Submitted:

09 November 2023

Posted:

09 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Background

1.2. Literature Review

1.2.1. Factors that Influence Heat Losses from Ground Floors

1.2.2. Factors that Influence Savings in Embodied and Operational Energy due to Application of Floor Slab Insulation Measures

1.2.3. The Floor-Slab Insulation Materials

2. Materials and Methods

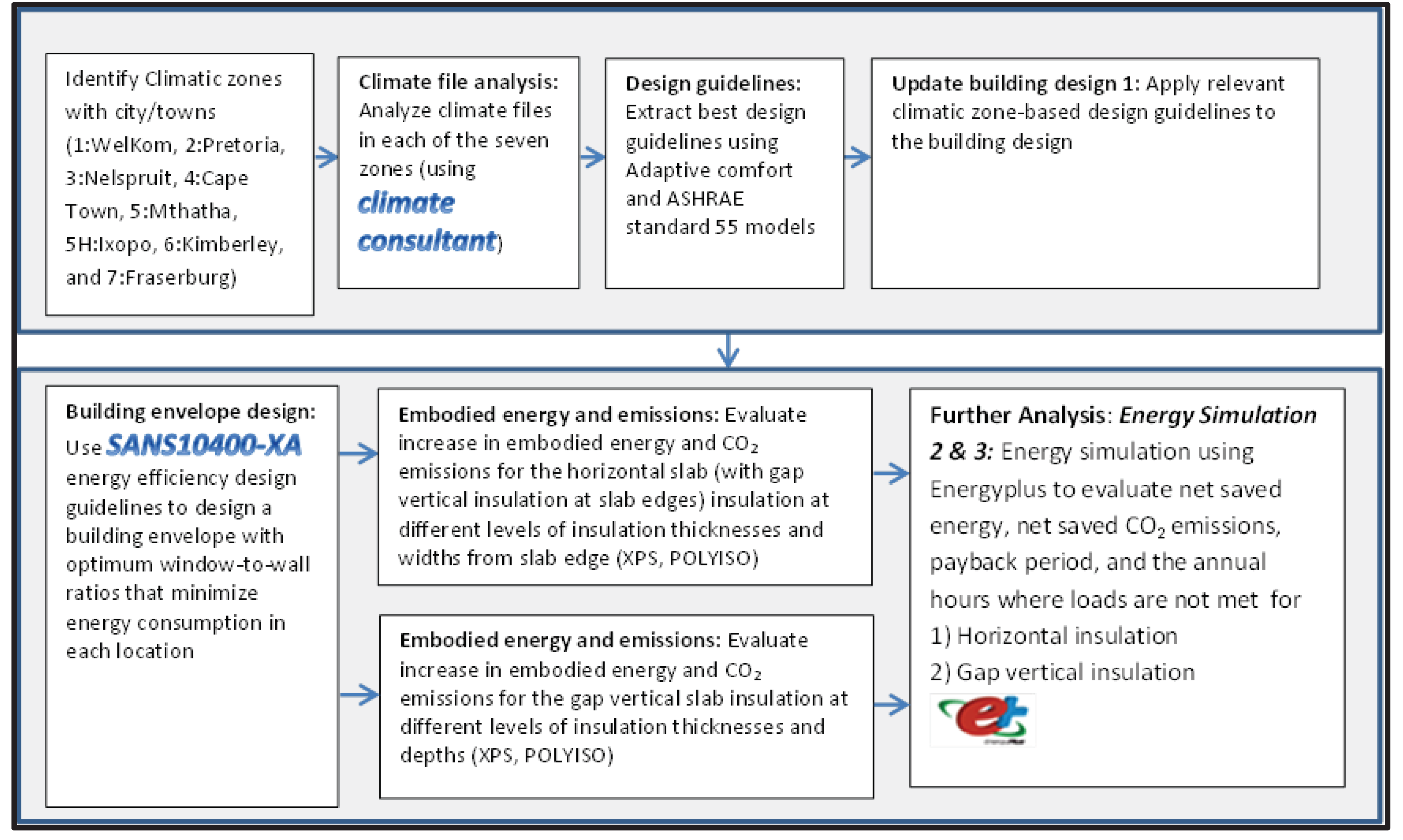

2.1. Overview of the Methodology Used

2.2. Data

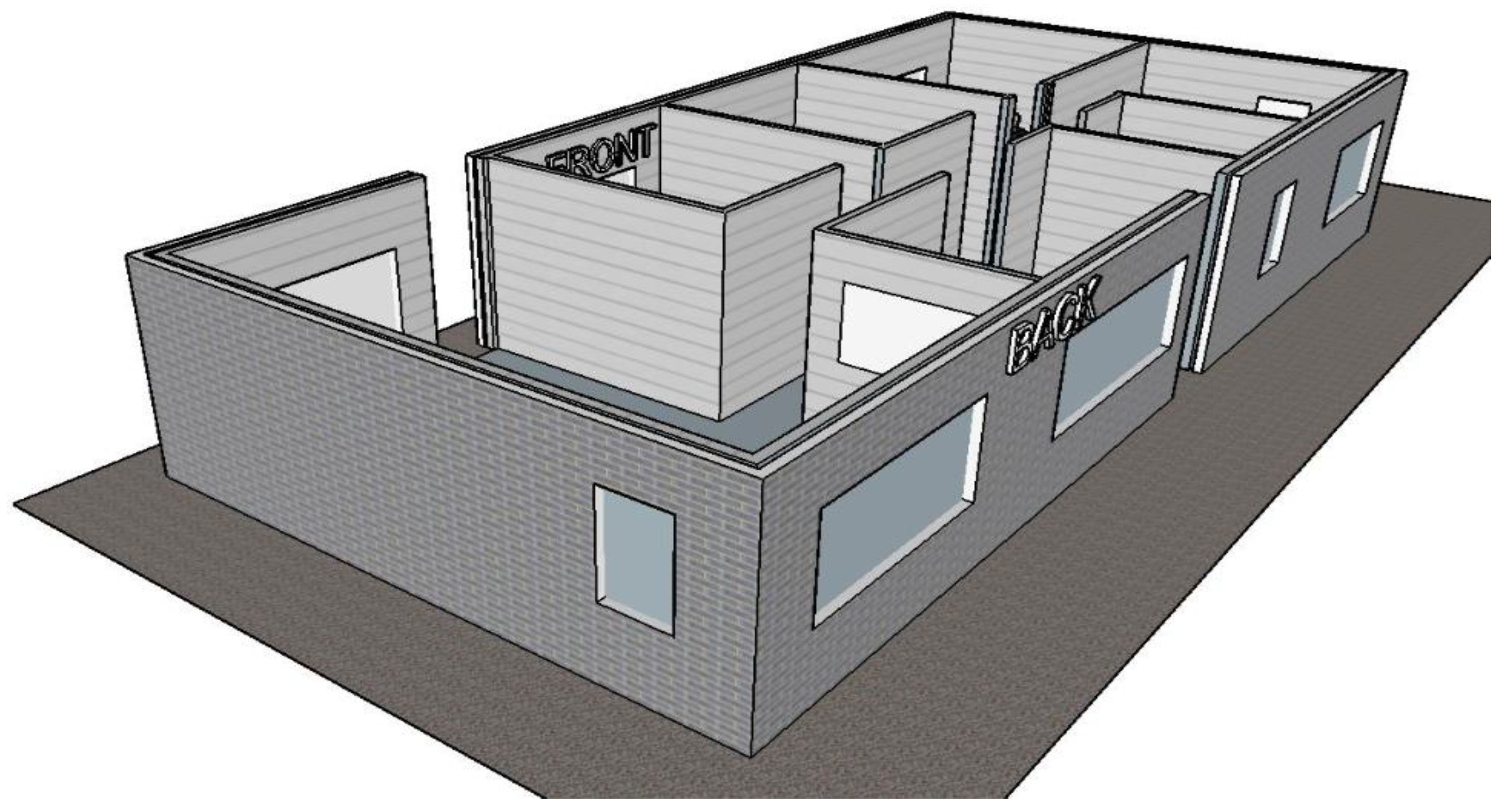

2.3. Architectural Design and Bills of Material

2.3.1. Properties of Building Materials

2.3.2. South African Energy Efficiency Standards for Wall Envelopes and the Surface Density

2.3.3. Optimum Window to Wall Ratios

2.3.4. Optimum Floor-Slab Insulation Thickness, and the Insulation Depth or Insulation Width

2.4. Estimation of IBT Embodied Energy and Emissions

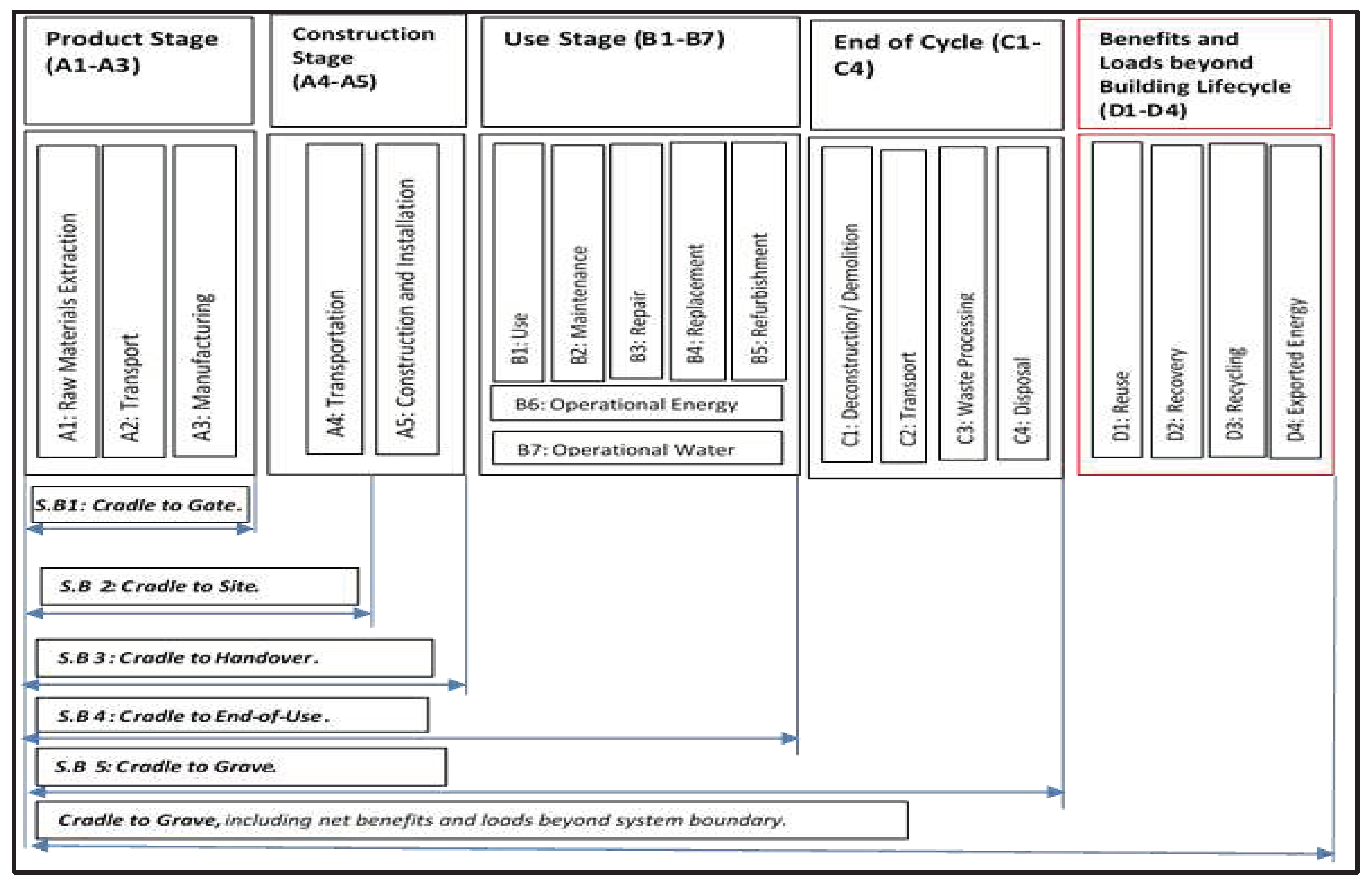

2.5. Cradle to gate approximate embodied quantities due to insulation measures

2.5.1. Vertical Gap insulation only. The cradle-to-gate embodied energy due to the floor-slab insulation measure is given by equations 2

