1. Introduction

The safety situation in China's construction industry has always been severe. Construction progress and quality are easily affected by objective conditions, as there are many open-air operations. Dangers at construction sites are everywhere. Personal injuries and fatalities caused by workers' unsafe behaviors occur from time to time, and the consequences of these accidents are serious[

1,

2].

The unsafe behavior of construction workers is the direct cause of accidents and the focus of construction safety management. In recent years, many scholars have carried out related research work on unsafe behavior. The research on unsafe behavior mainly focused on the safety climate during 1991-2000 and then on Behavior-based Safety (BBS) and organizational factors during 2001-2020. One of the hot topics in the current stage of research on unsafe behaviors is exploring the relationship between factors associated with unsafe behaviors through methods such as structural equations, neural networks, and system dynamics[

3].

However, most of the existing research has examined how individual characteristics of workers lead to unsafe behaviors or focused only on the mechanisms by which unsafe behaviors are transmitted in a group. There are not many studies that can comprehensively consider the effects of factors on unsafe behaviors in the dimensions of safety management, interactions among individuals within a workgroup, and the external environment. Therefore, Therefore, the research goal of this paper is to establish an integrated model and use SEM to verify the relevant hypotheses to explore the influence mechanisms between the external objective environment, safety management measures, interactions among individuals within the frontline workgroups, workers' perceptions, and unsafe behaviors.

2. Accident statistics and Literature review

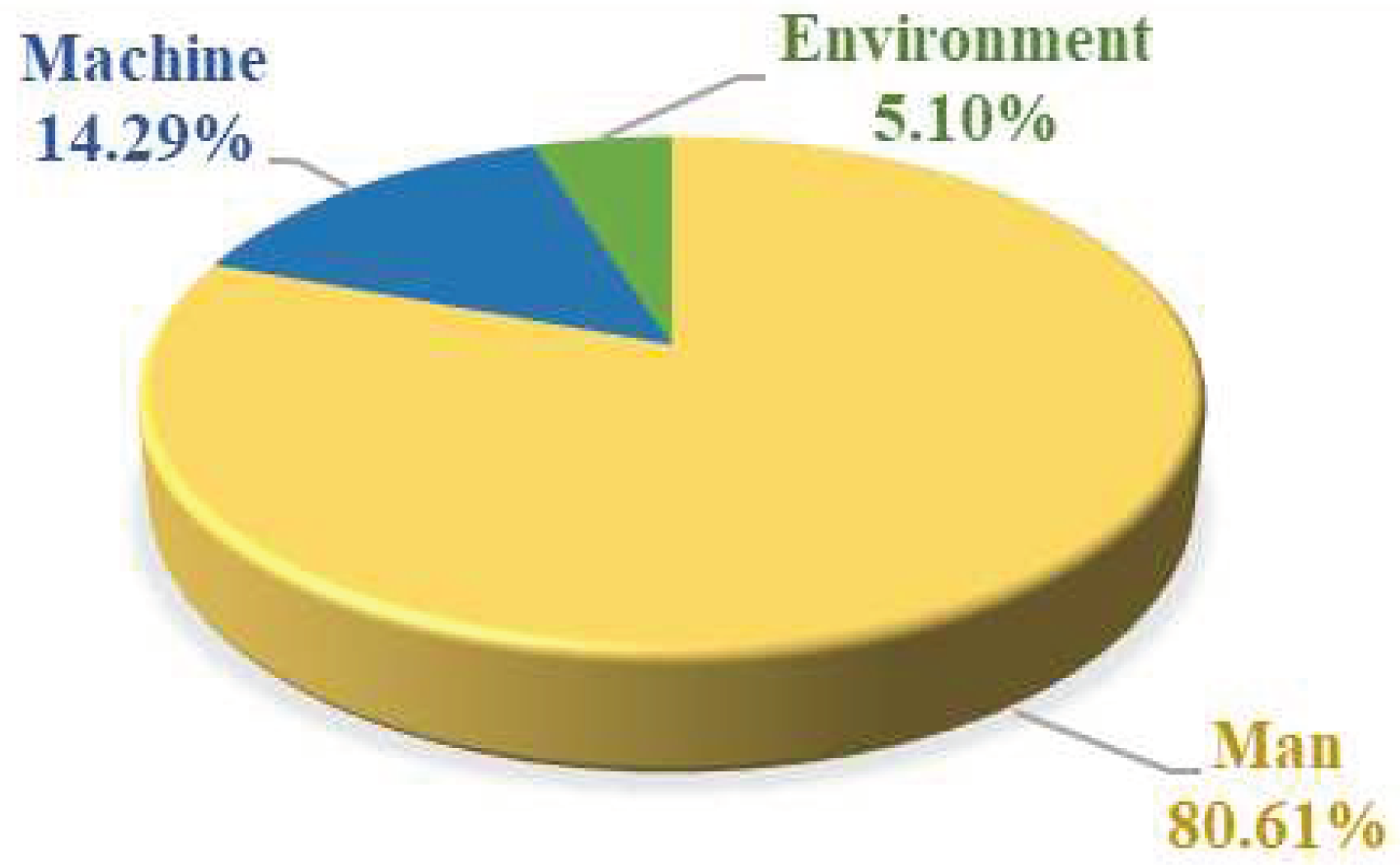

In this study, 93 construction accident cases in China were collected, ranging from October 2016 to October 2021, of which 80 accident investigation reports could be retrieved. After manual collation and statistics of the accident investigation reports, the proportion of accidents directly caused by human, machine, and environmental factors is shown in

Figure 1.

