Submitted:

26 December 2023

Posted:

27 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Literature Review

1.1.1. Mounting Solar Panels Onto Electric Vehicles (EVs)

1.1.2. Mounting Wind Turbines

1.1.3. Piezoelectricity to Convert Mechanical Energy to Electricity

1.1.4. EV Charging

1.1.5. Green House Gas (GHG) Emissions

2. Materials and Methods

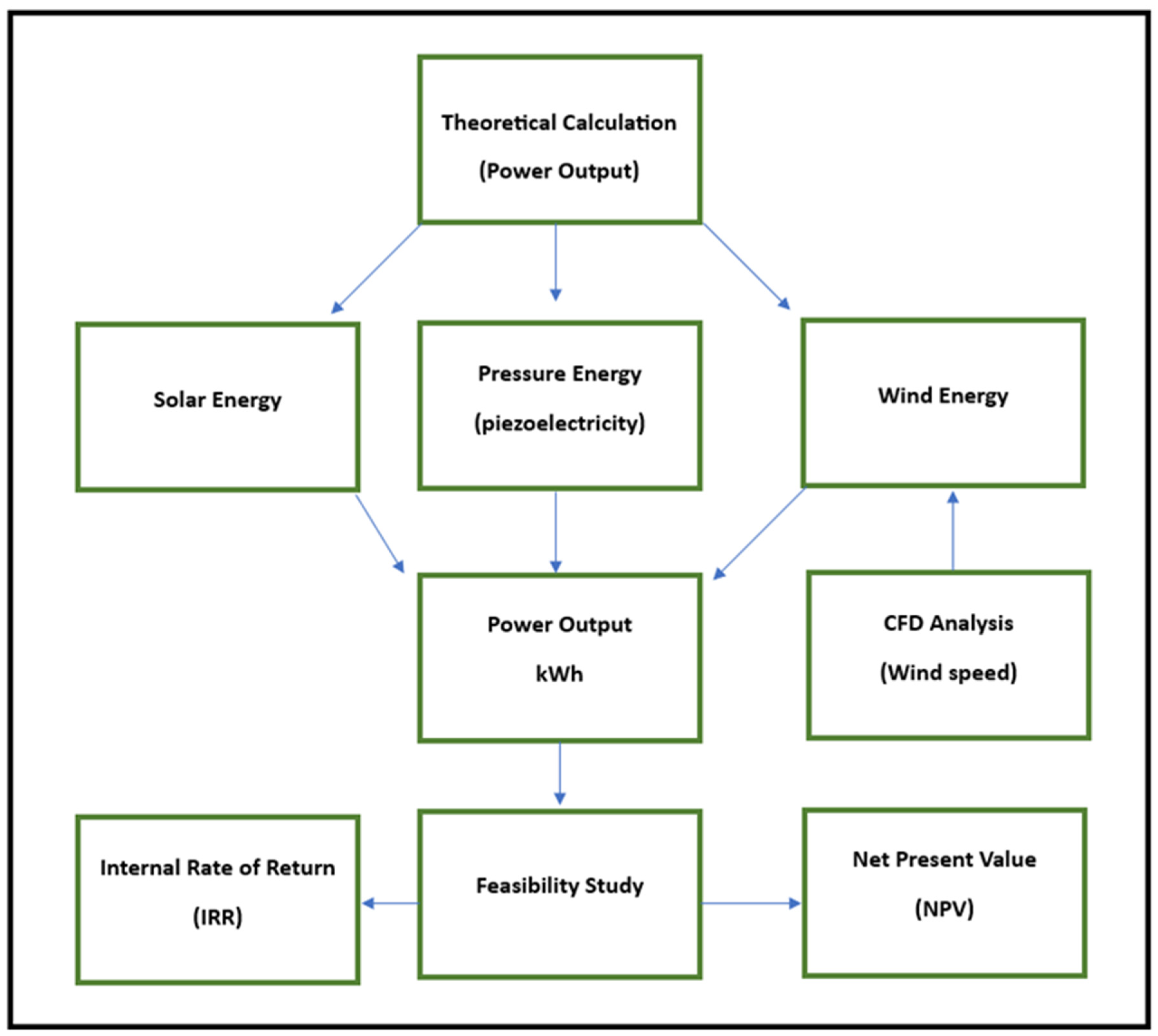

2.1. Methodology

2.2. Data Collection

2.3. Data Analysis

3. Results

3.1. Introduction

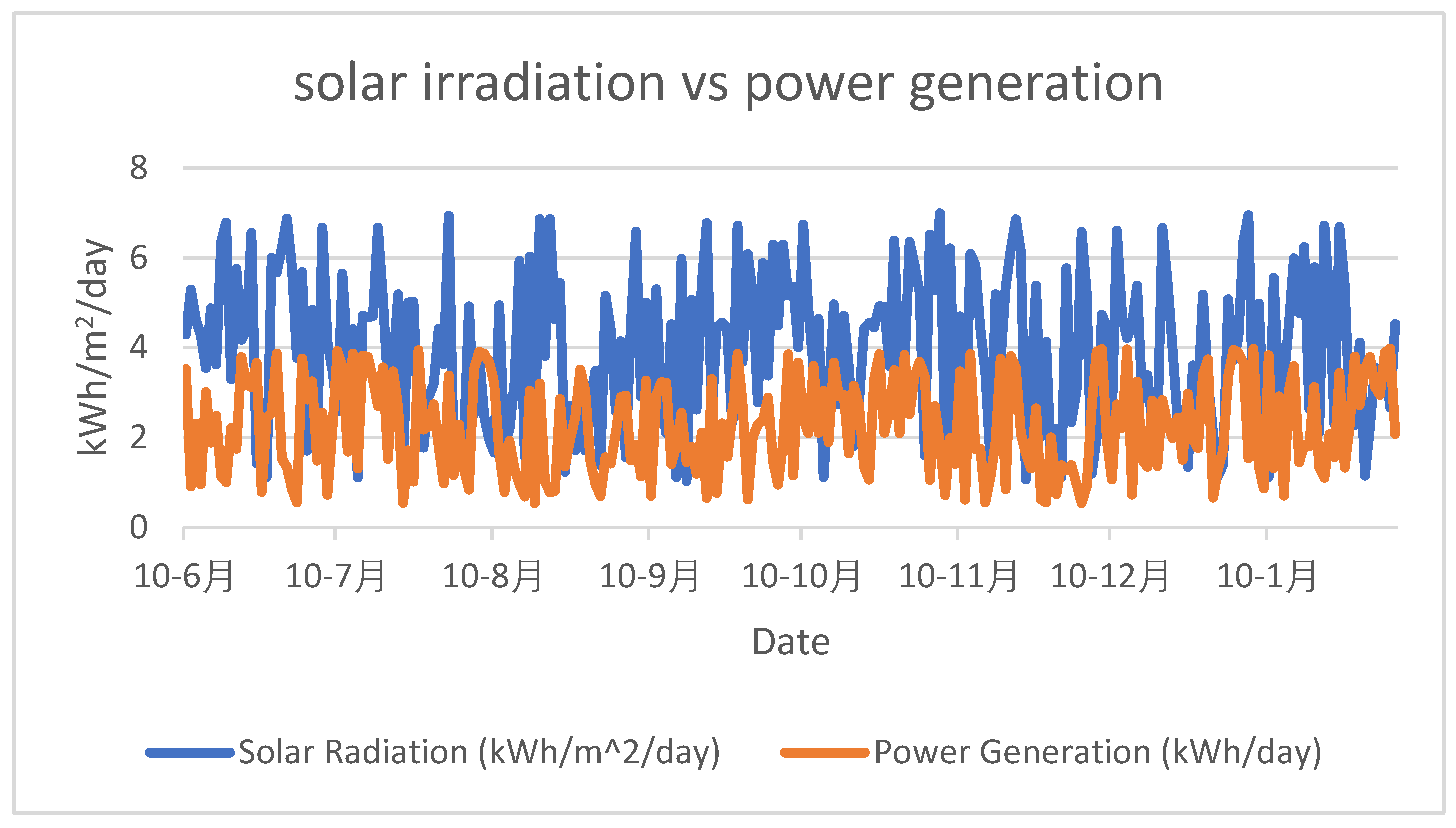

3.2. Solar Modules

- Solar Module Power Output Calculation

| User defined area | |

|---|---|

| Parameter | Value |

| Area (London) | 2013.00 km² |

| Perimeter | 183.02 km |

| Report generated | 14 July 2023, 16:16 |

| Area Info | |

| Parameters | Value (min-max range) |

| Specific photovoltaic power output | 2.80 – 2.89 kWh/kWp |

| Direct normal irradiation | 2.39 – 2.52 kWh/m² |

| Global horizontal irradiation | 2.81 – 2.90 kWh/m² |

| Diffuse horizontal irradiation | 1.57 – 1.58 kWh/m² |

| Global tilted irradiation | 3.30 – 3.41 kWh/m² |

| Optimum tilt of PV modules | 36 – 38 °C |

| Air temperature | 10.3 – 11.1 °C |

| Terrain elevation | -1 – 227 m |

- Solar Power output (kwh) = wattage ∗ peak sun hours ∗ performance ratio

- E = A ∗ r ∗ H ∗ PR

- E = Energy (kWh)

- A = Area (m²)

- r = Efficiency

- H = Annual average solar radiation (kWh/m²/day)

- PR = Performance Ratio, typically 0.75

- Bus Area Measurements

- Area of bus roof top:

- Area of the sides including the windows, doors, and all the other parts:

- A = legth (m) ∗ height (m) ∗ 2(both sides) + width (m) ∗ height (m) = 10.8 ∗ 4.3 ∗ 2 + 2.55 ∗ 4.3 = 103.85 m2

- Known Parameters

| Parameter | Value | Source |

|---|---|---|

| Area (A) | 27.54 m² (horizontally placed solar panels) / 20.77 m² (vertically placed solar panels) | [57] |

