Submitted:

01 November 2023

Posted:

02 November 2023

Read the latest preprint version here

Abstract

Keywords:

1. Introduction

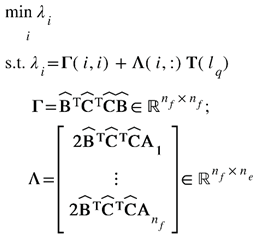

- It extends the 2D thermal model and objective function of the original SmartScan (Ramani et al., 2022) to incorporate 3D thermal effects, while introducing simplifying assumptions to reduce computational complexity due to larger model sizes.

- It generalizes the original SmartScan modeling and optimization methods to enable them to handle arbitrary scan patterns with scan vectors of varying lengths and inclination angles within each layer.

- It addresses the greedy (myopic) optimization strategy of prior versions of SmartScan by incorporating global foresight into the generalized SmartScan, enabling it to optimize temperature distribution more effectively in 3D parts with overhangs and other geometric features that can trap heat.

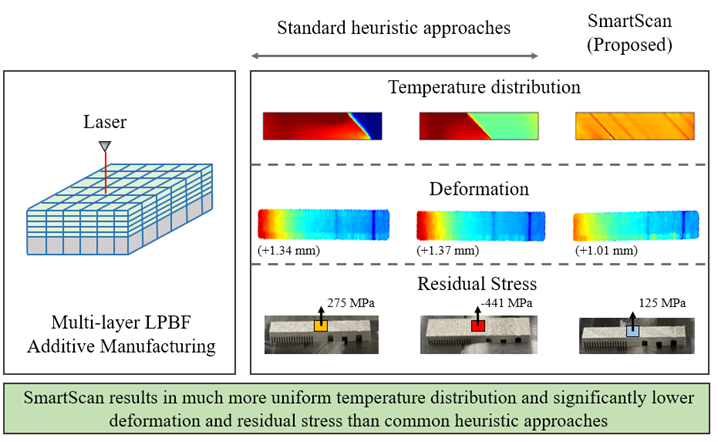

- It validates the effectiveness of the generalized SmartScan through simulations and experiments involving the printing of a complex 3D shape using AISI 316L stainless steel. The results demonstrate significantly reduced thermal inhomogeneity, residual stress, and distortion compared to standard heuristic scan sequences, at the expense of some increases in surface roughness.

