Clean hydrogen has the potential to meet up to 24% of the world’s energy demand. As the global community, including the European Union, commits to reducing reliance on fossil fuels, hydrogen is emerging as a versatile solution for converting renewable energy from sources like wind and solar into storable forms. Hydrogen can serve as a feedstock, fuel, energy carrier, and storage medium, offering numerous applications across industries, transportation, power generation, and construction [

1]. In the realm of zero-emission vehicle technologies, there are two prominent developments: battery-powered electric vehicles using lithium-ion batteries exclusively, and fuel cell vehicles employing compressed hydrogen tanks and proton exchange membrane (PEM) fuel cells to generate electricity from hydrogen gas [

2]. In the context of fuel cell assemblies, one crucial and energy-intensive component is the air compressor [

3]. Generally, higher airflow enhances fuel cell voltage and efficiency [

4], while lower mass flows can lead to operational challenges like water condensation and insufficient oxygen supply [

5]. High-velocity airflow is essential for removing water produced on the cathode side of the fuel cell, and it also increases oxygen partial pressure, thereby boosting fuel cell voltage [

6]. However, extended operation at high airflow rates can lead to insufficient membrane moisture and potential drying issues [

7]. The concept of the excess air ratio is vital, representing the ratio of actual airflow through the air compressor to the stoichiometric airflow required for complete oxygen consumption within the system [

8]. Typical values range from 1.5 to 3.0, depending on system parameters and design considerations [

9]. Furthermore, the pressure within the fuel cell system is influenced by the ratio of air compressor pressure to the pressure drop across the fuel cell [

10]. When using a throttle valve after the fuel cell assembly, it may lead to increased pressure resistance and cathode side pressure [

11]. Alternatively, employing an expander (turbine) in place of a throttle valve allows for the utilization of the energy from the pressurized air mass flow, enhancing system efficiency [

12]. The air supply system is of utmost importance for ensuring the stable and efficient operation of the fuel cell system [

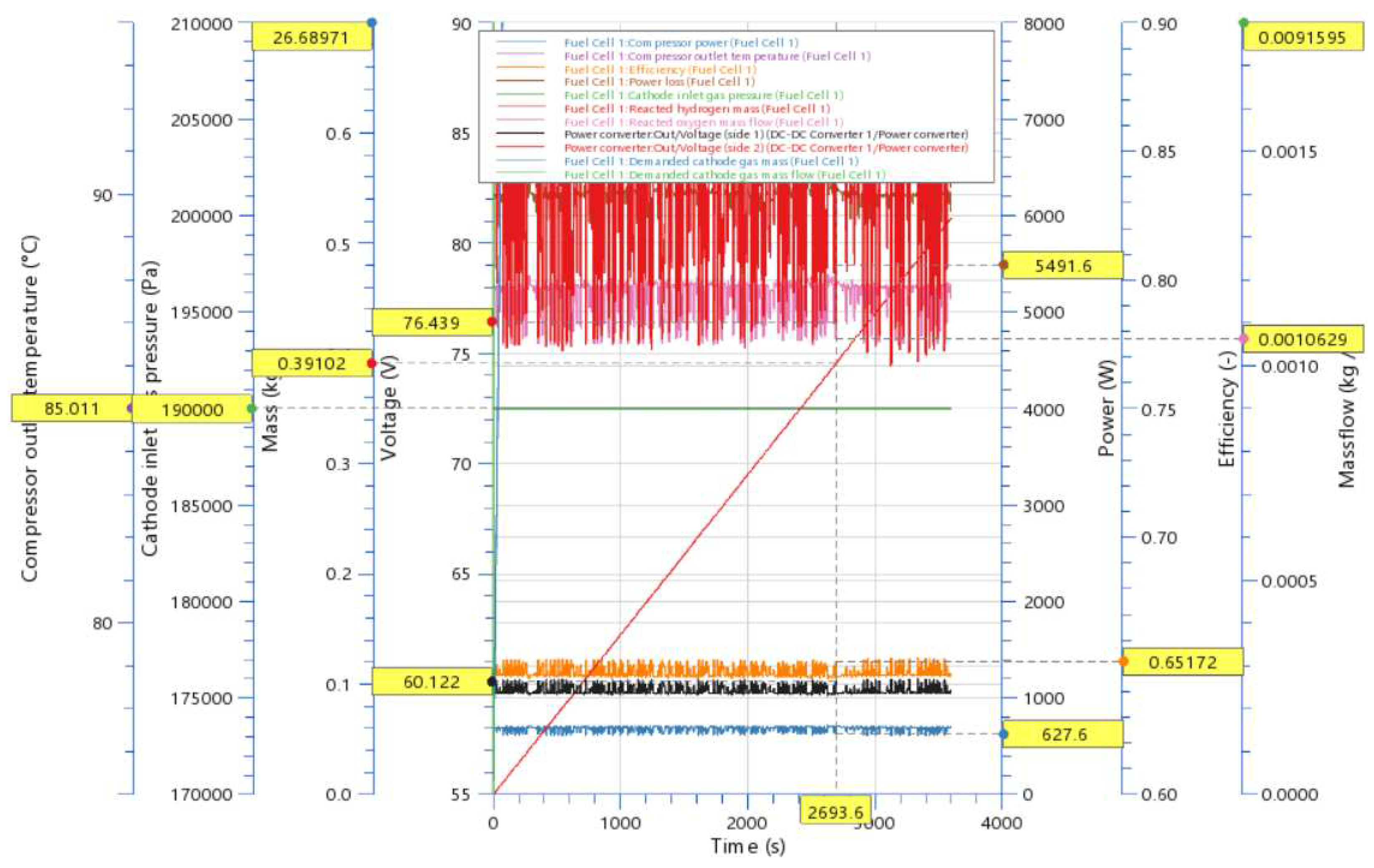

13]. Proper air supply system operation aids in moisture removal, impacting humidity levels, while the oxygen content in the air directly affects fuel cell voltage and efficiency. The air compressor can supply air at various flow rates and pressure levels to the chimney, and these operational parameters, along with the corresponding electricity consumption of the compressor, significantly influence system efficiency [

