1. Introduction

At present, the energy structure at home and abroad is mainly based on fossil fuels. However, fossil fuels are non-renewable energy. With the increasing demand for energy and the continuous exploitation and consumption of fossil energy, it is urgent to develop renewable energies, such as wind power, hydropower, solar energy, etc. Among them, solar energy is the most popular energy, and photovoltaic power generation is one of the main forms of solar energy utilization. Photovoltaic power generation includes rooftop photovoltaic, water photovoltaic, and traditional photovoltaic ground power stations. A photovoltaic greenhouse is an application form of photovoltaic power generation, which is mainly used in agricultural production, especially in areas with limited land resources or lack of power supply. Photovoltaic greenhouse converts solar energy into electricity, which can be directly supplied to lighting, heating, ventilation, and other equipment and automation systems in the greenhouse, and can also be connected to power grids [

1]. Photovoltaic greenhouse technology is closely related to sustainable development. The use of clean energy can reduce the dependence on traditional power grids, use less fossil energy, improve the utilization rate of solar energy, and contribute to environmental protection and sustainable economic development. In addition, when used properly, photovoltaic greenhouse can also provide a good growing environment, such as suitable temperature, light, and ventilation conditions, to promote the growth of crops and increase yields. However, the shading of photovoltaic modules will inevitably reduce the light intensity in the greenhouse, change the light distribution characteristics in the greenhouse, and affect the growth of plants. At present, the scattering film is mainly used as the light-transmitting component, which can expand the illumination area and improve the light distribution characteristics in the greenhouse, but the effect is not satisfactory. There are still some challenges in photovoltaic greenhouse technology, such as the cost, efficiency, and reliability of photovoltaic panels, as well as technical issues in terms of light uniformity, ventilation, and temperature control inside the greenhouse, and solving these challenges requires continuous technological innovations and improvements.

In order to solve the problem of uneven light distribution in photovoltaic greenhouses caused by the shading of photovoltaic cell modules from the perspective of light-transmitting modules on the greenhouse roof, the grating plates with high scattering and high transmittance used as light-transmitting modules to improve the light distribution in zigzag photovoltaic greenhouses can effectively improve the light intensity in the greenhouse [

2]. Liu Chengyu, et al. [

3] pointed out that a large number of experimental studies have been carried out on photovoltaic greenhouses. The experimental results of these studies have summarized the problems and opinions regarding the research and development of photovoltaic greenhouses, as well as the relatively low utilization rate of light energy and the high maintenance price of photovoltaic equipment, and it is particularly important to ensure that the light uniformity in the photovoltaic greenhouse is suitable for plant growth and ensure the thermal insulation function of the greenhouse while not affecting the operation of photovoltaic power generation in the greenhouse [

4].

In this study, grating panels with different thicknesses and number of lines were used as photovoltaic greenhouse light-transmitting modules, and ordinary glass was used as the control to test the light intensity and uniformity in the greenhouse. The use of grating panels as greenhouse roof covering material was evaluated.

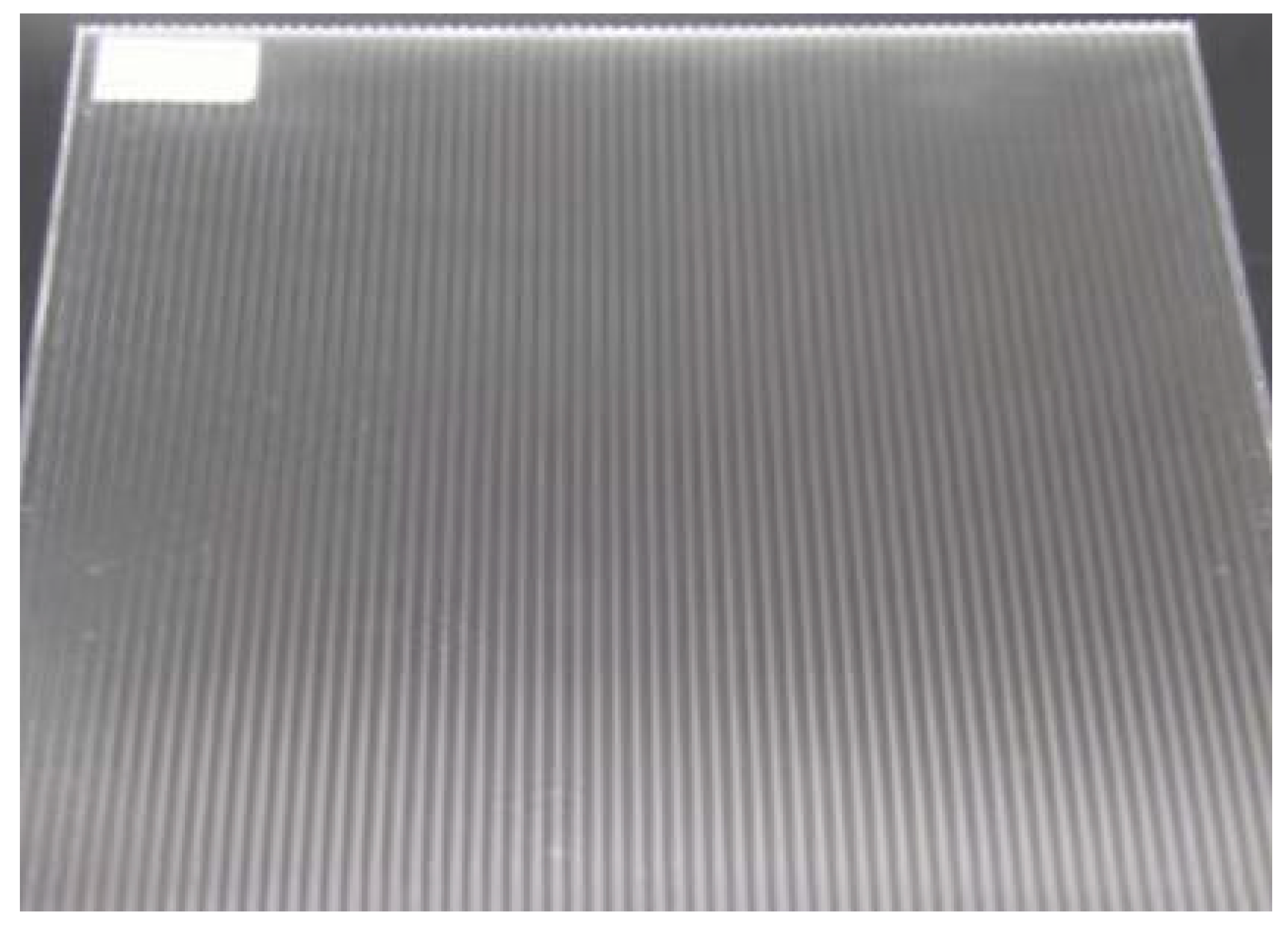

As shown in

Figure 1, the grating plate is a plastic material with one side extruded into a cylindrical line and one side as a complete plane, and the cylindrical line spacing is equal to that called "grating". The light transmittance of the grating plate used in this experiment is 93.77%, and the spectroscopic light waves of the grating will be diffracted at each slit, and the light waves diffracted through all slits will interfere to form interference fringes and be localized to infinity. When sunlight is incident on the grating plate, the area that can be irradiated by the light passing through the grating plate is greater than the area of the grating plate itself [

5]. As a polymer light scattering material, the grating plate converts the parallel direct light into an isotropic surface light source and expands the illumination area, thus solving the problem of illumination uniformity to a certain extent.

2. Materials

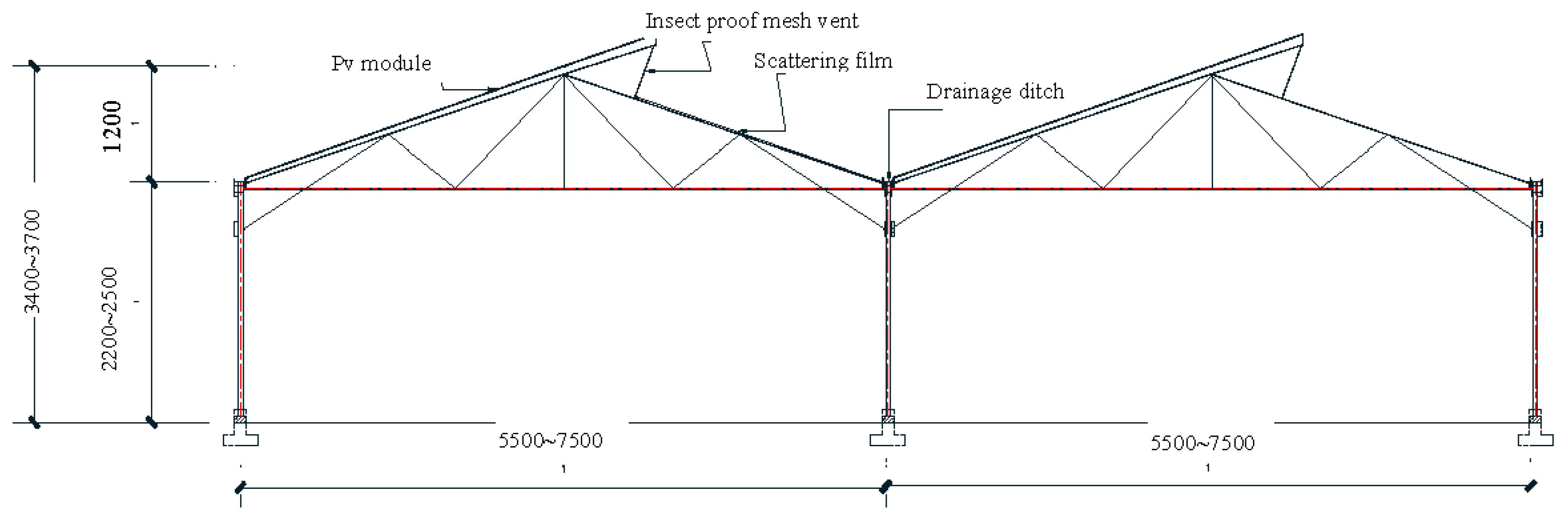

2.1. Zigzag photovoltaic greenhouse

The test greenhouse is a zigzag photovoltaic greenhouse [WS-GFJ-X.X(HD)] developed from the patented shed greenhouse of Professor Liu Jian of Hainan University: A Combined Photovoltaic Greenhouse Roof Structure (ZL201621352420.7) [

6]. The span of the photovoltaic greenhouse is 5.5-7.5m, the bay is 4m, the shoulder height is 2.2-2.5m, and the top height is 3.4-3.7m, as shown in

Figure 2 and

Figure 3.

Combined with the climatic characteristics of the Hainan hot area and the needs of the solar and thermal environment of vegetable planting, the standard sawtooth photovoltaic vegetable greenhouse reasonably optimizes the layout of the roof structure and uses photovoltaic modules as roof covering materials to replace some traditional transparent covering materials such as films. Because of its reasonable structure, the ground planting utilization rate becomes higher, and the light and heat environment are more suitable, which can achieve the goal of not reducing the output of vegetable production compared with open field planting, and can ensure the uninterrupted production of photovoltaic vegetable greenhouses [

7].

The research on indoor lighting problems of zigzag photovoltaic greenhouses mainly focuses on the location of the greenhouse (latitude and longitude, altitude, etc.), orientation, structure, light characteristics of covering materials and enclosure materials (light transmittance, reflectivity, etc.), surrounding features, weather and other factors that have a great impact on the lighting in the greenhouse. The problem of shading and lighting in greenhouses also needs to solve the problem of reasonable distribution of sunlight in crops and photovoltaic power generation, and to maximize the benefits of agriculture and photovoltaic industry.

