1. Introduction

Water is a precious resource in arid and semi-arid regions, particularly in the Kingdom of Saudi Arabia (KSA). In these regions, farmers are increasingly using protected farming methods, such as plastic mulch, tunnel farming, greenhouses and hydroponic systems to meet the year-round demands of fresh agricultural food commodities [

1]. Soil is essential for plant growth, providing nutrients, water and air. However, some soil types pose limitations to plant growth, such as coarse-textured sandy soils that homogenously exist in soil profiles of greenhouses. Sandy soils are characterized by high permeability, low water-holding capacity, and the presence of pathogenic organisms and nematodes [

2]. To overcome the challenges posed by sandy soils in greenhouses, soilless cultivation techniques provide an alternative strategy to enhance the water use efficiency [

3,

5]. It was indicated by Estidamah (2022) that when a soilless cultivation method with a drain collection system was set up, water consumption for greenhouse tomatoes could be reduced by 33% (1014 Lm-2) compared to soil-based cultivation (1518 Lm-2). The daily water requirement of a tomato plant varies depending on the growing system [

7]. A soilless cultivation system using a combination of cocopeat, perlite, and vermiculite (50:25:25) requires less water than a system using two substrates (50:50) or one substrate. The soilless cultivation system produced more tomatoes per unit of water, with a water productivity of 83.4 kg m-3 [

8].

Tomato (Solanum lycopersicum Mill.) is one of the widely cultivated and highly consumed vegetable crops in the world, especially in semi-arid areas [

9]. Tomato cultivation in the Mediterranean region requires high water supply and fertilization demands. Tomatoes grown using hydroponics have been shown to have increased nutritional benefits compared to tomatoes grown conventionally by soil-based methods [

10]. Greenhouse tomato cultivation in Saudi Arabia accounts for nearly 50% of total tomato production [

11]. Majority of cultivated areas in Saudi Arabia are dominated by sandy soils, which are prone to water scarcity [

12]. Therefore, it is necessary to use alternative water-saving techniques to improve water use efficiency of the tomato production in the Kingdom [

13].

A study compared the economic viability of three different methods of growing tomatoes was carried out in southeastern Spain. The open-field method, which uses perlite as a substrate, was the most expensive method, due to the high cost of irrigation and fertilization. The hydroponic deep flow method, was the second most expensive method due to the high cost of phytosanitary treatments and maintenance. The nutrient film technique (NFT) method, was the least expensive method, due to the low cost of energy [

14]. Similarly, a study was conducted at the Saidapur farm of the University of Agricultural Sciences in Dharwad to determine the best levels of irrigation and soilless media for growing tomatoes for the fresh market under hi-tech greenhouse conditions [

8]. The study found that the highest fruit yield and weight were obtained when tomatoes were grown with drip irrigation at 100% Epan and a soilless mixture of cocopeat, perlite, and vermiculite in a 50:25:25 ratio. This combination also resulted in higher gross and net returns than the other treatment combinations.

This study compared the effects of two different tomato-growing methods: hydroponic soilless (HSless) as an open system technique and a conventional soil-based (CSbased) technique. The aim of the study was to investigate how the two methods affected vegetative plant growth, fruit yield, water use efficiency, and the economics of greenhouse-grown tomato production. Moreover, the study intended to introduce a water-saving, inexpensive and environmental sound method, using local gravel and a mixture of peat moss, humin-substrate, and perlite in ratios of 4:3:1.5 for greenhouse tomato production.

2. Materials and Methods

The study experiment was conducted in a greenhouse at the research and training station of King Faisal University, Saudi Arabia (25o 17.1347’ N and 49o 29.1889’ E). In this study, the following two factors were considered:

2.1. Experimental Design

A two-factorial experiment was set as spilt plot design with three replications in the greenhouse,

Figure 1. The first factor consisted of two cultivation methods (CSbased and HSless), while the second factor included three levels of irrigation regimes imposed with emitters of 4, 6, and 8 L.h-1 design discharge.

2.2. Cultivation Methods

The soil-based cultivation (CSbased) is a conventional soil-culture practice prevailed in most of the low-tech greenhouses of the KSA for growing vegetables. Initially, soil samples were taken from the CSbased plot to determine its soil profile physical properties, as shown in

