Submitted:

28 November 2023

Posted:

28 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results

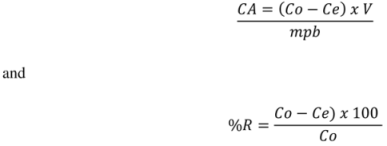

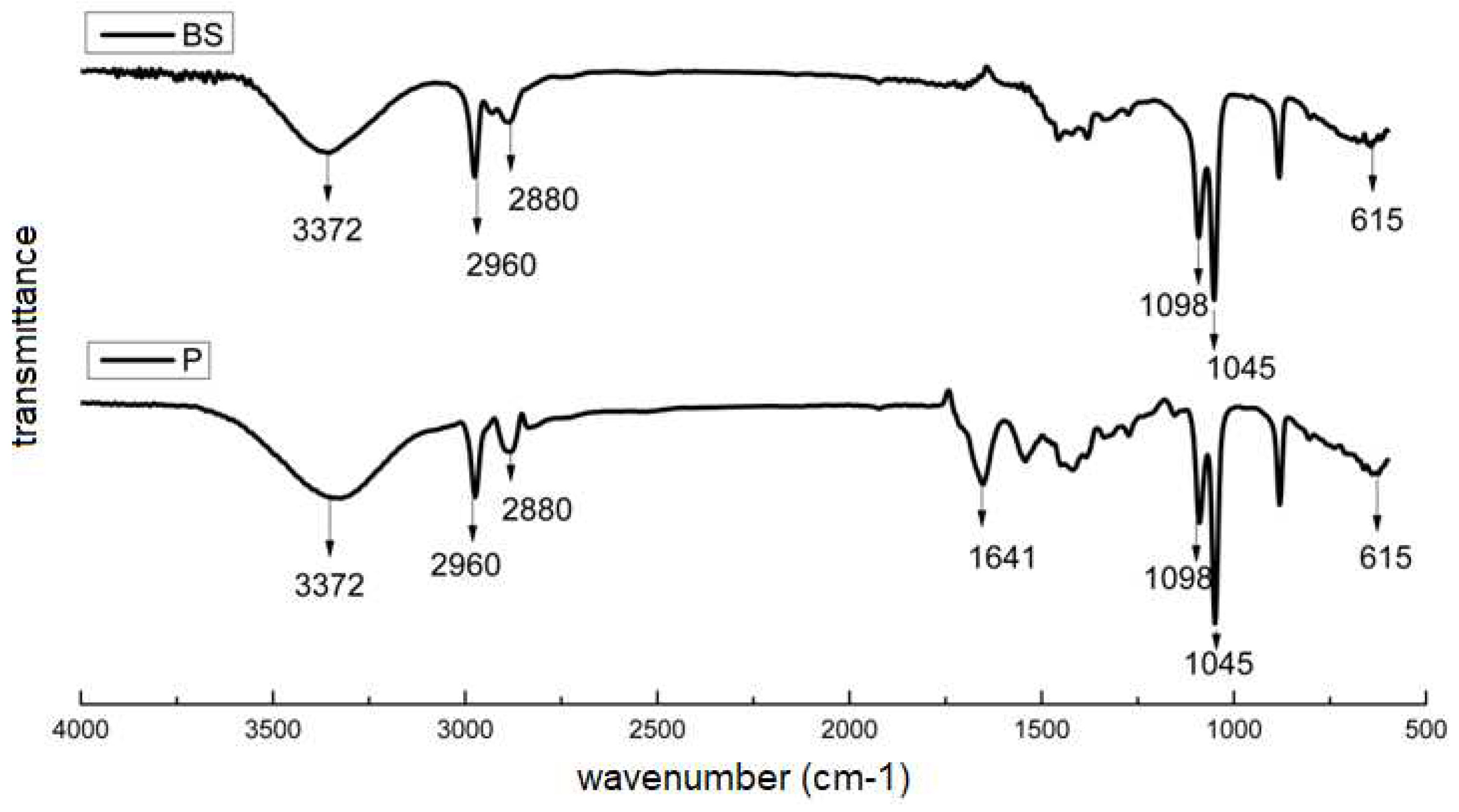

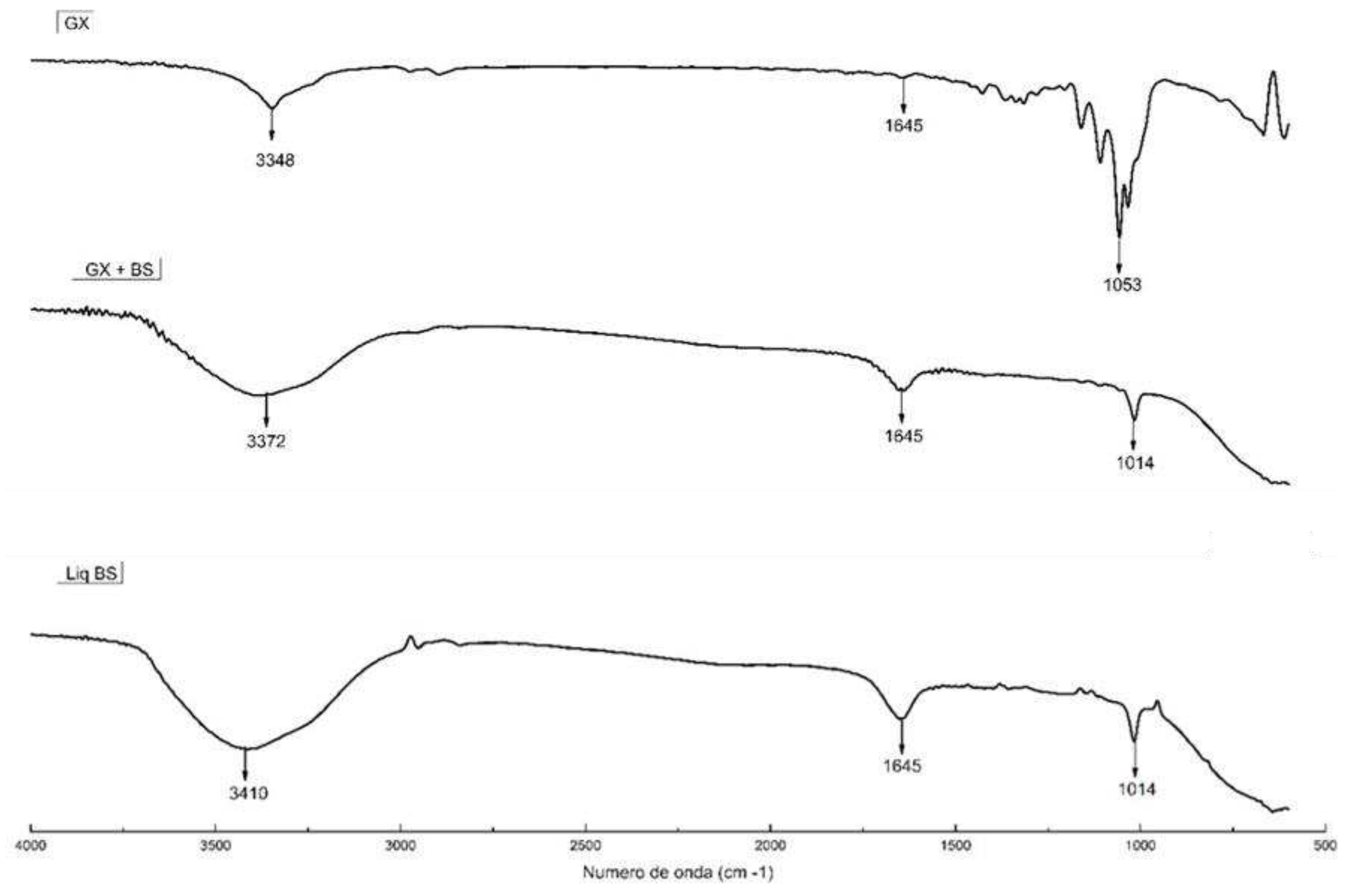

2.1. Biomaterials characterization

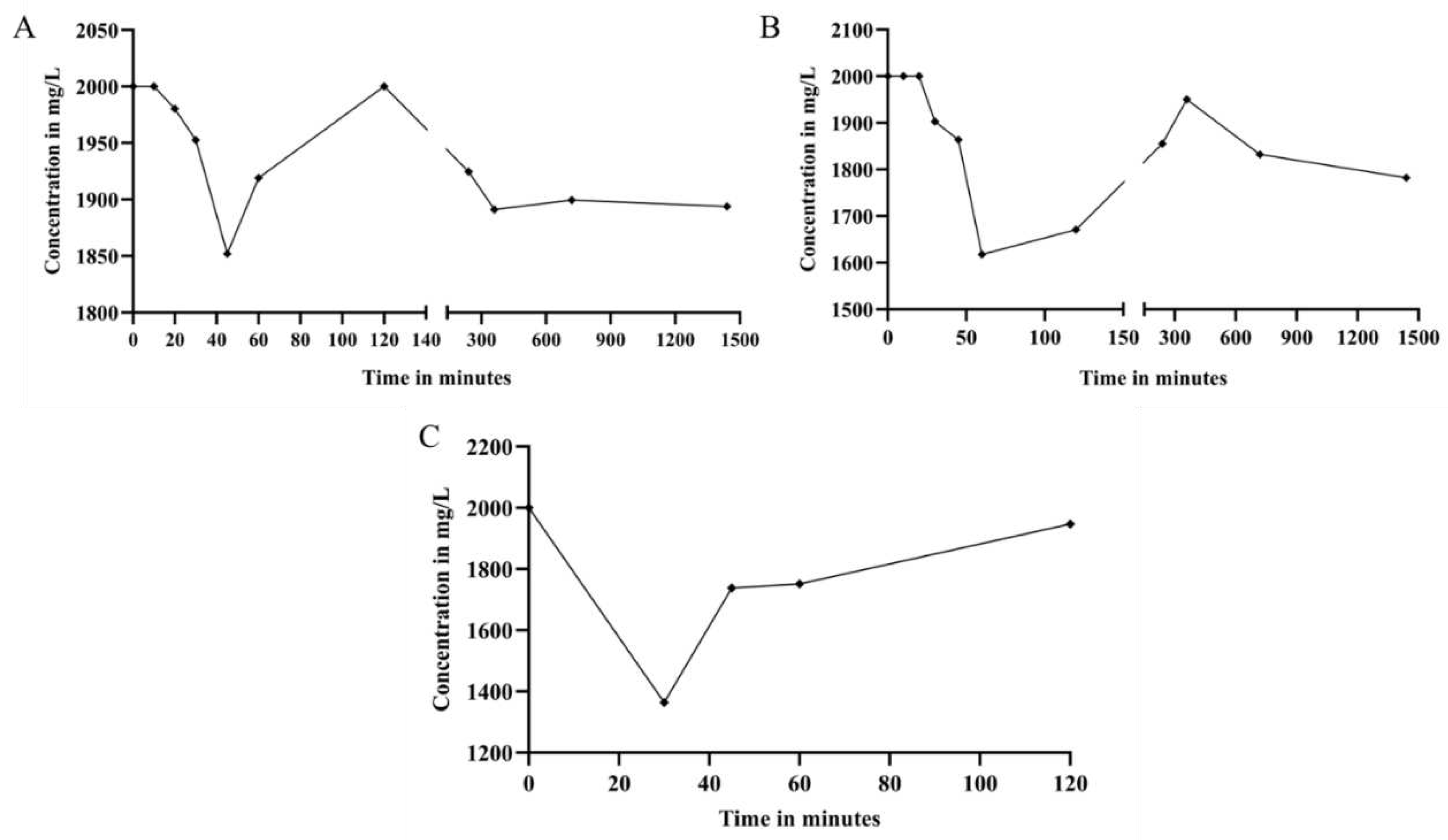

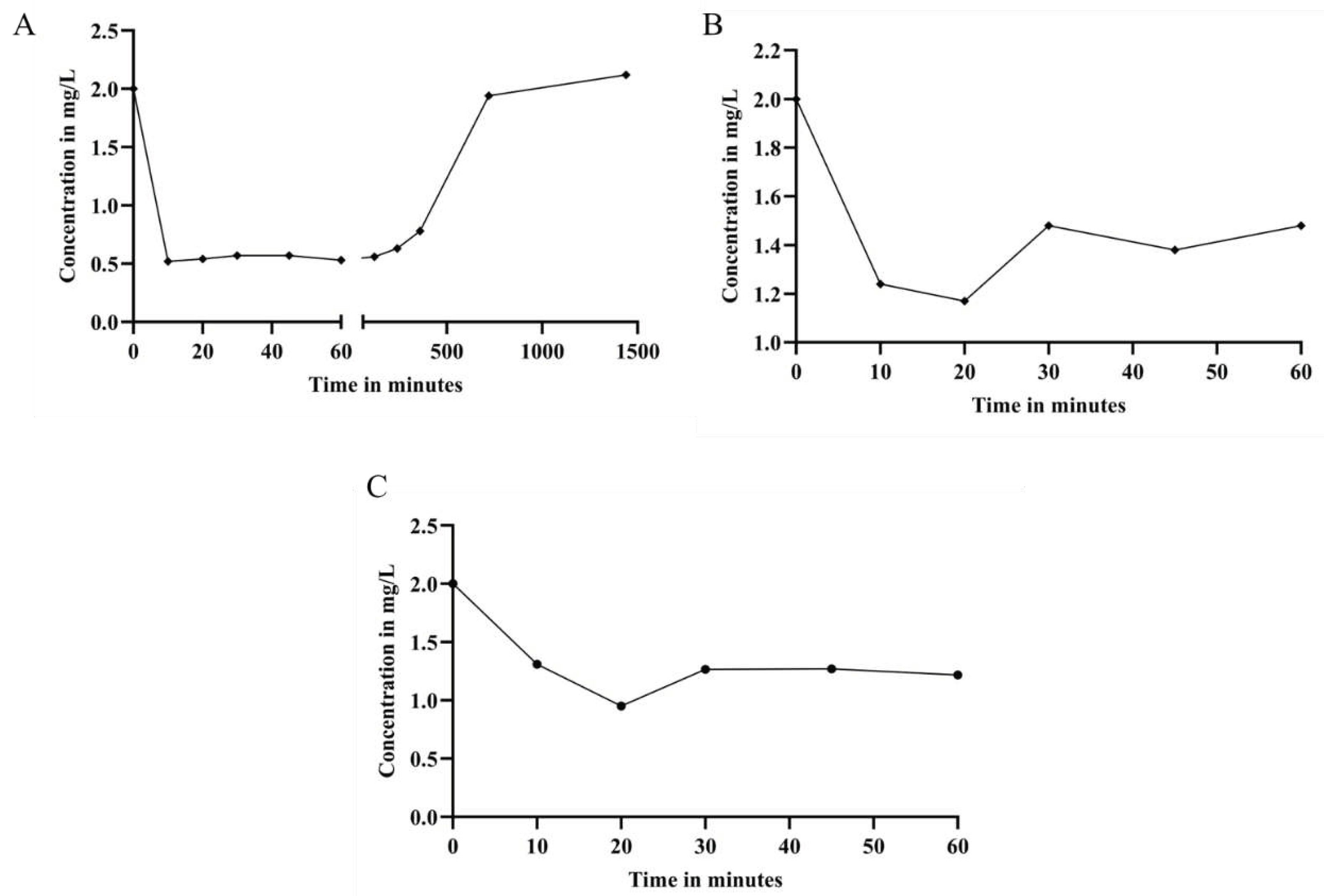

2.2. Adsorption kinetics

3. Discussion

4. Materials and Methods

4.1. Bacterial Cellulose Production

4.2. Biosurfactant Production

4.3. Incorporation

4.4. Adsorption kinetics

4.5. Evaluation of Acetaminophen by UV-Visible Spectrophotometer

4.6. Evaluation of Ethinylestradiol by High Performance Liquid Chromatography

4.7. Data analysis