| Efficiency (r) | 22% or 0.22 | [11] |

| Daily direct normal solar irradiation (H) | 2.39 kWh/m² | Table 3 |

| Performance Ratio (PR) | 0.75 | [50] |

- E = A ∗ r ∗ H ∗ PR

- Calculated Parameters

| Parameter | Value |

|---|---|

| Energy (E) | 10.86 kWh/day (horizontal) / 5.04 kWh/day (vertical) |

| Total Power Output (E_t) | 15.9 kWh/day |

| Cruising Range Increase | 10.72 km/day |

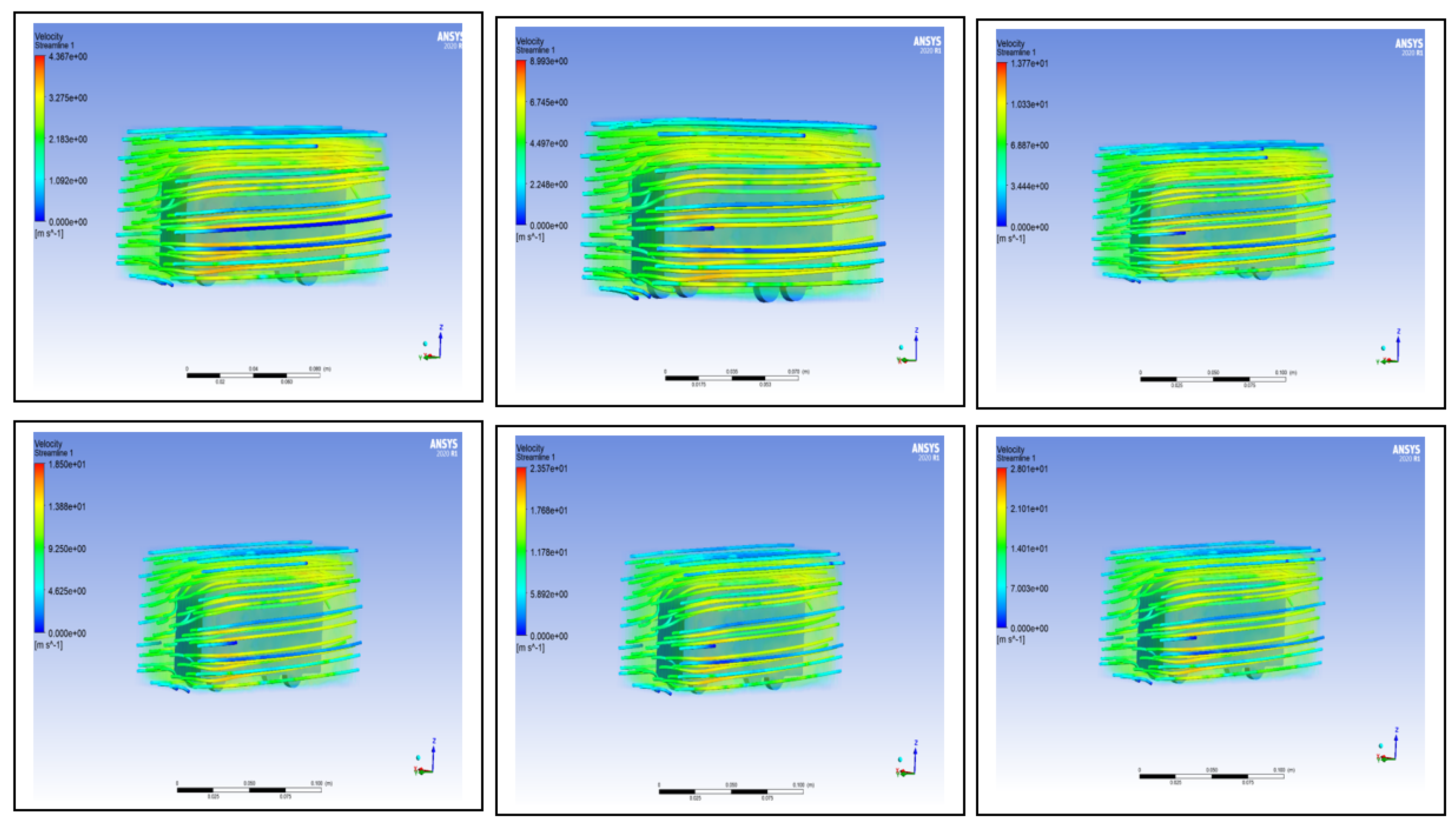

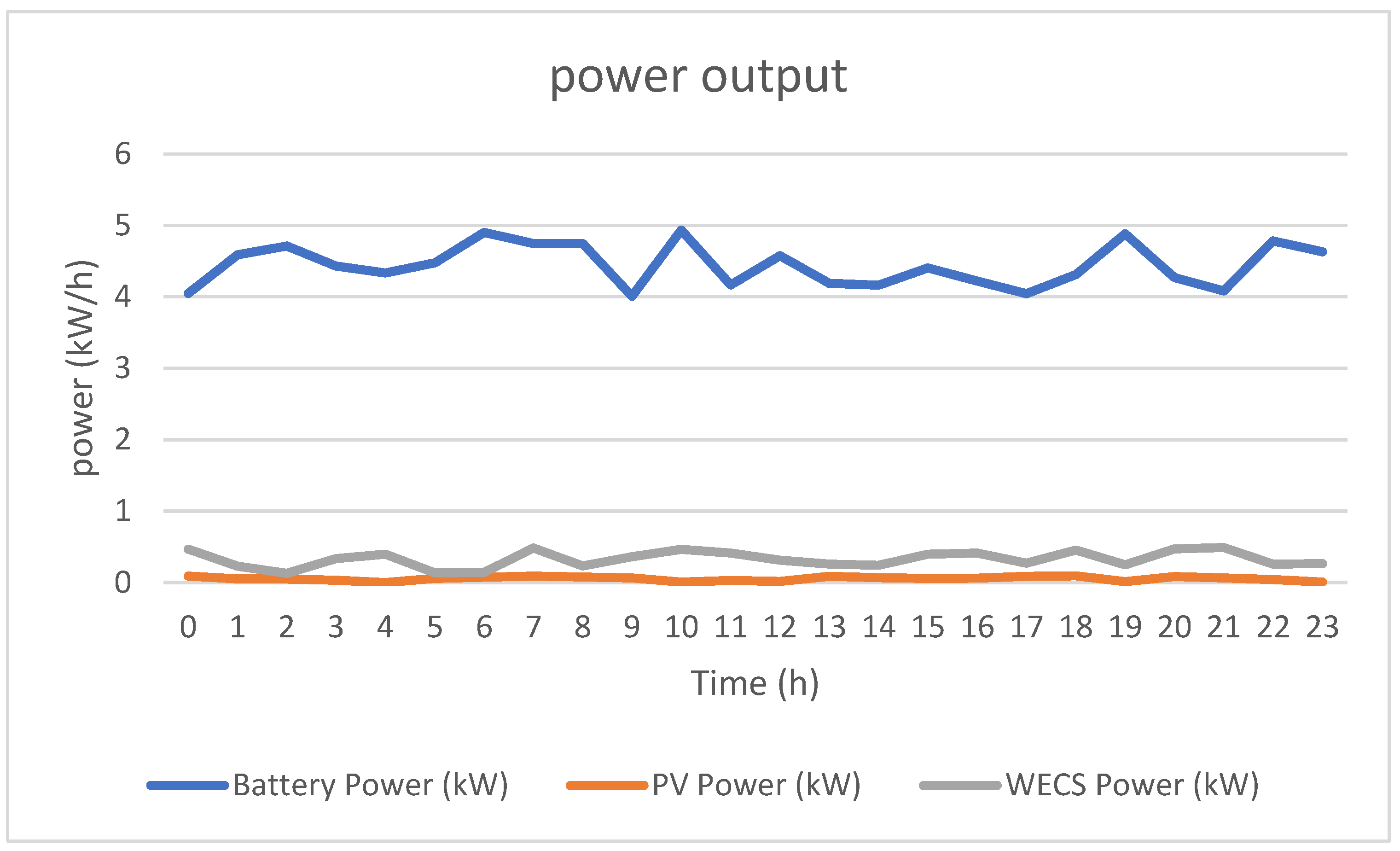

3.2. Mini-Wind Turbine

- Sweep area of WT:

- Vz is the wind speed at height z (meters)

- Vref is the reference wind speed at height Zref (usually 10 meters)

- Z is the desired height (1 meter in this case)

- Zref is the reference height (10 meters)

- α is friction coefficient or the power-law exponent (also called the Hellmann exponent), which depends on the surface roughness and atmospheric stability

| Landscape type | Friction coefficient α |

|---|---|

| Lakes, ocean and smooth hard ground | 0.10 |

| Grasslands (ground level) | 0.15 |

| Tall crops, hedges and shrubs | 0.20 |