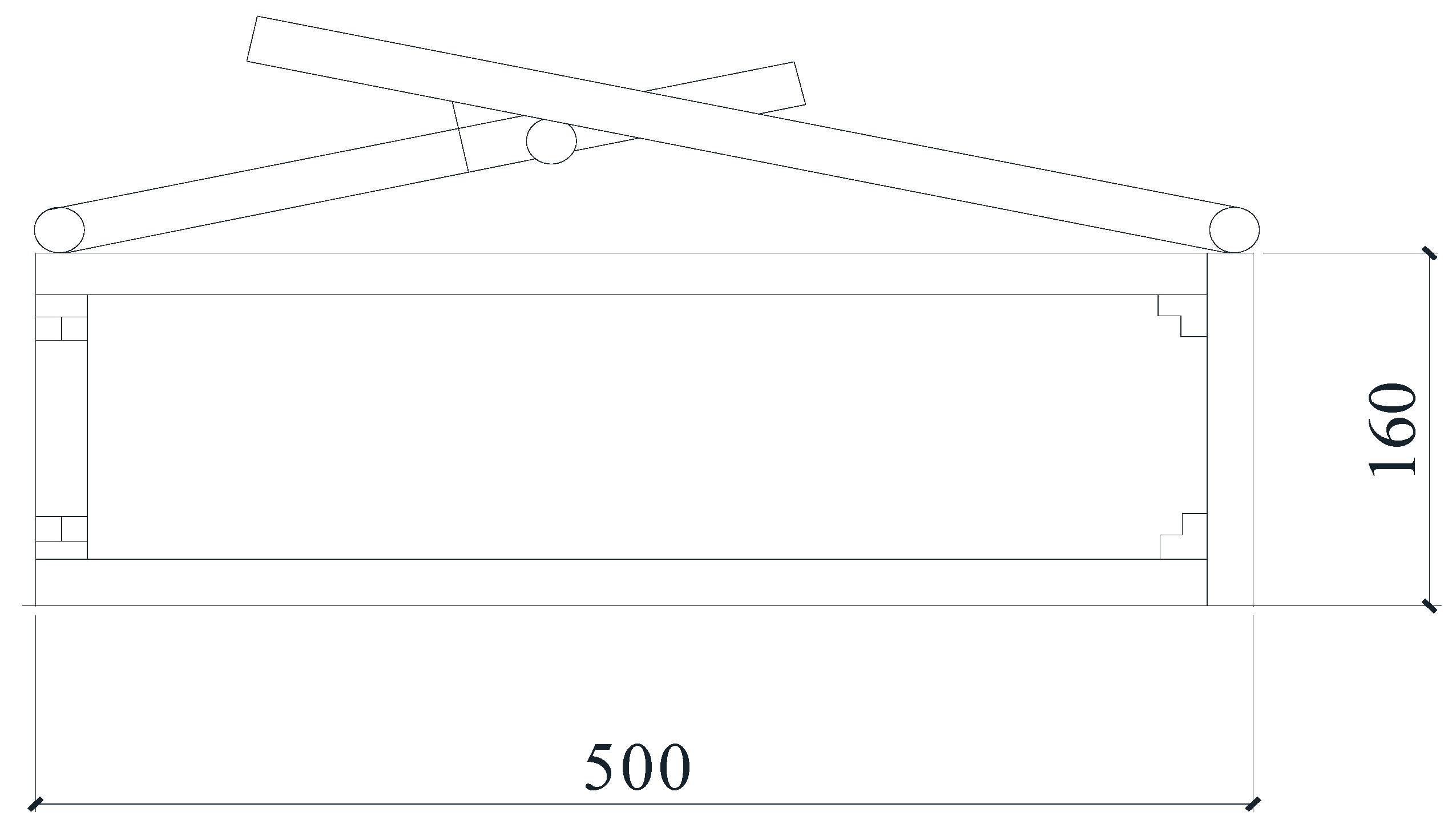

2.2. Zigzag photovoltaic greenhouse model

The model greenhouse is constructed according to the scale of 1:11 with a span of 500 mm, a column height of 160 mm, and a bay of 600 mm. 20mm×20mm aluminum profiles were used as the model greenhouse skeleton material. The azimuth of the greenhouse is set to due south, and the roof of the south slope is facing the sun [

8].

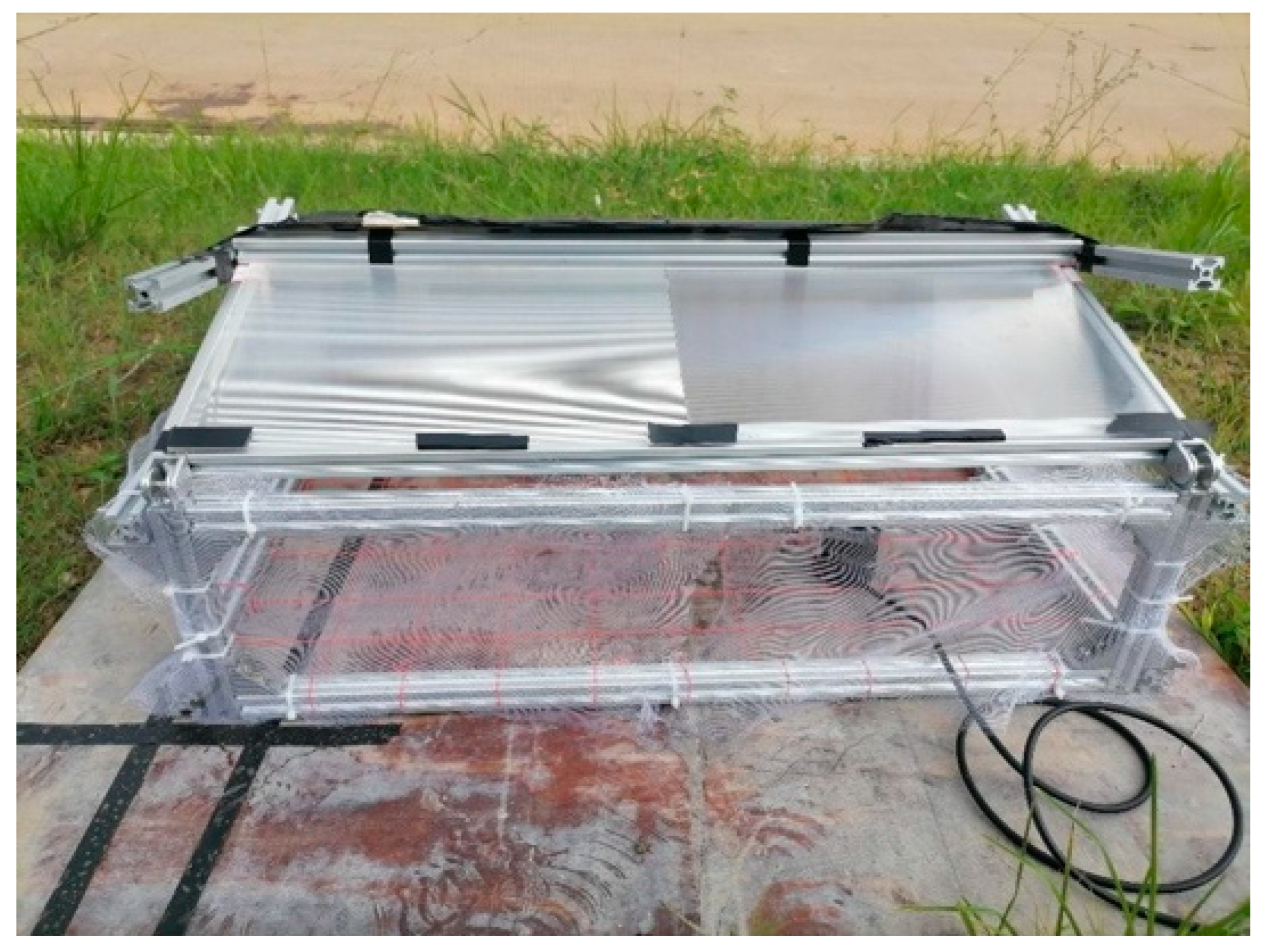

Figure 4,

Figure 5 and

Figure 6 shows the structural diagram and the physical drawing of the greenhouse model, the column and the roof beam of the model are connected by a rotating corner chain, the column and the beam part are connected by a vertical corner piece, the roof beam and the roof beam are connected by a vertical turning angle piece, and are covered with 40 mesh insect nets around it.

3. Experimental design and field management

3.1. Selection of test measurement sites

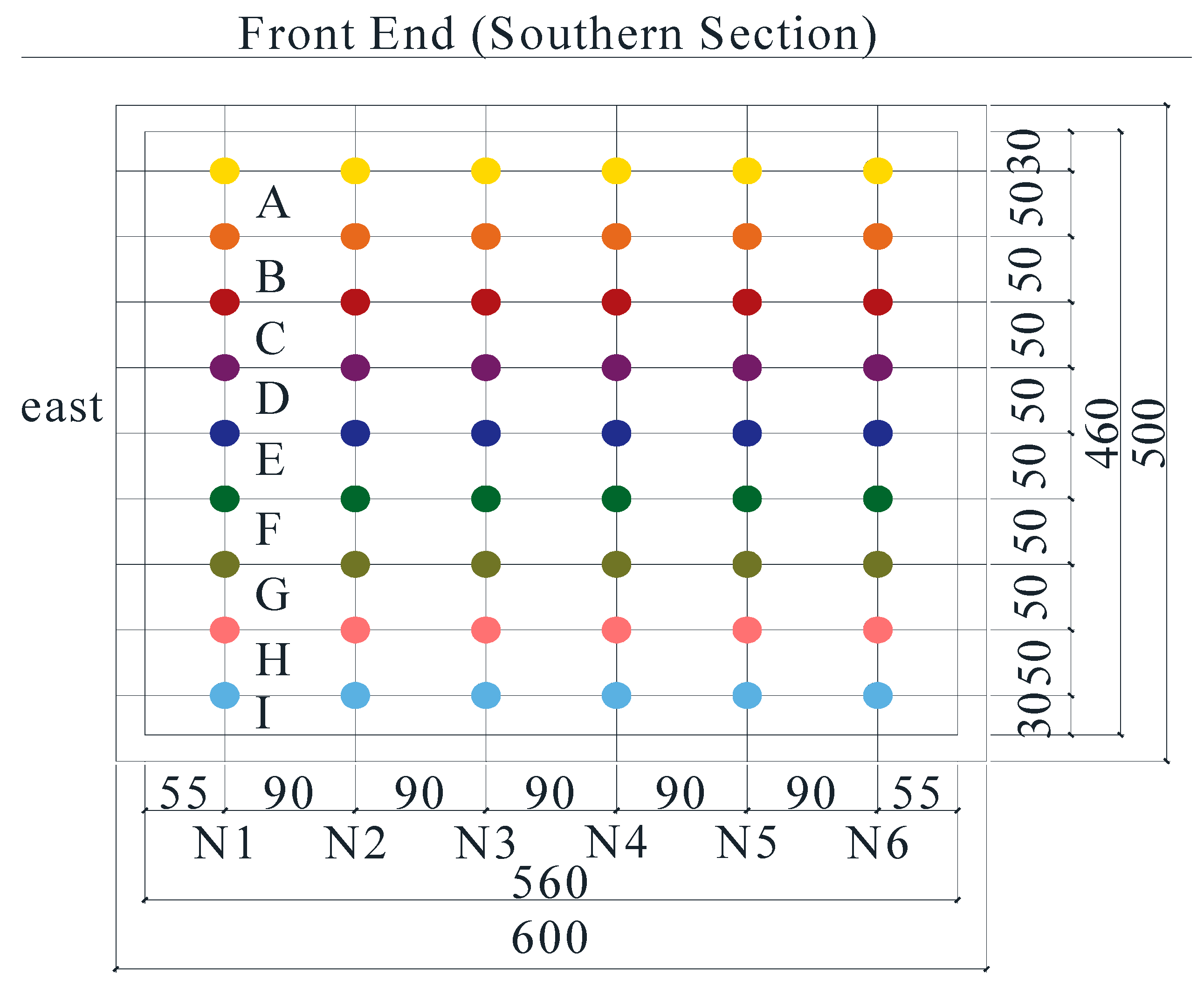

As shown in

Figure 7, six lines were set in the east-west direction of the greenhouse, which were respectively recorded as N1 to N6 at the distance from the 5.5.cm, 14.50cm, 23.50cm, 32.50cm, 41.50cm, and 50.50cm of the gable on the east side. There were nine points on each line, which were evenly distributed in the east-west direction and north-south direction from the inside of the greenhouse. The distances were 3.0cm, 8.0cm, 13.0cm, 18.0cm, 23.0cm, 28.0cm, 33.0cm, 38.0cm, and 43.0cm, which were recorded as point A to point I.

3.2. Experimental time

The outdoor experiment was conducted at the Agricultural Science Base of Danzhou Campus of Hainan University (19°11’N, 108°56’E) from 10:00 to 16:00 on June 1, 2023 (sunny) and from 10:00 to 16:00 on June 2 (sunny).

3.3. Experimental process

First of all, according to the formula mentioned in the

Environmental Engineering of Facility Agriculture edited by Zou Zhirong and Shao Xiaohou [

9]: the number of inclination angles of the south roof β>90°-40°-α=50°-α (α is the solar altitude angle at a certain time), the latitude of Danzhou at this time is 19°, and the solar regression movement from June 1 to 2 is moving from south to north, the days are getting longer, and the sunshine time in the northern hemisphere is all lengthened, we assume that the solar altitude angle is 38°, and 12° is selected as the inclination angle of the south roof; secondly, according to the test schedule in

Table 1, the relationship between the light transmitting components of different specifications and the light transmission of the point zone was tested one by one. Finally, Origin64 software was used for data analysis and comparison [

10].

