Submitted:

29 November 2023

Posted:

29 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

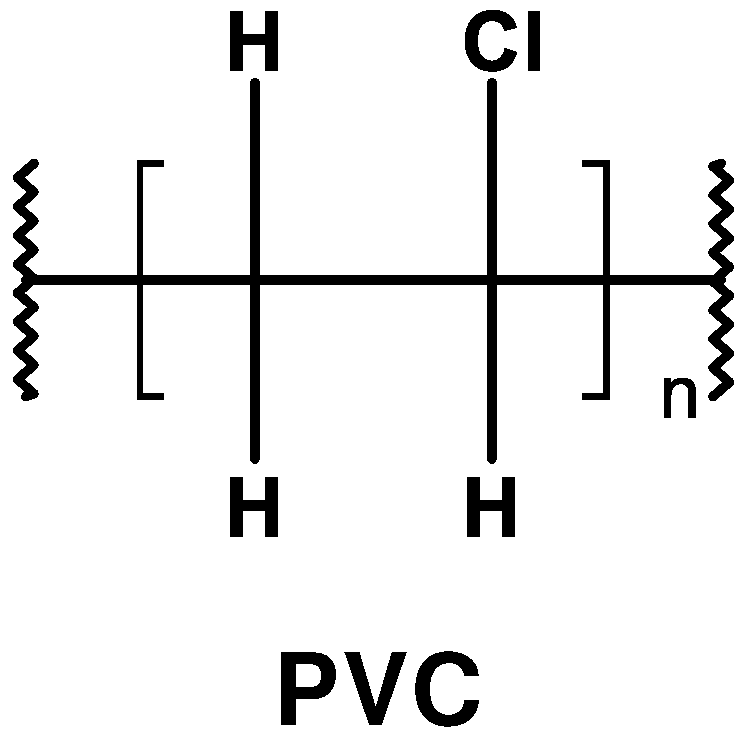

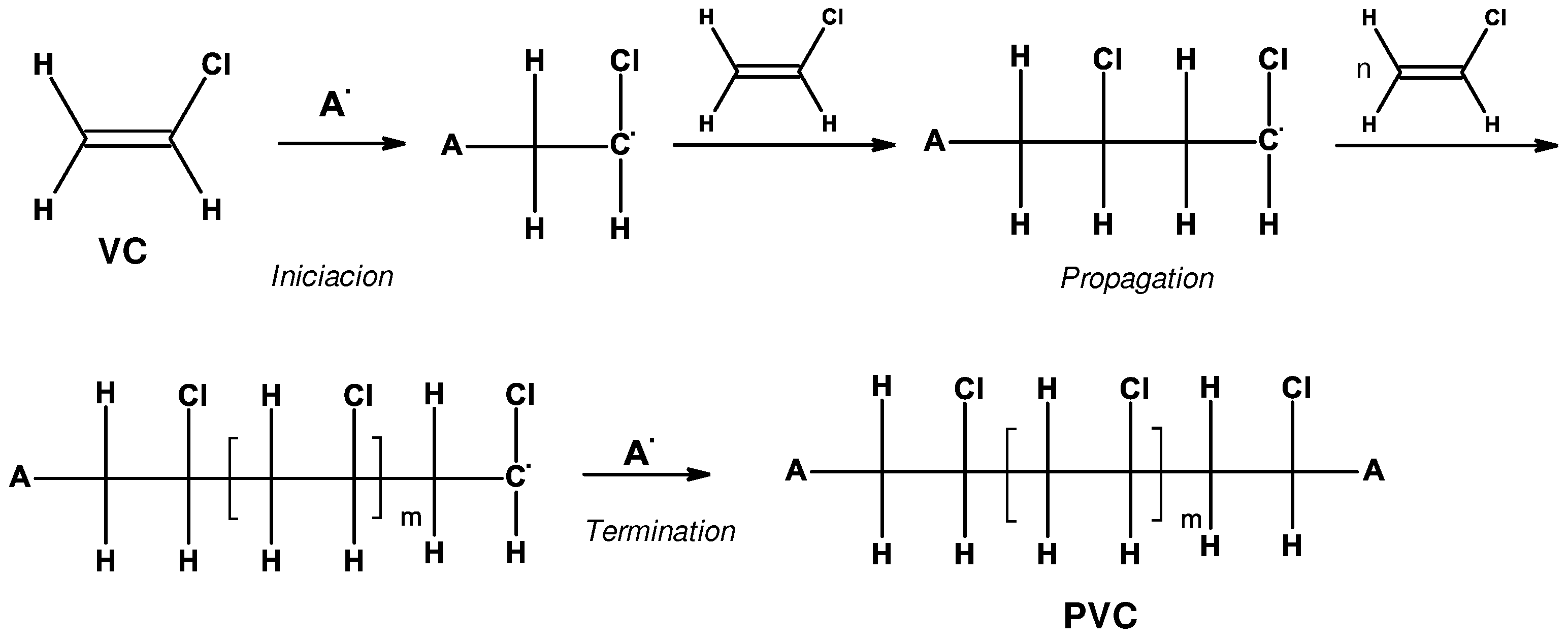

2. PVC characteristics

2.1. PVC physical properties

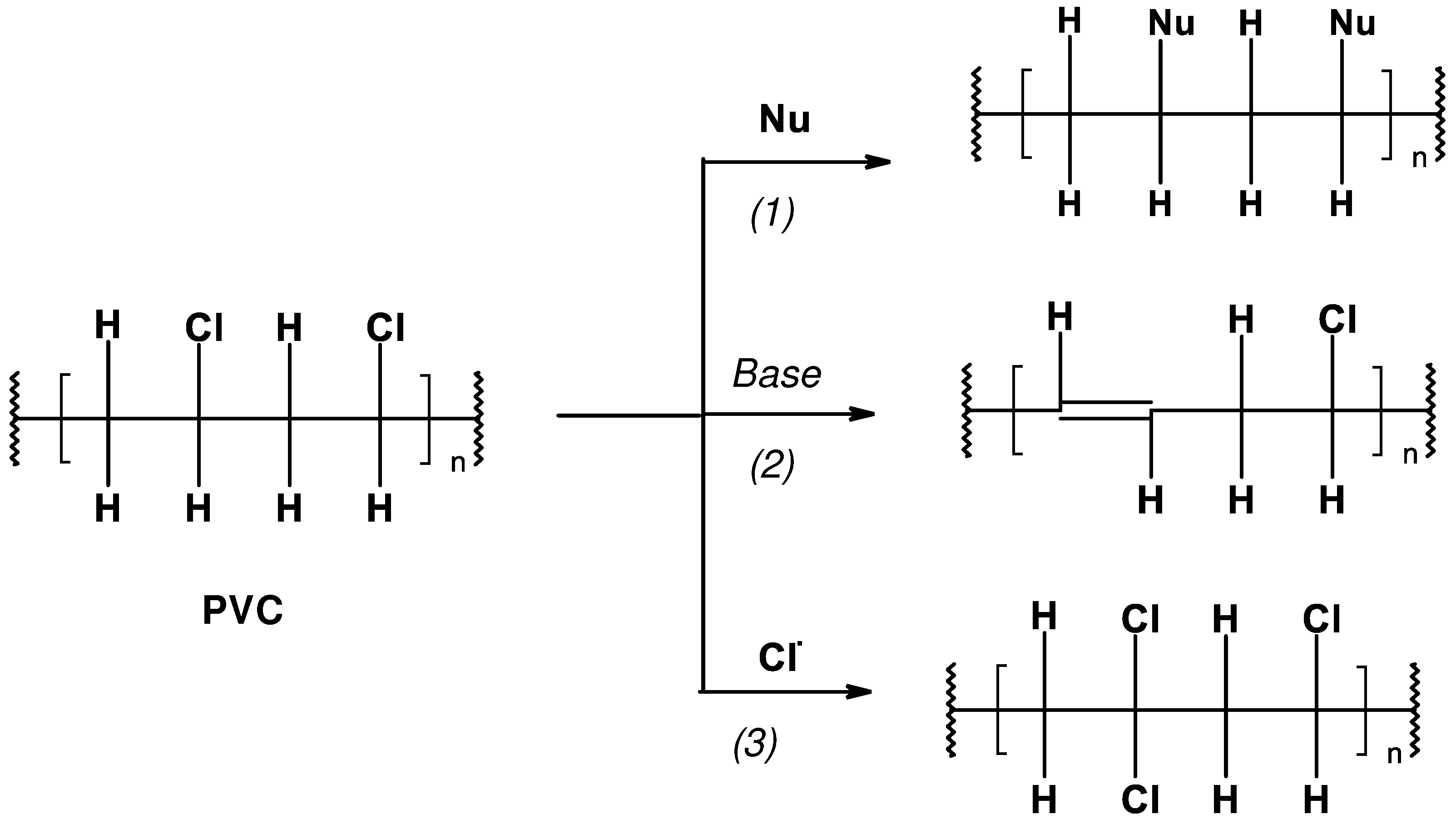

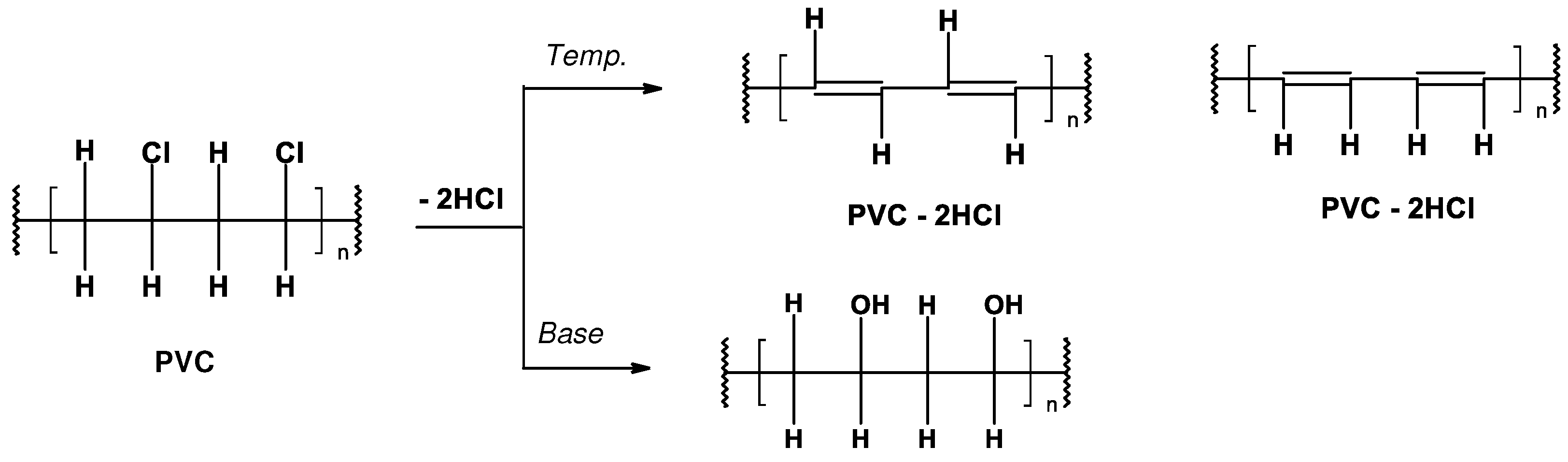

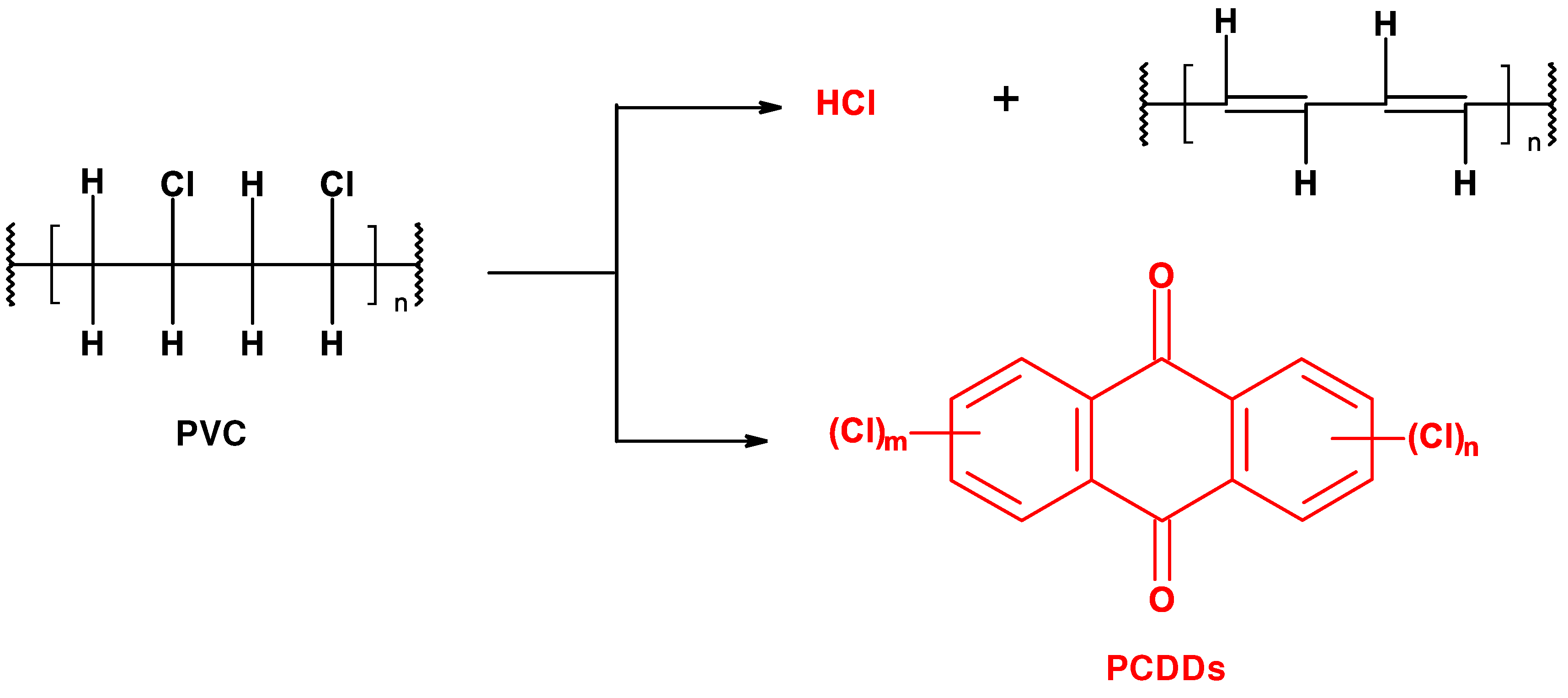

2.2. PVC chemical properties

- preliminary (occurring under the influence of temperature, so-called thermal) in anaerobic conditions at the molecular or ionic level,

- secondary as a result of increased temperatures and oxygen (thermo-oxidative degradation).

