Submitted:

11 December 2023

Posted:

12 December 2023

Read the latest preprint version here

Abstract

Keywords:

1. Introduction

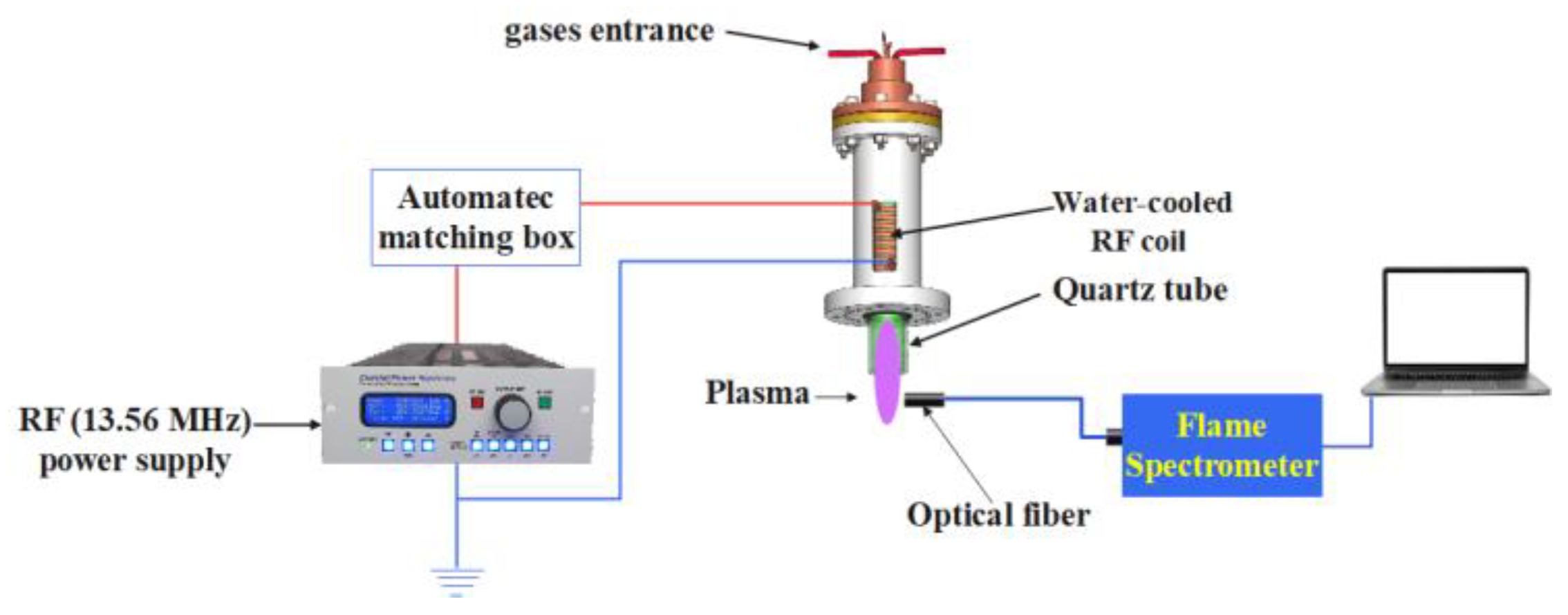

2. Materials and Methods

3. Results

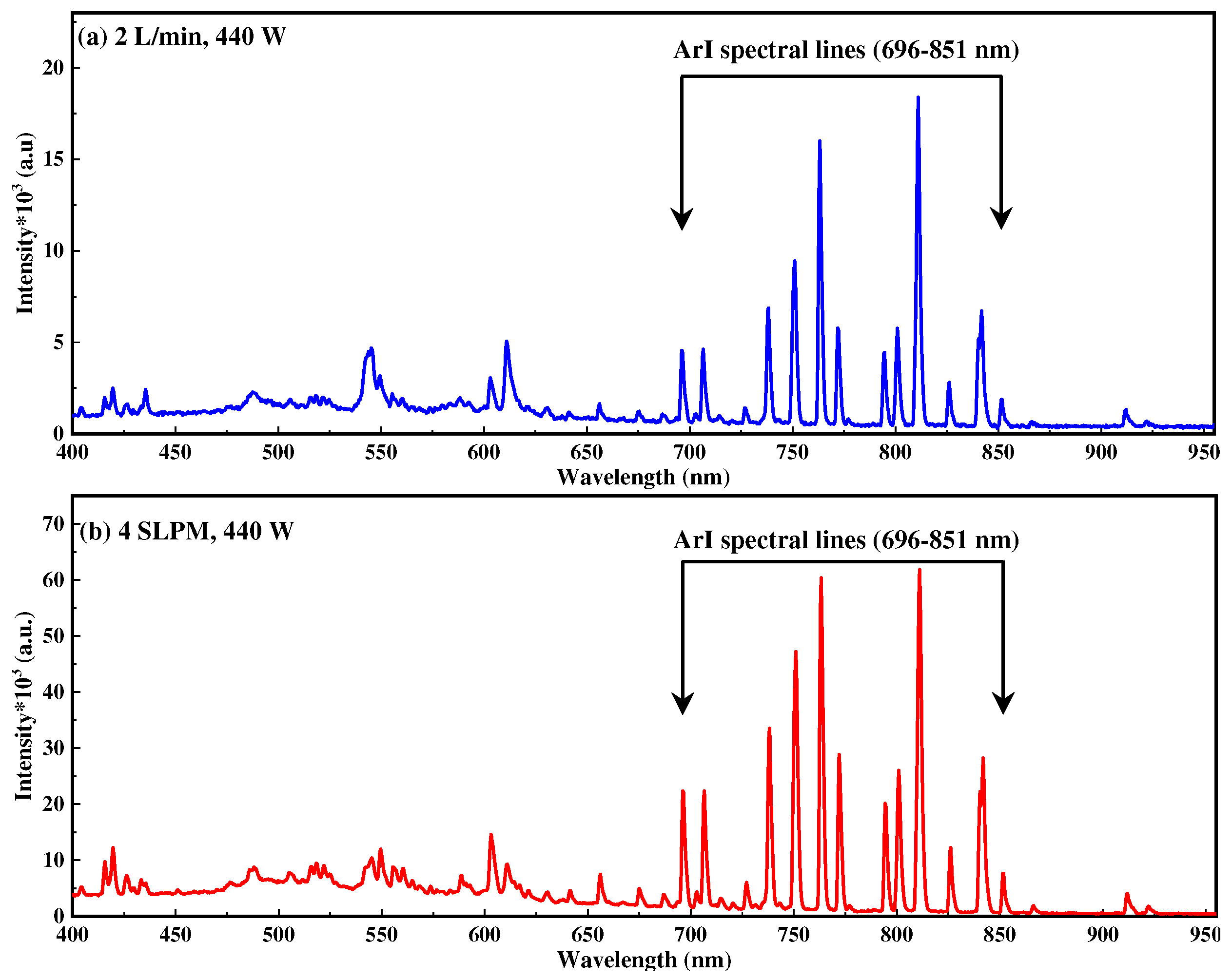

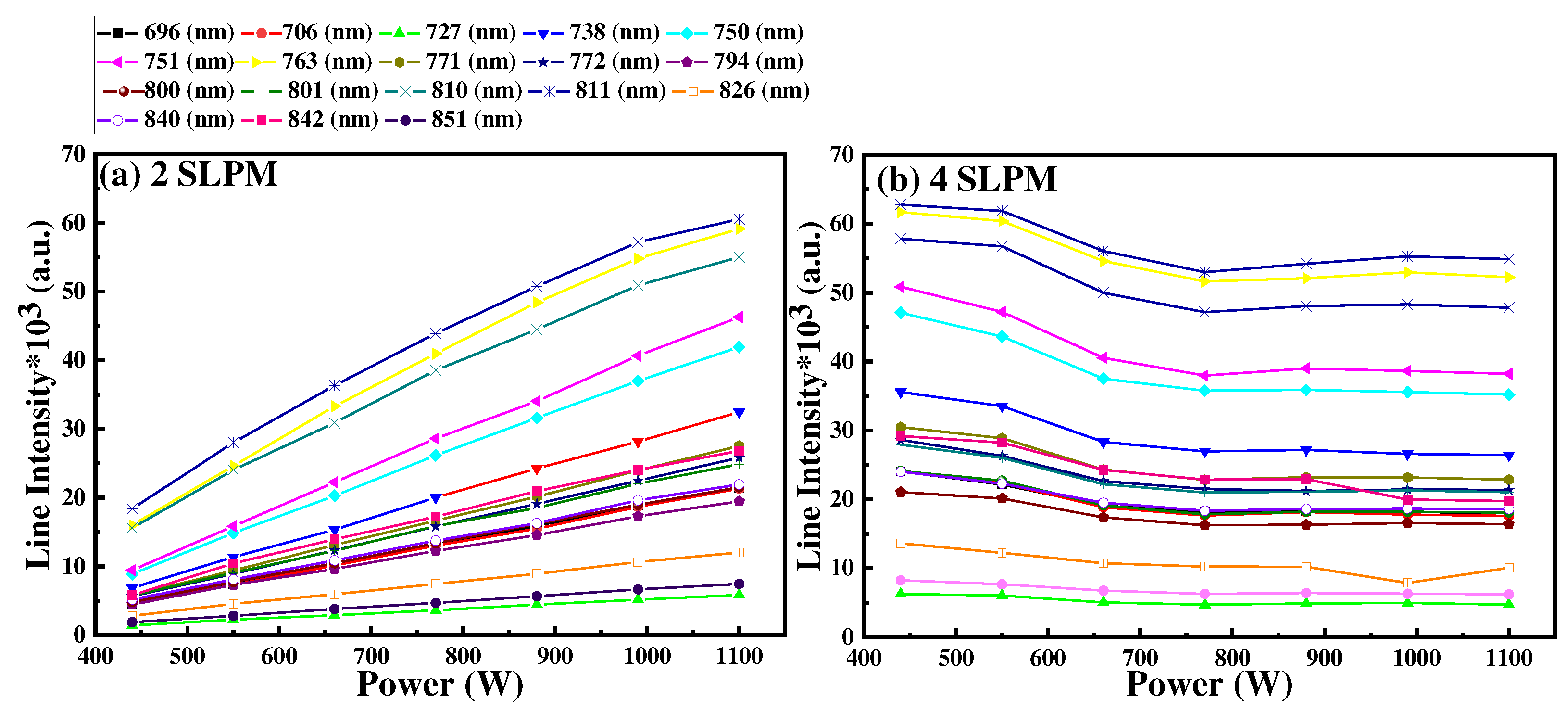

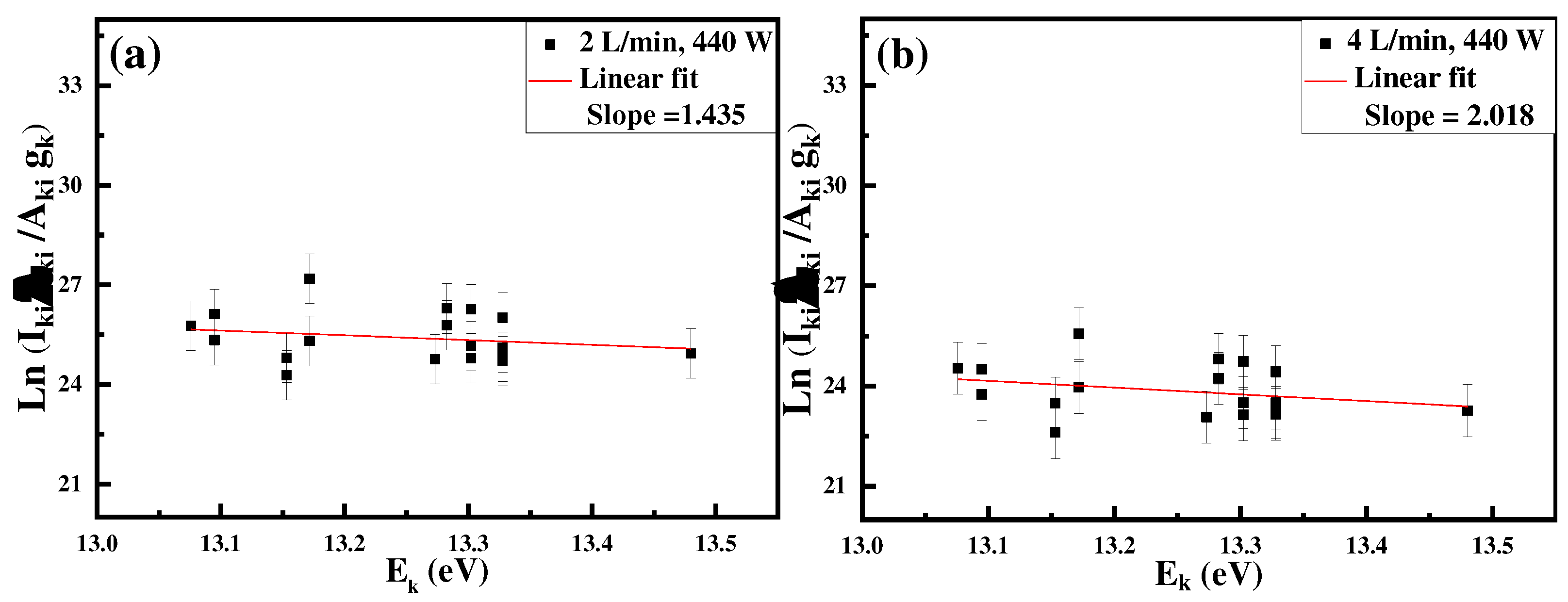

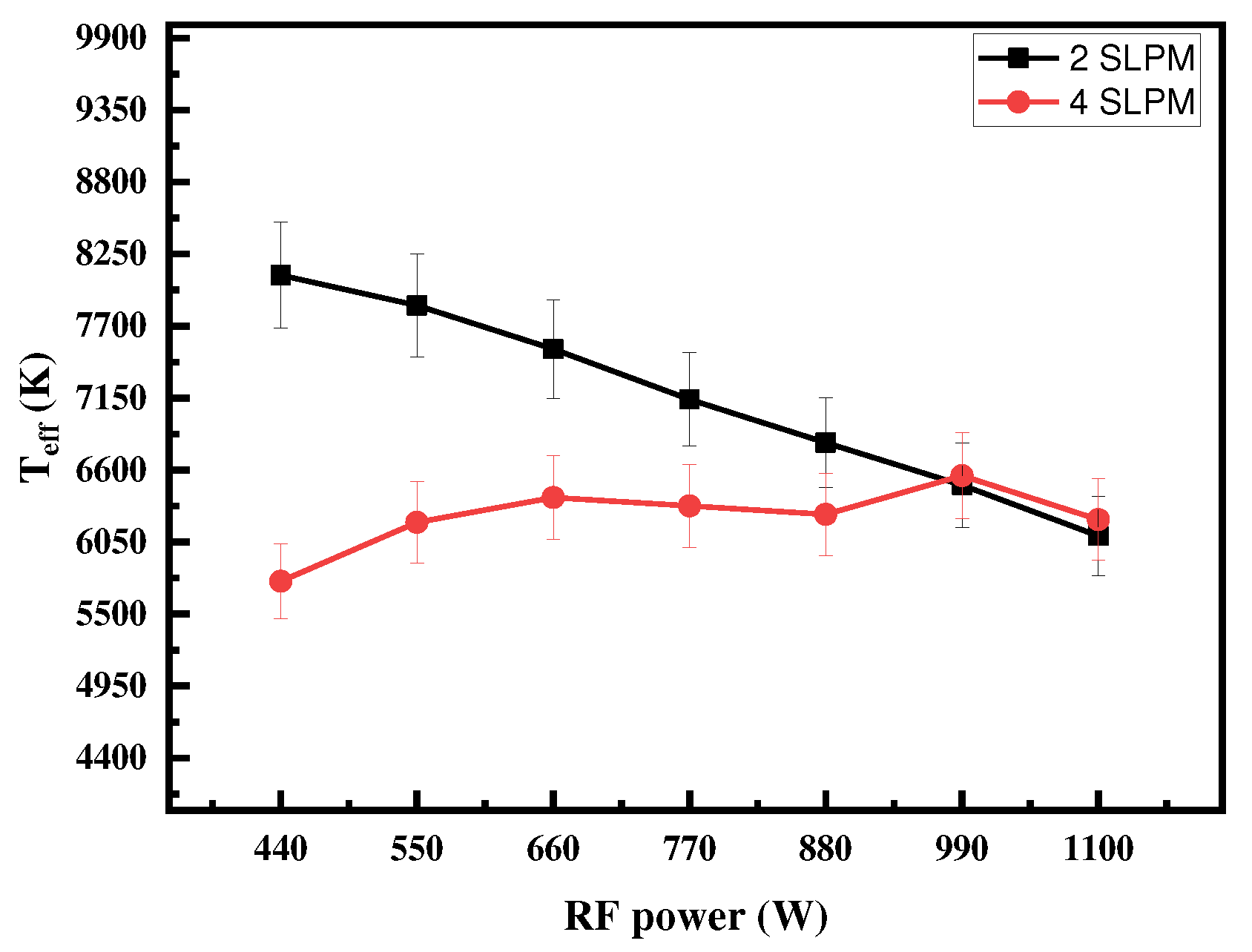

3.1. Excitation Temperature

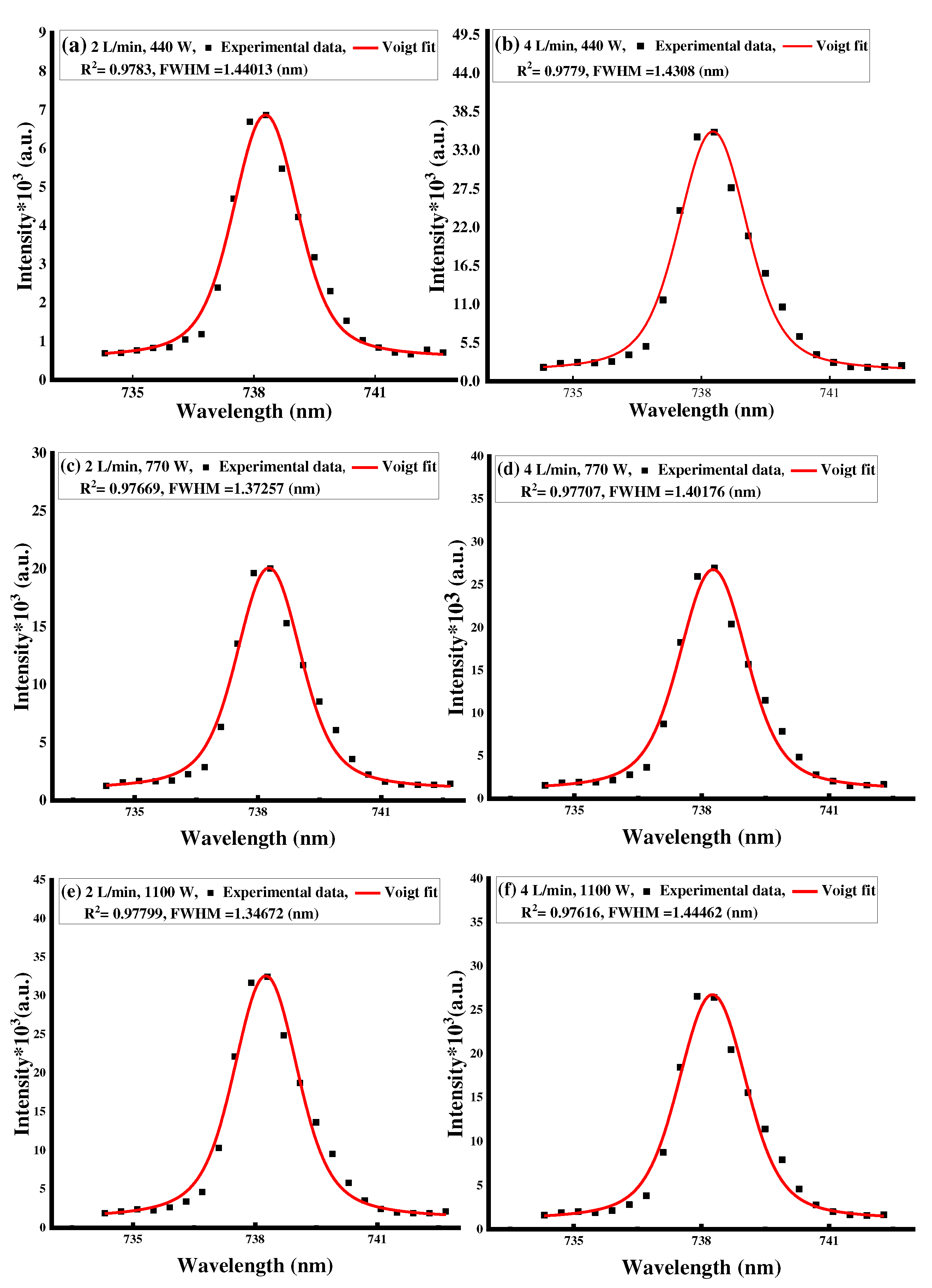

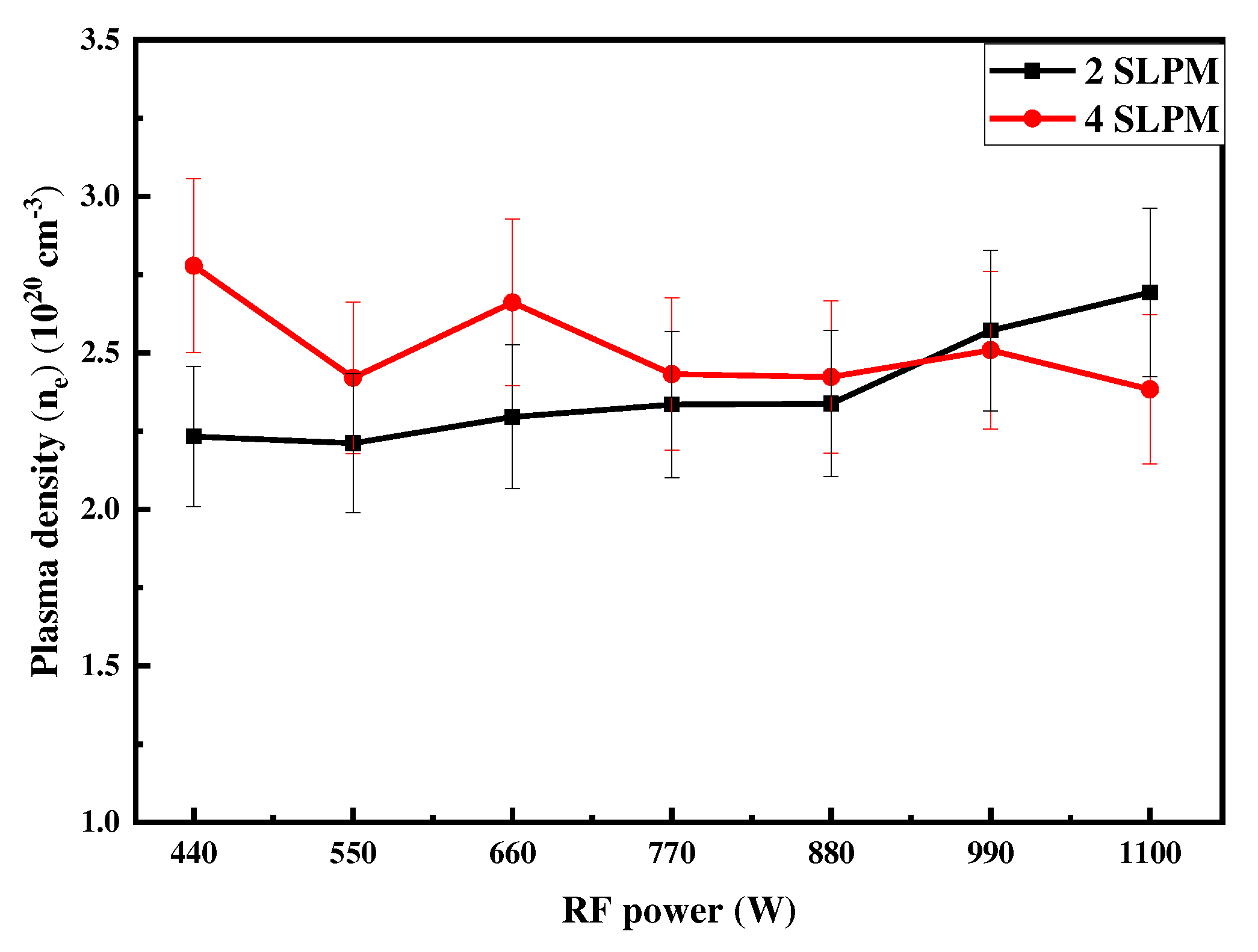

3.2. Electron Density

5. Conclusions

References

- Lombardi, L.; Carnevale, E.; Corti, A. A Review of Technologies and Performances of Thermal Treatment Systems for Energy Recovery from Waste. Waste Management 2015, 37, 26–44. [Google Scholar] [CrossRef] [PubMed]

