1. Introduction

Currently, environmentally-friendly products, known as ’green products,’ have continuously gained interest due to the global trend of environmental conservation, driven by campaigns promoting these green products. Composite-based green products, developed with a focus on sustainability, have garnered attention for their recycling, biodegradability, ease of disposal, and non-toxic properties, aligning with the goals of sustainable development [

1]. Composite materials typically involve combining at least two materials with differing properties, comprising a matrix and reinforcement [

2]. Currently, natural fibers are widely used as reinforcements due to their biodegradability, low cost, good mechanical properties, low density, and their contribution to reducing the reliance on synthetic fibers, aligning with the concept of green composites [

3,

4,

5].

The fabrication of composites involves various processes, with popular methods including hand lay-up, resin transfer molding, hot plate compression molding, pultrusion, and filament winding [

6]. The pultrusion process represents a form of continuous composite fabrication, characterized by a uniform cross-section, high mechanical properties due to continuous reinforcement fibers, cost-effectiveness in terms of equipment, and the potential for mass production [

7]. Typically, the pultrusion process utilizes thermoset resin as the matrix for the composite. In this process, thermosetting resins impregnate continuous fibers before being pulled through a hot die for curing [

8]. More recently, the pultrusion process has evolved by incorporating thermoplastic as the matrix, known as the thermoplastic pultrusion process. In this variant, reinforcement fibers and thermoplastic matrix fibers are pulled through a hot die, with the thermoplastic fibers melting and impregnating the reinforced fibers before taking shape through cooling [

9]. With a growing focus on environmentally-friendly products, ongoing research into thermoplastic pultrusion is of interest. The advantage of thermoplastic pultrusion lies in its use of thermoplastic materials, known for their recycling properties and their ability to contribute to pollution control [

6].

Jute fibers offer an alternative reinforcement material for enhancing composite materials due to their lightweight, affordability, environmental friendliness, and local availability as a continuous fiber [

6,

10]. While natural fibers are highly eco-friendly as reinforcement in composite materials, their mechanical properties are typically low. To address this limitation and boost the mechanical properties of composites, a hybrid composite approach is employed, combining two or more types of reinforcement. T This serves as an alternative for enhancing the mechanical properties of composites. Glass fibers are also widely utilized in the plastic composite industries, prized for their high strength, cost-effectiveness, high melting temperature, and continuous fiber shape [

11].

Polypropylene (PP) is a widely popular thermoplastic used in various industries, including automotive, food, and packaging, among others. Moreover, PP exhibits good mechanical properties and benefits from a relatively low molding temperature that doesn’t lead to the degradation of natural fibers [

6]. In the existing literature, numerous research studies have explored the use of jute/glass reinforcement with thermoset resins. However, it has not been extensively applied with thermoplastic materials [

12,

13]. This research focuses on the use of jute fiber and glass fiber as hybrid reinforcement materials with a polypropylene matrix. In the experiment, molding temperature and pulling speed were defined as parameters, and the final profile was examined to assess mechanical properties and microstructure. In the initial phase, the hybrid composites were fabricated and investigated to determine the optimal molding temperature. Subsequently, in the next step, the pulling speed was adjusted, as illustrated in

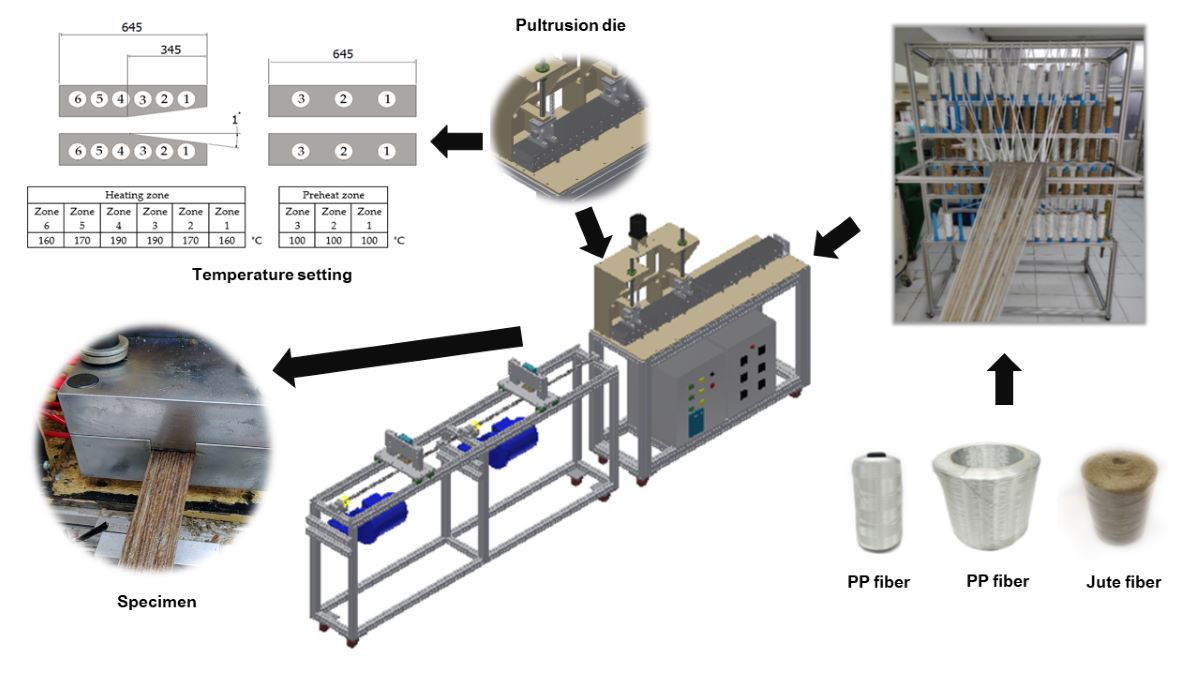

Figure 1, depicting the thermoplastic pultrusion process used in this experiment.

2. Materials and Methods

2.1. Materials

Jute yarn and glass fiber (GF) were used in combination with polypropylene (PP). The primary reinforcing fiber selected was jute yarn, which had a tex of 840 and a density of 1.440 g/cm3. This type of fiber has a degradation temperature of approximately 240 °C. [

14] A secondary reinforcing fiber, glass fiber, with a tex of 1,200 and a density of 2.620 g/cm3, was also incorporated. The matrix fiber employed in the continuous composite was polypropylene yarn, with a tex of 133 and a density of 0.946 g/cm3. The melting temperature of this matrix fiber was determined to be 178.8 °C through the analysis of results from a differential scanning calorimetry (DSC) test. The volume fraction of fiber and matrix was determined by adjusting the filling ratio [

6,

14], as described in the equation (1).

2.2. Molding Parameter

The study evaluated molding parameters for jute/glass fiber reinforcement with PP using the thermoplastic pultrusion process. The molding temperatures and pulling speeds were detailed in

Table 1. The volume fraction of continuous composites was designed as presented in

Table 2. Pulling speed was measured based on the frequency of the pulling motor revolutions, resulting in values of 40, 100, and 140 mm/min at 4, 6, and 8 Hz, respectively. The die temperature system for this experiment is illustrated in