2.1. Unsafe behaviors

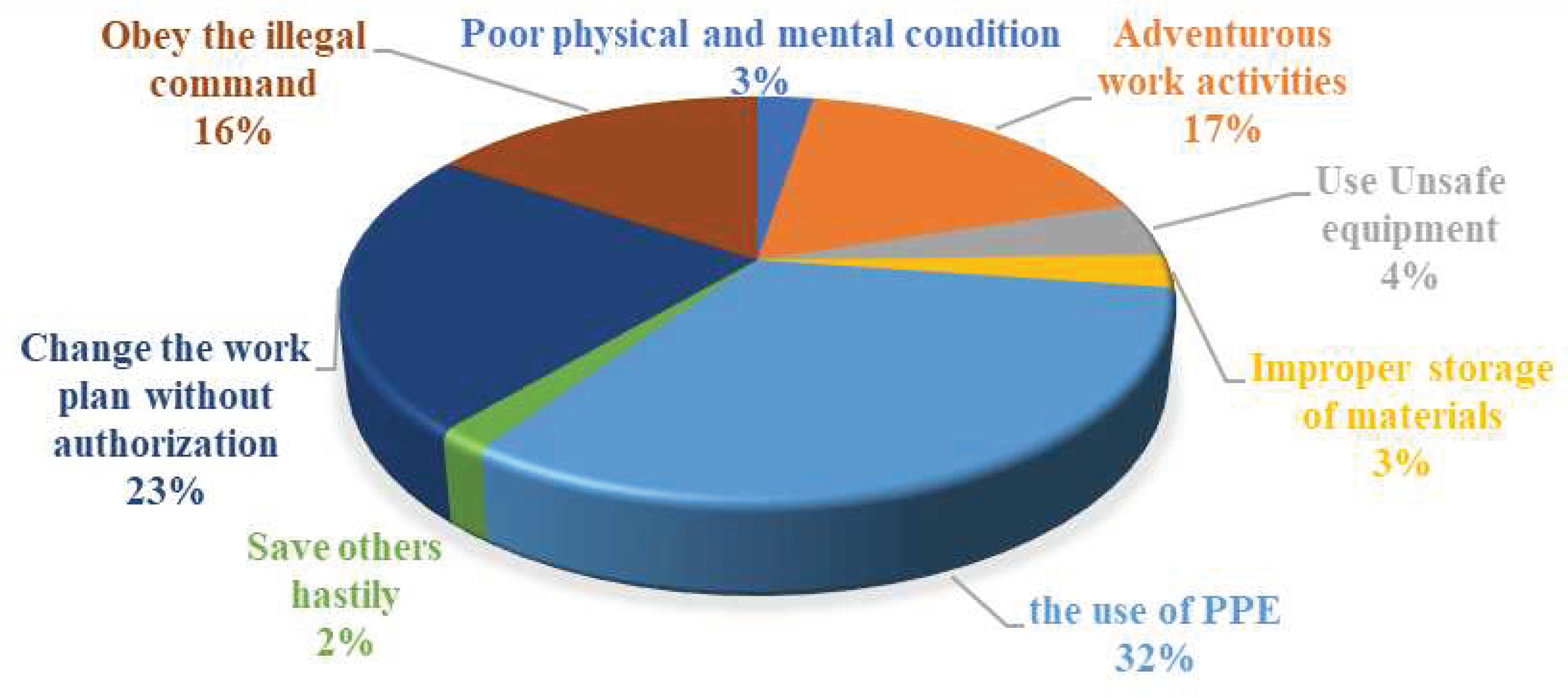

Unsafe behavior is often the direct cause of construction accidents. In the 80 investigation reports of construction accidents, the descriptions of unsafe behavior mainly include poor physical and mental condition (including sudden illness), adventurous work activities (including work without a qualification), incorrect use of Personal Protective Equipment (PPE), or failure to take safety precautions, unauthorized changes to the construction plan, using unsafe equipment or materials, improper storage of materials, obey the illegal command, and blind rescue. The corresponding word frequency statistical analysis was performed, in which the largest proportion was the incorrect use of PPE or failure to take safety precautions, followed by unauthorized changes to the construction plan, adventurous work activities, and illegal command. The percentages of various types related to human unsafe behaviors are shown in

Figure 2.

2.2. Objective conditions

As most construction sites are in open-air environments, environmental factors are also one of the causes of construction accidents, such as high temperature, high wind, severe cold, heavy rain, and other adverse weather conditions, as well as poor working conditions such as limited space and poor ventilation. Through accident case studies, we found that irregularities such as poor risk identification and misuse are more likely to occur when different trades perform crossover operations or joint operations. This means that the way construction operations are organized can also have an impact on personnel behavior. In addition, the objective complexity of the task can also affect the quality of personnel operations[

4].

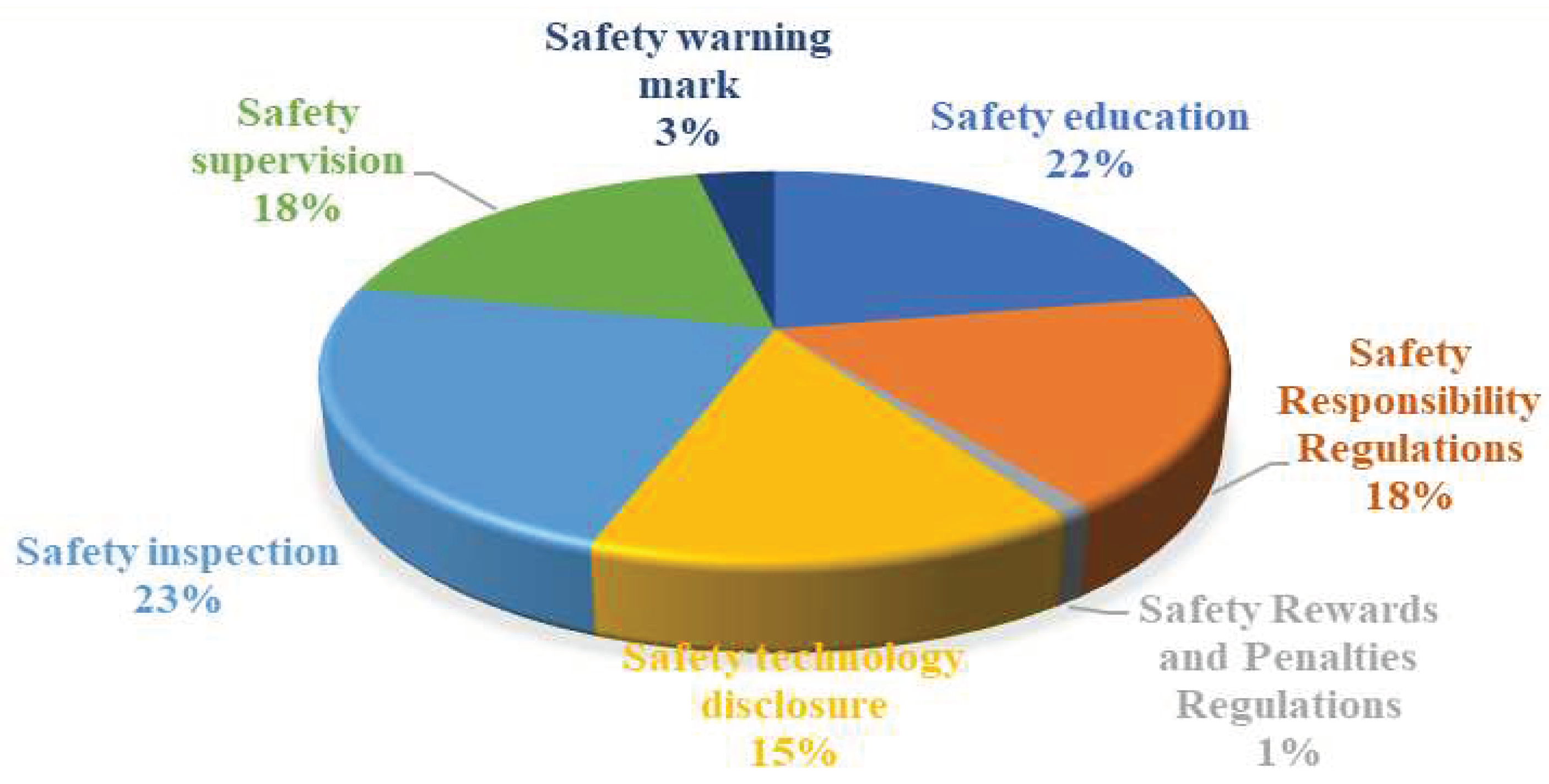

2.3. Safety management

In general, indirect causes in accident reports are characterized by the absence of relevant interventions in daily safety management. Most of the unsafe behaviors were caused by the weak safety awareness of workers, on the one hand, due to personal psychological reasons, such as a weak sense of responsibility and a preference for following the crowd, and on the other hand due to the lack of safety education and training [

5,

6]. Through the statistical analysis of 80 construction accident investigation reports, the safety management factors leading to personal casualties in China's construction mainly include inadequate safety education and training, imperfect or unimplemented safety management regulations, inadequate safety technical briefing, inadequate site safety inspection, inadequate site safety supervision, and failure to set safety warning signs as required. The proportion of each safety management factor is shown in

Figure 3.

2.4. Safety management

Personal perception in this study refers to the subjective perception of one's own safety knowledge and safety skills as a result of the intervention of safety management measures[

6]. It mainly includes a comprehensive understanding of the possible safety risks and occupational disease hazards in the work process, proficiency in safety techniques or preventive measures for work risks and occupational disease hazards, and the ability to use personal protective equipment correctly according to regulations.

2.5. Group Influence

The influence of organizational climate or person-to-person relationships within an organization on workers' unsafe behaviors has been one of the hot spots of research in recent years. Cao et al. (2011) point out that managers' management behaviors have significant effects on both workers' safety knowledge and safety motivation, which in turn influence workers' safety behavior choices[

7]. Yang and Wei (2017) verified that there is a high positive correlation between safety climate and safety behaviors[

8]. Guan (2020) explored the propagation pattern of unsafe behaviors among construction workers' groups by constructing a network model of the propagation path of unsafe behaviors, and the results showed that the influence of key figures as well as intimate figures has a certain contribution to the propagation of unsafe behaviors[

9].