2.3. Biological Activity of polyvinyl chloride

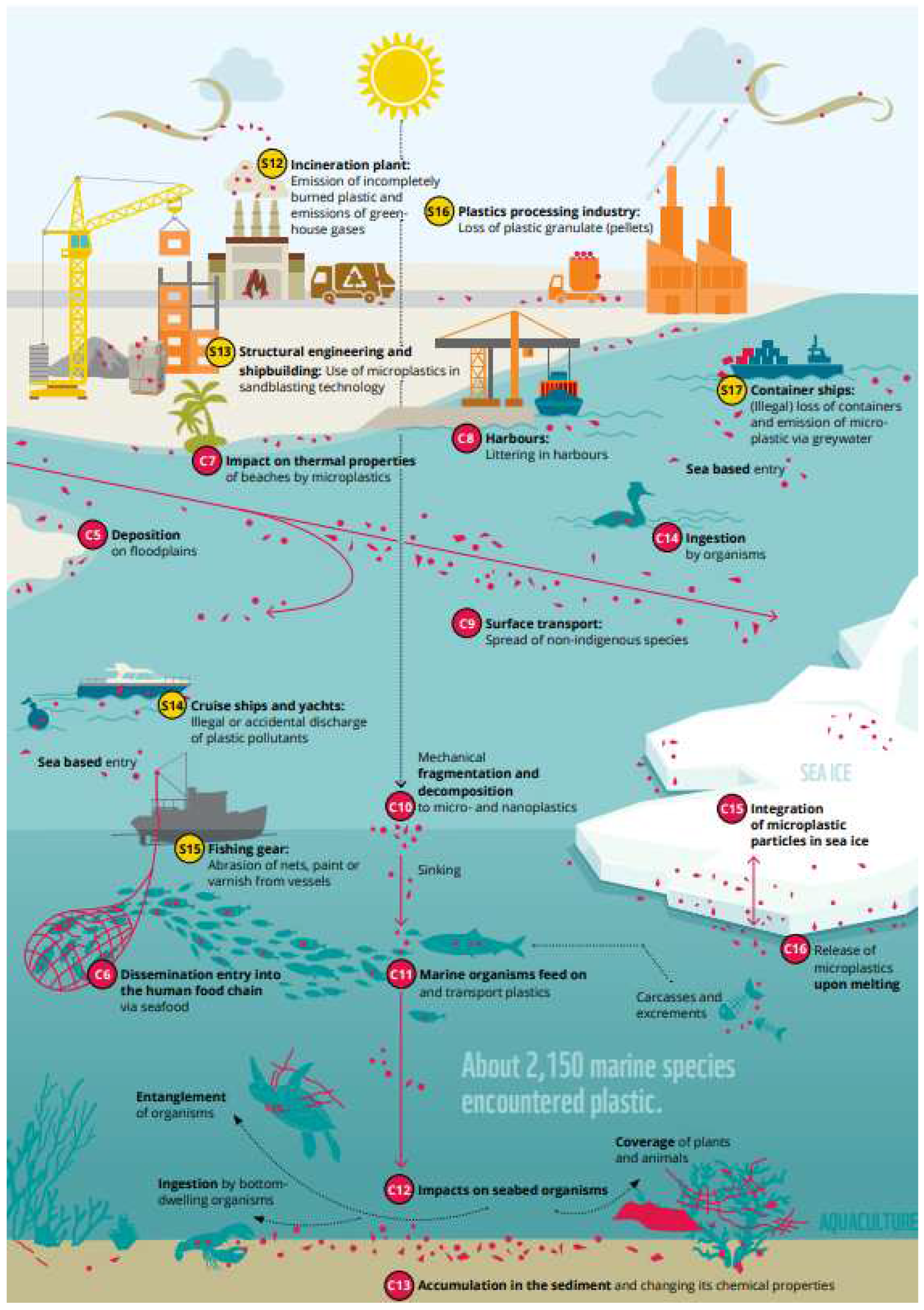

3. Threat related to the production and use of PVC

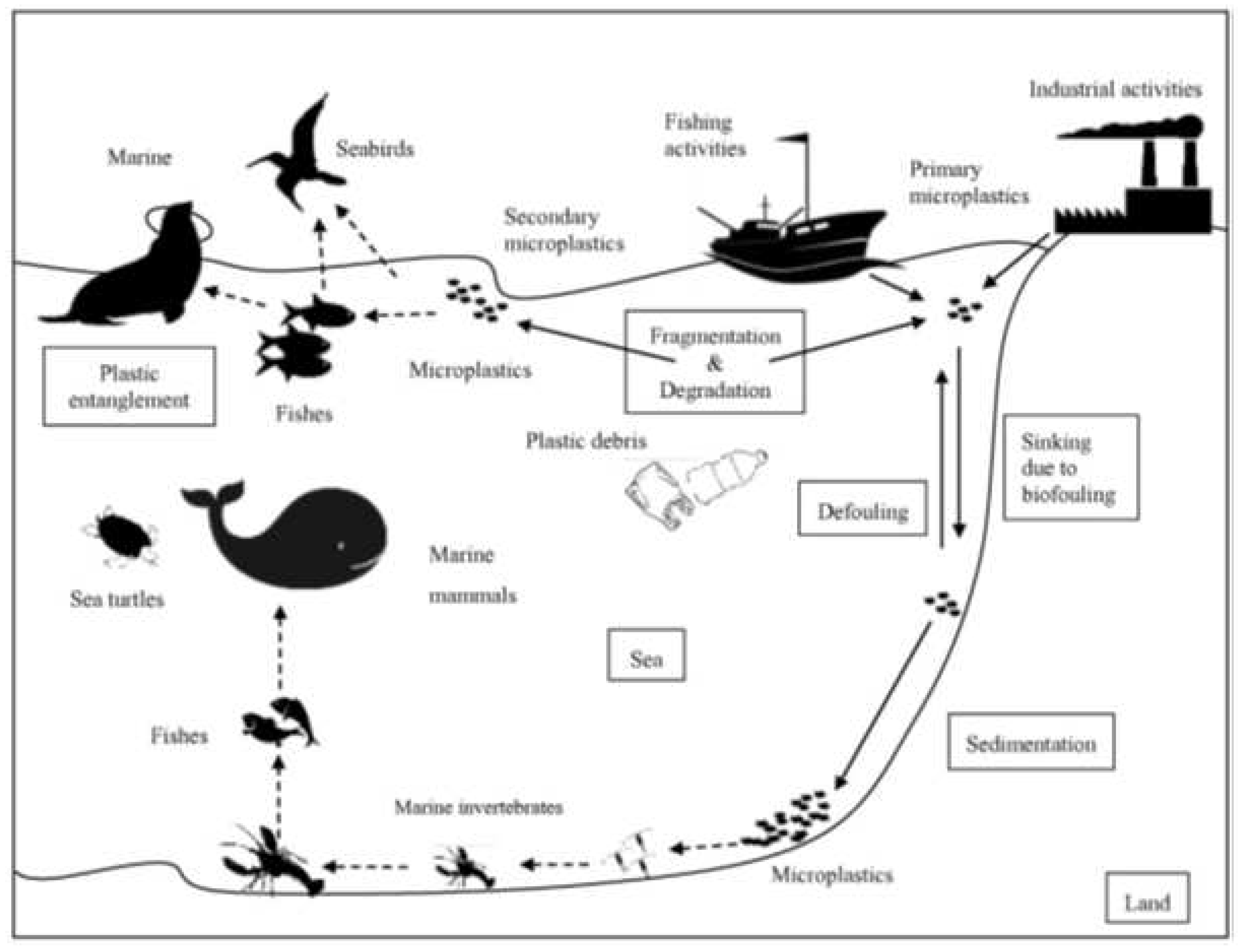

4. Worldwide pollution of the aquatic environment by the polyvinyl chloride industry

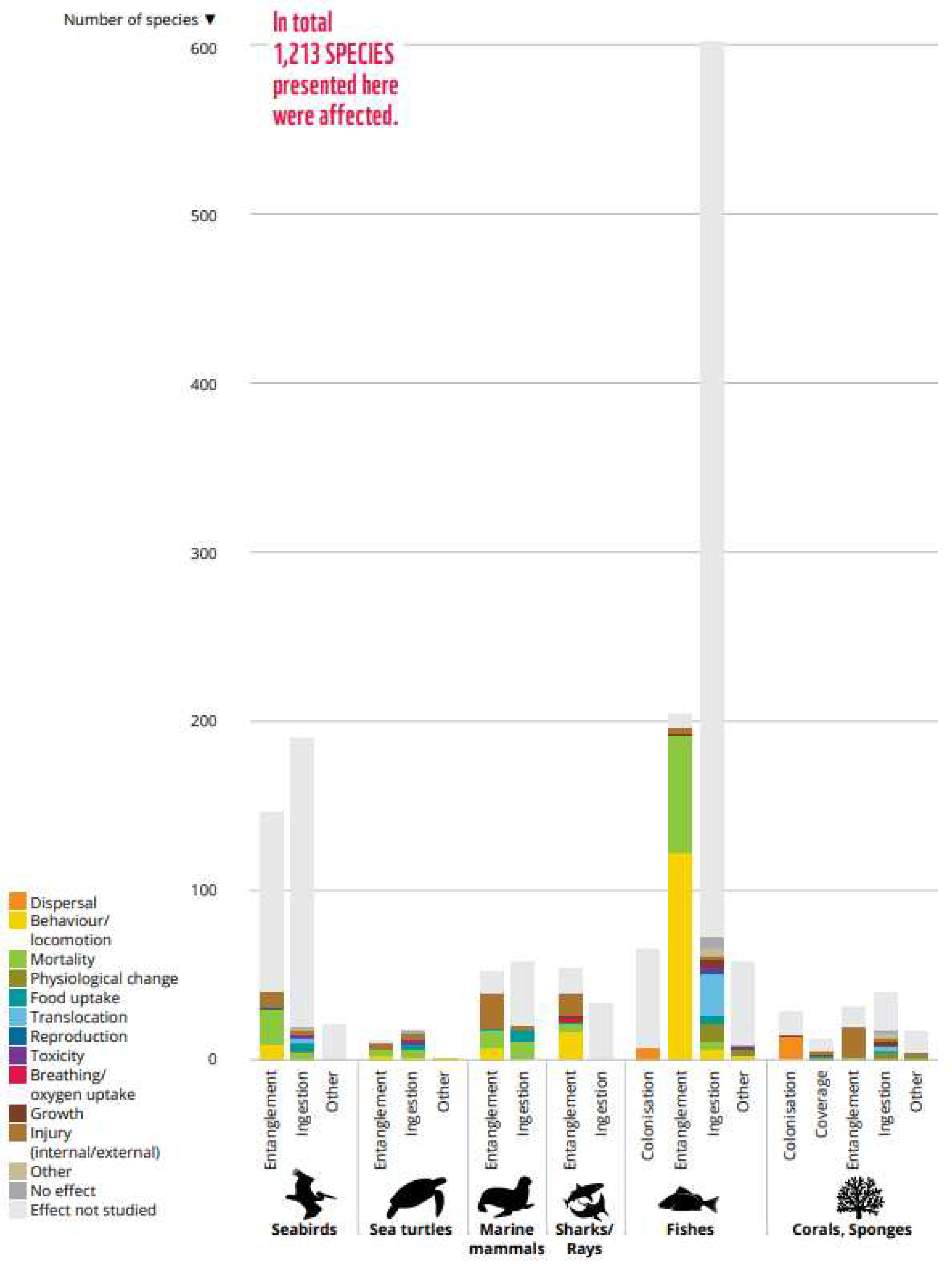

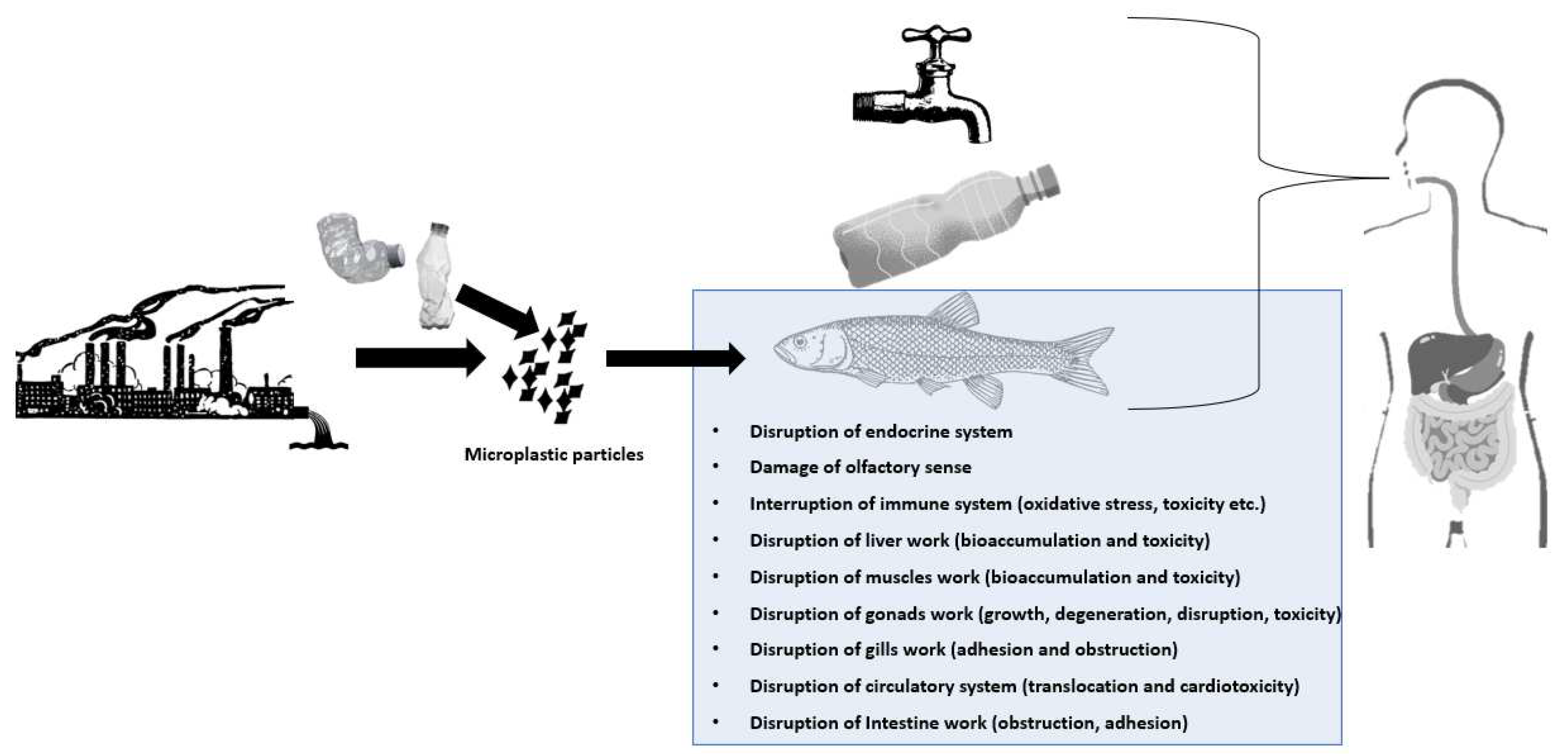

5. Toxicity of polyvinyl chloride to surface water trophic networks and humans

| Organism | Genus/Species | PVC-MPs conc. [unit] | Effect of PVC-MPs on the organism | Ref’s |

|---|---|---|---|---|

| Algae |

Chlamydomonas reinhardtii | 10 – 200 [mg/L] |

Growth inhibition; reduction of chlorophyll-A level. | Wang, 2020 |

|

Skeletonema costatum |

1-50 [mg/L] |

Inhibition of growth; inhibition of photosynthesis efficiency via decrease of chlorophyll content; adsorption and aggregation in algal cells | Zhang, 2016 | |

| Corals |

Zoanthus sociatus |

10 mg/L | Increase of adhesion to coral epidermis; OS induction; changes in photosynthethic efficiency | Rocha, 2020 |

| Plants | Utricularia aurea | 50 [mg/L] |

Growth, length and biomass inhibition; negative effects on physiological parameters (chlorophyll content) | Zhou, 2020 |

| Mussels |

Perna viridis | 21.6-2160 [mg/L] |

Decrease of clearance, respiration rates and byssus production; decrease of median survival times with increasing pollution by PVC | Rist, 2016 |

|

Mytilus galloprovincialis |

- | Accumulation in the organism | Gomiero, 2019b | |

| Arthro-pods | Daphnia magna | 50 [mg/L] | Induction of mortality; increase of the immobilization | Renzi, 2019 |

| Fish | Clarias gariepinus | 0.50;1.50; 3.0 [% of diet] |

Reduction of mean cell volume/ cell haemoglobin values; decrease of neutrophil counts; GPx alternation (brain, gill); SOD inhibition (brain, gill); CAD reduction (brain); increase of lipid peroxidation levels (brain); AChE inhibition (brain, gill); OS induction. | Iheanacho & Odo, 2020 |

| Cyprinus carpio | 10- 30 [% of diet] |

Growth inhibition; alternation of the antioxidant activities - inverse relationship between SOD, CAT after exposition on PVC; increase of the GPx activities; reduction of MDA levels; alternation of antioxidant-related gene expression in the livers of larvae; changes of the transcription; vacuolation of cytoplasmic in the liver under exposure over 20% additives of PVC to diet | Xia, 2020 | |

| Dicentrarchus labrax | 100; 500 [mg/kg diet] |

Increase of the phagocytic and respiratory burst activities of head kidney leucocytes; decrease of immunity and OS induction. | Espinosa, 2019 | |

| Dicentrarchus labrax | 0.1 [% of diet] |

Histopathological changes of the ingestine | Peda, 2016 | |

| Etroplus suratensis | 1.0 - 10.8 [mg/L] |

Influence on SOD activity (increase at 1.03-1.8 mg/L; decrease at 3.0- 10.8 mg/L); behavioral changes (fin flickering, burst swimming, and jerking movement); decrease of red and white blood cells; changes in antioxidant enzymes | Vijayaraghavan, 2022 | |

| Sparus aurata | 100; 500 [mg/kg diet] |

Gene expression changes: PRDX5 (decrease); PRDX1, PRDX3 (increase); UCP1 (up-regulation). | Espinosa, 2017 | |

| AChE – acetylcholinesterase; CAT – catalase; GPx - glutathione peroxidase; MDA -malondialdehyde; OS - oxidative stress; SOD - superoxide dismutase | ||||

6. Contamination of soil with PVC

7. Methods of eliminating polyvinyl chloride from the environment

| Method | Type | Mechanism | Ref’s |

|---|---|---|---|

| chemical dechlorination | chemical neutralization | modification consisting in replacing some chlorine atoms with various nucleophilic reagents | Lu, 2019 |

| hydrothermal dechlorination | physico-chemical neutralization | conducting modifications in supercritical or subcritical water which works as a solvent and reagent for reactions of organic compounds | Li, 2017 |

| photodegradation | physical degradation | breaking down the chemical bonds in a polymer by ultraviolet (UV) radiation | Yousif, 2015 |

| mechanical recycling | mechanical modification | recycling technique consisting in extruding and mixing the material with primary polymers | Sadat-Shojai & Bakhshandeh, 2011 |

| pyrolysis | physico-chemical degradation | polymers decomposition under high temperature | Yu, 2016 |

| biodegradation | biological degradation | polymers decomposition by the microorganisms such as bacteria and filamentous fungi, and organisms such as insects | Vivi et al., 2019 Giacomucci, 2019 Tsochatzis, 2021 |

| biofragmentation | biological modification | the breakdown of polymers into monomers, dimers or oligomers during a lytic process, involving decrease of reducing the molecular weight of the polymer and oxidation of the lower weight molecules using specific enzymes (oxidoreductases and hydrolases), as well as free radicals | Restrepo-Flórez, 2014 |

7.1. Recycling and utilization of PVC

- mechanical methods – consisting in extruding and mixing the material with primary polymers,

- chemical methods – changing the polymer structure of the material using chemical and thermal agents [Yin, 2021].

7.2. Biological utilization of PVC waste

8. Conclusions

9. Future Directions

References

