1. Introduction

With the increasing population and a shift in the eating habit, plant-based meat alternatives (PBMA) have gained enormous attention from the consumers around the world. According to a report by Bloomberg in 2021 [1], globally the plant-based food market is expected to reach up to $162 billion by 2030 from $29.4 billion in 2020 as the concept of flexitarian (a causal vegetarian) is getting quite popular in today’s generation with 14% vegetarians or vegan and 15% flexitarians, which is approximately 29% of total population [2]. Additionally, the people those are suffering from different health related issues like lactose intolerance or malabsorption, high cholesterol intake are also finding their ways to plant based alternative products [3].

Plant based alternatives are the products that are created to replicate the sensory and quality characteristics of the animal-based food products [4,5]. Currently, there is a large number of varieties for alternative products available in the market with the biggest percentage of milk (15%) followed by the plant-based meat (1.4%) only in USA [6], that means there is a considerable room for technological and formulation development to create a high-quality alternative of meat. The general composition of a meat alternative is 50-80% water content, 10-25% textured protein, 4-20% non-textured protein, 3-10% flavor additives, 0-15% fat content, 1-15% binding agents, and 0-5% coloring agents. All these nutritional and non-nutritional components provide the textural and sensorial characteristics to the end product. However, it is becoming more and more competitive in recipe formulation and technological advancement to produce a better product. Many food companies and the researchers are trying to find out the more suitable ways to produce the alternative not only for meat but also for fish, milk, cheese and yogurt with additional health-promoting properties. However, it is exceedingly difficult to replicate the texture and flavour of meat due to the differences in the molecular and physiochemical properties of plants and animals as well as the lower protein efficiency and lack of nutrients in plant materials.

Apart from production, the acceptance of the novel plant-based alternative by the consumer is also necessary to replace the meat in everyday dietary intake. The overall acceptance of product not solely depends upon the sensory property but also influenced by the ethical aspects, personal belief, awareness of that person. However, the sensory property plays an important role in the acceptance of any product before and during the consumption. Before the consumption, appearance, color, shapes have a greater influence on the purchasing behavior of the consumer while, after that the taste and texture profile that matters the most. According to a survey in 2021, about 82% consumer believe that the most influence factor to purchase a product is taste followed by cost (66%), health (58%), convenience (52%) and lastly the environmental sustainability with 31%. In reference to this data the unpalatable or surprising tastes is main barrier of any alternative product [7]. To predict the acceptance and preference pattern of the consumer for any product sensory evaluation is necessary. The sensory evaluation helps to collect the preferences of a consumer regarding the product which helps in further formulation by adding different seasoning ingredients, spices and other additives. The selection of ingredient and processing aid is also crucial for the optimizing the desirable sensory properties of the final product [8].

This review aims to provide a better understanding of the sensory differences between plant-based and animal-based meat alternatives by comparing their color, texture, and flavor profiles. It also discusses the techniques used in their development and the sensory evaluation to develop the consumer preferred alternative in both the qualitative and quantitative way.

2. Color Characteristics of Animal and Plant-based Meat

Color has always been an important trait of meat product as it reflects the freshness and quality of meat. The color of a meat depends on two attributes i.e., the achromatic (without color) and the chromatic attributes which can be measured in terms of the reflectance (absorption & scattering) on the surface of the meat [9] and this absorption of light to the meat surface depends upon the combination of the Haemoglobin, cytochrome c oxidase, and mainly the myoglobin. Myoglobin and its oxidative states oxy, deoxy and metmyoglobin attribute different colour as bright-red color, darker-purple and discoloration or brown, respectively. Myoglobin protein containing heme, is responsible for the bright-red color, while during the cooking myoglobin undergoes denaturation (75 ͦC) and produce a brown color end product [10–13]. However, the Achromatic factor effect the color of meat due to the difference in the light scattering to the variance in physical and structural properties of muscle. The scattering of light is determined by three major mechanisms from the surface meats: (1) Difference in the composition of protein and distribution of sarcoplasm (bound or free floating), (2) the light of the sarcomere (3) spacing between the myofilament with the myofibrils, the latter two mechanism cause the change in the diameter of myofibril [13].Whereas, the plant-based alternative is an unappealing grey product and does not have a bright red color appearance as shown in

Figure 1 [14] and depending upon the manufacturer it can only acquire limited shades like red-pink or brown.

