Submitted:

13 November 2023

Posted:

14 November 2023

You are already at the latest version

Abstract

Keywords:

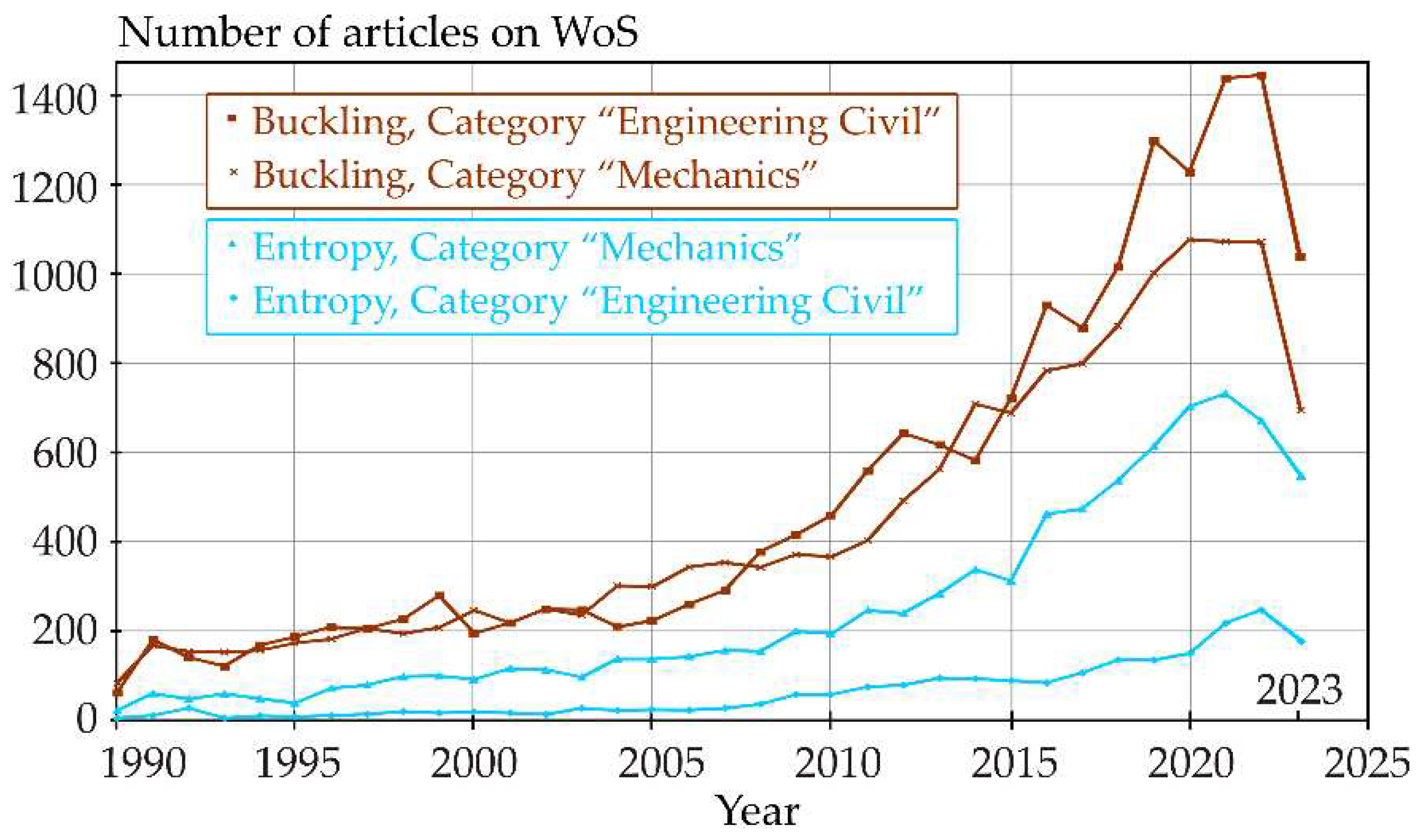

1. Introduction

2. State of the Art

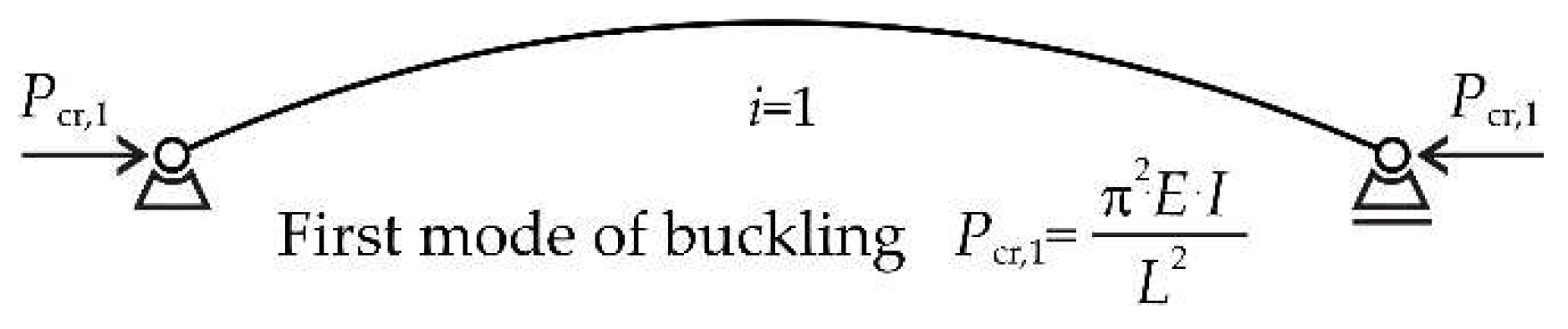

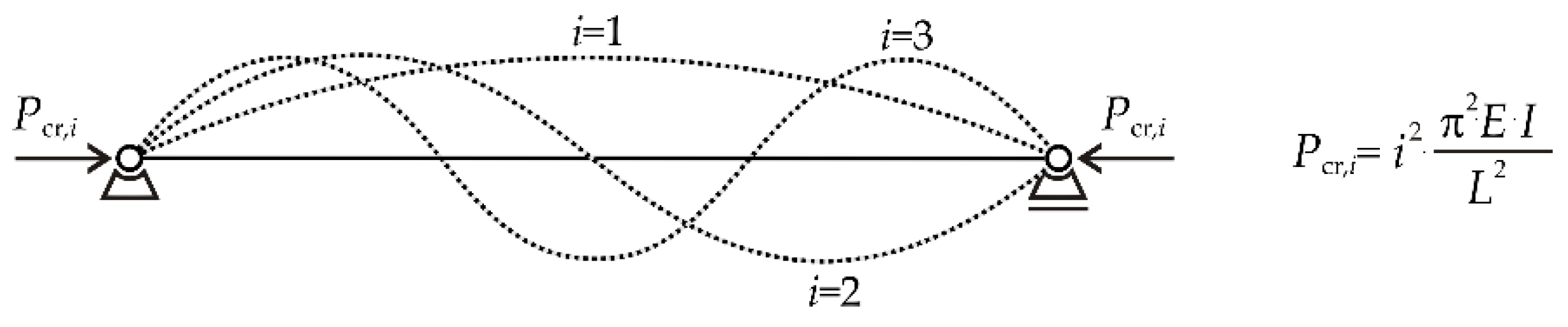