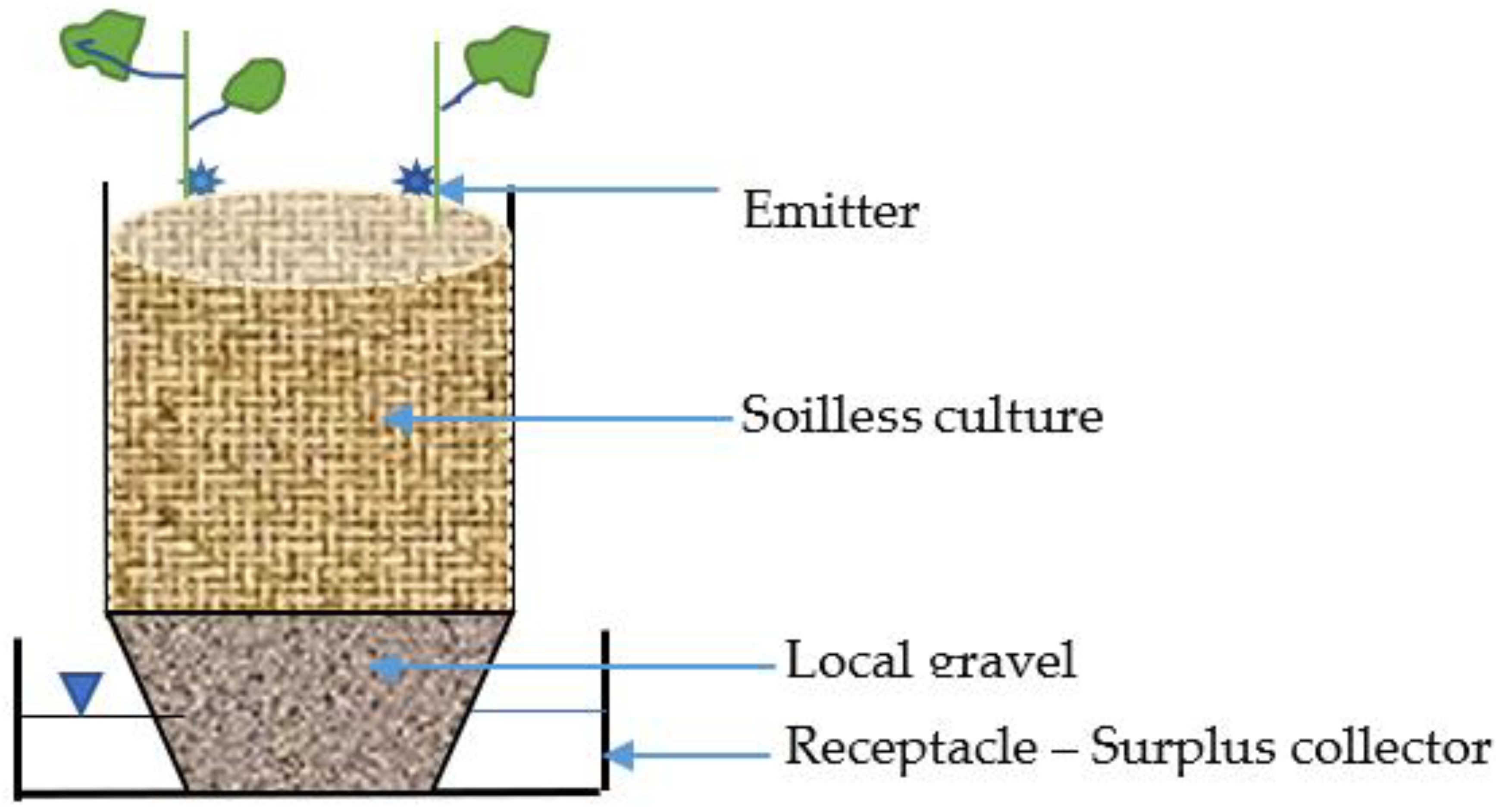

Table 1. In this study, the hydroponic soilless culture (HSless) was an open system where water and nutrient were supplied as in the conventional soil culture, but the surplus of the water and nutrient (about 15%) was manually collected and reused. The soilless culture of the HSless was made up of a peat-moss, humin-substrate, and perlite in the ratio of (4:3:1.5). The peat moss is capable of absorbing 16 to 36 times its dry weight, has low pH range from 3.4 to 4.8 and high porosity of more than 95%. The humin-substrate contained many humic acids and was characterized by high water absorption capacity. The perlite is a natural inorganic mineral used as a hydroponic medium; it stimulates root growth and helps drain excess water. The HSless cultivation plot consisted of 32 pots (20 liters) perforated from the bottom and placed in receptacles for the surplus collection. Local gravel was loaded up to 10 cm into each pot, then an equal amount of soilless culture was placed on the gravel as shown by the plot sketch (

Figure 1).

