1. Introduction

Atmospheric emissions are one of the biggest challenges facing agricultural systems. Agricultural systems are the main sources of NH

3 emissions into the atmosphere [

1]. Monitoring ammonia emissions requires accurate estimates of types of ventilation systems, detection of ammonia during the production process, and mitigation strategies. There are large variations in ammonia emissions between houses or system types, bird ages, flocks, and breeds [

2,

3].

Ammonia is the main pollutant gas emitted by poultry facilities because of the microbial degradation of uric acid present in poultry manure [

2,

4]. The main factors affecting NH

3 emissions during the production process include temperature, moisture content, pH, ventilation rates, litter management, and the type of composting process. Furthermore, environmental damage can be caused following ammonia deposition through direct toxicity. However, mitigation strategies are effective in reducing NH

3 emissions [

1].

An important, but still challenging, parameter in determining ammonia emissions as a function of gas concentration and ventilation rate is the accurate determination of the facility's ventilation rate, especially in facilities with natural ventilation [

5].

It is very important for poultry production to quantify, verify, and study estimates of ammonia concentration in the production process. Additionally, accurate estimates of emissions and concentrations from different breeds are needed to assess the impact on bird performance and health.

The objective of the study was to predict the risk of exposure to ammonia concentration in the production of broiler breeds of slow and fast-growing with low and high production density and correlate it with the incidence of health injuries in broiler chickens using a machine learning approach.

2. Material and Methods

An animal experiment was carried out during the winter in Spain in 2019 to predict the risk condition of ammonia levels and correlate them with the health risk of broiler chickens. The experiment was approved by the Animal Ethics Committee N2018/VSC/PEA/0067. This study is part of a doctoral thesis.

The experiment was conducted in accordance with EU animal research regulations, with protocol number 2018/VSC/PEA/0067. The test was carried out at the Animal Technology and Research Center (CITA-IVIA), located in Segorbe, (Castellón, Spain).

2.1. Experiment

Two identical rooms (Room 1 and Room 2) were used in this test, measuring 13.2 m x 5.95 m, totaling approximately 70 m2 for each room. An automated temperature control system was installed (DNP Climate Controller, Exafan, Spain), which controlled ventilation rates in accordance with commercial temperature recommendations. The room temperature was gradually decreased from 32ºC (day 1) to 19ºC (day 42). Temperature was controlled using the temperature control sensor and recorded along with relative humidity every 10 minutes using a data logger (HOBO U12, Onsetcomp, Country). Furthermore, each room was equipped with an electrochemical NH 3 sensor (DOL 53, Dräger, Germany). Room 1 was programmed to maintain a maximum of 10 ppm of NH3 , while Room 2 was programmed to maintain a maximum of 20 ppm. These environmental conditions (ammonia concentration) were programmed to be maintained from the fourth week onwards, that is, in the second half of the production cycle, when ammonia levels tend to be higher within broiler production systems. A propane heater was used to maintain an adequate room temperature.

The experiment was carried out during the winter period, when gas concentrations were expected to be higher due to lower ventilation rates. To ensure that the desired concentrations were achieved during a relevant part of the poultry production period, it was decided to apply a urea solution to the litter. The dosage was always 0.21 L/m2 of urea solution, with a concentration of 187.5 g/L on day 32 of the rearing cycle and 93.75 g/L on days 39, 51, and 56.

Two commercial lines of broiler chicken were used, one with fast-growing (Ross®, slaughter age 42 days) and another with slow-growing (Hubbard®, slaughter age 63 days). All slow-growing birds were housed at a density of 32 kg/m2. Fast-growing birds were housed in two different housing densities: low housing density with a final housing density of 16 kg/m 2 and high density with a final housing density of 32 kg/m2. A total of 1250 birds were used in this experiment, 450 of which were fast-growing birds and 800 were slow-growing birds. In each room, 306 birds were randomly distributed in 18 boxes (6 boxes for each treatment and 17 birds per box), each with 3 nipple drinkers and a manual feeder. The dimensions of the high-density boxes were 1 x 1.3m2 , while the low-density boxes had the same number of animals housed in a larger area, with dimensions of 2 x 1.3m2 . The remaining 319 birds were housed randomly throughout the room and outside the pens to simulate a commercial production system condition. All birds were fed with an initial commercial feed from day 1 to day 18 of the experiment, and from day 18 until the end, each breed was fed with different feeds according to their nutritional demands.

