1. Introduction and Literature Review

Food loss is a growing problem for our society. According to the United States Department of Agriculture (USDA) shows that 31 percent of food loss in the supply chain happens at the retail and consumer level, worth

$161 billion in the United States in a single year [

1]. This figure varies in different parts of the world according to the culture, customer's buying behavior, and consumption habit. The United States Environmental Protection Agency (EPA) proposed a food recovery hierarchy where the source reduction or earliest action on problem fruit is considered the topmost priority to reduce waste [

2]. Retail can play a vital role in reducing food loss by managing the presentation, pricing, and in-house reverse logistics activity. To do so, visual information on the fruit's condition is necessary. The parameters comprise looks and shapes, shelf life, packaging condition, level of decay, and spots on fruits and vegetables.

Showcasing and displaying methods affect the visual experience of a shopper. The effect of rack configuration on a customer's visual experience in a retail store has been examined, and it has been determined that rack orientation at a certain angle can increase exposure [

3]. At the same time, the retailer needs to identify problem fruit from the stack by seeing them.

The convenience of worker's labor is also an important concern in merchandising fruits. Manual merchandising, pricing, packaging, assembly, rehandling, policing, and customer services take significant labor costs and time, even in their proposed improved system [

4]. Automating and increasing the ease of work in those labor-intensive jobs is necessary.

Showcasing fruits in an open cart poses direct harm to customer health and safety. Apart from that, the cost of showcasing fruits in the display with the doors is less than the open display [

5]. They showed that the operational energy costs were 69 percent less for their proposed retrofit door display than the open display case. And it is also suitable to keep the product and process specific environment in terms of temperature and humidity.

Intervention and tracking are important to get sales data to analyze for getting prediction of customer choices, constraints, and behavior. Accurately and consistently labeling produce and tracking sales is difficult and requires significant support. A novel sales tracking method that is appropriate to recognize fruit conditions is helpful to evaluate and implement a novel low-technology and low-cost evaluation method [

6].

The state-of-the-art kind of fruit display that looks more attractive is introduced by Pluton F& V [

7]. The semi-vertical representation of fruits provides ease for cleaning and servicing, but the produces are still remaining in stack condition that, constrains the visibility of all fruits.

Some scholarly applications and experiments in the retail industry to reduce food waste are shown in

Table 1.

The complete package of fruit showcasing, including better visibility, convenience for inspection and sorting process with reduced time and space, is absent in literature and practice. The proposed design of fruit showcasing in retail stores is helpful for continuous diagnosis of the fruit condition in the periodic inspection process. It helps to reduce the extra use of packaging materials in the merchandising process and enhances the visual experience for both the customer and retailer.

