Introduction

The European Green Deal seeks to make Europe the first carbon-neutral continent by 2050 and reduce GHG emissions by at least 55% by 2030 [

1]. These goals are achievable through a broad energy transition in different sectors. Five emission sectors have been identified, and in Europe, the main one is the transport sector (28%) [

2]. The energy transition, which is widely studied and debated, will bring many benefits, such as increased energy reliability, economic growth, and job creation [

3,

4]. Gielen et al., pointed out that the use of renewable energies, and improved conversion factor, together with electrification of end uses, account for 94% of emission reductions [

3]. Although energy use for heating has remained stable since 2010, production systems are mostly powered by fossil fuels. The share powered by renewable energy is around 20% in 2019 [

5]. To meet Sustainable Development Scenario (SDS) objectives, clean energy technologies must exceed 50% of new heating equipment sales by 2030 [

6]. Heating and hot water account for 79% of total final energy use in EU countries [

7]. Solar energy, especially Concentrated Solar Power (CSP), can play a crucial role in this context, particularly for district heating networks in local communities [

8,

9,

10]. Solar energy is used in Solar District Heating (SDH) projects across Europe, contributing up to 20% of annual heat demand, and potentially more with seasonal storage [

11]. Among CSP technologies, the dish system offers high thermal efficiency for medium to high temperatures and is suitable for high-temperature applications [

12]. Efficient energy conversion is achieved with sun-tracking parabolic dish collectors and cavity receivers, minimizing heat losses [

13]. Parabolic dish collectors exhibit superior energy conversion efficiency among CSP systems, as investigated by Coventry et al., [

14]. However, each dish has a relatively low thermal power output, often in the tens of kilowatts. A positive aspect is the possibility of producing thermal and electrical energy in a combined way. These characteristics make dishes particularly attractive for domestic applications, small buildings and local communities. However, dish technology is not widely adopted, there is a need to extend the stability of conversion efficiency to increase commercial penetration [

15]. Only a few studies focus on the heating part of CSPs [

14]. Coventry et al., highlighted the operation of an ARUN system (2016), where an output of the system in addition to electricity is also the production of pressurised hot water, which can be used in a thermal energy distribution network [

14].

This work primarily involves evaluating the performance of an existing CSP dish located at the Energy Center of Politecnico di Torino. One of the main objectives of this study is to also study thermal energy production with the CSP, after previous publications related to the electricity production [

16,

17,

18,

19]. The CSP dish is integrated with a water storage tank, forming a system designed to provide hot water for integration into the Energy Centre's network. In the second part of the paper, a comprehensive life cycle analysis (LCA) will be conducted on the key components of the entire system used. In particular, the proposed configuration does not incorporate any fossil-based backup heating sources, ensuring no pollutant emissions during system operation. Therefore, the LCA presented here will focus on the entire life cycle of the main components, from their initial production to their eventual disposal. The main components considered in the analysis include the solar collector, the solar receiver, the domestic hot water tank, and the piping system.

Material and Methods

The concentrator consists of a single solar dish with an aperture of approximately 2.4 m (Elma net. Srl, TN). The system is composed of two motors to allow optimal orientation according to the time of day, and from the geographical coordinates of the site where the CSP is installed (Turin, 45.0676 N, 7.6563 E). Other useful geometric and technical parameters are listed in the following table (

Table 1), and in previous studies [

18,

20].

The concentrator-receiver system is built using Comsol multiphysics Inc. software (Sweden). In this work, an average value was set for the global irradiance (800 W/m

2). This value is derived from previous experimental measurements conducted in the plant and recently published [

16]. If the dish were a perfect reflector, i.e., if all incoming radiation were reflected specularly, if the dish were perfectly smooth and if the sun's rays behaved as planar waveforms from an infinitely distant point source, all incoming rays would focus on a single point in the collector - in the focus of the paraboloid. To make the system more realistic, some deviations from the ideal case were included in the analysed model:

Part of the incoming radiation is absorbed by the dish. In this model, the absorption coefficient is set to 0.1, which means that 90% of the incoming radiation is reflected.

Not all incident rays will be parallel; instead, the incident rays are sampled by a narrow cone with a maximum angle, 𝜓𝑚, of 4.56 mrad. In practice, a part of the radiation is also emitted from the circumsolar region surrounding the solar disc, instead of from the solar disc itself, but this radiation is neglected in the present model, i.e. a circumsolar ratio (CSR) of zero is assumed.

Since the surface of the parabola is not perfectly smooth, the reflected rays are not all released in the same direction. Instead, the surface normal is perturbed by an additional angle that is sampled by a Rayleigh distribution. This optical error is taken into account with a surface tilt error of 1.75 mrad.