| Heavily forested land | 0.25 |

| Small town with some trees and shrubs | 0.30 |

| City areas with high rise buildings | 0.40 |

| mph | m/s | Effective Wind speed on moving vehicle (m/s) |

|---|---|---|

| 5 | 2.24 | 2.18 |

| 10 | 4.47 | 4.5 |

| 15 | 6.71 | 6.89 |

| 20 | 8.94 | 9.25 |

| 25 | 11.18 | 11.78 |

| 30 | 13.41 | 14.01 |

| Air density (kg/m³) | Effective velocity (m/s) | Sweep area (m²) | WT efficiency | Power output (wh) |

|---|---|---|---|---|

| 1.225 | 2.18 | 0.79 | 0.45 | 2.2 |

| 1.225 | 4.5 | 0.79 | 0.45 | 22.66 |

| 1.225 | 6.89 | 0.79 | 0.45 | 56.72 |

| 1.225 | 9.25 | 0.79 | 0.45 | 220.16 |

| 1.225 | 11.78 | 0.79 | 0.45 | 397.16 |

| 1.225 | 14.01 | 0.79 | 0.45 | 2067.35 |

3.3. Piezo Electricity

- Introduction to PVDF in Piezoelectric Technology: while ceramic-based materials are commonly used for their high piezoelectric constant, PVDF has been identified as an efficient alternative for large-scale energy harvesting. Its flexibility and durability make it suitable for application in vehicle tires [44].

