Submitted:

06 December 2023

Posted:

07 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and method

2.1. Elements selection in critical minerals

2.2. Input-Output analysis

3. Results and discussion

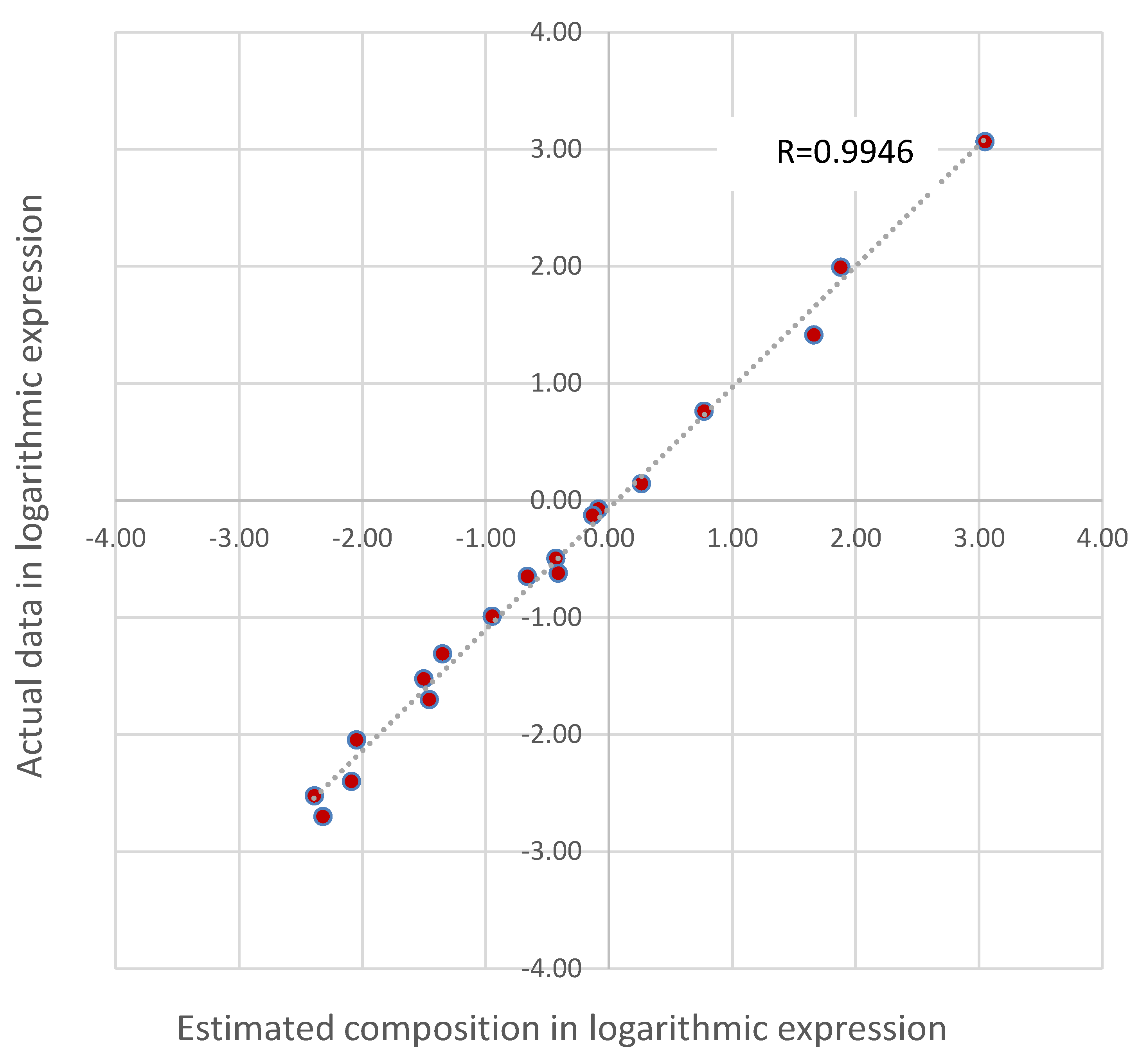

3.1. Test of the estimated element composition of products ()

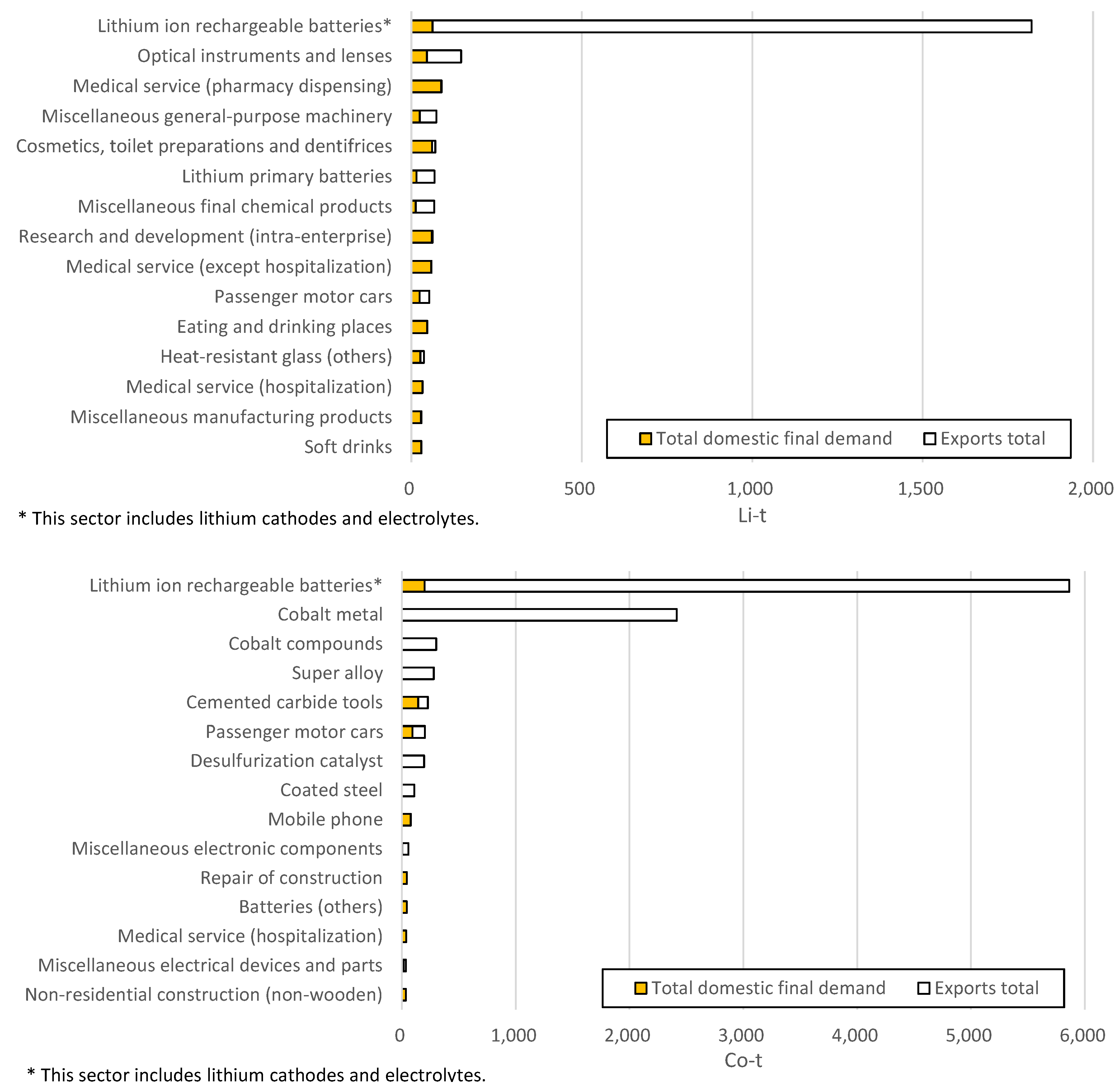

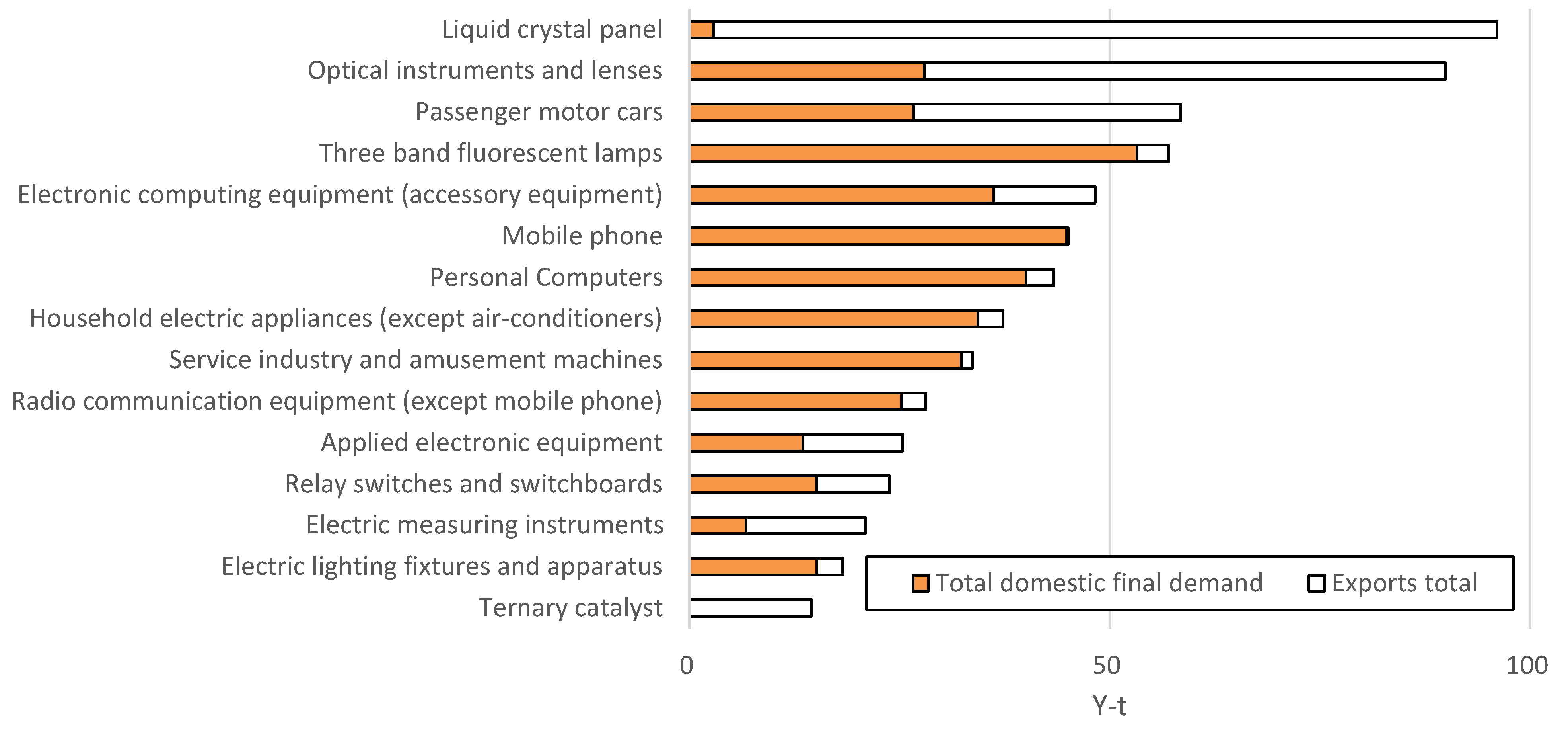

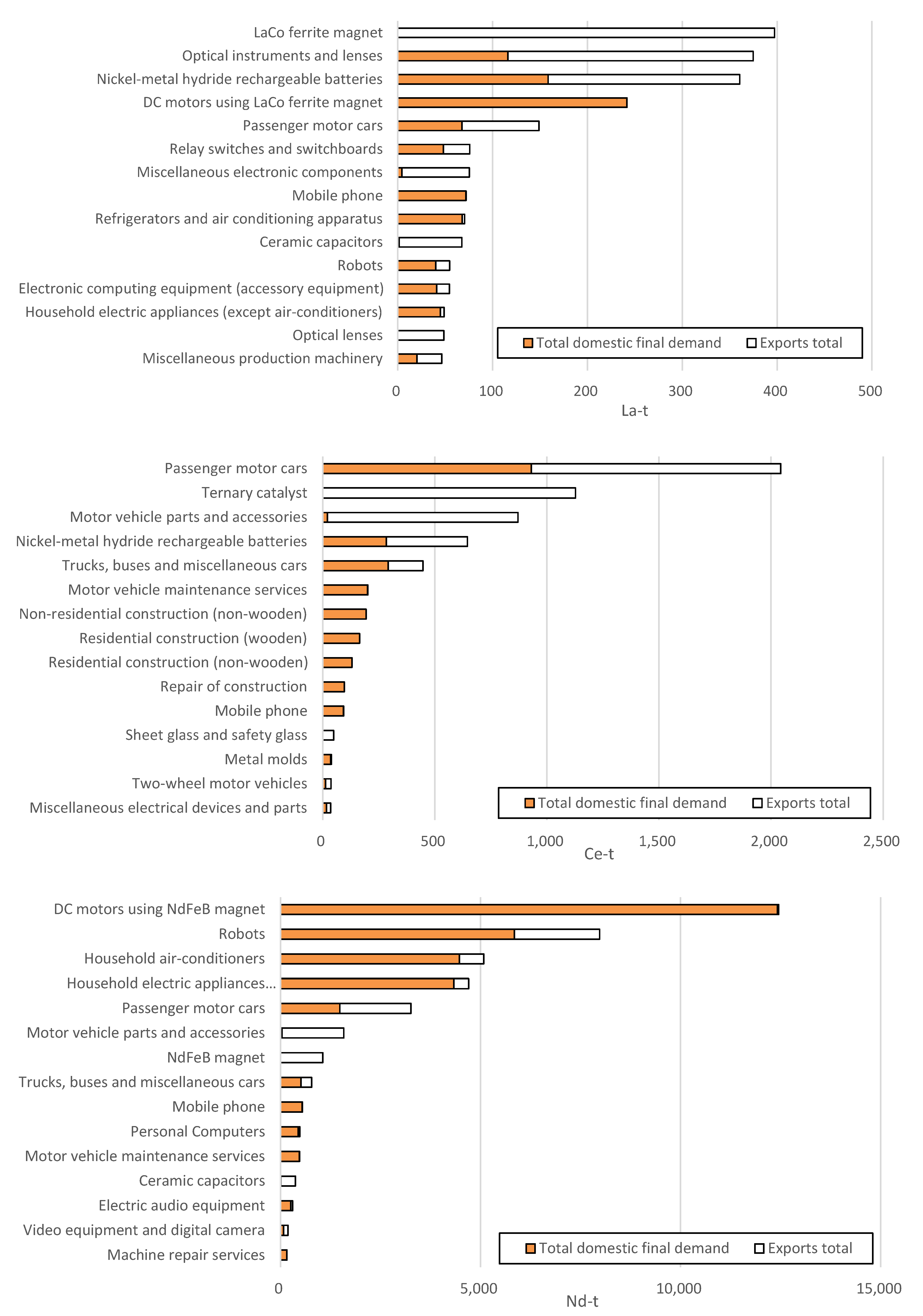

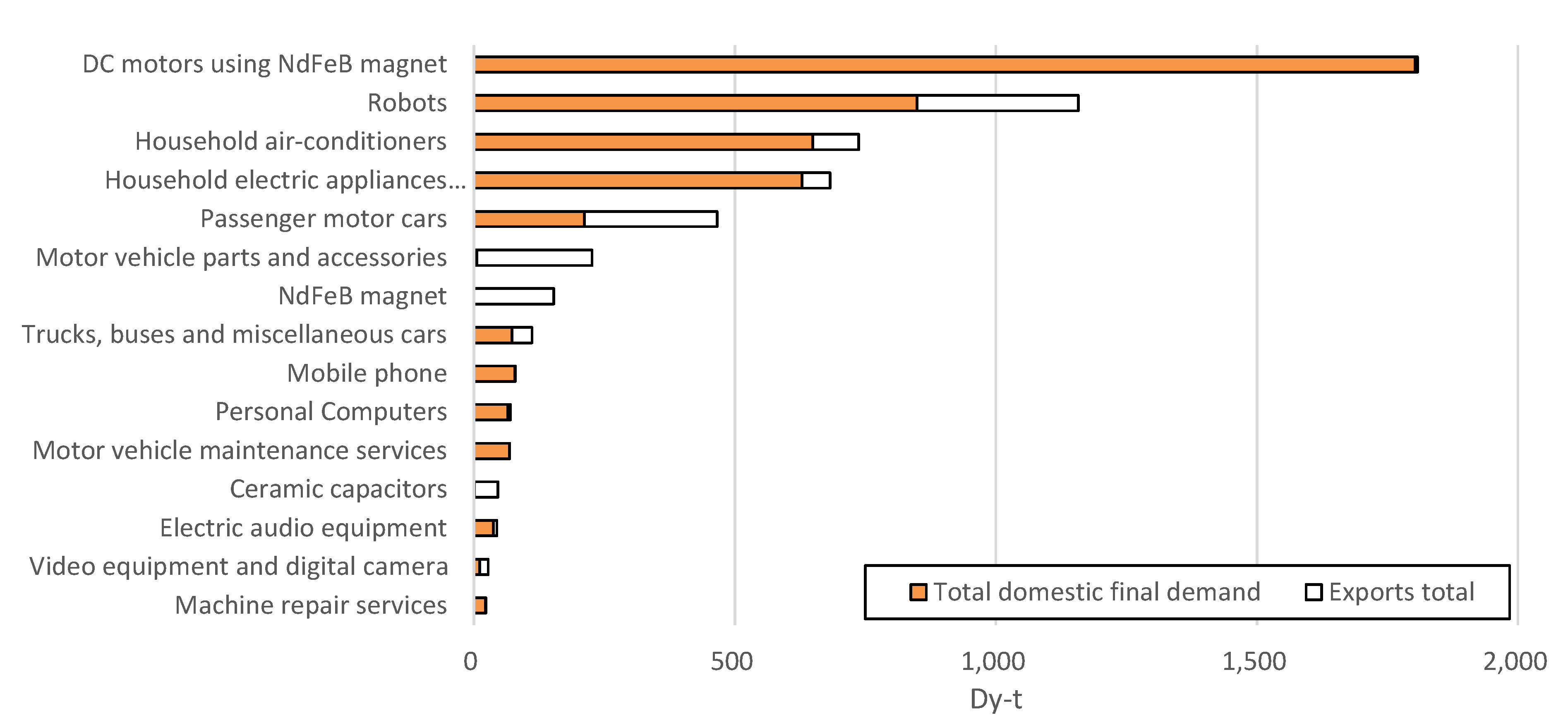

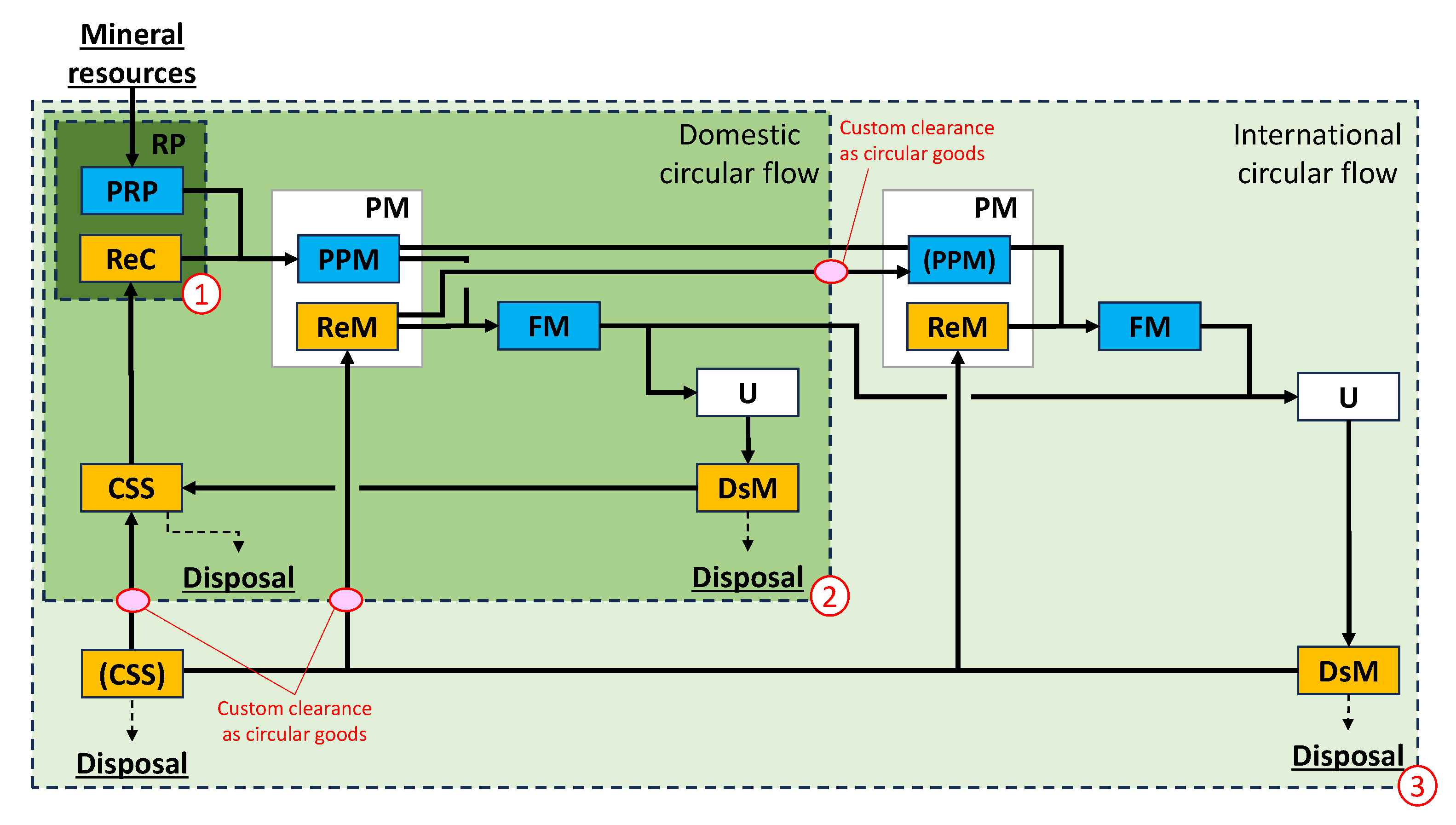

3.2. Final destination (domestic final demand and export) of critical minerals as social stocks

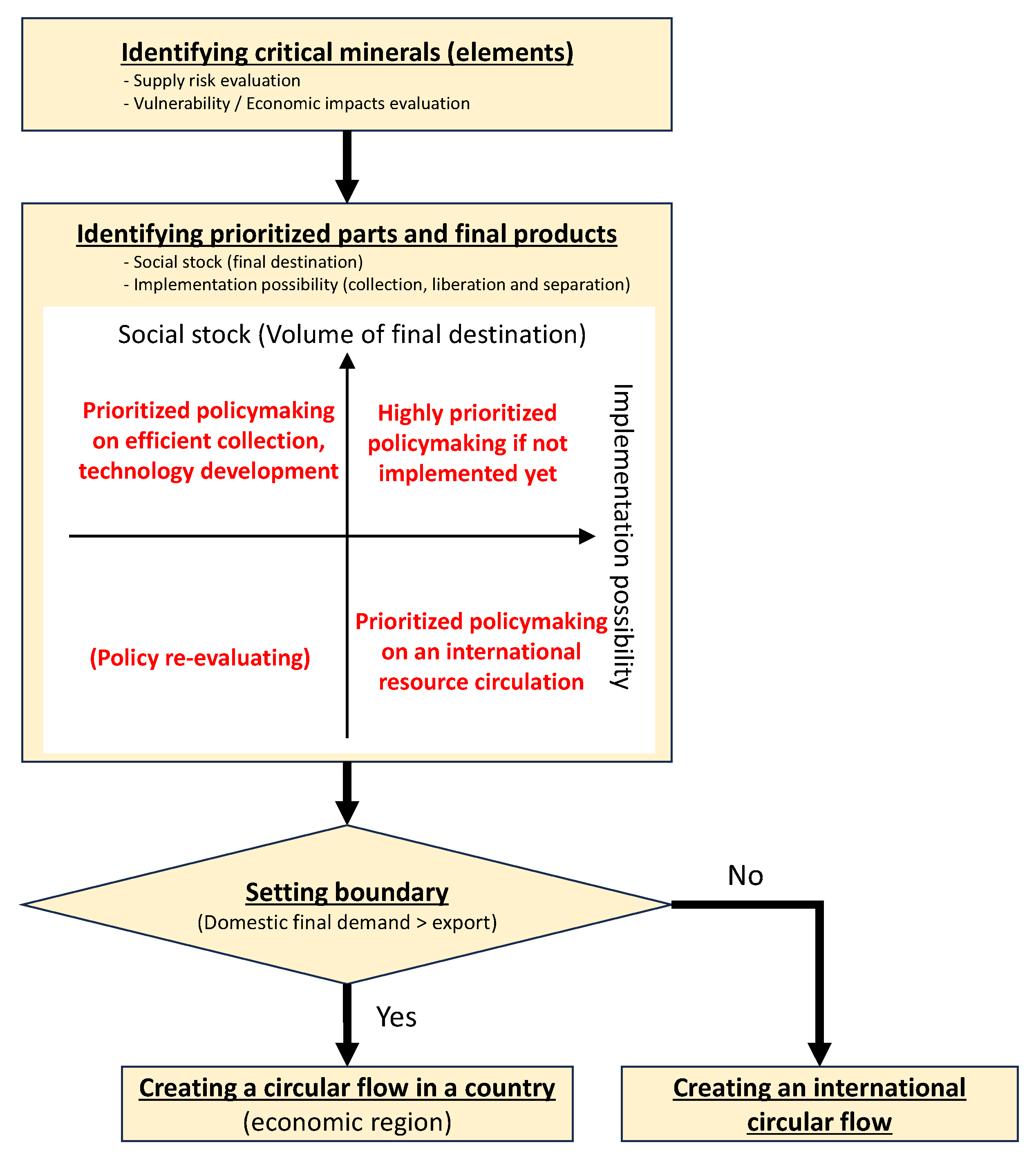

3.3. Guidance on mineral resources policy from national security and circular economy aspects

4. Conclusion and outlook

References

- Australian government, Critical Minerals Strategy 2023–2030. Australia, 2023. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15858-2022-critical-minerals-strategy.