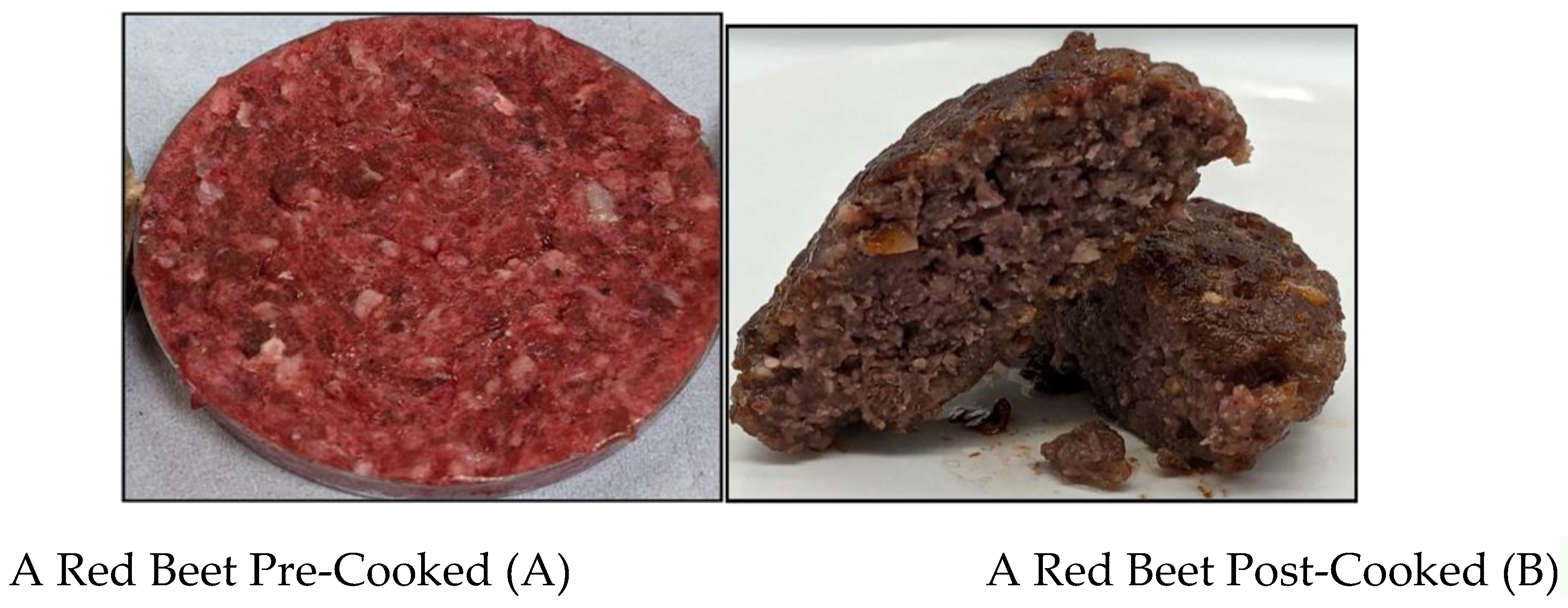

For a product to be an alternative, similar color before and after cooking should be delivered as it affect the purchasing power of the consumer [14].To improve the color profile of alternatives, different attempts had been made. For decades the synthetic food coloring agents have also been widely used in PBMA. However, customers find them undesirable due to side effects include toxicity, allergy, and neurocognitive consequences. Hence the naturally occurring pigment like anthocyanin, carotenoids, curcuminoids, used as coloring pigment. Initially, the heat stable colouring agents like annatto, carotenoids, caramels and turmin has been used to provide the desired color in sausages but as the meat generally required a change in color after cooking from red to brown. Therefore, the use of natural heat stable coloring agents is not appropriate. However, According to Plant-Ex Ingredients ltd.( an international company specialised in the manufacturing food ingredients from colors, flavours and extract) the red beet is an ideal coloring agent for the products like burgers and minced meat products (as incorporated in burger from The Beyond Burger company) as it gives a strong pink-red color to the raw product and after heating the sugar in the beet caramelise and gives a shade of brown, as in

Figure 2 (A) an uncooked alternative sample with red beet colorant and in 2 (B) the sample after cooking is shown which display the change in color from red to brown [16]. This change in color explain the objective of combining the reducing sugar (maltose, dextrose, lactose, mannose, arabinose) with the heat-labile colorant [17]. The other method is the use of myoglobin alternative. The food company like, Impossible Foods, are using a recombinantly produce soy leghaemoglobin from fungus and beetroot extract subsequently to mimic the raw meat color [15,16]. As before the cooking process the leghaemoglobin provides a fresh meat color to the product however after cooking the color change take place because of the Maillard reaction.

One other method is also been used which involves, the use of colorants with the protein containing materials after injecting the mixture into the extruder barrel i.e., the structuring process. Still, the final color obtained by all these processes is not of highest quality, owing to the fact as, different intrinsic and extrinsic factors affect the color of food, like presence of maltodextrin and alginate hydrate, and the PH, as the meat alternative PH can differ due to the addition of various acids like acetic acid, citric acid while formulation and affect the final color profile [17].

Recently the advanced technologies like artificial intelligence and machine learning are showing potential approaches in the area to mimic the color of meat products by conduct a thorough investigation on the molecular structure and analysing the ways in which component behave independently and in the presence of each other [21]. A company Eat Just, has developed and even marketed a plant-based egg alternative from an Indian legume [22]. The use of other technologies like the bioinformatics analysis with proteomics and the sarcoplasmic protein is also getting intention as it can used in the formation of better colored product [23].

3. Texture Profiling of Animal and Plant-based Meat

The textural profiling (firmness, juiciness, springiness and cohesiveness) is the main parameter for the quality and acceptability of a product and consumers are even willing to pay more to get a product with better texture [18]. For a product to consider as meat, the fibre structure of the product is necessary and to develop an alternative product with similar structure first the analyse of the structure of meat is important. The size of a typical muscle fiber is between 1-40 mm in length and 20-100 μm in diameter however till now the structural fiber of an alternative is produced at the micron level only [25,26].

The textural properties of muscle meat mainly depend upon the composition and structure of muscle fibre that are made up of myofibrils (actin and myosin filaments) and along with connective tissue, sarcomere length, intramuscular fat, and denaturation of protein during cooking [27–29]. Other than these factors the non-meat ingredients like fats/oils, binders, dietary fibres, additives also affect the tenderness of meat. The textural and rheological properties of the PBMA can also vary form one product to other according to the use of ingredient, processing like the meat from the different parts have different attribute. So according to the properties of desired end product an appropriate selection of raw ingredient and technique is necessary to mimic the fibral, connective and adipose structure of the product. The texturization of an alternative is basically the process (usually the extrusion) of re-arranging the protein ingredients to form a fibrous structure that can mimic the technical and functional aspects of a meat. As it is well known that the vegetable protein is globular shaped complex multimer while the meat is fibrous in nature, the difference in the structure of these two is the biggest challenge to produce alternative. The development of fibrous structure during the processing involves the occurrence of different events of unfolding, crossing, breakdown and gelatinisation. The plant protein undergoes various processing techniques like extrusion, spinning, shear force to texturized by the unfolding, cross linking [19,20]. The protein not only gives the nutrition but also contribute to other functional properties of the product like emulsifying, gelling, water/oil absorbing capacity which is essential.