3. Buckling of a Pin-ended Strut

3.1. Strain Energy

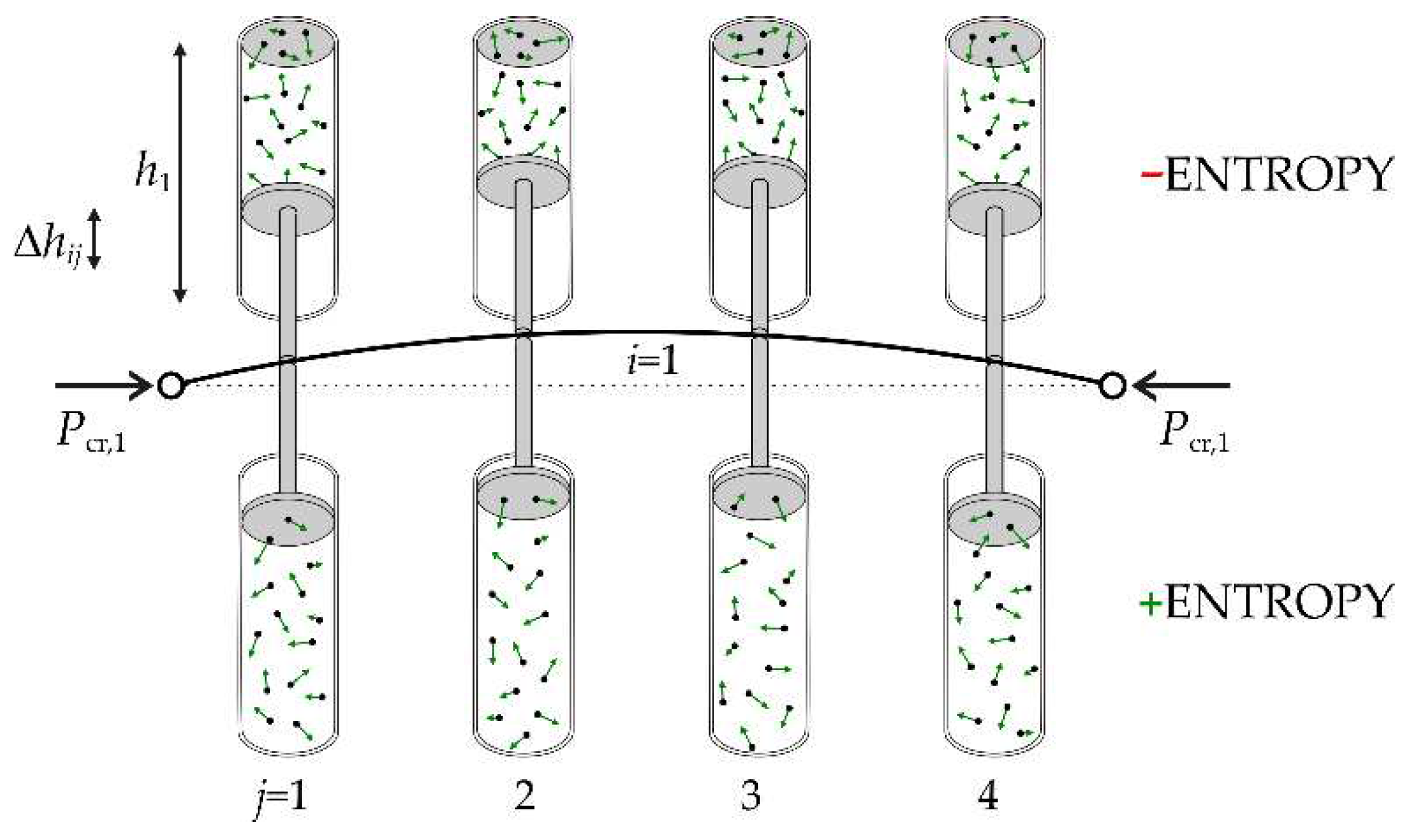

3.2. Why Entropy?

3.3. Entropy in the Surrogate model

3.4. Entropy and Virtual temperature

3.5. The Case study

4. Buckling of Cantilever

5. Buckling of Steel Plane Frames