A workgroup is the most basic organizational cell on a construction site in China, which consists of the group leader and the group members. Young et al. (2011) proposed that imitation is a manifestation of learning, that is, the learning of exemplary behavior[

10]. In a workgroup, exemplary people include the group leader, the technical backbone, the safety pacesetter, and the mentor. The behavior of group members can also be influenced by other workers in the same site project, such as closely interacting workers and fellow villagers. Psychological studies have shown that herding is a universal social psychological phenomenon, mainly manifested by individuals in a group being guided and pressured by the group to change their perceptions and behaviors, and involuntarily aligning with the majority. Therefore, group members' choices of unsafe behaviors are also influenced by the behavioral patterns of most workers.

3. Research method

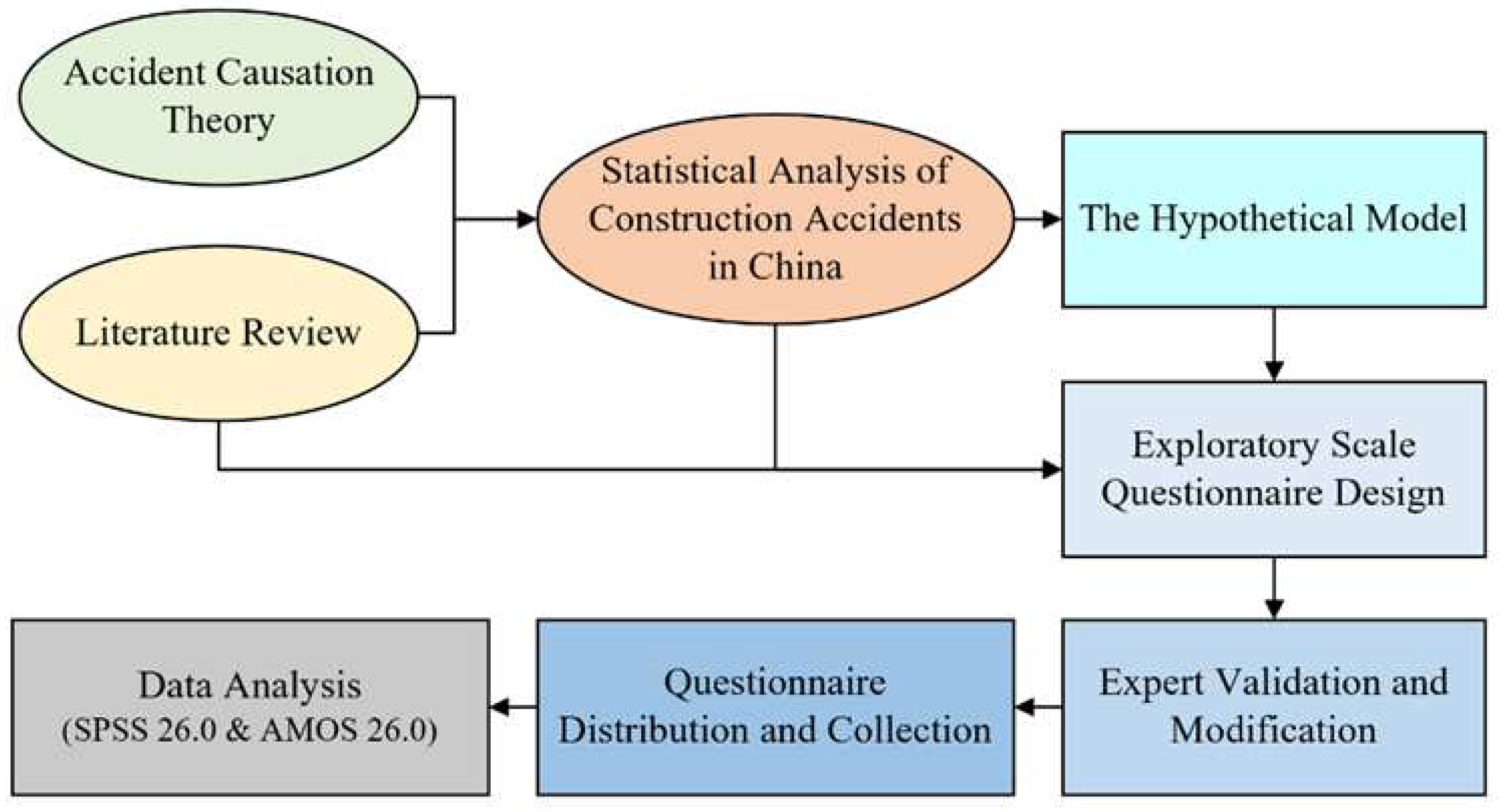

The research methodology of this study is shown in

Figure 4. SPSS is a commonly used statistical analysis software to characterize data and analyze the correlations between different factors in a statistical sense. AMOS is structural equation modeling software. Structural equation modeling (SEM) is a multivariate data analysis method in which researchers import research data after establishing a hypothetical theoretical model, test the influence relationship between variables through factor analysis and path analysis, and then revise the theoretical model. SEM has the advantage of theoretical apriority and is therefore widely used in the fields of psychology, behavior, and sociology. In this study, data analysis and model validation were carried out with SPSS 26.0 and AMOS 26.0 software.

