1. Introduction

With the realization that surface freshwater sources are shrinking due to growing water demand from climate change and growing populations, many drinking water providers have turned to groundwater [

1,

2,

3]. Their reliance on this source has led to significant drops in groundwater levels, with some areas around the world seeing declines between 91 and 274 m over the past 50 years [

4,

5,

6]. Further, the average groundwater depletion rate in the United States increased from an average of 2.4 km3/year between 1900 and 1945 to an average of 13.6 km3/year between 1945 and 1960. It increased again to 23.9 km3/year between 2000 and 2008 [

7]. These two issues of shrinking surface water sources and declining groundwater levels have led to a process that has been gaining traction around the world called Aquifer Storage and Recovery (ASR) or Managed Aquifer Recharge (MAR) [

8].

ASR was first developed in the 1950s and is composed of two parts: recharge and recovery. Recharge is the process where surface water is directly injected or infiltrated into underground aquifers, increasing storage in excessively wet seasons and helping to restore groundwater levels depleted by overuse. In recovery, water is extracted from wells to meet the demands of the community when other sources are running low [

8]. For example, during drought conditions or due to growing populations. ASR and MAR can have many benefits including expanding water storage capacity, not taking up land for water tanks (leaving land available for other uses), preventing water loss from evaporation, and storing unused water from water rights.

ASR is a water supply method that is highly integrated with what is known as the energy–water nexus. This nexus describes the interdependency of water production and energy production [

4,

9,

10,

11]. In ASR and other water supply processes, energy is needed to run equipment and operations such as pumps to pump water into or out of aquifers, metering equipment, SCADA systems, security features, lights, and equipment for water treatment processes. On the other hand, water is used in energy production to cool machinery, mine coal, produce thermoelectric and hydroelectric power, and to extract, produce, refine, and transport oil and natural gas. This interdependency leads to changes in the energy industry affecting the water industry and vice versa.

The energy-for-water side of the nexus, while perhaps less well characterized than the water-for-energy side, has received much attention in the past decade. It was estimated that in 2010, 12.6% of energy consumed in the United States was for the production and distribution of water and steam [

11]. It was further estimated that 4.7% of The United States’ energy was used by the public water sector [

12]. These data show the dependency of the water sector on energy.

Energy intensity is a measurement used to aid in the comparison of this energy and water dependence. This value is defined as the amount of energy used to produce a unit of water. Typically, it is measured in units of kilowatt–hours per million gallons (kWh/MG) or kilowatt–hours per cubic meters (kWh/m3) [

13,

14,

15]. Several studies agree that the energy intensities for drinking water in the United States are in the range of 0.07–3.0 kWh/m3 [

4,

12,

14,

15,

16,

17,

18]. However, local conditions can vary energy intensity; a 2005 report from the California Energy Commission concluded the theoretical lifecycle water energy intensity for California ranged from 0.50 to 9.88 kWh/m3 [

12,

19]. According to the pump energy intensity equation, it takes between 0.0026 to 0.0052 kWh to pump 1 m3 of water a height of 1 m. [

20]. These variations can be attributed to differences in topography, climate, water quality, proximity from the water supply to the end user from area to area, and water extraction [

12,

13,

21].

In regard to ASR, the recovery process has an extremely variable energy intensity that depends on the height the water needs to be pumped, the pressure the water is pumped to, the pumping rate, the frictional forces in the pumping system, and the pump and motor efficiency [

18,

22,

23]. On the contrary, the energy intensity for recharge is typically low since many aquifers are recharged through infiltration basins or gravity-fed direct injection wells.

With operations of the water sector using a large amount of energy, a significant portion of this sector’s total costs are those related to energy usage. Optimizing a service’s energy usage can substantially decrease these costs. In 2008, the Environmental Protection Agency (EPA) reported that 30%–60% of a city’s energy bill was contributed by water and wastewater plants, with 40% of a water provider’s operational costs typically being energy-related. This data led the agency to conclude that the largest controllable costs in the water sector are those related to energy usage [

10]. North Salt Lake, Utah put this to the test by increasing their energy efficiency, which in turn decreased their production costs by 22% [

24].

Many water utility agencies have a need and desire to optimize their energy usage, as was seen in a study that reviewed 29 guides on energy management [

25]. From the reasoning above, it can be concluded that finding ways to optimize energy usage in the water industry, particularly in ASR wellfields, will likely lead to a decrease in energy intensity leading to a greater cost benefit, a decrease in overall energy use, and long-term money savings for the water service [

10,

22,

26]. This should be a sought-after goal.

Many studies have explored individual aspects of ASR or energy usage such as groundwater depletion [

27], the energy–water nexus [

4,

9,

10,

15,

28], water quality [

29], and optimization [

26,

30]. Additionally, reports and journal articles were found from utility entities individually discussing energy usage and groundwater levels. However, we did not find any articles that analyzed the pairing of energy usage and ASR with observed data. We have attempted to do this through this study.

One possibly present trend is an economy of scale relationship between the volume of water recovered or recharged and the required energy intensity to do so. Studies have discovered an economy of scale in a wide range of industries and in a variety of scenarios, especially in the public service and water industries. In the water industry, economies of scale have been found in relating energy intensities of treated water with a water treatment plant’s size, or in relating the cost per volume treated to the total volume treated by a plant. In the energy sector, an economy of scale was found comparing the average cost per 1,000 kWh and the total kilowatt-hour output. These economies of scale have also been found in education, sanitation, garbage collection, and urban transportation, among other sources [

31,

32,

33,

34,

35,

36]. While this trend exists in many aspects of the water sector, it has not been examined in ASR.

In this paper, we examine energy and water data from two ASR wellfields in the western United States to determine if an economy of scale exists between energy intensity and the amount of volume recovered or recharged. By determining if this relationship exists and characterizing it using observed data, we can aid water utilities in better understanding steps that can be taken to optimize the design and operations of future and current ASR projects. From an energy standpoint, this can lead to a decrease in energy intensity, decreasing overall energy use, and providing more energy sustainable operations. From a money standpoint, more energy efficient operations would result in a decrease in energy costs, leading to a greater cost benefit, reducing operational costs, and leading to long-term money savings for the entity.

2. Materials and Methods

2.1. Study Sites

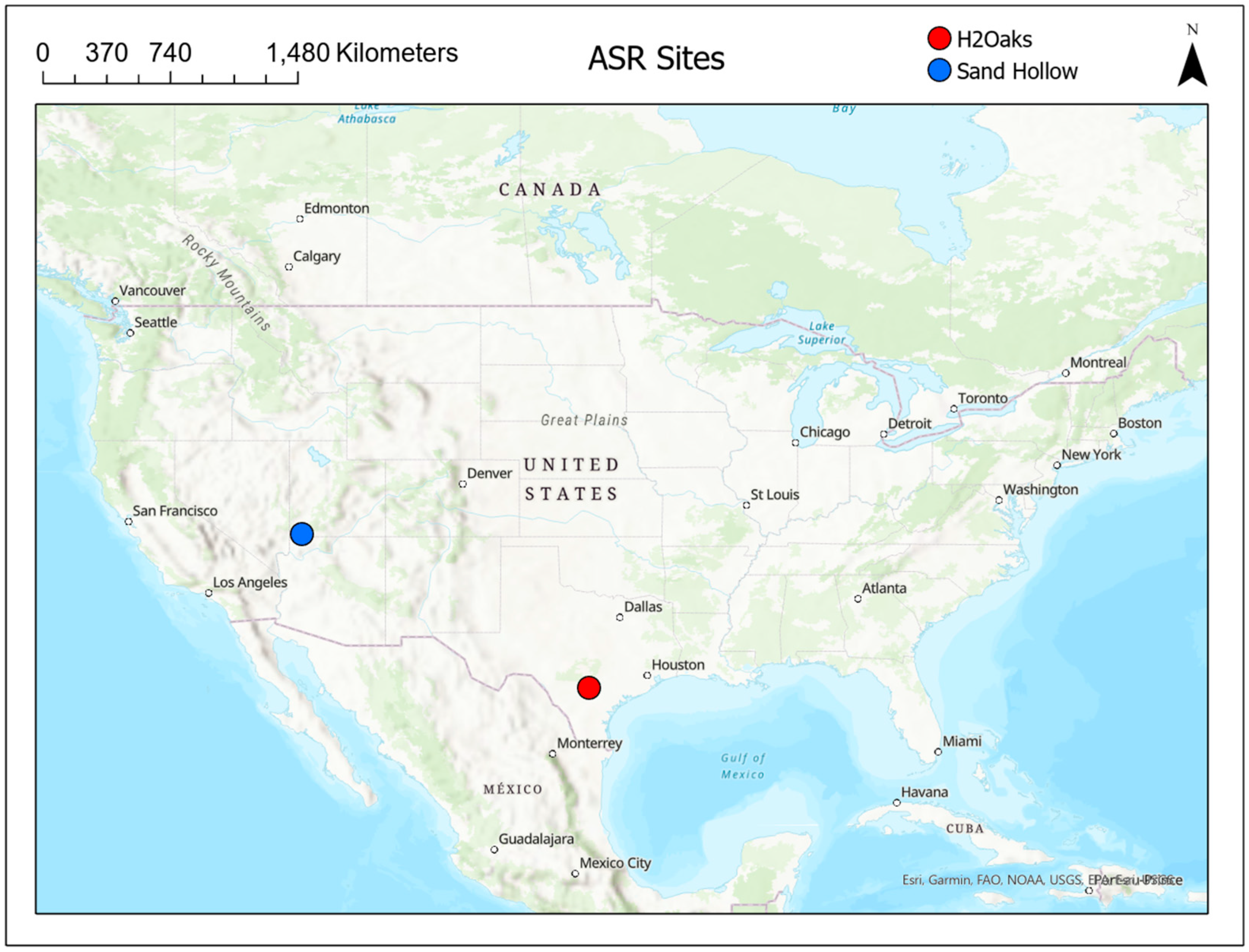

Figure 1 shows the location of the two study sites, H2Oaks and Sand Hollow. Each is described below.

2.1.1. H2Oaks

The H2Oaks Aquifer Storage and Recovery Facility is operated by the San Antonio Water System (SAWS). It is located in Elmendorf, Texas, approximately 40 km south of downtown San Antonio, Texas and has 29 operating ASR wells. As of July 2022, the site was the second-largest operating ASR wellfield in the United States. The construction of the H2Oaks facility was split into two phases. The first phase contained 17 wells and was completed in 2004; the second phase contained 12 wells and was completed in 2008 [

2].

