3. Results and discussions

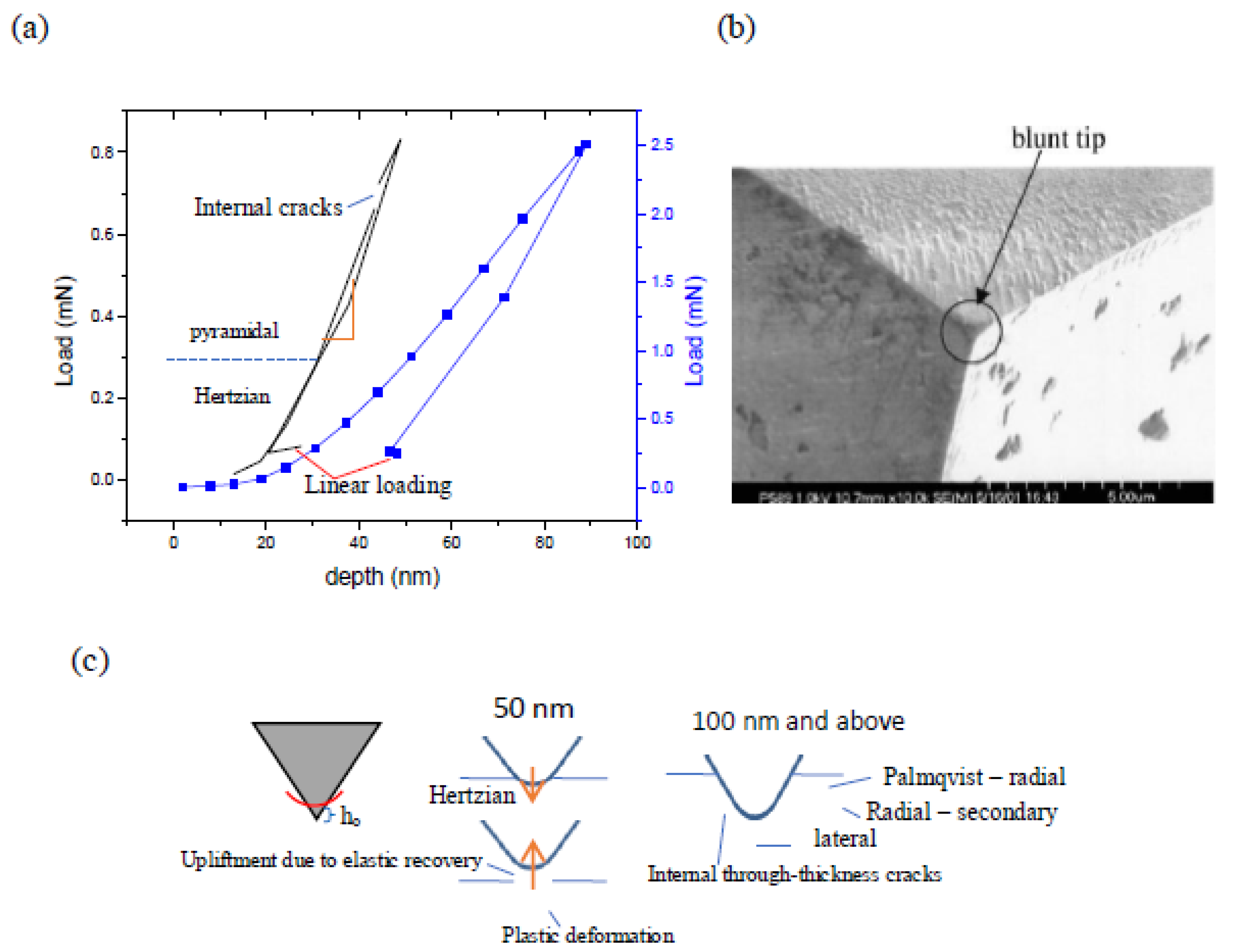

The load-depth (

P-h) plot for indentations performed at 50 and 100 nm depths is shown in

Figure 1(a). Interesting features of high elastic recovery and a discontinuity in the loading curve suggesting internal cracking were observed. A feeble plastic deformation is visible in the plot but there seems to be no residual depth. A ductile fracture can be inferred from these observations. Although a sharp three-sided pyramidal Berkovich indenter has been used, the contact established in such a shallow depth of 50 nm is Hertzian in nature mainly due to tip bluntness as depicted in the SEM image in