2.6. Saved Energy and Energy Payback Periods

2.6.1. Saved Energy after 50 Years

2.6.2. Energy Payback Periods

2.6.3. Validation of the building energy model

3. Results

3.1. Climatic Recommendations and SANS 10400-XA Test Results

Climate Consultant Results

3.2. Optimum Window to Wall Ratios

3.3. Energy Savings Model Validation for Vertical Gap Insulation

3.3.1. Site Energy Consumption Per Square Meter Floor Area (Vertical Gap Insulation)

3.3.2. Embodied Energy of the Building

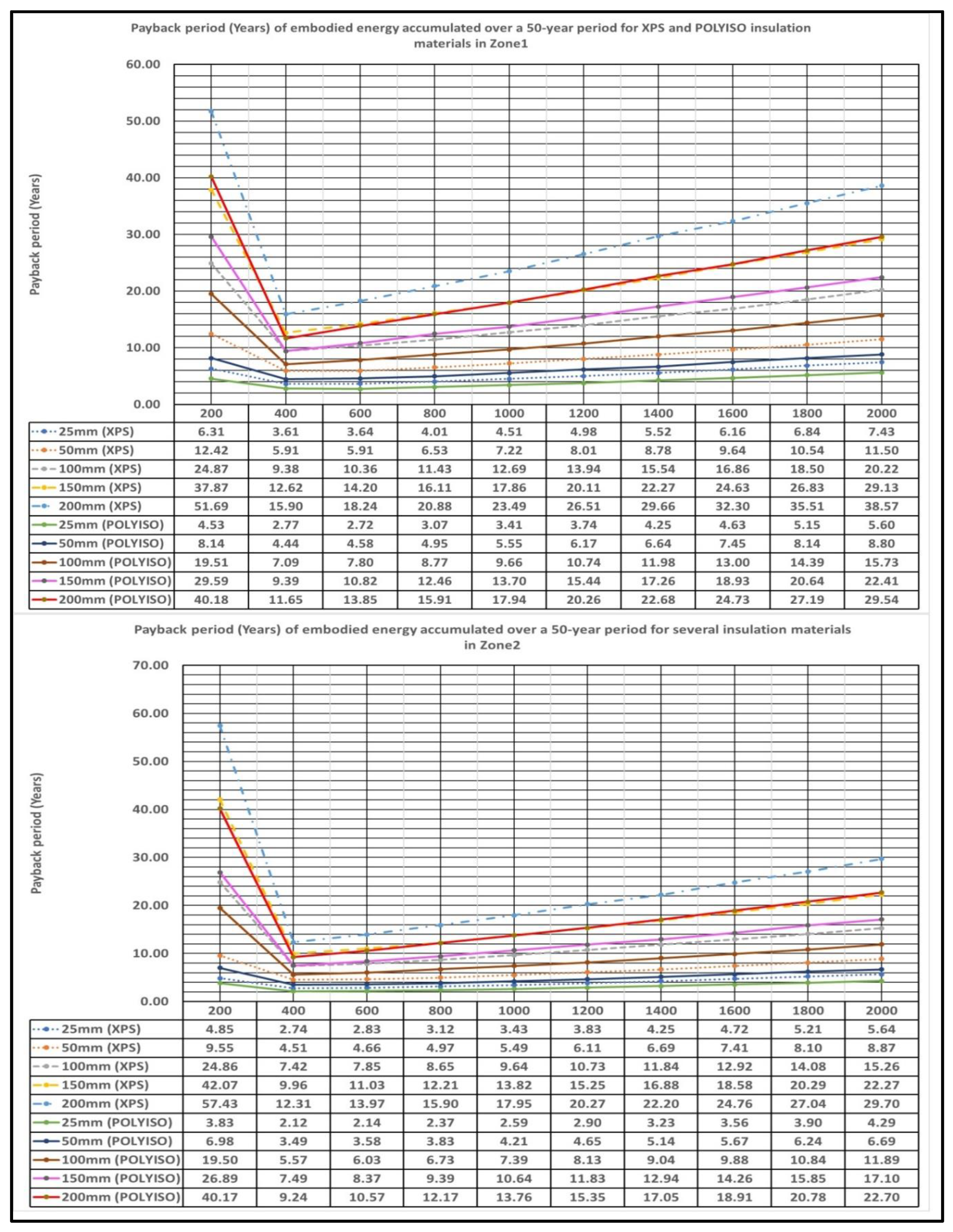

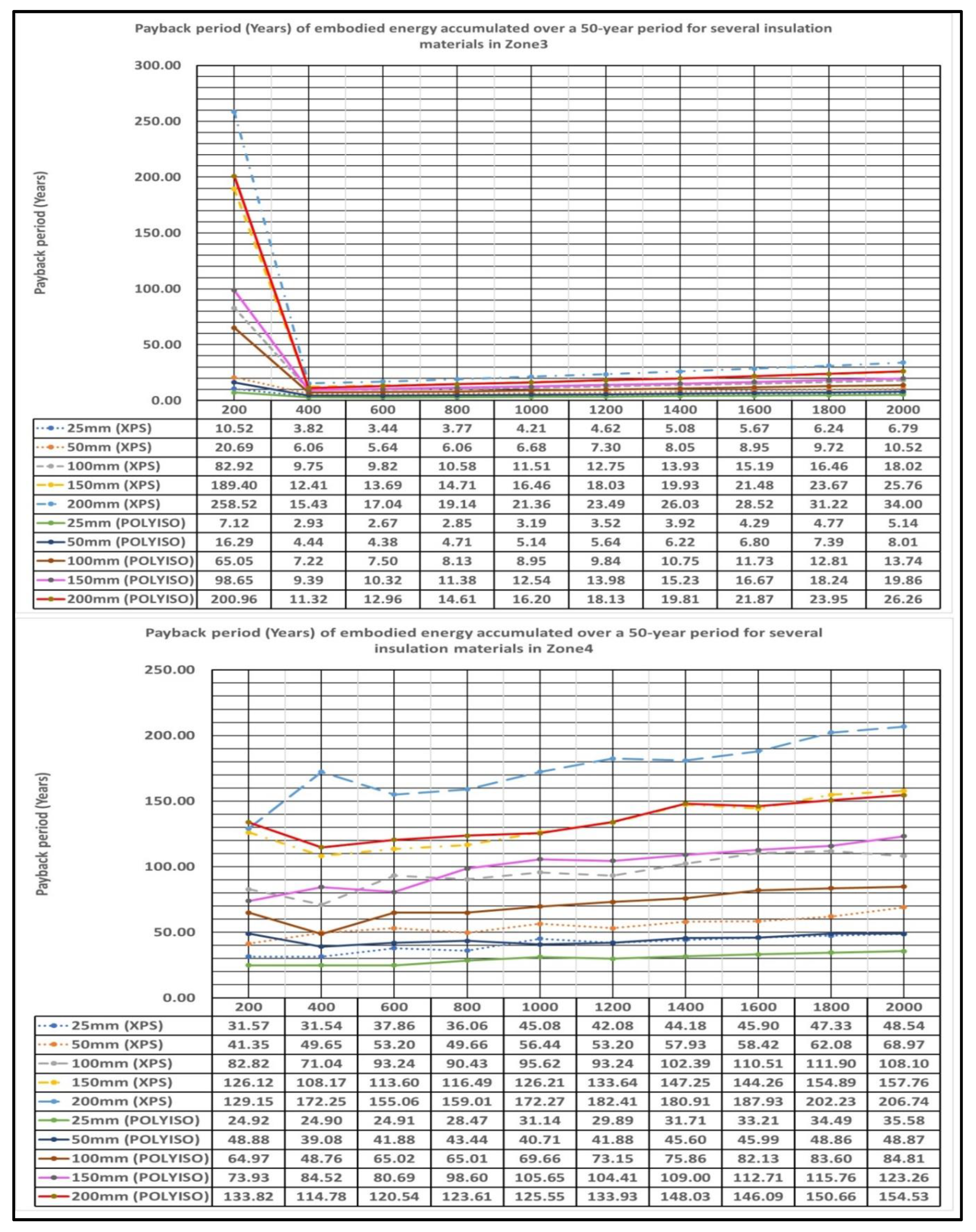

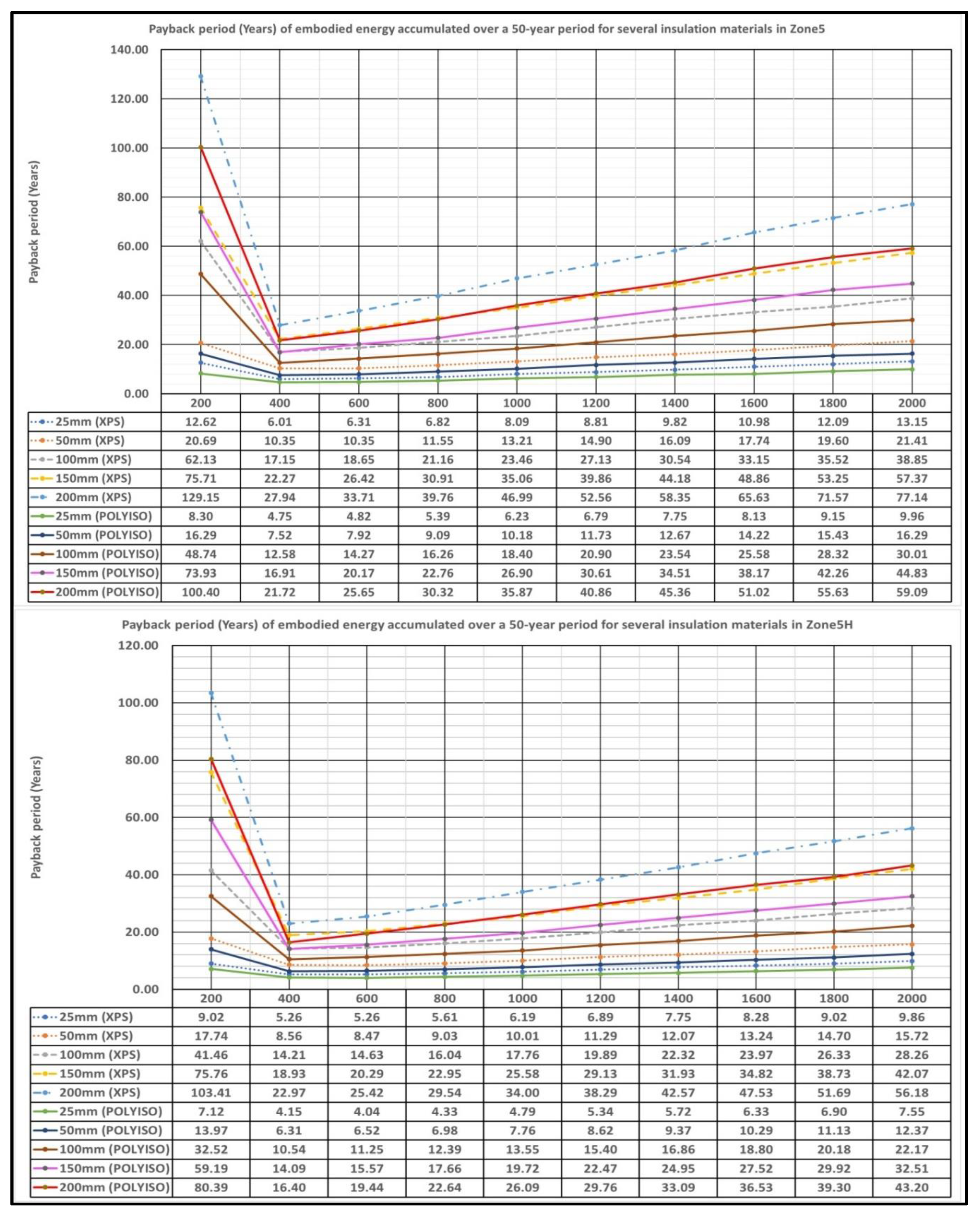

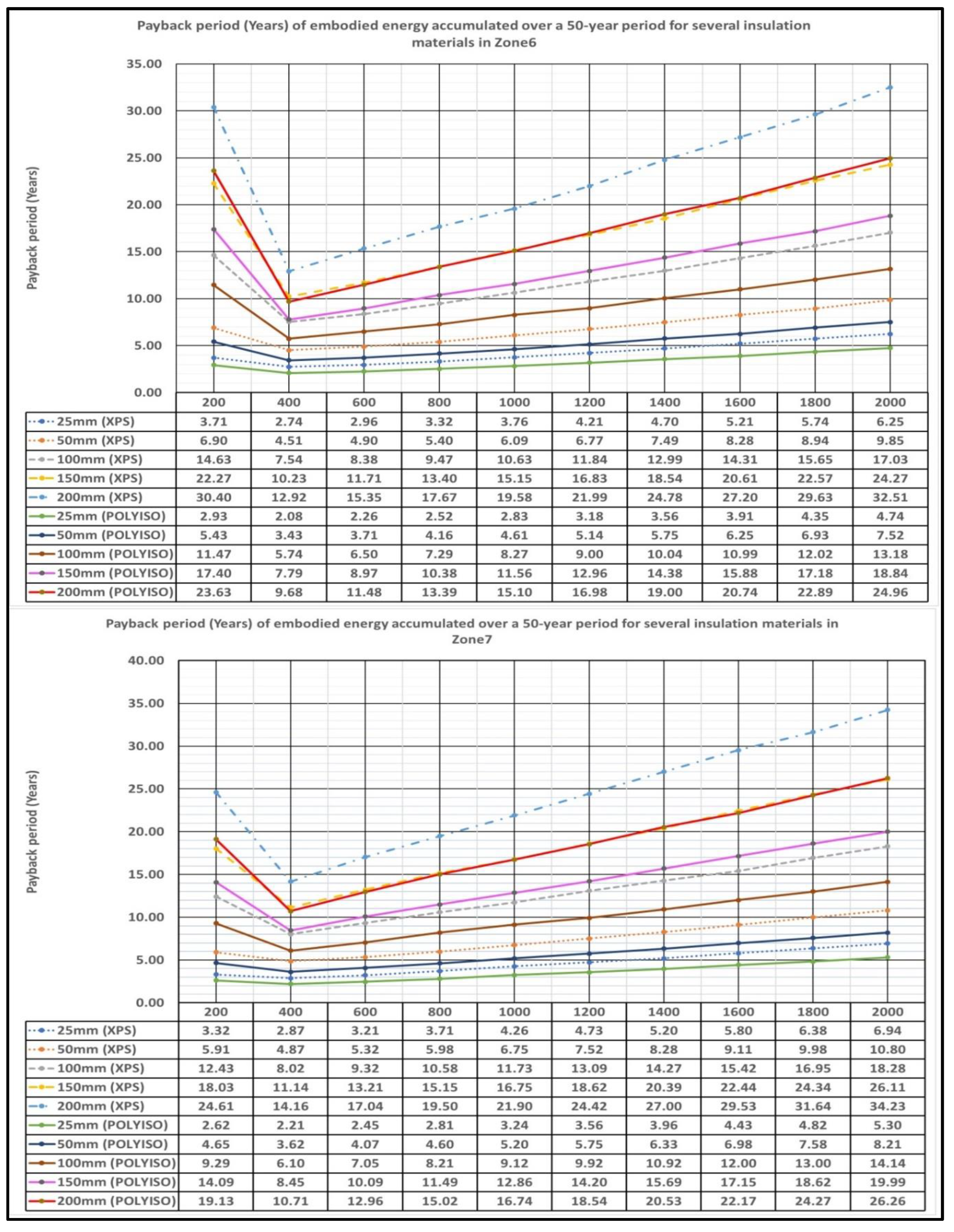

3.4. Energy Payback Periods for Vertical Gap Insulation Depths Greater or Equal to 0.4m

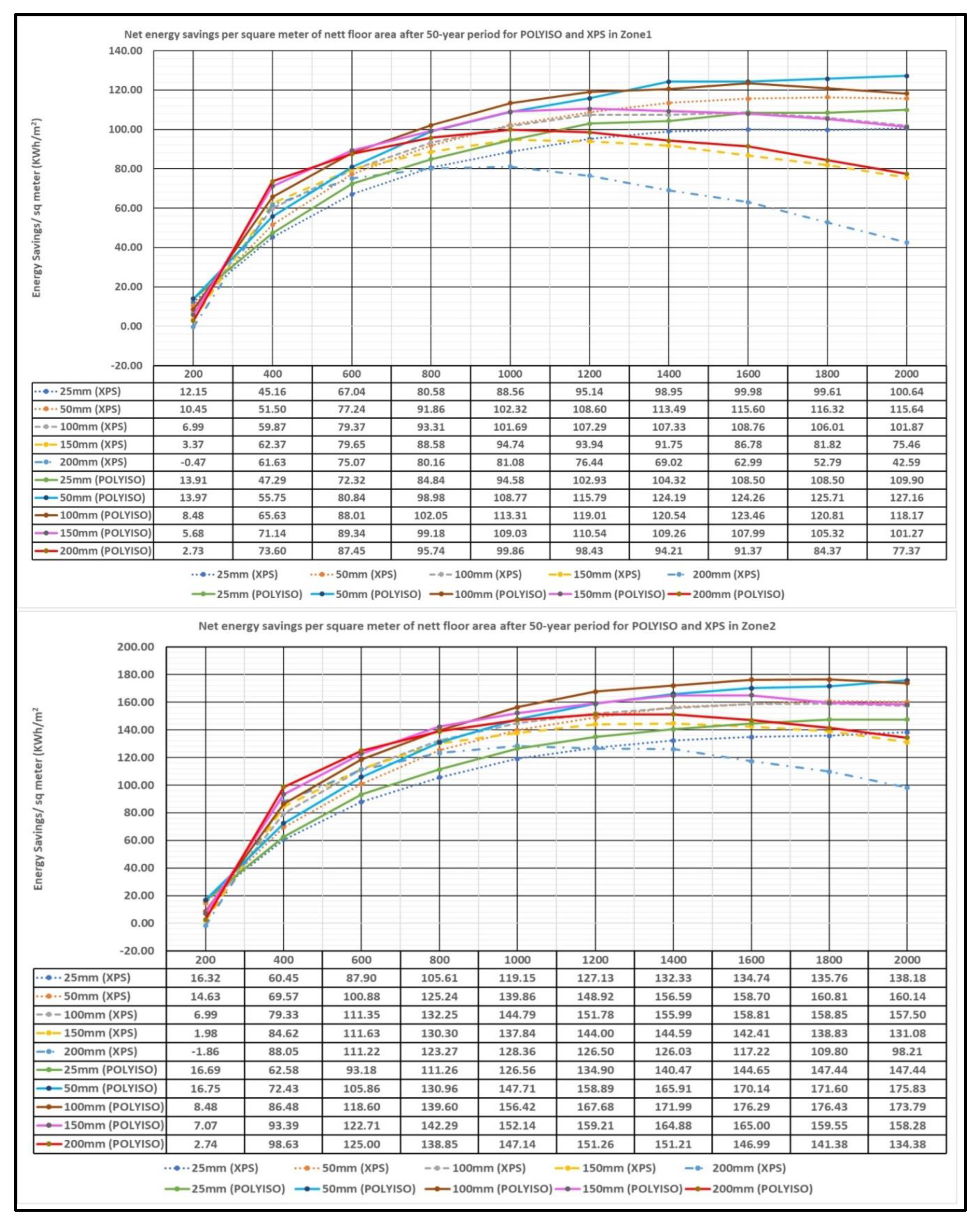

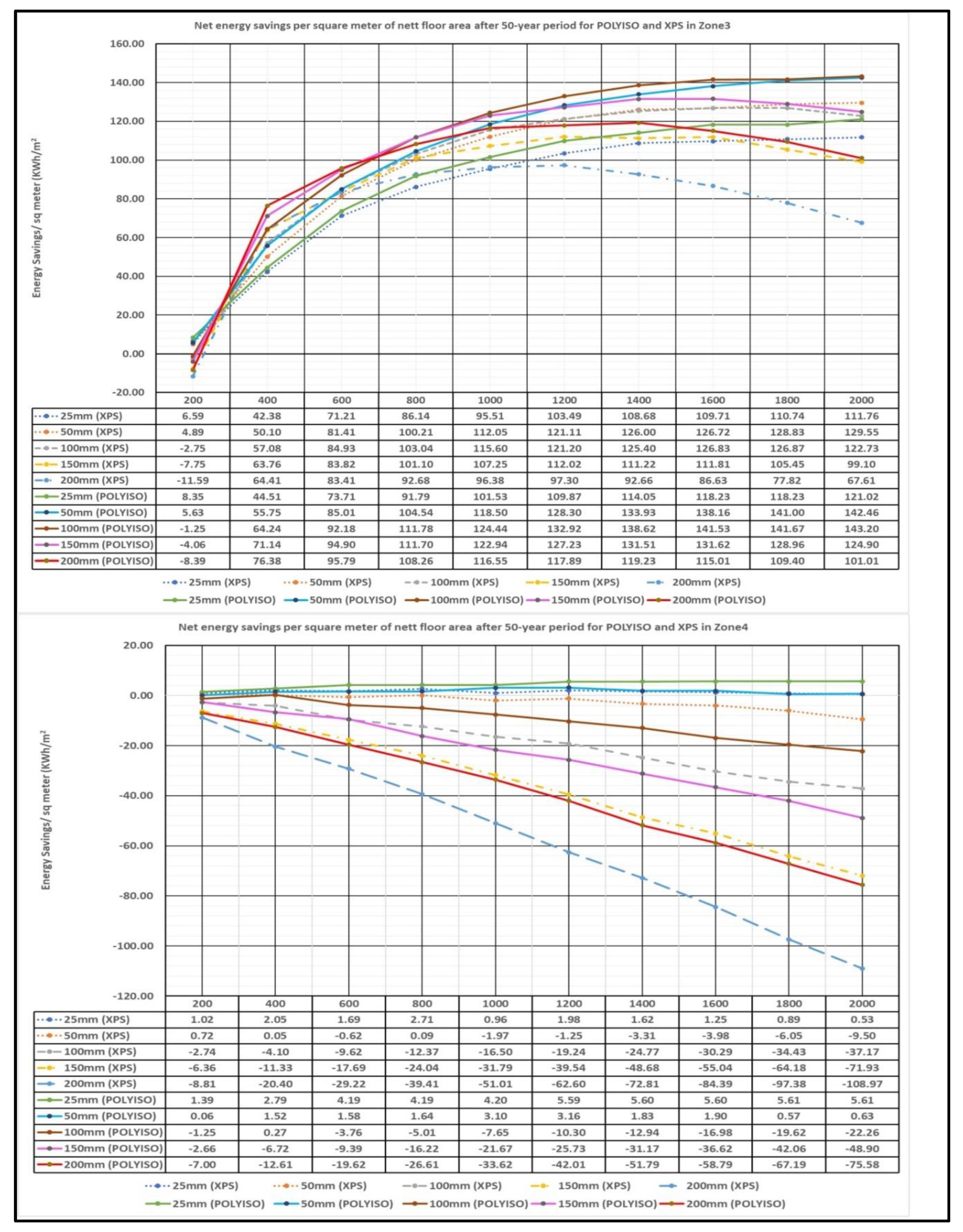

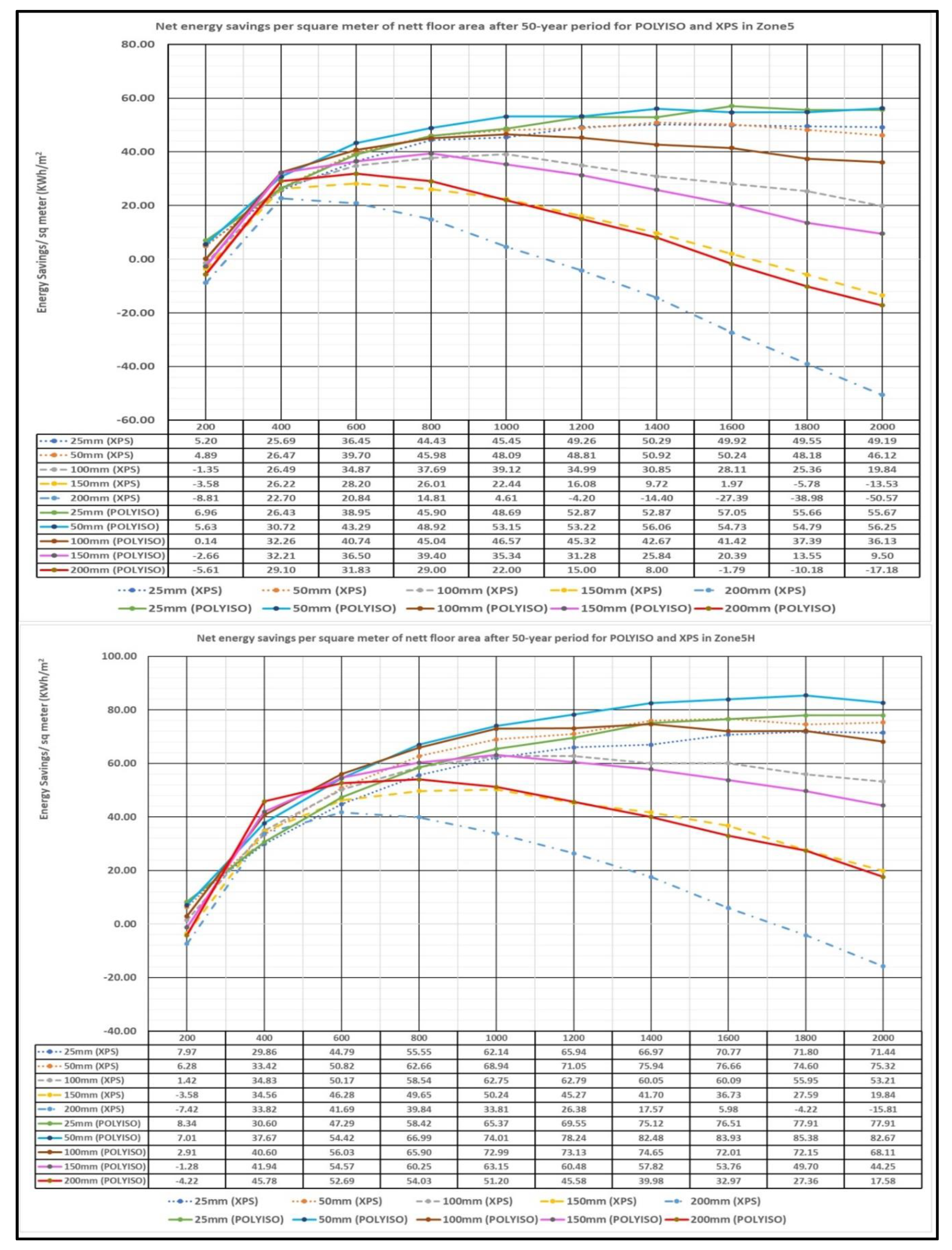

