1. Introduction

Agricultural residues, commonly known as agro-wastes, are the byproducts (i. e., crop remnants, fruits, roots, husks, residual stalks, and various types of vegetables, etc.) resulting from a wide range of agricultural procedures and activities. Their primary composition consists of carbohydrate polymers such as starch, lignocellulose, cellulose, and hemicellulose, as well as proteins, lipids, fibers, and other organic constituents. The substantial organic content in these residues, when not disposed of properly, can have adverse environmental implications. However, they also offer versatile utility, including their potential as a feedstock for clean energy production [

1,

2,

3,

4]. In this perspective the use of residuals from coffee chain production, which is one of the most popular beverages in the world, is of utmost importance due to the large quantity produced [

5]. Brazil is the world’s largest coffee producer, followed by Vietnam, Colombia, and Indonesia. In 2020, Brazil produced more than 60 million bags of processed coffee, that is, it is responsible for 35% of world production [

6].

The Brazilian coffee production cover an extensive area accommodating both Arabic and Conilon coffee species. In Brazil, Arabic coffee thrives in cooler regions, typically at altitudes above 500 meters, where the annual average temperature falls between 18°C and 22°C. In contrast, Conilon coffee is more suitable for areas where the average temperature ranges from 22°C to 26°C [

13] . In brazilian plantations, coffee cherries are typically dried to remove the exocarp, mesocarp, and endocarp, generating approximately 1 kg of husk for every 1 kg of coffee bean produced [

7,

8,

9,

10]. This residual is commonly employed as an organic fertilizer, distributing it across their plantation soils. Nonetheless, despite its favorable chemical composition, particularly in terms of nitrogen (N) and potassium (K) content when compared to other organic fertilizers, the husk poses challenges due to its bulkiness [

9,

11,

12]. This makes storage, handling, and soil integration problematic, resulting in only a portion of the husks being utilized as fertilizer. Additionally, its unwieldy texture renders coffee husks unsuitable as a caffeine source for pharmaceutical and beverage companies, but hold a great potential for applications in anaerobic digestion (AD) [

7,

9].

AD mineralizes organic compounds to methane (CH

4) and carbon dioxide (CO

2), and stands as the most ancient technology for harnessing energy from the biological breakdown of organics [

14]. At present, the primary role of AD biodigesters is to capture CH

4 emissions arising from the decomposition of organic matter, such as that from agricultural activities. In doing so, mitigating the release of greenhouse gases into the environment[

15]. AD process involves four key stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Among these, hydrolysis is the limiting factor due to the rigid cell walls in vegetal organics, resulting in extended digestion times and reduced biogas production [

15]. Many studies on lignocellulosic biomass-fed AD operate at 35-55°C, where reactions generally proceed more efficiently [

16]. Yet, maintaining these temperature ranges involves considerable energy costs, reducing the viability of anaerobic digestion for cost-effective smallholder digesters, which are generally operated at ambient temperatures (10°C-25°C) and influenced by the seasonal variations [

17,

18,

41,

42] . Psychrophilic AD has the potential to replace mesophilic or thermophilic AD, providing a promising solution for year-round sustainable biogas production. Applying not just to tropical and sub-tropical regions with temperatures up to 25°C but also to temperate regions where temperatures can drop as low as 10°C [

17,

18,

41,

42].

Research on psychrophilic AD is limited, and there is a noteworthy need for increased focus on strategies to accelerate the rate-limiting steps at this operational condition [

17,

18]. This could include the study of waste pretreatment, specifically the ones developed to enhance the digestion of lignocellulosic substrates. Thus, given the above and considering that coffee is more suitable for areas where the average temperature ranges from 18°C to 26°C, this research aims to compare the AD of coffee husk for CH

4 production at mesophilic (35°C) and at psychrophilic (20°C) operational conditions, as well as, at psychrophilic (20°C) temperatura but using biomass thermochemically pretreated as biomimetic strategy for the fermentation lignocellulosic biomass. Results might provide a solution to agricultural waste management at ambient temperature for farmers.

2. Materials and Methods

2.1. Coffee husk and inoculum

Coffee husk (CH) used in this study came from the 2022/2023 crop harvest of agricultural land in the municipality of São Sebastião do Paraíso, Minas Gerais, Brazil. Prior to anaerobic digestion, biomass was grinded to get pieces of 10 cm. The anaerobic sludge (AS) used as inoculum came from a pilot-scale anaerobic reactor treating slaughterhouse wastewater in Pereiras, São Paulo, Brazil. Before undergoing the AD process, the main physicochemical parameters of both the CH and AS were assessed. The total and volatile solids (TS and VS) contents were measured according to the USEPA method 1684, while, the measurement of pH was analyzed by procedures described by APHA method 4500B. The elemental composition (C, H, O, N, S) analysis was performed by CHNS elemental analyzer (LECO, CHNS-932).

Table 1 summarizes the main characteristics of CH and AS.