2.3. Assessment of Drip Irrigation Emitters

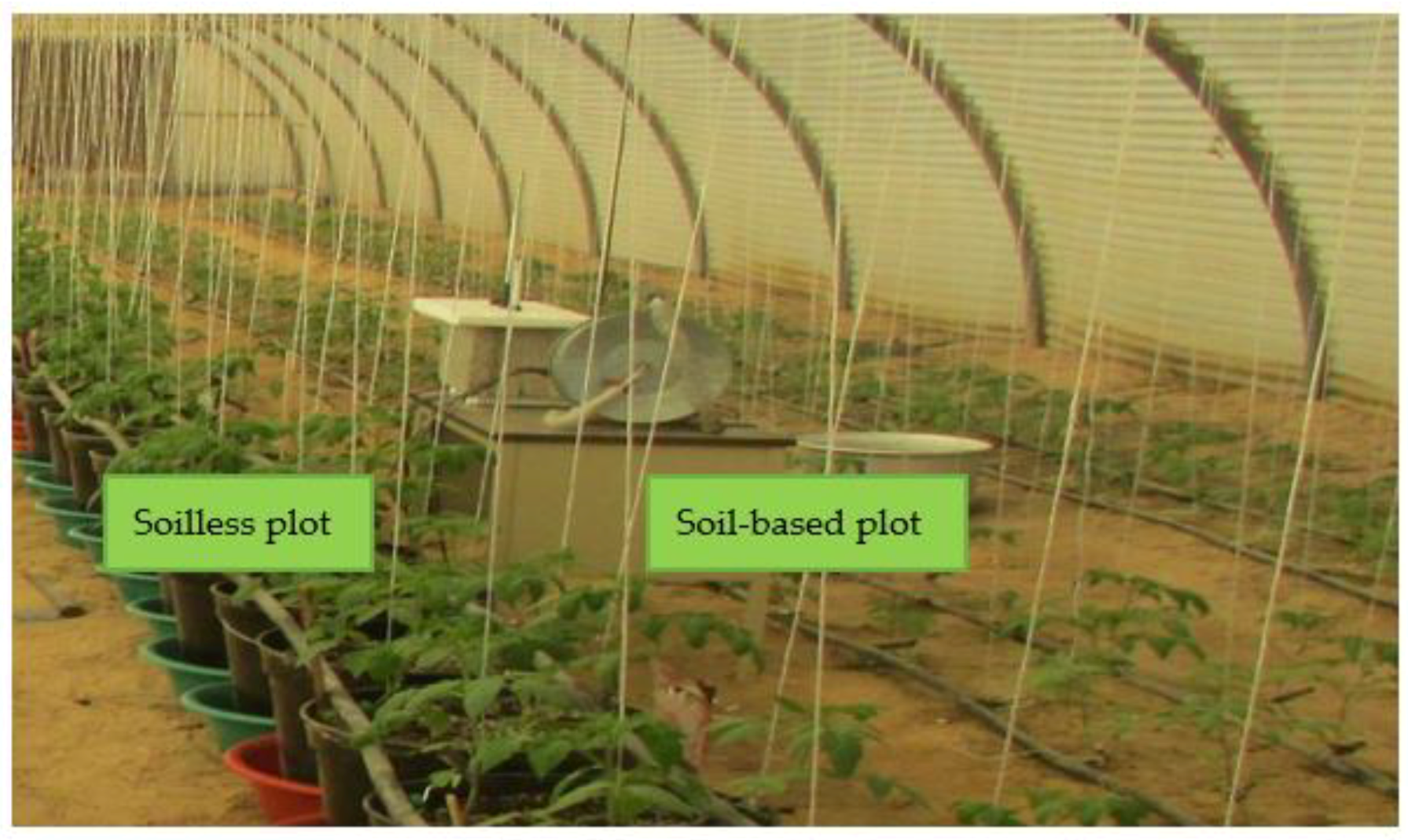

In each of the two cultivation method plots, as shown in

Figure 2, two parallel lateral driplines were placed on the soil ridges for the CSbased methodand on the pots for the HSless method. The two driplines were 30 cm apart and each dripline was loaded with 40 cm spaced emitters. In both cultivation plots, first eight pair of emitters, on the two lateral driplines, were 4 L.h-1 design discharge (subplot-I), while the middle eight pairs were 6 L.h-1 design discharge (subplot-II), and the last eight pairs were 8 L.h-1 design discharge (subplot-III). An operating pressure of 150 kPa during irrigation of the two cultivation plots was adopted throughout the experiment. Initially before the transplanting, emitters discharge under 150 kPa were measured; actual emitters discharge attained were 3.67, 5.55 and 7.30 L.h-1, respectively, for design emitters discharge of 4, 6, and 8 L.h-1.

2.4. Water Requirement and Irrigation Scheduling

In the control section of the drip irrigation system, a reservoir was filled with groundwater (1.3 dS m-1) connected to a water pump, timer, solenoid valves, and digital flow water meters. This control section was used to supply and measure irrigation water delivered to the HSless and CSbased cultivation plots. Water requirement of tomato plant per day grown by the CSbased system was determined using the following formula:

where in:

V: Volume of water irrigation (m3), Epan: Evaporation rate from a class A evaporation pan located in the greenhouse (mm), SA: Shadow Area (m2).

Then the duration time of irrigation for the CSbased plot was determined using the following relation:

The irrigation duration for the HSless cultivation plot was determined during the growing season when 15% of the surplus water was observed in receptacles.

2.5. Water Productivity

Water productivity (WP) under the HSless and CSbased cultivations was determined by the ratio between the total economic yield of the greenhouse tomato (kg) and the amount of water applied (m3) to a specific treatment during the growing season. It was computed using the following formula.

2.6. Benefit-Cost Analysis

Benefit-cost analysis is an indicator used to decide upon the economic viability of an investment. It associates costs with benefits to select the highest total benefit for the cost incurred [

11]. The benefit-cost ratio compares investments to choose the project, which yields the highest benefit-cost ratio, given by the following equation:

where BCR, B, and C denote the benefit-cost ratio, benefits, and costs, respectively.

Benefits and costs for the two cultivation systems were compared for the greenhouse tomato crop.

2.7. Break-Even Levels of Production and Prices

Researchers uses break-even analysis to determine the number of units that needed to be sold to cover the cost of production. Break-even analysis is a financial tool that calculates the point at which a business or investment will neither make a profit nor a loss [

15,

16]. The break-even point determines the number of units that must be marketed to obtain the returns required to cover all the expenses. The breakeven point equation is given by the following specification:

where BP, FC, VC and P represent break-even production level, fixed cost, variable cost per unit and price per unit, respectively.