- Canadian government, Canada’s Critical Minerals Strategy. Canada, 2022. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15869-critical-minerals-strategy-discussion-paper.

- Canadian government, Canadian Minerals and Metals Plan. Canada, 2019. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15700-the-canadian-minerals-and-metals-plan.

- Chinese government, 14th FYP for Raw Material Industry Development. People’s Republic of China, 2021. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/14702-14th-fyp-for-raw-material-industry-development.

- Chinese government, National Plan for Mineral Resources (2016-2020). People’s Republic of China, 2016. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15519-national-plan-for-mineral-resources-2016-2020.

- European Commission, Raw Materials Initiative. EU (European Union), 2008. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15696-european-raw-materials-initiative.

- European Commission, European Action Plan on Critical Raw Materials. EU (European Union), 2020. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15695-european-action-plan-on-critical-raw-materials.

- Finnish government, Finland’s Minerals Strategy. Finland, 2011. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/16740-finlands-minerals-strategy-minerals-list.

- French government, Resources for France Plan. France, 2018. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15650-resources-for-france-plan.

- German government, Raw materials strategy of the Federal Government: Securing a sustainable supply of non-energy mineral raw materials for Germany. Germany, 2010. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15266-raw-materials-strategy-of-the-federal-government-securing-a-sustainable-supply-of-non-energy-mineral-raw-materials-for-germany.

- German government, Raw materials strategy of the Federal Government: Securing a sustainable supply of non-energy mineral raw materials for Germany, updated. 2019. Accessed: Dec. 03, 2023. [Online]. Available: https://www.iea.org/policies/15266-raw-materials-strategy-of-the-federal-government-securing-a-sustainable-supply-of-non-energy-mineral-raw-materials-for-germany.

- Indian government, Critical Non-Fuel Mineral Resources for India’s Manufacturing Sector. India, 2016. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/16057-critical-non-fuel-mineral-resources-for-indias-manufacturing-sector.

- Japan Cabinet Office, Guidelines for Securing Resources (資源確保指針). Japan, 2008.

- Japanese government, Procurement Strategy of rare metals. Japan, 2009. Accessed: Nov. 28, 2023. [Online]. Available: https://warp.da.ndl.go.jp/info:ndljp/pid/6086248/www.meti.go.jp/press/20090728004/20090728004.html.

