1. Introduction

The Textile & Clothing (T&C) sector is an important part of the European manufacturing industry, and it plays a crucial role in the general economic and social well-being. According to Euratex, in 2021 this industrial sector had more than 143,000 companies, employing 1.3 million people and generating a turnover of €147 billion, 56% from textiles and man-made fibers, and 44% from clothing. Italy, Germany, France, Spain and Portugal account for three quarters of European Union (EU) production in this sector [

1].

The textile and clothing value chain, from the creation of raw materials to the creation of the final product, is long and very diversified in terms of the raw materials used. There are raw materials of different origins such as: natural fibers, like cotton, linen, wool, silk, etc.; artificial fibers, like viscose, modal etc.; and, synthetic fibers, like polyester, nylon or acrylic. Associated with creating these different raw materials there are different industries.

Regardless of the types of raw materials used, creating a garment typically involves the following main activities [

2,

3]:

Spinning: is a fiber processing technique where fibers undergo preparation, drafting, and twisting to transform them into yarn. During spinning, the fibers are drafted, or attenuated, to achieve consistent thickness, and simultaneously twisted to bind the fibers together, resulting in the formation of yarn;

Weaving: is a method of fabric production in which two sets of yarns, known as the warp and weft, interlace with each other at right angles to form a woven fabric. These interlacements create a stable and structured fabric.

Knitting: is a technique where loops of yarn are interlocked to create fabric. It involves manipulating a set of knitting needles or a knitting machine to form rows of interlocking loops.

Printing, dyeing, and finishing: Printing involves adding colors, patterns, or designs to fabrics, enhancing their visual appeal. Dyeing provides fabrics with vibrant and consistent colors, while finishing treatments improve their appearance, texture, and performance. These processes play a crucial role in the creation of customized and aesthetically pleasing textiles, while also ensuring that they meet the desired functional requirements of consumers.

Textile Manufacturing: is the process of transforming fabric into garments or textile products through cutting, sewing, and assembling. The final outcome is a completed garment or textile product ready for distribution or sale.

Each of these activities or steps in the value chain involves a series of industrial processes that are performed by different industry types and different companies. These companies may be located in places, and likely countries, that are far from each other, which leads to large displacements. In other words, products (raw material, intermediate products, or final products) may travel many kilometers from the creation of the raw material to reaching the final consumer.

The fabric itself is sometimes made up of different types of yarn. For example, a fabric maybe composed of cotton, wool, polyester, nylon, etc. This increases the number of companies involved in the creation of a garment and increases the complexity of the value chain.

Producing different raw materials causes different impacts on the environment, having some materials more harmful to the environment than others. In the end, creating a garment can be more, or less, harmful to the environment.

With economy globalization, also in the textile and clothing sector, and the search for cheaper labor by the companies, products and by-products often travel many kilometers around the world. These transports usually have a great negative environmental impact.

With regard to the social factor, some companies treat their employees better than others. Some companies pay better wages, provide health insurance, fairer working hours, and other perks. Companies that give less perks to their employees, normally produce cheaper products, achieving market advantages.

Consumers need, and deserve, to be informed about social and environment impact of the garment they are about to buy in order to decide what to buy, according to their conscience.

The work presented in this article reflects the main results of the PPS1 parcelar project ("Sustainable & Circular Textile ID 4.0") of the European mobilising project “STVgoDIGITAL: Digitization of the Textile and Clothing Value Chain” (

stvgodigital.pt), which aims to encompass a set of Research and Development (R&D) initiatives, with the central involvement of companies in the Textile and Clothing sector, and other complementary sectors, that foster digital transition and the adoption and transition to the new paradigm of Industry 4.0, with emphasis on information and communication technologies.

In the last years, the T&C sector in Portugal has earned global recognition and prestige for its quality, innovation, creativity, resilience and responsiveness. Data from Textile and Clothing Association of Portugal (ATP)) (

www.atp.pt) show that, in 2021, the Portuguese T&C sector represented 8% of the turnover in the Portuguese manufacturing industry and 5% of the EU T&C turnover. Regarding employment, 19% of the employment in the Portuguese manufacturing industry is provided by T&C sector, which represents almost 10% of the EU T&C employment.

The need for safe and reliable information on the sustainability of textile products derives from the great impact that this sector has on the environment and on people’s lives, especially in developing countries with precarious social and working conditions and corruption. According to the Global Fashion Agenda 2019 Pulse of the Fashion Industry report, the industry’s social and environmental performance has improved, but the global fashion industry is still far from being considered sustainable. So, increasing the supply chain’s traceability all the way down to the second-level suppliers is one of the priorities specified, in order to raise the degree of sustainability [

4].

The first step in changing the fashion industry is transparency. To promote this view, Fashion Revolution publishes an annual report on transparency in the fashion industry (Fashion Transparency Index), using a methodology to compare brands and taking into account five key areas: policy and commitments, governance, supply chain traceability, supplier assessment and remediation, as well as concerns like gender equality, decent work, tackling climate change, and responsible consumption and production [

5]. According to this report, no brand (of the 200 included in the study) has transparency levels above 70%, while the great majority (90%) has transparency levels below 50%. Additionally, it shows that, of the five areas assessed, traceability has the lowest average score [

5].

The European Commission is working on establishing sustainability principles and other appropriate ways to regulate multiple aspects of product life cycles to improve product durability, reusability, upgradability, and reparability, as well as addressing the presence of hazardous chemicals in products and increasing their energy and resource efficiency, as part of its Circular Economy Action Plan [

6]. The Action Plan mentions "mobilising the potential of digitisation of product information, including solutions such as digital passports, tagging, and watermarks [

7] The Wuppertal Institute has released a wide definition of Digital Product Passport (DPP) defining it as a data collection that summarizes a product’s components, materials, and chemical compounds, as well as information on reparability, spare parts, and proper disposal instructions. The data contained in the DPP is collected from all phases of the product life cycle and can be utilised to optimise design, production, usage, and disposal [

8,

9]. In the context of this project, and in this article, the DPP is a tool that can be used to promote transparency and responsibility in the production of products, allowing consumers to get detailed information about what they are buying and how it has been produced. At the same time, it can also be used by companies that wish to demonstrate their commitment to sustainability and social responsibility.

For all this, there is the need for a solution that can successfully provide value-chain-wide distributed traceability for tracing textile and clothing products [

10]. Various indicators should be traced and stored, based on resources consumption (e.g. water, energy) and pollutants emitted (e.g. CO2 and other greenhouse gases, sewage), to know information about each and every one of the value chain activities [

11].

This traceability platform should, then, provide its users, i.e. the value chain operators and consumers, with environmental, economical and social indicators of each of the traced product lots and respective value chain activities (e.g., spinning, weaving, dyeing), enabling the environmental, economical and social scoring of every traced product lot.

This way, it is possible to capture information from the primary production activities, all the way through each and every production activity of a T&C item, until its ultimate use, and even about its disposal or materials reuse, in a circular economy model [

3].

1.1. Article’s structure

The rest of this article is structured as follows. The next section presents the research methodology. Then,

Section 3 makes a brief survey of the existing platforms for traceability in the textile and clothing value chain. In

Section 4 the results of this research are presented, namely the environmental, economical and social indicators, traced by the proposed platform, (sub

Section 4.1). Sub

Section 4.2 presents our proposal for a new blockchain-based platform for tracing environmental, economical and social indicators throughout the T&C value chain, and calculate a sustainability index for each textile product batch. Sub

Section 4.3 presents the on-chain and off-chain data entity models. Sub

Section 4.4 presents the smart contract that is the basis for the traceability functionality. Sub

Section 4.5 presents the platform’s backend structure and API.

Section 4.6 presents the developed front-end applications, integrated with the traceability platform, for offering value chain operators and the final consumer, the intended functionalities.

Section 5 presents results and discusses limitations and challenges. And, finally,

Section 6 draws conclusions and suggests some ideas for future work.

2. Research methodology

The lack of a traceability platform for the environmental, economical and social impact of the textile and clothing sector takes the form of a research gap, which hinders the ability of the final consumer to select a product with less negative impact, in environmental, economical or social terms, as well as the ability of any business partner, at any level of the value chain, to select its suppliers or lots of intermediate products/materials based on information of their respective environmental, economical or social impact.

This research work is positioned within a sequence of research phases that include previous works from the same authors on which this research work is based. The goal of this research work is to propose a traceability platform for tracing environmental, economical and social indicators of value chain activities, and of final or intermediate product lots.

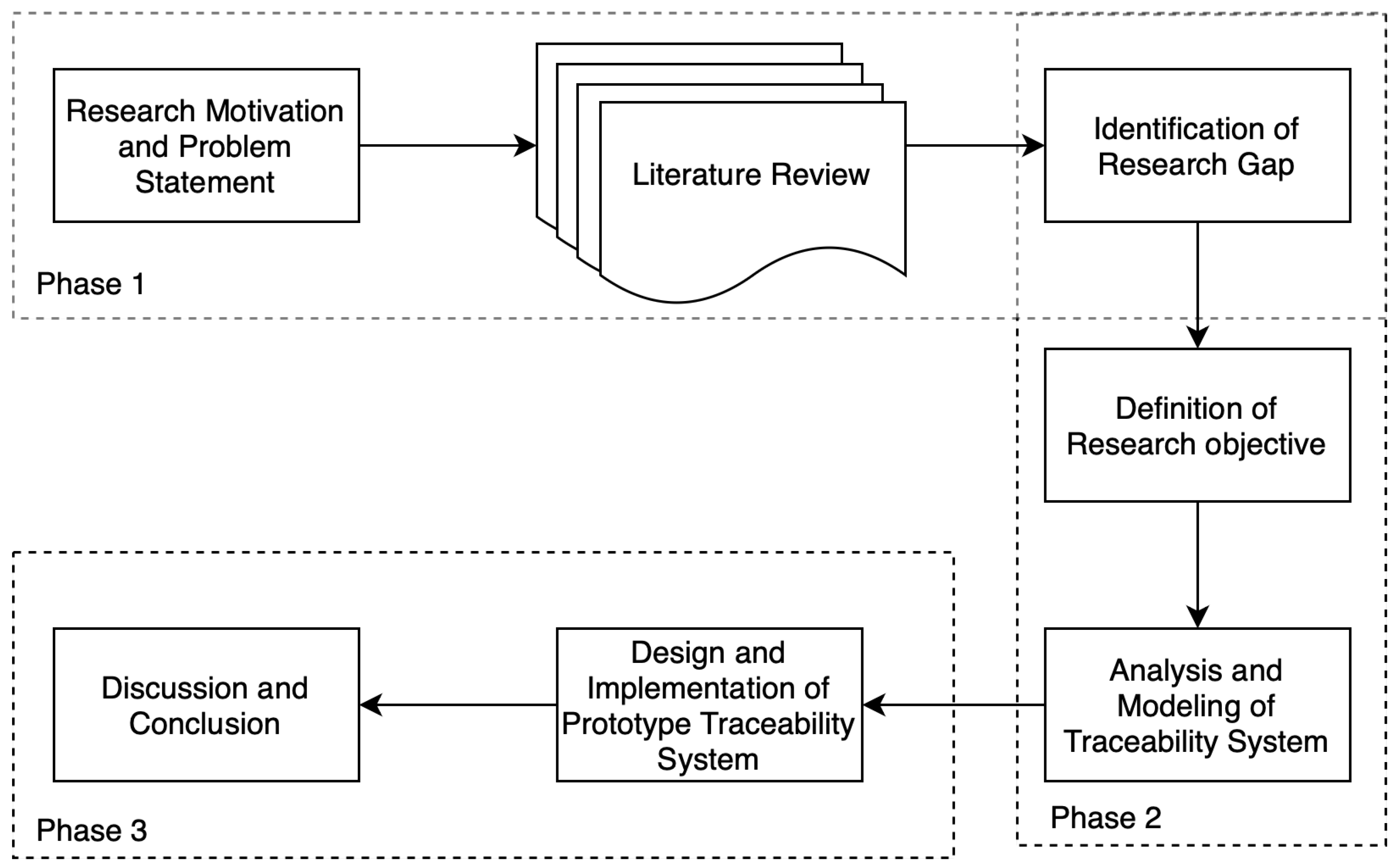

In

Figure 1, the research methodology followed can be seen. This methodology has been designed to obtain, as a result, a proof of concept of a traceability platform for environmental, economical and social sustainability indicators in the T&C value chain.