- Electricity Generation from Bus Tires: placing PVDF in the outer layer of car tires can generate electricity. This is based on the contact area between the tires and the ground.

-

Calculation of Power Output: To calculate the power output from the tires, the following steps are undertaken:

- o

-

Contact Area Calculation:

- -

- Each tire supports 4800 kg of the total 19200 kg bus weight [57].

- -

- Using a load per square cm value of 13.6 kg/cm², the contact area per tire is calculated to be 352.94 cm².

- o

-

Power Output Calculation:

- -

- PVDF polymer induces a power output of 0.00089 W/cm² [44].

- -

- The power output per tire is 0.31411 W (0.00089 W/cm² * 352.94 cm²).

- o

-

Total Power Output Calculation:

- -

- For all four tires, the total power output is 1.25644 W (0.31411 W * 4).

- o

-

Daily Energy Generation Calculation:

- -

- Assuming the bus operates for 18 hours a day, the total energy generated is 22.61592 Wh.

-

Energy Efficiency and Distance Calculation:

- o

- The energy required to drive a unit distance is calculated as 2387.5 Wh/km [57].

- o

- Using the 22.6 Wh generated, the bus can drive approximately 0.00947 km, under ideal conditions.

| Type of chargers | Charging Time per kWh (min) | Cost (£) | Time Saved (min) per day | Saved Cost (£) per day |

|---|---|---|---|---|

| Slow (3.7 kW) | 16.8 | Not available | 406.56 | Not available |

| Fast (22 kW) | 4.0 | 0.63 | 96.8 | 15.25 |

| Rapid (50 kW) | 1.6 | 0.73 | 38.72 | 17.67 |

| Ultra Rapid (150 kW) | 0.8 | 0.77 | 19.36 | 18.63 |

3.4. Feasibility Analysis of Solar Modules and Wind Turbines Fitted to Electric Buses

| Metric | Value |

|---|---|

| Pre-tax IRR - equity | 14.8% |

| Pre-tax MIRR - equity | 11.8% |

| Pre-tax IRR - assets | 2.7% |

| Pre-tax MIRR - assets | 5.3% |

| Simple payback | 9.5 yr |

| Equity payback | 7.9 yr |

| Net Present Value (NPV) | 11,256 GBP |

| Annual life cycle savings | 1,233 GBP/yr |

| Benefit-Cost (B-C) ratio | 1.7 |

| Debt service coverage | 1.4 |

| GHG reduction cost | -298 GBP/tCO2 |

| Energy production cost | 0.778 GBP/kWh |

4. Discussion

5. Conclusions and Future Work

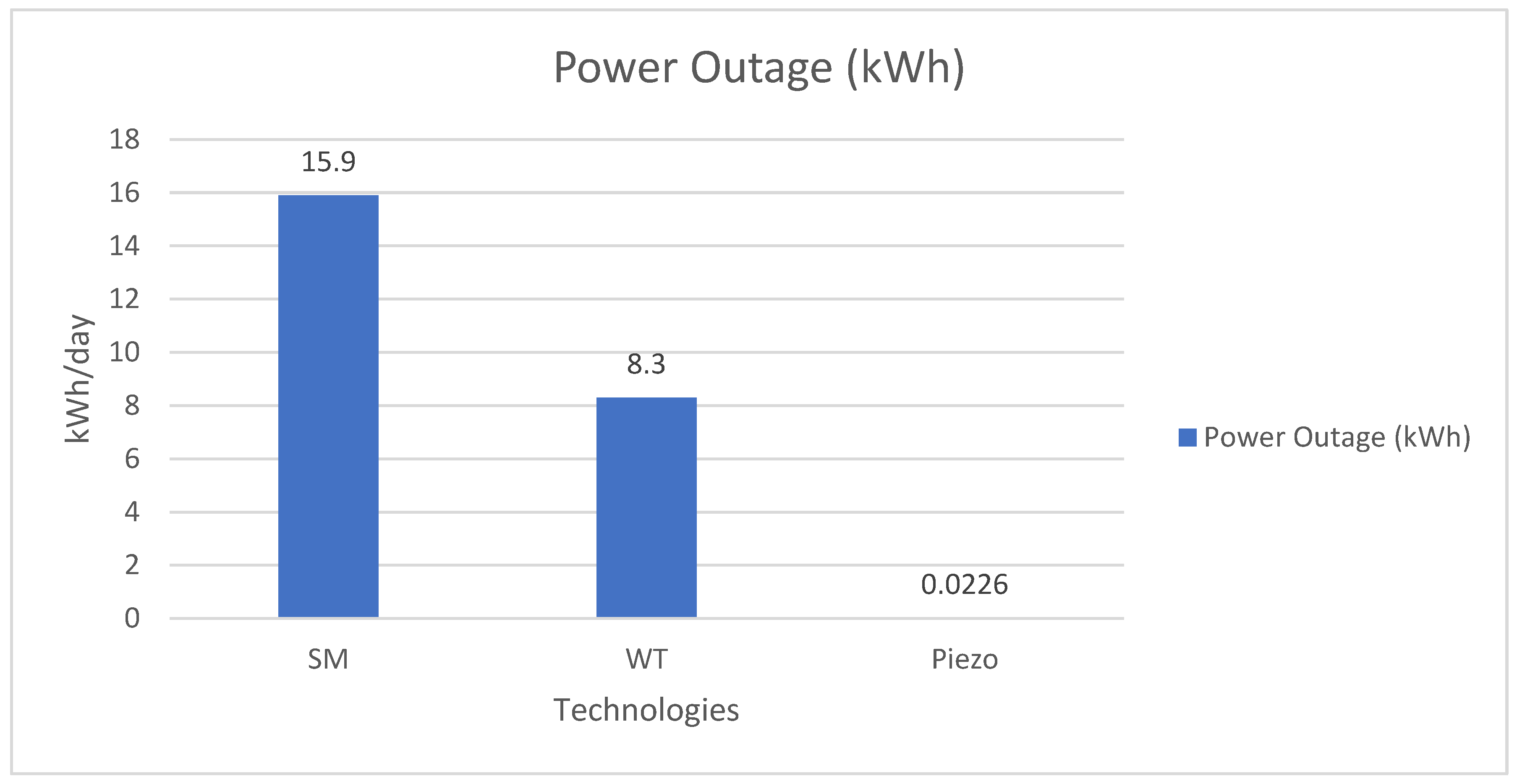

- The study examines the scope for key underpinning technologies to be adopted on double-decker electric buses in London in the UK according to an engineering modelling approach underpinned by techno-economic analysis.

