Highlights

- -

Human performance analysis for nuclear power plant operation

- -

EEG-based human performance monitoring

- -

SMR plant operation analysis with human performance

1. Introduction

1.1. NPP and SMR Plant Operation

Nuclear power plants have comprehensive safety features to ensure the safe operation of the reactor and prevent the release of radioactive materials (Canadian Nuclear Safety Commission, 2007). These features include redundant and diverse safety systems. For instance, emergency core cooling systems (ECCS) consist of multiple independent cooling mechanisms that provide coolant flow to the reactor core in case of an accident (Ahmed, 2019).

The control room also houses safety systems, control rods, and emergency shutdown mechanisms that allow operators to initiate a safe shutdown of the reactor if necessary [Simonsen & Osvalder, 2015; Densmore & Duffy, 2021). The operators are trained to handle various plant conditions, identify potential safety issues, and follow strict safety protocols and emergency procedures (Acuna et al., 2023)

On the other hand, Small Modular Reactors (SMRs) incorporate advanced passive safety features that enhance their inherent safety and reduce reliance on active systems (Mi et al., 2019). Passive safety systems utilize natural processes such as gravity, convection, and natural circulation, making them simpler, more reliable, and less susceptible to failures (Gaikwad et al., 2023). Passive heat removal mechanisms, such as passive heat exchangers or passive residual heat removal systems, utilize natural heat transfer processes to remove decay heat from the reactor during shutdown conditions (Gaikwad et al., 2023).

These passive safety features are designed to operate without human intervention or external power, providing robust safety even under challenging conditions (Butt et al., 2016). Small modular reactors typically have reduced staffing requirements compared to large-scale nuclear power plants due to their smaller size and simplified design (Popov et al., 2023). The exact staffing needs may vary depending on the specific SMR design and operational characteristics. However, even with reduced staffing, it is critical to ensure that the personnel operating SMRs possess the necessary qualifications, training, and expertise (Popov et al., 2023).

SMRs have unique characteristics and design features compared to larger reactors. The training programs for SMR operators focus on these specific aspects, such as the operation of passive safety systems, understanding the modular nature of the reactor, and familiarity with the specific control and instrumentation systems employed in the SMR design (Blackett et al., 2023). Operators undergo simulator-based training to enhance their skills and decision-making abilities. Simulators provide a realistic representation of the control room and allow operators to practice various scenarios, including normal plant operation, abnormal conditions, and emergency response. Simulator training helps operators develop familiarity with the unique characteristics of SMRs, improve their situational awareness, and enhance their ability to handle potential challenges or malfunctions (Blackett et al., 2023).

While the overall staffing requirements for SMRs may be reduced, there is still a need for maintenance and support staff to ensure the safe and efficient operation of the reactor. Maintenance technicians, engineers, and other specialists play essential roles in routine maintenance activities, equipment inspections, troubleshooting, and repairs (Butt et al., 2016). These personnel receive training specific to the SMR design and its unique maintenance requirements.

The relatively smaller number of SMRs compared to large-scale nuclear power plants makes collaboration and knowledge sharing among operators and industry experts crucial (Blackett et al., 2023).

1.2. Control Room Challenges

A critical aspect of designing a control room for an SMR is to ensure that operators have access to the information they need to monitor and control the reactor effectively (Poresky et al., 2022). Plant operation information presented on the displays should be designed to be easy to understand and interpret (Poresky et al., 2022). This involves using clear and simple language, avoiding technical jargon, and presenting information in a logical and intuitive manner (Liu et al., 2016). The displays should also use graphical elements such as color coding, symbols, and graphs to help operators quickly and accurately understand the information (Santoso et al., 2022). Information organization and presentation on the displays should be organized logically and meaningfully. Alarms are an important tool for alerting operators to abnormal conditions in the reactor (Ren et al., 2015). Alarm design should consider the frequency and type of alarms, as well as the response time required by the operator (Ren et al., 2015). Alarms should be designed to avoid overloading the operator with too many alarms at once and should be presented in a way that makes it easy for the operator to respond quickly and effectively (Sompura et al., 2017).

1.3. Human Factors and Performance Analysis in Plant Operation

Human factors are heavily involved in the design and operation of SMRs. It is able to highlight the unique challenges associated with SMRs, such as the need for complex system integration and the potential for increased human error due to the smaller workforce required to operate them (Henderson et al., 2002). There are several key areas of human performance that are important to consider in SMR operation (Blackett et al., 2023). Operator training and qualifications is an essential area where SMRs require operators with specialized training and qualifications to ensure safe and effective operation (Liu et al., 2016). The report discusses the importance of developing effective training programs and qualification requirements to ensure that operators have the necessary skills and knowledge to operate SMRs safely. Human-systems integration is important due to the complex nature of SMRs, which requires the integration of multiple systems and subsystems, which can create potential sources of human error (Henderson et al., 2002). The report emphasizes the importance of designing SMRs with human-systems integration in mind to minimize the potential for errors. Human factors engineering is widely analyzed in view of the operation activities of SMRs, such as the physical and cognitive abilities of operators, to ensure that they can operate SMRs effectively and safely (Gofuku & Niwa, 2001). Organizational and management factors are linked with plant operation, such as communication and decision-making processes, in ensuring safe and effective operation of SMRs.

The tasks a nuclear reactor operator performs are integral to the function and safety of the reactor. The operators create a mental model of the situation to complete their tasks. A mental model is a mapping of the properties of the task to its representation in the Operator's mind. (Gofuku & Niwa, 2001) Mental models used by an operator can be broadly categorized as skill-based, rule-based, and knowledge-based (Sepanloo & Jafarian, 2004). A skill-based model is used when operators perform repetitive tasks that do not require any cognitive effort (e.g., reading data from charts or meters). Rule-based models are used primarily when a checklist or manual is required to complete the task (e.g., following the steps documented in a manual to fix a specific problem in the reactor). Lastly, the knowledge-based model is a complex model used when operators are met with a new problem in which skill or rule-based models are unavailable (Lee et al., 2004; Kim et al., 2020).

From the Operator's perspective, while operating and maintaining the reactor requires all three mental models, on a task-by-task basis, only one form of mental model is used (Burgy et al., 1982). Adjusting or slight repairs on the machinery and other procedural activities are predominantly done using a rule-based mental model. A skill-based model best maps to day-to-day tasks like controlling generator output, starting, and stopping equipment at appropriate times, and communicating with supervisors, subordinates, and peers (Hari & Puce, 2023).

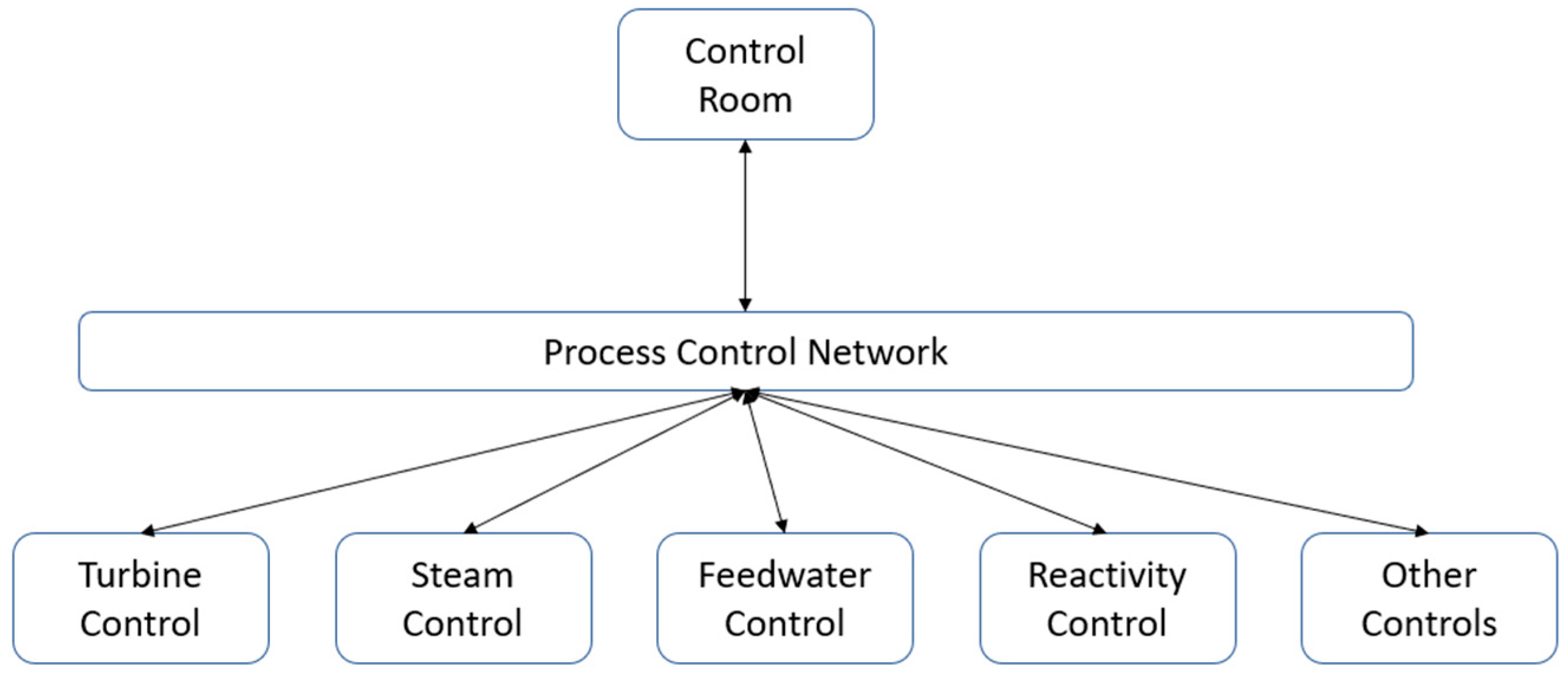

NPP Operators play a crucial role in the running of an NPP. They can control all of the aspects of the reactor, as shown in

Figure 1. The Control room is the center of the plant, where the function and safety of the reactor, steam generator, and other plant areas must be maintained.