All birds housed in the boxes were weighed weekly and their respective feed consumption was calculated. Average daily weight gain (GPM) per bird was calculated for each week of rearing and, average daily weight gain accumulated over the entire study period (42 days for fast-growing birds and 63 for slow-growing birds). Feed conversion (CA) was also obtained for each week and for accumulated periods, dividing the amount of food consumed by each pen by the weight gain of all birds present in it.

Room ammonia concentration data was collected by installing electrochemical sensors in each room. Assessments were carried out 24 hours a day, every day of the week.

In addition to the productive character determinations, during the development of the experiment, animals were sacrificed and samples were taken at four moments: day 0, day 21, day 42, and day 63 (day 63 only for animals from the slow-growing lineage). All the sacrificed birds were previously stunned by an electric shock.

In the first sampling, on day 0 of the study, 30 animals from each lineage were randomly sacrificed before distribution into the boxes. In the second and third sampling days 21 and 42 of the experiment, respectively, 5 animals were sampled from each pen, resulting in a total of 180 animals for each sampling day. After sacrifice, the animals were necropsied.

The fourth and final sampling was carried out on day 63 of the experiment with the same procedure as the previous two but involving only animals from the slow-growing lineage, since animals from the fast-growing lineage have a commercial production cycle of 42 days.

In the last two collections, at 42 days for fast-growing birds and at 63 days for fast-growing birds, the sampled animals were inspected for symptoms related to prolonged exposure to NH3 . These exams aimed to find epidermal lesions on the legs and injuries to the eyes and respiratory tract due to this irritating gas.

2.2. Data Mining Approach

The following data analysis steps were performed: data selection, pre-processing, transformation, mining, analysis, and interpretation of results.

The data preprocessing stage covers data understanding and data preparation, which includes standardizing nomenclatures, cleaning the raw data in the spreadsheet and, dividing the database in the Weka software (version 3.8.4).

For training and testing modeling. To stratify the data set, the “

stratified remove folds” filter was used to separate the data set between training and testing. Pre-processing also included the discretization of attributes into classes that reduces and simplifies the data, making learning faster and the results denser, according to the proposed methodologies [

6,

7].

In the processing stage, the data set was analyzed by applying predictive classification models for training (75% of the data set with 17062 instances) and for validation of the model with the test set (25% of the data set with 5688 instances).

The classification algorithms, decision tree (J48), SMO (Sequential Minimal Optimization), Naive Bayes and Multilayer Perceptron were applied to the training and test data sets to build a rule model for predicting ammonia risk levels in broiler chickens. The cross-validation technique (test mode: 10-fold cross-validation) was used to parameterize the analysis in all models. The number of attributes used in the modeling was seven, including “housing_condition”, “age_week”, “T-hobo”, “UR%”, “Vent”, “NH3_ppm” and the response attribute “Ammonia_concentration_risk”, with a total of 5688 instances.

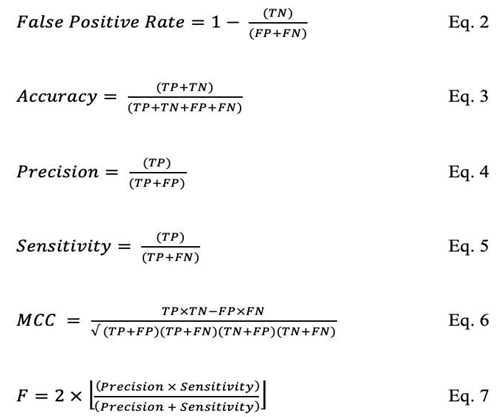

The study developed a machine learning model to predict the risk condition of ammonia concentration in the production of chickens of slow and fast-growing breeds with low and high production densities. The study also compared the performance of all algorithms with respect to their prediction abilities and model quality. When evaluating the models, the data was divided into training and testing subsets, and then the results were compared by the performance metrics of the algorithms. The flowchart used to identify the best test algorithm is shown in

Figure 1.

The criterion used to discretize the classes of the response attribute (target) “ammonia concentration risk condition” included ammonia concentration levels in five classes described in

Table 1.