Choosing a right protein source is important for the development of PBMA. The most commonly used protein source for the PBMA is soy protein concentrate and isolate as they are cost effective, easily available and have the similar mouthfeel and texture like meat after hydration [21]. The purified form of protein by fractionation of soy flour contains about 70 and 90% protein respectively. It has also been observed that the soy protein extenders can also improve the water holding capacity, chewiness and juiciness of beef [22].Palanisamy et al. in their study found the improvement in textural profile by increasing the iota-carrageenan concentration in soy protein. Combining soy protein with wheat gluten (insoluble protein) also enhance the formation of layered and fibrous structure in PBMA [23] as the use of single plant protein produce a weak structure, combining different protein can effectively improve the structure formation. The wheat gluten helps in the binding and act as stabilising agent while providing nutritional, swelling, binding and structural property [24,25]. Researchers have also observed that incorporating 30% of gluten in the preparation have the highest degree of texturization, chewiness, hardness and fibrous texture. Various legumes such as pea, lentil, beans are also used in the fabrication of PBMA. The pea protein can be a substitute for the soy protein as it can be allergic to some people and it is also cost effect, easily available however the structurization using pea protein is challenging it has low gel forming availability and also less feasible functional and sensory property [26,27]. Another protein source is oilseeds as they are rich in protein and can be utilised as a functional ingredient. The Rapeseed mainly contains two proteins, cruciferin and napin which initiate the gel formation at high temperature and pressure which aids to the texturization of PBMA [28,29]. Quinoa flour is also been used as gelling agents and fat replacer as it improves the nutritional property and reduce the cooking loss [30]. Other than plant-based meat currently insects are also been studied by researcher as a suitable alternative of meat. Starowicz et al. have provided the detailed information about edible insect as alternative [31].

Apart from the plant protein there are some constructional ingredients that helps in improving the texture profile of PBMA. As we have already mention that incorporation of wheat gluten and iota carrageenan improve the fibrous structure [23,32]. Additionally, in research by, they found that the 3% methylcellulose with texturized soy protein have similar texture including cohesiveness and springiness as of beef patties [33]. An another water-soluble dietary fiber Konjac glucomannan ( β−1,4-linked D-mannose and D-glucose) acts aa an emulsifier and stabiliser in alternative production [34]. A n enzyme derived from the streptoverticillium moberansae, Transglutaminase is also used as a crosslinking agent in alternative production [35,36].

Two main types of techniques are mainly used in the processing of alternative products: - Top-down and Bottom-up structuring techniques. In top-down technique (extrusion, freeze structuring, shear cell and the blending of hydrocolloids), the fibrous anisotropic structure is obtained by using external force on biopolymer blends [37–40]. Whereas in bottom-up technique, by wet spinning and electrospinning the individual fibres are combine to form an end product [41]. While, the ingredient used in the textured vegetable protein obtained from different sources like cereals, legumes and oilseeds not only have the difference nutrition properties but also has different functional properties like gelling, forming, emulsifying and water and oil holding capacity [42]. The transformation during extrusion depends upon different parameters such as operating parameters like the feed composition, geometrical factor of the machine (die dimension and type, screw design) and the process variables (moisture, temperature, and speed of the screw).

4. Flavor Profile of the Animal and Plant-based Meat

The flavor of the meat equates to the taste and eating quality of meat. It is the combination of stimulation caused by different bioactive compounds in the taste receptors of oral and nasal cavity of human [38]. The components like carbohydrates, fat, and protein acts like the precursors of meat flavor. There are more than 1000 flavor components present in meat which are responsible for the specific taste of the meat. The raw meat does not have any aroma and only has the flavor of blood, metal and salt however when it undergoes heating process due to the complex decomposition, oxidation, reduction and different chemical reaction various volatile compounds (alcohol, alkenes, aldehydes, ketones, ester, acids, ether) are produced to generate the meat like flavor [39–41]. Three main thermal reactions occur in meat products during cooking that developing this specific meaty flavour. 1). The Maillard reaction where the flavour precursors are reducing sugars, free amino acids, peptides which leads to the development of pyrazine, heterocyclic and sulfhydryl compounds (4 mercapto-5-methyl-3(4H)-furanone, 2 -methyl-3-furanthiol, 2-methyl-3-methylthiofuran, 2-methyl-3-methyldithiofuran). 2). The degradation reaction which utilizes the thiamine to produce thiols, sulfides and disulfides. 3) The oxidation reaction by using lipids and fatty acids to produce aldehydes, furans, unsaturated ketones, aliphatic hydrocarbons [43]. Because of these reactions meat has three major flavor profile i.e., meaty flavor which is derived from the amino acids and water-soluble reducing sugar in the meat, whereas the species-specific flavor is due to the difference in the composition of fatty acid and aromatic water-soluble compounds and the off-Flavors are developed because of oxidation of lipid and other degradation process during storage and processing.

While the PBMA mainly contains soy and legume protein exhibit the flavor that is a bit astringent, bitter because of the presence of compounds like phenols, saponin, isoflavones and phenolic acids and also has some beany taste due to the lipid oxidation and protein denaturation caused by lipid oxidation while processing [42,43]. Therefore, to achieve the meat like flavor and to mask the natural flavor profile of plant protein, the removal of unwanted flavor during the processing (extrusion and shear processing of protein) by the extraction and deactivation of lipoxygenase is necessary [44] with the addition of various flavoring agents (natural and synthetic). These flavoring agents have been displayed in Table 1

Table 1.

Types of different natural and synthetic flavoring agent.

Table 1.

Types of different natural and synthetic flavoring agent.

| Name |

Natural flavouring agents |

Synthetic flavouring agents |

| Definition |

Natural Flavouring agents are the substance that are extracted from plant, herbs, spices and microorganism. [45] |

Synthetic flavouring agents are substances that are similar to natural agents [45] |

| Type |

Herbs and spices: Garlic, onion [46,47] |

Artificial: artificial smoke flavour or synthetic version of natural flavours [48] |

| Yeast Extract [49,50] |

Flavour enhancer: Monosodium glutamate (MSG) |

| Fermented products: Miso, tamari [51] |

|

| Vegetable Extract: Tomatoes, mushrooms [45,52] |

|

| Cost |

Expensive [45] |

Less expensive [45] |

The high pressure and moisture extrusion processes also alter the flavor of the meat because of the changes in the constituents of flavor and dissemination of water and also the alternation in the conformation of protein. Additionally, the use of synthetic flavoring agents is also problematic as it reduces the quality of the product and also contain harmful components. To impart meat like flavor, various plant-based ingredients like Natural spices, yeast extract and Hydrolyzed vegetable protein (HVP) are also widely used in the alternative formulation. HVP is a nutritional food additive which is prepared from a variety of plant protein like soybean, corn, wheat etc. broken down into small peptides and amino acids using acid hydrolysis (can form carcinogenic compounds), enzymatic hydrolysis (mainly used method) under mild PH and temperature [53–55]. Due to the presence of many volatile components such as pyridines, pyrrole, organic acids, furans, furanones, sulfur containing compounds alcohols, ester, phenols treatment with sulfur compounds, reducing sugar and yeast autolysis they produce a strong meat like flavour [56]. Although the optimization of Flavor is still a big challenge in the production of alternative that taste like meat.