4. Results

4.1. Light distribution characteristics of the corresponding area of the light-transmitting material in the greenhouse

4.1.1. Characteristics of light distribution in the north-south direction of the greenhouse

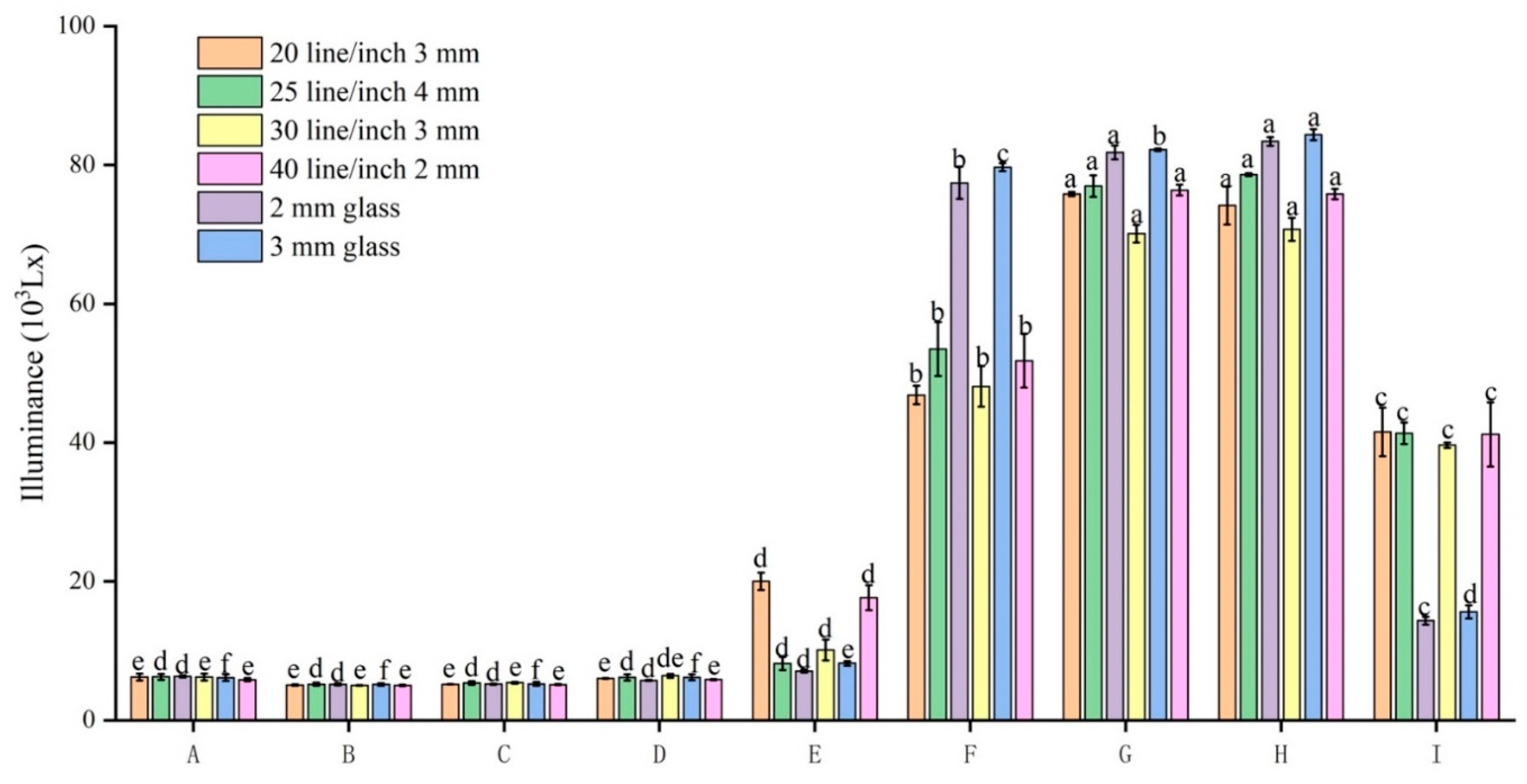

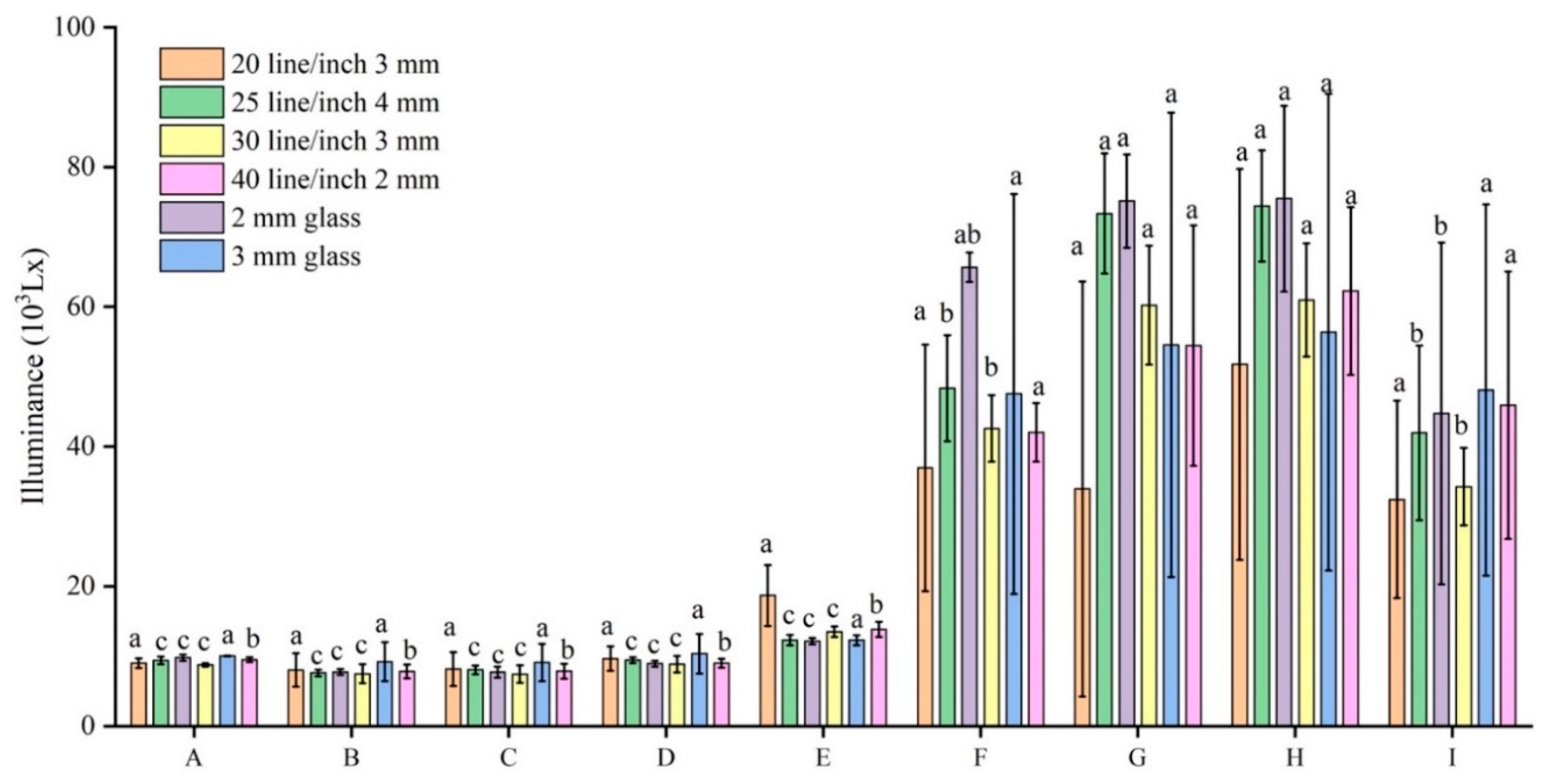

As shown in

Figure 8 below, the largest theoretical solar altitude angle is at 90 degrees when not considering the difference in the Tropic of Capricorn, and

Figure 8 shows the north-south light distribution characteristics of the corresponding area of each material during this time, which is at 12:00. Combined with the analysis method of Li H et al. [

11], the relevant lighting characteristics were analyzed by the one-day variation law and the significance Duncan analysis was performed on this basis.

On the whole, the light intensity from point A to point E is significantly lower than that from point F to point I, and the highest light intensity is at point G or H. In the southern area, the scattered light entering from the south increases the illumination intensity of point A, which is obviously higher than that of points B and C. In the middle area, the growth trend from point D to point E is lower than that from point E to point F, and the illuminance of glass at point F is greater than that of grating plate. The light intensity from point G to point H in the back-end area is generally greater than that of the grating plate, while point I is the opposite [

12].