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Llamas-Dios, M.I.; Vadillo, I.; Jiménez-Gavilán, P.; Candela, L.; Corada-Fernández, C. Assessment of a wide array of contaminants of emerging concern in a Mediterranean water basin (Guadalhorce river, Spain): Motivations for an improvement of water management and pollutants surveillance. Sci. Total Environ 2021, 788, 147822. [CrossRef]

- Weerasooriya, R.R., Liyanage, L.P.K., Rathnappriya, R.H.K. et al. Industrial water conservation by water footprint and sustainable development goals: a review. Environ Dev Sustain 2021, 23, 12661–12709. [CrossRef]

- Zhao, C.; Wang, Y.; Wang, X.; Dionysiou, D.D. Treatment of Contaminants of Emerging Concern and Pathogens Using Electro-photocatalytic Processes: A Review. Curr. Opin. Green Sustain. Chem 2021, 32, 100527. [CrossRef]

- Cantoni, B.; Penserini, L.; Vries, D.; Dingemans, M.M.L.; Bokkers, B.G.H.; Turolla, A.; Smeets, P.W.M.H.; Antonelli, M. Development of a quantitative chemical risk assessment (QCRA) procedure for contaminants of emerging concern in drinking water supply. Water Res 2021, 194, 116911. [CrossRef]

- de Aquino, S.F.; Brandt, E.M.F.; Bottrel, S.E.C.; Gomes, F.B.R.; Silva, S.d.Q. Occurrence of Pharmaceuticals and Endocrine Disrupting Compounds in Brazilian Water and the Risks They May Represent to Human Health. Int. J. Environ. Res. Public Health 2021, 18, 11765. [CrossRef] [PubMed]