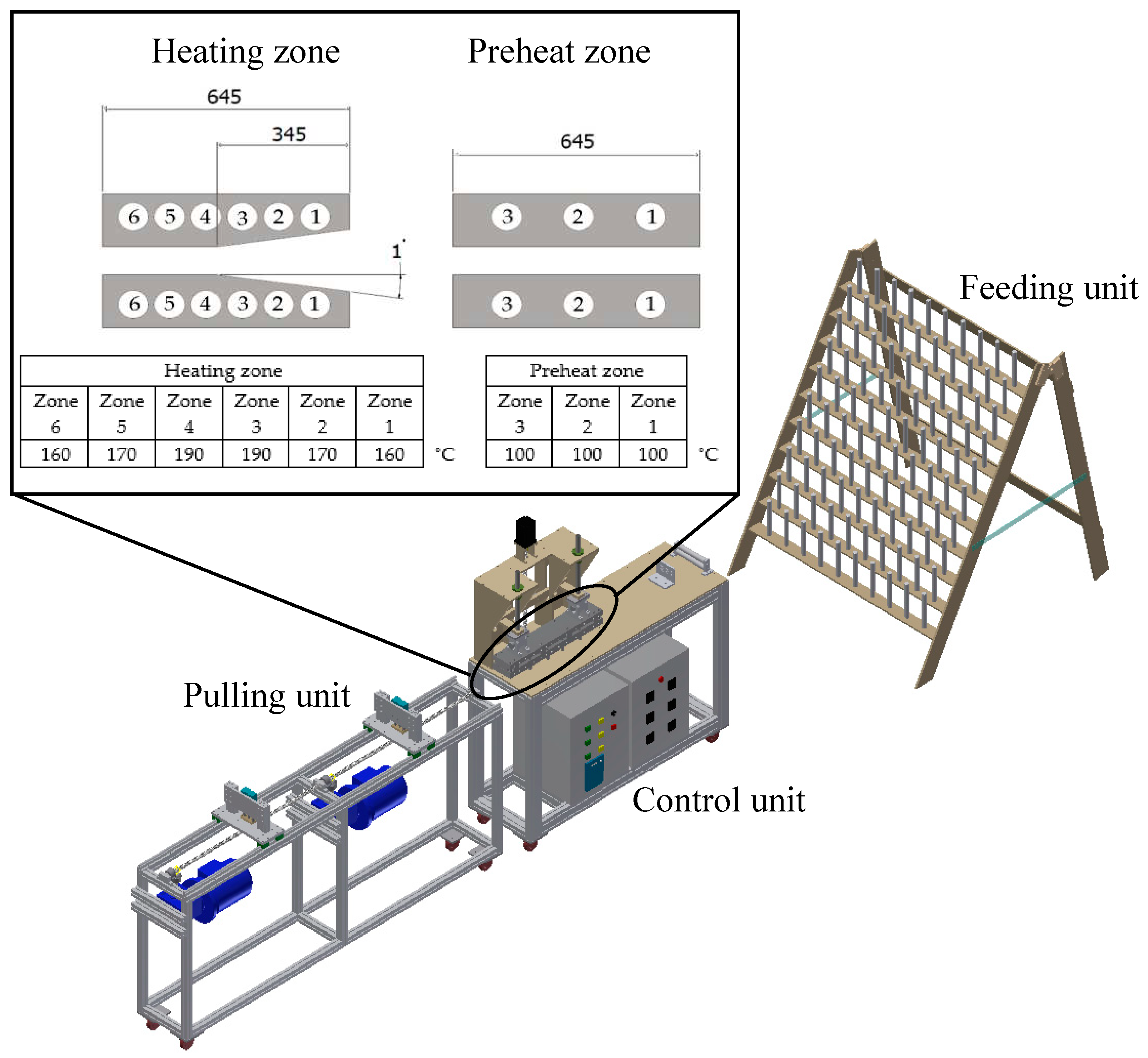

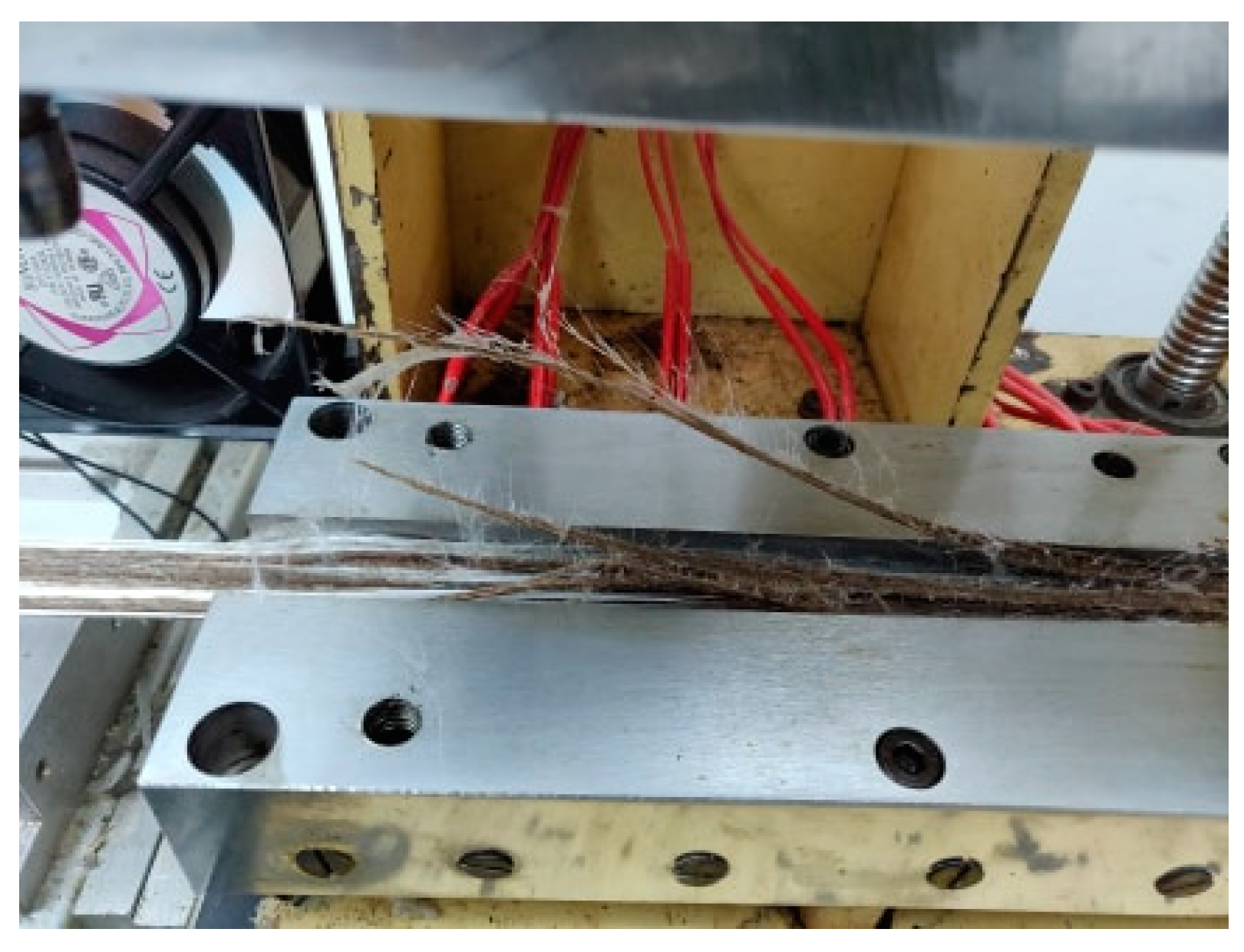

Figure 1, with heating zones 1 and 2 of the die considered to be associated with the melting point of PP fibers. It was essential to avoid the melting of PP fibers in zones 1 and 2 to prevent fiber breakage before reaching the die. Therefore, the die setup for zones 1 and 2 was configured at 160 and 170 °C, temperatures lower than the melting temperature of 178.8 °C as determined by DSC results. The die temperature system for zones 3 and 4 (Impregnation zone) was designed based on the results of Thermal Gravimetric Analysis (TGA) of jute fiber and PP fiber, as depicted in

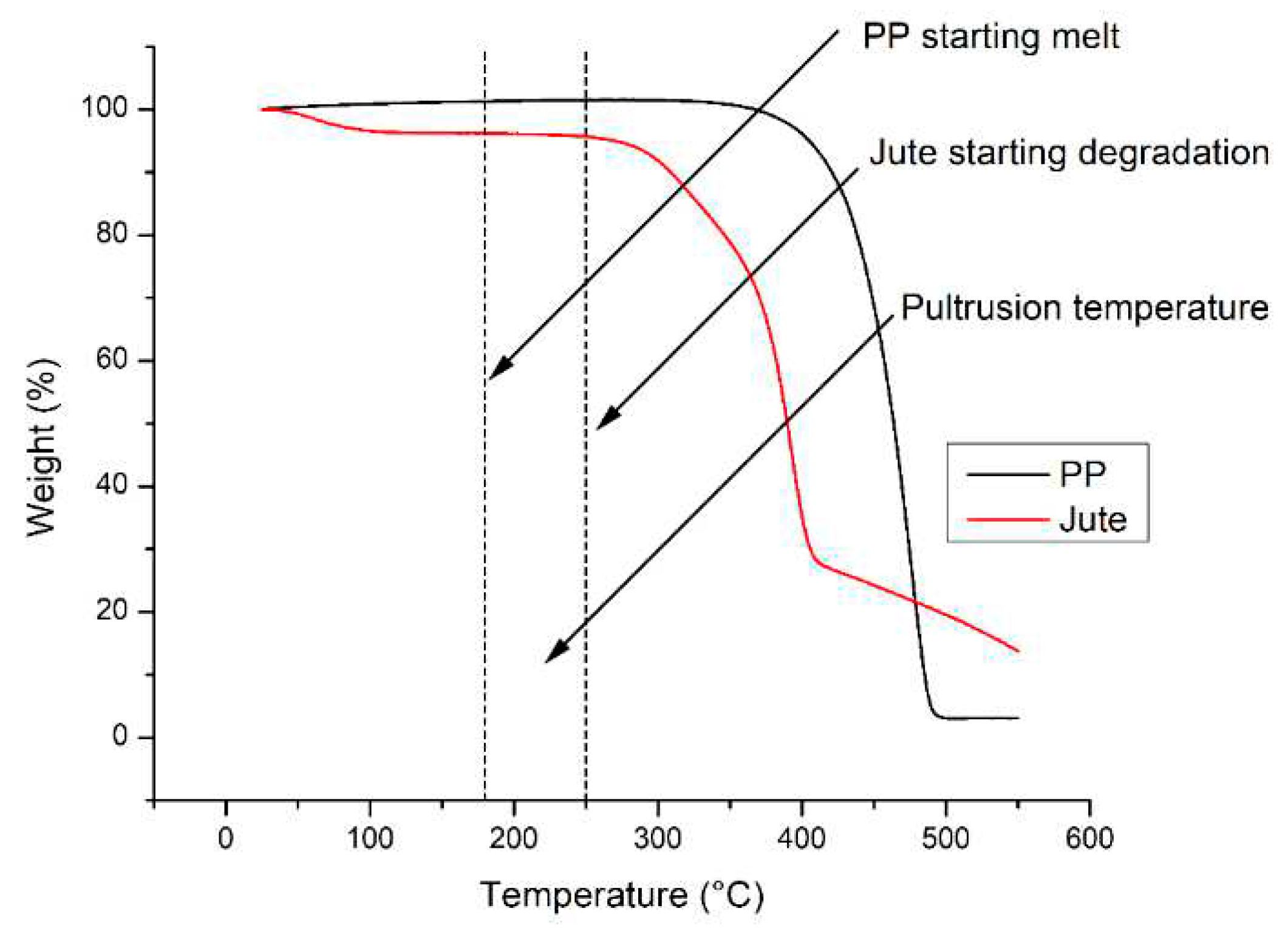

Figure 2. The TGA results indicated the degradation temperature of jute fibers to be approximately 240 °C and the degradation temperature of PP fibers around 290 °C. The melting temperature of PP was 180 °C. Consequently, the suitable range for molding temperature fell within the bracket of 180 °C to 240 °C. However, despite the degradation temperatures of PP fibers and jute fibers being 290°C and 240°C, respectively, the molding temperature could not be set above 220°C, as it would approach the degradation temperature of jute fiber. The failure of jute fiber at temperatures exceeding 220°C was confirmed in

Figure 3. Consequently, the molding temperatures were established at 190°C, 200°C, 210°C, and 220°C.

Figure 4 displays successfully pultruded specimens of the jute/glass polypropylene hybrid composite. In addition, the design of molding temperatures took into account the pulling speeds. For pulling speeds of 40, 100, and 140 mm/min, intermediate materials were pulled through the die in approximately 16.16, 6.45, and 4.61 minutes, respectively. In

Figure 1, the die temperature system of this experiment is illustrated, with variations occurring only in zones 3 and 4, while the preheat zones were set at 100°C. The selection of pulling speeds was based on the impregnation theory outlined in the literature [

6,

7,

12,

14,

15] which suggests that resin can adequately impregnate the materials over an extended period at lower pulling speeds. As a result, the preliminary pulling speed was set at the lowest value compatible with pultrusion techniques.

2.3. Mechanical Test

Tensile and flexural tests were carried out to investigate the mechanical properties. The dimensions of the tensile specimens were 25 x 250 x 4 mm in accordance with ASTM D3039 [

16]. These specimens had a gauge length of 150 mm, with 50 mm clamped at each end. Tensile tests were conducted using a Hounsfield Universal Testing machine, with a head speed set at 1 mm/min.

The flexural test was performed using a three-point bending test following ASTM D790 [

17]. The flexural specimens had dimensions of 25 x 100 x 4 mm. Flexural tests were conducted on a Hounsfield Universal Testing machine, with a head speed set at 2.16 mm/min and a span length of 72 mm.

