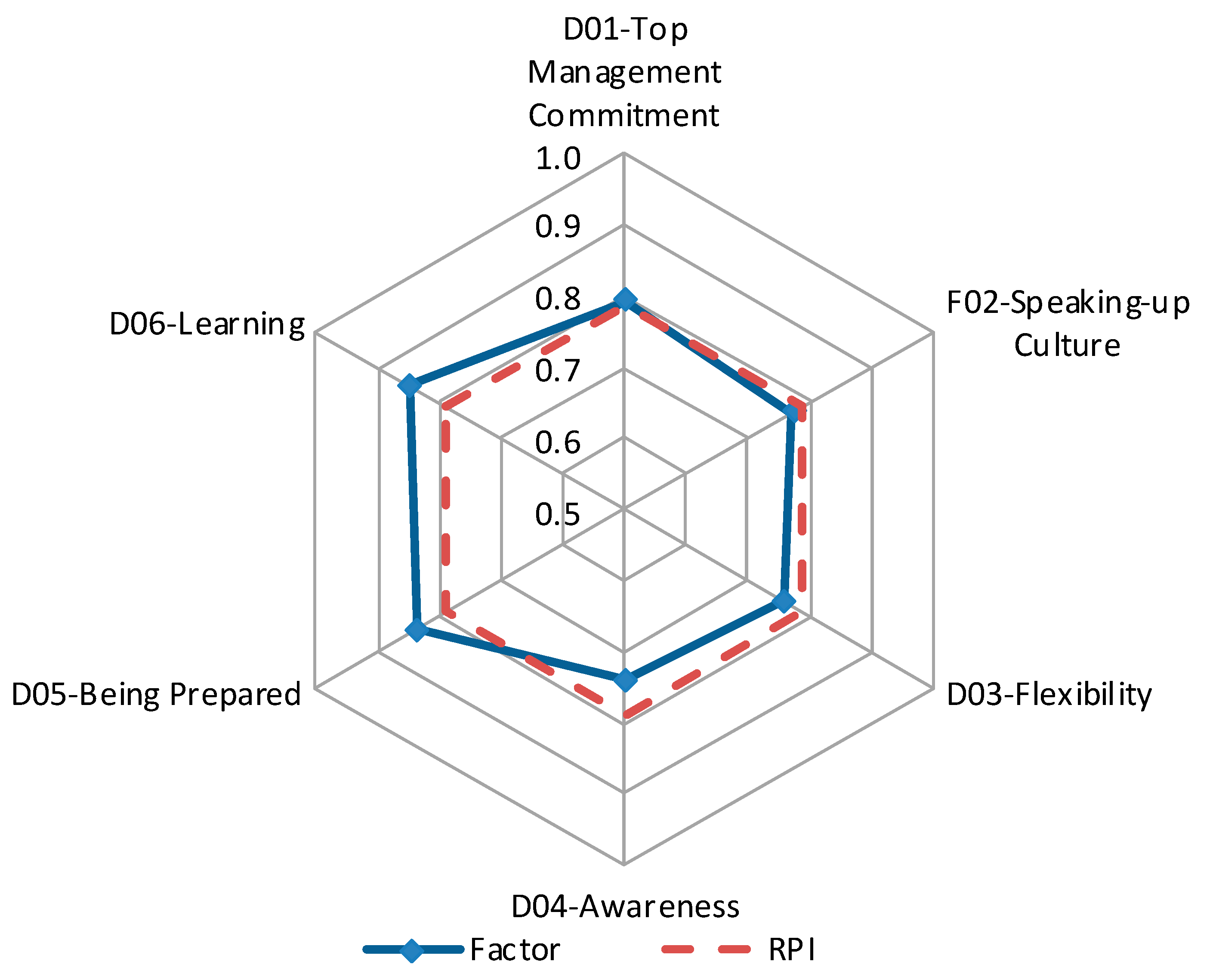

The result of the Relative importance index revealed the relative impact of REIs and its relation to the resilience dimensions, as shown below in

Figure 2.

5.2.2. Resilience Performance Index (RPI)

The main finding of this study was that the Resilience Engineering Indicators (REF) could be represented by a single index “Resilience Performance Index (RPI). RPI contains 24 constructs representing the REIs as distributed in 6 dimensions (i.e., D01- Top Management Commitment, D02-Speaking-up Culture, D03-Flexibility, D04-Awareness, D05-Being Prepared, and D06-Learning).