2. Methodology

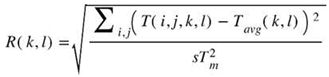

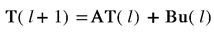

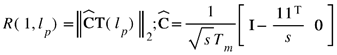

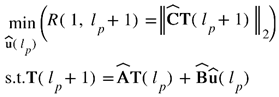

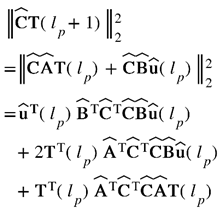

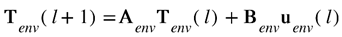

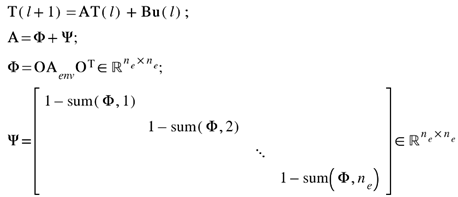

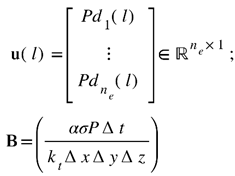

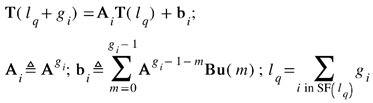

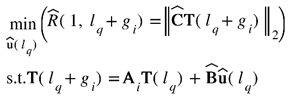

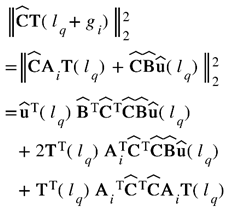

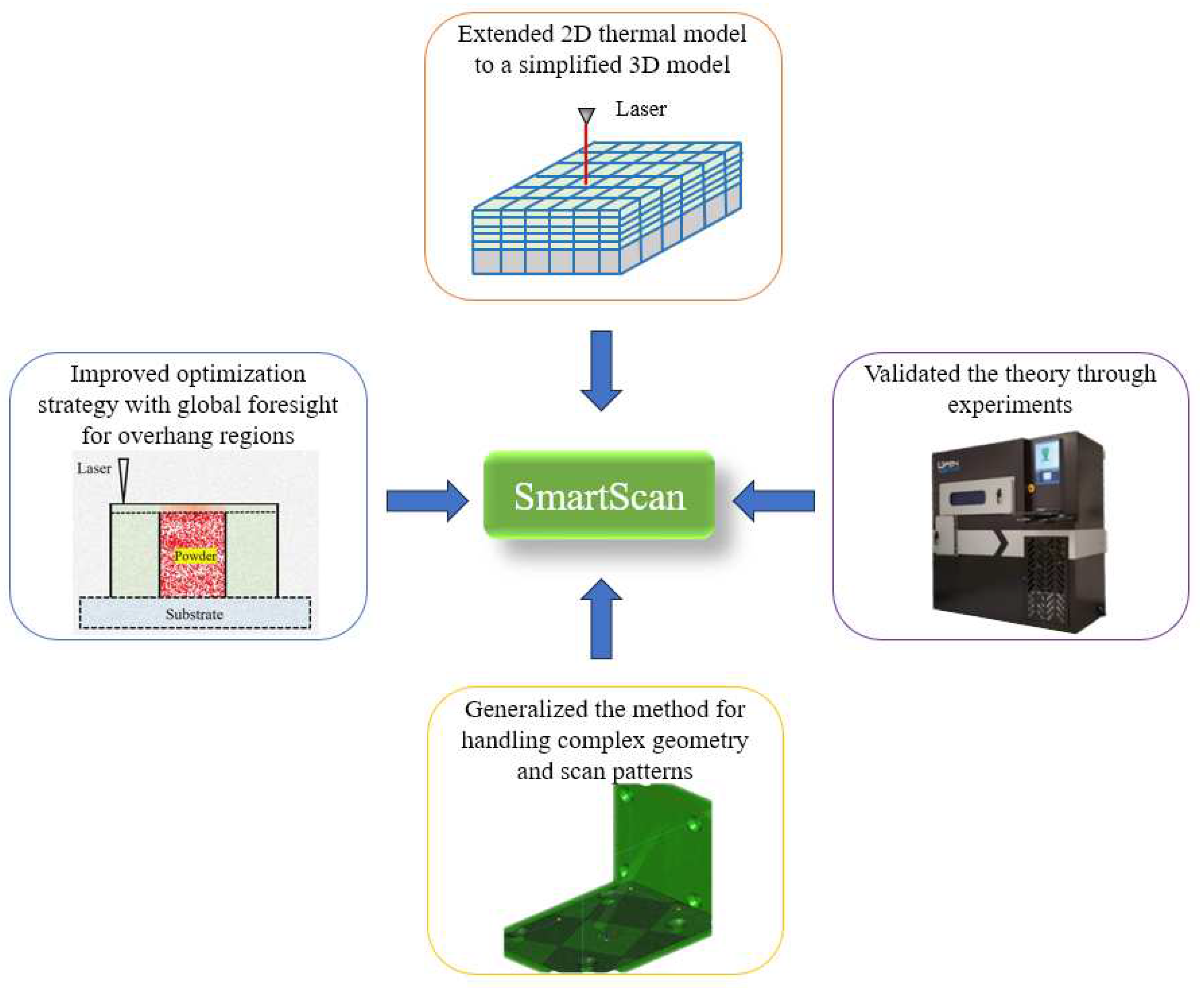

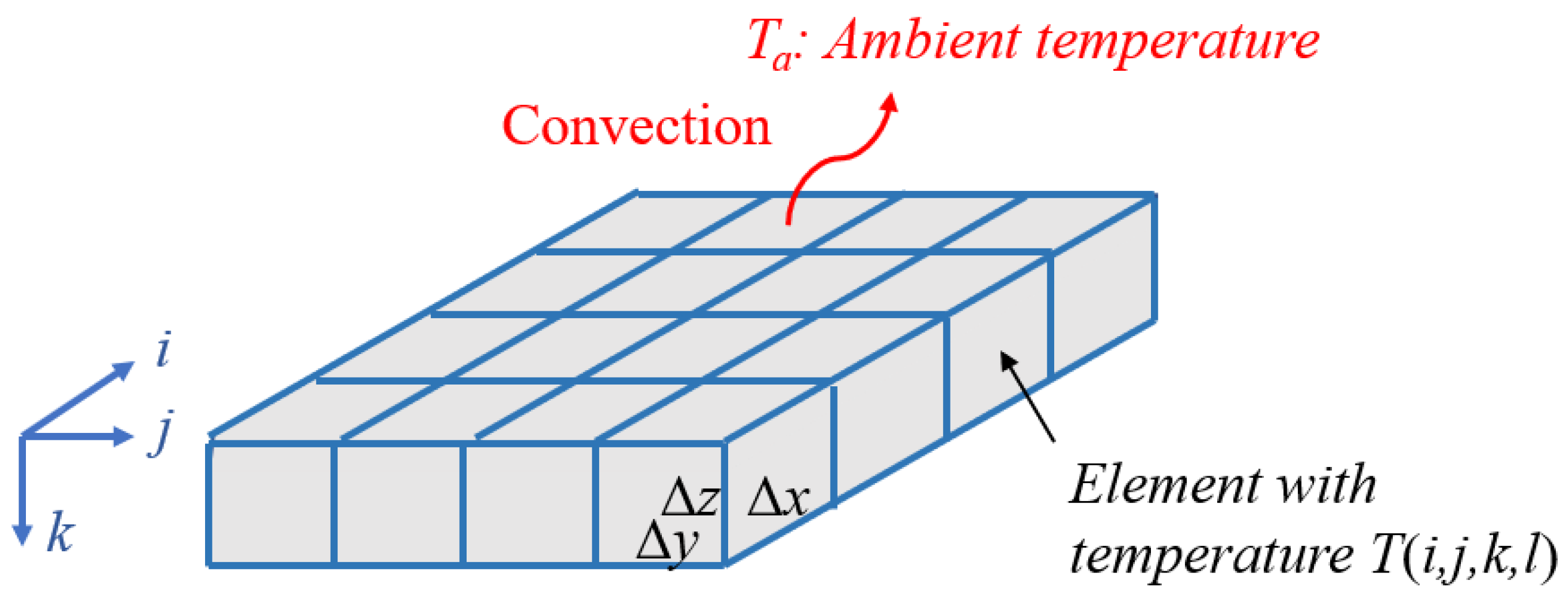

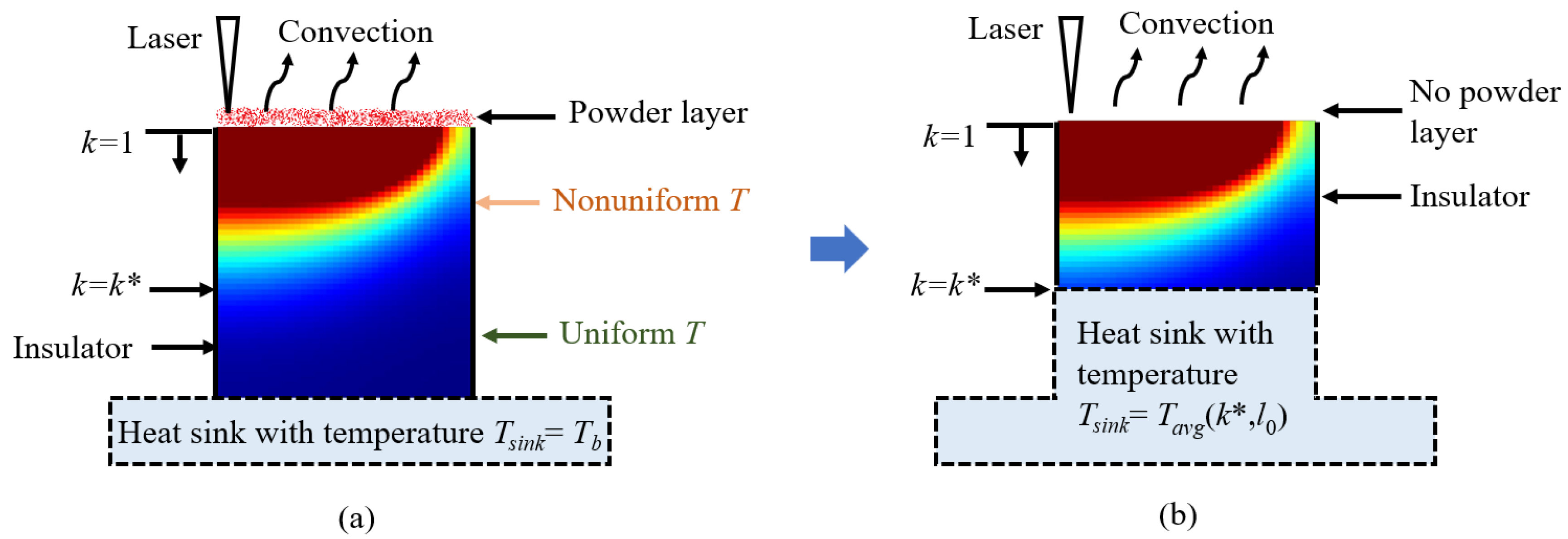

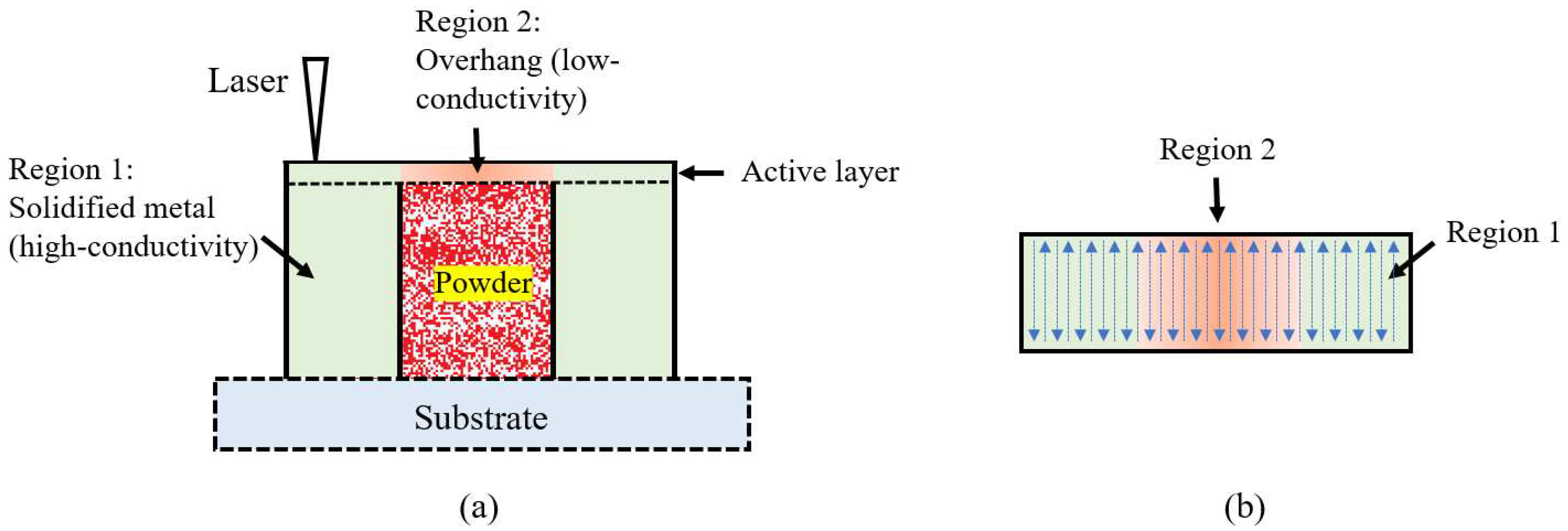

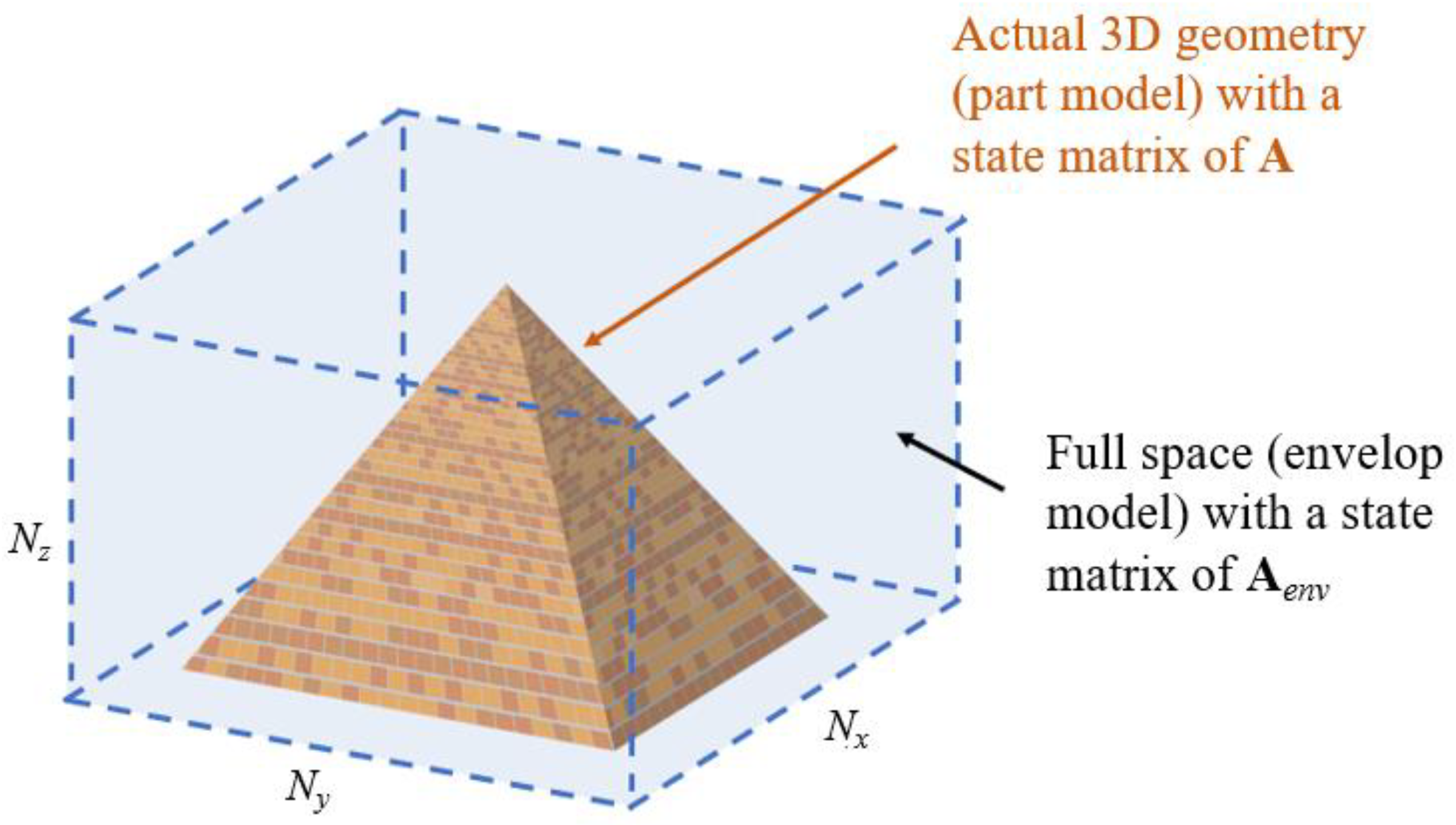

2.1. Extension of SmartScan Thermal Model and Optimization to Multiple Layers

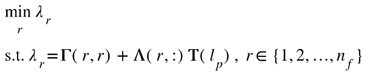

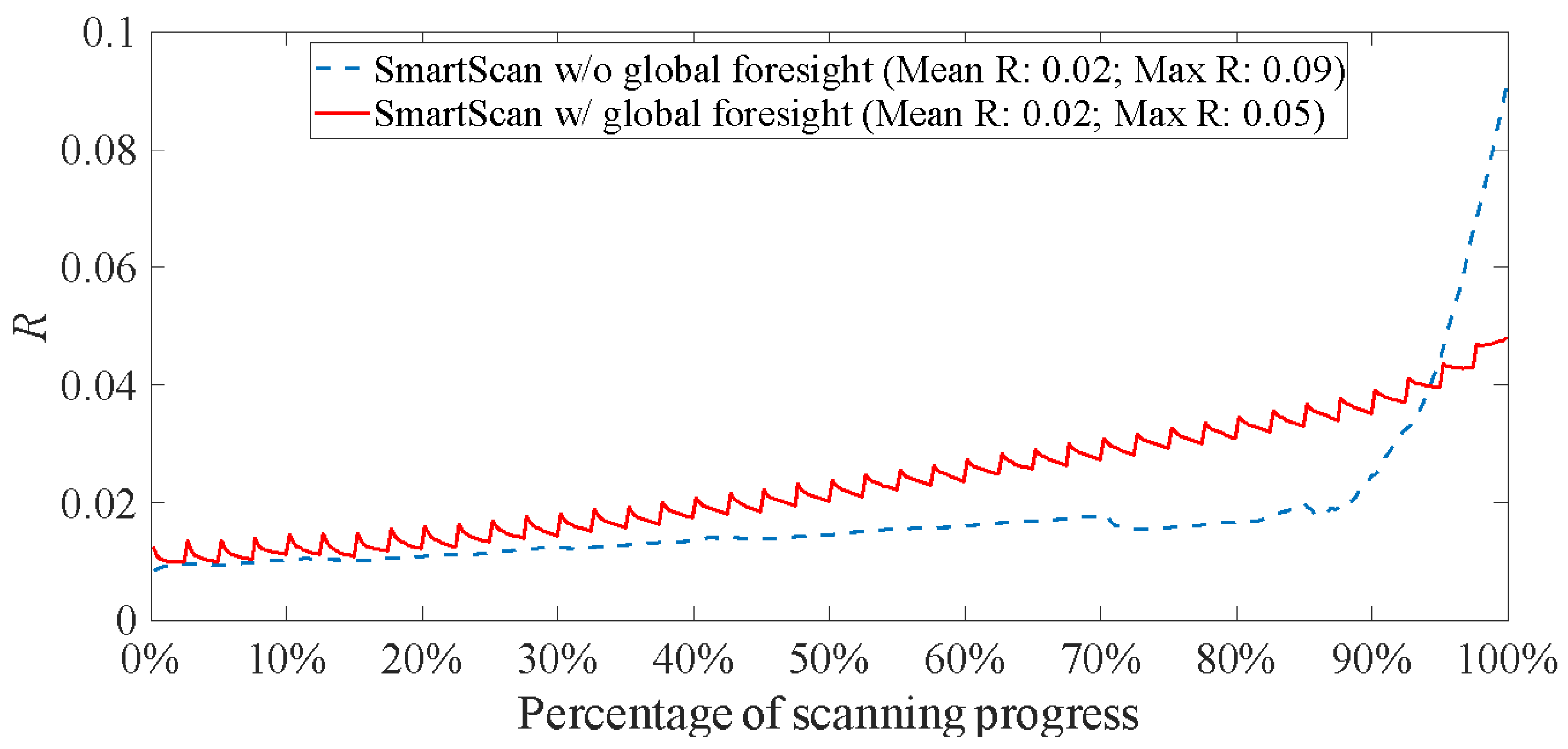

2.2. Providing SmartScan with Global Foresight

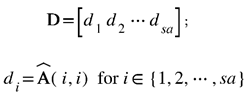

2.2.1. Demarcation of the Features into Clusters based on Heat Transfer

- Divide the dataset into nc clusters Gv, where v = 1, 2, …, nc, by iteratively assigning each data point di to the cluster with the nearest centroid and then updating the centroid of each cluster until convergence is achieved.

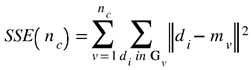

- Compute the sum of squared errors (SSE) for increasing values of nc, starting from nc = 1, using the formula given bywhere mv refers to the centroid (mean) of the cluster Gv.

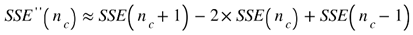

- Determine the optimal number of clusters (nc*) using the “elbow method” (F. Liu & Deng, 2021) which indicates the value of nc at which the SSE vs. nc graph exhibits an inflection. Approximate the elbow point by calculating the second derivative of the SSE vs. nc curve, and choose the point where the second derivative is highest (i.e., where the rate of change of the gradient is highest) aswhere SSE’’(nc) represents the second derivative of the SSE as a function of nc.

- Using nc*, determine the optimal clustering of the dataset D. The number of clusters represents the number of regions in a layer based on heat transfer.

- The clustering described in Step 4 is at the finite difference method (FDM) element level. The features are assigned to the nc* clusters based on the cluster v to which most of their elements belong. For example, if 100 elements in a feature belong to G1 and 20 elements belong to G2, then the feature will be assigned to G1.