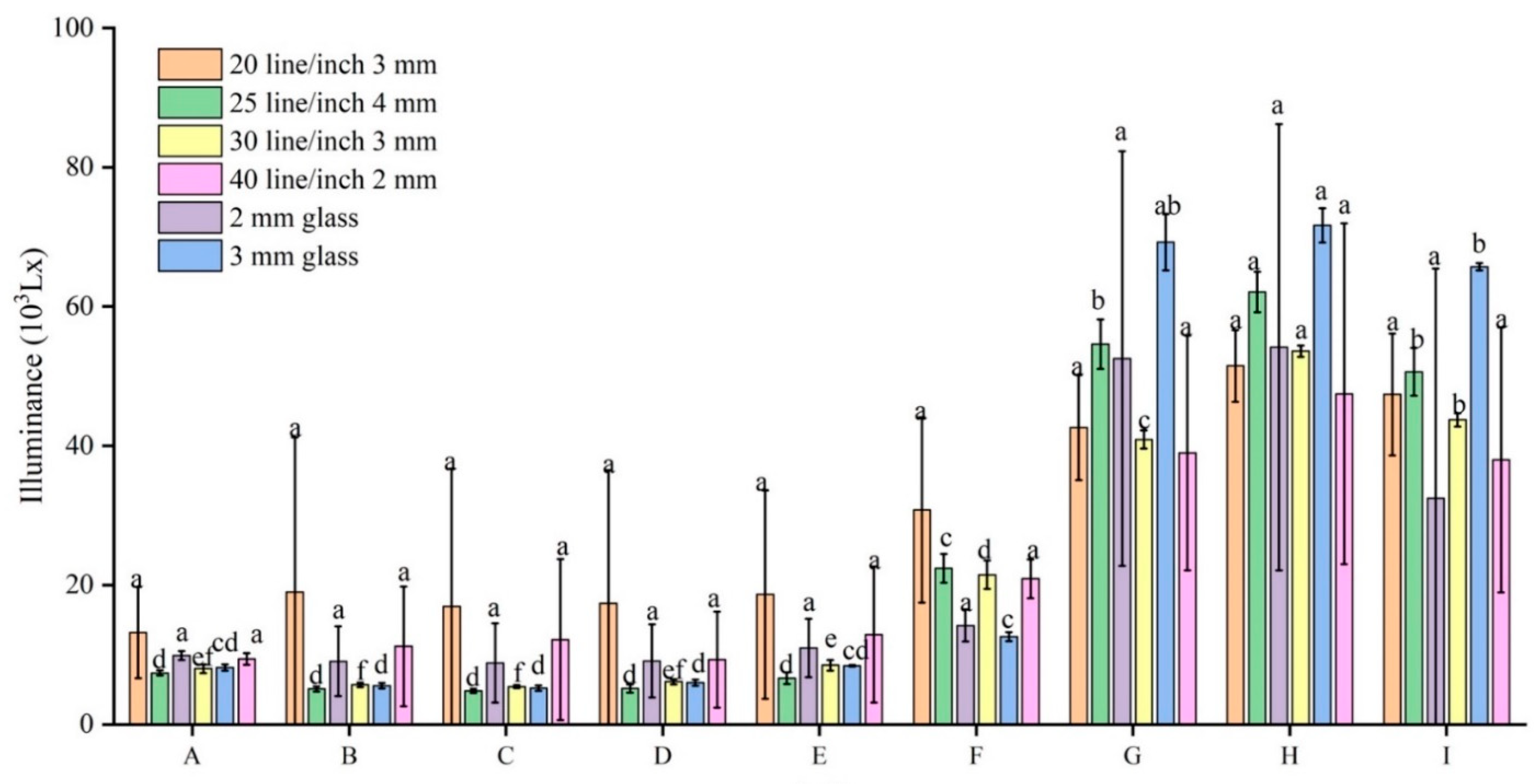

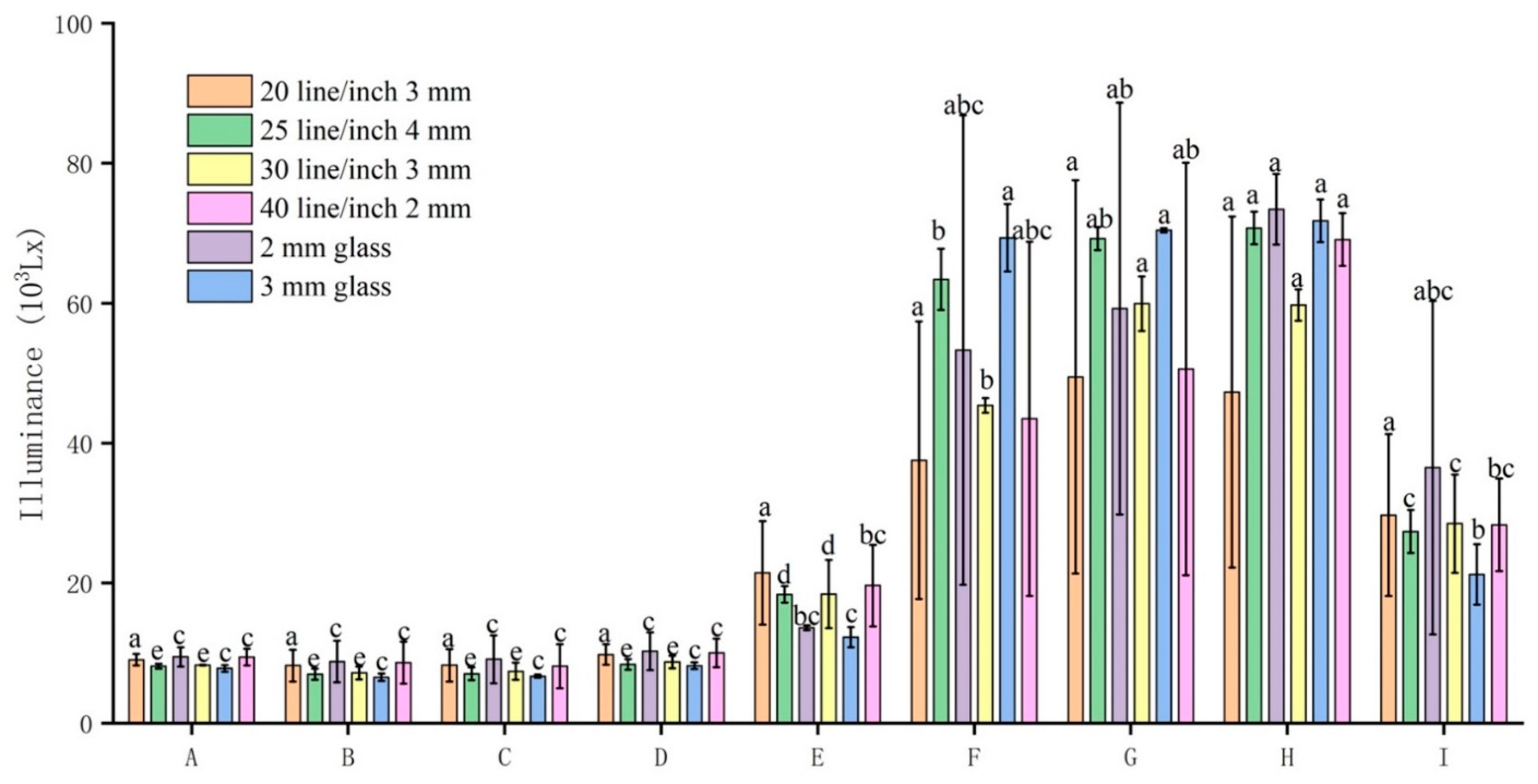

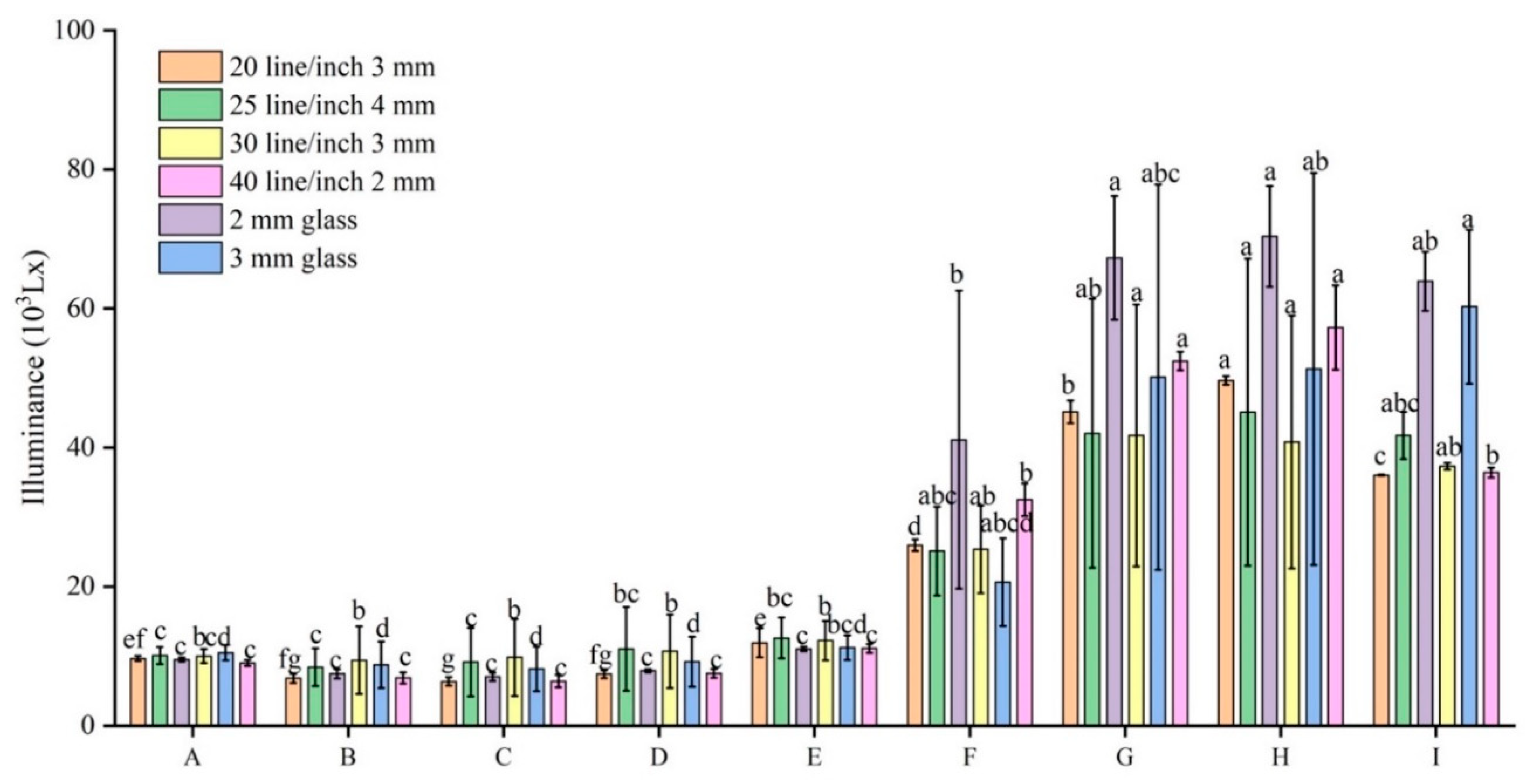

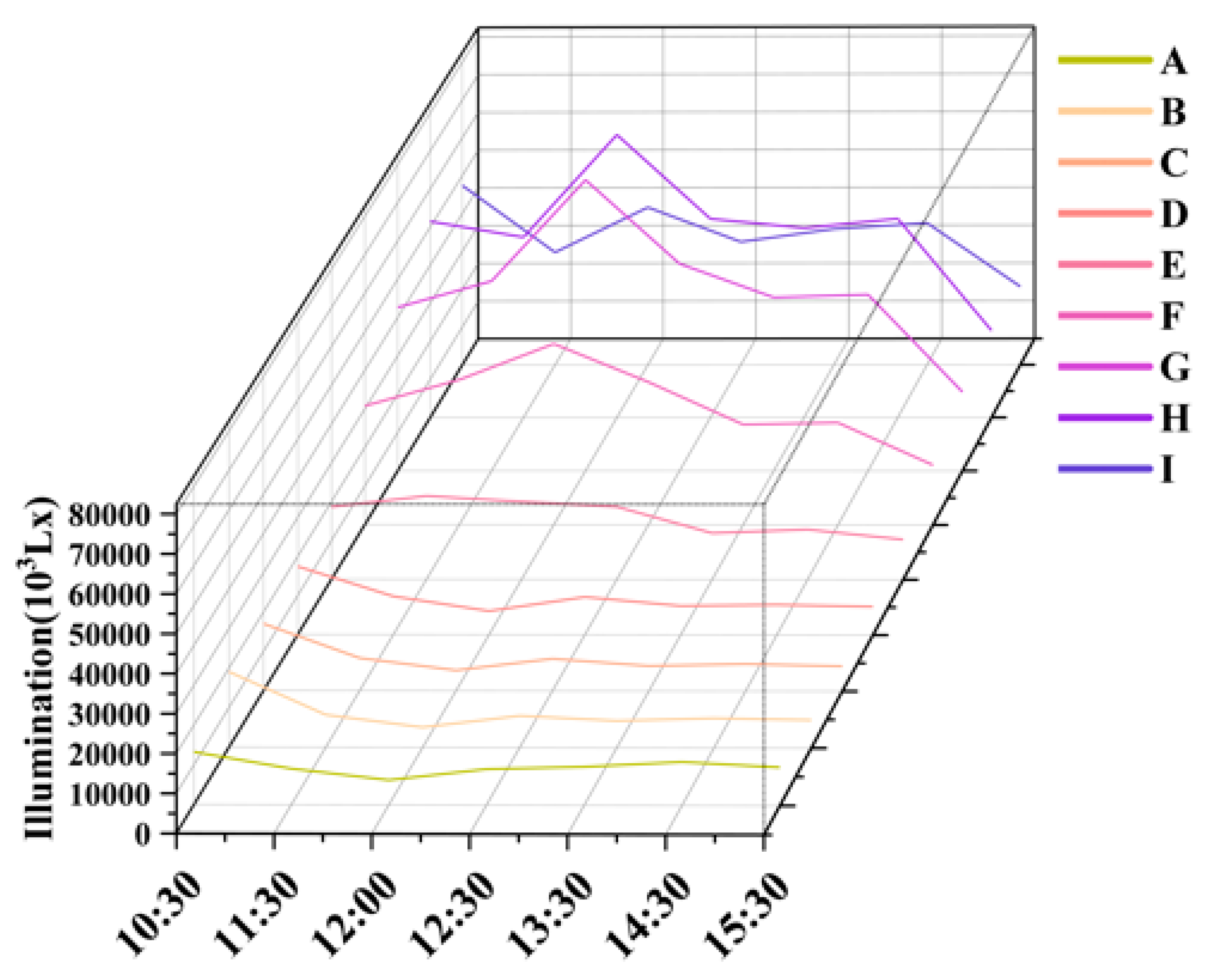

4.1.2. North-south light distribution in the greenhouse

The distribution of light intensity in the north-south direction in different time periods in the greenhouse is shown in

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13, and in general, the influence of cloud cover is excluded Choab N et al. [

13] Bulik, T, Piacentini et al. [

14] The distribution trend of light intensity in the north-south direction of each light transmitting material in each time period is as follows: the light intensity from point B to point G or H gradually increases and reaches the peak value. According to the analysis methods of Igoe, D, Turner et al. [

15], and Ayet A et al. [

16], it is inferred that point A is affected by the scattered light from the ground to the south, and the light intensity is greater than that of point B. The light intensity of glass as a light-transmitting component of a greenhouse is generally greater than that of grating panels [

17].