In phase 1, the literature review has been carried out [

3]. In phase 2, the analysis and modeling of a blockchain-based architecture and smart contract system prototype, capable of tracing environmental, economical and social indicators, has been made [

11]. Phase 3, the objective of this article, is where the integrated proof of concept traceability platform is designed and developed. In this article, the design model is presented, along with implemented features and experimentation of the proposed traceability platform and integrated applications.

3. Related Work

Product traceability, or the ability to trace or monitor a product, is receiving special attention as a result of the globalization of supply chains, especially in the food supply chains for reasons related to public health. To ensure the authenticity of a product’s origin, prevent forgeries, and be able to assess a product’s environmental impact, the T&C value chain must also be able to trace products, i.e., knowing its origin, and knowing a set of attributes’ values related with its production and usage in producing other products, and related with its transportation. In a previous work by some of this article’s authors, a state-of-the-art survey of the current approaches for traceability in the textile and clothing value chain has been presented [

3]. A short literature review about existing approaches to traceability in the T&C value chain, is presented, as well as some practical approaches available to the industry.

3.1. Literature Review

In [

12], the proposed system is based on Relational DataBase Management System (RDBMS) and eXtensible Markup Language (XML) to register information, with the purpose of tracing a textile item’s lifecycle within a value chain operator of the supply chain as well as more complex inter-actor value chains.

Agrawal

et al. [

13] suggested a traceability solution that relies on Quick Response (QR) Code tags that are mapped with a secure code to add an extra layer of authenticity and verification to combat the industry’s susceptibility to fake goods. It is ideal for a Circular Economy (CE) model, provided that these tags last long enough until the user chooses to recycle.

Besides traditional supply chain management implementations, blockchain-based solutions have also been proposed to tackle the transparency issues identified in the T&C value chain. Blockchain is a decentralized, distributed, and immutable database of transactions that can be tracked and verified. It has been applied in a number of financial uses because of these distinctive qualities. To enhance transparency, and traceability in particular, there has been a shift toward exploring these uses in the context of supply chains [

14]. Blockchain implementations can bring benefits in terms of decentralization, auditability, autonomy and transparency [

3].

A blockchain-based traceability framework for the textile business sector has been proposed by Agrawal

et al. [

14]. The authors propose a distributed ledger configuration structural solution for applicability on their use case, while maintaining data safety and trust among the value chain operators, and secure interactions between operators.

In [

15], Pérez

et al. explore how the application of blockchain technology can aid in the authentication of participants in the T&C supply chain as well as the identification of goods’ sources. They came to the conclusion that the use of a permissioned and open distributed ledger to keep significant data from the transactions of the manufacturing processes would be advantageous for the ultimate aim of textile traceability, using a case study of a woman’s shirt.

The work of [

16] integrates the use of blockchain with Big Data to enhance supply chain traceability and information sharing in the textile sector, a recurrent issue due to the global scale of the industry. It resulted in a solution that greatly reduces the risks associated with centralized information systems, and allows a more secure, distributed, transparent, and collaborative system by providing real-time information on the state of textile products to all participants in the supply chain.

In [

17] the authors study the way German companies in the T&C sector are dealing with sustainability, how they are preparing for the transition to the CE and the role that digital technologies can play in that transition. The authors conclude that these technologies still need to be further explored and new approaches must be developed.

3.2. Solutions from the Industry

There are already several practical solutions related to the traceability and transparency of the T&C value chain, some of which (the most significant) are presented next.

The CIRPASS (

cirpassproject.eu) is an initiative developed to establish a standard for the DPP of a garment. In order to lay the foundations for the Digital Product Passport that will be proposed by the European Commission, the Digital Product Passport Ecosystem (CIRPASS) was set up to prepare the ground for pilot projects and the gradual implementation of the Digital Product Passport, aligned with the requirements of the Ecodesign for Sustainable Products Regulation.

The French Initiative (

ecologie.gouv.fr) is also investing on the DPP of a garment. In this way, and according to Article 13 I of the Law on the fight against waste and the circular economy

1, which was published on 10 February 2020, the harmonisation, framing and specification of a series of environmental claims is envisaged.

The Circular.Fashion initiative (

circular.fashion) has been developed with the main purpose of increasing the number of recycled fabrics in the next few years. This initiative currently has a diverse set of awards, a significant number of partners, and a wide range of operations, such as circular business models, recycling process management, and software development.

The BCome (

bcome.biz) project is designed to enable textile and garment companies to build responsible supply chains and assure transparency from the production process to the final customer.

EON (

eon.xyz) is a joint initiative, by several European companies and organizations, to create a Digital Product Passport. The DPP can be used to offer precise information on a product’s environmental and social effect. The DPP is designed to increase transparency and traceability throughout the supply chain by allowing stakeholders to track a product’s path from its origin until its disposal.

The TextileGenesis (

textilegenesis.com) is another DPP initiative, aimed at boosting transparency and traceability in the textile business. The TextileGenesis Digital Product Passport intends to provide complete information on a product’s journey across the supply chain, including information about materials used, manufacturing processes, and environmental and social effect.

The TRICK project (

trick-project.eu) is an EU-funded initiative aimed at developing a DPP for textile items, and provides information about a product’s environmental impact and sustainability throughout its existence.

In addition to the aforementioned initiatives, and to accelerate sustainable transformation within global brands, the TrustTrace (

trustrace.com) initiative has been put into practice. The TrustTrace initiative empowers brands and suppliers to collaborate on the digital traceability of products and materials. The technology used in this initiative is based on IoT and artificial intelligence, to streamline data collection, and enables connections with existing supply chain solutions via OpenAPI.

The platform presented herein, STVgoDigital (

stvgodigital.pt), has as main objective the development of an innovative solution for the clothing and home textile sectors, to make it more transparent, traceable, and circular. Two different research and development lines have been defined for clothing and home textiles, tailored to the specific needs and characteristics of each sector. These include different resources, production processes, and supply chain structures. Another objective of the project is the collection of indicators that make it possible to calculate the sustainability index (environmental and social) of a textile product.

In

Table 1 the STVGoDigital solution (proposed here) and the other related existing systems are classified in several aspects. The first two solutions in the table are initiatives developed to establish a standard for the DPP of a garment. The table compares Digital Product Passport initiatives with regard to the treatment, or not, of several factors. The main factors addressed in the comparison are explained next.

Data Carrier Tag: Data carrier type refers to the tag that interconnects the physical product and the digital product. There are numerous product ID technologies available, including one-dimensional barcode, QR codes, Radio Frequency IDentification (RFID), and Near Field Communications (NFC). QR codes are two-dimensional codes that can be scanned with smartphones to convey product information. RFID uses radio waves to identify and monitor products in real time. Barcodes are also commonly used for product identification, with each product being issued a unique barcode that can be scanned using a barcode reader. NFC technology enables wireless data transfer between compatible devices.

Traceability: Refers to the type of Product and Company data that is traceable through the platform.

Environmental and Circular real and/or estimated data can provide information about the Product’s score (Environmental and Circular Score (ECS))

while Social and Economic data can provide information about the Company’s score (Economic and Social Score (ESS)).

These four dimensions can comprise values such as, for the economical dimension, e.g. company certifications, financial data, profitability and investments, for the social dimension, e.g. workers rights, wealth and safety at work, community involvement, for the environmental dimension, e.g., environmental aspects, environmental impacts, Life Cycle Assessment (LCA) indicators, for the circularity indicators, e.g. recycled content, recyclability, design for circularity and durability. Lastly, a sustainability score feature is also a point of evaluation for platform comparison.

Regarding the type of data, it can be REAL and/or ESTIMATED.

Real data is frequently used to refer to something’s true, tangible worth or value, as opposed to its perceived or nominal value. Real value considers a variety of aspects, including e.g., the amount of water and energy required in production and waste disposal.

Estimated data, on the other hand, is a determined approximation of something’s worth or real value based on available information and analysis. Estimated data, in the context of quantifying the environmental impact of textile products, can refer, for example, to a computed approximation of the environmental impact of numerous components involved in the product’s manufacture and use. This could include values of greenhouse gas emissions and use of chemicals, among other factors.

Data Storage - Centralized: The practice of storing all data in one centralized location, such as a data centre or a cloud server. Centralized storage makes it easier to scale up storage capacity as needed and ensures that all users have access to the same data, eliminating the need for duplicate copies of data to be stored in multiple locations. However, there are also potential drawbacks to centralized storage, e.g., the risk of data loss or corruption if the central storage location fails.

- -

Decentralized: Decentralized data storage spreads data across numerous locations, such as the cloud or different servers. This makes it more resistant to system faults and increases data accessibility. However, because the data is dispersed, it might be more difficult to manage and safeguard, requiring more complicated management systems.

As can be seen in

Table 1, and comparing with the other presented approaches, only the STVGoDigital solution proposes the calculation of a sustainability score to classify a textile product, in order to provide more information to the consumer and to better inform the consumer about the environmental and social performance of a specific textile product.

4. Results

4.1. Environmental, Circular, Economical and Social Indicators

To provide a clearer and quantitative analysis of the total environmental, economical and social impact of every textile product throughout its production lifecycle, the STVgoDigital system provides a Sustainability Index. This index is based on a simple and visual scale according to the total score, that ranges from A to F, with the following distribution:

This index helps the consumer to easily visualise the overall impact of the desired product and therefore raise its awareness for sustainability and promote more sustainable and ethical practices among their purchasing habits, while also empowering consumers to make more informed and responsible choices.

The Sustainability Index considers two different scores, the Environmental and Circular score (ECS), and the Economical and Social score (ESS). Together, these scores enable the calculation of the total Sustainability Index, which allows the analysis of the product performance in terms of environmental, economical and social sustainability.

Each of these two scores individually groups data values of indicators collected along the production activities in the textile value chain. The ECS score addresses environmental and circular aspects of the product batch being traced, and the ESS score addresses economic and social aspects of the company engaged in that specific industrial activity. It is important to highlight that the data used to calculate these indicator scores is collected from the various stakeholders throughout the T&C value chain. Furthermore, it is also relevant to mention that each score refers to different levels of information, being the ECS score specific to a particular product/batch, and the gathered data provided whenever a batch is produced, whereas the ESS score refers to a specific company and must be updated annually.

Since the ECS indicator score is specific to the product/batch being produced, the data collected is related to a wide range of activities, such as logistics activities, like transportation, and productive activities like spinning, weaving, dyeing, finishing, and garments manufacturing. For instance, the environmental footprint of each logistic activity is estimated based on the means of transport (e.g., airplane, train, container ship, etc.) used, the distance, and environmental data from known LCA databases that consider the estimated consumption of each type of transport. Similarly, productive activities are assessed based on the consumption of water, energy and chemicals, the generation of liquid effluents and solid waste, and the product estimated durability assessed by quality control tests. The full list of indicators considered is presented in

Table 2. After collecting all the data, each of these variables is suitably normalized and combined into a data model, to create indicators that can be used effectively to analyse the environmental impact of these activities.