It is important to note that the weight of each resilience factor shall play a role in the overall performance. The Relative importance index would reveal the relative impact of REIs on resilience performance. Therefore, the Resilience Performance Index (RPI) represented the average percentage of the relative importance indices of the 24 indicators. The formula expressed for RPI calculation is shown in Equation 4.

Where:

|

= |

Relative Importance Index of Indicator |

|

= |

Number of Indicators under consideration |

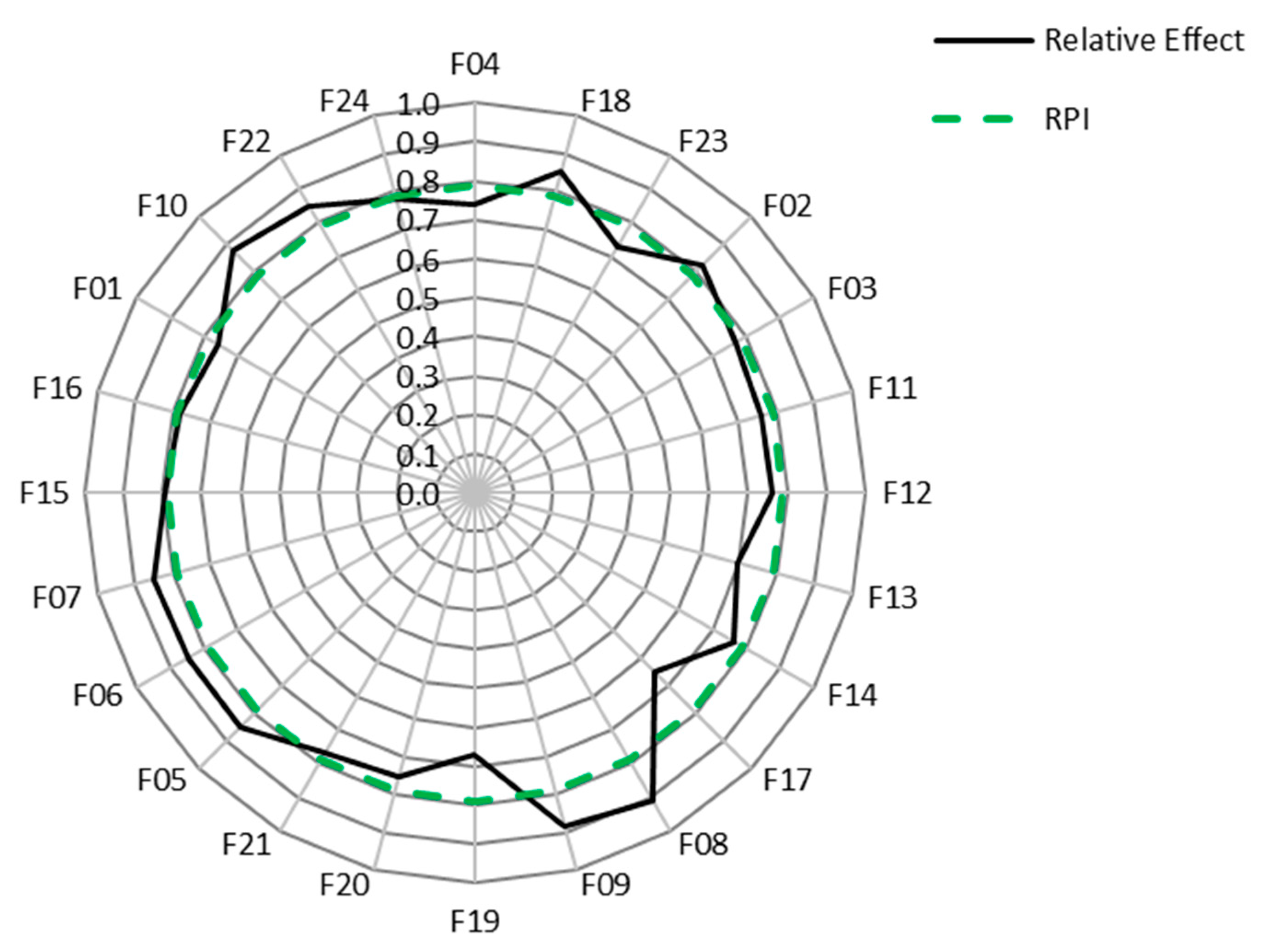

The weight of these 24 Indicators is shown below in

Figure 3, which shows almost a balanced disruption on the radar chart.