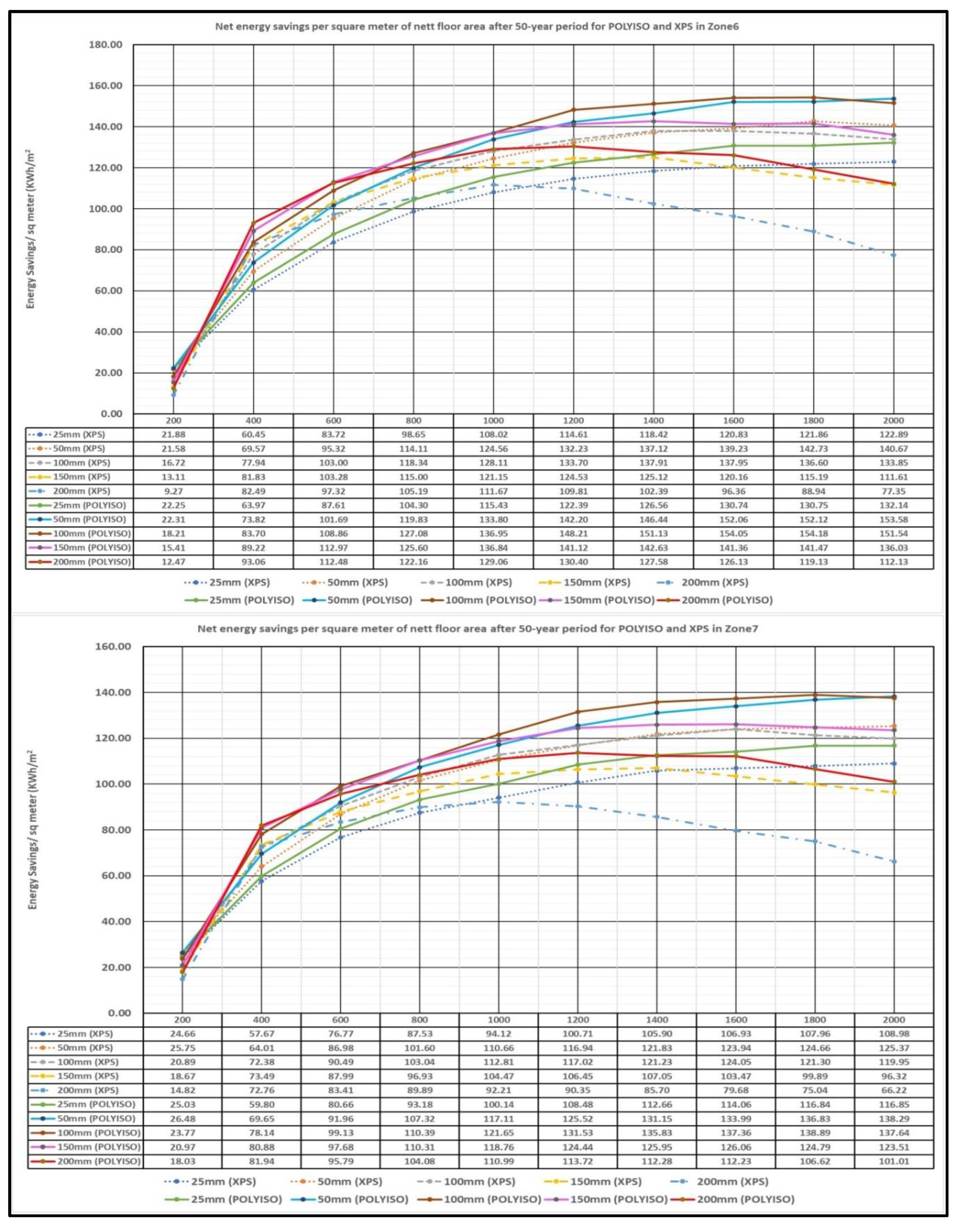

3.5. Net Saved Energy for Vertical Gap Insulation after 50 Years

3.5.1. Minimum and Maximum Values Per Energy Zone

| Zone1 (min ; max) | Zone2 (min ; max) | Zone3 (min ; max) | Zone4 (min ; max) | Zone5 (min ; max) | Zone5H (min ; max) | Zone6 (min ; max) | Zone7 (min ; max) | |

|---|---|---|---|---|---|---|---|---|

| XPS (25mm) | 12.1 ; 100.6 | 16.3 ; 138.2 | 6.6 ; 111.8 | 0.5 ; 2.7 | 5.2 ; 50.3 | 8 ; 71.8 | 21.9 ; 122.9 | 24.7 ; 109 |

| XPS (50mm) | 10.5 ; 116.3 | 14.6 ; 160.8 | 4.9 ; 129.5 | -9.5 ; 0.7 | 4.9 ; 50.9 | 6.3 ; 76.7 | 21.6 ; 142.7 | 25.7 ; 125.4 |

| XPS (100mm) | 7 ; 108.8 | 7 ; 158.8 | -2.7 ; 126.9 | -37.2 ; -2.7 | -1.4 ; 39.1 | 1.4 ; 62.8 | 16.7 ; 138 | 20.9 ; 124 |

| XPS (150mm) | 3.4 ; 94.7 | 2 ; 144.6 | -7.8 ; 112 | -71.9 ; -6.4 | -13.5 ; 28.2 | -3.6 ; 50.2 | 13.1 ; 125.1 | 18.7 ; 107 |