2. Design of the vertical fruit display

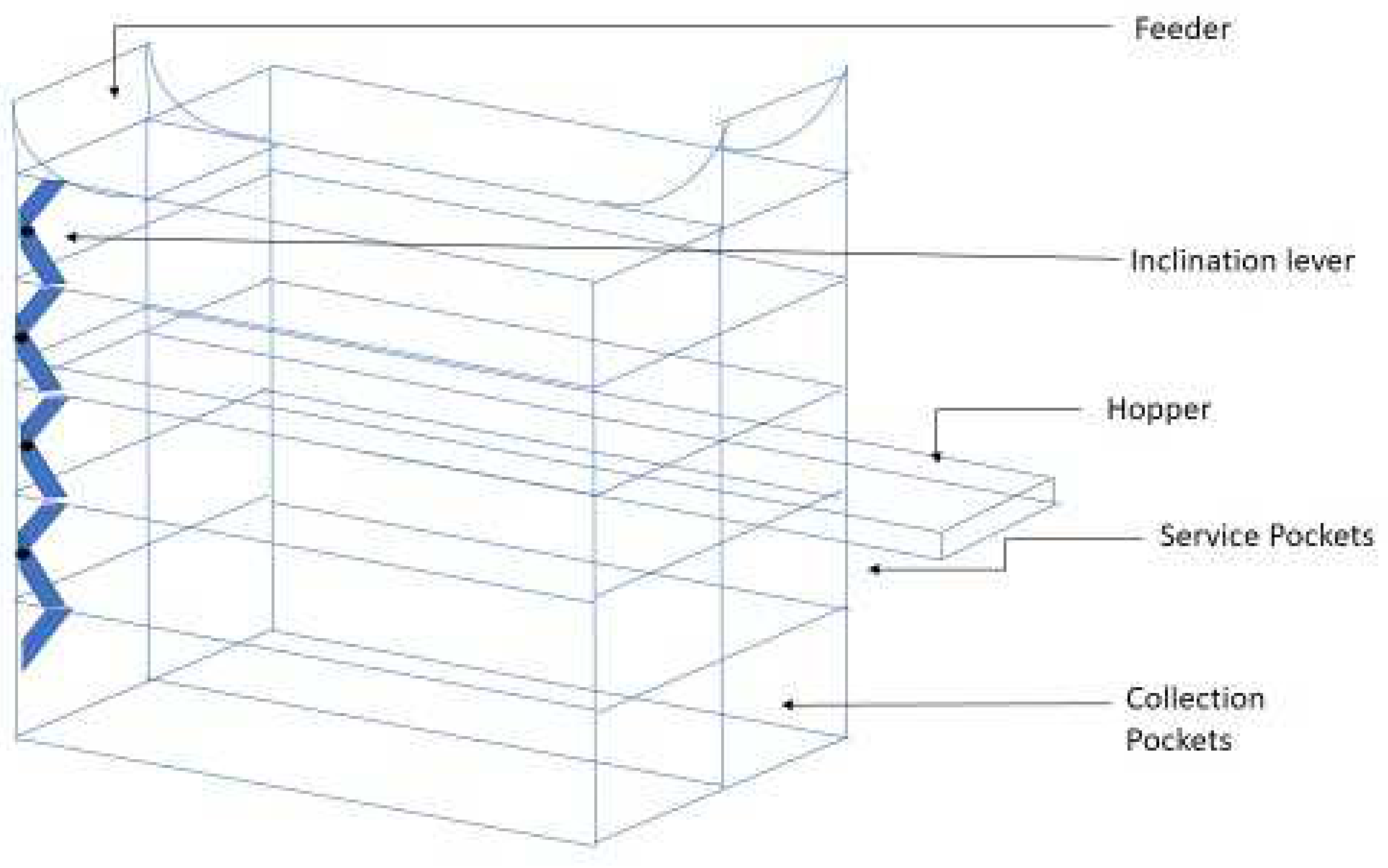

Figure 1 is the rack for displaying fruits and vegetables in a retail store constructed of transparent fiberglass and positioned vertically. The display has the capability of retailing fruit and vegetables in a manner that makes the product visible from all 360 degrees. Customers and retailers alike will have no trouble locating the goods that they seek inside this exhibition. The food items can be stored in a horizontal position on the trays that are included within the rack. These sloping trays include a lever that allows them to be moved inside the showcase. This allows the merchandise to be moved downward, where it can be collected by the consumer. Each tray has a separate pocket that the store clerk can use to pull the tray out horizontally and remove any damaged items.

3. Materials

Feeder: Semi funnel-type feeder is placed on the top of the showcase. Two feeders are situated on both sides in opposite directions. The showcase and its feeders have ample space to put fruits of round and semi-round shapes. Only the merchandiser and retail clerk can have the access to those feeder points.

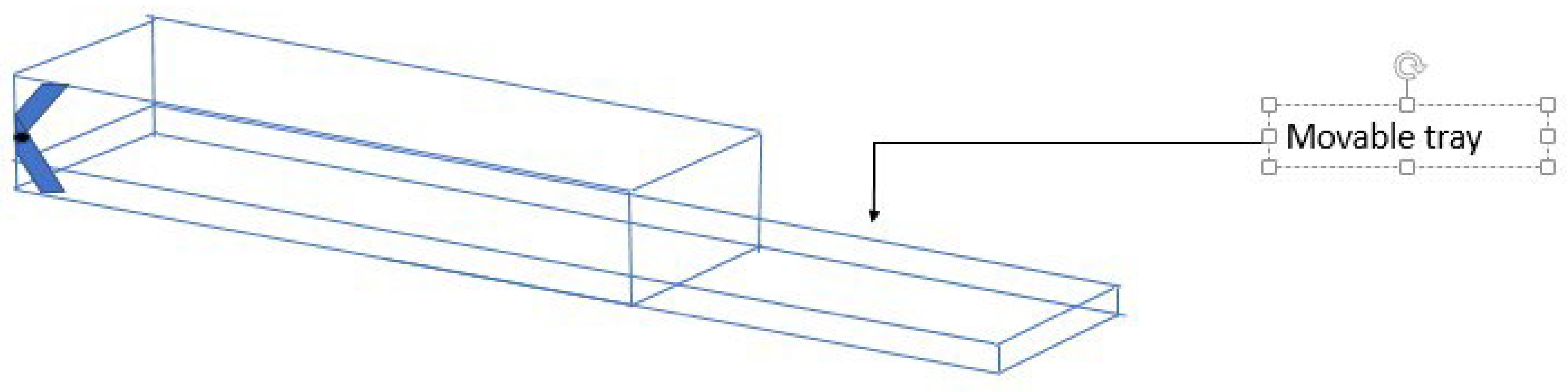

Trays: Trays are placed in every pocket of the racks. These are moveable sideways and inclinable at an appropriate degree to utilize gravitational force to move fruits inside the rack.

