I. Introduction

During the process of liquid droplet impact, various phenomena such as stacking, rebounding, and splashing can occur under the influence of the droplet properties and surface characteristics [1-3]. The rebound process refers to the lateral spreading of the droplet, with the conversion of kinetic energy to surface energy, gradually reaching the maximum spreading length

Dmax, after which the droplet recoils towards the center until it reaches a certain degree of contraction. Subsequently, the droplet rebounds from the surface [4-6]. The phenomenon of droplet impact has been extensively studied both numerically and experimentally [

7,

8], the rebound behavior of liquid droplets is influenced by various factors such as droplet properties [

9,

10], droplet radius and velocity [

11,

12], surface properties [

13,

14], and incident angle [

15,

16].

In previous studies on droplet impact, the predominant focus on stationary surfaces, and the maximum spreading length of the impacting droplet was dependent on the normal Weber number We

n, especially in cases involving low viscosity and limited wetting ability [

17]. The contact time was found to be contingent upon the radius and independent of the impact velocity [

18]. In this context, contact time is defined as the duration from the first contact of the droplet with the surface to the complete detachment. Research into contact time has garnered practical applications in the field of self-cleaning surfaces [

19]. Here, the design of macro-textures and microstructures can effectively reduce the contact time [

20,

21].

However, in practical applications, droplet impact phenomena mostly occur on moving surfaces, such as raindrops impacting aircraft wings and wind turbine blades [

22], and the directional transport of droplets in inkjet printing [

23]. A few studies have found that on the SHPSs, as the speed of the moving surface increases, elevated surface velocities amplify the extension of impacting droplets, consequently leading to a reduction in contact time [

24,

25]. Similar findings have also been observed on moving surfaces with macroscopic structures and wetting patterns [

26].

These conclusions mostly analyze droplets from a kinematic perspective, focusing on droplet spreading and contact time. There are still some conclusions related to momentum, some studies suggest the main cause of momentum transfer is the aerodynamic Leidenfrost effect [

27]. This phenomenon refers to the thin air film formed between the droplet and the moving surface, which is the primary factor generating viscous forces on the droplet. By analyzing the forces acting on the thin air film between droplet and surface, scaling relationships can be derived to summarize the contact time, spreading ratio, and horizontal distance. These dynamic conclusions have been well validated [

28]. However, in this experiments, the presence of an air film between the liquid droplet and the surface was not distinctly observe. Droplets will inevitably come into contact with the surface, and the reason for this difference may be due to insufficient surface velocity to generate a noticeable air layer. We tend to the view of the transfer of horizontal momentum is caused by the viscous boundary layer developing in the liquid [

29]. Throughout the impact process, energy dissipation due to viscous losses is observed. The fundamental physical principle of non-axisymmetric bouncing dynamics is the transfer of horizontal momentum during the impact process, gradually shifting from the bottom to the top of the droplet. Based on this, formulas related to the horizontal velocity of droplets have been proposed [

30], while the feasibility of this velocity formula has been well validated, there are still some sections for improvement. For example, in the derivation of this formula, the spreading region of the droplet is considered to be circular, which is accurate when impacting a stationary surface but imprecise on a moving surface, where the spreading region is elongated [

28,

31]. Furthermore, the contact time of the droplet is also assumed to be the same as the contact time on a stationary surface

τs, whereas on a moving surface the contact time

τm is shorter than

τs [

24,

25].

And there is still a lack of satisfactory solutions regarding how the spreading range of droplets is influenced by surface motion. In this study, the fundamental dynamic behaviors of droplet impact on moving surfaces are focused on being revealed, a more accurate correction has been made to the scaling formula for the droplet horizontal velocity. As well as analyzing the asymmetric evolution of the spreading radius at both ends of the droplet over time caused by surface motion.