3.1. Research model

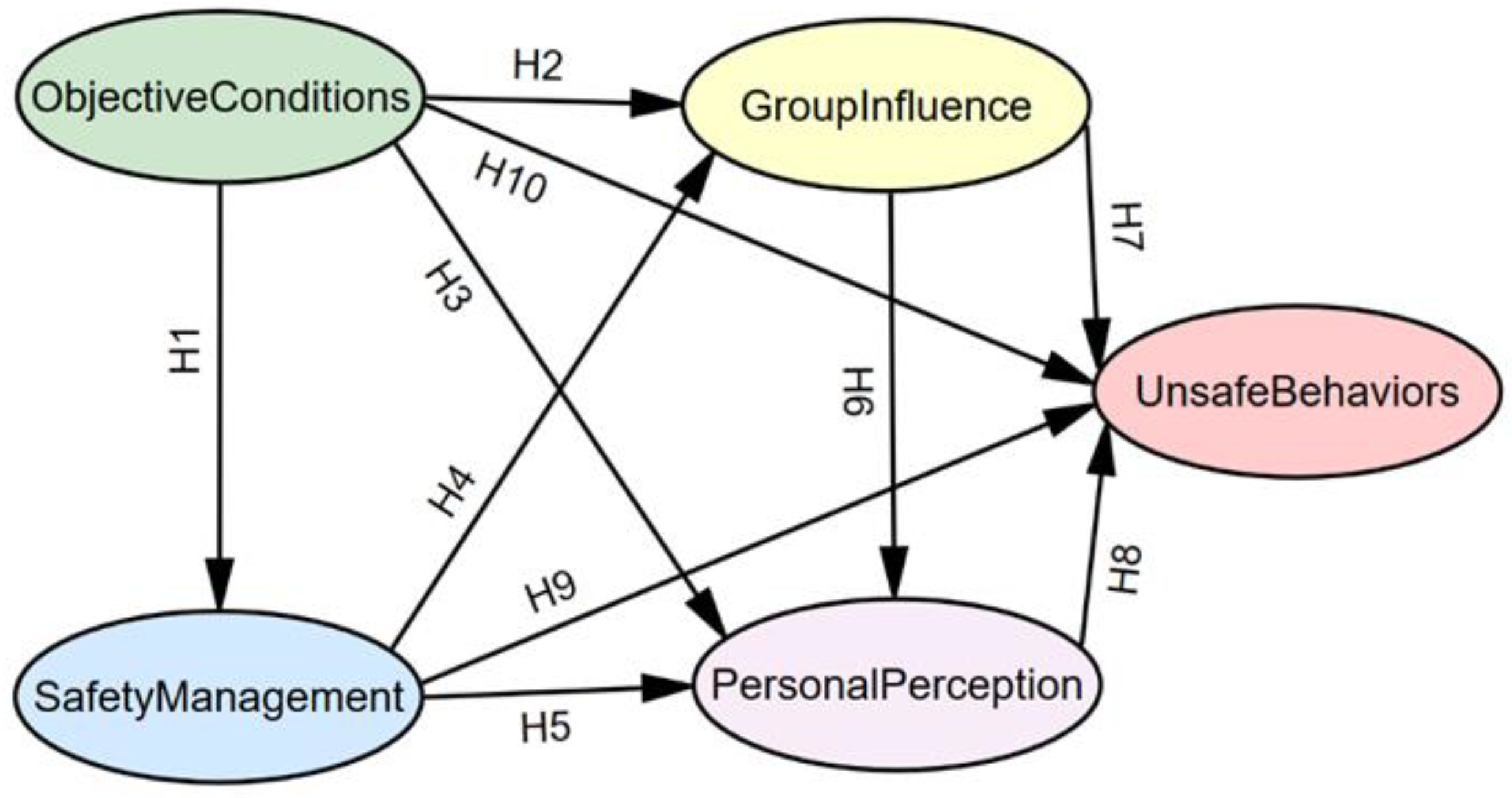

We developed a research model (

Figure 5) based on five constructs: objective conditions, safety management, group influence, personal perception, and unsafe behavior.

Objective conditions refer to the objective factors related to the completion of construction tasks.

Safety management refers to the safety management measures taken by the project department.

Group influence refers to the influence of people with different identities in the workgroup on individual workers' behavior and attitudes.

Personal perception refers to the workers' perception of the safety knowledge and safety skills they possess.

Unsafe behavior refers to the possible unsafe behavior of workers in the process of completing construction tasks.

Based on the content of the previous case study and literature review, we defined objective conditions and safety management as exogenous variables, while group influence and personal perception were defined as mediating variables. Unsafe behavior was the dependent variable. The following hypothetical model demonstrates the hypotheses of the influencing factors and their interrelationships on the unsafe behaviors of group workers in Chinese construction projects in this study.

H1. Objective conditions affect safety management.

H2. Objective conditions affect group influence.

H3. Objective conditions affect personal perception.

H4. Safety management affects group influence.

H5. Safety management affects personal perception.

H6. Group influence affects personal perception.

H7. Group influence affects unsafe behaviors.

H8. Personal perception affects unsafe behaviors.

H9. Safety management affects unsafe behaviors.

H10. Objective conditions affect unsafe behaviors.

3.2. Questionnaire structure

A questionnaire was developed based on a statistical analysis of accident cases in the Chinese construction industry and relevant influencing factors from the literature review, as shown in Table 1. The initial questionnaire had 36 items. Four experts with seven years of experience were invited to validate the question set, who were primarily responsible for construction safety management and had been involved in large infrastructure projects in Beijing, Shenzhen, Tianjin, and other cities in China. Each item of the initial questionnaire was set with three options: 1) Save; 2) Not sure; 3) Delete. The main purpose of this step was to ensure the feasibility and applicability of the exploratory questionnaire. Three items in the initial questionnaire were deleted after expert validation. The questionnaire consisted of two parts: 1) basic information about the respondents (9 questions in total); 2) questions about personal perceptions, unsafe behavior, objective conditions, safety management, and group influence (33 questions in total). It should be noted that the questionnaire was designed with positive and negative questions as well as trap questions (e.g., position level), a step that was taken to facilitate the subsequent screening of the raw data to maximize the exclusion of invalid data.

Table 1.

List of measurements.

Table 1.

List of measurements.

| Constructs |

Label |

Question contents |

Save/

Delete |

Objective

Conditions

(OC) |

OC1 |

Operation method[4] |

Save |

| OC2 |

Task complexity[4] |

Save |

| OC3 |

Working climate[11] |

Save |

| OC4 |

Working environment[11] |

Save |

Safety

Management

(SM) |

SM1 |

Safety education and training * |

Save |

| SM2 |

Safety responsibility regulations * |

Save |

| SM3 |

Safety rewards and penalties regulations * |

Save |

| SM4 |

Penalty strength[12] |

Delete |

| SM5 |

The practicality of the regulations[13] |

Delete |

| SM6 |

Safety technology disclosure * |

Save |

| SM7 |

Safety inspection[12,14] |

Save |

| SM8 |

Safety supervision[12,14] |

Save |

| SM9 |

Safety warning mark[15] |

Save |

Personal

Perception

(PP) |

PP1 |

Safety Knowledge of the occupational hazards[6] |

Save |

| PP2 |

Safety Knowledge of the technique and precautions[6] |

Save |

| PP3 |

The use of Personal Protective Equipment (PPE)[6] |

Save |

| PP4 |

Experience of being punished for violation of regulations[16] |

Delete |

Group

Influence

(GI) |

GI1 |

Leaders * |

Save |

| GI2 |

Workgroup leader[17,18] |

Save |

| GI3 |

Technical backbone[9] |

Save |

| GI4 |

Safety pacesetter[9] |

Save |

| GI5 |

Master worker[9] |

Save |

| GI6 |

Co-workers[9] |

Save |

| GI7 |

Co-workers with close contacts[9] |

Save |

| GI8 |

Co-workers from the same hometown[9,19] |

Save |

| GI9 |

Most of the co-workers[9] |

Save |

Unsafe

Behaviors

(UB) |

UB1 |

Poor physical and mental condition * |

Save |

| UB2 |

Adventurous work activities[20] |

Save |

| UB3 |

Use Unsafe equipment * |

Save |

| UB4 |

Improper storage of materials * |

Save |

| UB5 |

Disregard for unsafe behavior of others[14,21] |

Save |

| UB6 |

Tendency to follow - the use of PPE[14] |

Save |

| UB7 |

Tendency to follow - Adventurous activities[9] |

Save |

| UB8 |

Save others hastily * |

Save |

| UB9 |

Change the construction plan without authorization * |

Save |

| UB10 |

Obey the illegal command * |

Save |

3.3. Data collection

This study focused on the grassroots teams of construction projects in China. Affected by the COVID-19 epidemic, the questionnaire was administered online to members of the workgroups at three of China State Construction's under-construction projects in Beijing and Shenzhen. The safety officer of the project department explained to the respondents the precautions for completing the questionnaire and the explanation of the scale questions before the questionnaire was distributed to improve the accuracy and validity of the study.

The questionnaire survey started on May 19, 2022, and ended on May 25, 2022, with a final total of 504 questionnaires returned. SEM is a large-sample data analysis technique that generally requires a model with a ratio of observed variables to sample size between 1:10 and 1:15[

22], so the number of valid questionnaires for this study should be 350-525 is appropriate. It was verified that 460 respondents had no missing values to retain in the final analysis, which is consistent with the sample size required for SEM.

The demographic characteristics of the 460 respondents are presented in Table 2. 88.5% of the respondents were male. 92.6% of the respondents were over 25 years old and 28.5% were over 47 years old. 60.0% of respondents had junior high school education. 62.6% of respondents had more than 5 years of work experience. 85.0% of the respondents were team members undertaking construction tasks on the front line.

Table 2.

Demographic data for respondents.

Table 2.

Demographic data for respondents.

| Category |

Item |

Frequency |

Percentage |

| Gender |

Male |

407 |

88.5 |

| Female |

53 |

11.5 |

| Age |

≤25 |

34 |

7.4 |

| 26-32 |

73 |

15.9 |

| 33-39 |

123 |

26.7 |

| 40-46 |

99 |

21.5 |

| ≥47 |

131 |

28.5 |

| Educational background |

Primary school or below |

68 |

14.8 |

| Junior high school |

276 |

60.0 |

| Higher School |

101 |

22.0 |

| College degree |

8 |

1.7 |

| Bachelor’s or above |

7 |

1.5 |

| Experience |

≤1 |

19 |

4.1 |

| 1-3 |

78 |

17.0 |

| 3-5 |

75 |

16.3 |

| 5-10 |

107 |

23.3 |

| >10 |

181 |

39.3 |

| Positional level |

Frontline worker |

391 |

85.0 |

| Junior manager |

69 |

15.0 |

| Sum |

|

460 |

100 |

Table 3.