- Brunner, P.H. WTE: Thermal Waste Treatment for Sustainable Waste Management. In Recovery of Materials and Energy from Urban Wastes; Springer New York: New York, NY, 2019; pp. 523–536. [Google Scholar]

- Leckner, B. Process Aspects in Combustion and Gasification Waste-to-Energy (WtE) Units. Waste Management 2015, 37, 13–25. [Google Scholar] [CrossRef] [PubMed]

- Panepinto, D.; Tedesco, V.; Brizio, E.; Genon, G. Environmental Performances and Energy Efficiency for MSW Gasification Treatment. Waste Biomass Valorization 2015, 6, 123–135. [Google Scholar] [CrossRef]

- Manisalidis, I.; Stavropoulou, E.; Stavropoulos, A.; Bezirtzoglou, E. Environmental and Health Impacts of Air Pollution: A Review. Front Public Health 2020, 8, 505570. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life Cycle Assessment of Pyrolysis, Gasification and Incineration Waste-to-Energy Technologies: Theoretical Analysis and Case Study of Commercial Plants. Science of The Total Environment 2018, 626, 744–753. [Google Scholar] [CrossRef] [PubMed]

- Safavi, S.M.; Richter, C.; Unnthorsson, R. Dioxin and Furan Emissions from Gasification. In Gasification; Silva, V., Tuna, C.E., Eds.; IntechOpen: Rijeka, 2021; p. Ch. 5; ISBN 978-1-83968-796-9. [Google Scholar]