- Dzieweczynski, T. L., & Buckman, C. M. Acute exposure to 17α-ethinylestradiol disrupts audience effects on male-male interactions in Siamese fighting fish, Betta splendens. Hormones and behavior 2013, 63, 497–502. [CrossRef]

- Freo, U., Ruocco, C., Valerio, A., Scagnol, I., Nisoli, E. Paracetamol: A Review of Guideline Recommendations. Journal of clinical medicine 2021, 10, 3420. [CrossRef] [PubMed]

- 8. Moore, R.A.; Moore, N. Paracetamol and pain: The kiloton problem. Eur. J. Hosp. Pharm. 2016, 23, 187–188. [CrossRef] [PubMed]

- Jaeschke, H.; Murray, F.J.; Monnot, A.D.; Jacobson-Kram, D.; Cohen, S.M.; Hardisty, J.F.; Atillasoy, E.; Hermanowski-Vosatka, A.; Kuffner, E.; Wikoff, D.; et al. Assessment of the biochemical pathways for acetaminophen toxicity: Implications for its carcinogenic hazard potential. Regul. Toxicol. Pharmacol. RTP 2020, 120, 104859. [CrossRef] [PubMed]

- McGill, M.R.; Hinson, J.A. The development and hepatotoxicity of acetaminophen: Reviewing over a century of progress. Drug Metab. Rev 2020, 52, 472–500. [CrossRef] [PubMed]

- Kim, Y., Choi, K., Jung, J., Park, S., Kim, P. G., Park, J. Aquatic toxicity of acetaminophen, carbamazepine, cimetidine, diltiazem and six major sulfonamides, and their potential ecological risks in Korea. Environment international 2007, 33, 370–375. [CrossRef]