2.2. Experimental Setup

2.2.1. Adaptation and degassing stage

Biomethane potential (BMP) assays were carry out to determine the CH

4 production of CH residues at mesophilic (C1-35°C) and at psychrophilic (C2-20°C) operational conditions, as well as, at psychrophilic (20°C) but using biomass thermochemically pretreated (C3-20°C-w/pretreatment). Prior to the BMP assays, an adaptation stage was stablished to develop and intensify the lignocellulose (cellulose and hemicellulose) degrading activity in the culture [

19].The adaptation stage comprehend the acclimation of the AS with CH and it was performed in a glass bottle (2000 mL) with a working volume of 1200 mL. The operation solution was prepared by mixing CH with AS at a substrate/ inoculum ratio of 0.1 as states in the VDI 4630 norm [

20]. Prior the operation, the glass bottle was flushed with nitrogen gas (N

2), sealed, and incubated at 35±1°C. Feeding was carry out once and the stage was stopped till daily methane production ceased (data not shown) to deplete the residual biodegradable organic material present in it (methane production per day became less than 0.5% of the cumulative methane) [

20,

21,

22,

23,

24,

36] . The adjusted mass was calculated using the Equation (

1) and (

2) .

Where MAS and VSAS is the mass and volatil solids content of the inoculum; MCH and VSCH is the mass and volatil solids content of the coffee husks; VAS + VCH is the total working volume.

2.2.2. BMP tests

After six weeks of acclimation, glass bottles (500 mL) were fixed with a inoculum to substrate ratio of 0.5 based on a volatile solid (%VS) [

1]. For each test was performed using three biological replicates. Then, each glass bottle was connected to a glass graduated eudiometer, filled with a NaCl 6M phenolphthalein colored barrier solution. In the C1-35°C test, the temperature was maintained at 35°C, whereas in the C2-20°C and C3-20°C-w/pretreatment tests, the temperature was regulated at 20°C. In C3-20°C-w/pretreatment test, coffee husk was exposed to a thermochemical pretreatment (120°C, 0.5% HCl (v/v), 30 minute of exposition time) prior to the BMP assay [

25,

26].

2.2.3. Monitoring Biogas Production

The BMP performance of each test was evaluated in terms of CH

4 production rate, cumulative CH

4 production (mL) and CH

4 yield (mL CH

4/g VS). CH

4 production was recorded twice a week. Samples from the eudiometer headspace were taken to determine the amount of CH

4 in biogas by gas chromatography (Shimadzu mark GC-2030 model) equipped with thermal conductivity detector. For the gas volume normalization under standard temperature (T

0 =273.15 K) and pressure (P

0 = 1 atmosphere) (STP), the actual room temperature (T

r) and atmospheric pressure (P

r) were recorded at the same time as the gas volume (V) was measured according to Equation (

3) [

38]. All methane yields were expressed as mL of CH

4 at STP conditions per gram of organic substrate added (g VS).

2.2.4. Theoretical chemical oxygen demand, Theoretical biomethane potential and biodegradability

Theoretical methane potential is utilized to estimate the methane generation from a particular substrate characterized by its specific chemical composition. Accordingly with Cangussu et al., [

30] coffee husk has a high content of crude protein (7–17%). For biomass that contain proteins, the modified Buswell’s formula is generally used. The expression representing the stoichiometric formula and the methane yield is represented in Equations (

4) and (

5) [

31,

32,

33].

Where , , and ; BMPTh is the theoretical biomethane potential.

The stoichiometrically calculated chemical oxygen demand (COD

Th) was determined using the theoretical Equation (

6) [

34].

The adjusted Dulong formula (Equation (

7) and (

8)) was utilized to predict the energy potential and the maximum (CH

4) yield [

35]. This prediction relies on the energy value of the input material, which is also determined from its elemental composition [

35,

36]. The energy potential in KWh/Mt units was then determined by using the conversion factor of 3.6 MJ/kWh, and the conversion factor of the stoichiometrically calculated oxygen demand.

Where E0 is the energy value of the substrate (MJ/kg), methane energy content = 37.78 MJ/m3 at STP.

Biodegradability was calculated as shown in Equation (

9).

Where BMPexp (ml CH4/g VS) is the accumulated CH4 yield; BMPTh is the theoretical CH4 yield at STP ; and BDCH4 is the anaerobic biodegradability (%).

The methane yields experimental data obtained in the BMP tests was used to determine the energy output by using Equation (

10) :

Where ECH4Exp is the Energy output in (kJ/g VS removed), BMPExp is the cumulative CH4 yield (mL CH4/g VS), is the lower heating value of CH4 (35.800 kJ / m3 CH4), is the energy conversion factor of methane (0.9).

2.2.5. First-order kinetic model

This model is commonly employed when hydrolysis represents the rate-limiting stage in AD, particularly in cases where lignocellulosic feedstock serves as the substrate. This assumes that the gas production follows first order kinetics in which biogas accumulation was simulated using exponential rise to a maximum [

27,

28,

29]. Therefore, the production of methane was assumed to follow Equation (

11) and was simulated via non-linear regression analysis by using the ‘Solver’ function in Microsoft Excel Software, 2007. Then, the model predicted CH

4 yields which were plotted with their respective experimental CH

4 yields.

Where BMPPred is the cumulative predicted CH4 production (mL/g VS); BMPExp is the maximum CH4 production (mL/g VS); e is Exp(1)=2.718282; k is the first order kinetic constant (day -1); t is the digestion time (days). The kinetics of biogas production were evaluated using the following parameters: BMPPred, BMPExp, k, Adjusted R 2 and root mean square error (RMSE).