- Lopes, E.J.; Okamura, L.A.; Yamamoto, C.I. FORMATION OF DIOXINS AND FURANS DURING MUNICIPAL SOLID WASTE GASIFICATION. Brazilian Journal of Chemical Engineering 2015, 32, 87–97. [Google Scholar] [CrossRef]

- Magoua Mbeugang, C.F.; Li, B.; Lin, D.; Xie, X.; Wang, S.; Wang, S.; Zhang, S.; Huang, Y.; Liu, D.; Wang, Q. Hydrogen Rich Syngas Production from Sorption Enhanced Gasification of Cellulose in the Presence of Calcium Oxide. Energy 2021, 228, 120659. [Google Scholar] [CrossRef]

- Cortazar, M.; Santamaria, L.; Lopez, G.; Alvarez, J.; Zhang, L.; Wang, R.; Bi, X.; Olazar, M. A Comprehensive Review of Primary Strategies for Tar Removal in Biomass Gasification. Energy Convers Manag 2023, 276, 116496. [Google Scholar] [CrossRef]

- Yadav, A.; Karmakar, S.; Kar, S.; Kumar, M. Numerical Modelling of a Direct Current Non-Transferred Thermal Plasma Torch for Optimal Performance. Contributions to Plasma Physics 2023, 63, e202200088. [Google Scholar] [CrossRef]

- Li, J.; Liu, K.; Yan, S.; Li, Y.; Han, D. Application of Thermal Plasma Technology for the Treatment of Solid Wastes in China: An Overview. Waste Management 2016, 58, 260–269. [Google Scholar] [CrossRef]

- Nema, S.K.; Ganeshprasad, K.S. Plasma Pyrolysis of Medical Waste. Curr Sci 2002, 83, 271–278. [Google Scholar]

- Bosmans, A.; Vanderreydt, I.; Geysen, D.; Helsen, L. The Crucial Role of Waste-to-Energy Technologies in Enhanced Landfill Mining: A Technology Review. J Clean Prod 2013, 55, 10–23. [Google Scholar] [CrossRef]