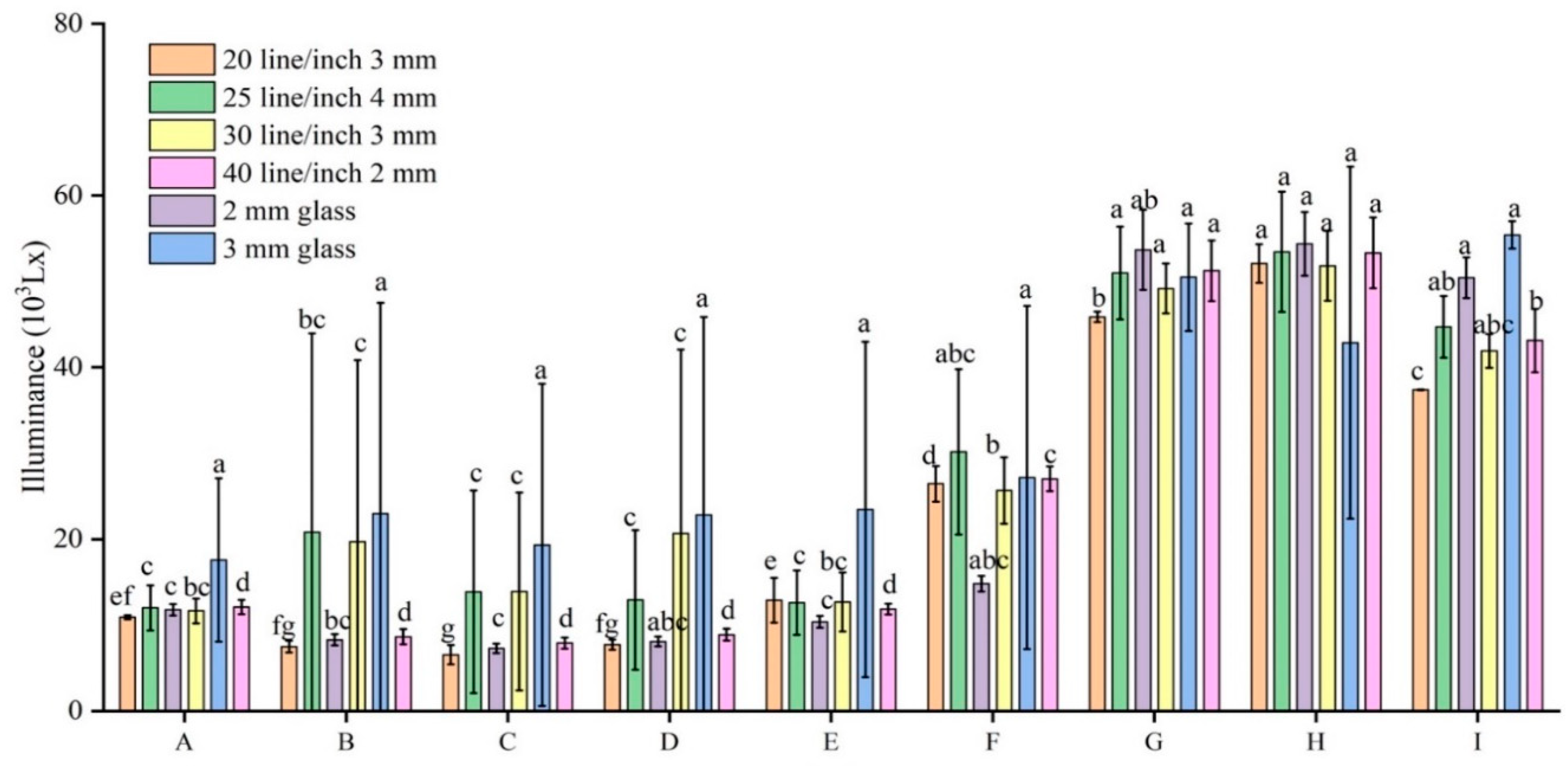

4.2. Data processing and analysis

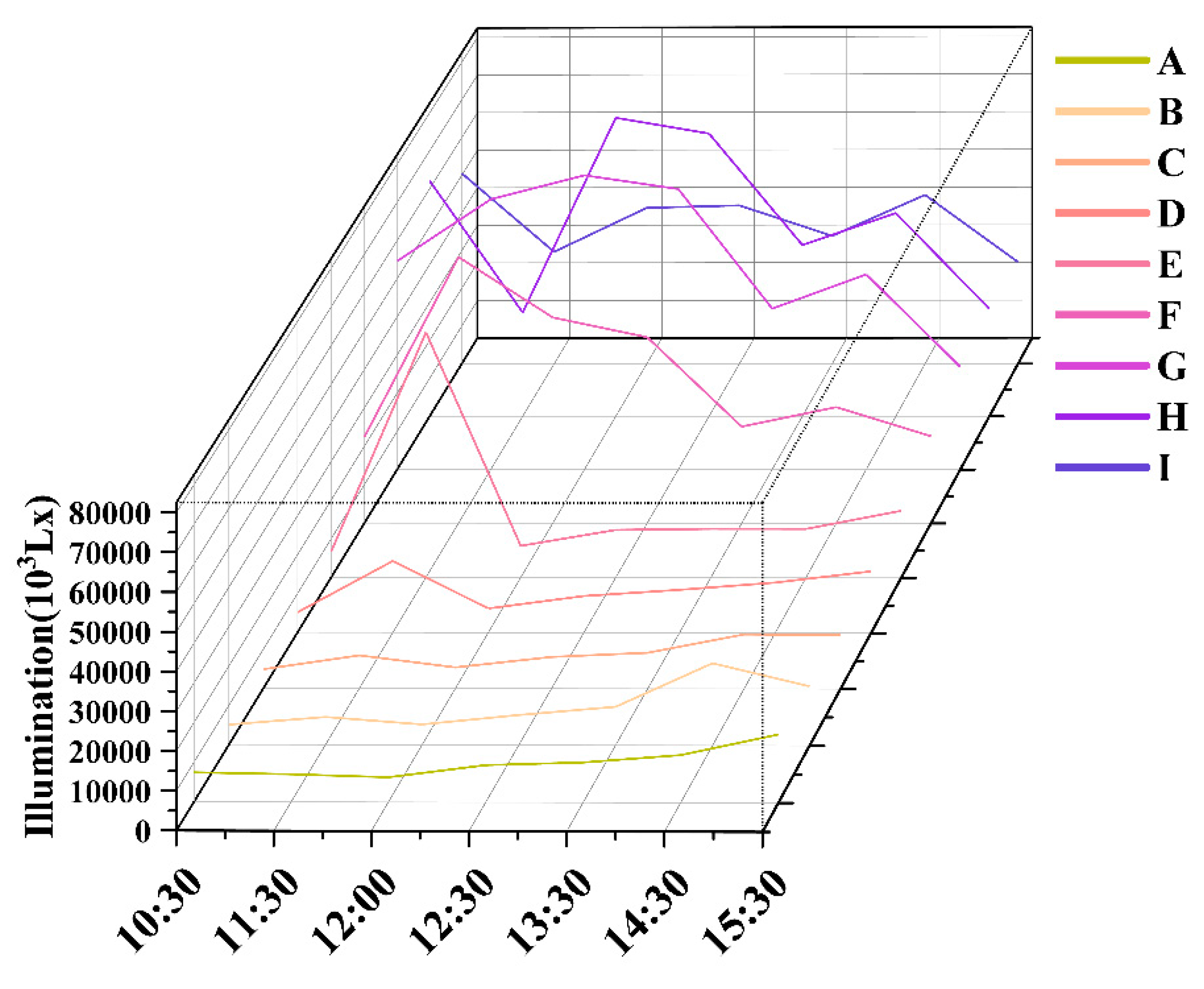

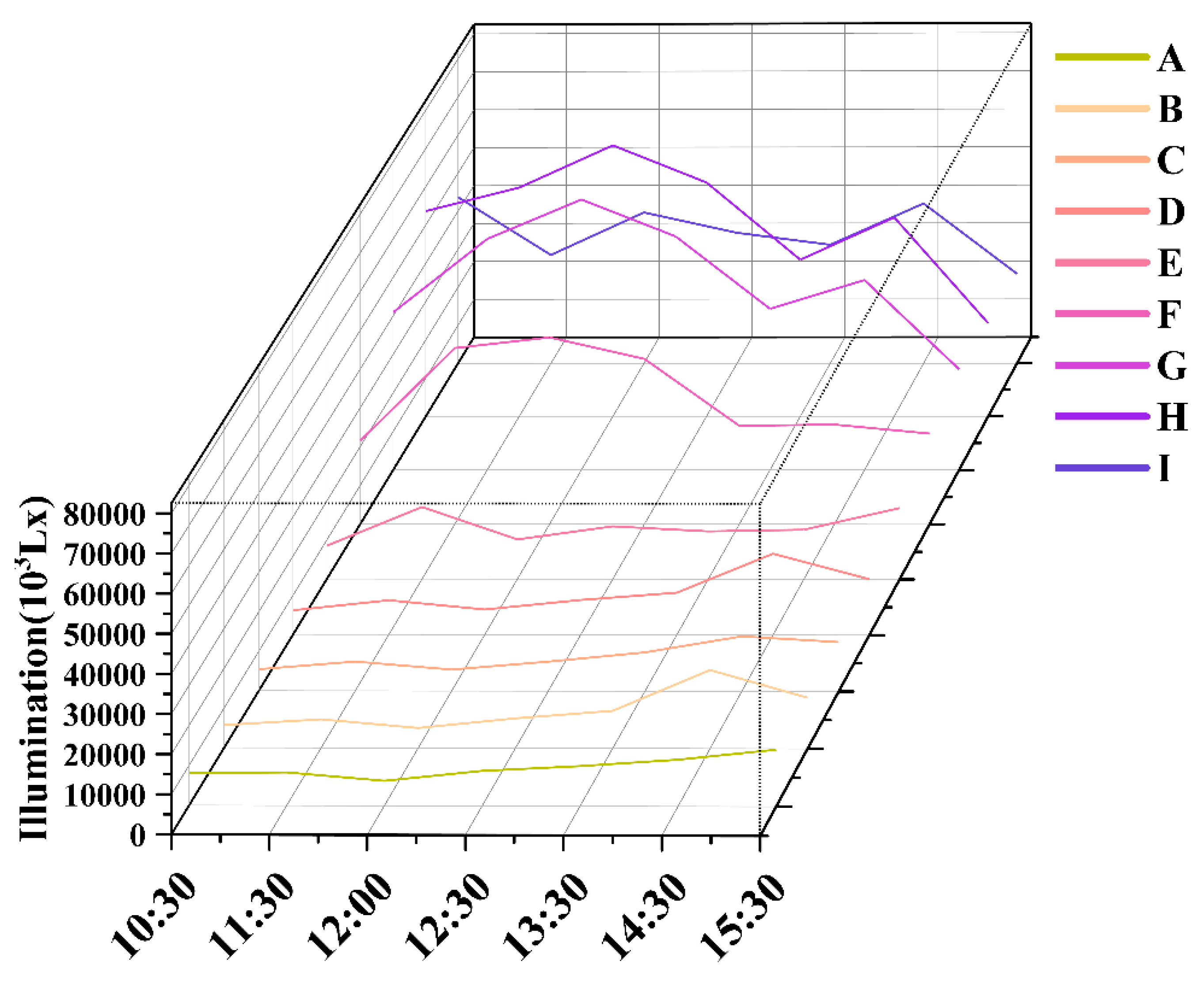

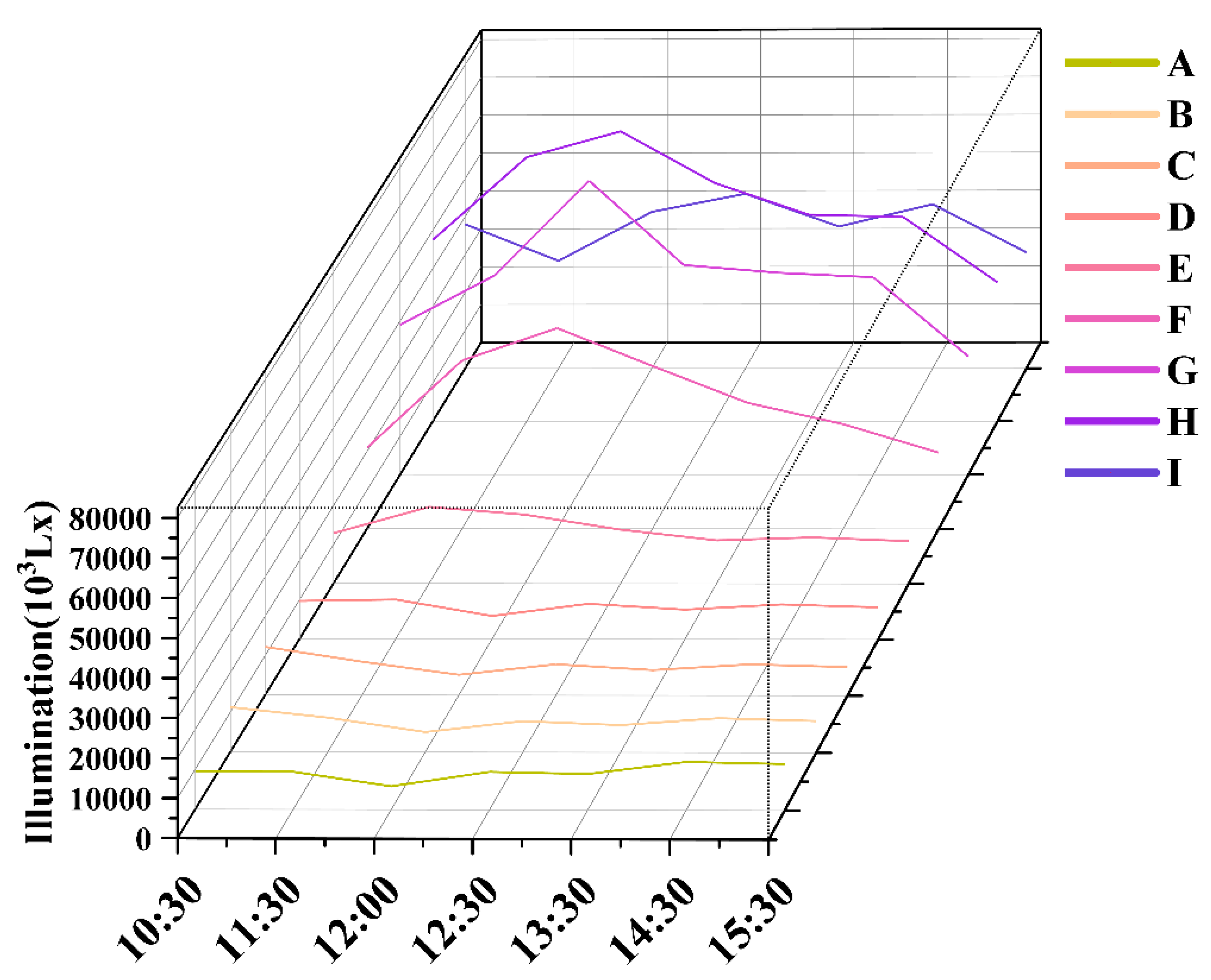

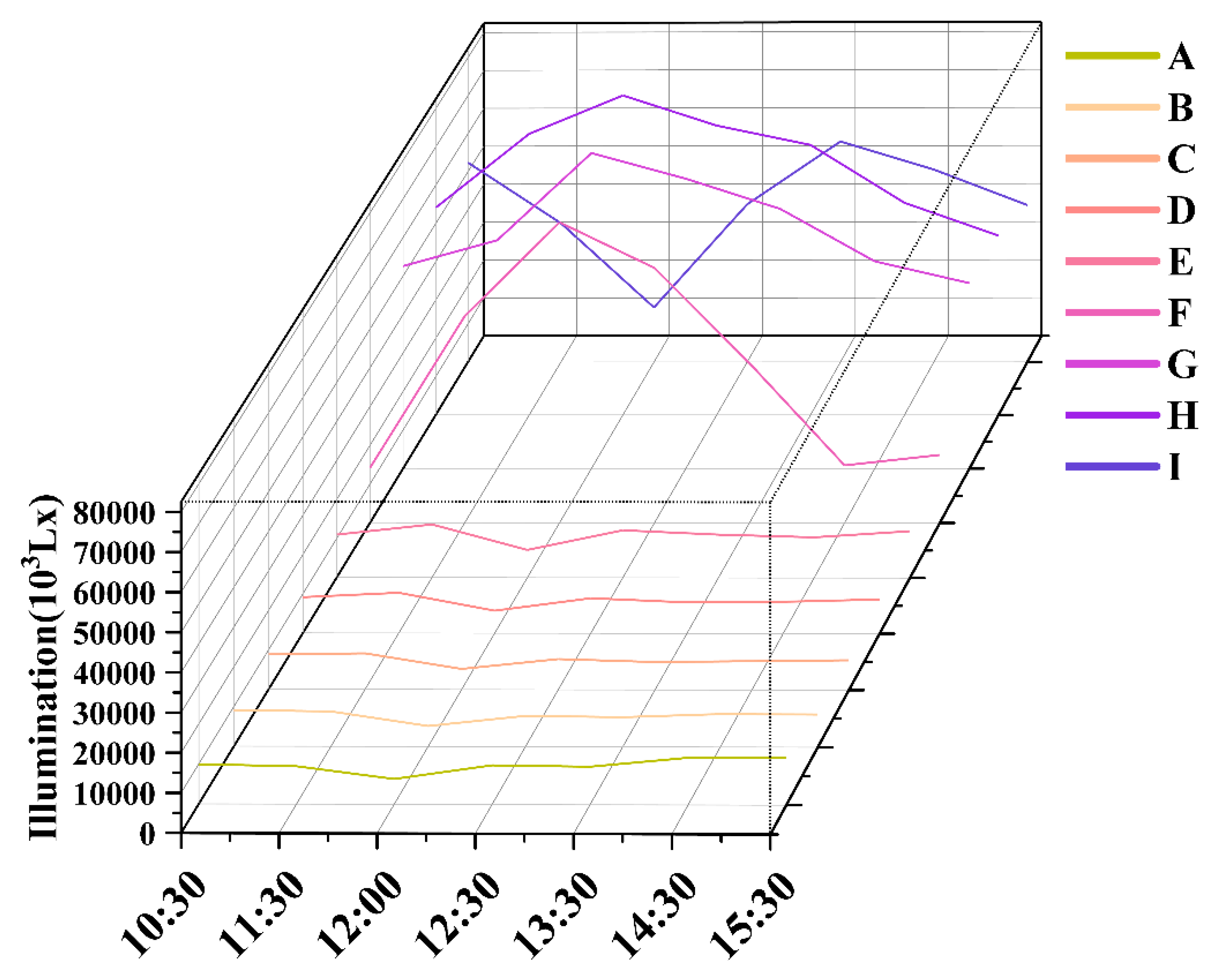

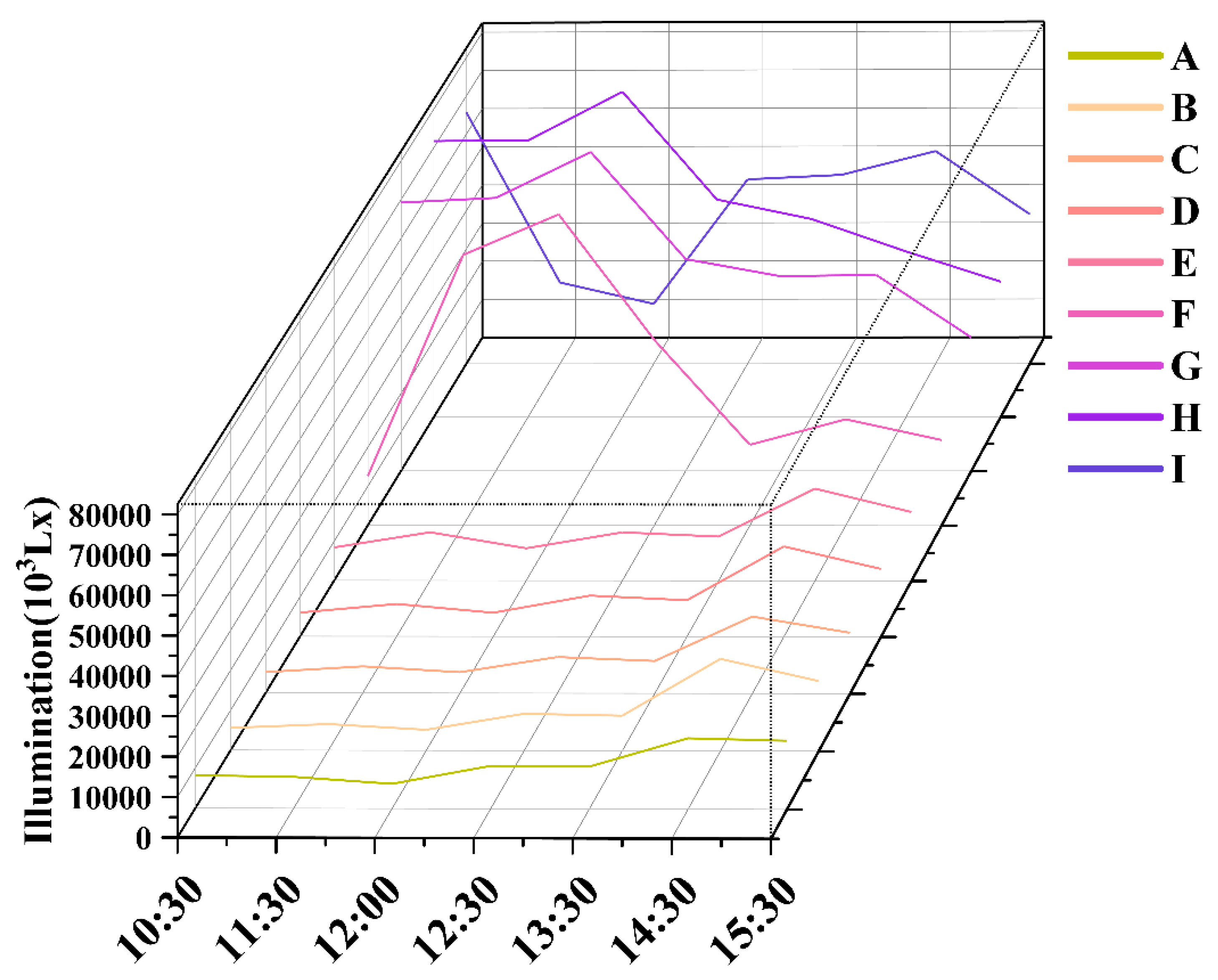

As shown in

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18 and

Figure 19, the variation of the illuminance of each material over time is distributed over time and appears in a "W" shape assuming that cloud interference is excluded [

18,

19]. The illumination intensity of each dot zone of each material will reach a small peak at 12:30 because the solar altitude angle is the highest and the light intensity is strongest at noon, and the illumination of each dot zone at 11:30 and 13:30 is lower than the value of 12:30. The illumination of each point at 10:30 and 14:30 is greater than that at 11:30 and 13:30, because the light measured at the N1 or N6 lines at the measurement points in the greenhouse is directly through the insect net and is not refracted through the light transmitting element and obscured by the greenhouse skeleton [

20]. In fact, the light intensity of the outdoors changes at any time [

21], the cloud layer is always moving, and the measurement process takes time, which makes the measurement results not exactly the same as the conjecture. Meanwhile, considering the evaporation of water vapor is the highest when the solar altitude angle at noon, the blocking of water vapor will also affect the measurement results [

22,

26,

27,

28].

4.3. Light uniformity in the greenhouse

4.3.1. Light uniformity and variation coefficient

Table 2,

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7 shows the light uniformity and variation coefficient in the model greenhouse at different time periods [

23] when the grating plate and glass are used as light-transmitting components. The data varied a lot due to the different measurement times of each point and the rapid change of the atmospheric cloud layer [

24]. The results of data processing are as follows:

In

Table 2, the illumination uniformity of the 20-line 3mm thick grating plate as the light transmitting module from point A to point I and from 10:30 to 14:30 increased with time, the variation coefficient increased with time, and the variance decreased with the increase of time.

In

Table 3, the illumination uniformity of the 25-line 4mm thick grating plate as the light transmitting module from point A to point I and from 10:30 to 14:30 decreased with the increase of time, the variation coefficient increased with the increase of time, the variance increased with the increase of time, the average point G, point H and point I decreased with the increase of time, and the other points increased with the increase of time.

In

Table 4, the illumination uniformity of the 30-line 3mm thick grating plate as the light transmitting module from point A to point I and from 10:30 to 14:30 decreased with the increase of time, the variation coefficient increased with time, the variance increased with the increase of time, and the variance increased with the increase of time.

In

Table 5, the illumination uniformity of the 40-line 2mm thick grating plate as the light transmitting module from point A to point I and from 10:30 to 14:30 increased with time, the variation coefficient decreased with the increase of time, and the variance decreased with the increase of time.

In

Table 6, the illumination uniformity of 2mm thick glass as the light transmitting module from point A to point I and from 10:30 to 14:30 increased with the increase of time, the variation coefficient decreased slightly with the increase of time, the rest of the points increased with time, the variance except for point A increased slightly with time, the variance decreased slightly with the increase of time, the variance except for point A increased slightly with time, and decreased with the increase of time, the average point A, point F, point G, point H increased with the increase of time, and point B, point C, point D, point E, and point I decreased with the increase of time.

In

Table 7, the illumination uniformity of the 3mm thick glass translucent module from point A to point I and from 10:30 to 14:30 decreased with the increase of time, the variation coefficient increased with the increase of time, the variance increased with the increase of time, the average points A, B, C, D, E, and F increased with the increase of time, and the average points G, H and I decreased with the increase of time.

5. Discussion

1. The use of grating plate as the light transmitting module can improve the light uniformity of the light and dark zone junction area in the low light area caused by the shading of photovoltaic modules in the zigzag photovoltaic greenhouse. However, the light transmittance of the grating plate is lower than that of the translucent glass, and the light entering through the translucent roof will be reduced, causing a low utilization rate of sunlight and lower light intensity under the grating plate in the greenhouse compared with ordinary translucent glass. From the perspective of light distribution characteristics, the grating plate has a high scattering feature to refract the light to an area larger than its own size, which improves the light intensity of some dark band areas, and the increased intensity would decrease with distance. Therefore, grating plates are a good way to deal with the need to block a part of the light and increase the light intensity near the band area. At the same time, it provides ideas for improving the light environment in the greenhouse by using the optical path of light transmitting materials to light.