2.4. Microstructure Analysis

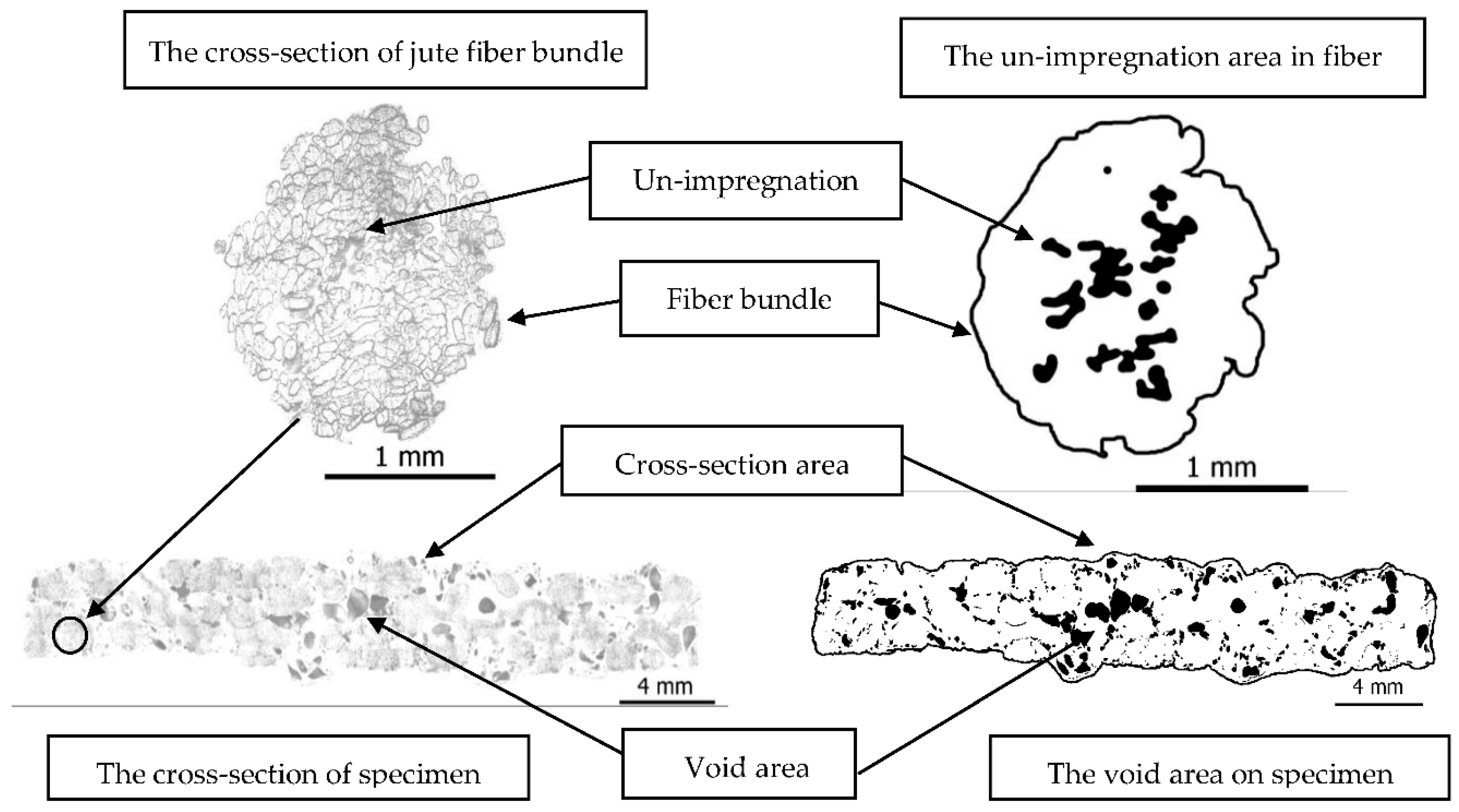

The microstructure analysis was performed using an Olympus microscope, with samples examined at 10 times magnification. This analysis primarily concentrated on void and un-impregnation assessment. Un-impregnation was determined by comparing the space area within the fiber bundle to the fiber bundle area, as illustrated in

Figure 5, where the black region within the fiber bundle represents un-impregnation. Void content, on the other hand, was calculated by measuring the void area in relation to the cross-section area, as also indicated in

Figure 5, where the black region on the specimen’s cross-section denotes void content.

3. Results and Discussions

In this experiment, the initial set of specimens entailed altering the molding temperatures to identify the most suitable temperature for subsequent investigations. The varying molding temperatures were adjusted based on

Table 1, focusing exclusively on zones 3 and 4. After selecting the optimal molding temperature, the study progressed to assess how different pulling speeds affected the mechanical properties of the composites.

