1. Introduction

Thermal conductivity of carbon nanotubes (CNTs) can vary and is determined by their geometry and number of defects. Before use CNTs are often functionalized - -OH, -COOH and other radicals are covalently attached to the CNTs by chemical means. Generally, the attachment of a radical happens over the course of a reaction involving oxidizers (HNO

3, H

2О

2, KMnO

4) [

1]. This procedure simultaneously changes the electric conductivity, thermal conductivity, sorptive capacity of the CNTs, adhesion to polymers and ceramic matrices, which must be accounted for while creating composites. Currently, there are no detailed complex studies on the influence of the number of functional groups and their type on the properties of CNTs, and it is often customary in the studies on composites with CNT additives [

2,

3,

4,

5,

6,

7] to simply state the fact of change in properties for the better as a result of functionalization. In works [

3,

6] it is explained by a more effective dispersion of CNTs within the volume of the composite, in [

5] – by an improvement of the kinetics of the agglomeration, in [

2,

4,

7] – by the fact that the functional group covalently connected the CNT with the polymer matrix.

While modeling the properties of solitary single-walled CNTs in works [

8,

9] it was established that increasing the number of functional groups decreases thermal conductivity of CNTs. The experiment in work [

10] also showed that functionalization of single-walled CNTs lowered the thermal conductivity of the composite, while functionalization of multi-walled ones lowered it only slightly. Work [

11] also confirms the deterioration of thermal conductivity of single-walled CNTs as a result of functionalization.

2. Materials and Methods

This work explored “Taunit”, “Taunit-M”, “Taunit-MD” and “Tuball” CNTs. Their characteristics are provided in

Table 1 [

12,

13]. Their functionalization involved reactions, that are well known in literature: attachment of –COOH groups [

14] (heating CNTs in a KMnO

4 solution at Т = 64

oС, the degree of functionalization was determined by the mass ratio of CNTs/ KMnO

4, which varied from 0.2 to 12), -OH groups [

15] (heating in a 30% hydrogen peroxide solution at Т = 100

oС, the degree of functionalization was determined by the time of the reaction, from 20 to 180 min), heating CNT-COOH in ammonia vapors at Т=250

oС for 12h in order to obtain –CNT-CONH

2 [

1]. The influence of the number of defects without functional groups was also studied. In order to obtain defects, CNTs were heated in the open air at the temperature of 250

oС. The number of defects was determined by the exposure time. The number of grafted functional groups during the reaction was measured by a Seven Compact conductivity meter (Mettler Toledo, Switzerland) by the method of conductometric titration. Thermophysical properties of the obtained CNTs were measured by a IT-Lambda-400 thermal conductivity meter to an accuracy of 5%. Measurements were carried out at a sample temperature of 50 - 60

oС.