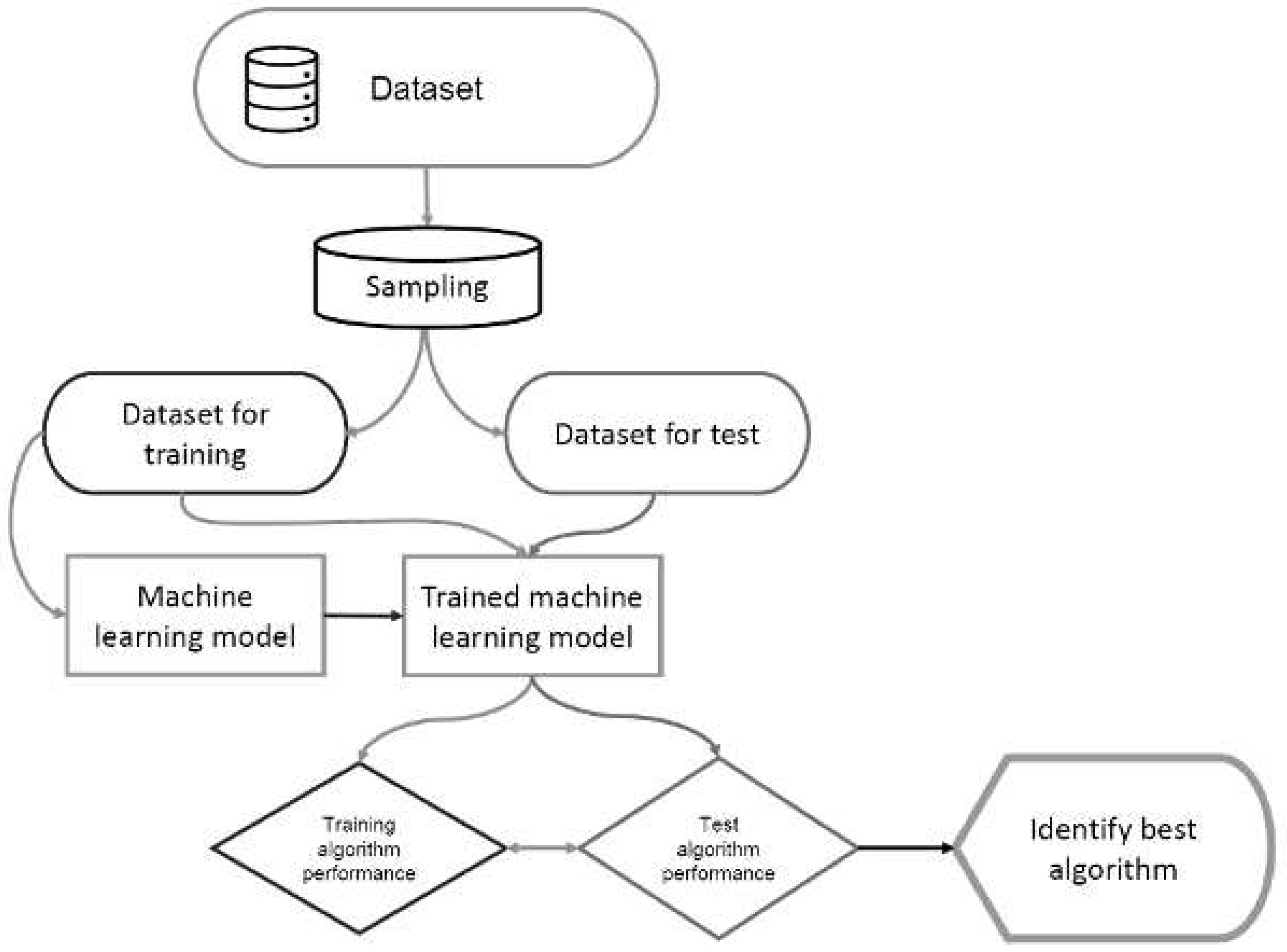

2.3. Performance Measures of Classification Models

The performance of the models was evaluated by different metrics including accuracy, incorrectly classified instances,

Kappa statistics, true positive rate, false positive rate, precision, sensitivity (recall), F value, Matthews Correlation Coefficient (MCC) and the confusion matrix [

13,

14].

Below are the equations used to evaluate the performance of the algorithms for accuracy, precision, sensitivity (

recall), Matthews correlation coefficient (MCC) and F value calculated from Equations (2) to (7), respectively:

where TP: true positive; TN: true negative; FP: false positive; FN: false negative.

The following items are calculated in the confusion matrix. true positives (TP), which are the positive tuples that were correctly labeled by the classifier; true negatives (TN), which are the negative tuples that were correctly labeled by the classifier; false positives (FP), which are negative tuples that were incorrectly labeled as positive; and false negatives (FN) which are the positive tuples that have been mistakenly labeled as negative. This shows the relationship between observed and predicted values in a classification problem [

14].

The study compares the performance of all algorithms with respect to their prediction abilities and model quality. The flowchart used to identify the best training algorithm is shown in

Figure 1.