III. Results and discussion

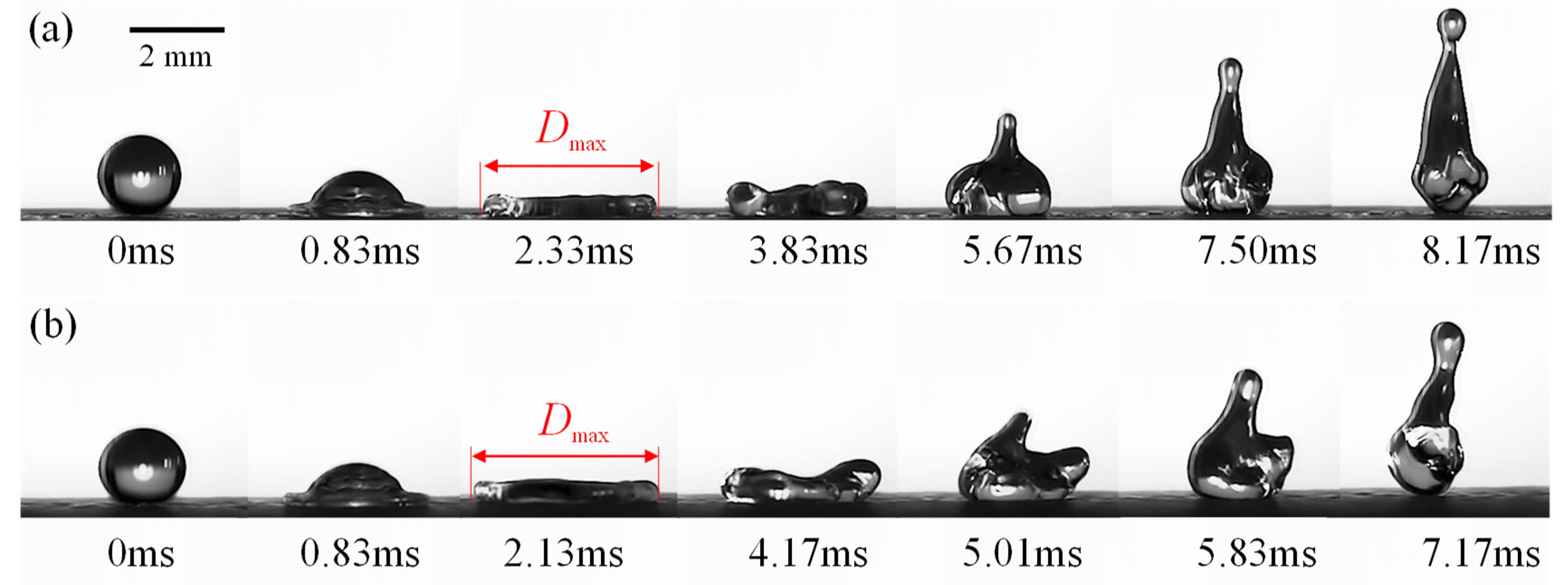

Figure 2 shows the spreading and receding stages of water droplets on a SHPS at We

n = 29.80, with We

t = 0 and We

t = 44.06 (Multimedia view). After the droplet hits the surface, a liquid film forms as it gradually spreads out towards the maximum spreading radius

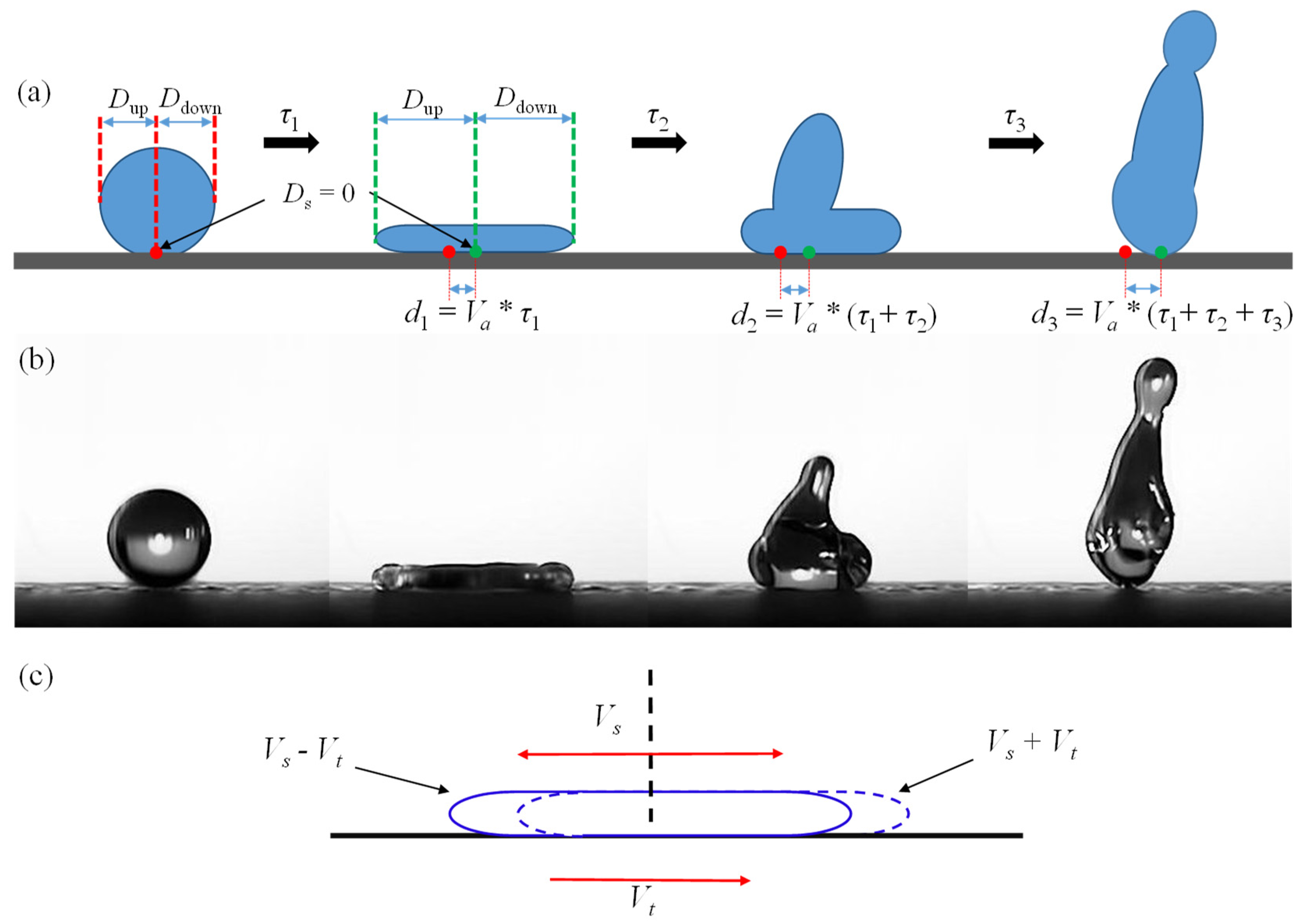

Dmax. The droplet then recedes from both ends towards the center, with its height gradually increasing due to the conversion of surface energy into kinetic energy. Once sufficient kinetic energy has accumulated, the droplet will start to bounce off the surface.

When the surface is stationary, the receding rates of the droplet from both ends are the same (

Figure 2(a),

t = 3.83

ms), resulting in a symmetric bouncing phenomenon. When the surface is in motion, the receding rate on the upstream side is faster than on the downstream side. (Where downstream refers to the side in the direction of surface movement and the upstream side refers to the opposite direction, as shown in

Figure 7(a), we will discuss the upstream and downstream in the subsequent sections.) This is due to the influence of surface velocity, causing more kinetic energy to accumulate on the upstream side resulting in a higher height than the downstream side, leading to an "L"-shaped droplet (

Figure 2(b),

t = 5.01 ~ 5.83

ms). As the surface velocity increases, the spreading length of the droplet is stretched longer under the influence of the surface forces, making the "L"-shape more pronounced. Subsequently, the droplet begins to bounce off the surface, compared to the stationary surface, the contact time is reduced from 8.17

ms to 7.17

ms when the surface is in motion. When the surface is stationary, both ends of the droplet simultaneously leave the surface, while in motion, the downstream side of the droplet will detach from the surface before the upstream side (

Figure 2(b),

t = 4.17

ms). This reduces the portion of the droplet in contact with the surface, leading to a reduction in the contact time [

33].