2.2.2. Proportional Scanning of Features in Every Cluster with Global Foresight

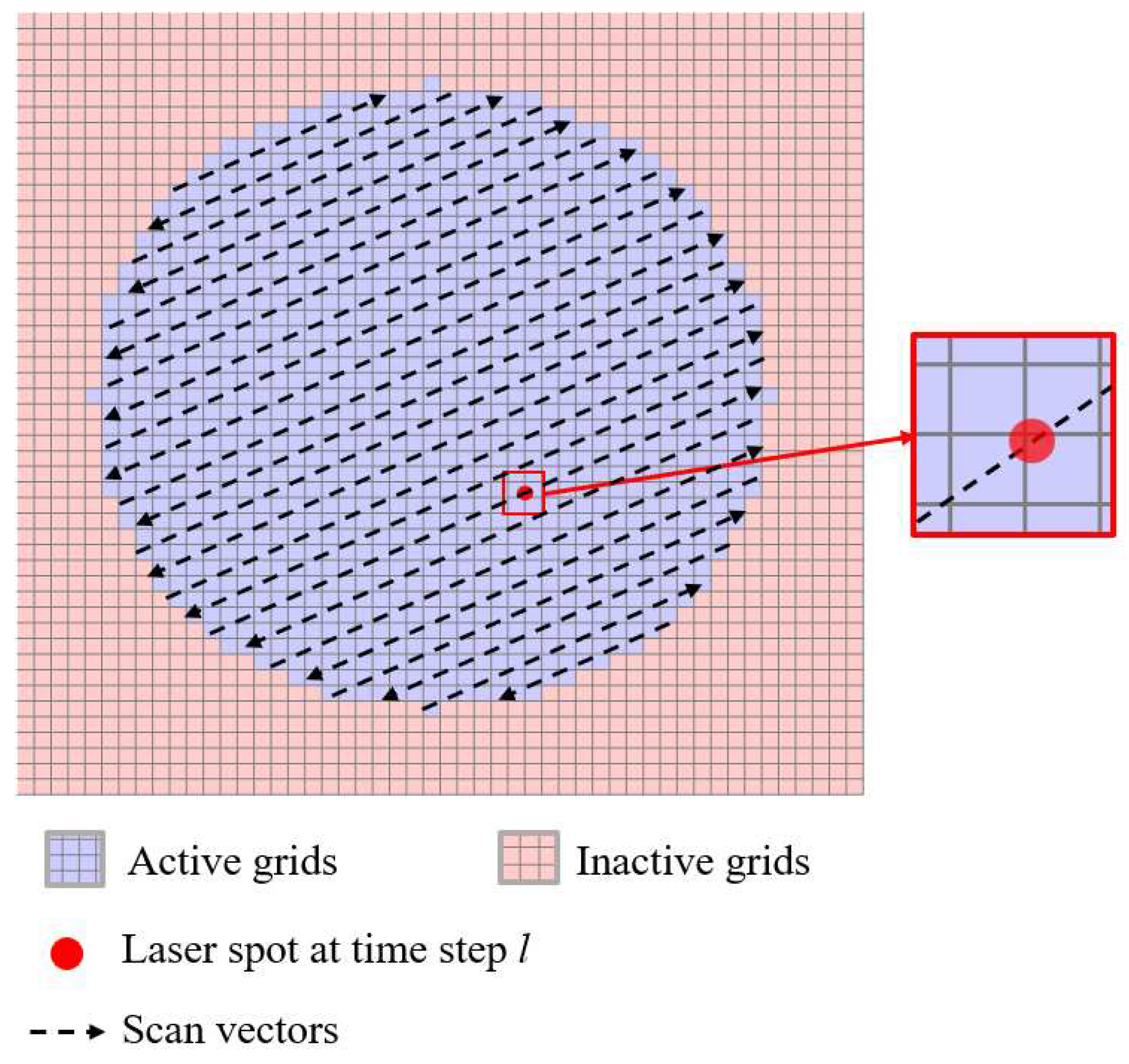

2.3. Incorporation of Ability to Handle Arbitrary Part Geometries and Scan Patterns

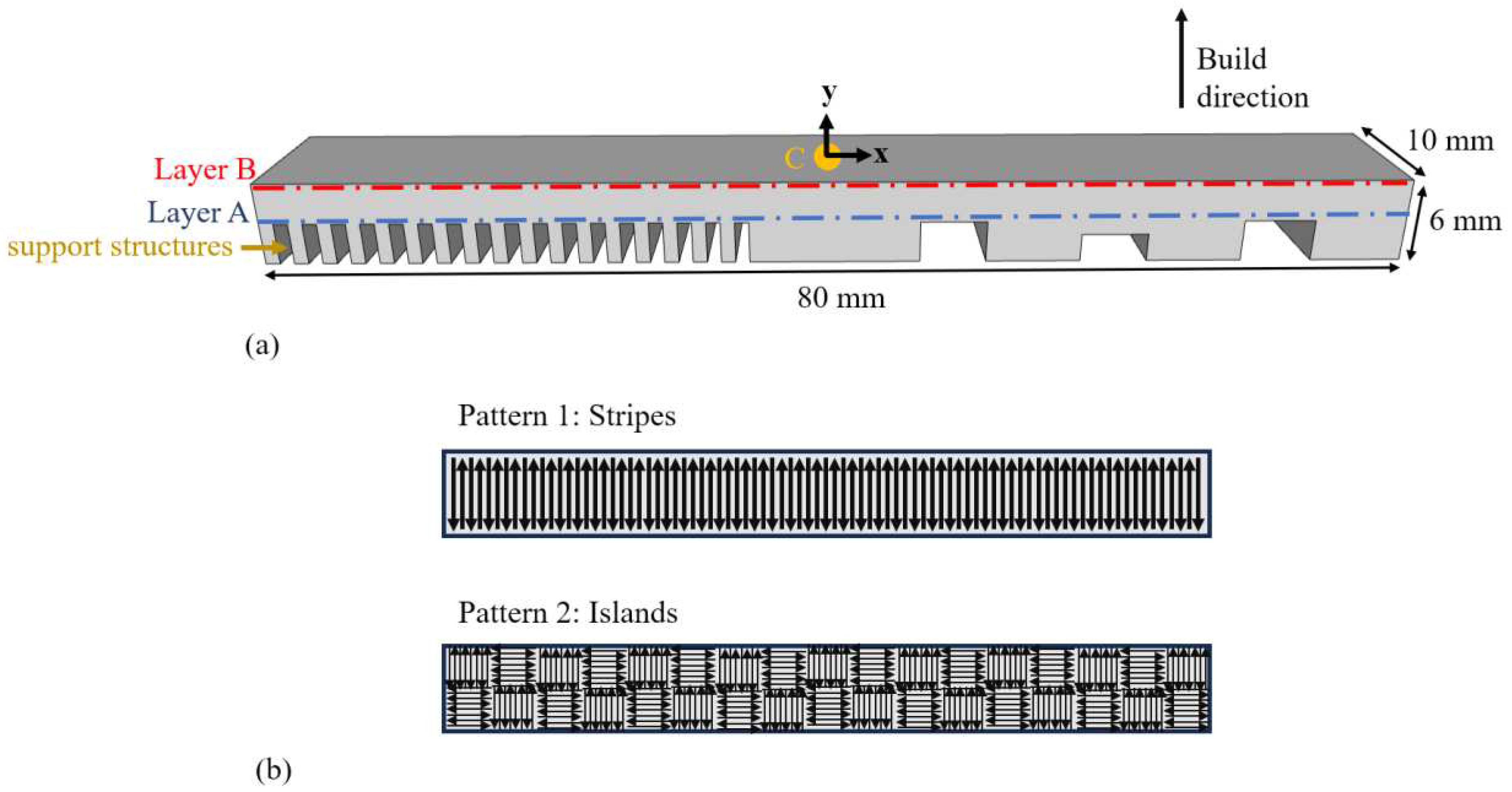

3. Simulation

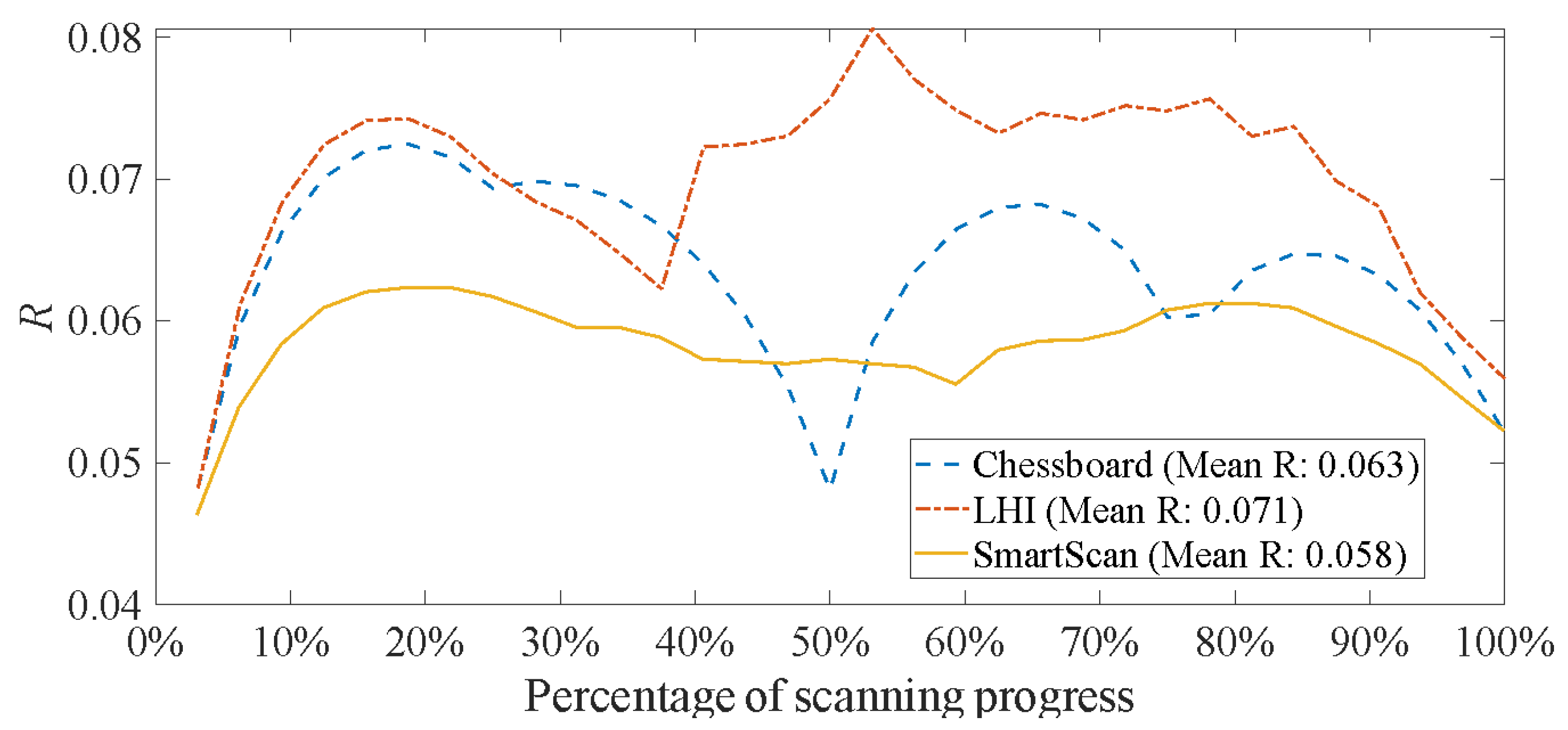

3.1. Evaluation of Global Foresight of SmartScan

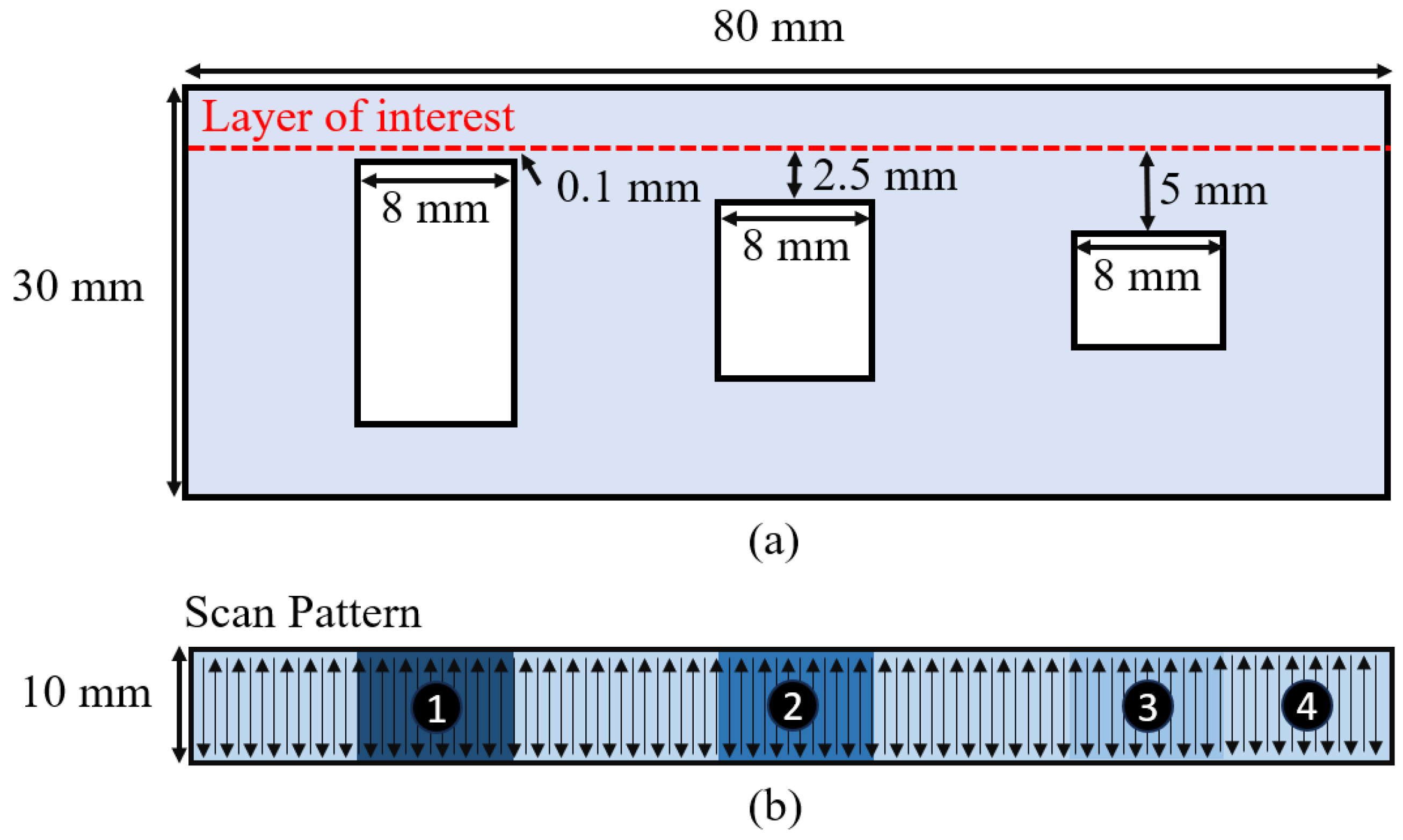

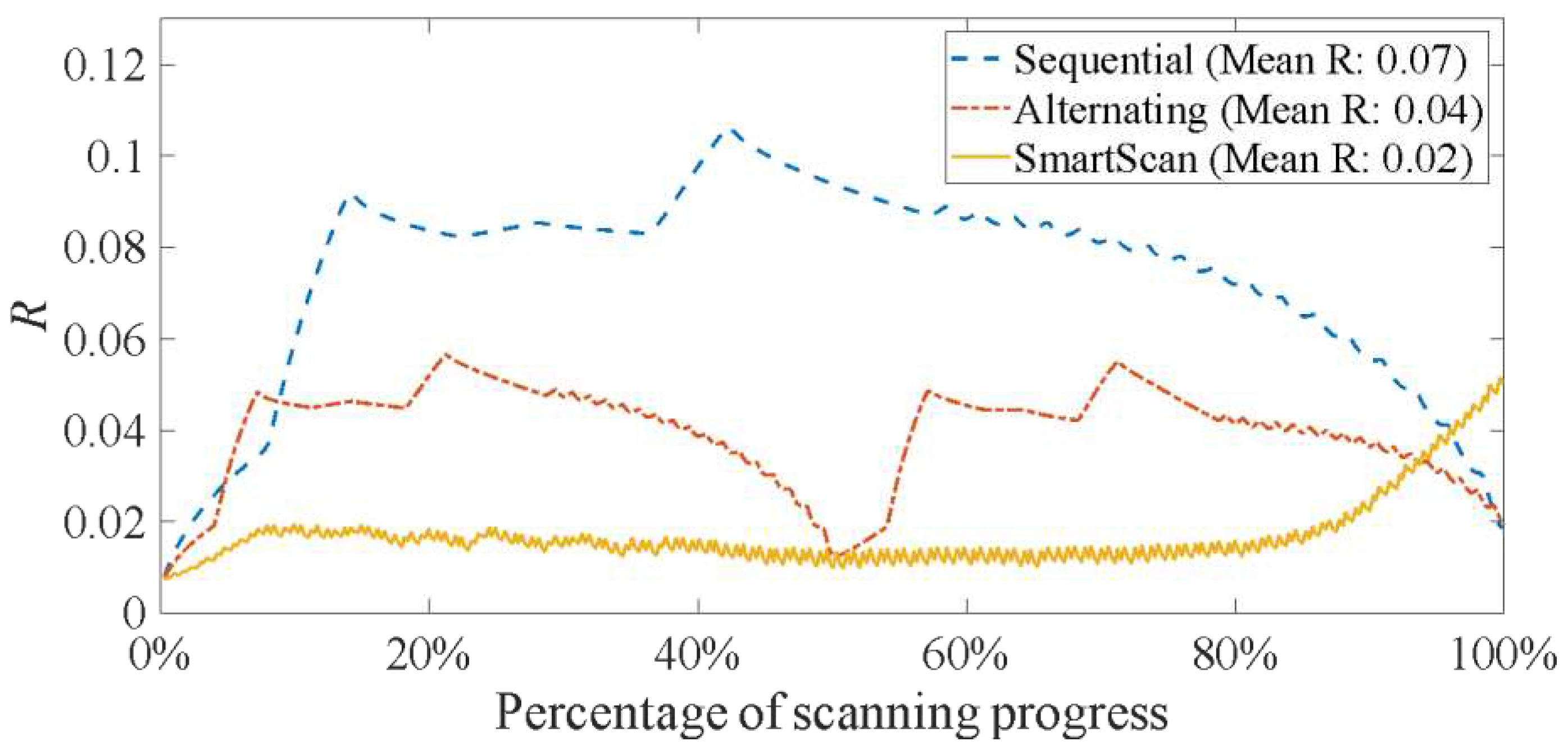

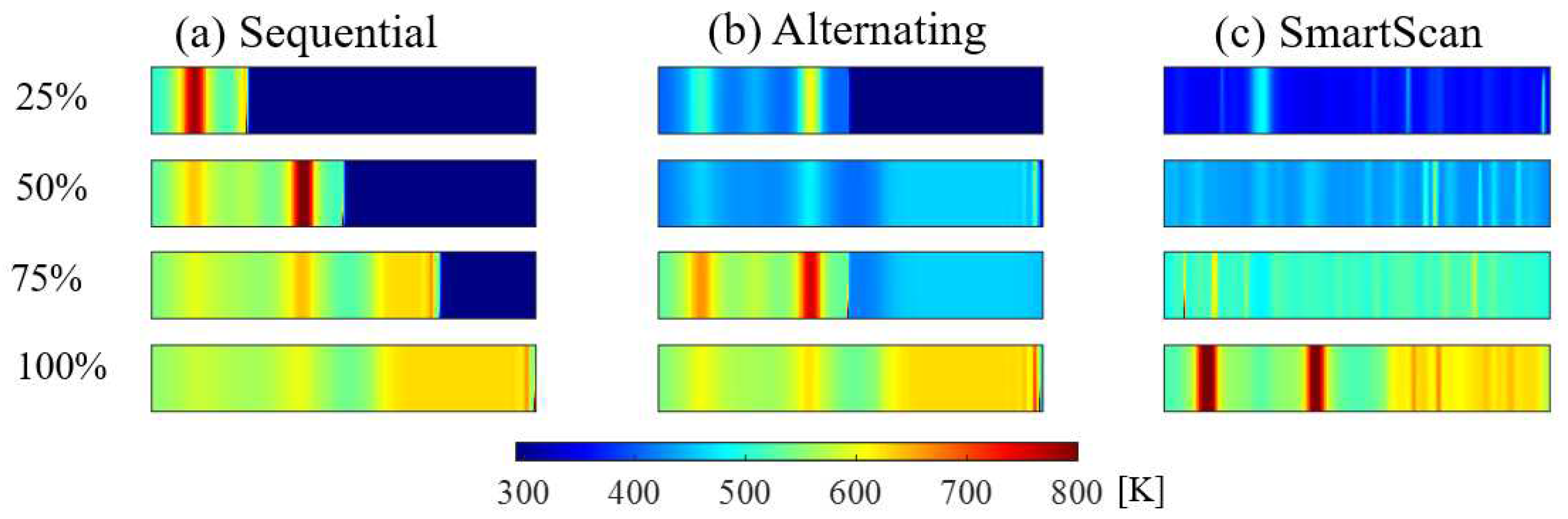

3.2. Simulation of Part Tested in Experiments

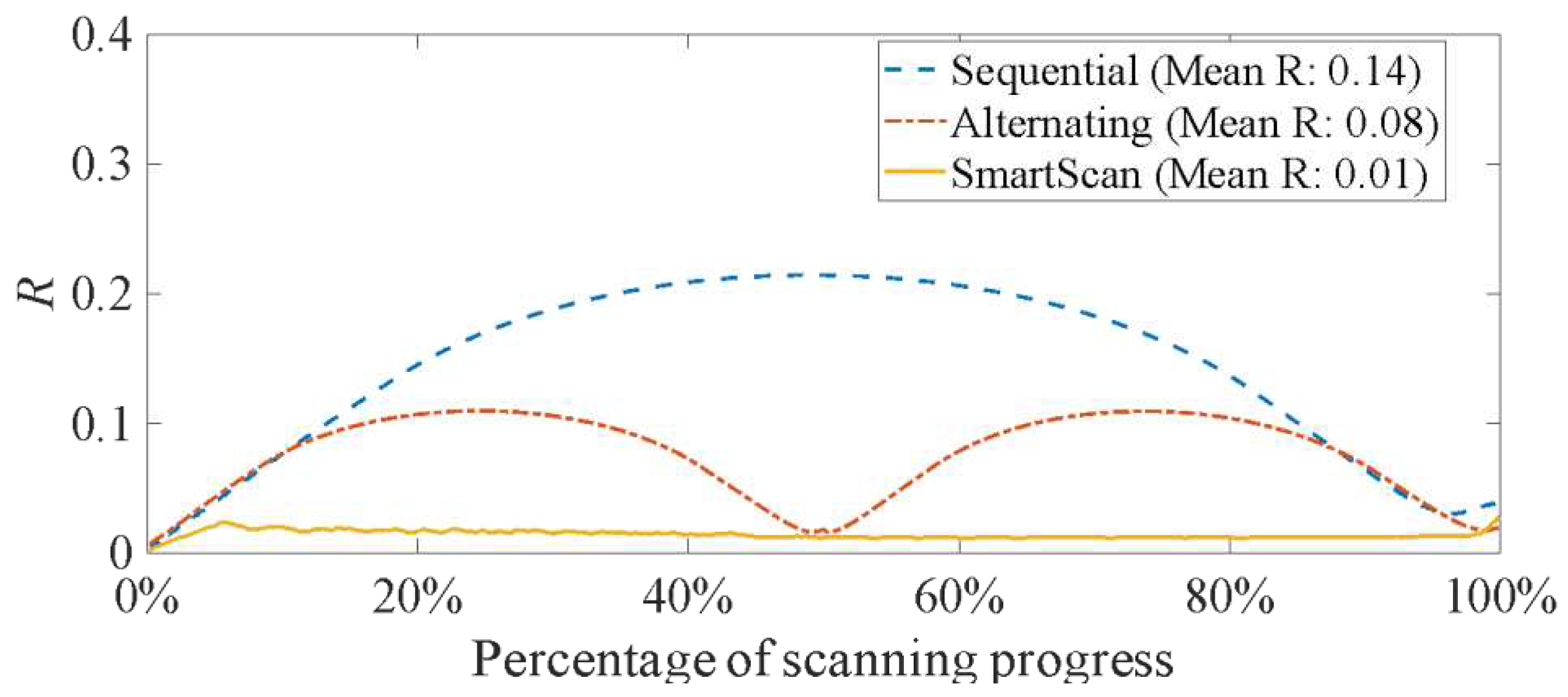

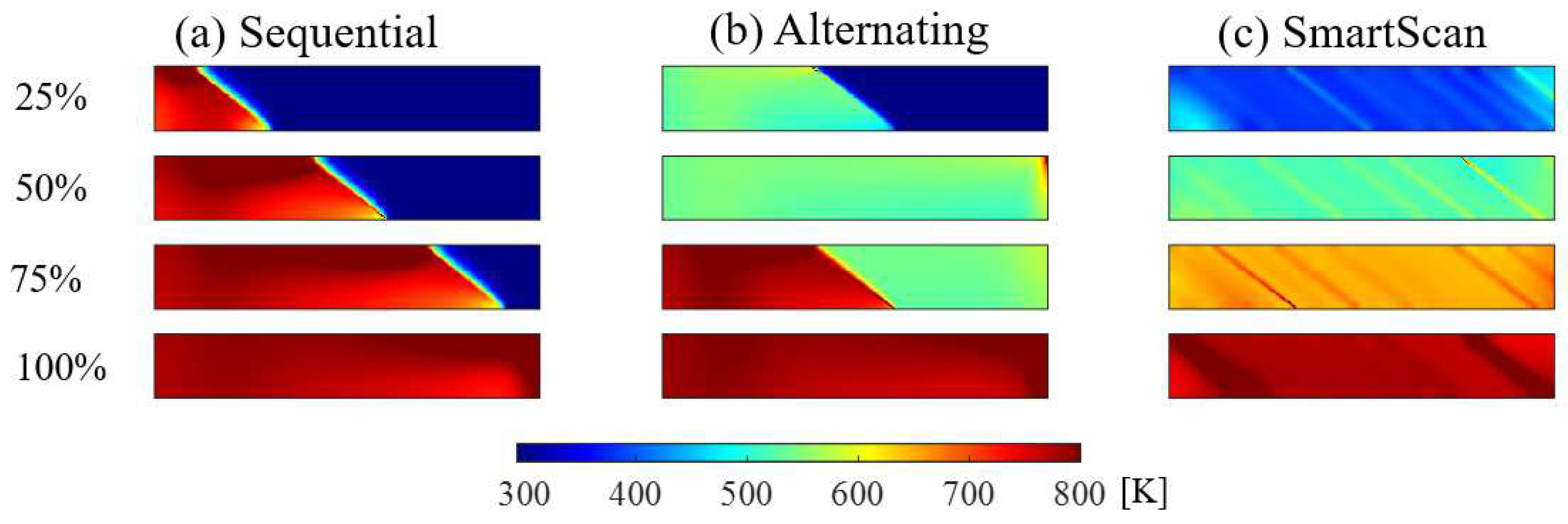

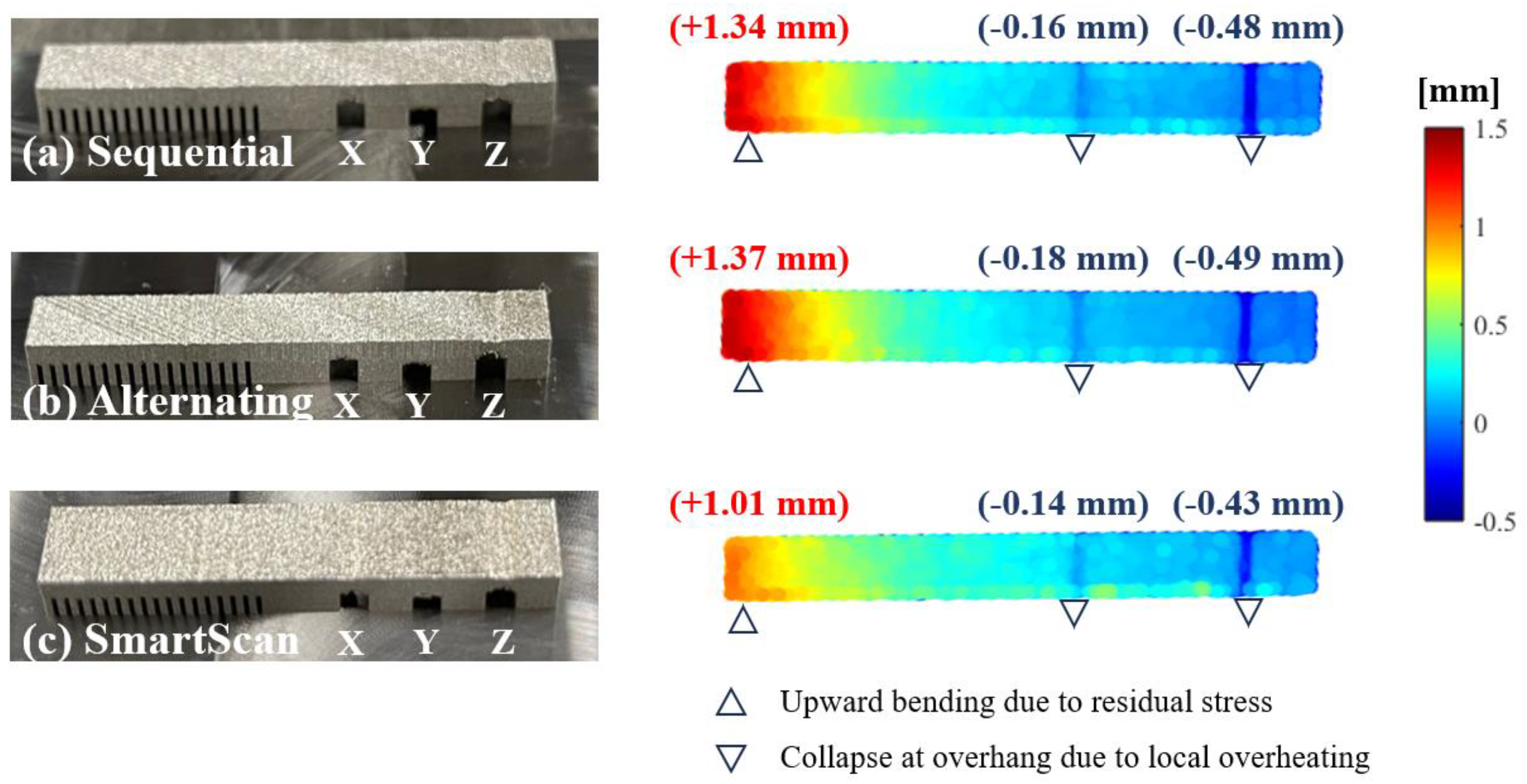

3.2.1. Case 1: Stripe Scan Pattern

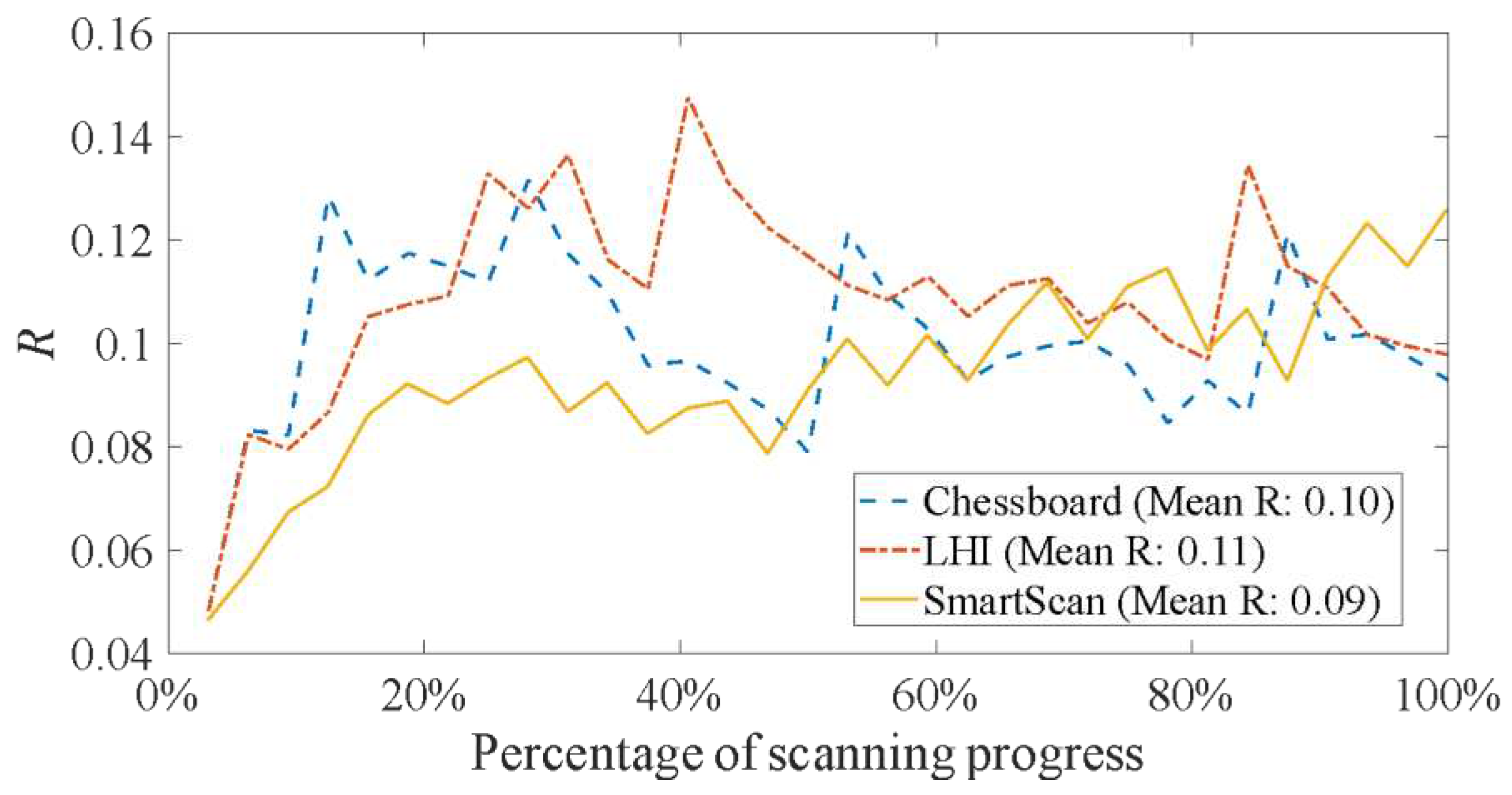

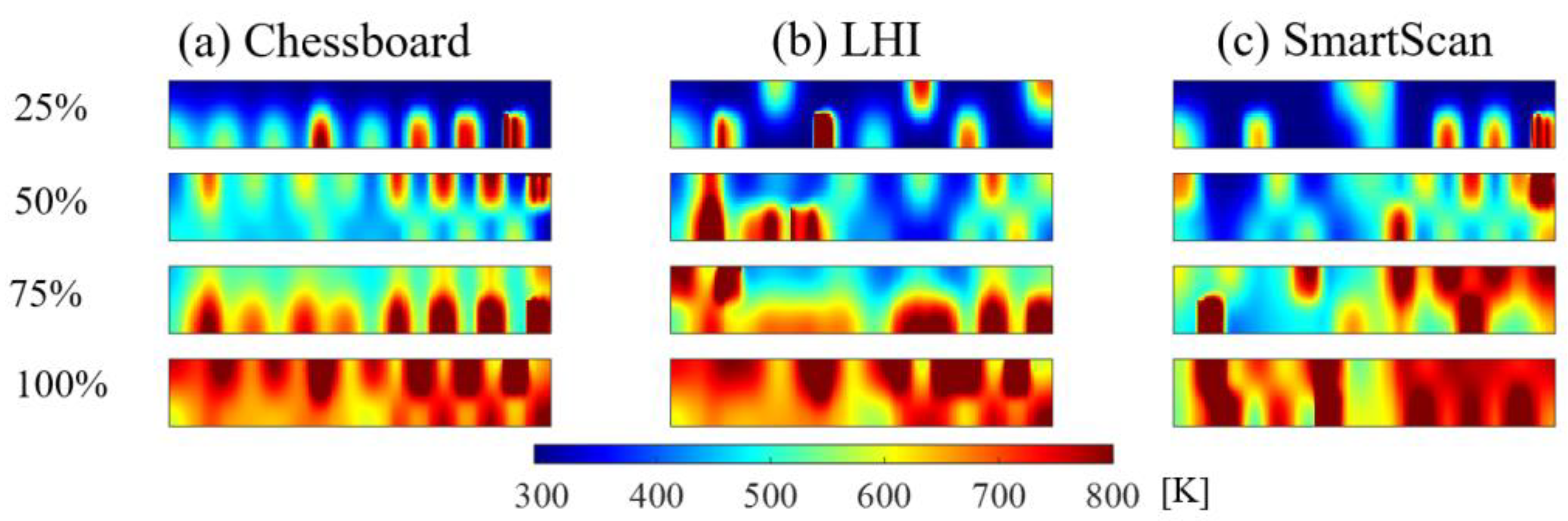

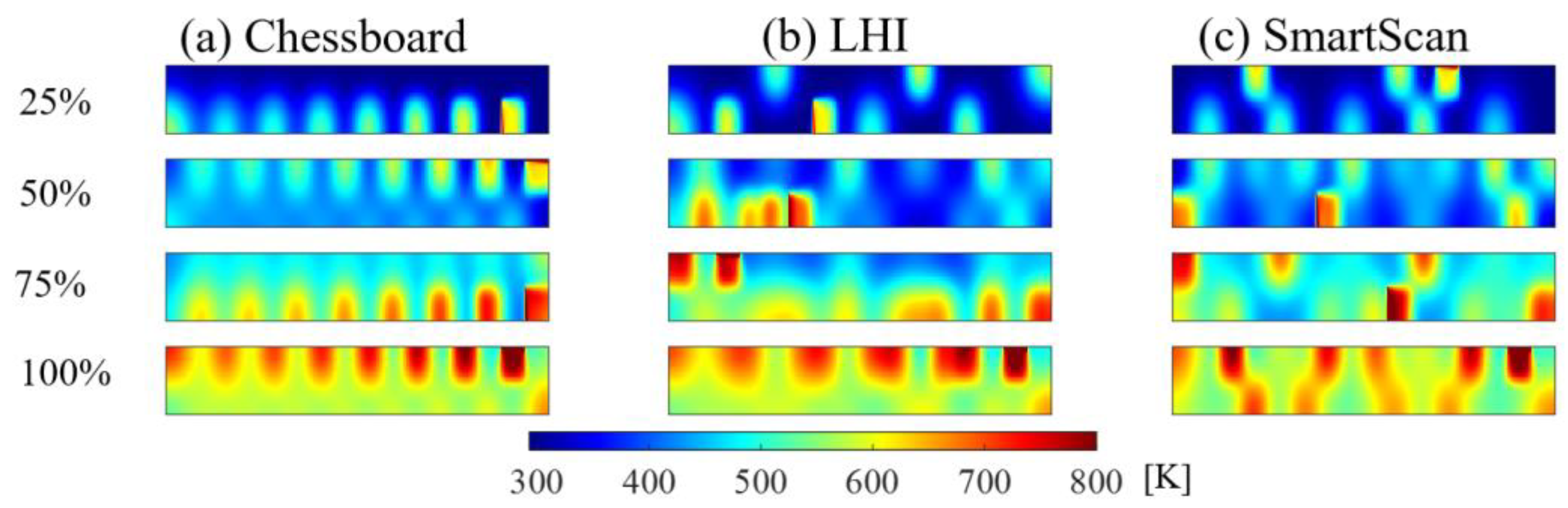

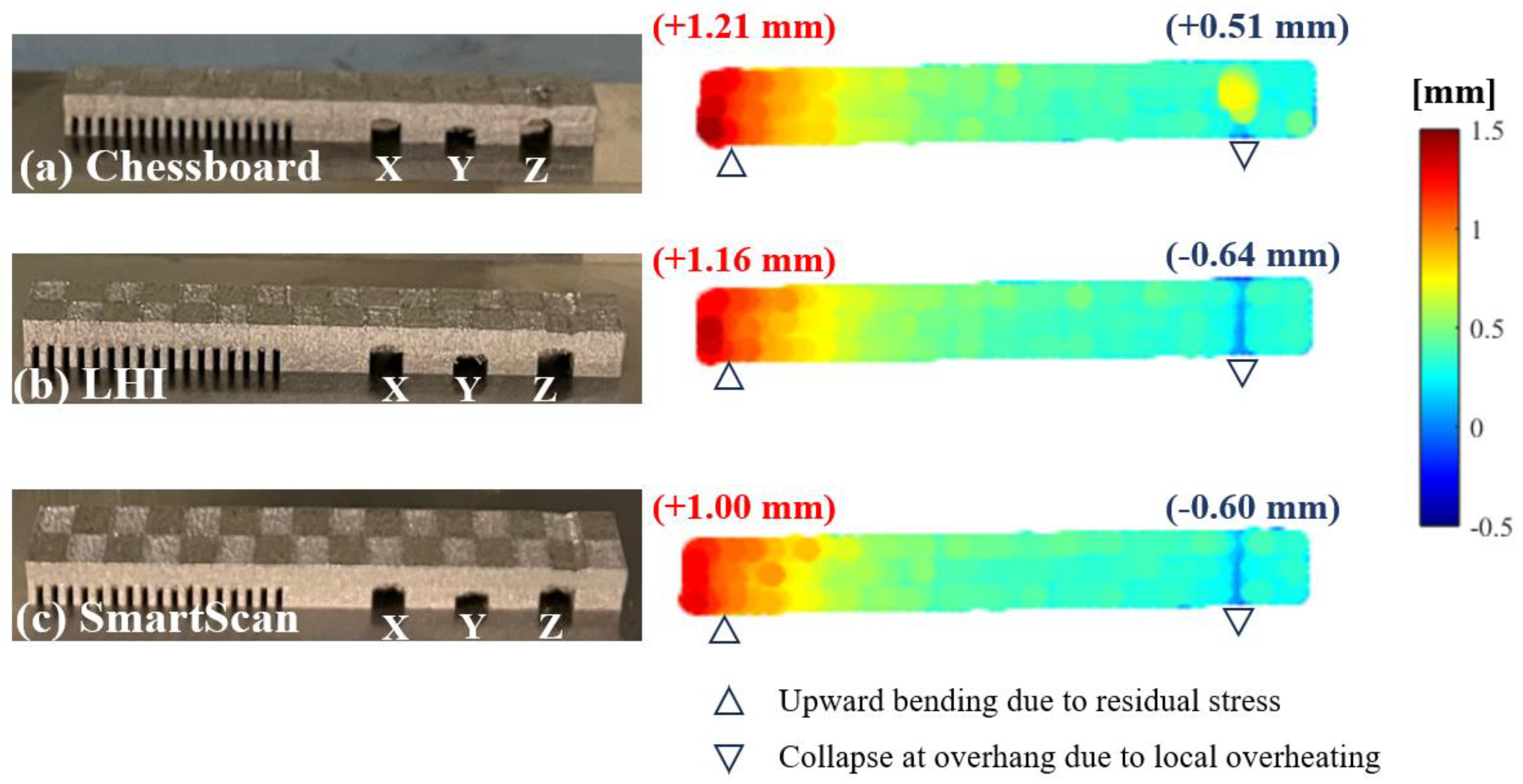