5. Sensory Evaluation Methods Used in Analysis

The sensory evaluation is the set of scientific discipline of the methods to measure, analyse and interpret the human response to the properties and components of food as recognise by the taste, smell, touch, appearance and hearing [57]. Different tests are used in different conditions to understand the sensory profiling of food. Mainly three type of sensory analysis is used in the evaluation of plant-based products: subjective analysis, descriptive analysis and Discrimination test. The most commonly used method is the 9-point hedonic scale also known as the consumer acceptability test or Subjective analysis it provides the information about the overall acceptance and rejection of a product based on the definite sensory properties like appearance, taste, texture, flavour performed by the untrained participant or consumers [58]. This test is basically based on concept of liking and disliking of consumer and give the producer an understanding about the desirability of consumer regarding the product. The consumer preference data also helps to increase the overall profiling of the product by varying the different formulation parameter during the processing. However, the analysis by the Descriptive sensory method (Objective analysis) gives a more elaborated assessment of the sensory profiling of the product based on the pre-defined scale. Here the qualitative and quantitative intensities of the sensory properties are determined.

Table 1.

Example of different studies for the sensory evaluation of different alternative products. The abbreviations used in the table are as follows: SPI(soy protein Isolate), PBA( Plant Based Alternative).

Table 1.

Example of different studies for the sensory evaluation of different alternative products. The abbreviations used in the table are as follows: SPI(soy protein Isolate), PBA( Plant Based Alternative).

| Product type |

Method |

Panelist |

Finding |

Reference |

| PBA to chicken Nuggets |

Consumer acceptability |

105 Untrained |

PBAs does not have the fibrous structure and have beany or off-flavor |

[59] |

| Peanut based alternative to beef patty |

Consumer acceptability |

60 Untrained |

The sensory properties were better than the soy based alternative and can be a substitute to consumer acceptable beef patty |

[60] |

| Chicken sausage (SPI) |

Descriptive Analysis |

8 trained |

The sausage was equally acceptable in terms of overall acceptability. |

[61] |

| PBA to beef patty |

Descriptive Analysis |

10 trained |

NO beany essence was noticed |

[4] |

| Sausage analogue (mushroom based &SPI) |

Consumer acceptability |

32 untrained |

Mostly closed characteristic like beef (can be applied as substitute) |

[62] |

| Meat Analogue (defatted soy, rice and bean flour) |

Odor and colour (after Sous-vide treatment) |

73 untrained |

Colour score were higher in analogue than beef |

[63] |

| Meat analogue (Oat-pea protein) |

Hedonic (appearance, taste, odor) |

8 trained |

Highly fibrous structure with Mild flavor |

[64] |

| Chicken analogue (SPI & Wheat gluten |

Consumer acceptability |

Unknown |

High fibrous structure in comparison to chicken breast |

[24] |

| Meat analogue( faba bean protein) |

Sensory and instrumental analysis |

Unknown |

The product had good bite-feeling, elasticity/firmness in comparison to meat |

[65] |

| PBA to chicken & beef |

Consumer acceptability |

71 untrained |

Meaty flavor and juiciness are absorbed. |

[66] |

| PBA (Gluten free& soy free) |

Consumer acceptability |

60 untrained |

The addition of anthocyanins increases the antioxidant capacity of the product with an acceptable colour change. |

[67] |

| Meat analogue |

Consumer acceptability |

93 untrained |

Similarity to meat does not seem to have an effect on the acceptance |

[68] |

Like the alternative is rated according to the different attributes like elasticity, fibrousness, brittleness, tenderness, juiciness, taste, flavor, appearance, smell [24,69–72]. For this the panellists should be trained under extensive training including texture profile, flavor profile, quantitative descriptive analysis, and sensory spectrum [58]. The information from this analysis percussively quantifies the factors and contribute in the development of better product. There is also one more sensory analysis test that is the discrimination test, to detect the difference in the sensory parameter of two or more product. This test is basically preformed in various ways: the triangle test, three different unknown sample are given to the panellist and they have to identify the dissimilar sample from them. While in duo-trio test, the panellist is given three sample one is known and two unknowns, they have to match the sample to the known one based on their sensory property. However, in ABX test, three samples are given to the panellist, two known and one unknown, and they have to match the unknown with one of the knowns. Table 1 is given to provide the sensory evaluation of different plant based alternative product done in different studies. Table 1 provides an overview about the methods used in the sensory evaluation of the plant-based products by different researchers.

6. Consumer Preferences and Acceptance

Our food habit not only affects our health but also the future of our planet. The production of meat in all these years have played a major role in the climate change. According to Thomas et al. [73] the global anthropogenic greenhouse gas emission from the agricultural activity is about 30%, with 14.5% from the livestock. Over the couple of years, the consumers have also changed their behaviours toward eating healthy products, driven the need to develop the alternative sustainable products. The eating habit of alternative also depend upon the social standard and education level for instance, people trends to change their eating preference to match with their peers [74]. The increasing variety of plant-based alternative in the market is providing a choice to the end consumer to replace the meat in their diet. According to the trends, the plant-based meat alternative would be more acceptable to the non-meat consumers [75] than meat eater. Not only the eating preference but also the gender is playing some role in the acceptance of alternative products. In one of the study by [76] the maleness is positively correlated with the mammal muscle meat however the females are mor acceptable to the vegetarian and vegan diet than males. There are several factors that positively affected the consumption of meat alternative but primarily it is the environmental concerns. Still there are some sensory obstacles like the dissimilar taste and texture in regards to meat, cost, colour and convenience to get the product [77]. The non-meat eater and meat eater both, thinks that the meat alternative should have more nutritious components like protein, vitamins and less calorie with affordable pricing.