- Rueda, Y.G.; Helsen, L. The Role of Plasma in Syngas Tar Cracking. Biomass Convers Biorefin 2020, 10, 857–871. [Google Scholar] [CrossRef]

- Mostaghimi, J.; Boulos, M.I. Thermal Plasma Sources: How Well Are They Adopted to Process Needs? Plasma Chemistry and Plasma Processing 2015, 35, 421–436. [Google Scholar] [CrossRef]

- Munir, M.T.; Mardon, I.; Al-Zuhair, S.; Shawabkeh, A.; Saqib, N.U. Plasma Gasification of Municipal Solid Waste for Waste-to-Value Processing. Renewable and Sustainable Energy Reviews 2019, 116, 109461. [Google Scholar] [CrossRef]

- Pancholi, K.C.; Sen, N.; Singh, K.K.; Vincent, T.; Kaushik, C.P. Transient Heat Transfer during Startup of a Thermal Plasma Chamber: Numerical Insights. Progress in Nuclear Energy 2022, 152, 104371. [Google Scholar] [CrossRef]

- Tang, L.; Huang, H. SOME OBSERVATIONS FROM STUDIES OF RF PLASMA PYROLYSIS OF WASTE TIRES. Chem Eng Commun 2010, 197, 1541–1552. [Google Scholar] [CrossRef]

- Khongkrapan, P.; Thanompongchart, P.; Tippayawong, N.; Kiatsiriroat, T. Microwave Plasma Assisted Pyrolysis of Refuse Derived Fuels. Central European Journal of Engineering 2014, 4, 72–79. [Google Scholar] [CrossRef]

- Zhang, Q.; Dor, L.; Fenigshtein, D.; Yang, W.; Blasiak, W. Gasification of Municipal Solid Waste in the Plasma Gasification Melting Process. Appl Energy 2012, 90, 106–112. [Google Scholar] [CrossRef]

- Boulos, M.I.; Fauchais, P.L.; Pfender, E. The Plasma State. Handbook of Thermal Plasmas 2016, 1–53. [Google Scholar] [CrossRef]

- Reed, T.B. Induction-Coupled Plasma Torch. J Appl Phys 1961, 32, 821–824. [Google Scholar] [CrossRef]

- Fazekas, P.; Czégény, Z.; Mink, J.; Bódis, E.; Klébert, S.; Németh, C.; Keszler, A.M.; Károly, Z.; Szépvölgyi, J. Decomposition of Poly(Vinyl Chloride) in Inductively Coupled Radiofrequency Thermal Plasma. Chemical Engineering Journal 2016, 302, 163–171. [Google Scholar] [CrossRef]

- Major, K.; Veilleux, J.; Brisard, G. Lithium Iron Phosphate Powders and Coatings Obtained by Means of Inductively Coupled Thermal Plasma. Journal of Thermal Spray Technology 2016, 25, 357–364. [Google Scholar] [CrossRef]

- Darthout, É.; Gitzhofer, F. Thermal Cycling and High-Temperature Corrosion Tests of Rare Earth Silicate Environmental Barrier Coatings. Journal of Thermal Spray Technology 2017, 26, 1823–1837. [Google Scholar] [CrossRef]

- Darthout, É.; Gitzhofer, F. Structure Stabilization by Zirconia Pinning Effect of Y2Si2O7 Environmental Barrier Coatings Synthesized by Solution Precursor Plasma Spraying Process. Surf Coat Technol 2017, 309, 1081–1088. [Google Scholar] [CrossRef]

- Berghaus, J.O.; Meunier, J.L.; Gitzhofer, F. Monitoring and Control of RF Thermal Plasma Diamond Deposition via Substrate. Meas Sci Technol 2003, 15, 161. [Google Scholar] [CrossRef]

- Todorovic-Marković, B.; Marković, Z.; Mohai, I.; Károly, Z.; Gál, L.; Föglein, K.; Szabó, P.T.; Szépvölgyi, J. Efficient Synthesis of Fullerenes in RF Thermal Plasma Reactor. Chem Phys Lett 2003, 378, 434–439. [Google Scholar] [CrossRef]

- Keszler, A.M.; Kováts, É.; Bódis, E.; Károly, Z.; Szépvölgyi, J. Effect of Metallic and Non-Metallic Additives on the Synthesis of Fullerenes in Thermal Plasma. Condensed Matter 2022, Vol. 7, Page 44 2022, 7, 44. [Google Scholar] [CrossRef]

- Tong, J.B.; Lu, X.; Liu, C.C.; Pi, Z.Q.; Zhang, R.J.; Qu, X.H. Numerical Simulation and Prediction of Radio Frequency Inductively Coupled Plasma Spheroidization. Appl Therm Eng 2016, 100, 1198–1206. [Google Scholar] [CrossRef]

- Yu, C.; Zhou, X.; Wang, D.; Van Linh, N.; Liu, W. Study on the RF Inductively Coupled Plasma Spheroidization of Refractory W and W-Ta Alloy Powders. Plasma Science and Technology 2017, 20, 014019. [Google Scholar] [CrossRef]

- Park, J.Y.; Park, K.B.; Kang, J.W.; Kim, H.G.; Hwang, N.M.; Park, H.K. Spheroidization Behavior of Water-Atomized 316 Stainless Steel Powder by Inductively-Coupled Thermal Plasma. Mater Today Commun 2020, 25, 101488. [Google Scholar] [CrossRef]

- Kim, K.H.; Choi, H.; Han, C. Tungsten Micropowder/Copper Nanoparticle Core/Shell-Structured Composite Powder Synthesized by Inductively Coupled Thermal Plasma Process. Metall Mater Trans A Phys Metall Mater Sci 2017, 48, 439–445. [Google Scholar] [CrossRef]

- Dhamale, G.D.; Tak, A.K.; Mathe, V.L.; Ghorui, S. Nucleation and Growth of Y 2 O 3 Nanoparticles in a RF-ICTP Reactor: A Discrete Sectional Study Based on CFD Simulation Supported with Experiments. J Phys D Appl Phys 2018, 51, 255202. [Google Scholar] [CrossRef]