3. Results and Discussion

3.1. Experimental Results

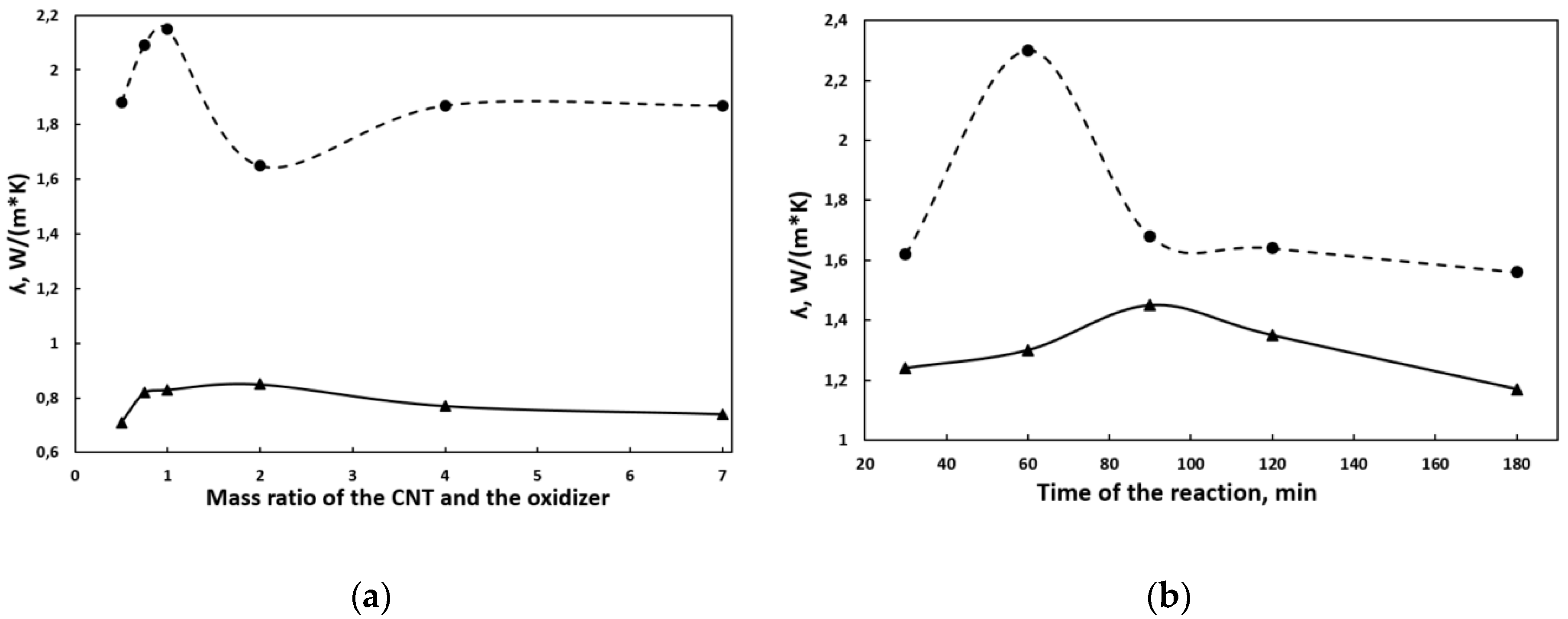

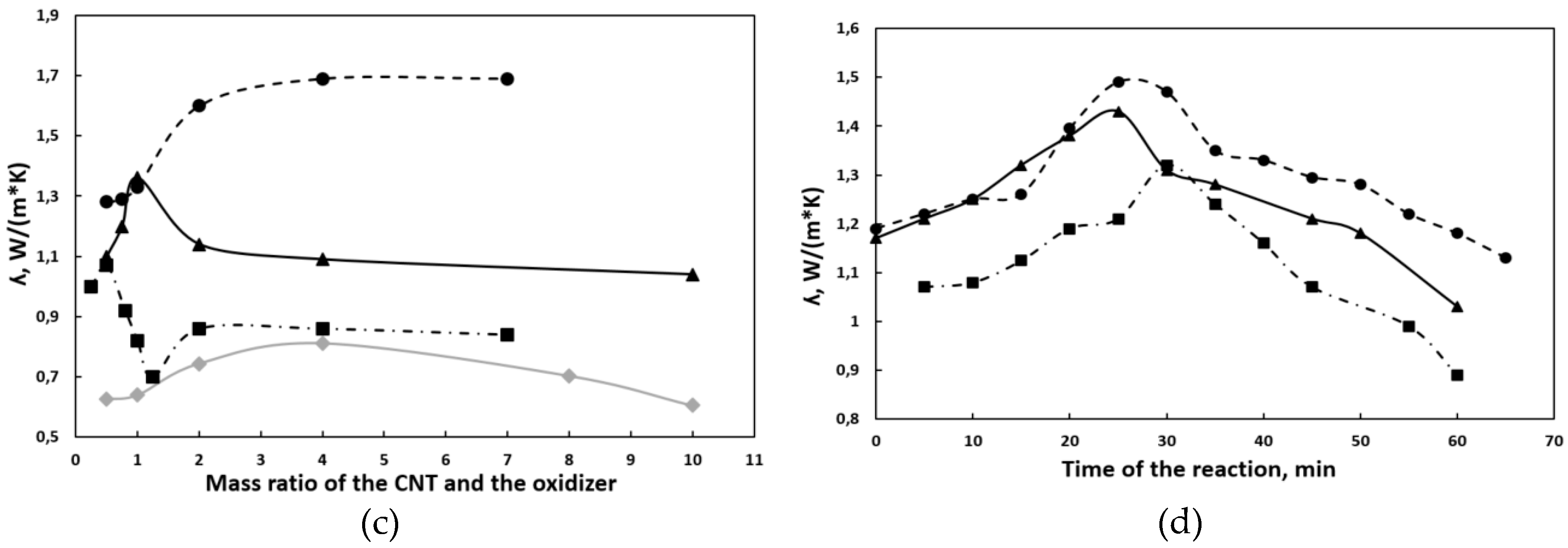

The obtained data (

Figure 1) allow us to assume that a high quality type of dependence of conductivity on the degree of functionalization is similar for different types of functional groups and multi-layer CNTs. The dependence can be divided into two sections.

In section A thermal conductivity improves upon an increase of the number of functional groups. The CNTs are cleaned from impurities (amorphous carbon, nanoparticles of metal catalysts) during oxidative functionalization. Removal of the amorphous phase should increase thermal conductivity, since amorphous carbon among the CNTs hinders the contact between them. The CNT geometry changes [

16], and that always leads to changes in subatomic distances, structure, and vibrational modes. The density of CNT agglomerates increases, since now they are not only connected by the weak van der Waals force, but also by the strong interaction between polar functional groups. In composites, CNTs spread out more evenly, forming a more consistent percolation network at a lower concentration.