7. Challenges and Future Research Prospectives

Currently, plant-based proteins don't fully satisfy the consumer on the qualities, which is necessary for a product to qualify as an alternative. One basic criterion for a plant-based product to an alternative of meat is to have the meat like texture and water binding ability. As the plant and the animal muscle have difference in protein type, amino acid composition, chemical composition, sequencing of peptide it is difficult to reproduce the same product. The beef’s most predicated structural property is its capacity to bind with water (contribute to the juiciness) and the structure of muscle fibre, however in alternative meat the low moisture after cooking is a typical disapproval from the consumers [78–81]. A study was done to find out the effect of buddle size on the tenderness in bovine muscle. Where they found that the bovine muscles with the smaller buddle size exhibits more tenderness after initial compression and less chewing force than the bovine with larger size. And also the Intramuscular fat(IMF) also positively affect the tenderness [82]. While in the case of PBMA the taste and textural profile can be enhanced by the marination and impregnation [83–86]. And The marinade composition could also affect the WHC of final product [87,88]. This water holding capacity (WHC) of a product can be describe by a cross-linked polymer network theory known as Flory-Rehner theory [89,90]. This theory relates the WHC of the polymer network to material properties like polymer- water affinity and density. The Flory- Rehner theory can also describe the WHC of simplified meat analogue and how the marinade PH and ionic strength effect it as it is not completely understood by the researchers [91]. Different types of thickener, water binding agents and texture enhancer are used in the processing of alternative product to obtain the properties of beef. Another parameter is to mimic the similar and expected taste as well as colour like animal meat [92]. The soy-proteins have a bitter-astringent flavor due to the naturally occurring saponin and isoflavone [93]. Furthermore, off- flavor can also be formed by the effect of heat on sugar and amino acids, by thermal degradation of thiamine. However, the bitterness of peas is mainly related to the saponin content, which depend on the variety of pea [94]. Hexanal is responsible of hay-like off-flavor in the frozen peas. Additionally, the sulphur containing compounds and aliphatic and aromatic hydrocarbons are also contributed in the off-flavoring of pea. To incorporate the flavor of processed meat and to mask their own taste, a whole range herbs and spices are added at the time of processing. These flavoring agents include sodium chloride, potassium chloride, soy sauce, cane sugar, molasses, lactose, mannitol, vinegar, onion powder, celery, yeast extract, garlic, liquid smoke, black pepper, sage, oregano, paprika, rosemary, walnut, lemon juices and others [95]. Other than masking the off-flavor of the raw ingredients there are certain methods that can also be used to remove the off-flavor before processing such as soaking and thermal treatment, germination, solvent extract, fermentation. These methods have been extensively described [96]. Recently, gelatin and alginate-based hydrogels have been reported as thermoresponsive carriers for flavour [97]. The emulsion-filled calcium alginate gel beads (EF-CAGs) can be prepared by combining an O/W emulsion and alginate solution and then injecting them into a calcium ion solution. These hydrogels are basically complex structure in which lipid droplets are trapped in crosslinked biomolecules [98]. Different studies have confirmed these are effective carriers for encapsulating bioactive agents to control their release in a simulated gastrointestinal environment by modifying their structures and properties [99,100]. However recently, several researchers have evaluated the effect of heat treatment on the physical properties of calcium alginate beads; they found that the core materials can be released by physical changes [101–104] establish that encapsulation of emulsion-filled microgels is useful to control the release of allyl methyl disulfide, a major flavor in garlic, during simulated cooking. The construction of nano emulsions and semi-solid gels has been successful to some extent for the flavor enhancement of the alternative products but it must be further investigated to study the ingredient functionality.

The basic requirement for a product that is similar to meat is to have the same structural building block as meat that include myofibrils, muscle cells and muscle tissue. To develop this structure from the plant-based protein and other components like the connective tissue layer to surround these myofibrils, binding agents, the study of ingredient functionality to get the similar meat like taste and technique to develop the plant-based fiber is necessary. The future investigations should focus on the fiber characterization present in alternative with respect to the size, geometry and interaction between them. But it has not been developed yet. And more advanced technology and tools should be developed that can analysis the texture more quickly and without destructing the product. Further investigation should be done to understand the change in the textural property of food after chewing or digestion.

8. Conclusion

Our existing protein source system has severally affected the human health, planet and animals. The plant based alternative products are the healthier and sustainable way to counter all these issues but at the moment the plant-based alternatives does not justify all the parameter of the animal product like nutritional level, sensory aspect, cost. The improvement in these parameters to produce the best possible alternative will help to maintain the market size of the alternative product. As we know, based on the ingredient composition and processing method the plant-based alternatives have different nutrition and sensory properties. It is essential to carefully studied the sensory properties of product in reference to the texture, color and taste as these parameters is mostly hindering the consumption and consumer acceptability. The field of plant alternative development requires the cooperation of all the related companies, scientists and economic expert to successfully tackle these issues.

Author Contributions

Conceptualization, S.K. and S-T. J.; methodology, S.K.; validation, AMM N.A. and Md. J. H.; formal analysis, E-Y. L.; investigation, S.K.; resources, S.K.; data curation, S-T.J.; writing—original draft preparation, S.K.; writing—review and editing, S.K. and S-T. J.; funding acquisition, Y-H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2020R1I1A206937911 & 2023R1A2C1004867).

Acknowledgments

In this section, you can acknowledge any support given which is not covered by the author contribution or funding sections. This may include administrative and technical support, or donations in kind (e.g., materials used for experiments).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bartashus, J., Plant-Based Foods Poised for Explosive Growth report. 2021: New York.

- AlGarf, D. Plant-based food takeover. 2023; Available from: https://infomineo.com/agriculture/plant-based-food-takeover/.

