2.1. Problem Description

The goal of the original study was to produce heat and electricity from biomass in a small rural region around the town of Bad Zell (Austria). The supply chain is summarized in

Figure 1.

Four types of biomass are available: animal manure, intercrops, grass, and corn silage. In fact, an objective of the original case study was to investigate the potential usage of intercrops.

There are dozens of individual agricultural suppliers for biomass. As a simplification, these are grouped into 8 supplier sites. The available biomass is transported via trucks to one of the 3 possible processing locations. Biomass is transported as fresh matter, that means it is not dried first. This is acceptable due to the short distances.

Each location may host multiple fermenter units which produce biogas (methane) from biomass, and multiple CHP plants. Biogas throughput is estimated based on the dry matter content of the fresh matter of each biomass type transported. Heat and biogas can be transferred via pipes to the central town, which can host additional CHP plants. Supporting infrastructure is also required: fermenters require heating, storage of biomass requires investing into a silo plate at each location, and electricity transfer requires a transformer. All purchased biomass and all produced biogas must be consumed inside the supply chain, no leftovers are allowed.

The optimization problem seeks to maximize profit from selling produced heat and electricity at the central town. It is assumed that all energy can be sold, there is no specific demand. The key decisions to be made are the locations, numbers, and sizes of the fermenter and CHP units, and required supporting infrastructure to be invested into, and also determine material flows. A payoff period of 15 years was used in the original work.

Both fermenter and CHP units are available in different sizes: 80 kW, 160 kW, 250 kW, 500 kW. In case of a CHP unit, the sizes denote electricity output. In case of a fermenter unit, the size indicates that the fermenter can just supply a CHP unit of the same size with biogas if both work at full capacity. However, it is not required that the fermenter is actually connected to such a CHP plant, there can be any numbers and combinations of both, even with a partial utilization, as long as material balance for biogas is satisfied.

Fermenter inputs are a critical point in the model. The original case study assumed 8 fixed input compositions for fermenters. These are shown in

Table 1 along with total available amounts.

The exact method of selecting these fixed compositions was not available, although there was one explicitly mentioned restriction: manure usage must be at least 30%, due to a regulation. This is implicitly true if any of the fixed input compositions are used, but must be explicitly stated as a constraint when a flexible model is formulated.

2.2. Initial MILP Model

The main part of our work consists of an initial and a modified MILP model formulation, and a P-Graph model formulation for the described problem. Symbols for sets, variables, and parameters are listed in

Appendix A. Implementations and results are made available as supplementary materials.

The initial MILP model is now presented. The purpose of the initial MILP model was to reproduce results from the original case study, using fixed input fermenters. Constraints are listed below.

An important note: the key decision variables denoting fermenter utilization, and and denoting CHP plant utilization are not binary but integer variables, allowing multiple identical units.

The fresh matter amounts

transported from suppliers to all locations

l cannot exceed the total biomass availability

at supplier

s.

The total of fresh matter amounts

transported to a location

l is equal to the total of inputs

of fermenters at that location, taking all sizes

k and input compositions

m into account.

The following constraint calculates biogas production from input biomass types t, for all fermenters of size k, with input composition m, at location l. Two conditions must hold.

Ratio of inputs is determined by the input composition m. Constant denotes the ratio for biomass type t in input composition m such that .

The total amount of biogas is obtained as a sum for each input t. The factor is used to convert fresh matter amounts to produced biogas amounts such that units of biomass type t yield a production of units of biogas.

Fermenter and CHP plant capacities are measured in full load working hours, of which

is assumed a year. Fermenters of size

k, composition

m at location

l work for an equivalent of

hours, although the exact distribution of load during the year is not considered in the model. For example, if a fermenter works at full, another identical one at half capacity, then

. Coefficient

converts working capacity to biogas production as follows, depending only on equipment size.

Biogas material balance at each location means that all production

is either transported to the town (

) or consumed in place. Used working capacity of CHP plants of size

k at location

l is

.

All biogas transported into the town are consumed by CHP plants. Variable

denotes working capacity of CHP plants of size

k at the town.