2. In addition to this experiment, the greenhouse model that can change the inclination angle of the roof can also be used to determine the lighting environment in the greenhouse under different roof coverage rates. Since the model greenhouse is based on the size of the actual greenhouse and is scaled down, the light intensity in the room is affected by the skeleton. At the same time, due to the volume of the measuring instrument, the existing model fails to measure the light intensity in the greenhouse from different heights.

6. Conclusions

In this study, on the basis of constructing a zigzag photovoltaic greenhouse model, the light intensity of the model greenhouse under different roof inclination angles and different simulated solar altitude angles was compared through pre-experiments using grating panels and ordinary glass as light-transmitting modules, and the optimal roof inclination angle range suitable for field experiments was obtained. On this basis, the illumination intensity of the model greenhouse was measured when the grating plate and ordinary glass were used as the light transmitting components in different time periods of the day, and the illuminance of each measurement point was obtained and compared [

25]. The following main conclusions were obtained:

(1) In the outdoor experiment, the roof inclination angle of the model greenhouse is 12 degrees, and the roof coverage rate is 41.92%. From the experimental results, it is not difficult to see that the light in the greenhouse with the light transmitting component is ordinary glass, the dark band is concentrated in the front end (A, B, C points) area, the bright band is concentrated in the rear end (G, H, I points) area, and the middle (D, E, F points) area belongs to the light and dark junction zone. At noon, when the grating plate is used as the light transmitting component, the uniformity of the points (A to I) in the north-south direction is the same as in the east-west direction. The light intensity in the front area of the greenhouse is the same as that of the grating group and the glass group. The grating plate can be used as the light transmitting module to reduce the light intensity of the bright belt, improve the light intensity at the intersection of light and dark, and expand the planting area in the photovoltaic greenhouse.

(2) When the grating plate is used as the light transmitting module, the light intensity from point G to point I in the greenhouse is greater than 20000Lx, and the light environment in other areas is less than 20000lx and greater than 5000Lx, which is suitable for planting shade-loving crops, and the light intensity of the 40-line specification with a thickness of 2mm can be maximized to improve the light intensity of the greenhouse. At present, the cost of grating plate on the market is about 90-120 yuan per square meter, which is roughly the same as the cost of glass, and there is the possibility of actual production.

In summary, grating panels can be used as greenhouse covering materials to improve the light intensity at the intersection of light and dark bands in photovoltaic greenhouses.

Author Contributions

Conceptualization, J.L.; methodology, B.W.; software, Y.S.; validation, Y.S.; formal analysis, B.W.; investigation, Y.S.; resources, B.W.; data curation,B.W.; writing—original draft preparation, Y.S.; writing—review and editing, B.W.; visualization, Y.S.; project administration, J.L.; funding acquisition, J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by China Huaneng Group Co., Ltd. Headquarters Technology Project, grant number HNKJ22-HF77; Hainan Provincial Natural Science Foundation of China, grant number 322RC583.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are presented in this article in the form of figures and tables.

Acknowledgments

We would like to thank the Innovation and utilization team of tropical melon crop genetic germplasm, Hainan University.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| U0

|

Illumination uniformity |

| Emin |

Minimum illumination value |

| Eav |

Average illuminance value |

References

- ZHOU C. Dr. Zhou inspected and visited the greenhouse facilities at the Arava scientific research base in Israel, Agricultural engineering Technology, 2016,36 (31): 65-68.

- Karpenko O.Optical Transmission Scanning and Hybrid Acousto-Optical Techniques for NDE and SHM of Structural Composites.Michigan State University. 2018.

- Singh R,;Gite L. Technological Change in Paddy Production: A Comparative Analysis of Traditional and Direct Seeding Methods of Cultivation. AMA-Agricultural Mechanization in Asia Africa and Latin America, 2012, 43,3, 41-46.

- Liu C,;Yang H,;Lai M. Evaluation of ecological compensation standards for county photovoltaic poverty alleviation in the context of agricultural modernization. Journal of Agricultural engineering, 2020,36 (16): 300-309. [CrossRef]

- Semple L,;Carriveau R,;Ting S K.Assessing heating and cooling demands of closed greenhouse systems in a cold climate.International Journal of Energy Research, 2017. [CrossRef]

- Boong-Joo,Lee.The Illumination Simulation in the Greenhouse using Daylight and Artificial Light for Energy Saving.The transactions of The Korean Institute of Electrical Engineers, 2017, 66(9):1359-1363. [CrossRef]

- Liu, J. A sawtooth shaped multi-span photovoltaic agricultural planting greenhouse: CN201320738494.4.2023.08.22.

- Liu J,;Wang B,;Sun F,;Chen Y,;Wu Xuyong. Practice and innovation of structural design of multi-building photovoltaic vegetable greenhouse in hot zone[J].Agricultural Engineering Technology, 2022, 42(16):22-29.

