Submitted:

06 December 2023

Posted:

07 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Instrumental texture

2.3. Sensory analysis

2.3.1. Sample preparation and presentation

2.3.2. Acceptance analysis

2.3.3. Check-All-That-Apply (CATA)

2.3.4. Projective Mapping (Napping)

2.4. Statistical analyses

3. Results and Discussion

3.1. Instrumental texture analysis

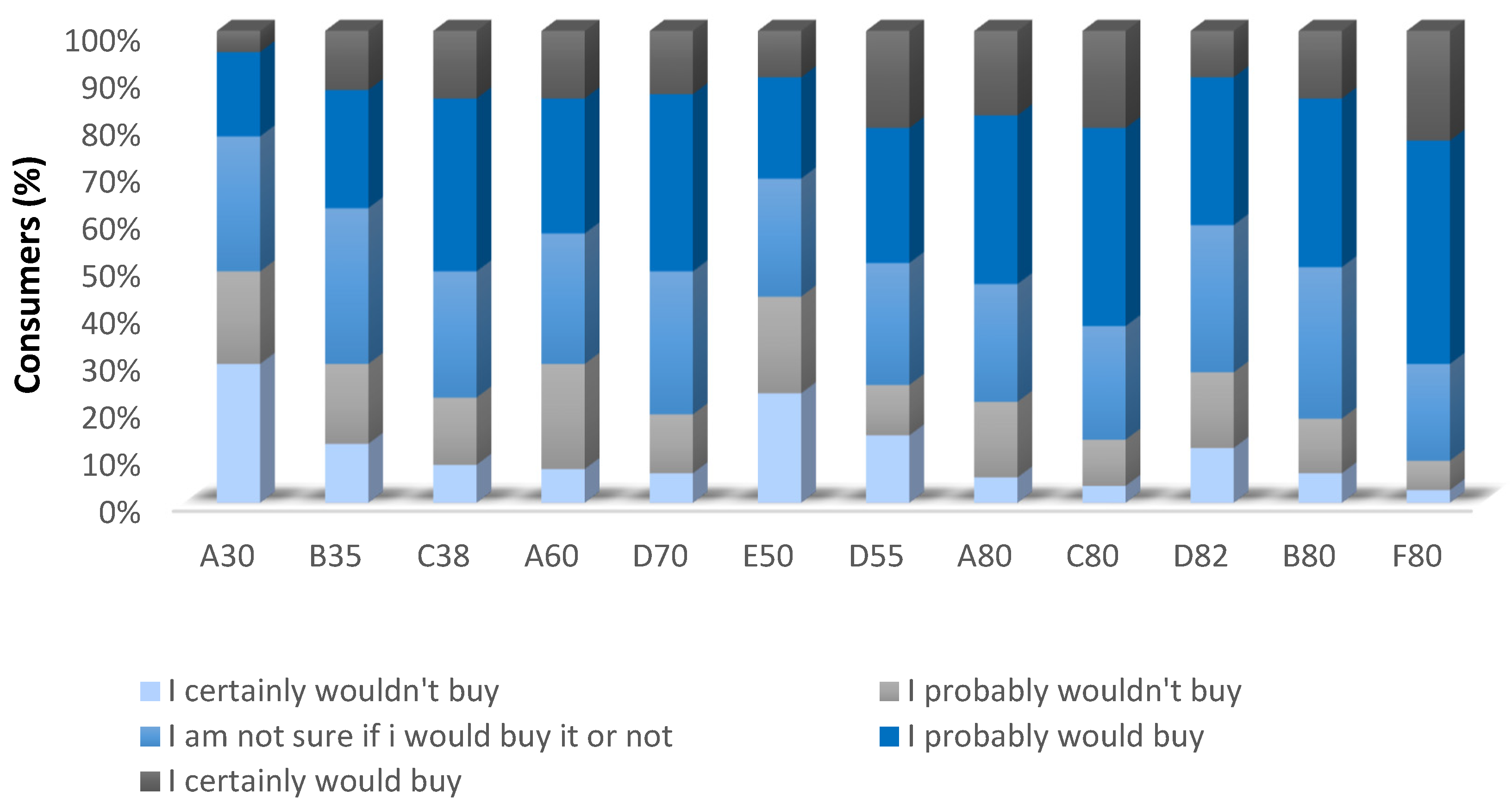

3.2. Acceptance test

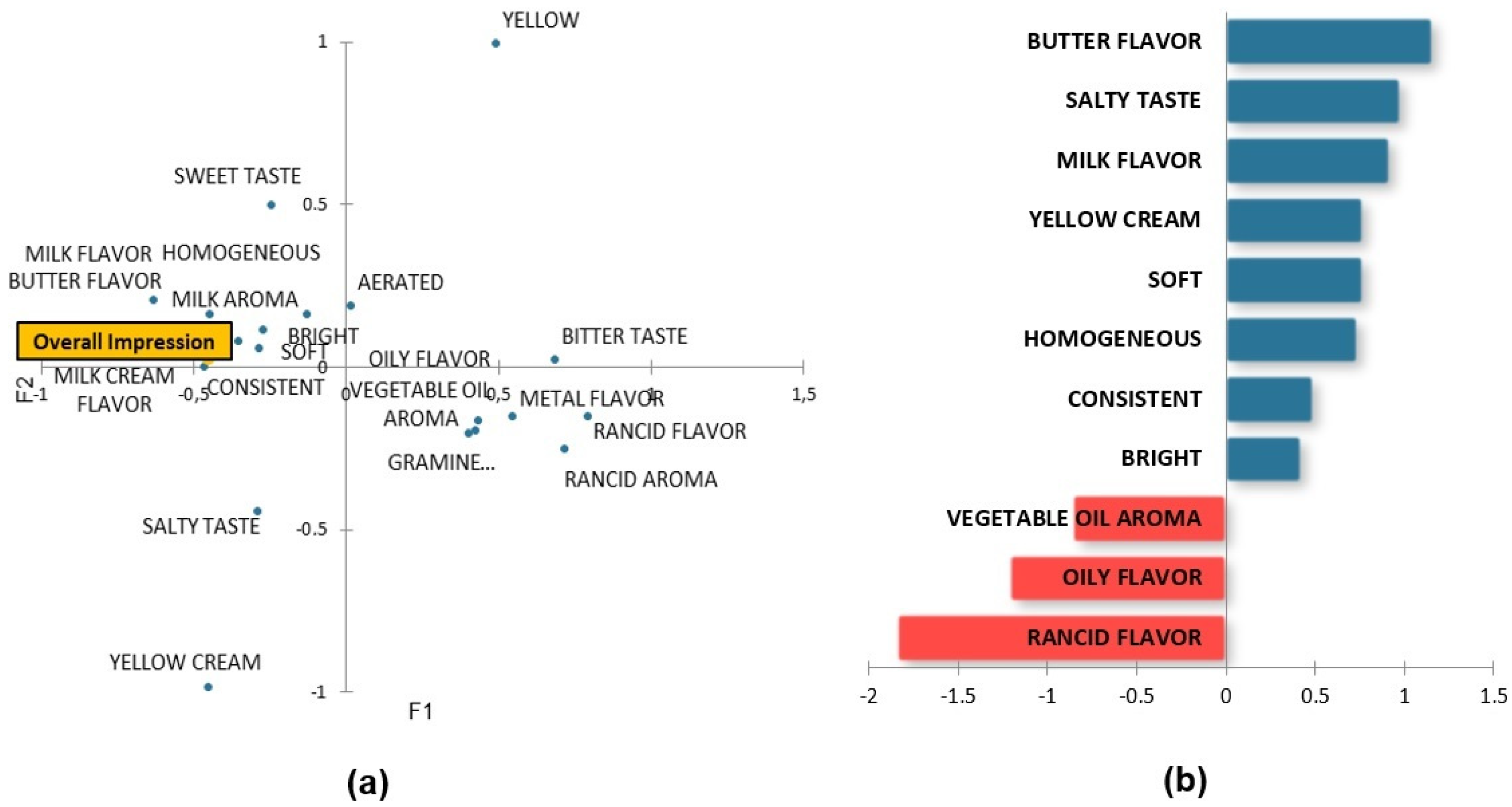

3.3. Check-All-That-Apply (CATA)

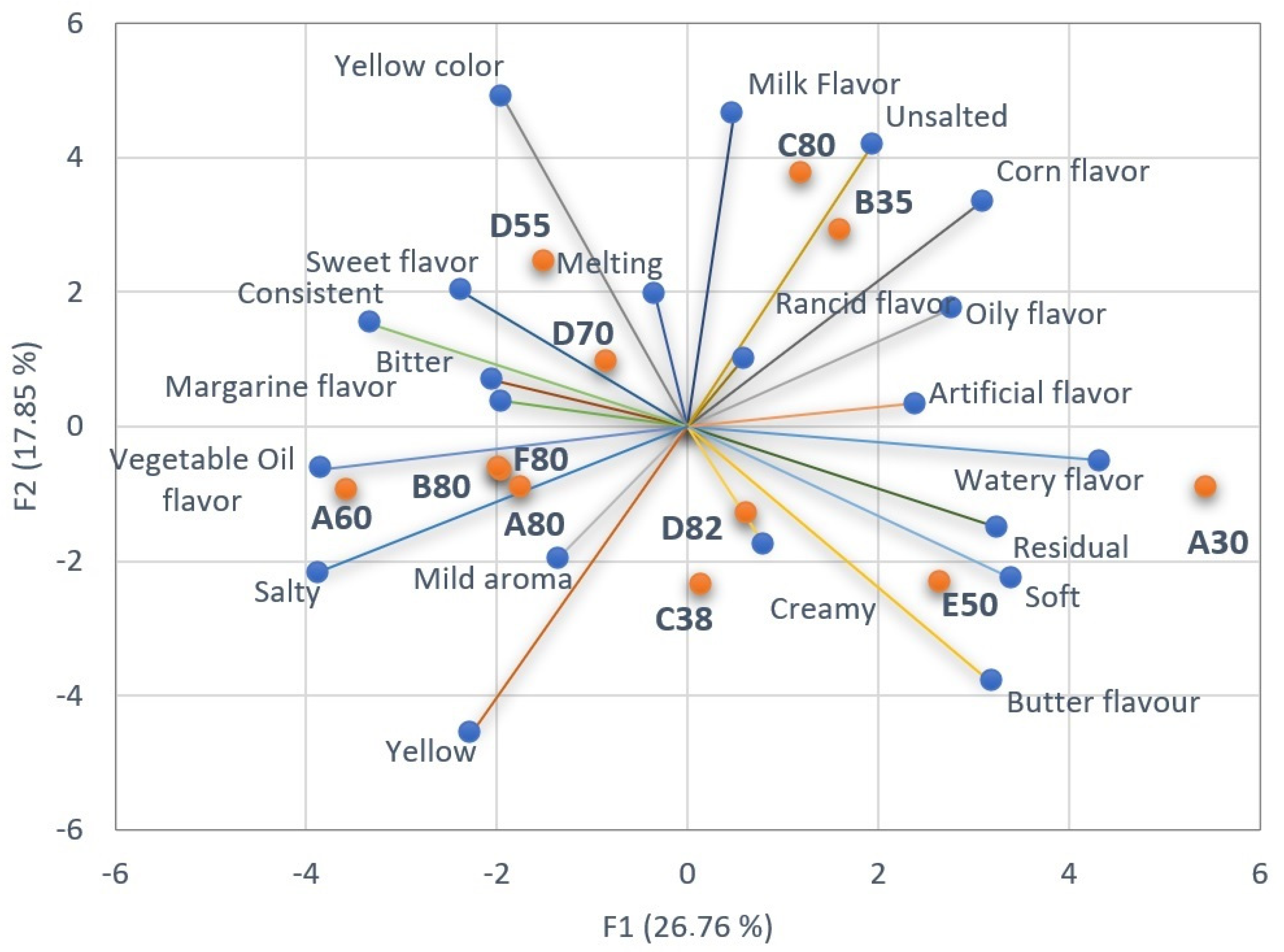

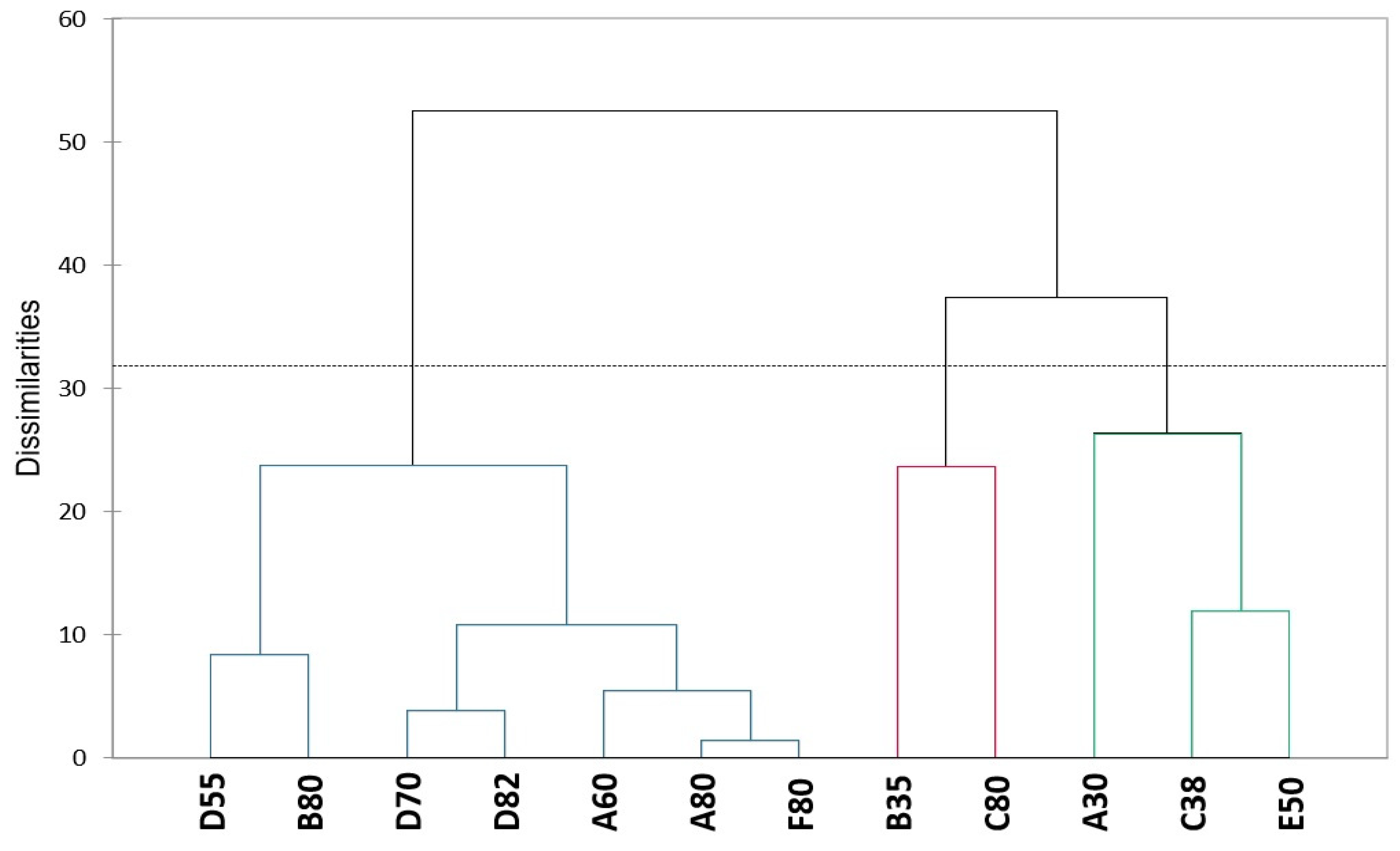

3.4. Projective Mapping (Napping)

4. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

References

- Rajah, K.K. Spreadable products. In Fats in Food Technology, 2nd ed.; Rajah, K.K., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; pp. 213–252. [Google Scholar] [CrossRef]

- Aleksić, A.D.; Gordić, D.R.; Šušteršič, V.M.; Babić, M.J. Application of fat trap for the waste water treatment in margarine production. Desalination Water Treat. 2016, 57, 3466–3472. [Google Scholar] [CrossRef]

- Silva, T.J.; Barrera-Arellano, D.; Paula, A.; Ribeiro, B. Margarines: Historical approach, technological aspects, nutritional profile, and global trends. Food Res. Int. 2021, 147, 110486. [Google Scholar] [CrossRef] [PubMed]

- Laia, O.M.; Ghazalia, H.M.; Cho, F.; Chong, C.L. Physical and textural properties of an experimental table margarine prepared from lipase-catalysed transesterified palm stearin: Palm kernel olein mixture during storage. Food Chem. 2000, 71, 173–179. [Google Scholar] [CrossRef]

- Pădure, S. The Quantification of Fatty Acids, Color, and Textural Properties of Locally Produced Bakery Margarine. Appl. Sci. 2022, 12, 1–12. [Google Scholar] [CrossRef]

- Palzer, S. Food Structures for Nutrition, Health and Wellness. Trends Food Sci. Technol. 2009, 20, 194–200. [Google Scholar] [CrossRef]

- Chaves, K.F.; Barrera-Arellano, D.; Ribeiro, A.P.B. Potential application of lipid organogels for food industry. Food Res. Int. 2018, 105, 863–872. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Cobb, L.K.; Vesper, H.W.; Asma, S. Global Surveillance of trans-Fatty Acids. Prev. Chronic. Dis. 2019, 16, 190121. [Google Scholar] [CrossRef] [PubMed]

- U.S. Department of Agriculture; U.S. Department of Health and Human Services. Dietary Guidelines for Americans, 2020–2025, 9th ed. 2020. Available online: https://www.dietaryguidelines.gov/sites/default/files/2020-12/Dietary_Guidelines_for_Americans_2020-2025.pdf (accessed on 1 January 2023).