- The solar modules are placed on the rooftop and sides of the bus generating 15.9 kWh/day and the wind turbine in the front bumper of the bus generates 8.3 kWh/day. Although the piezoelectric material generated only 22.6 Wh/day, rendering it an impractical inclusion in further analysis.

- Both the solar modules and wind turbines combined generate 24.2 kWh/day, which can increase the driving range by 16.3 km per day and this results in savings of 19.36 minutes for charging at the stations.

- Investing in such projects would have a positive return as the internal rate of return (IRR) and net present value (NPV) are 2.8% and £11,175 respectively. The annual revenue would be £6,712, and the greenhouse gas (GHG) reduction would be two metric tons annually.

- Electricity exported to the grid, the electricity export rate, and the initial investment are identified as key factors influencing power outage in a sensitivity analysis. In conclusion, this numerical modelling study paves the way for experimental validation towards implementation of renewable energy technologies on electric bus fleets.

References

- Oku, T. , 2016. Solar cells and energy materials, Walter de Gruyter GmbH & Co KG.

- Kennedy, D. , & Philbin, S. P. Techno-economic analysis of the adoption of electric vehicles. Frontiers of Engineering Management 2019, 6, 538–550. [Google Scholar]

- Rigogiannis, N. , Bogatsis, I., Pechlivanis, C., Kyritsis, A., & Papanikolaou, N. Moving towards Greener Road Transportation: A Review. Clean Technologies 2023, 5, 766–790. [Google Scholar]

- Vidhi, R. , Shrivastava, P., & Parikh, A. Social and technological impact of businesses surrounding electric vehicles. Clean Technologies 2021, 3, 81–97. [Google Scholar]

- Transport (2019) Available at: https://www.irena.org/Energy-Transition/Technology/Transport (Accessed: 27 August 2023).

- TfL sets out bold vision for electric buses in London (no date) Available at: https://transportandenergy.com/2023/06/22/tfl-sets-out-bold-vision-for-electric-buses-in-london/ (Accessed: 1 July 2023).

- London’s electric bus fleet becomes the largest in Europe (no date) Available at: https://www.london.gov.uk/press-releases/mayoral/londons-electric-bus-fleet-largest-in-europe (Accessed: 1 July 2023).

- Solar Electric Vehicle (no date) Available at: https://lightyear.one/ (Accessed: 27 August 2023).

- Kacher, G. (2022) Sono Motors Sion revealed: Solar-powered and on sale next year for £21K!. Available at: https://www.carmagazine.co.uk/car-news/tech/sono-sion/ (Accessed: 27 August 2023).

- Bus Fleet Data & Audits (no date) Available at: https://tfl.gov.uk/corporate/publications-and-reports/bus-fleet-data-and-audits (Accessed: 27 August 2023).

- Masuda, T. , Araki, K., Okumura, K., Urabe, S., Kudo, Y., Kimura, K., Nakado, T., Sato, A. and Yamaguchi, M. Static concentrator photovoltaics for automotive applications. Solar Energy 2017, 146, 523–531. [Google Scholar] [CrossRef]

- Alves, M. , Pérez-Rodríguez, A., Dale, P.J., Domínguez, C. and Sadewasser, S. Thin-film micro-concentrator solar cells. Journal of Physics: Energy 2019, 2, 012001. [Google Scholar]

- Abdelhamid, M. , Singh, R., Qattawi, A., Omar, M. and Haque, I. Evaluation of on-board photovoltaic modules options for electric vehicles. IEEE Journal of Photovoltaics 2014, 4, 1576–1584. [Google Scholar] [CrossRef]

- Yamaguchi, M. , Masuda, T., Araki, K., Sato, D., Lee, K.H., Kojima, N., Takamoto, T., Okumura, K., Satou, A., Yamada, K. and Nakado, T. Role of PV-powered vehicles in low-carbon society and some approaches of high-efficiency solar cell modules for cars. Energy and Power Engineering 2020, 12, 375–395. [Google Scholar] [CrossRef]

- Mangu, R. , Prayaga, K., Nadimpally, B. and Nicaise, S., 2010, April. Design, development and optimization of highly efficient solar cars: Gato del Sol I-IV. In 2010 IEEE Green Technologies Conference (pp. 1-6). IEEE.

- Chmielewski, A. , Szulim, P., Gregorczyk, M., Gumiński, R., Mydłowski, T. and Mączak, J., 2017, August. Model of an electric vehicle powered by a PV cell—A case study. In 2017 22nd International Conference on Methods and Models in Automation and Robotics (MMAR) (pp. 1009-1014). IEEE.

- Schuss, C. , Fabritius, T., Eichberger, B. and Rahkonen, T.,. Impacts on the output power of photovoltaics on top of electric and hybrid electric vehicles. IEEE Transactions on Instrumentation and Measurement 2019, 69, 2449–2458. [Google Scholar] [CrossRef]

- Uno, M. , Liu, X., Sato, H. and Saito, Y. Panel-to-Substring PWM differential power processing converter and its maximum power point tracking technique for solar roof of plug-in electric vehicles. IEEE Access 2022, 10, 42883–42896. [Google Scholar] [CrossRef]

- Nivas, M. , Naidu, R.K.P.R., Mishra, D.P. and Salkuti, S.R. Modelling and analysis of solar-powered electric vehicles. International Journal of Power Electronics and Drive Systems 2022, 13, 480. [Google Scholar]

- Gezelius, M. and Mortazavi, R. Effect of having solar panels on the probability of owning battery electric vehicle. World Electric Vehicle Journal 2022, 13, 125. [Google Scholar] [CrossRef]

- Shivsharan, B.A. , Magade, P.B., Chavan, S. and Magade, S., 2020. A Review Paper on Vehicle Mounted Wind Turbine. Journal of Seybold Report ISSN NO, 1533, p.9211.