The ESS indicator score, on the other hand, is derived from economic and social parameters of the engaged companies in the value chain, such as the number of employees, their salaries and differences in salaries, age, type of employment contracts, work schedules and training, as well as the company’s economic situation, certifications, and social initiatives - the full list of indicators considered is depicted in

Table 3. After the collection of the data, and similarly to the ECS indicator process, these variables are also normalized and combined using a predetermined model scale, in order to calculate the ESS indicator score.

Overall, the ECS and ESS scores provide a comprehensive method to evaluate the environmental and social sustainability of textile products. By calculating the total Sustainability Index using these indicator scores, it is possible to determine the performance of a textile product in terms of sustainability and identify areas for improvement in the textile value chain.

In the rest of this section, the proposed platform architecture is presented in sub

Section 4.2. Then, the platform’s domain entities model is presented in sub

Section 4.3. Also, some notes on the developed smart contract (sub

Section 4.4) and off-chain backend and Application Programming Interface (API) (sub

Section 4.5) are given.

4.2. Architecture of the proposed solution for traceability in the T&C value chain

The proposed solution provides traceability features that allow tracing the previously presented environmental and social indicators/scores along the T&C value chain. The solution for the traceability problem includes the use of Hyperledger Fabric, which is an open-source consortium oriented digital ledger platform [

18], created by the Linux Foundation’s Hyperledger project. Being consortium oriented, it is a permissioned network that enables the definition of different participant profiles, which respond to different needs in a value chain context. This means that authorization profiles need to be defined for all users of the platform, to access the network and take part in transactions. Because of this, Hyperledger Fabric is ideally suited for enterprise applications where data security and privacy are top priorities.

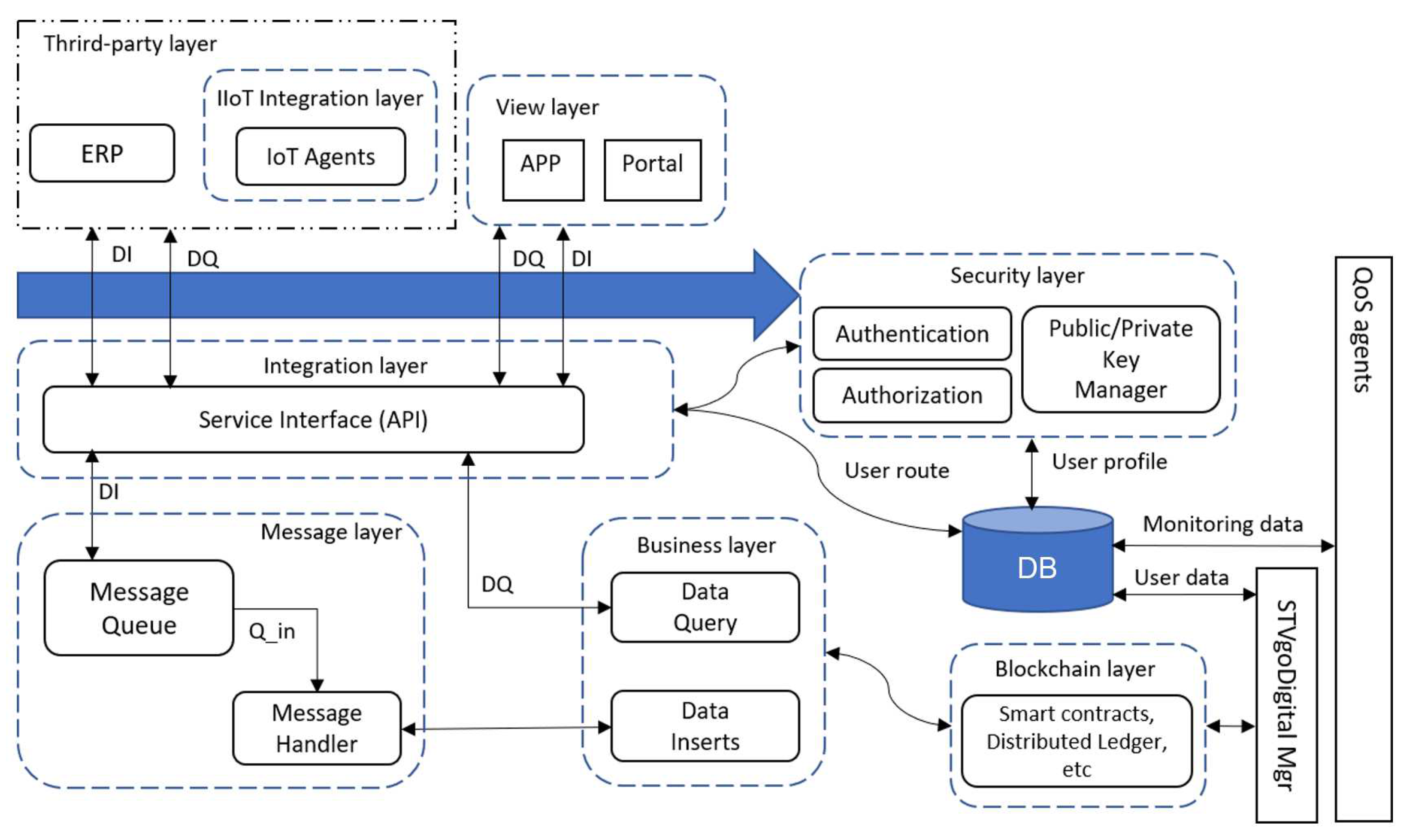

Regarding the architecture of the proposed traceability platform,

Figure 2 illustrates the different components and the way they interact with each other. From top to bottom, one can see that Enterprise Resource Planning (ERP) applications, from value chain’s business partners, integration portals, and other third-party applications (e.g., Internet of Things (IoT) agents, mobile apps) integrate with the traceability backend services through an integration layer API. A user interacts with these types of front-end applications (view layer), which make a request to the API. Subsequently, the following actions may occur:

An authentication process is completed to ensure that the user has access to the platform (security layer in

Figure 2), and an authorization process identifies the type of operations that the user can perform in the system;

Data insertion operations are then put into a message queue (message layer in

Figure 2), to be handled sequentially by the business layer, which calls the smart contract’s/chaincode’s methods for inserting traceability data onto the blockchain;

Data query operations are directly sent to the business layer, which calls the chaincode’s methods for querying traceability data from the blockchain;

A request to the blockchain is made through the Fablo Representational State Transfer (REST) API to execute a transaction in the chaincode. This request includes the chaincode method, to invoke or query the chaincode, when writing or reading data respectively, as well as the method’s arguments.

The chaincode, which is installed on every non-orderer peer and channel, directly reads, writes or deletes the assets represented as documents on the CouchDB key-value-based database (Hyperledger Fabric’s World State database). This database contains the world state, meaning the latest and up to date representation of the items of the blockchain network’s ledger;

If the transaction consensus is reached, the ledger and the world state database update themselves (if this was an invoke/put transaction). Query/get transactions do not need consensus approval.

Regarding the blockchain layer, Fablo is the tool used to generate a Hyperledger Fabric blockchain network and run its several components on Docker containers. Fabric is being used as the protocol provider as it is a consortium oriented platform. Fablo also deploys useful containerized tools, like Hyperledger Explorer, to take an in-depth look to on-chain ledger data, and Fablo REST, a simple REST API server, to call Fabric’s chaincode methods and provide them to the upper layers. Other components available in a standard Fabric network are the Certificate Authority (CA) containers for registering and enrolling users on the system, as well as tools containers for various auxiliary purposes like the peers’ Command Line Interface (CLI).

4.3. On-Chain and Off-chain Data Models

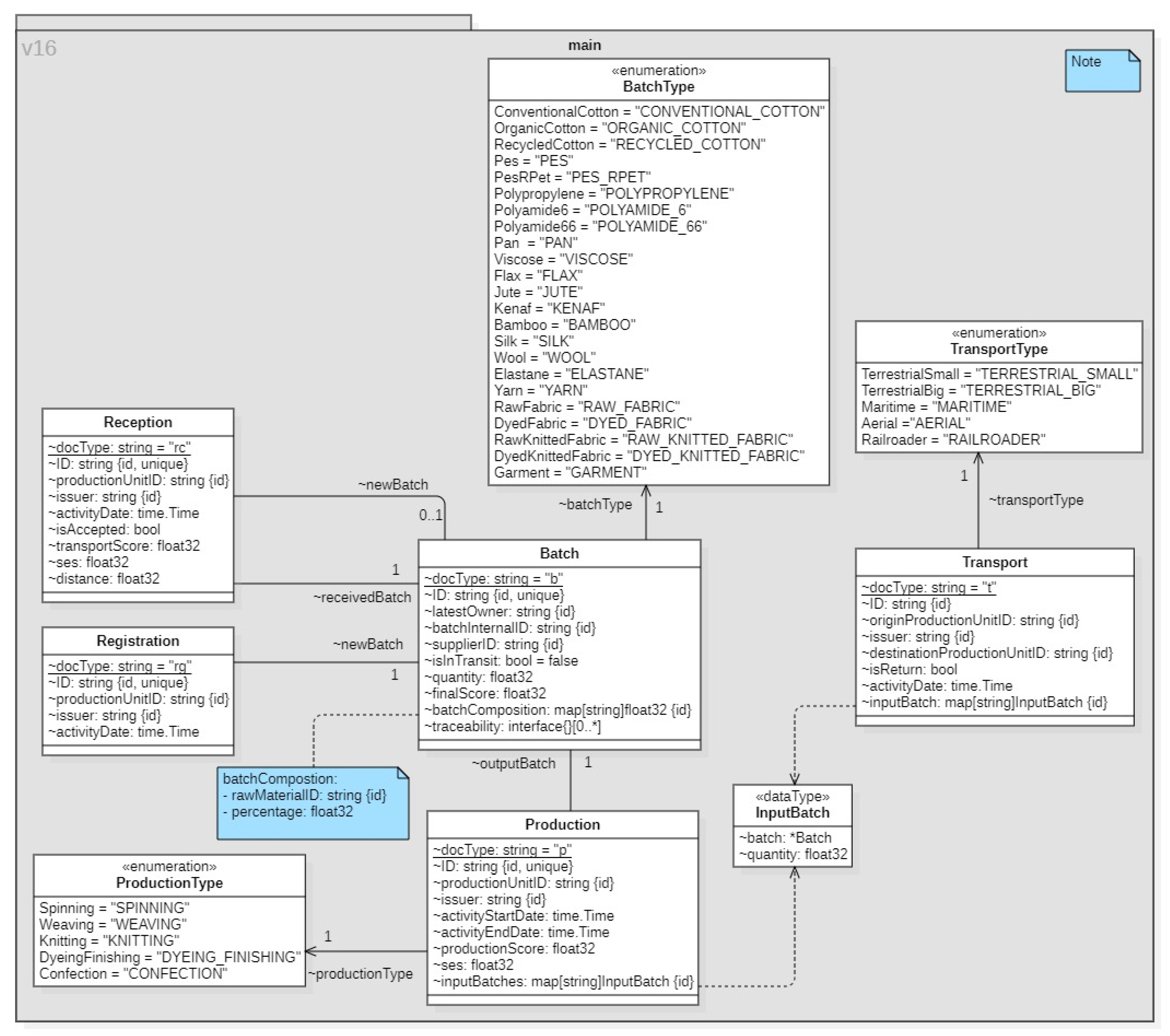

The traceability platform data model is divided into two parts: on-chain data (stored in a blockchain) and the off-chain data (stored in a relational database). On-chain data refers to the core traceability data and is persisted in the Hyperledger Fabric distributed ledger. This includes information of each product’s lot/batch environmental and social scores, the activities with environmental, economical and/or social impact, and its relation to other products’ batches. The on-chain data model is presented in

Section 4.3.1. The off-chain data refers to the non-traceability data, including the production unit that produced a product batch, and the registration of all the measurements of each activity’s environmental, economical and social indicators, stored in a relational database. These measurements are used for computing the social and environmental scores stored in the blockchain. The off-chain data model is presented in

Section 4.3.2.