3.2.2. Case 2: Island Scan Pattern

4. Experiments

4.1. Experimental Setup and Procedure

4.2. Results and Discussion

4.2.1. Deformation Analysis

4.2.2. Residual Stress Analysis

4.2.3. Surface Roughness Analysis

4.2.4. Printing Time and Computational Cost Analysis

5. Conclusions and Future Work

Acknowledgement

Conflicts of Interest

References

- Afazov, S., Denmark, W. A. D., Lazaro Toralles, B., Holloway, A., & Yaghi, A. (2017). Distortion prediction and compensation in selective laser melting. Additive Manufacturing, 17, 15–22. [CrossRef]

- Ahmed, M., Seraj, R., & Islam, S. M. S. (2020). The k-means Algorithm: A Comprehensive Survey and Performance Evaluation. Electronics, 9(8), 1295. [CrossRef]

- Boissier, M., Allaire, G., & Tournier, C. (2022). Time Dependent Scanning Path Optimization for the Powder Bed Fusion Additive Manufacturing Process. Computer-Aided Design, 142, 103122. [CrossRef]

- Cao, S., Zou, Y., Lim, C. V. S., & Wu, X. (2021). Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: process, post-process treatment, microstructure, and property. Light: Advanced Manufacturing, 2(2), 1. [CrossRef]

- Cao, Y., Moumni, Z., Zhu, J., Gu, X., Zhang, Y., Zhai, X., & Zhang, W. (2023). Effect of scanning speed on fatigue behavior of 316L stainless steel fabricated by laser powder bed fusion. Journal of Materials Processing Technology, 319, 118043. [CrossRef]

- Chen, Q., Taylor, H., Takezawa, A., Liang, X., Jimenez, X., Wicker, R., & To, A. C. (2021). Island scanning pattern optimization for residual deformation mitigation in laser powder bed fusion via sequential inherent strain method and sensitivity analysis. Additive Manufacturing, 46, 102116. [CrossRef]

- Dong, G., Wong, J. C., Lestandi, L., Mikula, J., Vastola, G., Jhon, M. H., Dao, M. H., Kizhakkinan, U., Ford, C. S., & Rosen, D. W. (2022). A part-scale, feature-based surrogate model for residual stresses in the laser powder bed fusion process. Journal of Materials Processing Technology, 304, 117541. [CrossRef]

- Guo, C., Li, S., Shi, S., Li, X., Hu, X., Zhu, Q., & Ward, R. M. (2020). Effect of processing parameters on surface roughness, porosity and cracking of as-built IN738LC parts fabricated by laser powder bed fusion. Journal of Materials Processing Technology, 285, 116788. [CrossRef]

- He, C., & Okwudire, C. (2023). Scan Sequence Optimization for Reduced Residual Stress and Distortion in PBF Additive Manufacturing – An AISI 316L Case Study. In Proceedings of the Ground Vehicle Systems Engineering and Technology Symposium (GVSETS), NDIA, Novi, MI, Aug. 15-17, 2023.