- Fathabadi, H. Utilizing solar and wind energy in plug-in hybrid electric vehicles. Energy conversion and management 2018, 156, 317–328. [Google Scholar] [CrossRef]

- Awal, M.R. , Jusoh, M., Sakib, M.N., Hossain, F.S., Beson, M.R.C. and Aljunid, S.A. Design and implementation of vehicle mounted wind turbine. ARPN J Eng Appl Sci 2015, 10, 8699–8860. [Google Scholar]

- Weng, F.T. and Huang, Y.X., 2018, April. An investigation of vehicle wind turbine system. In 2018 IEEE International Conference on Applied System Invention (ICASI) (pp. 1346-1349). IEEE.

- Yao, A. W.-L. , & Chiu, C. -H. Development of a Wind Power System on Trucks. Universal Journal of Mechanical Engineering 2015, 3, 151–163. [Google Scholar]

- Hussain, M.Z. , Anbalagan, R., Jayabalakrishnan, D., Muruga, D.N., Prabhahar, M., Bhaskar, K. and Sendilvelan, S. Charging of car battery in electric vehicle by using wind energy. Materials Today: Proceedings 2021, 45, 5873–5877. [Google Scholar]

- Anagie, G.A. , Hassen, A.A. and Sintie, Y.T., 2021. Performance Investigation of Small Wind Turbine Installed over a Pick up Vehicle to Charge an Electric Vehicle Battery.

- Chang, S.H. , Lim, Q.H. and Lin, K.H. A novel hybrid car design using a wind energy capturing device. Int. J. Simul. Syst. Sci. Technol 2014, 15, 21–29. [Google Scholar]

- Beesetty, M. Generation of Electricity by mounting Wind mill on moving vehicles for safe Food and Medicine Transfer by using wind energy conversion system. The International Journal Of Engineering And Science (IJES) 2015, 4, 22–25. [Google Scholar]

- Pavel, C.C. , Marmier, A., Alves Dias, P., Blagoeva, D., Tzimas, E., Schüler, D., Schleicher, T., Jenseit, W., Degreif, S. and Buchert, M., 2016. Substitution of critical raw materials in low-carbon technologies: lighting, wind turbines and electric vehicles. Luxembourg: European Commission, Oko-Institut eV.

- Jaen-Sola, P. , McDonald, A.S. and Oterkus, E. Lightweight design of direct-drive wind turbine electrical generators: A comparison between steel and composite material structures. Ocean Engineering 2019, 181, 330–341. [Google Scholar] [CrossRef]

- Pourrajabian, A. , Afshar, P.A.N., Ahmadizadeh, M. and Wood, D. Aero-structural design and optimization of a small wind turbine blade. Renewable Energy 2016, 87, 837–848. [Google Scholar] [CrossRef]

- Tang, X. , Huang, X., Peng, R. and Liu, X. A direct approach of design optimization for small horizontal axis wind turbine blades. Procedia CIRP 2015, 36, 12–16. [Google Scholar] [CrossRef]

- Chen, T.Y. , Liao, Y.T. and Cheng, C.C. Development of small wind turbines for moving vehicles: Effects of flanged diffusers on rotor performance. Experimental Thermal and Fluid Science 2012, 42, 136–142. [Google Scholar] [CrossRef]

- Sirenko, V. , Pavlovs’ ky, R. and Rohatgi, U.S., 2012, July. Methods of reducing vehicle aerodynamic drag. In Fluids Engineering Division Summer Meeting (Vol. 44755, pp. 97–102). American Society of Mechanical Engineers.

- Sudin, M.N. , Abdullah, M.A., Shamsuddin, S.A., Ramli, F.R. and Tahir, M.M. Review of research on vehicles aerodynamic drag reduction methods. International Journal of Mechanical and Mechatronics Engineering 2014, 14, 37–47. [Google Scholar]

- Fotso, B.M. , Nguefack, C.F., Talawo, R.C. and Fogue, M. Aerodynamic analysis of an electric vehicle equipped with horizontal axis savonius wind turbines. Int. J. Recent Trends Eng. Res. IJRTER 2019, 5, 17–26. [Google Scholar]

- Sofian, M. , Nurhayati, R., Rexca, A.J., Syariful, S.S. and Aslam, A. An evaluation of drag coefficient of wind turbine system installed on moving car. Applied Mechanics and Material 2014, 660, 689–693. [Google Scholar] [CrossRef]

- Kulkarni, H. , Zohaib, K., Khusru, A. and Aiyappa, K.S. Application of piezoelectric technology in automotive systems. Materials Today: Proceedings 2018, 5, 21299–21304. [Google Scholar]

- Esmaeeli, R. , Aliniagerdroudbari, H., Hashemi, S.R., Nazari, A., Alhadri, M., Zakri, W., Mohammed, A.H., Batur, C. and Farhad, S. A rainbow piezoelectric energy harvesting system for intelligent tire monitoring applications. Journal of Energy Resources Technology 2019, 141, 062007. [Google Scholar] [CrossRef]

- Song, Y. , Yang, C.H., Hong, S.K., Hwang, S.J., Kim, J.H., Choi, J.Y., Ryu, S.K. and Sung, T.H. Road energy harvester designed as a macro-power source using the piezoelectric effect. International Journal of Hydrogen Energy 2016, 41, 12563–12568. [Google Scholar] [CrossRef]

- Makki, N. and Pop-Iliev, R., 2011. Piezoelectric power generation in automotive tires. Proceedings of the Smart Materials & Structures/NDT in Aerospace/NDT in Canada, pp.1-10.

- Sezer, N. and Koç, M. A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Jung, I. , Shin, Y.H., Kim, S., Choi, J.Y. and Kang, C.Y. Flexible piezoelectric polymer-based energy harvesting system for roadway applications. Applied energy 2017, 197, 222–229. [Google Scholar] [CrossRef]

- Khalili, M. , Biten, A.B., Vishwakarma, G., Ahmed, S. and Papagiannakis, A.T. Electro-mechanical characterization of a piezoelectric energy harvester. Applied Energy 2019, 253, 113585. [Google Scholar] [CrossRef]

- Blanco, S. , 2009. How does weight affect a vehicle's efficiency. Available online via:(Accessed: 27-04-20).

- Hennings, W. , Mischinger, S. and Linssen, J. Utilization of excess wind power in electric vehicles. Energy policy 2013, 62, 139–144. [Google Scholar] [CrossRef]

- Al-Ogaili, A.S. , Hashim, T.J.T., Rahmat, N.A., Ramasamy, A.K., Marsadek, M.B., Faisal, M. and Hannan, M.A. Review on scheduling, clustering, and forecasting strategies for controlling electric vehicle charging: Challenges and recommendations. Ieee Access 2019, 7, 128353–128371. [Google Scholar] [CrossRef]

- Gupta, A. and Kumar, N. Energy regeneration in electric vehicles with wind turbine and modified alternator. Materials Today: Proceedings 2021, 47, 3380–3386. [Google Scholar]

- How to calculate the annual solar energy output of a photovoltaic system? (No date) Available at: https://photovoltaic-software.com/principle-ressources/how-calculate-solar-energy-power-pv-systems (Accessed: 05 April 2023).