The gap between the price and the variable cost per unit measures the contribution of each item produced to cover the investment’s fixed costs. Production at the breakeven point indicates that the investment revenue covers the cost of production (the profit at the breakeven point is zero; revenue is equal to cost). Production, above or below breakeven levels, indicates that the enterprise is operating at a profit or loss, respectively [

17]. The break-even prices, which represent prices that cover costs at specific sales volumes, were estimated.

2.8. Revenues over Variable Cost and Revenues on Investment

The hydroponic greenhouse production budget from Ohio State University [

18] was followed and modified to estimate the revenues over variable costs and revenues on investment for the two cultivation methods. This was done by using the variable and fixed costs experienced by each method.

Revenues and costs were calculated using current Saudi Riyal (SAR) prices. The total cost includes variable and fixed costs. Fixed costs are the costs of setting upthe investment, and they will be incurred even if no production is taking place. Variable cost are the costs of production inputs, and they are incurred when the production process begins. Total and net revenues were estimated for each production system by subtracting variable and total costs from total revenues.

The straight-line method was used [

19] to estimate fixed costs during the production period. This method calculates depreciation by dividing the asset’s cost by its useful life. The following specifications were used

The abbreviations FC, IC, RV, and UL stand for fixed cost, initial cost, residual value, and useful life, respectively. These terms are used to describe the costs associated with a used fixed asset. The fixed and variable costs of the HSless and CSbased methods are shown in

Supplementary Tables S1–S3. Explicit costs are those that require a direct outlay of money, such as wages, rent, and materials. Implicit costs are those that do not involve an immediate outlay of money, but represent the opportunity cost of using resources that could be used for other purposes.