- Hu, F.B., B.O. Otis, and G. McCarthy, Can plant-based meat alternatives be part of a healthy and sustainable diet? Jama 2019, 322, 1547–1548. [CrossRef]

- Bakhsh, A., et al., Evaluation of rheological and sensory characteristics of plant-based meat analog with comparison to beef and pork. Food Science of Animal Resources 2021, 41, 983. [CrossRef] [PubMed]

- Pointke, M., et al., A comparative analysis of plant-based milk alternatives part 1: composition, sensory, and nutritional value. Sustainability 2022, 14, 7996. [CrossRef]

- Kozicka, M., et al., Feeding climate and biodiversity goals with novel plant-based meat and milk alternatives. Nature Communications 2023, 14, 5316.

- Reipurth, M.F., et al., Barriers and facilitators towards adopting a more plant-based diet in a sample of Danish consumers. Food quality and preference 2019, 73, 288–292. [CrossRef]

- Kyriakopoulou, K., et al., Alternatives to meat and dairy. Annual Review of Food Science and Technology 2021, 12, 29–50. [CrossRef] [PubMed]

- MacDougall, D., Colour measurement of food: principles and practice, in Colour Measurement. 2010, Elsevier.

- Mancini, R. and M. Hunt, Current research in meat color. Meat science 2005, 71, 100–121. [CrossRef] [PubMed]

- Suman, S.P. and P. Joseph, Myoglobin chemistry and meat color. Annual review of food science and technology 2013, 4, 79–99. [CrossRef] [PubMed]

- Pakula, C. and R. Stamminger, Measuring changes in internal meat colour, colour lightness and colour opacity as predictors of cooking time. Meat science 2012, 90, 721–727. [CrossRef]

- Hollenbeck, J.J., et al., Cooked color of precooked ground beef patties manufactured with mature bull trimmings. Meat science 2019, 148, 41–49. [CrossRef]

- Resurreccion, A., Sensory aspects of consumer choices for meat and meat products. Meat science 2004, 66, 11–20. [CrossRef] [PubMed]

- Vrljic, M., et al., Methods and compositions for consumables. 2019, Google Patents.

- Fraser, R., S.C. Davis, and P.O.R. Brown, Secretion of heme-containing polypeptides. 2016, Google Patents.

- Orcutt, M.W., et al., Meat Compositions Comprising Colored Structured Protein Products. 2008, Google Patents.

- Sasaki, K., et al., Beef texture characterization using internationally established texture vocabularies in ISO5492: 1992: Differences among four different end-point temperatures in three muscles of Holstein steers. Meat Science 2010, 86, 422–429. [CrossRef] [PubMed]

- Malav, O., et al., Meat analog: A review. Critical reviews in food science and nutrition 2015, 55, 1241–1245. [CrossRef] [PubMed]

- Ismail, I., Y.-H. Hwang, and S.-T. Joo, Meat analog as future food: A review. Journal of animal science and technology 2020, 62, 111. [CrossRef]

- Sun, C., et al., Processing, quality, safety, and acceptance of meat analogue products. Engineering 2021, 7, 674–678. [CrossRef]

- Kassama, L., M. Ngadi, and G. Raghavan, Structural and instrumental textural properties of meat patties containing soy protein. International Journal of Food Properties 2003, 6, 519–529. [CrossRef]

- Krintiras, G.A., et al., On characterization of anisotropic plant protein structures. Food & function 2014, 5, 3233–3240.

- Chiang, J.H., et al., Effects of soy protein to wheat gluten ratio on the physicochemical properties of extruded meat analogues. Food Structure 2019, 19, 100102. [CrossRef]

- Samard, S. and G.H. Ryu, Physicochemical and functional characteristics of plant protein-based meat analogs. Journal of Food Processing and Preservation 2019, 43, e14123.

- Lam, A., et al., Pea protein isolates: Structure, extraction, and functionality. Food reviews international 2018, 34, 126–147. [CrossRef]

- Schreuders, F.K., et al., Comparing structuring potential of pea and soy protein with gluten for meat analogue preparation. Journal of Food Engineering 2019, 261, 32–39. [CrossRef]

- He, R., et al., Effects of high pressure and heat treatments on physicochemical and gelation properties of rapeseed protein isolate. Food and Bioprocess Technology 2014, 7, 1344–1353. [CrossRef]

- Jia, W., et al., Rapeseed protein concentrate as a potential ingredient for meat analogues. Innovative Food Science & Emerging Technologies 2021, 72, 102758.

- Bobreneva, I., et al., Possibility of using quinoa seeds (Chenopodium quinoa) in meat products and its impact on nutritional and organoleptic characteristics. Bioscience Research 2018, 15, 3307–3315.

- Starowicz, M., K.K. Poznar, and H. Zieliński, What are the main sensory attributes that determine the acceptance of meat alternatives? Current Opinion in Food Science 2022, 100924.

- Ko, H.J., et al., Meat analog production through artificial muscle fiber insertion using coaxial nozzle-assisted three-dimensional food printing. Food Hydrocolloids 2021, 120, 106898. [CrossRef]

- Bakhsh, A., et al., A novel approach for tuning the physicochemical, textural, and sensory characteristics of plant-based meat analogs with different levels of methylcellulose concentration. Foods 2021, 10, 560. [CrossRef]

- Jiang, Y., et al., Hydrocolloidal properties of flaxseed gum/konjac glucomannan compound gel. International journal of biological macromolecules 2019, 133, 1156–1163. [CrossRef]

- Manski, J., A. Van der Goot, and R. Boom, Influence of shear during enzymatic gelation of caseinate–water and caseinate–water–fat systems. Journal of food engineering 2007, 79, 706–717. [CrossRef]

- Miwa, N., Innovation in the food industry using microbial transglutaminase: Keys to success and future prospects. Analytical biochemistry 2020, 597, 113638.

- Dekkers, B.L., R.M. Boom, and A.J. van der Goot, Structuring processes for meat analogues. Trends in Food Science & Technology 2018, 81, 25–36.

- Manski, J.M., A.J. van der Goot, and R.M. Boom, Formation of fibrous materials from dense calcium caseinate dispersions. Biomacromolecules 2007, 8, 1271–1279. [CrossRef]

- Kweldam, A.C., Method for the preparation of a meat substitute product, meat substitute product obtained with the method and ready to consume meat substitute product. 2011, Google Patents.