- Japanese government, Procurement Strategy of Natural Resources. Japan, 2012. Accessed: Nov. 28, 2023. [Online]. Available: https://warp.da.ndl.go.jp/info:ndljp/pid/8556468/www.enecho.meti.go.jp/policy/shinenseisaku2.pdf.

- Japanese government, International Resource Strategy - National stockpiling system. Japan, 2020. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/16639-international-resource-strategy-national-stockpiling-system.

- Japanese government, Sixth Strategic Energy Plan - 2050 Carbon neutral. Japan, 2022. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/14391-sixth-strategic-energy-plan-2050-carbon-neutral.

- Korean government, New national strategies for securing strategic minerals for Korea. Korea, 2023. Accessed: Nov. 29, 2023. [Online]. Available: https://www.jetro.go.jp/biznews/2023/03/bf06360b00e2700b.html.

- New Zealand government, Responsibility Delivering Value: A Minerals and Petroleum Resource Strategy for Aotearoa New Zealand. New Zealand, 2019. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15880-responsibility-delivering-value-a-minerals-and-petroleum-resource-strategy-for-aotearoa-new-zealand.

- Spanish government, Roadmap for the sustainable management of mineral raw materials. Spain, 2021. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/16806-roadmap-for-the-sustainable-management-of-mineral-raw-materials.

- UK government, Resource Security Action Plan. United Kingdom, 2012. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15267-resource-security-action-plan.

- UK government, Resilience for the future: The UK’s critical minerals strategy. United Kingdom, 2023. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/16069-resilience-for-the-future-the-uks-critical-minerals-strategy.

- US government, Critical Materials Strategy. United States of America, 2010. Accessed: Nov. 28, 2023. [Online]. Available: https://www.osti.gov/servlets/purl/1000846.

- US government, Critical Minerals and Materials: US Department of Energy’s Strategy to Support Domestic Critical Mineral and Material Supply Chains. United States of America, 2021. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15533-critical-minerals-and-materials-us-department-of-energys-strategy-to-support-domestic-critical-mineral-and-material-supply-chains.

- US government, Final List of Critical Minerals 2018. 2018. Accessed: Dec. 03, 2023. [Online]. Available: https://www.federalregister.gov/documents/2018/05/18/2018-10667/final-list-of-critical-minerals-2018.

- European Commission, 2020 EU Critical Raw Materials List. EU (European Union), 2020. Accessed: Nov. 28, 2023. [Online]. Available: https://www.iea.org/policies/15274-the-2020-eu-critical-raw-materials-list.

- METI(Ministry of Economy Trade and Industry Japan), Initiatives to ensure stable supply of critical minerals. Tokyo, 2023. Accessed: Dec. 03, 2023. [Online]. Available: https://www.meti.go.jp/policy/economy/economic_security/metal/torikumihoshin.pdf.

- NRC (National Research Council), Minerals, critical minerals, and the U.S. economy. National Academies Press, 2008. [CrossRef]

- Ellen MacArthur Foundation, “CIRCULAR ECONOMY TOWARDS THE Economic and business rationale for an accelerated transition,” 2013. Accessed: Dec. 03, 2023. [Online]. Available: https://emf.thirdlight.com/file/24/xTyQj3oxiYNMO1xTFs9xT5LF3C/Towards%20the%20circular%20economy%20Vol%201%3A%20an%20economic%20and%20business%20rationale%20for%20an%20accelerated%20transition.pdf.

- M. Lewandowski, “Designing the business models for circular economy-towards the conceptual framework,” Sustainability (Switzerland), vol. 8, no. 1. MDPI, 2016. [CrossRef]

- P. Ghisellini, C. Cialani, and S. Ulgiati, “A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems,” J Clean Prod, vol. 114, pp. 11–32, Feb. 2016. [CrossRef]

- J. Potting, M. Hekkert, E. Worrell, and A. Hanemaaijer, “Circular economy: Measuring innovation in the product chain policy report,” Jan. 2017. Accessed: Dec. 04, 2023. [Online]. Available: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf.

- ISO/TC323, ISO/DIS 59004 Circular Economy – Terminology, Principles and Guidance for Implementation. 2023. [Online]. Available: www.iso.org.

- M. Nanjo, “Urban mine, new resources for the year 2000 and beyond,” Bulletin of the Research Institute of Mineral Dressing and Metallurgy, Tohoku University, vol. 43, no. 2, pp. 239–251, 1988, Accessed: Dec. 02, 2023. [Online]. Available: http://hdl.handle.net/10097/00114635.

- UNEP IRP (United Nations Environment Programme. International Resource Panel.), Metal recycling : opportunities, limits, infrastructure. 2013. Accessed: Dec. 03, 2023. [Online]. Available: https://www.resourcepanel.org/sites/default/files/documents/document/media/e-book_metals_report2b_recyclingopportunities_130919.pdf.

- National diet of Japan, Basic Act on Establishing a Sound Material-Cycle Society. Japan, 2000. Accessed: Dec. 03, 2023. [Online]. Available: https://www.japaneselawtranslation.go.jp/ja/laws/view/3799.

- National diet of Japan, Act on the Promotion of Effective Utilization of Resources Japan, 1991. Accessed: Nov. 27, 2023. [Online]. Available: https://www.japaneselawtranslation.go.jp/ja/laws/view/3819.

- National diet of Japan, Act on Recycling of Specified Kinds of Home Appliances. Japan, 2012. Accessed: Nov. 27, 2023. [Online]. Available: https://elaws.e-gov.go.jp/document?lawid=410AC0000000097_20200401_429AC0000000061.

- National diet of Japan, Act on Promotion of Recycling of Small Waste Electrical and Electronic Equipment. Japan, 2012. Accessed: Nov. 27, 2023. [Online]. Available: https://www.japaneselawtranslation.go.jp/ja/laws/view/3209.

- National diet of Japan, Act on Recycling of End-of-Life Automobiles. Japan, 2002. Accessed: Nov. 27, 2023. [Online]. Available: https://www.japaneselawtranslation.go.jp/ja/laws/view/3829.

- MURC (Mitsubishi UFJ Research and Consulting) , “Stock and flow analysis on mineral resources: lithium and nickel,” Tokyo, Mar. 2023. Accessed: Dec. 03, 2023. [Online]. Available: https://mric.jogmec.go.jp/wp-content/uploads/2023/05/survey_mineral_recycling_flow_stock_r4.pdf.

- MURC (Mitsubishi UFJ Research and Consulting) , “Stock and flow analysis on mineral resources: copper and rare earths,” Tokyo, Mar. 2022. Accessed: Dec. 03, 2023. [Online]. Available: https://mric.jogmec.go.jp/wp-content/uploads/2022/04/survey_mineral_recycling_flow_stock.pdf.

- JOGMEC (Japan Organization for Metals and Energy Security) , “Material flows of mineral resources 2021,” Tokyo, Mar. 2023. Accessed: Dec. 03, 2023. [Online]. Available: https://mric.jogmec.go.jp/report/?category%5B%5D=material_flow.

- European Commission. Joint Research Centre., Towards recycling indicators based on EU flows and raw materials system analysis data : supporting the EU-28 raw materials and circular economy policies through RMIS. 2018.