Heat balance must hold for each location

l. Heat is produced by CHP plants, calculated using the ,,working hours to heat” factor

, and extra heating

from a furnace. Heat is consumed by fermenters regarded by factor

or transported to the town, denoted by

.

Heat pipes, if built, may carry heat from locations to the town. For each location to build a heat or biogas pipe from l to the town, denotes the set of pipe sections that must be built. In short, our new formulation allows arbitrary pipe section requirements. In the original case study, there were 3 possible pipe sections: : from to town, : from to town, and : from to . Therefore, , , .

The following two constraints ensure that no more heat can be lost than being transported from any location

l, and that heat loss (

) at a pipe section

p is the sum of heat losses at that pipe section attributed to different locations (

).

Heat loss

at a pipe section is assumed to be proportional to pipe section length

with a constant rate

. Binary variable

denotes whether the pipe section is built.

Heat throughput to be sold is from direct production at the town, plus transported amounts, minus heat losses.

Electricity throughput

to be sold is calculated separately for each CHP plant size

k. The factor

converts working capacity to electricity throughput.

The following constraints state that if some investment is not made and the represented infrastructure is not built (denoted by integer variables), then a corresponding activity cannot take place. If the investment is made, then there is still usually an upper bound. Due to implementation reasons, there are constants on the maximum of identical equipment units at the same location or the town, and and for an upper limit (big-M) for biogas and heat transportation.

For example, working capacity

of CHP plants of size

k at the town is at maximum the number of such plants (

) times

. If a silo plate is built at a location (

), then a maximum of

identical fermenters are allowed there (

), otherwise the maximum is 0.

Annual income is from selling heat and electricity throughput. Note that due to regulations, the feed-in tariff

for electricity depends on plant size

k.

Investment costs are attributed to CHP plants, fermenters (

), silo plates, the transformer, biogas pipes, and heat pipes. All investment costs are fixed, except that biogas and heat pipes also have costs proportional to length, and heat pipes do not have a fixed part.

Expenses are due to biomass purchase costs, biomass transportation with fixed part and proportional to distance, silo operation, fermenter heating purchase, fermenter operation (

) and CHP plant operation, CHP plant electricity cost, and heat pipe electricity cost.

Fermenter investment cost

and operating cost

are separated for better explaining model modifications.

A payback period of

years was used as in the original case study. The objective is the annual profit, which equals the revenues minus annualized investment and operating costs.

2.3. Modified MILP Model with Flexible Inputs

The initial MILP model was modified to use fermenters with flexible inputs. The key change is that the fixed input compositions are not used, as each fermenter may have a variable input composition. To make it possible to have multiple such fermenters for the same size k and location l, a new identifier i is introduced instead of m. Constant is introduced as a practical maximum number of fermenters with flexible inputs of the same size and at a given location. For fermenters only, is a substitute of for identical units. The identifier i runs over the set . The new binary variable denoting fermenter utilization (existence) is . Note that unlike the former , the new is binary, allowing a single fermenter. Therefore, there can be distinct fermenters with flexible inputs for any size k and location l.

As a consequence, heating demands and investment costs of fermenters are calculated based on the input amounts for each biomass type t instead of the fixed input composition m. Therefore, as shown later, parameters and are used instead of and .

Note that fermenters of different sizes are still distinguished in the new model as well. The reason is that costs for different sizes are rather unique, mainly due to economies of scale.

Constraint

2 is replaced by the following equation. Variable

denotes the input of biomass type

t into a single fermenter of size

k, identifier

i at location

l. The sum of inputs is the sum of delivered biomass amounts

.

The new model allows a minimum ratio

for all flexible fermenters, for any biomass type

t. This is an example of the flexible input scheme allowing arbitrary linear constraints. In the original case study, the only such requirement was that there must be at least 30 % manure. (

).

The total biogas amount

produced by a single fermenter is obtained as a sum for all input biomass types

t. This replaces Constraint

3.

Fermenter working capacity

is connected to biogas production by the factor

. This is similar to Constraint

4, and replaces it.