4.3.1. On-chain Data

Figure 3 represents the (on-chain) data model, corresponding to the data structures to be persisted in the blockchain.

The main entity to consider is Batch, the digital representation of a product lot or batch in the value chain. Other entities have been defined to digitize the activities within the value chain with activity type granularity, resulting in the definition of Registration, Production, Transport & Reception. Other than the enumerations to specify enumerable values (BatchType, ProductionType, TransportType), the remaining is a data type definition of InputBatch, used in aggregation activities (Production & Transport) where there is the need of specifying quantities per batch.

Some attributes have an {id} tag next to them, to classify them as identifiers from other data structures that are off-chain (e.g., productionUnitID), which identifies the production unit that is endorsing the activity transactions that the issuer is invoking. Here is a more detailed explanation of the on-chain data entities:

Batch - is the main asset to be tracked on which the value chain operations work on. Besides the boilerplate docType & Identifier (ID), the batch definition contains an enumeration with enumerable values related to its type (batchType). Regarding off-chain identifiers, a batch has attributes to reference the production unit that owns it, supplier and internal batch identifiers for referencing a batch within the scope of a single company - productionUnitID, supplierID & batchInternalID respectively. The remaining off-chain identifier is present in batchComposition, where a key-value data structure holds the information about what materials and its percentages constitute the batch (e.g., {cotton: 50%, polyester: 50%}). Batch quantity lists the batch amount in kilograms. The attribute score is what holds the final score and ranks the batch sustainability claims. The calculations to reach the final score of the batch are made off-chain by other modules of the system, listing just the final value on-chain inside the batch entity. The auxiliary boolean attribute isInTransit, with a default value of false upon batch creation, helps to truthfully represent the batch current owner state when it is being shipped between production units. Lastly, the attribute traceability being a non-mandatory interface collection data type, can hold any type of data. This attribute will append the activities’ "objects" for each activity that a batch goes through, resulting in a recursive collection of activities and its input/output batches throughout the value chain activities until it reaches the current instance of a batch. Visually, this representation results in an inverted tree where the root is the current batch, the straight branches are activities with no aggregation (Registration, Transport & Reception) and the branches that split into 2 or more sub-branches are Production activities that have two or more input batches to merge into an output batch.

Registration - is an activity used when a production unit wants to register a batch that is created outside of the developed system, instead of being created through a production activity, but needs to enter the value chain to be used as an input batch for production activities. It is a simple activity that just has productionUnitID to identify the production unit where the batch registration was logged and activityDate as a timestamp for the registration, besides the boilerplate docType & ID attributes. Finally, the newly introduced batch needs to be associated with the registration.

Production - is an activity that consumes batch(es) and creates a batch, making it the only activity that can converge the history of one or more batches’ with a new batch, by using them as Input Batches. These input batches are structured in the inputBatches attribute as a key-value pair data type that can hold information regarding a batch pointer reference and the quantity to be used in an activity (e.g., {batchID: b-001, inputBatch: {batch: *b-001, quantity: 100}}). Besides the usual docType & ID attributes and the aforementioned off-chain identifier of input batches, this entity includes companyID & productionUnitID to identify the company and its production unit respectively. An enumeration with enumerable values related to the production type was also added ((productionType)). For timing purposes, activityStartDate & activityEndDate are timestamps point to the start and finish date and times of the production activity. At last, productionScore is a score indicator of the sustainability claims and resources spent in the production activity while ses (ESS) is related to a rating the company/production unit has relative to its social impact on its workers and operators.

Transport - is an activity used to register a shipment of a batch to another participant in the value chain. To support this functionality, this entity has off-chain IDs for specifying the origin and destination for the transport (originProductionUnitID & destinationProductionUnitID respectively). The use of Input Batch is also present in the attribute inputBatch where in this case it only has a cardinality of 1, making it mandatory to include just a single batch in transportation. Even though a shipment may carry more than a single batch, the transaction on-chain to log the transport activity only registers one batch per activity. The reasoning behind this decision is to decouple the batches’ traceability in the shipment from each other, maintaining a reliable tracking and tracing of each batch. Other attributes in this entity include predefined data related to its transportation type in transportType and distance for storing the distance of travel. A boolean isReturn attribute with a default value of false is also present to indicate if the shipment is a return transport in case of the destination production unit rejecting the batch upon receiving it (more in Reception activity below). Lastly, activityDate serves the purpose of logging the timestamp of shipment departure. The date and time of arrival is only registered when receiving the batch, leading up to the activity below.

Reception - is an activity issued upon the arrival of batches to a production unit. This activity is required after a transport activity because the transported batch should be properly received and its quality assessed, to continue through the value chain. Data related to this activity includes the usual docType & ID attributes and productionUnitID as off-chain production unit ID. Receptions must have a receivedBatch to reference the batch that was in transport and can have a newBatch depending on off-chain quality assurance results. It is necessary to have a boolean attribute as in isAccepted for quality assurance purposes, allowing the operators to accept/reject the batch upon reception. If accepted, newBatch is created. If rejected, it is not. The reception timestamp in activityDate not only does it useful for registering the date and time of the activity but, as previously mentioned, is used to log the arrival date and time of a transport (referencing the last transport activity already happens when appending the transport to the batch’s traceability). Last but not least, a transportScore & ESS were added for providing information regarding the environmental and socio-economic sustainability claims of the transport that just arrived to the production unit respectively.

In

Figure 3 it is worth mentioning that registration activities do not have sustainability scores because they’re a purely logistic activity that does not affect the areas of impact in those scores.

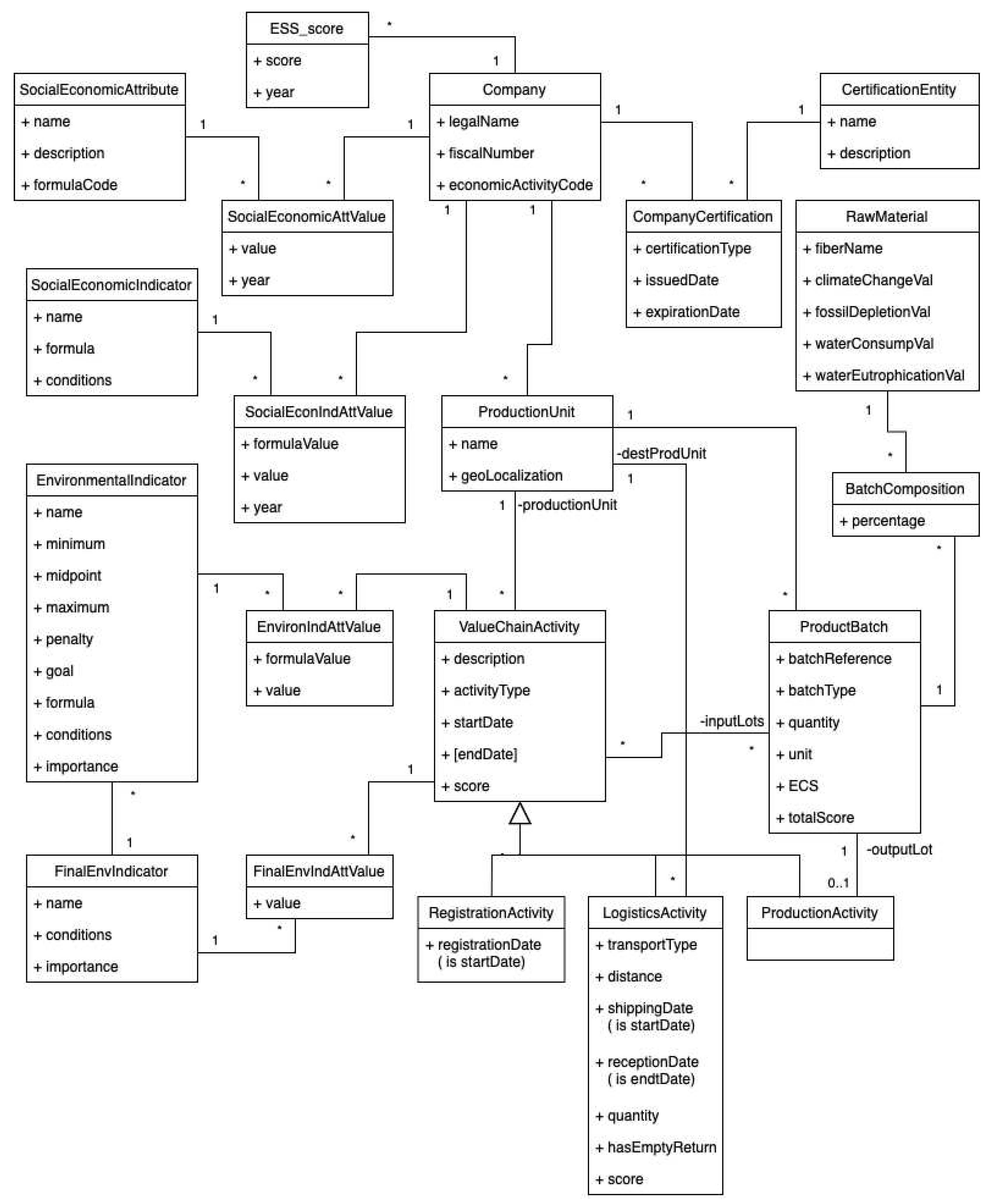

4.3.2. Off-chain Data

In this architecture, the off-chain database is a relational database composed of thirty-four tables. For simplicity, only the main entities are depicted in the off-chain domain model in

Figure 4. This model data, which adds to the data that is stored on the blockchain, serves as a starting point to calculate the identified environmental and social indicators.

There are five main data entities, which reference relevant on-blockchain entities:

Company, which is a company that performs value chain activities;

Logistics activity, which corresponds to a transportation between two production units;

Registration activity, which models a registration of a new batch from outside the traceability system;

Production activity, which corresponds to a value chain activity, such as spinning, weaving, dyeing, etc.; and,

Batch, corresponding to a product batch created and handled by the identified value chain activities.

These entities add detail to the information persisted in the on-chain entities with the same name. This detail includes the individual values of the environmental and social indicators used to calculate the environmental and social scores registered in the blockchain. The entities where the values from these calculations are stored are:

ESS_score, stores the calculated Economical and Social score (ESS) for a company/year;

SocialEconIndAttValue, stores values of a company’s Economical and Social indicator (c.f.

Table 3) for calculating the ESS;

SocialEconAttValue, stores other values of a company’s data;

company_certification, stores a company’s certificates yielded by a certifying entity;

EvironIndAttValue, stores temporary values of an activity’s environmental indicator (c.f.

Table 2);

FinalEnvIndAttValue, stores the final/end values of an activity’s environmental indicator (c.f.

Table 2);

4.4. Smart Contract / Chaincode

To operate the previously presented on-chain data model, a set of chaincode transaction methods has been defined to support the desired traceability functionality for the platform. The code available for the repository of this developed solution is available in

github.com/lcvalves/stvgd-chaincode.

Table 4 presents these methods, which mainly support the management of the batch activities that happen on the T&C value chain, as well as reading a batch’s information and traceability data. Some arguments are automatically filled, especially those with information regarding the production unit calling the transaction method, as well as the score’s data. Other methods need data to be manually inserted such as batches’ information, quantities and other information regarding the activity.