- Oh, J.-W.; Na, H.; Cho, Y.S.; Choi, H. In Situ Synthesis of Bimetallic Tungsten-Copper Nanoparticles via Reactive Radio-Frequency (RF) Thermal Plasma. Nanoscale Res Lett 2018, 13, 220. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Hayashida, R.; Tanaka, M.; Watanabe, T. Synthesis of Carbon-Coated Silicon Nanoparticles by Induction Thermal Plasma for Lithium Ion Battery. Powder Technol 2020, 371, 26–36. [Google Scholar] [CrossRef]

- Kim, K.S.; Couillard, M.; Shin, H.; Plunkett, M.; Ruth, D.; Kingston, C.T.; Simard, B. Role of Hydrogen in High-Yield Growth of Boron Nitride Nanotubes at Atmospheric Pressure by Induction Thermal Plasma. ACS Nano 2018, 12, 884–893. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Kingston, C.T.; Ruth, D.; Barnes, M.; Simard, B. Synthesis of High Quality Single-Walled Carbon Nanotubes with Purity Enhancement and Diameter Control by Liquid Precursor Ar–H2 Plasma Spraying. Chemical Engineering Journal 2014, 250, 331–341. [Google Scholar] [CrossRef]

- Li, J.; Hu, R.; Qu, H.; Su, Y.; Wang, N.; Su, H.; Gu, X. Radio-Frequency Thermal Plasma-Induced Novel Chainmail-like Core-Shell MoO2 as Highly Stable Catalyst for Converting Syngas to Higher Alcohols. Appl Catal B 2019, 249, 63–71. [Google Scholar] [CrossRef]

- Takigawa, A.; Kim, T.-H.; Igami, Y.; Umemoto, T.; Tsuchiyama, A.; Koike, C.; Matsuno, J.; Watanabe, T. Formation of Transition Alumina Dust around Asymptotic Giant Branch Stars: Condensation Experiments Using Induction Thermal Plasma Systems. Astrophys J Lett 2019, 878, L7. [Google Scholar] [CrossRef]

- Tanaka, Y. Recent Development of New Inductively Coupled Thermal Plasmas for Materials Processing. Adv Phys X 2021, 6, 1867637. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, F.; Chen, Q. Optical Emission Spectroscopy Diagnostics of Atmospheric Pressure Radio Frequency Ar-H2Inductively Coupled Thermal Plasma. IEEE Transactions on Plasma Science 2020, 48, 3621–3628. [Google Scholar] [CrossRef]

- Tu, X.; Chéron, B.G.; Yan, J.H.; Cen, K.F. Electrical and Spectroscopic Diagnostic of an Atmospheric Double Arc Argon Plasma Jet. Plasma Sources Sci Technol 2007, 16, 803. [Google Scholar] [CrossRef]

- Nikiforov, A.Y.; Leys, C.; Gonzalez, M.A.; Walsh, J.L. Electron Density Measurement in Atmospheric Pressure Plasma Jets: Stark Broadening of Hydrogenated and Non-Hydrogenated Lines. Plasma Sources Sci Technol 2015, 24, 034001. [Google Scholar] [CrossRef]

- Chen, C.; Fu, W.; Zhang, C.; Lu, D.; Han, M.; Yan, Y. Langmuir Probe Diagnostics with Optical Emission Spectrometry (OES) for Coaxial Line Microwave Plasma. Applied Sciences 2020, Vol. 10, Page 8117 2020, 10, 8117. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, P.; Yu, D.; Zhang, S.; Xin, Q.; Wan, Y. Monitoring and Diagnosis of the Inductively Coupled Atmospheric Pressure Plasma Jet for Deterministic Optical Processing. Optik (Stuttg) 2020, 214, 164815. [Google Scholar] [CrossRef]

- Galiwango, E.; A.Gabbar, H. Synergistic Interactions, Kinetic and Thermodynamic Analysis of Co-Pyrolysis of Municipal Paper and Polypropylene Waste. Waste Management 2022, 146, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Ganguli, A.; Tarey, R. Understanding Plasma Sources. Curr Sci 2002, 83, 279–290. [Google Scholar]

- Aldeeb, M.A.; Morgan, N.; Abouelsayed, A.; Amin, K.M.; Hassaballa, S. Electrical and Optical Characterization of Acetylene RF CCP for Synthesis of Different Forms of Hydrogenated Amorphous Carbon Films. Plasma Chemistry and Plasma Processing 2020, 40, 387–406. [Google Scholar] [CrossRef]

- OHNO, N.; RAZZAK, M.A.; UKAI, H.; TAKAMURA, S.; UESUGI, Y. Validity of Electron Temperature Measurement by Using Boltzmann Plot Method in Radio Frequency Inductive Discharge in the Atmospheric Pressure Range. Plasma and Fusion Research 2006, 1, 028–028. [Google Scholar] [CrossRef]

- Abbass, Q.; Ahmed, N.; Ahmed, R.; Baig, M.A. A Comparative Study of Calibration Free Methods for the Elemental Analysis by Laser Induced Breakdown Spectroscopy. Plasma Chemistry and Plasma Processing 2016, 36, 1287–1299. [Google Scholar] [CrossRef]

- Tu, X.; Chéron, B.G.; Yan, J.H.; Cen, K.F. Electrical and Spectroscopic Diagnostic of an Atmospheric Double Arc Argon Plasma Jet. Plasma Sources Sci Technol 2007, 16, 803–812. [Google Scholar] [CrossRef]

- Younus, M.; Rehman, N.U.; Shafiq, M.; Naeem, M.; Zaka-Ul-Islam, M.; Zakaullah, M. Evolution of Plasma Parameters in an Ar–N 2 /He Inductive Plasma Source with Magnetic Pole Enhancement. Plasma Science and Technology 2017, 19, 025402. [Google Scholar] [CrossRef]