2.4. Spearman Correlation Analysis

From the ammonia concentration risk classification data (attribute “Ammonia_concentration_risk”), only those that presented some degree of risk) the Spearman correlation coefficient (ρ, rho) was calculated, considering the presence values (numerical counts) of the following diseases and injuries quantified during the experimental phase: pododermatitis, vision/affected, and mucosal injury, which include assessments of trachea, bronchi, lungs, eyes, paw injury, and other injuries.

A non-parametric correlation measure was applied to the injury incidence data as a function of the ammonia risk level (1 and 10 ppm) with the aim of correlating the injury incidence and the ammonia level in the conditions studied, calculated from the Equation (1).

3. Results

The overall performance of the models showed an accuracy of 100% for J48, 91.58% for SMO, 92.44% for Naive Bayes, and 99.05% for Multilayer Perceptron. The biggest error in classification was for the SMO model. The Kappa statistic was also 100% for the J48 model, followed by 89.12% for the SMO model, 90.28% for the Naive Bayes model, and 98.77% for Multilayer Perceptron. The overall performance results indicate that the Multilayer Perceptron model was the best classification model for detecting risk from ammonia concentration in chicken production.

Table 2.

Overall performance of classification models.

Table 2.

Overall performance of classification models.

| Classifier model |

J48 Tree |

SMO |

Naive Bayes |

Multilayer Perceptron |

| Correctly classified instances (%) |

100 |

91.58 |

92.44 |

99.05 |

| Incorrectly classified instances (%) |

0 |

8.42 |

7.56 |

0.95 |

| Kappa statistic (%) |

100 |

89.12 |

90.28 |

98.77 |

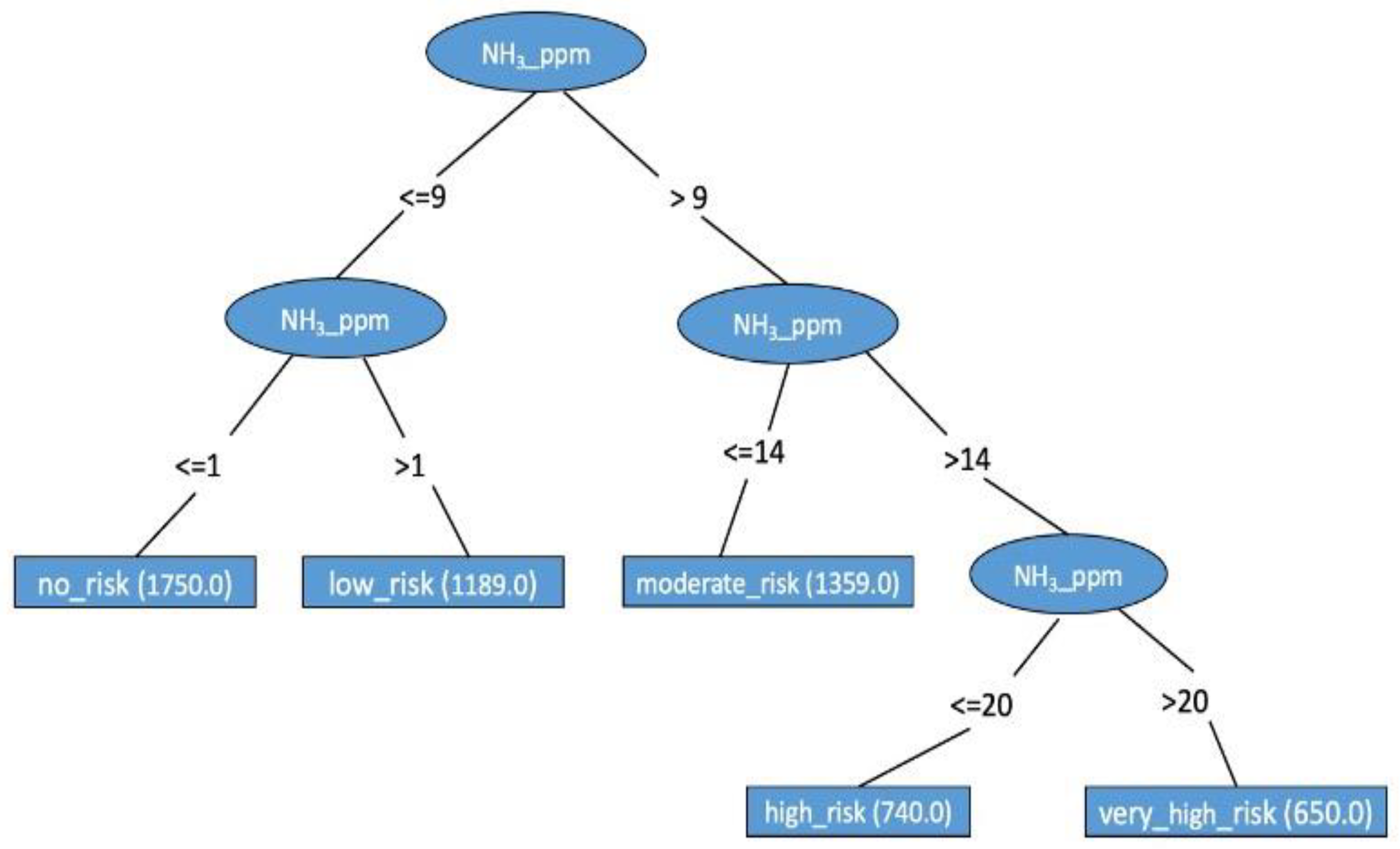

The visualization of the decision tree generated by the J48 classification model is shown in

Figure 2, the scheme indicates that if the ammonia concentration is > 9 ppm, the ammonia concentration must be observed, when this concentration is <= 14: o risk is moderate; when the ammonia concentration is > 14 ppm, the ammonia concentration must be observed, if the ammonia is <= 20 ppm, the risk is high, and if it is > 20ppm, the risk is very high for birds.

The main results presented in

Table 3 show that the J48 model generated good average performance (100%) in all metrics; the SMO model presented similar performance, but with a recall of 77% for the “low risk” class. The Naive Bayes model presented similar results, with values above 85% in all metrics, and the Multilayer Perceptron model obtained the best performance of all with the most adjusted metrics, as occurred with J48. However, these overfitted results may contain overfitting.

The models' confusion matrix is shown in

Table 4. The J48 model obtained 100% correct answers for all classes and did not present a classification error. The SMO and Naive Bayes models showed more classification errors than J48 and Multilayer Perceptron, indicating that these models can still be adjusted to increase accuracy per class. The smaller the error in classifying the risk of ammonia concentration in facilities, the better the possibility of managing this ammonia concentration when decision-making is required.