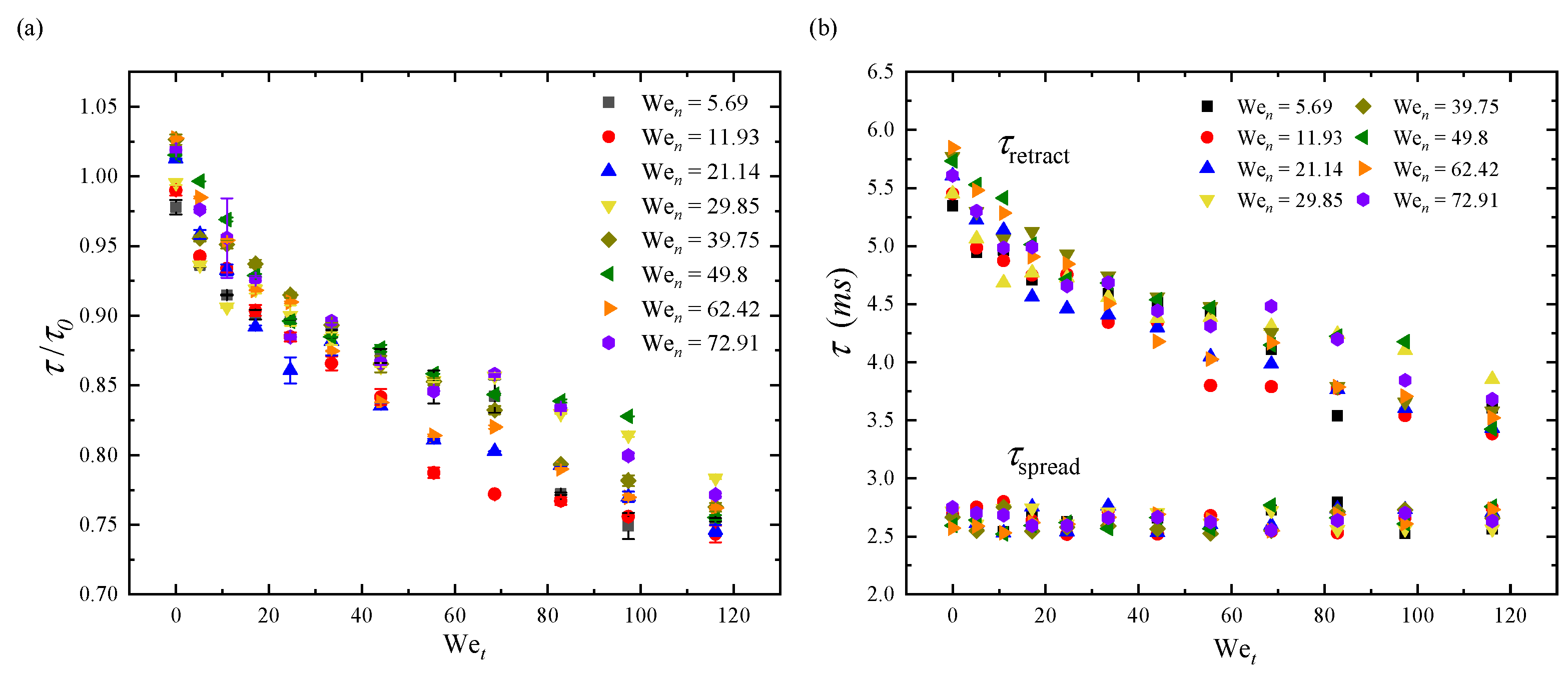

In addition, we conducted statistical analysis of experiments involving different We

t and We

n for contact time,

Figure 3(a) shows the normalized contact time

τ/τ0 as a function of We

t under different We

n conditions, where

is the inertial-capillary time [

34]. As seen, the contact time gradually decreases as We

t increases. The difference between the contact times at We

t = 0 and We

t= 116 is about 30%. However, the influence of different We

n groups on the contact time is relatively weak, these findings are consistent with previous conclusions on moving SHPSs [

24,

28].

-

A.

Momentum transfer of droplet on the moving surface.

The bouncing and spreading of droplets are essentially the exchange of kinetic energy and surface energy. When a droplet hits a stationary surface, it bounces vertically along the impact direction, while during surface motion, the rebound direction of the droplet tilts towards the direction of surface motion. Research has shown that there are two theories explaining the cause of this phenomenon. The first theory based on the aerodynamic Leidenfrost effect suggests it is due to the thin layer of air formed between the droplet and the surface [

28], while the second theory proposes it is the result of liquid-surface contact forming a viscous boundary layer [

30]. We are inclined towards the latter theory. Furthermore, this study is based on the no-slip boundary condition and derives the scaling relationship for the horizontal speed of droplet.