SAWS primarily supplies its service area with water from the Edwards Aquifer. In 1993, the Edwards Aquifer Authority (EAA) developed a permit program that limited the amount of water SAWS could take from Edwards Aquifer in a given period. To mitigate the effects of the permit, SAWS constructed an ASR well field. When recovery from the Edwards Aquifer is not limited, water can be recovered, transported, and recharged into the Carrizo Aquifer. When recovery from the Edwards Aquifer is restricted or during the summer months when water demand is high, the water stored in the Carrizo Aquifer can be recovered and used [

2]. These ASR wells are primarily used for recharge but are occasionally used for recovery when other water supply sources run low. Recharge occurs through gravity-fed injection through the same wells recovery takes place in. A typical ASR well site at SAWS is shown in

Figure 2 and

Figure 3.

2.2.2. Sand Hollow

The Sand Hollow ASR site is operated by the Washington County Water Conservancy District (WCWCD) and is located in the southern Utah desert near Hurricane, Utah. This project was completed in March 2002. Water is diverted from the Virgin River into Sand Hollow Reservoir where the water infiltrates into the underlying aquifer. The reservoir has a storage capacity of 63,000,000 m3 [

37]. Similar to the H2Oaks facility, Sand Hollow is primarily used for recharge, but water is occasionally recovered when needed. Recovery occurs through wells located around. There are a total of 20 production wells surrounding the reservoir, with 13 currently in operation [

38]. A well house for the ASR well site at Sand Hollow in

Figure 4.

2.2. Methods

For each well site, we computed a monthly sum for the volume recovered and/or recharged in cubic meters (m3). We normalized the amount of energy used per well site by its respective volume, yielding energy intensity in kilowatt-hours per cubic meter (kWh/m3). We compared the monthly volume and energy values and then, the monthly volume and the natural logarithm of energy intensity values to look for patterns that could aid in optimizing energy usage. The natural logarithm transformation for energy intensity was necessary to linearize the data over several orders of magnitude and is common in energy analysis of water facilities [

21,

39].

Microsoft Excel and the statistical software, JMP, were used to analyze data. Plots for each data set were created using JMP. For ease of reference, E represents energy in kilowatt-hours (kWh), V represents volume in cubic meters (m3), and ln(E/V) represents the natural logarithm of energy intensity in kilowatt-hours per cubic meters (kWh/m3). The monthly values for each were plotted. The data plots used are as follows: E vs. V cluster plot, ln(E/V) vs. V scatter plot and trendline plot (divided into an upper panel with no trendlines and a lower panel with trendlines), ln(E/V) Actual vs. Predicted plot with regards to ln(V), and ln(E/V) scattered residuals plot. We generated trendlines for the bottom panel of the ln(E/V) vs. V trendline plot using the local kernel, median method. These trendlines are only for visual convenience of relating the points for each well. The E vs. V cluster plot for the recovery processes include labeled groupings circled in red. These groupings were created through visual inspection and are to aid with the discussion.

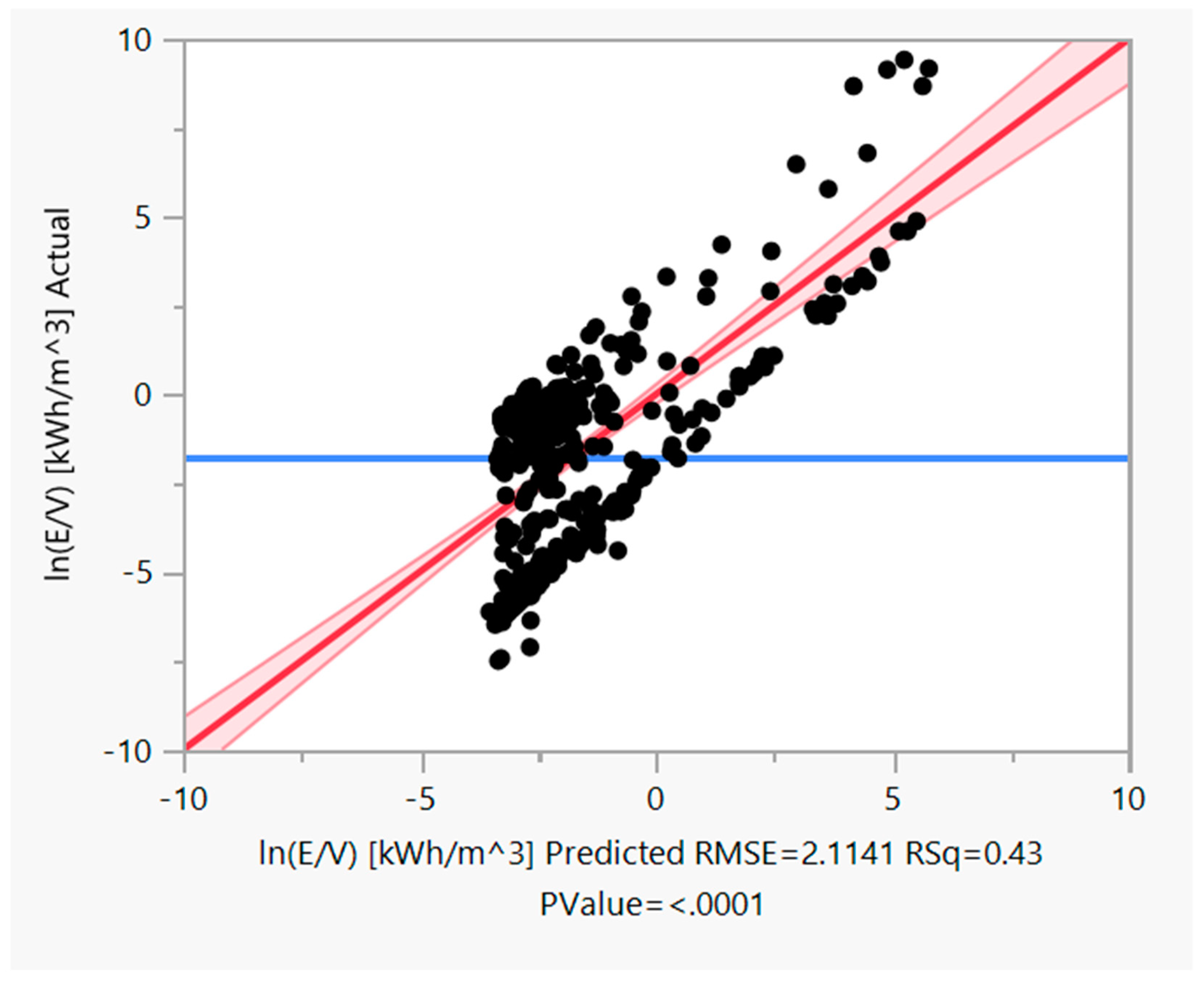

Statistical plots were created to analyze the data. The Actual vs. Predicted plot used values from the natural logarithm transformation to perform an Ordinary Least Squares regression test. This plot reported a RMSE, R2, and p-value. The reported values were considered statistically significant if the p-value was less than or equal to 0.05, if the R2 value was equal to or greater than 0.8, or if the RMSE value was between 0.2 and 0.5. In a literature review conducted on economies of scale in the local public service provision, out of seventy-six analyzed studies, thirty-five (46%) used the Ordinary Least Squares test, the largest percentage for a single test [

33]. To stay consistent with the findings from this study and others, we selected this test.