- U.S. Department of Agricultusre; U.S. Department of Health and Human Services. Dietary Guidelines for Americans, 2000–2005, 6th ed. 2000. Available online: https://health.gov/sites/default/files/2020-01/DGA2000.pdf (accessed on 1 January 2023).

- Weber, C.; Harnack, L.; Johnson, A.; Jasthi, B.; Pettit, J.; Stevenson, J. Nutrient comparisons of margarine/margarine-like products, butter blend products and butter in the US marketplace in 2020 post-FDA ban on partially hydrogenated oils. Public Health Nutr. 2021, 25, 1123–1130. [Google Scholar] [CrossRef]

- Fallahasgari, M.; Barzegar, F.; Abolghasem, D.; Nayebzadeh, K. An overview focusing on modification of margarine rheological and textural properties for improving physical quality. Eur. Food Res. Technol. 2023, 249, 2227–2240. [Google Scholar] [CrossRef]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food. Principles and Practices, 2nd ed.; Lawless, H.T., Heymann, H., Eds.; Springer-Science+Business Media, LLC.: Berlin/Heidelberg, Germany, 2010; Available online: http://www.amazon.com/Food-Analysis-Science-Text/dp/1441914773 (accessed on 1 January 2023).

- Dehlholm, C.; Brockhoff, B.; Meinert, L.; Aaslyng, M.D.; Bredie, W.L.P. Rapid descriptive sensory methods-Comparison of Free Multiple Sorting, Partial Napping, Napping, Flash Profiling and conventional profiling. Food Qual. Prefer. 2012, 26, 267–277. [Google Scholar] [CrossRef]

- Ares, G.; Barreiro, C.; Deliza, R.; Giménez, A.; Gámbaro, A. Application of a check-all-that-apply question to the development of chocolate milk desserts. J. Sens. Stud. 2010, 25, 67–86. [Google Scholar] [CrossRef]

- Stone, H.; Sidel, J.L. Sensory Evaluation Practices, 3rd ed.; Academic Press: Cambridge, MA, USA, 2004. [Google Scholar]

- Valentin, D.; Chollet, S.; Lelièvre, M.; Abdi, H. Quick and dirty but still pretty good: A review of new descriptive methods in food science. Int. J. Food Sci. Technol. 2012, 47, 1563–1578. [Google Scholar] [CrossRef]

- Ares, G. Methodological challenges in sensory characterization. Curr. Opin. Food Sci. 2015, 3, 1–5. [Google Scholar] [CrossRef]

- Nestrud, M.A.; Lawless, H.T. Perceptual Mapping of Apples and Cheeses Using Projective Mapping and Sorting. J. Sens. Stud. 2010, 25, 390–405. [Google Scholar] [CrossRef]

- Kennedy, J. Evaluation of Replicated Projective Mapping of Granola Bars. J. Sens. Stud. 2010, 25, 672–684. [Google Scholar] [CrossRef]

- Ross, C.F.; Weller, K.M.; Alldredge, J.R. Impact of Serving Temperature on Sensory Properties of Red Wine as Evaluated Using Projective Mapping by a Trained Panel. J. Sens. Stud. 2012, 27, 463–470. [Google Scholar] [CrossRef]

- Torri, L.; Dinnella, C.; Recchia, A.; Naes, T.; Tuorila, H.; Monteleone, E. Projective Mapping for interpreting wine aroma differences as perceived by naïve and experienced assessors. Food Qual. Prefer. 2013, 29, 6–15. [Google Scholar] [CrossRef]

- Louw, L.; Malherbe, S.; Naes, T.; Lambrechts, M.; Van Rensburg, P.; Nieuwoudt, H. Validation of two Napping techniques as rapid sensory screening tools for high alcohol products. Food Qual. Prefer. 2013, 30, 192–201. [Google Scholar] [CrossRef]

- Meyners, M.; Castura, J.C. Randomization of CATA attributes: Should attribute lists be allocated to assessors or to samples? Food Qual. Prefer. 2016, 48, 210–215. [Google Scholar] [CrossRef]

- Rogers, M.A. Novel structuring strategies for unsaturated fats—Meeting the zero-trans, zero-saturated fat challenge: A review. Food Res. Int. 2009, 42, 747–753. [Google Scholar] [CrossRef]

- Glibowski, P.; Zarzycki, P.; Krzepkowska, M.; Glibowski, P. The Rheological and Instrumental Textural Properties of Selected Table Fats. Int. J. Food Prop. 2008, 11, 678–686. [Google Scholar] [CrossRef]

- Ziarno, M.; Derewiaka, D.; Florowska, A.; Szymańska, I. Comparison of the Spreadability of Butter and Butter Substitutes. Appl. Sci. 2023, 13, 2600. [Google Scholar] [CrossRef]

- Sensory Analysis–General Guidance for the Designof Test Rooms. ISO 8589; ISO: Geneva, Switzerland, 2007.

