1. Introduction

One of the key aspects in the field of energy conservation in the mining industry is the transition from unregulated to regulated electric drives, which has been investigated in [

1,

2,

3]. This transition brings significant benefits, including energy savings and improvement in production processes [

4,

5].

To enhance energy efficiency, many industrial enterprises and companies in practice are adopting variable frequency drive technology for asynchronous electric drives. The use of frequency converters allows for substantial reduction in electricity expenses, improvement in operational economic efficiency, increased equipment reliability, extension of motor and mechanism lifespan, enhanced productivity, and implementation of intelligent electric drive control systems [

6,

7,

8].

Harmonic distortions, undesirable changes in electric current, can create serious problems for automated asynchronous drives [

9]. Harmonic distortions lead to interference and disturbances in the direct current line, resulting in reduced efficiency and sometimes causing serious issues such as data transmission failures, overheating, and equipment damage [

10].

Electric drive devices, such as motors and frequency converters, often act as sources of harmonics, increasing the complexity and difficulties in maintaining stable system performance. These effects not only shorten equipment lifespan but also increase costs for maintenance and repairs [

11].

To address this issue, methods such as the use of active filters like SAPF [

12] and MPPT [

13] are applied. These filters can eliminate unwanted harmonic distortions by introducing compensating current into the system. Research also focuses on developing a multi-level frequency converter structure to optimize performance and reduce harmonics in medium and high-power applications, such as the use of a five-level autonomous inverter with 53 = 125 output voltages, contributing to improved energy conversion efficiency [

14,

15]. However, applying a five-level autonomous inverter faces difficulties due to its relatively large and complex number of algorithms.

Additionally, research involving artificial neural network (ANN) algorithms [

16], fuzzy logic controls [

17,

18], ant colony optimization algorithm [

19] is actively underway. However, their practical implementation in industry also faces some challenges due to complex control structures and algorithms. Some other studies focus on algorithm modifications, such as combining direct torque control (DTC) with space vector modulation of sinusoidal pulse width modulation (SVPWM) [

20,

21,

22], or applying control systems with model reference adaptive system (MRAS) [

23], P-MRAS [

24]. Other research related to direct torque control of motors based on three-level converters is presented in the following works [

25,

26]. From these studies, it is evident that the implementation of a three-level autonomous inverter with a neutral point clamped (NPC) in a frequency converter represents significant progress in the field of energy conservation, aimed at optimizing performance and reducing harmonics in the alternating current line [

27].

Direct torque control (DTC) based on a three-level autonomous NPC inverter is an advanced method in the field of electric drives, providing high performance and accuracy. Since DTC is a control method that does not require the use of a model for the entire system, it significantly reduces calculation time [

28]. The application of DTC and a three-level autonomous NPC inverter ensures efficient and flexible motor control, minimizing the impact of harmonics, and optimizing electric drive performance [

29].

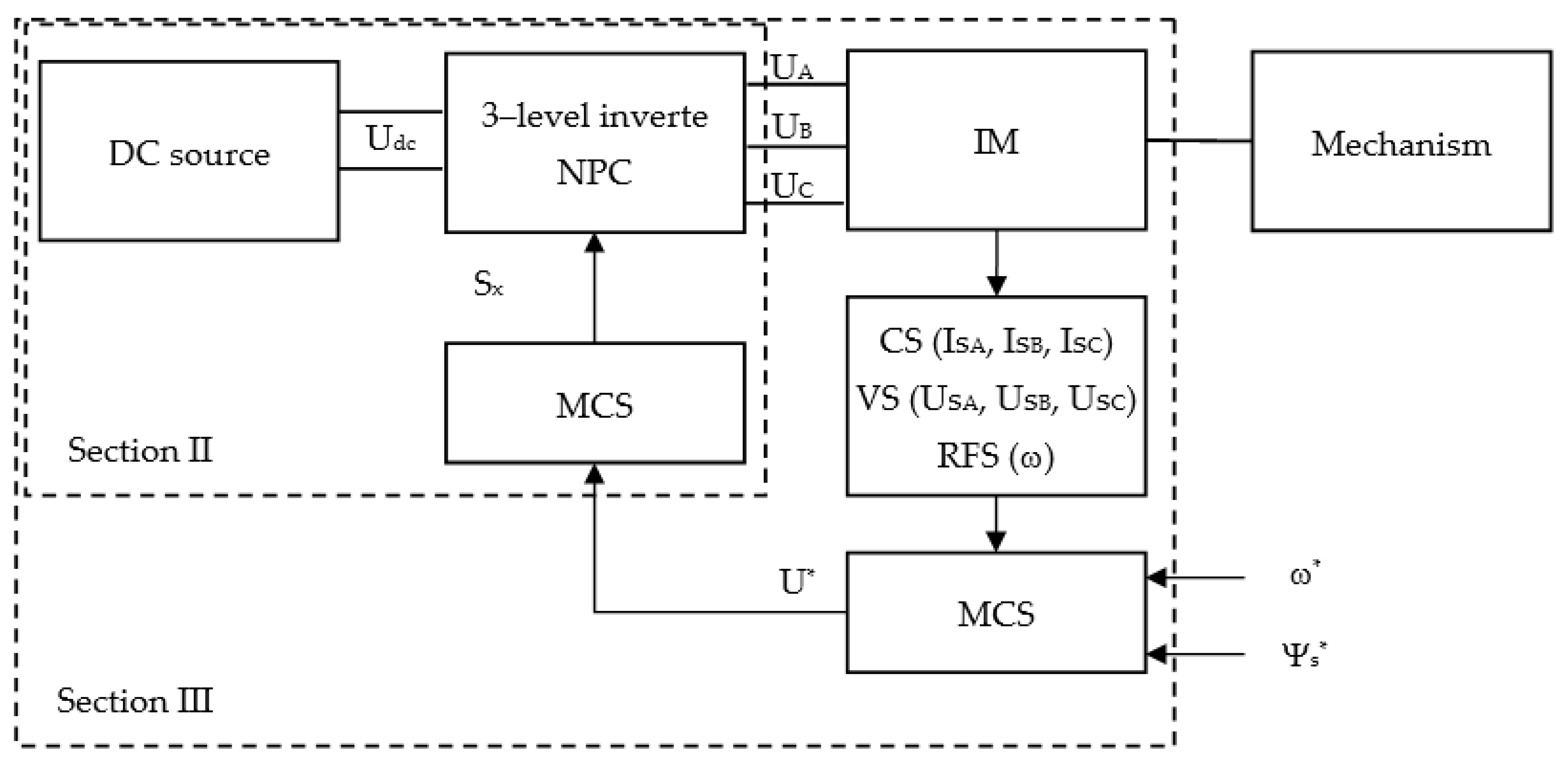

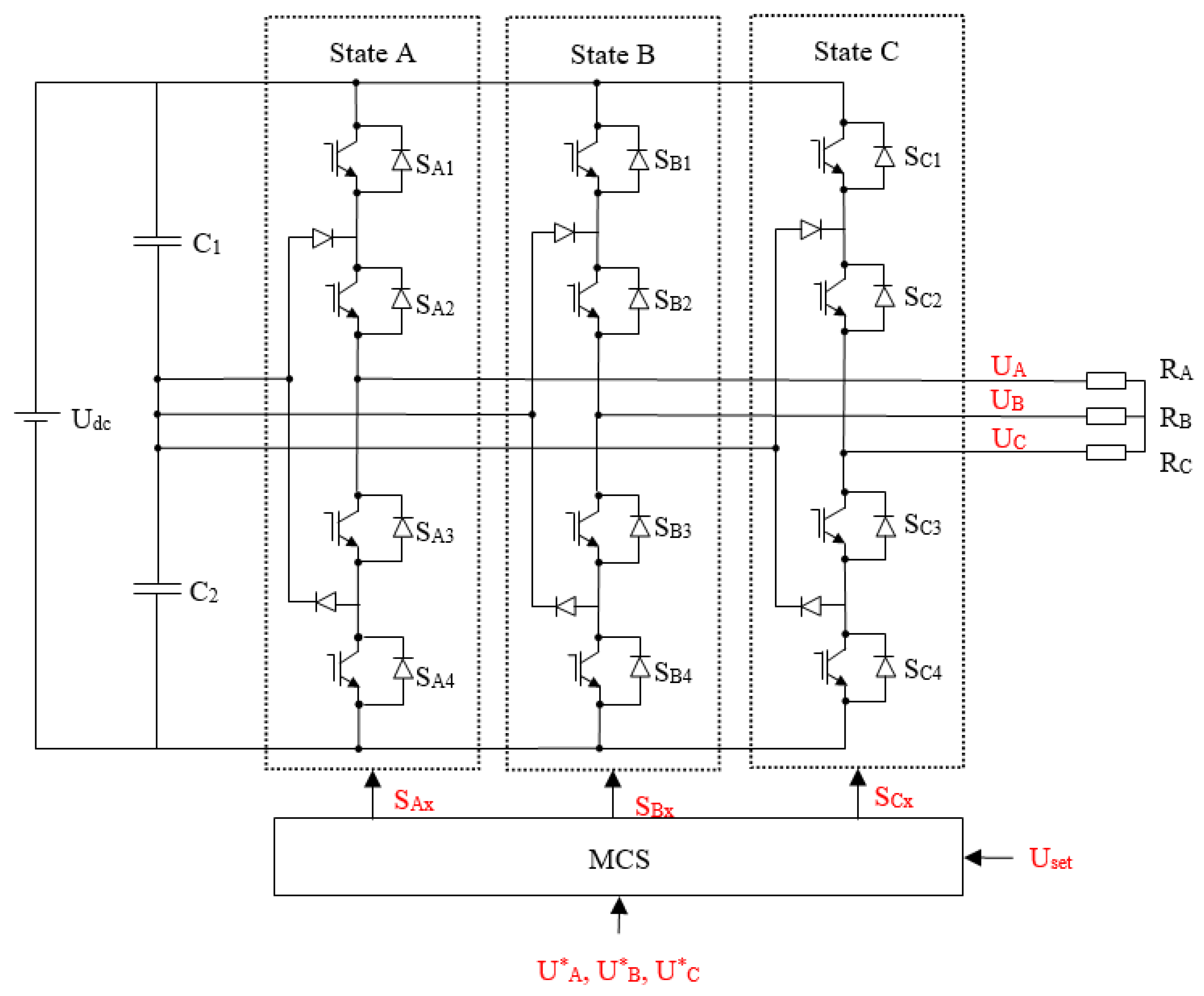

Based on the analysis of literature on the structure and control algorithms of asynchronous electric drives, a structural diagram of an automated asynchronous drive based on a three-level NPC inverter is proposed, as depicted in

Figure 1 [

30,

31,

32]. This system consists of a direct current source (battery), a three-level autonomous NPC inverter, a drive motor (IM), voltage sensors (VS), current sensors (CS), rotational frequency sensors (RFS), a motor control system (MCS), which, depending on the motor’s state and the required stator flux (Ψ

s*) and rotational frequency (ω

*), generates a specified voltage on the three-level inverter (Ux), and a modulation control system (MСS), which, depending on the specified voltage, creates commutation functions for the inverter (Sx).