This paper will present analysis of human factors and performance shaping factors and relate to SMR operator in the designated control rooms for improved performance.

2. Electroencephalography

The Electroencephalogram (EEG) device functions as a sensitive reader of the brain's electrical activities, detecting electromagnetic waves emitted because of synaptic activities. While a single neuron's action might not be easily captured, the synchronized firing of thousands of neurons produces an electrical field strong enough to permeate tissue, bone, and the skull, making it measurable on the head surface (Hari & Puce, 2023).

The signals detected by EEG devices are categorized based on frequency into delta, theta, alpha, beta, and gamma waves, each spanning a specific frequency range from 0.1 Hz to over 100 Hz. The EEG provides detailed information in both time (frequency) and voltage (amplitude) domains, offering insights into brain function and potential disorders (Kandel et al,. 2021).

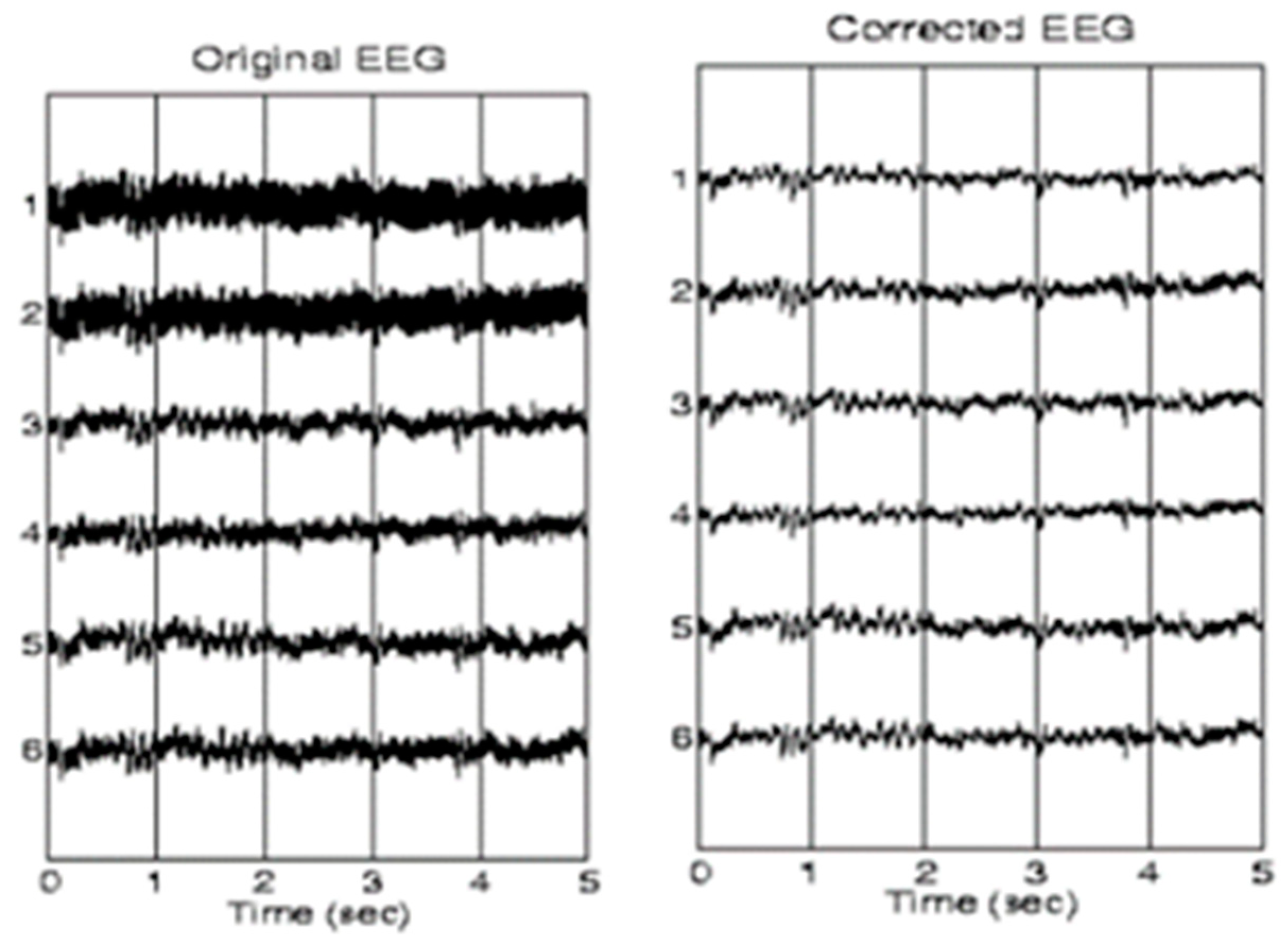

Since its inception in 1929, EEG has been a crucial tool for diagnosing various brain-related conditions such as seizures, traumatic brain injuries, tumors, and dementia by assessing the brain's electrical activity. However, the EEG recordings may contain "artifacts" resulting from movements like heartbeat, breathing, and muscle contractions. These artifacts, despite mimicking brain waves, are distinct and must be accounted for during EEG data interpretation, as shown in

Figure 2 (Kandel

et al., 2021).

2.1. Significance of 10Hz Frequency

The increase in band power at the 10Hz frequency is particularly noteworthy. This 10Hz activity falls within the alpha band, which has been previously correlated with varying levels of cognitive load and stress (Bazanova & Vernon, 2014; Klimesch, 1999). Other studies found that frontal lobe asymmetry can also appear if one is performing a cognitively demanding task (Coan et al., 2006).

2.2. Significance of 50Hz Frequency

Meanwhile observed surges in the 50Hz frequency correspond to the gamma band, a frequency that has been linked with various cognitive processes. Gamma band activity has previously been proposed as an EEG marker for acute psychosocial stress, especially the kind induced by paradigms like the Montreal Imaging Stress Task (MIST) (Dedovic et al., 2005). Further supporting the significance of gamma activity in stress-related contexts, research has highlighted its relevance in meditation-related studies, which often share parallels with relaxation or stress conditions (Lutz et al. 2004). However, it should be noted that while there's a wealth of EEG-based methods hinting at the role of gamma in reflecting stress, a universally recognized EEG marker for stress remains to be established.

While increased alpha band power has been studied as a marker for stress and cognitive load, the gamma band activity, particularly at 50Hz, may be considered a more sensitive and immediate marker for high-stress scenarios (Minguillon et al., 2016).

3. Human Performance Shaping Factors

The effectiveness of Small Modular Reactor (SMR) operation hinges upon a multitude of Performance Shaping Factors (PSFs) that encompass both internal and external elements.

3.1. PSF Classifications for SMR Plant Operation

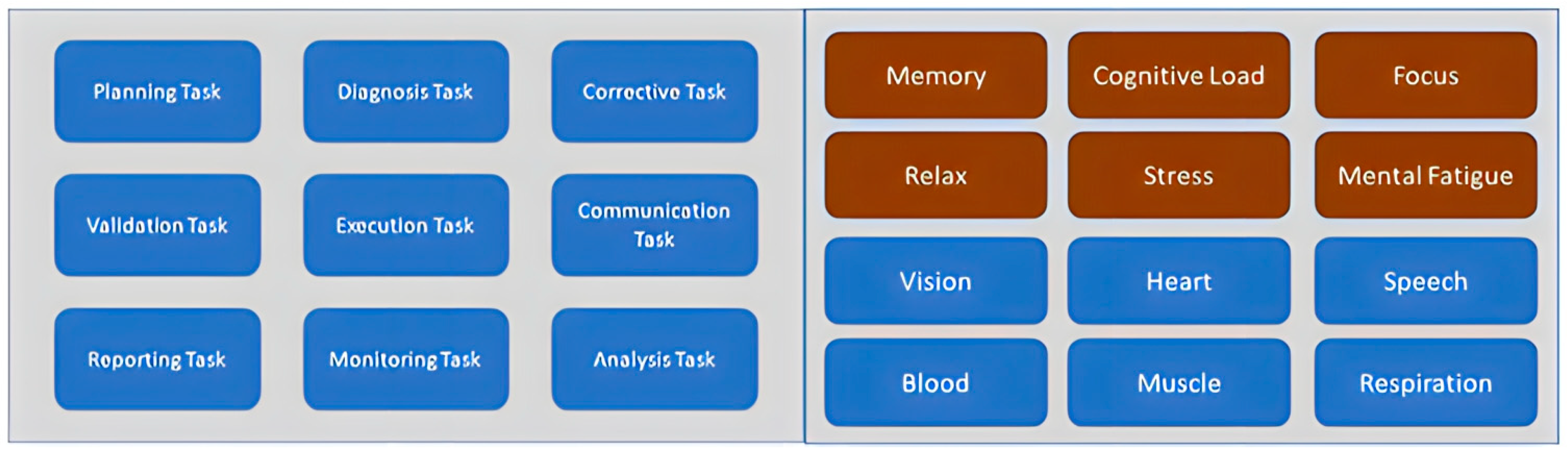

The PSFs can be broadly divided into several categories as shown in

Table 1 (Henderson

et al., 2002).