3. Results and discussion

3.1. Changes in biogas and methane productivity

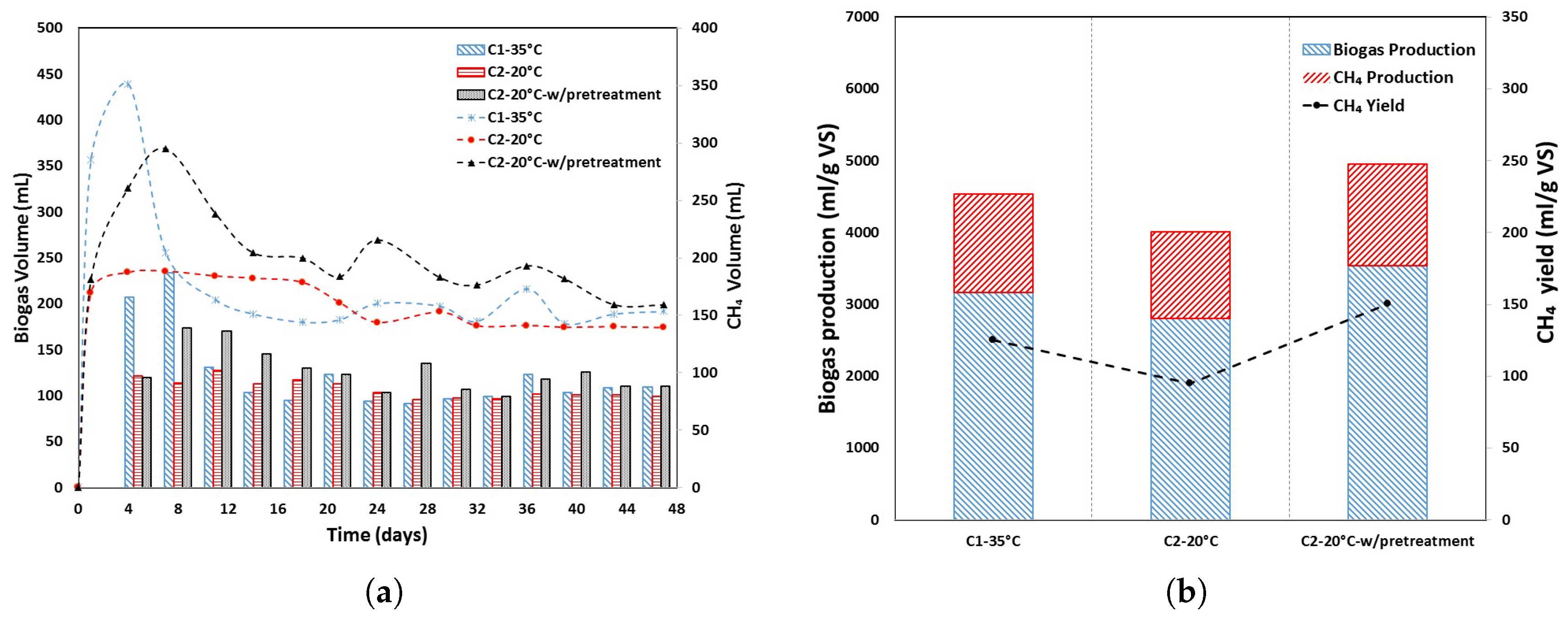

The biogas production and CH

4 production were analyzed periodically to evaluate the effects of temperature and the effect of thermochemical pretreatment on the BMP performance. The results were recorded for 47 days and ended when the BMP tests produced less than 0.5% of daily production. As it may be observed in

Figure 1a, the maximum gas production occurs between 4-12 days, after which the rate of gas production declines. Among all conditions, C2-20°C produced the lowest biogas production, reaching a maximum value of 235.25 mL on day 7, while C1-35°C and C3-20°C-w/pretreatment tests reach 439.29 mL and 368.61 mL on day 4 and day 7, respectively. In these days, similar performance was observed with the CH

4 productivity, where C3-20°C-w/pretreatment test presented a maximum value with 73% increase (139.15 mL CH

4) when compared with C2-20°C (101.69 mL CH

4), while C1-35°C just achieved 54% increase (186.87 mL CH

4). The cumulative biogas and cumulative CH

4 production are shown in

Figure 1b. Results revealed that the use of CH thermochemically pretreated influenced positively in the increase of biogas production (C3-20°C-w/pretreatment). This reach 3539.90 mL, approximately 20.64% higher than that produced by the untreated samples and operated at psychrophilic conditions (C2-20°C), while the cumulative biogas production by the untreated samples and operated at mesophilic conditions (C1-35°C) was approximately 11.20% higher (3163.38 mL). Likewise, their respective cumulative methane productivity were higher by 12.8% (1376.36 mL) and 15,3% (1417.38 mL). It can be noted that the AD process was constrained by the lower temperature (C2-20°C). This low performance could be attributed to the fact that anaerobic digestion of lignocellulosic biomass encounters limitations in psychrophilic (cold) conditions primarily because of the decreased activity and efficiency of enzymes and microorganisms, which are significantly enhanced in mesophilic and thermophilic anaerobic digestion processes [

43]. However, mesophilic operation does not outperform that of psychrophilic operation with pretreated CH, this exceptional outcome can be ascribed to the availability of cellulose, hemicellulose, and fermentable substances that become readily accessible to microorganisms when a feedstock is pretreated [

37,

39,

40]. According to [

25], this breakdown includes the deacetylation of hemicelluloses, which could lead to an elevation in acetic acid concentration within the reactive mixture, promoting the hydrolysis and deriving in higher biogas production consequently [

25,

37,

39,

40].