3.1. The Effect of Molding Temperature Parameter

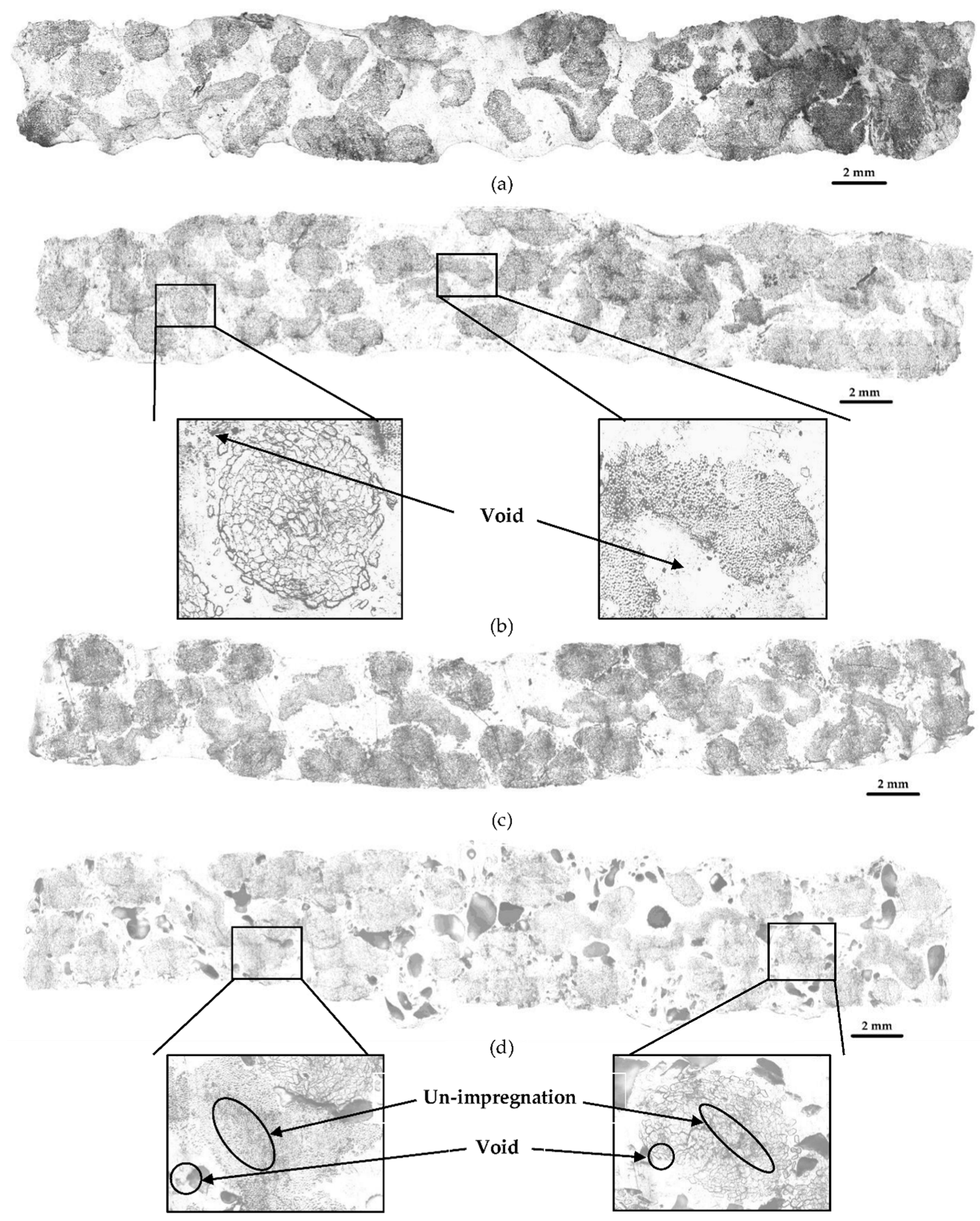

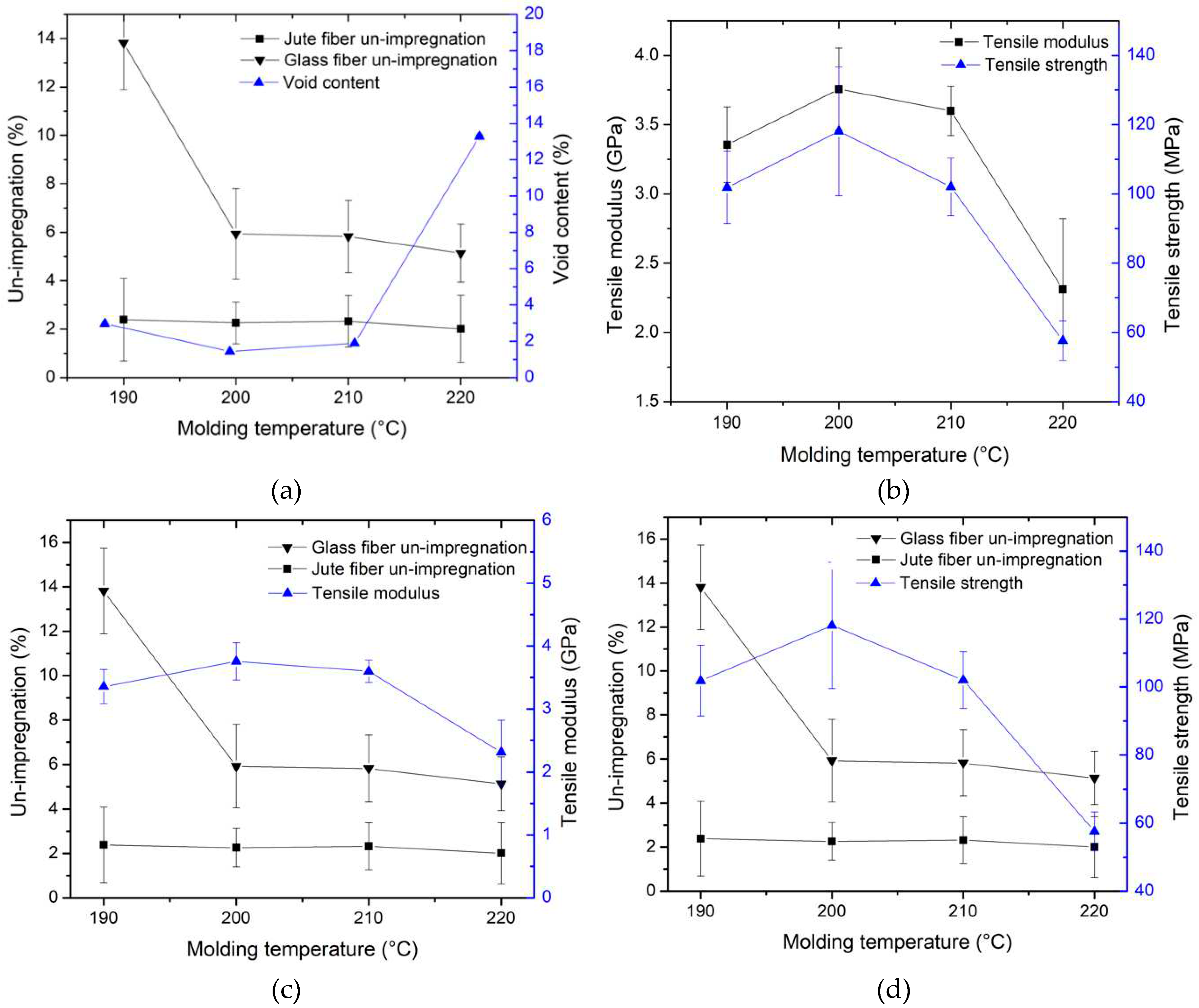

Figure 6 presents the microstructure of composite specimens at various molding temperatures. The findings reveal that the void content exhibited a noticeable increase at 220 °C, with a starting point for increased void content at 210 °C, as depicted in

Figure 6(d). Additionally,

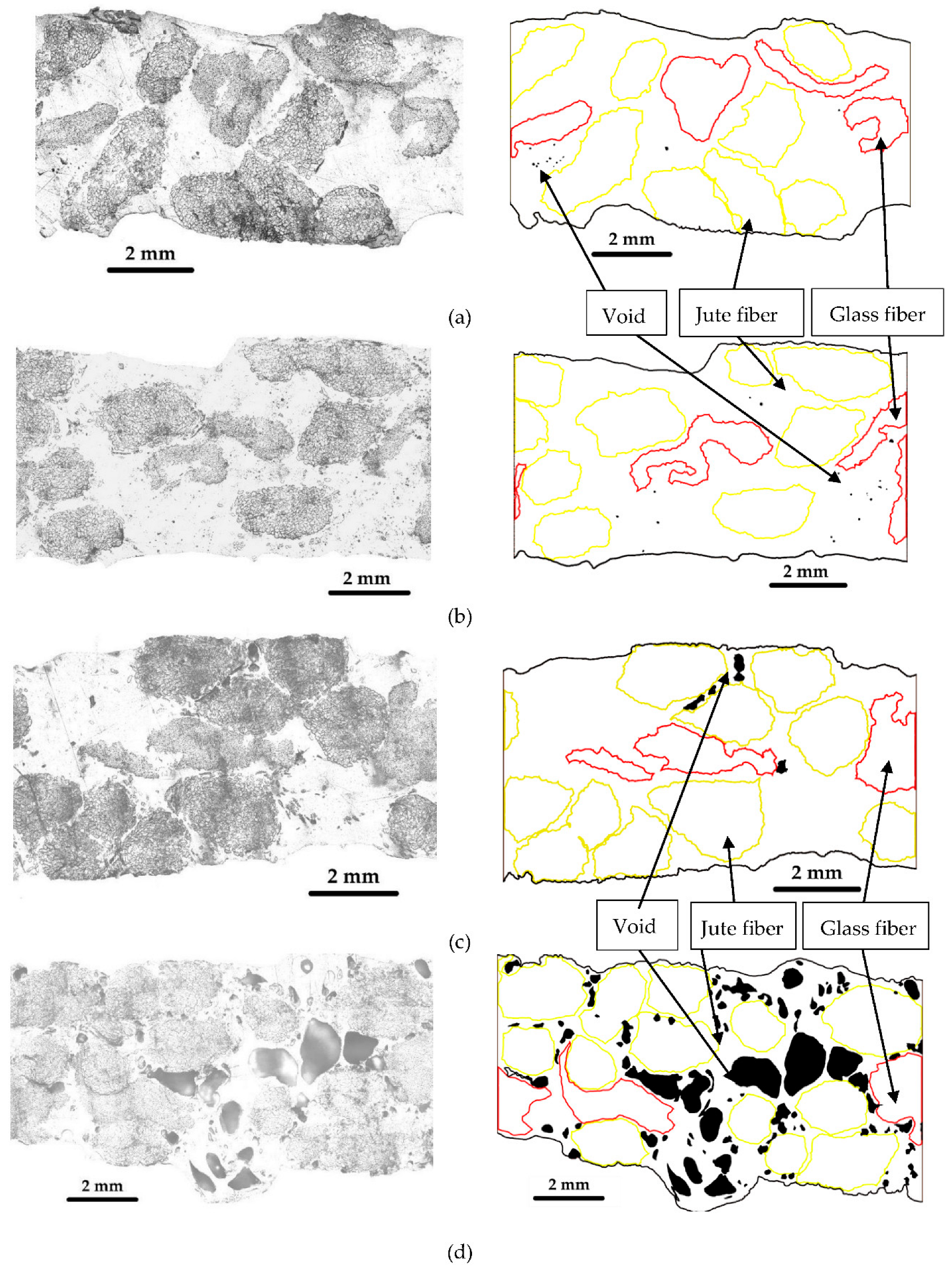

Figure 7 provides magnified cross-section areas that reveal the positions of jute fiber, glass fiber, and void content. It is clear that higher molding temperatures lead to an increase in void content, while the un-impregnation of resin decreases as the molding temperature rises. The presence of void content in the specimens may result from trapped moisture within the jute fiber, which is released at higher molding temperatures [

5]. From the microstructure results, the void content and un-impregnation analysis with mechanical properties are shown in

Figure 8 (a), (b), (c) and (d). The higher temperature has affected the speed of moisture evaporation from the jute fiber.

The results regarding the correlation between un-impregnation, void content, and molding temperature can be found in

Figure 8(a), whereas the relationship between molding temperature and tensile modulus, as well as tensile strength, is depicted in

Figure 8(b). In the un-impregnation results, there was a clear tendency for un-impregnation to decrease with an increase in molding temperature. Resin exhibited a greater ease of impregnation into the jute fiber compared to the glass fiber, primarily due to the jute fiber having more filament space within each bundle than the glass fiber. Notably, there was a significant issue with resin un-impregnation at a molding temperature of 190 °C for the glass fiber, with a rate as high as 13.81%. As temperatures increased, resin impregnation into the fiber became more effective compared to lower temperatures. This indicates that the resin viscosity decreases as the molding temperature increases, making it easier for the resin to impregnate. Effective resin impregnation into the fibers is crucial for enhancing mechanical properties. The results of void contents presented in

Figure 8(a) demonstrate that void content begins to increase at 210 °C, with the highest void content at 220 °C being approximately 13.28% and the lowest void content at 200 °C being about 1.44%. The presence of void content in the composite results from moisture in the jute fiber [

5]. In this case, voids appear when the molding temperature exceeds 210 °C, possibly due to interactions between the cellulose in the jute and water molecules [

18].

The presence of void content directly affects the mechanical properties of the composites [

19]. Both tensile modulus and tensile strength exhibit a decline as void content increases. The findings reveal that tensile modulus increases as the molding temperature escalates up to 200 °C, but thereafter, it begins to decline once the temperature surpasses 210 °C. The highest tensile modulus value was 3.76 GPa at a molding temperature of 200 °C. Tensile strength followed a similar trend, with the highest value of approximately 118.13 MPa occurring at a molding temperature of 200 °C. This effect can be attributed to the decreased viscosity of the resin at higher molding temperatures, facilitating its easier impregnation into the reinforcing fibers [

6,

20,

21]. Typically, resin can easily impregnate when it exhibits low viscosity or when molding temperatures are high [

6,

22]. However, in this case, at 220 °C, the jute fiber experiences high un-impregnation, possibly due to the presence of voids within the jute bundle, which further contributes to increased un-impregnation. Moreover, the decrease in tensile strength and modulus at 210 °C is attributed to the degradation of the jute fiber, which initiates decomposition at 200 °C [

22,

23].

Figure 8(c) illustrates the relationship between un-impregnation, molding temperature, and tensile modulus, while

Figure 8(d) presents the relationship between un-impregnation, tensile strength, and molding temperature. These results demonstrate the impact of un-impregnation on tensile modulus and tensile strength. Un-impregnation of the resin in the fibers decreased with an increase in molding temperature. Lower un-impregnation resulted in higher tensile modulus and tensile strength. However, even at 220 °C, where un-impregnation was low, tensile modulus and tensile strength remained low due to other factors, including void content and the degradation of the jute fiber.