Figure 1 (b) [

4]. For deeper penetration of 100 nm, the usual nature of the

P-h plot was found. A linear loading at the end of the unloading curve was observed in both cases where the indenter seems to be penetrating back into the sample without any application of load. The extent of linear unloading was higher for lower depths of penetration (50 nm). The contact is Hertzian till 28 nm (0.5 mN) and offers negligible plastic deformation. A deeper penetration changes the contact from Hertzian to pyramidal. The sharper contact provides high stress to any flaws pre-existing causing an internal fracture which gets expressed as a discontinuity (pop-in) in the plot. Pop-in events depict phononic friction induced in nanoindentation. An enhancement in lattice friction causes increased resistance to dislocation motion and as a result smaller pop-in width [

5]. Heterogeneous nucleation usually results in in-distinctive pop-ins [

6]. The energy stored before pop-in gets utilized in the plastic deformation during pop-in [

7].

A plastic deformation seems to be taking place as observed from the unloading plot till the contact again becomes Hertzian at 28 nm. A unique phenomenon of indentation impression being existent underneath the top surface but is not observable from the top. It indicates a very important observation that when subjected to shallow depths, the sample might not show deformation from the top surface but might have gone deformation or damage underneath. Being no indentation impression being formed at the top, the material recovers elastically. The release stress-induced however gets released by means of upliftment of the film surface from its pre-indented state establishing contact with the indenter resulting in linear unloading (

Figure 1 c). This phenomenon although occurring for 100 nm penetration as well, the intensity is much less. The internal cracks were also not so much prevailing for 100 nm penetration. This is because the tip sharpness is related to the ratio of compressive stress and shear stress being imposed. A sharper tip imposes a higher fraction of compressive stress than shear stress causing plastic deformation. For ductile failure, as the film thickness increases, the fracture toughness also increases but is followed by a decrease due to the transition from plane stress to plain strain condition, until a plateau is reached, after which the toughness remains insensitive to further increase in thickness.

The zero-point correction due to tip blunting makes the contact depth

hc represented as h

c = α (h – P/S + h

o) where h

o is the equivalent height of the tip defect as shown in

Figure 1(c), taken as 5 nm approximately. S is the stiffness (0.02 mN/nm) and α = 1.2 for the Berkovich indenter which is due to pile-up or sink-in [

8]. Due to tip blunting, the initial contact of the indenter tip for shallow depth (50 nm) with the sample is Hertzian (as for a spherical indenter). For higher indentation depths, sides of the indenter come in contact and the Hertzian contact is no more prevalent. The increased sharpness causes crack growth as shown in the schema. Palmqvist radial and secondary radial cracks are shown cross-sectionally in

Figure 1 (c), evidence of which can be found below (

Figure 2a). Palmqvist-radial, secondary-radial, picture frame, and through-thickness cracks can be observed originating from different regions of the nanoindentation impression whose cross-sectional schematic representation The dotted line showing indentation contact edges deviated from a geometrically perfect shape. These cracks are related to the toughness and adhesion of the films. The mechanism of different crack generation in nanoindentation can be found in ref [

9]. The formation of high-density of nanocrystallites (4.8 µm

-2) in the sputter deposition process provided resistance to crack propagation causing deflections indicating enhanced toughness (

Figure 2 c).