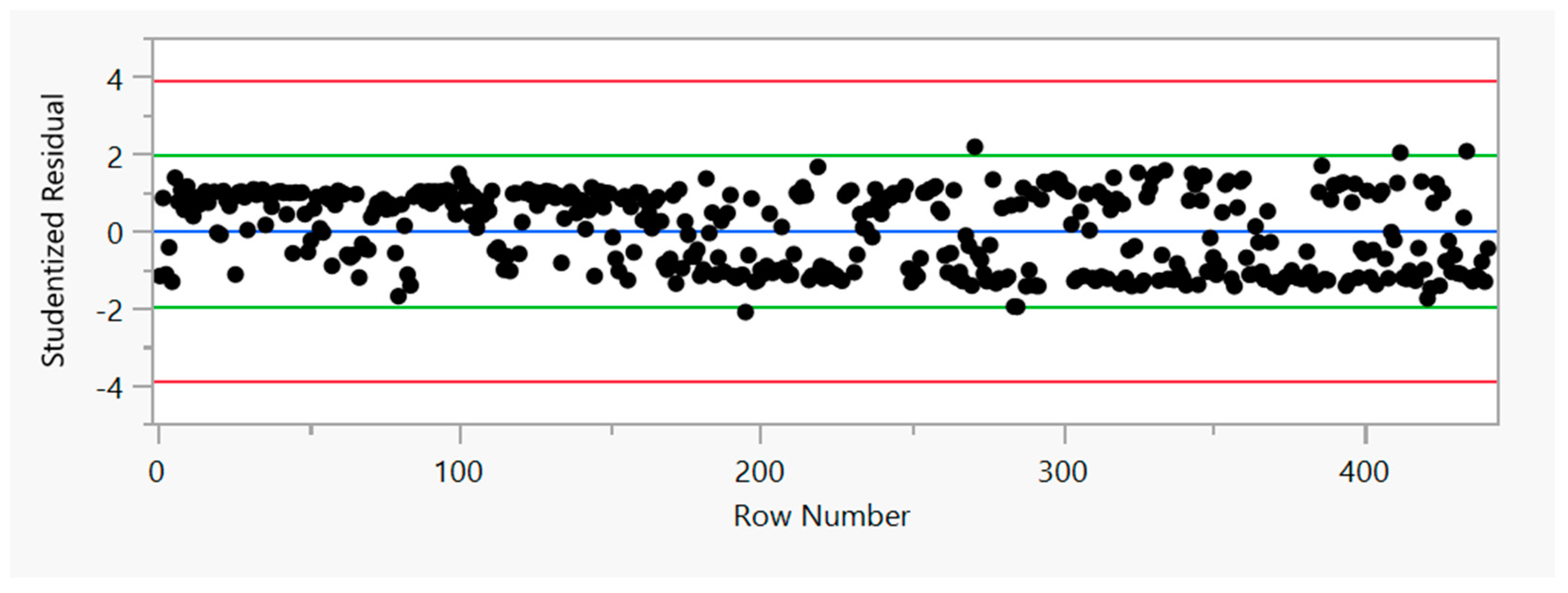

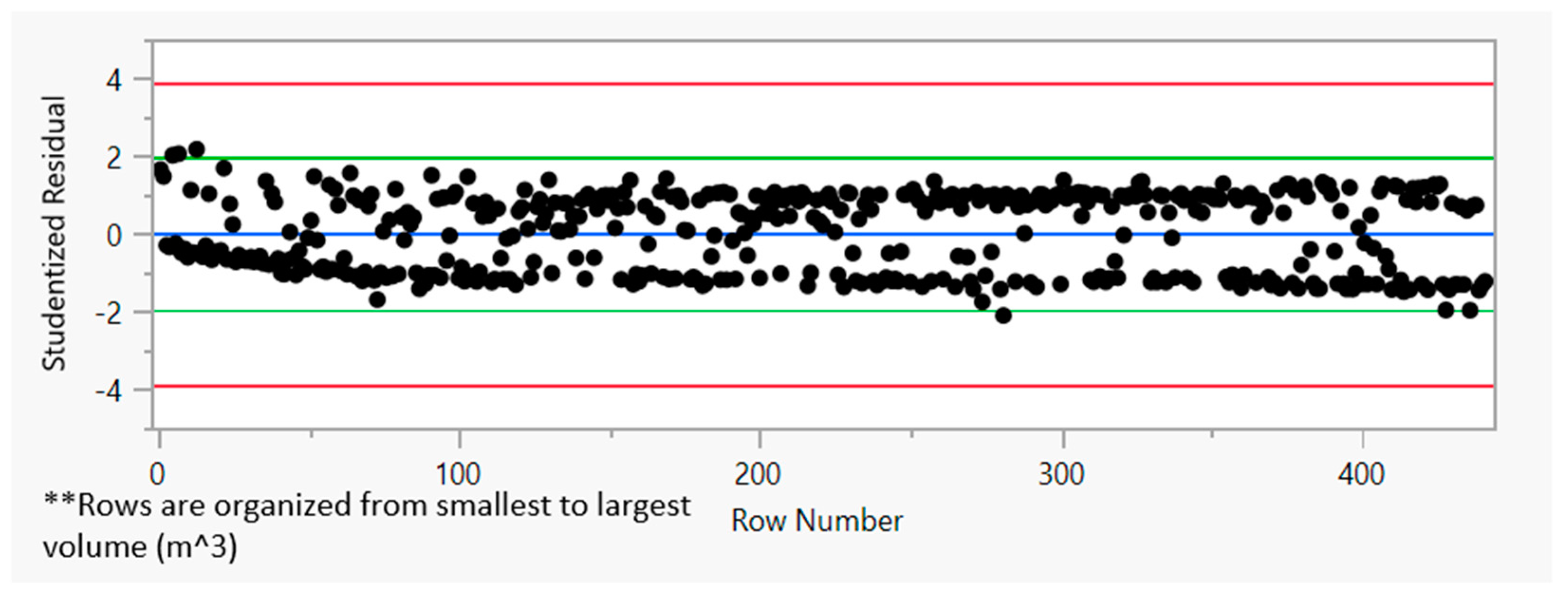

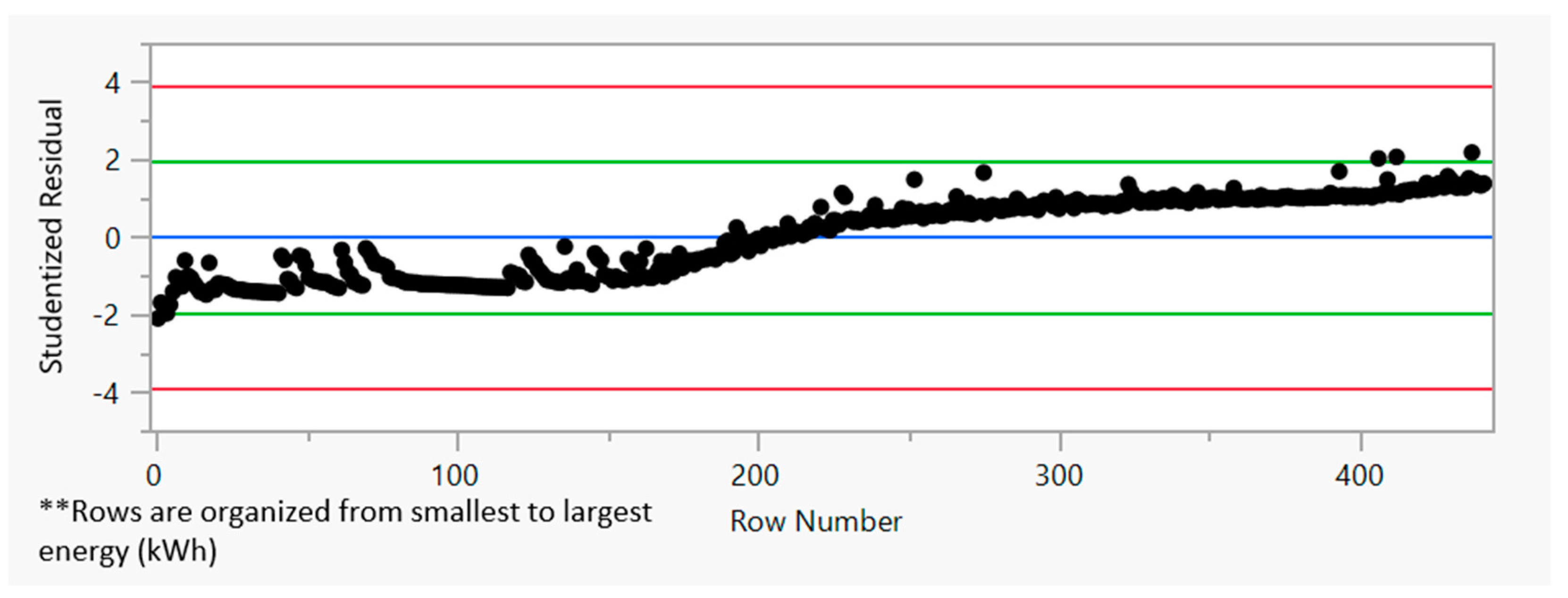

The second statistical plot is known as a studentized residuals plot. This plot takes the observed values minus the predicted values and divides the difference by their standard deviation. If correlations are present among the residuals, it shows the data is biased. There are three variations of these plots. For each dataset, there is a plot organized by row number, monthly volume usage, or monthly energy usage.

2.2.1. H2Oaks Data Set

The Project Coordinator, Manager, Director of Chilled Water and Energy Management, and Office of Energy Management’s Senior Resource Analyst from SAWS helped us obtain and interpret the data. Daily water and energy data for H2Oaks’ twenty-nine ASR wells were gathered from March 2013 to November 2022. Energy data for the ASR site is monitored by CPS Energy. Days when water metering equipment malfunctioned, as noted in the original records, were eliminated from the data set (broken pressure transducers, flowmeters, etc.)

Typically, only recovery or recharge occurred in each month. We isolated months where only recovery occurred from those where only recharge occurred. This allowed for direct analysis of how the volume recovered or recharged impacted energy intensity. Months where both recovery and recharge occurred were few and eliminated from the data set.

2.2.2. Sand Hollow Data Set

Two of the Associate General Managers and the Technical and Administrative Assistant of Operations and Planning from WCWCD helped us obtain and interpret the data. The Investigations Chief at the U.S. Geological Survey [USGS] at the Utah Water Science Center has spent a significant amount of time working on a groundwater model for this site and helped us to better understand it.

We obtained monthly data for 12 of Sand Hollow’s operating ASR wells from January 2017 to October 2022. For this data set, we only considered the recovery process since the recharge process occurred through infiltration in the reservoir and could not be directly measured.

Energy data was provided in the form of costs instead of kilowatt-hours. We converted these costs into kilowatt-hours using the average industrial electricity price per year for the state of Utah as provided by the U.S. Energy Information Administration (EIA). Kilowatt-hours was used instead of costs to help avoid the influence of inflation and the differences in costs among different states.

Table 1 gives the average industrial electricity price per year [

40].

3. Results

3.1. H2Oaks Gravity-Fed Recharge

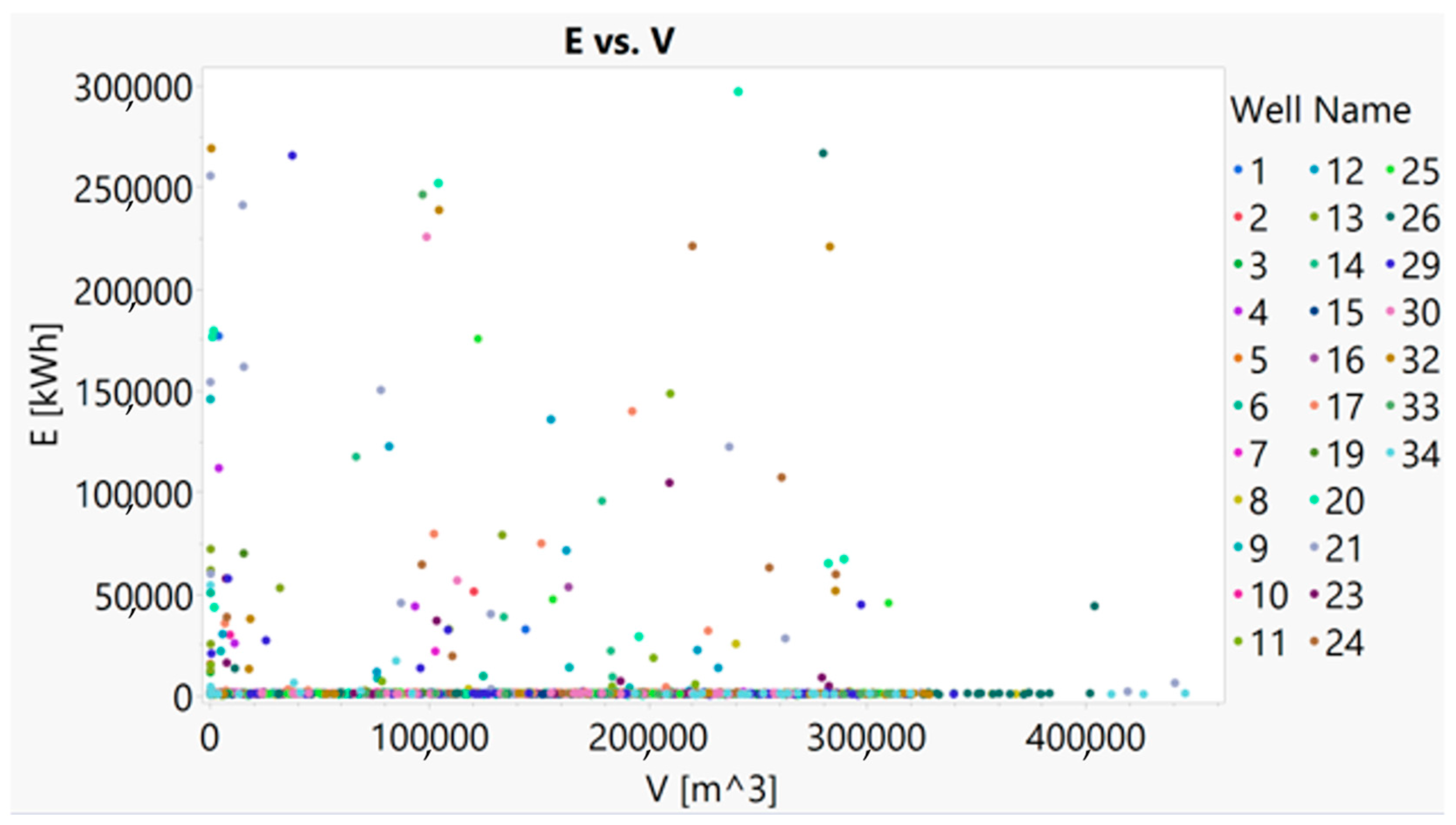

The H2Oaks Recharge Cluster Plot is shown in

Figure 5. In the middle of the graph are several scattered points. Some of these show a positive trend of increasing energy with increasing recharge. There are no points in the upper right corner of the plot, indicating a large recharge volume does not necessarily correlate with a large energy usage. Along the y-axis are several points that show a wide range of energy values, despite a low recharge volume. The opposite is shown along the x-axis where there are a wide range of volume values, despite a low energy usage. The points along the x-axis are likely indicative of recharge being a gravity-fed process at this site; showing energy use is not correlated with recharge at these points. Since the majority of the points fall into this category, this strongly implies that recharge is not correlated to energy use at the H2Oaks site. Since we concluded there was no correlation between energy and volume usage we decided to not make additional plots for this process.