3. Results and Discussion

3.1. Measured Actual Irrigation Amounts

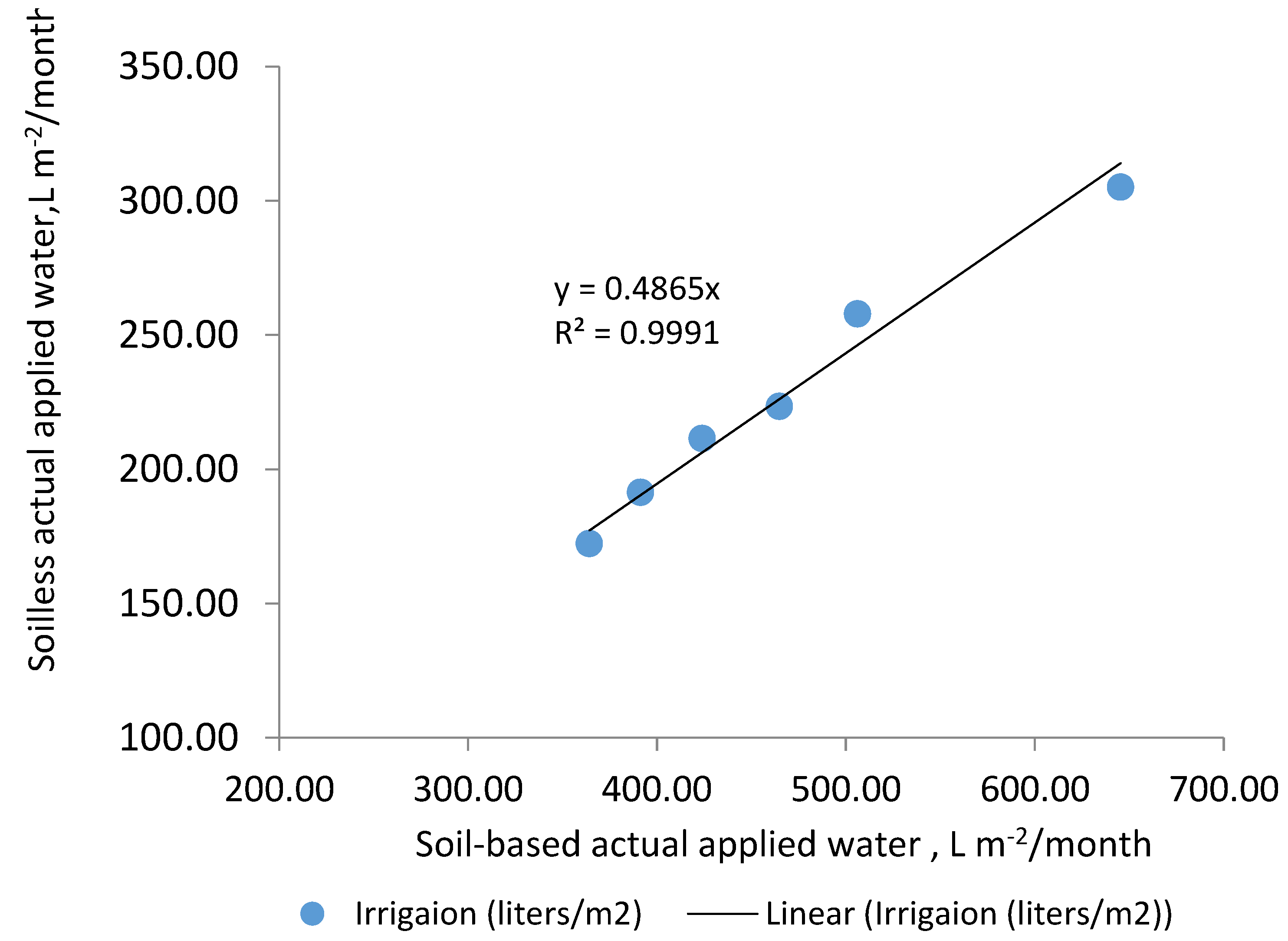

Initially, during first month of tomato growth cycle, the results showed the actual applied irrigation water were0.58, 0.87, 1.15 liters per plant per day for the HSless cultivation plot, and were 0.1.31, 1.95, 2.58 liters per plant per day was for the CSbased cultivation plot, respectively for D0.5, D0.75 and D1was. Considering irrigation regime of the emitters of high discharge (D1), the HSless cultivation method used 50% less irrigation water than the CSbased cultivation method. The amount of irrigation water used by both methods increased with the growth of the tomato plants (

Figure 3). The differences in irrigation amounts between the two approaches could be attributed to the difference in the water holding capacity of the soil and the hydroponic substrate mixture. Surplus drainage from the HSless was reused (15%), while surplus drainage from the CSbased cultivation method beyond the root zone was lost through deep percolation.

3.2. Vegetative Growth Response

Table 2 shows the least significant difference (LSD) in all-pairwise comparison tests of plant height and number of leaves for the cultivation methods, emitters design discharge (D) and growing time of the tomato plants. There were significant pairwise differences among the plant height means during the late growing time, but not during the early growing time for different emitters discharges (D0.5, D0.75 , D1) and under both cultivation methods (CSbased and HSless). Considering the mean number of leaves, there were significant pairwise differences between the two cultivation methods only for emitters discharge of D0.75 during the late growing time.

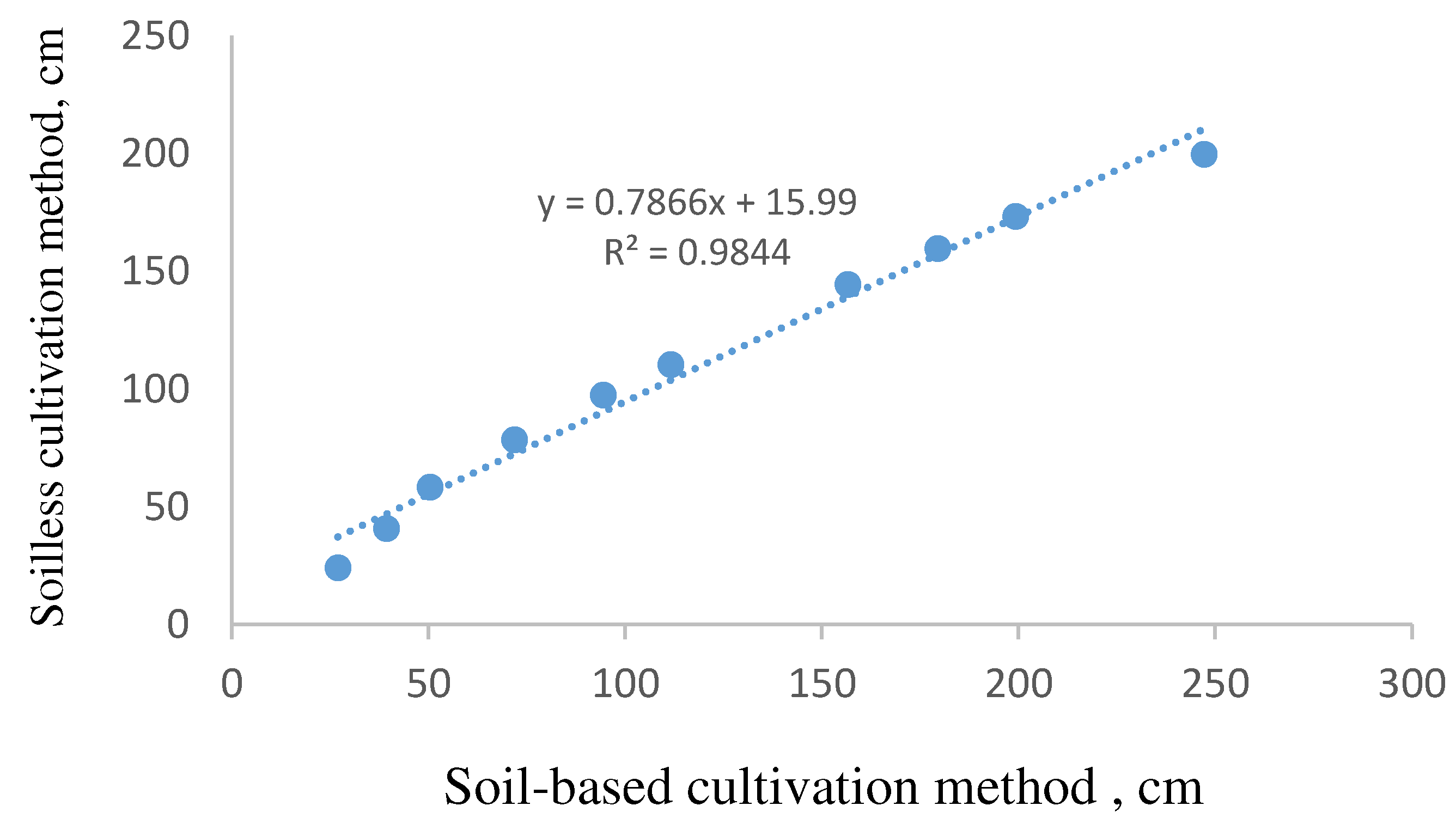

The results of the study showed that there was a strong linear relationship between the average plant height growths in the two cultivation methods (