| XPS (200mm) | -0.5 ; 81.1 | -1.9 ; 128.4 | -11.6 ; 97.3 | -109 ; -8.8 | -50.6 ; 22.7 | -15.8 ; 41.7 | 9.3 ; 111.7 | 14.8 ; 92.2 |

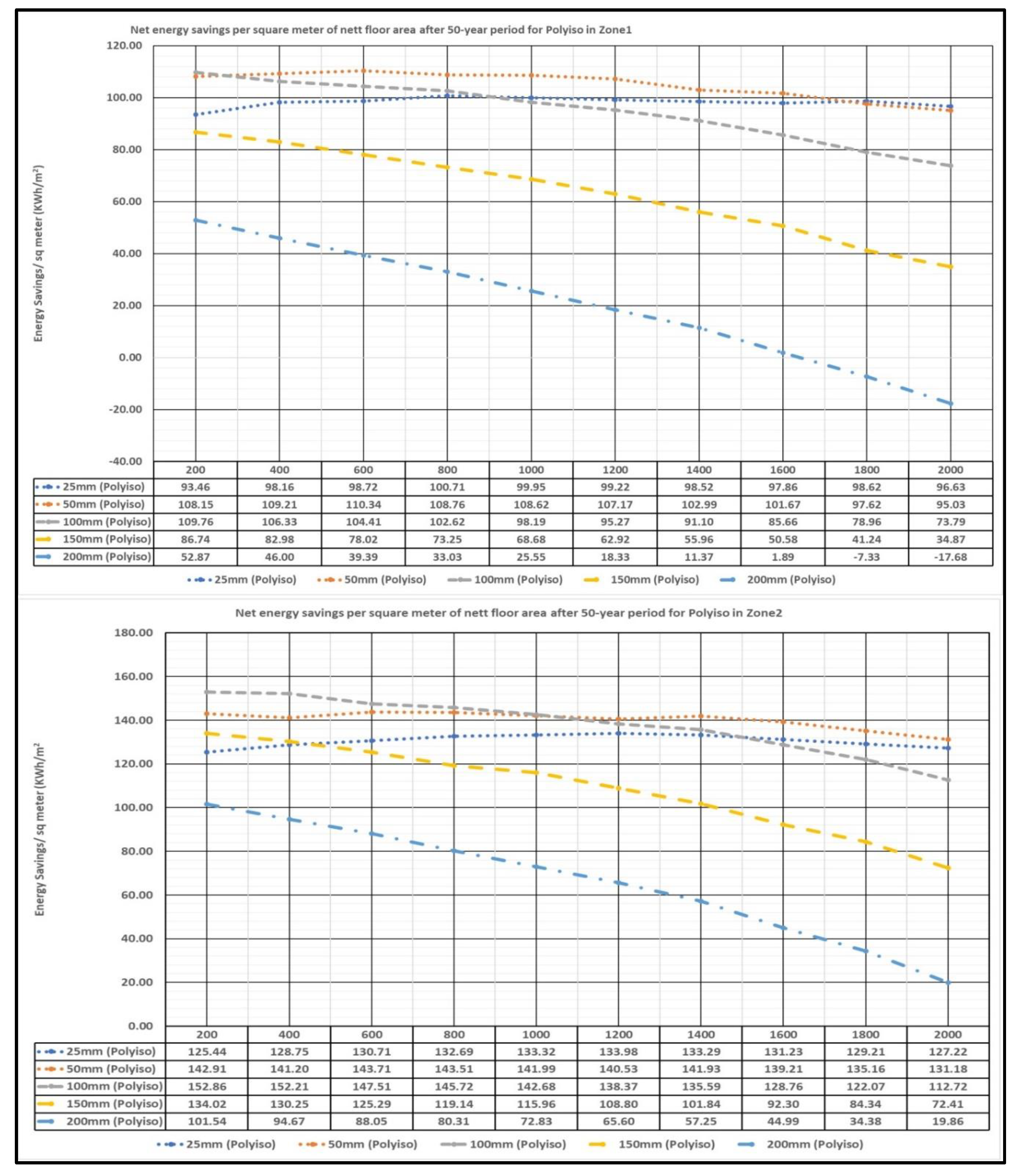

| Polyiso (25mm) | 13.9 ; 109.9 | 16.7 ; 147.4 | 8.3 ; 121 | 1.4 ; 5.6 | 7 ; 57 | 8.3 ; 77.9 | 22.3 ; 132.1 | 25 ; 116.8 |

| Polyiso (50mm) | 14 ; 127.2 | 16.8 ; 175.8 | 5.6 ; 142.5 | 0.1 ; 3.2 | 5.6 ; 56.3 | 7 ; 85.4 | 22.3 ; 153.6 | 26.5 ; 138.3 |

| Polyiso (100mm) | 8.5 ; 123.5 | 8.5 ; 176.4 | -1.3 ; 143.2 | -22.3 ; 0.3 | 0.1 ; 46.6 | 2.9 ; 74.7 | 18.2 ; 154.2 | 23.8 ; 138.9 |

| Polyiso (150mm) | 5.7 ; 110.5 | 7.1 ; 165 | -4.1 ; 131.6 | -48.9 ; -2.7 | -2.7 ; 39.4 | -1.3 ; 63.1 | 15.4 ; 142.6 | 21 ; 126.1 |

| Polyiso (200mm) | 2.7 ; 99.9 | 2.7 ; 151.3 | -8.4 ; 119.2 | -75.6 ; -7 | -17.2 ; 31.8 | -4.2 ; 54 | 12.5 ; 130.4 | 18 ; 113.7 |

