Submitted:

23 November 2023

Posted:

27 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

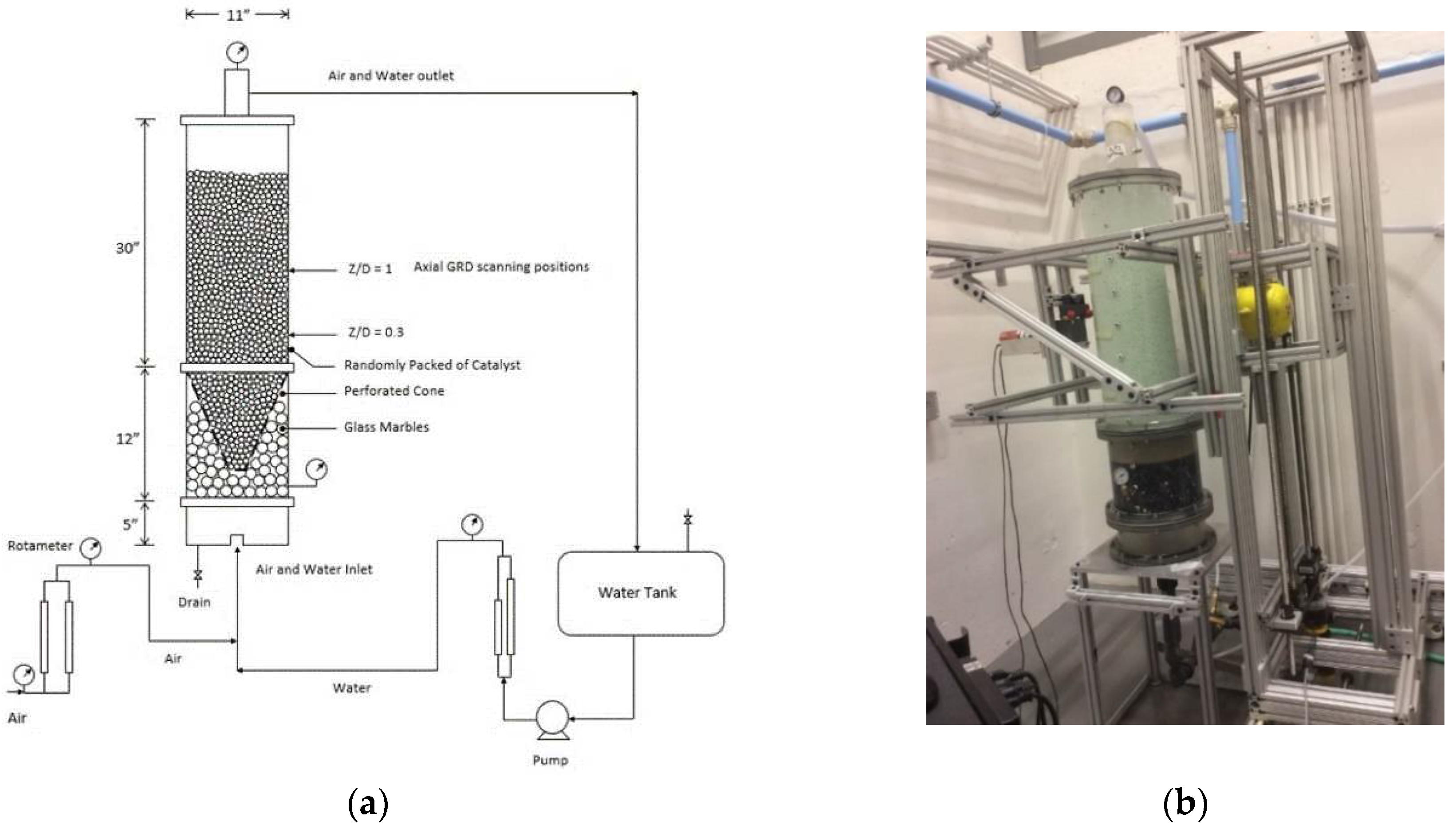

2.1. Experimental Setup

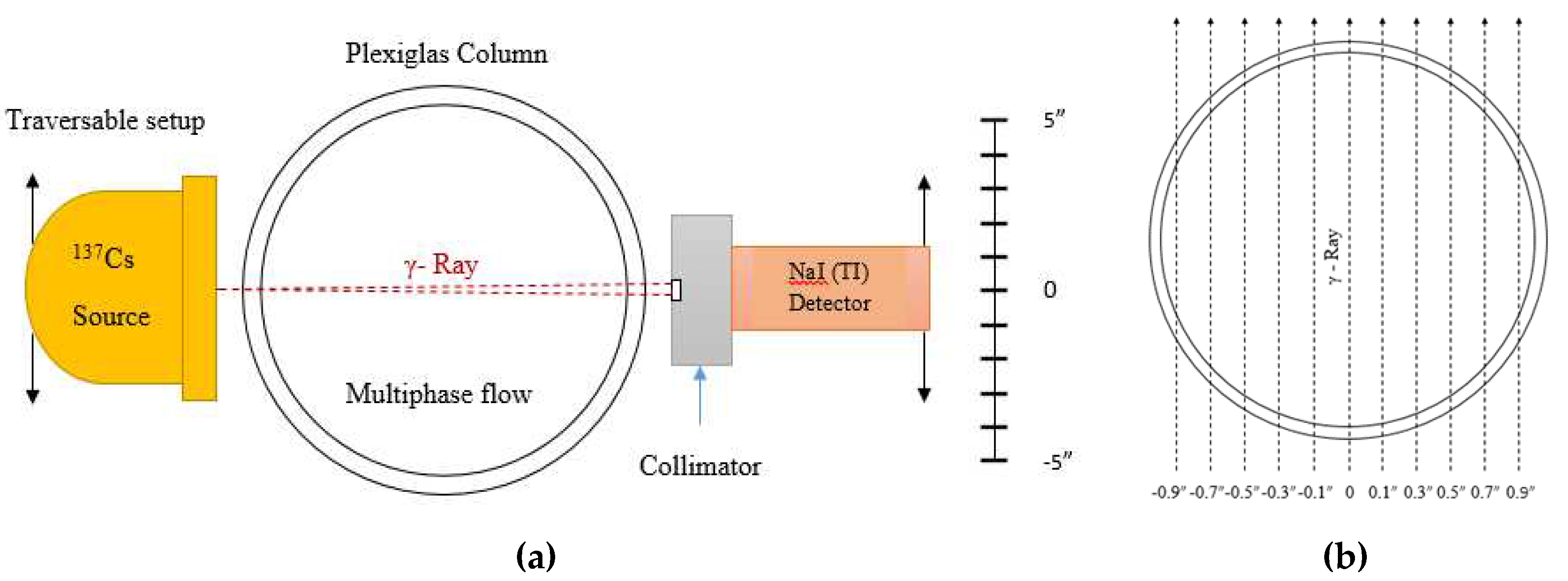

2.2. The Measurement Technique

2.3. The Principle of the Holdups’ Measurements and the New Methodology for Measuring External and Internal Liquid Holdups and Catalyst Porosity

- Gas – solid system: ()

- Liquid – solid system: ()

- Gas – liquid system: ()

- Gas phase: ()

- Solid phase: ()

- Liquid phase: ()

- Without column.