- Meilgaard, M.C.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 5th ed.; Meilgaard, M.C., Civille, G.V., Carr, B.T., Eds.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Vidal, L.; Cadena, R.S.; Antúnez, L.; Giménez, A.; Varela, P.; Ares, G. Stability of sample configurations from projective mapping: How many consumers are necessary? Food Qual. Prefer. 2014, 34, 79–87. [Google Scholar] [CrossRef]

- Varela, P.; Ares, G. Sensory profiling, the blurred line between sensory and consumer science. A review of novel methods for product characterization. Food Res. Int. 2012, 48, 893–908. [Google Scholar] [CrossRef]

- Dooley, L.; Lee, Y.-S.; Meullenet, J.-F. The application of check-all-that-apply (CATA) consumer profiling to preference mapping of vanilla ice cream and its comparison to classical external preference mapping. Food Qual. Prefer. 2010, 21, 394–401. [Google Scholar] [CrossRef]

- Pereira, C.T.M.; Pereira, D.M.; de Medeiros, A.C.; Hiramatsu, E.Y.; Ventura, M.B.; Bolini, H.M.A. Skyr yogurt with mango pulp, fructooligosaccharide and natural sweeteners: Physical aspects and drivers of liking. LWT-Food Sci. Technol. 2021, 150, 112054. [Google Scholar] [CrossRef]

- Jaeger, S.R.; Beresford, M.K.; Paisley, A.G.; Antúnez, L.; Vidal, L.; Cadena, R.S.; Giménez, A.; Ares, G. Check-all-that-apply (CATA) questions for sensory product characterization by consumers: Investigations into the number of terms used in CATA questions. Food Qual. Prefer. 2015, 42, 154–164. [Google Scholar] [CrossRef]

- Moskowitz, H.R. Product Testing and Sensory Evaluation of Foods: Marketing and R&D Approaches; Food & Nutrition Press: Trumbull, CT, USA, 1983. [Google Scholar]

- Bolini, H.M.A.; Lima, R.S.; de Freitas, R.L.; de Medeiros, A.C. Preference Drivers for Blackberry Nectar (Rubus spp., Rosaceae) with Different Sweeteners. Foods 2023, 12, 549. [Google Scholar] [CrossRef]

- Varela, P.; Berget, I.; Hersleth, M.; Carlehög, M.; Asioli, D.; Naes, T. Projective mapping based on choice or preference: An affective approach to projective mapping. Food Res. Int. 2017, 100, 241–251. [Google Scholar] [CrossRef]

- Esmerino, E.A.; Tavares Filho, E.R.; Carr, B.T.; Ferraz, J.P.; Silva, H.L.A.; Pinto, L.P.F.; Freitas, M.Q.; Cruz, A.G.; Bolini, H.M.A. Consumer-based product characterization using Pivot Profile, Projective Mapping and Check-all-that-apply (CATA): A comparative case with Greek yogurt samples. Food Res. Int. 2017, 99, 375–384. [Google Scholar] [CrossRef]

- Kennedy, J.; Heymann, H. Projective mapping and descriptive analysis of milk and dark chocolates. J. Sens. Stud. 2009, 24, 220–233. [Google Scholar] [CrossRef]

- de Oliveira Rocha, I.F.; Bolini, H.M.A. Passion fruit juice with different sweeteners: Sensory profile by descriptive analysis and acceptance. Food Sci. Nutr. 2015, 3, 129–139. [Google Scholar] [CrossRef]

- Pagès, J. Collection and analysis of perceived product inter-distances using multiple factor analysis:Application to the study of 10 white wines from the Loire Valley. Food Qual. Prefer. 2005, 16, 642–649. [Google Scholar] [CrossRef]

- Ergönül, P.G. Solid fat contents and instrumental textural attributes of margarines sold in Turkish market. Qual. Assur. Saf. Crops Foods 2013, 5, 157–161. [Google Scholar] [CrossRef]

- Bemer, H.L.; Limbaugh, M.; Cramer, E.D.; Harper, W.J.; Maleky, F. Vegetable organogels incorporation in cream cheese products. Food Rese 2016, 85, 67–75. [Google Scholar] [CrossRef]