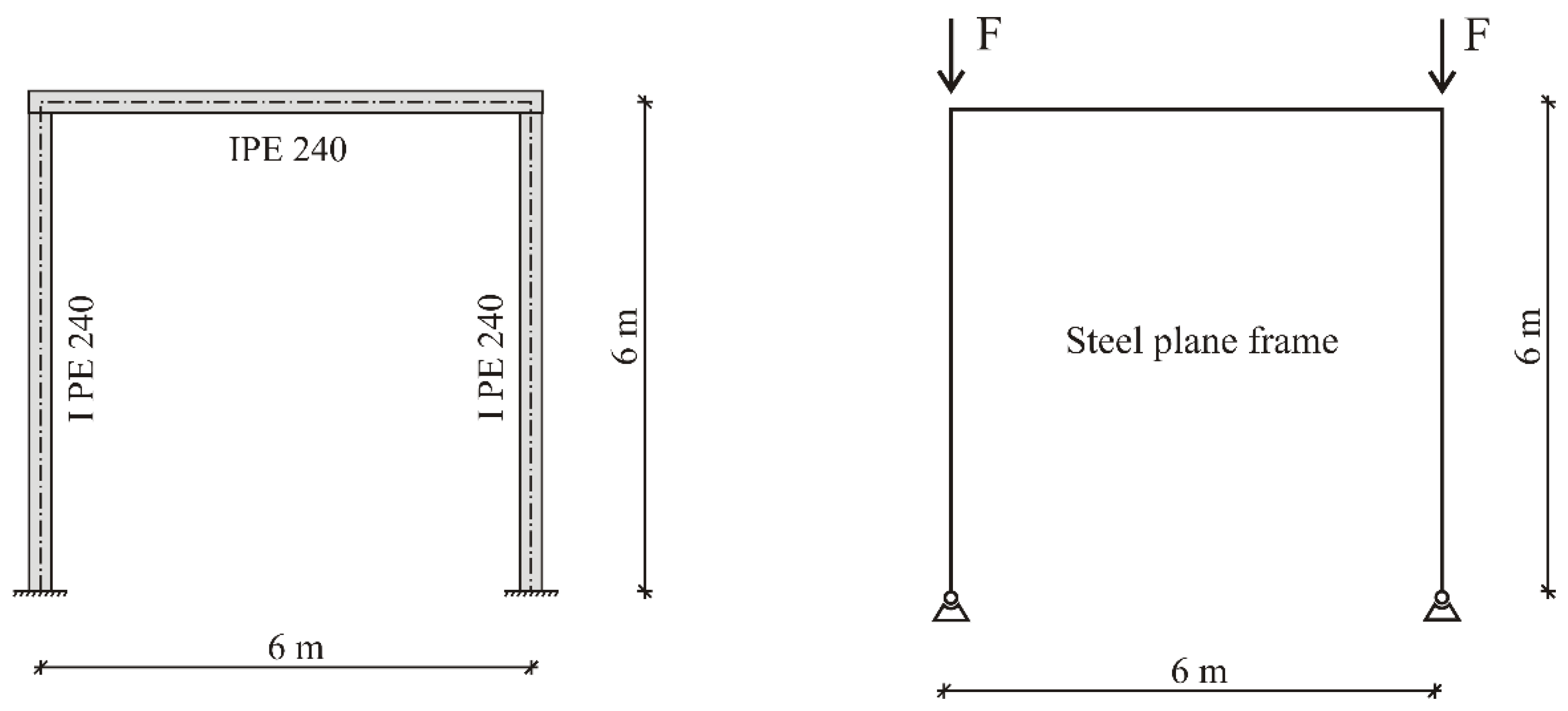

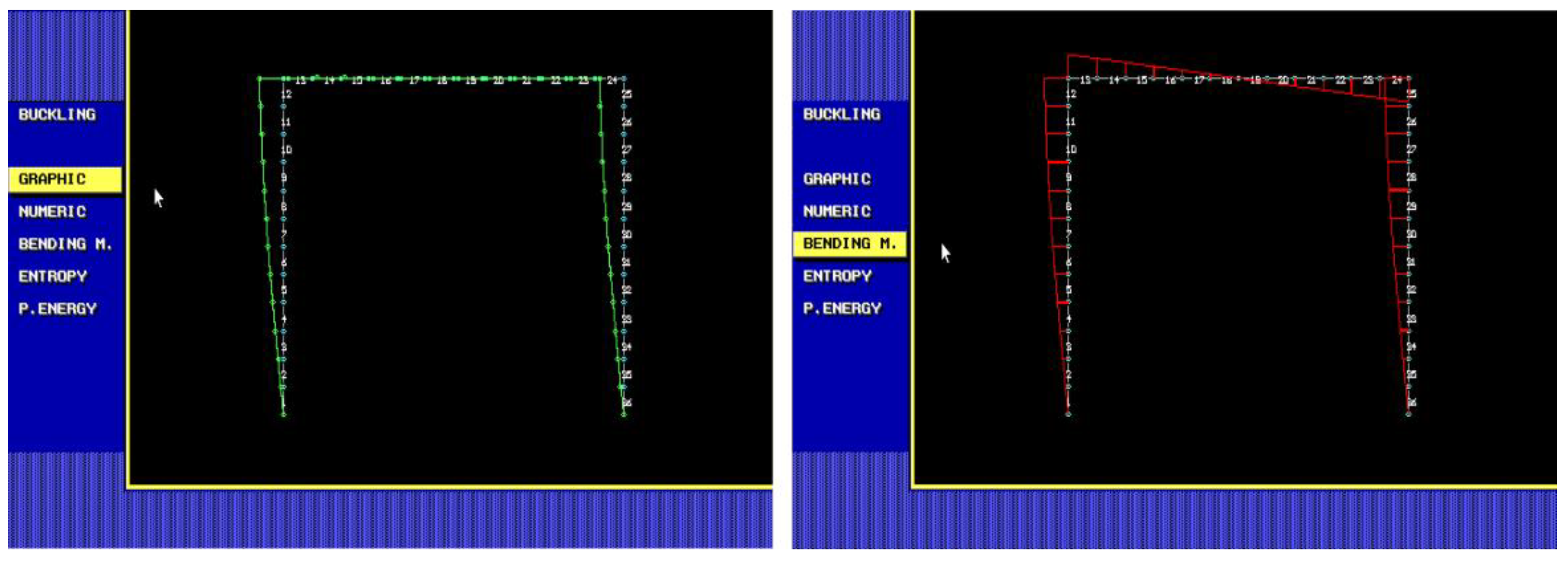

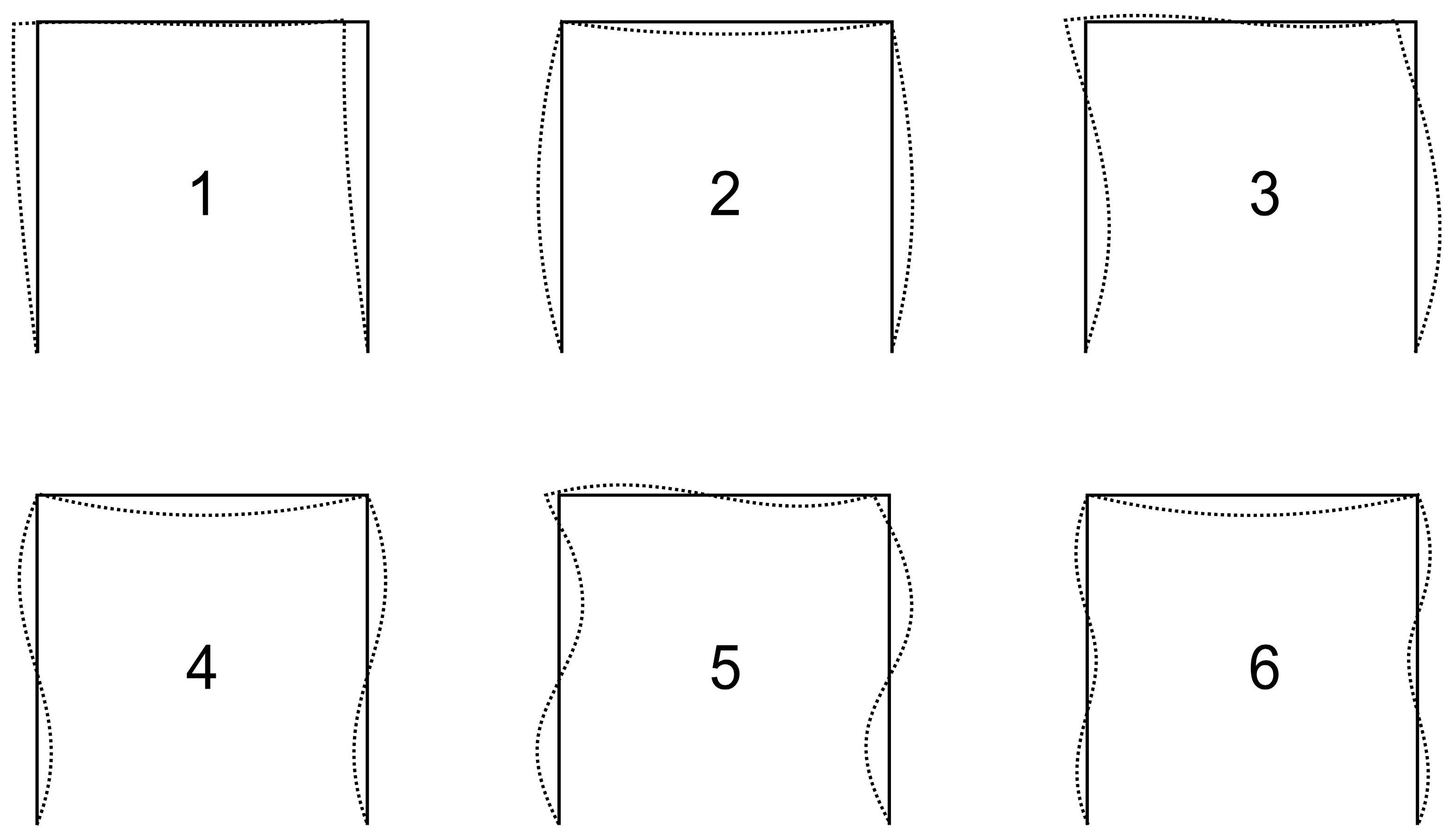

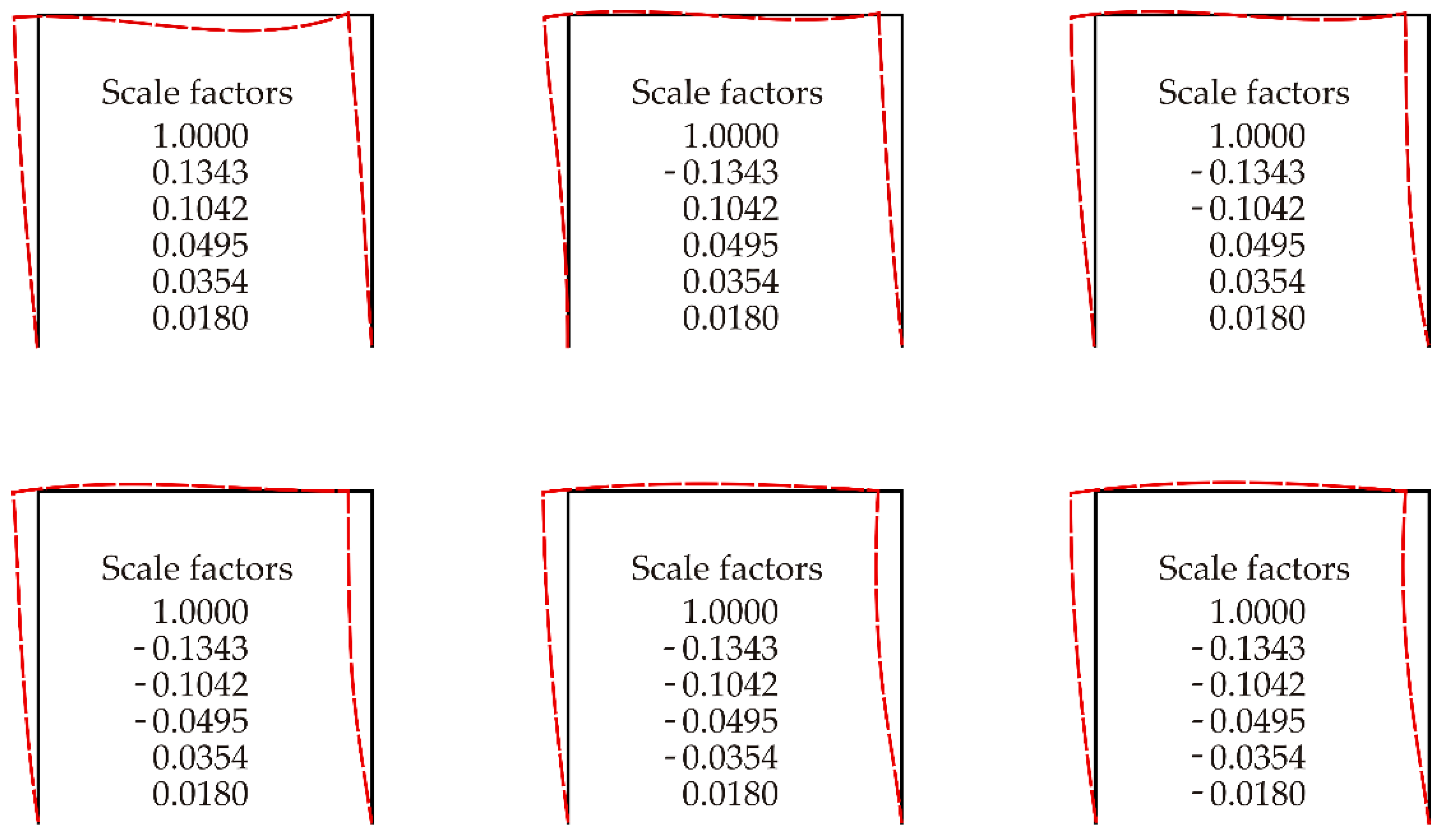

5.1. Steel Plane Frame: Case Study

6. Initial Geometrical Imperfections

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bažant, Z.P.; Cedolin, L. Stability of Structures: Elastic, Inelastic, Fracture and Damage Theories; Oxford University Press: New York, 1991. [Google Scholar]

- Galambos, T.V. Guide to Stability Design Criteria for Metal Structures, 5th ed.; Wiley: Hoboken, NJ, USA, 1998; 911p. [Google Scholar]