- J. Kirchherr, D. Reike, and M. Hekkert, “Conceptualizing the circular economy: An analysis of 114 definitions,” Resources, Conservation and Recycling, vol. 127. Elsevier B.V., pp. 221–232, 2017. [CrossRef]

- S. Murakami, K. Shimizu, C. Tokoro, and T. Nakamura, “Role of Resource Circularity in Carbon Neutrality,” Sustainability (Switzerland), vol. 14, no. 24, Dec. 2022. [CrossRef]

- S. Murakami, M. Yamanoi, T. Adachi, G. Mogi, and J. Yamatomi, “Material Flow Accounting for Metals in Japan,” Mater Trans, vol. 45, no. 11, pp. 3184–3193, 2004.

- S. Nakamura and K. Nakajima, “Waste Input-Output Material Flow Analysis of Metals in the Japanese Economy,” Mater Trans, vol. 46, no. 12, pp. 2250–2253, 2005.

- H. Ohno, Y. Fukushima, K. Matsubae, K. Nakajima, and T. Nagasaka, “Revealing final destination of special steel materials with input- output-based material flow analysis,” ISIJ International, vol. 57, no. 1, pp. 193–199, 2017. [CrossRef]

- H. Ohno, K. Matsubae, K. Nakajima, K. Nansai, Y. Fukushima, and T. Nagasaka, “Consumption-based accounting of steel alloying elements and greenhouse gas emissions associated with the metal use: the case of Japan,” J Econ Struct, vol. 5, no. 1, Dec. 2016. [CrossRef]

- S. Nakamura, K. Nakajima, Y. Kondo, and T. Nagasaka, “The Waste Input-Output Approach to Materials Flow Analysis Concepts and Application to Base Metals,” Journal of Industry Ecology, vol. 11, no. 4, pp. 50–63, 2007, [Online]. Available: www.f.waseda.jp/nakashin.

- P. Nuss, H. Ohno, W. Q. Chen, and T. E. Graedel, “Comparative analysis of metals use in the United States economy,” Resour Conserv Recycl, vol. 145, pp. 448–456, Jun. 2019. [CrossRef]

- H. Ohno, K. Matsubae, K. Nakajima, S. Nakamura, and T. Nagasaka, “Unintentional flow of alloying elements in steel during recycling of end-of-life vehicles,” J Ind Ecol, vol. 18, no. 2, pp. 242–253, 2014. [CrossRef]

- H. Ohno, K. Matsubae, K. Nakajima, Y. Kondo, S. Nakamura, and T. Nagasaka, “Toward the efficient recycling of alloying elements from end of life vehicle steel scrap,” Resour Conserv Recycl, vol. 100, pp. 11–20, Apr. 2015. [CrossRef]

- H. Ohno, P. Nuss, W. Q. Chen, and T. E. Graedel, “Deriving the Metal and Alloy Networks of Modern Technology,” Environ Sci Technol, vol. 50, no. 7, pp. 4082–4090, Apr. 2016. [CrossRef]

- MIC (Ministry of Industrial Affairs and Communications Japan), 2015 Input-Output Table for Japan, 2015th ed. Tokyo: Ministry of Industrial Affairs and Communications, Japan, 2020.

- CMAJ (Catalyst Manufacturers Association Japan) , Catalyst statistics 2015. Tokyo, 2016.

- EMAJ (Electronic Materials Manufacturers Association of Japan) , Table of permanent magnet applications. 1997.

- JOGMEC (Japan Organization for Metals and Energy Security) , “Material flows of mineral resources 2016,” Tokyo, Jan. 2017.

- JSNM (Japan Society of Newer Metals) , Rare earths demand statistics 2015. Tokyo, 2016.

- METI (Ministry of Economy Trade and Industry Japan), Current Survey of Supply and Demand of Non-ferrous Metals 2015. 2016.

- METI (Ministry of Economy Trade and Industry Japan), Current Survey of Production 2015 - Mineral resources, petroleum products, ceramics and building materials. 2016.

- METI (Ministry of Economy Trade and Industry Japan), Current Survey of Production 2015 - Machinery . 2016.

- METI (Ministry of Economy Trade and Industry Japan), Current Survey of Production 2015 - Iron and Steel, non-ferrous metals and fabricated metals . 2016.

- METI (Ministry of Economy Trade and Industry Japan), Current Survey of Production 2015 - Chemical industry. Tokyo, 2016.

- METI (Ministry of Economy Trade and Industry Japan), Census of Manufactures 2015 . Tokyo, 2017.

- MOF (Ministry of Finance Japan), Trade statistics 2015 Tokyo, 2016.

- Rare Metal News, Industrial Rare Metals Annual Review 2016. Tokyo, 2016.

- Y. Kobayashi, “Felite magnet,” The Special Steel, vol. 68, no. 6, Jul. 2019.

- METI (Ministry of Economy Trade and Industry Japan) and MOE (Ministry of Economy Trade and Industry Japan), “Draft framework of an incentive system for automobiles using advanced recycled materials ,” Tokyo, Sep. 2017.

- MURC (Mitsubishi UFJ Research and Consulting), “Domestic demand-supply structure of non-ferrous metals and current industry status of major resource countries ” Tokyo, 2010.

- Yano Research Institute, “Current state of metals recycling originated from end-of-life vehicles ,” Tokyo, Mar. 2015.

- MURC (Mitsubishi UFJ Research and Consulting) , “Current distribution of rare metals,” Tokyo, Feb. 2020.

- E. A. Olivetti, G. Ceder, G. G. Gaustad, and X. Fu, “Lithium-Ion Battery Supply Chain Considerations: Analysis of Potential Bottlenecks in Critical Metals,” Joule, vol. 1, no. 2. Cell Press, pp. 229–243, Oct. 11, 2017. [CrossRef]

- S. Nakamura and K. Nakajima, “Waste Input-Output Material Flow Analysis of Metals in the Japanese Economy,” Mater Trans, vol. 46, no. 12, pp. 2250–2553, 2005.

- K. Nakajima et al., “Simultaneous material flow analysis of nickel, chromium, and molybdenum used in alloy steel by means of input-output analysis,” Environ Sci Technol, vol. 47, no. 9, pp. 4653–4660, May 2013. [CrossRef]

- K. Nakajima, K. Nansai, K. Matsubae, M. Tomita, W. Takayanagi, and T. Nagasaka, “Global land-use change hidden behind nickel consumption,” Science of the Total Environment, vol. 586, pp. 730–737, May 2017. [CrossRef]

- K. Nakajima et al., “Global distribution of material consumption: Nickel, copper, and iron,” Resour Conserv Recycl, vol. 133, pp. 369–374, Jun. 2018. [CrossRef]

- S. Nakamura, Y. Kondo, K. Nakajima, H. Ohno, and S. Pauliuk, “Quantifying Recycling and Losses of Cr and Ni in Steel Throughout Multiple Life Cycles Using MaTrace-Alloy,” Environ Sci Technol, vol. 51, no. 17, pp. 9469–9476, Sep. 2017. [CrossRef]

- K. Nansai et al., “Global flows of critical metals necessary for low-carbon technologies: The case of neodymium, cobalt, and platinum,” Environ Sci Technol, vol. 48, no. 3, pp. 1391–1400, Feb. 2014. [CrossRef]

- K. Nansai, K. Nakajima, S. Kagawa, Y. Kondo, Y. Shigetomi, and S. Suh, “Global mining risk footprint of critical metals necessary for low-carbon technologies: The case of neodymium, cobalt, and platinum in Japan,” Environ Sci Technol, vol. 49, no. 4, pp. 2022–2031, Feb. 2015. [CrossRef]

- K. Nansai et al., “The role of primary processing in the supply risks of critical metals,” Economic Systems Research, vol. 29, no. 3, pp. 335–356, Jul. 2017. [CrossRef]

- K. Nansai et al., “Nexus between economy-wide metal inputs and the deterioration of sustainable development goals,” Resour Conserv Recycl, vol. 149, pp. 12–19, Oct. 2019. [CrossRef]

- H. Ohno et al., “Optimal Recycling of Steel Scrap and Alloying Elements: Input-Output based Linear Programming Method with Its Application to End-of-Life Vehicles in Japan,” Environ Sci Technol, vol. 51, no. 22, pp. 13086–13094, Nov. 2017. [CrossRef]

- W. Shi, I. Daigo, Y. Matsuno, and Y. Adachi, “Substance Flow Analysis of Dysprosium in Japan,” Japan Institute of Metals, 2010.