The relative contribution of each indicator to the RPI was calculated according to the formula presented above, and the RPI for the resilience level of the Oil and Gas sector in Qatar is 78.9 % or almost 80 %, which according to Rooshdi et al. [

26] can be considered as high level. In other words, Qatar’s Oil and Gas sector showed a high resilience level based on the level of calculated RPI, almost 80%.

Figure 4.

Relative effects of RE dimensions.

Figure 4.

Relative effects of RE dimensions.

5.2.3. Dimensions Performance Index (DPI)

Following the same concept of RPI as presented in Equation 4, the factor performance by a single index “Dimensions Performance Index (DPI) was calculated as we know that we have five resilience Dimensions namely F01-Top Management Commitment, F02-Speaking-up Culture, F03-Flexibility, F04-Awareness, D05-Being Prepared, and D06-Learning which has 3, 2, 5,5,5,4 REIs respectively as depicted in

Figure 5 below.

The resultant FPI scores are listed in

Table 6, and

Figure 6 shows the FPI score distribution concerning Resilience Dimensions.

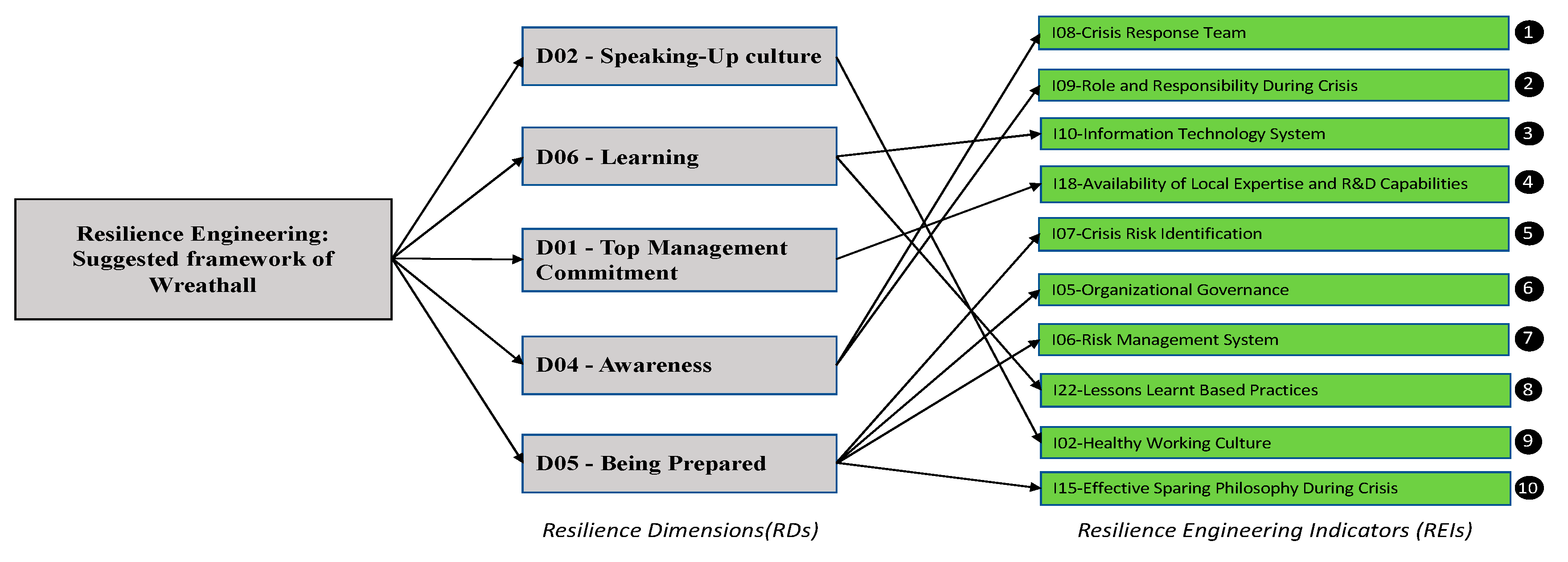

5.3. Discussion of Resilience Indicators and Dimensions

Table 7 provides a detailed listing of the resilience dimensions and their relevant REIs with their ranks. It is worth noting that the top-rated 10 REIs are only part of five resilient dimensions out of six: D05-Being Prepared, D06-Learning, D04-Awareness, D02-Speaking-Up Culture, and D01-Top Management. D05-Being Prepared is ranked as 1st dimension with a Dimensions Performance Index (DPI) score of 0.820 and has four of the top10-rated REIs; these REIs, as listed in the table, are I06-Risk Management System, I05-Organizational Governance, I07-Crisis Risk Identification, and I15-Effective Sparing Philosophy During Crisis. The D06- Learning dimension is ranked as 2nd dimension with DPI of 0.820 and has two of the top 10-rated REIs, namely I10-Information Technology System and I22-Lessons Learned Best Practices. D04-Awareness was ranked as the 3rd dimension with DPI of 0.798 and had two of the top 10-rated REIs, which are I08-Crisis Response Team and I09-Role and Responsibility During Crisis. D02 -Speaking-up Culture dimension was ranked 4th dimension with DPI of 0.798 and had one of the top 10-rated REIs, which is I02- Healthy Working Culture. The next dimension with one of the top 10-rated REI is F01- Top Management Commitment dimension and was ranked as the 5th dimension with DPI of 0.774. It has one REIs, I18- Availability of Local Expertise and R&D Capabilities. The final dimension, D03-Flexibity, did not have any of the top 10-rated REIs.

6. Conclusion and Recommendations

There is no doubt that Qatar’s oil and gas sector demonstrated resilience capacity; this was tested during disruptive events such as the June 2017 blockade by some of the GCC neighboring countries or the recent pandemic of COVID-19. As per