3.2. Internal PSFs

Operators experiencing high levels of stress or excessive workload are more prone to fatigue, which can decrease cognitive performance and increase error rates. Implementing measures to manage workload effectively, providing support to handle stress, and ensuring appropriate shift lengths and rest periods are vital for maintaining operator alertness and performance (Henderson et al., 2002).

The operator's level of training and experience greatly influences their ability to perform tasks and respond to operational anomalies effectively. Comprehensive training programs, simulation exercises, and ongoing learning initiatives prepare operators for various operational scenarios and equip them to respond appropriately during routine and emergency situations.

Each of these PSFs plays a unique role in shaping operator performance in SMRs. By focusing on these areas, potential for human errors in SMR operation can be minimized, thereby contributing to the overall safety and efficiency of the operation.

3.3. External PSFs

Ergonomics and Human-Machine Interface in SMRs often incorporate advanced digital and artificial intelligence-enhanced technologies (Henderson et al., 2002). The design of these interfaces, as well as the physical control room, heavily influences operator understanding and error rates. Poorly designed or cluttered interfaces can lead to misinterpretation of critical data, while well-organized, user-friendly interfaces enhance operator decision-making and performance (Henderson et al., 2002).

Procedures and Protocols should be clear and succinct to guide operators through both routine and emergency operations. Complex or ambiguous protocols can lead to confusion and potential errors. Regular review and streamlining of procedures, with operator feedback, contribute to increased procedural adherence and reduced risk of operational errors.

Effective communication is vital during shift changes, emergencies, or when dealing with unexpected events. Ineffective or unclear communication can lead to misunderstandings, potentially causing significant operational errors. Protocols for clear, concise, and timely information exchange among operators and other team members can mitigate these risks.

Organizational culture and policies directly shape operator behaviors. A safety-conscious culture that encourages open communication, prompt error reporting, and continuous learning can significantly reduce the incidence of human error, thereby enhancing the safety and reliability of SMR operations.

3.4. NPP Accident Risk Factors

The Institute of Nuclear Power Operations (INPO) is an organization established in 1979 by the U.S. nuclear power industry in response to the investigation of the Three Mile Island accident. INPO published a study (INPO 91-008) of NPP industry events from 1945 to 1990 (Nuclear Regulatory commission, n.d.). The results are shown in

Table 2.

Events are mainly attributed to "Personnel Performance," while no events were caused by team performance. One telling piece of information from the above table is that equipment or design issues rarely cause events but instead are caused by human error. Human error is why human performance techniques and teamwork are essential in the control room and the operating plant.

The report discusses nine significant NPP events and asses them by direct deficiencies in teamwork or other areas critical for effective teamwork (Nuclear Regulatory commission, n.d.). The results were:

- -

Supervisory oversight – leadership (7 of 9 events)

- -

Reactivity control – Improper Action (3 of 9 events)

- -

Teamwork (6 of 9 events)

- -

Crew decision-making (9 of 9 events)

- -

Application of knowledge Sensing / Understanding (2 of 9 events)

3.5. Operator Task Classification

- (a)

Based on Human Mental and Physical Models:

The first method, shown on the left side of

Figure 3, is based on human mental and physical models. This classification considers human abilities and limitations, ensuring tasks align with what is humanly possible and practical.

- (b)

Based on Operation Task Category:

The second method, visible on the right side of

Figure 3, classifies tasks based on operation task category. This approach focuses on the type and complexity of tasks, assigning them to operators with the appropriate skills and expertise.

These two methods help in organizing tasks effectively, aiding in the smooth flow of operations and reducing the likelihood of errors. These tasks are analyzed in view of PSFs and mapped to human performance for the selected test scenarios. Data collected and analyzed using the proposed EEG-based human performance monitoring system.