- Abdel-Naby, A.S.; A.A. Al-Ghamdi, Poly(vinyl chloride) blend with biodegradable cellulose acetate in presence of N-(phenyl amino) maleimides, Int. J. Biol. Macromol. 70 (2014) 124–130.. [CrossRef]

- Akovali, G. 2 - Plastic materials: polyvinyl chloride (PVC), in: F. Pacheco-Torgal, S. Jalali, A.B.T.-T. of B.M. Fucic (Eds.), Woodhead Publ. Ser. Civ. Struct. Eng., Woodhead Publishing, 2012: pp. 23–53.. [CrossRef]

- Alabi, O.A.; K.I. Ologbonjaye, O. Awosolu, O.E. Alalade, Public and Environmental Health Effects of Plastic Wastes Disposal: A Review, J. Toxicol. Risk Assess. 5 (2019) 021.. [CrossRef]

- Alharbi, K.; M. Aqeel, N. Khalid, A. Nazir, M.K. Irshad, F.M. Alzuaibr, H.A.S. AlHaithloul, N. Akhter, O.M. Al-Zoubi, M. Qasim, K.M.A. Syaad, M.A. AlShaqhaa, A. Noman, Microplastics in soil differentially interfere with nutritional aspects of chilli peppers, South African J. Bot. 160 (2023) 402–413.. [CrossRef]

- Ali, M.; Q. Perveen, B. Ahmad, I. Javed, R. Razi-Ul-Hussnain, S. Andleeb, N. Atique, P.B. Ghumro, S. Ahmed, A. Hameed, Studies on Biodegradation of Cellulose Blended Polyvinyl Chloride Films, Int. J. Agric. Biol. 11 (2009, 11, 577–580. DOI: api.semanticscholar.org/CorpusID:137917419.

- Ali, M.F.; M.N. Siddiqui, Thermal and catalytic decomposition behavior of PVC mixed plastic waste with petroleum residue, J. Anal. Appl. Pyrolysis. 74 (2005) 282–289. [CrossRef]

- Ali, M.I.; S. Ahmed, G. Robson, I. Javed, N. Ali, N. Atiq, A. Hameed, Isolation and molecular characterization of polyvinyl chloride (PVC) plastic degrading fungal isolates, J. Basic Microbiol. 54 (2014) 18–27.. [CrossRef]

- Ali, M.I.; S. Ahmed, I. Javed, N. Ali, N. Atiq, A. Hameed, G. Robson, Biodegradation of starch blended polyvinyl chloride films by isolated Phanerochaete chrysosporium PV1, Int. J. Environ. Sci. Technol. 11 (2014) 339–348.. [CrossRef]

- Alshehrei, F.Biodegradation of Synthetic and Natural Plastic by Microorganisms, J. Appl. Environ. Microbiol. 5 (2017) 8–19.. [CrossRef]

- Ambrogi, A.; Carfagna, C.; Cerruti, P.; Marturano, V., 4. Additives in Polymers. In Modification of Polymer Properties. 2017 Elsevier Inc. pp. 87-108. [CrossRef]

- Ammala, A.; S. Bateman, K. Dean, E. Petinakis, P. Sangwan, S. Wong, Q. Yuan, L. Yu, C. Patrick, K.H. Leong, An overview of degradable and biodegradable polyolefins, Prog. Polym. Sci. 36 (2011) 1015–1049.. [CrossRef]

- Amobonye, A.E.; P. Bhagwat, S. Singh, S. Pillai, Chapter 10 - Biodegradability of Polyvinyl chloride, in: A. Sarkar, B. Sharma, S.B.T.-B. of C.P. Shekhar (Eds.), Elsevier, 2023: pp. 201–220.. [CrossRef]

- Babinsky, R. PVC additives: a global review, Plast. Addit. Compd. 8 (2006) 38–40.. [CrossRef]

- Bacaloglu, R.; Fisch, M. Reaction mechanism of poly(vinyl chloride) degradation. Molecular orbital calculations. J. Vinyl Addit. Technol. 1995, 1, 241-249. [CrossRef]

- Bahl, S.; J. Dolma, J. Jyot Singh, S. Sehgal, Biodegradation of plastics: A state of the art review, Mater. Today Proc. 39 (2021) 31–34.. [CrossRef]

- Baitz, M.; J. Kreißig, E. Byrne, C. Makishi, T. Kupfer, N. Frees, N. Bey, M.S. Hansen, A. Hansen, T. Bosch, V. Borghi, J. Watson, M. Miranda, Final Report: ”Life Cycle Assessment of PVC and of principal competing materials”, Commissioned by the European Commission, July 2004.

- Barili, S.; A. Bernetti, C. Sannino, N. Montegiove, E. Calzoni, A. Cesaretti, I. Pinchuk, D. Pezzolla, B. Turchetti, P. Buzzini, C. Emiliani, G. Gigliotti, Impact of PVC microplastics on soil chemical and microbiological parameters, Environ. Res. 229 (2023) 115891.. [CrossRef]

- Beiras, R.; Verdejo, E.; Campoy-López, P.; Vidal-Liñán, L. Aquatic toxicity of chemically defined microplastics can be explained by functional additives. J. Hazard. Mater. 2021, 406, 124338. [CrossRef]

- Bermúdez, J.R.; P.W. Swarzenski, A microplastic size classification scheme aligned with universal plankton survey methods, MethodsX. 8 (2021) 101516.. [CrossRef]

- Bottausci, S.; E.-D. Ungureanu-Comanita, M. Gavrilescu, A. Bonoli, Environmental impacts quantification of pvc production, Environ. Eng. Manag. J. 20 (2021) 1693–1702. [CrossRef]

- Bouaicha, O.; T. Mimmo, R. Tiziani, N. Praeg, C. Polidori, L. Lucini, G. Vigani, R. Terzano, J.C. Sanchez-Hernandez, P. Illmer, S. Cesco, L. Borruso, Microplastics make their way into the soil and rhizosphere: A review of the ecological consequences, Rhizosphere. 22 (2022) 100542.. [CrossRef]

- Boyle, D.; A.I. Catarino, N.J. Clark, T.B. Henry, Polyvinyl chloride (PVC) plastic fragments release Pb additives that are bioavailable in zebrafish, Environ. Pollut. 263 (2020) 114422.. [CrossRef]

- Bożek, M.; B. Hanus-Lorenz, J. Rybak, The studies on waste biodegradation by Tenebrio molitor, E3S Web Conf. 17 (2017) 00011.. [CrossRef]

- Braun, D. PVC — origin, growth, and future, J. Vinyl Addit. Technol. 7 (2001) 168–176.. [CrossRef]

- Braun, D.; Poly(vinyl chloride) on the way from the 19th century to the 21st century, J. Polym. Sci. Part A Polym. Chem. 42 (2004) 578–586.. [CrossRef]

- Brennecke, D.; B. Duarte, F. Paiva, I. Caçador, J. Canning-Clode, Microplastics as vector for heavy metal contamination from the marine environment, Estuar. Coast. Shelf Sci. 178 (2016) 189–195.. [CrossRef]