Figure 4). The coefficient of determination, R2= 0.98, was very high, which means that the plant height growth for the two cultivation methods was almost identical. This suggests that about 50% of the irrigation water could be saved by using the HSless cultivation method instead of the CSbased cultivation method in greenhouses with homogenous sandy soil profiles.

The analysis of the variance (ANOVA) for tomato plant heights, as shown in

Table 3, found that there were significant differences between the cultivation methods, emitters discharge, and growing time (P=0.05). The LSD all-pairwise comparison tests in

Table 2 confirmed these findings. In addition, the interaction of the cultivation methods with the emitters discharge (D) or with the growing time (T) showed significant differences. However, the interaction of the cultivation methods with the emitters discharge (D) and with the growing time (T) was showed insignificant differences (P=0.998).

3.3. Tomato Fruit Yield and Components Responses

The average tomato fruit yield (TFY) per square meter were determined, along with the number of fruits and fruit diameters (

Table 4 and

Table 5). In comparison, during the early picking times, the TFY of the HSless cultivation was higher than the CSbased cultivation and vice versa for the late picking (

Table 5,

Figure 5). Using the emitters discharge of the D0.75 compared to the D1, reduced the average TFY per square meter under the HSless by 7.9%, while under the CSbased reduced by 11.8%. On the other hand, using the D0.5 emitters discharge reduced it by 38.9% under the CSbased and 25.1% under the HSless. Therefore, the reductions were pronounced more at the use of D0.5 emitters discharge under both cultivation systems than at the use of the D0.75. In comparison between the cultivations, the TFY under the HSless was 7.4% less than the CSbased at D1 and 11.3% at D0.75 but increased by 13.1% with D0.5 emitters discharge.

The outcomes showed the number of tomato fruits and weights were increasing under the CSbased cultivation during the first four fruit picks but inconsistent under the HSless cultivation. As shown in

Table 5, the total number of fruits and weights during the first picks were higher with the HSless than with the CSbased. Moreover, the total TFY produced by the HSless per square meter was 92.5% of the CSbased production.

The number and weight of tomato fruits decreased at the end of the growing season. This was likely due to the hot weather conditions outside the greenhouse in April and May. The average diameter of the tomato fruits also decreased under both cultivation methods.

Table 5 shows that, the average TFY of greenhouse tomatoes was 2.02 kg m

-2 (20.2 tons ha-1) for the CSbased cultivation method and 1.87 kg m

-2 (18.7 ton ha-1) for the HSless cultivation method. During the growth cycle, the amount of irrigation water received per square meter was 0.1306 m3 for the CSbased cultivation method and 0.07688 m

3 under the HSless cultivation method. This means that the water use efficiency of the CSbased cultivation method was 15.5 kg m

-3, while the water use efficiency of the HSless cultivation method was 24.3 kg m

-3. Therefore, it took 64.5 liters of water to produce 1 kg of tomatoes using the CSbased method, while it took 41.2 liters of water using the HSless method.

The ANOVA for TFY showed that there were significant differences in TFY when different emitters were used for irrigation, but there were no significant differences in TFY when different cultivation methods were used (P=0.05) (

Table 6). Additionally, there were significant differences in TFY when fruit was picked at different times, and there were also significant interactions between fruit picking time (PT) and cultivation method. However, there were significant differences in the tomato fruit yield for the interaction of the cultivation methods, emitters’ discharge and picking times. In other words, the type of emitter used for irrigation had a significant impact on TFY, but the type of cultivation method did not. The time at which fruit was picked also had a significant impact on TFY, and the impact of fruit picking time was different for different cultivation methods. These results suggest that the type of emitter used for irrigation and the time at which fruit is picked are both important factors that can affect TFY.

3.4. Economic of Tomato Fruit Production

The fixed cost per square meter was estimated at 4.4 SR for both cultivation methods. This is because the two systems have similar fixed costs (

Table 7). However, the variable cost for the hydroponic system was slightly higher than the conventional system. This is because the hydroponic system requires additional costs for hydroponic irrigation. The conventional system produces a higher yield of tomatoes, resulting in higher revenues and profits. Variable costs are the largest component of total costs for both systems. Variable cost topped fixed cost for both methods, a result that may be explained by the extended useful life of fixed cost items, lowering depreciation of fixed cost items. Variable costs for tomato cultivation under the HSless and CSbased systems account for 80% and 78% of total costs, respectively.

Table 8 illustrates results associated with the benefit-cost analysis for selecting the economic investment. The benefit-cost analysis for selecting the economic investment approved the aformentioned results (

Table 8). The benefit-cost analysis shows that both systems are economically viable, with benefit-cost ratios of 2.6 and 2.2 for CSbased cultivation and HSless cultivation, respectively. The conventional CSbased cultivation system is slightly more profitable, but both systems are viable options for tomato cultivation.