4. Method

4.1. EEG-Assisted Operator Performance Monitoring System

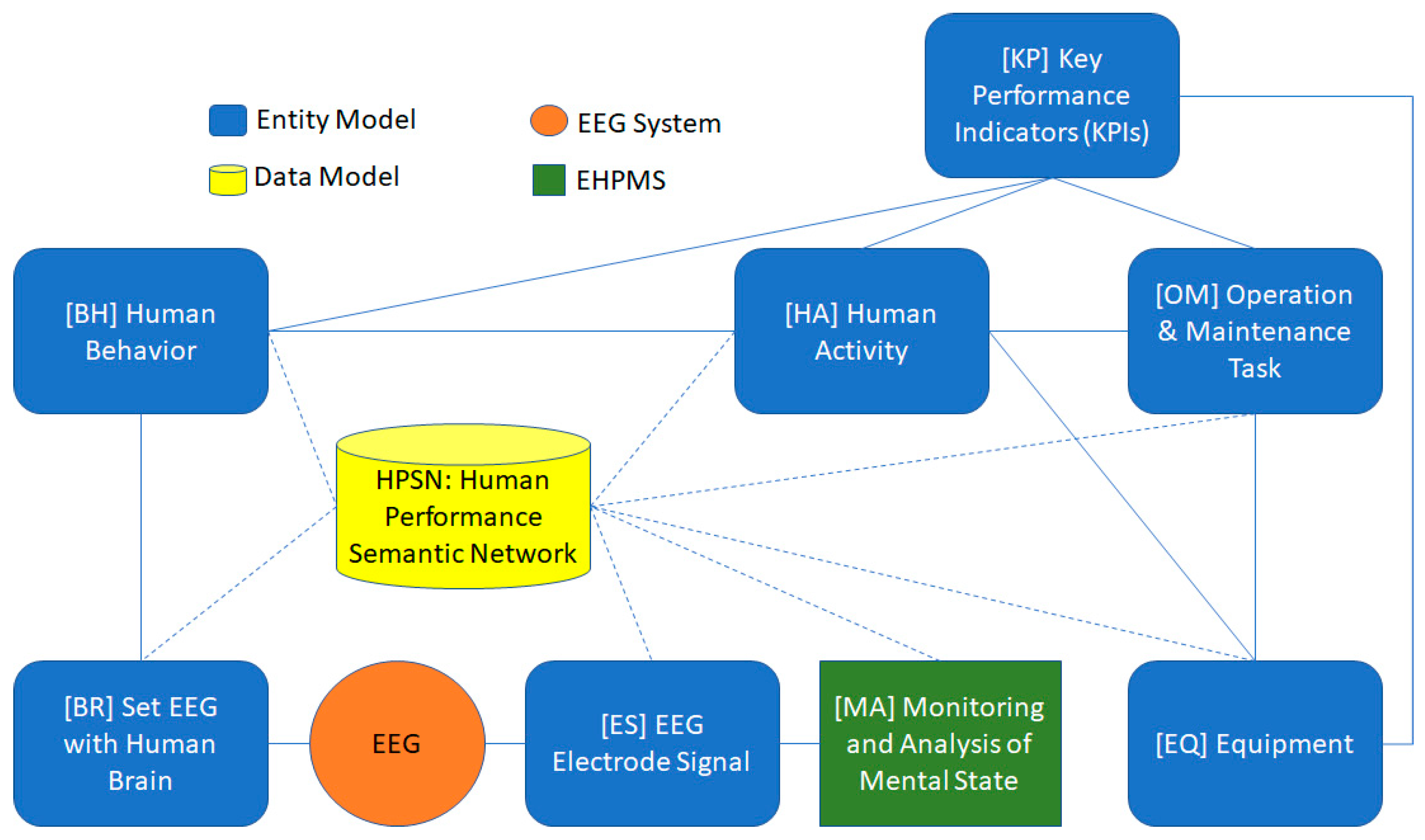

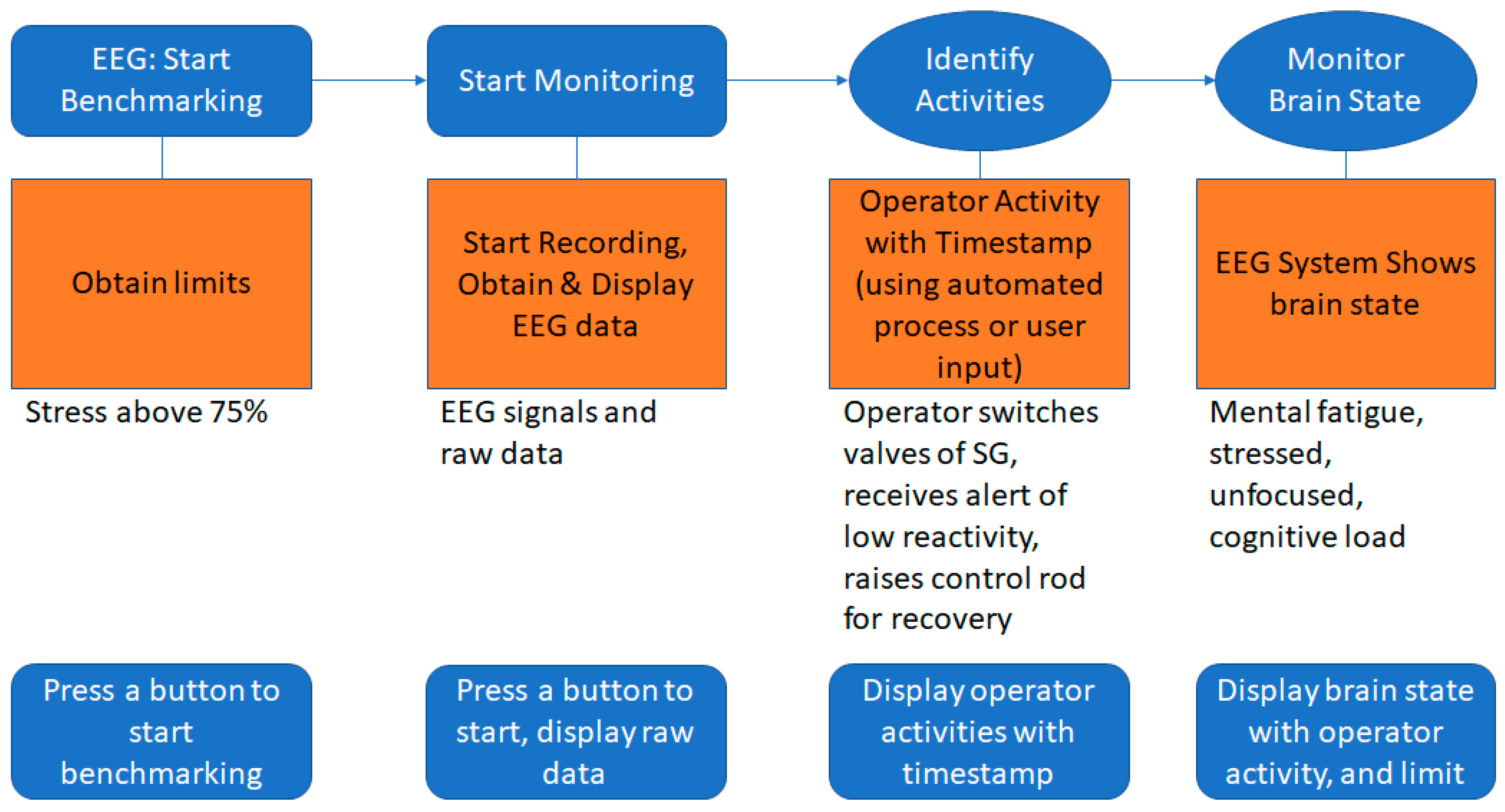

The proposed integrated system, called EEG-based Human Performance Management System (EHPMS), shows the analysis of plant operation tasks and link with operator activities and behavior and correlate with EEG signals.

Figure 4 shows the proposed design of EHPMS. The EHPMS is an innovative system designed to holistically assess human performance during operational tasks. By intertwining advanced EEG capabilities with essential physiological measures, it offers a multidimensional view of an operator's state and performance. Human Performance Semantic Network (HPSN) is developed to structure knowledge about human performance in different operation tasks and associated behavior. Human performance indicators and PSFs are defined and evaluated for different operation tasks and human responses, which are dynamically updated in HPSN.

Fundamental Principles: Electroencephalography (EEG) is a non-invasive method that records the electrical activities of the brain. The utilization of EEG in EHPMS allows for the mapping of human brain signals to behavioral and operational activities, leading to insightful evaluations of human behavior.

Real-Time Monitoring: One of the pivotal advantages of EEG incorporation is its capacity for real-time monitoring. EEG data offers an instantaneous view into the operator's cognitive state, granting the opportunity for timely interventions if any anomalies or concerning patterns are detected.

Objective Measures: EEG not only offers real-time monitoring but also ensures the objectivity of the data. Stress and cognitive load, traditionally gauged through self-reports which can be influenced by individual biases, are more accurately and reliably assessed with EEG. This adds a layer of precision and credibility to the EHPMS's assessments.

Identifying Stressors: The EHPMS, with its EEG component, is instrumental in pinpointing conditions or procedures that induce excessive stress or cognitive load on the operator. By recognizing these specific stressors, interventions can be timely, ensuring the operator's safety and the integrity of the operation.

Enhancing Operational Procedures: Beyond just identification, the insights derived from the EHPMS can assist in the optimization of performance shaping factors and human-centric operational protocols. By doing so, it ensures a more streamlined, effective, and safer operational environment.

Additional Physiological Measures: To complement the EEG data and provide a more comprehensive view of an operator's state, the EHPMS integrates other vital physiological measurements. These include monitoring the blood pressure, heart rate, and other pivotal signs, offering a more rounded view of the human state during operations.

4.2. Monitoring System & Test Environment

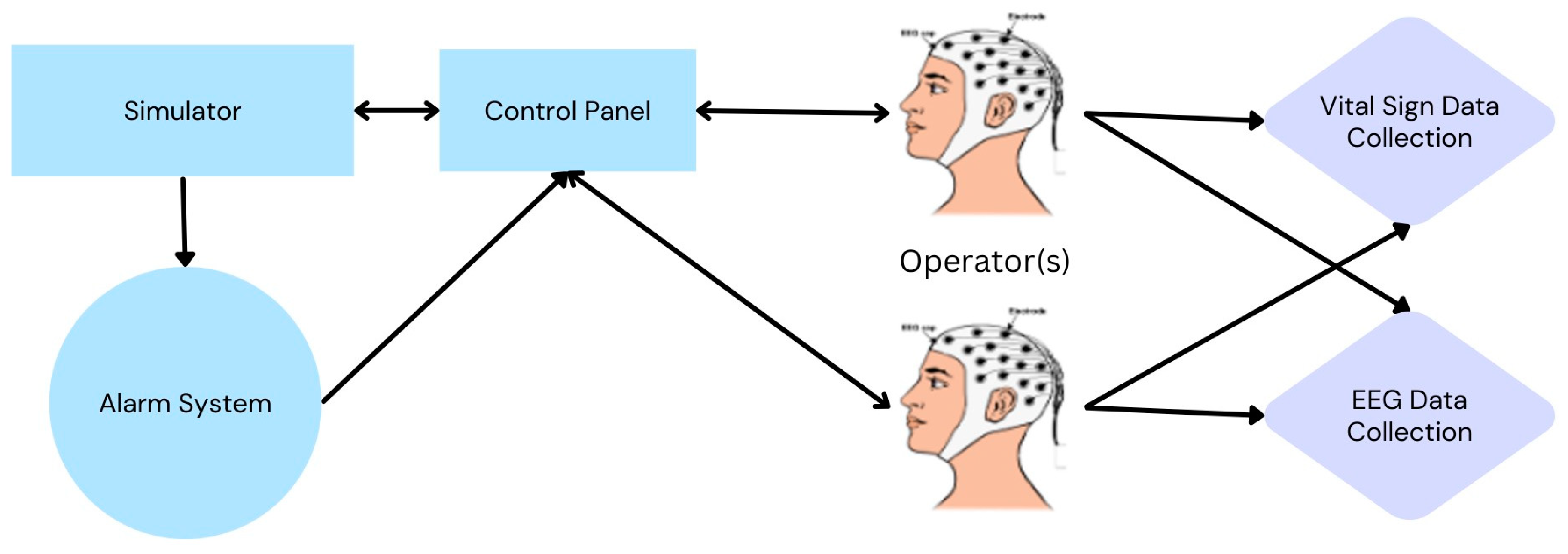

The test environment, as depicted in

Figure 5, is designed to emulate the operations of a Small Modular Reactor. At the heart of the setup is the SMR Simulator, providing a realistic and interactive representation of SMR operations and potential accident scenarios such as a gradual coolant leak. Operators, situated within this simulated control room environment, interact with a detailed Control Panel, designed to mimic the operational interface of actual SMR systems. The environment is further enhanced with a sophisticated Alarm System, which is configured to alert operators to specific incidents, enabling the assessment of response times and decision-making efficiency. To gauge the operators’ cognitive states and stress levels during the simulation tasks, EEG Data Collection is seamlessly integrated into the setup. Real-time EEG data are captured. This meticulously structured test environment ensures a thorough evaluation of operator performance in simulated SMR accident scenarios.

The Operator(s) will start the SMR simulator with the EEG cap equipped, reading brain waves as the operator(s) complete the test scenario. EEG data is collected for analysis.

The EEG data processing begins post data acquisition, the cleaned and organized EEG data undergo a detailed analysis. A frequency analysis is conducted to explore the brain rhythms, and their relationships with the observed responses to the stimuli.