- Bucol, L.A.; E.F. Romano, S.M. Cabcaban, L.M.D. Siplon, G.C. Madrid, A.A. Bucol, B. Polidoro, Microplastics in marine sediments and rabbitfish (Siganus fuscescens) from selected coastal areas of Negros Oriental, Philippines, Mar. Pollut. Bull. 150 (2020) 110685. [CrossRef]

- Canesi, L.; E. Fabbri, Environmental Effects of BPA: Focus on Aquatic Species, Dose-Response. 13 (2015) 1559325815598304.. [CrossRef]

- Capolupo, M.; L. Sørensen, K.D.R. Jayasena, A.M. Booth, E. Fabbri, Chemical composition and ecotoxicity of plastic and car tire rubber leachates to aquatic organisms, Water Res. 169 (2020) 115270.. [CrossRef]

- Carroll Jr., W.F.; Berger, T.C.; Borrelli, F.E.; Garrity, P.J.; Jacobs, R.A.; Ledvina, J.; Lewis, J.W.; McCreedy, R.L.; Smith, T.P.; Tuhovak, D.R.; Weston, A.F. Characterization of emissions of dioxins and furans from ethylene dichloride, vinyl chloride monomer and polyvinyl chloride facilities in the United States. Consolidated report. Chemosphere, 2001, 43, 689-700. [CrossRef]

- Chae, D.-H.; I.-S. Kim, S.-K. Kim, Y.K. Song, W.J. Shim, Abundance and Distribution Characteristics of Microplastics in Surface Seawaters of the Incheon/Kyeonggi Coastal Region, Arch. Environ. Contam. Toxicol. 69 (2015) 269–278.. [CrossRef]

- Chen, C.; L. Chen, Y. Yao, F. Artigas, Q. Huang, W. Zhang, Organotin release from polyvinyl chloride microplastics and concurrent photodegradation in water: Impacts from salinity, dissolved organic matter, and light exposure, Environ. Sci. Technol. 53 (2019) 10741–10752.. [CrossRef]

- Chen, W.; Gong, Y.; McKie, M.; Almuhtaram, H.; Sun, J.; Barrett, H.; Yang, D.; Wu, M.; Andrews, R.C.; Peng, H. Defining the chemical additives driving in vitro toxicities of plastics. Environ. Sci. Technol. 2022, 56 (20), 14627-14639. [CrossRef]

- Chen, X.; Zhuang, J.; Chen, Q.; Xu, L.; Yue, X.; Qiao, D. Chronic exposure to polyvinyl chloride microplastics induces liver injury and gut microbiota dysbiosis based on the integration of liver transcriptome profiles and full-length 16S rRNA sequencing data. Sci. Total Environ. 2022, 839, 155984. [CrossRef]

- Chen, X.; Zhuang, J.; Chen, Q.; Xu, L.; Yue, X.; Qiao, D. Polyvinyl chloride microplastics induced gut barrier dysfunction, microbiota dysbiosis and metabolism disorder in adult mice. Ecotoxicol. Environ. Saf. 241, 113809, 2022. [CrossRef]

- Choi, D.; C. Kim, T. Kim, K. Park, J. Im, J. Hong, Potential threat of microplastics to humans: toxicity prediction modeling by small data analysis, Environ. Sci. Nano. 10 (2023) 1096–1108.. [CrossRef]

- Chong, N.S.; S. Abdulramoni, D. Patterson, H. Brown, Releases of Fire-Derived Contaminants from Polymer Pipes Made of Polyvinyl Chloride, Toxics. 7 (2019).. [CrossRef]

- Čolnik, M.; P. Kotnik, Ž. Knez, M. Škerget, Degradation of Polyvinyl Chloride (PVC) Waste with Supercritical Water, Processes. 10 (2022) 1940.. [CrossRef]

- Colzi, I.; L. Renna, E. Bianchi, M.B. Castellani, A. Coppi, S. Pignattelli, S. Loppi, C. Gonnelli, Impact of microplastics on growth, photosynthesis and essential elements in Cucurbita pepo L., J. Hazard. Mater. 423 (2022) 127238.. [CrossRef]

- Comaniţă, E.-D.; C. Ghinea, M. Roşca, I.M. Simion, M. Petraru, M. Gavrilescu, Environmental impacts of polyvinyl chloride (PVC) production process, in: 2015 E-Health Bioeng. Conf., 2015: pp. 1–4.. [CrossRef]

- Cox, K.D.; G.A. Covernton, H.L. Davies, J.F. Dower, F. Juanes, S.E. Dudas, Human Consumption of Microplastics, Environ. Sci. Technol. 53 (2019) 7068–7074. DOI: 10.1021/ acs.est.9b01517.].

- Cutroneo, L., Reboa, A., Besio, G.; Borgogno, F.; Canesi, L.; Canuto, S.; Dara, M.; Enrile, F.; Forioso, I.; Greco, G.; Lenoble, V.; Malatesta, A.; Mounier, S.; Petrillo, M.; Rovetta, R.; Stocchino, A.; Tesan, J.; Vagge, G.; Capello, M.. Microplastics in seawater: sampling strategies, laboratory methodologies, and identification techniques applied to port environment. Environ Sci Pollut Res 27, 8938–8952 (2020). [CrossRef]

- Dai, Z.; H. Zhang, Q. Zhou, Y. Tian, T. Chen, C. Tu, C. Fu, Y. Luo, Occurrence of microplastics in the water column and sediment in an inland sea affected by intensive anthropogenic activities, Environ. Pollut. 242 (2018) 1557–1565. [CrossRef]

- Dainelli, M.; S. Pignattelli, N. Bazihizina, S. Falsini, A. Papini, I. Baccelli, S. Mancuso, A. Coppi, M.B. Castellani, I. Colzi, C. Gonnelli, Can microplastics threaten plant productivity and fruit quality? Insights from Micro-Tom and Micro-PET/PVC, Sci. Total Environ. 895 (2023) 165119.. [CrossRef]

- Danko, A.S.; L. Meizhong, C.E. Bagwell, R.L. Brigmon, D.L. Freedman, Involvement of Linear Plasmids in Aerobic Biodegradation of Vinyl Chloride, Appl. Environ. Microbiol. 70 (2004) 6092–6097.. [CrossRef]

- Danopoulos, E.; L. Jenner, M. Twiddy, J.M. Rotchell, Microplastic contamination of salt intended for human consumption: a systematic review and meta-analysis, SN Appl. Sci. 2 (2020) 1950.. [CrossRef]

- Darabi, H.; A. Baradaran, K. Ebrahimpour, Subacute toxic effects of polyvinyl chloride microplastics (PVC-MPs) in juvenile common carp, Cyprinus carpio (Pisces: Cyprinidae), Casp. J. Environ. Sci. 20 (2022) 233–242.. [CrossRef]

- Das, G.; N.K. Bordoloi, S.K. Rai, A.K. Mukherjee, N. Karak, Biodegradable and biocompatible epoxidized vegetable oil modified thermostable poly(vinyl chloride): Thermal and performance characteristics post biodegradation with Pseudomonas aeruginosa and Achromobacter sp., J. Hazard. Mater. 209–210 (2012) 434–442.. [CrossRef]

- de Haan, W.P.; A. Sanchez-Vidal, M. Canals, Floating microplastics and aggregate formation in the Western Mediterranean Sea, Mar. Pollut. Bull. 140 (2019) 523–535.. [CrossRef]

- Decker, C. Photodegradation of PVC, in: E.D. Owen (Ed.), Degrad. Stabilisation PVC, Springer Netherlands, Dordrecht, 1984: pp. 81–136.. [CrossRef]

- De-la-Torre, G.E.; Dioses-Salinas, D. C.; Pizarro-Ortega, C. I.; Santillán, L. New plastic formations in the Anthropocene. Sci. Total Environ. 2021, 754, 14221-6. [CrossRef]

- Ding, J.; F. Jiang, J. Li, Z. Wang, C. Sun, Z. Wang, L. Fu, N.X. Ding, C. He, Microplastics in the Coral Reef Systems from Xisha Islands of South China Sea, Environ. Sci. Technol. 53 (2019) 8036–8046.. [CrossRef]

- Ding, L.; R. fan Mao, X. Guo, X. Yang, Q. Zhang, C. Yang, Microplastics in surface waters and sediments of the Wei River, in the northwest of China, Sci. Total Environ. 667 (2019) 427–434.. [CrossRef]

- Elgharbawy, A.S. Poly Vinyl Chloride Additives and Applications - A Review. J. Risk Anal. Crisis Response, 2022, 12(3), 143-151. [CrossRef]

- Elizalde-Velázquez, G.A.; L.M. Gómez-Oliván, Microplastics in aquatic environments: A review on occurrence, distribution, toxic effects, and implications for human health, Sci. Total Environ. 780 (2021) 146551.. [CrossRef]

- Endo, K. Synthesis and structure of poly(vinyl chloride). Prog. Polym. Sci. 2002, 27(10), 2021-2054. [CrossRef]

- Espinosa, C.; A. Cuesta, M.Á. Esteban, Effects of dietary polyvinylchloride microparticles on general health, immune status and expression of several genes related to stress in gilthead seabream (Sparus aurata L.), Fish Shellfish Immunol. 68 (2017) 251–259. [CrossRef]

- Espinosa, C.; M.Á. Esteban, A. Cuesta, Dietary administration of PVC and PE microplastics produces histological damage, oxidative stress and immunoregulation in European sea bass (Dicentrarchus labrax L.), Fish Shellfish Immunol. 95 (2019) 574–583. [CrossRef]

- European Commission, Green Paper - Environmental issues of PVC, 2000. https://eur-lex.europa.eu/legal-content/SL/TXT/?uri=CELEX:52000DC0469.

- European Commission, The use of PVC (Poly Vinyl Chloride) in the contex of a non-toxic environment, 2022. https://op.europa.eu/en/publication-detail/-/publication/e9e7684a-906b-11ec-b4e4-01aa75ed71a1.

- Facchetti, S.V.; R. La Spina, F. Fumagalli, N. Riccardi, D. Gilliland, J. Ponti, Detection of Metal-Doped Fluorescent PVC Microplastics in Freshwater Mussels, Nanomaterials. 10 (2020).. [CrossRef]

- Fan, P.; W. Tan, H. Yu, Effects of different concentrations and types of microplastics on bacteria and fungi in alkaline soil, Ecotoxicol. Environ. Saf. 229 (2022) 113045. [CrossRef]

- Fan, Y.; K. Zheng, Z. Zhu, G. Chen, X. Peng, Distribution, sedimentary record, and persistence of microplastics in the Pearl River catchment, China, Environ. Pollut. 251 (2019) 862–870. [CrossRef]

- Fang, C.; Zheng, H. Chen, F. Hong, L. Lin, H. Lin, H. Guo, C. Bailey, H. Segner, J. Mu, J. Bo, Comparison of microplastic contamination in fish and bivalves from two major cities in Fujian province, China and the implications for human health, Aquaculture. 512 (2019) 734322. [CrossRef]

- Fayad, N.M.; S.Y. Sheikheldin, M.H. Al-Malack, A.H. El-Mubarak, N. Khaja, Migration of vinyl chloride monomer (VCM) and additives into PVC bottled drinking water, J. Environ. Sci. Heal.. Part A Environ. Sci. Eng. Toxicol. 32 (1997) 1065–1083.. [CrossRef]

- Fernández-González, V.; J.M. Andrade-Garda, P. López-Mahía, S. Muniategui-Lorenzo, Misidentification of PVC microplastics in marine environmental samples, TrAC Trends Anal. Chem. 153 (2022) 116649.. [CrossRef]

- Ferreira, M.; J. Thompson, A. Paris, D. Rohindra, C. Rico, Presence of microplastics in water, sediments and fish species in an urban coastal environment of Fiji, a Pacific small island developing state, Mar. Pollut. Bull. 153 (2020) 110991.. [CrossRef]

- Fischer, M.; I. Goßmann, B.M. Scholz-Böttcher, Fleur de Sel—An interregional monitor for microplastics mass load and composition in European coastal waters?, J. Anal. Appl. Pyrolysis. 144 (2019) 104711.. [CrossRef]

- Fishbein, L. Toxicity of the components of poly(vinylchloride) polymers additives. Prog. Clin. Biol. Res. 1983, 141, 113–136.