The limb darkening effect is considered to consider the variation in power of rays from different regions of the Sun. In particular, the rays emitted from the centre are more intense than those emitted from the peripheral regions of the solar disc.

Rays are released from 250000 distinct points.

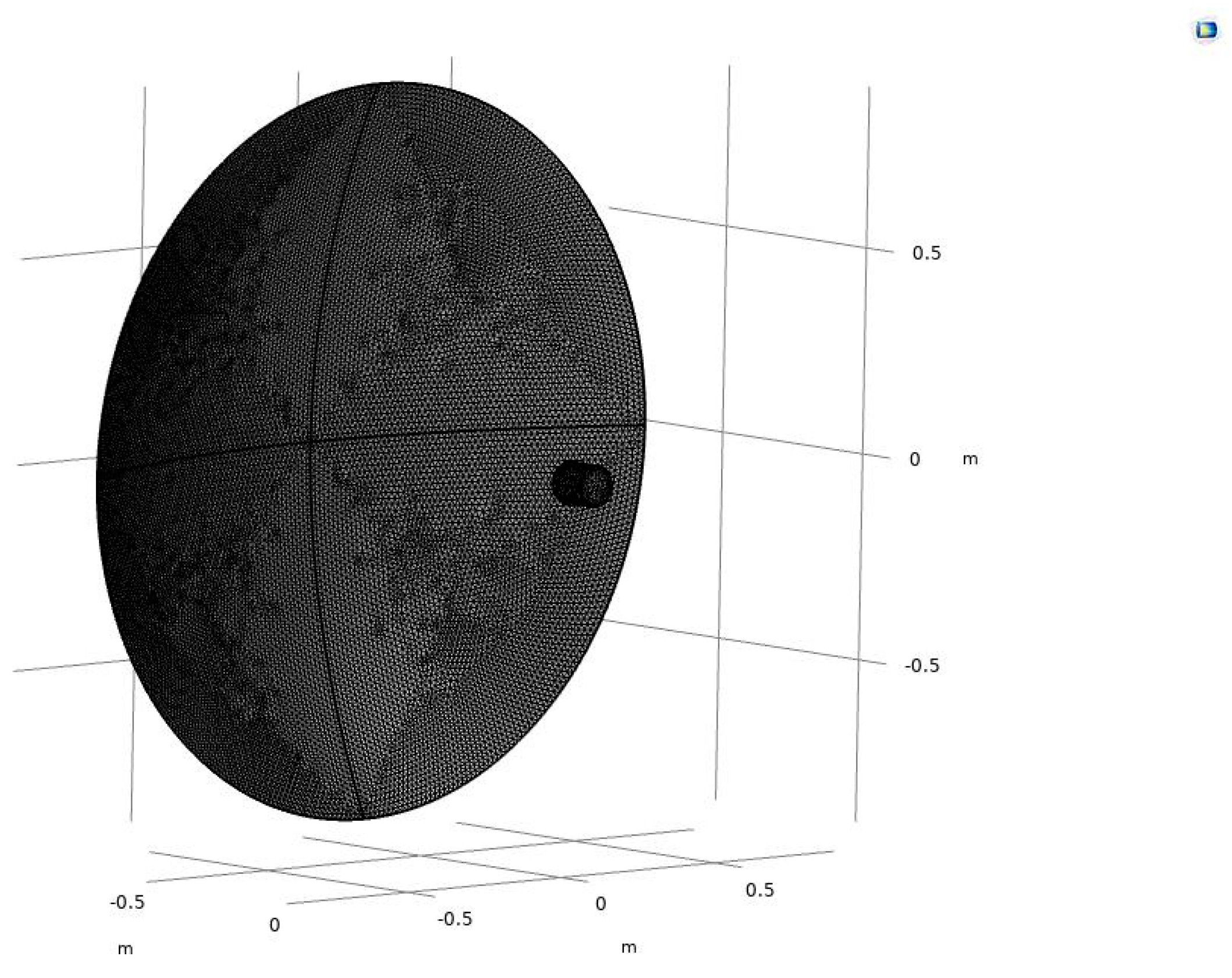

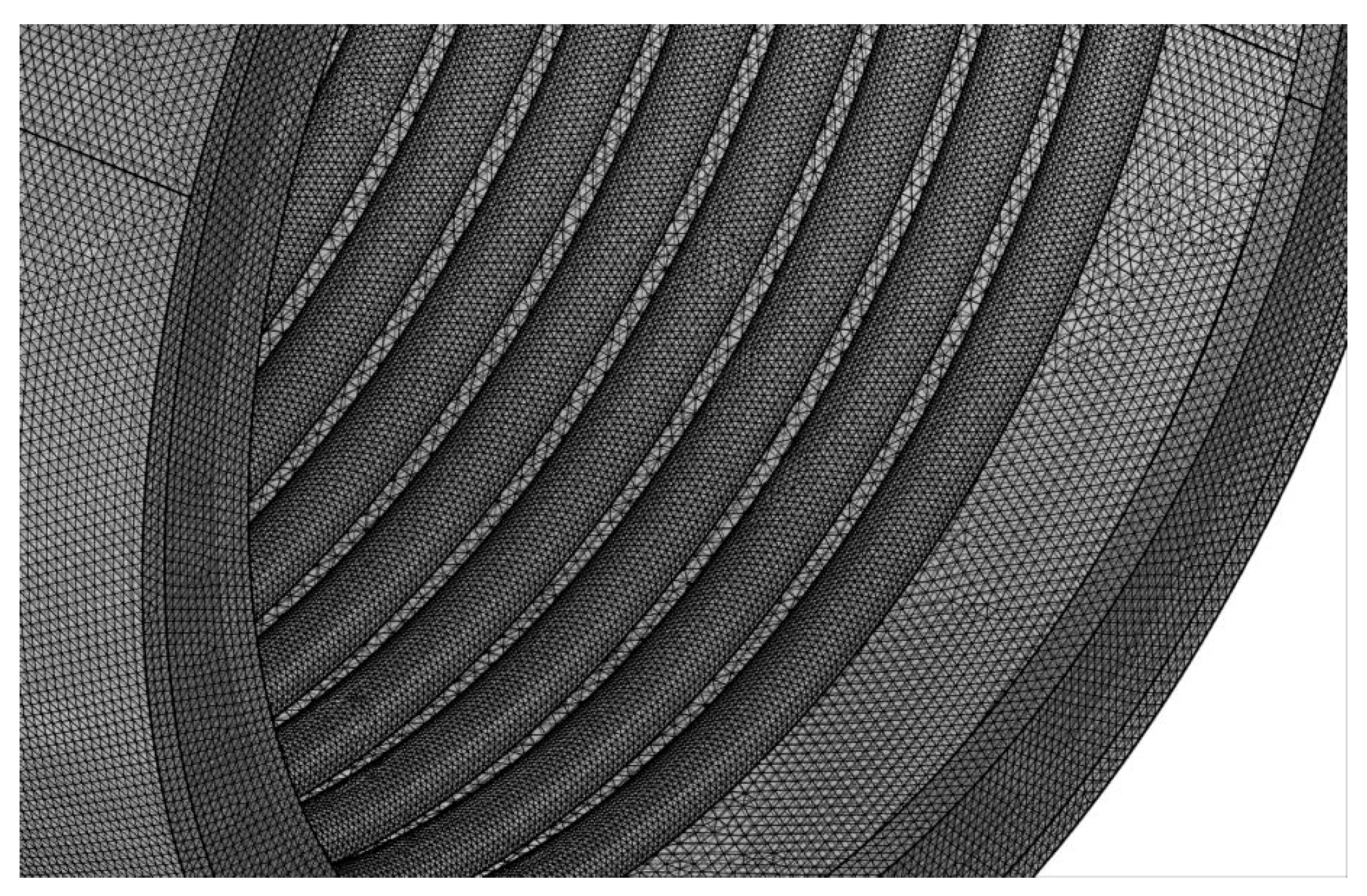

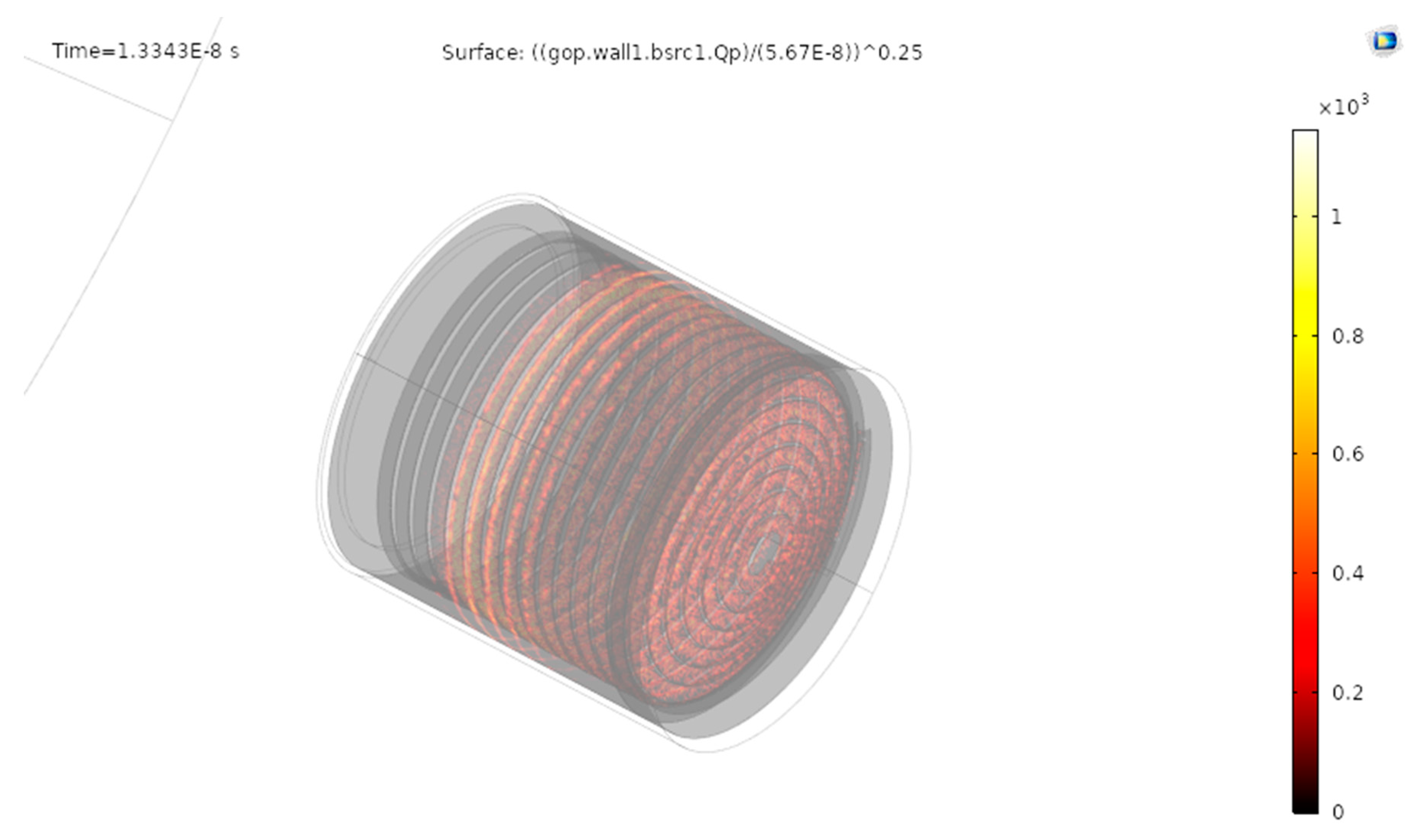

In the present work, a cavity solar receiver was chosen for its simplicity and ease of fabrication, see

Figure 1 and

Figure 2. The mesh must have a higher resolution on curved surfaces to accurately represent the surface normal. On the other hand, the mesh on flat surfaces can be coarser. A fine mesh on curved surfaces improves the accuracy of the reinitialised wave vectors of reflected and refracted rays [

21]. To reduce the mesh size on the curved surfaces without creating superfluous meshes, a curvature factor of 0.2 was selected. Furthermore, since the main objective is to determine the temperature distribution within the receiver, a customised free triangular mesh was used on the receiver with a maximum element size of 2E