Referring to

Table 4, the asterisk symbol (*) in the output batches of Transport and Reception indicate that the batch has an optional cardinality. On transport activities, when the batch to be shipped is not entirely used, it creates a "leftover" batch with the remaining quantity kept in the used one. On reception activities, if the production unit rejects the batch it does not refactor its IDs, therefore, it doesn’t need to create a new batch for that refactoring process. As stated, on both transport and reception activities, the creation of an output batch is entirely dependent on the activity’s arguments, hence the optional cardinality. Double asterisk (**), in

Table 4, regards the presence of the boolean attributes of

isReturn and

isAccepted in both automatic and manual arguments in Transport and Reception activities respectively. This happens due to the arguments having an automatic default value of false which can be manually set to true. Hence, both attributes are in the two columns, for automatic and manual attributes, in

Table 4.

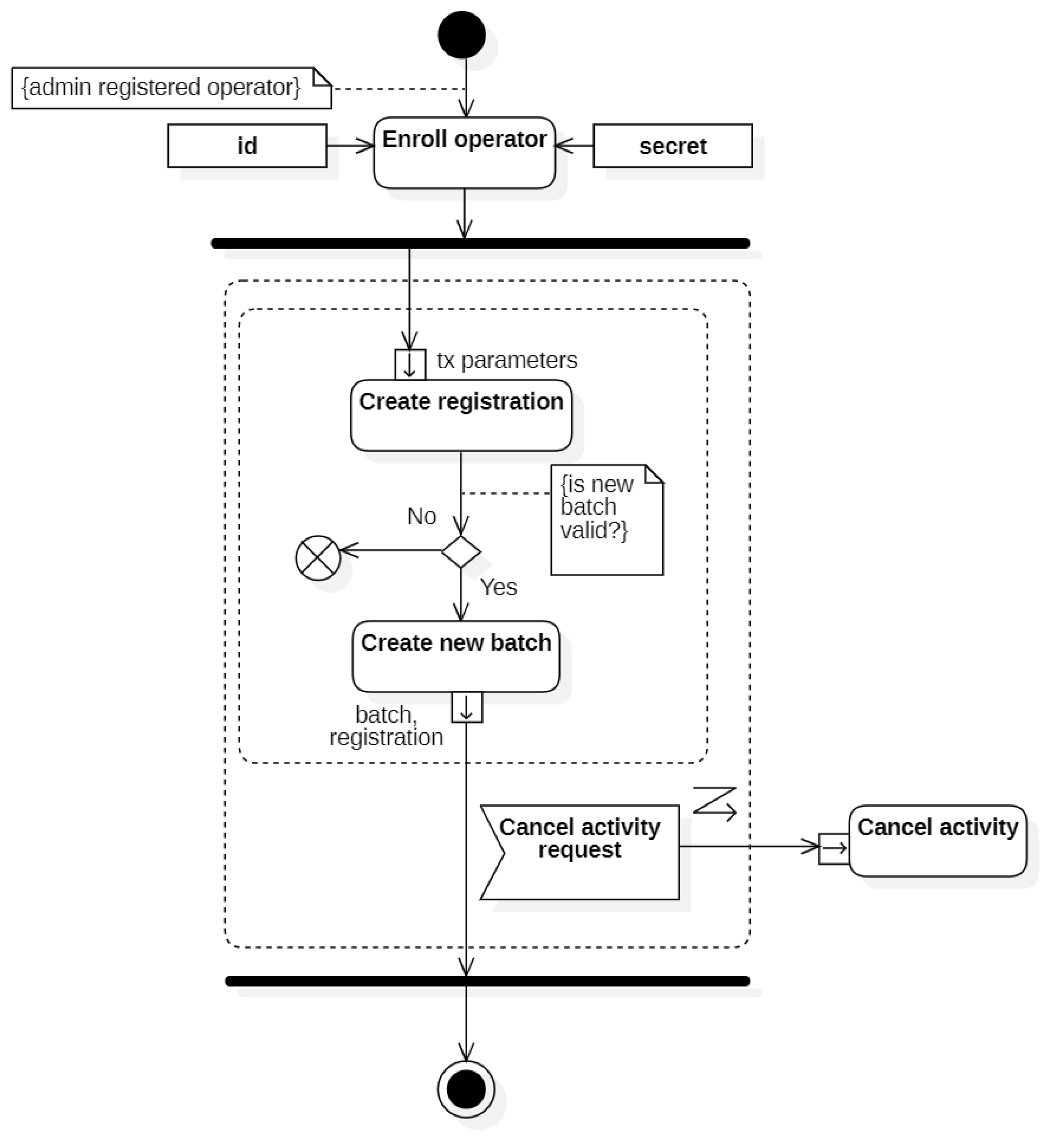

To further demonstrate the assets management and Business Logic Layer (BLL) behind the transactions,

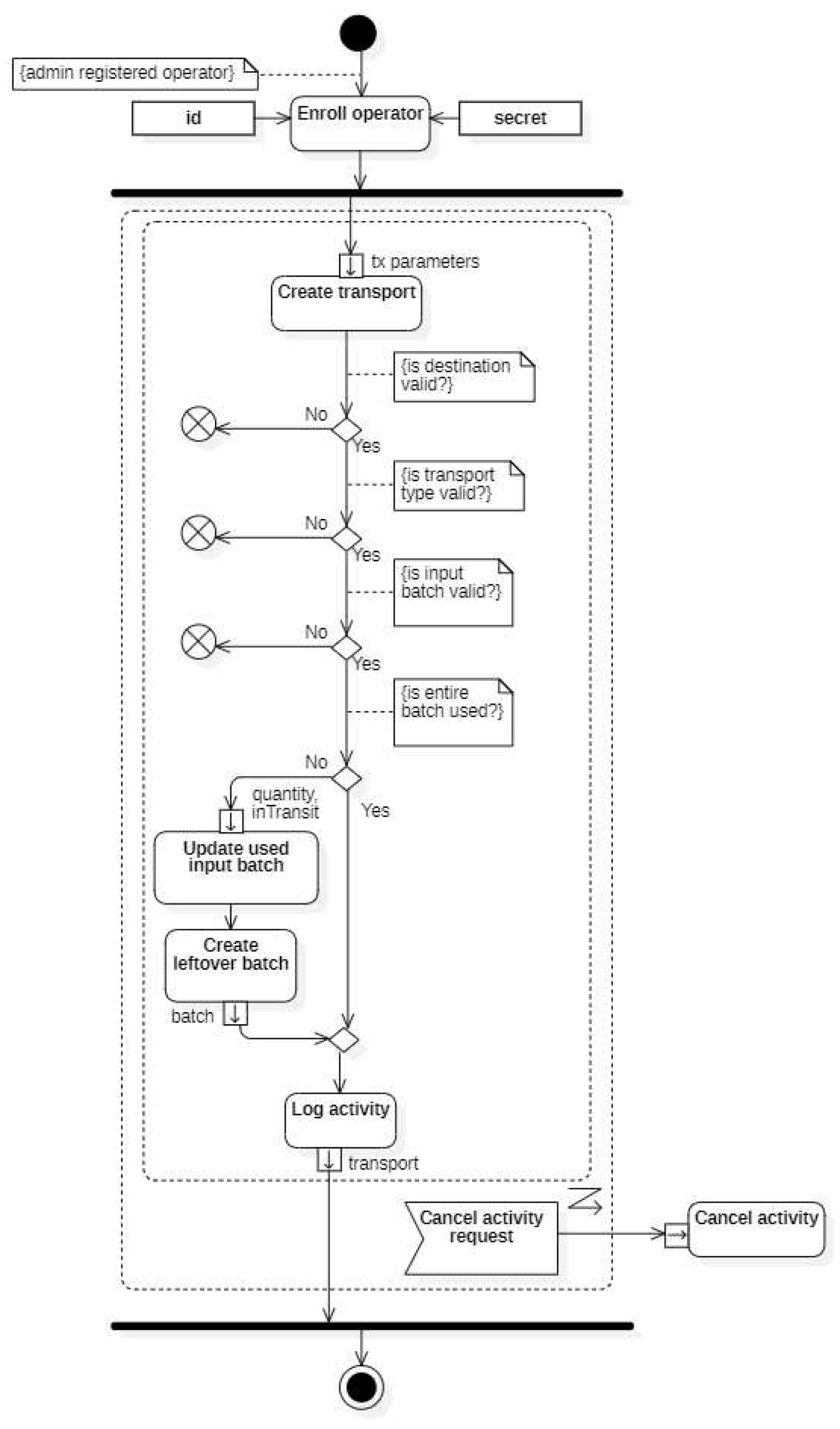

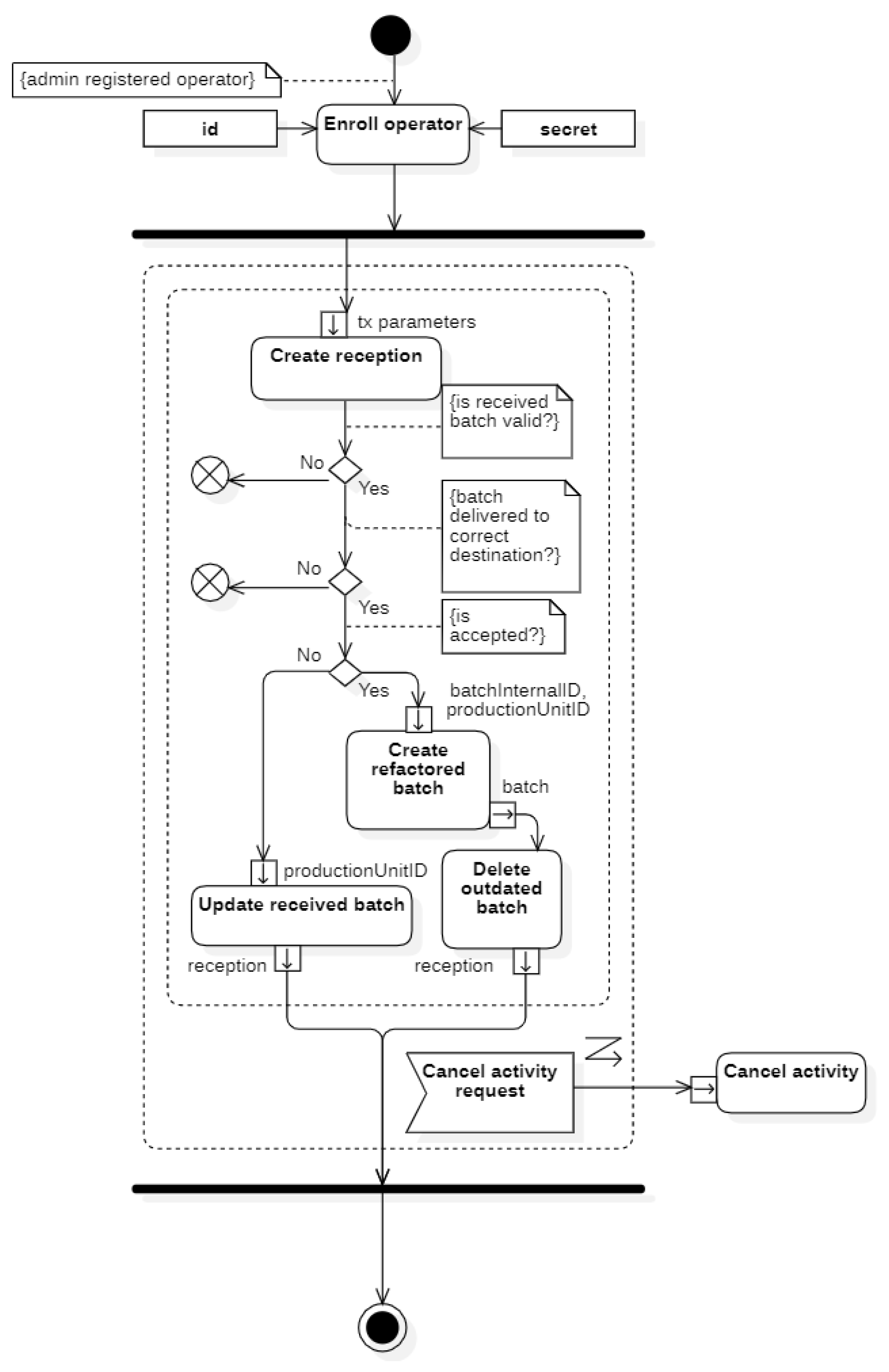

Figure 5,

Figure 6,

Figure 7 and

Figure 8 depict the validation on each method that issues a Registration / Production / Transport / Reception activity with a transaction activity diagram. Simple validation of parameters was not included in these diagrams for image fitting purposes. The diagrams indicate the BLL behind the creation of batches and the parameters that define the path of issuing the creation of assets. Every diagram starts with an enrollment section for user authentication purposes, where an operator identification issued by an administrator must sign-in in order to log any activity. Lastly, the transaction parameters get the value assigned by the automatic and manual arguments inserted by the operator as listed in

Table 4.