- The empty column for the wall attenuation.

- The column is filled only with water for the liquid attenuation.

- The column is filled with packed bed for a dry catalyst representing attenuation of the gas and solid phases.

- The packed column is filled with water first, then it is drained where the scan was for a wet catalyst attenuation.

- The packed bed is filled with water representing both liquid and solid attenuation.

- Scanning the gas-liquid-solid flow under the desired operation at the same position where the holdups for all the three phases can be obtained.

- Scanning without column (absorbing medium) (i.e., air only). In this scanning case, GRD beam passes through the atmosphere from the source to the detector without any absorbing medium in between them. The obtained attenuation is due to air only () which represents the incident radiation () [27]. The gamma ray source is placed on one side and the scintillation detector is on the other side.

-

Scanning the empty column, for wall attenuation of plexiglass (air inside only, base line). In this scanning case, the GRD beam passes through the empty column, the attenuation is due to the wall of the column and the gas (air) inside it. The obtained attenuation is due to wall column and air. The mass attenuation coefficient of the air () is negligible compared to the Plexiglas (), less interaction of air in comparison with Plexiglas. Hence:Where:: represents the attenuation coefficient due to column wall.

- Scanning the column full of water, for liquid attenuation (i.e., water inside only, liquid phase). In this scanning case, the same packed column filled with water only in which the GRD beam passes through the column wall and the water. The obtained attenuation is due to the wall of the column and the liquid inside it:Subtracting (eq.10) from (eq.11), yields the net attenuation of liquid ():Where the attenuation of the gas phase in this case represents the air outside the packed column is neglected as illustrated in step number II of the previous page.

- Scanning the column packed with dry solid catalyst, as a (i.e., dry catalyst inside only, dry solid phase). In this scanning case, the same packed column was packed with dry solid particles only in which the GRD beam passes through the column wall, the dry catalyst and the gas in voids. The obtained attenuation is due to the wall of the column, the dry solid catalyst and the gas in voids between solid catalysts, where the latter is negligible:By subtracting (eq.10) from (eq.13), the net attenuation of dry solid catalyst () is obtained:: represents the attenuation coefficient due to dry solid catalyst, and , so ≅ 0

-

Scanning the column packed with wet solid catalyst, i.e.,. wet catalyst inside only – wet solid phase). The same packed bed, that has the dry solid catalyst particles, was filled with water for a sufficient time then the column was left to drain for a number of hours to ensure that the static liquid becomes negligible. The static holdup in the step is negligible as proper draining ensures that is no liquid outside of the catalyst pores in the measured line averaged location. Hence the only left liquid is detained inside the catalyst porous due to the capillary force [16]. In this scanning case, the GRD beam passes through the column wall, the wet catalyst, and the void space of gas. The obtained attenuation is due to the wall of the column, the solid catalyst, liquid inside the catalyst (porous), and the gas in voids between solid catalysts, where the latter is negligible:The obtained attenuated of the air also neglected in this case as illustrated in step II.The net attenuation of wet solid catalyst () is obtained by subtracting (eq.10) from (eq.15),, Where:

- Scanning the column packed with solid and liquid, (water – catalyst inside, liquid – solid phase).The same packed bed, contains wet solid catalyst inside, was filled with water so the voids between the particles currently filled with water. In this scanning case, the GRD beam passes through the column wall, the solid catalyst and water. The obtained attenuation is due to the wall of the column, the solid catalyst, liquid inside the catalyst (porous) and the liquid outside the catalyst in voids between solid catalysts:By subtracting (eq.10) from (eq.17), the net attenuation of liquid-solid () is obtained in eq. (18), Since: . Hence,Where () is the line average void holdup which is completely occupied by the liquid, which is equal to the bed void.

- Scanning the column with the desired operation of gas and liquid phases, (air – water – catalyst, gas – liquid – solid). In this scanning case, the GRD beam passes through the column wall, catalyst, liquid, and gas as a three-phase liquid – solid – gas attenuation. The obtained attenuation is due to the wall of the column, the solid catalyst, liquid inside the pore, total liquid in external void (dynamic + static), and the gas phase:

