Submitted:

06 November 2023

Posted:

06 November 2023

You are already at the latest version

Abstract

Keywords:

Introduction

Results

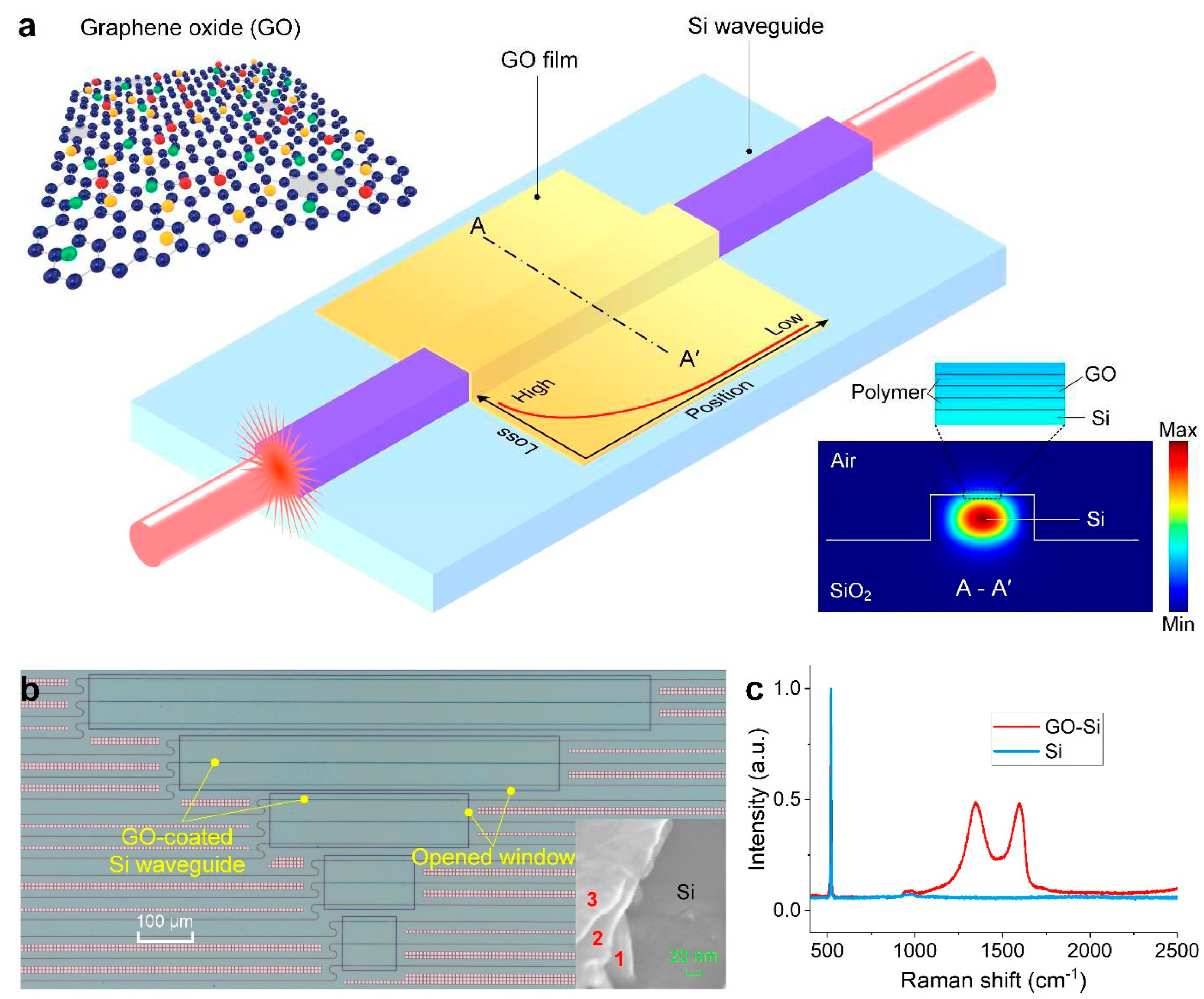

Device design and fabrication

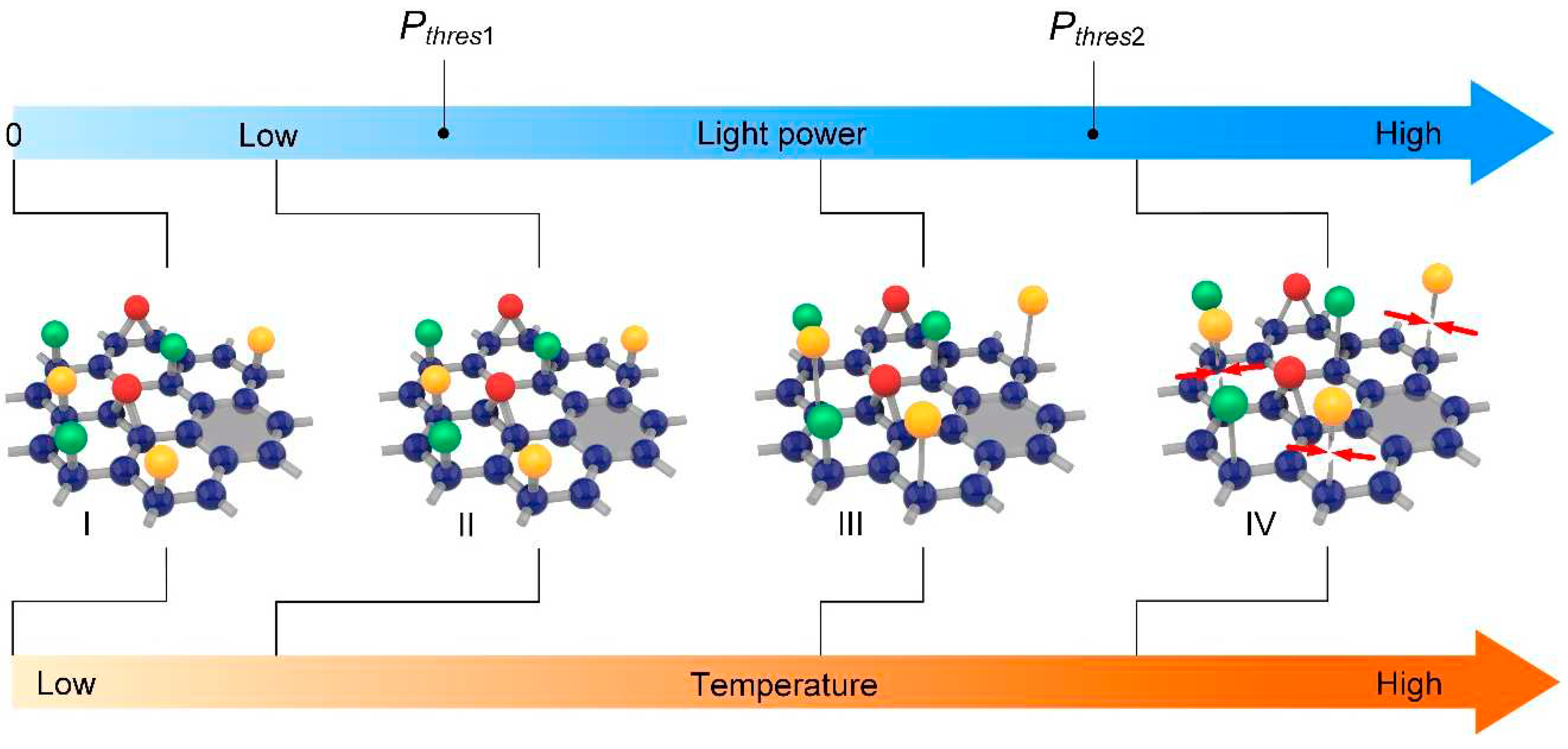

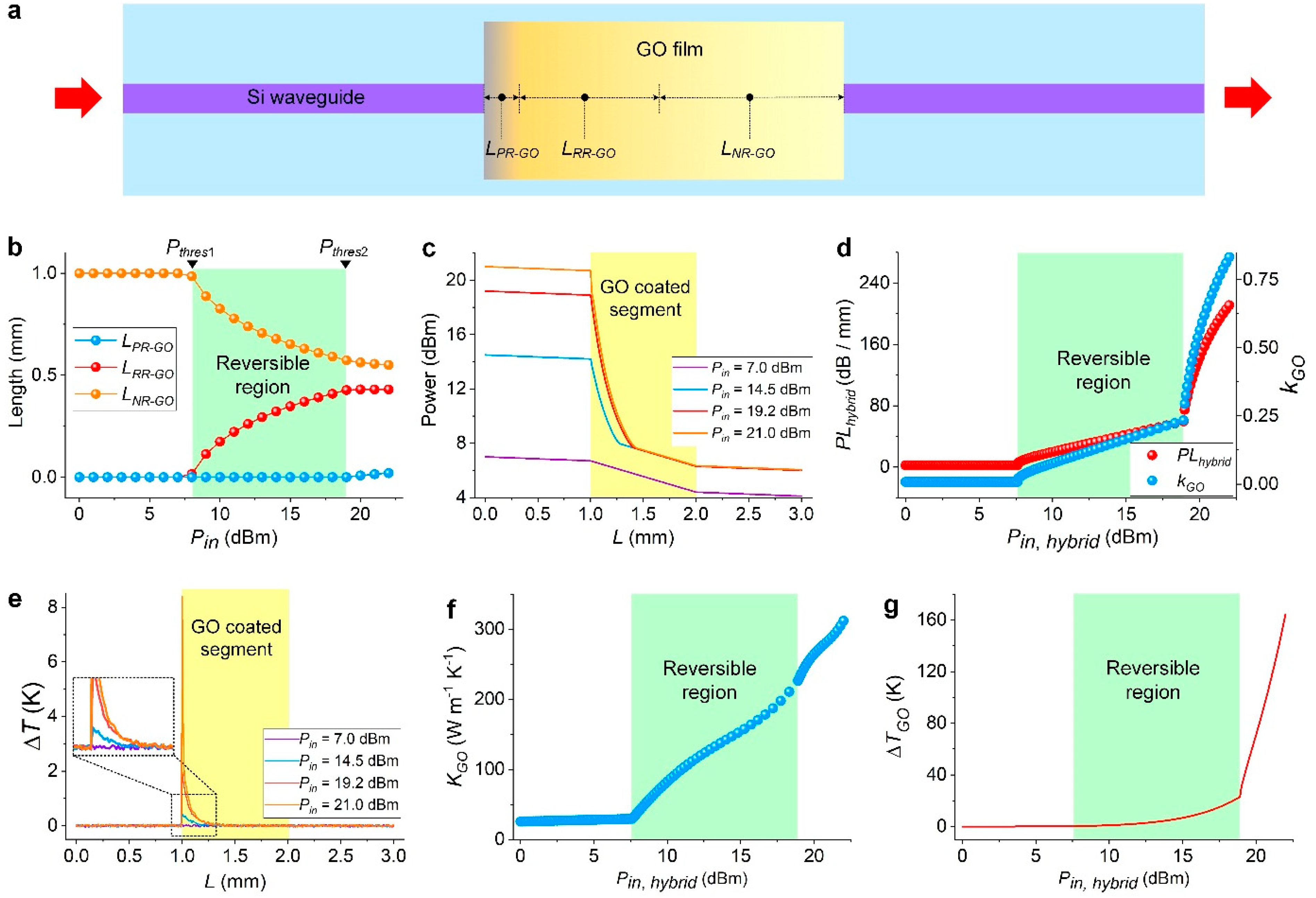

Photo-thermal effects in 2D GO films