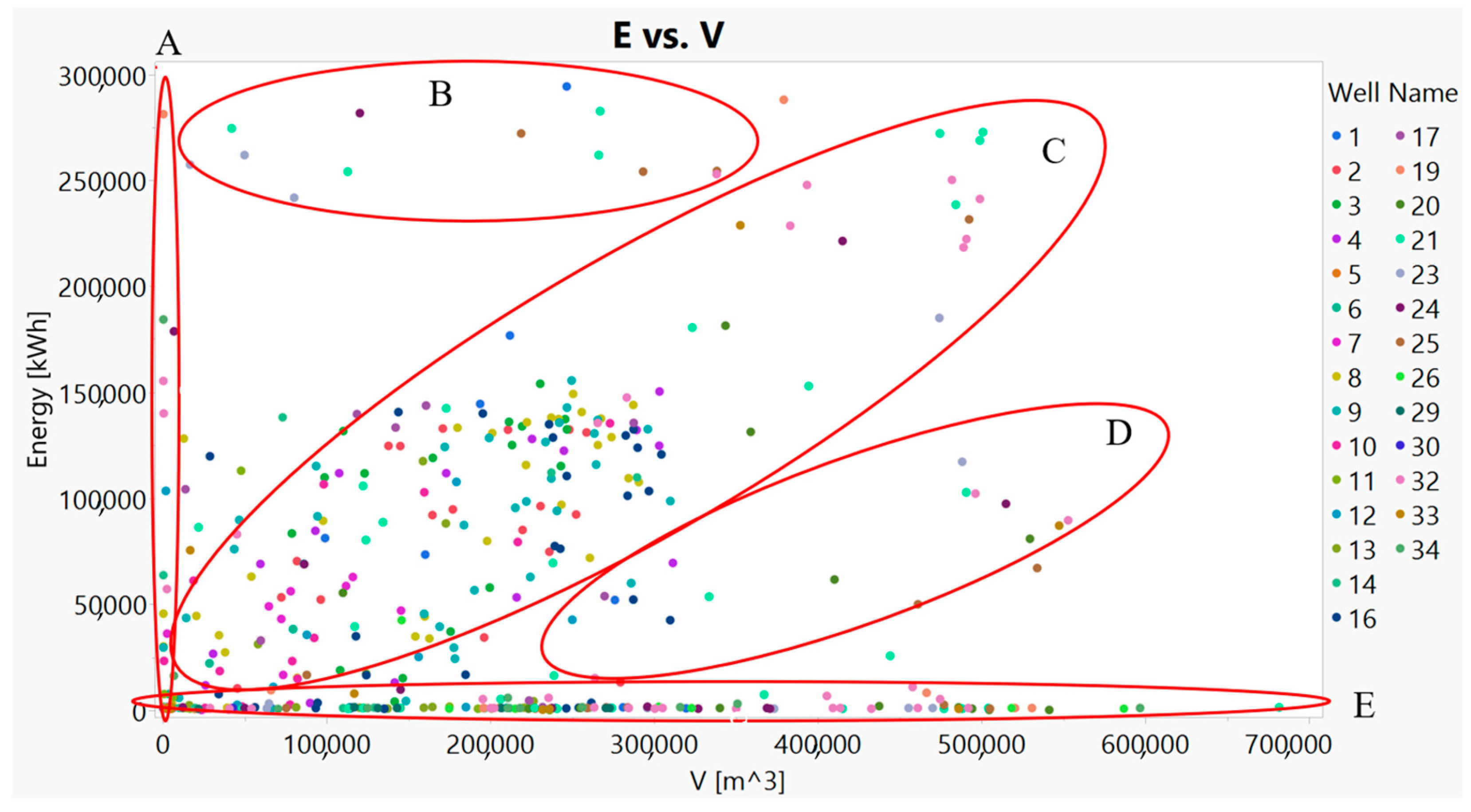

3.2. H2Oaks Recovery

Figure 6 shows the H2Oaks Recovery Cluster Plot. Many points in this plot have similar trends to what is seen in

Figure 5. Groups A and E have points centralized along the axes while groups C and D show an increasing positive trend between energy and volume. Cluster B primarily shows volume usage increasing while energy usage stays relatively constant. Since

Figure 6 shows a smaller concentration of points along the x-axis than for the recharge process, this likely indicates there is a higher correlation between energy and volume for the H2Oaks recovery process than for the H2Oaks recharge process.

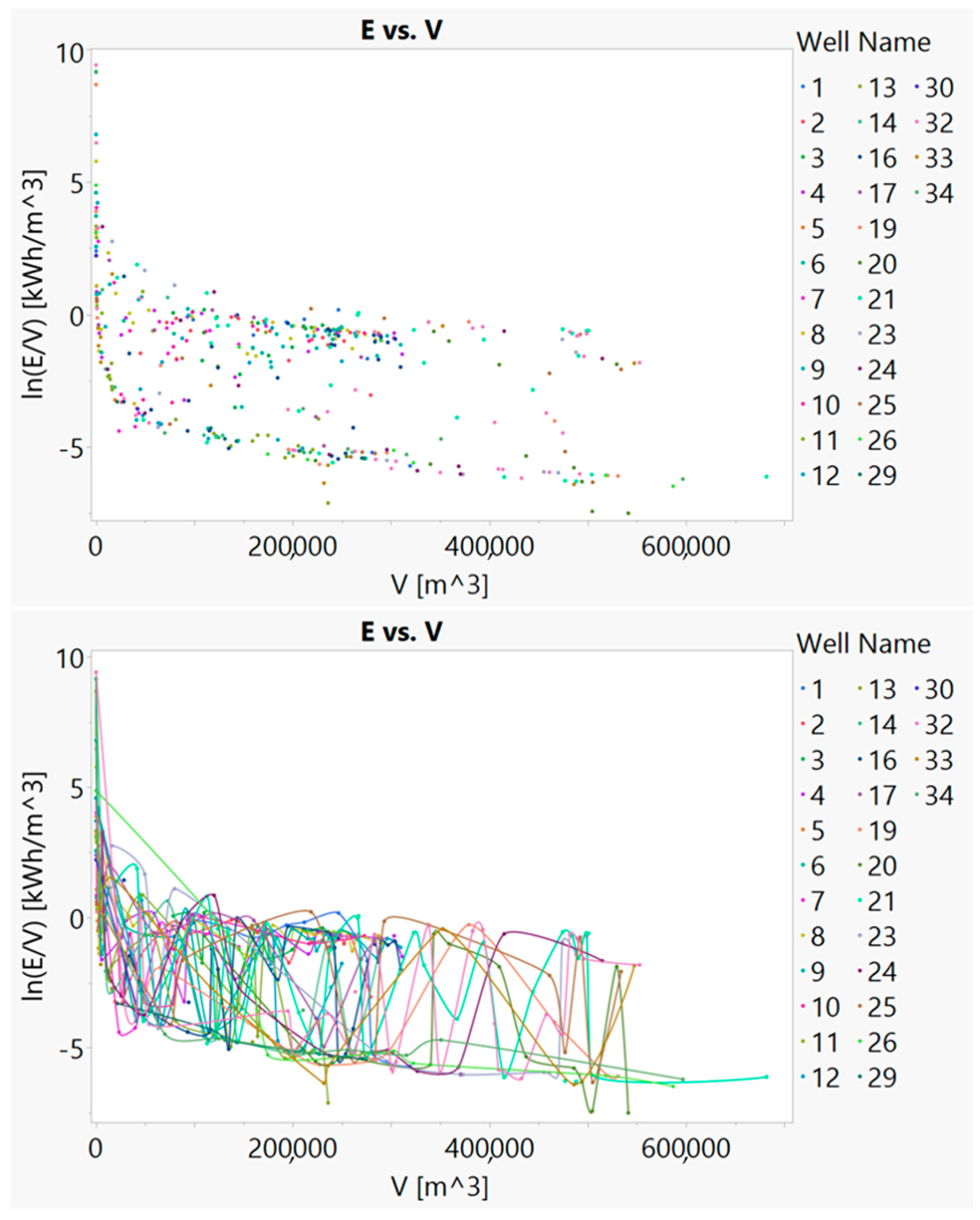

Figure 7 shows the ln(E/V) vs. V plot. This plot shows an exponentially decreasing trend indicating energy intensity decreases with increasing volume - known as an economy of scale.

Figure 7 displays two exponentially decreasing branches (one above the other). The lower branch clings tighter to a line of best fit than the upper one. Spacing between the line of best fit between the upper and lower curves seems to stay constant once approximately 200,000 m

3 is recovered. This process experienced a 78% decrease in the natural logarithm of energy intensity from 0 to 50,000 m

3. Indicating the greater the volume recovered in a given month, the less energy intensive the process is. As can easily be seen through the trendlines in the bottom panel, monthly datapoints for each well frequently jump between the upper and lower branches of this curve. It is unknown why this plot has two branches or why the data points for a given well tend to jump between the two.

Figure 8 shows the Actual by Predicted plot for ln(E/V) with respect to ln(V). The RMSE value is 2.1. This value is not statistically significant by our definition of 0.2–0.5. The R

2 value is 0.43, again not statistically significant by our definition of 0.8. These values indicate our points are not tightly centered around the line of best fit. The p value is less than 0.0001, showing the results are statistically significant and that there is a high probability that our values have some correlation. While these values show the datapoints are not heavily concentrated along the line of best fit, they do show some correlation.