- Wu, W., Jiang, W., Zhang, W., Lin, D., & Yang, K. Influence of functional groups on desorption of organic compounds from carbon nanotubes into water: insight into desorption hysteresis. Environmental science & technology 2013, 47, 8373–8382. [CrossRef]

- Kim, T.Y., Park, S.K., Cho, S.Y. et al. Adsorption of heavy metals by brewery biomass. Korean J. Chem. Eng 2005, 22, 91–98. [CrossRef]

- 1Alluri, H., Ronda, S.R., Settalluri, V.S., Singh, J.P., Bondili. Biosorption: An eco-friendly alternative for heavy metal removal. African Journal of Biotechnology 2007, 6, 2924-2931. [CrossRef]

- Hazaimeh, D., Ahmed, E.S. Bioremediation perspectives and progress in petroleum pollution in the marine environment: a review. Environ Sci Pollut Res 2012, 28, 54238–54259. [CrossRef]

- Hassanshahian, M., Emtiazi, G., & Cappello, S. Isolation and characterization of crude-oil-degrading bacteria from the Persian Gulf and the Caspian Sea. Marine pollution bulletin 2012, 64, 7–12. [CrossRef]

- 1Nuñal, S.N. Bioremediation of oil-contaminated seawater and sediment by an oil-degrading bacterial consortium 2014, 19, 11–22.

- Zhang, R., Somasundaran, P. Advances in adsorption of surfactants and their mixtures at solid/solution interfaces. Advances in colloid and interface science 2006, 123-126, 213–229. [CrossRef]

- Ron, E. Z., Rosenberg, E. Natural roles of biosurfactants. Environmental microbiology 2001, 3, 229–236. [CrossRef]

- Cameotra, S. S., Makkar, R. S., Kaur, J., Mehta, S. K.Synthesis of biosurfactants and their advantages to microorganisms and mankind. Advances in experimental medicine and biology 2010, 672, 261–280. [CrossRef]

- Dos Santos, C. R., Lebron, Y. A. R., Moreira, V. R., Koch, K., & Amaral, M. C. S. Biodegradability, environmental risk assessment and ecological footprint in wastewater technologies for pharmaceutically active compounds removal. Bioresource technology 2022, 343, 126150. [CrossRef]

- Vedaraman, N., Venkatesh, N. Production of surfactin by bacillus subtilis mtcc 2423 from waste frying oils. Brazilian Journal of Chemical Engineering 2011, 28, 175-180. [CrossRef]

- Das, P., Mukherjee, S., Sen, R. Antimicrobial potential of a lipopeptide biosurfactant derived from a marine Bacillus circulans, Journal of Applied Microbiology 2008, 104, 1675–1684. [CrossRef]

- Sánchez-Soto, M., Pagés, P., Lacorte, T., Briceño, K., Carrasco, F. Curing FTIR study and mechanical characterization of glass bead filled trifunctional epoxy composites. Composites Science and Technology 2007, 67, 1974-1985. [CrossRef]

- Li, Z., Fredericks, P.M., Rintoul, R., b, Ward, C.R. Application of attenuated total reflectance micro-Fourier transform infrared (ATR-FTIR) spectroscopy to the study of coal macerals: Examples from the Bowen Basin, Australia. International Journal of Coal Geology 2007, 70, 1-3, p. 87-94, 2007. [CrossRef]

- Çetiner, S., Karakas, H., Ciobanu, R.C., Olariu, M.A., Kaya, N.U., Unsal, C., Kalaoglu, F., & Sarac, A.S. Polymerization of pyrrole derivatives on polyacrylonitrile matrix, FTIR–ATR and dielectric spectroscopic characterization of composite thin films. Synthetic Metals 2010, 160, 1189-1196. [CrossRef]