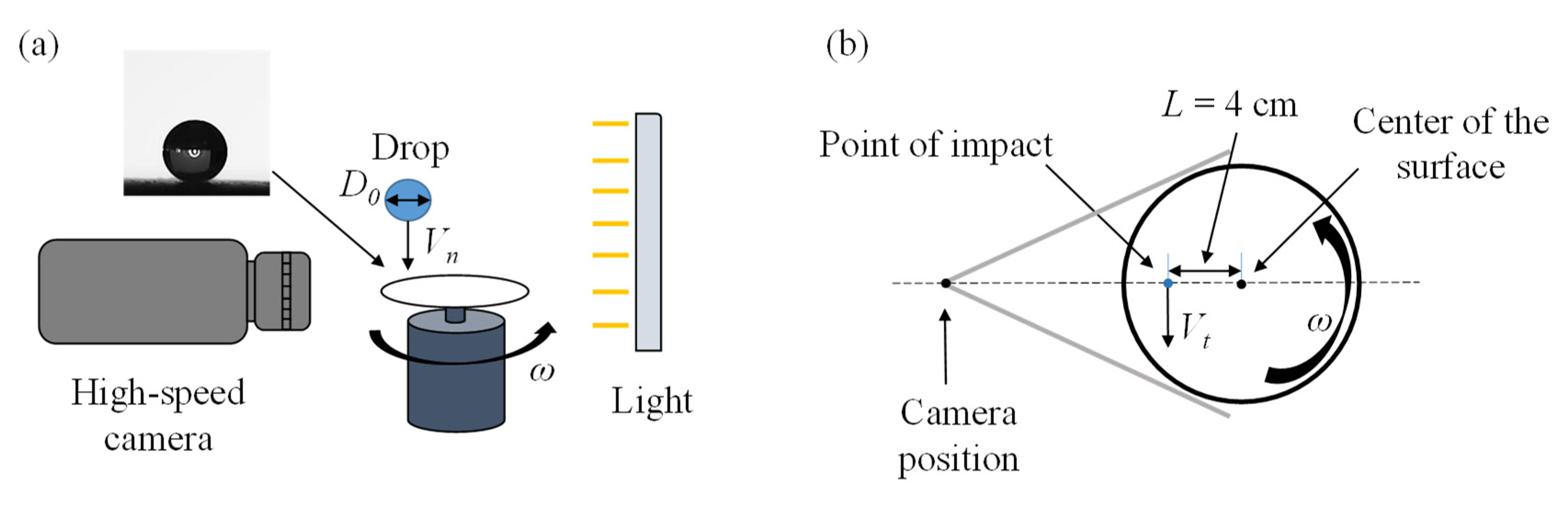

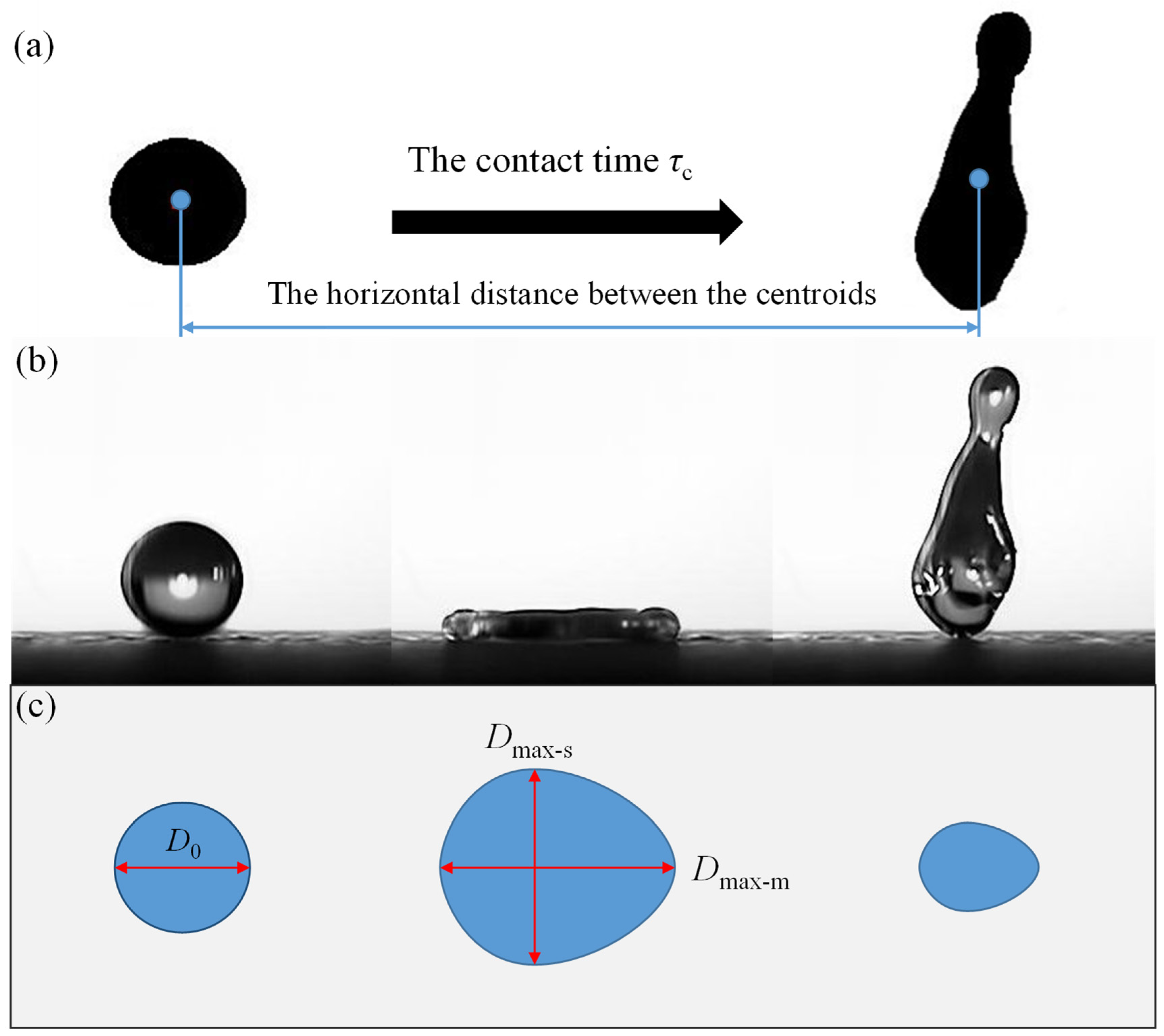

Accordingly, we calculated the center of mass from the shape of droplet in the side view, taking the moment of contact

t = 0

ms as the starting point and the moment of rebound as the end point [

Figure 4(a)], by measuring the displacement of the center of mass and the contact time, the averaged horizontal velocity

Va of droplet can be obtained.