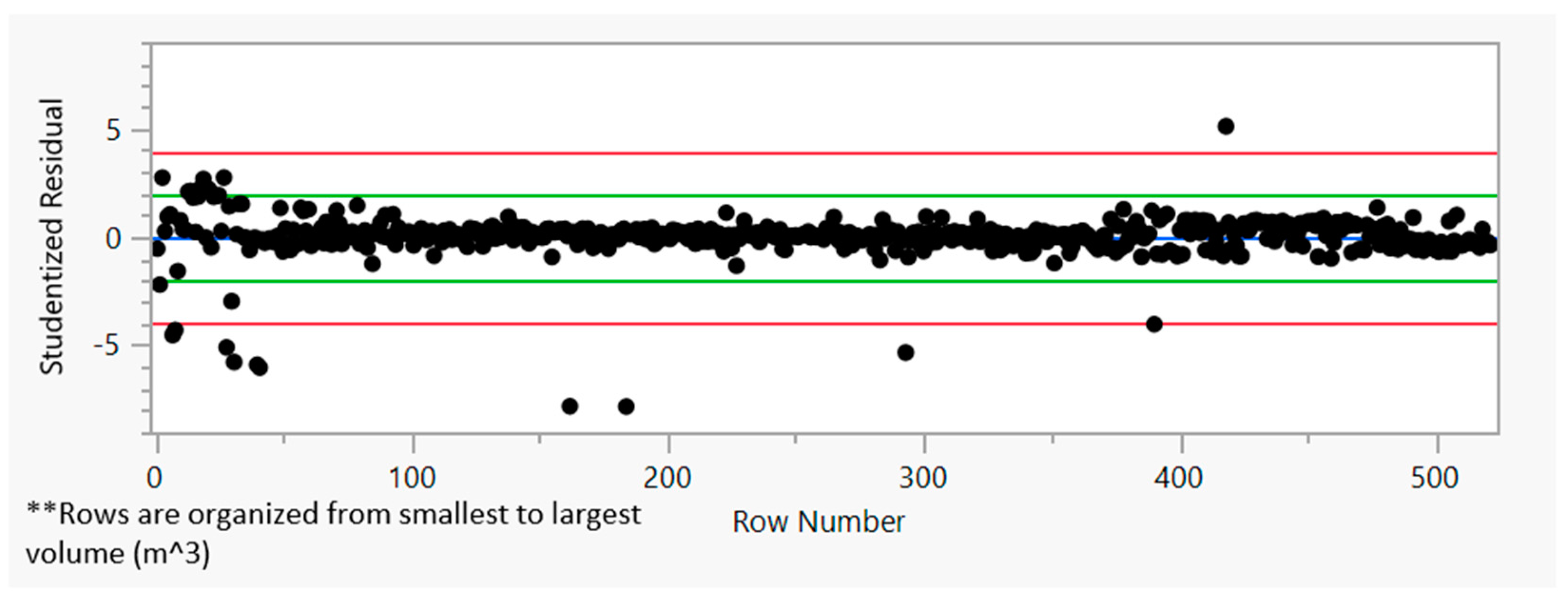

Figure 9,

Figure 10 and

Figure 11 show the studentized residuals organized by row number, volume, and energy, respectively. None of these figures have points outside of four studentized residuals which would indicate potential outliers.

Figure 9 and

Figure 10 do not show any correlations among results.

Figure 11 shows the studentized residuals increase as the energy usage increases. This could be indicative of external variables or nonlinear effects influencing the relationship.

In addition to the above figures, a box and whisker plot was created to determine if any correlation exists between the volume recovered and which months the recovery took place. There was found to be no correlation between the two.

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10 and

Figure 11 show there is a moderately strong economy of scale between energy intensity and the volume recovered at the H2Oaks site. While the statistical plots show energy intensity is not highly predictive of the volume recovered, they also show there is correlation between the two. It is clear that although the economy of scale is not incredibly strong, an increase in the volume recovered does lead to a decrease in energy intensity.

3.3. Sand Hollow Recovery

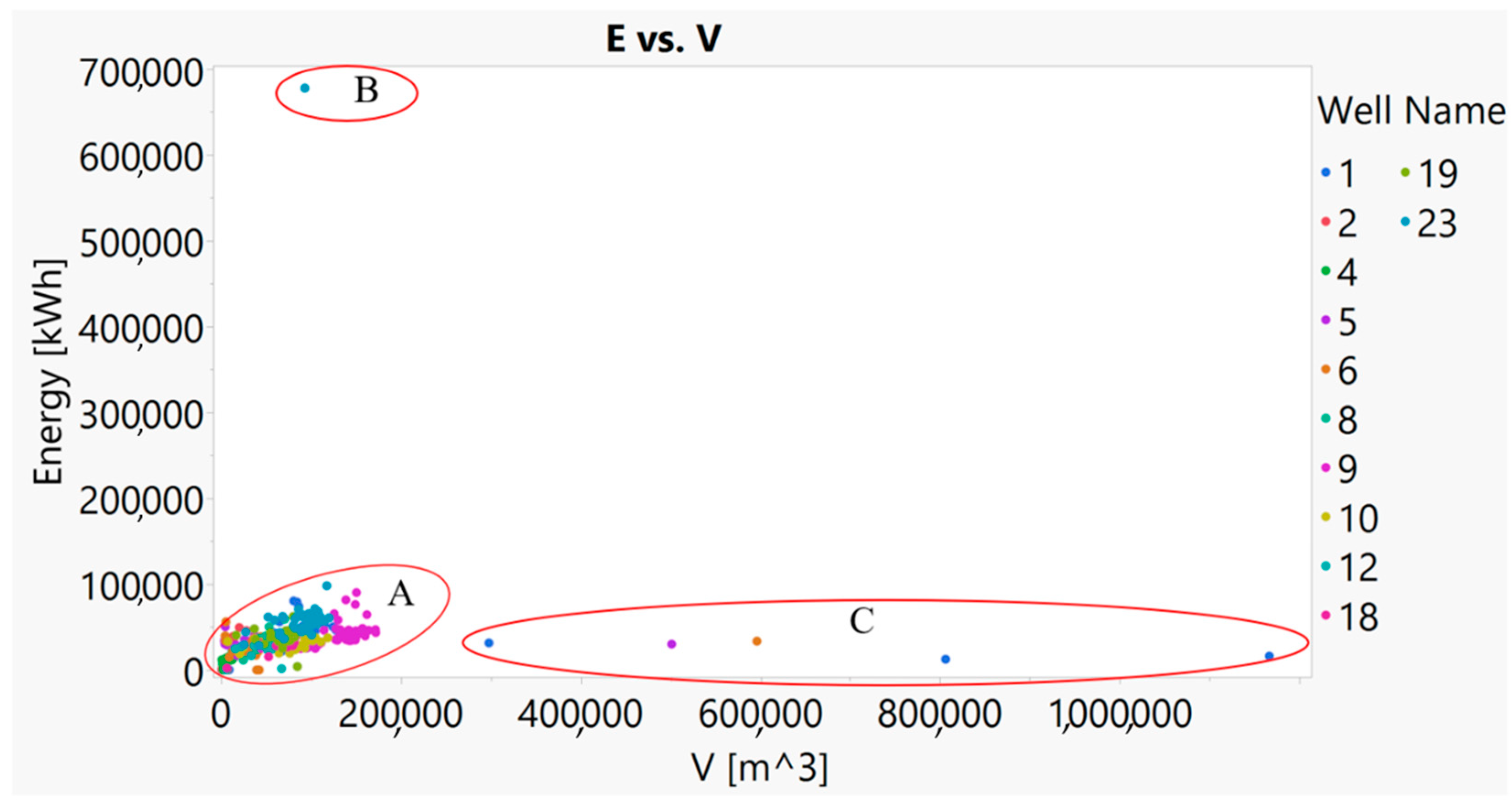

Figure 12 shows the Sand Hollow Recovery Cluster Plot (Recharge through the reservoir could not be analyzed). This plot shows a few trends similar to what was seen in

Figure 6. One instance is group A in the Sand Hollow Recovery Cluster Plot and group C in the H2Oaks Recovery Cluster Plot. Both groups show a trend of increasing energy usage correlating with an increase in volume. Since the majority of points for the Sand Hollow Recovery site fall into this category, it is likely that this site has an even greater correlation between energy usage and volume than the H2Oaks Recovery site.

Group C in the Sand Hollow Recovery Cluster Plot and group E in the H2Oaks Recovery Cluster Plot look similar upon first inspection (both groups have points along the x-axis). While the largest volume recovered for the H2Oaks site was approximately 682,000 m3, the Sand Hollow site shows a maximum recovery volume greater than 1,000,000 m3, larger than the expected well capacity for each well at this site. After calculating the well capacity for several wells, it was determined that any values larger than 329,000 m3 were not credible and likely due to reading errors. We decided to eliminate all points in group C. Group B does not show any resemblance to the H2Oaks Recovery Cluster Plot and is an outlier. Hence, only values in Group A were considered in the rest of the analysis. While equipment errors were denoted in the H2Oaks data, they were not denoted in the Sand Hollow data. We believe this is the reason for the errors in group C.