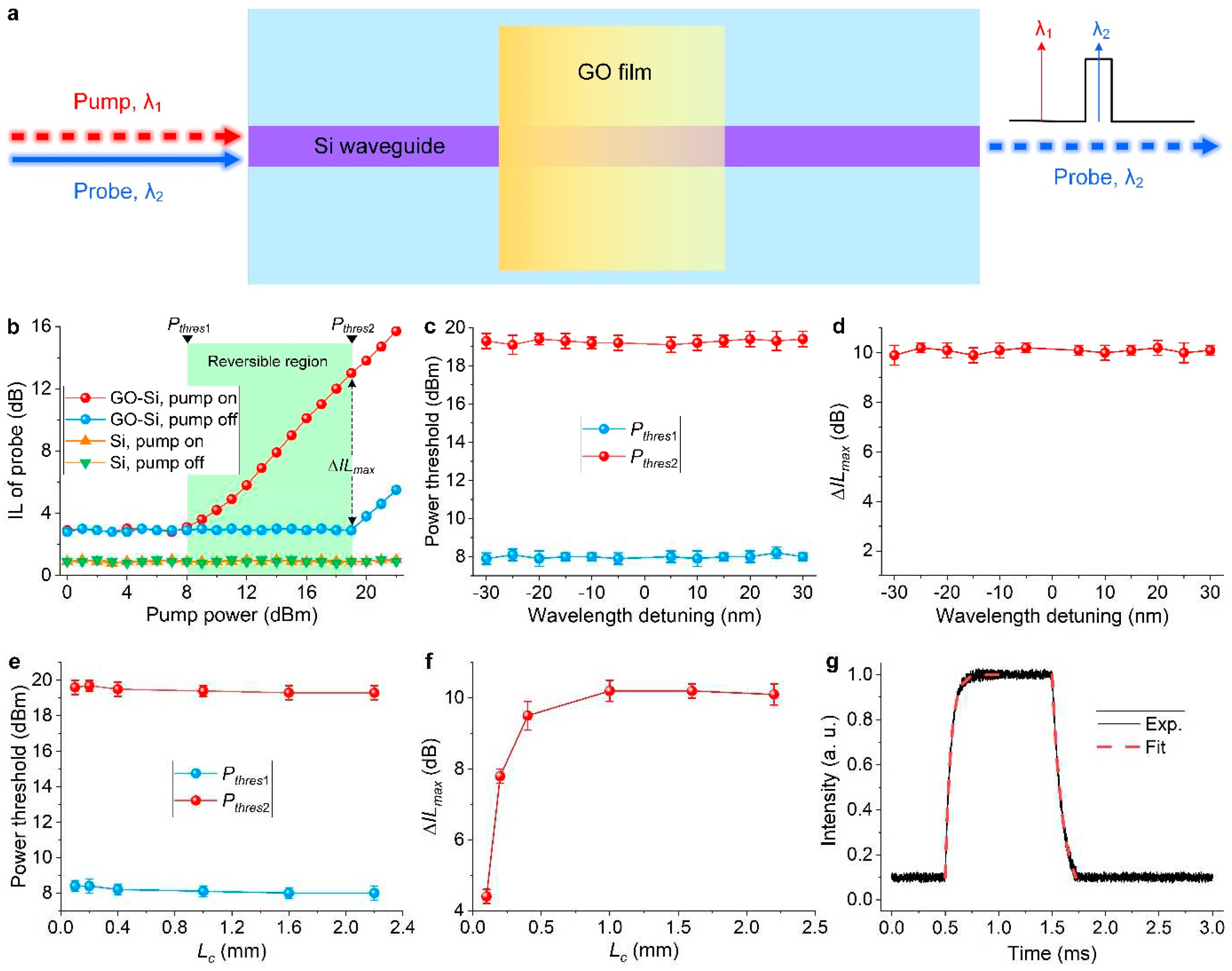

All-optical control and switching

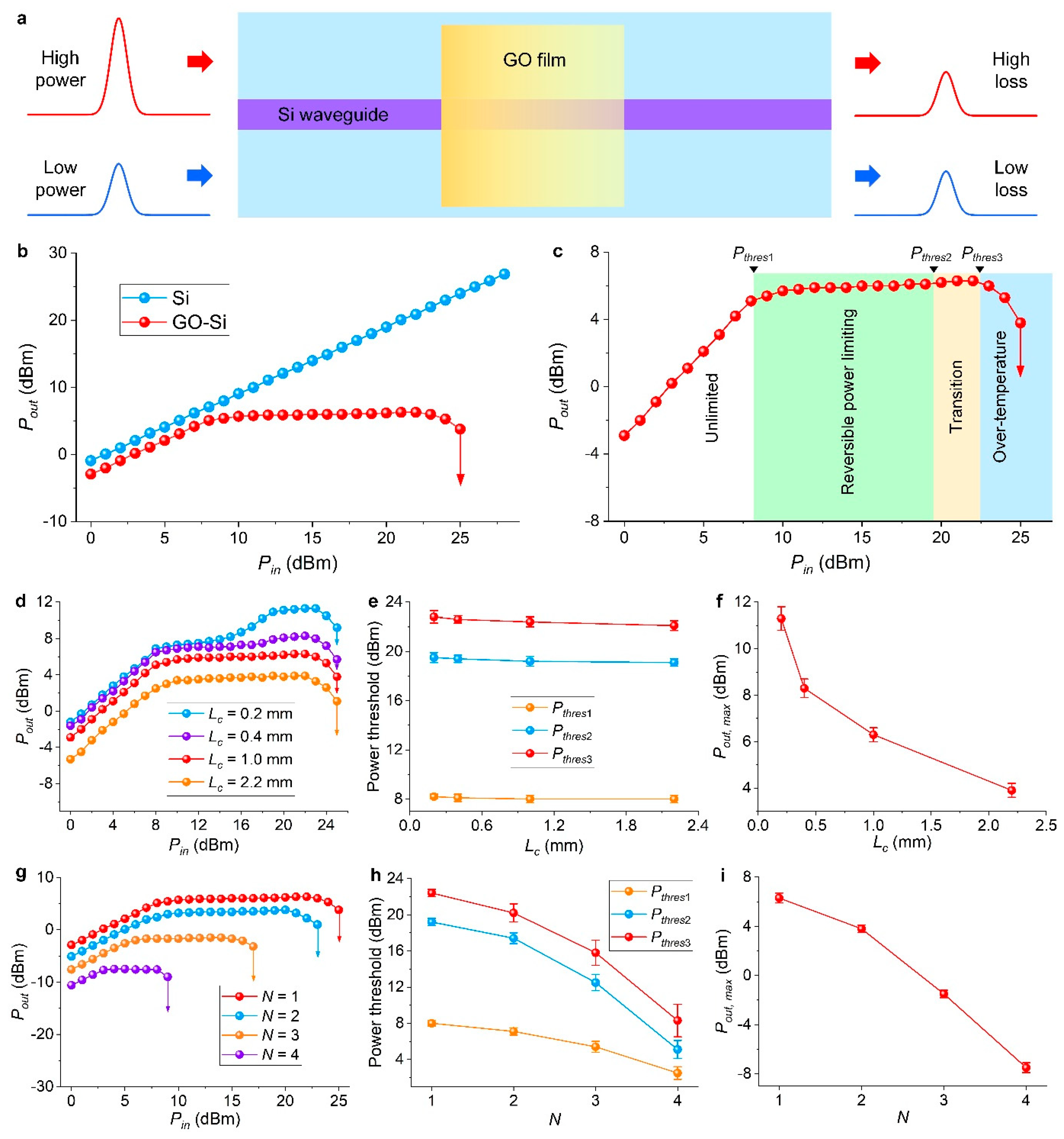

Optical power limiting

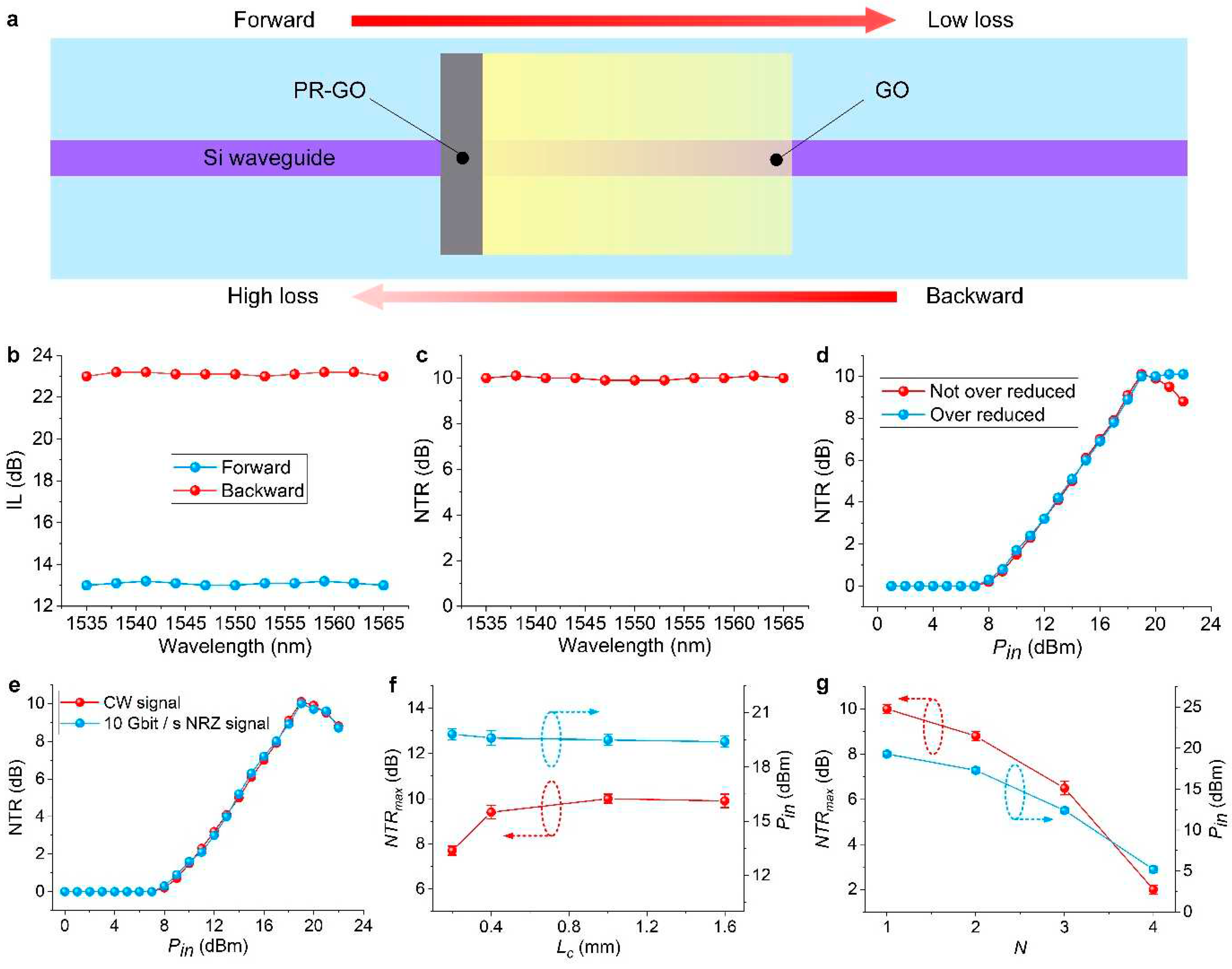

Non-reciprocal light transmission

Theoretical analysis and discussion

Conclusion

Methods

Conflicts of Interest

References

- Bogaerts, W.; et al. Programmable photonic circuits. Nature 2020, 586, 207–216. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; et al. A photonic integrated circuit–based erbium-doped amplifier. Science 2022, 376, 1309–1313. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; et al. Deep learning with coherent nanophotonic circuits. Nat. Photonics 2017, 11, 441–446. [Google Scholar] [CrossRef]