EFA and reliability testing results.

Table 3.

EFA and reliability testing results.

| Items |

Factor Loadings |

Cronbach’s α |

Objective

conditions |

Safety

management |

Personal

perception |

Group

influence |

Unsafe

behaviors |

| OC2 |

.820 |

|

|

|

|

.879 |

| OC3 |

.801 |

|

|

|

|

| OC4 |

.784 |

|

|

|

|

| OC1 |

.710 |

|

|

|

|

| SM7 |

|

.847 |

|

|

|

.906 |

| SM8 |

|

.819 |

|

|

|

| SM1 |

|

.804 |

|

|

|

| SM9 |

|

.797 |

|

|

|

| SM2 |

|

.723 |

|

|

|

| SM6 |

|

.710 |

|

|

|

| SM3 |

|

.657 |

|

|

|

| PP3 |

|

|

.621 |

|

|

.704 |

| PP1 |

|

|

.600 |

|

|

| PP2 |

|

|

.542 |

|

|

| GI6 |

|

|

|

.862 |

|

.926 |

| GI5 |

|

|

|

.834 |

|

| GI7 |

|

|

|

.792 |

|

| GI2 |

|

|

|

.775 |

|

| GI9 |

|

|

|

.772 |

|

| GI3 |

|

|

|

.756 |

|

| GI8 |

|

|

|

.716 |

|

| GI4 |

|

|

|

.511 |

|

| UB6 |

|

|

|

|

.857 |

.895 |

| UB4 |

|

|

|

|

.850 |

| UB1 |

|

|

|

|

.783 |

| UB9 |

|

|

|

|

.766 |

| UB5 |

|

|

|

|

.758 |

| UB3 |

|

|

|

|

.635 |

| UB7 |

|

|

|

|

.604 |

| UB2 |

|

|

|

|

.597 |

4. Results

4.1. Exploratory Factor Analysis (EFA)

Generally, researchers develop questionnaires by first identifying the main constructs based on theory and then designing appropriate questions for each construct. For exploratory questionnaires, EFA is used to validate the soundness of the questionnaire structure after data collection is completed[

23].

In this study, EFA was conducted using SPSS 26.0 software. Before EFA, it was necessary to determine whether the obtained data were suitable for conducting factor analysis. The judgment was based on the Kaiser-Meyer-Olkin (KMO) Measure of Sampling Adequacy and Bartlett’s Test of Sphericity. A KMO value of at least 0.6 was required to perform factor analysis. In this study, the KMO value was 0.901, which is much higher than the criterion of 0.6, and the p-value of Bartlett's test was close to 0 (p<0.05), indicating that the data were suitable for factor analysis.

Principal component analysis and varimax rotation were performed in EFA. Factors with eigenvalues greater than 1 and factor loadings (FL) greater than 0.5 in absolute value were retained. The results showed that the cumulative contribution of the total variance explained by the five constructs (67.229%) reached the requirement of greater than 60%, and the items with FL less than 0.5 were excluded according to the grouping of the rotated matrix. Thus, after this step, GI1, UB8, and UB10 were removed (see Table 3). In addition, Cronbach's α greater than 0.6 indicated that the data were adequate and reliable. It was found that the values of Cronbach's α for all five constructs were greater than 0.6, as shown in Table 3, indicating good internal consistency of the scale.

4.2. Confirmatory Factor Analysis(CFA)

In the social and behavioral sciences, researchers often get more information from CFA than SEM because CFA can provide details about the model setting and the results are more reliable with a structural model adjusted by CFA [

23,

24]. A good measurement model is a prerequisite for analyzing causal relationships between potential variables, while a bad measurement model can lead to erroneous conclusions about the strength and direction of effects between constructs. Therefore, CFA was conducted using Amos 26.0 software for the five constructs of objective conditions, safety management, individual perceptions, group influence, and unsafe behavior before conducting structural model testing.

Taking the group influence construct as an example, the measurement model of group influence and its factors was constructed in Amos 26.0 software. A factor should be deleted when: 1) the standardized factor loadings (Std. FL) were less than 0.5; 2) the squared multiple correlations (SMC) were less than 0.36 (GI4, UB3). Once the fitness index of the measurement model still did not meet the statistical criteria (see Table 6), it indicated the presence of non-independence between the different variables under this construct. Items with high residual correlation were removed according to the modification indices (OC1, SM2, SM8, GI3, GI5, GI8, UB7). It is worth noting that the personal perception construct had only three items that were "just determined" in the statistical sense, in which case the items were all retained once the factor loadings were satisfied. By analogy, all the constructs and their items were identified (see Table 4).

A reliability analysis was performed afterward. The composite reliability (CR) of each construct was greater than 0.7, indicating that the indicators under each construct had good internal consistency. The average variance extracted (AVE) was greater than 0.5, indicating that each construct had high convergent validity (See Table 4).

Thereafter, a discriminant validity analysis was conducted to compare the square root of the AVE with the Pearson correlation coefficient of the latent variable to verify whether the correlation between the indicators within the constructs was higher than the correlation between the constructs. The bolded numbers on the diagonal of Table 5 are the square root of the AVE, and the values outside the diagonal are Pearson correlation of constructs. It should be noted that the square root of AVE for personal perception is 0.707, which is slightly smaller than the Pearson correlation value between safety management and personal perception of 0.775. Since the difference between these two values is not significant, it is considered to meet the statistical criteria in this study. The results showed that the Pearson correlation value for the constructs was almost smaller than the square root of the AVE for each construct, which indicates that the model has good discriminant validity.

Table 4.

Reliability analysis (CR&AVE).

Table 4.

Reliability analysis (CR&AVE).

| Constructs |

Items |

Significance Estimation |

Std. FL |

SMC |

CR |

AVE |

| Unstd.FL |

S.E. |

t-Value |

P |

Objective

Conditions |

OC2 |

1.000 |

|

|

|

.716 |

.513 |

.892 |

.735 |

| OC3 |

1.103 |

.060 |

18.531 |

*** |

.933 |

.870 |

|

|

| OC4 |

1.121 |

.061 |

18.509 |

*** |

.907 |

.823 |

|

|

Safety

Management |

SM7 |

.926 |

.049 |

19.057 |

*** |

.834 |

.696 |

.876 |

.589 |

| SM9 |

.948 |

.050 |

18.847 |

*** |

.826 |

.682 |

|

|

| SM6 |

1.000 |

|

|

|

.796 |

.634 |

|

|

| SM1 |

.849 |

.050 |

17.062 |

*** |

.759 |

.576 |

|

|

| SM3 |

.807 |

.062 |

12.927 |

*** |

.599 |

.359 |

|

|

Group

Influence |

GI2 |

1.000 |

|

|

|

.718 |

.516 |

.902 |

.698 |

| GI6 |

1.286 |

.068 |

18.855 |

*** |

.923 |

.852 |

|

|

| GI7 |

1.298 |

.072 |

18.042 |

*** |

.871 |

.759 |

|

|

| GI9 |

1.194 |

.071 |

16.907 |

*** |

.815 |

.664 |

|

|

Personal

Perception |

PP1 |

1.000 |

|

|

|

.495 |

.245 |

.737 |

.500 |

| PP2 |

1.669 |

.223 |

7.484 |

*** |

.926 |

.857 |

|

|

| PP3 |

1.042 |

.113 |

9.246 |

*** |

.630 |

.397 |

|

|

Unsafe

Behavior |

UB9 |

1.000 |

|

|

|

.742 |

.551 |

.896 |

.596 |

| UB6 |

1.302 |

.065 |

20.034 |

*** |

.913 |

.834 |

|

|

| UB5 |

1.168 |

.071 |

16.378 |

*** |

.757 |

.573 |

|

|

| UB4 |

1.228 |

.063 |

19.511 |

*** |

.889 |

.790 |

|

|

| UB1 |

1.056 |

.065 |

16.169 |

*** |

.748 |

.560 |

|

|

| UB2 |

.643 |

.059 |

10.898 |

*** |

.517 |

.267 |

|

|

Table 5.