Spearman's correlation assessed the interrelationship between the risk variable of exposure to ammonia and the incidence of diseases resulting mainly from ammonia gas (

Table 5). Spearman's correlation between the risk of exposure to ammonia and the incidence of lung health problems showed a correlation of 0.549, the risk for the bronchi 0.189, for the eyes 0.378, and for the paws 0.375, so if the value of ⍴ is approached 0, the association between the two intervals is weaker. The higher the absolute value of the coefficient, the stronger the relationship between the variables. The correlation involving other injuries caused by ammonia showed a strong correlation when compared to other types of injuries, indicating a greater association between the appearance of injuries when birds are exposed to higher levels of ammonia in the production process.

4. Discussion

Risk levels of ammonia concentration when evaluated for different broiler production systems considering fast and slow growing birds can show a scenario of the impact caused by ammonia concentration in the production process. There is a convergence between the ammonia concentration levels and the type of production systems and technology for both broiler and egg production. Many studies (

Table 6) have evaluated ammonia concentrations at different ages, with different construction and ventilation systems, breeds, and regions.

In the context of Machine Learning, IoT data has been successfully employed in predicting injuries known to negatively impact poultry production. Although there has been a steady increase in literature addressing applications of digital technology in agribusiness in recent years, there is a notable lack of peer-reviewed articles that focus on AI-enabled IoT systems in managing poultry health and welfare. Furthermore, most previous studies are limited to specific aspects of bird welfare [

23].

Similarly to this study, researchers was conducted monitoring and observations covering variables such as temperature, humidity, feces content, ammonia levels, and humidity in the poultry environment. [

24,

26].

Studies show the implementation of sensors to supervise and regulate environmental conditions, activating appropriate devices such as ventilation, lighting, refrigeration, and heating systems, as mentioned in previous research [

27,

28,

29,

30,

31].

As an example, following the approach of this study to predict injury risks, designed as system for automatically detecting sick chickens. This system, based on the ResNet residual network, achieved a remarkable 93.70% accuracy when monitoring the behavioral physiology and productive performance of meat birds. In this study, even greater accuracy was obtained in predicting injuries caused by ammonia, with values above 98% for the Multilayer Perceptron model. [

32].

Was introduced a system with low computational complexity that demonstrated an accuracy of 80.00%. This system has the ability to automatically adjust the environmental behavior of birds, taking into account variables such as temperature, humidity, light intensity, and population density [

33].