-4 [mm] and a minimum element size of 4E

-5 [mm].

The shape and dimensions of the receiver, the solar absorptance of its inner surface, and the type of reflection on its inner surface, in conjunction with the parameters introduced earlier, collectively influence the uneven absorption of heat flux by the receiver's inner surface. These factors play a crucial role in determining the actual distribution of absorbed radiant flux density.

The mesh independence analysis was accomplished using the same procedure reported in Marra et al., [

16]. The model built was validated with experimental temperature measured inside the receiver structure using a B-type thermocouple (Tersid srl, Italy). The system modelled (CSP + cavity receiver) is connected to a water storage tank to meet the hot water needs. Thermal demand for domestic hot water can be expressed by the following equation:

Where

, is the daily demand of DHW in

; temperature,

can be generally assumed to be in the range

. While the temperature from the aqueduct is related to the average temperature of the ground at

depth. In Italy

vary between

in the Po Valley. The demand for DHW is equal to around

or

for the selected case study. An important aspect related to the performance of a TES is maintaining a high degree of stratification of the reactor volume connected to the users. Thermal stratification allows a limited operation of the auxiliary energy supply. For sensible TES the lower and upper temperature limits determine the maximum storage capacity. However, maximum storage capacities are not accessible in real storage systems [

22].

Dimensioning of storage is based on the following equation:

Where

is the thermal energy demand,

is the maximum temperature in the tank (

for non – pressurized water tank),

is the minimum temperature for satisfying the demand (

) [

22]. In this work, maximum tank temperature was set to

(to prevent legionella disease) and minimum to

and using DHW demand previously calculated, a volume of

is sufficient.

Energy demand for heating this volume of water can be evaluated by the following equation:

Where

is the amount of thermal energy demanded to heat water,

is the water tank dimension,

is the specific heat of the water, while

is equal to 15 °C.