In this article, the authors evaluated a novel solution for controlling an asynchronous motor based on a three-level frequency converter with a neutral point clamped NPC, using the proposed voltage switching table. Simulation results were developed in the Matlab/Simulink environment to demonstrate the feasibility of the proposed table. The study confirmed the success of the proposed table in improving system performance. This opens up broad prospects for application in industrial systems and represents a significant contribution to the development of asynchronous motor control systems.

The article is organized as follows:

Section 2 discusses the possibility of optimizing the modulation control system of the three-level NPC inverter by studying the impact of different commutation frequencies on the operation of the automated asynchronous drive.

Section 3 discusses the possibility of modifying the direct torque control algorithm of the asynchronous motor based on the three-level NPC inverter with the proposed voltage switching table and its various tests. Simulation results using Matlab/Simulink software and conclusions are drawn in

Section 4.

2. Optimization of the Modulation Control System Based on the Three-Level Autonomous NPC Inverter

Currently, modulation control systems with constant switching frequency, such as pulse width modulation (PWM), PWM with predistortion, and SVPWM, are a common method for controlling power inverters [

33,

34,

35]. They maintain a constant switching frequency of the inverter keys for a certain period, regardless of changes in the output voltage. Despite numerous advantages, modulation control systems with constant switching frequency also have some drawbacks discussed in works, such as:

Since the switching frequency remains constant, this system may face difficulties in regulating the output voltage and current, especially during sudden load changes. This may require more complex control algorithms to maintain stable system characteristics.

Constant switching frequency can cause resonance phenomena with some elements in the system, such as filters and loads, leading to increased harmonic levels or current distortion.

High-frequency harmonics can arise in the systems, creating problems with electromagnetic compatibility and causing electromagnetic interference.

To address this issue, a pulse width modulation system with functional switching frequency modification has been introduced. The main principle of operation of this system is to control the duration of the inverter key control pulses.

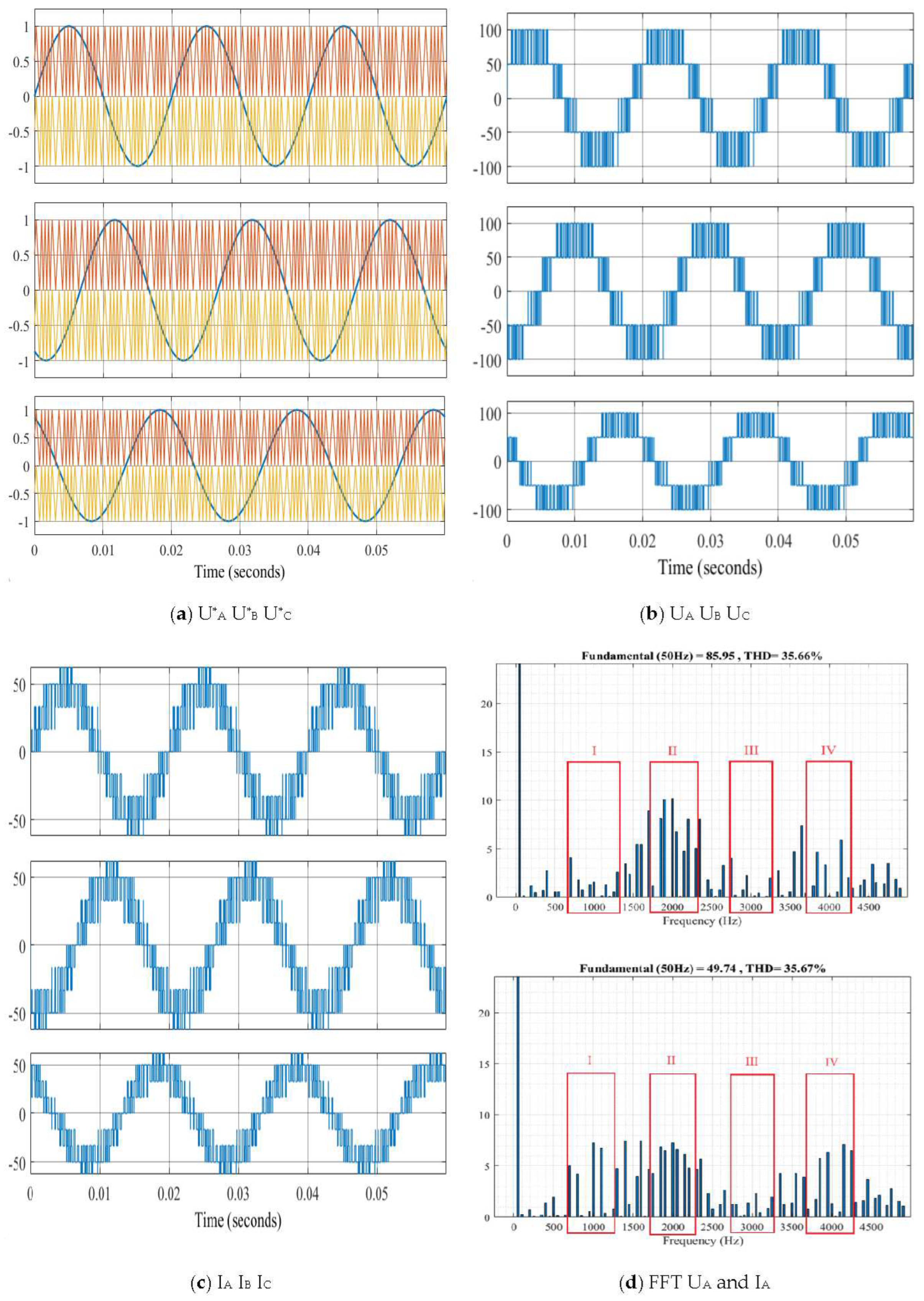

To analyze the impact of applying pulse width modulation systems with constant and functionally modified switching frequency on the stator currents, an equivalent diagram of an automated asynchronous drive based on a three-level NPC inverter was constructed (

Figure 2).

This diagram consists of an equivalent load (RA = RB = RC =1 Ω), which is connected to the three-level NPC inverter through a constant voltage source Udc = 100 V. Voltage and current waveforms were generated with different frequency settings throughout the period without the use of a choke, including:

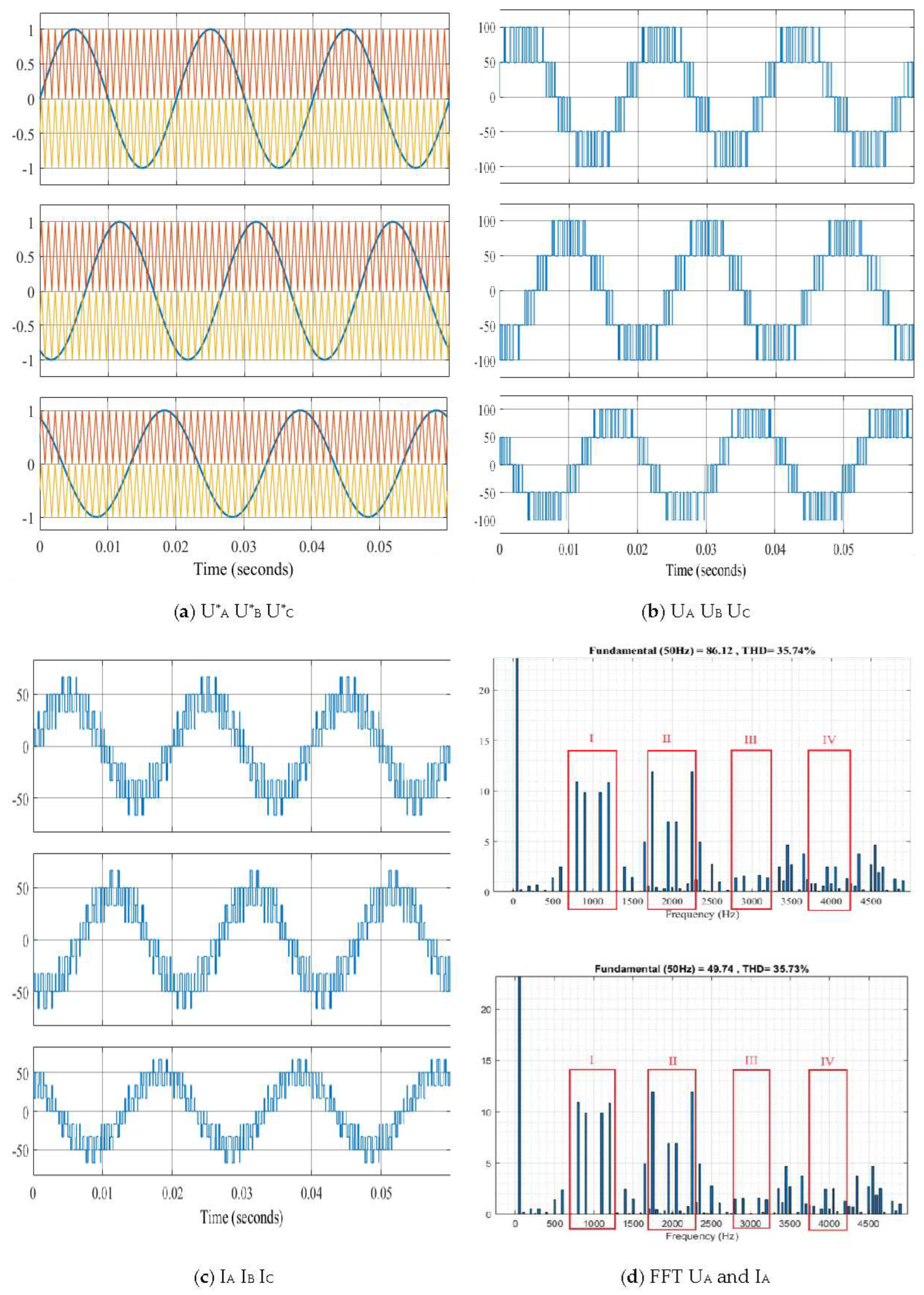

Variant 1: at a constant switching frequency f = 1000 Hz (

Figure 3);

Variant 2: at a constant switching frequency f = 2000 Hz (

Figure 4);