In section B thermal conductivity deteriorates upon an increase of the number of functional groups. Functionalization was conducted through oxidative reactions, so the number of defects increases. Integration of a functional group breaks the covalent bond in the carbon skeleton, which leads to the formation of an additional defect. Defects scatter phonons. A perfect, flawless CNT has a ballistic conductivity [

17], phonons do not scatter inside of it, their free path length exceeds the CNT length, and the resistance of the CNT does not depend on its length. As the number of defects increases, the conductivity mechanism becomes quasi-ballistic – the conductivity deteriorates, but a dependence on the tube length does not manifest. A further increase in the number of defects initiates a transition to the regular conductivity mechanism. In addition, an excessive number of functional groups can prevent close contact of CNTs, serving as an insulating layer.

The mechanism of dependence of the covalent functionalization is not entirely clear. All CNTs possess anisotropic thermal conductivity, which is high along the tube axis. Moreover, a property manifests, which is known as ballistic conduction of phonons. Thermal conductivity is significantly lower across the CNT axis. The mechanisms that determine changes in the conductivity of CNTs upon covalent functionalization require further research. Thermophysical properties of solitary functionalized CNTs need to be measured.

Thermal conductivity of “Taunit-MD” CNTs is higher than that of “Taunit-M” CNTs because of a greater aspect ratio. The diameter of a CNT also affects thermal conductivity – the smaller the diameter, the higher the conductivity [

18].

The highest thermal conductivity was achieved upon a –OH type functionalization of both for a “Taunit-MD” CNT and a “Taunit-M” CNT.

The data on thermal conductivity of single-walled “Tuball” CNTs condradict the data in works [

8,

9,

10,

11], which state that functionalization always impairs thermal conductivity. It is likely that the authors of those works used a degree of functionalization that was too high and led to excessive CNT agglomeration or shortening of nanoobjects as a result of their destruction.

The dependence of thermal conductivity on the number of defects, which is shown in

Figure 1d, deserve special attention. These dependences are homogeneous. First, the CNTs are cleaned from amorphous carbon (it oxidizes faster than the CNTs), which leads to deterioration of the contact between CNTs and increases thermal conductivity. Then the accumulated defects start to hinder heat transfer. The reader may think that, since an increase in thermal conductivity in

Figure 1d on the order of magnitude is in line with similar increases in other figures, functional groups have no positive influence. However, that conclusion would be too hasty. To start with, even though molded samples of CNTs are a percolation network in regards to heat transfer, they are vastly different from CNTs in a polymer matrix. There, the ability of functional groups to facilitate CNT deagglomeration and a more consistent distribution of additives throughout the whole volume of the composite. In addition, functional groups can covalently crosslink with polymers. This can facilitate permeation of phonons into CNTs.

4. Conclusions

We presuppose the existence of competing processes that increase conductivity (a more consistent distribution of CNT agglomerates, improvement of the contact between CNTs, facilitation of permeation of phonons into CNTs through functional groups, changes in the CNT geometry) and resistance (emergence of defects and scattering centers). The data obtained can be used for controlling conductive properties of CNTs as well as determining the optimal degree of functionalization during the development of composites and nanodevices. In particular, the authors of the article use the obtained data to improve a protective superhydrophobic coating [

19].

The technology of covalent functionalization of CNTs allows to obtain CNTs with a given concentration of functional groups, which makes it possible to vary the thermal conductivity of the CNTs. The authors hope that this article will rouse interest in the suggested topic and possibly provide researchers with materials for creating theoretical models, describing charge and heat transfer in percolation systems of CNTs.

Author Contributions

Conceptualization, S.N.K.; methodology, S.N.K. and A.S.L.; validation, Y.V.T., S.N.K. and A.S.L.; formal analysis, S.N.K.; investigation A.S.L.; resources, S.N.K; data curation, A.S.L.; writing—original draft preparation, Y.V.T., S.N.K. and A.S.L.; writing—review and editing, Y.V.T.; visualization, Y.V.T. and A.S.L.; supervision, Y.V.T.; funding acquisition, S.N.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Russian Science Foundation, grant number 22-22-20115.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dyachkova, T.P.; Tkachev, A.G. Methods for functionalization and modification of carbon nanotubes; Publishing house Spektr: Moscow, Russia, 2013; p. 152. [Google Scholar]

- Jo, J. O.; Saha, P.; Kim, N.; Ho, Ch.; Kim, J. Development of nanocomposite with epoxidized natural rubber and functionalized multiwalled carbon nanotubes for enhanced thermal conductivity and gas barrier property. Mater. Des. 2015, 83, 777–785. [Google Scholar] [CrossRef]