4.3. EEG System

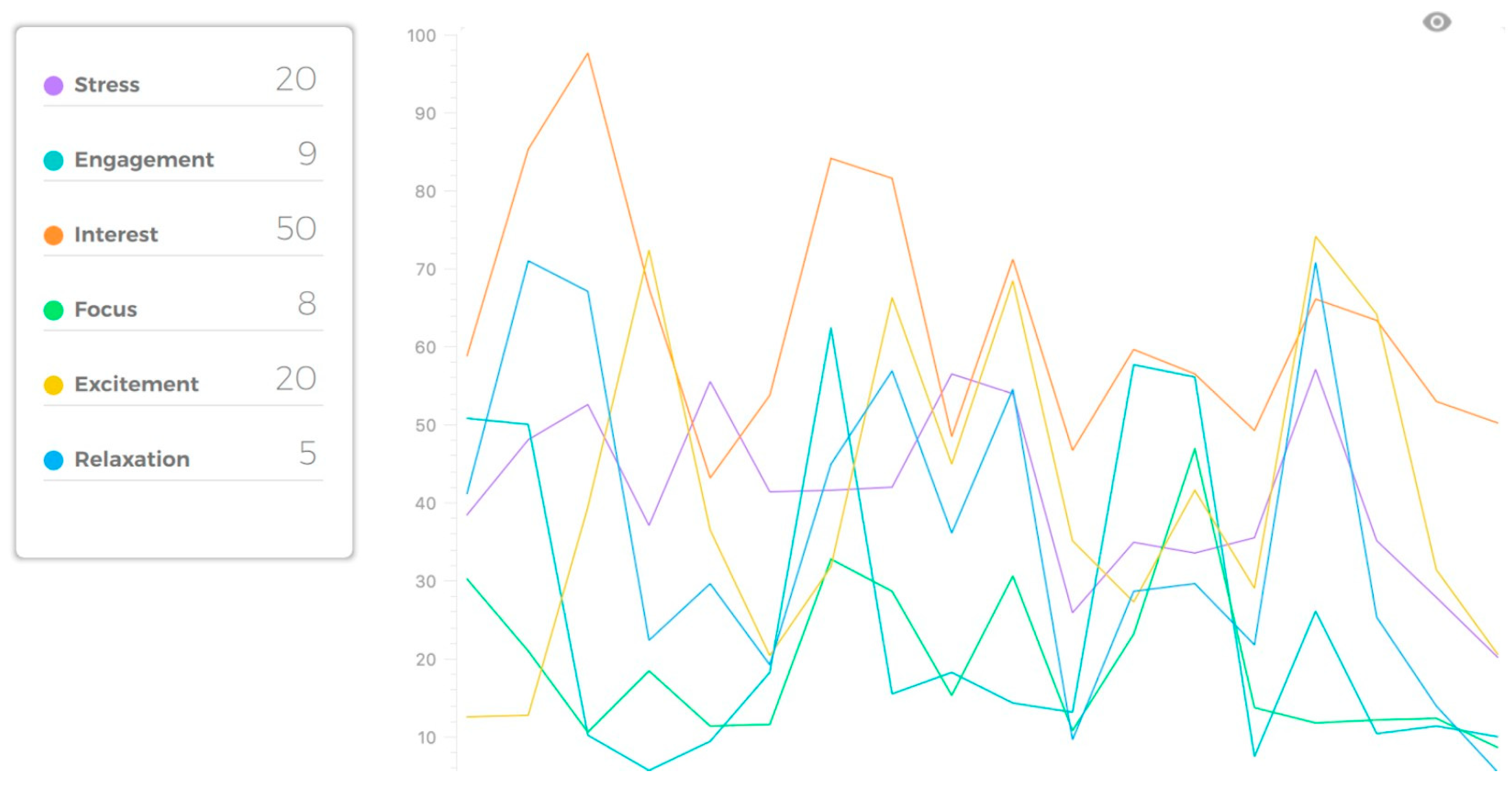

The EEG cap selected for this project was the EMOTIV EPOC Flex, a 12-channel, wireless EEG cap with EmotivBCI, a Brain-Computer Interface that provides quantitative performance scores (Strmiska & Koudelkova, 2018). To enhance the EEG data processing, our study employs the EmotivBCI tool for further data refinement. This tool aids in the amplification of the EEG data, performing an additional round of artifact removal. Stress is a measure of comfort with the current challenge. High stress can result from an inability to complete a difficult task, feeling overwhelmed and fearing negative consequences for failing to satisfy the task requirements. Generally, a low to moderate stress level can improve productivity, whereas a higher level tends to be destructive and can have long-term consequences for health and wellbeing (Kumar& Kumar, 2016). Focus measures fixed attention to one specific task. Focus measures the depth of attention and the frequency that attention switches between tasks. A high level of task switching indicates poor focus and distraction. Studies testing the efficacy of these performance metrics found that the levels of stress calculated by the BCI correlate with the task's difficulty (Gofuku & Niwa, 2001; Kumar & Kumar, 2016). The task tested was a set of two math problems, the first more complex than the second. When participants completed both problem sets while being monitored by the BCI system, the levels of stress were elevated for the duration of both tests, with the first problem set having a high-stress level than the second (Kumar & Kumar, 2016).

The EmotivBCI assists in the quantification of the data, providing insightful performance metrics based on their proprietary analysis of the EEG signals, examples shown in

Figure 6. In summary, the EEG data processing in our study is a structured and detailed pathway from initial artifact correction to data analysis.

4.4. Electrocardiogram Hardware

The contemporary advancements in wearable technology have introduced an array of physiological monitoring devices that capture a variety of data, such as electrocardiograms (ECGs), stress levels, blood pressure, and heart rate. Among these, Samsung's smartwatches have made significant strides, facilitating non-invasive and continuous monitoring of these parameters.

A key strength of Samsung smartwatches lies in their ability to record electrocardiograms (ECGs) (Tison et al., 2020). ECGs measure the electrical activity of the heart and can reveal a wealth of information about an individual's cardiovascular health. In the context of SMR operations, changes in heart rate variability - a parameter derived from ECGs - can indicate fluctuations in stress levels and cognitive load among operators. This data could be crucial in understanding how operators respond under high-stress scenarios such as an emergency. Moreover, the ability to continuously monitor heart rate enables the detection of rapid changes that may occur in response to specific events, offering real-time insights into the operator’s state.

Additionally, Samsung smartwatches are equipped with photoplethysmography (PPG) sensors, enabling the measurement of stress and blood pressure. Stress detection is typically achieved by analyzing the variation in time intervals between consecutive heartbeats, also known as heart rate variability (HRV). It's well-documented that elevated stress levels are associated with decreased HRV, suggesting a heightened sympathetic response and diminished parasympathetic activity (Shaffer & Ginsberg, 2017). This presents an opportunity to infer operator stress levels during critical incidents, contributing to a more holistic understanding of operator performance.

Furthermore, the capability of the watch to measure blood pressure offers a supplementary physiological indicator of stress. Increased blood pressure is a well-recognized physiological response to stress, making this an essential parameter to gauge operator strain during critical events in SMR operations.

However, while the wealth of data available from the Samsung smartwatch is potentially beneficial, it is crucial to bear in mind that several factors, including physical movement and placement of the watch, can influence the accuracy of readings. Therefore, careful calibration and interpretation of the data is necessary to ensure reliable conclusions.

The combined potential of ECG, stress, blood pressure, and heart rate measurements from Samsung smartwatches offers a promising avenue for the evaluation of psychophysiological responses in SMR operators. Paired with EEG and other relevant performance metrics, these data points could enhance the understanding of human factors in SMR operations, supporting optimized performance and safety outcomes.

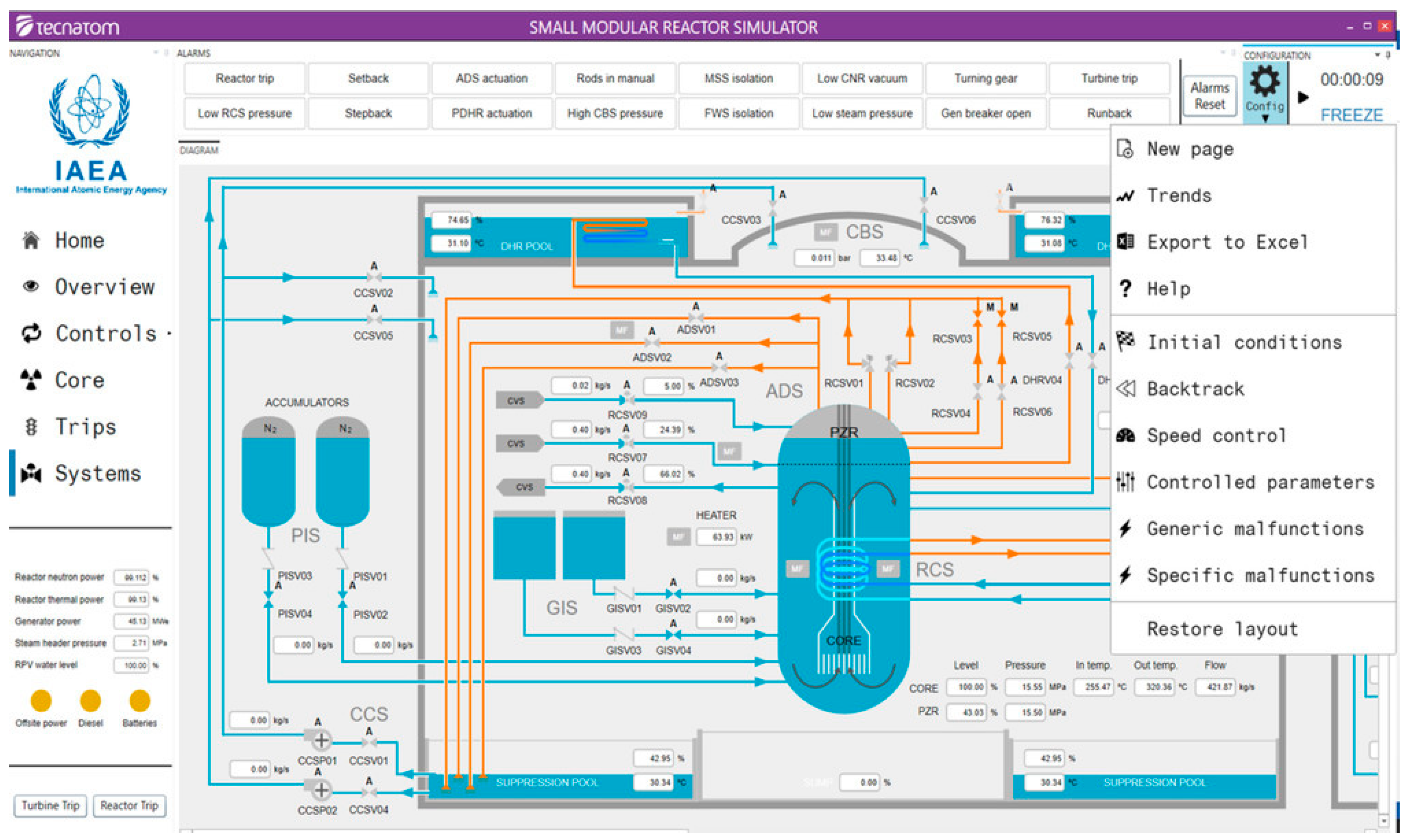

4.5. SMR Simulator

This study utilizes the integral Pressurized Water Reactor (iPWR) simulator, shown in

Figure 7, as a sophisticated tool endorsed by the International Atomic Energy Agency (IAEA). Its high-fidelity simulation environment meticulously replicates real-time iPWR operations, providing a framework for the examination of various operational and safety facets of nuclear reactor systems.