In the second part of the paper, a life cycle analysis was performed. Despite the widespread use of concentrating solar power plants, their environmental assessment is still little investigated. Reviewing the literature studies on the LCA of CSP, it can be seen that most of the references concern CSP plants based on parabolic troughs and solar tower technology [

23,

24,

25]. Leamnatou et al. state that the impact of CSP plants depends on the use of water and the materials used for storage. Carnevale et al. presented a general case of LCA of solar energy systems [

26,

27]. By reviewing the literature, further investigations are needed on plate systems, storage materials, water-saving strategies, and the soiling effect, for even small systems focused on small CSP systems.

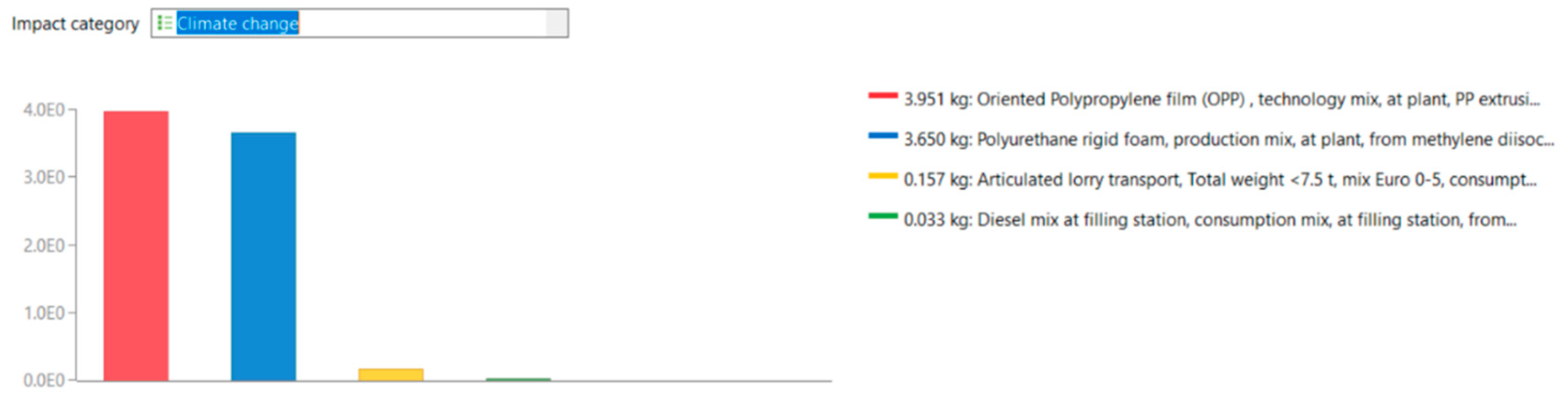

This analysis aims to study the impacts of a solar parabolic dish (CSP) used for energy production from cradle to grave, as in literature there are not any similar studies. LCA analysis is done on macro components of the system. These components are solar parabolic dish, solar receiver, water storage tank and pipes. This choice is due to several limitations, one of which is the database used. As the database has limited sources, electronic components were excluded from the analysis - the same applies to the welding of parts. The functional unit chosen in this study is "a hot water tank" and, in accordance with ISO 14040 and 14044, the results of the LCA are expressed in terms of this functional unit.