3. Results

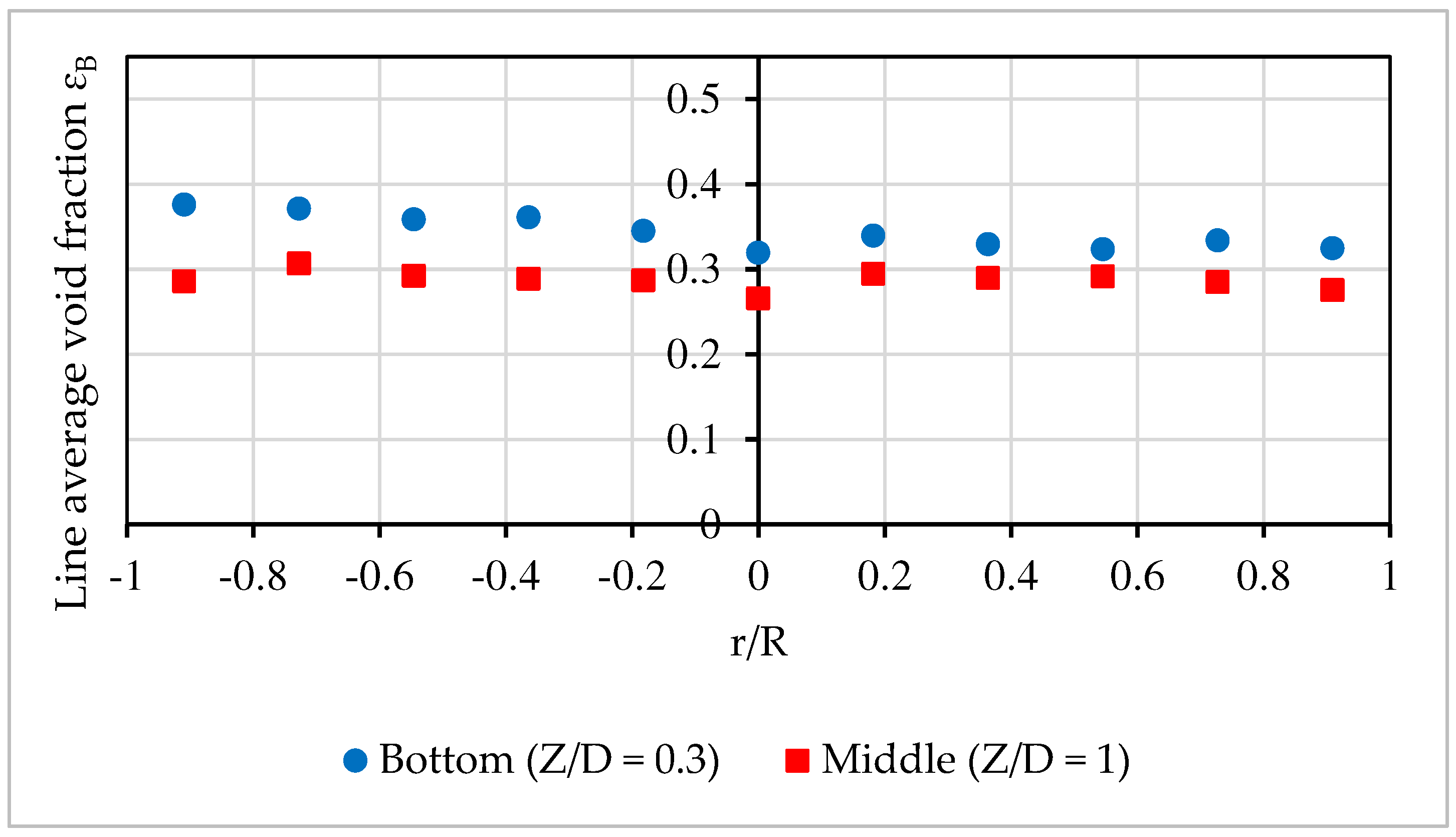

3.1. Diameter Profile of the Void Fraction with Wet Catalyst

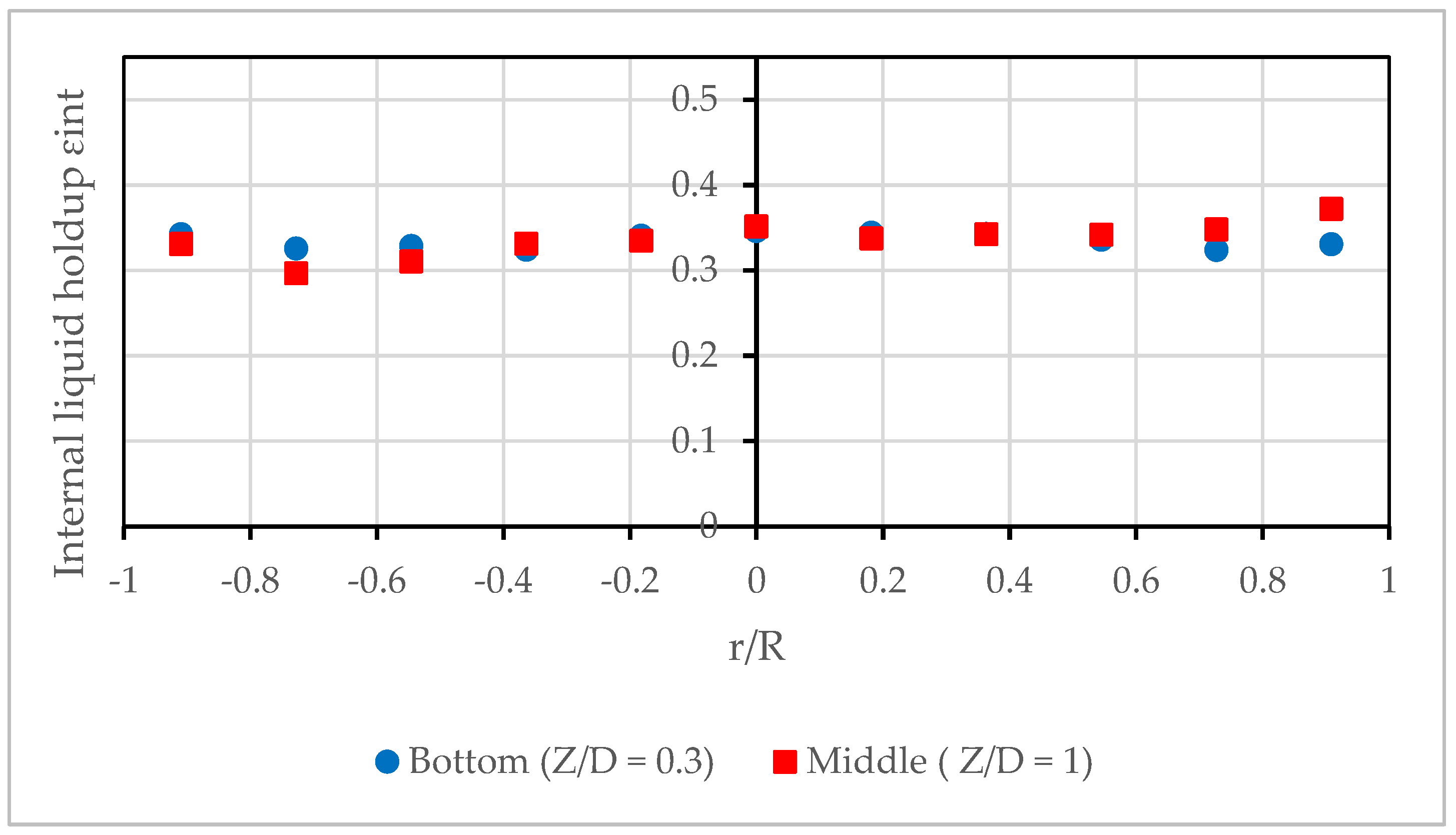

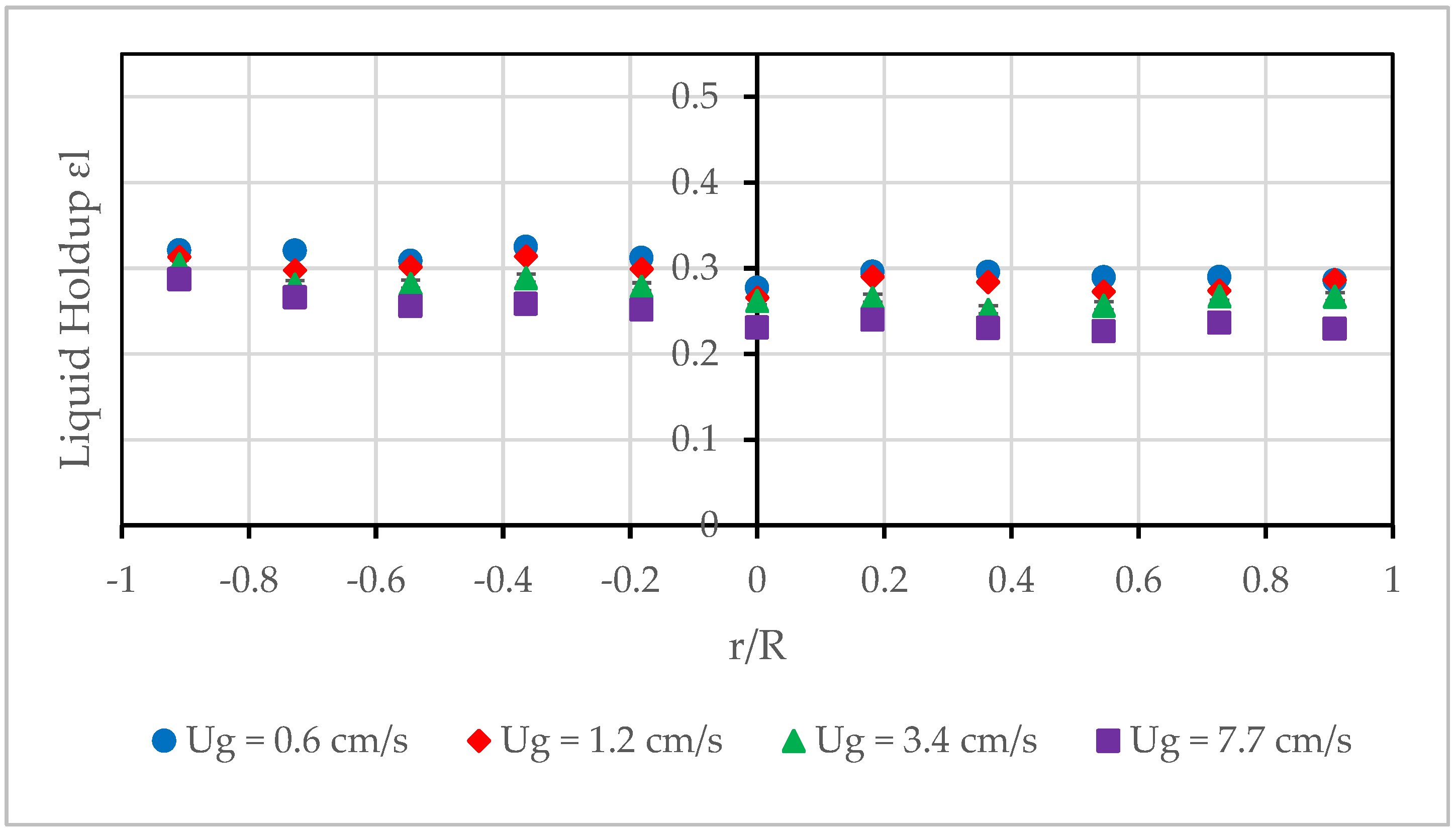

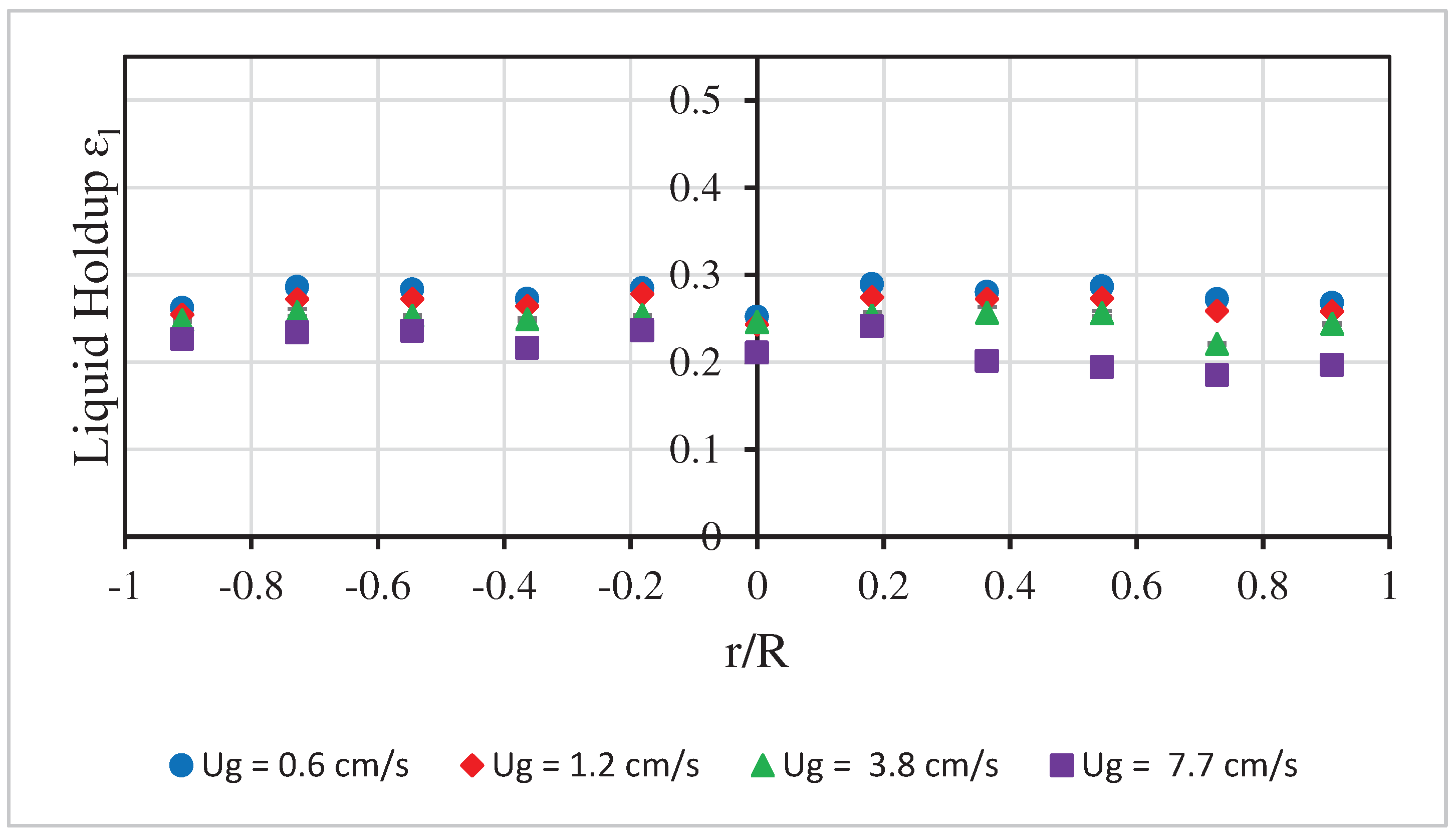