Table 4, 70.4% of participating organizations in this study had a high level of Resilience, and approximately 25% had a moderate level of Resilience. Therefore, measuring resilience engineering Indicators REIs for these organizations will lead to a good understanding of what made them resilient. The approach followed in this study is to assess these organizations based on how well they comply with the identified REIs, which were derived from RDs developed by Wreathall [

2]. The main interest is identifying the characteristics of resilient organizations, such as resources, strategies, and behaviors that strengthen organizational Resilience [

7]. Participants were asked to evaluate these REFs based on their importance to their organizations, which resulted in making resilience organizations.

Based on the outcome of this study, the RII values and ranking of proposed resilience engineering Indicators (REIs) were calculated based on agreement scale values from all the participants.

We found that the ten most critical resilience indicators indicate building a crisis response team with defined roles and responsibilities during the crisis, developing an Information Technology System(IT), ensuring the availability of local expertise and R&D capabilities, ensuring the availability of suppliers and vendors, and the support of services of Original Equipment Manufacturer (OEM), and ensuring the supply of materials and spare part to avoid operation disruptions along with developing risk management system, and building continues improvements system to capture lessons learned and implement best practices, as well as making sure that the working environment is a healthy working culture that encourages speaking up and reporting issues and concerns to be addressed on timely faction. The following

Figure 7. highlights the RDs and their related REIs.

In conclusion, this research provides resilience engineering Indicators (REIs) that can be applied to improve organizational Resilience. These indicators are descriptive of the outcome of resilient organizations, which can be used to build organizational resilience. Such an outcome of this study supports the national preparedness and readiness to handle emergencies and unpredictable, disruptive events, learning from the successful resilience model of Qatar’s oil and gas sector. These indicators can be integrated into different institutions’ strategies to improve the efforts and enhance governance of national response. Furthermore, participants in this study provided feedback (as a response to question #29), and as a result, the researchers would recommend the following points to improve the organization’s performance:

Develop immediate response plan (IRP) or Be-Well Prepared plans or backup plans as supported by lessons learned and best practices for more flexibility and innovation in managing business with minimal human interference.

Adopt fast digital transformation and Artificial Intelligence digitalization programming.

Develop structured training for all employees on crisis management. This also includes the COVID Task Force to mitigate any future threat.

Increase investment in internal R&D and Qatari talent to develop local expertise.

Implement a more dynamic Human Resources Process and

Empower the local market and build relationships with more reliable suppliers.