Initially,

Va = 0, but due to the shear effect of the surface, the momentum increases during the impact process. Considering the total viscous force and combine Newton’s second law in the horizontal direction

mdVa/

dt = F(

t), the average velocity in the horizontal direction can be obtained [

30]:

where

μ is the viscosity of the liquid,

δ0 is the thickness of the boundary layer,

t is the contact time of the droplet on the moving surface and

D2(

t) represents the contact area of the droplet. In previous studies,

D2(

t) is considered to be the square of the maximum spreading length on a stationary surface

Dmax-s. However, the droplet is not circular on a moving surface. It will be stretched along the direction of surface movement, and the maximum spreading of the droplet in that direction is defined as

Dmax-m, as shown in

Figure 4(c). While the maximum spreading length in the perpendicular to horizontal direction is evidently smaller than

Dmax-m, and this spreading length is approximately equal to the spreading length

Dmax-s on a stationary surface have been demonstrated [

35]. Based on this, we can deduce:

With the maximal spreading ratio of the drop

βmax =

Dmax/

D0, the dimensionless integral mean value of boundary layer thickness

δ =

δ0/

D0, the dimensionless contact time

τ=

Vnt/D0, we can derive that:

On the moving surface, the maximum spreading ratio

βmax-m~We

n1/4Ca

1/6 [

28], where the capillary number Ca=

μVt/γ. (Despite this equation being based on the aerodynamic Leidenfrost effect, our experimental results have shown good agreement with it, the comparative results in Supplementary Material

Figure S1.) While on the stationary surface, the maximum spreading ratio

βmax-s~We

n1/4(1-cosθ)

-1/2 [

36].

Another aspect that distinguishes our work from previous research is that they considered the contact time

τ in Eq. (3) as the contact time on a stationary surface

τs, while we consider

τ as the contact time on a moving surface

τm. In

Figure 3(a), we can clearly observe a significant difference in contact time between

τs and

τm. Based on volume conservation, the relationship between these two is given by [

37]:

The validation of Eq. (3) can be observed in Supplementary Material

Figure S2. The contact time on the stationary surface

τs~We

n1/2(1-cosθ)

-1/2. By combining Eq. (3) and Eq. (4) with the above scaling relationships, we can deduce:

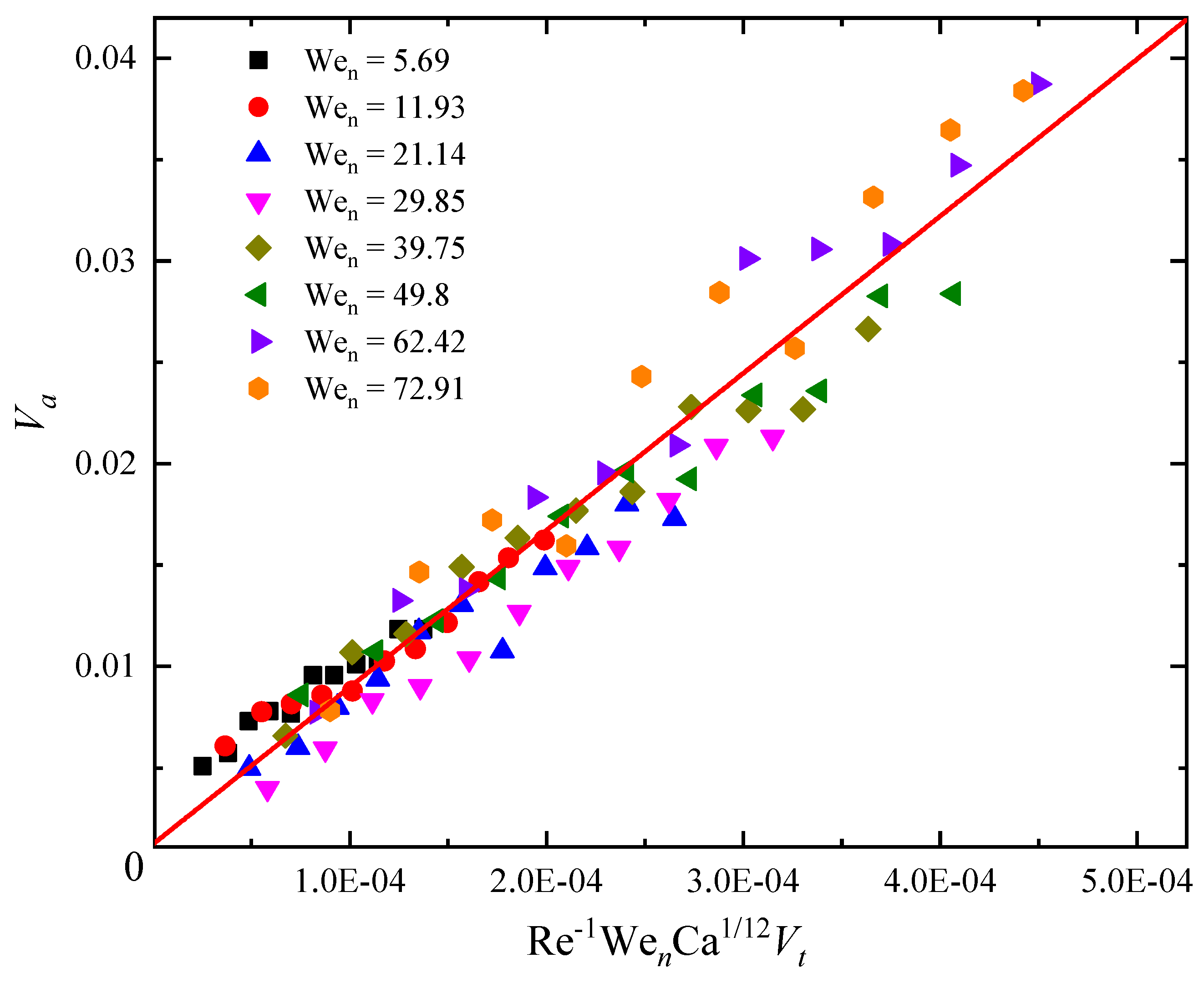

Where the dimensionless Reynolds number is defined as Re=

ρVnD0/

μ, Eq. (5) is derived using the contact time

τm and maximum spreading ratio

βmax-m on a moving surface. If we were to derive it using the contact time

τs and maximum spreading ratio

βmax-s on a stationary surface [

30], we can derive:

When comparing Eq. (5) and (6), the difference is the additional influence of the capillary number Ca in Eq. (5). This inclusion of Ca enhances the influence of surface motion on the droplet velocity and making it a more accurate representation. The boundary layer thickness and contact angle can be regarded as constant values. Therefore, the Eq. (5) can be expressed as:

In

Figure 5, we can observe a good consistency between the experimental data and Eq. (6).

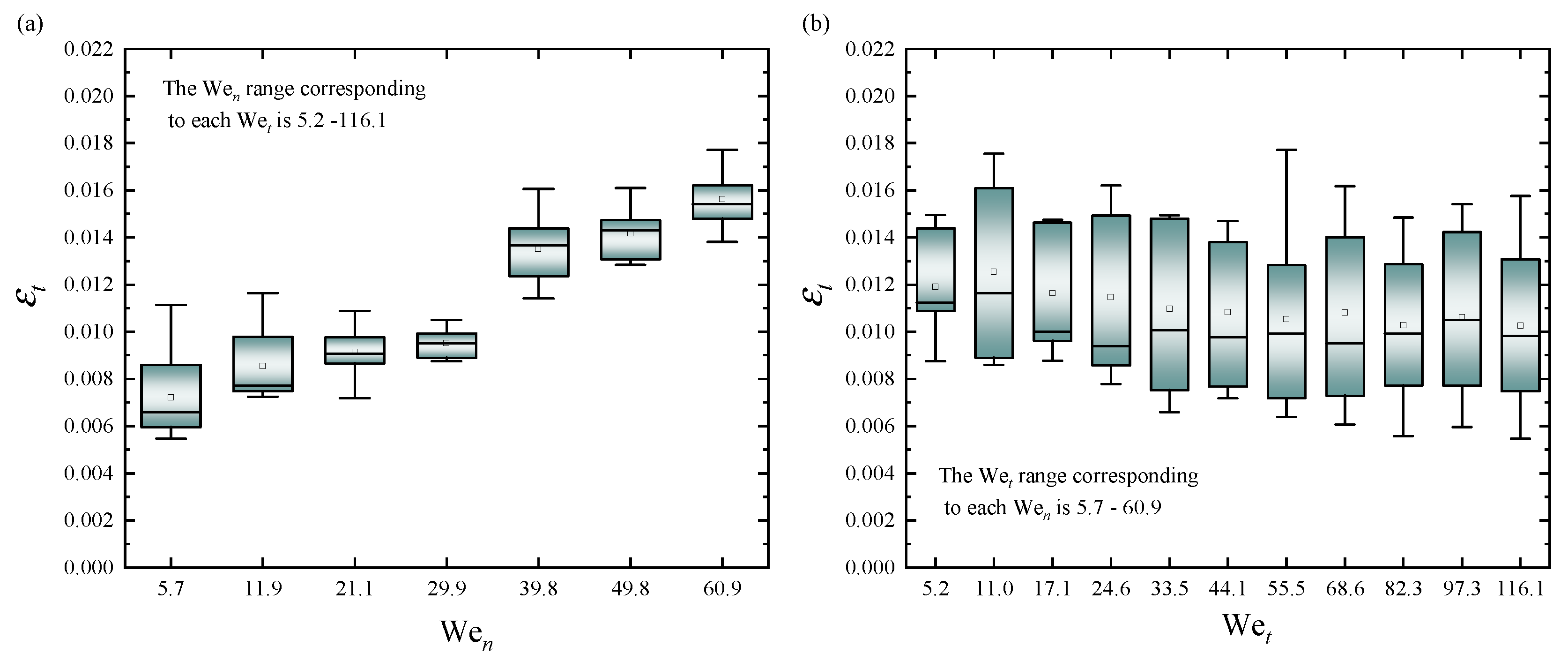

As previously mentioned, the conversion of momentum during droplet impact involves the consumption of energy. This implies that the averaged horizontal velocity of the droplet

Va should be lower than the surface velocity

Vt. We found that the velocity of the droplet is only about 1% of the surface movement velocity. As a result, we defined the averaged restitution coefficient

εt = Va/Vt. Previous research has demonstrated a negative correlation between We

n and

εt because higher We

n impacts can cause more significant droplet deformation, leading to more energy dissipation during rebound and a decrease in

εt [38-42]. However, our study on the moving surface revealed an opposing result, we found that

εt increases with the increase of We

n, as shown in

Figure 6(a), and there is no significant change with the increase of We

t, as shown in

Figure 6(b), the black line in the box represents the median line, and the point in the middle is the mean value. The upper and lower boundaries of the box represent the upper interquartile and lower interquartile, respectively, while the whiskers represent the extreme values. Firstly, previous studies focused on instantaneous velocity, while this study specifically examines the average velocity throughout the entire impact process. Secondly, a significant factor is that as the droplet impacts a moving surface, with an increase in the Weber number, the spreading length increases. This results in the viscous boundary layer length between the droplet and the surface also increasing, leading to an increase in the force exerted on the droplet in the horizontal direction. Ultimately, this is manifested as an increase in the coefficient of restitution.

-

B.