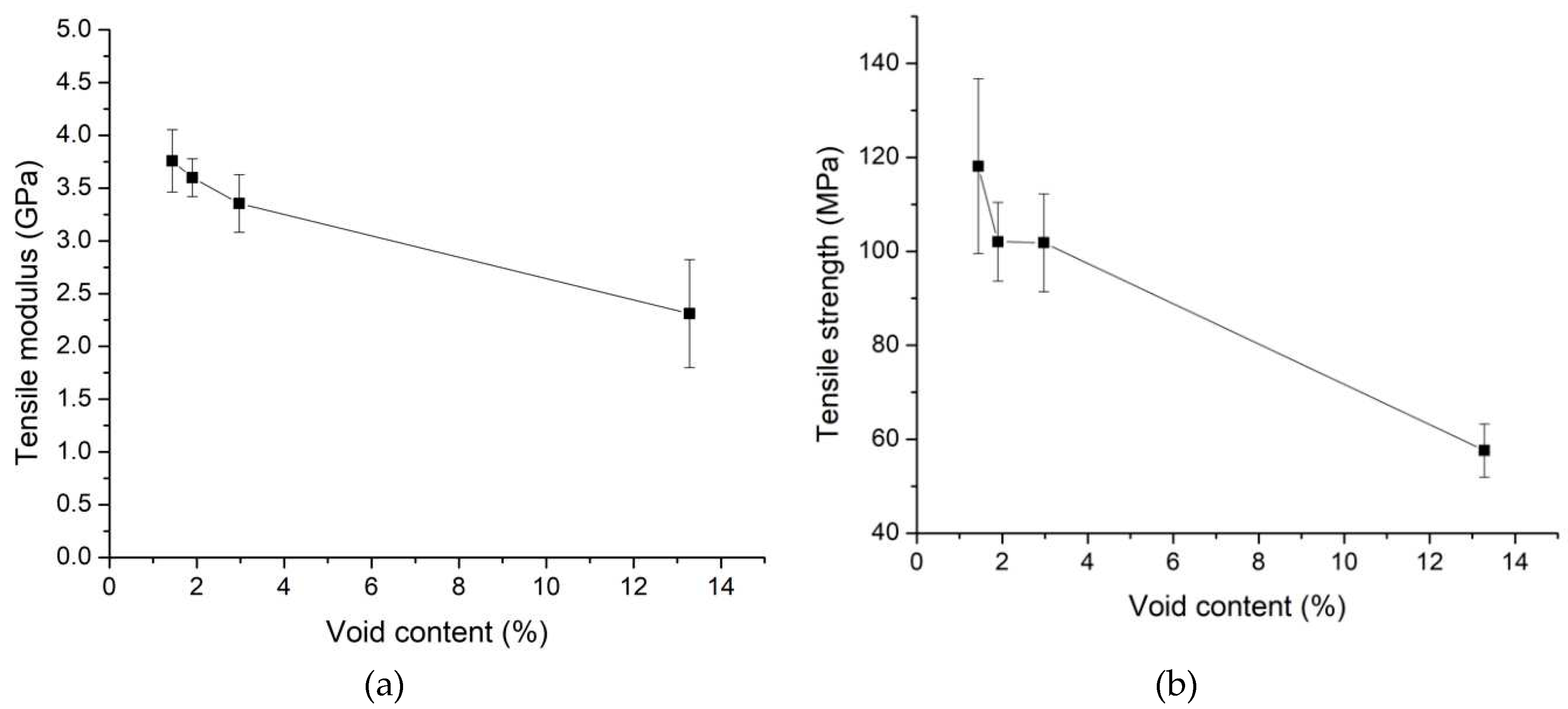

The void content of the specimens directly influenced their mechanical properties, with mechanical properties decreasing as void content increased. The void content at various molding temperatures was measured at 1.44%, 1.9%, 2.97%, and 13.28%, respectively. The relationships between (a) tensile modulus and void content and (b) tensile strength and void content are depicted in

Figure 9. It is evident that tensile strength decreases with an increase in void content, consistent with findings in the literature [

19,

23]. The presence of void content created spaces within the specimen, leading to a decrease in tensile strength and tensile modulus. These voids originated from moisture within the jute fiber.

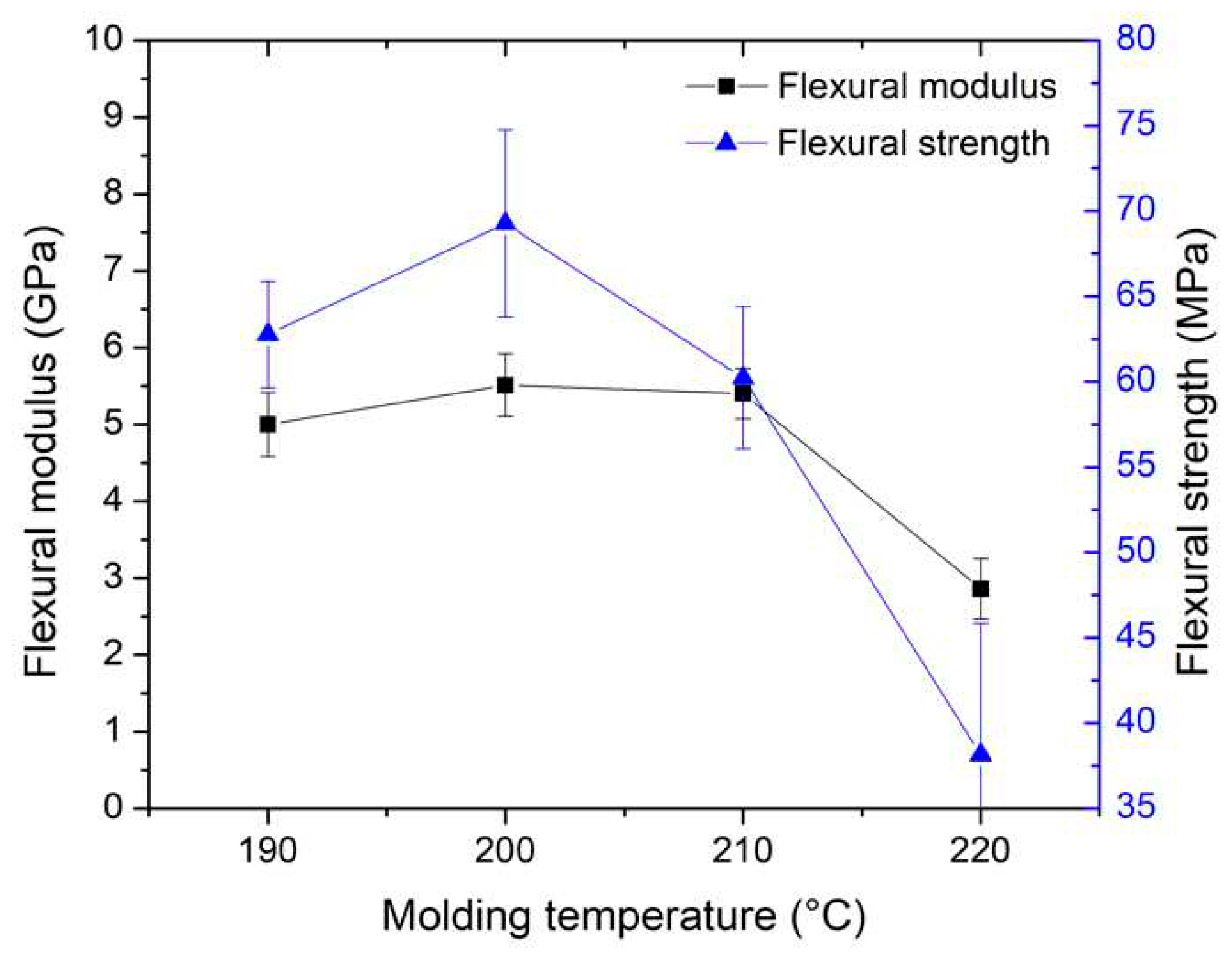

The results, as depicted in

Figure 10, illustrate the connection between molding temperature, flexural modulus, and flexural strength, exhibiting a pattern akin to the tensile properties. A rise in the molding temperature led to an increase in both flexural modulus and strength, up to 210 °C, beyond which they showed a decline. The peak values for flexural modulus and strength, reaching 5.51 GPa and 69.27 MPa, respectively, were observed at a molding temperature of 200 °C.

Even though resin impregnation is good, the mechanical properties are not always favorable. This suggests that the mechanical properties at a molding temperature of 220 °C decreased, as they are also influenced by void content and the degradable temperature of the jute fiber. The results show that the highest void content at 220 °C of molding temperature had a significant impact on the previously low mechanical properties. Additionally, at 220 °C of molding temperature, the jute fibers began to degrade. Based on the microstructure analysis and the discussion of mechanical properties, a molding temperature of 200 °C was selected as the optimal temperature for further investigation into the influence of pulling speed.

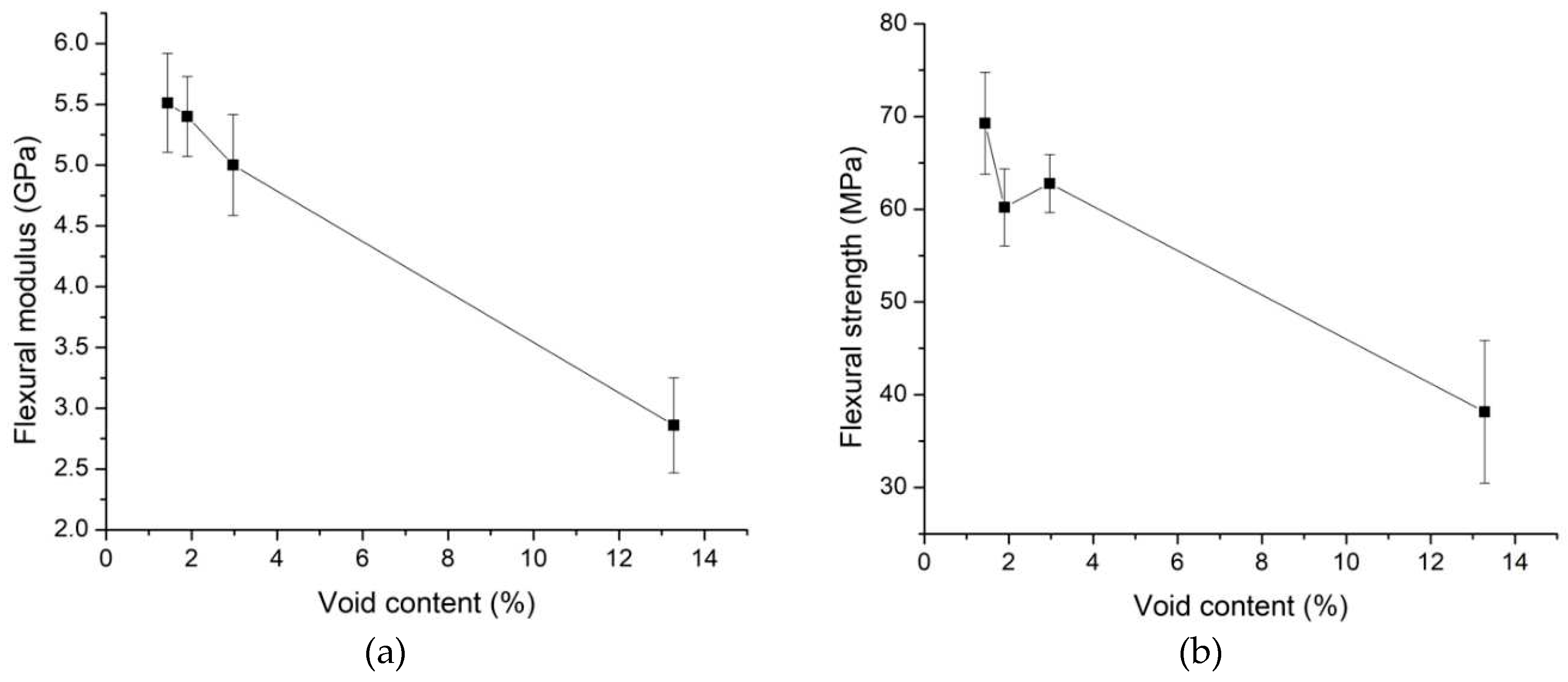

The relationships between flexural modulus, flexural strength, void content, varied molding temperature, and pulling speed are presented in

Figure 11. The results indicate that flexural strength and flexural modulus exhibit a trend similar to that of tensile strength and tensile modulus. They both decrease with an increase in void content. Consequently, the presence of void content in the specimens contributes to a decrease in mechanical properties.