This study has a limitation in using organizational resilience lagging indicators to build the foundation of organizational resilience. This is an opportunity for future work to analyze leading indicators to build Resilience.

The research findings, as well as the limitations of the research, pave the way for future research. The following are the possibilities to extend this research by conducting case studies on specific oil and gas companies to validate these resilience Indicators for future applications. Develop a Resilience Framework using the study outcome of these REIs. Develop organization resilience assessment tools to measure organizational Resilience and identify gaps. They are developing a set of tools to help the implementation of Resilience for different organizations.

Author Contributions

Conceptualization, IA, KN and AH; methodology, IA and AH; formal analysis and investigation, IA; writing—original draft preparation, IA; AMH; KN, and GA writing—review and editing, IA, AMH, GA and HN; supervision, KN and AH; and GA. All authors have read and agreed to the published version of the manuscript.

Funding

Open Access funding provided by the Qatar National Library. This publication was made possible particially by NPRP14C-0920-210017 provided by Qatar National Research fund (a member of Qatar foundation). The findings achieved herein are solely the responsibilities of the authors.

Data Availability

Data and models generated or used during the study are available from the corresponding author by request.

Acknowledgments

Open Access funding provided by the Qatar National.

Conflicts of Interest

The authors declare no conflict of interest.

References

- M. F. Costella, T. A. Saurin and L. B. d. M. Guimarães, “A method for assessing health and safety management systems from the resilience engineering perspective,” Safety Science, p. 1056–1067, 2009. [CrossRef]

- J. Wreathall, “Properties of Resilient Organizations: An Initial View,” in Resilience Engineering Concepts and Precepts, Aldershot, Ashgate Publishing Limited, 2006, pp. 275-286.

- E. Hollnagel and D. D. Woods, JOINT COGNITIVE SYSTEMS Foundations of Cognitive Systems Engineering, Boca Raton, FL: CRC Press Taylor & Francis Group, 2005.

- World Economics, “World Economics,” April 2023. [Online]. Available: https://www.worldeconomics.com/Wealth/Qatar.aspx.

- I. G. Union, “13th edition of the IGU World LNG Report,” International Gas Union (IGU), London United Kingdom, 2022.

- S. Al-Haidous, R. Govindan, A. Elomri and T. Al-Ansari, “An optimization approach to increasing sustainability and enhancing resilience against environmental constraints in LNG supply chains: A Qatar case study,” Energy Reports, p. 9742–9756, 2022. [CrossRef]

- F. Bento, L. Garotti and M. P. Mercado, “Organizational resilience in the oil and gas industry: A scoping review,” Safety Science, pp. 1-11, 2020. [CrossRef]

- S. Hosseini, K. Barker and J. E. Ramirez-Marquez, “A review of definitions and measures of system resilience,” Reliability Engineering and System Safety, p. 47–61, 2016. [CrossRef]

- American Society of Mechanical Engineers (ASME), Innovative Technological Institute (ITI), Washington, DC: ASME ITI, 2009.

- A. Azadeh, S. M. Asadzadeh and M. Tanhaeean, “A consensus-based AHP for improved assessment of resilience engineering in maintenance organizations,” Journal of Loss Prevention in the Process Industries, pp. 151-160, 2017. [CrossRef]

- C. Nemeth and R. Cook, “Infusing Healthcare with Resilience,” INCOSE, pp. 1073-1087, 2014. [CrossRef]

- A. Azadeh, V. Salehi, B. Ashjari and M. Saberi, “Performance evaluation of integrated resilience engineeringfactors by data envelopment analysis: The case of apetrochemical plant,” Process Safety and Environmental Protection, pp. 231-241, 2014. [CrossRef]

- J. F. Hair, W. C. Black, B. J. Babin and R. E. Anderson, Multivariate data analysis (7th Edition ed.), New Jersey, United States: Pearson, 2014.

- M. S. Pamulu, “Strategic management practices in the construction industry: a study of Indonesian enterprises,” Queensland University of Technology, Queensland, Australia., 2010.

- J. Pallant, “Survival manual: A step by step guide to data analysis using SPSS (4th edition ed.),” 2011.

- B. M. Byrne, Structural equation modeling with AMOS: Basic concepts, applications, and programming, New York: Taylor & Francis Group, 2010.

- R. B. Kline, “Principles and practice of structural equation modeling,” 2015.