3.2. Stoichiometry, Theoretical COD, Theoretical biomethane potential and biodegradability

The chemical formula of the CH was found as C

0.55H

0.85O

0.43N

0.02 regarding to the elements C, H, O and N from the stoichiometric equation (Equation

5) (

Table 2). H

2S was desconsidered since it was abscent in the biogas mixture (data not shown). As is shown in

Table 3, BMP

Th, as calculated from the elemental composition, exceeded the BMP

Exp. Buswell’s equation predicted a BMP

Th of 405.52 mL CH

4/g VS (434 mL CH

4/g COD), while the corresponding BMP

E0 with modified Dulong’s equation was 402.26 mL CH

4/g VS (430.50 mL CH

4/g COD). However, experimental BMP

Exp among all conditions ranged from 94.96 to 150 mL/g VS (

Figure 1b). As discussed in [

24], BMP

Th approaches tend to overstate the CH

4 production in comparison to experimental methods due to the Buswell formula’s inability to distinguish between biodegradable and non-biodegradable matter, with a portion of biodegradable material being allocated for cell growth, metabolites and protoplasm synthesis of microbes [

55]. According to previous authors, CH has a large variability values for cellulose (14.7–46.1%), hemicellulose (10.2–29.7%) and lignin (10.1–34.2%) [

30]. As lignin is a component of the cell wall and is known for its high resistance, it may have exerted a significant influence on both the yield and efficiency of the process [

46,

54].

The C3-20°C-w/pretreatment test resulted in an increase of 36.89% (150.47 mL CH

4/g VS; 161.04 mL CH

4/g COD), whereas the C1-35°C test showed a 24.03% increase (124.99 mL CH

4/g VS; 133.77 mL CH

4/g COD), both compared to the C2-20°C test (94.96 mL CH

4/g VS ; 101.63 mL CH

4/g COD). Notably, the C3-20°C-w/pretreatment test yielded superior results. This could be ascribed to the high biodegradability (37.11%) of CH when it was thermochemically pretreated. The biodegradability decrease under untreated conditions at mesophilic AD (30.82%), followed by psychrophilic AD (23.42%) conditions. The order of biodegradation could be understood as inversely related to lignin content and directly related to the quantity of cellulose and hemicelluloses, which may contribute to an increase in the concentration of readily degradable organics [

44,

54]. Comparable findings were achieved in earlier studies concentrating on various pretreatment approaches to enhance the biodegradability and bioavailability of CH to microorganisms during mesophilic AD. For instance, as reported in [

45], CH

4 yield was significantly lower in the absence of any pretreatment (i.e., 100 mL CH

4/g VS). However, when subjected to thermal hydrolysis pretreatment, there was an improvement in the ultimate CH

4 yield, with increases of 37% and 23% observed at 120 and 180 °C, respectively. Furthermore, significantly improved outcomes were observed through the co-digestion and co-pretreatment of coffee husks and microalgal biomass, demonstrating enhancements ranging from 61% to 96%. In [

44], all steam explosion pretreatment conditions applied were worthwhile when compared to non-pretreated CH. Here, the best condition was 120 °C for 60 min, in which a 2.37 severity showed the highest methane yield (144.96 mL CH

4/g COD).