3.5.2. General Results for Net Saved Energy after 50 Years Based on Zones

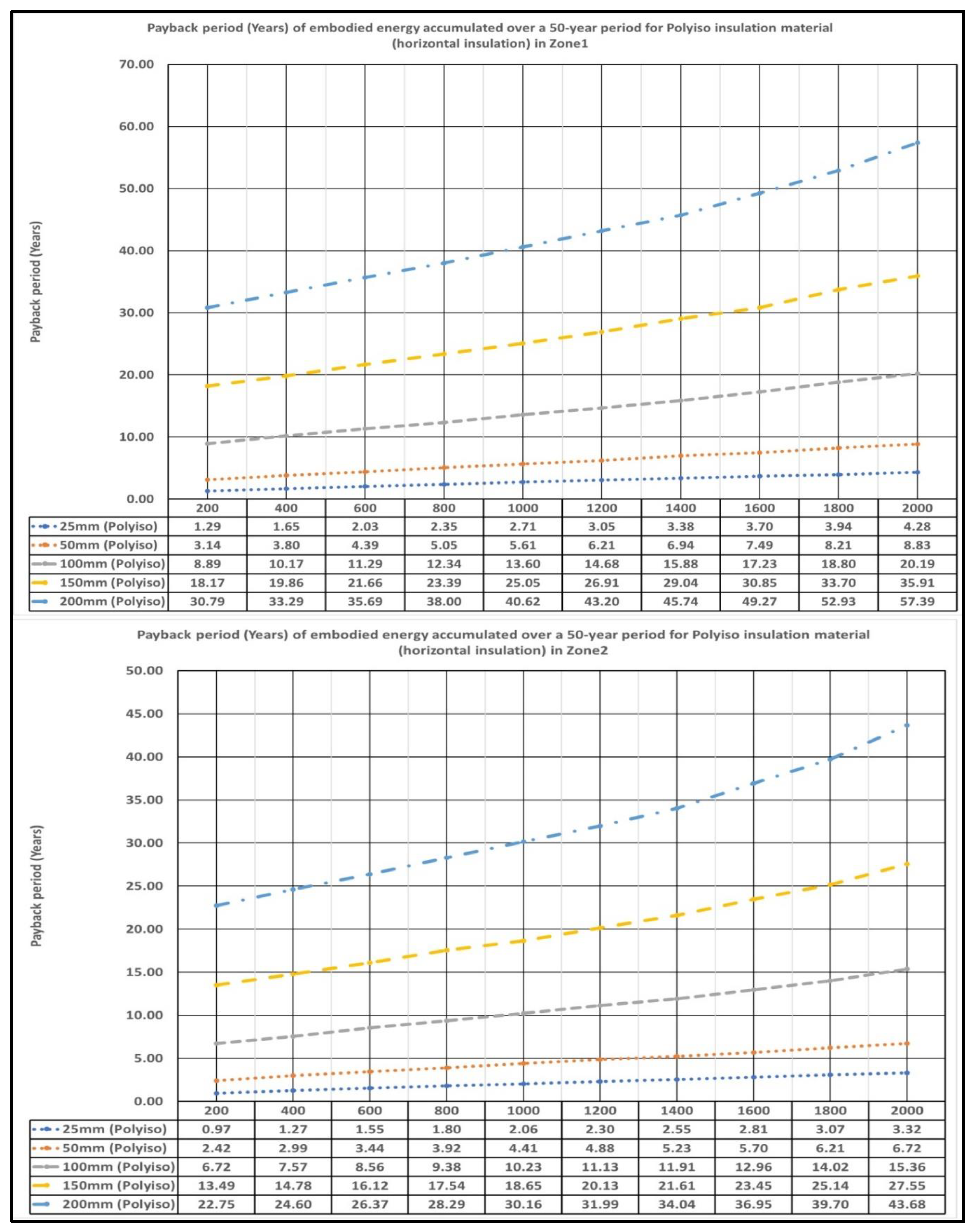

3.6. Horizontal Perimeter Insulation (with Vertical Gap Insulation along Floor Slab Edges)

3.6.1. Site Energy Consumption Per Square Meter Floor Area (Horizontal Insulation in General)

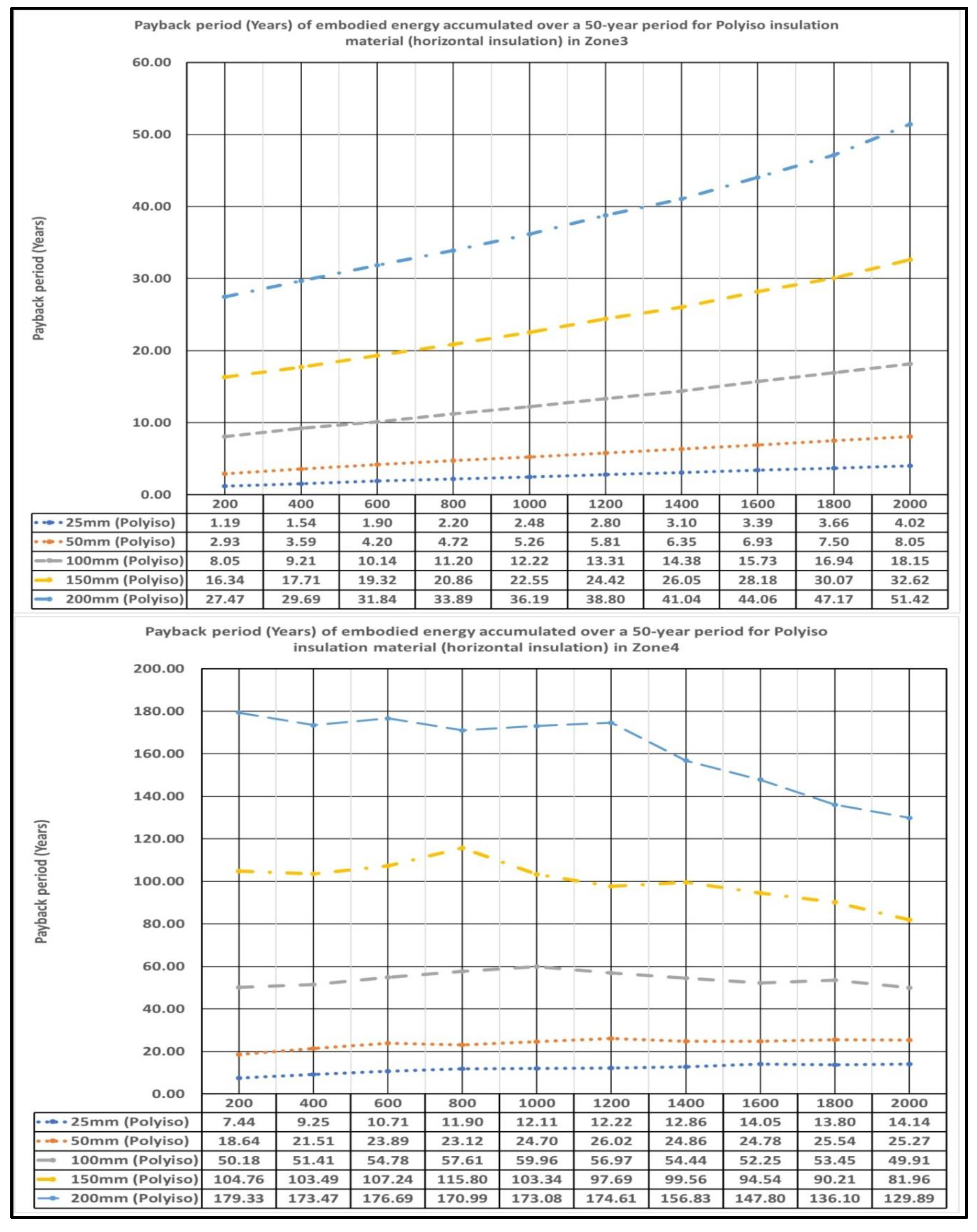

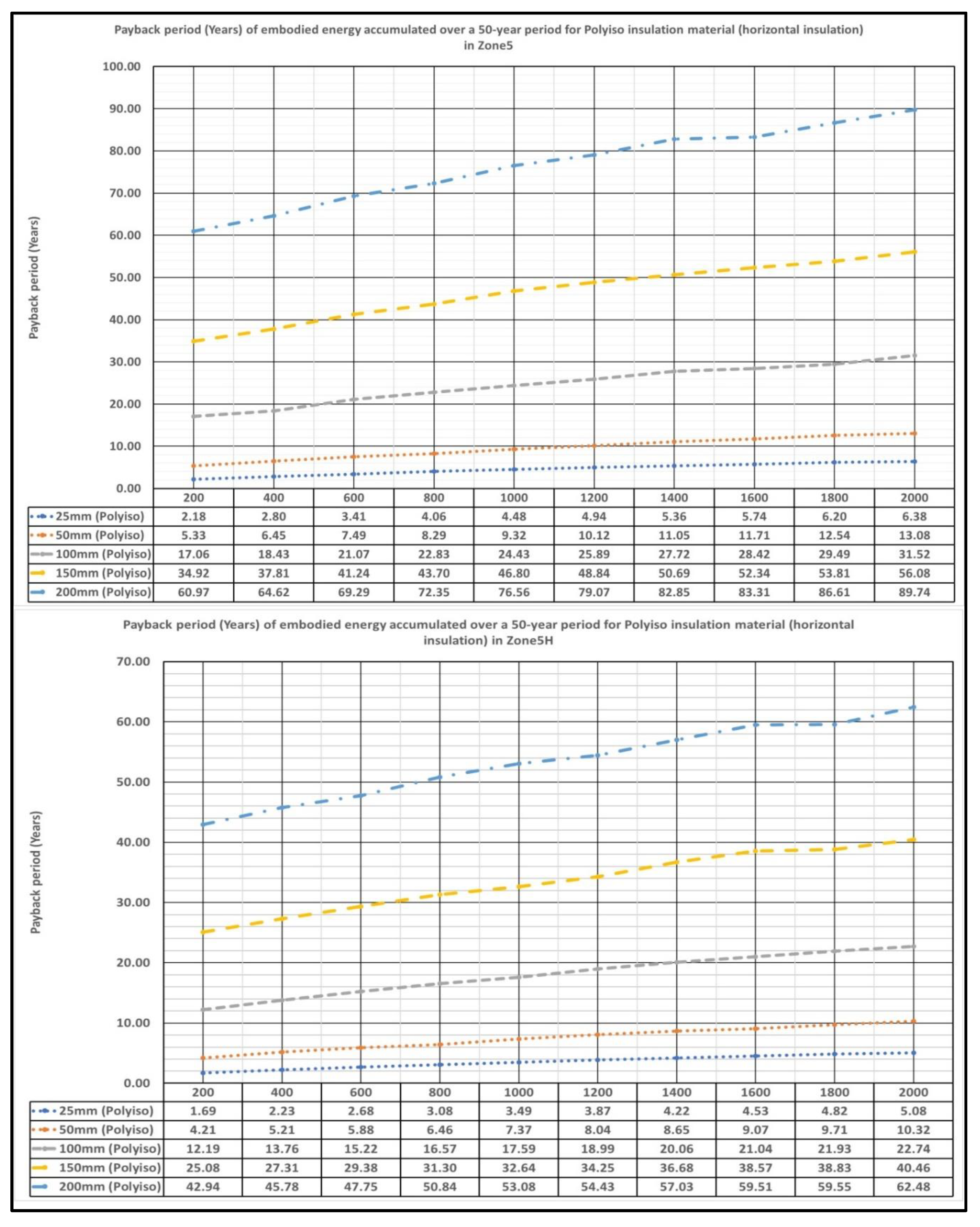

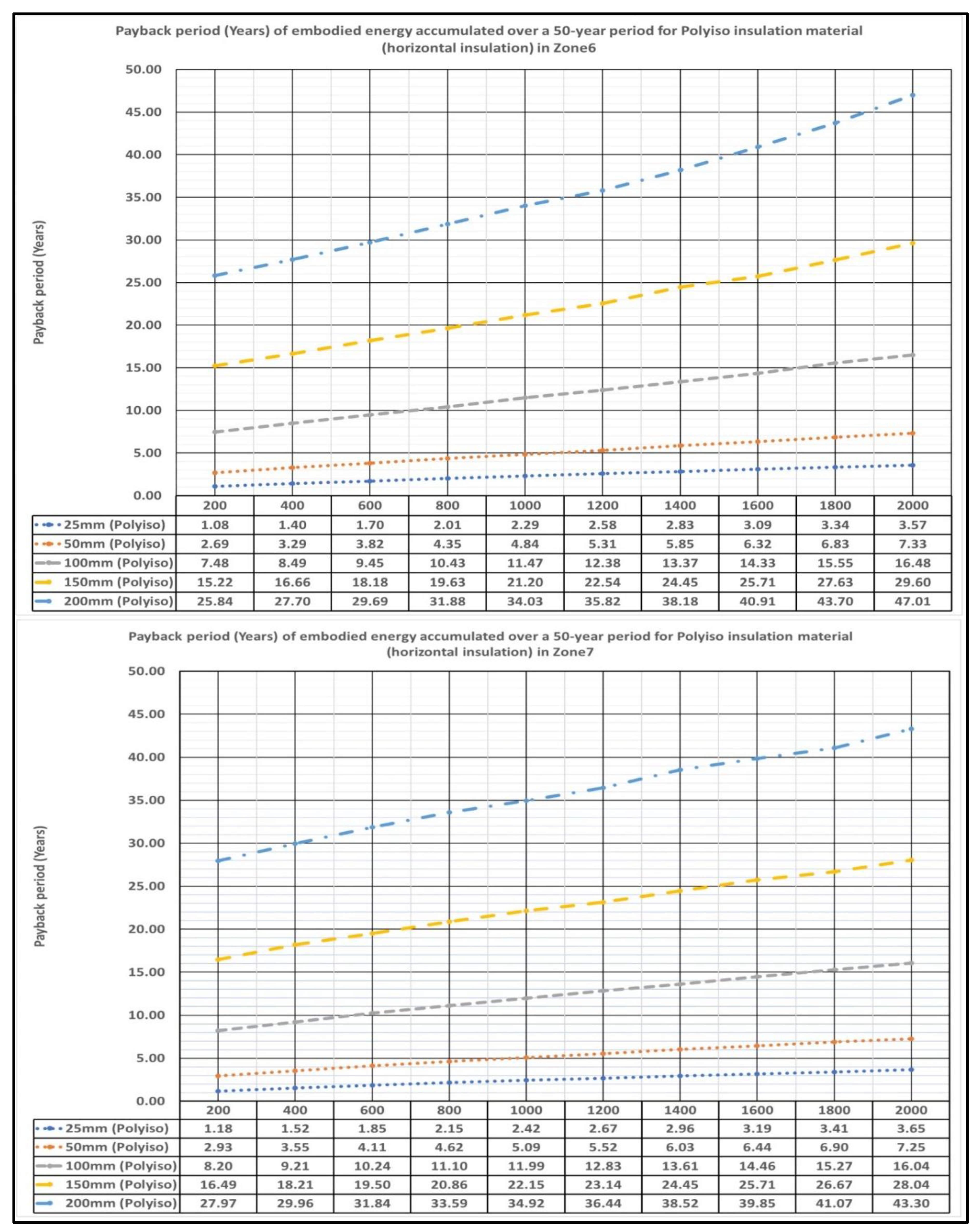