- Chang, L., Liu, S. & Bowers, J. E. Integrated optical frequency comb technologies. Nat. Photonics 2022, 16, 95–108. [CrossRef]

- Moss, D. J., Morandotti, R., Gaeta, A. L. & Lipson, M. New cmos-compatible platforms based on silicon nitride and hydex for nonlinear optics. Nat. Photonics 2013, 7, 597–607. [CrossRef]

- Sun, Y.; et al. Applications of optical microcombs. Advances in Optics and Photonics 2023, 15, 86. [Google Scholar] [CrossRef]

- Rickman, A. The commercialization of silicon photonics. Nat. Photonics 2014, 8, 579–582. [Google Scholar] [CrossRef]

- Reed, G. T., Mashanovich, G., Gardes, F. Y. & Thomson, D. J. Silicon optical modulators. Nat. Photonics 2010, 4, 518–526. [CrossRef]

- Melikyan, A.; et al. High-speed plasmonic phase modulators. Nat. Photonics 2014, 8, 229–233. [Google Scholar] [CrossRef]

- Koos, C.; et al. All-optical high-speed signal processing with silicon–organic hybrid slot waveguides. Nat. Photonics 2009, 3, 216–219. [Google Scholar] [CrossRef]

- Sorianello, V.; et al. Graphene–silicon phase modulators with gigahertz bandwidth. Nat. Photonics 2017, 12, 40–44. [Google Scholar] [CrossRef]

- Novoselov, K. S.; et al. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Koppens, F. H.; et al. Photodetectors based on graphene, other two-dimensional materials and hybrid systems. Nat. Nanotechnol. 2014, 9, 780–793. [Google Scholar] [CrossRef]

- Wu, J.; et al. Graphene oxide for integrated photonics and flat optics. Adv. Mater. 2006, 33, 2006415. [Google Scholar] [CrossRef]

- Jiayang Wu, H. Lin, D. J. Moss, T.K. Loh, Baohua Jia, “Graphene oxide: new opportunities for electronics, photonics, and optoelectronics”, Nature Reviews Chemistry 7 (3) 162–183 (2023). [CrossRef]

- Wu, J.; et al. 2D layered graphene oxide films integrated with micro-ring resonators for enhanced nonlinear optics. Small 2020, 16, 1906563. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; et al. Graphene oxide waveguide and micro-ring resonator polarizers. Laser Photonics Rev. 2019, 13, 1900056. [Google Scholar] [CrossRef]

- Shen, T. Z., Hong, S. H. & Song, J. K. Electro-optical switching of graphene oxide liquid crystals with an extremely large kerr coefficient. Nat. Mater. 2014, 13, 394–399. [CrossRef]

- Loh, K. P., Bao, Q., Eda, G. & Chhowalla, M. Graphene oxide as a chemically tunable platform for optical applications. Nat. Chem. 2010; 2, 1015–1024. [CrossRef]

- Bonaccorso, F., Sun, Z., Hasan, T. & Ferrari, A. C. Graphene photonics and optoelectronics. Nat. Photonics 2010, 4, 611–622. [CrossRef]

- Zhang, Y.; et al. Graphene oxide for nonlinear integrated photonics. Laser Photonics Rev. 2023, 2200512. [Google Scholar] [CrossRef]

- Voiry, D.; et al. High-quality graphene via microwave reduction of solution-exfoliated graphene oxide. Science 2016, 353, 1413. [Google Scholar] [CrossRef]

- Guo, S., Garaj, S., Bianco, A. & Ménard-Moyon, C. Controlling covalent chemistry on graphene oxide. Nature Reviews Physics 2022. [CrossRef]

- Lin, H.; et al. Chalcogenide glass-on-graphene photonics. Nat. Photonics 2017, 11, 798–805. [Google Scholar] [CrossRef]

- Lin, H.; et al. A 90-nm-thick graphene metamaterial for strong and extremely broadband absorption of unpolarized light. Nat. Photonics 2019, 13, 270–276. [Google Scholar] [CrossRef]

- Lin, K. T., Lin, H., Yang, T. & Jia, B. Structured graphene metamaterial selective absorbers for high efficiency and omnidirectional solar thermal energy conversion. Nat. Commun. 2020, 11, 1389. [CrossRef]

- Yang, Y.; et al. Graphene metamaterial 3d conformal coating for enhanced light harvesting. ACS Nano 2022. [Google Scholar] [CrossRef]

- Zhang, Y.; et al. Enhanced kerr nonlinearity and nonlinear figure of merit in silicon nanowires integrated with 2d graphene oxide films. ACS Appl. Mater. Interfaces 2020, 12, 33094–33103. [Google Scholar] [CrossRef]

- Jia, L.; et al. Fabrication technologies for the on-chip integration of 2d materials. Small Methods 2022, 2101435. [Google Scholar] [CrossRef]

- Zhang, Y.-L.; et al. Photoreduction of graphene oxides: Methods, properties, and applications. Advanced Optical Materials 2014, 2, 10–28. [Google Scholar] [CrossRef]

- Chong, W. Y.; et al. Photo-induced reduction of graphene oxide coating on optical waveguide and consequent optical intermodulation. Sci. Rep. 2016, 6, 23813. [Google Scholar] [CrossRef]

- Qu, Y.; et al. Enhanced four-wave mixing in silicon nitride waveguides integrated with 2d layered graphene oxide films. Advanced Optical Materials 2001, 8, 2001048. [Google Scholar] [CrossRef]

- Ono, M.; et al. Ultrafast and energy-efficient all-optical switching with graphene-loaded deep-subwavelength plasmonic waveguides. Nat. Photonics 2019, 14, 37–43. [Google Scholar] [CrossRef]

- Li, Y.; et al. Transforming heat transfer with thermal metamaterials and devices. Nature Reviews Materials 2021, 6, 488–507. [Google Scholar] [CrossRef]

- Li, W.; et al. Ultrafast all-optical graphene modulator. Nano Lett. 2014, 14, 955–959. [Google Scholar] [CrossRef]

- Liu, F., Li, Q., Zhang, Z., Qiu, M. & Su, Y. Optically tunable delay line in silicon microring resonator based on thermal nonlinear effect. IEEE J. Sel. Top. Quantum Electron. 2008, 14, 706–712. [CrossRef]

- Zhou, G. J. & Wong, W. Y. Organometallic acetylides of pt(ii), au(i) and hg(ii) as new generation optical power limiting materials. Chem. Soc. Rev. 2011, 40, 2541–2566. [CrossRef]

- Pascal, S., David, S., Andraud, C. & Maury, O. Near-infrared dyes for two-photon absorption in the short-wavelength infrared: Strategies towards optical power limiting. Chem. Soc. Rev. 2021, 50, 6613–6658. [CrossRef]