- Li J,;Zuo S,; Wu F.The Tianlai Cylinder Pathfinder array: System functions and basic performance analysis. Chinese Science: Physics, Mechanics, Astronomy English Edition, 2020, 63(12):27. [CrossRef]

- Zou Z,; Shao X.Environmental Engineering in Facility Agriculture, China Agriculture Press, Beijing,2006, p. 19.

- Seifert E.OriginPro9.1: Scientific Data Analysis and GraphingSoftware Software Review.Journal of Chemical Information and Modeling, 2014, 54(5):1552-1552. [CrossRef]

- Li H,;Ji D,;Hu X.Comprehensive evaluation of combining CFD simulation and entropy weight to predict natural ventilation strategy in a sliding cover solar greenhouse. International Journal Of Agricultural And Biological Engineering, 2021(006):014.

- Zhang J,;Shen K,;Chen D. Analysis of spatiotemporal changes in canopy characteristic temperature of solar greenhouses based on the Internet of Things. Journal of Agricultural Machinery, 2021,52 (07): 335-342.

- Choab N,;Allouhi A,;El Maakoul A.Review on greenhouse microclimate and application: Design parameters, thermal modeling and simulation, climate controlling technologies.Solar Energy, 2019, 191(Oct.):109-137. [CrossRef]

- Bulik,T,;Piacentini.Selection of astrophysical/astronomical/solar sites at the Argentina East Andes range taking into account atmospheric components.Advances in Space Research the Official Journal of the Committee on Space Research, 2016.

- Igoe,D,;Turner.Characterization of cloud cover with a smart phone camera.Instrumentation science & technology: Designs and applications for chemistry, biotechnology, and environmental science, 2016, 44(1):23-34. [CrossRef]

- Ayet A,;Tandeo P.Nowcasting solar irradiance using an analog method and geostationary satellite images.Solar Energy, 2018, 164(APR.):301-315. [CrossRef]

- Zhou Bo,; Sun W,; Guo Wl. Analysis of the impact of the gutter structure of a multi-span glass greenhouse on the light environment in cultivation areas. Journal of Agricultural Machinery, 2021,52 (05): 286-292.

- Giovannini L,; Goia F,;Lo V.A Comparative Analysis of the Visual Comfort Performance between a PCM Glazing and a Conventional Selective Double Glazed Unit.Sustainability, 2018, 10(10). [CrossRef]

- Xu M,; Bu X,;Yu J.Compensation method of cloud infrared radiation interference based on a spinning projectile’s attitude measurement.Journal of Applied Remote Sensing, 2018, 12(1):1. [CrossRef]

- Lindh U,;Jgerbrand A K.Perceived Lighting Uniformity on Pedestrian Roads: From an Architectural Perspective.Energies, 2021. [CrossRef]

- Hoda R,;Socio-Technical Grounded Theory for Software Engineering. 2021. [CrossRef]

- Li X,;Lu Z,;Zhou Q.A Cloud Detection Algorithm with Reduction of Sunlight Interference in Ground-Based Sky Images.Atmosphere, 2019(11). [CrossRef]

- Yang Y,;Chen Z,; Xu T.Comparing the uniformity of light glass fiber felt based on process improvement, microstructural forming mechanism and physical properties.SAGE PublicationsSage UK: London, England, 2019(17). [CrossRef]

- Lopez-Cruz I,;,Efrén F,; Salazar-Moreno R.Development and analysis of dynamical mathematical models of greenhouse climate: A review. European Journal of Horticultural Science, 2018, 83(5):269-279. [CrossRef]

- Bubolz K,;Schenk H,; Hirsch T.Influence of spatiotemporally distributed irradiance data input on temperature evolution in parabolic trough solar field simulations. SolarPACES 2015, 13.-16. Okt. [CrossRef]

- Lhmus,M,Bowlan.Diffraction of ultrashort optical pulses from circularly symmetric binary phase gratings[J].Optics Letters, 2012, 37(7):1238-1240. [CrossRef]

- Sahin M,;Oguz Y,;Buyuktumturk F.ANN-based estimation of time-dependent energy loss in lighting systems[J].Energy & Buildings, 2016, 116(mar.):455-467. [CrossRef]

- Shaik S,;Bhardwaj M,;Agarwal S.Evaluation of Optical Transmissivity of Transparent Materials on the Performance of Solar Flat Plate Collectors[J].Journal of Solar Energy Engineering, 2021(5):143. [CrossRef]

Figure 2.

Schematic diagram of zigzag photovoltaic greenhouse structure (mm).

Figure 2.

Schematic diagram of zigzag photovoltaic greenhouse structure (mm).

Figure 3.

A real picture of the zigzag photovoltaic greenhouse.

Figure 3.

A real picture of the zigzag photovoltaic greenhouse.

Figure 4.

Schematic diagram of greenhouse model structure (mm).

Figure 4.

Schematic diagram of greenhouse model structure (mm).

Figure 5.

North end of the field experiment model (insect net can be opened).

Figure 5.

North end of the field experiment model (insect net can be opened).

Figure 6.

Side view of the field experiment model.

Figure 6.

Side view of the field experiment model.

Figure 7.

Schematic diagram of the front and back sections of the light intensity measurement point (mm).

Figure 7.

Schematic diagram of the front and back sections of the light intensity measurement point (mm).

Figure 8.

12:00 a.m. The light distribution of each point in the north-south direction of the corresponding area in each plate greenhouse.

Figure 8.

12:00 a.m. The light distribution of each point in the north-south direction of the corresponding area in each plate greenhouse.

Figure 9.

10:30 a.m. Average light intensity at each point.

Figure 9.

10:30 a.m. Average light intensity at each point.

Figure 10.

11:30 a.m. Average light intensity at each point.

Figure 10.

11:30 a.m. Average light intensity at each point.

Figure 11.

12:30 p.m. Average light intensity at each point.

Figure 11.

12:30 p.m. Average light intensity at each point.

Figure 12.

13:30 p.m. Average light intensity at each point.

Figure 12.

13:30 p.m. Average light intensity at each point.

Figure 13.

14:30 p.m. Average light intensity at each point.

Figure 13.

14:30 p.m. Average light intensity at each point.

Figure 14.

The average illumination intensity of each point of the 20line\inch 3mm thick grating plate at different times (Illuminance at different time points from point A to point I).

Figure 14.

The average illumination intensity of each point of the 20line\inch 3mm thick grating plate at different times (Illuminance at different time points from point A to point I).

Figure 15.

The average illumination intensity of each point of the 25line\inch 4mm thick grating plate at different times (Illuminance at different time points from point A to point I).

Figure 15.

The average illumination intensity of each point of the 25line\inch 4mm thick grating plate at different times (Illuminance at different time points from point A to point I).

Figure 16.

The average illumination intensity of each point of the 30line\inch 3mm thick grating plate at different times (Illuminance at different time points from point A to point I).

Figure 16.

The average illumination intensity of each point of the 30line\inch 3mm thick grating plate at different times (Illuminance at different time points from point A to point I).

Figure 17.

The average illumination intensity of each point of the 40line\inch 2mm thick grating plate at different times (Illuminance at different time points from point A to point I).

Figure 17.

The average illumination intensity of each point of the 40line\inch 2mm thick grating plate at different times (Illuminance at different time points from point A to point I).

Figure 18.

The average light intensity of each dot band of 2 mm thick glass at different time (Illuminance at different time points from point A to point I).

Figure 18.

The average light intensity of each dot band of 2 mm thick glass at different time (Illuminance at different time points from point A to point I).

Figure 19.

The average light intensity of each dot band of 3 mm thick glass at different time (Illuminance at different time points from point A to point I).

Figure 19.

The average light intensity of each dot band of 3 mm thick glass at different time (Illuminance at different time points from point A to point I).

Table 1.

Experimental arrangement.

Table 1.

Experimental arrangement.

Roof inclination

angle\° |

Point |

Translucent components |

Data Acquisition

(Time) |

| 12 |

A |

Translucent glass: |

10:30 |

| |

B |

2mm glass |

11:30 |

| |

C |

3mm glass |

12:00 |

| |

D |

Grating plate: |

12:30 |

| |

E |

20 line\inch 3mm |

13:30 |

| |

F |

30line\inch3mm |

14:30 |

| |

G |

25 line\inch 4mm |

|

| |

H |

40 line\inch2mm |

|

| |

I |

|

|

Table 2.

Light uniformity and variation coefficient of 20line\inch 3mm grating transmittance component.

Table 2.

Light uniformity and variation coefficient of 20line\inch 3mm grating transmittance component.

| Time |

20line\inch 3mm |

A |

B |

C |

D |

E |

F |

G |

H |

I |

| 10:30 |

Average(Lux) |

13204 |

19023 |

16967 |

17407 |

18648 |

30788 |

42619 |

51477 |

47391 |

| Variance |

6540 |

22226 |

19731 |

19084 |

14952 |

13310 |

7521 |

5145 |

8753 |

| Cv |

0.495 |

1.168 |

1.163 |

1.096 |

0.802 |

0.432 |

0.176 |

0.100 |

0.185 |

| Illumination(%) |

68.27 |

29.86 |

31.12 |

33.93 |

47.29 |

69.89 |

88.47 |

93.12 |

87.35 |

| 11:30 |

Average(Lux) |

9048 |

8280 |

8264 |

9791 |

21463 |

37555 |

49452 |

43701 |

29714 |

| Variance |

829 |

2293 |

2334 |

1469 |

7380 |

19831 |

28091 |

25080 |

11564 |

| Cv |

0.092 |

0.279 |

0.282 |

0.150 |

0.344 |

0.528 |

0.568 |

0.530 |

0.389 |

| Illumination(%) |

94.48 |

81.46 |

81.24 |

86.97 |

61.38 |

39.35 |

34.41 |

38.78 |

55.07 |

| 12:30 |

Average(Lux) |

9028 |

8038 |

8154 |

9658 |

18696 |

36957 |

53929 |

52073 |

32435 |

| Variance |

691 |

2395 |

2417 |

1724 |

4369 |

17637 |

30407 |

29221 |

14127 |

| Cv |

0.077 |

0.298 |

0.296 |

0.178 |

0.234 |

0.477 |

0.564 |

0.542 |

0.436 |

| Illumination(%) |

94.50 |

79.81 |

81.84 |

89.51 |

75.73 |

45.28 |

35.27 |

37.43 |

50.33 |

| 13:30 |

Average(Lux) |

9658 |

6819 |

6363 |

7419 |

11937 |

25959 |

45146 |

46941 |

35807 |

| Variance |

371 |

661 |

623 |

557 |

2081 |

847 |

1631 |

620 |

403 |

| Cv |

0.038 |

0.097 |

0.098 |

0.075 |

0.174 |

0.033 |

0.036 |

0.012 |

0.011 |

| Illumination(%) |

97.25 |

90.36 |

94.24 |

95.22 |

80.80 |

96.31 |

96.94 |

98.56 |

98.71 |

| 14:30 |

Average(Lux) |

10925 |

7501 |

6888 |

7732 |

12879 |

26428 |

45861 |

52064 |

37354 |

| Variance |

236 |

672 |

680 |

587 |

2602 |

2088 |

598 |

2253 |

44 |

| Cv |

0.022 |

0.090 |

0.099 |

0.076 |

0.202 |

0.079 |

0.013 |

0.043 |

0.001 |

| Illumination(%) |

98.40 |

91.94 |

93.22 |

94.86 |

79.45 |

91.40 |

99.02 |

95.20 |

99.92 |

Table 3.

Light uniformity and variation coefficient of 25line\inch 4mm grating transmittance component.

Table 3.

Light uniformity and variation coefficient of 25line\inch 4mm grating transmittance component.

| Time |

25line\inch 4mm |

A |

B |

C |

D |

E |

F |

G |

H |

I |

| 10:30 |

Average(Lux) |

7396 |

5065 |

4822 |

5164 |

6655 |

22408 |

54588 |

62107 |

50615 |

| Variance |

355 |

339 |

292 |

612 |

845 |

2064 |

3541 |

2908 |

3423 |

| Cv |

0.048 |

0.067 |

0.060 |

0.119 |

0.127 |

0.092 |

0.065 |

0.047 |

0.068 |

| Illumination(%) |

95.54 |

92.42 |

93.06 |

87.17 |

85.35 |

94.28 |

94.56 |

95.85 |

93.81 |

| 11:30 |

Average(Lux) |

8112 |

6979 |

7042 |

8397 |

18387 |

63385 |

69224 |

70738 |

27373 |

| Variance |

347 |

800 |

918 |

745 |

1173 |

4378 |

1649 |

2320 |

3084 |

| Cv |

0.043 |

0.115 |

0.130 |

0.089 |

0.064 |

0.069 |

0.024 |

0.033 |

0.113 |

| Illumination(%) |

96.59 |

90.7 |

89.51 |

92.99 |

95.94 |

92.03 |

97.35 |

96.22 |

87.24 |

| 12:30 |

Average(Lux) |

9381 |

7627 |

8062 |

9429 |

12317 |

48343 |

73348 |

74430 |

41962 |

| Variance |

540 |

468 |

615 |

412 |

755 |

7606 |

8581 |

7972 |

12486 |

| Cv |

0.058 |

0.061 |

0.076 |

0.044 |

0.061 |

0.157 |

0.117 |

0.107 |

0.298 |

| Illumination(%) |

94.52 |

95.11 |

94.92 |

95.22 |

94.04 |

83.84 |

87.28 |

88.4 |

65.64 |

| 13:30 |

Average(Lux) |

10104 |

9750 |

9164 |

11042 |

12616 |

25106 |

42049 |

45063 |

33875 |

| Variance |

1211 |

4999 |

4936 |

6048 |

2943 |

6374 |

19338 |

22079 |

13807 |

| Cv |

0.120 |

0.513 |

0.539 |

0.548 |

0.233 |

0.254 |

0.460 |

0.490 |

0.408 |

| Illumination(%) |

91.56 |

69.21 |

64.09 |

64.40 |

81.90 |

70.71 |

47.25 |

44.30 |

53.65 |

| 14:30 |

Average(Lux) |

12001 |

20822 |

13874 |

12921 |

12601 |

30164 |

50966 |

53427 |

44685 |

| Variance |

2623 |

23121 |

11788 |

8119 |

3735 |

9618 |

5415 |

6994 |

3589 |

| Cv |

0.219 |

1.110 |

0.850 |

0.628 |

0.296 |

0.319 |

0.106 |

0.131 |

0.080 |

| Illumination(%) |

82.33 |

34.12 |

49.32 |

59.76 |

78.10 |

79.42 |

87.79 |

85.88 |

92.01 |

Table 4.