- Premalatha, M.; Jeevaraj, A. Kingson. Study on the Thermal Conductivity and Rheological Properties of Carboxyl (–COOH) Functionalized Multi-Walled Carbon Nanotube (MWCNT)-Dowtherm A Nanofluids. J. Bionanosci. 2018, 12, 370–377. [Google Scholar] [CrossRef]

- Yang, Shin-Yi; Ma, Chen-Chi; Teng, Chih-Chun; Huang, Yen-Wei; Liao, Shu-Hang; Huang, Yuan-Li; Tien, Hsi-Wen; Lee, Tzong-Ming; Chiou, Kuo-Chan. Effect of Functionalized Carbon Nanotubes on the Thermal Conductivity of Epoxy Composites. Carbon 2010, 48, 592–603. [Google Scholar] [CrossRef]

- Premalatha, M.; Vathi, P.; Padmavathi, S.; Jeevaraj, A. Kingson. Enhanced Thermal Conductivity of Carboxyl (–COOH) Functionalized Multi-Walled Carbon Nanotube (MWCNT)-Silicone Oil Based Nanofluids. Sens. Lett. 2020, 8, 52–54. [Google Scholar] [CrossRef]

- Ji, P.; Sun, H.; Zhong, Y.; Feng, W. Improvement of the thermal conductivity of a phase change material by the functionalized carbon nanotubes. Chem. Eng. Sci. 2012, 81, 140–145. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, W.; Zhao, Y.; Yang, K.; Du, B.; Ding, L.; Yang, W.; Wu, S. Surface NH2-functionalized by C doping of boron nitride nanotube to improve the thermal conductivity of epoxy composites. Compos. B: Eng. 2021, 223, 109106. [Google Scholar] [CrossRef]

- Boroushak, H.; Ajori, S.; Ansari, R. Thermal conductivity of perfect and defective carbon nanotubes functionalized with carbene: a molecular dynamics study. Mol. Simul. 2021, 47, 1–9. [Google Scholar] [CrossRef]

- Pan, R.; Xu, Z.; Zhu, Z.; Wang, Z. Thermal conductivity of functionalized single-wall carbon nanotubes. Nanotechnology 2007, 18, 285704. [Google Scholar] [CrossRef]

- Gulotty, R.; Castellino, M.; Jagdale, P.; Tagliaferro, A.; Balandin, A.A. Effects of Functionalization on Thermal Properties of Single-Wall and Multi-Wall Carbon Nanotube–Polymer Nanocomposites. ACS Nano 2013, 7, 5114. [Google Scholar] [CrossRef] [PubMed]

- Lan, X.; Liu, C.; Wang, T.; Hou, J.; Xu, J.; Tan, R.; Nie, G.; Jiang, F. Effect of Functional Groups on the Thermoelectric Performance of Carbon Nanotubes. J. Electron. Mater. 2019, 48, 6978. [Google Scholar] [CrossRef]

- NanoTechCenter LLC. Available online: http://www.nanotc.ru/ (accessed on 13 August 2023).

- OCSiAl. Available online: https://ocsial.com/ (accessed on 13 August 2023).

- Chen, J.; Chen, Q.; Ma, Q.; Li, Y.; Zhu, Zh. Chemical treatment of CNTs in acidic KMnO4 solution and promoting effects on the corresponding Pd–Pt/CNTs catalyst. J Mol. Catal. A Chem. 2012, 356, 114. [Google Scholar] [CrossRef]

- Weydemeyer, E.J.; Sawdon, A.J.; Peng, Ch.-A. Controlled slicing of single walled carbon nanotubes under continuous flow. ChemComm 2015, 51, 27–5939. [Google Scholar]

- Breslavskaya, N.H.; Dyachkov, P.N. Stereospecificity of fluorination of CnFk nanotubes (n = 160-165, k = 1-18). Russ. J. Inorg. Chem. 2000, 45, 1830–1837. [Google Scholar]

- Eletskii, A.V. Transport properties of carbon nanotubes. Phys. Usp. 2009, 52, 209–224. [Google Scholar] [CrossRef]

- Pronevsky, A.G.; Tivanov, M.S. Modeling the dependence of the thermal conductivity of defect-free single-walled carbon nanotubes on their geometric parameters and temperature. Bulletin of BSU. Ser. 1, Physics. Mathematics. Informatics 2015, 1, 48–52. [Google Scholar]

- Kapustin, S.N.; Zabolotny, S.I.; Eseev, M.K.; Tsykareva, Y.V. Double-Layer Superhydrophobic Anti-Icing Coating Based on Carbon Nanoparticles. Crystals 2022, 12, 1501. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).