Constraint

5 is replaced by the following equation for biogas balance at locations. The produced biogas is either transported to the town (

) or consumed by local CHP plants.

A similar replacement is done for Constraint

7 expressing heat balance at locations. A significant change is that fermenter heating requirement is not based on working hours and parameter

for each input composition

m. It is instead proportional to input amounts, expressed by the new parameter

for each biomass type

t. The constraint claims that the amount generated by CHP plants plus the purchased extra heating is either consumed by fermenters or transported to the town.

The logical Constraint

16 expressing silo plate usage is also replaced. The silo plate is needed if there is a fermenter at the location.

Similarly, Constraint

27 is replaced. The annual operating cost of any fermenter of size

k is

as in the initial model.

Fermenter investment costs are more difficult to formulate. A linear estimation is made based on the amounts

, as for the heating requirement in Constraint

34. A new parameter

is introduced for the investment cost per unit amount of biomass type

t consumed. The following is a possible estimation of investment cost (not included as a constraint).

The issue with Equation

37 is that the investment cost should not scale down if a fermenter is used below full capacity and consumes less. For this reason, the slack biogas amount

is also calculated for each fermenter. This slack is the amount which is actually not produced but would be if the fermenter was working at full capacity. Variable

denotes whether the fermenter is built.

Therefore, depends only on k, not on the inputs. Since the biogas production from t is , the value expresses investment cost per unit biogas production.

The idea is to calculate the investment cost based on the slack as if it was actual consumption of biomass type

t with maximal

. With this choice, the calculated investment cost is an upper bound of the actual one, being strict if the fermenter is used at full capacity, or if the fermenter only uses inputs

t for which

is maximal. The final constraint for fermenter investment costs is the following.

2.4. P-Graph Model, Flexible Inputs

The maximal structure of the P-Graph model is too large to be depicted in a whole. Instead, operating unit nodes are detailed here. Node labels are listed in the nomenclature.

The raw material nodes are for available biomass types t at suppliers s, and for extra heating. The single product node is . Subtracting costs of the network from the amount gives the objective.