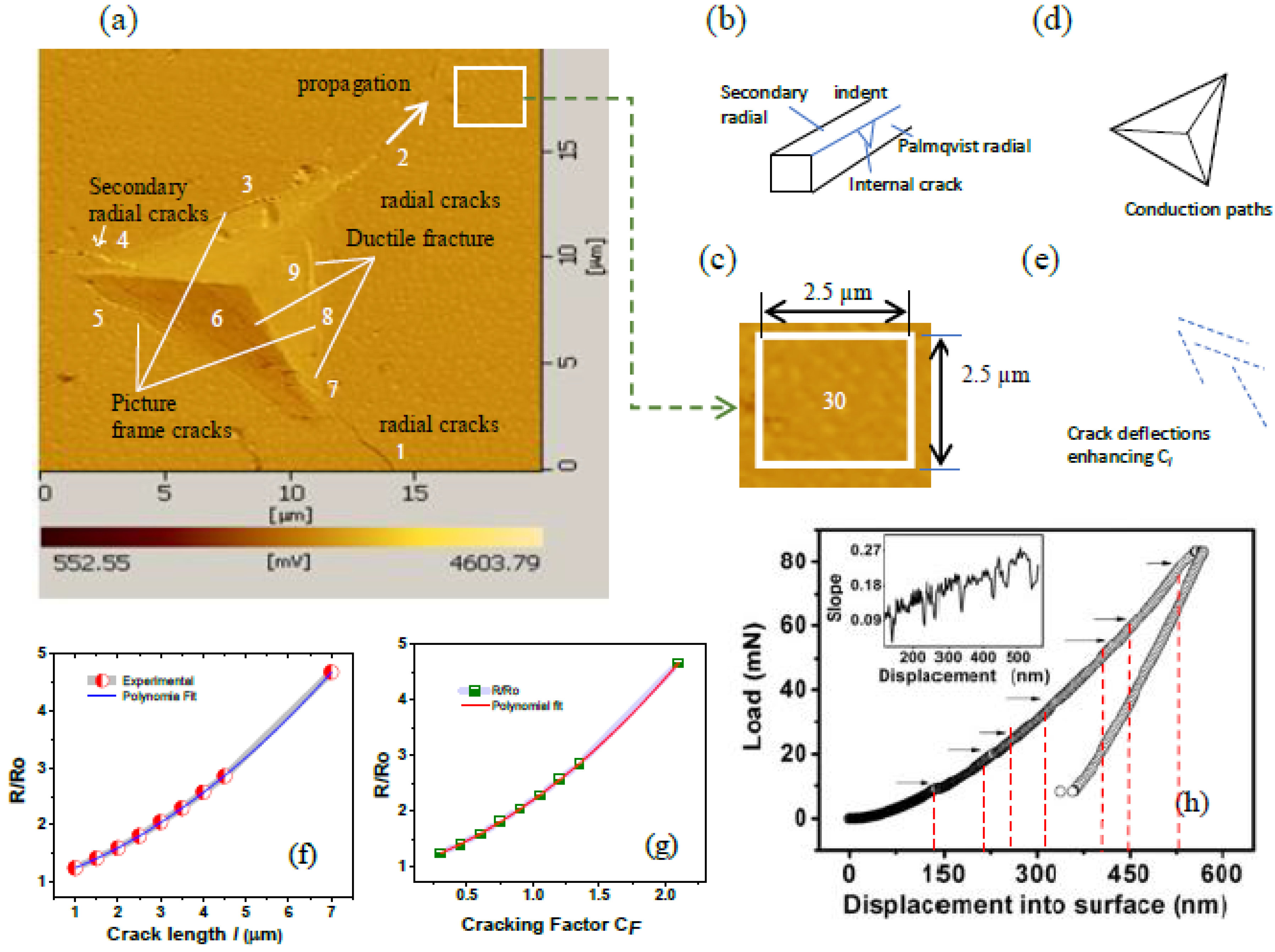

Internal through-thickness cracks occur and are arrested in the indenter impression region. They are evidence of ductile to brittle transitions. In ductile fracture, appreciable plastic deformation occurs before crack initiation and during crack propagation. As observed above, the Berkovich indenter is specially made to cause plastic deformation even at shallow depths, DBT again results in. cracks which are internal (inside the and have not been able to propagate to the surface. Based upon the mV scale bar, the conduction paths in the indent and originating through the cracks, as well as crystallites, can be identified (

Figure 2 d) which are significant for the TiB

2 films used in interconnects.