- Silva, T.J.; Barrera-Arellano, D.; Ribeiro, A.P.B. The impact of fatty acid profile on the physicochemical properties of commercial margarines in Brazil. J. Am. Oil Chem. Soc. 2022, 99, 469–483. [Google Scholar] [CrossRef]

- Doi, T.; Wang, M.; Mcclements, D.J. Emulsion-based control of flavor release profiles : Impact of oil droplet characteristics on garlic aroma release during simulated cooking. Food Res. Int. 2019, 116, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Foguel, A.; Neves Rodrigues Ract, J.; Claro da Silva, R.; Juliana Neves Rodrigues Ract, C. Sensory characterization of commercial cream cheese by the consumer using check-all-that-apply questions. J. Sens. Stud. 2021, 36, e12658. [Google Scholar] [CrossRef]

- Moskowitz, H.R. Margarine: The Drivers of Liking and Image. J. Sens. Stud. 2001, 16, 53–72. [Google Scholar] [CrossRef]

- Roberts, D.D.; Pollien, P.; Antille, N.; Lindinger, C.; Yeretzian, C. Comparison of Nosespace, Headspace, and Sensory Intensity Ratings for the Evaluation of Flavor Absorption by Fat. J. Agric. Food Chem. 2003, 51, 3636–3642. [Google Scholar] [CrossRef]

- Relkin, P.; Fabre, M.; Guichard, E. Effect of Fat Nature and Aroma Compound Hydrophobicity on Flavor Release from Complex Food Emulsions. J. Agric. Food Chem. 2004, 52, 6257–6263. [Google Scholar] [CrossRef] [PubMed]

- Afoakwa, E.O.; Paterson, A.; Fowler, M.; Ryan, A. Matrix effects on flavour volatiles release in dark chocolates varying in particle size distribution and fat content using GC–mass spectrometry and GC–olfactometry. Food Chem. 2009, 113, 208–215. [Google Scholar] [CrossRef]

- Arancibia, C.; Jublot, L.; Costell, E.; Bayarri, S. Flavor release and sensory characteristics of o/w emulsions. Influence of composition, microstructure and rheological behavior. Food Res. Int. 2011, 44, 1632–1641. [Google Scholar] [CrossRef]

- Andersen, B.V.; Brockhoff, B.; Hyldig, G. The importance of liking of appearance,-odour,-taste and-texture in the evaluation of overall liking. A comparison with the evaluation of sensory satisfaction. Food Qual. Prefer. 2019, 71, 228–232. [Google Scholar] [CrossRef]