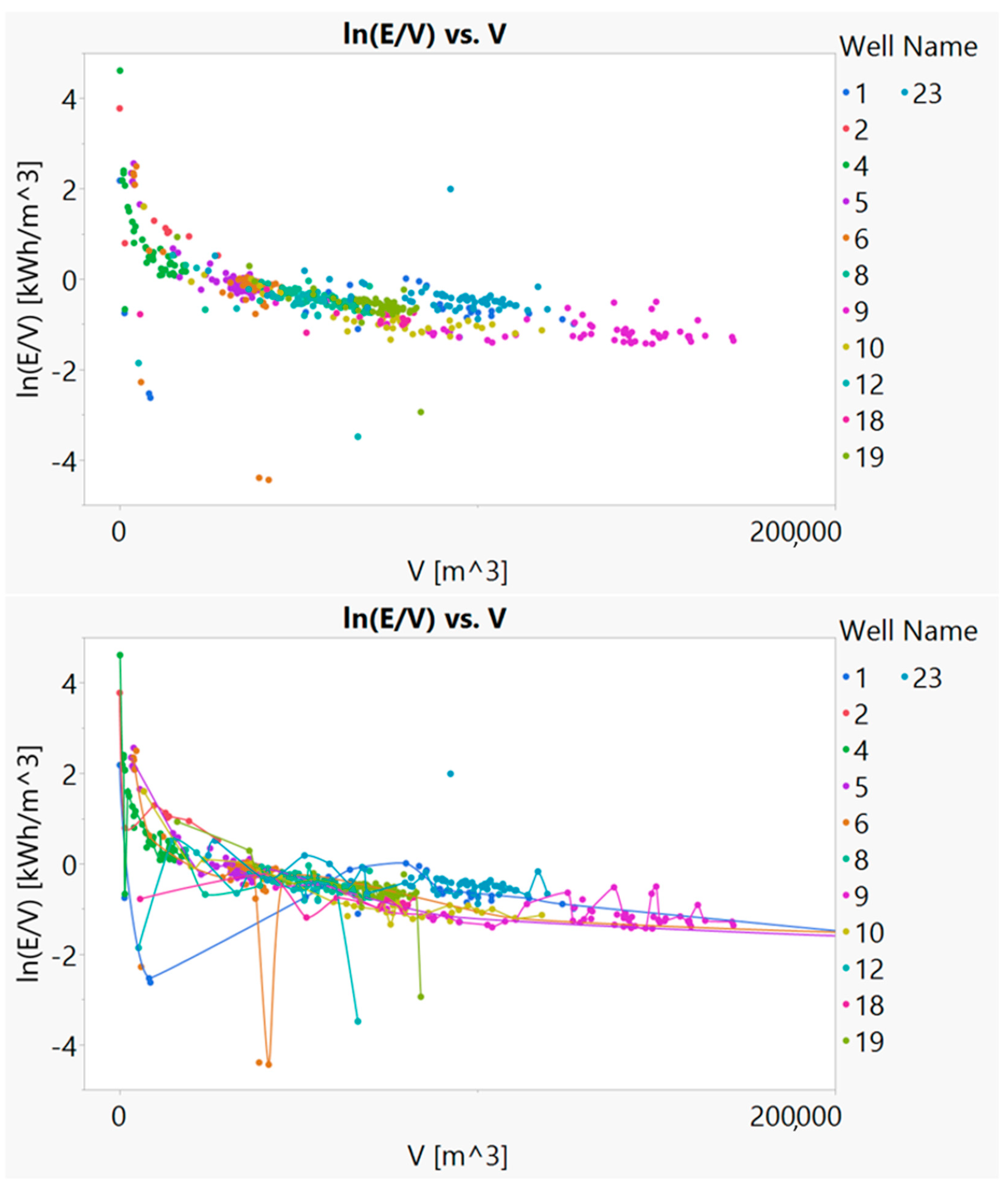

Figure 13 shows the ln(E/V) vs. V plot. This plot shows an economy of scale like in

Figure 7.

Figure 13 only displays one exponentially decreasing branch, unlike

Figure 7 which displayed two. The Sand Hollow Recovery process experienced a 43% decrease in the energy intensity from 0 to 50,000 m

3 versus the H2Oaks Recovery site which had a 78% decrease from 0 to 50,000 m

3. While the percentage change varied, this confirms the general principle that the more recovers in a month, the less energy intensive the process becomes.

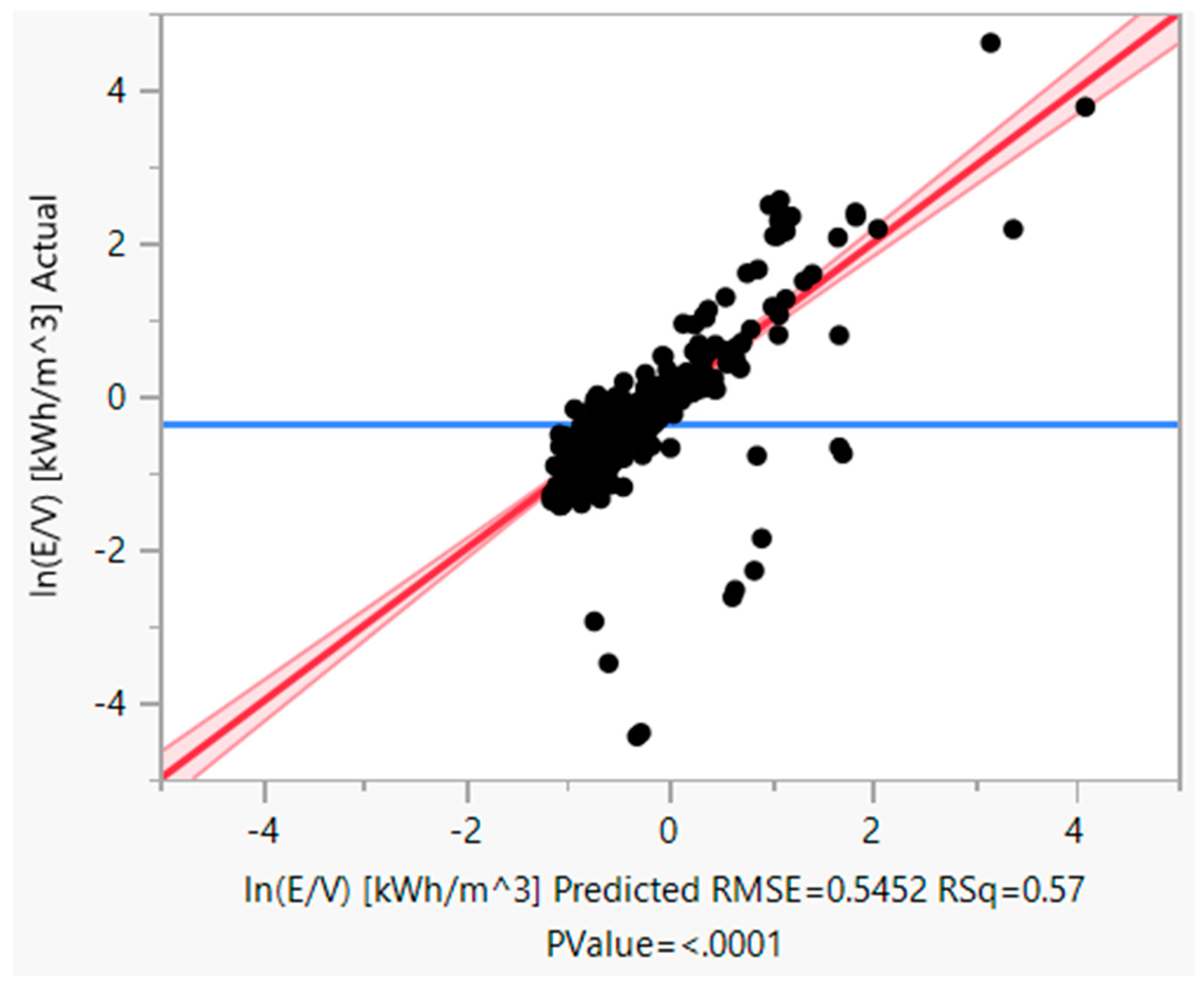

Figure 14 shows the Actual by Predicted plot for ln(E/V) with respect to ln(V). The RMSE value is 0.55. This value is not statistically significant by our definition of 0.2 – 0.5 but is close to this range and significantly closer than the RMSE for the H2Oaks Recovery process. The R

2 value is 0.57, again not statistically significant by our definition of 0.8, but higher than for the H2Oaks Recovery Process. These values indicate our points for the Sand Hollow Recovery site are more tightly centered around the line of best fit than for the H2Oaks Recovery site. The p value for this site is less than 0.0001 (same as the H2Oaks recovery site), showing the results are statistically significant and that there is a high probability that our values have some correlation. While these values show the datapoints are not heavily concentrated along the line of best fit by our statistical definition, they do show a higher correlation is present for the Sand Hollow Recovery site than for the H2Oaks Recovery site.