Light uniformity and variation coefficient of 30line\inch 3mm grating transmittance component.

Table 4.

Light uniformity and variation coefficient of 30line\inch 3mm grating transmittance component.

| Time |

30line\inch 3mm |

A |

B |

C |

D |

E |

F |

G |

H |

I |

| 10:30 |

Average(Lux) |

8011 |

5681 |

5429 |

6154 |

8516 |

21483 |

40911 |

53604 |

43729 |

| Variance |

623 |

314 |

221 |

369 |

762 |

2041 |

1320 |

810 |

943 |

| Cv |

0.078 |

0.055 |

0.041 |

0.060 |

0.089 |

0.095 |

0.032 |

0.015 |

0.022 |

| Illumination(%) |

91.18 |

93.62 |

95.44 |

94.21 |

93.37 |

94.32 |

97.12 |

98.94 |

97.83 |

| 11:30 |

Average(Lux) |

8284 |

7163 |

7400 |

8724 |

18439 |

45389 |

59922 |

59721 |

28496 |

| Variance |

32 |

910 |

1243 |

910 |

4871 |

1065 |

3915 |

2257 |

7023 |

| Cv |

0.004 |

0.127 |

0.168 |

0.104 |

0.264 |

0.023 |

0.065 |

0.038 |

0.246 |

| Illumination(%) |

99.76 |

92.24 |

88.06 |

93.97 |

74.35 |

97.44 |

92.46 |

95.64 |

74.01 |

| 12:30 |

Average(Lux) |

8766 |

7496 |

7453 |

8850 |

13514 |

42574 |

60516 |

60966 |

34265 |

| Variance |

257 |

1370 |

1240 |

1178 |

743 |

4757 |

8019 |

8106 |

5524 |

| Cv |

0.029 |

0.183 |

0.166 |

0.133 |

0.055 |

0.112 |

0.133 |

0.133 |

0.161 |

| Illumination(%) |

97.58 |

87.98 |

90.22 |

91.38 |

94.96 |

87.65 |

85.8 |

86.97 |

81.71 |

| 13:30 |

Average(Lux) |

10004 |

9421 |

9822 |

10729 |

12250 |

25349 |

41733 |

40815 |

31104 |

| Variance |

1007 |

4856 |

5564 |

5299 |

2827 |

6305 |

18830 |

18184 |

10752 |

| Cv |

0.101 |

0.516 |

0.566 |

0.494 |

0.231 |

0.249 |

0.451 |

0.446 |

0.346 |

| Illumination(%) |

93.45 |

66.27 |

63.77 |

66.86 |

84.47 |

73.61 |

47.95 |

48.83 |

60.1 |

| 14:30 |

Average(Lux) |

11645 |

19694 |

13903 |

20654 |

12680 |

25656 |

41968 |

51813 |

41898 |

| Variance |

1454 |

21146 |

11520 |

21417 |

3433 |

3852 |

2897 |

4085 |

1971 |

| Cv |

0.125 |

1.074 |

0.829 |

1.037 |

0.271 |

0.150 |

0.059 |

0.079 |

0.047 |

| Illumination(%) |

92.41 |

35.91 |

48.63 |

37.28 |

80.91 |

84.56 |

95.57 |

91.14 |

96.06 |

Table 5.

Light uniformity and variation coefficient of 40line\inch 2mm grating transmittance component.

Table 5.

Light uniformity and variation coefficient of 40line\inch 2mm grating transmittance component.

| Time |

40line\inch 2mm |

A |

B |

C |

D |

E |

F |

G |

H |

I |

| 10:30 |

Average(Lux) |

9405 |

11212 |

12172 |

9641 |

12899 |

20918 |

38975 |

47467 |

37986 |

| Variance |

845 |

8610 |

11568 |

6609 |

9737 |

2795 |

16851 |

24483 |

19033 |

| Cv |

0.091 |

0.768 |

0.950 |

0.686 |

0.755 |

0.134 |

0.432 |

0.516 |

0.501 |

| Illumination(%) |

90.85 |

50.88 |

41.87 |

56.51 |

50.87 |

85.18 |

50.30 |

40.44 |

42.14 |

| 11:30 |

Average(Lux) |

9427 |

8627 |

8439 |

10027 |

19644 |

43479 |

51796 |

69087 |

28332 |

| Variance |

1190 |

2989 |

2872 |

2065 |

5843 |

25311 |

30460 |

3758 |

6618 |

| Cv |

0.126 |

0.346 |

0.340 |

0.206 |

0.297 |

0.582 |

0.588 |

0.054 |

0.234 |

| Illumination(%) |

91.34 |

78.53 |

78.16 |

86.61 |

66.10 |

32.85 |

32.10 |

94.25 |

73.18 |

| 12:30 |

Average(Lux) |

9503 |

7830 |

7856 |

9000 |

13836 |

42032 |

54445 |

62260 |

45913 |

| Variance |

348 |

1001 |

1058 |

655 |

1104 |

4201 |

17210 |

12000 |

19112 |

| Cv |

0.037 |

0.128 |

0.135 |

0.073 |

0.080 |

0.100 |

0.316 |

0.193 |

0.416 |

| Illumination(%) |

97.71 |

90.29 |

89.38 |

92.20 |

92.94 |

90.50 |

69.21 |

82.21 |

55.49 |

| 13:30 |

Average(Lux) |

9021 |

6865 |

6417 |

7534 |

11112 |

32497 |

52424 |

53927 |

37280 |

| Variance |

428 |

800 |

912 |

655 |

634 |

2331 |

1324 |

1066 |

1625 |

| Cv |

0.047 |

0.117 |

0.142 |

0.087 |

0.057 |

0.072 |

0.025 |

0.020 |

0.044 |

| Illumination(%) |

96.76 |

93.04 |

87.64 |

91.52 |

94.55 |

93.54 |

97.31 |

97.84 |

96.26 |

| 14:30 |

Average(Lux) |

12096 |

8644 |

7912 |

8880 |

11863 |

27015 |

51228 |

53309 |

43105 |

| Variance |

832 |

899 |

653 |

684 |

623 |

1454 |

3546 |

4118 |

3685 |

| Cv |

0.069 |

0.104 |

0.083 |

0.077 |

0.053 |

0.054 |

0.069 |

0.077 |

0.085 |

| Illumination(%) |

92.34 |

90.60 |

93.81 |

95.33 |

94.91 |

95.22 |

94.57 |

95.50 |

91.58 |

Table 6.

Light uniformity and variation coefficient of 2mm thick glass transmittance component.

Table 6.

Light uniformity and variation coefficient of 2mm thick glass transmittance component.

| Time |

2mm glass |

A |

B |

C |

D |

E |

F |

G |

H |

I |

| 10:30 |

Average(Lux) |

9902 |

9074 |

8832 |

9122 |

10991 |

14192 |

52549 |

54144 |

52454 |

| Variance |

628 |

5010 |

5686 |

5235 |

4189 |

2291 |

29768 |

32019 |

31339 |

| Cv |

0.063 |

0.522 |

0.644 |

0.574 |

0.381 |

0.161 |

0.566 |

0.591 |

0.597 |

| Illumination(%) |

93.99 |

65.98 |

59.89 |

62.86 |

75.45 |

90.64 |

34.62 |

31.72 |

31.01 |

| 11:30 |

Average(Lux) |

9456 |

8788 |

9121 |

10278 |

13611 |

53302 |

59227 |

73413 |

36486 |

| Variance |

1367 |

2964 |

3416 |

2708 |

346 |

33545 |

29411 |

5037 |

23825 |

| Cv |

0.145 |

0.337 |

0.375 |

0.263 |

0.025 |

0.629 |

0.497 |

0.069 |

0.653 |

| Illumination(%) |

91.16 |

78.5 |

76.51 |

84.28 |

97.50 |

28.08 |

42.81 |

93.06 |

48.73 |

| 12:30 |

Average(Lux) |

9793 |

7747 |

7734 |

8933 |

12144 |

65639 |

75127 |

75470 |

41387 |

| Variance |

434 |

400 |

791 |

405 |

441 |

2096 |

6677 |

13279 |

21467 |

| Cv |

0.044 |

0.052 |

0.102 |

0.045 |

0.036 |

0.032 |

0.089 |

0.176 |

0.519 |

| Illumination(%) |

94.97 |

96.91 |

92.75 |

97.03 |

95.86 |

96.79 |

90.76 |

83.68 |

40.41 |

| 13:30 |

Average(Lux) |

9494 |

7467 |

7027 |

7905 |

11045 |

41105 |

67277 |

70382 |

57833 |

| Variance |

300 |

663 |

586 |

210 |

326 |

21427 |

8882 |

7255 |

10947 |

| Cv |

0.032 |

0.089 |

0.083 |

0.027 |

0.030 |

0.521 |

0.132 |

0.103 |

0.189 |

| Illumination(%) |

96.94 |

93.44 |

94.97 |

96.99 |

96.60 |

42.86 |

85.33 |

88.23 |

78.97 |

| 14:30 |

Average(Lux) |

11773 |

8288 |

7283 |

8085 |

10378 |

14806 |

53669 |

55271 |

50436 |

| Variance |

667 |

651 |

561 |

562 |

707 |

915 |

4657 |

3782 |

2368 |

| Cv |

0.057 |

0.079 |

0.077 |

0.070 |

0.068 |

0.062 |

0.087 |

0.068 |

0.047 |

| Illumination(%) |

94.77 |

91.89 |

91.11 |

92.19 |

93.22 |

95.10 |

91.45 |

92.38 |

96.20 |

Table 7.

Light uniformity and variation coefficient of 3mm thick glass transmittance component.

Table 7.

Light uniformity and variation coefficient of 3mm thick glass transmittance component.

| Time |

3mm glass |

A |

B |

C |

D |

E |

F |

G |

H |

I |

| 10:30 |

Average(Lux) |

8165 |

5556 |

5200 |

5998 |

8404 |

12613 |

69234 |

71640 |

65709 |

| Variance |

439 |

380 |

397 |

463 |

110 |

643 |

4043 |

2468 |

510 |

| Cv |

0.054 |

0.068 |

0.076 |

0.077 |

0.013 |

0.051 |

0.058 |

0.034 |

0.008 |

| Illumination(%) |

93.93 |

96.01 |

94.71 |

93.46 |

99.10 |

95.32 |

93.36 |

96.47 |

99.40 |

| 11:30 |

Average(Lux) |

7820 |

6548 |

6691 |

8200 |

12278 |

69336 |

70410 |

71778 |

21230 |

| Variance |

473 |

527 |

222 |

491 |

1446 |

4832 |

299 |

3039 |

4317 |

| Cv |

0.060 |

0.0800 |

0.033 |

0.060 |

0.118 |

0.070 |

0.004 |

0.042 |

0.203 |

| Illumination(%) |

94.76 |

90.96 |

96.24 |

93.52 |

93.10 |

93.04 |

99.52 |

96.29 |

83.32 |

| 12:30 |

Average(Lux) |

10639 |

9223 |

9104 |

10371 |

12292 |

47526 |

52557 |

56379 |

48093 |

| Variance |

1032 |

2777 |

2676 |

2827 |

727 |

28626 |

33213 |

34108 |

26582 |

| Cv |

0.097 |

0.301 |

0.294 |

0.273 |

0.059 |

0.602 |

0.609 |

0.605 |

0.553 |

| Illumination(%) |

94.15 |

81.45 |

82.24 |

83.67 |

93.61 |

33.56 |

33.61 |

33.59 |

36.9 |

| 13:30 |

Average(Lux) |

10511 |

8768 |

81.2 |

9220 |

11238 |

20650 |

50111 |

51299 |

48239 |

| Variance |

1093 |

3339 |

3201 |

3593 |

1783 |

6321 |

27683 |

28179 |

27861 |

| Cv |

0.104 |

0.381 |

0.393 |

0.390 |

0.159 |

0.306 |

0.552 |

0.549 |

0.566 |

| Illumination(%) |

91.42 |

76.30 |

76.20 |

76.97 |

89.80 |

77.44 |

36.36 |

37.09 |

35.00 |

| 14:30 |

Average(Lux) |

17584 |

22986 |

19327 |

22834 |

23440 |

27171 |

50479 |

42862 |

55392 |

| Variance |

9495 |

24502 |

18756 |

22999 |

19510 |

19982 |

6235 |

20472 |

1599 |

| Cv |

0.540 |

1.066 |

0.970 |

1.007 |

0.832 |

0.735 |

0.124 |

0.478 |

0.092 |

| Illumination(%) |

68.53 |

38.23 |

42.01 |

39.32 |

48.24 |

55.98 |

87.98 |

44.88 |

96.68 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).