| Samples | Lipids (%) | Total fat (g) | Saturated fat (g) |

|---|---|---|---|

| A30 | 30 | 3.0 | 0.7 |

| B35 | 35 | 3.5 | 1.2 |

| C38 | 38 | 3.8 | 1.1 |

| A60 | 60 | 6.0 | 1.8 |

| D70 | 70 | 7.0 | 2.0 |

| E50 | 50 | 5.0 | 1.4 |

| D55 | 55 | 5.5 | 1.0 |

| A80 | 80 | 8.0 | 1.8 |

| C80 | 80 | 8.0 | 2.0 |

| D82 | 82 | 8.2 | 2.3 |

| B80 | 80 | 8.0 | 2.0 |

| F80 | 80 | 8.0 | 2.0 |

| Samples | Hardness (N) | Adhesiveness (Ns) | Cohesiveness | Resilience (Ns) |

|---|---|---|---|---|

| A30 | 168.008ab* | -688.280cd | 0.670cd | 0.023e |

| B35 | 209.665abc | -976.496bc | 0.693d | 0.016cd |

| C38 | 120.477a | -539.837d | 0.645cd | 0.015bcd |

| A60 | 523.980g | -2182.356a | 0.601bcd | 0.008a |

| D70 | 255.746bcd | -1230.185b | 0.548bcd | 0.010ab |

| E50 | 304.365de | -1227.701b | 0.618bcd | 0.012abc |

| D55 | 263.479cd | -1159.119b | 0.714d | 0.020de |

| A80 | 735.396h | -1233.076b | 0.270a | 0.008a |

| B80 | 432.320f | -1971.677a | 0.629cd | 0.007a |

| C80 | 259.202bcd | -1124.580b | 0.538bcd | 0.008a |

| D82 | 319.208de | -1128.141b | 0.495bc | 0.007a |

| F80 | 370.914ef | -1097.906b | 0.432ab | 0.007a |

| Samples | Appearance | Aroma | Flavor | Texture | Overall Impression |

|---|---|---|---|---|---|

| A30 | 6.69ab* | 5.35b | 3.84f | 5.73c | 4.49e |

| B35 | 6.93ab | 5.98ab | 5.05de | 6.41abc | 5.62cd |

| C38 | 7.09ab | 6.41a | 5.68bcd | 6.89a | 6.04abc |

| A60 | 7.21a | 6.54a | 4.53ef | 6.58ab | 5.94bcd |

| D70 | 6.99ab | 6.27a | 5.82abcd | 6.12bc | 6.02abc |

| E50 | 6.61b | 6.22a | 4.53ef | 6.57ab | 5.20de |

| D55 | 6.73ab | 6.16a | 5.46cd | 6.12bc | 5.97bc |

| A80 | 7.00ab | 6.70a | 6.01abc | 6.89a | 6.32abc |

| B80 | 6.91ab | 6.28a | 6.44ab | 6.83a | 6.49ab |

| C80 | 6.71ab | 6.21a | 5.56bcd | 6.37abc | 5.86bcd |

| D82 | 7.07ab | 6.24a | 6.01abc | 6.70ab | 6.31abc |

| F80 | 7.19ab | 6.16a | 6.64a | 6.91a | 6.76a |

| MSD** | 0.59 | 0.78 | 0.90 | 0.67 | 0.76 |

| * Means with the same letters on the same column do not differ statistically by Tukey’s test (p ≤ 0.05).** Minimum significant difference. | |||||

| SAMPLES | p -value (p < 0.05) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A30 | A60 | A80 | B35 | B80 | C38 | C80 | D55 | D70 | D82 | E50 | F80 | ||

| Yellow | 43 | 6 | 8 | 14 | 20 | 16 | 8 | 2 | 4 | 39 | 83 | 12 | <0.0001 |

| Yellow cream | 54 | 94 | 84 | 88 | 84 | 85 | 95 | 92 | 96 | 63 | 26 | 86 | <0.0001 |

| Aerated | 11 | 10 | 9 | 9 | 5 | 14 | 13 | 9 | 6 | 5 | 14 | 7 | 0.081 |

| Bright | 56 | 58 | 58 | 47 | 60 | 53 | 67 | 48 | 58 | 67 | 67 | 74 | <0.0001 |

| Butter flavor | 37 | 53 | 67 | 43 | 53 | 51 | 54 | 55 | 55 | 56 | 42 | 71 | <0.0001 |

| Milk aroma | 15 | 23 | 32 | 17 | 26 | 15 | 23 | 26 | 21 | 20 | 14 | 22 | 0.010 |

| Rancid aroma | 32 | 10 | 11 | 11 | 7 | 11 | 7 | 16 | 15 | 16 | 14 | 7 | <0.0001 |

| Vegetable oil aroma | 41 | 29 | 19 | 38 | 29 | 34 | 29 | 32 | 25 | 32 | 24 | 19 | 0.001 |

| Milk flavor | 14 | 22 | 44 | 14 | 22 | 17 | 36 | 41 | 30 | 20 | 19 | 34 | <0.0001 |

| Rancid flavor | 52 | 29 | 23 | 23 | 15 | 27 | 7 | 10 | 22 | 28 | 28 | 13 | <0.0001 |

| Sweet taste | 7 | 6 | 9 | 8 | 10 | 6 | 16 | 15 | 9 | 12 | 17 | 12 | 0.050 |

| Gramine flavor | 11 | 5 | 10 | 15 | 9 | 13 | 11 | 13 | 6 | 7 | 9 | 2 | 0.035 |

| Oily flavor | 79 | 57 | 50 | 62 | 58 | 60 | 51 | 57 | 62 | 65 | 66 | 58 | 0.002 |

| Metal flavor | 23 | 13 | 12 | 20 | 13 | 14 | 5 | 10 | 15 | 12 | 7 | 9 | 0.004 |

| Salty taste | 30 | 43 | 58 | 37 | 62 | 51 | 56 | 43 | 48 | 40 | 9 | 66 | <0.0001 |

| Bitter taste | 19 | 1 | 4 | 12 | 9 | 9 | 6 | 4 | 9 | 7 | 8 | 2 | <0.0001 |

| Soft | 65 | 66 | 61 | 63 | 69 | 78 | 81 | 62 | 69 | 58 | 70 | 70 | 0.014 |

| Homogeneous | 60 | 79 | 80 | 69 | 72 | 71 | 81 | 75 | 71 | 76 | 73 | 75 | 0.044 |

| Consistent | 25 | 43 | 50 | 46 | 44 | 40 | 41 | 46 | 39 | 42 | 38 | 46 | 0.013 |

| Milk cream flavor | 11 | 24 | 27 | 17 | 19 | 18 | 29 | 31 | 17 | 13 | 16 | 25 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).