- Wind Turbine Calculator (2021) Available at: https://windcycle.energy/wind_turbine_calculator/#:~:text=How%20to%20calculate%20the%20power%20generated%20by%20a,power%20...%204%20Calculating%20the%20output%20power%20 (Accessed: 05 April 2023).

- Ro, K.S. and Hunt, P.G. Characteristic wind speed distributions and reliability of the logarithmic wind profile. Journal of environmental engineering 2007, 133, 313–318. [Google Scholar] [CrossRef]

- Bañuelos-Ruedas, F. , Angeles-Camacho, C. and Rios-Marcuello, S. Methodologies used in the extrapolation of wind speed data at different heights and its impact in the wind energy resource assessment in a region. Wind farm-Technical regulations, potential estimation and siting assessment 2011, 97, 114. [Google Scholar]

- Fernando, J. (2023) Net present value (NPV): What it means and steps to calculate it, Investopedia. Available at: https://www.investopedia.com/terms/n/npv.asp (Accessed: 04 September 2023).

- Fernando, J. (2023) Internal Rate of Return (IRR) rule: Definition and example, Investopedia. Available at: https://www.investopedia.com/terms/i/irr.asp (Accessed: 04 September 2023).

- Global Solar Atlas (no date) Available at: https://globalsolaratlas.info/ (Accessed: 3 April 2023).

- 57. Meet the BYD–Alexander Dennis Enviro400EV (no date). Available at: https://www.evbus.co.uk/products/byd-adl-enviro400ev/ (Accessed: December 1, 2022).

- Law, D.C. , Edmondson, K.M., Siddiqi, N., Paredes, A., King, R.R., Glenn, G., Labios, E., Haddad, M.H., Isshiki, T.D. and Karam, N.H., 2006, May. Lightweight, flexible, high-efficiency III-V multijunction cells. In 2006 IEEE 4th World Conference on Photovoltaic Energy Conference (Vol. 2, pp. 1879–1882). IEEE.

- Fernández, P. (2008).Available at: http://www.termica.webhop.info (Accessed: 5 April 2023).

- Gilbert, M.M. , 2004. Renewable and efficient electric power systems.

- Patel, M.R. , 2006. Wind and solar power systems: design, analysis, and operation, 2nd edn, CRC Taylor & Francis. ISBN-10: 0-8493-1570-0, ISBN-13, 970, p.978.

- ANSYS. (2023). ANSYS Student 2023 R2. [Software]. Available at: https://www.ansys.com/academic/students/ansys-student (Accessed: March 2023).

- london-digital-speed-limit-map.pdf (tfl.gov.uk) (no date) Available at: https://content.tfl.gov.uk/london-digital-speed-limit-map.pdf (Accessed: 3 April 2023).

- How long does it take to charge an electric car? (no date) Available at: https://pod-point.com/guides/driver/how-long-to-charge-an-electric-car (Accessed: 03 August 2023).

- ESB Energy for Electric Vehicles (no date). Available at: https://www.esbenergy.co.uk/ev (Accessed: 03 August 2023).

- D. Clark and 16, A. D. Clark and 16, A. (2023) UK inflation rate 2023, Statista. Available at: https://www.statista.com/statistics/306648/inflation-rate-consumer-price-index-cpi-united-kingdom-uk/ (Accessed: 20 August 2023).

- Ten-fold increase in carbon offset cost predicted (2022). Available at: https://www.ucl.ac.uk/news/2021/jun/ten-fold-increase-carbon-offset-cost-predicted (Accessed: 21 August 2023).

- RETScreen International 2023, 'RETScreen Expert - Professional', version 9.0.1.94, Natural Resources Canada [Software]. Available at: https://natural-resources.canada.ca/maps-tools-and-publications/tools/modelling-tools/retscreen/7465 (Accessed: March 2023).

| Type | Potential (%) | Attained (%) | Reach (%) | Year |

|---|---|---|---|---|

| Mono crystalline Si | 28.8 | 26.7 | 92.7 | 2017 |

| Gallium arsenide | 30 | 29.1 | 97 | 2018 |

| III-V based 3J | 42 | 37.9 | 90.2 | 2013 |

| III-V based 6J | 46 | 39.2 | 85.2 | 2019 |

| III-V/Si | 42 | 35.9 | 85.5 | 2017 |

| SLVPV (2-4 suns) | 40 | 27.6 | 69 | 2019 |

| III-V/Si etc. | 40 | 27.6 | 69 | 2019 |

| CIGS | 27.7 | 23.4 | 84.5 | 2018 |

| CdTe | 27.7 | 22.1 | 79.8 | 2015 |

| Perovskite | 27.7 | 24.2 | 87.4 | 2019 |

| Organic | 20.2 | 16.4 | 81.2 | 2019 |

| Number | Formula | Description | Variables | |

|---|---|---|---|---|

|

1 |

|

Global formula to calculate solar panel power output (kWh) [50] |

PR: performance ratio which is typically (0.75 [50]) H: Annual average solar radiation r: efficiency A: Area E: energy (kWh) |

|

|

2 |

|

global formula to calculate power output of wind turbines [51]. | ||

|

3 |

|

global formula for available wind power [51]. |

A = sweep area ρ = air density (usually 1.225 kg/m3) V = wind speed (usable range is 3-25 m/s Pwind = available wind power |

|

|

4 |

|

Sweep area formula [51]. |

A: sweep area π: mathematical constant (a circle’s circumference to its diameter ratio) L: blade length or radius of horizontal axis turbine |

|

|

5 |

|

Logarithmic Wind Method [52] |

Vz: is the wind speed at height z. Vref: is the reference wind speed at height Zref. Z: is the desired height Zref: is the reference height. z0: is the surface roughness length |

|

|

6 |

|

Power-law model [53] |

Vz: is the wind speed at height z Vref: is the reference wind speed at height zref (usually 10 meters) Z: is the desired height (1 meter in this case) Zref: is the reference height (10 meters) α: is friction coefficient or the power-law exponent (also called the Hellmann exponent), which depends on the surface roughness and atmospheric stability |

|

|

7 |

|

Net Present Value (NPV) formula [54] |

Ct: cash flow C0: initial investment NPV: initial investment IRR: required return or discount rate. t: number of time periods |