- He, J., et al., A review of research on plant-based meat alternatives: Driving forces, history, manufacturing, and consumer attitudes. Comprehensive Reviews in Food Science and Food Safety 2020, 19, 2639–2656. [CrossRef]

- Heuvel, M., et al. Food-grade electrospinning of proteins. in InsideFood Symposium 2013. 2013.

- Joshi, A.U., C. Liu, and S.K. Sathe, Functional properties of select seed flours. LWT-Food Science and Technology 2015, 60, 325–331. [CrossRef]

- Khan, M.I., C. Jo, and M.R. Tariq, Meat flavor precursors and factors influencing flavor precursors—A systematic review. Meat science 2015, 110, 278–284. [CrossRef]

- Kaczmarska, K.T., et al., Aroma characteristics of lupin and soybean after germination and effect of fermentation on lupin aroma. Lwt 2018, 87, 225–233. [CrossRef]

- Singh, M., et al., Plant-based meat analogue (PBMA) as a sustainable food: A concise review. European Food Research and Technology 2021, 247, 2499–2526. [CrossRef]

- Teng, X., M. Zhang, and S. Devahastin, New developments on ultrasound-assisted processing and flavor detection of spices: A review. Ultrasonics sonochemistry 2019, 55, 297–307. [CrossRef]

- Lanzotti, V., The analysis of onion and garlic. Journal of chromatography A 2006, 1112, 3–22. [CrossRef]

- Spendrup, S. and H.P. Hovmalm, Consumer attitudes and beliefs towards plant-based food in different degrees of processing–The case of Sweden. Food Quality and Preference 2022, 102, 104673. [CrossRef]

- Lin, M., et al., Aroma-active components of yeast extract pastes with a basic and characteristic meaty flavour. Journal of the Science of Food and Agriculture 2014, 94, 882–889. [CrossRef]

- Alim, A., et al., Flavour-active compounds in thermally treated yeast extracts. Journal of the Science of Food and Agriculture 2018, 98, 3774–3783. [CrossRef]

- Molfetta, M., et al., Protein sources alternative to meat: state of the art and involvement of fermentation. Foods 2022, 11, 2065. [CrossRef]

- Zioga, E., et al., Bringing plant-based Cli-meat closer to original meat experience: insights in flavor. Future Foods 2022, 5, 100138. [CrossRef]

- Wu, Y.F., et al., Development of a meat-like process flavoring from soybean-based enzyme-hydrolyzed vegetable protein (E-HVP). Journal of food science 2000, 65, 1220–1227. [CrossRef]

- Wu, Y., et al., Preparation of meat flavor by enzymatic hydrolysis of vegetable protein. Science Technology and Food Industrial 2003, 24, 53–55.

- Aaslyng, M.D., et al., Chemical and sensory characterization of hydrolyzed vegetable protein, a savory flavoring. Journal of Agricultural and Food Chemistry 1998, 46, 481–489. [CrossRef]

- Song, H. and B. Sun, The production of natural meat flavourings by using biochemical techniques. FOOD AND FERMENTATION INDUSTRIES 1999, 25, 50–54.

- Civille, G.V. and K.N. Oftedal, Sensory evaluation techniques—Make “good for you” taste “good”. Physiology & Behavior 2012, 107, 598–605.

- Lawless, H.T. and H. Heymann, Sensory evaluation of food: principles and practices. Vol. 2. 2010: Springer.

- Ettinger, L., et al., Consumer perception and acceptability of plant-based alternatives to chicken. Foods 2022, 11, 2271. [CrossRef]

- Moss, R., et al., A Prospective Review of the Sensory Properties of Plant-Based Dairy and Meat Alternatives with a Focus on Texture. Foods 2023, 12, 1709. [CrossRef] [PubMed]

- Kamani, M.H., et al., Partial and total replacement of meat by plant-based proteins in chicken sausage: Evaluation of mechanical, physico-chemical and sensory characteristics. Journal of food science and technology 2019, 56, 2660–2669. [CrossRef] [PubMed]

- Yuan, X., et al., Textural, sensory and volatile compounds analyses in formulations of sausages analogue elaborated with edible mushrooms and soy protein isolate as meat substitute. Foods 2021, 11, 52. [CrossRef] [PubMed]

- Gómez, I., F.C. Ibañez, and M.J. Beriain, Physicochemical and sensory properties of sous vide meat and meat analog products marinated and cooked at different temperature-time combinations. International Journal of Food Properties 2019, 22, 1693–1708. [CrossRef]

- Kaleda, A., et al., Physicochemical, textural, and sensorial properties of fibrous meat analogs from oat-pea protein blends extruded at different moistures, temperatures, and screw speeds. Future Foods 2021, 4, 100092. [CrossRef]

- do Carmo, C.S., et al., Meat analogues from a faba bean concentrate can be generated by high moisture extrusion. Future Foods 2021, 3, 100014. [CrossRef]

- Godschalk-Broers, L., G. Sala, and E. Scholten, Meat analogues: relating structure to texture and sensory perception. Foods 2022, 11, 2227. [CrossRef]

- Szpicer, A., et al., The optimization of a gluten-free and soy-free plant-based meat analogue recipe enriched with anthocyanins microcapsules. LWT 2022, 168, 113849. [CrossRef]

- Elzerman, J.E., et al., Consumer acceptance and appropriateness of meat substitutes in a meal context. Food quality and preference 2011, 22, 233–240. [CrossRef]

- Lin, S., H. Huff, and F. Hsieh, Extrusion process parameters, sensory characteristics, and structural properties of a high moisture soy protein meat analog. Journal of Food Science 2002, 67, 1066–1072. [CrossRef]

- Grahl, S., et al., Towards more sustainable meat alternatives: How technical parameters affect the sensory properties of extrusion products derived from soy and algae. Journal of Cleaner Production 2018, 198, 962–971. [CrossRef]

- Palanisamy, M., et al., Influence of iota carrageenan addition on the properties of soya protein meat analogues. Lwt 2018, 87, 546–552. [CrossRef]

- Taylor, J., et al., Consumers’ perceptions and sensory properties of beef patty analogues. Foods 2020, 9, 63. [CrossRef]

- Gerber, P.J., et al., Tackling climate change through livestock: a global assessment of emissions and mitigation opportunities. 2013: Food and Agriculture Organization of the United Nations (FAO).