14]. The maximum inlet air pressure in the fuel cell is constrained by the surging line of the air compressor [

15], while the lowest pressure is determined by the pressure drop of the fuel cell and the air compressor’s choke. It’s essential to avoid operating points below the choke line and above the surging line to prevent compressor damage due to overheating, high pressure, and pressure fluctuations [

16]. Higher reactant pressures result in increased fuel cell voltage, power, and efficiency [

18]. Typically, for PEM fuel cells, the voltage increase diminishes when the operating pressure exceeds 4 bar due to mass transfer limitations. Therefore, the optimal operating pressure for PEM fuel cells typically falls between 3 and 4 bar [

19]. Research has suggested that an operating pressure of 2 bar yields optimal system efficiency, especially when using a screw compressor [

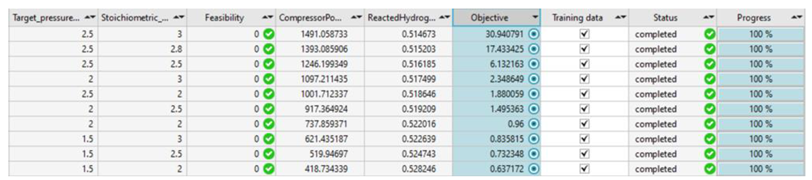

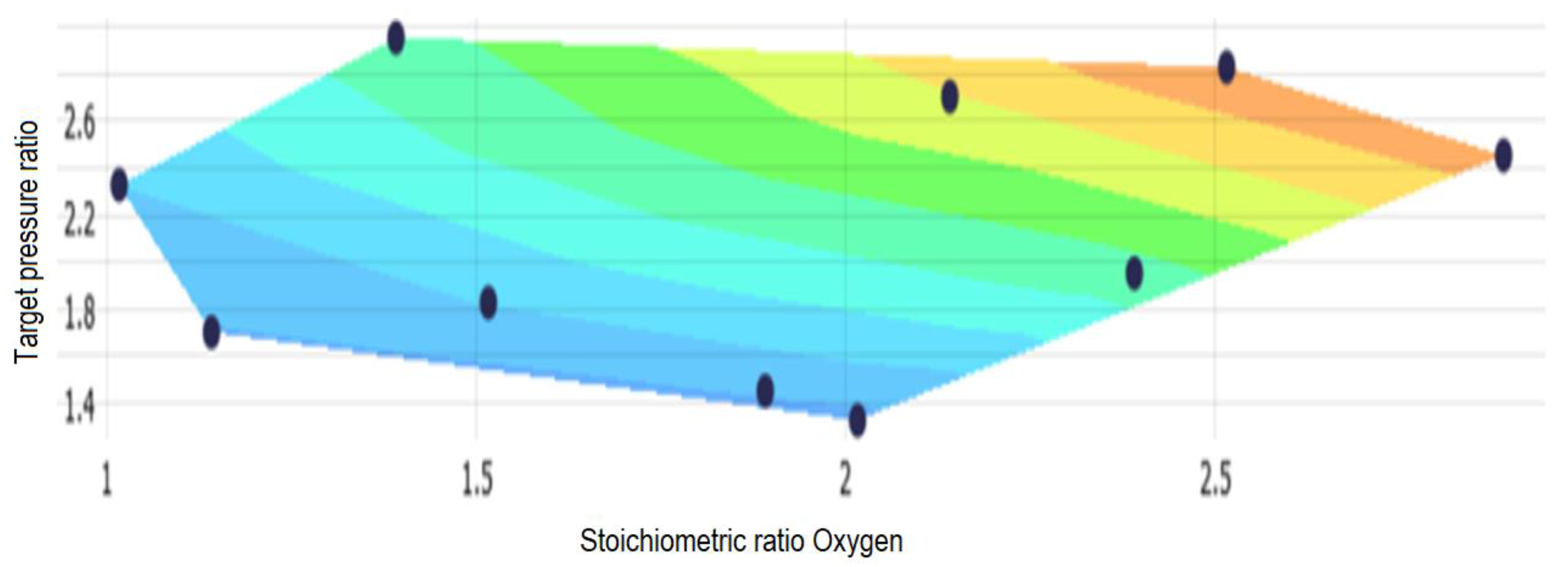

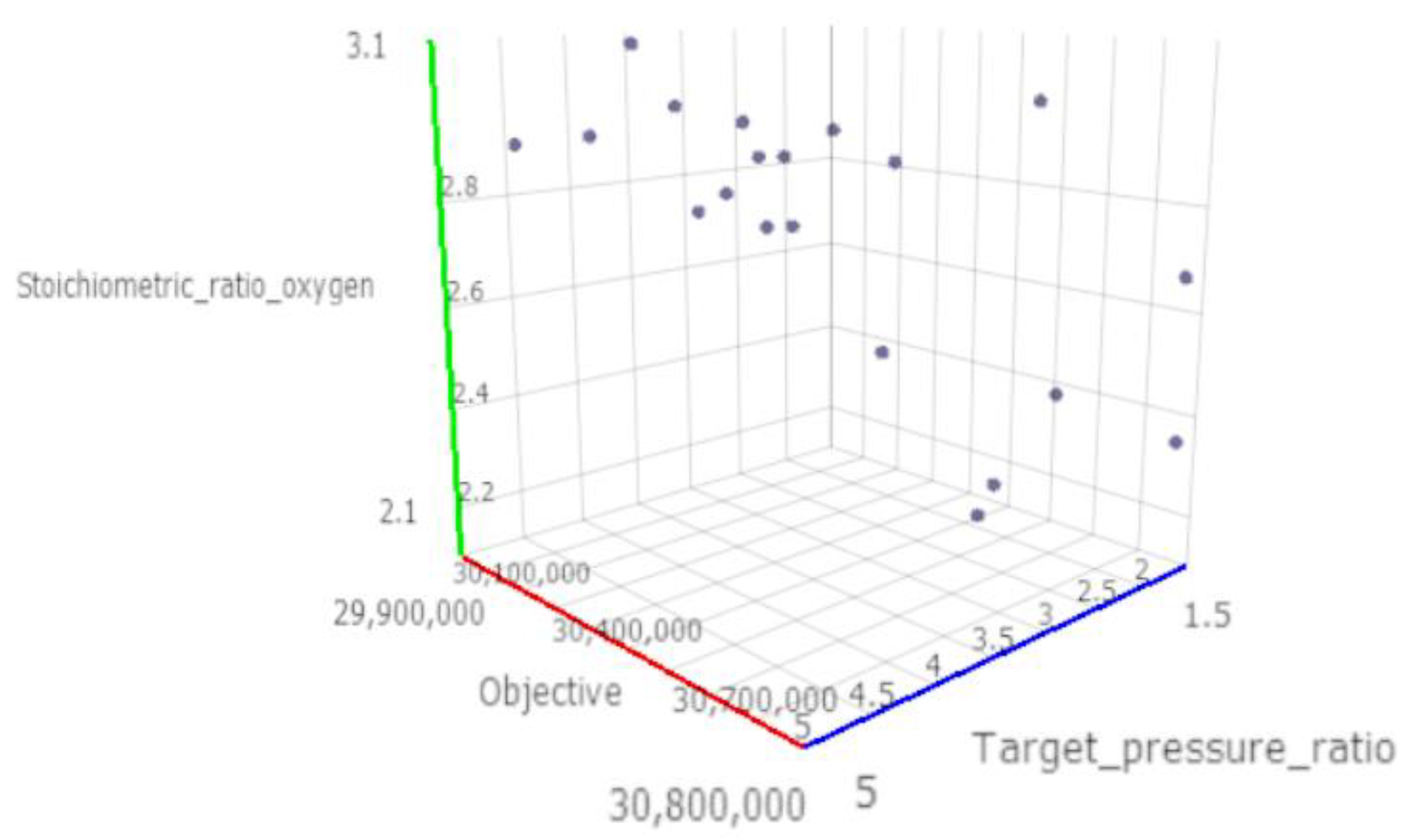

20]. A study has investigated the impact of different pressure levels and excess air ratios on net cell voltage levels, utilizing the Nernst equation [

21]. The optimal point was identified at 2 bar for an excess air ratio of 2. For excess air ratios exceeding 3, the net stress level was found to be negative. In another study [

22], an 80 kW fuel cell vehicle was analyzed concerning blower speed and back pressure control valve. It was observed that at low loads, system power decreases as the regulating pressure valve angle increases (opens), with the influence of blower speed being more significant at higher valve angles. At high loads, for most fan speeds, system power increases when the back pressure valve opens and reaches a maximum before decreasing again if the valve is opened further. This behavior can be attributed to the modeled humidity inside the stack, affected by both blower speed (excess air ratio) and back pressure level. Furthermore, research into air mass flow and pressure optimization for PEM systems for fuel cell range extension found that various factors, such as feed gas humidity, operating temperature, feed gas stoichiometry, air pressure, fuel cell size, and gas flow patterns, affect both steady-state and dynamic fuel cell responses. The air stoichiometric flow rate directly influences fuel cell performance by supplying oxygen and indirectly by affecting membrane humidity and water flooding in the cathode side [

24]. For air pressures exceeding 1.8 bar(a), the fuel cell stack’s power gain due to pressurization is offset by the increased power required for air compression [

25]. The optimization of super-high-speed electric air compressors for hydrogen fuel cell vehicles is a subject of investigation [