Hopper: Every individual tray can be pulled out sideways from the rack to create the hopper. Retail clerks and merchandisers can access those points at any time for inspecting and sorting.

Figure 2.

Service gateway and hopper of vertical fruit showcase.

Figure 2.

Service gateway and hopper of vertical fruit showcase.

Service pockets: Service pockets are available on the width side of the showcase on every stair. It is accessible by the retail clerk and merchandiser for moving the tray manually to pull out and put back the trays and troubleshooting.

Collection pockets: Only accessible service pockets for customers and available at the lower stair of the showcase. These pockets are designed differently to collect the product by customers. A weight measuring scale is attached to the collection pocket to get the weight and price for collection. A manually controlled gate is attached to the pocket that can use for collecting the desired amount of product by the customer.

Inclination lever: Inclination levers are attached to every stair of the rack to incline and decline the trays. Those levers can be manually operatable for inclining and declining the trays at any appropriate angle.

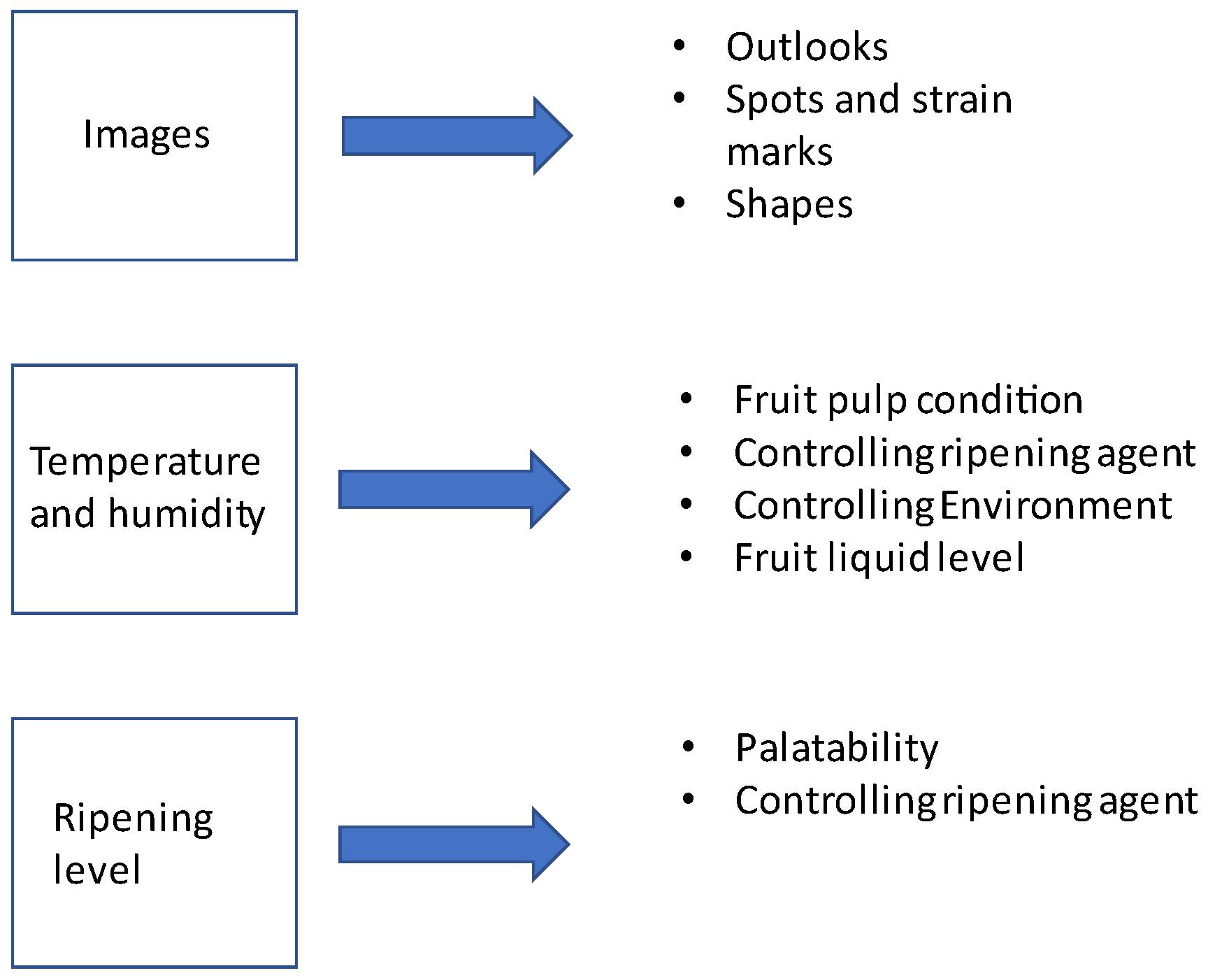

IoT interface: Three main pieces of information consist of the image, temperature, and ripening level required to determine the fruit condition inside the showcase. The types of derived data from those parameters are shown in

Figure 3.

MQ3 sensors are used to extract riping level information. This the most commonly used sensors of MQ sensor series. The sensed data go through the Arduino IDE (Integrated Development Environment). At the same time camera capture the real-time image and send to Arduino IDE. Live temperature and humidity information are also recorded to analyze the data.

4. Concluding Remarks

It takes up a significant amount of room inside a retail store for the presentation of fresh fruits and vegetables. In addition to that, merchants typically spend a substantial amount of time arranging products in a manner that is visually appealing to customers. When they have to sort the fruit for different grading activities and inspections, it makes things much more difficult for them. Because the fruit is arranged in a single layer that is either thick or sloped or in a horizontal or vertical stack.

Moreover, It is also not advised to purchase fruits from this stack during the present covid outbreak because the product itself can be the vector of communicable diseases. This is a common practice among the customers that they usually touch, pinch and break fruits for testing fruit quality. No matter how well described the quality and freshness on the label, customers tend to do those unnecessary activities. It damages the quality of fruit and fruit skin. It is important to prevent those activities and communicable diseases.