3.2. Diameter Profile of Line Average Internal Liquid Holdup

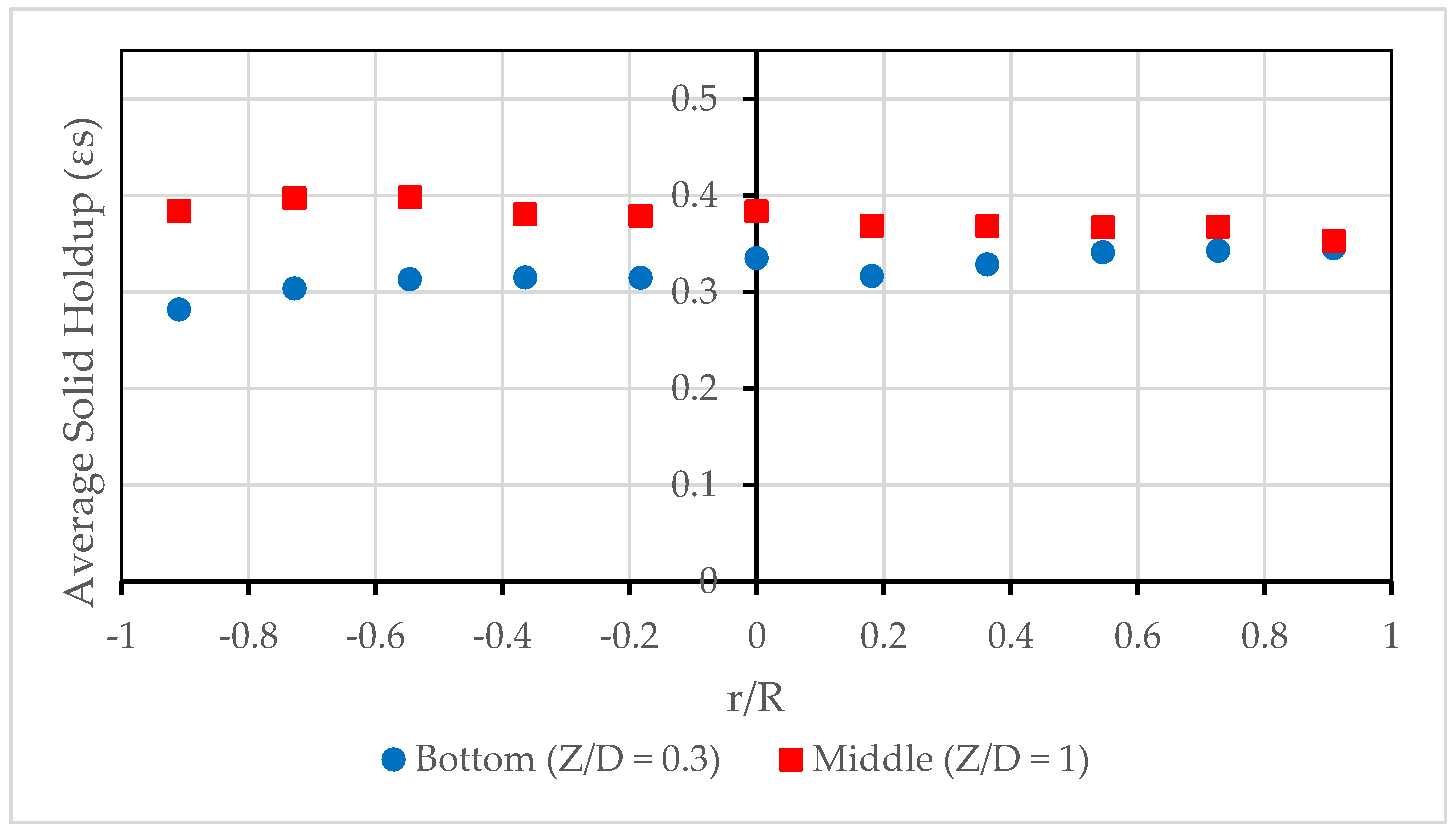

3.3. Radial Distribution of Solid holdup (

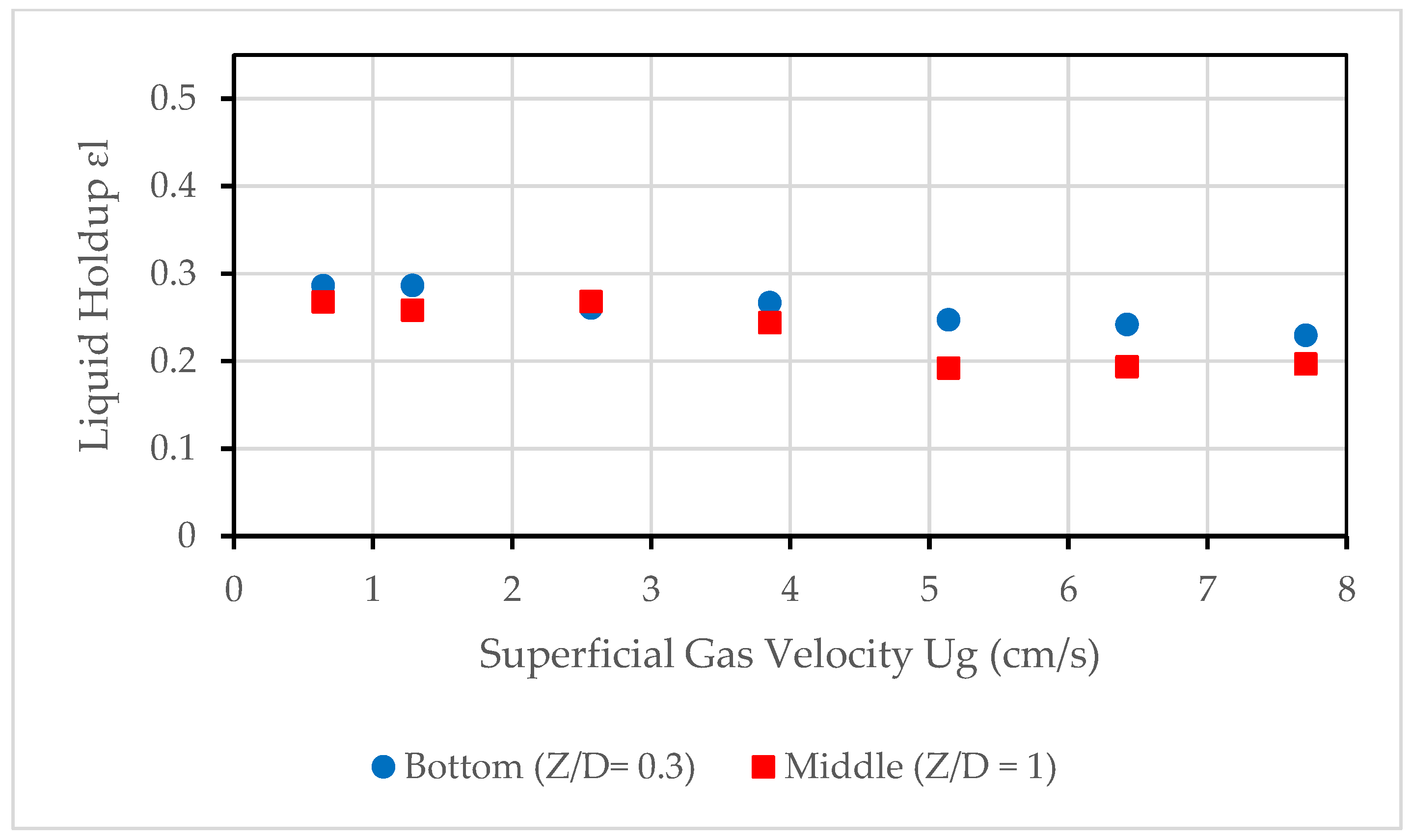

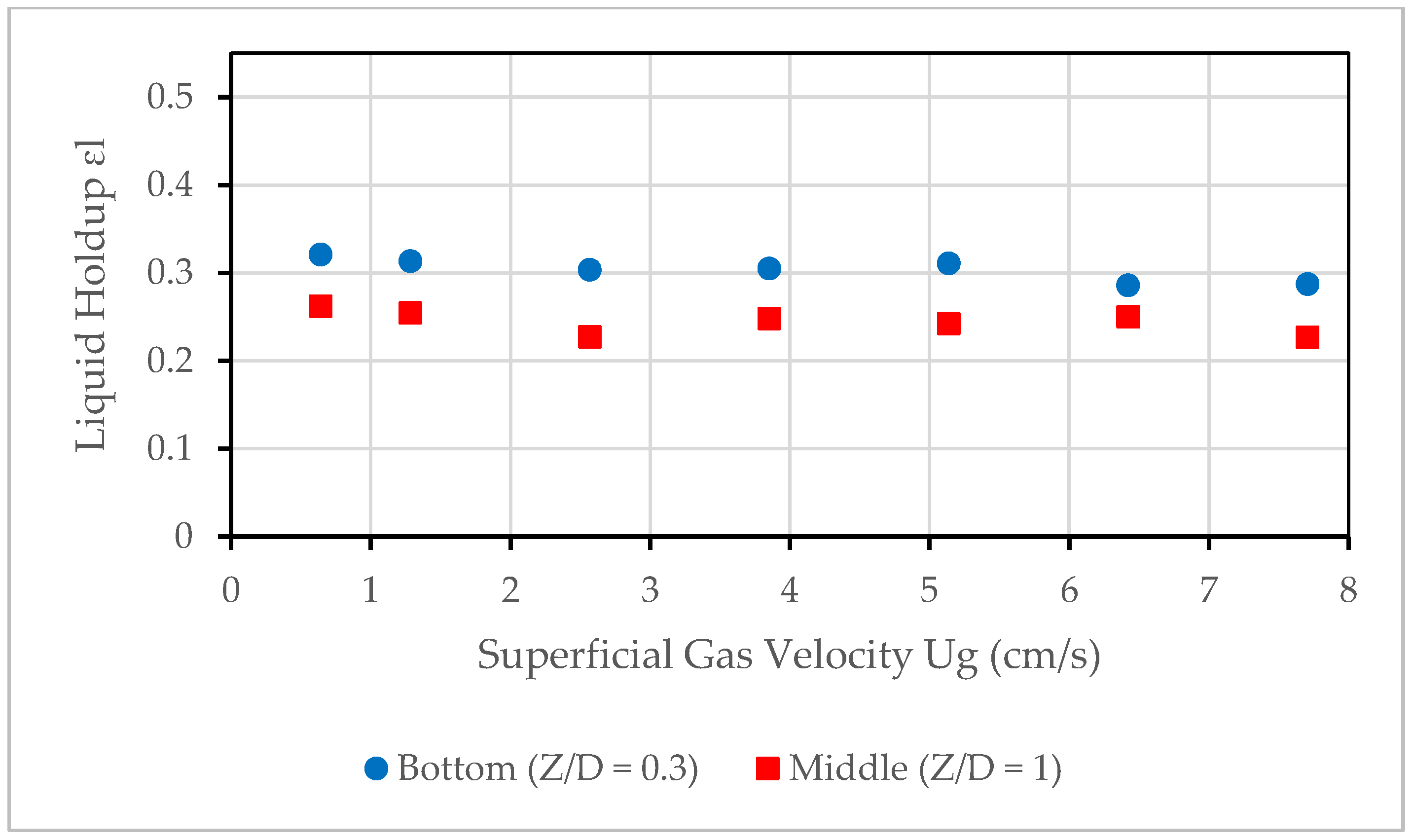