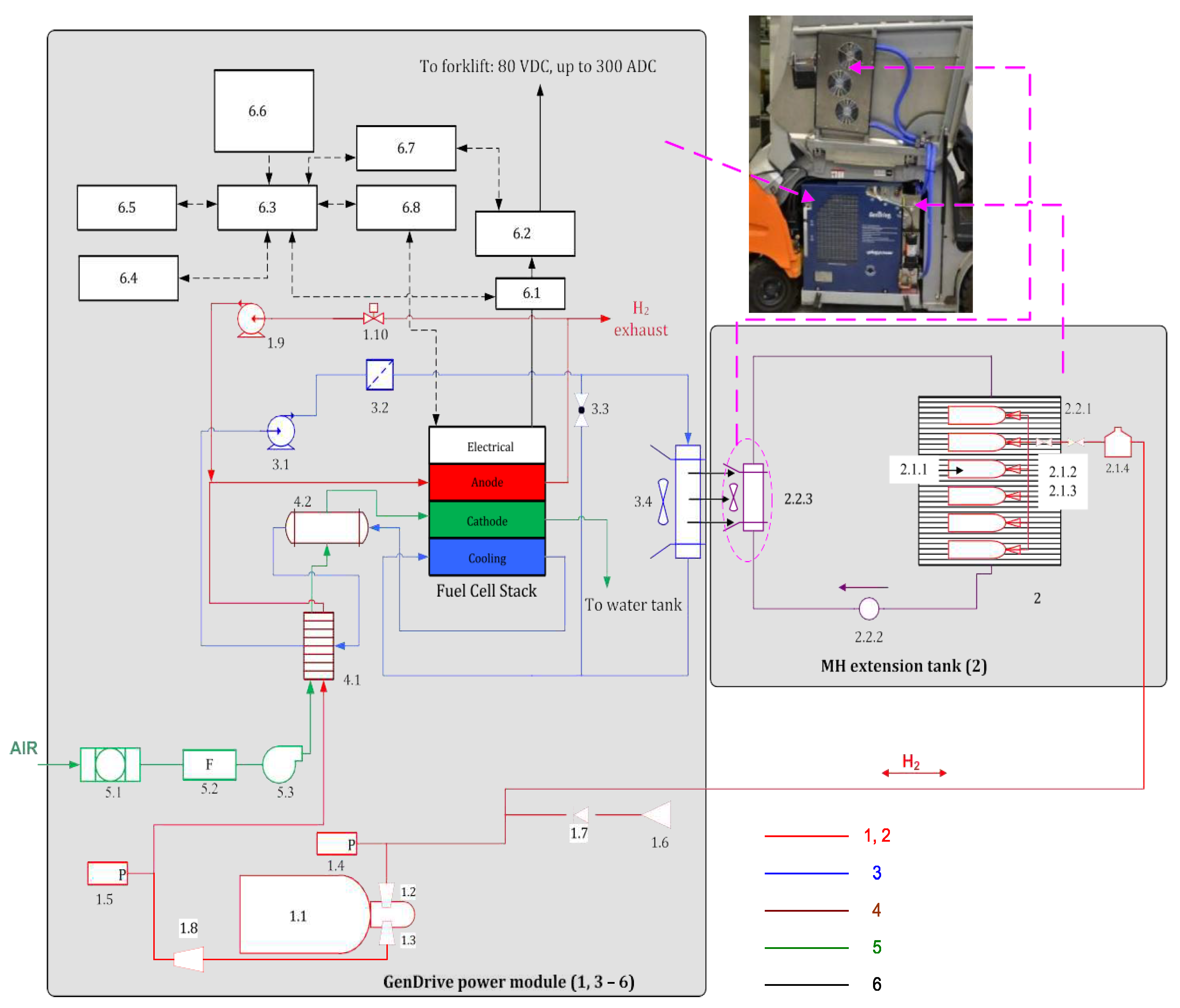

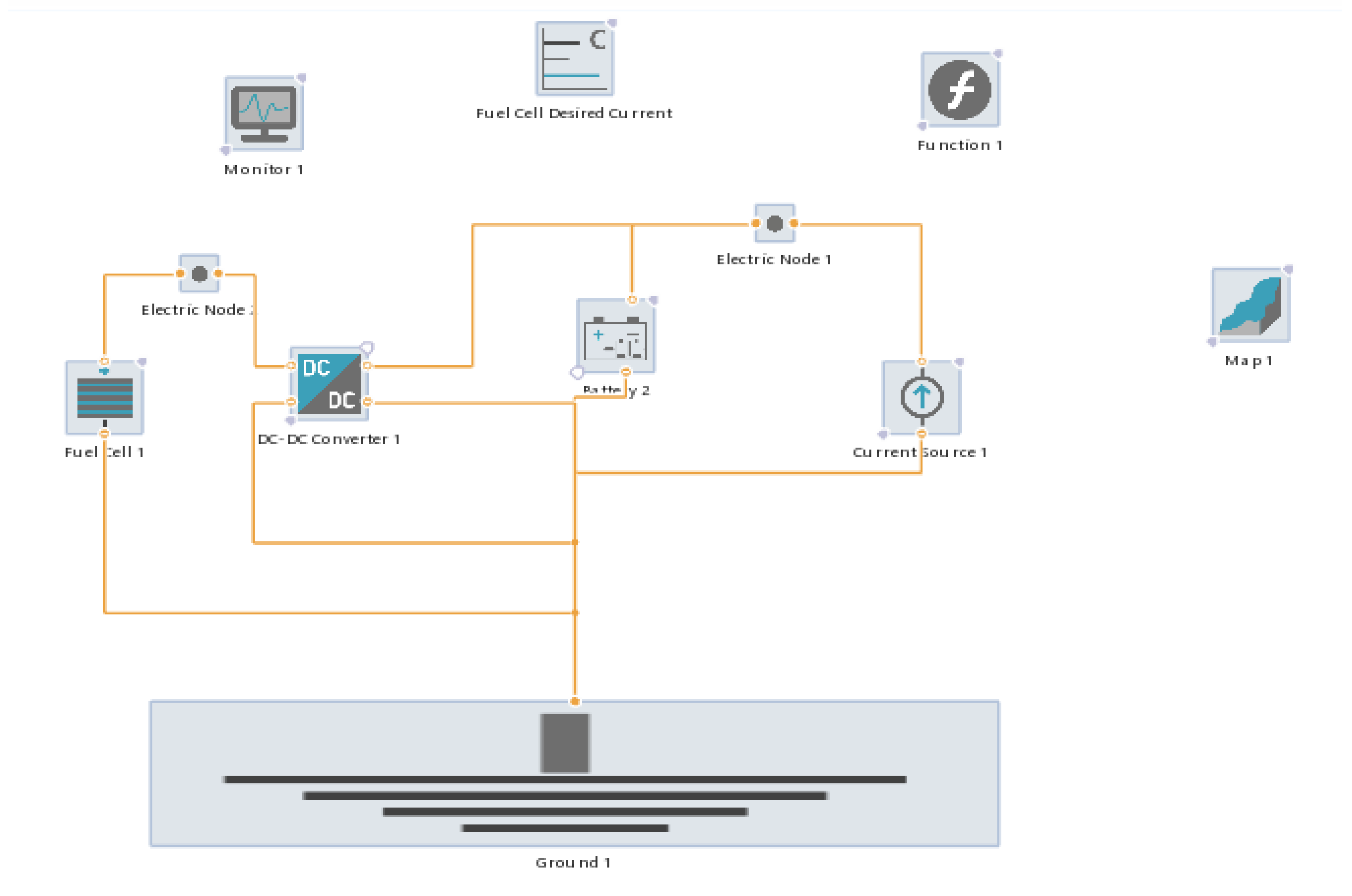

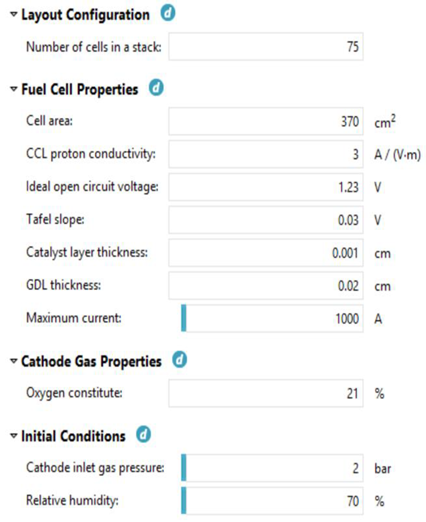

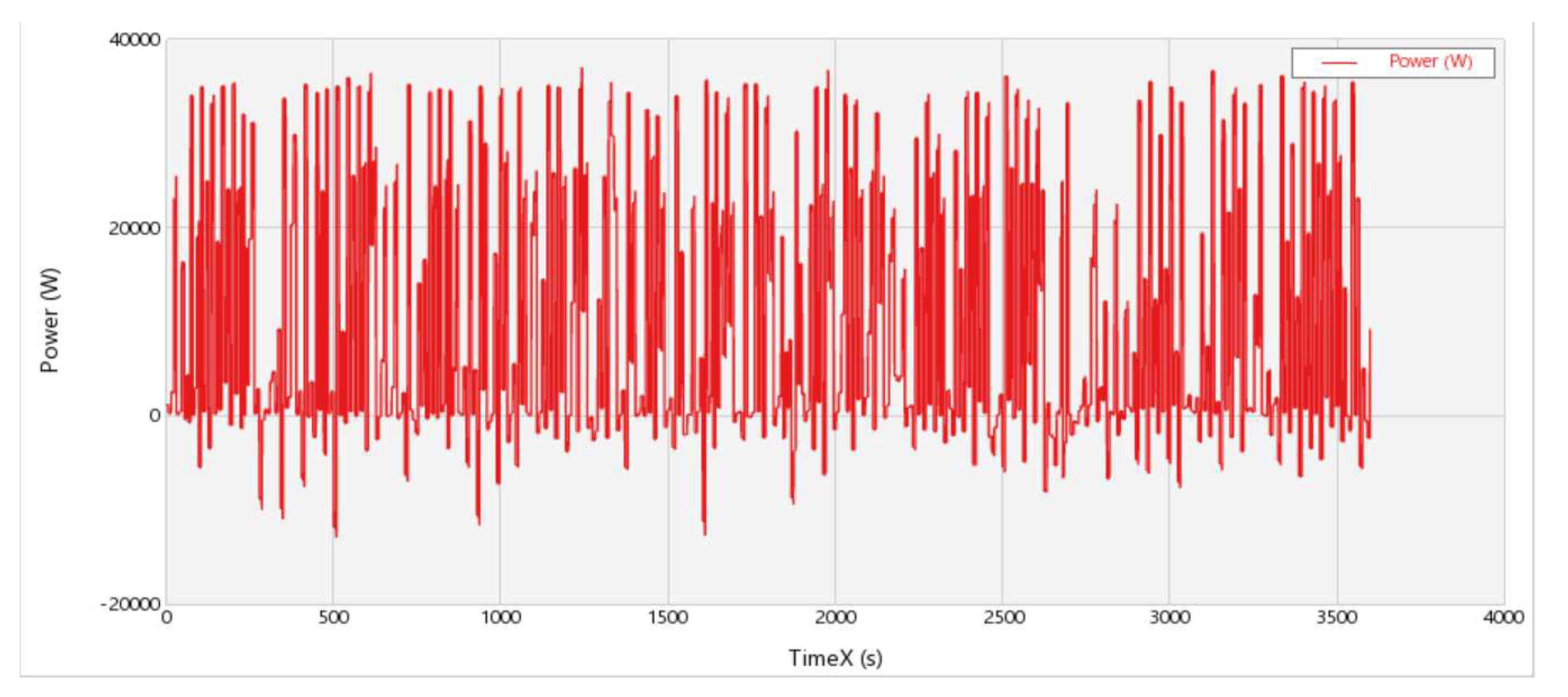

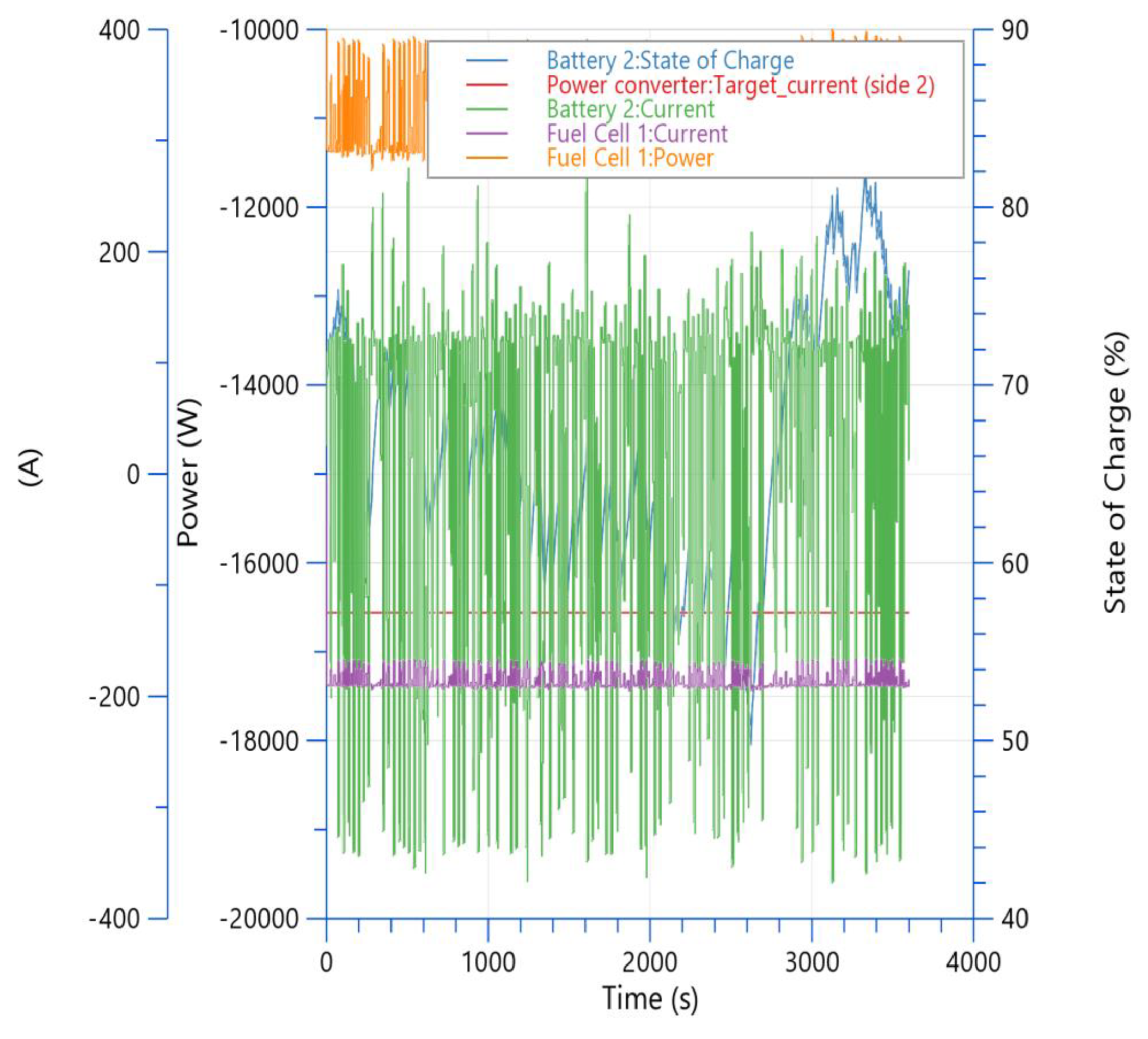

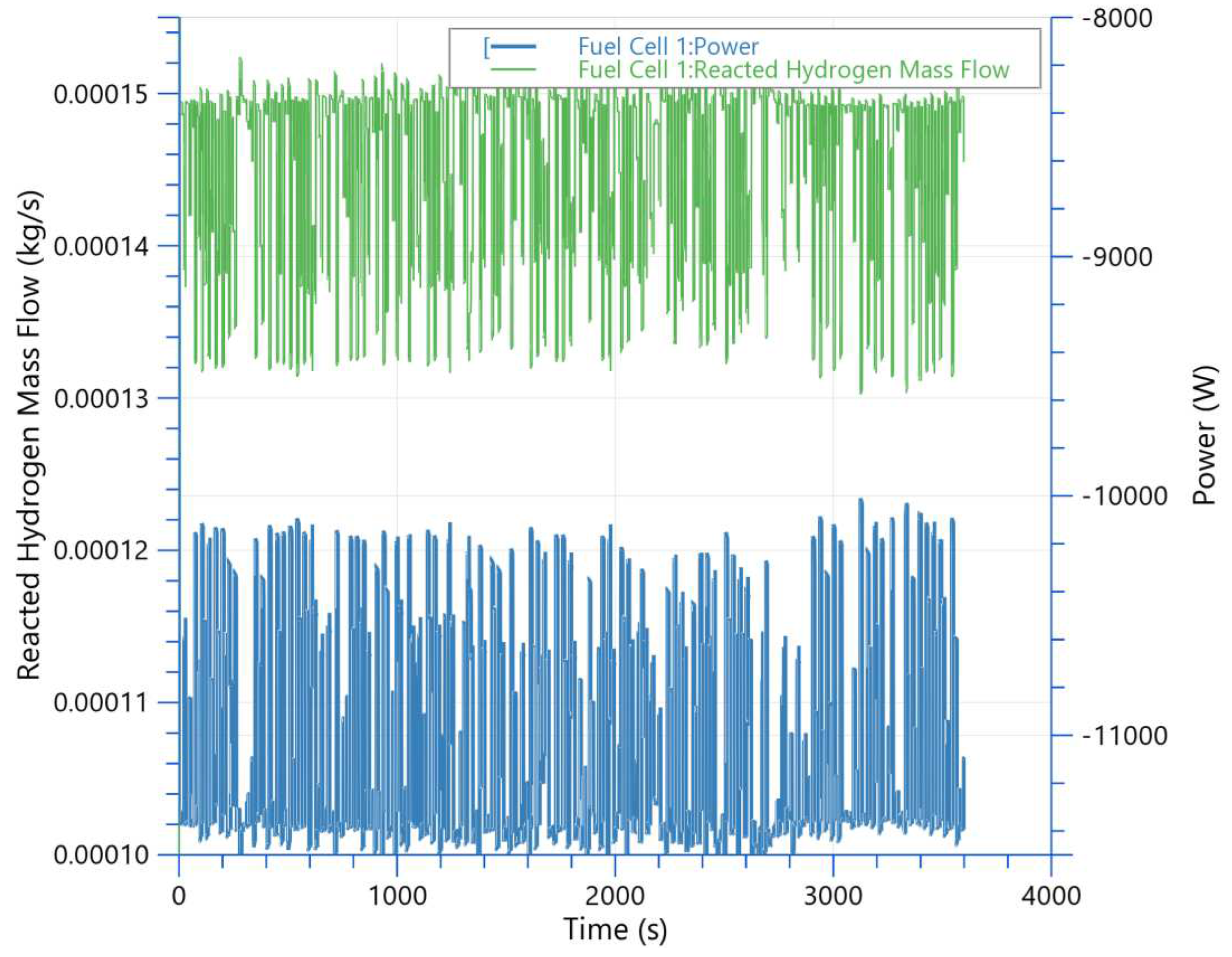

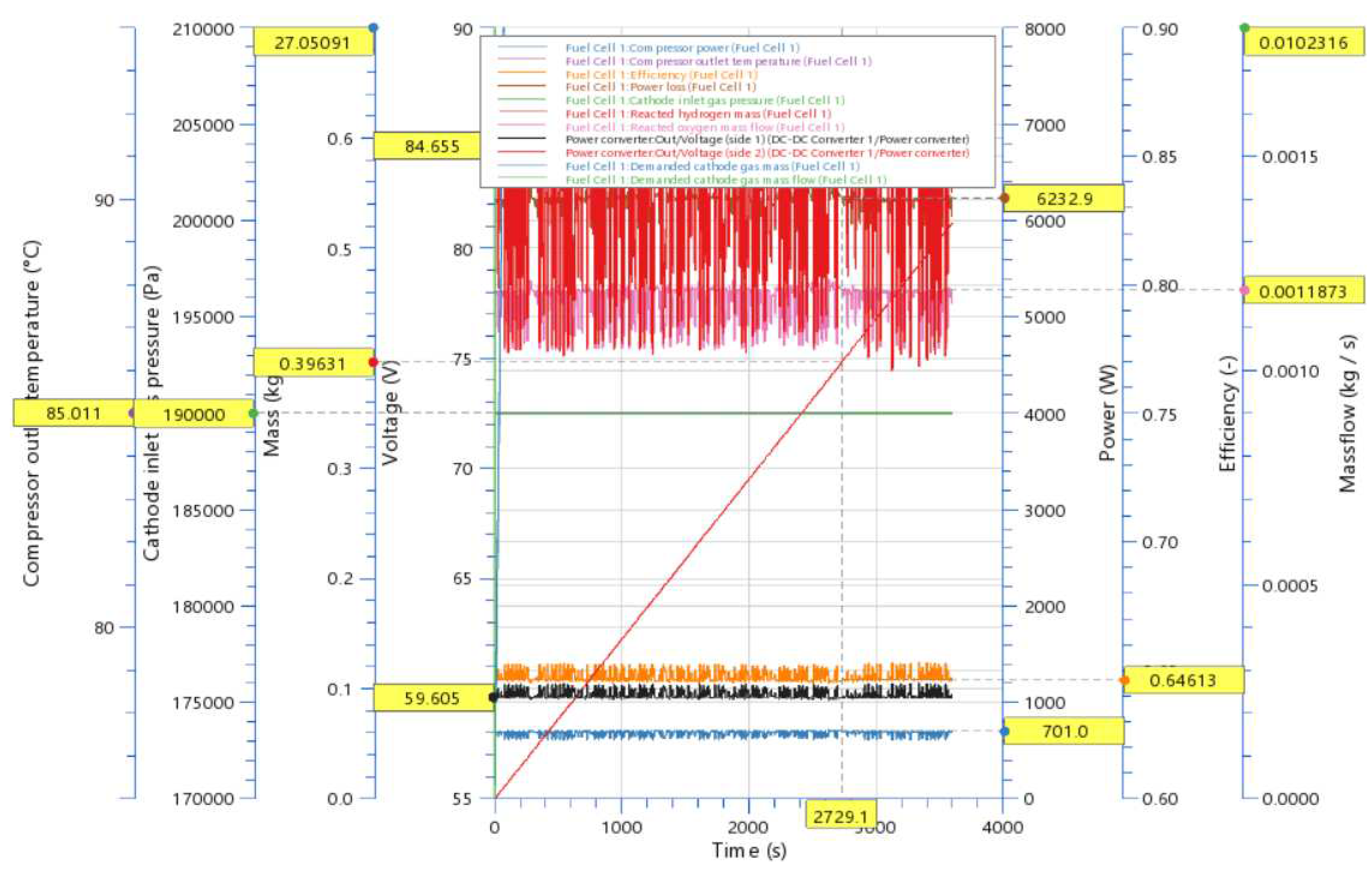