- Sounas, D. L. & Alù, A. Non-reciprocal photonics based on time modulation. Nat. Photonics 2017, 11, 774–783. [CrossRef]

- Fan, L.; et al. An all-silicon passive optical diode. Science 2012, 335, 447–450. [Google Scholar] [CrossRef] [PubMed]

- Li, A. & Bogaerts, W. Reconfigurable nonlinear nonreciprocal transmission in a silicon photonic integrated circuit. Optica 2020, 7, 7. [CrossRef]

- Tian, H.; et al. Magnetic-free silicon nitride integrated optical isolator. Nat. Photonics 2021, 15, 828–836. [Google Scholar] [CrossRef]

- White, A. D. et al. Integrated passive nonlinear optical isolators. Nat. Photonics 2022. [CrossRef]

- Kittlaus, E. A.; et al. Electrically driven acousto-optics and broadband non-reciprocity in silicon photonics. Nat. Photonics 2020, 15, 43–52. [Google Scholar] [CrossRef]

- Bi, L.; et al. On-chip optical isolation in monolithically integrated non-reciprocal optical resonators. Nat. Photonics 2011, 5, 758–762. [Google Scholar] [CrossRef]

- Yang, K. Y.; et al. Inverse-designed non-reciprocal pulse router for chip-based lidar. Nat. Photonics 2020, 14, 369–374. [Google Scholar] [CrossRef]

- Kim, J., Kuzyk, M. C., Han, K., Wang, H. & Bahl, G. Non-reciprocal brillouin scattering induced transparency. Nat. Phys. 2015, 11, 275–280. [CrossRef]

- Shen, Z.; et al. Experimental realization of optomechanically induced non-reciprocity. Nat. Photonics 2016, 10, 657–661. [Google Scholar] [CrossRef]

- Feng, L.; et al. Nonreciprocal light propagation in a silicon photonic circuit. Science 2011, 333, 329–733. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.; et al. Parity–time-symmetric whispering-gallery microcavities. Nat. Phys. 2014, 10, 394–398. [Google Scholar] [CrossRef]

- Jalas, D.; et al. What is — and what is not — an optical isolator. Nat. Photonics 2013, 7, 579–582. [Google Scholar] [CrossRef]

- Renteria, J. D.; et al. Strongly anisotropic thermal conductivity of free-standing reduced graphene oxide films annealed at high temperature. Adv. Funct. Mater. 2015, 25, 4664–4672. [Google Scholar] [CrossRef]

- Seol, J. H.; et al. Two-dimensional phonon transport in supported graphene. Science 2010, 328, 213–216. [Google Scholar] [CrossRef] [PubMed]

- Sengupta, I., Chakraborty, S., Talukdar, M., Pal, S. K. & Chakraborty, S. Thermal reduction of graphene oxide: How temperature influences purity. J. Mater. Res. 2018, 33, 4113–4122. [CrossRef]

- Zhang, L.; et al. Free-standing functional graphene reinforced carbon films with excellent mechanical properties and superhydrophobic characteristic. Composites Part A: Applied Science and Manufacturing 2015, 74, 96–106. [Google Scholar] [CrossRef]

- Yang, Y. Y.; et al. Graphene-based multilayered metamaterials with phototunable architecture for on-chip photonic devices. ACS Photonics 2019, 6, 1033–1040. [Google Scholar] [CrossRef]

- Zheng, X., Jia, B., Chen, X. & Gu, M. In situ third-order non-linear responses during laser reduction of graphene oxide thin films towards on-chip non-linear photonic devices. Adv. Mater. 2014, 26, 2699–2703. [CrossRef]

- Jia, L.; et al. Highly nonlinear BiOBr nanoflakes for hybrid integrated photonics. APL Photonics 2019, 4, 090802. [Google Scholar] [CrossRef]

- Yuning Zhang, Jiayang Wu, Yang Qu, Yunyi Yang, Linnan Jia, Baohua Jia, and David J. Moss, “Enhanced supercontinuum generated in SiN waveguides coated with GO films”, Advanced Materials Technologies 8 (1) 2201796 (2023). [CrossRef]

- Yuning Zhang, Jiayang Wu, Linnan Jia, Yang Qu, Baohua Jia, and David J. Moss, “Graphene oxide for nonlinear integrated photonics”, Laser and Photonics Reviews 17 2200512 (2023). [CrossRef]

- Yang Qu, Jiayang Wu, Yuning Zhang, Yunyi Yang, Linnan Jia, Baohua Jia, and David J. Moss, “Photo thermal tuning in GO-coated integrated waveguides”, Micromachines 13 1194 (2022). [CrossRef]

- Yuning Zhang, Jiayang Wu, Yunyi Yang, Yang Qu, Houssein El Dirani, Romain Crochemore, Corrado Sciancalepore, Pierre Demongodin, Christian Grillet, Christelle Monat, Baohua Jia, and David J. Moss, “Enhanced self-phase modulation in silicon nitride waveguides integrated with 2D graphene oxide films”, IEEE Journal of Selected Topics in Quantum Electronics 29 (1) 5100413 (2023). [CrossRef]

- Yuning Zhang, Jiayang Wu, Yunyi Yang, Yang Qu, Linnan Jia, Baohua Jia, and David J. Moss, “Enhanced spectral broadening of femtosecond optical pulses in silicon nanowires integrated with 2D graphene oxide films”, Micromachines 13 756 (2022). [CrossRef]

- Linnan Jia, Jiayang Wu, Yuning Zhang, Yang Qu, Baohua Jia, Zhigang Chen, and David J. Moss, “Fabrication Technologies for the On-Chip Integration of 2D Materials”, Small: Methods 6, 2101435 (2022). [CrossRef]

- Yuning Zhang, Jiayang Wu, Yang Qu, Linnan Jia, Baohua Jia, and David J. Moss, “Design and optimization of four-wave mixing in microring resonators integrated with 2D graphene oxide films”, Journal of Lightwave Technology 39 (20) 6553-6562 (2021). Print ISSN: 0733-8724, Online ISSN: 1558-2213 (2021). [CrossRef]

- Yuning Zhang, Jiayang Wu, Yang Qu, Linnan Jia, Baohua Jia, and David J. Moss, “Optimizing the Kerr nonlinear optical performance of silicon waveguides integrated with 2D graphene oxide films”, Journal of Lightwave Technology 39 (14) 4671-4683 (2021). [CrossRef]

- Yang Qu, Jiayang Wu, Yuning Zhang, Yao Liang, Baohua Jia, and David J. Moss, “Analysis of four-wave mixing in silicon nitride waveguides integrated with 2D layered graphene oxide films”, Journal of Lightwave Technology 39 (9) 2902-2910 (2021). [CrossRef]

- Y. Qu, J. Wu, Y. Zhang, L. Jia, Y. Yang, X. Xu, S. T. Chu, B. E. Little, R. Morandotti, B. Jia, and D. J. Moss, “Graphene oxide for enhanced optical nonlinear performance in CMOS compatible integrated devices”, Paper No. 11688-30, PW21O-OE109-36, 2D Photonic Materials and Devices IV, SPIE Photonics West, San Francisco CA March 6-11 (2021). [CrossRef]

- Yang Qu, Jiayang Wu, Yunyi Yang, Yuning Zhang, Yao Liang, Houssein El Dirani, Romain Crochemore, Pierre Demongodin, Corrado Sciancalepore, Christian Grillet, Christelle Monat, Baohua Jia, and David J. Moss, “Enhanced nonlinear four-wave mixing in silicon nitride waveguides integrated with 2D layered graphene oxide films”, Advanced Optical Materials vol. 8 (21) 2001048 (2020). arXiv:2006.14944. [CrossRef]