3.6.2. Payback periods (horizontal perimeter insulation).

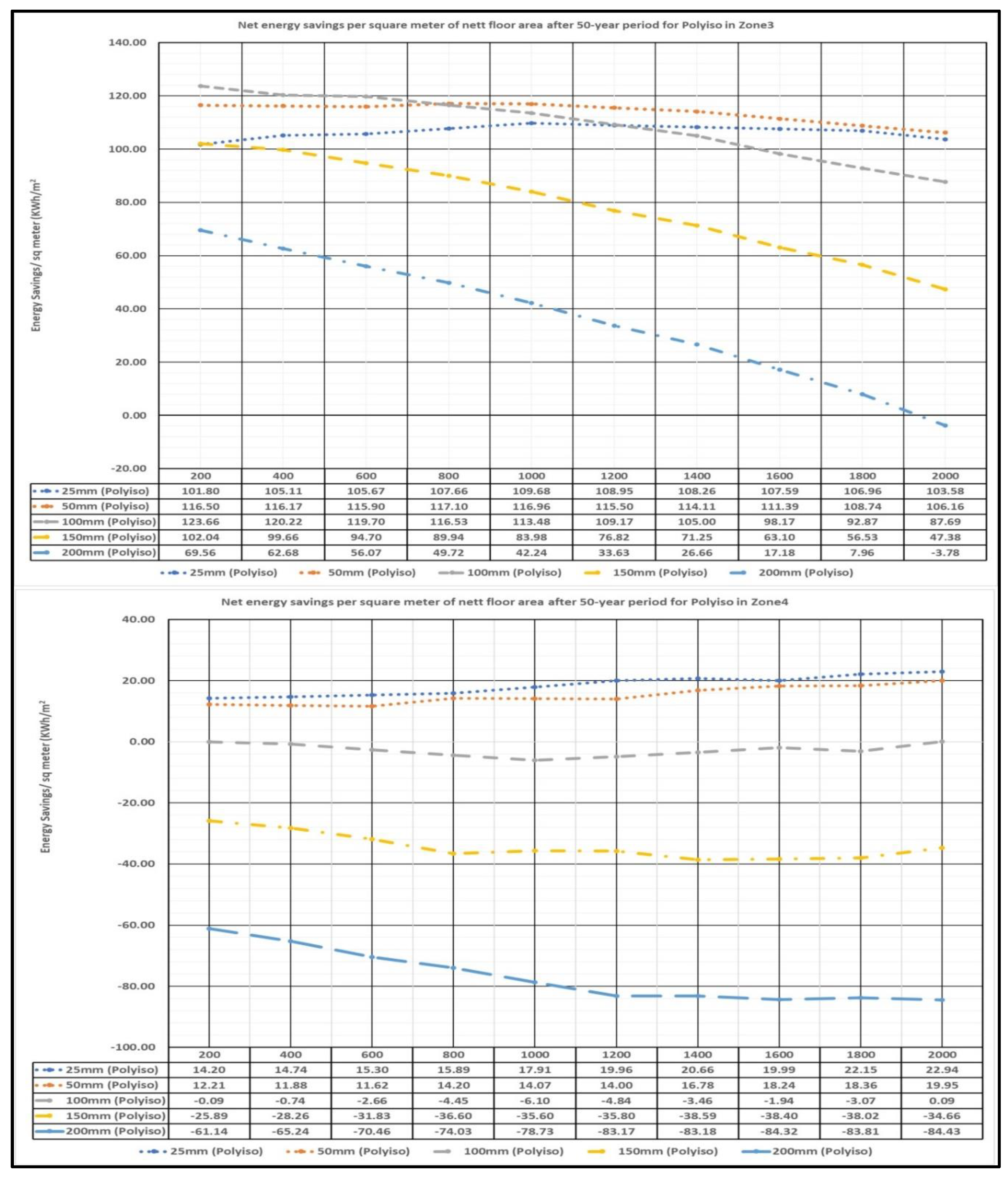

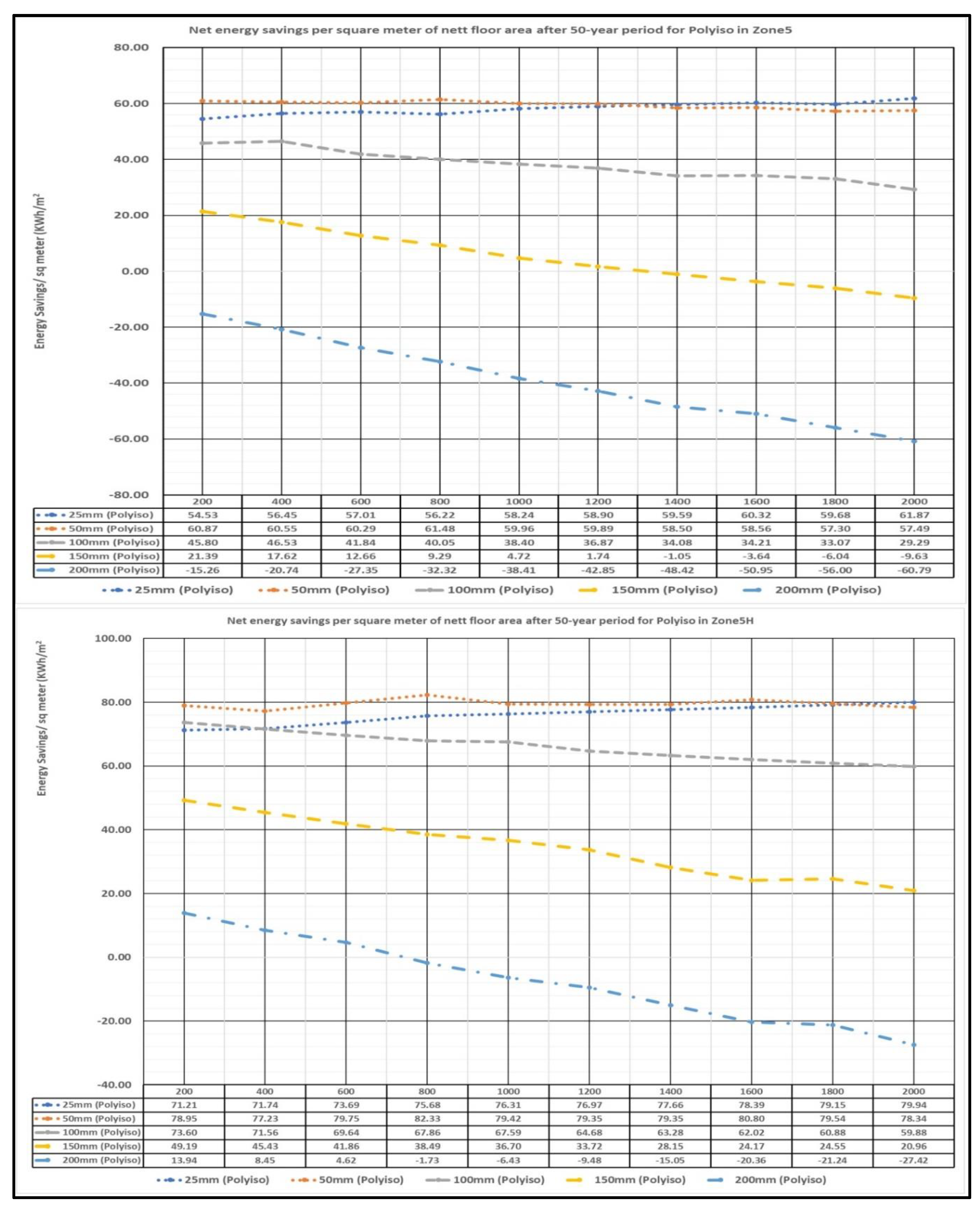

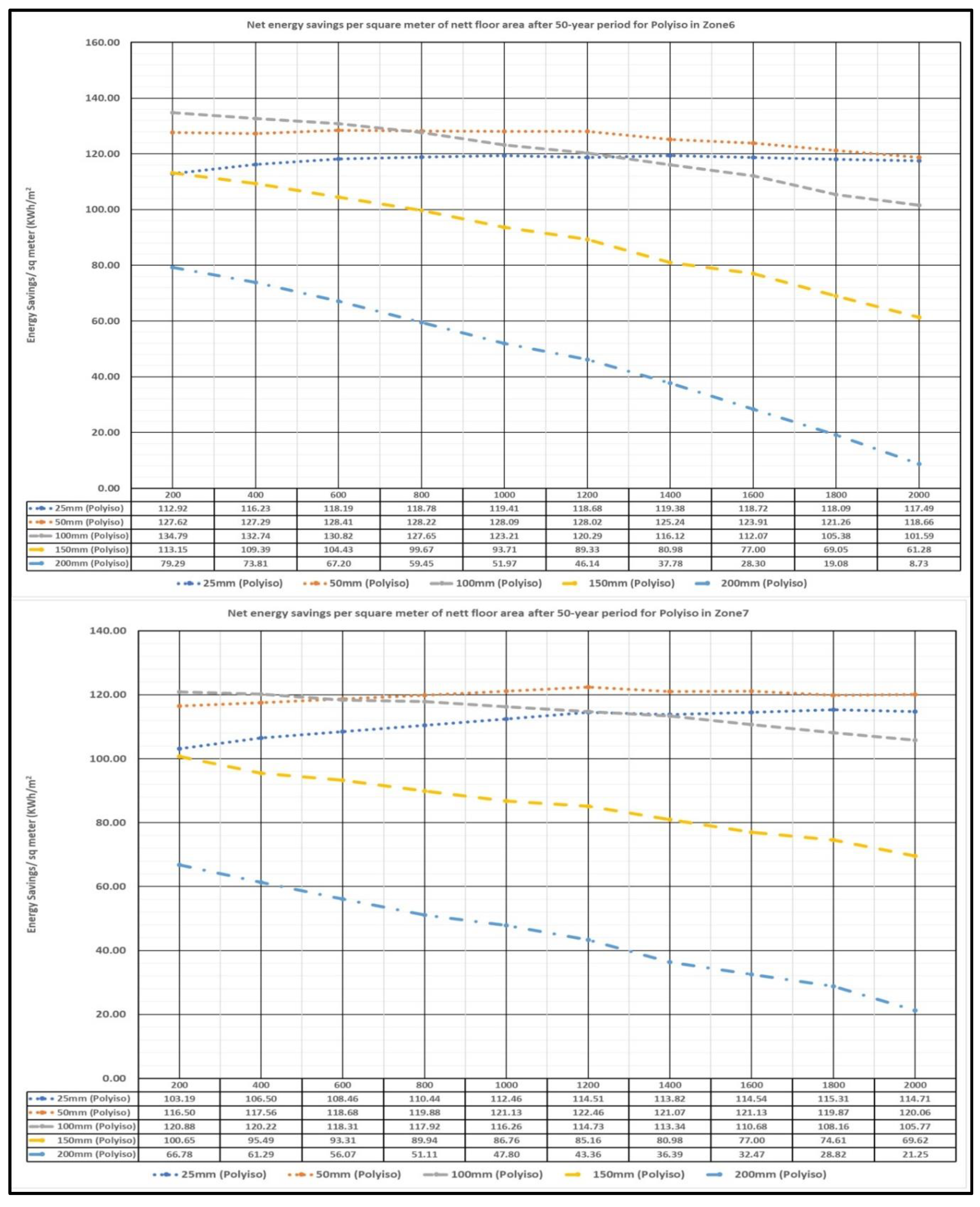

3.6.3. Minimum and Maximum Values of Net Energy Savings after 50 Years

| Zone1 (min ; max) | Zone2 (min ; max) | Zone3 (min ; max) | Zone4 (min ; max) | Zone5 (min ; max) | Zone5H (min ; max) | Zone6 (min ; max) | Zone7 (min ; max) | |