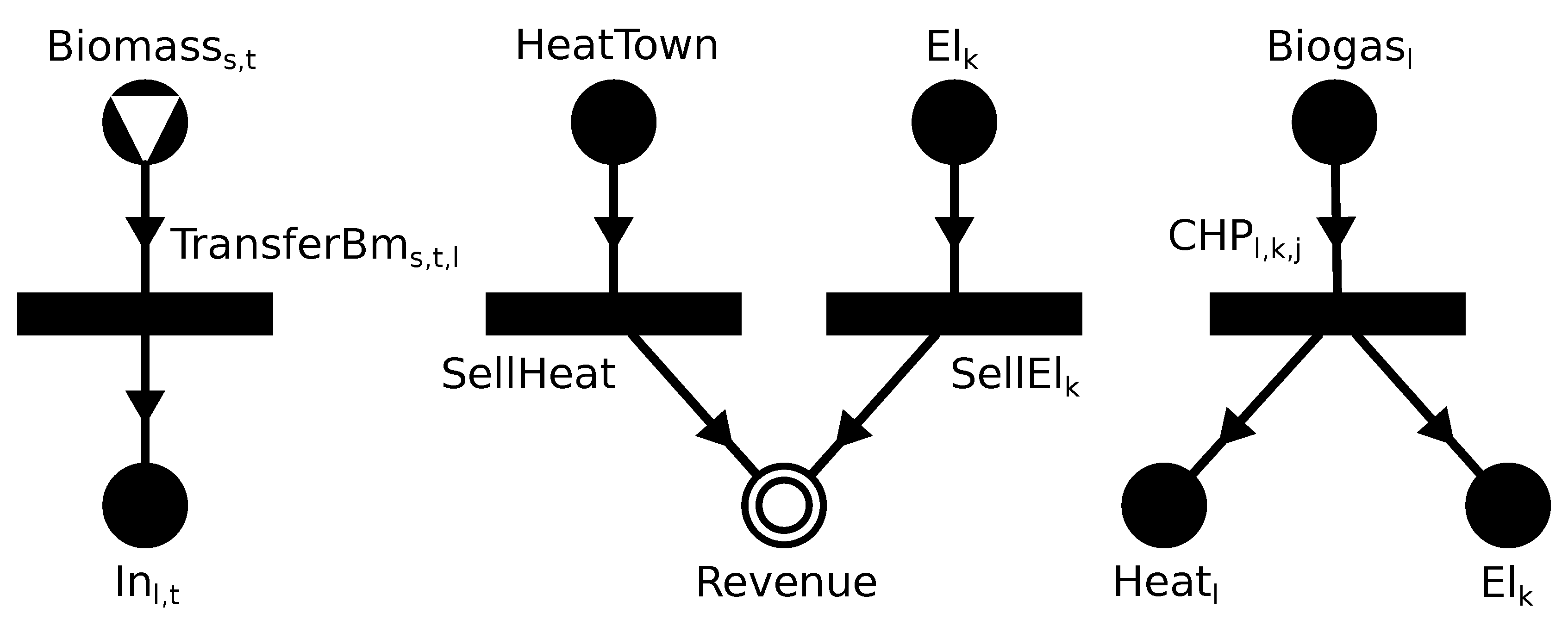

Some operations like material transfers or conversions, listed below, can be modeled by an operating unit with a single input material.

Operating units for biomass transfer are introduced for each supplier s, biomass type t and location l. The single input material node is , the output is which represents input for fermenters.

Operating units denote purchase of into the available heat for each location l.

Operating units denote transportation of available biogas at each location l to the town, denoted by the node.

Operating units and for all sizes k denote selling energy. Their single inputs are and , the output is in all cases.

The CHP plant at location l, with size k, and identifier j is denoted by operating unit node . Since identical plants are allowed, . The single input is the available biogas , the two outputs are available heat and electricity .

The CHP plant at the town, with size k, and identifier j is modeled similarly, by operating unit node . The single input is , and the two outputs are available heat and electricity .

Figure 2 shows three of the aforementioned operations. In the final P-Graph model, individual nodes are introduced for each index set.