- Yuning Zhang, Yang Qu, Jiayang Wu, Linnan Jia, Yunyi Yang, Xingyuan Xu, Baohua Jia, and David J. Moss, “Enhanced Kerr nonlinearity and nonlinear figure of merit in silicon nanowires integrated with 2D graphene oxide films”, ACS Applied Materials and Interfaces vol. 12 (29) 33094−33103 June 29 (2020). [CrossRef]

- Jiayang Wu, Yunyi Yang, Yang Qu, Yuning Zhang, Linnan Jia, Xingyuan Xu, Sai T. Chu, Brent E. Little, Roberto Morandotti, Baohua Jia,* and David J. Moss*, “Enhanced nonlinear four-wave mixing in microring resonators integrated with layered graphene oxide films”, Small vol. 16 (16) 1906563 April 23 (2020). [CrossRef]

- Jiayang Wu, Yunyi Yang, Yang Qu, Xingyuan Xu, Yao Liang, Sai T. Chu, Brent E. Little, Roberto Morandotti, Baohua Jia, and David J. Moss, “Graphene oxide waveguide polarizers and polarization selective micro-ring resonators”, Paper 11282-29, SPIE Photonics West, San Francisco, CA, 4 - 7 February (2020). [CrossRef]

- Jiayang Wu, Yunyi Yang, Yang Qu, Xingyuan Xu, Yao Liang, Sai T. Chu, Brent E. Little, Roberto Morandotti, Baohua Jia, and David J. Moss, “Graphene oxide waveguide polarizers and polarization selective micro-ring resonators”, Laser and Photonics Reviews vol. 13 (9) 1900056 (2019). [CrossRef]

- Yunyi Yang, Jiayang Wu, Xingyuan Xu, Sai T. Chu, Brent E. Little, Roberto Morandotti, Baohua Jia, and David J. Moss, “Enhanced four-wave mixing in graphene oxide coated waveguides”, Applied Physics Letters Photonics vol. 3 120803 (2018). [CrossRef]

- Linnan Jia, Yang Qu, Jiayang Wu, Yuning Zhang, Yunyi Yang, Baohua Jia, and David J. Moss, “Third-order optical nonlinearities of 2D materials at telecommunications wavelengths”, Micromachines (MDPI), 14, 307 (2023). [CrossRef]

- Linnan Jia, Dandan Cui, Jiayang Wu, Haifeng Feng, Tieshan Yang, Yunyi Yang, Yi Du, Weichang Hao, Baohua Jia, David J. Moss, “BiOBr nanoflakes with strong nonlinear optical properties towards hybrid integrated photonic devices”, Applied Physics Letters Photonics vol. 4 090802 (2019). [CrossRef]

- Linnan Jia, Jiayang Wu, Yunyi Yang, Yi Du, Baohua Jia, David J. Moss, “Large Third-Order Optical Kerr Nonlinearity in Nanometer-Thick PdSe2 2D Dichalcogenide Films: Implications for Nonlinear Photonic Devices”, ACS Applied Nano Materials vol. 3 (7) 6876–6883 (2020). [CrossRef]

- E.D Ghahramani, DJ Moss, JE Sipe, “Full-band-structure calculation of first-, second-, and third-harmonic optical response coefficients of ZnSe, ZnTe, and CdTe”, Physical Review B 43 (12), 9700 (1991)A. Pasquazi, et al., “Sub-picosecond phase-sensitive optical pulse characterization on a chip”, Nature Photonics, vol. 5, no. 10, pp. 618-623 (2011). [CrossRef]

- C Grillet, C Smith, D Freeman, S Madden, B Luther-Davies, EC Magi,... “Efficient coupling to chalcogenide glass photonic crystal waveguides via silica optical fiber nanowires”. Optics Express 2006, 14(3), 1070–1078. [CrossRef]

- S Tomljenovic-Hanic, MJ Steel, CM de Sterke, DJ Moss, “High-Q cavities in photosensitive photonic crystals”. Optics Letters 2007, 32(5), 542–544. [CrossRef]

- E Ghahramani, DJ Moss, JE Sipe, “Second-harmonic generation in odd-period, strained, (Si(Ge/Si superlattices and at Si/Ge interfaces”. Physical Review Letters 1990, 64(23), 2815. [CrossRef]

- M Ferrera et al., “On-Chip ultra-fast 1st and 2nd order CMOS compatible all-optical integration”. Optics Express 2011, 19(23), 23153–23161. [CrossRef] [PubMed]

- VG Ta’eed et al., “Error free all optical wavelength conversion in highly nonlinear As-Se chalcogenide glass fiber”. Optics Express 2006, 14(22), 10371–10376. [CrossRef] [PubMed]

- M Rochette, L Fu, V Ta’eed, DJ Moss, BJ Eggleton, “2R optical regeneration: an all-optical solution for BER improvement”. IEEE Journal of Selected Topics in Quantum Electronics 2006, 12(4), 736–744. [CrossRef]

- TD Vo, et al., “Silicon-chip-based real-time dispersion monitoring for 640 Gbit/s DPSK signals”. Journal of Lightwave Technology 2011, 29(12), 1790–1796. [CrossRef]

- C Monat, C Grillet, B Corcoran, DJ Moss, BJ Eggleton, TP White,..., et al., “Investigation of phase matching for third-harmonic generation in silicon slow light photonic crystal waveguides using Fourier optics”. Optics Express 2010, 18(7), 6831–6840. [CrossRef] [PubMed]

- L Carletti, P Ma, Y Yu, B Luther-Davies, D Hudson, C Monat,...., et al., “Nonlinear optical response of low loss silicon germanium waveguides in the mid-infrared”. Optics Express 2015, 23(7), 8261–8271. [CrossRef] [PubMed]

- Bao, C.; et al. Direct soliton generation in microresonators. Opt. Lett 2017, 42, 2519. [Google Scholar] [CrossRef] [PubMed]

- M.Ferrera et al., “CMOS compatible integrated all-optical RF spectrum analyzer”. Optics Express 2014, 22(18), 21488–21498. [CrossRef] [PubMed]

- M. Kues, et al., “Passively modelocked laser with an ultra-narrow spectral width”. Nature Photonics 2017, 11(3), 159. [CrossRef]

- L. Razzari, et al., “CMOS-compatible integrated optical hyper-parametric oscillator,”. Nature Photonics 2010, 4(1), 41–45. [CrossRef]

- M. Ferrera, et al., “Low-power continuous-wave nonlinear optics in doped silica glass integrated waveguide structures,”. Nature Photonics 2008, 2(12), 737–740. [CrossRef]

- M.Ferrera et al.“On-Chip ultra-fast 1st and 2nd order CMOS compatible all-optical integration”. Opt. Express 2010, 19(23), 23153–23161. [CrossRef]

- D. Duchesne, M. Peccianti, M. R. E. Lamont, et al., “Supercontinuum generation in a high index doped silica glass spiral waveguide,”. Optics Express 2010, 18(2), 923–930. [CrossRef] [PubMed]

- H Bao, L Olivieri, M Rowley, ST Chu, BE Little, R Morandotti, DJ Moss,... “Turing patterns in a fiber laser with a nested microresonator: Robust and controllable microcomb generation”. Physical Review Research 2020, 2(2), 023395. [CrossRef]

- M. Ferrera, et al., “On-chip CMOS-compatible all-optical integrator”. Nature Communications 2010, 1, 29. [CrossRef]

- Pasquazi, et al., “All-optical wavelength conversion in an integrated ring resonator,”. Optics Express 2010, 18(4), 3858–3863. [CrossRef]