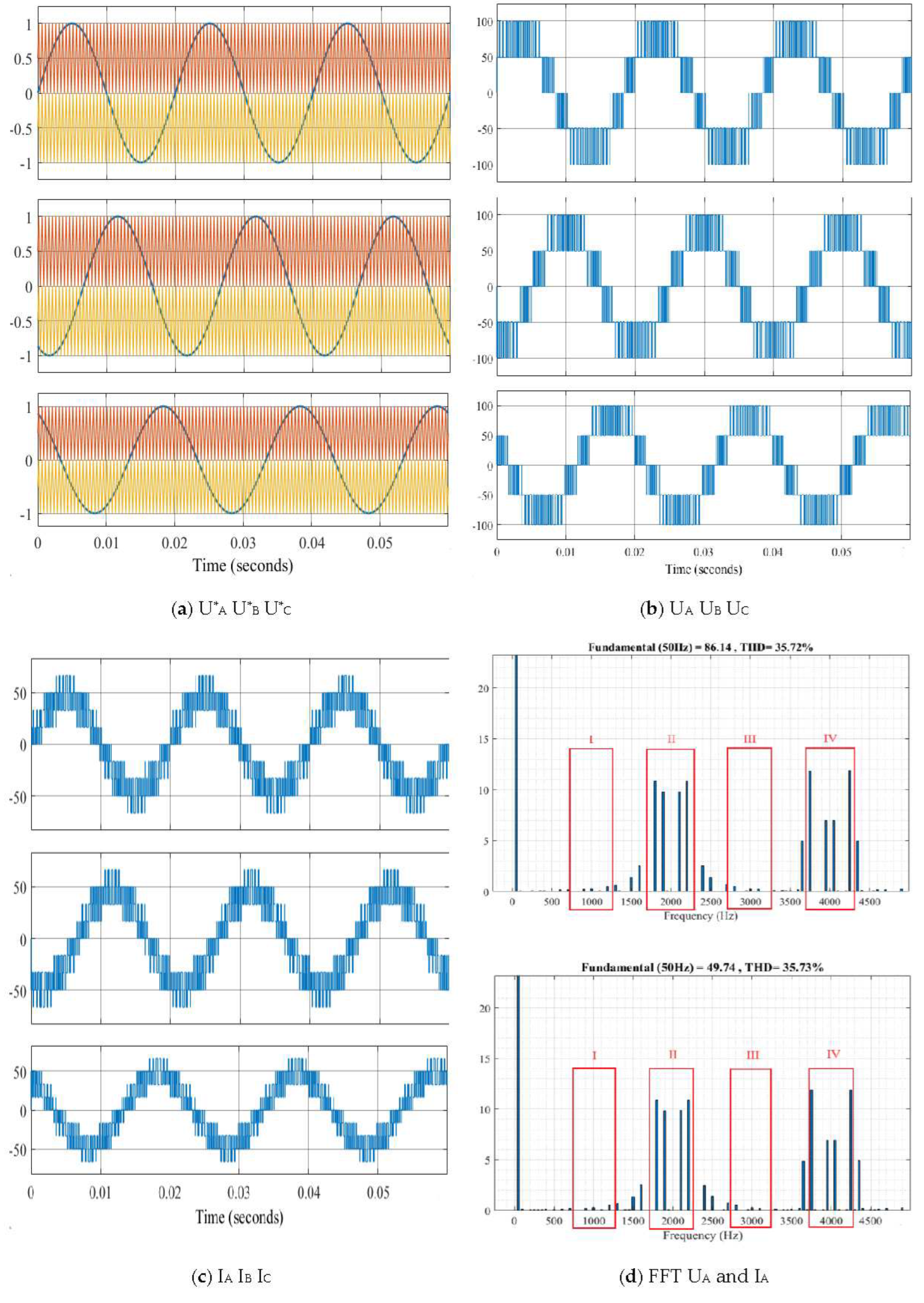

Variant 3: with a combination of switching frequencies f = 2000 and f = 1000 Hz (

Figure 5);

Variant 4: with a combination of switching frequencies f = 1000 and f = 2000 Hz (

Figure 6).