Initially, it is crucial to monitor environmental parameters on a poultry farm, including elements such as temperature, humidity, ammonia levels, and light. This monitoring is essential to ensure effective control of internal conditions by automation systems. Several Machine Learning techniques are employed to monitor these environmental parameters, ranging from linear regression to fuzzy logic neuro-fuzzy and neural networks, as well as deep learning [

15,

24,

29,

34].

In this study was designed a remarkable system, achieving an accuracy of 97.00%. This system aims to control hydrothermal parameters, including temperature and relative humidity, as well as contaminating gases. This results in the creation of ideal conditions for efficient poultry production. The accuracy of the model developed, reached values close to those of this study, demonstrating the efficiency of these models for predicting environmental conditions [

29].

Additionally, wasimplemented a MultiBox Detector for automated diagnosis of the health status of broiler chickens. The proposed algorithm achieved an impressive average accuracy of 99.70%. This model achieved higher accuracy than the models studied in the ammonia risk prediction study [

35].

When it comes to activity recognition was conducted a comparison between decision trees, Naïve Bayes, and neural networks to identify the activities of broiler chickens [

36]. The results indicated that neural networks demonstrated the best overall accuracy, reaching 82.10%. Similarly, applied the classification tree algorithm to identify behaviors in broiler breeders, achieving an overall success rate of 70.30% in the validation set. Like these studies, in the research carried out to predict risk due to ammonia, the Naïve Bayes model also presented excellent results, with values above 85% [

37].

Ammonia represents a primary air pollutant in poultry facilities, exerting a significant adverse impact on the ecosystem, the environment, bird welfare, and human health [

15]. Therefore, accurately estimating the concentration of NH

3 becomes an essential imperative for adequate waste management, aiming to preserve environmental health, human health, and animal welfare [

15,

24].

In this research conducted a performance evaluation involving four models, namely: multilayer perceptron, adaptive neuro-fuzzy inference systems integrated with grid partitioning and subtractive clustering (ANFIS-GP and ANFIS-SC), as well as multiple linear regression analysis. The results highlighted that ANFIS-SC stood out as the most accurate, recording an R-squared value of 0.86 in the validation set. In this study, when performing the calculation for Spearman's correlation, a greater correlation was observed between exposure to ammonia and the incidence of lung health problems, with a correlation of 0.549 [

15].

In the context of estimating ammonia concentration in poultry farms, employed a subtractive clustering technique to determine the optimal input parameters in their regression model [

15]. Furthermore, proposed a real-time segmentation algorithm based on K-means clustering and the ellipse model, aiming at automated diagnosis of the health status of broiler chickens [

35].

The Multilayer Perceptron demonstrated remarkable performance, establishing itself as an excellent tool for predicting the risk of injuries in broiler chickens related to ammonia concentration.

5. Conclusion

The best predictive model capable of evaluating and obtaining better performance is the Multilayer Perceptron when we consider greater accuracy by risk level of exposure to ammonia in the broiler chicken production process, including fast and slow growth.

Birds exposed to higher levels of ammonia concentration have a higher correlation coefficient when the relationship between the variables is strong. Spearman's correlation coefficient shows a stronger association between higher risks of exposure to ammonia and the incidence of lesions in chickens.

Author Contributions

All authors contributed to the study's conception and design. XXXX: conceptualization, methodology, data collection, and analysis were performed, writing-original draft. XXXX: writing-reviewing, editing, and supervision. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Funding

This research was funded by the National Institute for Agricultural Research and Experimentation and the Ministry of Economy, Industry and Competitiveness (RTA 2017-00013, Program: MINECO, Ministerio de Economía y Competitividad). Capes and CNPq grants were awarded to support Leonardo Valentino's participation in this research.

Ethics approval and consent to participate

The experiment was conducted in accordance with EU animal research regulations, with protocol number 2018/VSC/PEA/0067. The test was carried out at the Animal Technology and Research Center (CITA-IVIA), located in Segorbe, (Castellón, Spain).

Consent for publication

All authors have checked the manuscript and have agreed to the publication

Acknowledgments

We would like to thank the Universidad Politrécnica de València, the State University of Campinas and the Instituto Valenciano de Pesquisas Agrárias for the physical space, laboratories and resources provided. We thank the National Institute for Agricultural Research and Experimentation and the Ministry of Economy, Industry and Competitiveness of Spain for funding the research. And also Capes and Cnpq for granting scholarships.

Conflicts of Interest

The authors declare that they have no competing interests.