- Pasquazi, Y. Park, J. Azana, et al., “Efficient wavelength conversion and net parametric gain via Four Wave Mixing in a high index doped silica waveguide,”. Optics Express 2010, 18(8), 7634–7641. [CrossRef]

- M. Peccianti, M. Ferrera, L. Razzari, et al., “Subpicosecond optical pulse compression via an integrated nonlinear chirper,”. Optics Express 2010, 18(8), 7625–7633. [CrossRef]

- Little, B. E. et al., “Very high-order microring resonator filters for WDM applications”. IEEE Photonics Technol. Lett. 2004, 16, 2263–2265. [CrossRef]

- M. Ferrera et al., “Low Power CW Parametric Mixing in a Low Dispersion High Index Doped Silica Glass Micro-Ring Resonator with Q-factor > 1 Million”. Optics Express 2009, 17(16), 14098–14103. [CrossRef]

- M. Peccianti, et al., “Demonstration of an ultrafast nonlinear microcavity modelocked laser”. Nature Communications 2012, 3, 765. [CrossRef]

- Pasquazi, et al., “Self-locked optical parametric oscillation in a CMOS compatible microring resonator: a route to robust optical frequency comb generation on a chip,”. Optics Express 2013, 21(11), 13333–13341. [CrossRef]

- Pasquazi, et al., “Stable, dual mode, high repetition rate mode-locked laser based on a microring resonator,”. Optics Express, 2012; 20, 24, 27355–27362. [CrossRef]

- Pasquazi, A. et al. Micro-combs: a novel generation of optical sources. Physics Reports 2018, 729, 1–81. [CrossRef]

- Moss, D. J. et al., “New CMOS-compatible platforms based on silicon nitride and Hydex for nonlinear optics”, Nature photonics 7, 597 (2013). [CrossRef]

- H. Bao, et al., Laser cavity-soliton microcombs. Nature Photonics 2019, 13(6), 384–389. [CrossRef]

- Antonio Cutrona, Maxwell Rowley, Debayan Das, Luana Olivieri, Luke Peters, Sai T. Chu, Brent L. Little, Roberto Morandotti, David J. Moss, Juan Sebastian Totero Gongora, Marco Peccianti, Alessia Pasquazi, “High Conversion Efficiency in Laser Cavity-Soliton Microcombs”, Optics Express Vol. 30, Issue 22, pp. 39816-39825 (2022). [CrossRef]

- M.Rowley, P.Hanzard, A.Cutrona, H.Bao, S.Chu, B.Little, R.Morandotti, D. J. Moss, G. Oppo, J. Gongora, M. Peccianti and A. Pasquazi, “Self-emergence of robust solitons in a micro-cavity”. Nature 2022, 608(7922), 303–309. [CrossRef]

- A. Cutrona, M. Rowley, A. Bendahmane, V. Cecconi,L. Peters, L. Olivieri, B. E. Little, S. T. Chu, S. Stivala, R. Morandotti, D. J. Moss, J. S. Totero-Gongora, M. Peccianti, A. Pasquazi, “Nonlocal bonding of a soliton and a blue-detuned state in a microcomb laser”. Nature Communications Physics 2023, 6. [CrossRef]

- A. Cutrona, M. Rowley, A. Bendahmane, V. Cecconi,L. Peters, L. Olivieri, B. E. Little, S. T. Chu, S. Stivala, R. Morandotti, D. J. Moss, J. S. Totero-Gongora, M. Peccianti, A. Pasquazi, “Stability Properties of Laser Cavity-Solitons for Metrological Applications”, Applied Physics Letters 122 (12) 121104 (2023); X. Xu, J. Wu, M. Shoeiby, T. G. Nguyen, S. T. Chu, B. E. Little, R. Morandotti, A. Mitchell, and D. J. Moss, “Reconfigurable broadband microwave photonic intensity differentiator based on an integrated optical frequency comb source,” APL Photonics, vol. 2, no. 9, 096104, Sep. 2017. [CrossRef]

- Xu, X., et al., Photonic microwave true time delays for phased array antennas using a 49 GHz FSR integrated micro-comb source. Photonics Research 2018, 6, B30–B36. [CrossRef]

- X. Xu, M. Tan, J. Wu, R. Morandotti, A. Mitchell, and D. J. Moss, “Microcomb-based photonic RF signal processing”. IEEE Photonics Technology Letters, 2019; 31, 23, 1854–1857. [CrossRef]

- Xu, et al., “Advanced adaptive photonic RF filters with 80 taps based on an integrated optical micro-comb source,”. Journal of Lightwave Technology 2019, 37(4), 1288–1295. [CrossRef]

- X. Xu, et al., “Photonic RF and microwave integrator with soliton crystal microcombs”, IEEE Transactions on Circuits and Systems II: Express Briefs, vol. 67, no. 12, pp. 3582-3586, 2020. [CrossRef]

- X. Xu, et al., “High performance RF filters via bandwidth scaling with Kerr micro-combs,”. APL Photonics 2019, 4(2), 026102. [CrossRef]

- M. Tan, et al., “Microwave and RF photonic fractional Hilbert transformer based on a 50 GHz Kerr micro-comb”. Journal of Lightwave Technology 2019, 37(24), 6097–6104. [CrossRef]

- M. Tan, et al., “RF and microwave fractional differentiator based on photonics”, IEEE Transactions on Circuits and Systems: Express Briefs, vol. 67, no.11, pp. 2767-2771, 2020. [CrossRef]

- M. Tan, et al., “Photonic RF arbitrary waveform generator based on a soliton crystal micro-comb source”, Journal of Lightwave Technology, vol. 38, no. 22, pp. 6221-6226 (2020). [CrossRef]

- M. Tan, X. Xu, J. Wu, R. Morandotti, A. Mitchell, and D. J. Moss, “RF and microwave high bandwidth signal processing based on Kerr Micro-combs”, Advances in Physics X, VOL. 6, NO. 1, 1838946 (2021). [CrossRef]

- X. Xu, et al., “Advanced RF and microwave functions based on an integrated optical frequency comb source,”. Opt. Express 2018, 26(3), 2569. [CrossRef] [PubMed]

- M. Tan, X. Xu, J. Wu, B. Corcoran, A. Boes, T. G. Nguyen, S. T. Chu, B. E. Little, R.Morandotti, A. Lowery, A. Mitchell, and D. J. Moss, ““Highly Versatile Broadband RF Photonic Fractional Hilbert Transformer Based on a Kerr Soliton Crystal Microcomb”. Journal of Lightwave Technology 2021, 39(24), 7581–7587. [CrossRef]

- Wu, J. et al. RF Photonics: An Optical Microcombs’ Perspective. IEEE Journal of Selected Topics in Quantum Electronics 2018, 24, 6101020. [CrossRef]

- T. G. Nguyen et al., “Integrated frequency comb source-based Hilbert transformer for wideband microwave photonic phase analysis,”. Opt. Express 2015, 23(17), 22087–22097. [CrossRef]

- X. Xu, et al., “Broadband RF channelizer based on an integrated optical frequency Kerr comb source,”. Journal of Lightwave Technology 2018, 36(19), 4519–4526. [CrossRef]

- X. Xu, et al., “Continuously tunable orthogonally polarized RF optical single sideband generator based on micro-ring resonators,”. Journal of Optics 2018, 20(11), 115701. [CrossRef]

- X. Xu, et al., “Orthogonally polarized RF optical single sideband generation and dual-channel equalization based on an integrated microring resonator,”. Journal of Lightwave Technology 2018, 36(20), 4808–4818. [CrossRef]

- X. Xu, et al., “Photonic RF phase-encoded signal generation with a microcomb source”. J. Lightwave Technology 2020, 38(7), 1722–1727. [CrossRef]

- X. Xu, et al., Broadband microwave frequency conversion based on an integrated optical micro-comb source. Journal of Lightwave Technology, 2020; 38, 2, 332–338.