- OHNO, N.; RAZZAK, M.A.; UKAI, H.; TAKAMURA, S.; UESUGI, Y. Validity of Electron Temperature Measurement by Using Boltzmann Plot Method in Radio Frequency Inductive Discharge in the Atmospheric Pressure Range. Plasma and Fusion Research 2006, 1, 028–028. [Google Scholar] [CrossRef]

- Godyak, V.A. Electrical and Plasma Parameters of ICP with High Coupling Efficiency. Plasma Sources Sci Technol 2011, 20, 025004. [Google Scholar] [CrossRef]

- Godyak, V.A.; Piejak, R.B.; Alexandrovich, B.M. Electron Energy Distribution Function Measurements and Plasma Parameters in Inductively Coupled Argon Plasma. Plasma Sources Sci Technol 2002, 11, 525–543. [Google Scholar] [CrossRef]

- Jun-Feng, Z.; Xin-Chao, B.; Qiang, C.; Fu-Ping, L.; Zhong-Wei, L. Diagnosis of Methane Plasma Generated in an Atmospheric Pressure DBD Micro-Jet by Optical Emission Spectroscopy. Chinese Physics Letters 2009, 26, 035203. [Google Scholar] [CrossRef]

- Kolobov, V. The Anomalous Skin Effect in Bounded Systems. In Electron Kinetics and Applications of Glow Discharges; Kluwer Academic Publishers: Boston; pp. 293–311.

- Nikiforov, A.Y.; Leys, C.; Gonzalez, M.A.; Walsh, J.L. Electron Density Measurement in Atmospheric Pressure Plasma Jets: Stark Broadening of Hydrogenated and Non-Hydrogenated Lines. Plasma Sources Sci Technol 2015, 24, 034001. [Google Scholar] [CrossRef]

- Sadeghzadeh Lari, E.; Ranjbar Askari, H.; Meftah, M.T.; Shariat, M. Calculation of Electron Density and Temperature of Plasmas by Using New Stark Broadening Formula of Helium Lines. Phys Plasmas 2019, 26, 023519. [Google Scholar] [CrossRef]

- Sadeghzadeh Lari, E.; Ranjbar Askari, H.; Meftah, M.T.; Shariat, M. Calculation of Electron Density and Temperature of Plasmas by Using New Stark Broadening Formula of Helium Lines. Phys Plasmas 2019, 26. [Google Scholar] [CrossRef]

- Nijdam, S.; Teunissen, J.; Ebert, U. The Physics of Streamer Discharge Phenomena. Plasma Sources Sci Technol 2020, 29, 103001. [Google Scholar] [CrossRef]

- Tamošiūnas, A.; Valatkevičius, P.; Valinčius, V.; Grigaitienė, V.; Kavaliauskas, Ž. Diagnostic Methods Used for Atmospheric Pressure Thermal Arc Plasma. Phys Scr 2014, T161, 014059. [Google Scholar] [CrossRef]

- Ali, A.M.; Abu Hassan, M.A.; Ibrahim, R.R.K.; Jalil, A.A.; Mat Nayan, N.H.; Abdulkarim, B.I.; Sabeen, A.H. Analysis of Solid Residue and Flue Gas from Thermal Plasma Treatment of Petroleum Sludge. J Environ Chem Eng 2019, 7, 103207. [Google Scholar] [CrossRef]

- Bhatt, K.P.; Patel, S.; Upadhyay, D.S.; Patel, R.N. A Critical Review on Solid Waste Treatment Using Plasma Pyrolysis Technology. Chemical Engineering and Processing - Process Intensification 2022, 177, 108989. [Google Scholar] [CrossRef]

- Cai, X.; Cai, H.; Shang, C.; Du, C. Two-Stage Pyrolysis/Gasification and Plasma Conversion Technology for the Utilization of Solid Waste. IEEE Transactions on Plasma Science 2021, 49, 191–213. [Google Scholar] [CrossRef]

| λ (nm) | Ek (eV) | Aik (106 S-1) | gk |

|---|---|---|---|

| 696 | 13.328 | 6.40 | 3 |

| 706 | 13.302 | 3.80 | 5 |

| 727 | 13.328 | 1.83 | 3 |

| 738 | 13.302 | 8.50 | 5 |

| 750 | 13.479 | 45 | 1 |

| 751 | 13.273 | 40 | 1 |

| 763 | 13.172 | 24 | 5 |

| 771 | 13.153 | 5.20 | 3 |

| 772 | 13.328 | 11.7 | 3 |

| 794 | 13.283 | 18.6 | 3 |

| 800 | 13.172 | 49 | 5 |

| 801 | 13.095 | 9.30 | 5 |

| 810 | 13.153 | 25 | 3 |

| 811 | 13.076 | 33 | 7 |

| 826 | 13.328 | 15.3 | 3 |

| 840 | 13.302 | 22.3 | 5 |

| 842 | 13.095 | 21.5 | 5 |

| 851 | 13.283 | 13.9 | 3 |

| 2 SLPM | 4 SLPM | ||||

|---|---|---|---|---|---|

| Power (W) |

(nm) |

(nm) |

Power (W) |

(nm) |

(nm) |

| 440 | 1.431 | 1.126 | 440 | 1.440 | 1.138 |

| 550 | 1.406 | 1.096 | 550 | 1.358 | 1.037 |

| 660 | 1.415 | 1.108 | 660 | 1.461 | 1.162 |

| 770 | 1.402 | 1.091 | 770 | 1.372 | 1.055 |

| 880 | 1.377 | 1.061 | 880 | 1.363 | 1.044 |

| 990 | 1.436 | 1.133 | 990 | 1.419 | 1.113 |

| 1100 | 1.445 | 1.143 | 1100 | 1.346 | 1.023 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).