Morphology of droplet on moving surface

We conducted an analysis of changes in droplet behavior from a momentum perspective. In addition, the most significant difference between the stationary and moving surfaces is not only the contact time, but also the asymmetric spreading and receding of the droplet on the upstream and downstream sides.

Figure 7.

(a) Schematic diagram distinguishing the upstream and downstream spreading of the droplet. The red dot represents the initial center of impact of the droplet, while the green dot indicates the position after moving with velocity Va. The green dot serves as the reference for defining the boundary between the upstream and downstream regions, where Ds=0. (b) Side view of the droplet at different time instances. (c) Schematic representation of the velocity superposition of Vs and Vt.

Figure 7.

(a) Schematic diagram distinguishing the upstream and downstream spreading of the droplet. The red dot represents the initial center of impact of the droplet, while the green dot indicates the position after moving with velocity Va. The green dot serves as the reference for defining the boundary between the upstream and downstream regions, where Ds=0. (b) Side view of the droplet at different time instances. (c) Schematic representation of the velocity superposition of Vs and Vt.

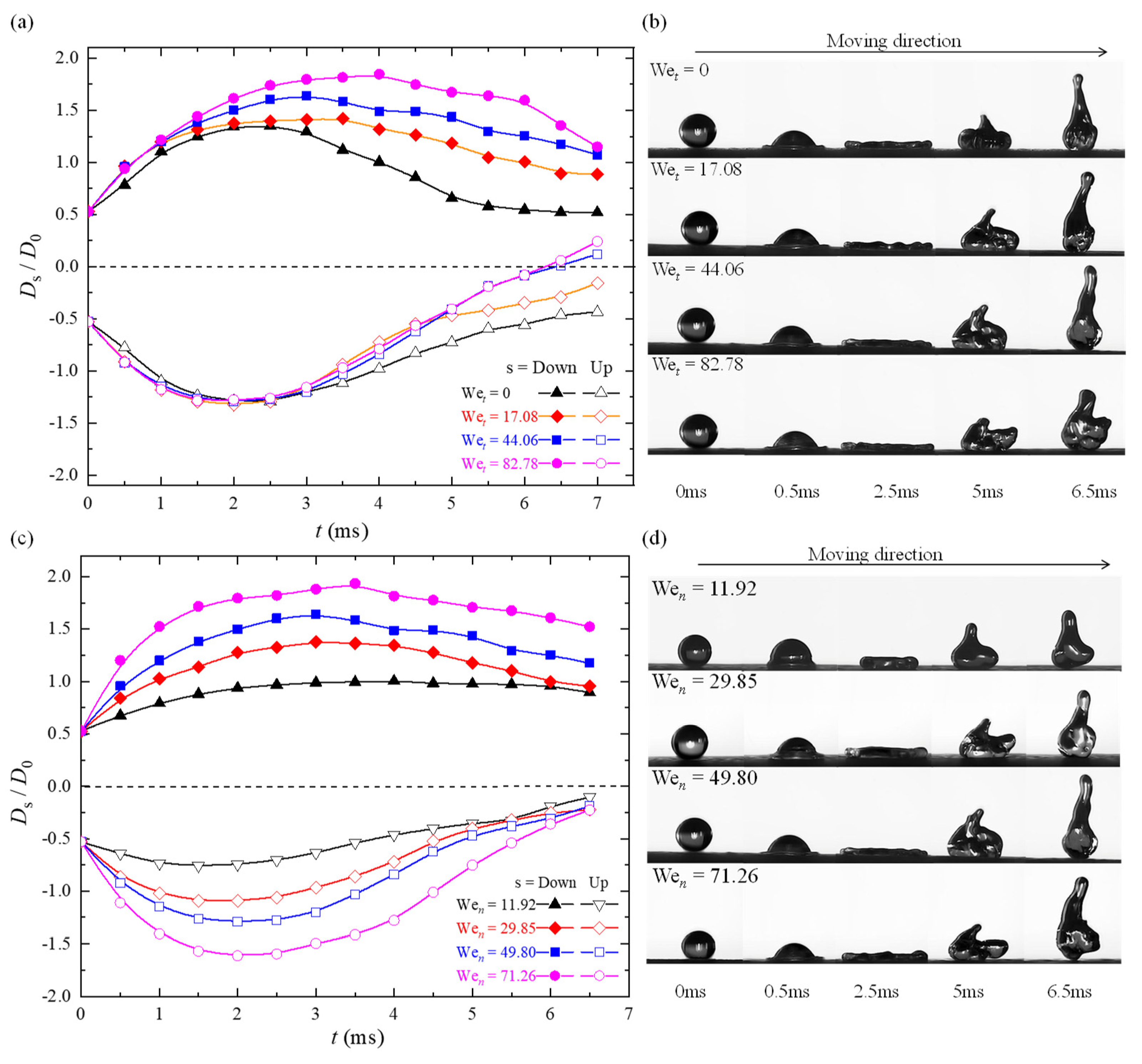

Therefore, we divided the droplet into two portions

Dup and

Ddown based on the impact center point. Initially, the positions of the center points

Ds=0 is represented by the red dot [

Figure 7(a)]. And it varies at different moments, it moves with the horizontal velocity

Va of the droplet, as indicated by the green point in

Figure 7(a). The distance from the point along the moving direction to the edge of the droplet is referred to as

Dup, and the distance from the point along the opposite direction of motion to the edge of the droplet is referred to as

Ddown. When We

t =0, the spreading length of the droplet on the upstream and downstream sides is symmetrically distributed along

Ds=0. However, as We

t increases, the spreading length of the droplet on the upstream side gradually increases, and its spreading time becomes longer, as shown in

Figure 8(a) and 8(b), the negative values in

Figure 8(a) represent that the droplet is located to the right of the boundary point. In addition, the time of initiating receding on the upstream side is later than that on the downstream side. For different We

t values, the spreading time of the downstream side is around 2

ms, and it has almost no effect on the length of spreading. However, the length during the receding phase gradually reduces with the increase of surface speed. In

Figure 8(c) and 8(d), with a fixed We

t = 44.06 and different We

n, the spreading length on both the upstream and downstream sides increases with We

n, with the increment being more significant on the downstream side.