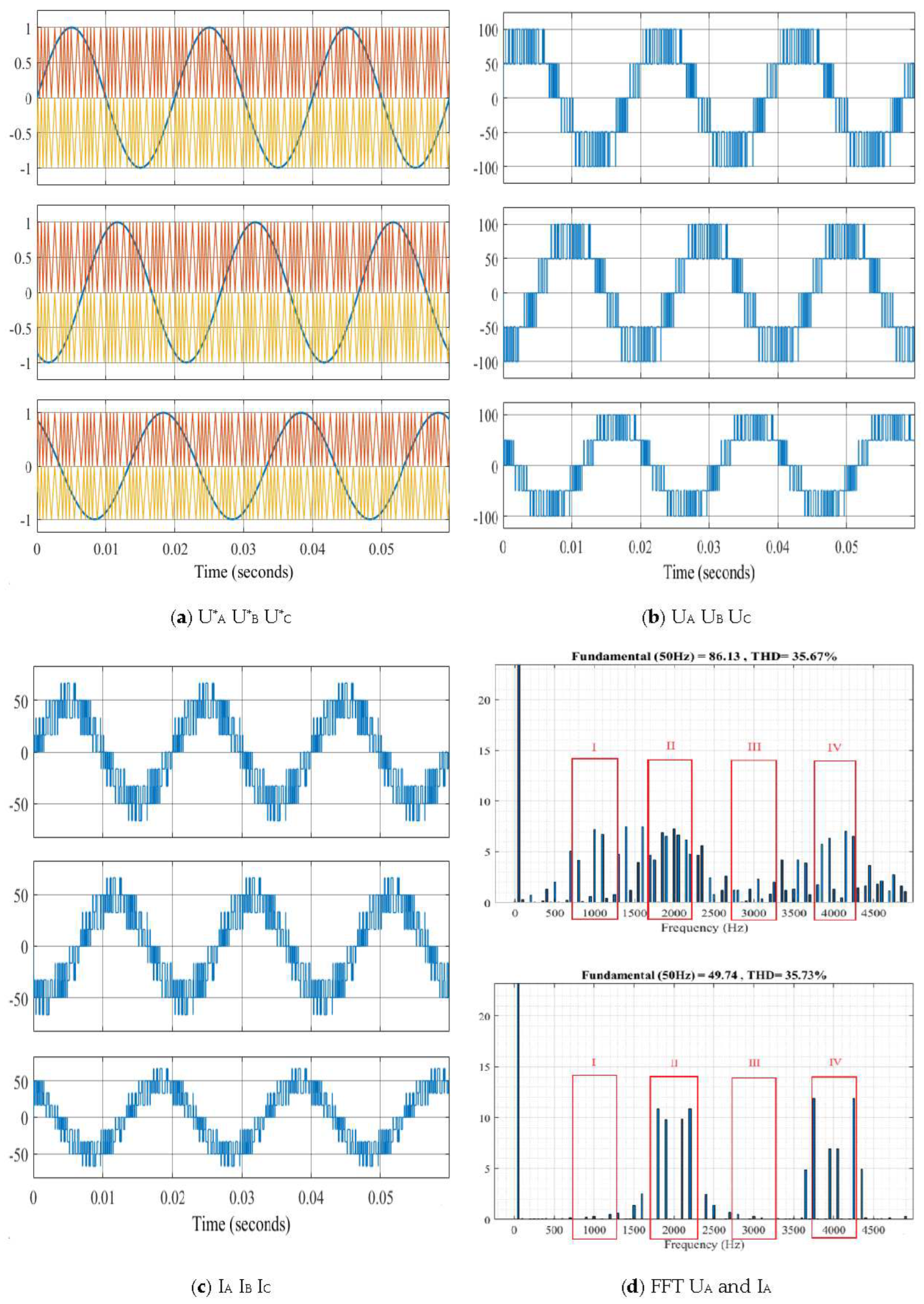

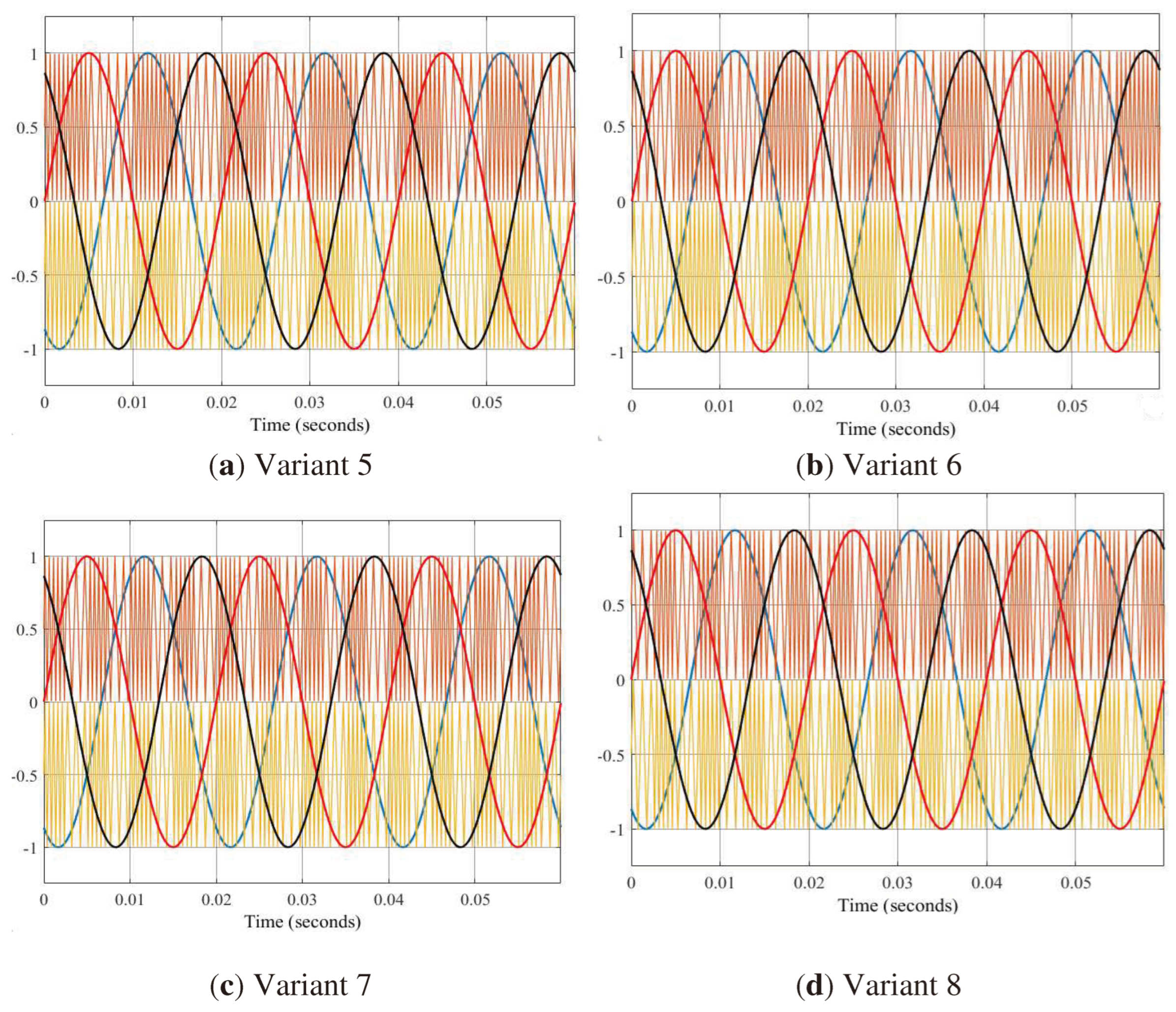

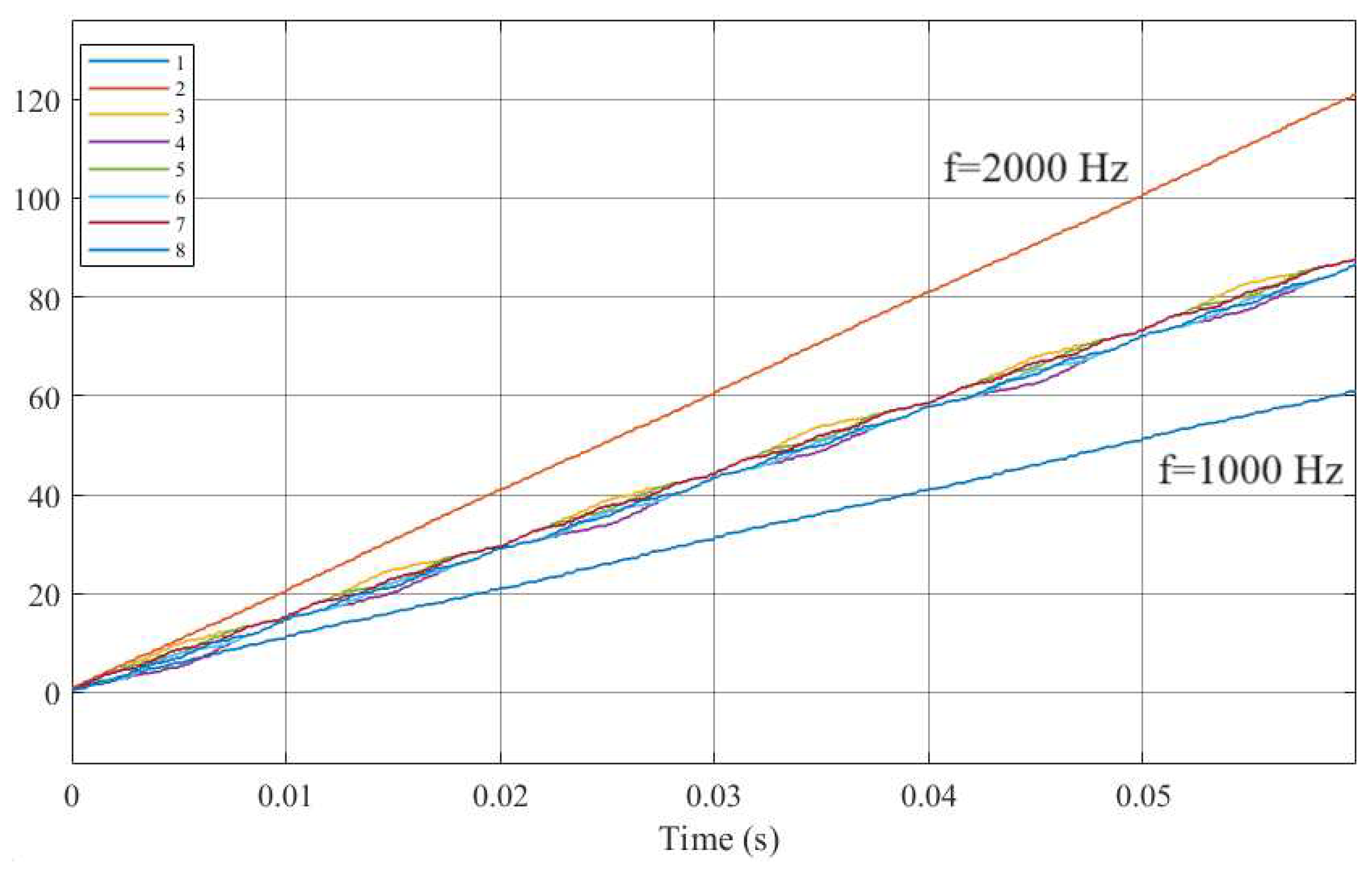

In addition to the proposed variants, the authors suggest other options for investigating random commutation frequencies, as depicted in

Figure 7. The research results are presented in

Table 1.

To investigate the impact of random commutation frequencies on the alternating current line, an inductance L=1 mH is introduced into the specified system, and research is conducted for eight different scenarios. The research results are presented in

Table 2.

The maximum amplitudes of voltage and current distortion without the L filter and with the L filter installed are presented in

Table 3 and

Table 4.

From

Table 1, the following conclusions can be drawn: the application of random commutation frequencies maintains the amplitudes of the output voltage (UA) at approximately 86.1 and the current (IA) at approximately 49.7.

From

Table 2, the following conclusions can be made: the application of inductance minimizes current distortions in the alternating current line (from approximately 35.7% to 3-4%), while reducing the current amplitude from approximately 49.7 to about 47.5.

From

Table 3 and

Table 4, the following conclusions can be drawn: the maximum amplitudes of voltage and current distortion without a choke or with a choke have low values in Zones I and II, and moderate values in Zones III and IV (Variant 5 reduces the maximum amplitudes of voltage and current distortion by almost 2 times).

From

Figure 8, the following conclusion can be made: random commutation frequency has an average value in terms of the number of transistor switching’s in the inverter (approximately 80 switching’s in 0.06 seconds), which helps reduce switching losses in the transistors.

The main drawbacks when using random commutation frequency are that altered commutation frequencies can cause electromagnetic interference, requiring additional components for suppression.

In conclusion, the application of random commutation frequency has many advantages, including reducing the switching frequency of transistors and the amplitudes of voltage and current distortion, with or without a choke. Currently, random commutation frequency is being researched and implemented in direct torque control systems.

3. Modification of the direct control system based on the three-level autonomous NPC inverter

Limitations when studying the three-level autonomous NPC inverter in the scheme of connecting an asynchronous motor to a constant voltage source without a motor choke:

At any given time during the inverter operation, a set of two switches is turned on.

The formation of output voltages should follow a periodic law.

Pairs in one column should be in an anti-phase.

The inverter state changes through the switching of a pair of switches.

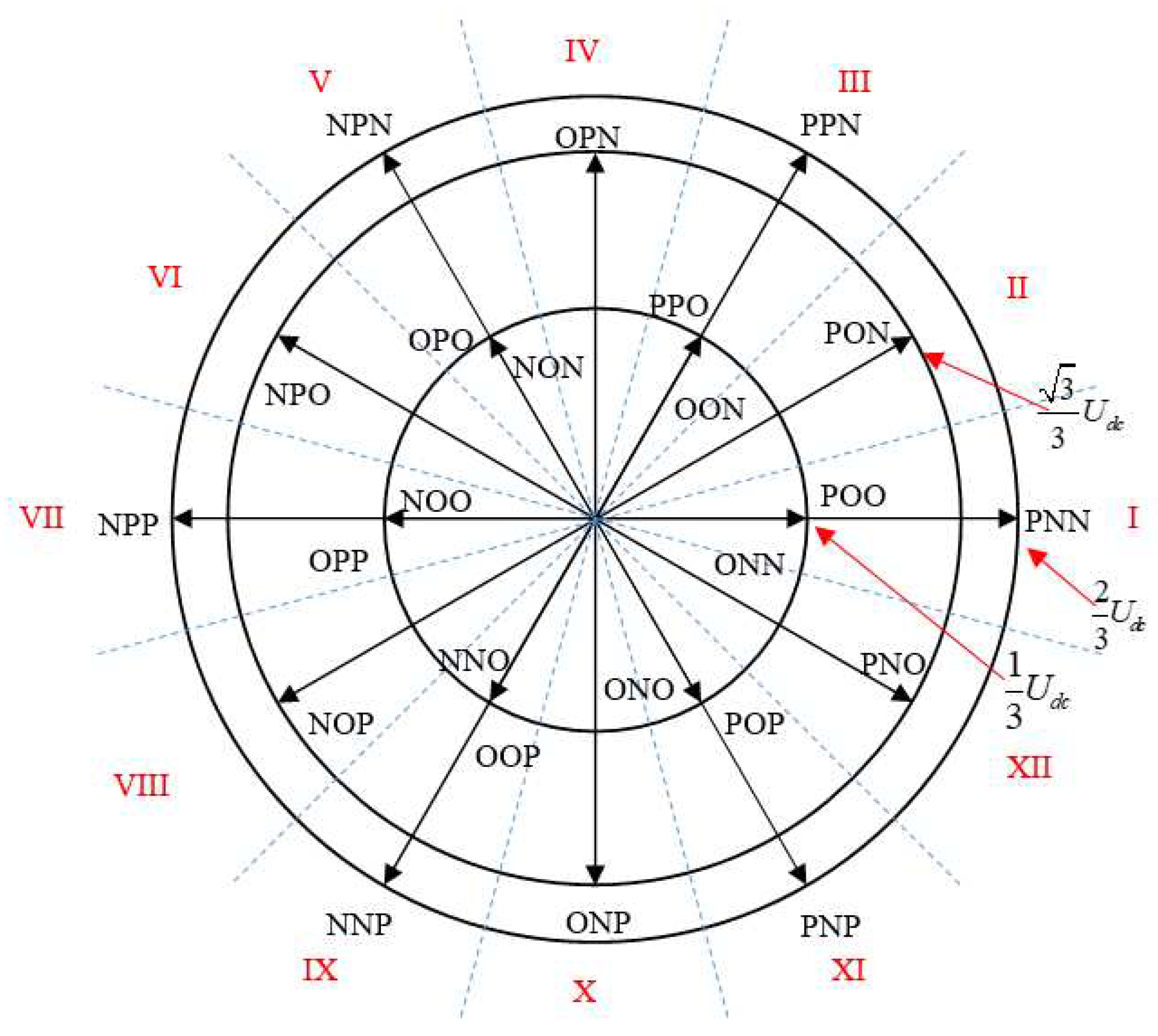

From

Table 5, it can be concluded that the voltage vectors of the three-level inverter include four main groups:

Zero vectors: V0 000 V7 PPP V26 NNN

Short vectors: V1 POO, V8 ONN, V2 PPO, V9 OON, V3 OPO, V10 NON, V4 OPP, V11 NOO, V5 OOP, V12 NNO, V6 POP, V13 ONO.

Long vectors: V14 PNN, V17 NPP, V15 PPN, V18 NNP, V16 NPN, V19 PNP.