- Fisher, I.; W.F. Schmitt, H.C. Porth, M.W. Allsopp, G. Vianello, Ullmann’s Encyclopedia of Industrial Chemistry, Wiley, New Jersey, 2014. [CrossRef]

- Ganesh K.A.; Anjana K.; Hinduja M.; Sujitha K.; Dharani G. Review on plastic wastes in marine environment – Biodegradation and biotechnological solutions, Mar. Pollut. Bull. 150 (2020) 110733.. [CrossRef]

- Ge, X.; Starnes, W.H. Chlorination of poly(vinyl chloride) model compounds in radical-complexing solvents. J. Vinyl Addit. Technol., 2016, 22, 405–409. [CrossRef]

- Geyer, R.; J.R. Jambeck, K.L. Law, Production, use, and fate of all plastics ever made, Sci. Adv. 3 (2023) e1700782.. [CrossRef]

- Giacomucci, L.; N. Raddadi, M. Soccio, N. Lotti, F. Fava, Biodegradation of polyvinyl chloride plastic films by enriched anaerobic marine consortia, Mar. Environ. Res. 158 (2020) 104949. [CrossRef]

- Giacomucci, L.; N. Raddadi, M. Soccio, N. Lotti, F. Fava, Polyvinyl chloride biodegradation by Pseudomonas citronellolis and Bacillus flexus, N. Biotechnol. 52 (2019) 35–41. [CrossRef]

- Gilbert, M.; S. Patrick, Poly(Vinyl Chloride), Brydson’s Plast. Mater. Eighth Ed. (2017) 329–388.. [CrossRef]

- Gola, D.; P. Kumar Tyagi, A. Arya, N. Chauhan, M. Agarwal, S.K. Singh, S. Gola, The impact of microplastics on marine environment: A review, Environ. Nanotechnology, Monit. Manag. 16 (2021) 100552.. [CrossRef]

- Gomiero, A.; K.B. Øysæd, T. Agustsson, N. van Hoytema, T. van Thiel, F. Grati, First record of characterization, concentration and distribution of microplastics in coastal sediments of an urban fjord in south west Norway using a thermal degradation method, Chemosphere. 227 (2019) 705–714.. [CrossRef]

- Gomiero, A.; P. Strafella, K.B. Øysæd, G. Fabi, First occurrence and composition assessment of microplastics in native mussels collected from coastal and offshore areas of the northern and central Adriatic Sea, Environ. Sci. Pollut. Res. 26 (2019) 24407–24416.. [CrossRef]

- Gotlib, E.; Sadykova, D.; Vdovina, T.; Galeeva, L.; Sokolova, A. Evaluation of bactericidal properties of PVC-compositions for linoleum production. E3S Web Conf. 2019, 97, 02001. [CrossRef]

- Grause, G.; Hirahashi, S.; Toyoda, H.; Kameda, T.; Yoshioka, T. Solubility parameters for determining optimal solvents for separating PVC from PVC-coated PET fibers. J. Mater. Cycles Waste Manag. 2015. [CrossRef]

- Guardiola, J.J.; Beier, J.I.; Falkner, K.C.; Wheeler, B.; McClain, C.J.; Cave, M. Occupational exposures at a polyvinyl chloride production facility are associated with significant changes to the plasma metabolome. Toxicol. Appl. Pharmacol. 2016, 313, 47–56. [CrossRef]

- Halden, R.U. Plastics and Health Risks, Annu. Rev. Public Health. 31 (2010) 179–194. [CrossRef]

- Hara, J.; J. Frias, R. Nash, Quantification of microplastic ingestion by the decapod crustacean Nephrops norvegicus from Irish waters, Mar. Pollut. Bull. 152 (2020) 110905. [CrossRef]

- Henkel, C.; T. Hüffer, T. Hofmann, Polyvinyl Chloride Microplastics Leach Phthalates into the Aquatic Environment over Decades, Environ. Sci. Technol. 56 (2022) 14507–14516. [CrossRef]

- Ho, B.T.; T.K. Roberts, S. Lucas, An overview on biodegradation of polystyrene and modified polystyrene: the microbial approach, Crit. Rev. Biotechnol. 38 (2018) 308–320. [CrossRef]

- Howard, M.; Exploring the Global Polyvinyl Chloride (PVC) Market Size: Trends, Challenges, and Opportunities, Demand, Growth, 2030, Https://Www.Zionmarketresearch. Com/Sample/Polyvinyl-Chloride-Pvc-Market. (n.d.).

- Huang, C.-Y.; Huang, K.-L.; Cheng, T.-J.; Wang, J.-D.; Hsieh, L.-L. The GST T1 and CYP2E1 genotypes are possible factors causing vinyl chloride induced abnormal liver function. Archiv. Toxicol. 1997, 71, 482–488. [CrossRef]

- Huang, S.; T. Guo, Z. Feng, B. Li, Y. Cai, D. Ouyang, W. Gustave, C. Ying, H. Zhang, Polyethylene and polyvinyl chloride microplastics promote soil nitrification and alter the composition of key nitrogen functional bacterial groups., J. Hazard. Mater. 453 (2023) 131391. [CrossRef]

- Ibeto, C.N.; C.E. Enyoh, A.C. Ofomatah, L.A. Oguejiofor, T. Okafocha, V. Okanya, Microplastics pollution indices of bottled water from South Eastern Nigeria, Int. J. Environ. Anal. Chem. (2021) 1–20.. [CrossRef]

- Iheanacho, S.C.; G.E. Odo, Neurotoxicity, oxidative stress biomarkers and haematological responses in African catfish (Clarias gariepinus) exposed to polyvinyl chloride microparticles, Comp. Biochem. Physiol. Part C Toxicol. Pharmacol. 232 (2020) 108741. [CrossRef]

- Jiang, C.; L. Yin, X. Wen, C. Du, L. Wu, Y. Long, Y. Liu, Y. Ma, Q. Yin, Z. Zhou, H. Pan, Microplastics in Sediment and Surface Water of West Dongting Lake and South Dongting Lake: Abundance, Source and Composition, Int. J. Environ. Res. Public Health. 15 (2018) 2164.. [CrossRef]

- Ju, P.; Zhang, Y.; Zheng, Y.; Gao, F.; Jiang, F.; Li, J.; Sun, C. Probing the toxic interactions between polyvinyl chloride microplastics and Human Serum Albumin by multispectroscopic techniques. Sci. Total Environ. 2020, 734, 139219. [CrossRef]

- Ju, P.; Zhang, Y.; Ding, J.; Jiang, F.; Sun, C.; Jiang, F.; Sun, C. New insights into the toxic interactions of polyvinyl chloride microplastics with bovine serum albumin. Environ. Sci. Pollution Res. 2021, 28, 5520–5531. [CrossRef]

- Kaczmarek, H.; K. Bajer, Biodegradation of plasticized poly(vinyl chloride) containing cellulose, J. Polym. Sci. Part B Polym. Phys. 45 (2007) 903–919. [CrossRef]

- Kameda, T.; Fukuda, Y.; Grause, G.; Yoshioka, T. Chemical modification of rigid poly(vinyl chloride) by the substitution with nucleophiles. J. Appl. Polym. Sci., 2010, 116, 36-44. [CrossRef]

- Kameda, T.; Ono, M.; Grause, G.; Mizoguchi, T.; Yoshioka, T. Chemical modification of poly(vinyl chloride) by nucleophilic substitution. Polym. Degrad. Stab., 2009, 94, 107–112. [CrossRef]

- Kanhai, L.D.K.; C. Johansson, J.P.G.L. Frias, K. Gardfeldt, R.C. Thompson, I. O’Connor, Deep sea sediments of the Arctic Central Basin: A potential sink for microplastics, Deep Sea Res. Part I Oceanogr. Res. Pap. 145 (2019) 137–142.. [CrossRef]

- Kapp, R.W. Book Chapter. Vinyl Chloride. Encyclopedia of Toxicology: Third Ed., pp. 934–938, 2014. [CrossRef]

- Kavya, A.N.V.L.; S. Sundarrajan, S. Ramakrishna, Identification and characterization of micro-plastics in the marine environment: A mini review, Mar. Pollut. Bull. 160 (2020) 111704. [CrossRef]

- Khalik, W.M.A.W.M.; Y.S. Ibrahim, S. Tuan Anuar, S. Govindasamy, N.F. Baharuddin, Microplastics analysis in Malaysian marine waters: A field study of Kuala Nerus and Kuantan, Mar. Pollut. Bull. 135 (2018) 451–457.. [CrossRef]

- Khandare, S.D.; D.R. Chaudhary, B. Jha, Bioremediation of polyvinyl chloride (PVC) films by marine bacteria, Mar. Pollut. Bull. 169 (2021) 112566.. [CrossRef]

- Kirstein, I.V.; F. Hensel, A. Gomiero, L. Iordachescu, A. Vianello, H.B. Wittgren, J. Vollertsen, Drinking plastics? – Quantification and qualification of microplastics in drinking water distribution systems by µFTIR and Py-GCMS, Water Res. 188 (2021) 116519.. [CrossRef]

- Kokalj, A. J.; P. Horvat, T. Skalar, A. Kržan, Plastic bag and facial cleanser derived microplastic do not affect feeding behaviour and energy reserves of terrestrial isopods, Sci. Total Environ. 615 (2018) 761–766.. [CrossRef]

- Kumar, R.; Manna, C.; Padha, S.; Verma, A.; Sharma, P.; Dhar, A.; Ghosh, A.; Bhattacharya, P. Micro(nano)plastics pollution and human health: How plastics can induce carcinogenesis to humans? Chemosphere 2022, 298, 134267. DOI:. 10.1016/j.chemosphere.2022.134267.

- Lakshmanan, S.; Murugesan, T. The chlor-alkali process: Work in progress. Clean Technol. Environ. Policy 2014, 16, 225–234. [CrossRef]

- Lamb, J.B.; B.L. Willis, E.A. Fiorenza, C.S. Couch, R. Howard, D.N. Rader, J.D. True, L.A. Kelly, A. Ahmad, J. Jompa, C.D. Harvell, Plastic waste associated with disease on coral reefs, Science 359 (2018) 460–462.. [CrossRef]

- Lefebvre, C.; C. Saraux, O. Heitz, A. Nowaczyk, D. Bonnet, Microplastics FTIR characterisation and distribution in the water column and digestive tracts of small pelagic fish in the Gulf of Lions, Mar. Pollut. Bull. 142 (2019) 510–519.. [CrossRef]

- Lei, L.; S. Wu, S. Lu, M. Liu, Y. Song, Z. Fu, H. Shi, K.M. Raley-Susman, D. He, Microplastic particles cause intestinal damage and other adverse effects in zebrafish Danio rerio and nematode Caenorhabditis elegans, Sci. Total Environ. 619–620 (2018) 1–8.. [CrossRef]

- Lewandowski, K.; K. Skórczewska, A Brief Review of Poly(Vinyl Chloride) (PVC) Recycling, Polymers (Basel). 14 (2022) 3035.. [CrossRef]

- Li, T.; P. Zhao, M. Lei, Z. Li, Understanding Hydrothermal Dechlorination of PVC by Focusing on the Operating Conditions and Hydrochar Characteristics, Appl. Sci. 7 (2017). [CrossRef]

- Li, W.; H.-S. Lo, H.-M. Wong, M. Zhou, C.-Y. Wong, N.F.-Y. Tam, S.-G. Cheung, Heavy metals contamination of sedimentary microplastics in Hong Kong, Mar. Pollut. Bull. 153 (2020) 110977.. [CrossRef]

- Li, W.; Wang, Z.; Li, W.; Li, Z. Impacts of microplastics addition on sediment environmental properties, enzymatic activities and bacterial diversity. Chemosphere 2022, 307, 135836. [CrossRef]

- Lieberzeit, P.; D. Bekchanov, M. Mukhamediev, Polyvinyl chloride modifications, properties, and applications: Review, Polym. Adv. Technol. 33 (2022) 1809–1820.. [CrossRef]

- Liu, Y.; J. Zhang, H. Zhao, J. Cai, Y. Sultan, H. Fang, B. Zhang, J. Ma, Effects of polyvinyl chloride microplastics on reproduction, oxidative stress and reproduction and detoxification-related genes in Daphnia magna, Comp. Biochem. Physiol. Part C Toxicol. Pharmacol. 254 (2022) 109269. [CrossRef]

- Lozoya, J.P.; F. Teixeira de Mello, D. Carrizo, F. Weinstein, Y. Olivera, F. Cedrés, M. Pereira, M. Fossati, Plastics and microplastics on recreational beaches in Punta del Este (Uruguay): Unseen critical residents?, Environ. Pollut. 218 (2016) 931–941.. [CrossRef]

- Lu, J.; S. Ma, J. Gao, Study on the Pressurized Hydrolysis Dechlorination of PVC, Energy & Fuels. 16 (2002) 1251–1255.. [CrossRef]

- Lu, L.; S. Kumagai, T. Kameda, L. Luo, T. Yoshioka, Degradation of PVC waste into a flexible polymer by chemical modification using DINP moieties, RSC Adv. 9 (2019) 28870–28875. [CrossRef]

- Lusher, A., Tirelli, V., O’Connor, I. ; Officer, R. Microplastics in Arctic polar waters: the first reported values of particles in surface and sub-surface samples. Sci. Rep. 5, 14947 (2015). [CrossRef]

- Ma, D.; L. Liang, E. Hu, H. Chen, D. Wang, C. He, Q. Feng, Dechlorination of polyvinyl chloride by hydrothermal treatment with cupric ion, Process Saf. Environ. Prot. 146 (2021) 108–117. [CrossRef]

- Mahadevan, G.; Valiyaveettil, S. Comparison of genotoxicity and cytotoxicity of polyvinyl chloride and poly(methyl methacrylate) nanoparticles on normal human lung cell lines. Chem. Res. Toxicol. 2021, 34, 1468–1480. [CrossRef]

- Mai, L., Bao, LJ., Shi, L.; Wong, C.S.; Zeng, E.Y. A review of methods for measuring microplastics in aquatic environments. Environ. Sci. Pollut. Res. 2018, 25, 11319–11332. [CrossRef]

- Marcilla, A.; S. Garcı́a, J.C. Garcı́a-Quesada, Study of the migration of PVC plasticizers, J. Anal. Appl. Pyrolysis. 71 (2004) 457–463.. [CrossRef]

- Mark, J.E. (Ed.) Physical Properties of Polymers Handbook; Springer: New York, NY, USA, 2007.

- Meem, R.A.; A. Ahmed A., K.M. Maraz, Md Shamim Hossain, and R.A. Khan, A Review on the Impact of Plastic Debris on Marine Environment, Modern Concepts in Material Science, 4(5), 1-7 (2021).