Discriminant validity analysis.

Table 5.

Discriminant validity analysis.

| Constructs |

Unsafe

Behaviors |

Personal

Perception |

Group

Influence |

Safety

Management |

Objective

Conditions |

Unsafe

Behaviors

|

.772 |

|

|

|

|

Personal

Perception

|

-.203 |

.707 |

|

|

|

Group

Influence

|

.478 |

.127 |

.835 |

|

|

Safety

Management

|

-.226 |

.775 |

.194 |

.767 |

|

Objective

Conditions

|

.013 |

.550 |

.305 |

.579 |

.857 |

Table 6.

Model fit indices.

Table 6.

Model fit indices.

| Indices |

Fitted model |

Acceptable

values |

Supporting literature |

| (a) |

(b) |

| χ2 |

494.427 |

497.765 |

- |

- |

| χ2/df |

2.762 |

2.720 |

<3 |

Iacobucci (2010) |

| p value |

.000 |

.000 |

<.05 |

Tanaka (1993); Maruyama (1997) |

| GFI |

.907 |

.907 |

≥.90 |

Doll et al. (1994) |

| AGFI |

.881 |

.883 |

≥.80 |

Doll et al. (1994); Arpaci and Baloglu (2016) |

| CFI |

.947 |

.947 |

≥.90 |

Iacobucci (2010) |

| NFI |

.920 |

.919 |

≥.90 |

Hair et al. (2006) |

| RMSEA |

.062 |

.061 |

<.08 |

Hair et al. (2006) |

| SRMR |

.0599 |

.0608 |

<.10 |

Iacobucci (2010); Kline (2023) |

4.3. Structural Equation Modeling (SEM)

SEM is used to verify the relationship between potential variables[

14]. Structural models that meet acceptable criteria accurately reflect the relationships between variables. Commonly used fit metrics in SEM include Chi-square/degrees of freedom (χ2/df), p-value, the goodness of fit index (GFI), adjusted goodness of fit index (AGFI), comparative fit index (CFI), normed fit index (NFI), root mean square error of approximation (RMSEA), and standardized root means residual (SRMR)[

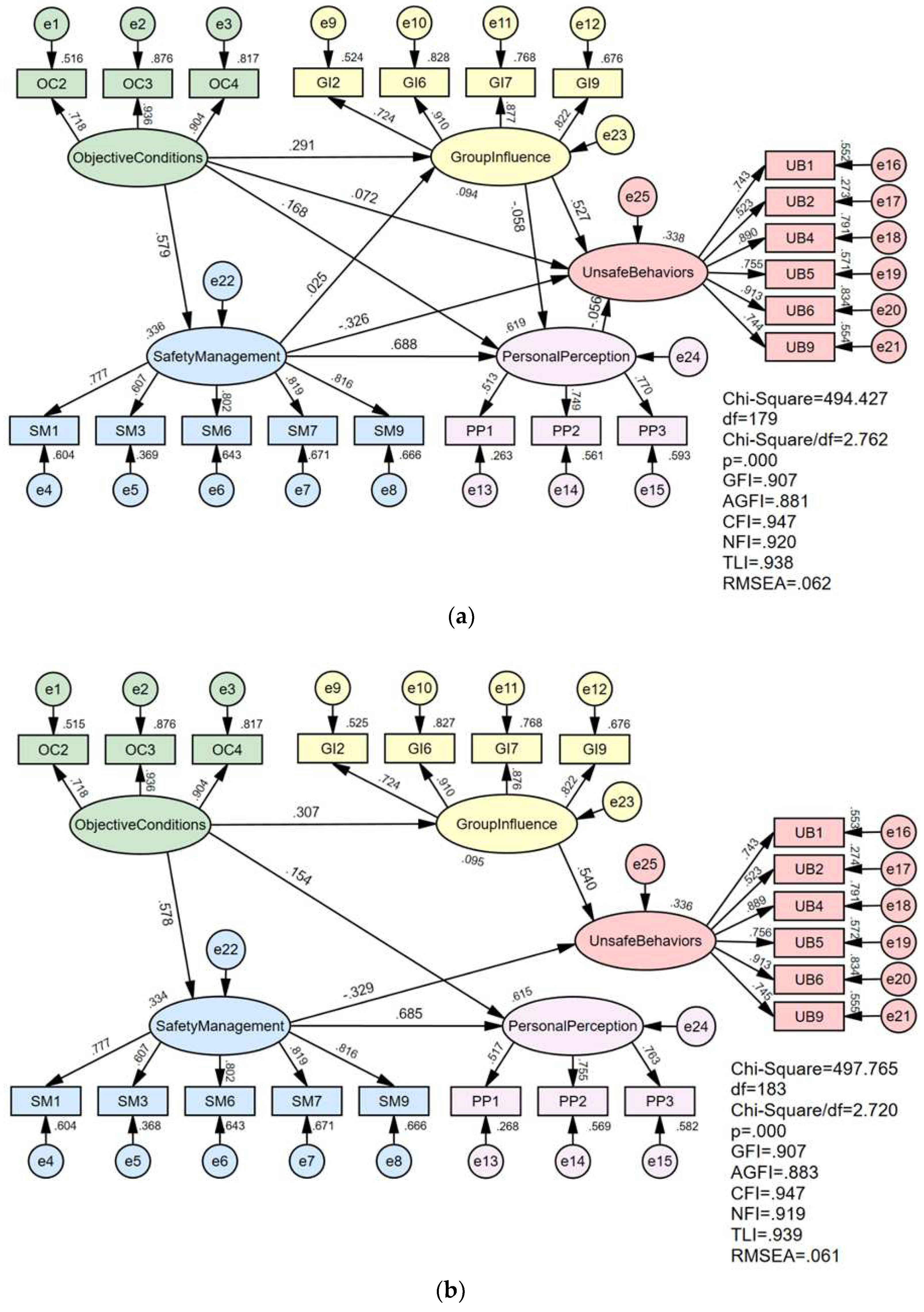

24]. The fit indices of the final SEM (see

Figure 6(a)) validated by EFA and CFA were within the acceptable range[

25], as shown in Table 6.

The results of the hypothesis validation are elaborated in Table 7. Four of the ten initial hypotheses (H4, H6, H8, and H10) were rejected and the remaining six hypotheses proved to be statistically significant. The final structural model of safety behavior under the influence of multidimensional factors is shown in

Figure 6(b). In the path analysis, the influence between variables contains both direct and indirect effects[

23], and the total influence values of exogenous variables on endogenous variables are presented in Table 8.

Table 7.

The final output relationship of multilevel safety intervention with safety behavior.

Table 7.

The final output relationship of multilevel safety intervention with safety behavior.

| Hypothesis |

Estimate |

S.E. |

C.R. |

P |

Result |

| H1 |

OC → SM |

.405 |

.039 |

10.395 |

*** |

Supported |

| H2 |

OC → GI |

.287 |

.065 |

4.451 |

*** |

Supported |

| H3 |

OC → PP |

.098 |

.037 |

2.674 |

.008 |

Supported |

| H4 |

SM → GI |

.035 |

.090 |

.393 |

.694 |

Rejected |

| H5 |

SM → PP |

.572 |

.068 |

8.367 |

*** |

Supported |

| H6 |

GI → PP |

-.034 |

.027 |

-1.265 |

.206 |

Rejected |

| H7 |

GI → UB |

.773 |

.082 |

9.405 |

*** |

Supported |

| H8 |

PP → UB |

-.140 |

.245 |

-.572 |

.567 |

Rejected |

| H9 |

SM → UB |

-.677 |

.194 |

-3.498 |

*** |

Supported |

| H10 |

OC → UB |

.104 |

.085 |

1.223 |

.221 |

Rejected |

Table 8.