- Thomas, J.M., et al., The effects of liking norms and descriptive norms on vegetable consumption: a randomized experiment. Frontiers in Psychology 2016, 7, 442.

- Siegrist, M. and C. Hartmann, Impact of sustainability perception on consumption of organic meat and meat substitutes. Appetite 2019, 132, 196–202. [CrossRef]

- Judge, M. and M.S. Wilson, A dual-process motivational model of attitudes towards vegetarians and vegans. European Journal of Social Psychology 2019, 49, 169–178. [CrossRef]

- Bryant, C.J., We can’t keep meating like this: Attitudes towards vegetarian and vegan diets in the United Kingdom. Sustainability 2019, 11, 6844. [CrossRef]

- Warner, R.D., The eating quality of meat: IV—Water holding capacity and juiciness, in Lawrie's meat science. 2023, Elsevier. p. 457-508.

- Aaslyng, M.D., et al., Cooking loss and juiciness of pork in relation to raw meat quality and cooking procedure. Food quality and preference 2003, 14, 277–288. [CrossRef]

- Pearce, K.L., et al., Water distribution and mobility in meat during the conversion of muscle to meat and ageing and the impacts on fresh meat quality attributes—A review. Meat science 2011, 89, 111–124. [CrossRef]

- Puolanne, E. and M. Halonen, Theoretical aspects of water-holding in meat. Meat science 2010, 86, 151–165. [CrossRef]

- Choi, Y.M., L.G. Garcia, and K. Lee, Correlations of sensory quality characteristics with intramuscular fat content and bundle characteristics in bovine longissimus thoracis muscle. Food science of animal resources 2019, 39, 197. [CrossRef]

- Burke, R. and F. Monahan, The tenderisation of shin beef using a citrus juice marinade. Meat Science 2003, 63, 161–168. [CrossRef]

- Alvarado, C. and S. McKee, Marination to improve functional properties and safety of poultry meat. Journal of Applied Poultry Research 2007, 16, 113–120. [CrossRef]

- Lee, Y., D. Sehnert, and C. Ashmore, Tenderization of meat with ginger rhizome protease. Journal of Food Science 1986, 51, 1558–1559. [CrossRef]

- Sheard, P. and A. Tali, Injection of salt, tripolyphosphate and bicarbonate marinade solutions to improve the yield and tenderness of cooked pork loin. Meat science 2004, 68, 305–311. [CrossRef]

- Lebert, A. and J.-D. Daudin, Modelling the distribution of aw, pH and ions in marinated beef meat. Meat science 2014, 97, 347–357. [CrossRef]

- English, A.E., Phase transitions in polyampholytic polymers and hydrogels. 1996, Massachusetts Institute of Technology.

- Van der Sman, R., Moisture transport during cooking of meat: An analysis based on Flory–Rehner theory. Meat science 2007, 76, 730–738. [CrossRef] [PubMed]

- Van der Sman, R., Thermodynamics of meat proteins. Food Hydrocolloids 2012, 27, 529–535. [CrossRef]

- Yusop, S.M., et al., Effect of marinating time and low pH on marinade performance and sensory acceptability of poultry meat. Meat science 2010, 85, 657–663. [CrossRef]

- Graça, J., C.A. Godinho, and M. Truninger, Reducing meat consumption and following plant-based diets: Current evidence and future directions to inform integrated transitions. Trends in Food Science & Technology 2019, 91, 380–390.

- Boatright, W. and G. Lu, Hexanal synthesis in isolated soy proteins. Journal of the American Oil Chemists' Society 2007, 84, 249–257. [CrossRef]

- Heng, L., et al., Bitterness of saponins and their content in dry peas. Journal of the Science of Food and Agriculture 2006, 86, 1225–1231. [CrossRef]

- Sha, L. and Y.L. Xiong, Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges. Trends in Food Science & Technology 2020, 102, 51–61.

- Roland, W.S., et al., Flavor aspects of pulse ingredients. Cereal Chemistry 2017, 94, 58–65. [CrossRef]

- Kim, Y.M., et al., Thermoresponsive semi-interpenetrating gelatin-alginate networks for encapsulation and controlled release of scent molecules. International Journal of Biological Macromolecules 2022, 208, 1096–1105. [CrossRef]

- Zhang, Z., et al., Encapsulation of curcumin in polysaccharide-based hydrogel beads: Impact of bead type on lipid digestion and curcumin bioaccessibility. Food Hydrocolloids 2016, 58, 160–170. [CrossRef]

- Criado, P., et al., Effect of cellulose nanocrystals on thyme essential oil release from alginate beads: Study of antimicrobial activity against Listeria innocua and ground meat shelf life in combination with gamma irradiation. Cellulose 2019, 26, 5247–5265. [CrossRef]

- Piornos, J.A., et al., Highly efficient encapsulation of linseed oil into alginate/lupin protein beads: Optimization of the emulsion formulation. Food Hydrocolloids 2017, 63, 139–148. [CrossRef]

- Wang, M., T. Doi, and D.J. McClements, Encapsulation and controlled release of hydrophobic flavors using biopolymer-based microgel delivery systems: Sustained release of garlic flavor during simulated cooking. Food Research International 2019, 119, 6–14. [CrossRef]

- Saqib, M.N., et al., Thermo-mechanical response of liquid-core beads as affected by alginate molecular structure. Food Hydrocolloids 2022, 131, 107777. [CrossRef]

- Kim, S., et al., Effects of thermal treatment on the physical properties of edible calcium alginate gel beads: Response surface methodological approach. Foods 2019, 8, 578. [CrossRef] [PubMed]

- Jeong, C., et al., Changes in the physical properties of calcium alginate gel beads under a wide range of gelation temperature conditions. Foods 2020, 9, 180. [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).