- Godoy, L.A. Historical sense in the historians of the theory of elasticity. Meccanica 2006, 41, 529–538. [Google Scholar] [CrossRef]

- Van Den Broek, J.A. Euler's classic paper “On the strength of columns”. Journal of Physics 1947, 12, 309–318. [Google Scholar] [CrossRef]

- Euler, L. Methodus Inveniendi Lineas Curvas Maximi Minimive Proprietate Gaudentes, Sive Solutio Problematis Isoperimetrici Lattissimo Sensu Accepti; Marcum Michaelem Bosquet: Lausanne, 1744. [Google Scholar]

- Von Mises, R.; Ratzersdorfer, J. Die Knicksicherheit von Rahmentragwerken. Zeitschrift für Angewandte Mathematik und Mechanik (ZAMM) 1926, 6, 181–199. [Google Scholar] [CrossRef]

- Chwalla, E. Die Stabilität zentrisch und exzentrisch gedrückter Stäbe aus Baustahl. Sitzungsberichte der Akademie der Wissenschaften mathematisch-naturwissenschaftliche Klasse 1928, 137, 469–512. [Google Scholar]

- Belytschko, T.; Liu, W.K.; Moran, B.; Elkhodary, K. Nonlinear Finite Elements for Continua and Structures. John Wiley & Sons, 2014. [Google Scholar]

- Chan, S.L.; Huang, H.Y.; Fang, L.X. Advanced analysis of imperfect portal frames with semirigid base connections. Journal of Engineering Mechanics 2005, 131, 633–640. [Google Scholar] [CrossRef]

- Mageirou, G.E.; Lemonis, M.E. Influence of imperfections on the progressive collapse of steel moment resisting frames. Journal of Constructional Steel Research 2021, 183, 106744. [Google Scholar] [CrossRef]

- Kala, Z.; Valeš, J. Sensitivity assessment and lateral-torsional buckling design of I-beams using solid finite elements. Journal of Constructional Steel Research 2017, 139, 110–122. [Google Scholar] [CrossRef]

- Zhang, H.; Shayan, S.; Rasmussen, K.J.R.; Ellingwood, B.R. System-based design of planar steel frames, I: Reliability framework. Journal of Constructional Steel Research 2016, 123, 135–143. [Google Scholar] [CrossRef]

- Kala, Z.; Valeš, J.; Jönsson, J. Random fields of initial out of straightness leading to column buckling. Journal of Civil Engineering and Management 2017, 23, 902–913. [Google Scholar] [CrossRef]

- Jindra, D.; Kala, Z.; Kala, J. Buckling curves of stainless steel CHS members: Current state and proposed provisions. Journal of Constructional Steel Research 2022, 198, 107521. [Google Scholar] [CrossRef]

- Jindra, D.; Kala, Z.; Kala, J. Flexural buckling of stainless steel CHS columns: Reliability analysis utilizing FEM simulations. Journal of Constructional Steel Research 2022, 188, 107002. [Google Scholar] [CrossRef]

- Gu, J.X.; Chan, S.L. Second-order analysis and design of steel structures allowing for member and frame imperfections. International Journal for Numerical Methods in Engineering 2005, 62, 601–615. [Google Scholar] [CrossRef]

- Kala, Z. Global sensitivity analysis in stability problems of steel frame structures. Journal of Civil Engineering and Management 2016, 22, 417–424. [Google Scholar] [CrossRef]

- Bažant, Z.; Xiang, Y. Postcritical imperfection-sensitive buckling and optimal bracing of large regular frames. Journal of Structural Engineering 1997, 123, 513–522. [Google Scholar] [CrossRef]

- Kala, Z. Geometrically non-linear finite element reliability analysis of steel plane frames with initial imperfections. Journal of Civil Engineering and Management 2012, 18, 81–90. [Google Scholar] [CrossRef]

- Ben–Naim, A. A Farewell to Entropy: Statistical Thermodynamics Based on Information; World Scientific: Singapore, 2008. [Google Scholar]

- Charlton, T.M. Energy Principles in Theory of Structures; Oxford University Press, 1973. [Google Scholar]

- Arthurs, A.M.; Jones, M.E. On variational principles for linear initial value problems. Journal of Mathematical Analysis and Applications 1976, 54, 840–845. [Google Scholar] [CrossRef]

- Van Groesen, E.W.C. Variational Methods in Mathematical Physics; Technische Hogeschool Eindhoven, 1978; p. 216. [Google Scholar] [CrossRef]

- Washizu, K. Variational Methods in Elasticity and Plasticity; Pergamon Press: Oxford, UK, 1982; p. 630. [Google Scholar]

- Auchmuty, G. Duality for non-convex variational principles. Journal of Differential Equations 1983, 50, 80–145. [Google Scholar] [CrossRef]

- Berdichevsky, V.L. Variational Principles of Continuum Mechanics; Springer: Berlin/Heidelberg, Germany, 2009; p. 1011. [Google Scholar]

- Fanaie, N.; Shirpour, A. Analytical and numerical evaluation of quarter-elliptic-braced steel moment frames (QEB-MFs). Structures 2023, 49, 426–442. [Google Scholar] [CrossRef]

- Zheng, A.; Shi, H.-R.; Gong, Z.; Wang, C.-L.; Meng, S. Experimental study on bamboo-shaped buckling-retrained energy dissipater with different grades of steel. Journal of Constructional Steel Research 2023, 211, 108164. [Google Scholar] [CrossRef]

- Ou, T.; Mei, C.; Mao, J.; Wang, D. Seismic analysis and connection optimization of the side column on modular prefabricated four-sided connected composite shear wall. The Structural Design of Tall and Special Buildings 2022, 32, 426–442. [Google Scholar] [CrossRef]

- Gorgogianni, A.; Eliáš, J.; Le, J.-L. Mesh objective stochastic simulations of quasibrittle fracture. Journal of the Mechanics and Physics of Solids 2022, 159, 104745. [Google Scholar] [CrossRef]

- Zheng, X.; Shen, Y.; Zong, X.; Su, H.; Zhao, X. Vulnerability analysis of main aftershock sequence of aqueduct based on incremental dynamic analysis method. Buildings 2023, 13, 1490. [Google Scholar] [CrossRef]

- Yang, J.; Wang, W.; Xu, L.; Shi, Y. Global buckling analysis on cold-formed steel built-up box-shape columns at ambient and elevated temperatures. Structures 2023, 57, 105301. [Google Scholar] [CrossRef]