Standardized Direct, indirect, and total effects.

Table 8.

Standardized Direct, indirect, and total effects.

| Construct A → Construct B |

Direct effects |

Indirect effects |

Total effects |

| Objective Conditions |

Safety

Management |

.578 |

\ |

.578 |

Group

Influence |

.307 |

\ |

.307 |

Personal

Perception |

.154 |

.396 |

.550 |

Unsafe

Behaviors |

\ |

-.024 |

-.024 |

| Group Influence |

Unsafe

behaviors |

.540 |

\ |

.540 |

| Safety Management |

Personal

Perception |

.685 |

\ |

.685 |

Unsafe

behaviors |

-.329 |

\ |

-.329 |

5. Discussion

The standardized path coefficient of "Objective Conditions → Safety Management" is 0.578, p<0.001, and H1 is supported that Objective Conditions have a significant positive influence on Safety Management. The more complex the construction task is, the more obvious the role of safety management measures in restraining the unsafe behavior of frontline workers. Similarly, the harsher the weather or working environment conditions are, the more obvious the role of safety management measures in restraining unsafe behaviors.

The standardized path coefficient of "Objective Conditions → Group Influence" is 0.307, p<0.001, and H2 is supported that Objective Conditions have a significant positive influence on Group Influence. The worse the objective conditions (task complexity, weather, or operating environmental conditions) are, the more obvious the interference of the operational behavior of key people on the behavioral decisions of individual workers, in which case the herd effect of unsafe behaviors is more likely to occur within the workgroup.

The standardized path coefficient of "Objective Conditions → Personal Perception " is 0.154, p<0.05, and H3 is supported that Objective Conditions have a significant positive influence on Personal Perception. Complex construction tasks, adverse weather, or operating conditions can elevate workers' perceptions. That is, in this case, they believe that they are aware of the possible risks and the corresponding precautions during the operation and that they can use the PPE correctly. Therefore, complex construction tasks, adverse weather conditions, or operating environments may prompt workers to raise their safety awareness and take the necessary precautions to ensure personal safety.

The standardized path coefficient of "Safety Management → Personal Perception " is 0.685, p<0.001, and H5 is supported that Safety Management has a significant positive influence on Personal Perception.

It indicates that the implementation of safety management measures such as safety education and training, safety reward and punishment regulations, safety technical disclosure, safety inspection, and safety warning signs can help workers to improve their personal perception level. In addition, both H1 and H5 are supported, which suggests that objective conditions positively influence personal perception indirectly through safety management (0.578 × 0.685 ≈ 0.396).

The standardized path coefficient of "Group Influence → Unsafe Behavior" is 0.540, p<0.001, and H7 is supported that Group Influence has a significant positive influence on Unsafe Behavior. As the main leader of the workgroup, the group leader has a certain role in demonstrating and guiding the behavioral choices of the workers. Some studies have proved that the safety leadership role of the team leader is conducive to improving workers' compliance with safety procedures and participation in safety behaviors. However, overemphasizing the safety leadership role of the team leader can also lead to attachment anxiety among workers[

2]. Therefore, construction units can appropriately strengthen the safety training and education of team leaders to remind them to play a reasonable role in safety leadership and enhance the safety behavior of team members. In addition, as the most basic unit on the construction site, the workgroup has the most frequent communication among its members, and the unsafe behaviors of individual workers are easy to spread within the group. Therefore, the construction unit needs to strengthen the group consciousness of the workgroup, optimize the employee safety behavior supervision regulations, and form a positive atmosphere in the workgroup to remind each other and avoid unsafe behaviors together.

The standardized path coefficient of "Safety Management → Unsafe Behavior" is -0.329, p<0.001, and H9 is supported that Safety Management has a significant negative influence on Unsafe Behavior. The implementation of safety management measures helps to reduce the occurrence of unsafe behaviors among workers. Safety education and training provide front-line workers with the necessary safety knowledge and continuously improve their safety capabilities. Safety reward and punishment regulations indicate clear safety behavior expectations and requirements for frontline workers, which can correct safety motivation and balance safety psychology. Safety technical disclosure is the most common safety management measure on construction sites. Training of workers on safety operation procedures and precautions by management personnel before the commencement of construction operations can effectively reduce the likelihood of accidents caused by non-compliant operations. Daily safety inspections and periodic safety inspections are both necessary safety management measures that can timely detect not only unsafe behaviors of frontline workers, but also abnormal states of equipment, unsafe factors in the environment, and deficiencies in construction site management [

14]. Safety warning signs can strengthen workers' safety awareness, remind them of the potential risks in the construction process, and standardize their work behavior.

The p-value of the path "Objective Conditions → Unsafe Behavior" is 0.221 > 0.05, which means that H10 is rejected and the direct effect of Objective Conditions on Unsafe Behavior is not significant. After the previous discussion, H1, H2, H7, and H9 are supported, which suggests that Objective Conditions negatively influence Unsafe Behaviors mainly indirectly through influencing Group Influence and Safety Management (0.307 x 0.540 + 0.578 x (-0.329) ≈ -0.024).

The p-value of the path "Safety Management → Group Influence" is 0.694 > 0.05, which means that H4 is rejected and the direct effect of Safety Management on Group Influence is not significant. Safety management measures are supposed to help inhibit the spread of unsafe behaviors among workgroup members. There are two possible reasons why the direct effect is not statistically significant: 1) the design of the safety management questions in the questionnaire of this study mostly involves on-site safety management measures, such as technical safety disclosure, safety inspections, safety warning signs, etc. These safety management measures have a direct effect on individual frontline workers, but have no direct effect on the spread of unsafe behaviors among group members; 2) safety education and training, including safety rewards and punishments, are one of the means to develop a safety culture, which contributes to the formation of a good safety atmosphere and indirectly reduces the spread of unsafe behaviors in the team. Therefore, safety climate may be a mediating variable between Safety Management and Group Influence. Further validation by adding mediating variables to the model will be considered afterward.

The p-value of the path "Group Influence → Personal Perception" is 0.206 > 0.05, which means that H6 is rejected and the direct effect of Group Influence on Personal Perception is not significant. According to the survey data of this study, 65.9% of the respondents would follow the work attitude, method, or behavior of the workgroup leader, 64.3% would follow the behavior of the workers they work with, 60.2% would follow the behavior of the workers in the workgroup who are close to them, and 58.5% would follow the behavior of most of the workers in the construction work. It shows that the work attitude and behavior of key persons in the work group have a certain "infectious" effect, which does not directly affect the workers' perception of their safety ability but directly affects the workers' behavioral choices.

The p-value of the path "Personal Perception → Unsafe Behavior" is 0.567 > 0.05, which means that H8 is rejected and the direct effect of Personal Perception on Unsafe Behavior is not significant. Workers' judgments of their safety knowledge and skills had no significant positive or negative effect on unsafe behavior. The hypothesis was disproved, but this result is a good illustration of why risky work is the most common cause of accidents in construction accidents in China. Even if workers believe that they have appropriate safety knowledge and that they can use PPE correctly, they may still engage in unsafe behaviors during construction operations due to a sense of chance or a lack of safety motivation to adhere to rules and regulations.