3.3. First-order kinetic model

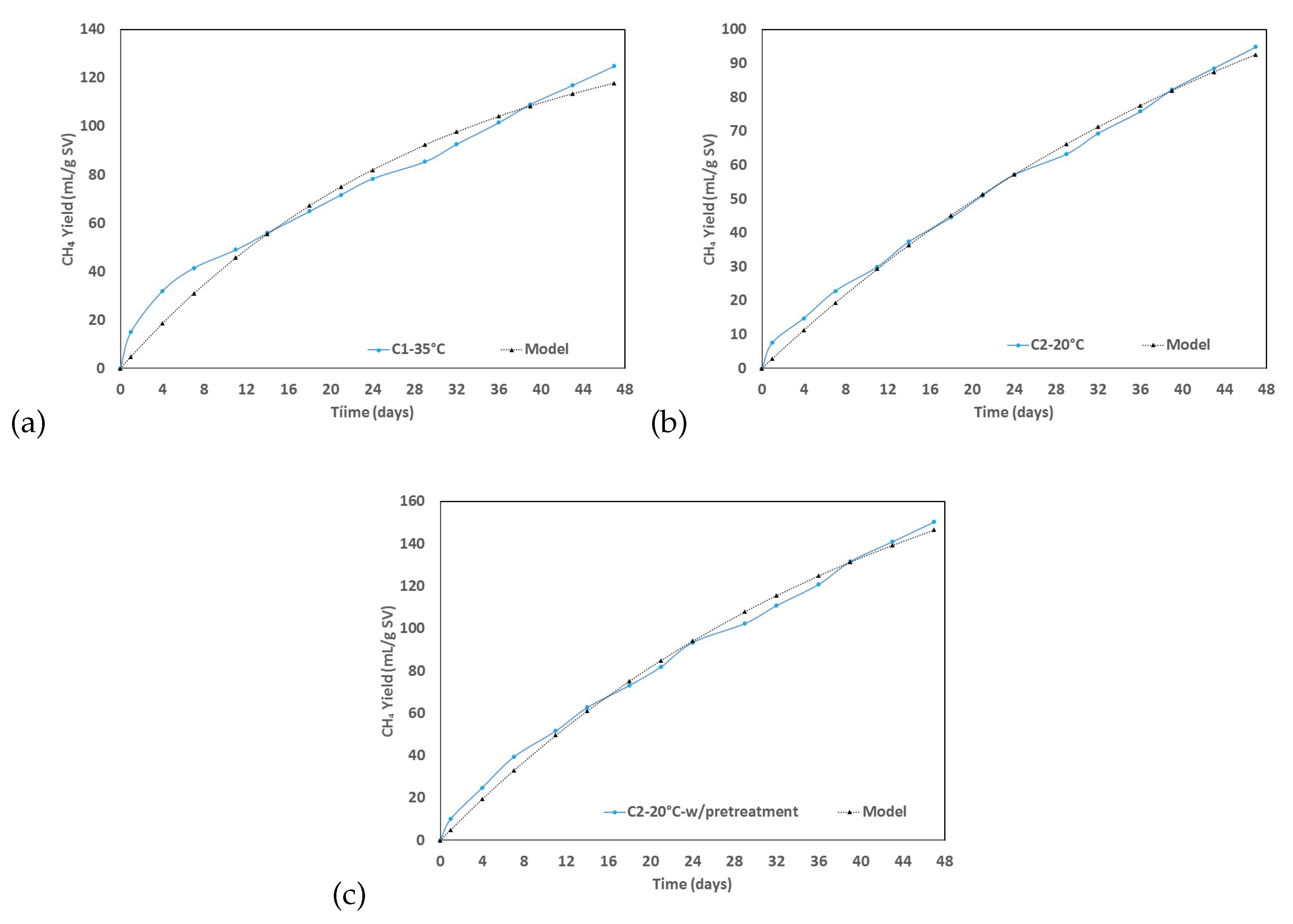

The model fitness statistics are detailed in

Table 4. By plotting experimental data and simulation of first-order model was depicted

Figure 2. The methane yield and hydrolysis constant covered a ranges of values from 149.07 mL to 221.90 mL and from 0.019 d

-1 to 0.033 d

-1, respectively. All results fit very well with the measured data with Adj. R

2 > 0.97 for all BMPs. The coefficient of determination (R

2 ) between the cumulative methane production curve and first-order kinetic curves was highest for C2-20°C test, i.e. 0.996. For C3-20°C-w/pretreatment test, the value obtained was similar (0.994) while for C1-35°C test, R

2 was comparatively low (0.970). The first-order kinetic constant k was highest when coffee husks were fermented at 35°C (0.033 d

-1), showing rapid degradation of substrate (in 30 days). The reason for the higher degradation rate is probably the influence of mesophilic conditions that provide a kinetic advantage for the degradation rate. The C3-20°C-w/pretreatment test (0.023 d

-1) had a slightly lower k value than the C1-35°C test. This could be because pretreatment could increase the generation of toxic and recalcitrant compounds, that may have been inhibitory to the methanogenic population.

3.4. Energy content and Energy output

The energy content or High heating Value (HHV) of coffee husk on dry basis (13.09 MJ/kg TS; 15.04 MJ/kg VS) was calculated based on the elemental composition (

Table 2 and

Table 3). According to the literature, theoretical HHVs of coffee husk are usually around 13-21 MJ/kg [

47,

48,

49,

50,

51]. If we consider that the predicted overall coffee husk harvest in 2023 amounted to 54.94 million 60 kg bags, equivalent to approximately 3.3 tons of coffee waste annually, this would yield a potential electrical energy of 12.04 MWh each year [

52]. Thus, it can be inferred that coffee husk show great potential as a green and sustainable energy source, simultaneously mitigating pollution and offering a practical approach to coffee waste management.

The energy output has been estimated from BMP

Exp data by using Equation (

10). The energy output values were 2.9 KJ/g CH, 3.9 KJ/g CH and 4.6 KJ/g CH for C1-35°C, C2-20°C and C3-20°C-w/pretreatment, respectively. These values correspond to 1072.8 KWh/T CH, 815.1 KWh/T CH and 1291.6 KWh/T CH, respectively. Assuming that 3.3 tons of coffee waste are generated annually, these values would yield a potential electrical energy of 3540.4 KWh/year, 2689.8 KWh/year and 4262.2 KWh/year, respectively. These electrical outputs could supply electricity for 488.371 and 588 residences per year in the southest region of Brazil where the per-capita comsumption is 2.60 KWh/hab. per year, respectively. Another best practice application could involve meeting additional energy requirements in agriculture. This might include delivering thermal energy for grain dryers, supplying electrical energy for coffee processing machines, and utilizing CH

4 as a fuel source for various agricultural machinery, among other applications. Based on the findings, employing psychrophilic AD of thermochemically pretreated CH could serve as a viable alternative for conducting anaerobic digestion at ambient temperature, offering advantages in terms of both cost-effectiveness and environmental considerations.