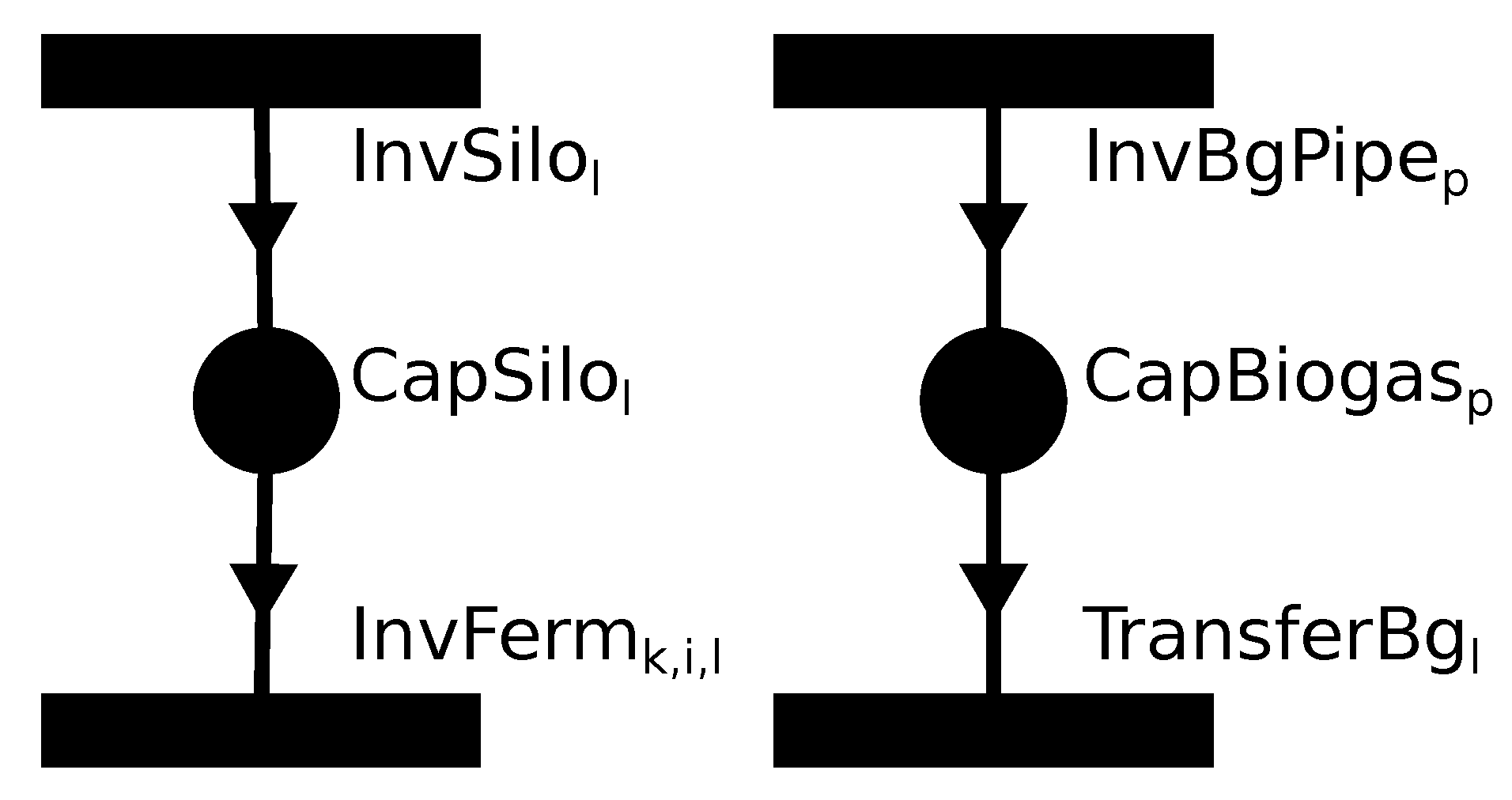

If an operating unit requires another operating unit to be present, it can be modeled by a logical constraint. The required operating unit produces a dummy capacity material, which is consumed by the depending operating unit. The exact amounts of the dummy capacity material are not important.

Logical constraints of this kind are applied to operating unit nodes representing investment into some equipment. Instances are listed below. Examples are shown in

Figure 3.

Investment into the fermenter of size k, identifier i, location l, is denoted by operating unit . It requires the silo plate, denoted by operating unit and dummy capacity material .

CHP plant operation for any size k and identifier j at the town () or a location l () requires the transformer, denoted by operating unit and capacity .

Biogas transfer from any location l denoted by operating unit across a pipe section requires building that pipe section, denoted by operating unit and capacity .

Heat transfer has the same rules as biogas transfer, but due to different heat loss and cost calculation, the implementation is different. is the operating unit for heat transfer, and is the operating unit for heat pipe investment, but there are distinct capacities for each l, .