- chartner, J., Güldenhaupt, J., Mei, B.T., Rögner, M., Muhler, M., Gerwert, K., & Kötting, C. Universal method for protein immobilization on chemically functionalized germanium investigated by ATR-FTIR difference spectroscopy. Journal of the American Chemical Society 2013, 135 10, 4079-87. [CrossRef]

- Chércoles Asensio, R., San Andrés Moya, M., de la Roja, J. M., & Gómez, M. Analytical characterization of polymers used in conservation and restoration by ATR-FTIR spectroscopy. Analytical and bioanalytical chemistry 2009, 395, 2081–2096. [CrossRef] [PubMed]

- Jozala, A. F., Pértile, R. A., dos Santos, C. A., de Carvalho Santos-Ebinuma, V., Seckler, M. M., Gama, F. M., & Pessoa, A., Jr. Bacterial cellulose production by Gluconacetobacter xylinus by employing alternative culture media. Applied microbiology and biotechnology 2015, 99, 1181–1190. [CrossRef]

- Popa, L., Ghica, M. V., Tudoroiu, E. E., Ionescu, D. G., & Dinu-Pîrvu, C. E. (2022). Bacterial Cellulose-A Remarkable Polymer as a Source for Biomaterials Tailoring. Materials (Basel, Switzerland) 2022, 15, 1054. [CrossRef]

- Pinto, A. M. C. Modificação in situ e ex situ da celulose bacteriana: efeito da composição do meio de cultura no seu rendimento e propriedades. Dissertação de Mestrado, UMinho, Braga – Portugual, 2013.

- Ayoub S. S. (2021). Paracetamol (acetaminophen): A familiar drug with an unexplained mechanism of action. Temperature (Austin, Tex.), 8(4), 351–371. [CrossRef]

- Singh, A., Van Hamme, J. D., & Ward, O. P. Surfactants in microbiology and biotechnology: Part 2. Application aspects. Biotechnology advances 2007, 25(1), 99–121. [CrossRef]

- acwa-Płociniczak, M., Płaza, G. A., Piotrowska-Seget, Z., Cameotra, S. S.Environmental applications of biosurfactants: recent advances. International journal of molecular sciences 2011, 12(1), 633–654. [CrossRef]

- uo, Y. P., Hu, Y. Y., Lin, H., & Ou, X. L. Sorption and desorption of 17α-ethinylestradiol onto sediments affected by rhamnolipidic biosurfactants. Journal of hazardous materials 2018, 344, 707–715. [CrossRef]

- Żółtowska-Aksamitowska, S., Bartczak, P., Zembrzuska, J., & Jesionowski, T. Removal of hazardous non-steroidal anti-inflammatory drugs from aqueous solutions by biosorbent based on chitin and lignin. The Science of the total environment 2018, 612, 1223–1233. [CrossRef]

- Ferandin Honorio, J., Veit, M. T., Suzaki, P. Y. R., Coldebella, P. F., Sloboda Rigobello, E., & Tavares, C. R. G. Adsorption of naturals hormones estrone, 17β-estradiol, and estriol by rice husk: monocomponent and multicomponent kinetics and equilibrium. Environmental technology 2020, 41(9), 1075–1092. [CrossRef]

- Silva, L. S., Carvalho, J., Bezerra, R. D. S., Silva, M. S., Ferreira, F. J. L., Osajima, J. A., & da Silva Filho, E. C. Potential of Cellulose Functionalized with Carboxylic Acid as Biosorbent for the Removal of Cationic Dyes in Aqueous Solution. Molecules (Basel, Switzerland) 2018, 23(4), 743. [CrossRef]

- Debs, K. B., da Silva, H. D. T., de Lourdes Leite de Moraes, M., Carrilho, E. N. V. M., Lemos, S. G., & Labuto, G. Biosorption of 17α-ethinylestradiol by yeast biomass from ethanol industry in the presence of estrone. Environmental science and pollution research international 2019, 26(28), 28419–28428. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).