- Y. Seo and S. Morimoto, “Comparison of dysprosium security strategies in Japan for 2010-2030,” Resources Policy, vol. 39, no. 1, pp. 15–20, Mar. 2014. [CrossRef]

- Y. K. H. O. A. Aoki, “The safety and evaluation test of Lithium-Ion Secondary Battery,” in Microelectronics Symposium 2012, Osaka, Sep. 2012. Accessed: Dec. 04, 2023. [Online]. Available: https://www.jstage.jst.go.jp/article/mes/22/0/22_187/_pdf/-char/ja.

- US Geological Survey, Mineral Commodity Summaries, 2023rd ed. US Geological Survey, 2023. Accessed: Dec. 04, 2023. [Online]. Available: https://www.usgs.gov/centers/national-minerals-information-center/commodity-statistics-and-information.

- Ginya Adachi, Introduction to Chemistry of Rare Earths. Kyoto: Kagaku-Dojin Publishing Company,INC, 2015.

- US Geological Survey, Mineral Yearbook Volume I - Metals and Minerals, 2023rd ed. 2022. Accessed: Dec. 04, 2023. [Online]. Available: https://www.usgs.gov/centers/national-minerals-information-center/commodity-statistics-and-information.

- US Geological Survey, Critical mineral resources of the United States—Economic and environmental geology and prospects for future supply. US Geological Survey, 2017. Accessed: Dec. 05, 2023. [Online]. Available: https://pubs.usgs.gov/publication/pp1802.

- US Geological Survey, Mineral Commodity Summaries, 2009th ed. 2009. Accessed: Dec. 05, 2023. [Online]. Available: https://www.usgs.gov/centers/national-minerals-information-center/commodity-statistics-and-information#R.

- T. Ota, “Resource economics on rare earths industry,” 2010. Accessed: Dec. 04, 2023. [Online]. Available: https://ndlonline.ndl.go.jp/#!/detail/R300000001-I000011114632-00.

- B. Achzet and C. Helbig, “How to evaluate raw material supply risks-an overview,” Resources Policy, vol. 38, no. 4, pp. 435–447, 2013. [CrossRef]

- C. Helbig, L. Wietschel, A. Thorenz, and A. Tuma, “How to evaluate raw material vulnerability - An overview,” Resources Policy, vol. 48, pp. 13–24, Jun. 2016. [CrossRef]

- S. Owada, T. Komuro, T. Ono, and R. Hayashi, “Concentration of Minor Rare Metals form E-scraps by Combining New Comminution and Physical Separation Processes,” in 12th International Symposium on East Asian Resources Recycling Technology (EARTH2013), Hunan, China, 2013.

| Original sectors | Subdivided sectors in this study | Evaluated elements | ||

| Miscellaneous ores (domestic production only) | 160,237* | - Iron ores (imported) - Copper ores (imported) - Nickel ores (imported) - Miscellaneous ores (domestic production and imported others) |

130,954,875 t 4,815,914 t 4,394,770 t 367,961* |

Fe Cu Ni - |

| Miscellaneous industrial inorganic chemicals | 925461 * | - Lithium carbonate and lithium hydrocarbonate (imported) - Lithium bromide - Lithium chloride - Cobalt compounds - Yttrium oxide - Cerium oxide - Miscellaneous industrial inorganic chemicals (others) |

20,921 t 2,000 t 615 t 402 t 951 t 12,365 t 898,500* |

Li Li Li Co Y (REE) Ce (REE) - |

| Miscellaneous final chemical products | 2,002,522* | - Desulfurization catalyst - Ternary catalyst - Ferrocerium (imported) - Miscellaneous final chemical products (others) |

16,496 t 9,908 t 958 t 1,802,279* |

Co Y, La, Ce, Nd (REE) Ce - |

| Sheet glass and safety glass | 501,284* | - Ultraviolet protection glass - Sheet glass and safety glass (others) |

12,989 t 488,295* |

Ce (REE) - |

| Miscellaneous glass products | 542,317* | - Heat-resistant glass (pipes and bars) - Optical lenses - Heat-resistant glass (others) - Miscellaneous glass products (others) |

2,276 t 7,648 t 2,276 t 469,457* |

Li Y, La, Ce Li - |

| Abrasive and its products | 227,375* | - Chemical mechanical polishing powder - Abrasive and its products (others) |

2,800 t 226,255* |

Ce - |

| Pig iron | 3,033,611* | - Pig iron | 81,010,826 t | Fe |

| Ferro-alloys | 338,026* | - Ferro-alloys | 1,054,265 t | Fe |

| Crude steel (converters) | 4,449,985* | - Crude steel (converters) | 81,081,155 t | Fe |

| Crude steel (electric furnaces) | 1,481,049* | - Crude steel (electric furnaces) | 24,053,223 t | Fe |

| Scrap iron | 394,010* | - Scrap iron | 39,956,970 t | Fe |

| Copper | 1,027,515* | - Copper matte (imported) - Copper (except copper matte) |

4,924 t 1,482,601 t |

Cu Cu |

| Aluminum (including regenerated aluminum) | 664,369* | - Aluminum oxide and aluminum hydroxide - Aluminum (imported) (primary) - Aluminum (secondary) |

24,796 t 1,459,036 t 1,291,211 t |

Al Al Al |

| Miscellaneous non-ferrous metals | 1,500,558* | - Smelting cold materials (scrap copper) - Lithium metal - Super alloy - Nickel matte and mixed sulfide - Cobalt matte (imported) - Cobalt metal - Lanthanum oxide - Mischmetal - Neodymium oxide - Neodymium metal and ferro-neodymium - Dydimium - Dysprosium oxide - Dysprosium metal and ferro-dysprosium - Miscellaneous non-ferrous metals (others) |

207,075 t 68 t 4,679 t 93,957 t 0 t 4,260 t 2,264 t 2,409 t 670 t 0 t 3,463 t 0 t 437 t 1,327,729* |

Cu Li Co Co Co Co La (REE) La, Ce (REE) Nd (REE) Ne (REE) Nd (REE) Dy (REE) Dy (REE) - |

| Non-ferrous metal scrap | 426,784* | - Dross - Scrap aluminum - Scrap copper - Scrap cobalt - Scrap cemented carbide - Scrap magnet - Non-ferrous metal scrap (others) |

79,734 t 1,161,769 t 1,178,920 t 1,278 t 0 t 0 t 189,496* |

Al Al Cu Co Co Nd, Dy (REE) - |

| Miscellaneous non-ferrous metal products | 822,523* | - Super alloy products - Miscellaneous non-ferrous metal products (others) |