References

- TI, C. et al. Potential for mitigating global agricultural ammonia emission: a meta-analysis. Environmental Pollution, v. 245, p. 141–148, 2019. [CrossRef]

- NICHOLSON, F. A.; CHAMBERS, B. J.; WALKER, A. W. Ammonia emissions from broiler litter and laying hen manure management systems. Biosystems Engineering, v. 89, n. 2, p. 175–185, 2004. [CrossRef]

- PESCATORE, A. J.; CASEY, K. D.; GATES, R. S. Ammonia emissions from broiler houses. Journal of Applied Poultry Research, v. 14, n. 3, p. 635–637, 2005. [CrossRef]

- ZHAO, L. et al. Ammonia concentrations and emission rates at a commercial poultry manure composting facility. Biosystems Engineering, v. 150, p. 69–78, 2016. [CrossRef]

- OLIVEIRA, M. D. et al. Ammonia emission in poultry facilities: a review for tropical climate areas. Atmosphere, v. 12, n. 9, p. 1091, 2021. [CrossRef]

- HALL, M. et al. The WEKA data mining software: an update. ACM SIGKDD explorations newsletter, v. 11, n. 1, p. 10–18, 2009.

- LAROSE, D. T. Data mining and predictive analytics. [s.l.] John Wiley & Sons, 2015.

- UÇAR, M. K. et al. The effect of training and testing process on machine learning in biomedical datasets. Mathematical Problems in Engineering, v. 2020, 2020. [CrossRef]

- CARLILE, F. S. Ammonia in Poultry Houses: A Literature Review. World’s Poultry Science Journal, v. 40, n. 2, p. 99–113, 1984. [CrossRef]

- COMMISSION, E.--E. Directive 2000/39/EC of 8 June 2000 establishing a first list of indicative occupational exposure limit values in implementation of Council Directive 98/24/EC on the protection of the health and safety of workers from the risks related to chemical agents at work. [s.l: s.n.].

- EUROPEA, C. Commission directive 2009/161/EU of 17 December 2009 establishing a third list of indicative values of occupational exposure. La Medicina del lavoro, v. 101, n. 2, p. 145, 2010.

- KRISTENSEN, H. H.; WATHES, C. M. Ammonia and poultry welfare: a review. World’s Poultry Science Journal, v. 56, n. 03, p. 235–245, 2000. [CrossRef]

- BOWES, D.; HALL, T.; GRAY, D. Comparing the performance of fault prediction models which report multiple performance measures: recomputing the confusion matrix. 2012.

- HAN, J.; KAMBER, M.; PEI, J. Data mining concepts and techniques third edition. University of Illinois at Urbana-Champaign Micheline Kamber Jian Pei Simon Fraser University, 2012.

- KÜÇÜKTOPCU, E.; CEMEK, B. Comparison of neuro-fuzzy and neural networks techniques for estimating ammonia concentration in poultry farms. In: Journal of Environmental Chemical Engineering, v. 9, n. 4, 2021, p. 105699. [CrossRef]

- ALMUHANNA, E.; HASSAN (A.S. AHMED), A.; YOUSIF, Y. M. Effect of Air Contaminants on Poultry Immunological and Production Performance. International Journal of Poultry Science, v. 10, p. 461–470, 1 jun. 2011. [CrossRef]

- OWADA, A. N. et al. Estimativa de bem-estar de frango de corte em função da concentração de amônia e grau de luminosidade no galpão de produção. Engenharia Agricola, v. 27, n. 3, p. 611–618, 2007.

- NÄÄS, I. DE A. et al. Ambiência aérea em alojamento de frangos de corte: poeira e gases. Engenharia Agrícola, v. 27, p. 326–335, 2007. [CrossRef]

- ZARNAB, S. et al. Effects of induced high ammonia concentration in air on gross and histopathology of different body organs in experimental broiler birds and its amelioration by different modifiers. Pakistan Veterinary Journal, v. 39, n. 3, p. 371–376, 2019. [CrossRef]

- TAUSON, R.; HOLM, K. E. First furnished small group cages for laying hens in evaluation program on commercial farms in Sweden. 2001.

- KOERKAMP, P. W. G. G.; BLEIJENBERG, R. Effect of type of aviary, manure and litter handling on the emission kinetics of ammonia from layer houses. British Poultry Science, v. 39, n. 3, p. 379–392, 1998. [CrossRef]

- HINZ, T.; WINTER, T.; LINKE, S. Luftfremde Stoffe in und aus verschiedenen Haltungssystemen für Legehennen–Teil 1: Ammoniak. Landbauforsch, v. 60, n. 3, p. 139–150, 2010.