The two farming systems, conventional and hydroponic, are both economically viable, as they both generate positive revenues over both variable and total costs (

Table 9). However, the conventional CSbased system appears to be more profitable than the HSless system.

The breakeven prices for tomato cultivation under the two systems are shown in

Table 10 (profit at the breakeven price equals zero). Higher breakeven prices to cover variable and total costs per kg for the HSless method were observed, explained by higher variable and total costs coupled with a lower yield of tomatoes cultivated under the hydroponic greenhouse system. Deducting total cost per kg from market price, the profit per kilogram of tomatoes was 3.56 for the HSless method and 4 for the CSbased method, respectively. Based on the estimated breakeven volume of production for the period considered, the breakeven yield for the hydroponic soilless system was calculated at around 1.05 kg m

-2, which is below the actual yield of 7.48 kg m

-2 by 6.43 kg m

-2. In contrast, breakeven yield per square meter for the conventional soil based method was estimated at 0.96, below the actual yield of 8.08 kg m

-2 by around 7.12 kg m

-2 (

Table 1 and

Table 4). Since fixed cost and prices are the same for both systems, the difference in breakeven yield for the two systems arises from the difference in contribution margin, which is influenced by per unit variable cost.

5. Conclusions

This study found that HSless cultivation method is a more water-efficient and environmentally friendly way to grow vegetables in greenhouses than the CSbased cultivation method. It has the potential to save irrigation water and enhance water productivity. The water productivity of HSless cultivation was almost 50% higher than the CSbased cultivation meaning that the same amount of water produced more tomatoes. Additionally, HSless cultivation method does not require soil sterilization, which can release harmful chemicals into the environment. Both cultivation methods were profitable, but CSbased cultivation system had a higher yield, revenue, and profitability. Results highlighted a tradeoff situation facing policymakers and specialists between the CSbased method for higher economic returns and the HSless method for water conservation advantage. Further research on the economic evaluation of HSless cultivation methods for other essential crops is suggested.

Appendix A

Supplementary Tables S1–S3:

Table S1.

fixed and variable cost for tomato under Hydroponic soilless and conventional soil-based cultivation methods.

Table S1.

fixed and variable cost for tomato under Hydroponic soilless and conventional soil-based cultivation methods.

| Total area of the greenhouse 346.5 m2 |

| Item No. |

Item name |

Unit |

Initial Cost (SR) |

Expected life (SR) |

Residual (SR) |

Depreciation |

| 1 |

Galvanized iron frame |

1 |

19200 |

30 |

192 |

634 |

| 2 |

Fans |

2 |

3700 |

30 |

37 |

122 |

| 3 |

Cooling system |

10 |

950 |

4 |

0 |

238 |

| 4 |

Control unit |

1 |

1300 |

30 |

0 |

43 |

| 5 |

Submerge pump |

1 |

700 |

15 |

0 |

47 |

| 6 |

Fiber glass |

9 |

12150 |

8 |

0 |

1519 |

| 7 |

Irrigation system water pump (1/2 H.P) |

1 |

600 |

7 |

12 |

84 |

| 8 |

Timer |

1 |

500 |

20 |

0 |

25 |

| 9 |

drip irrigation |

1 |

500 |

5 |

0 |

100 |

| 10 |

pots |

32 |

352 |

5 |

0 |

70 |

| 11 |

Solenoid valve |

1 |

75 |

3 |

0 |

25 |

| 12 |

Owner’s time (opportunity cost) |

|

|

|

|

500 |

| 13 |

Land rent (opportunity cost) |

|

|

|

|

128 |

| |

Fixed cost/year |

3534 |

| |

Total Fixed cost/production period |

1555 |

| |

Fixed cost/m2 ((greenhouse area ) 346.5m2) |

4.4 |

Table S2.

Variable cost for hydroponic soilless cultivation.

Table S2.

Variable cost for hydroponic soilless cultivation.

| Item |

|

|

| 1 |

Tomato seeds (SR) |

105 |

| 2 |

Gravel (SR) |

75 |

| 3 |

1/3 Perlite + 1/3 Patmos + Botong soil (SR) |

133 |

| 4 |

Filtered Irrigation Water m3 /m2/ (SR) |

98 |

| 5 |

Electricity cost (SR) |

2 |

| 6 |

Pesticides +fungicides /PP |

100 |

| 7 |

Labors + marketing (SR) |

50.9 |

| |

Total variable cost (SR) |

563.9 |

| |

Area of production m2 |

32m2 |

| |

Variable cost per m2 (SR) |

17.6 |

| |

Tomato Yield/m2 |

7.48 Kg |

| |

Price/kg (SR) |

6.5 SR |

| |

|

|

Table S3.

Variable cost for conventional soil-based cultivation.

Table S3.