The distribution of cracks particularly the crack density and size in a solid influence the conduction properties of a material [

10]. Evidence of conductive bridges within the cracks has been found [

11,

12]. A parameter known as cracking factor C

F defined as the product of crack length (

a) and linear crack density (C

l, no. of cracks per unit length) can be used in relation to the conductivity (relative resistance) of films as given in

eqn 1 [

13] where Ro is the resistance without any cracking. The indentation sides are 10 µm in length and associated with radial, secondary, and picture frame cracks, the linear crack density comes out to be 0.3 µm

-1 (C

l). The C

F, therefore, was calculated for the different cracks marked numerically in

Figure 2(a). and given in

Table 1

The plots of relative resistance (

R/Ro) with crack length (

Cl) and Crack Factor (

CF) are given in

Figure 2 (f, g) which shows an increasing trend. The polynomial fit for both the plots has a relation given in

eqn 2 and 3. These plots can be considered calibration charts useful for device fabrication.

A deviation in crack propagation occurs due to the high density of nanocrystallites as observed for crack no. 1. This can be considered an effective increase in the local linear density of cracks as the cracks before and after deviation are treated separately (

Figure 2e). For a crack length of 4.5 µm, four cracks can be considered making the local linear crack density.0.9 µm

-1 and C

F = 4 will overshoot the calibration chart. This indicates although cracks generated may cause conduction paths, deflections occurring enhances the resistance. This shows that the nanocrystalline growth of films is essential for failure-free electronic devices