4. Conclusions

Experimental findings suggest that biomethane production can occur at psychrophilic conditions, yet it demonstrates enhanced efficiency when coffee husk, a type of lignocellulosic biomass, undergoes a thermochemical pretreatment (i.e., 120°C, 0.5% HCl (v/v), 30 minute of exposition time). This superior performance is even observed when compared to AD processes carried out at mesophilic temperatures. Furthermore, it was estimated that it could yield a potential electrical energy of 4262.2 KWh/year that could meet the energy needs of 588 residences annually. This represents an increase of 100 and 217 residences compared to mesophilic and psychrophilic AD of CH without pretreatment, respectively. Therefore, the utilization of thermochemical pretreatment on lignocellulosic biomass emerges as a potential approach for implementing AD at ambient temperature. Moreover, coffee processing facilities could have the opportunity to utilize this energy potential for both electrical and thermal energy, contributing to the improvement of their own operational sustainability. In sum, this could eliminate the necessity for external energy input and offer compelling economic benefits, making it a crucial consideration.

Author Contributions

Conceptualization, Yang, T.; formal analysis, investigation, Yang, T.; data curation, Yang, T., Flores-Rodriguez, C.; writing—original draft preparation, Yang, T., Flores-Rodriguez, C.; writing—review and editing, Yang, T., Flores-Rodriguez, C., Torres-Albarracin, L., Da Silva, A.J.; supervision, Da Silva, A.J.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Institutional Program of Scientific Initiation Scholarships PIBIC-UNICAMP. Brazil.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors wish to thank the College of Agricultural Engineering at Universidade Estadual de Campinas (FEAGRI-UNICAMP) for providing research funding PIBIC-UNICAMP.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| TS |

Total Solids |

| VS |

Volatil Solids |

| AD |

Anaerobic Digestion |

| BD |

Biodegradability |

| BMP |

Biochemical methane potential |

| COD |

Chemical Oxygen Demand |

|

Theoretical Chemical Oxygen Demand |

| E0 |

Energy Content |

References

- Gómez-Salcedo, Y., Baquerizo-Crespo, R., Da Silva, A. J., Oliva-Merencio, D., & Pereda-Reyes, I. Anaerobic digestion of solid wastes from coffee wet processing. Revista Internacional de Contaminacion Ambiental 2021, 37, 281–292. [CrossRef]

- Neri, A.; Bernardi, B.; Zimbalatti, G.; Benalia, S. An Overview of Anaerobic Digestion of Agricultural By-Products and Food Waste for Biomethane Production. Energies 2023, 16, 6851. [CrossRef]

- Shu-Yuan P., Cheng-Yen T., Chen-Wuing L., Sheng-Wei W., Hyunook K., Chihhao F. Anaerobic co-digestion of agricultural wastes toward circular bioeconomy. iScience 2021, 24. [CrossRef]

- Lakshana, G. N., Komal, A., Pradeep, V. An overview of sustainable approaches for bioenergy production from agro-industrial wastes. Energy Nexus 2022, 6. [CrossRef]

- Peshev, D., Mitev, D., Peeva, L., & Peev, G. Valorization of spent coffee grounds – A new approach. Separation and Purification Technology 2018, 192, 271–277. [CrossRef]

- International cofee organization. 2021. World coffee production.

- Mazzafera, P. Degradation of caffeine by microorganisms and potential use of decaffeinated coffee husk and pulp in animal feeding. Scientia Agricola 2002, 59. [CrossRef]

- Karolyne, A., Lages Leal, A., Santos Silva, R., Cristina, E., Ferreira, S., Soares, R., Ferreira, P. The quality of roasted and ground brazilian coffee: Chemical analysis of the effect of fixed mineral residue e different types of packaging on moisture content. Research Society and Development 2021, 10(5):1. [CrossRef]

- Oliveira, L., Franca, A. Chapter 31 - An Overview of the Potential Uses for Coffee Husks. In book: Coffee in Health and Disease Prevention; Academic Press, 2015, pp. 283-291, ISBN 9780124095175. [CrossRef]

- Oliveira, F., Srinivas, K., Helms, G., Isern, N., Cort, J., Gonçalves, A., Ahring, B. Characterization of coffee (Coffea arabica) husk lignin and degradation products obtained after oxygen and alkali addition. Bioresource Technology 2018, 257,172-180, ISSN 0960-8524. [CrossRef]

- Matos, A.T, de. Waste treatment in post-harvest coffee. In: BOREM, F. M. (Ed.). Pós-colheita do café. Lavras, MG Ed. UFLA 2008, 6,159-201.

- Galanakis, C. Handbook of coffee processing by-product. Sustainable applications. Academic Press 2017, ISBN 978-0-12-811290-8.

- Guerra, A., Freitas, J., Ferreira, L., Cruz, O. Chapter 5. Coffees of Brazil Research, sustainability and innovation. In: TELHADO, S. F. P. e; CAPDEVILLE, G. de (ed.). Land-saving technologies 2021. Brasília, DF: Embrapa, 2021.