Medium vectors: V20 PON, V23 NOP, V21 OPN, V24 ONP, V22 NPO, V25 PNO.

The distribution of these vectors is clearly presented in

Figure 11. The estimated values of the torque and stator flux are compared with their corresponding required values. The results of this comparison serve as input data for creating the control law.

The space of voltage vectors of the three-level NPC inverter is divided into 12 sectors (

Figure 8), each comprising 30°. To implement direct torque control for a motor connected to a three-level NPC inverter, an optimized commutation table needs to be developed, taking into account the inverter’s state capabilities.

The construction of the table depends on the choice of the applied voltage vector to increase or decrease the value of the electromagnetic torque and stator flux. For a three-level inverter, it is necessary to consider the change in the torque when designing the control table, which is determined by the formula:

where:

– constants value;

Ψs и Ψr – stator and rotor flux;

θ – angle between the stator and rotor flux.

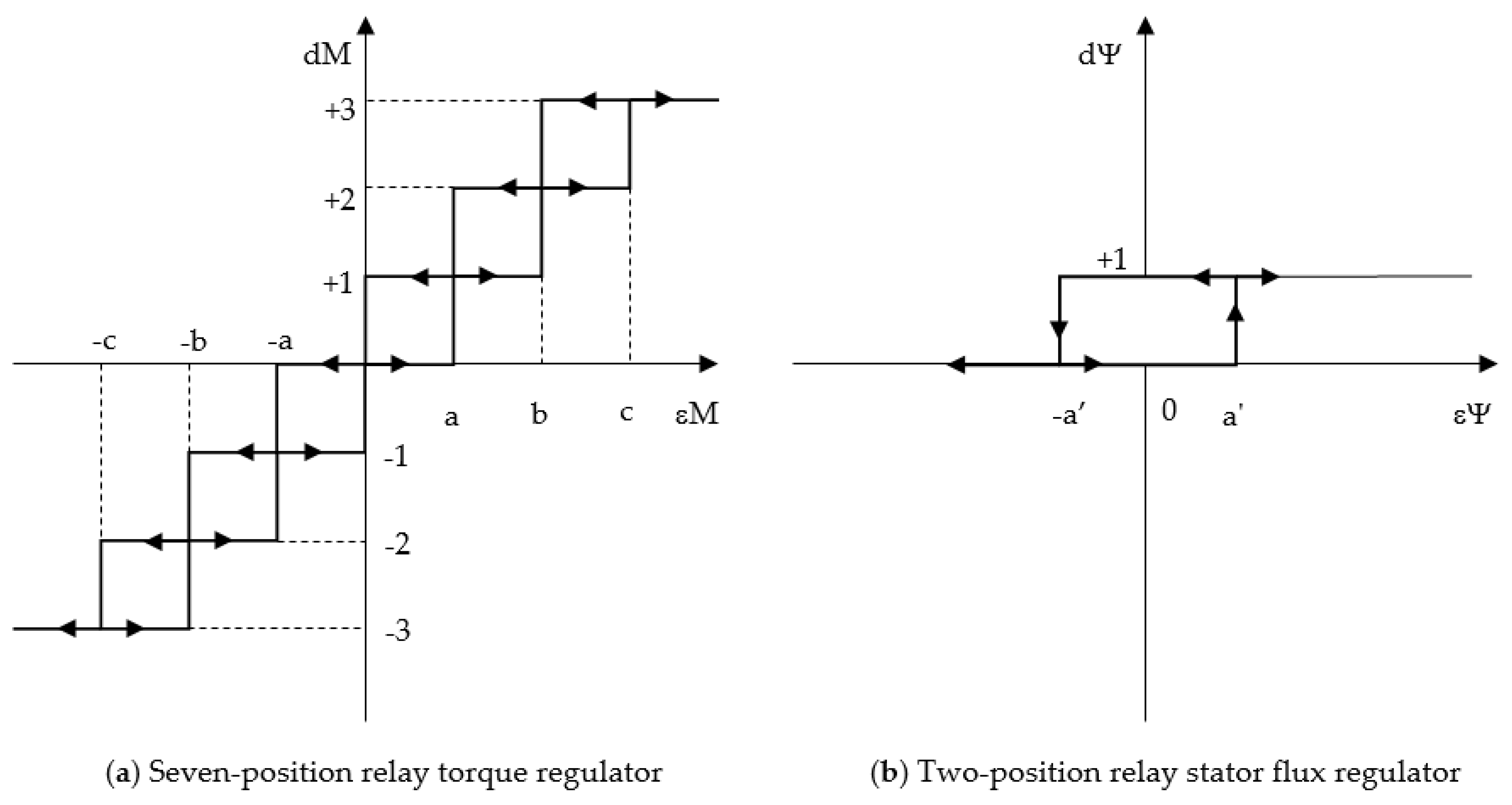

In Direct Torque Control (DTC) with a two-level inverter, a three-position relay controller checks the torque state (±1, 0), and for the stator flux linkage, a two-position relay controller is applied (1,0). Usually, it is recommended to use the highest error state values (positive or negative) for large voltage vectors to achieve rapid changes in torque. The smallest values (positive or negative) are recommended for small voltage vectors to achieve slow changes in torque.

From the formula above, it can be seen that the rate of change of torque depends on the choice of the voltage vector to change the stator flux linkage and the angle between the stator and rotor flux linkages. To account for the fact that the stator and rotor flux linkages of an asynchronous motor should remain at a nominal level, the impact of the voltage vector on the change in torque should be evaluated based on the influence of the voltage vector on the angle between the stator and rotor flux linkages.

When considering that the stator flux linkage vector tends to approach the voltage vector, two positions can be highlighted:

If the voltage vector leads to an increase in the angle between the stator and rotor flux linkage vector (1 > sin(θ) > 0), shifting the stator and rotor flux linkage vectors, this vector leads to an increase in torque. The rate of increase depends on the voltage vector’s value and the angle between the stator and rotor flux linkages.

If the voltage vector leads to a decrease in the angle between the stator and rotor flux linkage vector (0 > sin(θ) > -1), bringing the stator and rotor flux linkage vectors closer, this vector leads to a decrease in torque. The rate of increase depends on the voltage vector’s value and the angle between the stator and rotor flux linkages.

Figure 9.

Voltage vector space of three-level NPC inverter.

Figure 9.

Voltage vector space of three-level NPC inverter.

Considering the case where the rotor flux linkage vector is in sector I at time t, based on the torque formula,

Figure 8, and the presented theory, a relationship can be established between these vectors:

Vectors U15, U20, U02/U09, U16, U21, U03/U10 lead to an increase in torque. Specifically, U15 and U16 have strong effects, while U02/U09 and U03/U10 have weak effects.

Vectors U19, U25, U06/U13, U18, U24, U05/U12 lead to a decrease in torque. Specifically, U19 and U18 have strong effects, while U06/U13 and U05/U12 have weak effects.

Vectors U15, U20, U02/U09, U06/U13, U25, U19 lead to an increase in stator flux linkage torque.

Vectors U16, U21, U03/U10, U05/U12, U24, U18 lead to a decrease in stator flux linkage torque.

In the case where the rotor flux linkage vector is in sector II at time t+Δt, based on the torque formula,

Figure 8, and the presented theory, a relationship can be established between these vectors:

Vectors U21, U15, U02/U09, U16, U22, U03/U10 lead to an increase in torque. Specifically, U15 and U16 have strong effects, while U02/U09 and U03/U10 have weak effects.

Vectors U14, U25, U06/U13, U19, U24, U05/U12 lead to a decrease in torque. Specifically, U19 and U18 have strong effects, while U06/U13 and U05/U12 have weak effects.

Vectors U15, U21, U02/U09, U06/U13, U25, U14 lead to an increase in stator flux linkage torque.

Vectors U16, U22, U03/U10, U05/U12, U24, U19 lead to a decrease in stator flux linkage torque.

The odd sectors repeat the law of sector I, and the even sectors repeat the law of sector II. The research results are presented in voltage switching table (

Table 6).

From this table, it can be concluded that there are four options for applying short vectors:

Using only six vectors: U1–6 (Variant 1).

Using only six vectors: U8–13 (Variant 2).

Using six vectors: U1–6 to increase torque and U8–13 to decrease torque (Variant 3).

Using six vectors: U1–6 to decrease torque and U8–13 to increase torque (Variant 4).

The effectiveness of the proposed direct torque control table for the asynchronous motor was evaluated through numerical simulation using the Matlab/Simulink environment.

Using the following equations as the variable calculator algorithm for the direct control system of the asynchronous motor:

Using the following equations as the algorithm for the direct control system controller block:

Simulation models of asynchronous drives are constructed in Matlab/Simulink based on

Figure 1,

Figure 10 and

Figure 11 and

Table 6. The simulation results are presented in Figures 12–15.

Figure 10.

Structural diagram of the direct control system based on a three-level inverter and PI controllers.

Figure 10.

Structural diagram of the direct control system based on a three-level inverter and PI controllers.

Figure 11.

Static characteristic of the relay regulator.

Figure 11.

Static characteristic of the relay regulator.