Figure 5 depicts the BLL behind the creation of a Registration activity. The chaincode internally validates the parameters with the defined BLL and creates the batch document and registration document as output assets if the new batch data is valid.

Figure 6 depicts the BLL behind the creation of a Production activity. The chaincode iterates through the inserted input batches and internally validates the input batches’ parameters with the defined BLL. If passed, it updates each of the used input batch quantity, deleting the batch itself if it’s entirely used (no quantity left). Then it validates the inserted output batch data and production type. If both are valid, the batch and production document are created as output assets.

Figure 7 depicts the BLL behind the creation of a Transport activity. The chaincode validates if the destination, transport type and input batch data are valid. If so, it will then check if the entire batch will be used for transport. If true, the chaincode will log the activity and create the transport document as an output asset. If false, before creating the transport document, the chaincode will update the used input batch quantity and "in transit" state. It will also create a leftover batch document as an output asset with the rest of the batch that was left behind in transport.

Figure 8 depicts the BLL behind the creation of a Reception activity. The chaincode validates the received batch, destination, and "accepted" state (related to quality assessment processes). After approving the received batch and destination data, if the batch is accepted, the chaincode will create a refactored batch document as an output asset with similar data to the received batch but with new internal and production unit identification while deleting the "outdated" received batch. However, if the batch is not accepted, the chaincode will just update the received batch production unit to the current operator’s production unit. Either way, after any of both processes the chaincode will create the reception document as an output asset.

It is worth mentioning that any of these activity creation processes can be cancelled while the operator is inserting the data as arguments on which interface it decides to use.

4.5. Backend and API

For integrating on-chain and off-chain data, and provide applicational business logic through services for frontend applications, such as the companies’ ERP’s and the integration Web platform, a backend component with a REST API has been developed.

This backend component has been developed using Java Spring Boot. The API has been created to offer endpoint services to perform all Create, Read, Update and Delete (CRUD) operations on the off-chain database configuration tables, such as transport_type and batch_type tables. In addition, endpoints were also created to register all the movements of a batch, thus registering all the data related to productive and logistical activities until it reaches the final product (i.e., the product for the end consumer).

When registering a production or logistics activity, the data sent in the service body are not only stored in the off-chain database, but, in addition, are processed through certain formulas to calculate the value of the circular and environmental score of the corresponding product batch. Once this score has been calculated, it is stored in the off-chain database, and is also sent to the blockchain component through the endpoints created with Fablo REST.

To perform the ECS and ESS score calculations, the exp4j library has been used for evaluating mathematical expressions. This library allows to use mathematical expressions, such as sin, avg or abs, making the calculations easier to perform, and it also allows to design conditions where the defined variables can perform different formulas depending on the specific situation.

4.6. Applications

The proposed traceability platform has been designed to be used along the textile and clothing value chain, giving consumers access to the traceability information and sustainability index of textile products at the moment of purchase, and giving also traceability and sustainability information about every intermediate product to every business partner along the value chain. This enables any user to be aware of the social-economic and environmental impact associated with a textile product’s manufacturing and transportation along the value chain, and to know every company that has been directly or indirectly involved in that textile product’s production and transportation, including each company’s social-economical and environmental responsibility score. Moreover, the system also contains information about the textile product composition and components, thereby facilitating the tasks of properly disposing of the item and assisting with recycling sorting, simplifying the process to identify the best recycling method for a given textile product.

For having this functionality available to every business player in the value chain, a set of frontend applications are needed.

4.6.1. Integration with Organizational Applications

Business players, both industrial and logistics, along the T&C value chain typically use ERP software for managing their daily business activities, such as accounting, procurement, production, and supply chain operations, among other activities. The integration of ERP software of the T&C business players with the traceability platform will simplify and streamline the registration of traceability information on the platform. A version of the comercial ERP software solution (Multi, from Infos), tailored for the Apparel and Textile industry, has been modified to integrate the traceability data. To perform the integration between Multi ERP and the STVgoDigital Platform, the authors used the backend API previously presented. Thus, the following steps have been taken for a smooth integration:

When an official ERP document is created (e.g., dispatch advice) or a manufacturing order is completed, the ERP generates an appropriate message and sends it to a RabbitMQ broker queue. The RabbitMQ queue is used to enable the asynchronous processing of requests;

A set of microservices, which have been developed for this integration, are in charge of listening to the RabbitMQ queue and getting the message;

Then, the message is unpacked and the appropriate service is called on the endpoint from the STVgoDigital backend API to send the production data.

Overall, the integration brings advantages to companies using integrated ERPs, since data are automatically sent to the STVgoDigital platform, thus avoiding the sharing of delayed data, errors, and penalties from the platform with manual data inputs, mainly concerning the consumption of energy, water, etc., which are used in a product’s production.

4.6.2. Portal for non-integrated Organizations

In order to create an inclusive platform, one that allows companies with non integrated ERPs to integrate their data with the traceability platform, a Web portal has been created. The created Web portal provides an alternative solution for companies in the textile supply chain who lack access to an integrated ERP or other type of organizational application, as it is possible to see in

Figure 9

This web portal is specifically designed to facilitate the data input process required for the system under consideration, an innovative concept that seeks to promote sustainability and ethical production practices in the textile industry, enabling companies to input their data directly into the system through a user-friendly interface. This feature expands the scope of participation in the system under consideration beyond large companies that have already implemented such software, only being needed a stable internet connection to access it. Overall, the Web portal offers a practical and cost-effective solution for textile value chain companies that want to join this traceability system and improve their sustainability and ethical production practices, but lack the resources to implement or acquire an Organizational Application. In this instance, the web portal providers will analyse and validate the data, issuing warnings on specific parameters that appear to be out of context, adding this additional layer to validate the data that is provided.

Other integration solutions may be developed in the future, as the backend API is available for new software integrations.

5. Analysis of Results and Discussion

To assess and validate the software artifacts that resulted from the STVgoDigital R&D project, a set of validation tests have been performed.

In order to test the developed system, two case studies were designed, one focusing on an article of clothing, with a partitioned supply chain, and another one focusing on an article of home textiles, with a vertical supply chain. For each case study, two items were considered, one with a light colour and one with a dark colour, to understand the system’s flexibility in evaluating two comparable products with different colours, which should result in different environmental performances. Before describing the case studies, it is worth noting that they were developed as part of a pilot project with Portuguese textile companies. Although the pilot was limited to Portuguese companies, it is important to remember that, as previously stated, the Portuguese textile cluster encompasses all the productive activities associated with the production of a textile product.

5.1. Case study 1: a home textile product (towel)

In the first case study, the focus of the pilot is a home textile product, resulting from a vertical supply chain, which means that all productive activities, from spinning to manufacturing, passing through weaving and dyeing, were carried out by the same company. Because the supply chain is vertical, and all productive activities are performed within the same company, there are no logistical activities between the various productive activities. Furthermore, the granularity studied is at the batch level, implying that the processing and analysis are being performed on a collection of textile products (batch) that originated from the same productive activities, rather than on individual items.

For these tests, the measured indicators for computing the ESS and ECS, started on the spinning activity, hence the consumptions associated with the cultivation/production of the raw material were estimated according to a defined LCA database. As a result, the company only needed to specify each raw material associated with the textile product, as well as the origin of the raw material, for the system to input the consumption’s of the cultivation/production of the raw material considered to the textile article performance. Following this activity, data was gathered across the various productive activities associated with the creation of the home textile product, encompassing all activities from spinning and weaving, to dyeing and finishing and manufacturing of the textile product. Following this collection of data, the company needed to specify to which customer the batch has sent, in order to complete the data collection process and input the consumption of this logistical activity to the textile product performance.

Following the completion of the data gathering, it was possible to aggregate the data into a comprehensible manner, allowing the consumer to access the information by scanning a QR code, enabling the consumer to make a more conscious and responsible purchase.

The analysis of the case study created for the home textile product can be further detailed by referring to

Appendix A.