- Meng, J.; W. Li, C. Diao, Z. Li, J. Zhao, G. Haider, H. Zhang, J. Xu, M. Hu, S. Shan, H. Chen, Microplastics drive microbial assembly, their interactions, and metagenomic functions in two soils with distinct pH and heavy metal availability, J. Hazard. Mater. 458 (2023) 131973. [CrossRef]

- Miliute-Plepiene, J.; A. Fråne, A.M. Almasi, Overview of polyvinyl chloride (PVC) waste management practices in the Nordic countries, Clean. Eng. Technol. 4 (2021) 100246. [CrossRef]

- Mintenig, S.M.; M.G.J. Löder, S. Primpke, G. Gerdts, Low numbers of microplastics detected in drinking water from ground water sources, Sci. Total Environ. 648 (2019) 631–635. [CrossRef]

- Morgana, S.; L. Ghigliotti, N. Estévez-Calvar, R. Stifanese, A. Wieckzorek, T. Doyle, J.S. Christiansen, M. Faimali, F. Garaventa, Microplastics in the Arctic: A case study with sub-surface water and fish samples off Northeast Greenland, Environ. Pollut. 242 (2018) 1078–1086. [CrossRef]

- Moulay, S. Chemical modification of poly(vinyl chloride)—Still on the run, Prog. Polym. Sci. 35 (2010) 303–331. [CrossRef]

- Nor, N.H.M.; J.P. Obbard, Microplastics in Singapore’s coastal mangrove ecosystems, Mar. Pollut. Bull. 79 (2014) 278–283.. [CrossRef]

- Oleru, U.G.; Onyekwere, C. Exposures to polyvinyl chloride, methyl ketone and other chemicals - The pulmonary and non-pulmonary effect. Int. Archiv. Occup. Environ. Health 1992, 63, 503–507. [CrossRef]

- Olkova, A. Toxicity of water after short-term contact with pvc materials depending on the temperature and components of the polymer composition. Ecol. Eng. Environ. Technol. 2021, 22, 119–125. [CrossRef]

- Othman, A.R.; H.A. Hasan, M.H. Muhamad, N. ’Izzati Ismail, S.R.S. Abdullah, Microbial degradation of microplastics by enzymatic processes: a review, Environ. Chem. Lett. 19 (2021) 3057–3073.. [CrossRef]

- Palatinus, A.; M. Kovač Viršek, U. Robič, M. Grego, O. Bajt, J. Šiljić, G. Suaria, S. Liubartseva, G. Coppini, M. Peterlin, Marine litter in the Croatian part of the middle Adriatic Sea: Simultaneous assessment of floating and seabed macro and micro litter abundance and composition, Mar. Pollut. Bull. 139 (2019) 427–439.. [CrossRef]

- Pan, Z.; Guo, H.; Chen, H.; Wang, S.; Sun, X.; Zou, Q.; Zhang, Y.; Lin, H.; Cai, S.; Huang, J. Microplastics in the Northwestern Pacific: Abundance, distribution, and characteristics. Sci. Total Environ. 2019, 650, Part 2, 1913-1922. [CrossRef]

- Pardo-Rodríguez, M.L.; P.J.P. Zorro-Mateus, Biodegradation of polyvinyl chloride by Mucor sp and Penicillium sp isolated from soil, Rev. Investig. Desarro. e Innovación. 11 (2021) 387–400. [CrossRef]

- Patil, R.; Bagde,. U.S., Isolation of polyvinyl chloride degrading bacterial strains from environmental samples using enrichment culture technique, African J. Biotechnol. 11 (2012) 7947–7956.. [CrossRef]

- Paul, M.B.; Fahrenson, C.; Givelet, L. Herrmann, T.; Loeschner, K.; Böhmert, L.; Thünemann, A.F.; Braeuning, A.; Sieg, H. Beyond microplastics - investigation on health impacts of submicron and nanoplastic particles after oral uptake in vitro. Micropl. Nanopl. 2022, 2, 16. [CrossRef]

- Pedà, C.; L. Caccamo, M.C. Fossi, F. Gai, F. Andaloro, L. Genovese, A. Perdichizzi, T. Romeo, G. Maricchiolo, Intestinal alterations in European sea bass Dicentrarchus labrax (Linnaeus, 1758) exposed to microplastics: Preliminary results, Environ. Pollut. 212 (2016) 251–256. [CrossRef]

- Peixoto, J.; L.P. Silva, R.H. Krüger, Brazilian Cerrado soil reveals an untapped microbial potential for unpretreated polyethylene biodegradation, J. Hazard. Mater. 324 (2017) 634–644. [CrossRef]

- Peng, B.-Y.; Z. Chen, J. Chen, H. Yu, X. Zhou, C.S. Criddle, W.-M. Wu, Y. Zhang, Biodegradation of Polyvinyl Chloride (PVC) in Tenebrio molitor (Coleoptera: Tenebrionidae) larvae, Environ. Int. 145 (2020) 106106.. [CrossRef]

- Phuong, N.N.; A. Zalouk-Vergnoux, A. Kamari, C. Mouneyrac, F. Amiard, L. Poirier, F. Lagarde, Quantification and characterization of microplastics in blue mussels (Mytilus edulis): protocol setup and preliminary data on the contamination of the French Atlantic coast, Environ. Sci. Pollut. Res. 25 (2018) 6135–6144.. [CrossRef]

- Pivokonsky, M.; L. Cermakova, K. Novotna, P. Peer, T. Cajthaml, V. Janda, Occurrence of microplastics in raw and treated drinking water, Sci. Total Environ. 643 (2018) 1644–1651. [CrossRef]

- Pivokonský, M.; L. Pivokonská, K. Novotná, L. Čermáková, M. Klimtová, Occurrence and fate of microplastics at two different drinking water treatment plants within a river catchment, Sci. Total Environ. 741 (2020) 140236. [CrossRef]

- Plastics Europe, Plastics - the Facts 2021, 2021. https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/.

- Pospı́šil, J.; Z. Horák, Z. Kruliš, S. Nešpůrek, S. Kuroda, Degradation and aging of polymer blends I. Thermomechanical and thermal degradation, Polym. Degrad. Stab. 65 (1999) 405–414. [CrossRef]

- PPI TR-19. The Plastics Pipe Institute, Inc. TR-19. Chemical resistance of plastic piping materials. 04.28.2023. https://www.plasticpipe.org/.

- Qi, R.; D.L. Jones, Z. Li, Q. Liu, C. Yan, Behavior of microplastics and plastic film residues in the soil environment: A critical review, Sci. Total Environ. 703 (2020) 134722. [CrossRef]

- Rad, M.M.; H. Moghimi, E. Azin, Biodegradation of thermo-oxidative pretreated low-density polyethylene (LDPE) and polyvinyl chloride (PVC) microplastics by Achromobacter denitrificans Ebl13, Mar. Pollut. Bull. 181 (2022) 113830.. [CrossRef]

- Rajagopalan, K.; J.R.S.S. Christyraj, S.C. Karthikeyan, M. Jeevanandam, H. Ganesan, M.G.R. Mathews, J.D. Selvan Christyraj, Chapter 29 - Biodegradation of microplastics and synthetic polymers in agricultural soils, in: J.A.B.T.-M. and M.B. for G.R. Malik (Ed.), Elsevier, 2022: pp. 563–573. [CrossRef]

- Ren, H.; W. Zhou, M. Makowski, H. Yan, Y. Yu, T. Ma, Incorporation of life cycle emissions and carbon price uncertainty into the supply chain network management of PVC production, Ann. Oper. Res. 300 (2021) 601–620. [CrossRef]

- Renzi, M.; E. Grazioli, A. Blašković, Effects of different microplastic types and surfactant-microplastic mixtures under fasting and feeding conditions: A case study on Daphnia magna, Bull. Environ. Contam. Toxicol. 103 (2019) 367–373.. [CrossRef]

- Restrepo-Flórez, J.-M.; A. Bassi, M.R. Thompson, Microbial degradation and deterioration of polyethylene – A review, Int. Biodeterior. Biodegradation. 88 (2014) 83–90. [CrossRef]

- Richards, R.J.; Desai, R.; Hext, P.M.; Rose, F.A. Biological reactivity of PVC dust. Nature 1975, 256(5519), 664–665. [CrossRef]

- Rillig, M.C.; A. Lehmann, A.A. de Souza Machado, G. Yang, Microplastic effects on plants, New Phytol. 223 (2019) 1066–1070. [CrossRef]

- Rillig, M.C.; L. Ziersch, S. Hempel, Microplastic transport in soil by earthworms, Sci. Rep. 7 (2017) 1362.. [CrossRef]

- Rillig, M.C.; M. Bonkowski, Microplastic and soil protists: A call for research, Environ. Pollut. 241 (2018) 1128–1131. [CrossRef]

- Rist, S.E.; K. Assidqi, N.P. Zamani, D. Appel, M. Perschke, M. Huhn, M. Lenz, Suspended micro-sized PVC particles impair the performance and decrease survival in the Asian green mussel Perna viridis, Mar. Pollut. Bull. 111 (2016) 213–220. DOI: 10.1016/j.marpolbul.2016. 07.006.

- Rocha, R.J.M;. A.C.M. Rodrigues, D. Campos, L.H. Cícero, A.P.L. Costa, D.A.M. Silva, M. Oliveira, A.M.V.M. Soares, A.L. Patrício Silva, Do microplastics affect the zoanthid Zoanthus sociatus? Sci. Total Environ. 713 (2020) 136659. [CrossRef]

- Rodrigues, M.O.; Abrantes, N.; Gonçalves, F.J.M.; Nogueira, H.; Marques, J.C.; Gonçalves, A.M.M. Impacts of plastic products used in daily life on the environment and human health: What is known? Environ. Toxicol. Pharmacol. 2019, 72, 103239. [CrossRef]

- Sadat-Shojai, M.; G.-R. Bakhshandeh, Recycling of PVC wastes, Polym. Degrad. Stab. 96 (2011) 404–415. [CrossRef]

- Saeed, S.; A. Iqbal, F. Deeba, Biodegradation study of Polyethylene and PVC using naturally occurring plastic degrading microbes, Arch. Microbiol. 204 (2022) 497. [CrossRef]

- Saeki, Y.; T. Emura, Technical progresses for PVC production, Prog. Polym. Sci. 27 (2002) 2055–2131.. [CrossRef]

- Saha, M.; A. Naik, A. Desai, M. Nanajkar, C. Rathore, M. Kumar, P. Gupta, Microplastics in seafood as an emerging threat to marine environment: A case study in Goa, west coast of India, Chemosphere. 270 (2021) 129359. [CrossRef]

- Sakhalkar, S.; R.L. Mishra, Screening and identification of soil fungi with potential of plastic degrading ability, Indian J. Appl. Res. 3 (2013) 62–64.

- Sampson, J.; De Korte, D. Review DEHP-plasticised PVC: Relevance to blood services. Transfus. Med. 2011, 21, 73–83. [CrossRef]

- Sass, J.B.; Castleman, B.; Wallinga, D. Vinyl Chloride: A Case study of data suppression and misrepresentation. Environ. Health Perspect. 2005, 113, :809–812. [CrossRef]

- Sharman, M.; Rose, M.; Parker, I.; Mercer, A.; Castle, L.; Gilbert, J.; Startin, J. Migration from plasticized films into foods. 1. Migration of di-(2-ethylhexyl)adipate from PVC films during home-use and microwave cooking. Food Addit. Contam. 1987, 4, 385-398. DOI: 10.1080/02652038709373647.

- Shen, H.; Y. Sun, H. Duan, J. Ye, A. Zhou, H. Meng, F. Zhu, H. He, C. Gu, Effect of PVC microplastics on soil microbial community and nitrogen availability under laboratory-controlled and field-relevant temperatures, Appl. Soil Ecol. 184 (2023) 104794. DOI: 10.1016/j.apsoil.2022.104794.

- Shen, M.; Z. Zeng, X. Wen, X. Ren, G. Zeng, Y. Zhang, R. Xiao, Presence of microplastics in drinking water from freshwater sources: the investigation in Changsha, China, Environ. Sci. Pollut. Res. 28 (2021) 42313–42324.. [CrossRef]

- Shi, S.Q.; L. Cai, Y. Weng, D. Wang, Y. Sun, Comparative life-cycle assessment of water supply pipes made from bamboo vs. polyvinyl chloride, J. Clean. Prod. 240 (2019) 118172. [CrossRef]

- Shimao, M.; T. Tamogami, S. Kishida, S. Harayama, The gene pvaB encodes oxidized polyvinyl alcohol hydrolase of Pseudomonas sp. strain VM15C and forms an operon with the polyvinyl alcohol dehydrogenase gene pvaAThe DDBJ accession number for the sequence reported in this paper is AB008494., Microbiology. 146 (2000) 649–657. [CrossRef]

- Shue, M.F.; Liou, J.J.; Tasi, J.L.; Tang, H.C.; Huang, W.J.; Liao, M.H. Cytotoxicity studies on combustion gas of polyvinyl chloride (PVC) resin. Aerosol Air Qual. Res. 2009, 9, 305-308. [CrossRef]

- Sil, D.; S. Chakrabarti, Photocatalytic degradation of PVC–ZnO composite film under tropical sunlight and artificial UV radiation: A comparative study, Sol. Energy. 84 (2010) 476–485. [CrossRef]

- Skelly, P.W.; L. Li, R. Braslau, Internal plasticization of PVC, Polym. Rev. 62 (2022) 485–528. [CrossRef]

- Skjevrak, I.; A. Due, K.O. Gjerstad, H. Herikstad, Volatile organic components migrating from plastic pipes (HDPE, PEX and PVC) into drinking water, Water Res. 37 (2003) 1912–1920. [CrossRef]

- Smith, M.; D.C. Love, C.M. Rochman, R.A. Neff, Microplastics in Seafood and the Implications for Human Health, Curr. Environ. Heal. Reports. 5 (2018) 375–386. [CrossRef]

- Smith, M.D.; Grant, M.H.; Blass, C.R.; Courtney, J.M.; Barbenel, J.C. Poly(vinyl chloride) formulations: Acute toxicity to cultured human cell lines. J. Biomater. Sci., Polym. Ed. 1996, 7, 453–459. [CrossRef]

- Sokolova, Y.; Gotlib, E.; Kozhevnikov, R.; Sokolova, A. • Modification of PVC-compositions for linoleum. IOP Conf. Series: Mater. Sci. Eng. 2018, 365, 032021. [CrossRef]

- Song, Y.K.; S.H. Hong, M. Jang, G.M. Han, W.J. Shim, Occurrence and Distribution of Microplastics in the Sea Surface Microlayer in Jinhae Bay, South Korea, Arch. Environ. Contam. Toxicol. 69 (2015) 279–287.. [CrossRef]

- Sree, C.G.; V. Buddolla, B.A. Lakshmi, Y.-J. Kim, Phthalate toxicity mechanisms: An update, Comp. Biochem. Physiol. Part C Toxicol. Pharmacol. 263 (2023) 109498. [CrossRef]

- Stapleton, P.A. Microplastic and nanoplastic transfer, accumulation, and toxicity in humans, Curr. Opin. Toxicol. 28 (2021) 62–69. [CrossRef]

- Stock, V.; Laurisch, C.; Franke, J.; Dönmez, M.H.; Voss, L.; Böhmert, L.; Braeuning, A.; Sieg, H. Uptake and cellular effects of PE, PP, PET and PVC microplastic particles. Toxicol. In Vitro. 2021, 70, 105021. [CrossRef]

- Su, L.; S.M. Sharp, V.J. Pettigrove, N.J. Craig, B. Nan, F. Du, H. Shi, Superimposed microplastic pollution in a coastal metropolis, Water Res. 168 (2020) 115140. [CrossRef]

- Suman, K.H.; M.N. Haque, M.J. Uddin, M.S. Begum, M.H. Sikder, Toxicity and biomarkers of micro-plastic in aquatic environment: a review, Biomarkers. 26 (2021) 13–25. [CrossRef]

- Sumathi, T.; B. Viswanath, A. Sri Lakshmi, D.V.R. SaiGopal, Production of Laccase by Cochliobolus sp. isolated from plastic dumped soils and their ability to degrade low molecular weight PVC, Biochem. Res. Int. 2016 (2016) 9519527.. [CrossRef]

- Sun, Y.; X. Ren, J. Pan, Z. Zhang, T.-H. Tsui, L. Luo, Q. Wang, Effect of microplastics on greenhouse gas and ammonia emissions during aerobic composting, Sci. Total Environ. 737 (2020) 139856. [CrossRef]

- Sustainable Solution Corporation, Life cycle assessment of PVC water and sewer pipe and comparative sustainability analysis of pipe materials, 2017. https://www.uni-bell.org/files/Reports/Life_Cycle_Assessment_of_PVC_Water_and_Sewer_Pipe_and_Comparative_Sustainability_Analysis_of_Pipe_Materials.pdf.