- OJO, R. O., AJAYI, A. O., OWOLABI, H. A., OYEDELE, L. O., AKANBI, L. A. Internet of Things and Machine Learning techniques in poultry health and welfare management: A systematic literature review. Computers and Electronics in Agriculture, 200, 107266. ISSN 0168-1699, 2022. [CrossRef]

- DEBAUCHE, O.; MAHMOUDI, S.; MANNEBACK, P.; BINDELLE, J.; LEBEAU, F. Edge computing and artificial intelligence for real-time poultry monitoring. In: Procedia Computer Science, v. 175, 2020, p. 534-541. [CrossRef]

- FERNANDEZ, A.; NORTON, T.; TULLO, E.; VAN HERTEM, T.; YOUSSEF, A.; EXADAKTYLOS, V.; VRANKEN, E.; GUARINO, M.; BERCKMANS, D. Real-time monitoring of broiler flock’s welfare status using camera-based technology. In: Biosystems Engineering, v. 173, 2018, p. 103-114.

- LASHARI, M.; MEMON, A.; SHAH, S.; NENWANI, K.; SHAFQAT, F. IoT Based Poultry Environment Monitoring System. In: IEEE International Conference on Internet of Things and Intelligence System, 2018, p. 1-5.

- CHOUKIDAR, G.; DAWANDE, N. Smart poultry farm automation and monitoring system. In: International Conference on Computing, Communication, Control and Automation, 2017, p. 1-5.

- GUNAWAN, T.; SABAR, M.; NASIR, H.; KARTIWI, M.; MOTAKABBER, S. Development of smart chicken poultry farm using RTOS on Arduino. In: IEEE International Conference on Smart Instrumentation, Measurement and Application, 2019, p. 1-5.

- LAHLOUH, I.; RERHRHAYE, F.; ELAKKARY, A.; SEFIANI, N. Experimental implementation of a new multi-input multi-output fuzzy-PID controller in a poultry house system. In: Heliyon, v. 6, n. 8, 2020, e04645. [CrossRef]

- LI, G.; JI, B.; LI, B.; SHI, Z.; ZHAO, Y.; DOU, Y.; BROCATO, J. Assessment of layer pullet drinking behaviors under selectable light colors using convolutional neural network. In: Computers and Electronics in Agriculture, v. 172, 2020, p. 105333. [CrossRef]

- LORENCENA, M.; SOUTHIER, L.; CASANOVA, D.; RIBEIRO, R.; TEIXEIRA, M. A framework for modeling, control, and supervision of poultry farming. In: International Journal of Production Research, v. 58, n. 10, 2020, p. 3164-3179.

- 32-H. ZHANG AND C. CHEN, "Design of Sick Chicken Automatic Detection System Based on Improved Residual Network," 2020 IEEE 4th Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chongqing, China, 2020, pp. 2480-2485. [CrossRef]

- SO-IN, CHAKCHAI, POOLSANGUAN, SARAYUT, RUJIRAKUL, KANOKMON. 2014. "A hybrid mobile environmental and population density management system for smart poultry farms." Computers and Electronics in Agriculture 109: 287-301. ISSN 0168-1699. [CrossRef]

- PEREIRA, WARISTON FERNANDO, LEONARDO DA SILVA FONSECA, FERNANDO FERRARI PUTTI, BRUNO CÉSAR GÓES, LUCIANA DE PAULA NAVES. 2020. "Environmental monitoring in a poultry farm using an instrument developed with the internet of things concept." Computers and Electronics in Agriculture 170: 105257. ISSN 0168-1699. [CrossRef]

- ZHUANG, XIAOLIN, AND ZHANG, TIEMIN. 2019. "Detection of sick broilers by digital image processing and deep learning." Biosystems Engineering 179: 106-116. ISSN 1537-5110. [CrossRef]

- BANERJEE, D.; BISWAS, S.; DAIGLE, C.; SIEGFORD, J. Remote activity classification of hens using wireless body-mounted sensors. In: Proceedings of the 2012 Ninth International Conference on Wearable and Implantable Body Sensor Networks, 2012, p. 107-112.

- PEREIRA, DANILO F., MIYAMOTO, BRUNO C.B., MAIA, GUILHERME D.N., SALES, G. TATIANA, MAGALHÃES, MARCELO M., GATES, RICHARD S. 2013. "Machine vision to identify broiler breeder behavior." Computers and Electronics in Agriculture 99: 194-199. ISSN 0168-1699. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).