The followings are the primary objective that is fulfilled by the proposed vertical fruit display for the retail store.

Reducing store space for displaying fruits.

Increasing convenience for retailers and customers.

Increasing visibility to diagnose fruit condition.

Preventing communicable diseases.

Preventing unnecessary human contact.

Improving temperature and humidity management.

Improving shopper's visual experience

Flexible to integrate IoT.

References

- Loss F, Waste. Food and Drug Administration. U.S; 2021. Available from: https://www.fda.gov/food/consumers/food-loss-and-waste.

- 2015. Available from: https://www.epa.gov/sustainable-management-food.

- Nayik GA, Muzaffar K. Developments in packaging of fresh fruits-shelf life perspective: A review. American Journal of Food Science and Nutrition Research. 2014 Jan 1;1(5):34-9.

- Rojas-Aranda JL, Nunez-Varela JI, Cuevas-Tello JC, Rangel-Ramirez G. Fruit classification for retail stores using deep learning. InPattern Recognition: 12th Mexican Conference, MCPR 2020, Morelia, Mexico, June 24–27, 2020, Proceedings 12 2020 (pp. 3-13). Springer International Publishing.

- Smith B, Shayanfar S, Walzem R, Alvarado CZ, Pillai SD. Preserving fresh fruit quality by low-dose electron beam processing for vending distribution channels. Radiation Physics and Chemistry. 2020 Mar 1;168:108540. [CrossRef]

- Kleih AK, Lehberger M, Sparke K. The potential of salient branding of fresh fruit on the supermarket shelf for consumer brand recall. Food Quality and Preference. 2022 Mar 1;96:104415. [CrossRef]

- Mowrey CH, Parikh PJ, Gue KR. The impact of rack layout on visual experience in a retail store. INFOR: Information Systems and Operational Research. 2019 Jan 2;57(1):75-98. [CrossRef]

- Anderson EE. An analysis of retail display space: Theory and methods. Journal of Business. 1979 Jan 1:103-18. [CrossRef]

- de Frias JA, Luo Y, Kou L, Zhou B, Wang Q. Improving spinach quality and reducing energy costs by retrofitting retail open refrigerated cases with doors. Postharvest Biology and Technology. 2015 Dec 1;110:114-20.

- Sadeghzadeh CJ, Soldavini J, Uslan D, De Marco M. Novel sales tracking method to evaluate a healthy corner store intervention. Health Promotion Practice. 2020 May;21(3):401-9. [CrossRef]

- 2022. Available from: https://refrigerationcomponents.co.uk/pluton-space-f-v.html.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).