- Serna-Jiménez, J.A.; Siles, J.A.; de los Ángeles Martín, M.; Chica, A.F. A Review on the Applications of Coffee Waste Derived from Primary Processing: Strategies for Revalorization. Processes 2022, 10, 2436. [CrossRef]

- Hernández-Sarabia, M., Sierra-Silva, J., Delgadillo-Mirquez, L., Ávila-Navarro, J., Carranza, L. The Potential of the Biodigester as a Useful Tool in Coffee Farms. Applied Sciences 2021, 11, 6884. [CrossRef]

- Amador-Diaz. 2019. Anaerobic digestion of lignocellulosic biomass via cotreatment: a techno-economic analysis. M.Sc. dissertation/thesis, Pennsylvania State University, Pennsylvania, USA, May 19.

- Akindolire, M., Rama, H., Roopnarain, A. Psychrophilic anaerobic digestion: A critical evaluation of microorganisms and enzymes to drive the process. Renewable and Sustainable Energy Reviews 2022, 161,112394, ISSN 1364-0321. [CrossRef]

- Tiwari, B., Rouissi, T., Brar, S., Surampalli, R. Critical insights into psychrophilic anaerobic digestion: Novel strategies for improving biogas production. Waste Management 2021, 131,513-526, ISSN 0956-053X. [CrossRef]

- Ahmed, A.M.S., Buezo, K.A. & Saady, N.M.C. Adapting anaerobic consortium to pure and complex lignocellulose substrates at low temperature: kinetics evaluation. Int. J. Recycl. Org. Waste. agric. 2019, 8, 99–110. [CrossRef]

- VDI 4630. Fermentation of Organic Materials: Characterisation of the Substrate, Sampling, Collection of Material Data, Fermentation Tests. Germany Association of Engineers 2006, Germany, 92.

- VDI 4630. 2016 Fermentation Tests: Fermentation of Organic Materials: Characterisation of the Substrate, Sampling, Collection of Material Data. Germany Association of Engineers 2016, Germany.

- Angelidaki I, Alves M, Bolzonella D, Borzacconi L, Campos JL, Guwy AJ, Kalyuzhnyi S, Jenicek P, van Lier JB. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci Technol 2009. 59(5):927-934. [CrossRef]

- Elbeshbishy, E., Nakhla, G., Hafez. H. Biochemical methane potential (BMP) of food waste and primary sludge: Influence of inoculum pre-incubation and inoculum source. Bioresource Technology 2012, 110, 18-25, ISSN 0960-8524. [CrossRef]

- Nurzulaifa S., Buyong F. Comparative of experimental and theoreticaurzulaifal biochemical methane potential generated by municipal solid waste. Environmental Advances 2023, 11,100345, ISSN 2666-7657. [CrossRef]

- Soares, N., Arantes, Y., Gomes, A., Herrera, O., Alves, L., Valderrama, J., Luna, H., Lobo, B. Coffee Husk Waste Valorization Using Thermal Pretreatment Associated to Bioprocess to Produce Bioproducts: Characterization, Kinetic, Economic Assessment, and Challenges. Microbial Bioprocessing of Agri-food Wastes 2023, 1st Edition, ImprintCRC Press, p29, ISBN9781003128977.

- Reis, J., Abreu, L., Rodrigues, L., Sousa, M. Thermochemical treatment of coffee peels for the production of biogas by anaerobic digestion. Annals of the Giulio Massarani Journey of Scientific, Technological, Artistic and Cultural Initiation 2021.

- Lymperatou, A., Engelsen, T., Skiadas, I., Gavala, H. Prediction of methane yield and pretreatment efficiency of lignocellulosic biomass based on composition, Waste Management 2023,155,302-310, ISSN 0956-053X. [CrossRef]

- Mussatto, S.I.; Dragone, G., Fernandes, M.; Milagres, A.M.F. Effect of hemicellulose and lignin on enzymatic hydrolysis of cellulose from brewer’s spent grain. Enzym. Microb. Technol 2008. 43, 124–129. [CrossRef]

- Li, P.; Li, W.; Sun, M.; Xu, X.; Zhang, B.; Sun, Y. Evaluation of Biochemical Methane Potential and Kinetics on the Anaerobic Digestion of Vegetable Crop Residues. Energies 2019, 12, 26. [CrossRef]

- Cangussu, L.B., Melo, J.C., Franca, A.S., Oliveira, L.S. Chemical Characterization of Coffee Husks, a By-Product of Coffea arabica Production. Foods 2021. 10(12):3125. [CrossRef]

- Lübken, M., Gehring, T. & Wichern, M. Microbiological fermentation of lignocellulosic biomass: current state and prospects of mathematical modeling. Appl Microbiol Biotechnol 2010, 85, 1643–1652. [CrossRef]

- Contreras, L.M., Schelle, H., Sebrango, C.R., Pereda, I. Methane potential and biodegradability of rice straw, rice husk and rice residues from the drying process. Water Sci Technol 2012, 65 (6):1142–1149. [CrossRef]

- Baquerizo-Crespo, R., Astals, S., Pérez-Ones, O., Pereda-Reyes, I. Mathematical Modeling Challenges Associated with Waste Anaerobic Biodegradability. In book: Advances in the Domain of Environmental Biotechnology 2021, 357-392,ISBN : 978-981-15-8998-0.