- B. Xiong, M. Skitmore and B. Xia, “A critical review of structural equation modeling applications in construction research,” Automation in Construction, vol. 49, pp. 59-70, 2015. [CrossRef]

- S. Kalaian and R. M. Kasim, “Terminating Sequential Delphi Survey Data Collection,” Practical Assessment, Research, and Evaluation, pp. Vol 17, No 5, 2012.

- A. Field, “Discovering statistics using SPSS (3 ed.),” 2009.

- H. Zahoor, A. P. C. Chan, R. Gao and W. P. Utama, “The factors contributing to construction accidents in Pakistan: their prioritization using the Delphi technique,” Engineering, Construction and Architectural Management, vol. 24, no. 3, pp. 463-485, 2017. [CrossRef]

- M. A. Seboru, “An Investigation into Factors Causing Delays in Road Construction Projects in Kenya,” American Journal of Civil Engineering, 2015. [CrossRef]

- G. A. Bekr, “Factors affecting performance of construction projects in unstable political and economic situations,” ARPN Journal of Engineering and Applied Sciences, vol. 12, no. 19, pp. 5384-5395, 2017.

- M. Gunduz, Y. Nielsen and M. Ozdemir, “Fuzzy Assessment Model to Estimate the Probability of Delay in Turkish Construction Projects,” Journal of Management in Engineering, vol. 31, no. 4, 2015. [CrossRef]

- A. L. Sambowo and A. Hidayatno, “Resilience Index Development for the Manufacturing Industry based on Robustness, Resourcefulness, Redundancy, and Rapidity,” International Journal of Technology, pp. 1177-1186, 2021. [CrossRef]

- R. R. R. M. Rooshdi, M. Z. Abd Majid, S. R. Sahamir and N. A. A. Ismail, “Relative importance index of sustainable design and construction activities criteria for green highway,” Chemical Engineering Transactions, vol. 63, pp. 151-156, 2018.

- A. P. C. Chan, F. K. W. Wong, C. K. H. Hon, A. Ali Javed and S. Lyu, “Construction safety and health problems of ethnic minority workers in Hong Kong. Engineering, Construction and Architectural Management,” Engineering, Construction and Architectural Management, pp. 901-919, 2017. [CrossRef]

- A. S. Faridi and S. M. El-Sayegh, “Significant factors causing delay in the UAE construction industry,” Construction management and economics, vol. 24, no. 11, pp. 1167-1176, 2006. [CrossRef]

- Z. Zamiar and Z. Ścibiorek, “The role of information in crisis management,” Scientific Journal of the Military University of Land Forces, pp. 245-255, 2022.

- C. Folke, S. R. Carpenter, B. Walker, M. Scheffer, T. Chapin and J. Rockström, “Resilience Thinking: Integrating Resilience, Adaptability and Transformability,” Ecology and Society 15(4): 20, p. 15(4): 20, 2010.

- Y. Kim, “Building organizational resilience through strategic internal communication and organization–employee relationships,” JOURNAL OF APPLIED COMMUNICATION RESEARCH, p. 589–608, 2021. [CrossRef]

- S. Margheritti, A. Gragnano, R. Villa, M. Invernizzi, M. Ghetti and M. Miglioretti, “Being an Emotional Business Leader in the Time of the COVID-19 Pandemic: The Importance of Emotions during a Crisis,” Sustainability, pp. 15(4), 3392, 2023. [CrossRef]

- I. I. PRATIWI, A. APRIANINGSIH, M. Z. AFIF and A. P. PUTRI, “Proposed Model of Business Retail Continuity Process during Pandemic Covid-19 Based on Risk identification and Response,” CEEOL, pp. 12-07, 2021.

- E. HOLLNAGEL, D. D. WOODS and N. LEVESON, Resilience Engineering Concepts and Precepts, Aldershot, UK: Ashgate Publishing Limited, 2006.

- S. Nassereddine, “Corporate governance between the theoretical framework and application mechanisms: literature review,” Journal of Financial, Accounting and Managerial Studies, pp. 337-358, 2022.

- A. Yahya, “Analysis of project success factors in Middle east construction industry,” American University of Sharjah, 2014.

- M. Li, “A waste management system for small and medium enterprises engaged in office building retrofit projects. (Doctor of Philosophy),” Queensland University of Technology, Queensland, Australia, 2012.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).