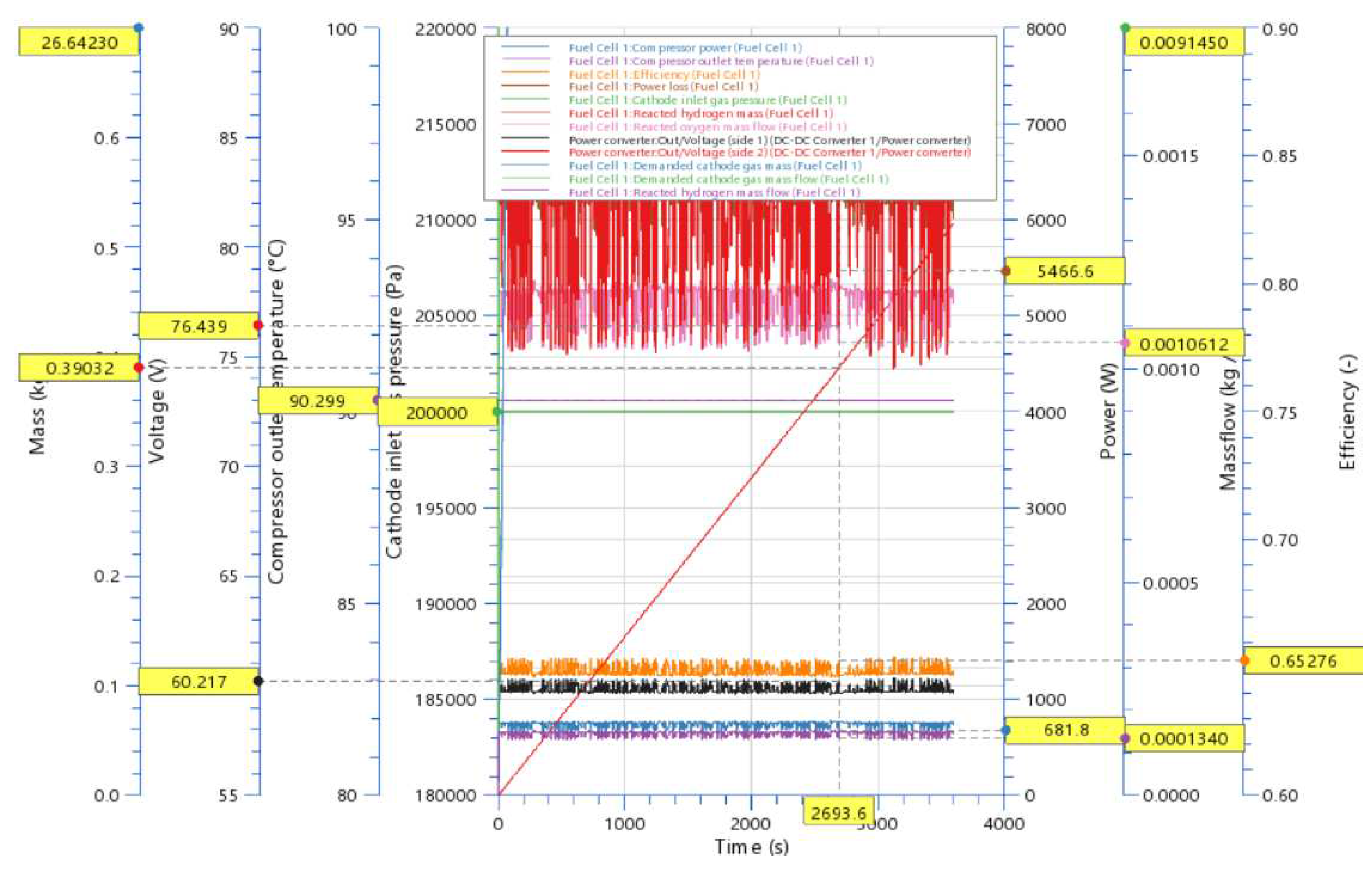

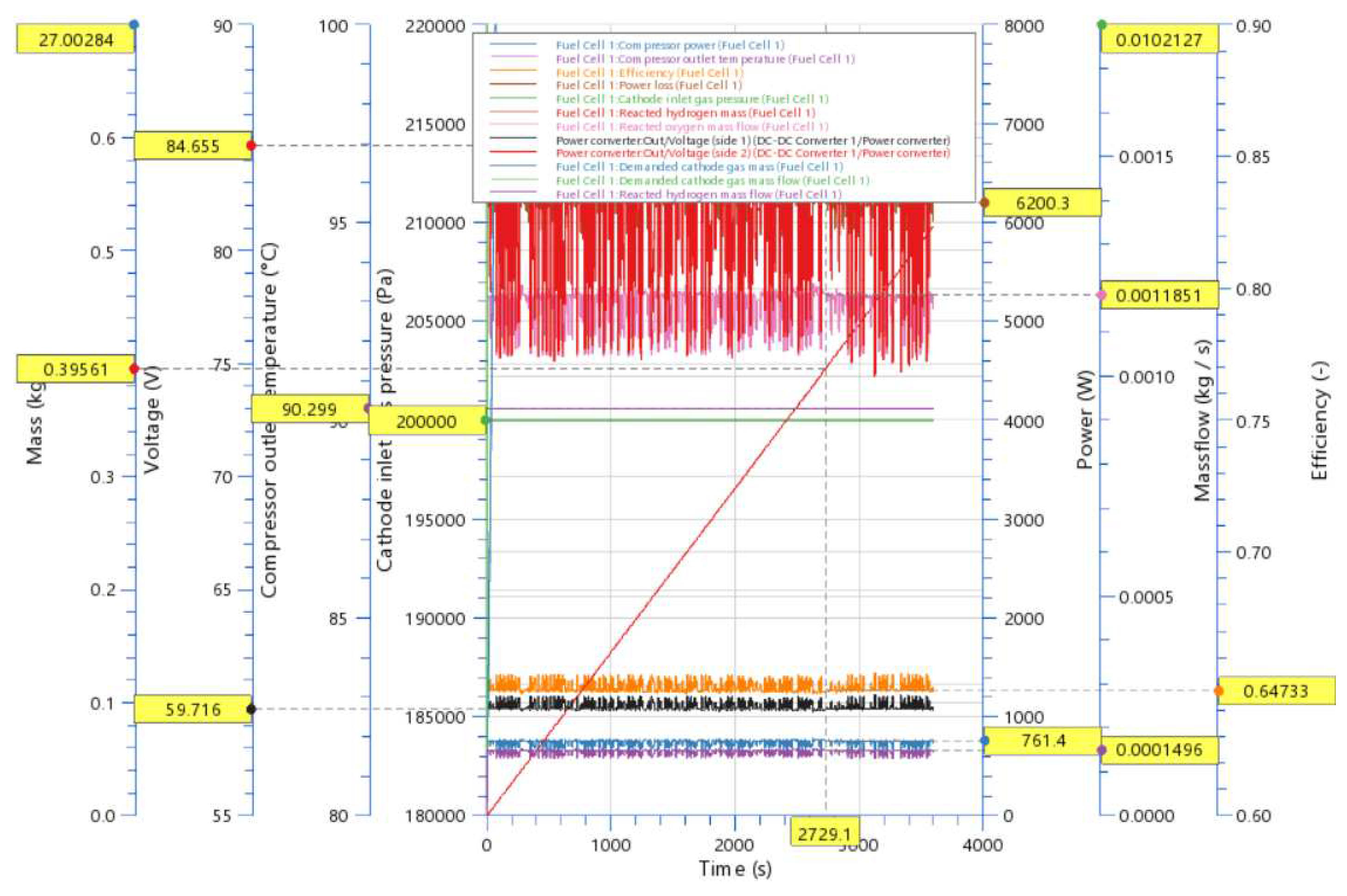

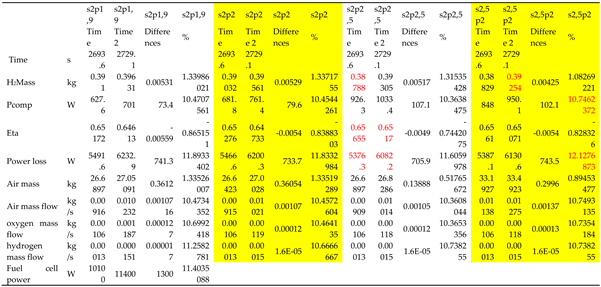

26]. This paper assesses the optimal system efficiency of a PEM fuel cell system at different load points. The novelty of this work lies in the verified model development and combined investigation of air pressure and air mass flow on the system efficiency of an 11 kW power module with a PEM fuel cell designed for forklift applications. The study analyzes the trade-off between higher oxygen partial pressure inside the stack (resulting in higher efficiency) and the additional power consumption of the air compressor (leading to lower efficiency) for two distinct load points. To achieve this, a power module with a fuel cell stack model was developed and validated using experimental data obtained during forklift operations under VDI60 load cycles in real-world conditions. Simulations encompass various parameters of air mass flow and air pressure to assess their impact on system efficiency. Additionally, all models employed in the study were verified against measured data to ensure reliable simulation results.