- Syakti, A.D.; R. Bouhroum, N.V. Hidayati, C.J. Koenawan, A. Boulkamh, I. Sulistyo, S. Lebarillier, S. Akhlus, P. Doumenq, P. Wong-Wah-Chung, Beach macro-litter monitoring and floating microplastic in a coastal area of Indonesia, Mar. Pollut. Bull. 122 (2017) 217–225. [CrossRef]

- Takeshita, T.; K. Kato, K. Takahashi, Y. Sato, S. Nishi, Basic study on treatment of waste polyvinyl chloride plastics by hydrothermal decomposition in subcritical and supercritical regions, J. Supercrit. Fluids. 31 (2004) 185–193. [CrossRef]

- Tang, K.H.D. Effects of Microplastics on Agriculture: A Mini-review, Asian J. Environ. Ecol. 13 (2020) 1–9. [CrossRef]

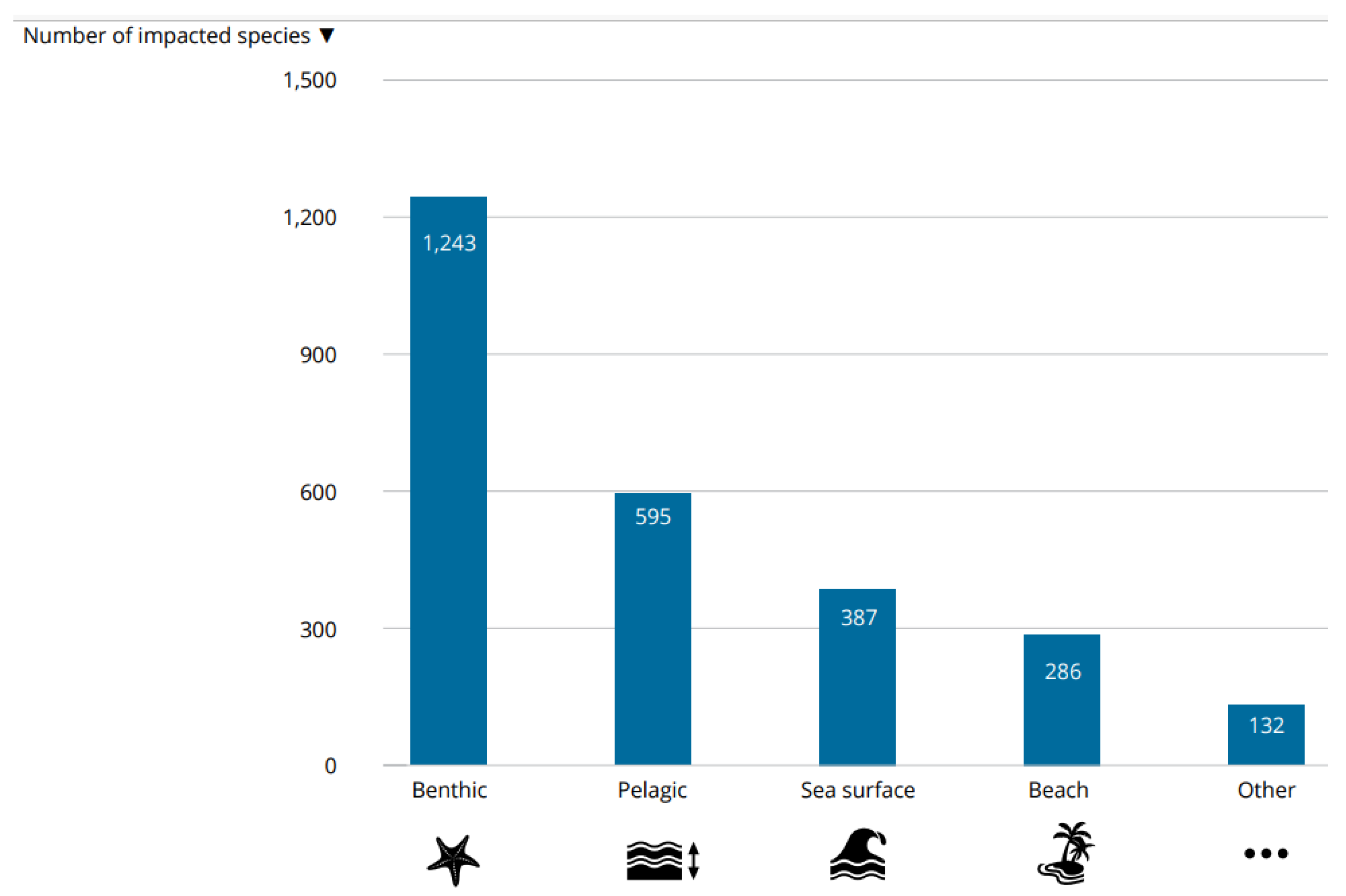

- Tekman, M. B., Walther, B. A., Peter, C., Gutow, L. and Bergmann, M. (2022): Impacts of plastic pollution in the oceans on marine species, biodiversity and ecosystems, 1–221, WWF Germany, Berlin. [CrossRef]

- Temporiti, M.E.; L. Nicola, E. Nielsen, S. Tosi, Fungal Enzymes Involved in Plastics Biodegradation, Microorganisms. 10 (2022). [CrossRef]

- Tian, X.; H. Fan, J. Wang, J. Ippolito, Y. Li, S. Feng, M. An, F. Zhang, K. Wang, Effect of polymer materials on soil structure and organic carbon under drip irrigation, Geoderma. 340 (2019) 94–103.. [CrossRef]

- Titow, W. V.; PVC Polymers BT - PVC Plastics: Properties, Processing, and Applications, in: W. V Titow (Ed.), Springer Netherlands, Dordrecht, 1990: pp. 53–101. [CrossRef]

- Tekman, M. B.; Walther, B. A.; Peter, C.; Gutow, L. and Bergmann, M. (2022): Impacts of plastic pollution in the oceans on marine species, biodiversity and ecosystems, 1–221, WWF Germany, Berlin. [CrossRef]

- Tran, V.Q.C.; D. V Le, D.R. Yntema, P.J.M. Havinga, A Review of Inspection Methods for Continuously Monitoring PVC Drinking Water Mains, IEEE Internet Things J. 9 (2022) 14336–14354.. [CrossRef]

- Tsochatzis, E.; J.A. Lopes, H. Gika, G. Theodoridis, Polystyrene biodegradation by Tenebrio molitor larvae: Identification of generated substances using a GC-MS untargeted screening method, Polymers (Basel). 13 (2021). [CrossRef]

- Tunçer, S.; O.B. Artüz, M. Demirkol, M.L. Artüz, First report of occurrence, distribution, and composition of microplastics in surface waters of the Sea of Marmara, Turkey, Mar. Pollut. Bull. 135 (2018) 283–289. [CrossRef]

- United Nations Environment Programme, Overview Report II: An Overview of Current Scientific Knowledge on the Life Cycles, Environmental Exposures, and Environmental Effects of Select Endocrine Disrupting Chemicals (EDCs) and Potential EDCs, Https://Wedocs.Unep.Org/20.500.11822/25634. (2017).

- Vianello, A.; A. Boldrin, P. Guerriero, V. Moschino, R. Rella, A. Sturaro, L. Da Ros, Microplastic particles in sediments of Lagoon of Venice, Italy: First observations on occurrence, spatial patterns and identification, Estuar. Coast. Shelf Sci. 130 (2013) 54–61. [CrossRef]

- Vijayaraghavan, G.; K.V. Neethu, B.P. Aneesh, A. Suresh, K.S. Saranya, S. Bijoy Nandan, K.V. Sharma, Evaluation of toxicological impacts of Polyvinyl Chloride (PVC) microplastics on fish, Etroplus suratensis (Bloch, 1790), Cochin estuary, India, Toxicol. Environ. Health Sci. 14 (2022) 131–140. [CrossRef]

- Vilakati, B.; V. Sivasankar, B.B. Mamba, K. Omine, T.A.M. Msagati, Characterization of plastic micro particles in the Atlantic Ocean seashore of Cape Town, South Africa and mass spectrometry analysis of pyrolyzate products, Environ. Pollut. 265 (2020) 114859. [CrossRef]

- VinylPlus, 2018. Progress Report. Reporting on 2017 Activities. https://vinylplus.eu/upl oads/Modules/Documents/vinylplus-progress-report-2018.pdf. (Accessed 27 October 2018).

- Vivi, V.K.; S.M. Martins-Franchetti, D. Attili-Angelis, Biodegradation of PCL and PVC: Chaetomium globosum (ATCC 16021) activity, Folia Microbiol. (Praha). 64 (2019) 1–7. [CrossRef]

- Wagoner, J.K. Toxicity of vinyl chloride and poly(vinyl chloride): A critical review. Environ. Health Perspect. 1983, 52, 61–66. [CrossRef]

- Wang, Q.; X. Wangjin, Y. Zhang, N. Wang, Y. Wang, G. Meng, Y. Chen, The toxicity of virgin and UV-aged PVC microplastics on the growth of freshwater algae Chlamydomonas reinhardtii, Sci. Total Environ. 749 (2020) 141603. [CrossRef]

- Wang, S.; Y. Wang, Y. Liang, W. Cao, C. Sun, P. Ju, L. Zheng, The interactions between microplastic polyvinyl chloride and marine diatoms: Physiological, morphological, and growth effects, Ecotoxicol. Environ. Saf. 203 (2020) 111000.. [CrossRef]

- Wang, W.; W. Yuan, Y. Chen, J. Wang, Microplastics in surface waters of Dongting Lake and Hong Lake, China, Sci. Total Environ. 633 (2018) 539–545. [CrossRef]

- Waring, R.H.; R.M. Harris, S.C. Mitchell, Plastic contamination of the food chain: A threat to human health?, Maturitas. 115 (2018) 64–68. [CrossRef]

- Webb, J.S.; M. Nixon, I.M. Eastwood, M. Greenhalgh, G.D. Robson, P.S. Handley, Fungal Colonization and Biodeterioration of Plasticized Polyvinyl Chloride, Appl. Environ. Microbiol. 66 (2000) 3194–3200. [CrossRef]

- Wendee, N. Microplastics in Seafood: How Much Are People Eating?, Environ. Health Perspect. 129 (2023) 34001. [CrossRef]

- Wertz, J.T.; B. Béchade, Chapter Three - Symbiont-mediated degradation of dietary carbon sources in social herbivorous insects, in: K.M. Oliver, J.A.B.T.-A. in I.P. Russell (Eds.), Mech. Underlying Microb. Symbiosis, Academic Press, 2020: pp. 63–109. [CrossRef]

- Wootton, N.; M. Ferreira, B. Gillanders, A comparison of microplastic in fish from Australia and Fiji, Front. Mar. Sci. 8 (2021) 690991.