|

|

8 |

|

Internal Rate of Return Formula [55] |

IRR: internal rate of return FV: future value t: periods PV: present value |

| Parameter | Value | Source |

|---|---|---|

| USDGBP exchange rate | 0.8 | User defined |

| Cumulative inflation rate | 2.79% | [66] |

| Fuel cost escalation rate | 2% | RETScreen |

| Discount rate | 9% | RETScreen |

| Project life | 20 years | RETScreen |

| Debt ratio | 70% | RETScreen |

| Debt interest rate | 7% | RETScreen |

| Debt term | 15 years | RETScreen |

| GHG reduction credit rate | 70 GBP/tCO2 | [67] |

| GHG reduction credit duration | 20 years | RETScreen |

| Electricity export rate (price of charging cars) | £0.77 | [64,65] |

| Solar Panel Cost per kWh | £3,604 | RETScreen with user modification |

| O&M costs | 50.11 GBP/KW-year | RETScreen |

| Mini wind turbine including installation cost | £333,000 | User defined |

| O&M costs | 50 GBP/kW-year | RETScreen |

| Vehicle Design with SM and WT Mounted | £2000 | User defined |

| WT and SM Installation | £2000 | User defined |

| Heating design temperature | -1.0 | ||||||||

| Cooling design temperature | 25.6 | ||||||||

| Earth temperature amplitude | 15.3 | ||||||||

| Month | Air Temperature (°C) | Relative Humidity (%) | Precipitation (mm) | Daily Solar Radiation - Horizontal (kWh/m²/d) | Atmospheric Pressure (kPa) | Wind Speed (m/s) | Earth Temperature (°C) | Heating Degree-days (°C·d) | Cooling Degree-days (°C·d) |

| January | 5.8 | 78.9 | 63.55 | 0.64 | 100.9 | 8.1 | 3.1 | 378 | 0 |

| February | 5.3 | 75.8 | 45.92 | 1.19 | 100.9 | 8.1 | 3.4 | 356 | 0 |

| March | 7.9 | 73.2 | 47.49 | 2.16 | 100.7 | 8.1 | 5.8 | 313 | 0 |

| April | 9.5 | 68.9 | 51.0 | 3.87 | 100.9 | 8.1 | 8.5 | 255 | 0 |

| May | 12.9 | 69.7 | 53.32 | 4.75 | 101.0 | 8.1 | 12.1 | 158 | 0 |

| June | 15.7 | 70.4 | 57.9 | 5.65 | 101.0 | 8.1 | 15.2 | 69 | 0 |

| July | 18.7 | 68.2 | 67.85 | 5.87 | 101.0 | 8.1 | 17.7 | 0 | 0 |

| August | 18.3 | 70.1 | 58.59 | 3.98 | 101.0 | 8.1 | 17.5 | 0 | 0 |

| September | 15.7 | 73.5 | 54.0 | 2.83 | 101.0 | 8.1 | 14.3 | 69 | 0 |

| October | 12.7 | 77.9 | 72.54 | 1.66 | 100.8 | 8.1 | 10.5 | 164 | 0 |

| November | 8.7 | 80.1 | 67.5 | 0.84 | 100.9 | 8.1 | 6.2 | 279 | 0 |

| December | 7.4 | 80.1 | 66.96 | 0.5 | 100.8 | 8.1 | 3.8 | 329 | 0 |

| Annual | 11.6 | 73.9 | 694.51 | 2.58 | 100.9 | 8.1 | 9.9 | 2370 | 1043 |

| Parameter | Unit | Value |

|---|---|---|

| Inflation rate | % | 2.8% |

| Discount rate | % | 9% |

| Reinvestment rate | % | 9% |

| Project life | yr | 20 |

| Debt ratio | % | 70% |

| Debt | GBP | 39,900 |

| Equity | GBP | 17,100 |

| Debt interest rate | % | 7% |

| Debt term | yr | 15 |

| Debt payments | GBP/yr | 4,381 |

| Description | Unit | Value |

|---|---|---|

| Electricity export revenue | ||

| Electricity exported to grid | MWh | 8.7 |

| Electricity export rate | GBP/kWh | 0.77 |

| Electricity export revenue | GBP | 6,712 |

| Electricity export escalation rate | % | 2% |

| GHG Reduction Revenue | ||

| Net GHG reduction | tCO2/yr | 2 |

| Net GHG reduction - 20 yrs | tCO2 | 40 |

| GHG reduction credit rate | GBP/tCO2 | 70 |

| GHG reduction revenue | 139 | |

| GHG reduction credit duration | yr | 20 |

| Net GHG reduction - 20 yrs | tCO2 | 39.7 |

| Category | Percentage | Currency | Value |

|---|---|---|---|

| Initial costs | |||

| Initial cost | 93% | GBP | 53,000 |

| Vehicle Design with SM and WT Mounted | 3.5% | GBP | 2,000 |

| WT and SM Installation | 3.5% | GBP | 2,000 |

| Total initial costs | 100% | GBP | 57,000 |

| Yearly cash flows - Year 1 | |||

| Annual costs and debt payments | GBP | 828 | |

| O&M costs (savings) | GBP | 4,381 | |

| Debt payments - 15 yrs | GBP | ||

| Total annual costs | GBP | 5,209 | |

| Annual savings and revenue | |||

| Electricity export revenue | GBP | 6,712 | |

| GHG reduction revenue - 20 yrs | GBP | 139 | |

| Other revenue (cost) | GBP | 0 | |

| CE production revenue | GBP | 0 | |

| Total annual savings and revenue | GBP | 6,850 | |

| Net yearly cash flow - Year 1 | GBP | 1,641 | |

| Yearly | Pre-tax | cumulative |

|---|---|---|

| # | GBP | GBP |

| 0 | -17,100 | -17,100 |

| 1 | 1,753 | -15,347 |

| 2 | 1,866 | -13,482 |

| 3 | 1,981 | -11,501 |

| 4 | 2,098 | -9,402 |

| 5 | 2,218 | -7,184 |

| 6 | 2,340 | -4,845 |

| 7 | 2,463 | -2,381 |

| 8 | 2,590 | 208 |

| 9 | 2,718 | 2,926 |

| 10 | 2,849 | 5,775 |

| 1 | 2,982 | 8,757 |

| 12 | 3,118 | 11,875 |

| 13 | 3,256 | 15,131 |

| 14 | 3,396 | 18,528 |

| 15 | 3,540 | 22,067 |

| 16 | 8,066 | 30,133 |

| 17 | 8,215 | 38,348 |

| 18 | 8,366 | 46,714 |

| 19 | 8,519 | 55,233 |

| 20 | 8,676 | 63,909 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).