The utilization of the iPWR simulator in this research facilitates an exploration into the neural dimensions of operator task performance within a simulated nuclear reactor context. This advanced simulation environment affords an insight into the impact of different operational scenarios on cognitive load and stress markers, as observed through electroencephalographic (EEG) data.

5. Case Study

5.1. Test Scenarios

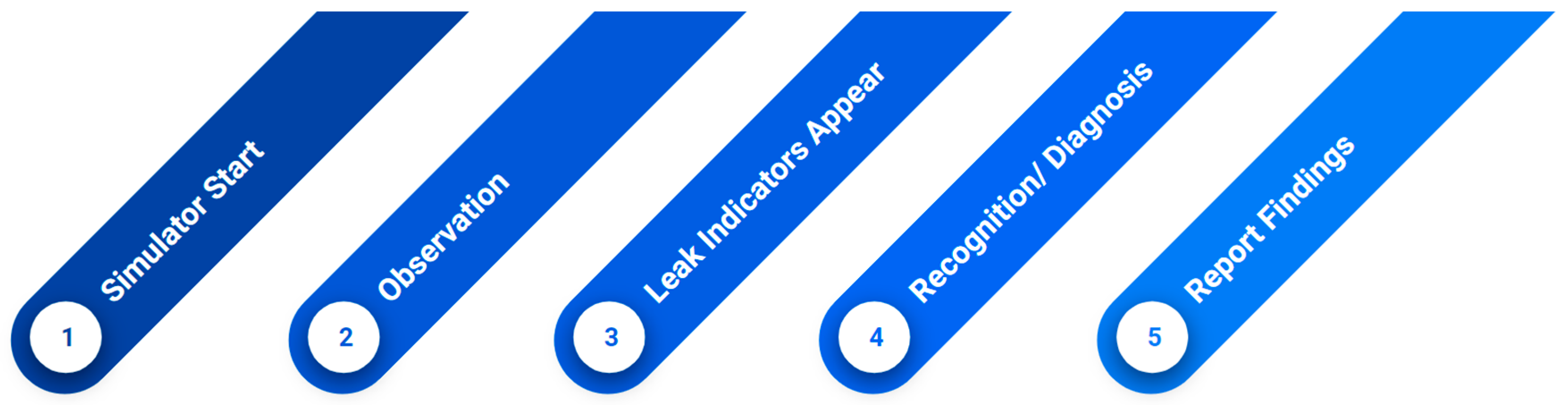

A demo scenario was used to analyze the risks of NPP Operators properly. The Operator will begin the scenario by completing a task when an alert sounds. The scenario execution framework is proposed, as shown in

Figure 8. The framework starts when the operator receives alerts from the control system and attempts to interpret. The mental model is established for the selected situation. A series of steps are identified and executed to satisfy the alert. These steps are recorded in the logbook.

The EEG will monitor the Operators brain waves while the BCI calculates the Operator's performance metrics. This Demo scenario will be conducted multiple times, with different operators are different times of the day and shifts. Longer shifts and late-night shifts increase the likelihood of accidents occurring and high levels of mental fatigue.

In the proposed test scenarios, two volunteer operators were used to simulate SMR/NPP operation. Participants are all members of the lab. Generic operating steps are included below.

5.2. Test Run-1: Interaction with SMR Simulator

The operator is placed in a simulator with the plant running under normal conditions.

Figure 9 shows the test framework. The Operator is initially tasked with recording state variable of the plant, ensuring that the plant is running optimally. Unknown to them, a scenario is initiated where a small leak develops in the reactor's primary coolant system. This leak results in slow but steady changes in several control panel parameters.

The operator is asked to observe the control panel without intervening and report any perceived anomalies. They are not informed about the planned leak, making it a true test of their observational skills and system knowledge.

Over time, the control panel would show:

Slight Decrease in Coolant Pressure: A gradual drop in the reactor coolant system pressure would be the first noticeable sign of the leak.

Increase in Reactor Core Temperature: As the coolant leak continues, there would be less coolant to remove heat from the reactor core, leading to a gradual increase in core temperature.

Increase in Coolant Makeup Flow: To compensate for the lost coolant, the makeup water system would start to increase its flow, which could also be noticed by the operator.

Change in Radiation Levels: If the leak is severe enough, there might be a slight increase in radiation levels in the containment building, as detected by radiation monitoring systems.

The operator's task would be to notice these changes, understand their significance, and report their findings to the experiment supervisor. The operator's performance could then be evaluated based on how accurately and quickly they identify the signs of the coolant leak.

5.3. Test Run-2: Interaction with NPP Simulation

Generic Testing Steps

Attach EEG electrodes to the participants' scalps according to standard placement protocols. Ensure the EEG equipment is calibrated and validated for accurate data collection. Set the sampling rate and ensure a sufficient number of channels to capture relevant brainwave activity.

- 2.

Experimental Conditions

Set up a simulated control room environment resembling an SMR control room. Introduce stress-inducing elements such as time pressure, simulated alarms, equipment malfunctions, and communication challenges. Ensure the scenario is safe and realistic but not overly hazardous to participants.

- 3.

Sample Selection

Recruit volunteers who are familiar with emergency response procedures.

- 4.

Stress Induction

Simulate an emergency scenario, such as a reactor malfunction, loss of power, or cooling system failure. Create time pressure by imposing strict deadlines for response actions. Incorporate realistic stressors like simulated alarms, flashing lights, and communication interruptions.

- 5.

Experimental Protocol:

Provide participants with a pre-simulation briefing, explaining the emergency scenario and their role in responding to it. Start the simulation and monitor participants' responses, including decision-making, communication, and task execution. Continuously record EEG data throughout the simulation.

- 6.

Data Collection:

Capture EEG data, focusing on relevant brainwave activity associated with stress and cognitive load (e.g., beta and gamma waves, event-related potentials). Consider incorporating additional physiological measurements like heart rate, skin conductance, or eye-tracking to complement the EEG data.

- 7.

Performance Evaluation:

Assess participants' performance based on predefined criteria, such as response time, accuracy of decisions, and adherence to emergency procedures. Correlate participants' stress levels (as measured by the EEG) with their performance metrics to understand the relationship between stress and proficiency.

The test operators were tasked with recording values of different parts of the reactor (Turbine speed, Generator Power, Steam Hdr Pressure ETC.). While completing their task, a malfunction occurs in the reactor, resulting in a Steam Generator Valve Failing Open. The Operator must promptly record the values and the valve malfunction. This scenario is meant to evoke levels of stress and mental fatigue in a short period; this allows us to experiment many times in different conditions such as time of day and length of shift. Each participant will conduct the scenario at 6 A.M., 1 P.M., and 9 P.M.

An EMOTIV - EPOC Flex Kit made of sintered Ag-Ag chloride will be used for the scenario. The system includes the EMOTIV electrode cap with a bandwidth of 0.16-43Hz and digital notch filters at 50Hz and 60Hz. The NPP simulator used for this experiment is the CANDU simulator by Cassiopeia technologies, which provides accurate timing and control of an NPP control room. The simulator is capable of programming malfunctions to occur at certain times and contains a separate panel for alerts for clear reading.

5.4. Key Performance Indicators

Key Performance Indicators (KPIs) are specific, measurable values that demonstrate how effectively an organization or individual is achieving key objectives. For Gradual Coolant leak accident simulation for SMR operators, KPIs can help gauge the effectiveness of training and operator performance.

Table 3 shows the list of Key performance indicators relevant to the two experimental scenarios and to the designing of the SMR control room and other human factors.

6. Results

6.1. EEG Data Analysis

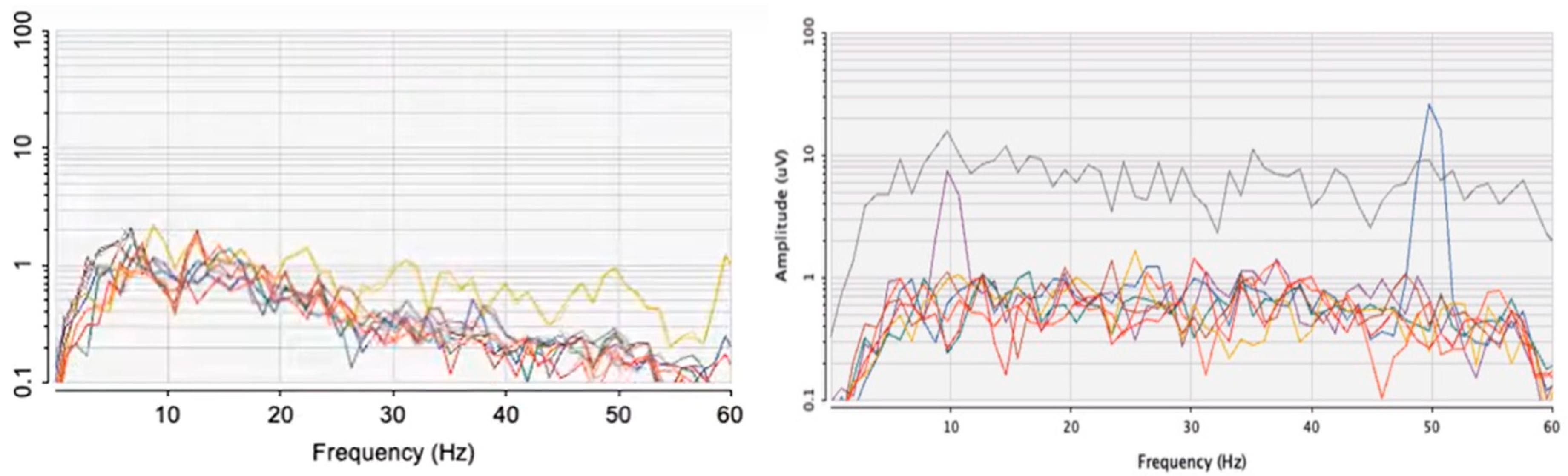

Analysis of the EEG data resulting from the SMR trials revealed an increase in band power at the 10Hz and 50Hz regions upon Fast Fourier Transform of EEG data, following the Small Modular Reactor (SMR) simulation tasks (

Figure 10). This was a consistent observation across all participating operators during the simulation.