3.1. The Effect of Molding Temperature Parameter

After a study of the molding temperature parameter, the molding temperature was selected at 200 °C for the study of pulling speed parameters. The pulling speed is one parameter that is important in the pultrusion process. Normally, pulling speed parameters can affect resin impregnation [

24,

25,

26].

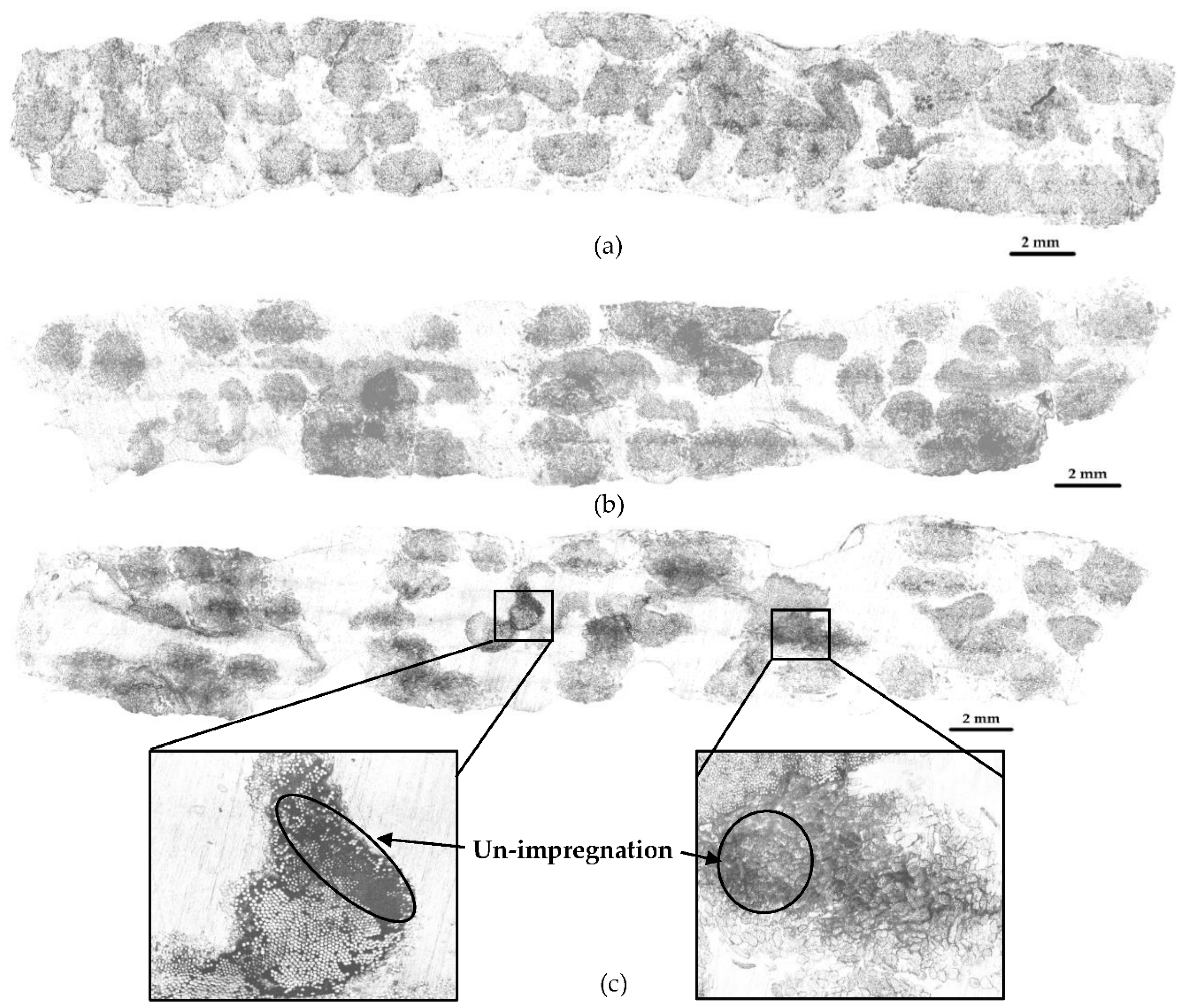

Figure 12 presents the analysis of the microstructure of composite specimens at various pulling speeds, ranging from 40 to 140 mm/min, through microscopic examination. The findings reveal that un-impregnation grows with an escalation in pulling speed, as seen in

Figure 12 (c). Following this, an assessment of void content and un-impregnation was carried out.

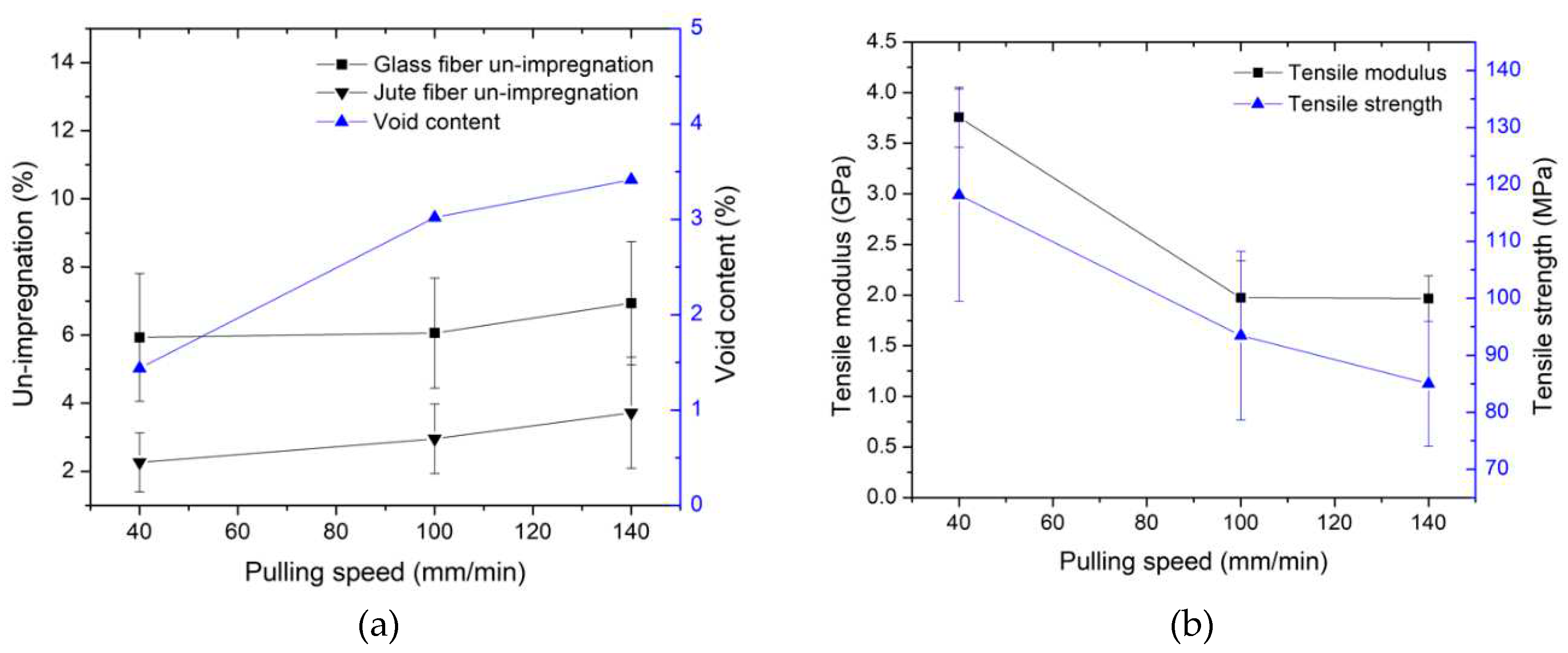

The results regarding the relationship between un-impregnation, void content, and pulling speed are presented in

Figure 12(a), while the relationship between tensile modulus, tensile strength, and pulling speed is depicted in

Figure 12(b). Similar to the un-impregnation results at different molding temperatures discussed previously, it is observed that the un-impregnation of glass fiber is higher than that of jute fiber. This difference can be attributed to the reduced space between filaments in glass fiber compared to jute fiber. As a result, the resin can impregnate the glass fiber bundle to a lesser extent than the jute fiber bundle, as shown in

Figure 12(c), in the magnified area illustrating un-impregnation between glass fiber and jute fiber. In the sections involving different pulling speeds, un-impregnation increased with an increase in pulling speeds [

14,

25,

26] because the resin can impregnate over a longer duration at lower pulling speeds. Consequently, higher pulling speeds allow for shorter impregnation times. This explains why the un-impregnation value can be used to confirm the decrease in mechanical properties at higher pulling speeds, in accordance with previous literature. The results also show an increase in void contents with higher pulling speeds. However, these variations in void content were relatively small, ranging from about 1% to 2%, with the lowest void value observed at 40 mm/min pulling speed, at approximately 1.44% of void content. These minimal differences had limited effects on the mechanical properties. The tensile modulus decreased with an increase in pulling speed because specimens remained in the mold for a longer time, allowing the resin to impregnate for an extended period. The results indicated a tensile modulus of 3.76 GPa at a pulling speed of 40 mm/min. Tensile strength in

Figure 13(b) exhibited a similar trend to the tensile modulus, with the highest tensile strength value of approximately 118.13 MPa observed at a pulling speed of 40 mm/min. These results align with existing literature [

25,

26].