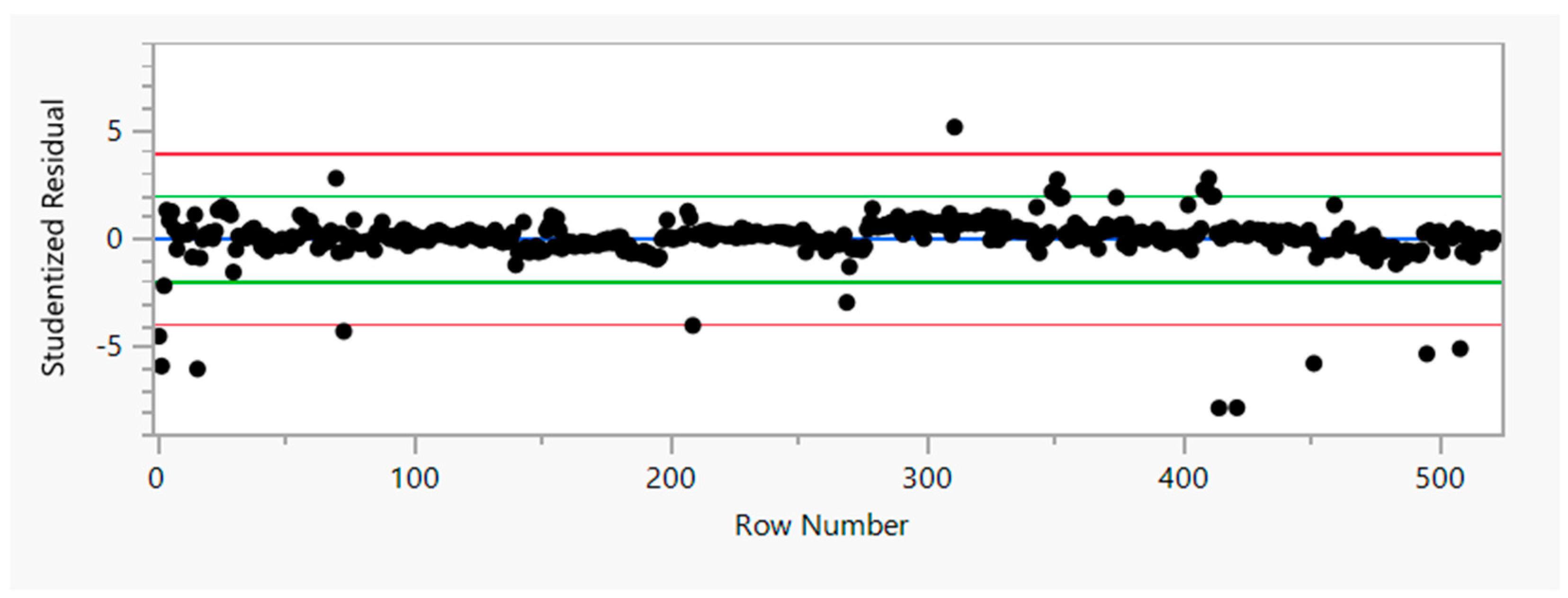

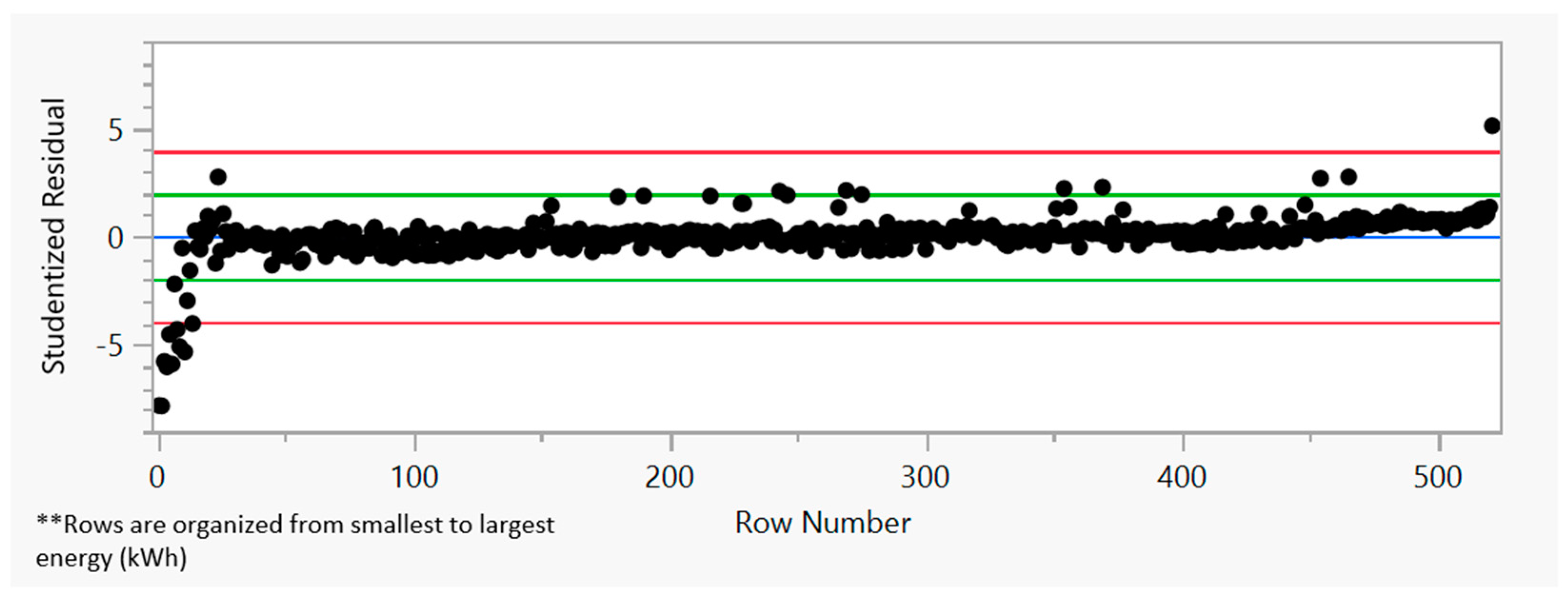

Figure 15,

Figure 16 and

Figure 17 show studentized residuals organized by row number, volume, and energy, respectively. Each figure shows points outside of the four studentized residuals indicating the presence of potential outliers. There does not seem to be significant correlation among the residuals for any of these plots. However,

Figure 17 does show a slight increase in residuals toward the far-right side of the plot similar to

Figure 11, but not as exaggerated. This could be indicative of external variables or nonlinear effects influencing the relationship.

In addition to the above figures, a box and whisker plot was created to determine if any correlation exists between the volume recovered and which months the recovery took place. There was found to be no correlation between the two.

The Sand Hollow recovery data generally agree with H2Oaks recovery data: energy intensity decreases with water volume.

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16 and

Figure 17 show a moderately strong economy of scale between the natural logarithm of energy intensity and the volume recovered at the H2Oaks site. The data shows there is a stronger economy of scale relationship present for the Sand Hollow recovery process than for the H2Oaks Recovery process.

4. Discussion

There are three major findings from this study. The first being an economy of scale in the recovery process, second being no economy of scale in the recharge process, third improving data coupling among water and energy data, and fourth the need for more studies relating ASR and energy use.

Figure 7 and

Figure 13 show a moderately strong economy of scale relationship between energy intensity and volume recovered. The greater the volume of water recovered, the less energy-intensive the recovery process becomes. On the other hand,

Figure 5 shows there is no relationship present between the volume recharged through gravity and the energy intensity, much less an economy of scale relationship.

It may seem counterintuitive that energy intensity decreases with an increase in volume recovered, since an increase in volume recovered would increase the distance the water would need to be pumped, increasing energy usage. However, the reason is attributed to several factors. One is the energy baseload required to run metering equipment, SCADA systems, security features, and the static head that needs to be overcome before any water moves. The energy baseload is relatively constant; as the volume increases, the energy baseload is divided by a larger water volume, decreasing the energy intensity overall. Another factor is that it takes a significant amount of energy to turn the recovery pumps on. Hence, the more frequently a pump is turned on, the greater the energy usage even if only a small volume is recovered. This concept is similar to how one obtains better gas mileage going faster on the freeway than when going slower but frequently starting and stopping.

This economy of scale phenomenon, as seen in the recovery process, is very prevalent in the water industry. Economies of scale relating to water supply and water sanitation have been seen in various countries around the world including Portugal, Ireland, Spain, and multiple developing countries [

33,

41,

42,

43]. One study found an economy of scale between unit costs and the size of community water systems; as the size of community water systems increased, their unit costs decreased [

35]. Another example found a similar trend between energy intensities and the volume of water produced among water treatment plants; the larger the volume of water produced, the less energy intensive the process was found to be [

31]. These trends have not only been found in the water industry, but also in services such as transportation, garbage collection, public schooling, and electricity [

32,

33].

This economy of scale recovery relationship has certain implications for the design and operation of energy and cost-efficient ASR systems. From a recovery standpoint, the larger the ASR wellfield, the greater the volume recovered and hence, the less energy intensive the process is.

Figure 7 and

Figure 13 show the largest drop in energy per unit volume of water occurs between a recharge or recovery volume of 0 to 10 m

3, right at the beginning of the plot. Operators who recover after this initial drop (typically between 10 and 100 m

3) will experience the greatest cost benefit, long-term money savings, reduction in energy intensity, and more energy sustainable operations. From a gravity-fed recharge perspective, the size of the site does not have any implications since no relationship was found between volume and energy. Since recharge and recovery were analyzed individually, this concept can be applied to all recharge and recovery wells whether or not they are paired with an ASR project.

Another major finding from this study was the difficulty in finding easily accessible, long-term, detailed, and coupled energy and water data from water utilities across the United States [

15,

44,

45]. With limited data, the analysis process was not straightforward and resulted in a substantial amount of manipulation to result in a usable format. Data manipulation takes a significant amount of time, making it difficult for individual utilities, especially those which are small and understaffed, to analyze their water and energy data. Due to this limitation, as well as a limited number of ASR projects in the United States, only two sites were analyzed in this study—one recharge process and two recovery processes. It will be beneficial for water utilities to consolidate energy and water data into a format that can be easily used for future analysis of the energy-water nexus, either through their own staff or through the hiring of a consultant. This can aid in the development of more confident conclusions between ASR and the energy-water nexus, better guiding water utilities on how to design and operate ASR wellfields, as well as wellfields in general. Furthermore, consolidation and analysis of a specific utility’s energy and water data will lead to more personalized savings for the respective utility, reducing energy usage further and increasing savings.

The last major finding was a lack of studies about ASR and energy use. Many studies have explored individual aspects of ASR or energy usage such as groundwater depletion [

27], the energy–water nexus [

4,

9,

10,

15,

28], water quality [

29], and optimization [

26,

30]. Additionally, reports and journal articles were found from utility entities individually discussing energy usage and groundwater levels. However, we did not find any articles that analyzed the pairing of energy usage and ASR with observed data. In order to better understand the relationships between ASR and energy use, more studies need to be completed to address this.

There were several limitations to this study. One being the lack of sites with long term and coupled energy and water data. Due to this, only two sites were studied. To confirm the accuracy of the conclusions in this paper, this study should be performed on additional ASR wellfields and active well sites. Another limitation is the fact that water and energy reading intervals typically do not overlap leading to inconsistencies when comparing data. For example, a monthly reading may go from November 1st to November 30th while the energy reading only goes from November 1st to November 25th causing the December month’s reading to start on November 26th. This variation in when energy readings take place is typical in the energy industry but leads to not achieving accurate comparisons between water and energy usage. Furthermore, limitations came from only considering electricity and not other energy sources such as natural gas [

12,

15], data inaccuracies, assumptions made, or errors introduced by deriving the energy use from the cost.

A limitation for the H2Oaks site was in isolating months where only recharge occurred, from those where only recovery occurred, from those where both recharge and recovery occurred. This was done so the recharge and recovery processes could be analyzed separately. Since in the majority of months, only recharge or recovery occurred, the majority of data did not have to be eliminated. However, months where both recovery and recharge occurred were eliminated. For the Sand Hollow site, a limitation was that the total energy usage had to be converted from a cost to energy. While the EIA provided the yearly cost per kilowatt-hour for the state of Utah, these costs do not take into account potential changes in costs on a daily or monthly basis nor do they account for changes in different regions in the state. Hence, the energy usage actually used will vary from that which was calculated. Furthermore, the demand charge was ignored in deriving the energy use from the Sand Hollow power bills, which can lead to overestimating energy use if the demand charge is a substantial portion of the expense. Another limitation is that malfunctions in measurement equipment were not denoted in the records for this site and hence, errors due to these malfunctions were not eliminated from this data set.

5. Conclusions

This study analyzed two ASR wellfields—H2Oaks in Texas and Sand Hollow in Utah—for relationships that could aid utilities in better understanding the connection between ASR and the energy–water nexus. An economy of scale relationship was found between energy intensity and the volume of water for the recovery processes, but not for the recharge process. This economy of scale is as follows: the greater the volume recovered in a set increment, the less energy intensive the process becomes. The H2Oaks recovery process experienced a 78% decrease in energy intensity from 0 to 50,000 m3, while the Sand Hollow site experienced a 43% decrease in energy intensity from 0 to 50,000 m3 recovered.

Through finding this economy of scale relationship for recovery and characterizing it using observed data, we have aided water utilities in better understanding what steps can be taken to optimize the design and operations of future and current ASR projects. A few of these steps include designing and operating large ASR wellfields with the storage capacity to recover large volumes of water at less frequent intervals instead of recovering small volumes of water at more frequent intervals. Whereas operators do not need to be concerned with the recharge process since an economy of scale relationship was not found for this process. This information is not only applicable to ASR wellfields, where recharge and recovery are paired, but also to any well undergoing one of these processes.

Applying this information can lead to many benefits for well operators. From an energy standpoint, this would likely lead to a decrease in energy intensity, decreasing overall energy use, and providing more energy sustainable operations. From a money standpoint, the more energy efficient operations would result in a decrease in energy costs, leading to greater cost benefit, reducing operational costs, and leading to long-term money savings for the entity.

Future work should include improving energy and water data coupling among water suppliers, performing similar analyses on additional wellfields, and developing data-driven guidance to support energy-efficient design and operation of ASR systems.