10Hz Frequency Results: Our findings revealed a notable increase in the 10Hz frequency post-SMR simulation. This elevation underscores a shift towards enhanced relaxation and alertness among participants.

50Hz Frequency Results: Similarly, a marked increase was observed in the 50Hz frequency.

Results of the NPP trials are shown in

Table 4, showing the Stress and Focus performance modalities provided by the EMOTIV BCI. The three values captured are the performance metric recorded at the start of the simulation in percentiles, at the moment of the malfunction, and 1 minute after the malfunction.

In The NPP Simulation, Both Operators experienced an increase in stress in all three zones, spiking immediately after noticing the malfunction and gradually reducing afterward. The Focus modality also saw an increase when the malfunction was noticed. The morning and night scenarios had higher stress levels and lower focus levels. Whether or not an operator performs better in the morning or night scenario.

6.2. ECG Data Analysis

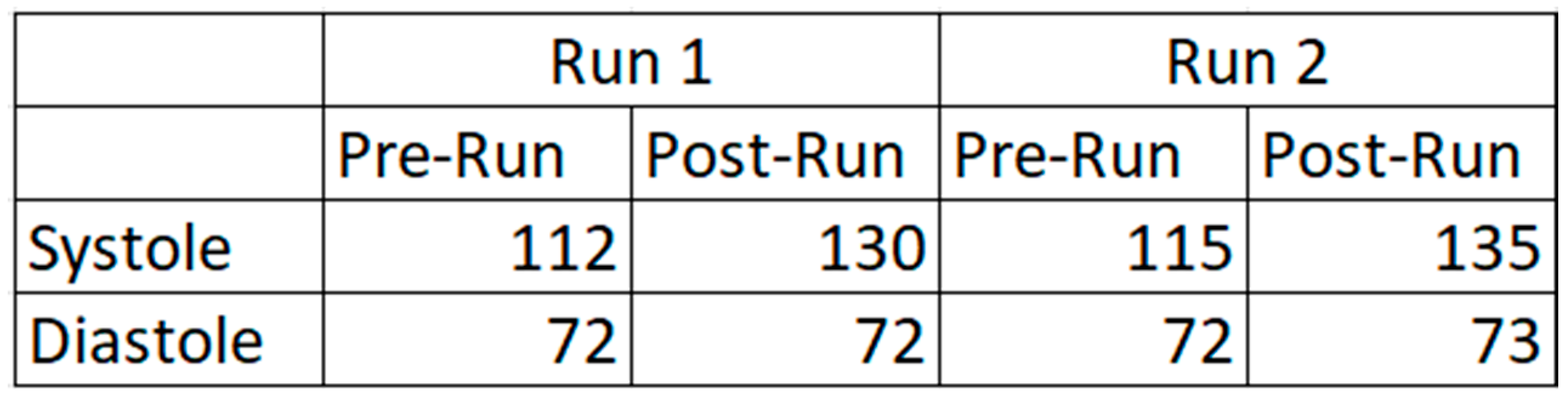

A test was conducted wherein an operator undertook a task in a simulated SMR environment, and their blood pressure (BP) was recorded both before and after the test run using a Samsung Galaxy Watch 3.

During the initial execution of the scenario, without any external interferences, there was a notable elevation in both systolic and diastolic BP levels post-test. This rise in BP corresponded with the operator's detection of a malfunction in the simulation (

Table 5).

To further understand the implications of distractions on the operator's stress levels and response time, the scenario was repeated. However, in this iteration, additional visual and auditory distractions were introduced. The results indicated a more pronounced increase in BP, suggesting heightened stress. Additionally, the time taken by the operator to correctly diagnose the malfunction was extended, indicating potential challenges in cognitive performance amidst distractions.

Table 5.

Blood Pressure Measurements by Smart Watch Pre and Post Test-run.

Table 5.

Blood Pressure Measurements by Smart Watch Pre and Post Test-run.

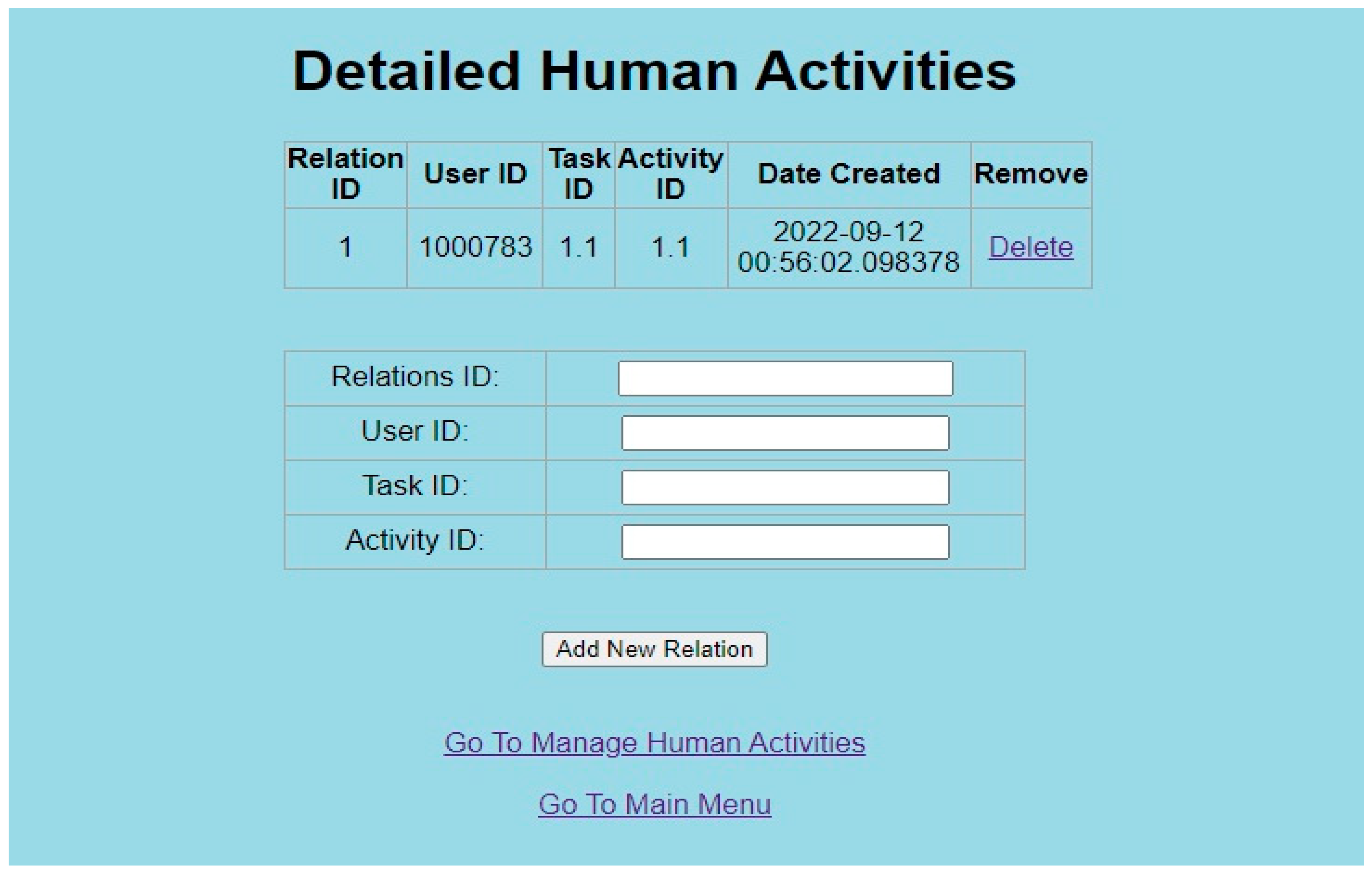

6.3. Solution Implementation

an EEG alert system was developed that notifies the user when they succumb to high mental fatigue or cognitive load levels. The proposed solution could work in active or passive modes. Active Monitoring System: Once a qualitative value for the Operator's performance is calculated, a baseline is set. The Active Monitoring system consists of real-time monitoring of the 6 Performance metrics, which are being compared to their baseline levels; if the current levels pass the acceptable limit for the metric, the system will then alert the Operators and other relevant persons. Passive Monitoring System: The Passive monitoring system controls the background monitoring of the Operator, such as the duration of work, facial expressions, eye movements and motion sensor data. Benchmarks are also required for proper calibration. These other metrics also contribute to determining mental fatigue levels, as factors such as long work shifts, and certain facial expressions are symptoms or causes of high mental fatigue. Both systems will work together to pinpoint mental fatigue states, alert the Operator, and prevent mental fatigue-caused accidents. The developed solution is shown in

Figure 11, with a user interface depicting the proposed solution shown in

Figure 12.