- Hamed, A.A.; Samadi, A.; Charkhtab Basim, M. Topology and shape optimization of steel plate shear walls for enhancing the seismic energy dissipation capacity. Journal of Building Engineering 2022, 57, 104828. [Google Scholar] [CrossRef]

- Zheng, Z.-Q.; Liu, H.-Z.; Zhuo, L.; Xiao, M.-L.; Xie, H.-Q.; He, J.-D.; Peng, M.-L. Experimental study on the dilatancy and energy evolution behaviors of red-bed rocks under unloading conditions. Materials 2023, 16, 5759. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Pan, Y.; He, K.; Wang, F.; Gao, L.; Pu, S.; Li, E. Dynamic Mechanical Properties and Damage Evolution Characteristics of Beishan Deep Granite under Medium and High Strain Rates. Materials 2023, 16, 5235. [Google Scholar] [CrossRef]

- Fujii, K. Peak and Cumulative Response of Reinforced Concrete Frames with Steel Damper Columns under Seismic Sequences. Buildings 2022, 12, 275. [Google Scholar] [CrossRef]

- Pandit, U.K.; Mondal, G.; Punera, D. Lateral torsional buckling analysis of corrugated steel web girders using homogenization approach. Journal of Constructional Steel Research 2023, 210, 108099. [Google Scholar] [CrossRef]

- Rezaiee-Pajand, M.; Masoodi, A.R.; Alepaighambar, A. Critical buckling moment of functionally graded tapered mono-symmetric I-beam. Steel and Composite Structures 2021, 39, 599–614. [Google Scholar] [CrossRef]

- Stupishin, L.; Mondrus, V. Implementation of the weak link problem for trusses. Buildings 2023, 13, 1230. [Google Scholar] [CrossRef]

- Dehwah, O.H.A.; Al-Gahtani, H.J. Energy-based solution for the plastic buckling of stainless steel circular cylindrical shells. Structures 2023, 48, 2024–2036. [Google Scholar] [CrossRef]

- Jafari, M.M.; Jahandari, S.; Ozbakkaloglu, T.; Rasekh, H.; Jahed Armaghani, D.; Rahmani, A. Mechanical properties of polyamide fiber-reinforced lime–cement concrete. Sustainability 2023, 15, 11484. [Google Scholar] [CrossRef]

- Fujii, K.; Mogi, Y.; Noguchi, T. Predicting maximum and cumulative response of a base-isolated building using pushover analysis. Buildings 2020, 10, 91. [Google Scholar] [CrossRef]

- Muc, A. Buckling of composite structures with delaminations—laminates and functionally graded materials. Appl. Sci. 2022, 12, 11408. [Google Scholar] [CrossRef]

- Shima, H. Buckling of carbon nanotubes: A state of the art review. Materials 2012, 5, 47–84. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Yao, X.; Sun, Z. Wang, D. Study seismic performance of duplex stainless steel under large strain amplitude by cyclic loading test. Journal of Constructional Steel Research 2022, 194, 107332. [Google Scholar] [CrossRef]

- Liu, C.; Sun, Z. Calculation theory of shear stress distribution in box girder with corrugated steel webs based on the energy method. Buildings 2023, 13, 2547. [Google Scholar] [CrossRef]

- Khaleel Ibrahim, S.; Movahedi Rad, M. Optimal elasto-plastic analysis of prestressed concrete beams by applying residual plastic deformation limitations. Sustainability 2023, 15, 5742. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, Q.; Zheng, J.; Li, Z. Analytical model for the nonlinear buckling responses of the confined polyhedral FGP-GPLs lining subjected to crown point loading. Engineering Structures 2023, 282, 115780. [Google Scholar] [CrossRef]

- Hai, L.; Ban, H.; Yang, X.; Huang, C.; Shi, Y. Cyclic behavior of hot-rolled titanium-clad bimetallic steel under large plastic strain reversals. Journal of Constructional Steel Research 2023, 210, 108112. [Google Scholar] [CrossRef]

- Stupishin, L.; Mondrus, V. Critical Energy Properties Study for Unsymmetrical Deformable Structures. Buildings 2022, 12, 779. [Google Scholar] [CrossRef]

- Kala, Z.; Kalina, M. Static equilibrium states of von Mises trusses. International Journal of Mechanics 2016, 10, s. 294–298. [Google Scholar]

- Chen, L.-M.; Li, Z.-B.; Zhang, H.; Liu, Y.-J.; Zeng, Y.-H.; Zhou, Y.-Y.; Dong, S.-L. Design optimisation of a cable–strut tensile structure according to the importance of elements. Buildings 2022, 12, 1528. [Google Scholar] [CrossRef]

- Simão, P.D.; Rodrigues, J.P.C.; Fernandes, H.D. A voxels-based Rayleigh-Ritz method for the post-buckling elasto-plastic analysis of restrained steel columns in fire. Journal of Constructional Steel Research 2023, 210, 107736. [Google Scholar] [CrossRef]

- Abdelrahman, A.H.A.; Lotfy, S.; Liu, S.-W. Generalized line-element formulations for geometrically nonlinear analysis of nonsymmetric tapered steel members with warping and Wagner effects. Engineering Structures 2022, 273, 115052. [Google Scholar] [CrossRef]

- Kerdsuk, P.; Pulngern, T.; Tangbanjongkij, C.; Chucheepsakul, S.; Jiammeepreecha, W. Elastic buckling of oblate hemi-ellipsoidal shells subjected to hydrostatic pressure. International Journal of Structural Stability and Dynamics, 2023, 2023, 2450028. [Google Scholar] [CrossRef]

- Elsayed, M.; A. Mutalib, A.; Elsayed, K. Numerical study of structural performance and wind flow dynamic behavior for PPVC steel modular construction (MSC) under various extreme wind loads. Buildings 2022, 12, 1347. [Google Scholar] [CrossRef]

- Hajdú, G.; Pasternak, H.; Papp, F. Lateral-torsional buckling assessment of I-beams with sinusoidally corrugated web. Journal of Constructional Steel Research 2023, 207, 107916. [Google Scholar] [CrossRef]

- Li, C.; Liu, N.; Liu, W.; Feng, R. Study on characteristics of energy storage and acoustic emission of rock under different moisture content. Sustainability 2021, 13, 1041. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, Y.; Yang, X.; Sun, L.; Wang, P. Study on the bending performance of high-strength and high-ductility CRE-reinforced concrete beams. Buildings 2023, 13, 2746. [Google Scholar] [CrossRef]