- M. Tan, et al., “Photonic RF and microwave filters based on 49GHz and 200GHz Kerr microcombs". Optics Comm. 2020, 465, 125563. [CrossRef]

- X. Xu, et al., “Broadband photonic RF channelizer with 90 channels based on a soliton crystal microcomb”, Journal of Lightwave Technology, Vol. 38, no. 18, pp. 5116 – 5121 (2020). [CrossRef]

- M. Tan et al, “Orthogonally polarized Photonic Radio Frequency single sideband generation with integrated micro-ring resonators”, IOP Journal of Semiconductors, Vol. 42 (4), 041305 (2021). [CrossRef]

- Mengxi Tan, X. Xu, J. Wu, T. G. Nguyen, S. T. Chu, B. E. Little, R. Morandotti, A. Mitchell, and David J. Moss, “Photonic Radio Frequency Channelizers based on Kerr Optical Micro-combs”, IOP Journal of Semiconductors Vol. 42 (4), 041302 (2021). [CrossRef]

- B. Corcoran, et al., “Ultra-dense optical data transmission over standard fiber with a single chip source”. Nature Communications 2020, 11, 2568. [CrossRef]

- X. Xu et al, “Photonic perceptron based on a Kerr microcomb for scalable high speed optical neural networks”, Laser and Photonics Reviews, vol. 14, no. 8, 2000070 (2020). [CrossRef]

- X. Xu, et al., “11 TOPs photonic convolutional accelerator for optical neural networks”. Nature 2021, 589, 44–51. [CrossRef] [PubMed]

- X. Xu et al., “Neuromorphic computing based on wavelength-division multiplexing”, 28 IEEE Journal of Selected Topics in Quantum Electronics Vol. 29 Issue: 2, Article 7400112 (2023). [CrossRef]

- Yang Sun, Jiayang Wu, Mengxi Tan, Xingyuan Xu, Yang Li, Roberto Morandotti, Arnan Mitchell, and David Moss, “Applications of optical micro-combs”, Advances in Optics and Photonics 15 (1) 86-175 (2023). [CrossRef]

- Yunping Bai, Xingyuan Xu,1, Mengxi Tan, Yang Sun, Yang Li, Jiayang Wu, Roberto Morandotti, Arnan Mitchell, Kun Xu, and David J. Moss, “Photonic multiplexing techniques for neuromorphic computing”, Nanophotonics 12 (5): 795–817 (2023). [CrossRef]

- Chawaphon Prayoonyong, Andreas Boes, Xingyuan Xu, Mengxi Tan, Sai T. Chu, Brent E. Little, Roberto Morandotti, Arnan Mitchell, David J. Moss, and Bill Corcoran, “Frequency comb distillation for optical superchannel transmission”, Journal of Lightwave Technology 39 (23) 7383-7392 (2021). [CrossRef]

- Mengxi Tan, Xingyuan Xu, Jiayang Wu, Bill Corcoran, Andreas Boes, Thach G. Nguyen, Sai T. Chu, Brent E. Little, Roberto Morandotti, Arnan Mitchell, and David J. Moss, “Integral order photonic RF signal processors based on a soliton crystal micro-comb source”, IOP Journal of Optics 23 (11) 125701 (2021). [CrossRef]

- Yang Sun, Jiayang Wu, Yang Li, Xingyuan Xu, Guanghui Ren, Mengxi Tan, Sai Tak Chu, Brent E. Little, Roberto Morandotti, Arnan Mitchell, and David J. Moss, “Performance analysis of microcomb-based microwave photonic transversal signal processors with experimental errors”, Journal of Lightwave Technology Vol. 41 Special Issue on Microwave Photonics (2023).

- Mengxi Tan, Xingyuan Xu, Andreas Boes, Bill Corcoran, Thach G. Nguyen, Sai T. Chu, Brent E. Little, Roberto Morandotti, Jiayang Wu, Arnan Mitchell, and David J. Moss, “Photonic signal processor for real-time video image processing at 17 Tb/s”. Communications Engineering 2023, 2. [CrossRef]

- Mengxi Tan, Xingyuan Xu, Jiayang Wu, Roberto Morandotti, Arnan Mitchell, and David J. Moss, “Photonic RF and microwave filters based on 49GHz and 200GHz Kerr microcombs”, Optics Communications, 465, Article: 125563 (2020). [CrossRef]

- Yang Sun, Jiayang Wu, Yang Li, Mengxi Tan, Xingyuan Xu, Sai Chu, Brent Little, Roberto Morandotti, Arnan Mitchell, and David J. Moss, “Quantifying the Accuracy of Microcomb-based Photonic RF Transversal Signal Processors”, IEEE Journal of Selected Topics in Quantum Electronics 29 no. 6, pp. 1-17, Art no. 7500317 (2023). [CrossRef]

- Kues, M. et al. “Quantum optical microcombs”, Nature Photonics 13, (3) 170-179 (2019). [CrossRef]

- C. Reimer, L. Caspani, M. Clerici, et al., “Integrated frequency comb source of heralded single photons,”. Optics Express 2014, 22(6), 6535–6546. [CrossRef]

- C. Reimer, et al., “Cross-polarized photon-pair generation and bi-chromatically pumped optical parametric oscillation on a chip”, Nature Communications, vol. 6, Article 8236, 2015. [CrossRef]

- L. Caspani, C. Reimer, M. Kues, et al., “Multifrequency sources of quantum correlated photon pairs on-chip: a path toward integrated Quantum Frequency Combs,”. Nanophotonics 2016, 5(2), 351–362. [CrossRef]

- C. Reimer et al., “Generation of multiphoton entangled quantum states by means of integrated frequency combs,”. Science 2016, 351(6278), 1176–1180. [CrossRef]

- M. Kues, et al., “On-chip generation of high-dimensional entangled quantum states and their coherent control”. Nature 2017, 546(7660), 622–626. [CrossRef]

- P. Roztocki et al., “Practical system for the generation of pulsed quantum frequency combs,”. Optics Express 2017, 25(16), 18940–18949. [CrossRef]

- Y. Zhang, et al., “Induced photon correlations through superposition of two four-wave mixing processes in integrated cavities”, Laser and Photonics Reviews, vol. 14, no. 7, pp. 2000128, 2020. [CrossRef]

- Reimer, et al., “High-dimensional one-way quantum processing implemented on d-level cluster states”. Nature Physics 2019, 15(2), 148–153. [CrossRef]

- P.Roztocki et al., “Complex quantum state generation and coherent control based on integrated frequency combs”. Journal of Lightwave Technology 2019, 37(2), 338–347. [CrossRef]

- S. Sciara et al., “Generation and Processing of Complex Photon States with Quantum Frequency Combs”, IEEE Photonics Technology Letters 31 (23) 1862-1865 (2019). [CrossRef]

- Stefania Sciara, Piotr Roztocki, Bennet Fisher, Christian Reimer, Luis Romero Cortez, William J. Munro, David J. Moss, Alfonso C. Cino, Lucia Caspani, Michael Kues, J. Azana, and Roberto Morandotti, “Scalable and effective multilevel entangled photon states: A promising tool to boost quantum technologies”, Nanophotonics 10 (18), 4447–4465 (2021). [CrossRef]

- L. Caspani, C. Reimer, M. Kues, et al., “Multifrequency sources of quantum correlated photon pairs on-chip: a path toward integrated Quantum Frequency Combs,”. Nanophotonics 2016, 5(2), 351–362. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).