- Wright, S.L.; F.J. Kelly, Plastic and Human Health: A Micro Issue?, Environ. Sci. Technol. 51 (2017) 6634–6647. [CrossRef]

- Wright, S.L.; R.C. Thompson, T.S. Galloway, The physical impacts of microplastics on marine organisms: A review, Environ. Pollut. 178 (2013) 483–492. [CrossRef]

- Xia, X.; M. Sun, M. Zhou, Z. Chang, L. Li, Polyvinyl chloride microplastics induce growth inhibition and oxidative stress in Cyprinus carpio var. larvae, Sci. Total Environ. 716 (2020) 136479. [CrossRef]

- Xiong, X.; Q. Liu, X. Chen, R. Wang, M. Duan, C. Wu, Occurrence of microplastic in the water of different types of aquaculture ponds in an important lakeside freshwater aquaculture area of China, Chemosphere. 282 (2021) 131126.. [CrossRef]

- Xiu, F.-R.; K. Zhou, X. Yu, Y. Qi, Co-treatment of PVC and used LCD panels in low-temperature subcritical water: Enhanced dechlorination and mechanism, Process Saf. Environ. Prot. 151 (2021) 10–19.. [CrossRef]

- Xiu, F.-R.; Y. Lu, Y. Qi, DEHP degradation and dechlorination of polyvinyl chloride waste in subcritical water with alkali and ethanol: A comparative study, Chemosphere. 249 (2020) 126138.. [CrossRef]

- Xu, B.; F. Liu, P.C. Brookes, J. Xu, Microplastics play a minor role in tetracycline sorption in the presence of dissolved organic matter, Environ. Pollut. 240 (2018) 87–94. [CrossRef]

- Xu, H.; Dinsdale, D.; Nemery, B.; Hoet, P.H.M. Role of residual additives in the cytotoxicity and cytokine release caused by polyvinyl chloride particles in pulmonary cell cultures. Toxicol. Sci. 2003, 72, 92–102. [CrossRef]

- Xu, H.; Hoet, P.H.; Nemery, B. In vitro toxicity assessment of polyvinyl chloride particles and comparison of six cellular systems. J. Toxicol. Environ. Health A. 2002, 65, 1141-1159. [CrossRef]

- Xu, Y.; Z.-N. Xian, W. Yue, C.-F. Yin, N.-Y. Zhou, Degradation of polyvinyl chloride by a bacterial consortium enriched from the gut of Tenebrio molitor larvae, Chemosphere. 318 (2023) 137944. [CrossRef]

- Yan, M.; H. Nie, K. Xu, Y. He, Y. Hu, Y. Huang, J. Wang, Microplastic abundance, distribution and composition in the Pearl River along Guangzhou city and Pearl River estuary, China, Chemosphere. 217 (2019) 879–886. [CrossRef]

- Yan, Y.; F. Zhu, C. Zhu, Z. Chen, S. Liu, C. Wang, C. Gu, Dibutyl phthalate release from polyvinyl chloride microplastics: Influence of plastic properties and environmental factors, Water Res. 204 (2021) 117597. [CrossRef]

- Yang, H.; Li, X.; Guo, M.; Cao, X.; Zheng, X.; Bao, D. UV-induced microplastics (MPs) aging leads to comprehensive toxicity. Marine Poll. Bull. 2023, 189, 114745. [CrossRef]

- Yang, R.; Z. Zhao, Y. Pu, K. Xiao, R. Liu, H. Cao, Y. Wang, X. Wang, Study of the photoaging process of polyvinyl chloride in different media with the electrical sensing zone method, Reg. Stud. Mar. Sci. 65 (2023) 103073. [CrossRef]

- Yang, X.-G.; P.-P. Wen, Y.-F. Yang, P.-P. Jia, W.-G. Li, D.-S. Pei, Plastic biodegradation by in vitro environmental microorganisms and in vivo gut microorganisms of insects, Front. Microbiol. 13 (2023).. [CrossRef]

- Ye, L.; C. Qi, J. Hong, X. Ma, Life cycle assessment of polyvinyl chloride production and its recyclability in China, J. Clean. Prod. 142 (2017) 2965–2972. [CrossRef]

- Ye, X.; P. Wang, Y. Wu, Y. Zhou, Y. Sheng, K. Lao, Microplastic acts as a vector for contaminants: the release behavior of dibutyl phthalate from polyvinyl chloride pipe fragments in water phase, Environ. Sci. Pollut. Res. 27 (2020) 42082–42091. [CrossRef]

- Yin, F.; Q. Zhuang, T. Chang, C. Zhang, H. Sun, Q. Sun, C. Wang, L. Li, Study on pyrolysis characteristics and kinetics of mixed plastic waste, J. Mater. Cycles Waste Manag. 23 (2021) 1984–1994.. [CrossRef]

- Yin, L.; C. Jiang, X. Wen, C. Du, W. Zhong, Z. Feng, Y. Long, Y. Ma, Microplastic Pollution in Surface Water of Urban Lakes in Changsha, China, Int. J. Environ. Res. Public Health. 16 (2019) 1650.. [CrossRef]

- Yousif, E.; A. Hasan, Photostabilization of poly(vinyl chloride) – Still on the run, J. Taibah Univ. Sci. 9 (2015) 421–448.. [CrossRef]

- Yu, J.; L. Sun, C. Ma, Y. Qiao, H. Yao, Thermal degradation of PVC: A review, Waste Manag. 48 (2016) 300–314. [CrossRef]

- Yuan, G.; D. Chen, L. Yin, Z. Wang, L. Zhao, J.Y. Wang, High efficiency chlorine removal from polyvinyl chloride (PVC) pyrolysis with a gas–liquid fluidized bed reactor, Waste Manag. 34 (2014) 1045–1050. [CrossRef]

- Yuan, Z.; Nag, R.; Cummins, E. Human health concerns regarding microplastics in the aquatic environment - From marine to food systems. Sci. Total Environ. 2022, 823, 153730. [CrossRef]

- Yuan, Z.; R. Nag, E. Cummins, Human health concerns regarding microplastics in the aquatic environment - From marine to food systems, Sci. Total Environ. 823 (2022) 153730. [CrossRef]

- Zakharyan, E.M.; N.N. Petrukhina, E.G. Dzhabarov, A.L. Maksimov, Pathways of Chemical Recycling of Polyvinyl Chloride. Part 2, Russ. J. Appl. Chem. 93 (2020) 1445–1490. [CrossRef]

- Zakharyan, E.M.;N.N. Petrukhina, A.L. Maksimov, Pathways of Chemical Recycling of Polyvinyl Chloride: Part 1, Russ. J. Appl. Chem. 93 (2020) 1271–1313. [CrossRef]

- Zelko, I.N.; Taylor, B.S.; Das, T.P.; Watson, W.H.; Sithu, I.D.; Wahlang, B.; Malovichko, M.V.; Cave, M.C.; Srivastava, S. Effect of vinyl chloride exposure on cardiometabolic toxicity. Environ. Toxicol. 2022, 37, 245–255. [CrossRef]

- Zeri, C.; A. Adamopoulou, D. Bojanić Varezić, T. Fortibuoni, M. Kovač Viršek, A. Kržan, M. Mandic, C. Mazziotti, A. Palatinus, M. Peterlin, M. Prvan, F. Ronchi, J. Siljic, P. Tutman, T. Vlachogianni, Floating plastics in Adriatic waters (Mediterranean Sea): From the macro- to the micro-scale, Mar. Pollut. Bull. 136 (2018) 341–350. [CrossRef]

- Zhang, C.; X. Chen, J. Wang, L. Tan, Toxic effects of microplastic on marine microalgae Skeletonema costatum: Interactions between microplastic and algae, Environ. Pollut. 220 (2017) 1282–1288. [CrossRef]

- Zhang, X.; Y. Li, D. Ouyang, J. Lei, Q. Tan, L. Xie, Z. Li, T. Liu, Y. Xiao, T.H. Farooq, X. Wu, L. Chen, W. Yan, Systematical review of interactions between microplastics and microorganisms in the soil environment, J. Hazard. Mater. 418 (2021) 126288. [CrossRef]

- Zhang, Y.; T. Sun, D. Zhang, Z. Shi, X. Zhang, C. Li, L. Wang, J. Song, Q. Lin, Enhanced photodegradability of PVC plastics film by codoping nano-graphite and TiO2, Polym. Degrad. Stab. 181 (2020) 109332. [CrossRef]

- Zhang, Y.-T.; W. Wei, J. Sun, Q. Xu, B.-J. Ni, Long-Term Effects of Polyvinyl Chloride Microplastics on Anaerobic Granular Sludge for Recovering Methane from Wastewater, Environ. Sci. Technol. 54 (2020) 9662–9671. [CrossRef]

- Zhao, P.; T. Li, W. Yan, L. Yuan, Dechlorination of PVC wastes by hydrothermal treatment using alkaline additives, Environ. Technol. 39 (2018) 977–985.. [CrossRef]

- Zhou, J.; Y. Cao, X. Liu, H. Jiang, W. Li, Bladder entrance of microplastic likely induces toxic effects in carnivorous macrophyte Utricularia aurea Lour, Environ. Sci. Pollut. Res. 27 (2020) 32124–32131. [CrossRef]

- Zhou,X.; J. Wang, H. Li, H. Zhang, Hua-Jiang, D.L. Zhang, Microplastic pollution of bottled water in China, J. Water Process Eng. 40 (2021) 101884. [CrossRef]

- Zhu, J.; S. Liu, H. Wang, D. Wang, Y. Zhu, J. Wang, Y. He, Q. Zheng, X. Zhan, Microplastic particles alter wheat rhizosphere soil microbial community composition and function, J. Hazard. Mater. 436 (2022) 129176. [CrossRef]

- Zimmermann, L.; Bartosova, Z.; Braun, K.; Oehlmann, j.; Völker, C.; Wagner, M. Plastic products leach chemicals that induce in vitrotoxicity under realistic use conditions. Environ. Sci. Technol. 2021, 55, 11814–11823. [CrossRef]

- Zimmermann, L.; S. Göttlich, J. Oehlmann, M. Wagner, C. Völker, What are the drivers of microplastic toxicity? Comparing the toxicity of plastic chemicals and particles to Daphnia magna, Environ. Pollut. 267 (2020) 115392. [CrossRef]

|

|

|

|

|

| Phthalates DEHP (R = iC8); DIDP (R=iC10), DINP (R=iC9) | Adipates (n = 4) DINA (R = iC9); DIDA (R-iC10)) |

Sebacates (n = 8) DBS (R = C4); DOS (R = iC10) |

Citrates TEC (R = Et ) |

Phosphates TCP (Ar = Tol) |

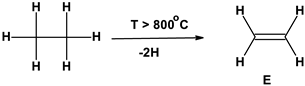

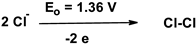

| St. | PVC production process steps |

WI [kg]/a |

WsWO [kg] /a |

| 1 | Ethylene (E) and Chlorine (Cl2) Production | ||

| 1.1. |  |

0 | 0 |

| 1.2 |  |

0 | 0 |

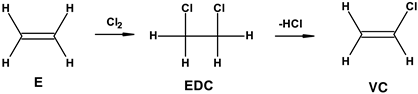

| 2 | VCM production process | 1.03 | 0.63 |

|

|||

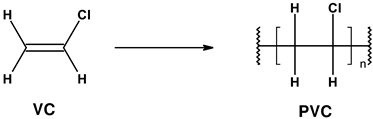

| 3 | PVC production process | 2.24 | 1.83 |

|

|||

| 1-3 | Total | 2.24; 3.27 | 2.46 |

|

E – Ethylene; EDC – Ethylene DiChloride; VC - Vinyl Chloride; PVC – PolyVinyl Chloride; WI - Water input; WsWO - Wastewater output. In the Oxy-chlorination process ethylene reacted with the mixture of chlorine and oxygen. /a Rounded to the second decimal place. 1.2 According to Lakshmanan & Murugesan, 2014]. | |||

| Impact category | Unit | Manufacturing | Use and waste disposal | Total impact |

|---|---|---|---|---|

| Global warming | g CO2 eq | 272 308.0 | 223 031.1 | 495 339.1 |

| Acidification | H+ moles eq | 63 922.6 | 25 215.8 | 89 138.5 |

| Human health-cancer | g C6H6 eq | 44,720.6 | 428.5 | 45 149.1 |

| Human health-noncancer | g C7H7 eq | 56 880 581.6 | 627 435.7 | 57 508 017.3 |

| Eutrophication | g N eq | 94.2 | 47.4 | 141.7 |

| Ecotoxicity | g 2,4-D eq | 3 304.5 | 223.5 | 3 528.0 |

| Smog | g NOx eq | 858.7 | 214.2 | 1 072.9 |

| Habitat alteration | T&E count | 1.55·10-13 | 4.65·10-13 | 6.2·10-13 |

| Ozone depletion | g CFC-11 eq | 0.0008 | 0.004 | 0.006 |

| Waters & Sediments | ||||

| Water supply |

Changsha (Hunan), China | Yin, 2019; Shen, 2021 | ||

| NW Germany | Mintenig, 2019 | |||

| Surface fresh water | Wei River, Yellow River's tributary, China | Ding, 2019 | ||

| Pearl River catchment, China | Fan, 2019; Yan, 2019 | |||

| Honghu Lake, China | Xiong, 2021 | |||

| Sediments & surface fresh water | West Lakes, China | Jiang, 2018; Wang, 2019 |

||

| Surface and sub-surface seawater | Korean coastal regions | Chae, 2015; Song, 2015 | ||

| Marmara Sea | Tunçer, 2018 | |||

| Kuantan of Malaysia | Khalik, 2018 | |||

| Greenland | Morgana, 2019 | |||

| Arctic Ocean | Lusher, 2015 | |||

| NW Pacific | Pan, 2019 | |||

| Water column | NW Mediterranean Sea | Lefebvre, 2019 | ||

| Bohai Sea-Yellow Sea | Dai, 2018 | |||

| Floating and bottom sediment microplastics |

Adriatic Sea | Zeri, 2018; Palatinus, 2019 | ||

| W. Mediterranean Sea | de Haan, 2019 | |||

| Cilacap, Java (Indonesia) | Syakti, 2017 | |||

| Surface seawater and sediment | Melbourne coastal metropolis | Su, 2020 | ||

| Suva coastal area of Fiji | Ferreira, 2020 | |||

| Bottom sediments | Arctic Ocean | Kanhai, 2019 | ||

| Norwegian fjords | Gomiero, 2019 | |||

| Venetian islands | Vianello, 2013 | |||

| Singapore coastline mangrove ecosystems | Nor, 2014 | |||

| Sand seashore | Atlantic seashore, Cape Town, South Africa | Vilakati, 2020 | ||

| Atlantic seashore, Punta del Este, Uruguay | Lozoya, 2016 | |||

| Marine Animals and Organisms | ||||

| Fishes | Siganus fuscescens | Coastal sediments, Negros, Philippine | Bucol, 2020 | |

| Nephrops norvegicus | Coasts of Ireland. | Hara, 2020 | ||

| Sardines | NW Mediterranean Sea | Lefebvre, 2019 | ||

| Triglops nybelini , Boreogadus saida | Arctic Ocean | Lusher, 2015 | ||

| Various species |

Australian markets | Wootton, 2021 | ||

| Suva coastal area, Fiji | Ferreira, 2020 | |||

| Markets in Fujian, China | Fang, 2019 | |||

| Shellfishes | Mytilus edulis | Mussel and oyster farming zone, Pen-Bé, France | Phuong, 2018 | |

| Meretrix meretrix | Markets in Fujian & Xiamen, China | Fang, 2019 | ||

| Various species |

Sal Estuary River, Goa, India | Saha, 2021 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).