- Godoy, L.A.; Ameijeiras, M.P. Plastic buckling of oil storage tanks under blast loads. Structures 2023, 53, 361–372. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, Y. A new method for establishing the total potential energy equations of steel members based on the principle of virtual work. Structures 2023, 52, 904–920. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, L.; Pang, F.; Li, P.; Liu, F. Characteristics of energy dissipation in T-Shaped fractured rocks under different loading rates. Sustainability 2023, 15, 13695. [Google Scholar] [CrossRef]

- Sun, G.; Lai, J.; Zheng, Y.; Zheng, K.; Shi, J. Investigation of the performance of RC beams reinforced with FRP and ECC materials. Journal of Civil Engineering and Management 2022, 28, 523–535. [Google Scholar] [CrossRef]

- Clausius, R. Ueber verschiedene für die Anwendung bequeme Formen der Hauptgleichungen der mechanischen Wärmetheorie. Annalen der Physik 1865, 201, 353–400. (In German) [Google Scholar] [CrossRef]

- Wang, X.; Qian, L.; Hong, M.; Zhang, J. Evolution and abrupt change for water use structure through matrix-based Renyi's alpha order entropy functional. Stochastic Environmental Research and Risk Assessment 2022, 36, 1413–1428. [Google Scholar] [CrossRef]

- Jessop, A. Some reflections on maxEnt. Civil Engineering and Environmental Systems 2023, 40, 60–71. [Google Scholar] [CrossRef]

- Chen, C.; Yang, Y.; Hou, H.; Peng, C.; Xu, W. Real-time hybrid simulation with multi-fidelity Co-Kriging for global response prediction under structural uncertainties. Earthquake Engineering and Structural Dynamics 2022, 51, 2591–2609. [Google Scholar] [CrossRef]

- Gao, C.; Elzarka, H.; Yan, H.; Chakraborty, D.; Zhou, C. A hybrid TOPSIS-structure entropy weight group subcontractor selection model for large construction companies. Buildings 2023, 13, 1535. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Q.; Leng, S.; Cui, H.; Xu, B. Effect of dry-wet cycles on mechanical properties of polyurethane porous mixture. International Journal of Pavement Engineering 2023, 24, 2212315. [Google Scholar] [CrossRef]

- Qiu, D.; Chen, J.; Fu, H. Research on the comprehensive evaluating index of seismic performance of underground large-scale frame structures. Structures 2022, 37, 645–660. [Google Scholar] [CrossRef]

- Pedretti, D.; Bianchi, M. GEOENT: A toolbox for calculating directional geological entropy. Geosciences 2022, 12, 206. [Google Scholar] [CrossRef]

- Keerthana, M.; Harikrishna, P. Signal complexity approach based investigation of flutter instability in sectional models of bridges in wind tunnel. Advances in Structural Engineering 2023, 26, 2520–2542. [Google Scholar] [CrossRef]

- Wang, Y.; Qu, Z. TMD Design by an Entropy Index for Seismic Control of Tall Shear-Bending Buildings. Entropy 2023, 25, 1110. [Google Scholar] [CrossRef] [PubMed]

- Abi, E.; Yuan, H.; Cong, Y.; Wang, Z.; Jiang, M. Experimental study on the entropy change failure precursors of marble under different stress paths. KSCE Journal of Civil Engineering 2023, 27, 356–370. [Google Scholar] [CrossRef]

- Luo, D.; Dong, H.; Niu, D. Geographic division of exposure environment for concrete structure based on fuzzy clustering-rough set information entropy. Structural Concrete 2023, 24, 485–503. [Google Scholar] [CrossRef]

- Wang, C.; Zou, F.; Yap, J.B.H.; Wood, L.C.; Li, H.; Ding, L. System dynamics tool for entropy-based risk control on sleeve grouting in prefabricated buildings. Engineering, Construction and Architectural Management 2023, 30, 538–567. [Google Scholar] [CrossRef]

- Su, L.; Wang, T.; Li, H.; Chao, Y.; Wang, L. Multi-criteria decision making for identification of unbalanced bidding. Journal of Civil Engineering and Management 2020, 26, 43–52. [Google Scholar] [CrossRef]

- Xie, W.; Gao, D.; Lee, E.W. Detecting undeclared-leader-follower structure in pedestrian evacuation using transfer entropy. IEEE Transactions on Intelligent Transportation Systems 2022, 23, 17644–17653. [Google Scholar] [CrossRef]

- Yang, N.; Jia, Y.T.; Bai, F.; Qin, S.J. Reliability estimation of a Tibetan heritage timber structure with inclination in its Que-Ti joints. Structures 2022, 43, 257–270. [Google Scholar] [CrossRef]

- Luo, Z.; Guo, J.; Han, J.; Wang, Y. Reliability estimation of a Tibetan heritage timber structure with inclination in its Que-Ti joints. Engineering, Construction and Architectural Management 2022. [Google Scholar]

- Kamiński, M.; Strąkowski, M. An application of relative entropy in structural safety analysis of elastoplastic beam under fire conditions. Energies 2023, 16, 207. [Google Scholar] [CrossRef]

- Wang, T.; Li, Z.; Fan, W.; Ang, A.H.-S. Structural system reliability assessment using generalized factorized dimensional reduction method and iterative maximum entropy method. Structure and Infrastructure Engineering 2022. [Google Scholar] [CrossRef]

- Civera, M.; Surace, C. Instantaneous spectral entropy: An application for the online monitoring of multi-storey frame structures. Buildings 2022, 12, 310. [Google Scholar] [CrossRef]

- Qu, S.; Fang, Y.; Liang, J.; Zheng, J.-H.; Zheng, K. A Physical mechanism-based model of CoCrFeMnNi high entropy alloy considering adiabatic heat effect for hot bulk forming processes. Metals 2022, 12, 1011. [Google Scholar] [CrossRef]

- Shi, J.; Gong, H.; Yang, F.; Liang, H.; Cong, L. Image processing of aggregate skeleton structure of asphalt mixture for aggregate uniformity quantification. Journal of Materials in Civil Engineering 2023, 35, 04022388. [Google Scholar] [CrossRef]

- Krylovas, A.; Kosareva, N.; Zavadskas, E.K. WEBIRA-Comparative analysis of weight balancing method. International Journal of Computers, Communications and Control 2017, 12, 238–253. [Google Scholar] [CrossRef]

- Kala, Z. New importance measures based on failure probability in global sensitivity analysis of reliability. Mathematics 2021, 9, 2425. [Google Scholar] [CrossRef]

- Kala, Z. Modelling initial geometric imperfections of steel plane frames using entropy and eigenmodes. International Journal of Mechanics 2023, 17, 64–73. [Google Scholar] [CrossRef]