Variable cost for conventional soil-based cultivation.

| Item |

|

|

| 1 |

Tomato seeds |

105 |

| 2 |

Gravel |

150 |

| 3 |

Filtered Irrigation Water m3 /m2/PP |

98 |

| 4 |

Electricity K-Watt /day/greenhouse |

2 |

| 5 |

Pesticides +fungicides /PP |

100 |

| 6 |

Labors /PP |

50.9 |

| |

total |

505.9 |

| |

Area of production m2 |

32m2 |

| |

Variable cost per m2 (SR) |

15.8 |

| |

Tomato Yield/m2 |

8.08 Kg |

| |

Price/kg (SR) |

6.5 SR |

References

- J. Winpenny, I. Heinz, and S. Koo-Oshima, “The Wealth of Waste : The Economics of Wastewater Use in Agriculture,” FAO Water Rep., no. 35, 2010.

- Fussy and J. Papenbrock, “An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability,” Plants, vol. 11, no. 9, pp. 1–32, 2022. [CrossRef]

- M. Hooshmand, M. Albaji, S. Boroomand nasab, and N. Alam zadeh Ansari, “The effect of deficit irrigation on yield and yield components of greenhouse tomato (Solanum lycopersicum)in hydroponic culture in Ahvaz region, Iran,” Scientia Horticulturae, vol. 254. 2019. [CrossRef]

- Nederhoff/Elly and Stanghellini/Cecilia, “Water use efficiency of tomatoes,” Pract. Hydroponics Greenhouses, no. 115, pp. 52–59. [CrossRef]

- Lizarraga, H. Boesveld, F. Huibers, and C. Robles, “Evaluating irrigation scheduling of hydroponic tomato in Navarra, Spain,” Irrig. Drain., vol. 52, no. 2, 2003. [CrossRef]

- Estidama, “Soilless cultivation Systems,” 2022. https://estidamah.gov.sa/en/publications/posters/evaluation-soilless-cultivation-systems.

- M. A. Wahb-Allah, A. A. Alsadon, and A. A. Ibrahim, “Drought tolerance of several tomato genotypes under greenhouse conditions,” World Appl. Sci. J., vol. 15, no. 7, 2011.

- R. Parameshwarareddy, S. S. Angadi, M. S. Biradar, and R. H. Patil, “Water productivity of tomato as influenced by drip irrigation levels and substrates,” J. Pharmacogn. Phytochem., vol. 7, no. 2, 2018.

- Sánchez-Rodríguez, R. Leyva, C. Constán-Aguilar, L. Romero, and J. M. Ruiz, “How does grafting affect the ionome of cherry tomato plants under water stress?,” Soil Sci. Plant Nutr., vol. 60, no. 2, 2014. [CrossRef]

- T. Suvo, H. Biswas, M. Jewel, M. Islam, and M. Khan, “Impact of substrate on soilless tomato cultivation,” Int. J. Agric. Res. Innov. Technol., vol. 6, no. 2, 2017. [CrossRef]

- Abdulaziz et al., “TOMATO GRAFTING IMPACTS ON YIELD AND FRUIT QUALITY UNDER WATER STRESS CONDITIONS,” J. Exp. Biol. Agric. Sci., vol. 5, pp. S136–S147, 2017. [CrossRef]

- M. Al-Omran, A. R. Al-Harbi, M. A. Wahb-Allah, N. Mahmoud, and A. Al-Eter, “Impact of irrigation water quality, irrigation systems, irrigation rates and soil amendments on tomato production in sandy calcareous soil,” Turkish J. Agric. For., vol. 34, no. 1, 2010. [CrossRef]

- N. Geboloǧlu, E. Yilmaz, P. Çakmak, M. Aydin, and Y. Kasap, “Determining of the yield, quality and nutrient content of tomatoes grafted on different rootstocks in soilless culture,” Sci. Res. Essays, vol. 6, no. 10, 2011. [CrossRef]

- J. M. Cámara-Zapata, J. M. Brotons-Martínez, S. Simón-Grao, J. J. Martinez-Nicolás, and F. García-Sánchez, “Cost–benefit analysis of tomato in soilless culture systems with saline water under greenhouse conditions,” J. Sci. Food Agric., vol. 99, no. 13, 2019. [CrossRef]

- J. McGee, “Break-even analysis,” In Wiley Encyclopedia of Management. John Wiley & Sons, pp. 1–1, 2015.

- N. A. Elmulthum et al., “Water Use Efficiency and Economic Evaluation of the Hydroponic versus Conventional Cultivation Systems for Green Fodder Production in Saudi Arabia,” Sustain., vol. 15, no. 1, 2023. [CrossRef]

- M. Naumann, R. C. Karl, C. N. Truong, A. Jossen, and H. C. Hesse, “Lithium-ion battery cost analysis in PV-household application,” in Energy Procedia, 2015, vol. 73. [CrossRef]

- Uiversity/Ohio, “Green House Industry,” 2017. https://u.osu.edu/greenhouse/hydroponic-crop-program-links/.

- Aswir and H. Misbah, Non-current assets depreciation and impairment between legal, accounting at tax rules: evidence from romania, vol. 2, no. 1. 2018. [Online]. Available: http://link.springer.com/10.1007/978-3-319-76887-8%0Ahttp://link.springer.com/10.1007/978-3-319-93594-2%0Ahttp://dx.doi.org/10.1016/B978-0-12-409517-5.00007-3%0Ahttp://dx.doi.org/10.1016/j.jff.2015.06.018%0Ahttp://dx.doi.org/10.1038/s41559-019-0877-3%0Aht. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).