- He, C., Ramani, K. S., & Okwudire, C. E. (2023). An intelligent scanning strategy (SmartScan) for improved part quality in multi-laser PBF additive manufacturing. Additive Manufacturing, 64, 103427. [CrossRef]

- He, C., Ramani, K. S., Tsai, Y.-L., & Okwudire, C. E. (2022). A Simplified Scan Sequence Optimization Approach for PBF Additive Manufacturing of Complex Geometries. 2022 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), 1004–1009. [CrossRef]

- He, C., Tsai, Y.-L., & Okwudire, C. E. (2022, June 27). A Comparative Study on the Effects of an Advanced Scan Pattern and Intelligent Scan Sequence on Thermal Distribution, Part Deformation, and Printing Time in PBF Additive Manufacturing. In proceedings of the ASME 2022 17th International Manufacturing Science and Engineering Conference (MSEC), Jun. 2022. [CrossRef]

- Kaleli Alay, T., Cagirici, M., Yalcin, M. Y., Yagmur, A., Tirkes, S., Aydogan, E., & Gur, C. H. (2023). Tailoring the microstructure and mechanical properties of IN718 alloy via a novel scanning strategy implemented in laser powder bed fusion. Materials Science and Engineering: A, 884, 145543. [CrossRef]

- Khan, H. M., Karabulut, Y., Kitay, O., Kaynak, Y., & Jawahir, I. S. (2021). Influence of the post-processing operations on surface integrity of metal components produced by laser powder bed fusion additive manufacturing: a review. Machining Science and Technology, 25(1), 118–176. [CrossRef]

- Kim, S. I., & Hart, A. J. (2022). A spiral laser scanning routine for powder bed fusion inspired by natural predator-prey behaviour. Virtual and Physical Prototyping, 17(2), 239–255. [CrossRef]

- Kruth, J. P., Froyen, L., Van Vaerenbergh, J., Mercelis, P., Rombouts, M., & Lauwers, B. (2004). Selective laser melting of iron-based powder. Journal of Materials Processing Technology, 149(1–3), 616–622. [CrossRef]

- Kumar, V. P., & Jebaraj, A. V. (2023). Comprehensive review on residual stress control strategies in laser-based powder bed fusion process– Challenges and opportunities. Lasers in Manufacturing and Materials Processing, 10(3), 400–442. [CrossRef]

- Liu, F., & Deng, Y. (2021). Determine the Number of Unknown Targets in Open World Based on Elbow Method. IEEE Transactions on Fuzzy Systems, 29(5), 986–995. [CrossRef]

- Liu, Y., Li, J., Xu, K., Cheng, T., Zhao, D., Li, W., Teng, Q., & Wei, Q. (2022). An optimized scanning strategy to mitigate excessive heat accumulation caused by short scanning lines in laser powder bed fusion process. Additive Manufacturing, 60, 103256. [CrossRef]

- Mahmoodkhani, Y., Ali, U., Imani Shahabad, S., Rani Kasinathan, A., Esmaeilizadeh, R., Keshavarzkermani, A., Marzbanrad, E., & Toyserkani, E. (2019). On the measurement of effective powder layer thickness in laser powder-bed fusion additive manufacturing of metals. Progress in Additive Manufacturing, 4(2), 109–116. [CrossRef]

- Maleki Pour, E. (2018). Innovative Tessellation Algorithm for Generating More Uniform Temperature Distribution in the Powder-bed Fusion Process. [Master’s dissertation, Purdue University].

- Mugwagwa, L., Dimitrov, D., Matope, S., & Yadroitsev, I. (2019). Evaluation of the impact of scanning strategies on residual stresses in selective laser melting. The International Journal of Advanced Manufacturing Technology, 102(5–8), 2441–2450. [CrossRef]

- Ning, J., Sievers, D. E., Garmestani, H., & Liang, S. Y. (2019). Analytical Thermal Modeling of Metal Additive Manufacturing by Heat Sink Solution. Materials, 12(16), 2568. [CrossRef]

- Pant, P., Salvemini, F., Proper, S., Luzin, V., Simonsson, K., Sjöström, S., Hosseini, S., Peng, R. L., & Moverare, J. (2022). A study of the influence of novel scan strategies on residual stress and microstructure of L-shaped LPBF IN718 samples. Materials & Design, 214, 110386. [CrossRef]

- Parry, L., Ashcroft, I. A., & Wildman, R. D. (2016). Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Additive Manufacturing, 12, 1–15. [CrossRef]

- Qin, M., Qu, S., Ding, J., Song, X., Gao, S., Wang, C. C. L., & Liao, W.-H. (2023). Adaptive toolpath generation for distortion reduction in laser powder bed fusion process. Additive Manufacturing, 64, 103432. [CrossRef]

- Ramani, K. S., He, C., Tsai, Y.-L., & Okwudire, C. E. (2022). SmartScan: An Intelligent Scanning Approach for Uniform Thermal Distribution, Reduced Residual Stresses and Deformations in PBF Additive Manufacturing. Additive Manufacturing, 102643. [CrossRef]

- Ramos, D., Belblidia, F., & Sienz, J. (2019). New scanning strategy to reduce warpage in additive manufacturing. Additive Manufacturing, 28, 554–564. [CrossRef]

- Reiff, C., Bubeck, W., Krawczyk, D., Steeb, M., Lechler, A., & Verl, A. (2021). Learning Feedforward Control for Laser Powder Bed Fusion. Procedia CIRP, 96, 127–132. [CrossRef]

- Riensche, A., Bevans, B. D., Smoqi, Z., Yavari, R., Krishnan, A., Gilligan, J., Piercy, N., Cole, K., & Rao, P. (2022). Feedforward control of thermal history in laser powder bed fusion: Toward physics-based optimization of processing parameters. Materials & Design, 224, 111351. [CrossRef]

- Sames, W. J., List, F. A., Pannala, S., Dehoff, R. R., & Babu, S. S. (2016). The metallurgy and processing science of metal additive manufacturing. International Materials Reviews, 61(5), 315–360. [CrossRef]

- Wang, R., Standfield, B., Dou, C., Law, A. C., & Kong, Z. J. (2023). Real-time process monitoring and closed-loop control on laser power via a customized laser powder bed fusion platform. Additive Manufacturing, 66, 103449. [CrossRef]

- Wang, Z., Yang, Z., Liu, F., & Zhang, W. (2023). Influence of the scanning angle on the grain growth and mechanical properties of Ni10Cr6W1Fe9Ti1 HEA fabricated using the LPBF–AM method. Materials Science and Engineering: A, 864, 144596. [CrossRef]

- Wei, L. C., Ehrlich, L. E., Powell-Palm, M. J., Montgomery, C., Beuth, J., & Malen, J. A. (2018). Thermal conductivity of metal powders for powder bed additive manufacturing. Additive Manufacturing, 21, 201–208. [CrossRef]

- Yang, H., Sha, J., Zhao, D., He, F., Ma, Z., He, C., Shi, C., & Zhao, N. (2023). Defects control of aluminum alloys and their composites fabricated via laser powder bed fusion: A review. Journal of Materials Processing Technology, 319, 118064. [CrossRef]

| Parameter (Units) | Value |

|---|---|

| Laser power, P (W) | 290 |

| Laser spot diameter (μm) | 77 |

| Absorptance, σ | 0.37 |

| Mark/scan speed, vscan (mm/s) | 1200 |

| Jump speed (mm/s) | 6000 |

| Hatch spacing (μm) | 100 |

| Layer thickness (μm) | 40 |

| Conductivity, kt (W/(mK)) | 22.5 |

| Diffusivity, α (m2/s) | 5.632 ×10-6 |

| Melting temperature, Tm (K) | 1658 |

| Convection coefficient, h (W/(m2K)) | 25 |

| Initial temperature, T(x,y,z,0) | 293 |

| Ambient temperature, Ta (K) | 293 |

| Base plate temperature, Tb (K) | 293 |

| Uniformity criterion, ε | 0.05 |

| Scan Sequence | X-component Residual Stress [MPa] | Y-component Residual Stress [MPa] |

|---|---|---|

| Sequential | 82.0 | 275.5 |

| Alternating | 152.2 | -441.2 |

| SmartScan | 57.7 | 125.0 |

| Scan Sequence | X-component Residual Stress [MPa] | Y-component Residual Stress [MPa] |

|---|---|---|

| Chessboard | 69.2 | 234.4 |

| LHI | 34.6 | 196.9 |

| SmartScan | 20.5 | 31.1 |

| Stripe Pattern | Ra [μm] | Island Pattern | Ra [μm] |

| Sequential | 20.0 | Chessboard | 23.0 |

| Alternating | 18.2 | LHI | 22.4 |

| SmartScan | 21.9 | SmartScan | 23.3 |

| Stripe Pattern | Print time [min] | Island Pattern | Print time [min] |

|---|---|---|---|

| Sequential | 35 | Chessboard | 35 |

| Alternating | 35 | LHI | 35 |

| SmartScan | 37 | SmartScan | 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).