- Callen, H.B. Thermodynamics and an Introduction to Thermostatistics; John Wiley & Sons, 1985. [Google Scholar]

- Yang, B. Stress, Strain, and Structural Dynamics; Elsevier Inc., 2005. [Google Scholar]

- European Committee for Standardization (CEN). EN 1993-1-9. Eurocode3: Design of Steel Structures, Part 1–1: General Rules and Rules for Buildings; European Standards: Brussels, Belgium, 2005. [Google Scholar]

- Feistel, R.; Ebeling, W. Entropy and the self-organization of information and value. Entropy 2016, 18, 193. [Google Scholar] [CrossRef]

- Verlinde, E. On the origin of gravity and the laws of Newton. Journal of High Energy Physics 2011, 2011, 29. [Google Scholar] [CrossRef]

- Klotz, I.M.; Rosenberg, R.M. Chemical Thermodynamics: Basic Concepts and Methods; John Wiley & Sons, 2008. [Google Scholar]

- Atkins, P.W. Physical Chemistry; Freeman: New York, 1998. [Google Scholar]

- Liu, W.; Rasmussen, K.J.R.; Zhang, H.; Xie, Y.; Liu, Q. , Dai, L. Probabilistic study and numerical modelling of initial geometric imperfections for 3D steel frames in advanced structural analysis. Structures 2023, 57, 105190. [Google Scholar] [CrossRef]

- Sfintesco, D. Fondement expérimental des courbes européennes de flambement. Construction Métallique 1970, 3, 5–12. [Google Scholar]

- Fukumoto, Y.; Itoh, Y. Evaluation of multiple column curves using the experimental data-base approach. Journal of Constructional Steel Research 1983, 3, 2–19. [Google Scholar] [CrossRef]

- Gu, J.X.; Chan, S.L. Second-order analysis and design of steel structures allowing for member and frame imperfections. International Journal for Numerical Methods in Engineering 2005, 62, 601–615. [Google Scholar] [CrossRef]

- Kim, S.-E.; Lee, D.-H. Second-order distributed plasticity analysis of space steel frames. Engineering Structures 2002, 24, 735–744. [Google Scholar] [CrossRef]

- Alvarenga, A.R.; Silveira, R.A.M. Second-order plastic-zone analysis of steel frames - Part II: Effects of initial geometric imperfection and residual stress. Latin American Journal of Solids and Structures 2009, 6, 323–342. [Google Scholar]

- Shayan, S.; Rasmussen, K.J.R.; Zhang, H. On the modelling of initial geometric imperfections of steel frames in advanced analysis. Journal of Constructional Steel Research 2014, 98, 167–177. [Google Scholar] [CrossRef]

- Zeinoddini, V.M.; Schafer, B.W. Simulation of geometric imperfections in cold-formed steel members using spectral representation approach. Thin-Walled Structures 2012, 60, 105–117. [Google Scholar] [CrossRef]

- Sadovský, Z.; Kriváček, J.; Ivančo, V.; Ďuricová, A. Computational modelling of geometric imperfections and buckling strength of cold-formed steel. Journal of Constructional Steel Research 2012, 78, 1–7. [Google Scholar] [CrossRef]

- Sadovský, Z.; Kriváček, J. Influential geometric imperfections in buckling of axially compressed cylindrical shells – A novel approach. Engineering Structures 2020, 223, 111170. [Google Scholar] [CrossRef]

- Kala, Z. Sensitivity analysis of steel plane frames with initial imperfections. Engineering Structures 2011, 33, 2342–2349. [Google Scholar] [CrossRef]

| Buckling mode index | Critical force Frc,i [kN] |

ci | Strain energy ΔΠi [MJ] |

Virtual temperature Ti [K] |

Entropy ΔSi[J·K-1] |

|---|---|---|---|---|---|

| 1 | 651.7 | 1 | 0.536 | 842.0 | 636.62 |

| 2 | 2606.9 | 1 | 8.576 | 13472.7 | 636.62 |

| 3 | 5865.5 | 1 | 43.418 | 68200.3 | 636.62 |

| 4 | 10427.6 | 1 | 137.221 | 215546.7 | 636.62 |

| 5 | 16293.1 | 1 | 335.013 | 526237.0 | 636.62 |

| 6 | 23462.0 | 1 | 694.683 | 1091205.0 | 636.62 |

| Buckling mode index | Critical force Frc,i [kN] |

ci | Strain energy ΔΠi [MJ] |

Virtual temperature Ti [K] |

Entropy ΔSi[J·K-1] |

|---|---|---|---|---|---|

| 1 | 651.7 | 1 | 0.536 | 1.0000 | 636.62 |

| 2 | 2606.9 | 0.25 | 0.536 | 15.3229 | 159.15 |

| 3 | 5865.5 | 0.111 | 0.536 | 25.0961 | 70.74 |

| 4 | 10427.6 | 0.063 | 0.536 | 58.2375 | 39.79 |

| 5 | 16293.1 | 0.04 | 0.536 | 72.6713 | 25.46 |

| 6 | 23462.0 | 0.028 | 0.536 | 130.7333 | 17.68 |

| Buckling mode index | Critical force Frc,i [kN] |

Strain energy ΔΠi [J] (from normalized eigenmodes) | Scale factor κi (~ entropy) | Approximation of strain energy ≈ i4 ΔΠ1 [J] |

|---|---|---|---|---|

| 1 | 412.5 | 1.1056 | 1.0000 | 1.1056 |

| 2 | 2925.8 | 61.3416 | 1.0000 | 17.6905 |

| 3 | 3830.9 | 101.8158 | 1.0000 | 89.5581 |

| 4 | 9784.0 | 451.7487 | 1.0000 | 283.0477 |

| 5 | 11085.0 | 880.4734 | 1.0000 | 691.0345 |

| 6 | 21023.4 | 1406.9822 | 1.0000 | 1432.9292 |

| Buckling mode index | Critical force Frc,i [kN] |

Given strain energy ΔΠi [J] (by scaled eigenmodes) |

Scale factor κi (for ΔΠi = ΔΠ1) |

Entropy ~ κi |

|---|---|---|---|---|

| 1 | 412.5 | 1.1056 | 1.0000 | 1.0000 |

| 2 | 2925.8 | 1.1056 | 0.1343 | 0.1343 |

| 3 | 3830.9 | 1.1056 | 0.1042 | 0.1042 |

| 4 | 9784.0 | 1.1056 | 0.0495 | 0.0495 |

| 5 | 11085.0 | 1.1056 | 0.0354 | 0.0354 |

| 6 | 21023.4 | 1.1056 | 0.0180 | 0.0180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).