By implementing our solution, operator performance and safety measures are improved in nuclear power plant and SMR operation.

7. Conclusions

Through the comprehensive analysis of EEG data during SMR accident simulations, it highlights an observable increase in certain brain frequencies, indicative of elevated levels of stress among operators during simulation. These findings underscore the crucial need for robust and refined training approaches, particularly focusing on stress management and effective communication. The implementation of Key Performance Indicators (KPIs) is advocated to rigorously assess and enhance operator responses, aiding in the continual improvement of safety and operational protocols. The developed EEG alert system, functioning in both active and passive modes, proves to be an effective tool for the real-time monitoring of performance metrics, ensuring timely intervention in case of emerging mental fatigue and potentially reducing the incidence of related errors or accidents. This research contributes to the enhancement of operator safety and performance in SMR operations. Future studies are encouraged to build upon these findings for the continued improvement and innovation in SMR operational safety and efficiency.

Biography

John Gaber is currently pursuing a B.Sc. in Health Science with a specialization in Kinesiology at York University, Toronto. His primary research emphasis lies at the intersection of neuropsychology and industrial applications. His work includes the analysis of human activities in critical settings, especially in nuclear power plants, and the utilization of EEG systems to understand human mental states and activities. Through collaborations, he has published extensively, examining risk factors in nuclear power plant operations using EEG systems and exploring EEG-based solutions for diverse applications, from drivers' health to nuclear plant operator performance. His contributions have been recognized at various international conferences, including the International Conference on Neuropsychology and the Symposium on Plasma And Nuclear Systems. Gaber continues to expand the landscape of his research.

Dr. Jing Ren is an associate professor in the Faculty of Engineering and Applied Science at Ontario Tech University. She obtained her MASc and PhD both from Western University in 2003 and 2005 respectively. She has published more than 90 journal and conference papers in the fields of deep learning, robotics, image processing and automotive technologies. She received the University Faculty Award in 2006 for her pioneer work in medical simulations using haptics.

Dr. Hossam A.Gabbar is a Professor at Ontario Tech University in the Faculty of Engineering and Applied Science. He is specializing in smart energy systems, autonomous systems, nuclear power plant operation.

Acknowledgments

Authors would like to thank members at the Smart Energy Systems Lab (SESL) at Ontario Tech University. Special thanks to Matthew Immanuel Samson and NVS for their support.

References

- Acuña, G., Giménez, M., Sánchez, M., di nardo, M., & Madsen, D. (2023). Nuclear safety management: A model of nuclear power plant operation based on system dynamics.

- Ahmed, S. (2019). The impact of emergency operating safety procedures on mitigation the nuclear thermal power plant severe accident. Annals of Nuclear Energy, 125, 222-230. [CrossRef]

- Bazanova, O.M., & Vernon, D. (2014). Interpreting EEG alpha activity. Neuroscience & Biobehavioral Reviews, 44, 94–110. [CrossRef]

- Blackett, C., Skraaning, G., Kaarstad, M., & Eitrheim, M. H. (2023). Human factors considerations for remote operation of small modular reactors.

- Burgy, D. C., Newell, W. J., & van Cott, H. P. (1982). Task Analysis of Nuclear Power Plant Control Room crews data collection approach and methodology. Proceedings of the Human Factors Society Annual Meeting, 26(7), 668–668. [CrossRef]

- Butt, H., Ilyas, M., Ahmad, M., & Aydogan, F. (2016). Assessment of passive safety system of a small modular reactor (SMR). Annals of Nuclear Energy, 98, 191-199. [CrossRef]

- Canadian Nuclear Safety Commission. (2007). New nuclear power plants in Canada: Supplementary information on design review process for new build.

- Coan, J.A., Allen, J.J., & McKnight, P.E. (2006). A capability model of individual differences in frontal EEG asymmetry. Biological Psychology, 72, 198–207. [CrossRef]

- Dedovic, K., Renwick, R., Mahani, N. K., Engert, V., Lupien, S. J., & Pruessner, J. C. (2005). The montreal imaging stress task: using functional imaging to investigate the effects of perceiving and processing psychosocial stress in the human brain. Journal of Psychiatry & Neuroscience, 30, 319–325.

- Densmore, T., & Duffy, V. (2021). Systematic literature review of nuclear safety systems in small modular reactors. [CrossRef]

- Gaikwad, A., Maheshwari, N., Chandrakar, D., Solanki, R., Bhanuprakash, & Paul, U. (2023). Ensuring safety of new, advanced small modular reactors for fundamental safety and with an optimal main heat transport systems configuration. Kerntechnik, 88. [CrossRef]

- Gofuku, A., & Niwa, Y. (2001). Extraction of mental models of operators on safety functions of nuclear power plants. IFAC Proceedings Volumes, 34(16), 475–480. [CrossRef]

- Hari, R., & Puce, A. (2023). An Overview of EEG and MEG. [CrossRef]

- Henderson, J., Wright, K., & Brazier, A. (2002). Human factors aspects of remote operation in process plants. HSE Books.

- Kandel, E. R., Koester, J., Mack, S., & Siegelbaum, S. (2021). Principles of neural science (6th ed.). New York: McGraw Hill. ISBN 978-1-259-64223-4.

- Kim, C. M., Jung, E.-S., & Yim, M.-S. (2020). Biosignal-based attention monitoring to support nuclear operator safety-relevant tasks. Frontiers in Computational Neuroscience, 14. [CrossRef]

- Klimesch, W. (1999). EEG alpha and theta oscillations reflect cognitive and memory performance: a review and analysis. Brain Research Reviews, 29, 169–195. [CrossRef]

- Kumar, N., & Kumar, J. (2016). Measurement of cognitive load in HCI systems using EEG Power Spectrum: An experimental study. Procedia Computer Science, 84, 70–78. [CrossRef]

- Lee, J. H., Lee, M. R., Kim, J. T., & Kim, J. S. (2004). Analysis of acoustic emission signals for condition monitoring of check valve at nuclear power plants. Key Engineering Materials, 270-273, 531–536. [CrossRef]

- Liu, P., Lv, X., Li, Z., Qiu, Y., Hu, J., & He, J. (2016). Conceptualizing Performance Shaping Factors in Main Control Rooms of Nuclear Power Plants: A Preliminary Study. Lecture Notes in Computer Science, 9736, 322-333. [CrossRef]

- Lutz, A., Greischar, L. L., Rawlings, N. B., Ricard, M., & Davidson, R. J. (2004). Long-term meditators self-induce high-amplitude gamma synchrony during mental practice. Proceedings of the National Academy of Sciences USA, 101, 16369–16373. [CrossRef]

- Mi, Y., Zeliang, C., Tokuhiro, A., & Lu, L. (2019). A comparative assessment of passive safety systems in integral pressurized water reactor type small modular reactor. The Proceedings of the International Conference on Nuclear Engineering (ICONE), 2019.27, 1872. [CrossRef]

- Minguillon, J., Lopez-Gordo, M. A., & Pelayo, F. (2016). Stress Assessment by Prefrontal Relative Gamma. Frontiers in Computational Neuroscience, 10, 101. [CrossRef]

- Nuclear Regulatory Commission. (n.d.). Reactor Oversight Process Task Force FAQ Log. https://www.nrc.gov/docs/ML1710/ML17100A263.pdf.

- Popov, O., Iatsyshyn, A., Valeriia, K., Andrіi, I., Neklonskyi, I., & Zakora, A. (2023). Is there a future for small modular reactors in Ukraine? Comparative analysis with large capacity reactors. [CrossRef]

- Poresky, C., Alivisatos, C., Kendrick, J., Peterson, P., Lew, R., Ulrich, T., & Boring, R. (2022). Advanced reactor control and operations (ARCO): A university research facility for developing optimized digital control rooms. Nuclear Technology, 209, 1-12. [CrossRef]

- Ren, L.-H., Feng, Y., Wang, B.-X., Li, S.-X., & Huang, W.-J. (2015). The alarm management for instrument and control system in nuclear power plant. Nuclear Engineering and Design, 35, 827-832.

- Santoso, S., Suryono, T., Maerani, R., Sudarno, S., Pambudi, Y., & Dwiardika, D. (2022). Preliminary design of human-machine interface for control room of modular reactor. AIP Conference Proceedings, 2501, 040011. [CrossRef]

- Sepanloo, K., & Jafarian, R. (2004). Analysis of cognitive activities of Bushehr Nuclear Power Plant Control Room operators in case of abnormal conditions. Probabilistic Safety Assessment and Management, 266–271. [CrossRef]

- Shaffer, F., & Ginsberg, J. P. (2017). An Overview of Heart Rate Variability Metrics and Norms. Frontiers in Public Health, 5, 258. [CrossRef]

- Simonsen, E., & Osvalder, A.-L. (2015). Aspects of the nuclear power plant control room system contributing to safe operation. Procedia Manufacturing, 3. [CrossRef]

- Sompura, J., Patil, P., Gamit, S., Srinivasan, B., & Srinivasan, R. (2017). Lessons Learnt from Alarm Management in a Combined-Cycle Gas Turbine Power Plant. [CrossRef]

- Strmiska, M., & Koudelkova, Z. (2018). Analysis of Performance Metrics using Emotiv EPOC+. MATEC Web of Conferences, 210, 04046. [CrossRef]

- Tison, G. H., et al. (2020). Passive Detection of Atrial Fibrillation Using a Commercially Available Smartwatch. Journal of the American Medical Association (JAMA), 321(19), 1901–1902.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).