3.4. The Line Average Total External Liquid Holdup

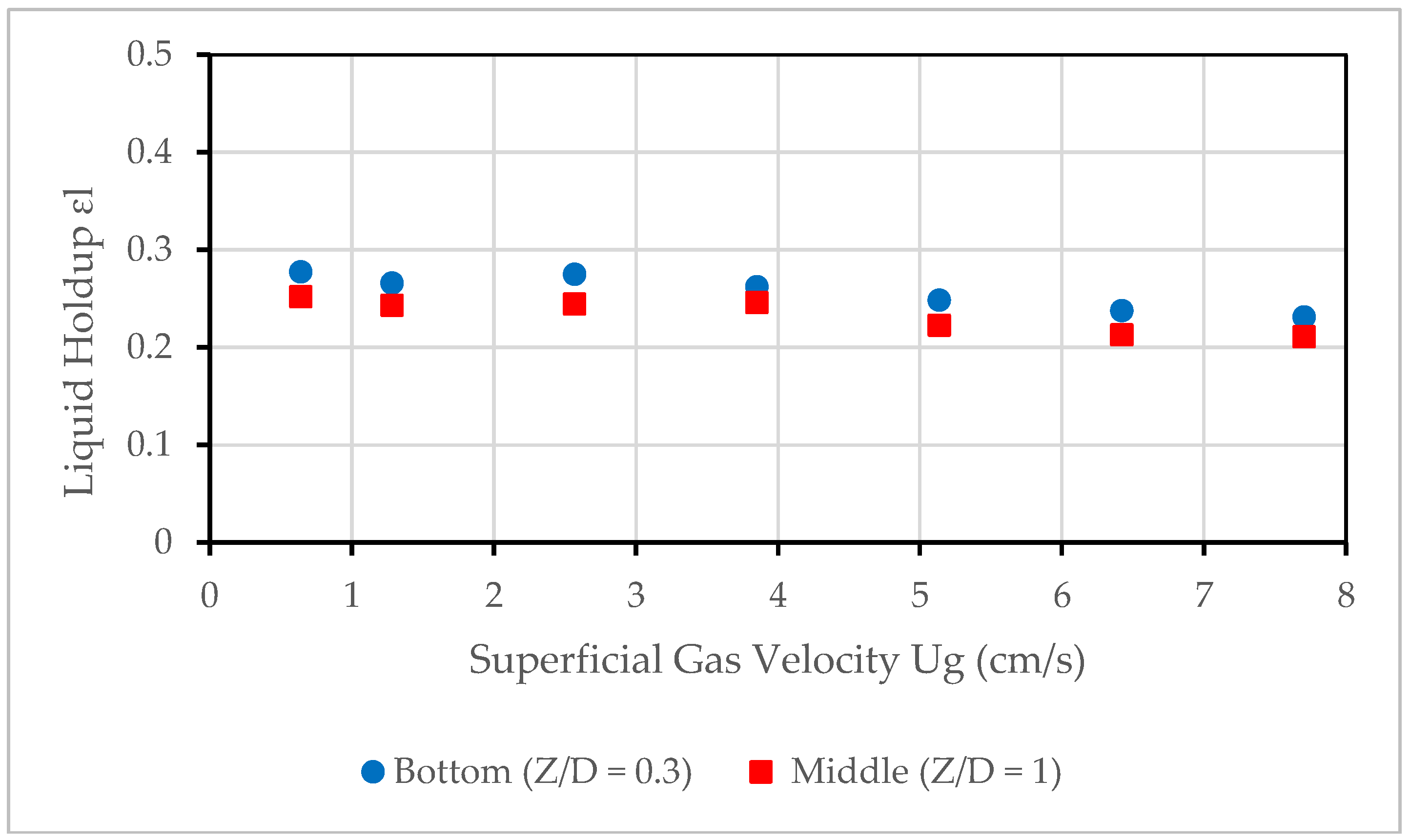

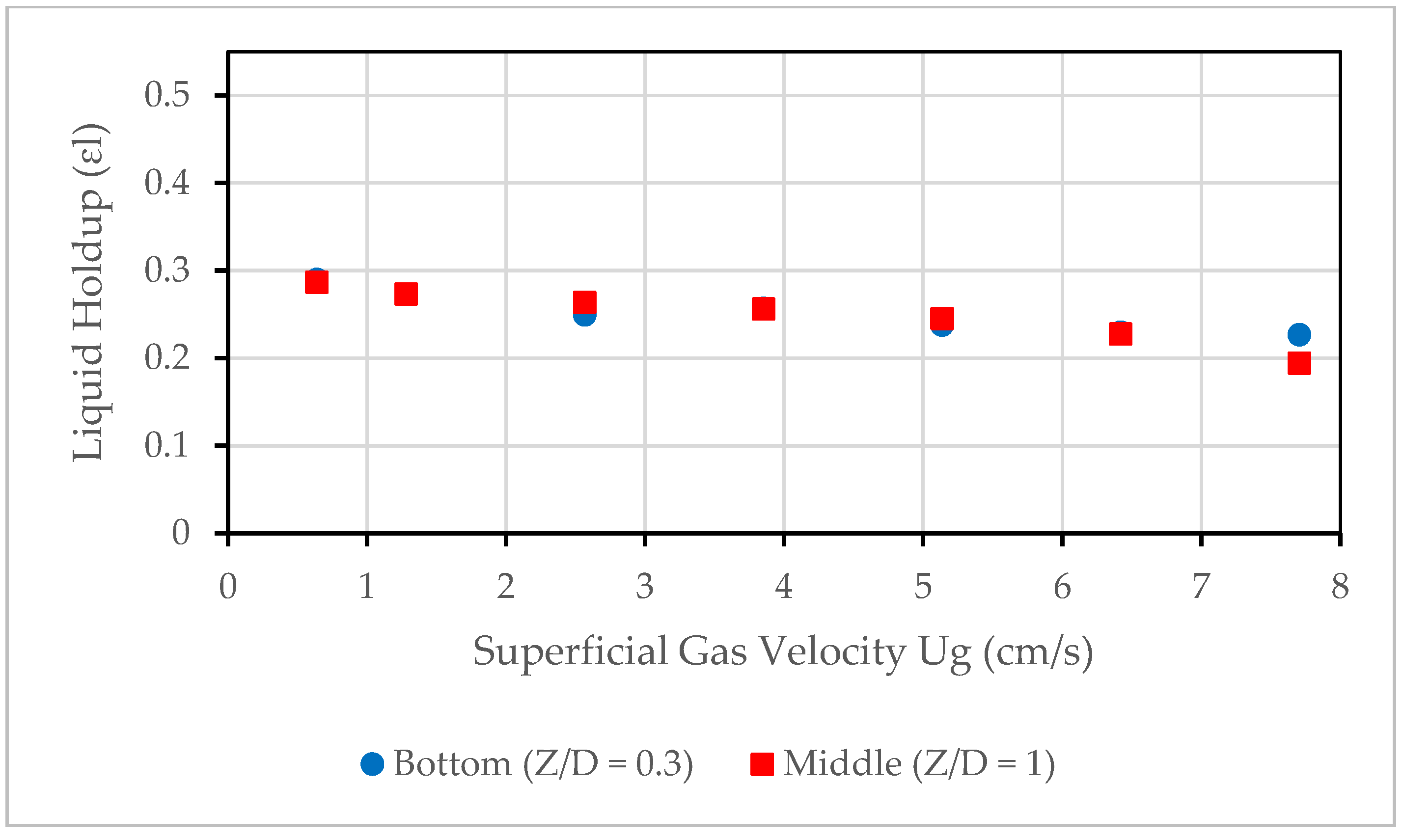

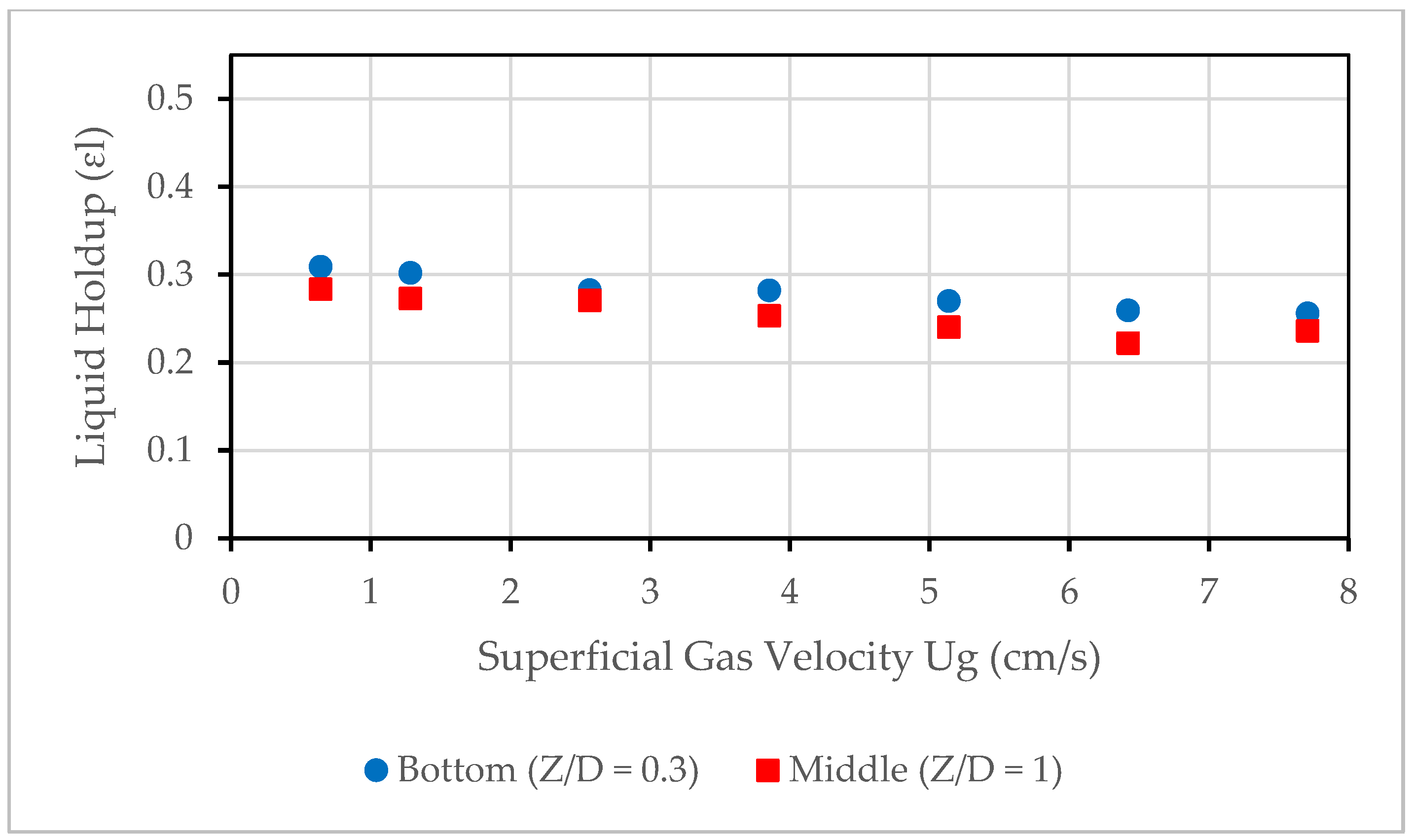

3.5. Effect of Superficial Velocity on the External Liquid Holdup

4. Conclusion

Conflicts of Interest

References

- Liu, Y. Recent advances in heavy oil hydroprocessing technologies. Recent Patents on Chemical Engineering 2009, 2, 22–36. [Google Scholar] [CrossRef]

- Bartholomew, C. Catalyst Deactivation in Hydrotreating of Residua: A Review. Marcel Dekker: New York, NY, USA, 1994. [Google Scholar]

- Ancheyta, J.; Alvarez-Majmutov, A.; Leyva, C. Hydrotreating of oil fractions. Multiphase Catalytic Reactors: Theory, Design, Manufacturing, and Applications, 2016: p. 295-329.