|---|---|---|---|---|---|---|---|---|

| Polyiso: (25mm) | 93.5 ; 100.7 | 125.4 ; 134 | 101.8 ; 109.7 | 14.2 ; 22.9 | 54.5 ; 61.9 | 71.2 ; 79.9 | 112.9 ; 119.4 | 103.2 ; 115.3 |

| Polyiso: (50mm) | 95 ; 110.3 | 131.2 ; 143.7 | 106.2 ; 117.1 | 11.6 ; 19.9 | 57.3 ; 61.5 | 77.2 ; 82.3 | 118.7 ; 128.4 | 116.5 ; 122.5 |

| Polyiso: (100mm) | 73.8 ; 109.8 | 112.7 ; 152.9 | 87.7 ; 123.7 | -6.1 ; 0.1 | 29.3 ; 46.5 | 59.9 ; 73.6 | 101.6 ; 134.8 | 105.8 ; 120.9 |

| Polyiso: (150mm) | 34.9 ; 86.7 | 72.4 ; 134 | 47.4 ; 102 | -38.6 ; -25.9 | -9.6 ; 21.4 | 21 ; 49.2 | 61.3 ; 113.2 | 69.6 ; 100.6 |

| Polyiso: (200mm) | -17.7 ; 52.9 | 19.9 ; 101.5 | -3.8 ; 69.6 | -84.4 ; -61.1 | -60.8 ; -15.3 | -27.4 ; 13.9 | 8.7 ; 79.3 | 21.2 ; 66.8 |

3.6.4. Net Saved Energy for Horizontal Perimeter Insulation after 50 Years

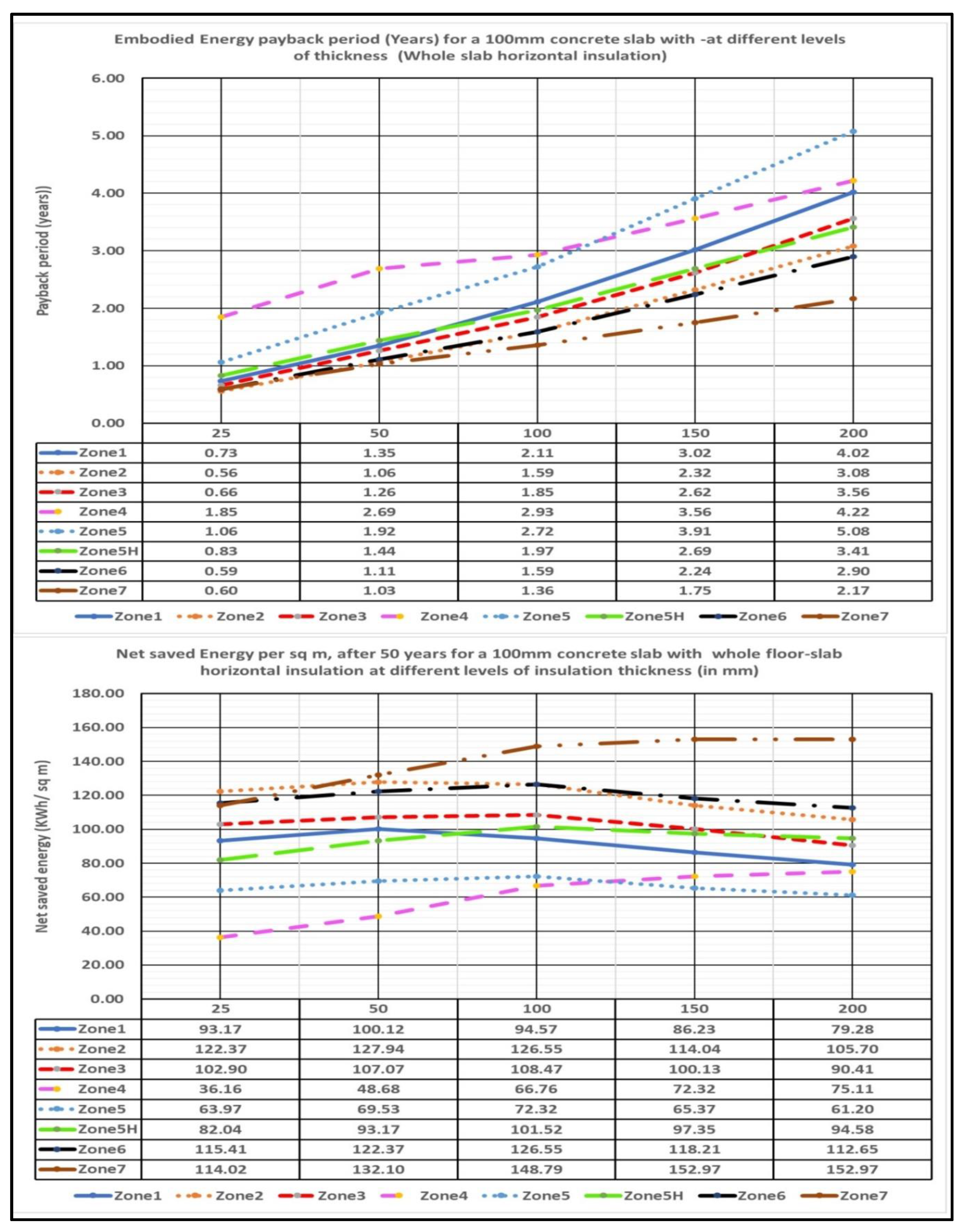

3.7. Energy Payback Periods and Net Saved Energy for Horizontal Full Floor Slab Insulation after 50 Years

4. Discussions

5. Conclusion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abouhamad, M and Abu-Hamd, M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability 2021, 13. [CrossRef]

- ARUP, 2022. Carbon footprint of façades: significance of glass. Findings from the life cycle assessment of 16 façade typologies & 18,000 design simulation. [pdf] Available at : https://www.shareyourgreendesign.com/wp-content/uploads/2022/08/texto-3.pdf [Accessed on 15 July 2023].

- Carbon Leadership Forum, 2017. Embodied Carbon Benchmark Study LCA for Low Carbon Construction: Part One. [pdf] Available at : https://carbonleadershipforum.org/wp-content/uploads/2017/02/CLF-Embodied-Carbon-Benchmark-Study.pdf [Accessed on 22 July 2023].

- Chastas, P; Theodosiou, T; Kontoleon, K.J. & Bikas, D. Normalising and assessing carbon emissions in the building sector: A review on the embodied CO2 emissions of residential buildings. Building and Environment 2018, 130, 212-226. [CrossRef]

- Circular Ecology, 2023. Inventory for Carbon and Energy Database [Online] Available at https://circularecology.com/embodied-carbon-footprint-database.html [Accessed 26 May 2023].

- Climate.OneBuilding.Org, 2023. Repository of free climate data for building performance simulation. [online] Available at: https://climate.onebuilding.org/ [Accessed on 15 June 2023].

- Cox-Smith, I. 2016. Perimeter insulation of concrete slab foundations. Study Report SR352, BRANZ Ltd, Judgeford, New Zealand. [pdf] Available at: https://d39d3mj7qio96p.cloudfront.net/media/documents/SR352_Perimeter_insulation_of_concrete_slab_foundations.pdf [Accessed 28 October 2023].

- Crawford, R.H. Embodied energy of common construction assemblies (Version 1.0). The University of Melbourne, 2019, Melbourne.

- Dhansay, T; Musekiwa, C; Ntholi, T; ChevallierI, L; ColeI, D and de Wit, M. South Africa's geothermal energy hotspots inferred from subsurface temperature and geology. South African Journal of Science 2017, 113, 11-12. [CrossRef]

- Dong, Y; Kong, J; Mousavi, S; Rismanchi, B and Yap, P. Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives. Thermo 2023, 3, 38–65. [CrossRef]

- EDF, 2023.Acomplete Guide to Floor Insulation [Online] Available at https://www.edfenergy.com/heating/advice/complete-guide-floor-insulation [Accessed on 23 October 2023].

- Füchsl, S; Rheude, F and Roder, H. Life cycle assessment (LCA) of thermal insulation materials: A critical review. Cleaner Materials 2022, 5, 10011. [CrossRef]

- Gervasio, H; Dimova,S. & Pinto A; 2018. Benchmarking the Life-Cycle Environmental Performance of Buildings. Sustainability 2018, 10. doi:10.3390/su10051454.

- Hlavac, M ; 2022. stargazer: Well-Formatted Regression and Summary Statistics Tables. R package version 5.2.3. [online] Available at: https://CRAN.R-project.org/package=stargazer [Accessed on 20 July 2023].

- IEA, 2016. Basics for the Assessment of Embodied Energy and Embodied GHG Emissions for Building Construction. Guideline for Designers and Consultants – Part 1. [pdf] Available at: http://www.iea-ebc.org/Data/publications/EBC_Annex_57_Guideline_for_Designers_Part_1.pdf [Accessed on 10 January 2022].

- IEA (INTERNATIONAL ENERGY AGENCY). 2023a. World Energy Outlook 2023 [pdf] Available at: https://iea.blob.core.windows.net/assets/2b0ded44-6a47-495b-96d9-2fac0ac735a8/WorldEnergyOutlook2023.pdf [Accessed on 29 October 2023].

- IEA (INTERNATIONAL ENERGY AGENCY). 2023b. Buildings [Online] Available at: https://www.iea.org/energy-system/buildings [Accessed 29 October 2023].

- Intelligent Communities Lifecycle (2023). Table 6: Thermal Conductivity, Specific Heat Capacity and Density [Online] Available at: https://help.iesve.com/ve2021/table_6_thermal_conductivity__specific_heat_capacity_and_density.htm [Accessed on 12 May 2022].

- Lazo, M; Puga, I; Macías, M.A; Barragan, A; Manzano, P ; Rivas, A and Rigail-Cedeno, A. Mechanical and thermal properties of polyisocyanurate rigid foams reinforced with agricultural waste. Case Studies in Chemical and Environmental Engineering 2023, 8, 100392. [CrossRef]

- Melo, A.P; Lamberts, R; Versage, R.S and Zhang, Y. 2015. Is thermal insulation always beneficial in hot climate? Proceedings of BS2015: 14th Conference of International Building Performance Simulation Association, Hyderabad, India, 7-9 December 2015. [Online] Available at: http://www.ibpsa.org/proceedings/BS2015/p2188.pdf [Accessed 25 June. 2023].

- Netsch, N; Simons, M; Feil, A; Leibold, H; Richter, F; Slama, J; Yogish, S.P; Greiff, K. and Stapf, D. Recycling of polystyrene-based external thermal insulation composite systems – Application of combined mechanical and chemical recycling. Waste Management 2022, 150, 141–150. [CrossRef]

- Larwa, B. Heat Transfer Model to Predict Temperature Distribution in the Ground. Energies, 2019, 12, 25. [CrossRef]

- Liu, H; LI, J; Sun, Y; Wang, Y. And Zhao, H. Estimation Method of Carbon Emissions in the Embodied Phase of Low Carbon Buildings. Advances in Civil Engineering 2020, 1, 1-9. [CrossRef]

- Pokorska-Silva, I; Kadela, M; Orlik-Kozdon, B and Fedorowicz, L. Calculation of Building Heat Losses through Slab-on-Ground Structures Based on Soil Temperature Measured In Situ. Energies 2022, 15, 114. [CrossRef]

- Reynoso, L.E; Romero, A.B.C; Viegas, G.M and San Juan, G.A. Characterization of an alternative thermal insulation material using recycled expanded polystyrene. Construction and Building Materials 2021, 301, 124058. [CrossRef]

- Royal Institution of Chartered Surveyors, 2017. Whole life carbon assessment for the built environment. RICS Professional Statement. RICS, London [pdf] Available at: https://www.rics.org/content/dam/ricsglobal/documents/standards/Whole_life_carbon_assessment_PS_Sept23.pdf [Accessed on 17August 2023].