Although the increment of spreading length on the upstream side during the receding phase is relatively small compared to that in the spreading phase, it still increases overall. Thus, we postulate that when the droplet reaches its maximum spreading length, the length of the upstream and downstream portions should be a function of the impact velocity

Vn and surface velocity

Vt. Assuming that the averaged spreading velocity is

Vs and the surface velocity is

Vt, the averaged velocity of the upstream can be treated as

Vup =

Vs -

Vt, similarly, the averaged velocity of the downstream is

Vdown =

Vs +

Vt, as shown in

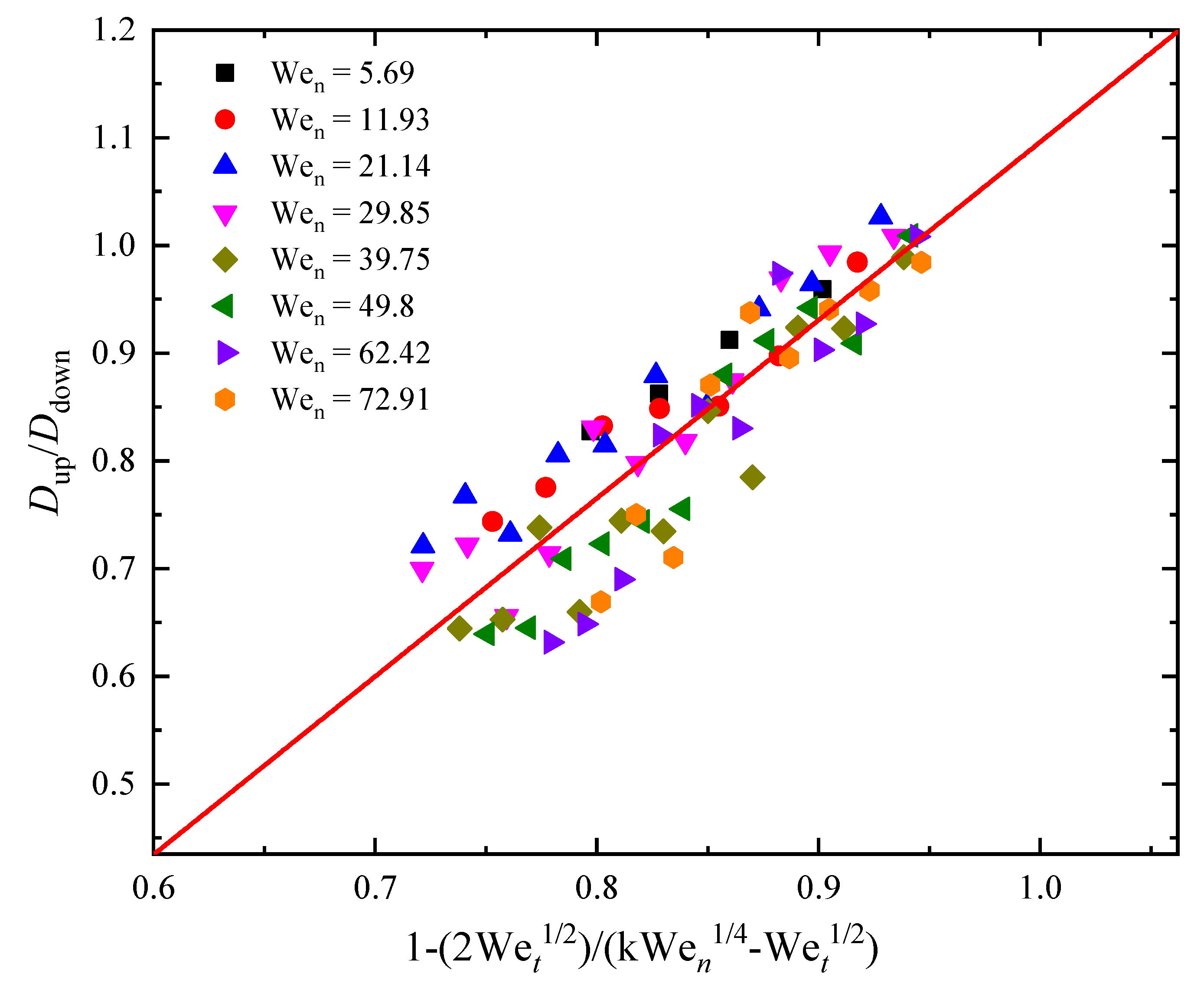

Figure 7(c). Taking into account that droplet will also move a certain distance caused by the moving substrate, the maximal spread length ratio of the upstream to downstream can be expressed as:

If the droplet's upstream and downstream are distinguished based on the calculated moving distance of the green dot, then the term

Vaτs representing the sliding distance of the droplet in Eq. (7) can be eliminated, the formula can be simplified as:

Obviously,

Vt ~

αWe

t1/2, and for

Vs, it is a function of the maximum spreading length and spreading time,

Vs ~

Dmax/

τspread. As can be observed in

Figure 3(b), the spreading time

τspread is independent of surface velocity and impact velocity, which is consistent with previous research findings [

3,

28]. Therefore, we can treat

τspread as a constant, while

Dmax ~

D0We

n1/4, based on these, we can derive the expression for

Vs ~

βWe

n1/4, Substituting these values into Eq. (8) we have:

Where coefficients

α and

β are related constants, Eq. (10) can be written as Eq. (11):

Where coefficients

k=

α/

β. In

Figure 9, we can observe a good consistency between the experimental data and Eq. (11). This scaling relationship has practical applications such as using water to cool rotating machinery, understanding the spreading range of droplet holds significance for such applications [

43].