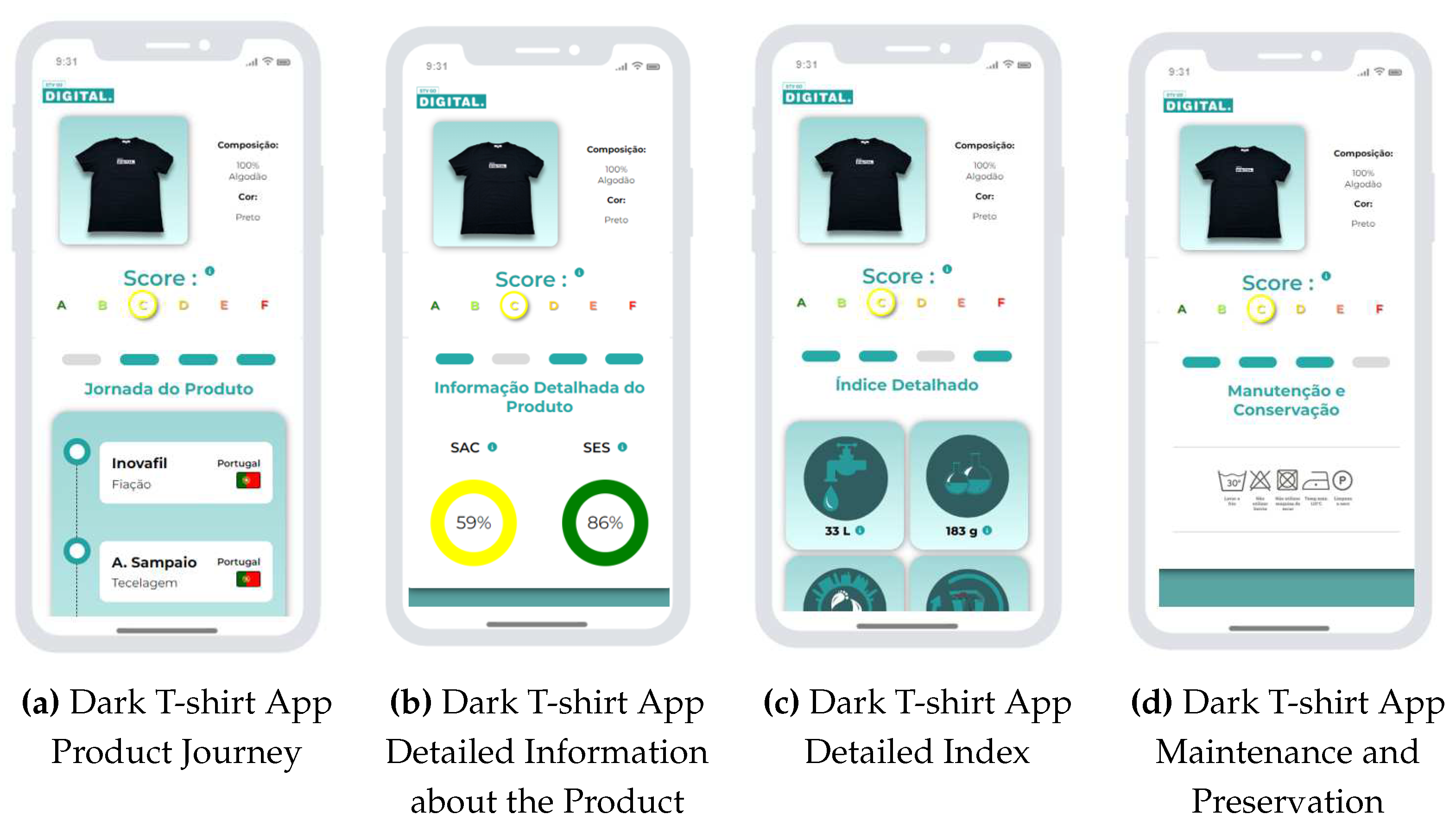

5.2. Case study 2: a garment (T-shirt)

Regarding the second case study, the focus was on a clothing product and its underlying supply chain. In this case, the supply chain is partitioned, so, each productive activity is developed by a different company. The method for gathering data for this case study begins with the company that does the spinning process, indicating the raw material associated with the textile product, as well as the origin of the raw material. After providing the data regarding the raw materials performance, this company provided the data that characterise the environmental performance of its productive activity. After the conclusion of this productive activity and the collection of the data, the batch is sent to the next company in the supply chain, which in this case is the company responsible for the knitting process. Since this pilot’s supply chain was partitioned, it follows that a logistical activity is required to move the batch from one company to another after each productive activity. The enterprise must therefore identify where the batch was dispatched and how it was transported after the producing activity is complete, for this information to be included in the performance of the textile product. This process was repeated for the knitting, dyeing and finishing, and manufacturing productive activities, bearing in mind that each time that the batch was transported from one company to another, the company responsible for ensuring the transport needed to specify where the batch was sent to, as well as its means of transportation. To finalise the data collection process, the last company in the supply chain, responsible for the manufacturing productive activity, needed to specify to which customer the batch was being sent, and input the consumption of this logistical activity to the textile product performance. After the data collection was concluded, it was possible to aggregate the data in a comprehensible manner, allowing the consumer to access the data through the scanning of a smart tag, enabling the consumer to make a more conscious and responsible purchase. It is possible to further detail the way the data was aggregated for the light-coloured T-shirt and the dark-coloured T-shirt, by referring to

Appendix B.

These case studies made it feasible to comprehend how the developed system meets the functional and technological requirements of the textile ecosystem regarding the exchange of traceability and sustainability information throughout the whole supply chain. It is clear that the system performed equally well for both supply chains considered, whether the supply chain is vertical or partitioned. Furthermore, it is also clear that the way the data is presented would enhance consumer awareness in buying a more sustainable textile product, and, with given time, even enhance the consumer consciousness regarding the environmental impact of the production of a textile product. In the clothing case study, the consumer can clearly perceive that the dark-coloured T-shirt has a worse sustainability score than the light-coloured T-shirt, as well as much more consumption regarding the different indicators, e.g. Water consumptions and Chemicals consumption. In addition, after scanning the smart tag, the consumer may also access the product’s maintenance and care instructions, as well as its composition, which could be seen as an opportunity to replace the compulsory physical tags with this information. It was also possible to understand some limitations of the developed system. Mainly, the system does not consider that different products are expected to have different consumptions and therefore different environmental performances, so the sustainability score should address the corresponding type of product. This can be seen in the home textile case study, where two towels were produced, and although the dark-coloured towel had a higher environmental impact, the sustainability score was still the same for the light-coloured towel, which reveals a need to consider the different type of products associated with the textile industry.

6. Conclusions and Future Work

In this article the results of the subproject PPS1, of the STVgoDigital project, have been described. This project has been developed with the goal of implementing traceability along the textile and clothing value chain, and computing and storing the environmental and social score of a product.

The created platform uses blockchain technology, namelly Hyperledger Fabric, as a way to decentralize and share the collected information. Only the information needed to trace a product is stored in the blockchain (mostly codes and scores), and other detailing information is stored in a relational database. The information stored in both places are related through fields with the same codes and thus allows contextualizing the information stored in the blockchain.

In order to be able to calculate the environmental and social score of a product, several indicators are collected along the value chain. The platform is prepared to collect information from companies with different technological levels, from automatic data collection through companies’ ERPs and IoT devices, to manual data collection through a web portal, for non-integrated business partners.

To demonstrate the platform, two case studies have been developed, together with several Portuguese textile manufacturing enterprises, including small, medium and large companies. It should be noted that, with the exception of the production of the raw material (cotton), all the other stages of the value chain were carried out in Portugal. One of the case studies was focused on the clothing supply chain and another focused on home textiles. From these two case studies, one may say that the created platform is able to collect environmental, circular, economic and social indicators covering all companies in the textile supply chain, allows the calculation of a sustainability index (Environmental and Circular Score - ECS), and improves the traceability and transparency through the whole supply chain, from the spinning mill to the final product.

The two test case scenarios involved only Portuguese manufacturing companies. Enlarging the pool of participants, to international business partners and involving other types of companies (e.g., brand managers), testing this system with international supply chains, is left for future work. Also, only a linear supply chain has been tested. For future work, we intend to apply this system to lot-dividing scenarios, making lot/batch traceability to be non-linear, and looking like a tree diagram. Also, applying the platform to a circular supply chain, involving sorting and recycling companies, is also left for future work. This would allow determining if and how this platform could be also applicable to these stakeholders.

Another important aspect to take into account is consumers’ green literacy, i.e., the consumer’s ability to analyse the data provided through the app. To this end, a future work of this project could be, to raise awareness and educate consumers about this information and to use gamification strategies in order to promote good consumption practices [

19].

Other future work will be to determine the deterioration of performance, when augmenting the number of activities on one product batch. This is due to the growing transaction size as the traceability attribute, in the blockchain, increases each time a batch and its descendants go through value chain activities.

The work developed in the STVgoDigital project - PPS1, answers to almost every requirement within the guidelines proposed by the European Commission regarding the Digital Product Passport. Future work will completely align the proposed traceability platform with the goals of the Textile and Clothing Digital Product Passport.

Author Contributions

For research articles with several authors, a short paragraph specifying their individual contributions must be provided. The following statements should be used “Conceptualization, M.Sá, E.F.C. and A.M.R.C.; methodology, A.M.R.C.; software, L.A. and T.A.; validation, J.O., M.A. and M.Santos; formal analysis, A.M.R.C.; investigation, L.A. and M.Sá; resources, J.O. and M.Sá; writing—original draft preparation, L.A., M.Sá, E.F.C. and M.A.; writing—review and editing, E.F.C. and A.M.R.C.; supervision, J.O., M.Santos and A.M.R.C.. All authors have read and agreed to the published version of the manuscript.”, please turn to the

CRediT taxonomy for the term explanation. Authorship must be limited to those who have contributed substantially to the work reported.

Funding

This work has been partially developed within the scope of the project “STVgoDigital: Digitalização da Cadeia de Valor do Setor Têxtil e Vestuário”, specifically in its PPS1, with reference POCI-01-0247-FEDER-046086, financed by the European Regional Development Fund (ERDF), through the Competitiveness and Internationalization Operational Program (COMPETE 2020), and partially within the scope of the project “BE@T: Bioeconomia Sustentável fileira Têxtil e Vestuário-Medida 1”, financed by the “Recovery and Resilience Plan” (PRR), through of measure TC-C12-i01 of the Environmental Fund.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| API |

Application Programming Interface |

| ATP |

Textile and Clothing Association of Portugal |

| BLL |

Business Logic Layer |

| CA |

Certificate Authority |

| CE |

Circular Economy |

| CLI |

Command Line Interface |

| CRUD |

Create, Read, Update and Delete |

| DPP |

Digital Product Passport |

| ECS |

Environmental and Circular Score |

| ERDF |

European Regional Development Fund |

| ERP |

Enterprise Resource Planning |

| ESS |

Economic and Social Score |

| EU |

European Union |

| ID |

Identifier |

| IoT |

Internet of Things |

| LCA |

Life Cycle Assessment |

| NFC |

Near Field Communications |

| REST |

Representational State Transfer |

| R&D |

Research and Development |

| RDBMS |

Relational DataBase Management System |

| QR |

Quick Response |

| RFID |

Radio Frequency IDentification |

| T&C |

Textile & Clothing |

| XML |

eXtensible Markup Language |

Appendix A

In this appendix, the analysis of the case study created for the home textile product (a towel) is further detailed.

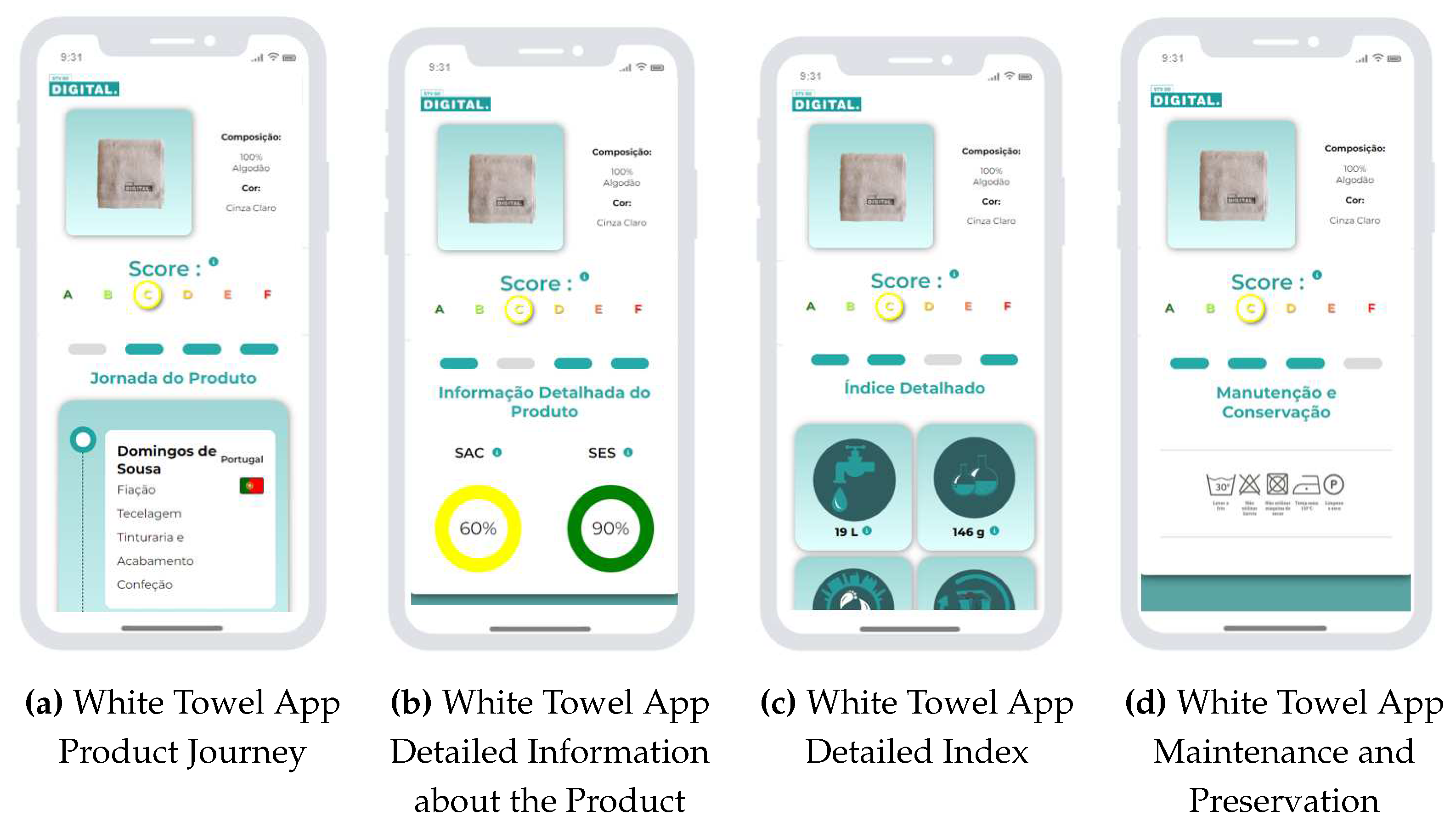

In

Figure A1, screens from the customer app related to the light colour towel, are shown. In