- SANS10400-XA, 2022. The application of the National BuildingRegulationsPart X: Environmental sustainability Part XA: Energy usage in buildings. SABS Standards Division. https://www.spectechonline.com/10400-xa [Accessed on 13 March, 2022].

- Society of Building Science Educators, 2023. Climate Cosultant. [Online] Available at: https://www.sbse.org/resources/climate-consultant [Accessed on 15 July 2023].

- Tariku,F; Shang, Y, and Molleti, S. Thermal performance of flat roof insulation materials: A review of temperature, moisture and aging effects. Journal of Building Engineering 2023, 76, 107142. [CrossRef]

- Thermtest Instruments, 2023. Materials Thermal Properties Database [Online] Available at https://thermtest.com/thermal-resources/materials-database [Accessed on 02 July 2023].

- Tsilingiridis, G and Papakostas, K. 2014. Investigating the relationship between air and ground temperature variations in shallow depths in northern Greece. Energy 2014, 7, 1007–1016. [CrossRef]

- United States Energy Information Administration, 2022. South Africa [Online] Available at: https://www.eia.gov/international/overview/country/ZAF [Accessed on 22 September, 2023].

- US Department of Energy, 2023. Insulation Materials. [Online] Available at https://www.energy.gov/energysaver/insulation-materials [Accessed on 10 July 2023].

- Zhang, X; Liu, K. & Zhang, Z. 2020. Life cycle carbon emissions of two residential buildings in China: Comparison and uncertainty analysis of different assessment methods. Journal of Cleaner Production 2020, 266. [CrossRef]

| Guideline Number | Design Guideline | Zone1 | Zone2 | Zone3 | Zone4 | Zone5 | Zone 5H | Zone6 | Zone7 |

|---|---|---|---|---|---|---|---|---|---|

| 11 | Heat gain from lights, people, and equipment greatly reduces heating needs so keep home tight, well insulated (to lower Balance Point temperature) | 5 | 4 | 4 | 1 | 1 | 1 | 7 | 2 |

| 58 | Shade to prevent over-heating, open house to breezes in summer and use passive solar gain in winter. | 1 | 2 | 1 | 2 | 3 | 8 | 3 | 7 |

| 62 | Use light-weight construction, with slab on grade, operable walls and shaded outdoor spaces | 2 | 1 | 2 | 3 | 2 | 3 | 2 | 4 |

| 35 | Good natural ventilation: use shaded windows that are oriented to prevailing breezes. | 3 | 3 | 3 | 4 | 4 | 5 | 1 | 5 |

| 56 | Screened porches and patios can provide passive comfort cooling by ventilation in warm weather and can prevent insect problems. | 9 | 6 | 5 | 5 | 10 | 9 | ||

| 63 | In overcast cool climates, use low mass tightly sealed well insulated construction to provide rapid heat build-up in morning. | 6 | 6 | ||||||

| 55 | Use low-pitched roofs with wide overhangs | 8 | 7 | 7 | 7 | 9 | 11 | 8 | 10 |

| 19 | For passive solar heating, face most of the glass area north to maximize winter sun exposure, but overhangs should be designed to fully shade in summer. | 4 | 8 | 8 | 8 | 5 | 2 | 4 | 1 |

| 10 | Glazing should minimize conductance loss and gain because undesired solar radiation gain has less impact on the temperate climate in Port Elizabeth | 9 | 4 | ||||||

| 33 | Long narrow building floor plan helps to maximize cross-ventilation in this temperate, hot humid climate. | 7 | 5 | 6 | 10 | 6 | 10 | 6 | 9 |

| 20 | Provide double pane high performance glazing (Low-E) on west, south, and east, but clear on north for maximum passive solar gain | 6 | 9 | 10 | 7 | 5 | 3 | ||

| 3 | For heating and cooling, lower the indoor comfort temperature at night to reduce energy consumption (At home: 6pm to midnight=70-80oF; Midnight to 6am =55-78oF; 6am to 8am=70-80oF; Not at home (work, school):8am to 6pm=65-85oF) | 10 | 12 | 8 | 7 | 6 | |||

| 31 | Organize floorplan so winter sun penetrates into daytime use spaces with specific functions that coincide with solar orientation | 10 | |||||||

| 36 | To facilitate cross ventilation, locate door and window openings on opposite sides of building with larger openings facing up-wind if possible | 9 | |||||||

| 37 | Window overhangs (designed for this latitude) or operable sunshades (awnings that extend in summer) can reduce or eliminate air conditioning | 10 | |||||||

| 8 | Sunny wind-protected outdoor spaces can extend living areas in cool weather (seasonal sun rooms, enclosed patios, courtyards, or verandahs) | 9 | |||||||

| 1 | Tiles or slate (even on wood floors) or a stone-faced fireplace provides enough surface mass to store winter daytime solar gain and summer nighttime 'coolth' | 8 |

| Item | Details |

|---|---|

| Energy Zones: | Energy zones 1, 2, 3, 4, 5, 5H, 6 and 7 |

| Location: | Welkom=zone1; Pretoria=zone2; Nespruit=zone3; Cape Town=zone4; Mthatha=zone5; Ixopo=zone5H; Kimberley=zone6; Fraserburg=zone7; |

| Shading depths (m) | Welkom =0.62; Pretoria=0.54; Nelspruit=0.54; Cape Town=0.73; Mthatha=0.68; Ixopo=0.68; Kimberley=0.57; Fraserburg=0.68. |

| Orientation of Building | Front wall faces North; Back wall faces South; Right wall faces East; Left wall faces West |

| Inside Length of the floor (m): runs East-West direction | 15.5m |

| Inside Width of the floor (m): runs North-South direction | 6.8m |

| Nett floor area (m2) | 105.40 m2 |

| Wall height (m) | 2.7m |

| Inner wall thickness (m) | 0.90m |

| Net Inner wall area (m2) | 89.06m2 |

| Cavity wall thickness: Gypsum plaster, Clay brick leaf1, Air Gap, Clay brick leaf 2, Gypsum plaster (units: m) | 0.010m, 0.110m, 0.050m, 0.110m, 0.010m |

| Cavity wall: Surface Density; R-Value; U-Value; [SANS10400-XA Reference R-Values] | 431.08 Kg/m2 ; 0.68 m2K/W; 1.46 W/m2K; [Ref R: 0.4 & 0.6 m2K/W] |

| Roof: materials | Lightweight metal Material; Gypsum plasterboard ceiling; OSB decking/sheathing, Insulation |

| Roof: R-Value; U-Value; [SANS10400-XA Reference R-Value] | 3.8 m2K/W; 0.46 W/m2K; [3.7 m2K/W] |

| Fenestration | |

| Fenestration to Nett floor area ; total fenestration area (m2) | 0.228 m2 ; 11.886 m2 |

| U-Value; [SANS10400-XA U-Value reference upper limit] | 2.258; [5.20 W/m2K] |

| SHGC ; [SANS10400-XA reference upper limit] | 0.571; [0.66] |

| Window to wall ratios (WWRs) | |

| Front; Back; Left; Right WWRs [Overall WWR] | 0.277; 0.240; 0.05; 0.05 [0.20] |

| Window to floor area | 0.22 |

| Cavity wall materials | Values (Density; Specific heat; conductivity; Embodied energy coefficient; Embodied CO2 coefficient): SI units |

| 1.Clay brick (Service life=150 years or more) | 1826Kgm-3; 0.835KJ/Kg.K; 0.820W/m.K; 3.20MJ/Kg; 0.240KgCO2/Kg |

| Floor | |

| Floor slab thickness (m) | 0.100 |

| XPS vertical insulation (service life=100 years) | 32 Kgm-3; 1.50 KJ/Kg.K; 0.028 W/m.K; 89.5 MJ/Kg; 2.80 (-1.41) KgCO2/Kg |

| Polyiso vertical insulation (service life=120 years) | 35 Kgm-3; 0.80 KJ/Kg.K; 0.025 W/m.K; 72 MJ/Kg; 3.9695 KgCO2/Kg |

| Insulation depths analysed (m) | 0.20 to 2.0 m an intervals of o,20m |

| Insulation thicknesses analysed (mm) | 25, 50, 100, 150, 200mm |

| Foundation thickness (m): Strip Foundation (Stones used) | 0.220m |

| WWR computation | Source energy was used as basis. (The only source of energy was electricity) |

| Model validation | Site energy was compared to standards (The only source of energy was electricity) |

| Model’s determination of impact of insulation measures | Energy savings were based on site energy(The only source of energy was electricity) |

| Schedules: Cooling set point; Heating set point; Relative Humidity (weekdays and weekend) | 25oC ; 19oC ; 60% |

| Zone1 | Zone2 | Zone3 | Zone4 | Zone5 | Zone5H | Zone6 | Zone7 | |

|---|---|---|---|---|---|---|---|---|

| Site Energy(Source Energy) | ||||||||

| Maximum (KWh/m2) | 24.61 (77.7) | 25.61 (80.79) | 25.72 (81.23) | 24.11 (76.14) | 23.08 (72.69) | 24.5 (77.36) | 27.09 (85.35) | 28.06 (88.29) |

| Minimum (KWh/m2) | 20.83 (65.82) | 20.69 (65.27) | 21.47 (67.63) | 23.39 (73.72) | 21.19 (66.88) | 21.91 (69.16) | 22.61 (71.3) | 23.8 (75.14) |

| Mean (KWh/m2) | 22.22 (70.09) | 22.49 (70.94) | 23.13 (72.94) | 23.75 (74.94) | 21.82 (68.85) | 22.82 (71.97) | 24.22 (76.36) | 25.43 (80.21) |

| SD (KWh/m2) | 1.005 (3.164) | 1.341 (4.231) | 1.197 (3.797) | 0.182 (0.566) | 0.5 (1.576) | 0.71 (2.24) | 1.156 (3.653) | 1.043 (3.284) |

| SANS10400-XA Reference (KWh/m2) | 90 | 100 | 50 | 80 | 85 | 60 | 110 | 110 |

| Annual heating and cooling load not met | ||||||||

| Maximum (% hours) | 0% | 2% | 1% | 0% | 2% | 1% | 1% | 0% |

| Minimum (% hours) | 0% | 0% | 0% | 0% | 1% | 0% | 0% | 0% |

| Mean (% hours) | 0% | 1% | 0% | 0% | 1% | 0% | 0% | 0% |

| SD (% hours) | 0.00% | 0.61% | 0.20% | 0.00% | 0.23% | 0.26% | 0.08% | 0.00% |

| SANS 10400-XA Reference (% hours) | 5% | 5% | 5% | 5% | 5% | 5% | 5% | 5% |

| Zone1 | Zone2 | Zone3 | Zone4 | Zone5 | Zone5H | Zone6 | Zone7 | |

|---|---|---|---|---|---|---|---|---|

| Site Energy(Source Energy) | ||||||||

| Maximum (KWh/m2) | 24.61 (77.7) | 25.61 (80.79) | 25.72 (81.23) | 24.11 (76.14) | 23.08 (72.69) | 24.5 (77.36) | 27.09 (85.35) | 28.06 (88.29) |

| Minimum (KWh/m2) | 21.86 (68.86) | 21.89 (69.02) | 22.64 (71.41) | 23.03 (72.64) | 21.47 (67.69) | 22.28 (70.36) | 23.78 (74.97) | 24.83 (78.45) |

| Mean (KWh/m2) | 22.17 (69.91) | 22.38 (70.6) | 23.04 (72.69) | 23.48 (74.06) | 21.66 (68.33) | 22.58 (71.2) | 24.18 (76.22) | 25.25 (79.65) |

| SD (KWh/m2) | 0.426 (1.363) | 0.584 (1.852) | 0.49 (1.555) | 0.205 (0.677) | 0.228 (0.713) | 0.338 (1.083) | 0.514 (1.608) | 0.514 (1.604) |

| SANS10400-XA Reference (KWh/m2) | 90 | 100 | 50 | 80 | 85 | 60 | 110 | 110 |

| Annual heating and cooling load not met | ||||||||

| Maximum (% hours) | 0% | 2% | 1% | 0% | 2% | 1% | 0% | 0% |

| Minimum (% hours) | 0% | 1% | 0% | 0% | 1% | 0% | 0% | 0% |

| Mean (% hours) | 0% | 1% | 0% | 0% | 2% | 0% | 0% | 0% |

| SD (% hours) | 0.00% | 0.24% | 0.04% | 0.00% | 0.06% | 0.13% | 0.07% | 0.00% |

| SANS 10400-XA Reference (% hours) | 5% | 5% | 5% | 5% | 5% | 5% | 5% | 5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).