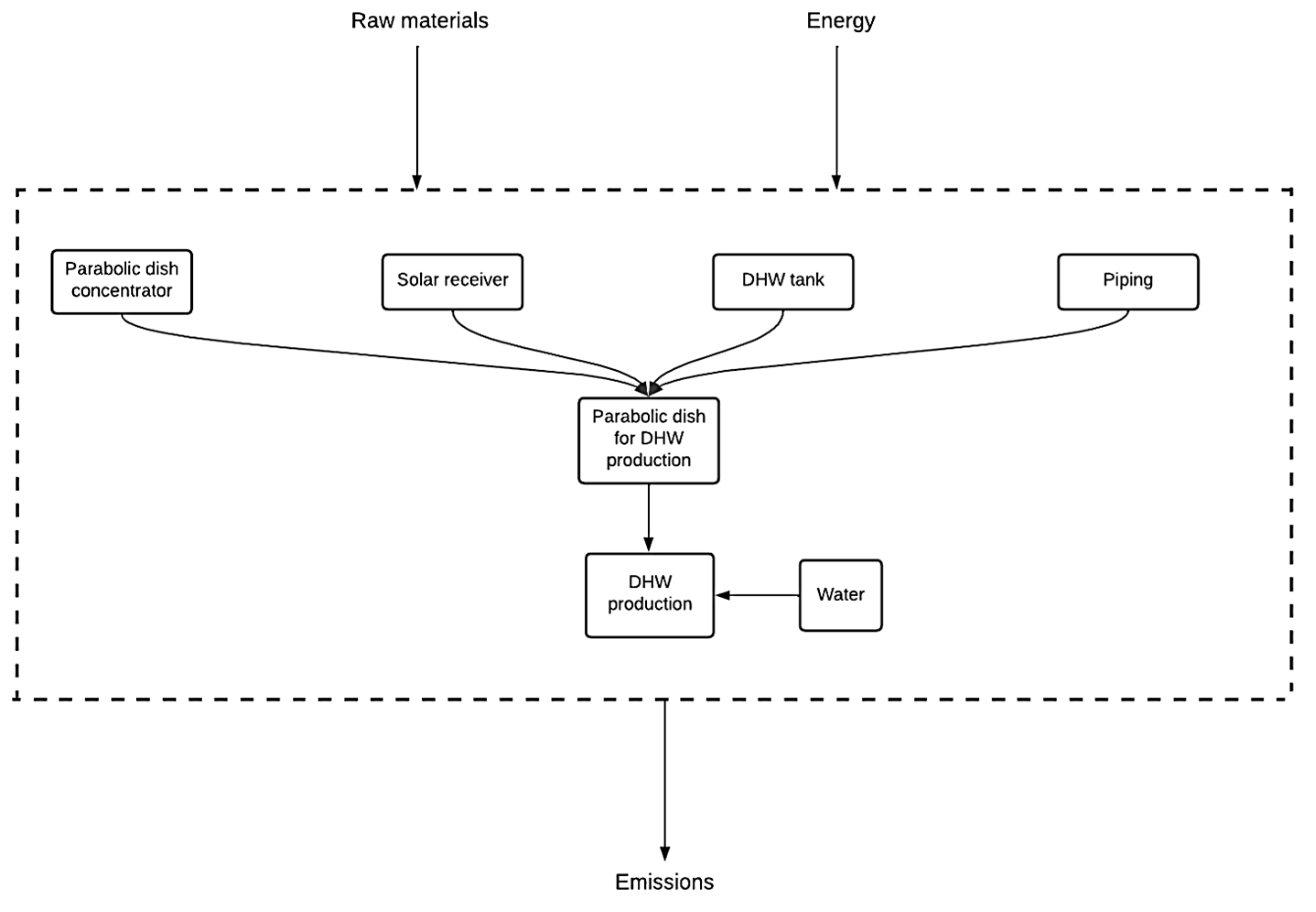

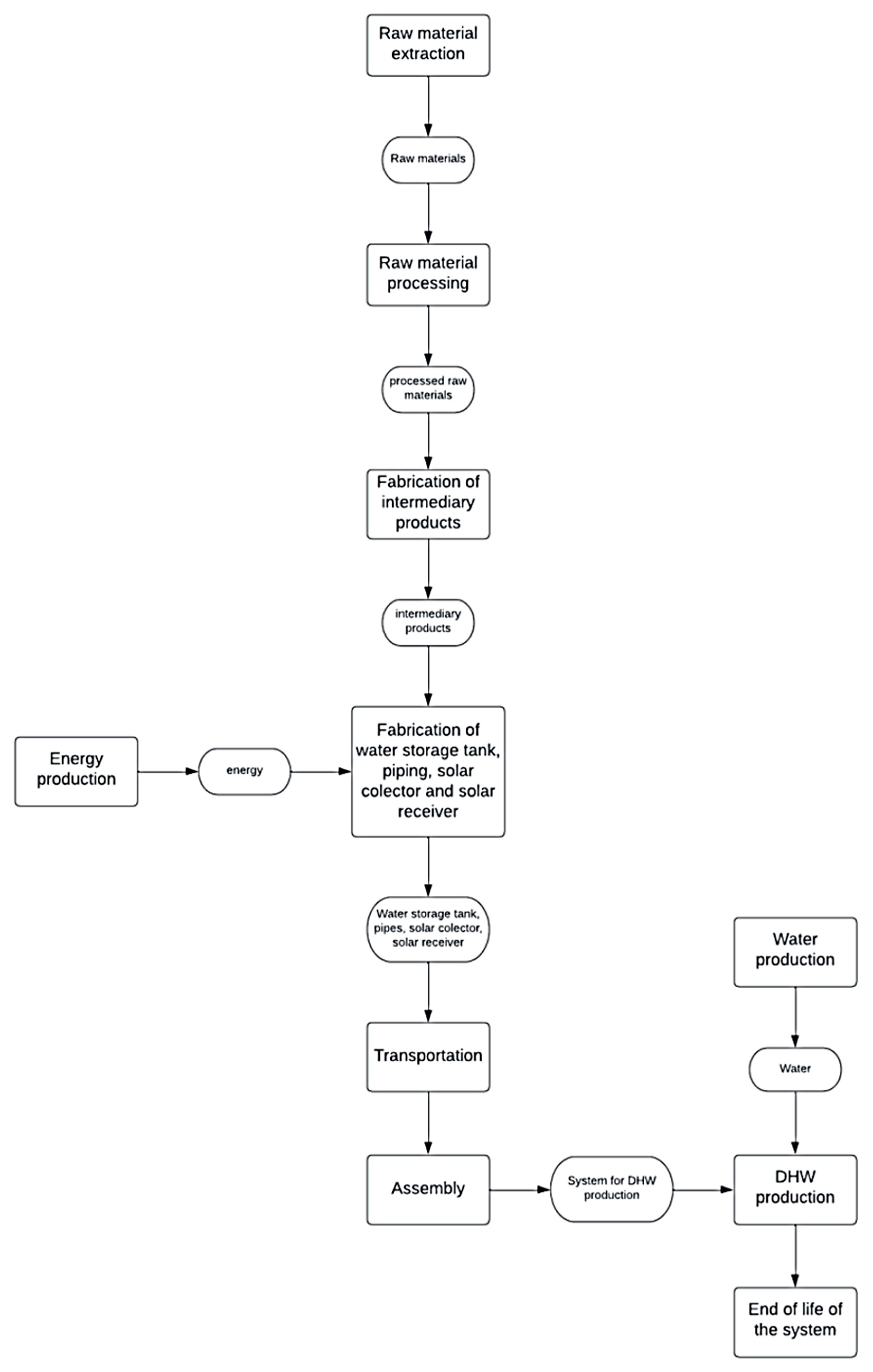

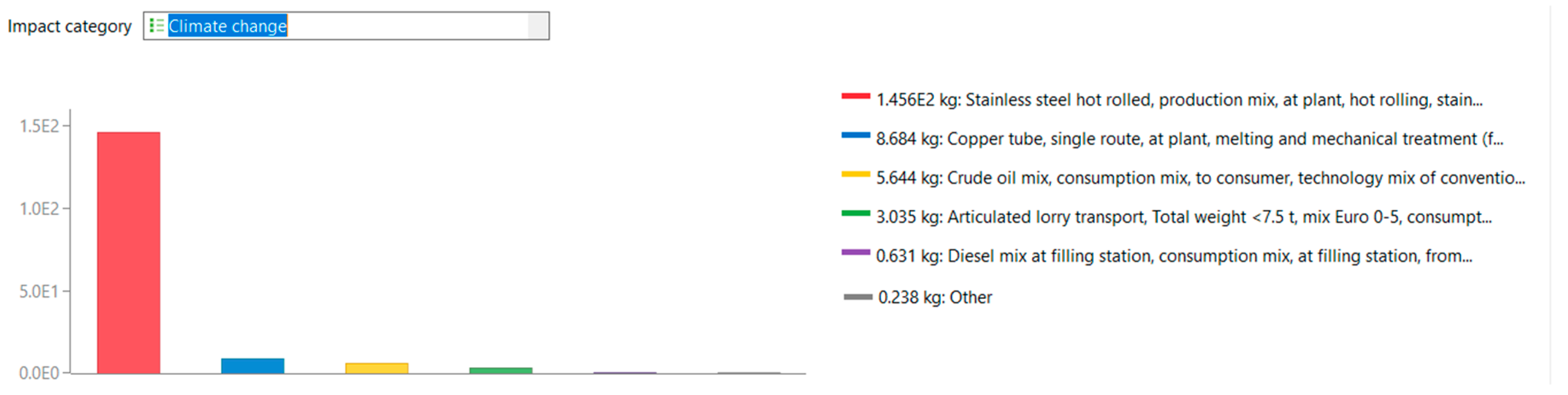

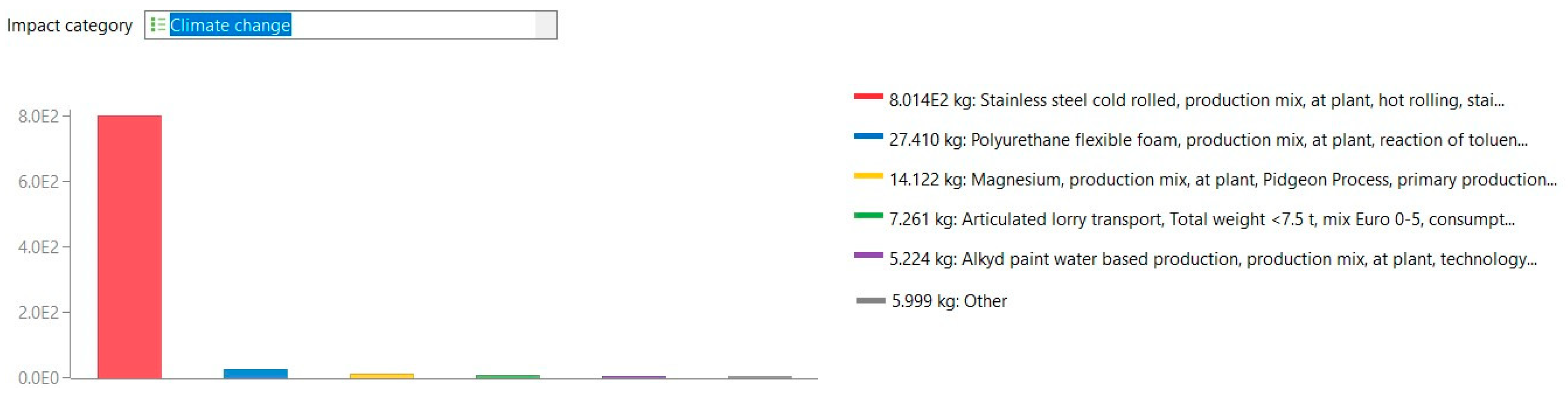

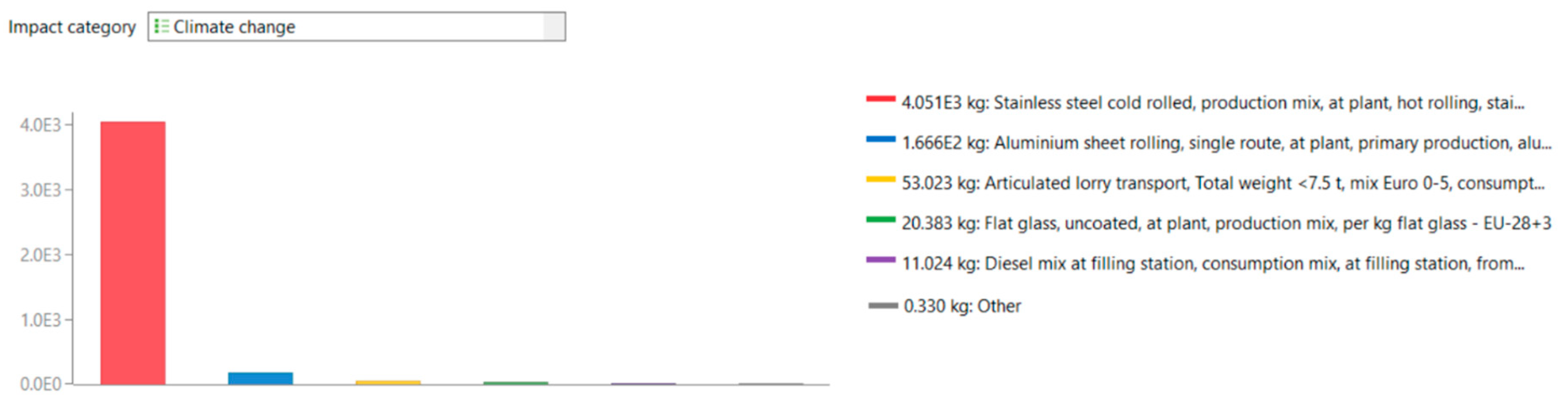

The system boundary shown in

Figure 3 includes the production, utilisation, and final decommissioning phases. Four different processes were considered separately to produce the system. Each of the processes includes raw material extraction and end-of-life treatment. The process "Parabola for hot water production" represents a process that includes all the outputs of the previous processes. In fact, it includes four upstream processes as inputs and their transport from the production site to the utilisation site. The output of the process "Parabola for domestic hot water production" is the input of "Domestic hot water production", together with "water". The last process is the functional unit to which all results will be referred: a domestic hot water tank. In this last process, which represents the utilisation phase, water consumption is also included. In this case, the transport of water from the extraction source to the point of use is not considered. The manufacturing processes of the hot water tank, receiver, piping and solar collector do not include the impacts of their assembly. These impacts were omitted due to a lack of reliable data. Furthermore, due to the difficulty of finding accurate information on the quantities of materials used, the analysis was based on product data sheets and estimates from the literature. The life expectancy of the components is assumed to be 30 years. Assuming that a tank full of water is consumed every day, the consumption can be translated into 10950 days. If the tank operates for 255 days per year and considering, the previously introduced functional unit - a domestic hot water tank - the weight of one day of operation is equal to 1.307E-4 of the life expectancy, see

Figure 4. Since the dish under analysis is in Turin, Italy, whenever possible, the processes used for data representation were in Italy, Europe or a European country. The software used is openLCA 1.10.3 (GreenDelta GmbH, Germany) and the database is version 1.00 of the open-source Environmental Footprint database.