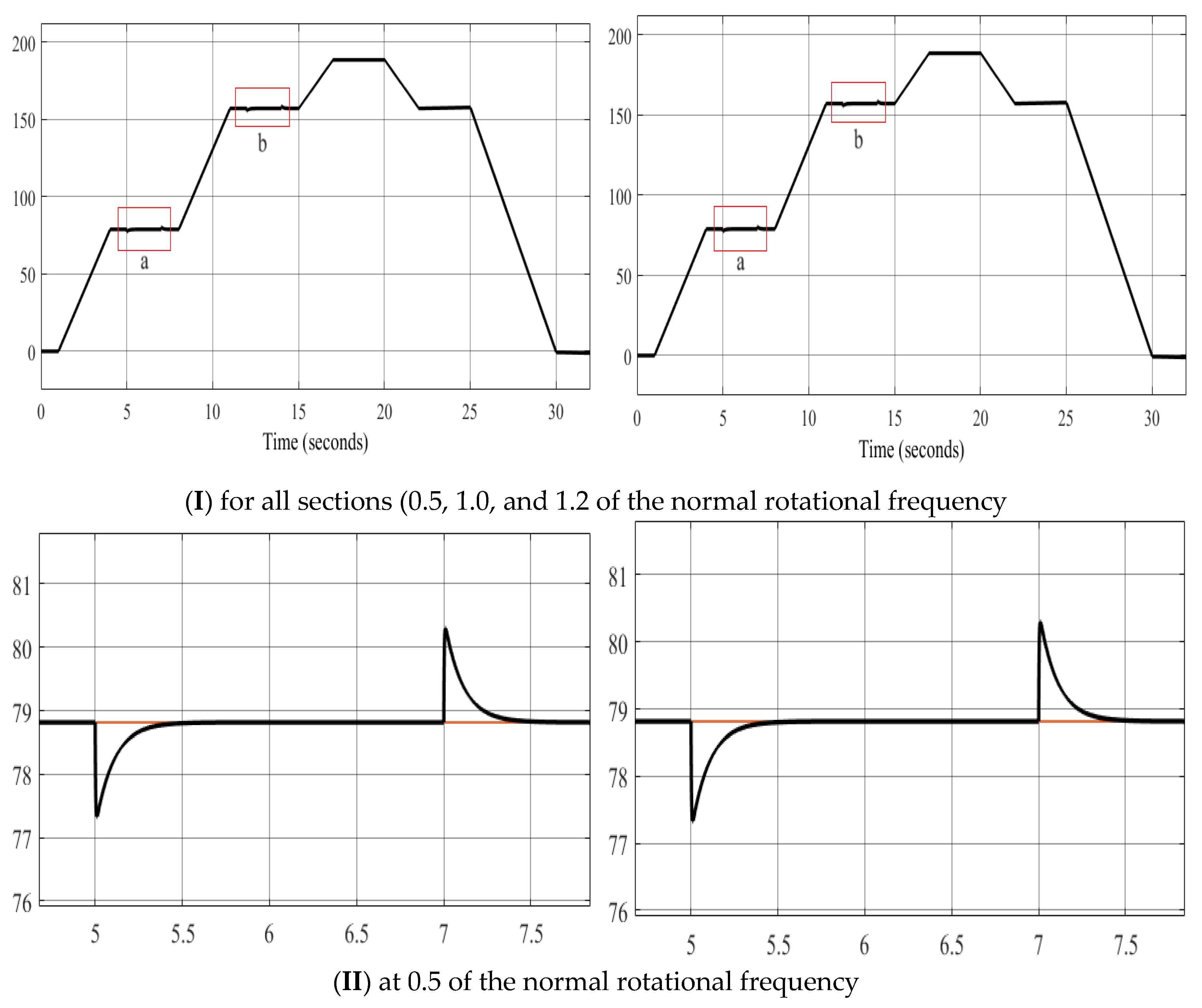

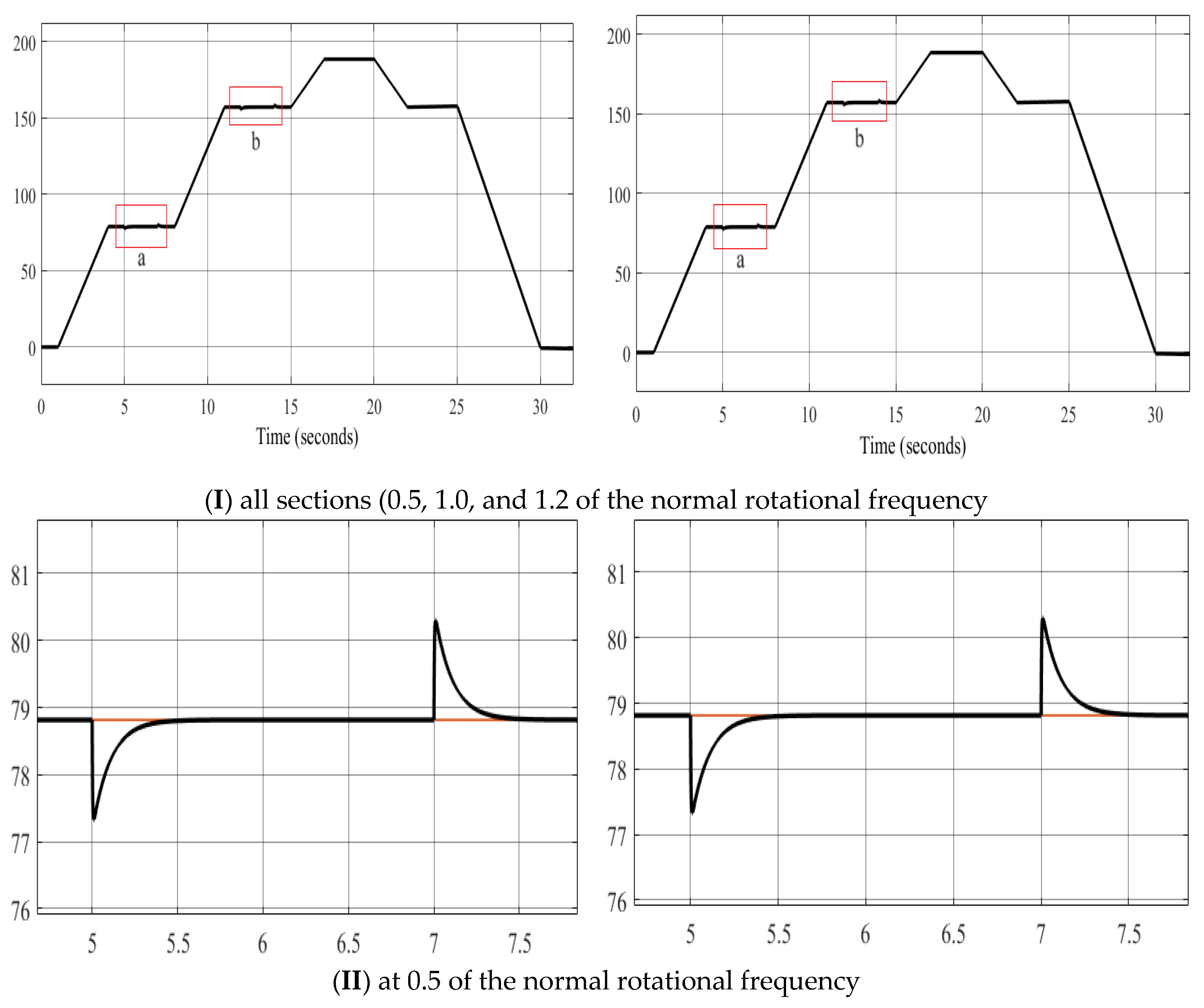

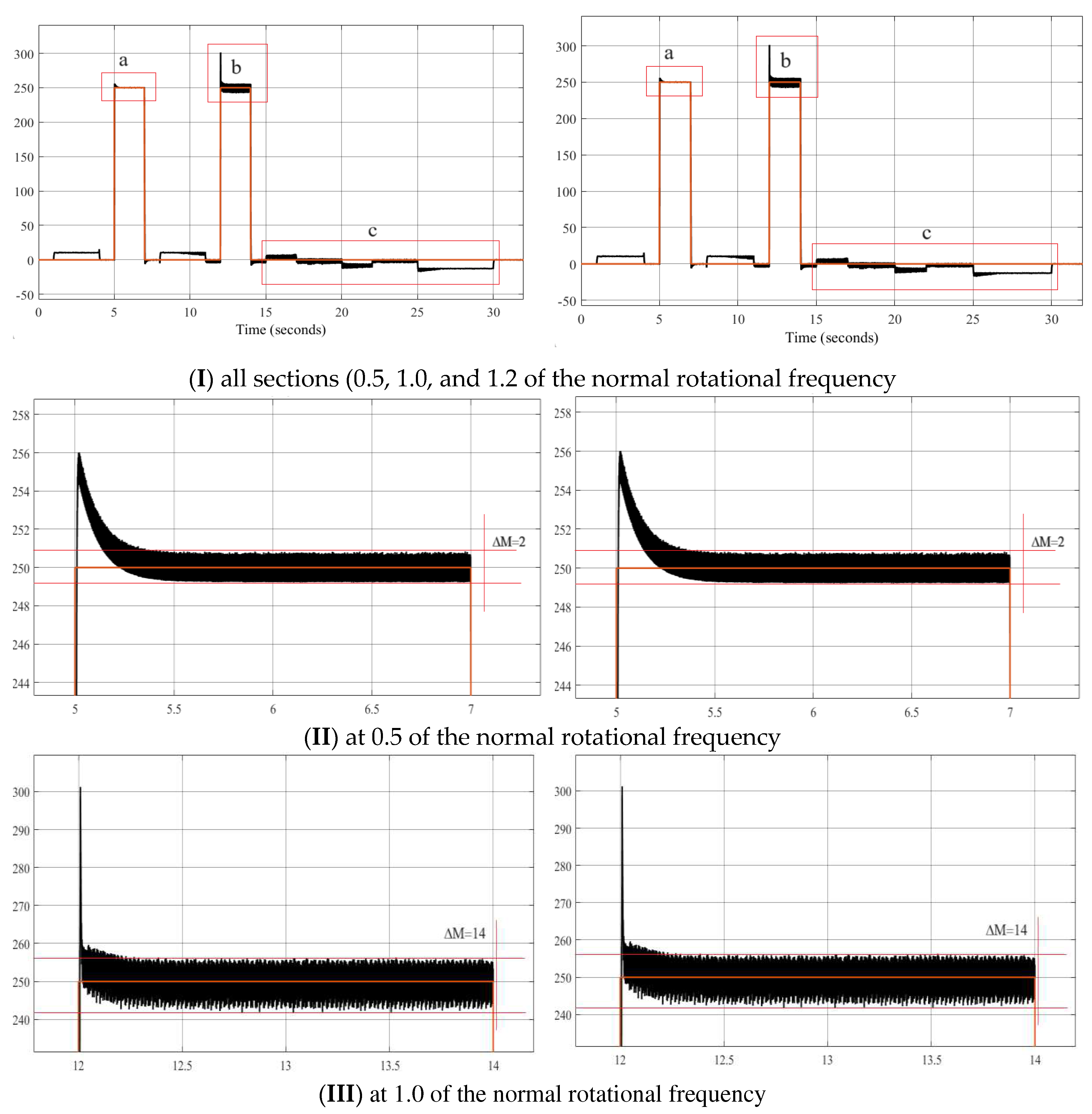

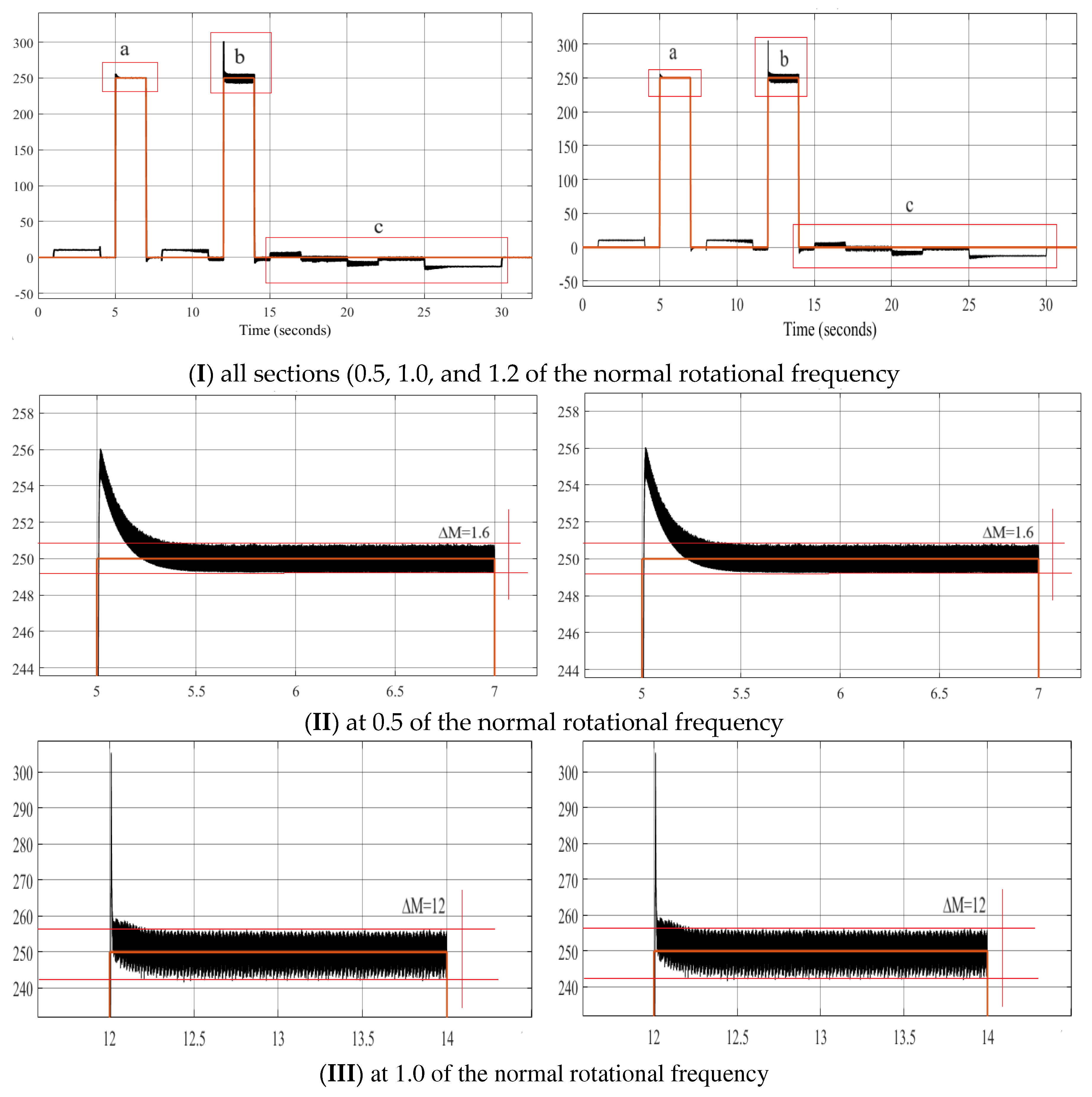

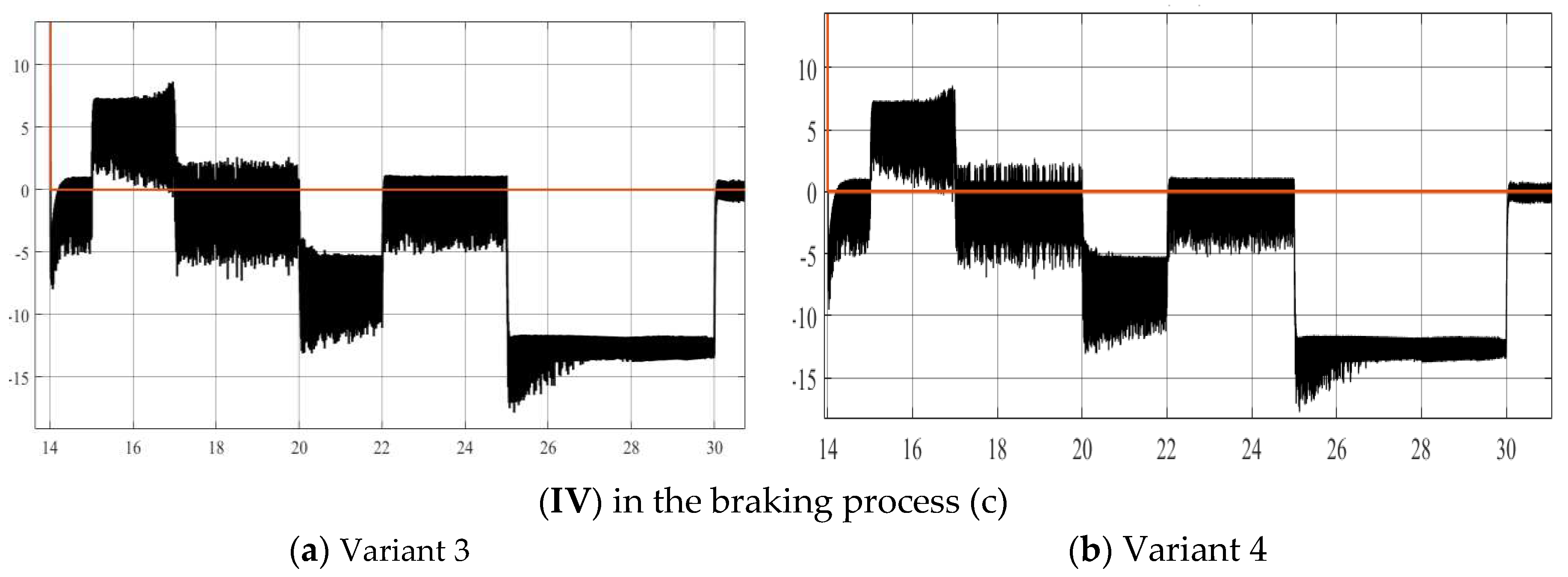

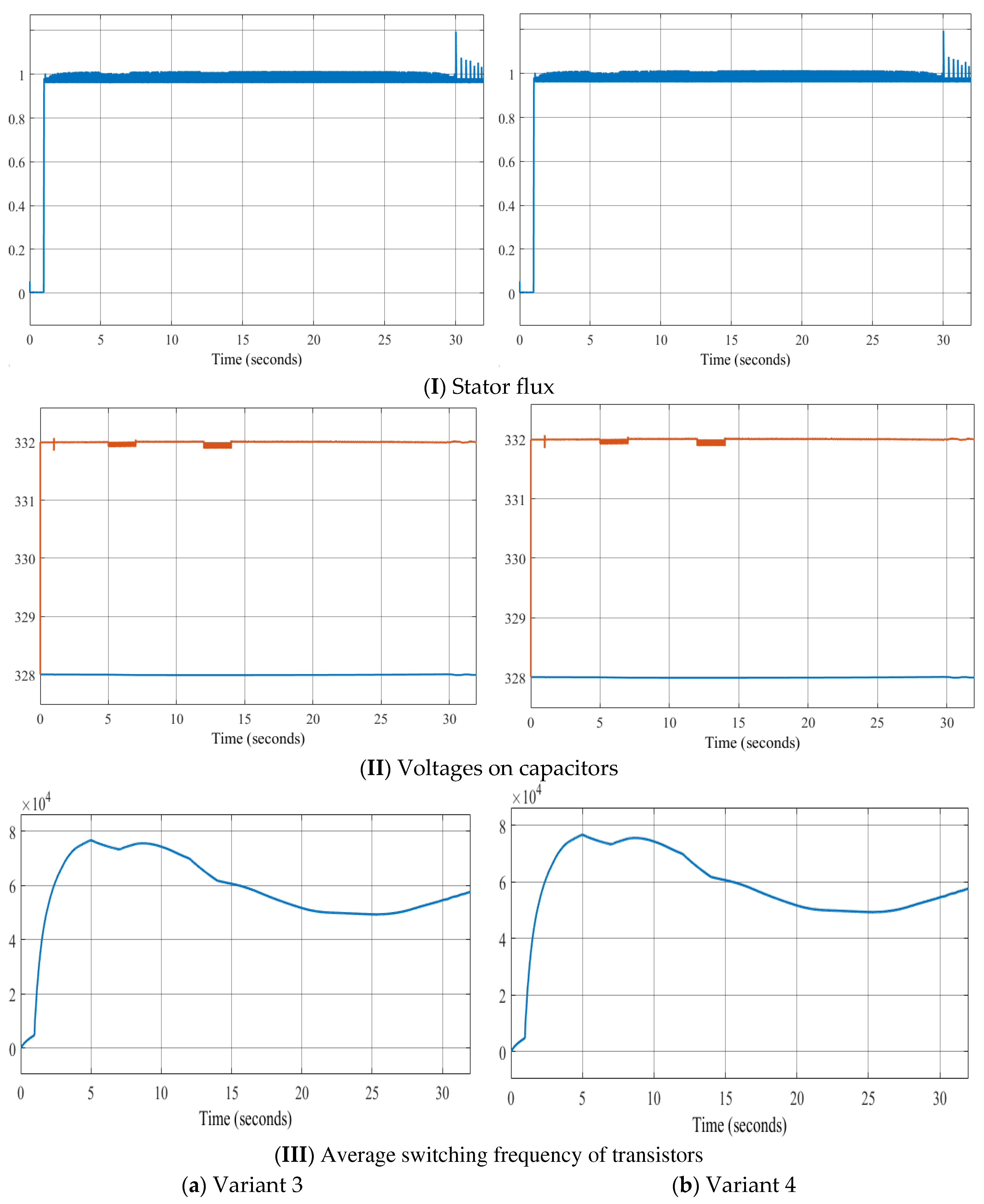

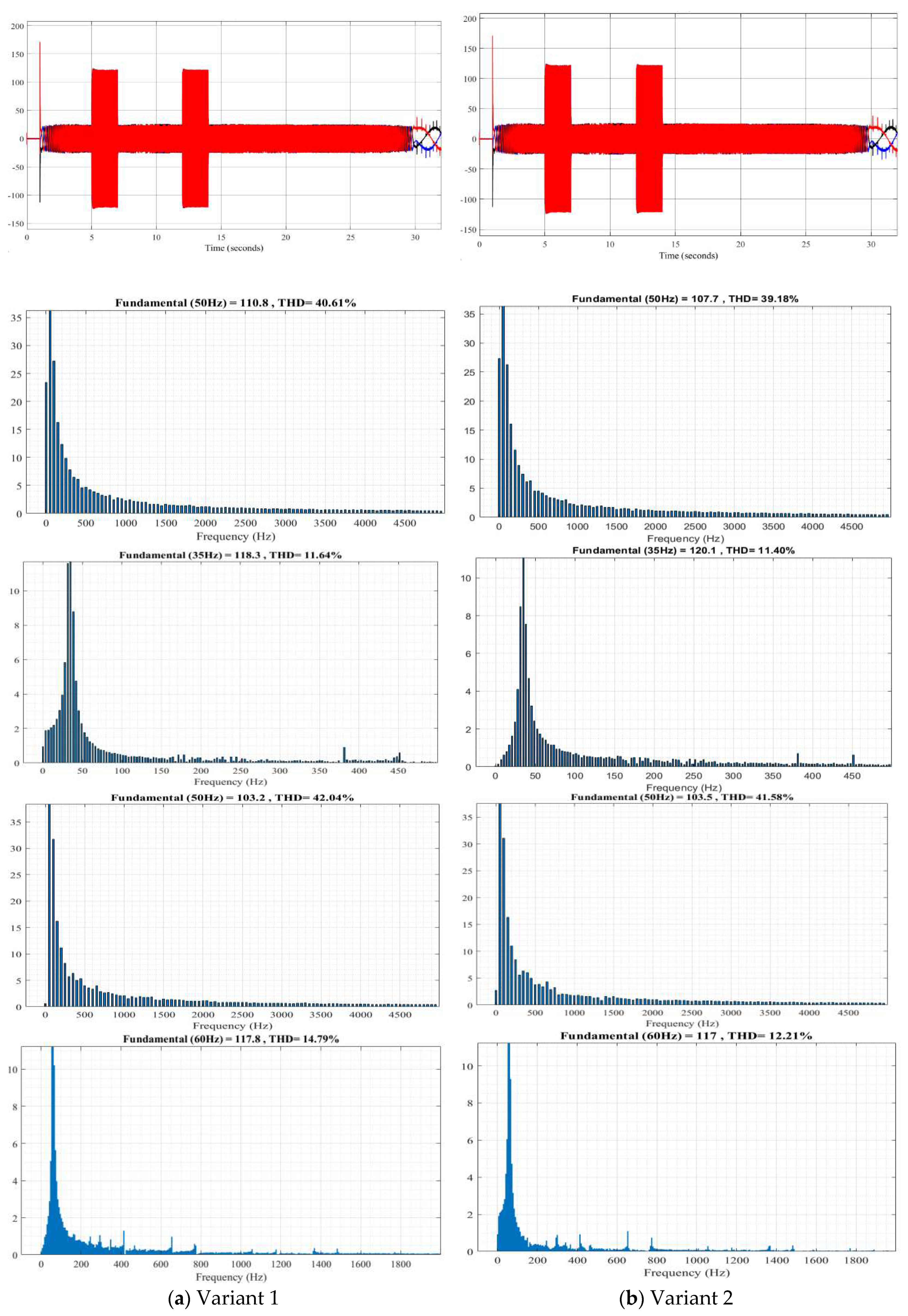

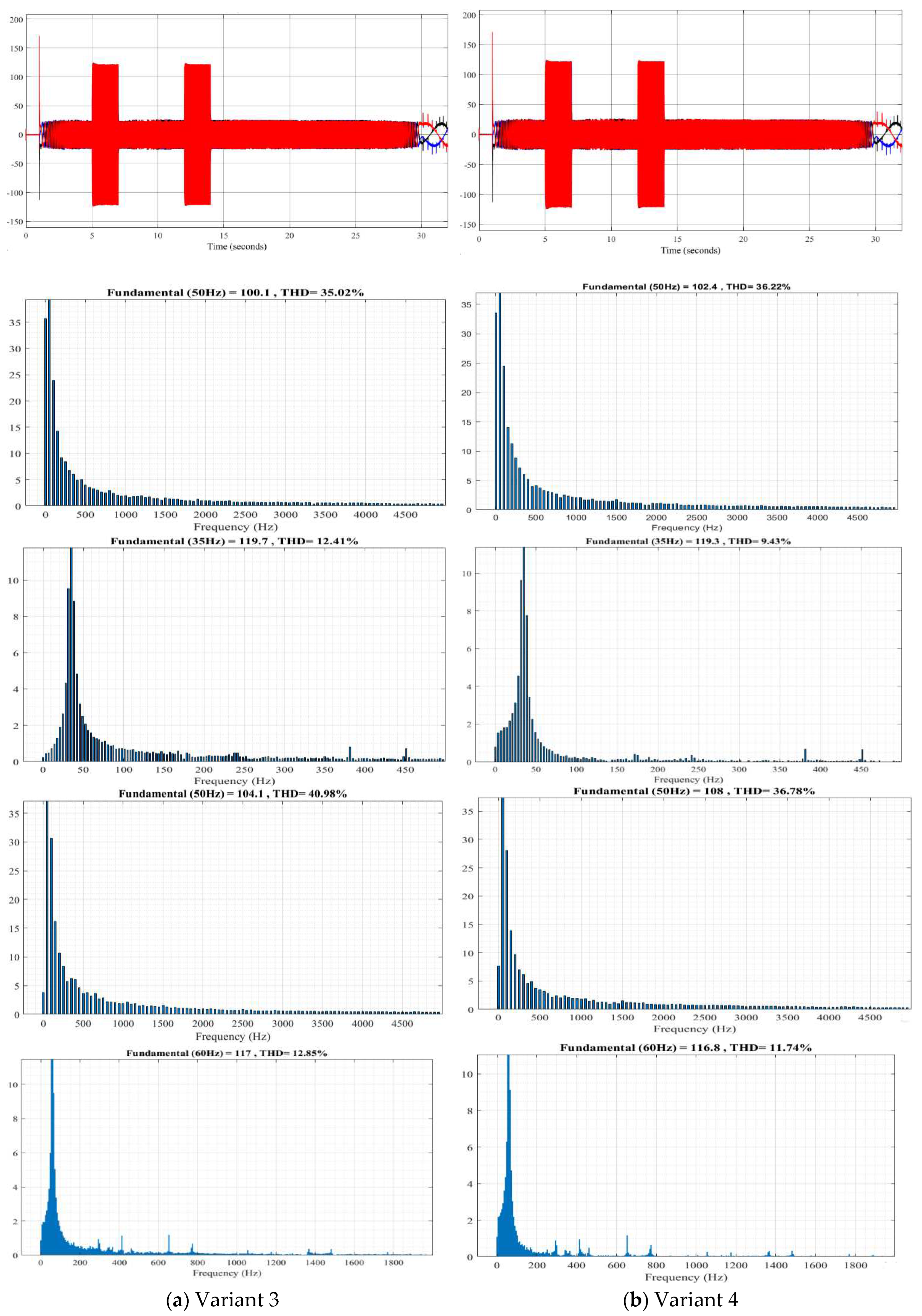

Performing oscillography of the following variables: rotation speed; stator flux linkage, electric