Figure A1a, it is possible to analyse the picture of the textile product, its composition and colour, as well as its environmental score. It is also possible to see the product journey of the textile product, in other words, all the production steps involved in the production of this textile product. In

Figure A1b, it is possible to assess the ECS and ESS indicators. In

Figure A1c, it is possible to analyse the specific consumptions of the textile product, considering the following dimensions: water consumption, chemicals consumption, percentage of generated and recovered waste and CO2 footprint. In

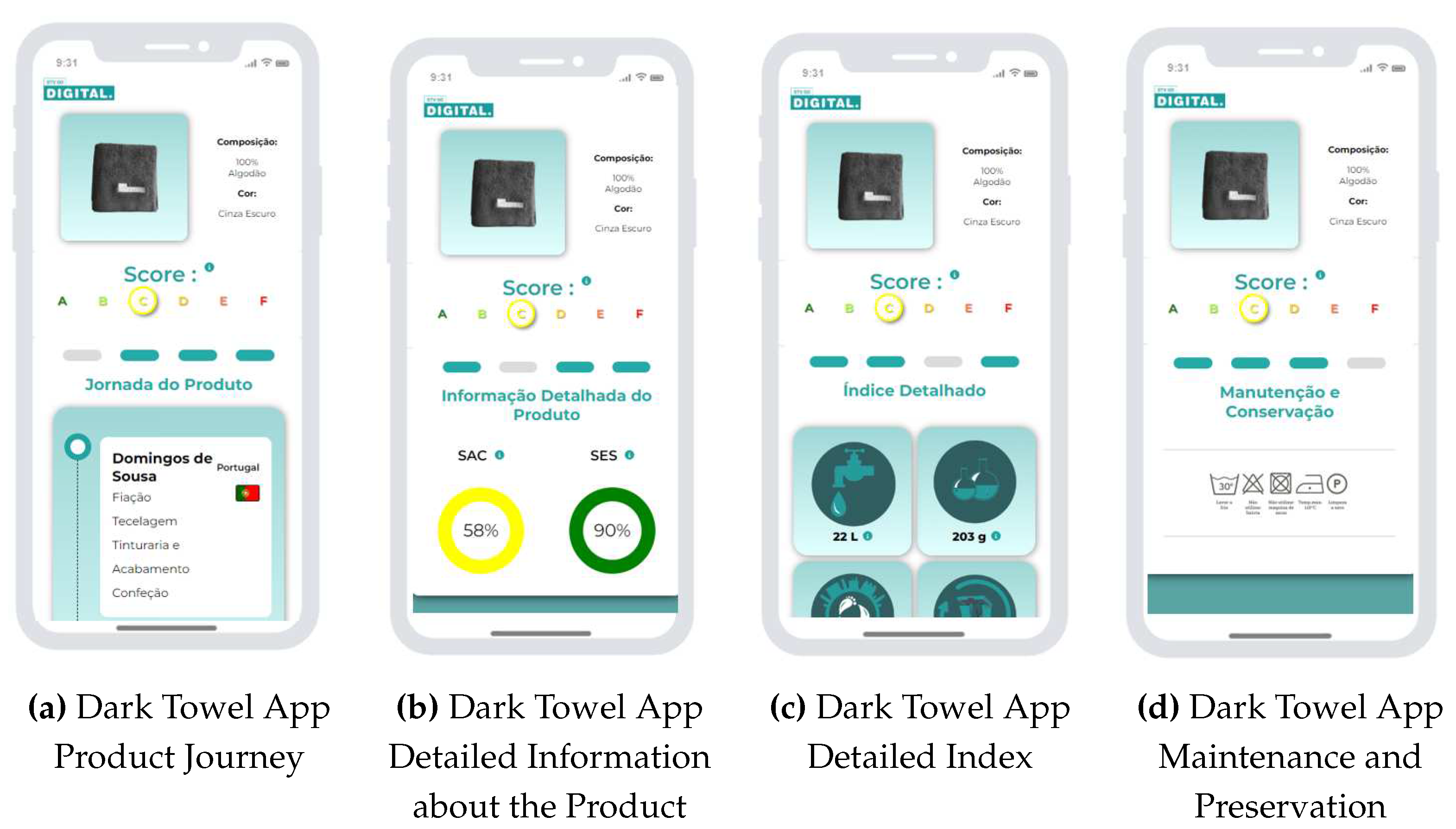

Figure A1d, it is possible to analyse the maintenance and care instructions. In addition, in this case study, a pilot was developed to analyse the performance of a dark-coloured towel, compared with a light-coloured towel. Thus, in

Figure A2, it’s possible to analyse the data related to the dark-coloured towel. Images of the consumer application relative to the case study for traceability and other product information of white and dark colour Towels.

Figure A1.

Consumer application depicting traceability and other product information, for the Home Textile value chain - White colour towel.

Figure A1.

Consumer application depicting traceability and other product information, for the Home Textile value chain - White colour towel.

Figure A2.

Consumer application depicting traceability and other product information, for the Home Textile value chain - Dark colour towel.

Figure A2.

Consumer application depicting traceability and other product information, for the Home Textile value chain - Dark colour towel.

Appendix B

In this appendix, the analysis of the case study created for the clothing article (a T-shirt) is further detailed. It is possible to better understand the way the data has been aggregated and presented to the consumer, for the light-coloured T-shirt, in

Figure A3, and for the dark-coloured T-shirt, in

Figure A4.

Figure A3.

Consumer application depicting traceability and other product information, for the Clothing value chain - White colour T-shirt.

Figure A3.

Consumer application depicting traceability and other product information, for the Clothing value chain - White colour T-shirt.

Figure A4.

Consumer application depicting traceability and other product information, for the Clothing value chain - Dark colour T-shirt.

Figure A4.

Consumer application depicting traceability and other product information, for the Clothing value chain - Dark colour T-shirt.

References

- EURATEX, E.; Statistics. FACTS & KEY Figure 2022 OF THE EUROPEAN TEXTILE AND CLOTHING INDUSTRY, 2022. August Update.

- Cura, K.; Sheenam, J.; Niinimäki, K. Transparency and traceability in the textile value chain. Technical report, 2022.

- Alves, L.; Ferreira Cruz, E.; Lopes, S.I.; Faria, P.M.; Rosado da Cruz, A.M. Towards circular economy in the textiles and clothing value chain through blockchain technology and IoT: A review. Waste Management and Research 2022, 40, 3–23. doi:10.1177/0734242X211052858. [CrossRef]

- Lehmann, M.; Arici, D.; Boger, E.; Martinez-Pardo, A.; Krueger, N.; Schneider, L.; Carrière-Pradal, M.; Schou, K. Pulse of the Fashion Industry. Report, 2019. Global Fashion Agenda, Boston Consulting Group, and Sustainable Apparel Coalition.

- Fashion Revolution. Fashion Transparency Index 2022 edition, 2022.

- European Union. Circular Economy Action Plan, 2020.

- European Comission. A new Circular Economy Action Plan For a cleaner and more competitive Europe, 2020.

- Götz, T.; Adisorn, T.; Tholen, L. Developing a Framework for Traceability Implementation in the Textile Supply Chain. Technical report, 2021. doi:10.48506/opus-7694. [CrossRef]

- Götz, T.; Adisorn, T.; Tholen, L. Towards a Digital Product Passport Fit for Contributing to a Circular Economy. MDPI 2021. doi:10.3390/en14082289. [CrossRef]

- Huang, S.; Wang, G.; Yan, Y.; Fang, X. Blockchain-based data management for digital twin of product. Journal of Manufacturing Systems 2020, 54, 361–371. doi:https://doi.org/10.1016/j.jmsy.2020.01.009. [CrossRef]

- Alves, L.; Cruz, E.F.; Rosado Da Cruz, A.M. Tracing Sustainability Indicators in the Textile and Clothing Value Chain using Blockchain Technology. 2022 17th Iberian Conference on Information Systems and Technologies (CISTI), 2022, pp. 1–7. doi:10.23919/CISTI54924.2022.9820241. [CrossRef]

- Kumar, V.; Hallqvist, C.; Ekwall, D. Developing a Framework for Traceability Implementation in the Textile Supply Chain. MDPI 2017.

- Agrawal, T.K.; Koehl, L.; Campagne, C. A secured tag for implementation of traceability in textile and clothing supply chain. The International Journal of Advanced Manufacturing Technology 2018, 99, 2563–2577. doi:10.1007/s00170-018-2638-x. [CrossRef]

- Agrawal, T.K.; Kumar, V.; Pal, R.; Wang, L.; Chen, Y. Blockchain-based Framework for Supply Chain Traceability: A Case Example of Textile and Clothing Industry. Computers & Industrial Engineering 2021.

- Bullón Pérez, J.J.; Queiruga-Dios, A.; Gayoso Martínez, V.; Martín del Rey, Á. Traceability of Ready-to-Wear Clothing through Blockchain Technology. Sustainability 2020, 12. doi:10.3390/su12187491. [CrossRef]

- Hader, M.; Tchoffa, D.; Mhamedi, A.E.; Ghodous, P.; Dolgui, A.; Abouabdellah, A. Applying integrated Blockchain and Big Data technologies to improve supply chain traceability and information sharing in the textile sector. Journal of Industrial Information Integration 2022, 28, 100345. doi:10.1016/j.jii.2022.100345. [CrossRef]

- Wiegand, T.; Wynn, M. Sustainability, the Circular Economy and Digitalisation in the German Textile and Clothing Industry. Sustainability 2023, 15. doi:10.3390/su15119111. [CrossRef]

- Androulaki, E.; Barger, A.; Bortnikov, V.; Cachin, C.; Christidis, K.; De Caro, A.; Enyeart, D.; Ferris, C.; Laventman, G.; Manevich, Y.; Muralidharan, S.; Murthy, C.; Nguyen, B.; Sethi, M.; Singh, G.; Smith, K.; Sorniotti, A.; Stathakopoulou, C.; Vukolić, M.; Cocco, S.W.; Yellick, J. Hyperledger Fabric: A Distributed Operating System for Permissioned Blockchains. Proceedings of the Thirteenth EuroSys Conference; Association for Computing Machinery: New York, NY, USA, 2018; EuroSys ’18. doi:10.1145/3190508.3190538. [CrossRef]

- Alves, L.; Faria, P.M.; Cruz, E.F.; Lopes, S.I.; Rosado da Cruz, A.M. Eco-Gamification Platform to Promote Consumers’ Engagement in the Textile and Clothing Circular Value Chain. Sustainability 2023, 15. doi:10.3390/su15065398. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).