6. Conclusions

This study is based on the unsafe behaviors and influencing factors of workgroup members in construction projects in China. A total of 80 investigation reports on Chinese construction accidents in the past five years were collected, and common factors such as Objective Conditions, Safety Management, and Unsafe Behaviors were sorted out. A comprehensive theoretical model was proposed, and some hypotheses were verified using SEM to explore the relationships among Objective Conditions, Safety Management, Group Influence, Personal Perception, and Unsafe Behaviors. The results show that the direct influence of Safety Management and Group Influence on workers' Unsafe Behavior is statistically significant, the direct influence of Objective Conditions and Safety Management on workers' Personal Perception is statistically significant, and the Objective Conditions influence workers' Unsafe Behavior through Safety Management and Group Influence. Decision makers and managers of Chinese construction companies can accordingly develop appropriate measures to guide the safety behavior of workgroup workers. For example, complex construction tasks and poor operating conditions shall increase the likelihood of spreading unsafe behaviors within a workgroup, in which case decision-makers and managers need to pay more attention to monitoring the implementation of safety management measures.

The advantages of this study include the following two points. First, construction accident survey reports in China were collected and analyzed. Objective Conditions, Safety Management, and Unsafe Behavior factors that are more in line with reality are refined, the questionnaire is easy to be understood by the respondents and the data obtained are more reliable. Second, a theoretical model of the influence mechanism of unsafe behaviors of workgroup personnel is proposed based on the system perspective, which integrates individual, organizational, environmental, and other factors. The influence relationship between those factors was verified through structural modeling. The results of the study can help decision-makers or managers understand the influence mechanism of unsafe behavior and take more appropriate measures to guide workers' safe behavior and provide conditions for construction workers to become a sustainable workforce.

This study also has some limitations. First, the object of this study is frontline workgroup members in a broad sense. However, there may be differences in the influence mechanisms of unsafe behaviors among workers in different geographic regions and job types. Future research needs to further refine the research object, expand the sample size, and even conduct some comparative studies. Second, the model validation results of this study indicate that the direct effect of Safety Management on Group Influence is not significant. Subsequent studies need to determine the existence of mediating variables and explore the influence patterns.

Author Contributions

Conceptualization, Li. Y., and Wang. S.Y.; methodology, Li. Y.; software, Li. Y.; validation, Li. Y.; formal analysis, Li. Y. and Pei. J.J.; investigation, Li. Y. and Wang. S.Y.; writing—original draft preparation, Li. Y.; writing—review and editing, Pei. J.J.; supervision, Luo. Y.; funding acquisition, Pei. J.J.. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (NSFC): Research on theoretical methods of risk evaluation and resilience prevention and control of urban accident and disaster emergencies, grant number No. 52004258.

Data Availability Statement

The accident investigation reports collected and used in this study were obtained from the official websites of the Ministry of Emergency Management of the People's Republic of China (MEMP), the National Energy Administration (NEA), and subordinate emergency management departments at all levels. As the researcher has promised the questionnaire respondents that no specific information will be disclosed, the questionnaire data is not available due to privacy concerns.

Acknowledgments

The first author would like to express appreciation to Yongbei Zhang, Xiaojiao Yan, Wei Wang, and Yan Fang for their advice and assistance in the preparation and distribution of the questionnaire.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Fang, D.; Huang, Y.; Guo, H.; Lim, H.W. LCB approach for construction safety. Safety Science 2020, 128. [Google Scholar] [CrossRef]

- Huang, Y.C.; Li, B.N.; Yu, X.X.; Wang, Y.; Fang, D.P. Path analysis attachment in the safety interactions of construction team members. J Tsinghua Univ(Sci & Technol) 2023, 63, 169–178. [Google Scholar] [CrossRef]

- Malakoutikhah, M.; Alimohammadlou, M.; Rabiei, H.; Faghihi, S.A.; Kamalinia, M.; Jahangiri, M. A scientometric study of unsafe behavior through Web of Science during 1991-2020. International Journal of Occupational Safety and Ergonomics 2021. [Google Scholar] [CrossRef] [PubMed]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.F.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction accidents. Applied Ergonomics 2005, 36, 401–415. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.H.; Tang, W.J.; Miao, J.Y.; Wang, Z.M.; Wang, P.X. Safety climate measurement at workplace in China: A validity and reliability assessment. Safety Science 2008, 46, 1037–1046. [Google Scholar] [CrossRef]

- Zhang, M.; Fang, D. Cognitive causes of construction worker’s unsafe behaviors and management measures. China Civil Engineering Journal 2012, 45, 297–305. [Google Scholar] [CrossRef]

- Cao, Q.; Li, K.; Li, J. Impact of Manager's Behavior on Coalminer's Unsafe Behavior. Journal of Management Science 2011, 24, 69–78. [Google Scholar]

- Yang, G.S.; Wei, Y. Analysis on the Relationship Between Construction Safety Climate and Safety Behavior. Journal of Engineering Management 2017, 31, 124–129. [Google Scholar] [CrossRef]

- Guan, Y. Study on the Propagation Path and Management Countermeasures of Construction Workers' Unsafe Behavior. Master, Liaoning Technical University, 2020.

- Young, G.S.; Rogers, S.J.; Hutman, T.; Rozga, A.; Sigman, M.; Ozonoff, S. Imitation From 12 to 24 Months in Autism and Typical Development: A Longitudinal Rasch Analysis. Developmental Psychology 2011, 47, 1565–1578. [Google Scholar] [CrossRef] [PubMed]

- Bao, X.Y. The Influence of Individual, Organization and Environment on the Evolution of Unsafe Behavior of Construction workers. Master, Jiangsu University, 2022.

- Wu, X.Y. Research on the Relationship between Manager's Behavior and Construction Worker's safety Behavior: the Moderating Effect of Social Capital. Doctor, Tianjin University of Finance and Economics, 2017.

- Feng, Y. Research on the relationships among the Construction Unsafe Behavior —— Based on Social Network Analysis. Master, Tianjin University of Finance and Economics, 2017.

- Zaira, M.M.; Hadikusumo, B.H.W. Structural equation model of integrated safety intervention practices affecting the safety behaviour of workers in the construction industry. Safety Science 2017, 98, 124–135. [Google Scholar] [CrossRef]

- Lu, C.-S.; Yang, C.-S. Safety climate and safety behavior in the passenger ferry context. Accident Analysis and Prevention 2011, 43, 329–341. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L. Research on Forming Mechanism of Miner's Unsafe Behaviors and its Dual Effects. Doctor, Liaoning Technical University, 2015.

- Larsson, S.; Pousette, A.; Torner, M. Psychological climate and safety in the construction industry-mediated influence on safety behaviour. Safety Science 2008, 46, 405–412. [Google Scholar] [CrossRef]

- Wu, H. Safety culture and behavior-based safety for construction projects: Theoretical and empirical study. Doctor, Tsinghua Univ., Beijing, 2013.

- Wang, D.; Guan, Y.; Jia, Q. Research on propagation path of construction workers' unsafe behavior based on social network analysis. Journal of Safety Science and Technology 2018, 14, 180–186. [Google Scholar]

- Sun, C.; Ahn, S.; Ahn, C.R. Identifying Workers' Safety Behavior-Related Personality by Sensing. Journal of Construction Engineering and Management 2020, 146. [Google Scholar] [CrossRef]

- Gu, b.; Cao, S.; Wang, Y.; Huang, Y.; Fang, D. Types and Characteristic of Unsafe Behaviors in Construction Teamwork. J Tsinghua Univ(Sci & Technol) 2023, 63, 160–168. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate data analysis (Vol. 6). 2006. [Google Scholar]

- Wu, M. Structural Equation Modeling: Operations and Applications of AMOS (2nd Edition); Chongqing University Press: Chongqing, 2017. [Google Scholar]

- Jackson, D.L.; Gillaspy Jr, J.A.; Purc-Stephenson, R. Reporting practices in confirmatory factor analysis: an overview and some recommendations. Psychological methods 2009, 14, 6. [Google Scholar] [CrossRef] [PubMed]

- Arpaci, I.; Baloglu, M. The impact of cultural collectivism on knowledge sharing among information technology majoring undergraduates. Computers in Human Behavior 2016, 56, 65–71. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).