Author Contributions

Alyson H. Rapp contributed to the conceptualization, methodology, formal analysis, and writing – original draft, review, and editing. Rob B. Sowby contributed to the conceptualization, methodology, formal analysis, and writing – review and editing. Gustavious Williams contributed to the formal analysis and writing – review and editing.

Funding

This research was funded by the Civil and Construction Engineering Sustainability Lab at Brigham Young University.

Data Availability Statement

Data supporting reported results can be found by emailing Alyson H. Rapp at arapp34@byu.edu

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mahajan, S.; Martinez, J.; Water; water, but not everywhere: analysis of shrinking water bodies using open access satellite data," International Journal of Sustainable Development & World Ecology, vol. 28, no. 4, pp. 326-338, 2021. [CrossRef]

- Snyder, G.L.; Pyne, R.D.G.; Morrison, K.; Nixon, K., "San Antonio Water System, Texas Carrizo Aquifer Storage Recovery Program," Groundwater, vol. 60, no. 5, pp. 641-647, 2022. [CrossRef]

- Hutchinson, A.S.; Woodside, G.D.; Herndon, R.L., "Increasing the Sustainable Yield of the Orange County Groundwater Basin with Managed Aquifer Recharge," Groundwater, vol. 60, no. 5, pp. 628-633, 2022. [CrossRef]

- DOE (United States Department of Energy), Energy Demands On Water Resources: Report to Congress on the Interdependency of Energy and Water (no. 201107). DOE, Washington D.C., 2006.

- Rojanasakul, M.; Flavelle, C.; Migliozzi, B.; Murray, E. "America Is Using Up Its Groundwater Like There's No Tomorrow," New York Times. [Online]. Available: https://www.nytimes.com/interactive/2023/08/28/climate/groundwater-drying-climate-change.html.

- Searcey, D.; Erdenesanaa, D. "A Tangle of Rules to Protect America's Water is Falling Short," New York Times. [Online]. Available:https://www.nytimes.com/interactive/2023/11/02/climate/us-groundwater-depletion-rules.html?unlocked_article_code=1.70w.olqP.O3kwpYa6Ney6&smid=url-share.

- Konikow, L.F., "Long-Term Groundwater Depletion in the United States," Groundwater, vol. 53, no. 1, pp. 2-9, 2015. [CrossRef]

- Pyne, R.D.G. Groundwater Recharge and Wells: A Guide to Aquifer Storage and Recovery, 1 ed. CRC Press, Inc., Boca Raton, 1995, p. 400.

- Hussey, K.; Pittock, J. "The Energy–Water Nexus: Managing the Links between Energy and Water for a Sustainable Future," Ecology and Society, vol. 17, no. 1, 2012. [CrossRef]

- EPA (U.S. Environmental Protection Agency), Ensuring a Sustainable Future: An Energy Management Guidebook for Wastewater and Water Utilities. EPA, Washington D.C., 2008.

- Sanders, K.T.; Webber, M.E., "Evaluating the energy consumed for water use in the United States," Environmental Research Letters, vol. 7, no. 3, 2012, 034034, 2012; 3. [CrossRef]

- Twomey, K.M.; Webber, M.E., "Evaluating the Energy Intensity of the U.S. Public Water System," presented at the ASME 2011 5th International Conference on Energy Sustainability, 2011. [Online]. [CrossRef]

- Jones, S.C.; Sowby, R.B. , "Quantifying Energy Use in the US Public Water Industry — A Summary," ASCE EWRI Currents, vol. 16, no. 4, pp. 6-9, 2014.

- Sowby, R.B.; Burian, S.J. , "Survey of Energy Requirements for Public Water Supply in the United States," Journal AWWA, vol. 109, no. 7, pp. E320-E330, 2017. [CrossRef]

- Chini, C.M.; Stillwell, A.S. , "The State of U.S. Urban Water: Data and the Energy-Water Nexus," Water Resources Research, vol. 54, no. 3, pp. 1796-1811. [CrossRef]

- Cohen, R.; Wolff, G.; Nelson, B. , Energy Down The Drain: The Hidden Costs of California's Water Supply. Natural Resources Defense Council and Pacific Institute (NRDC), Oakland, 2004.

- Goldstein, R.; Smith, W. , Water & sustainability (volume 4): US electricity consumption for water supply & treatment-the next half century. Electric Power Research Institute (EPRI), Palo Alto, 2002.

- Plappally, A.K.; Lienhard V, J.H. , "Energy requirements for water production, treatment, end use, reclamation, and disposal," Renewable and Sustainable Energy Reviews, vol. 16, no. 7, pp. 4818-4848, 2012. [CrossRef]

- Klein, G. California's Water–Energy Relationship (California, USA). California Energy Commission (CEC), Sacramento, 2005.

- Sowby, R.B.; Krieger, K.M. , Derivation and Use of Pump Energy Intensity Equation for Water System Energy Analysis. Authorea., 2023.

- Sowby, R.B.; Burian, S.J. , "Statistical Model and Benchmarking Procedure for Energy Use by US Public Water Systems," Journal of Sustainable Water in the Built Environment, vol. 4, no. 4, 2018, 04018010. [CrossRef]

- Ahlfeld, D.P.; Laverty, M.M. , "Analytical solutions for minimization of energy use for groundwater pumping," Water Resources Research, vol. 47, no. 6, 2011, W06508. [CrossRef]

- Martin, D.L.; Dorn, T.W.; Melvin, S.R.; Corr, A.J.; Kranz, W.L. , "Evaluating Energy Use for Pumping Irrigation Water. Proceedings of the 2011 Central Plains Irrigation Conference, Burlington, Colorado, February 22-23: Evaluating Energy Use for Pumping Irrigation Water," 2011. [Online]. Available: http://hdl.handle.net/10217/47726.

- Sowby, R.B.; Jones, S.C.; Christiansen, S.; Jensen, M. , "Energy Management Program Leads to Operational Improvements," Opflow, vol. 45, no. 5, pp. 10-14, 2019. [CrossRef]

- Sowby, R.B.; Morehead, N.; Burdette, S. , "Review of Energy Management Guidance for Water and Wastewater Utilities," Energy Nexus, vol. 11, 2023, 100235. [CrossRef]

- Majumdar, S.; Miller, G.R.; Sheng, Z. , "OOptimizing Multiwell Aquifer Storage and Recovery Systems for Energy Use and Recovery Efficiency," Groundwater, vol. 59, no. 5, pp. 629-643, 2021. [CrossRef]

- Hsieh, P.A. , "Deformation-Induced Changes in Hydraulic Head During Ground-Water Withdrawal," Groundwater, vol. 34, no. 6, pp. 1082-1089, 1996. [CrossRef]

- DOE (U.S. Department of Energy), The Water-Energy Nexus: Challenges and Opportunities. DOE, Washington D.C., 2014, p. 238.

- Pyne, R.D.G. , "Water Quality in Aquifer Storage and Recovery (ASR) Wells," 2003. [Online]. Available: http://asrforum.com/fatestudy/documents/asrpopa111503.pdf.

- Fatkhutdinov, A.; Stefan, C. , "Multi-Objective Optimization of Managed Aquifer Recharge," Groundwater, vol. 57, no. 2, pp. 238-244, 2019. [CrossRef]

- Sowby, R.B.; Thompson, M.J. , "Energy Profiles of Nine Water Treatment Plants in the Salt Lake City Area of Utah and Implications for Planning, Design, and Operation," Journal of Environmental Engineering, vol. 147, no. 7, 2021, 04021018. 2021; 7. [Google Scholar] [CrossRef]

- Christensen, L.R.; Greene, W.H. , "Economies of Scale in U.S. Electric Power Generation," Journal of Political Economy, vol. 84, no. 4, Part 1, pp. 655-676, 1976. [CrossRef]

- Gómez-Reino, J.L.; Lago-Peñas, S.; Martinez-Vazquez, J. , "Evidence on Economies of Scale in Local Public Service Provision: A Meta-Analysis," International Center for Public Policy (ICEEP) Working Papers. 21-16., 2021.

- Kim, H.Y.; Clark, R.M. , "Economies of Scale and Scope in Water Supply," Regional Science and Urban Economics, vol. 18, no. 4, pp. 479-502, 1988. [CrossRef]

- Shih, J.S.; Harrington, W.; Pizer, W.A.; Gillingham, K. , "Economies of scale in community water systems," Journal AWWA, vol. 98, no. 9, pp. 100-108, 2006. [CrossRef]

- Cetrulo, T.B.; Marques, R.C.; Malheiros, T.F. , "An analytical review of the efficiency of water and sanitation utilities in developing countries," Water Research, vol. 161, pp. 372-380, 2019. [CrossRef]

- WCWCD (Washington County Conservancy District). "Reservoirs." WCWCD. https://www.wcwcd.org/infrastructure/reservoirs/ (accessed 22 Septemeber 2023.

- Marston, T.M.; Nelson, N.C. , "Assessment of Managed Aquifer Recharge at Sand Hollow Reservoir, Washington County, Utah, updated to conditions through 2016," in "Open-File Report 2018-1140," Reston, VA, 2018. [Online]. [CrossRef]

- Carlson, S.W.; Walburger, A. , Energy Index Development for Benchmarking Water and Wastewater Utilities. AwwaRF, Denver, 2007.

- EIA (U.S. Energy Information Administration). "Electricity Data Browser." EIA, Washington D.C. https://www.eia.gov/electricity/data/browser/ (accessed September 1, 2023, 2023).

- Marques, R.C.; De Witte, K. , "Is big better? On scale and scope economies in the Portuguese water sector," Economic Modelling, vol. 28, no. 3, pp. 1009-1016, 2011. [CrossRef]

- Turley, G.; McDonagh, J.; McNena, S.; Grzedzinski, A. , "Optimum Territorial Reforms in Local Government: An Empirical Analysis of Scale Economies in Ireland," The Economic and Social Review, vol. 49, no. 4, pp. 463-488, 2018. [Online]. Available: https://www.esr.ie/article/view/1034/0.

- Prieto, Á.M.; Zofío, J.L.; Álvarez, I. ; Cost economies, urban patterns and population density: The case of public infrastructure for basic utilities," Papers in Regional Science, vol. 94, no. 4, pp. 795-816, 2015. [CrossRef]

- Chini, C.M.; Stillwell, A.S. , "Where Are All the Data? The Case for a Comprehensive Water and Wastewater Utility Database," Journal of Water Resources Planning and Management, vol. 143, no. 3, 2017, 01816005. [CrossRef]

- Sowby, R.B.; Burian, S.J.; Chini, C.M.; Stillwell, A.S. , "Data Challenges and Solutions in Energy-for-Water: Experience From Two Recent Studies," Journal AWWA, vol. 111, no. 2, pp. 28-33, 2019. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).