torque; voltage on the capacitors, average switching frequency of transistors, stator currents and its distortion coefficient for various options.

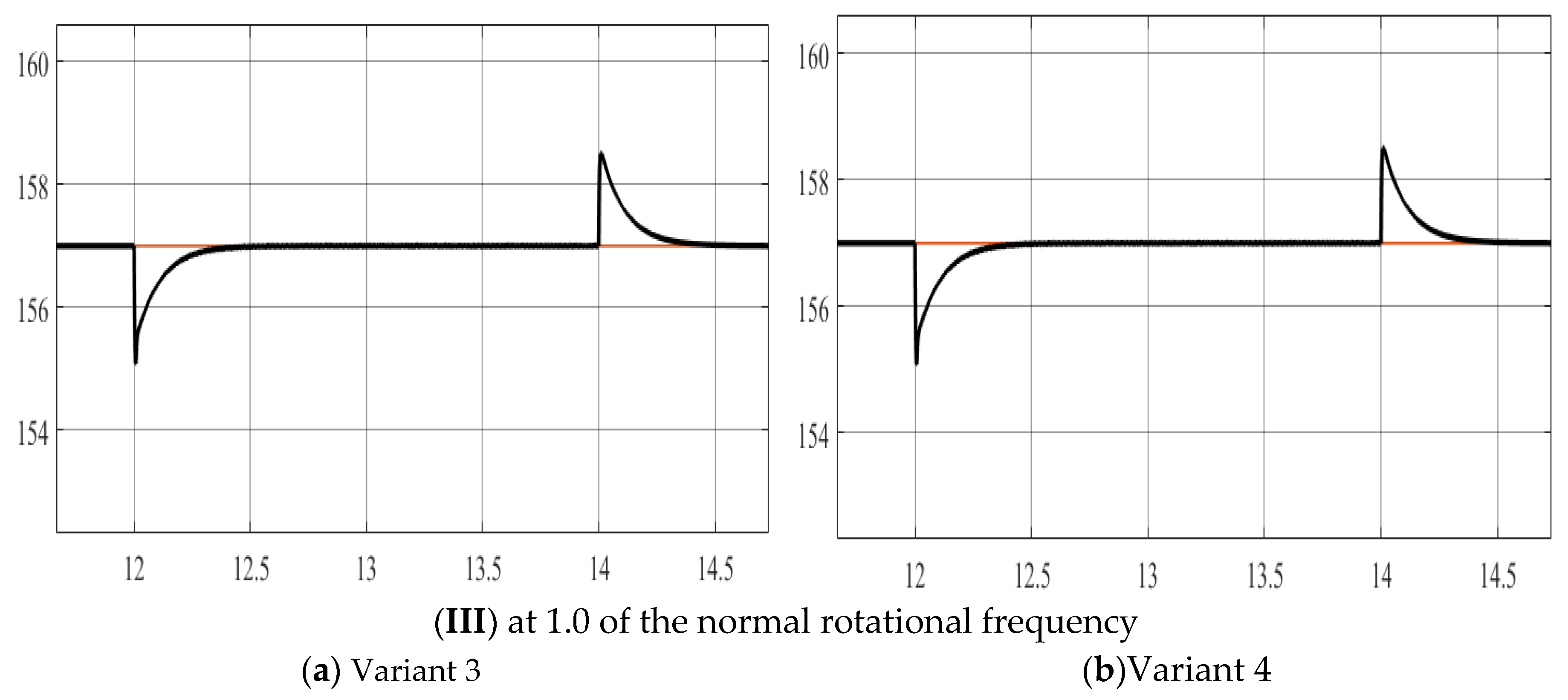

Figure 12a.

Rotational frequency.

Figure 12a.

Rotational frequency.

Figure 12b.

Rotational frequency.

Figure 12b.

Rotational frequency.

Figure 13a.

Electrical torque.

Figure 13a.

Electrical torque.

Figure 13b.

Electrical torque.

Figure 13b.

Electrical torque.

Figure 14a.

Research results for Variant 1–2.

Figure 14a.

Research results for Variant 1–2.

Figure 14b.

Research results for Variant 3–4.

Figure 14b.

Research results for Variant 3–4.

Figure 15a.

Research results for Variant 1–2.

Figure 15a.

Research results for Variant 1–2.

Figure 15b.

Research results for Variant 3–4.

Figure 15b.

Research results for Variant 3–4.