4,679 t 791,168* |

Co - |

| Plumbing accessories, powder metallurgy products and tools | 949,085* | - Cemented carbide - Plumbing accessories, powder metallurgy products and tools (others) |

8,128 t 695,902* |

Co - |

| Machinists' precision tools | 882,958* | - Cemented carbide tolls - Machinists' precision tools (others) |

8,128 t 629,775* |

Co |

| Liquid crystal panel | 2,190,471* | - Liquid crystal panel | 496,523,000 units |

Y, La, Ce (REE) |

| Flat-panel and electron tubes | 72,693* | - Flat-panel and electron tubes | 1,228,672 units |

Y, La, Ce (REE) |

| Miscellaneous electronic components | 5,330,247* | - Ceramic capacitors - Miscellaneous electronic components (others) |

4,118 t 4,863,518* |

La, Nd, Dy (REE) - |

| Rotating electrical equipment | 1,249,851* | - DC motors using LaCo ferrite magnet - DC motors using NdFeB magnet - Rotating electrical equipment (others) |

240,383,897 units 3,210,548 units 726,857* |

Co, La (REE) Nd, Dy (REE) - |

| Electric bulbs | 297,768* | - Three-band fluorescent lamps - Electric bulbs (others) |

76,523,500 Units 263,265* |

Y, La, Ce (REE) - |

| Batteries | 1,053,412* | - Lithium primary batteries - Lithium-ion rechargeable batteries (This sector includes lithium cathodes and electrolytes.) - Nickel-metal hydride rechargeable batteries - Batteries (others) |

710,161,000 Units 983,242,000 units 365,003,000 units 537,540* |

Li Li, Co La, Ce (REE) - |

| Miscellaneous electrical devices and parts | 750,999* | - LaCo ferrite magnet - NdFeB magnet - Miscellaneous electrical devices and parts (others) |

8,668 t 11,970 t 664,598* |

Co, La (REE) Nd, Dy (REE) - |

| Category | Sector's name | Evaluated elements |

| Resources | - Miscellaneous ores (domestic production and imported others) | - |

| - Dysprosium oxide | Dy (REE) | |

| Materials | - Iron ores (imported) - Copper ores (imported) - Nickel ores (imported) |

Fe Cu Ni |

| - Lithium carbonate and lithium hydrocarbonate (imported) - Yttrium oxide - Cerium oxide |

Li Y (REE) Ce (REE) |

|

| - Ferrocerium (imported) | Ce | |

| - Ferro-alloys | Fe | |

| - Scrap iron | Fe | |

| - Copper matte (imported) | Cu | |

| - Aluminum oxide and aluminum hydroxide - Aluminum (imported) (primary) |

Al Al |

|

| - Nickel matte and mixed sulfide - Cobalt matte (imported) - Lanthanum oxide - Mischmetal (La) - Mischmetal (Ce) - Neodymium oxide - Neodymium metal and ferro-neodymium - Dydimium - Dysprosium metal and ferro-dysprosium |

Co Co La (REE) La (REE) Ce (REE) Nd (REE) Ne (REE) Nd (REE) Dy (REE) |

|

| - Dross - Scrap aluminum - Scrap copper - Scrap cobalt - Scrap cemented carbide - Scrap magnet (Nd) - Scrap magnet (Dy) |

Al Al Cu Co Co Nd (REE) Dy (REE) |

|

| Products | All the other sectors | - |

| Sectors | Composition data | ||||||||||

| Fe | Cu | Al | Li | Co | Y | La | Ce | Nd | Dy | ||

| Ternary catalyst (t/t) |

E | 0.187 | 0.011 | 0.205 | 0.000 | 0.000 | 0.005 | 0.004 | 0.371 | 0.011 | 0.000 |

| A (a) | - | - | - | - | - | 0.002 | 0.003 | 0.320 | - | - | |

| Optical lenses (t/t) |

E | 0.069 | 0.003 | 0.009 | 0.000 | 0.000 | 0.008 | 0.035 | 0.000 | 0.000 | 0.000 |

| A (a) | - | - | - | - | - | 0.004 | 0.020 | - | - | - | |

| Cemented carbide tools (t/t) |

E | 0.283 | 0.006 | 0.033 | 0.000 | 0.044 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| A (d) | - | - | - | - | 0.049 | - | - | - | - | - | |

| Lithium-ion rechargeable batteries (g/unit) |

E | 56.1 | 6.5 | 5.1 | 1.8 | 5.9 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| A (b, c) | - | - | - | 1.4 | 5.8 | - | - | - | - | - | |

| LaCo magnet (t/t) |

E | 0.821 | 0.001 | 0.002 | 0.000 | 0.009 | 0.000 | 0.113 | 0.000 | 0.000 | 0.000 |

| A (d, e) | 0.850 | - | - | - | 0.009 | - | 0.103 | -- | - | - | |

| NdFeB magnet (t/t) |

E | 0.735 | 0.002 | 0.003 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.217 | 0.031 |

| A (f) | 0.750 | - | - | - | - | - | - | - | 0.225 | 0.030 | |

| Sectors | Composition (kg per unit of Passenger motor cars) | |||||||||

| Fe | Cu | Al | Li | Co | Y | La | Ce | Nd | Dy | |

| Estimated (this study) |

1,114 | 46 | 75 | 0.01 | 0.02 | 0.01 | 0.02 | 0.24 | 0.39 | 0.06 |

| Actual data [70,72] |

1,169 | 26 | 99 | 0.24 | 0.12 | |||||

| Rare earth element (atomic symbol) | Major application |

| *Lanthanum (La) | LaCo ferrite magnet, Optical glass, Fluid catalytic cracking (FCC) catalyst, Ceramic capacitor, Phosphor |

| *Cerium (Ce) | Promotor for automobile exhaust gas catalyst, Chemical mechanical polishing (CMP) powder, Ultraviolet protection glass, Fluid catalytic cracking (FCC) catalyst |

| Praseodymium (Pr) | Coloring (green) material for glass, Chromogenic (yellow) material for ceramics, Ceramic capacitor |

| *Neodymium (Nd) | NdFeB magnet, Ceramic capacitor |

| Promethium | (Few industrial application) |

| Samarium (Sm) | SmCo magnet |

| Europium (Eu) | Phosphor (blue and red), Optical glass |

| Gadolinium (Ga) | Optical glass, Neutron-absorbing material |

| Terbium (Tb) | NdFeB magnet, Phosphor (green), Optical glass, Mageto-optical disk target |

| *Dysprosium (Dy) | NdFeB magnet, Ceramic capacitor |

| Holmium (Ho) | (Few industrial applications) |

| Erbium (Er) | |

| Thulium (Tm) | |

| Ytterbium (Yb) | |

| Lutetium (Lu) | |

| *Yttrium (Y) | Phospher (red), Optical glass, Stabilizing material for zirconia |

| Scandium (Sc) | Light aluminum scandium alloys |

| Rare earth element (atomic symbol) | Major domestic final demands (applications) | |||||||||

| Final products | Inter. products | |||||||||

| Three band fluorescent lamps | Mobile phones and PCs* | Cars* | Household electric appliances* | Optical instruments | Construction* | Robots | Nickel-metal hydride batteries | DC motors* | ||

| Yttrium (Y) | ✓ | ✓ | ✓ | |||||||

| Lanthanum (La) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Cerium (Ce) | ✓ | ✓ | ✓ | |||||||

| Neodymium (Nd) | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Dysprosium (Dy) | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).