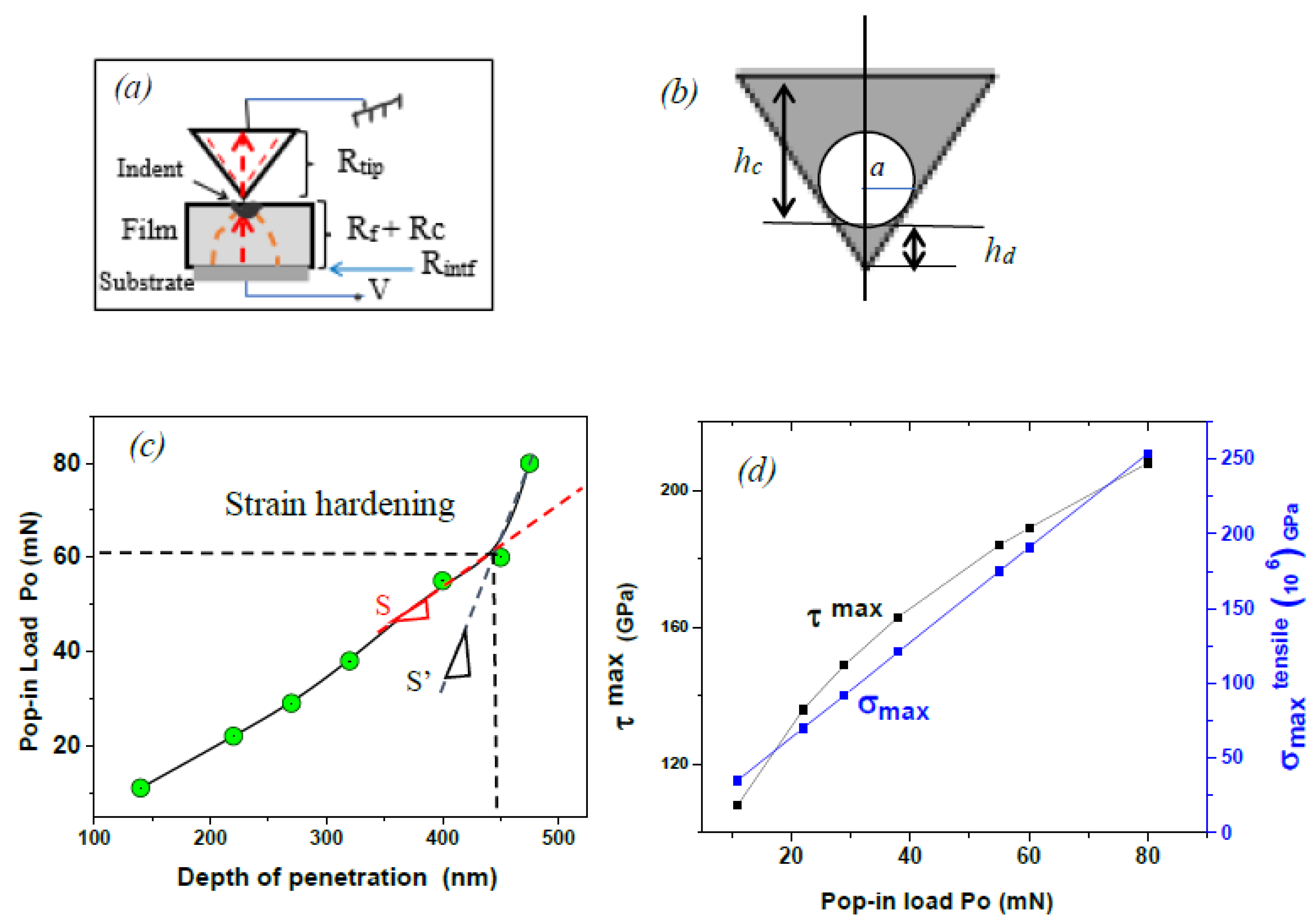

Conduction between the indenter tip and sample surface requires the application of an external bias in the current direction, as shown in

Figure 3a. The resistances that are impacted by indentation and any associated phenomena are the contact resistance R

f and the constriction resistance (R

C) [

14,

15]. The resistance at the coating/substrate interface R

intf, which may not be active at shallow depths of indentation (less than 10% thickness), is the resistance component that is affected subject to mechanical stimulation delivered by the indenter in addition to R

c specifically for a film/substrate system.

Nanoindentation performed on TiB

2 films on silicon substrate showed fracture events as represented through the pop-in in the load-depth plot. The maximum shear stress, τ

max, and the maximum tensile stress (σ

maxtensile ) induced during the indentation process at the point of pop-in are given as

eq 4 and 5 [16]

where R is the tip radius, P

o is the pop-in load, E

r is the reduced modulus and a is the contact radius at the pop-in. The period for which the fracture (pop-in) took place was estimated to be about 10 s. The impulse (ΔP/Δt) which caused the fracture was 0.02 mN/s. This impulse usually sends shock waves into the films and can hamper any conduction process taking place between the tip and the sample. The pop-in event is the onset of inelastic deformations and competition between dislocation-induced plasticity (by τ

max) and crack formation (σ

max tensile) which depends on the stress beneath the indenter tip. For sharper indenters, dislocation plasticity occurs prior to crack formation. The pop-in loads obtained from

Figure 2h showed steady increase with penetration depth initially and an increase at the later stages caused by strain hardening due to new dislocations formed in the plastic zone of radius r

p beneath the indentation as per

eq 6 (

Figure 3c) [

17]. The onset of strain hardening is at 65 mN with a corresponding penetration depth of 450 nm gives the yield stress as (σ

y= P

omax/24.5 h

max2) 13 GPa. The plastic radius comes out as 1.54 μm which is the similar dimension of the coating thickness, indicating the strain hardening is taking place in the coating with no substrate influence. The change in stiffness (ΔS=S

’-S=4.8 μN/m) as indicated in the figure divided by r

p gives a value of 3Pa as the flow stress existing in the plastic zone. The maximum nominal shear and tensile stress were proportional to the increasing pop-in load with penetration (

Figure 3d)