- Prem, C., Shanmugam P. Correlation between empirical formulae based stoichiometric and experimental methane potential and calorific energy values for vegetable solid wastes. Energy Reports 2021, 7,19-31, ISSN 2352-4847. [CrossRef]

- Browne, J.D., Murphy, J.D. Assessment of the resource associated with biomethane from food waste. Applied Energy 2012,104,170-177, ISSN 0306-2619. [CrossRef]

- Jingura, R.M. and Kamusoko, R. Methods for Determination of Biomethane Potential of Feedstocks: A Review. Biofuel Research Journal 2017, 4, 573-586. [CrossRef]

- Wang, Dou, Fei Shen, Gang Yang, Yanzong Zhang, Shihuai Deng, Jing Zhang, Yongmei Zeng, Tao Luo, and Zili Mei. “Can Hydrothermal Pretreatment Improve Anaerobic Digestion for Biogas from Lignocellulosic Biomass?”. Bioresource Technology 2018, 249,117–124. [CrossRef]

- Wang B, Nges IA, Nistor M, Liu J. Determination of methane yield of cellulose using different experimental setups. Water Sci Technol 2014, 70(4):599-604. [CrossRef]

- Carrere, H.; Antonopoulou, G.; Affes, R.; Passos, F.; Battimelli, A.; Lyberatos, G.; Ferrer, I. Review of feedstock pretreatment strategies for improved anaerobic digestion: From lab-scale research to full-scale application. Bioresource Technology 2016, 199, 386–397. [CrossRef]

- Dumlu, L., Ciggin, A.S., Ručman, S., Perendeci, N.A. Pretreatment, Anaerobic Codigestion, or Both? Which Is More Suitable for the Enhancement of Methane Production from Agricultural Waste?. Molecules 2021, 26(14):4175. [CrossRef]

- Lettinga, G., Rebac, S., Zeeman, G., Challenge of psychrophilic anaerobic wastewater treatment. Trends Biotechnology 2001. [CrossRef]

- Dhaked, R.K., Singh, P., Singh, L. Biomethanation under psychrophilic conditions. Waste Manage 2010, 30(12):2490-6. [CrossRef]

- Agregán, R.; Lorenzo, J.M.; Kumar, M.; Shariati, M.A.; Khan, M.U.; Sarwar, A.; Sultan, M.; Rebezov, M.; Usman, M. Anaerobic Digestion of Lignocellulose Components: Challenges and Novel Approaches. Energies 2022, 15, 8413. [CrossRef]

- Lobo, B., Miranda, P., Passos, F., Alves, L., Aquino, S., Fdz-Polanco, F. Steam explosion pretreatment improved the biomethanization of coffee husks. Bioresource Technology 2017, 245,66-72, ISSN 0960-8524. [CrossRef]

- Passos, F., Miranda Cordeiro, P.H., Lobo Baeta, B., Aquino, S.F., Perez-Elvira, S.I. Anaerobic co-digestion of coffee husks and microalgal biomass after thermal hydrolysis. Bioresource Technology 2018. 253, 49-54, ISSN 0960-8524. [CrossRef]

- Neves L, Oliveira R, Alves MM. Anaerobic co-digestion of coffee waste and sewage sludge. Waste Management 2006, 26(2):176-181. [CrossRef]

- Twinomuhwezi, H., Wozeyi, P., Igwe, V. S., Amagwula, I. O., & Awuchi, C. G. Heat of Combustion of Coffee Pulp and Husks as Alternative Sources of Renewable Energy. European Journal of Agriculture and Food Sciences 2021, 3(2), 1–4. [CrossRef]

- Amertet, S., Mitiku, Y., & Belete, G. Analysis of a Coffee Husk Fired Cogeneration Plant in South Western Ethiopia Coffee Processing Industries. Low Carbon Economy 2021, 12, 42-62. [CrossRef]

- Manrique, R., Vásquez, D., Ceballos C., Chejne, F., Amell, A. Evaluation of the Energy Density for Burning Disaggregated and Pelletized Coffee Husks. ACS Omega 2019, 4, 2, 2957–2963. [CrossRef]

- Bonilla, J., Gordillo, G., Cantor, C. Experimental Gasification of Coffee Husk Using Pure Oxygen-Steam Blends. Frontiers in Energy Research 2019, 7. [CrossRef]

- Vale, A., Gentil, L., Gonçalez, Joaquim C., Costa, A. Caracterização energética e rendimento da carbonização de resíduos de grãos de café (Coffea arabica, L) e de madeira (Cedrelinga catenaeformis), Duke CERNE 2007, 13, 416-420.

- CONAB, Companhia Nacional de Abastecimento, 2019. Avalilable: https://www.conab.gov.br. Acess: 29 mar. 2019.

- Yono, B., Syaichurrozi, I., Sumardiono, S. Kinetic Model of Biogas Yield Production from Vinasse at Various Initial pH: Comparison between Modified Gompertz Model and First Order Kinetic Model. Research Journal of Applied Sciences, Engineering and Technology 2014, 7. 2798-2805. [CrossRef]

- Passos, F., Ortega, V., Donoso-Bravo, A. Thermochemical pretreatment and AD of dairy cow manure: experimental and economic evaluation. Bioresource Technology 2017, 227:239–246. [CrossRef]

- Sagarika, P., Brajesh, K.D. Electrochemical pretreatment of yard waste to improve biogas production: Understanding the mechanism of delignification, and energy balance. Bioresource Technology 2019, 292, 121958, ISSN 0960-8524. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).