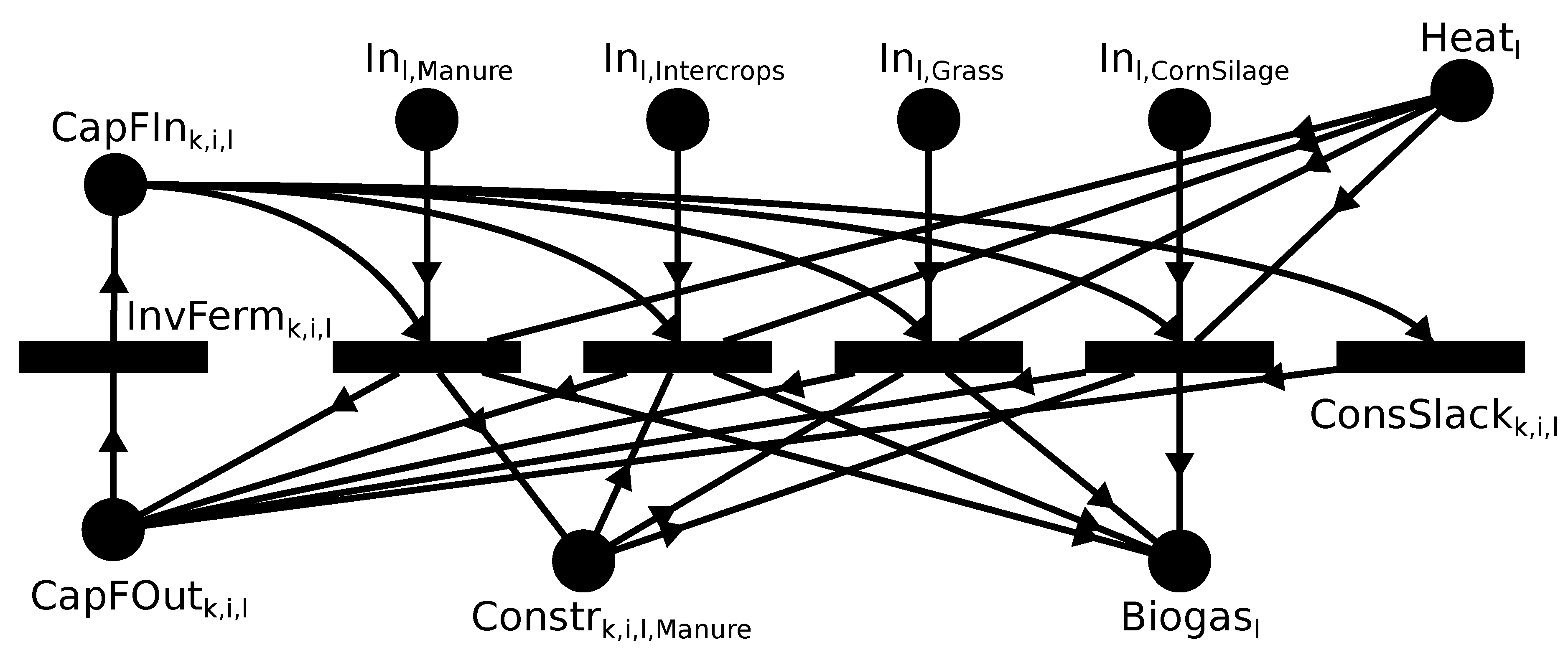

The model of the fermenters with flexible inputs is the most complex. It is shown in

Figure 4, and is now detailed. The basic flexible input technique from [

36] is involved, and is further extended.

The size k, identifier i (with ) and location l together identify a single fermenter unit. For all four biomass types t, namely: manure, intercrops, grass, and corn silage, operating unit node represents consumption of input materials . Nodes play the key role, in the following ways.

Input node represents the required fermenter heating, which depends on the amounts of each t with its specific flow rate.

The 30 % minimum ratio of manure is ensured by a single logical material node

, produced by

(second operating unit in

Figure 4) with flow rate 7, and consumed by

for all other biomass types

t with flow rate 3.

represents the investment into the fermenter, producing its full capacity , which is then consumed by each , and also . This structure is mirrored: is produced, which is an input to . This ensures that consumes all the remaining capacity. Therefore, the investment cost can be calculated based on the amounts processed by and .

is the output of all production except for the slack, with appropriate flow rates for each biomass type t.