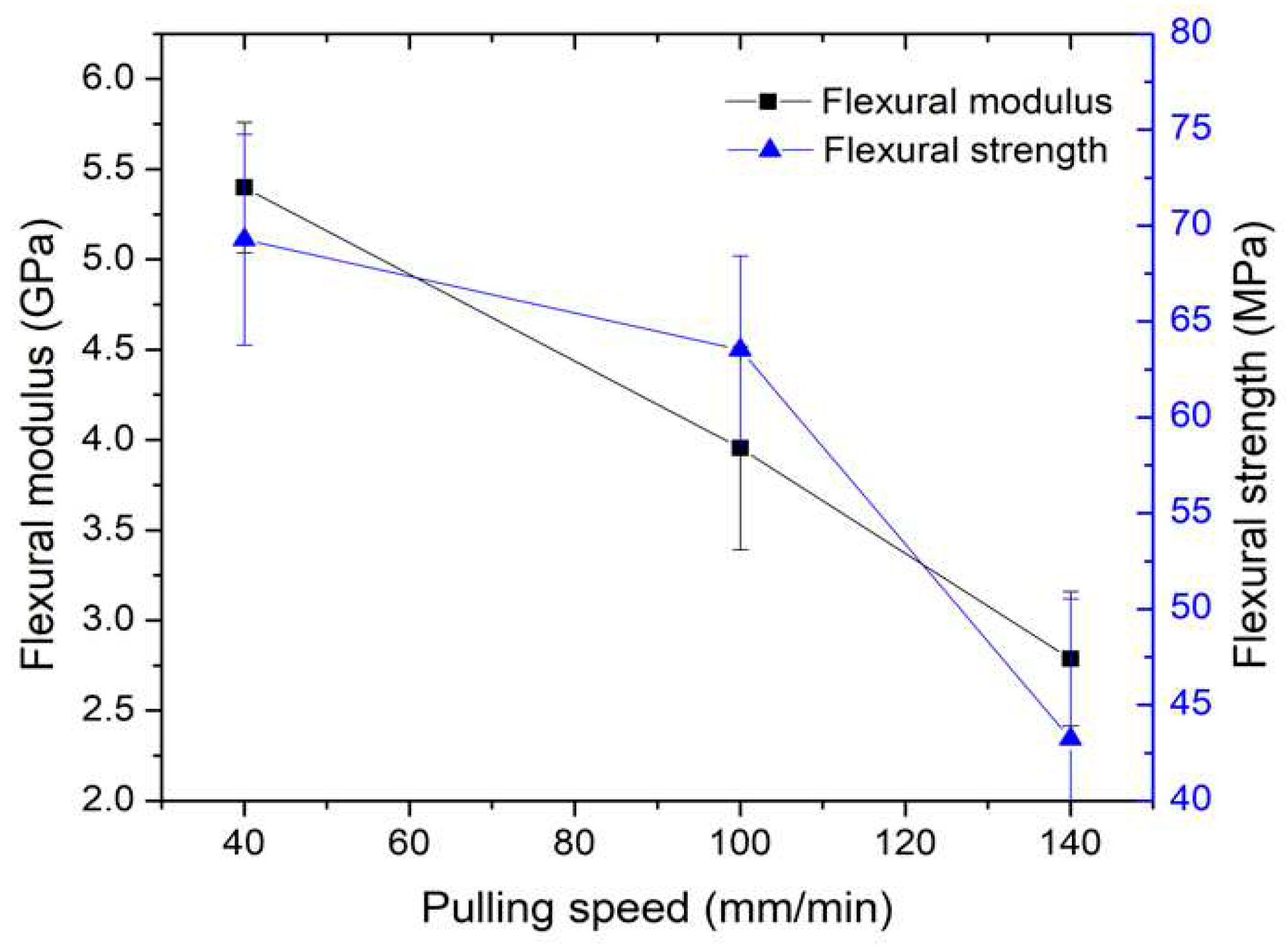

The results regarding the relationship between flexural modulus, flexural strength, and pulling speed are presented in

Figure 14, illustrating a decrease in flexural strength and modulus with an increase in pulling speeds. Similar to the trends observed with tensile modulus and strength, these specimens experienced an increase in pulling speeds, resulting in less impregnation time for the resin, leading to lower flexural strength and modulus. Notably, the flexural strength and flexural modulus reached their highest values at a pulling speed of 40 mm/min, measuring 69.27 MPa and 5.51 GPa, respectively. As a result, a pulling speed of 40 mm/min yielded the highest mechanical properties in terms of tensile strength, tensile modulus, flexural strength, and flexural modulus.

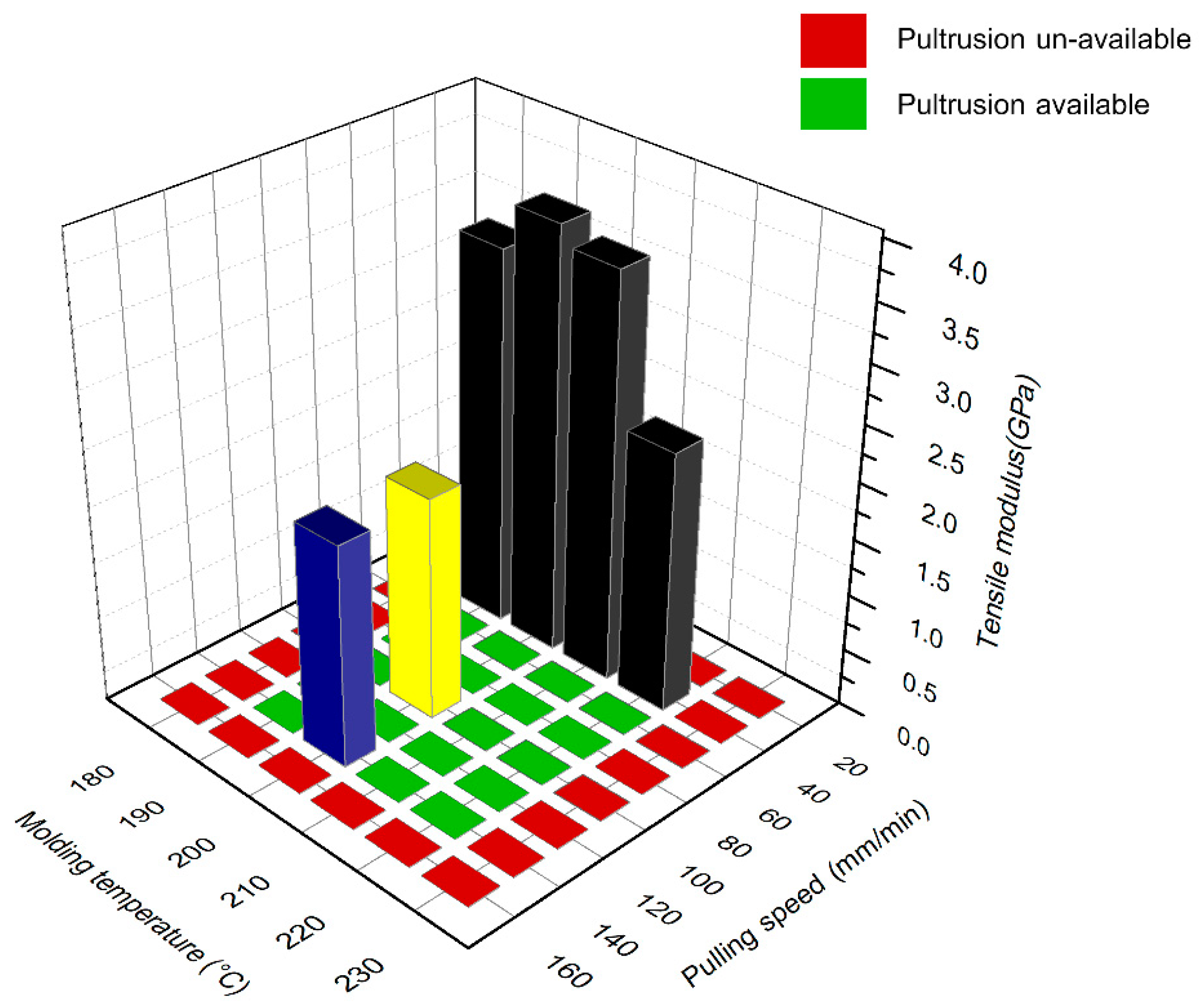

For the analysis of the results, a window processing can be defined based on molding temperature and pulling speed, as shown in

Figure 15. A lower molding temperature leads to poor impregnation and high viscosity of thermoplastic, which in turn impacts the mechanical properties, given that they rely on impregnation quality. Furthermore, high viscosity of thermoplastic can cause jute fiber breakage before being pulled out from the hot die. Thus, the lowest feasible molding temperature for pultrusion is 190 °C. On the other hand, a higher molding temperature has a positive effect on impregnation and lowers viscosity. However, it’s important to note that jute fibers start to degrade at 220 °C of molding temperature. Therefore, the recommended molding temperature range for continuous composite pultrusion is 190 to 220 °C. Regarding pulling speed, lower pulling speeds result in better impregnation, but they can also lead to the degradation of jute fiber. Conversely, higher pulling speeds are associated with lower impregnation. The acceptable pulling speed range for composite pultrusion is 40 to 140 mm/min.

5. Conclusions

In this study, jute and glass fibers were utilized to reinforce a polypropylene (PP) matrix using the pultrusion process. The pultrusion process involved the adjustment of molding temperature and pulling speed as key parameters. To evaluate the impact of these parameters, the study examined the mechanical properties of the jute/glass polypropylene hybrid composite, specifically focusing on tensile strength, tensile modulus, flexural strength, and flexural modulus. The research also involved detailed micrograph analysis, void content analysis, and un-impregnation analysis to understand how pultrusion parameters influenced these factors. The results revealed a significant correlation between pultrusion parameters, void content, un-impregnation, and the mechanical properties of the composite.

The mechanical properties increased with an increase in molding temperature, but after reaching a certain point, they started to decrease. These effects were influenced by void content, un-impregnation, and the degradation of jute fibers. Void content increased with higher molding temperatures, while un-impregnation decreased. Another important parameter in the pultrusion process is pulling speed, which has previously been shown to impact mechanical properties. As pulling speed increased, it led to a decrease in mechanical properties, accompanied by an increase in void content and un-impregnation. Based on the results, it is evident that both molding temperature and pulling speed are crucial parameters for enhancing the quality of composite materials in the thermoplastic pultrusion process.

In the thermoplastic pultrusion process of jute/glass fiber reinforced with PP, a window of processing is defined by the molding temperature and pulling speed parameters. The feasible range for molding temperatures is 190 to 220°C, and for pulling speeds, it is 40 to 140 mm/min.

This study plays a significant role in the development of pultruded composites for jute/glass fiber reinforced with PP through thermoplastic pultrusion. It marks the initiation of continuous thermoplastic pultrusion hybrid composites, aligning with green and recycling initiatives by utilizing jute fiber from nature. This alternative method broadens the application range of continuous composite materials.