- Scheuerman, G.L.; Johnson, D.R.; Reynolds, B.E.; Bachtel, R.W.; Threlkel, R.S. Advances in Chevron RDS technology for heavy oil upgrading flexibility. Fuel Process. Technol. 1993, 35, 39–54. [Google Scholar] [CrossRef]

- Yin, F.; Afacan, A.; Nandakumar, K.; Chuang, K.T. Liquid holdup distribution in packed columns: gamma ray tomography and CFD simulation. Chem. Eng. Process. - Process. Intensif. 2002, 41, 473–483. [Google Scholar] [CrossRef]

- Reynolds, B.E., et al., Upflow reactor system with layered catalyst bed for hydrotreating heavy feedstocks. 2003, Google Patents.

- Delmon, B. New technical challenges and recent advances in hydrotreatment catalysis. A critical updating review. Catal. Lett. 1993, 22, 1–32. [Google Scholar] [CrossRef]

- Jasim, A.A.; Sultan, A.J.; Al-Dahhan, M.H. Influence of heat-exchanging tubes diameter on the gas holdup and bubble dynamics in a bubble column. Fuel 2018, 236, 1191–1203. [Google Scholar] [CrossRef]

- Iliuta, I.; Larachi, F. Catalytic Wet Oxidation in Three-Phase Moving-Bed Reactors: Modeling Framework and Simulations for On-Stream Replacement of a Deactivating Catalyst. Ind. Eng. Chem. Res. 2012. [Google Scholar] [CrossRef]

- Chander, A.; Kundu, A.; Bej, S.; Dalai, A.; Vohra, D. Hydrodynamic characteristics of cocurrent upflow and downflow of gas and liquid in a fixed bed reactor. Fuel 2001, 80, 1043–1053. [Google Scholar] [CrossRef]

- Al-Dahhan, M.H.; Duduković, M.P. Catalyst bed dilution for improving catalyst wetting in laboratory trickle-bed reactors. AIChE J. 1996, 42, 2594–2606. [Google Scholar] [CrossRef]

- Urrutia, G.; Bonelli, P.; Cassanello, M.; Cukierman, A. On dynamic liquid holdup determination by the drainage method. Chem. Eng. Sci. 1996, 51, 3721–3726. [Google Scholar] [CrossRef]

- Kumar, R.K., et al. Liquid Holdup in Concurrent Gas Liquid Upflow Through Packed Column with Random and Corrugated Structured Packing. in Proceedings of the World Congress on Engineering and Computer Science. 2012.

- Guo, J.; Al-Dahhan, M. Liquid holdup and pressure drop in the gas–liquid cocurrent downflow packed-bed reactor under elevated pressures. Chem. Eng. Sci. 2004, 59, 5387–5393. [Google Scholar] [CrossRef]

- Hamidipour, M.; Larachi, F. Characterizing the liquid dynamics in cocurrent gas–liquid flows in porous media using twin-plane electrical capacitance tomography. Chem. Eng. J. 2010, 165, 310–323. [Google Scholar] [CrossRef]

- Al-Dahhan, M.; Highfill, W. Liquid holdup measurement techniques in laboratory high pressure trickle Bed Reactors. Can. J. Chem. Eng. 1999, 77, 759–765. [Google Scholar] [CrossRef]

- Hubers, J.L.; Striegel, A.C.; Heindel, T.J.; Gray, J.N.; Jensen, T.C. X-ray computed tomography in large bubble columns. Chem. Eng. Sci. 2005, 60, 6124–6133. [Google Scholar] [CrossRef]

- Boyer, C.; Duquenne, A.-M.; Wild, G. Measuring techniques in gas–liquid and gas–liquid–solid reactors. Chemical Engineering Science 2002, 57, 3185–3215. [Google Scholar] [CrossRef]

- Park, H.-S.; Chung, C.-H. Design and application of a single-beam gamma densitometer for void fraction measurement in a small diameter stainless steel pipe in a critical flow condition. Nucl. Eng. Technol. 2007, 39, 349–358. [Google Scholar] [CrossRef]

- Shollenberger, K.; Torczynski, J.; Adkins, D.; O‘Hern, T.; Jackson, N. Gamma-densitometry tomography of gas holdup spatial distribution in industrial-scale bubble columns. Chem. Eng. Sci. 1997, 52, 2037–2048. [Google Scholar] [CrossRef]

- Alexander, V.; Albazzaz, H.; Al-Dahhan, M. Gas phase dispersion/mixing investigation in a representative geometry of gas-liquid upflow Moving Bed Hydrotreater Reactor (MBR) using developed gas tracer technique and method based on convolution/regression. Chem. Eng. Sci. 2018, 195, 671–682. [Google Scholar] [CrossRef]

- Toukan, A.; Alexander, V.; AlBazzaz, H.; Al-Dahhan, M.H. Identification of flow regime in a cocurrent gas – Liquid upflow moving packed bed reactor using gamma ray densitometry. Chem. Eng. Sci. 2017, 168, 380–390. [Google Scholar] [CrossRef]

- Wild, G.; Larachi, F.; Laurent, A. The Hydrodynamic Characteristics of Cocurrent Downflow and Cocurrent Upflow Gas-Liquid-Solid Catalytic Fixed Bed Reactors: the Effect of Pressure. Oil Gas Sci. Technol. 1991, 46, 467–490. [Google Scholar] [CrossRef]

- Al-Dahhan, M.H.; Kemoun, A.; Cartolano, A.R. Phase distribution in an upflow monolith reactor using computed tomography. AIChE J. 2005, 52, 745–753. [Google Scholar] [CrossRef]

- Rados, N.; Shaikh, A.; Al-Dahhan, M. Phase Distribution in a High Pressure Slurry Bubble Column via a Single Source Computed Tomography. Can. J. Chem. Eng. 2008, 83, 104–112. [Google Scholar] [CrossRef]

- Efhaima, A.; Al-Dahhan, M.H. Local time-averaged gas holdup in fluidized bed reactor using gamma ray computed tomography technique (CT). Int. J. Ind. Chem. 2015, 6, 143–152. [Google Scholar] [CrossRef]

- Schlieper, G. Principles of gamma ray densitometry. Met. Powder Rep. 2000, 55, 20–23. [Google Scholar] [CrossRef]

- Kumar, R.K., et al. Liquid holdup in concurrent gas liquid upflow through packed column with random and corrugated structured packing. in Proceedings Proceedings of the World Congress on Engineering and Computer Science2012. 2012.

- Bouteldja, H.; Hamidipour, M.; Larachi, F. Hydrodynamics of an inclined gas–liquid cocurrent upflow packed bed. Chem. Eng. Sci. 2013, 102, 397–404. [Google Scholar] [CrossRef]

- Jasim, A.A.; Sultan, A.J.; Al-Dahhan, M.H. Impact of heat exchanging internals configurations on the gas holdup and bubble properties in a bubble column. Int. J. Multiph. Flow 2018, 112, 63–82. [Google Scholar] [CrossRef]

- Saroha, A.K.; Khera, R. Hydrodynamic study of fixed beds with cocurrent upflow and downflow. Chem. Eng. Process. - Process. Intensif. 2006, 45, 455–460. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).