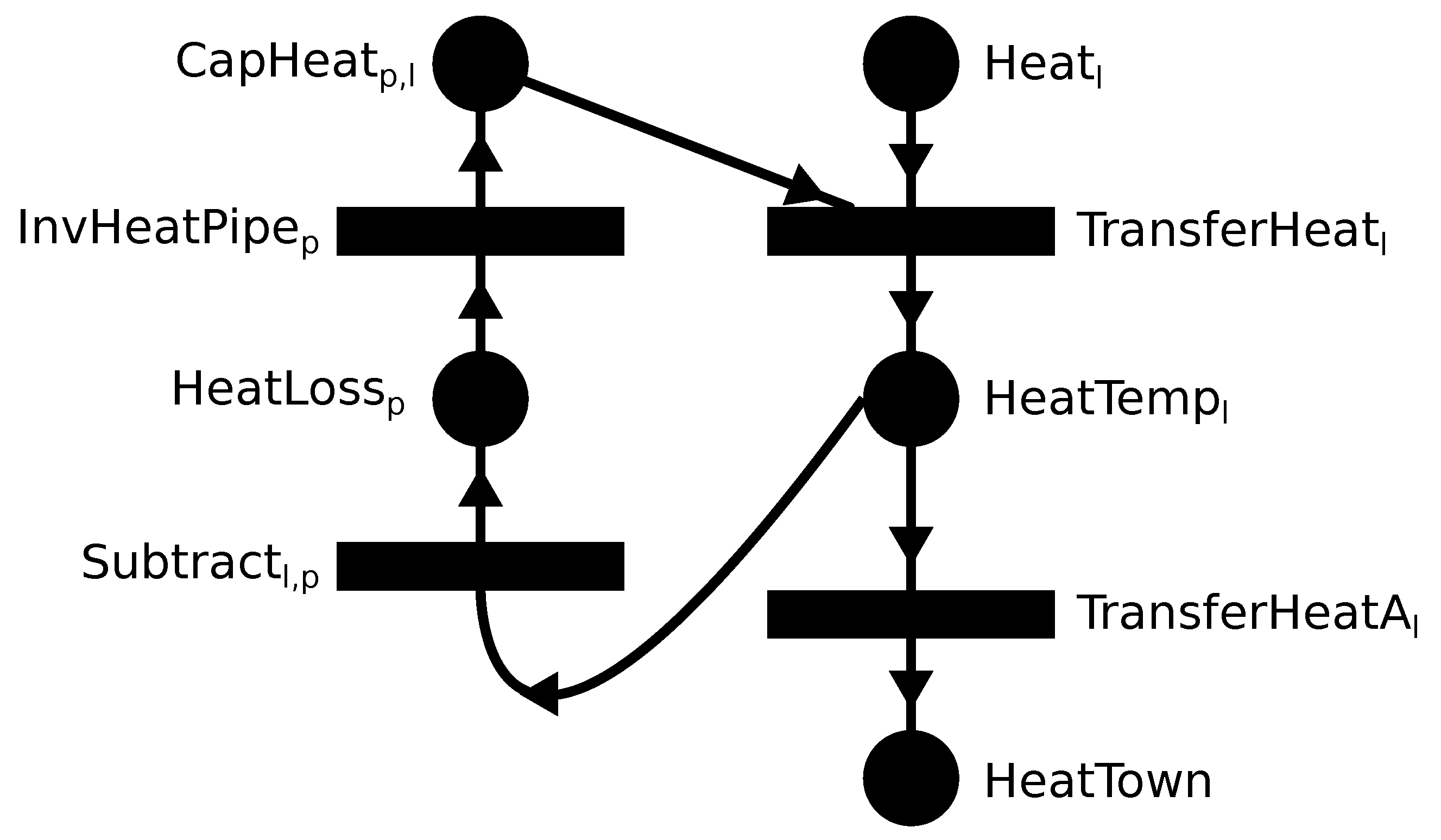

The last remaining part is the calculation of heat loss, which is a fixed term in this model for each pipe section

, but the required pipe sections

for a location

l can be arbitrary. The model is shown in

Figure 5. Nodes with indices

l,

p or pair of

l and

p are introduced for each index

,

or pair of

and

, respectively.

Heat transfer from does not immediately goes into but into a temporary material of which only a part is forwarded to . Some amount is subtracted by operating unit into representing heat loss amounts. This happens for each . Finally, if sufficient amount of is present, operating unit produces all dummy capacity materials for which . Note that also models investment into the heat pipe section p.

This part of the formulation is rather cumbersome. A future direction of research is finding a simple technique for achieving a similar modeling goal.