Author Contributions

Conceptualization, P.T. and A.M.; methodology, P.T. and A.M.; software, P.T.; validation, A.M., P.T., S.P. and P.U.; formal analysis, A.M.; investigation, A.M.; resources, A.M.; data curation, A.M.; writing—original draft preparation, A.M.; writing—review and editing, A.M., P.T., S.P. and P.U.; visualization, A.M.; supervision, A.M..; project administration, A.M.; funding acquisition, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Research and Researchers Funds for Industries (RRi), National Research Council of Thailand (NRCT) under project code MSD60I0028.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This research project was funded by Research and Researchers Funds for Industries (RRi), National Research Council of Thailand (NRCT) under project code MSD60I0028.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Lin, Y.-C.; Chang, C.-c.A. Double Standard: The Role of Environmental Consciousness in Green Product Usage. J. Mark. 2012, 76, 125–134. [Google Scholar] [CrossRef]

- Nijssen, R.P.L. Composite Materials: an introduction; A VKCN publication: Amsterdam, 2015. [Google Scholar]

- Samuel, O.D.; Agbo, S.; Adekanye, T.A. Assessing Mechanical Properties of Natural Fibre Reinforced Composites for Engineering Applications. J. Miner. Mater. Charact. Eng. 2012, 11, 780–784. [Google Scholar] [CrossRef]

- Sharath, S.H.S.; M. Ramachandra. Green Composites: A Review. Mater. Today 2018, 5, 2518–2526. [CrossRef]

- Umar Nirmal, a.n.; Jamil Hashim, a.; Ahmad, M.M.H.M. A review on tribological performance of natural fibre polymeric composites. Tribol. Int. 2015, 183, 77–104. [CrossRef]

- Memon, A.; Nakai, A. Mechanical Properties of Jute Spun Yarn/PLA Tubular Braided Composite by Pultrusion Molding. Energy Procedia 2013, 34, 818–829. [Google Scholar] [CrossRef]

- Safonova, A.A.; Carloneb, P.; Akhatova, I. Mathematical simulation of pultrusion processes: A review. Compos. Struct. 2018, 184, 153–177. [Google Scholar] [CrossRef]

- Wilcox, J.A.D.; Wright, D.T. Towards pultrusion process optimisation using artificial neural networks. Journal of Materials Processing Technology 1998, 83, 131–141. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef] [PubMed]

- Biswas, S.; Ahsan, Q.; Cenna, A.; Hasan, M.; Hassan, A. Physical and Mechanical Properties of Jute, Bamboo and Coir Natural Fiber. Fibers Polym. 2013, 14, 1762–1767. [Google Scholar] [CrossRef]

- Hashmi, S. Reference module in materials science and materials engineering; Elsevier: Amsterdam, 2001. [Google Scholar]

- Bindal, A.; Singh, S.; Batra, N.K.; Khanna, R. Development of Glass/Jute Fibers Reinforced Polyester Composite. Indian J. Eng. Mater. Sci. 2013, 1–6. [Google Scholar] [CrossRef]

- Zamri, M.H.; Akil, H.M.; Bakar, A.A.; Arifin, Z.; Ishak, M.; Cheng, L.W. Effect of water absorption on pultruded jute/glass fiber-reinforced unsaturated polyester hybrid composites. J. Compos. Mater. 2011, 0, 1–11. [Google Scholar] [CrossRef]

- Memon, A.; Tipboonsri, P. Optimizing thermoplastic pultrusion parameters for quality long fiber thermoplastic pellets in glass fiber-reinforced polypropylene. Polymers and Polymer Composites 2023, 31, 1–11. [Google Scholar] [CrossRef]

- Velde, K.V.D.; Kiekens, P. Thermoplastic pultrusion of natural fiber-reinforced composites. Compos. Struct. 2001, 54, 355–360. [Google Scholar] [CrossRef]

- ASTM Standard 3039. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International 2017, PA. [Google Scholar] [CrossRef]

- D790, A.S. Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International 2010, PA. [Google Scholar] [CrossRef]

- Khazraji, A.C.; Robert, S. Interaction Effects between Cellulose and Water in Nanocrystalline and Amorphous Regions: A Novel Approach Using Molecular Modeling. J. Nanomater. 2013, 1–10. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, B.M.; Wang, D.F.; Wu, Z.J. Effects of cure cycles on void content and mechanical properties of composite laminates. Compos. Struct. 2006, 73, 303–309. [Google Scholar] [CrossRef]

- Tipboonsri, P.; Wattanajitsiri, V.; Memon, A. Long fiber thermoplastic pellets of glass fiber/polypropylene from pultrusion process. Journal of Physics: Conference Series 2021, 1719, 012066. [Google Scholar] [CrossRef]

- Lan, H.Y.; Tseng, H.C. Temperature Correction on Shear Heating for the Viscosity of PP/Supercritical CO2 Mixture at High Shear Rates. J. Chin. Inst. Chem. Engrs. 2003, 34, 405–415. [Google Scholar] [CrossRef]

- Memon, A.; Nakai, A. Fabrication and Mechanical Properties of Jute Spun Yarn/PLA Unidirectional Composite by Compression Molding. Energy Procedia 2013, 34, 830–838. [Google Scholar] [CrossRef]

- Patou, J.; De Luycker, E.; Bernhart, G. Influence of void content on the mechanical properties of carbon/pps laminates. In Proceedings of the European Conference on Composite Materials Munich, Germany, June 26-30, 2016, 2016.

- Minchenkov, K.; Gusev, S.; Sulimov, A.; Alajarmeh, O.; Sergeichev, I.; Safonov, A. Experimental and numerical analyses of the thermoplastic pultrusion of large structural profiles. Materials & Design 2023, 232, 112149. [Google Scholar] [CrossRef]

- Angelov, I.; Wiedmer, S.; Evstatiev, M.; Friedrich, K.; Mennig, G. Pultrusion of a flax/polypropylene yarn. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1431–1438. [Google Scholar] [CrossRef]

- Tanaka, Y.; Torun, A.R.; Lebel, L.L.; Ohtani, A.; Nakai, A. Development of pultrusion system for the continuous fiber-reinforced thermoplastic composite tube with braiding technique. In Proceedings of the The 10th International Conference on Flow Processes in Composite Materials, Switzerland, July 12-15, 2010, 2010.

Figure 1.

Schematic of thermoplastic pultrusion process and heating position of die.

Figure 1.

Schematic of thermoplastic pultrusion process and heating position of die.

Figure 2.

TGA results of jute fiber and pp fiber.

Figure 2.

TGA results of jute fiber and pp fiber.

Figure 3.

Failure of jute fiber at temperature over 220 ˚C.

Figure 3.

Failure of jute fiber at temperature over 220 ˚C.

Figure 4.

Successfully pultruded specimen of jute/glass polypropylene hybrid composite.

Figure 4.

Successfully pultruded specimen of jute/glass polypropylene hybrid composite.

Figure 5.

Analysis of difference between void content and un-impregnation.

Figure 5.

Analysis of difference between void content and un-impregnation.

Figure 6.

Cross-section of differential molding temperatures (a) specimen at 190 °C, (b) specimen at 200 °C, (c) specimen at 210 °C and (d) specimen at 220 °C.

Figure 6.

Cross-section of differential molding temperatures (a) specimen at 190 °C, (b) specimen at 200 °C, (c) specimen at 210 °C and (d) specimen at 220 °C.

Figure 7.

Cross-setion obsevation of specimens (a) specimen at 190 °C, (b) specimen at 200 °C, (c) specimen at 210 °C and (d) specimen at 220 °C.

Figure 7.

Cross-setion obsevation of specimens (a) specimen at 190 °C, (b) specimen at 200 °C, (c) specimen at 210 °C and (d) specimen at 220 °C.

Figure 8.

Relation between (a) un-impregnation, void content and molding temperature, (b) tensile modulus, tensile strength and molding temperature, (c) un-impregnation, tensile modulus and molding temperature and (d) un-impregnation, tensile strength and molding temperature.

Figure 8.

Relation between (a) un-impregnation, void content and molding temperature, (b) tensile modulus, tensile strength and molding temperature, (c) un-impregnation, tensile modulus and molding temperature and (d) un-impregnation, tensile strength and molding temperature.

Figure 9.

Relation between (a) tensile modulus and void content and (b) tensile strength and void content.

Figure 9.

Relation between (a) tensile modulus and void content and (b) tensile strength and void content.

Figure 10.

Relation between flexural modulus, flexural strength and molding temperature.

Figure 10.

Relation between flexural modulus, flexural strength and molding temperature.

Figure 11.

Relation between (a) flexural modulus and void content and (b) flexural strength and void content.

Figure 11.

Relation between (a) flexural modulus and void content and (b) flexural strength and void content.

Figure 12.

Cross-section of different pulling speeds (a) specimen at 40 mm/min, (b) specimen at 100 mm/min and (c) specimen at 140 mm/min. There are differences in the length of cross-section figures because of different pulling speeds. The molding temperature was selected at 200 °C for the study the effect of pulling speed parameters.

Figure 12.

Cross-section of different pulling speeds (a) specimen at 40 mm/min, (b) specimen at 100 mm/min and (c) specimen at 140 mm/min. There are differences in the length of cross-section figures because of different pulling speeds. The molding temperature was selected at 200 °C for the study the effect of pulling speed parameters.

Figure 13.

Relation between (a) un-impregnation, void content and pulling speed and (b) tensile modulus, tensile strength and pulling speed. The molding temperature was selected at 200 °C for the study the effect of pulling speed parameters.

Figure 13.

Relation between (a) un-impregnation, void content and pulling speed and (b) tensile modulus, tensile strength and pulling speed. The molding temperature was selected at 200 °C for the study the effect of pulling speed parameters.

Figure 14.

Relation between flexural modulus, flexural strength and pulling speed. The molding temperature was selected at 200 °C for the study the effect of pulling speed parameters.

Figure 14.

Relation between flexural modulus, flexural strength and pulling speed. The molding temperature was selected at 200 °C for the study the effect of pulling speed parameters.

Figure 15.

Window processing of jute/glass fiber reinforced with PP composite by thermoplastic pultrusion.

Figure 15.

Window processing of jute/glass fiber reinforced with PP composite by thermoplastic pultrusion.

Table 1.

Thermoplastic pultrusion conditions.

Table 1.

Thermoplastic pultrusion conditions.

Preform

No. |

Temperature

(˚C) |

Pulling speed

(mm/min) |

| 1 |

190 |

40 |

| 2 |

200 |

40 |

| 3 |

210 |

40 |

| 4 |

220 |

40 |

| 5 |

200 |

100 |

| 6 |

200 |

140 |

Table 2.

Volume fraction of continuous composite.

Table 2.

Volume fraction of continuous composite.

VF of matrix

(%) |

VF of Jute

(%) |

VF of GF

(%) |

Filling ratio

(%) |

| 68.5 |

23.1 |

9.0 |

100.5 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).